High-precision mold equipment with informatization and digitization functions

A high-precision mold technology, applied in the field of molds, can solve problems such as uneven heating of molds, poor molding, energy consumption of injection molds, etc., and achieve the effect of real-time precise temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

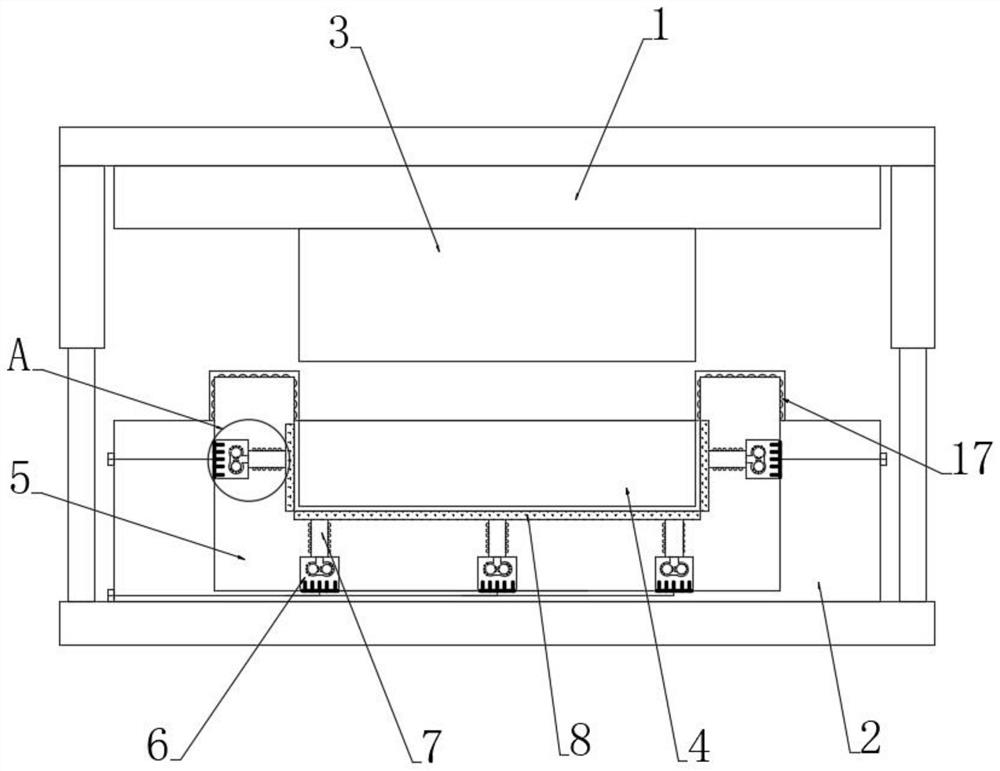

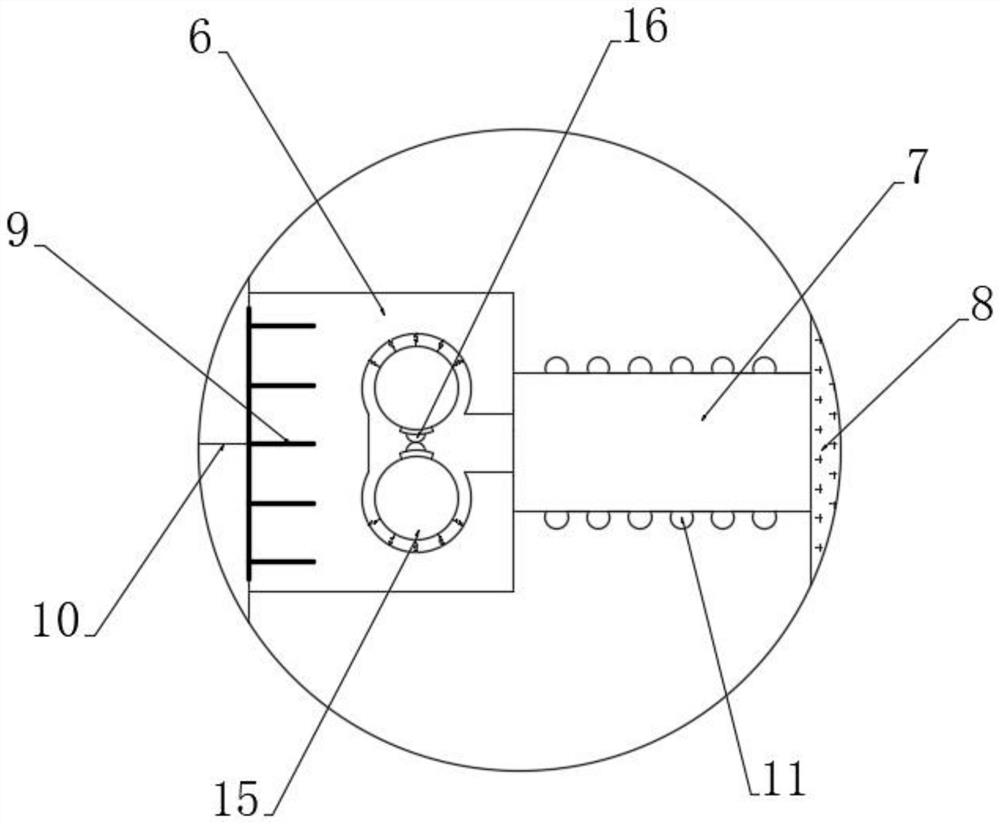

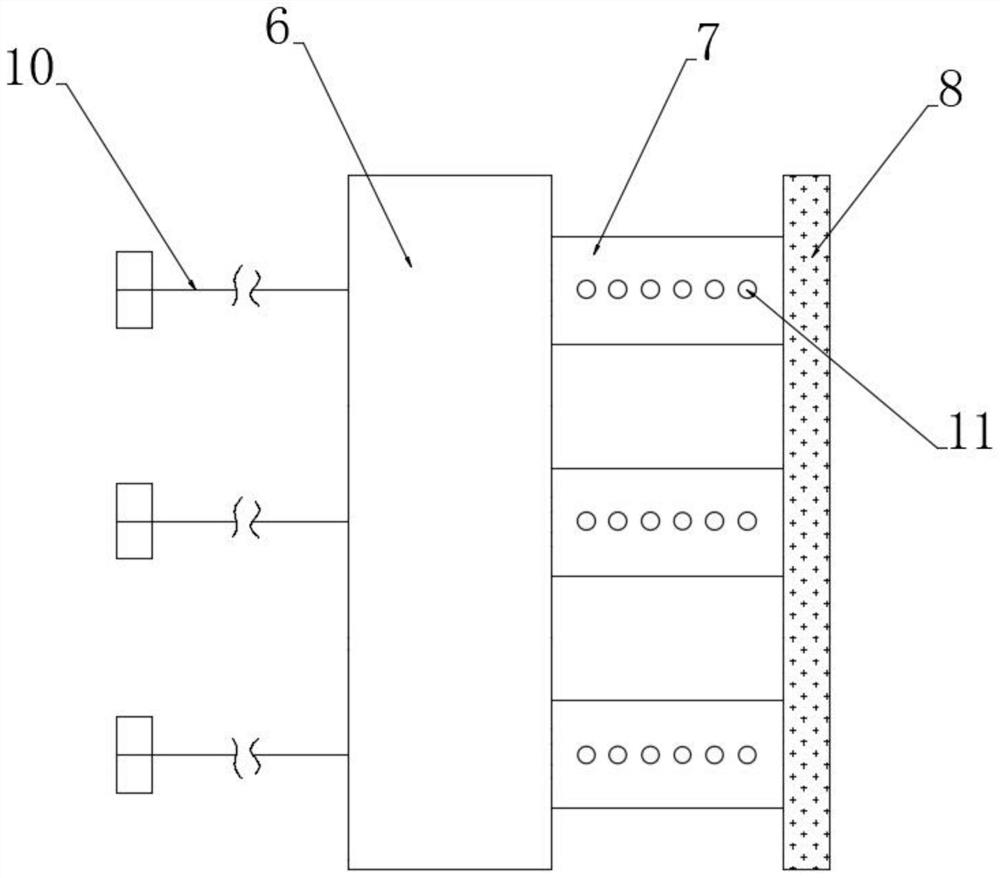

[0041] see Figure 1-3 , a high-precision mold equipment with informatization and digitalization, including an upper mold 1 and a lower mold 2, the bottom of the upper mold 1 is provided with a punch 3, and the upper end of the lower mold 2 is provided with a concave mold that matches the punch 3 Cavity 4, the inside of the lower mold 2 is provided with a heating chamber 5 located at the edge side of the die cavity 4, the top of the lower die 2 is connected with a heat storage tank 17 connected to the top of the heating chamber 5, and the heating chamber 5 is far away from the die cavity 4 A plurality of heating plates 6 are attached at intervals on the inner wall of one side, and the outer ends of the plurality of heating plates 6 are fixedly connected with multiple groups of temperature-sensing section layers 7, and the inner wall of the heating cavity 5 close to the die cavity 4 is attached There is a heat conduction pad 8, and one end of a plurality of temperature-sensing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com