Patents

Literature

160results about How to "Fast through" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Skin care composition with moisturizing and wrinkle-resistant effects

InactiveCN105919827ANot allergicGood moisturizing effectCosmetic preparationsToilet preparationsTryptophanTyrosine

The invention discloses a skin care composition with moisturizing and wrinkle-resistant effects. The composition is prepared by using sterile deionized water as a solvent, and the solute comprises amino acids, vitamins and trace elements including glycine, phenylalanine, alanine, proline, glutamine, serine, arginine, threonine, asparagine, tryptophan, aspartic acid, tyrosine, cysteine, valine, cystine, vitamin H, glutamic acid, nicotinamide, histidine, vitamin B6, isoleucine, vitamin B2, leucine, and vitamin B1. The skin care composition has good moisturizing and wrinkle-resistant effects, and has the advantages of safety without side effect, skin nourishing and good skin penetration capacity.

Owner:BEIJING SINOCELL CO LTD

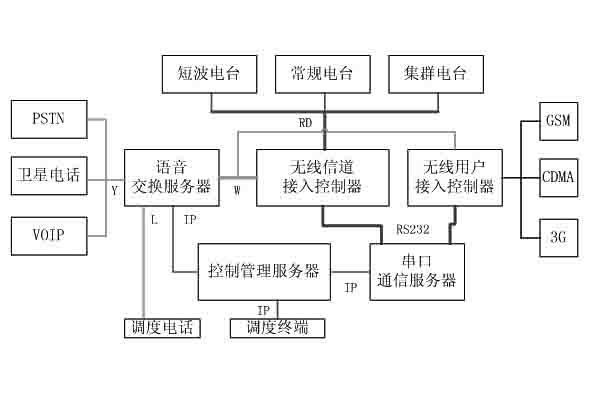

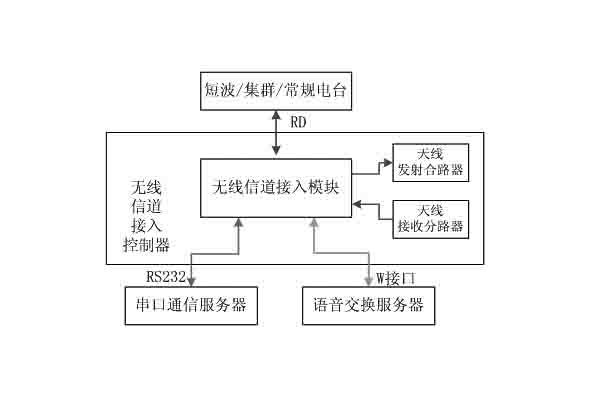

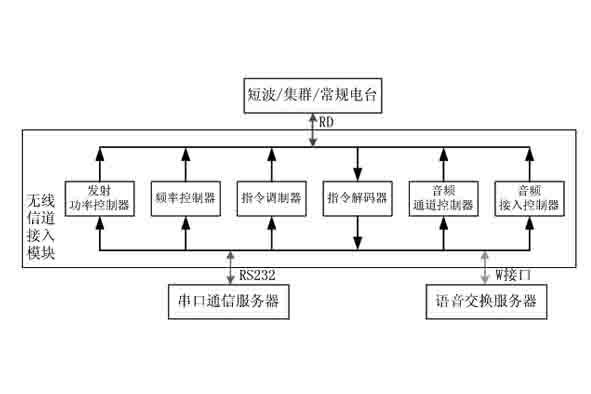

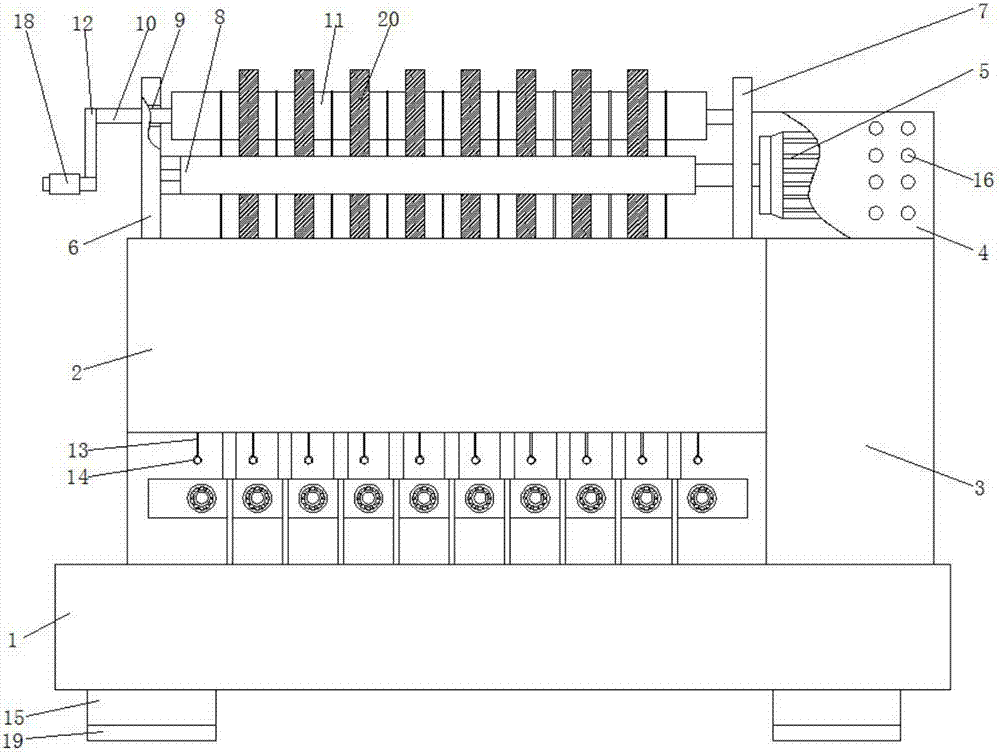

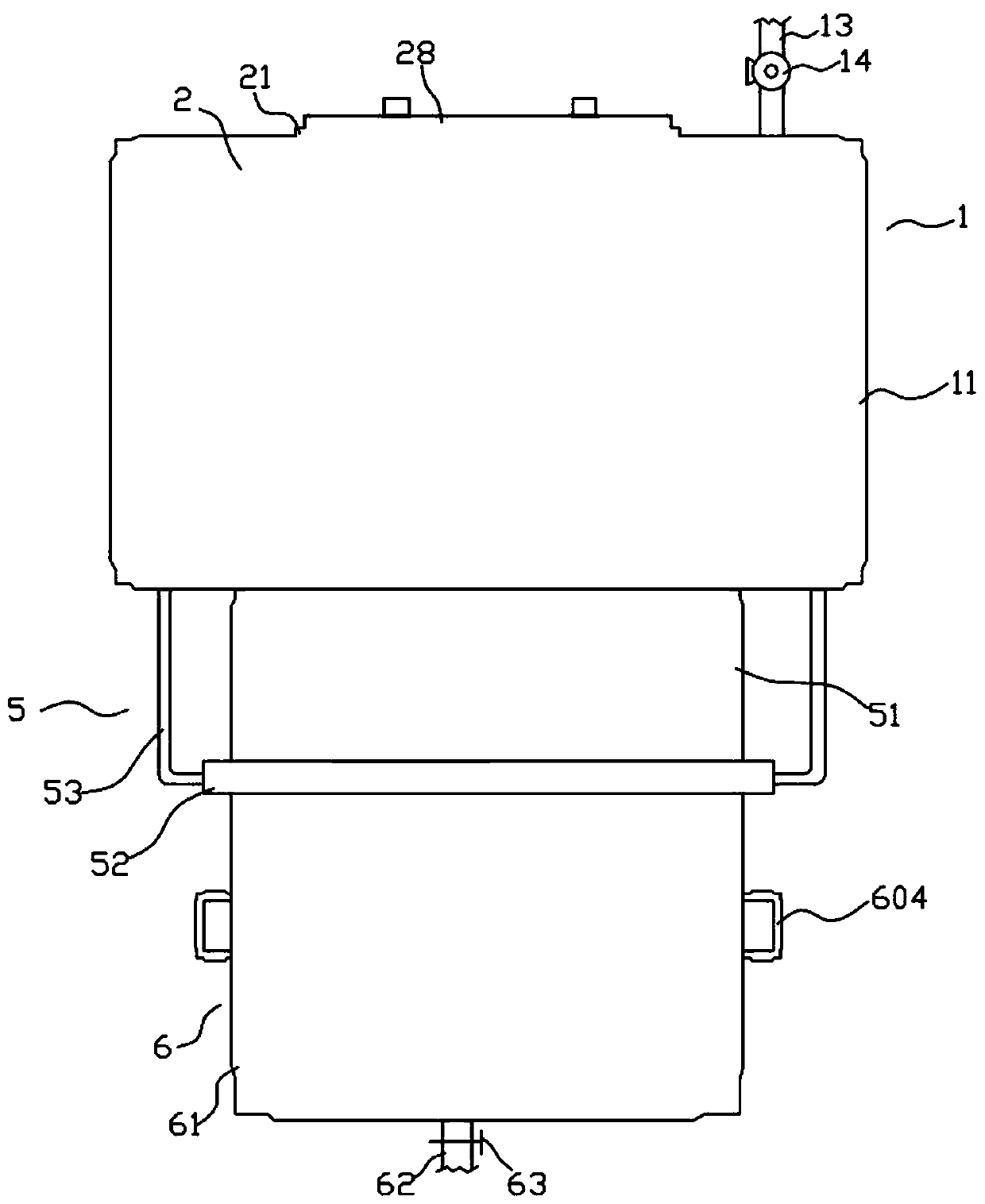

Intelligent networking management platform for fire emergency communication

InactiveCN102185714AFast throughGuaranteed non-interferenceData switching networksVoice communicationRs 232 interface

The invention discloses an intelligent networking management platform for fire emergency communication, which relates to the technical field of fire wired and wireless voice communication. The intelligent networking management platform comprises a wireless channel access controller, a wireless user access controller, a serial port communication server, a voice switching server and a control management server, wherein the front end of the wireless channel access controller is connected with a various wireless channel machines or terminals, and the backend of the wireless channel access controller is in tandem with the serial port communication server and the voice switching server by a standard RS232 interface and a three-wire system audio interface to realize the wireless voice communication network access and control of a system. The intelligent networking management platform for the fire emergency communication configures parameters by manual operations or a reading plan in on fire-fighting and rescue site, can rapidly group different communication means and roles according to a commanding principle to avoid interference on communication among groups, and also can enable a commander to directly command and schedule any fighting unit on the site by voices in a wired / wireless way so as to improve the firefighting and rescue efficiency.

Owner:SHENYANG FIRE RES INST OF THE MIN OF PUBLIC SECURITY

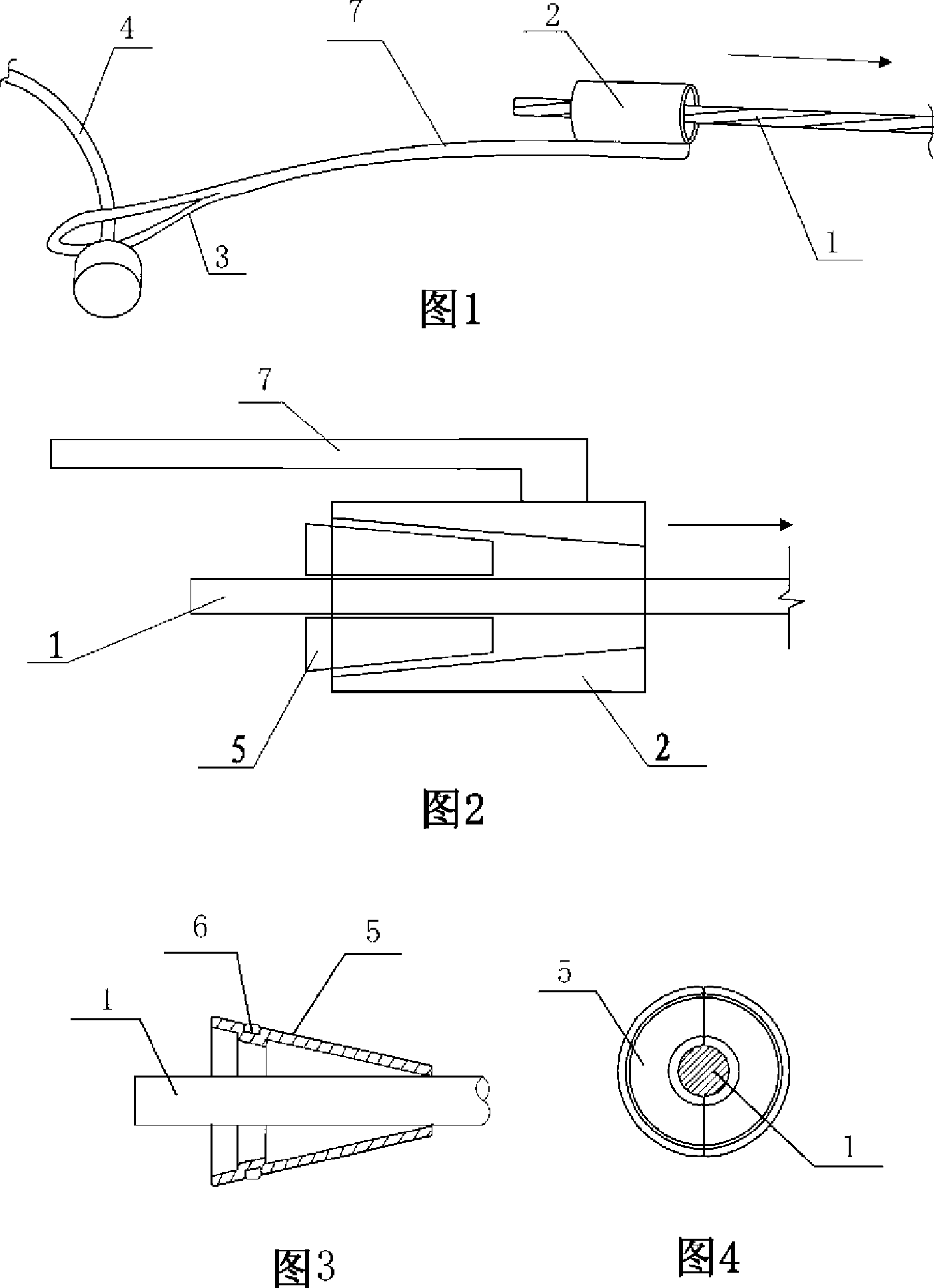

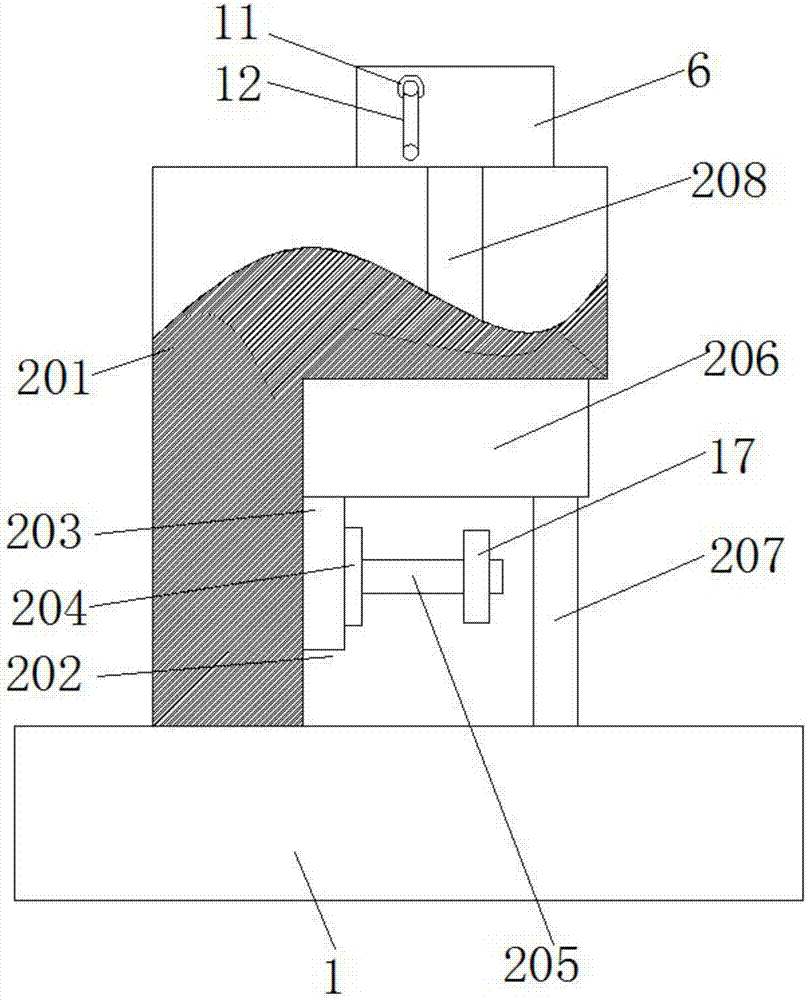

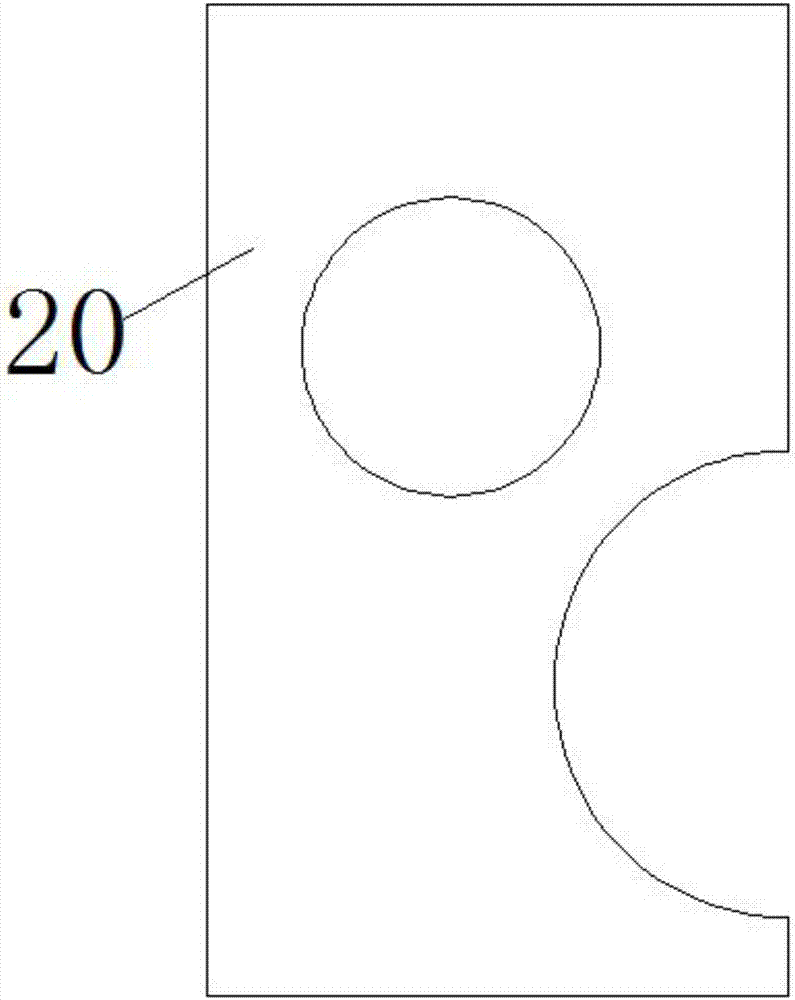

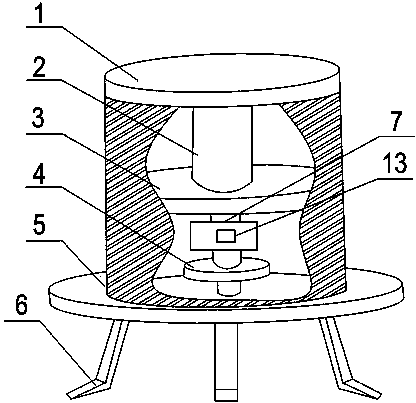

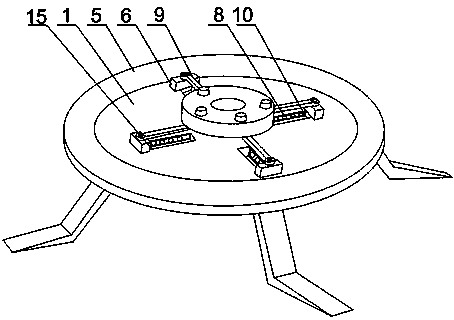

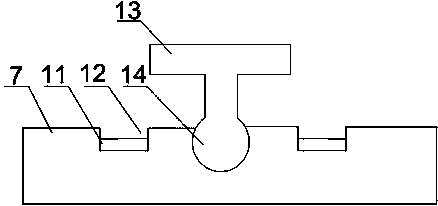

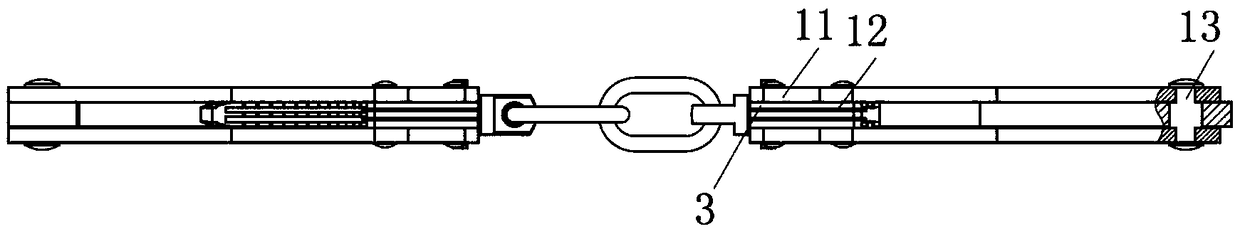

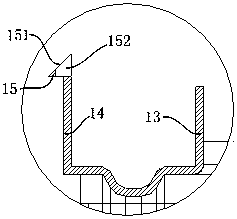

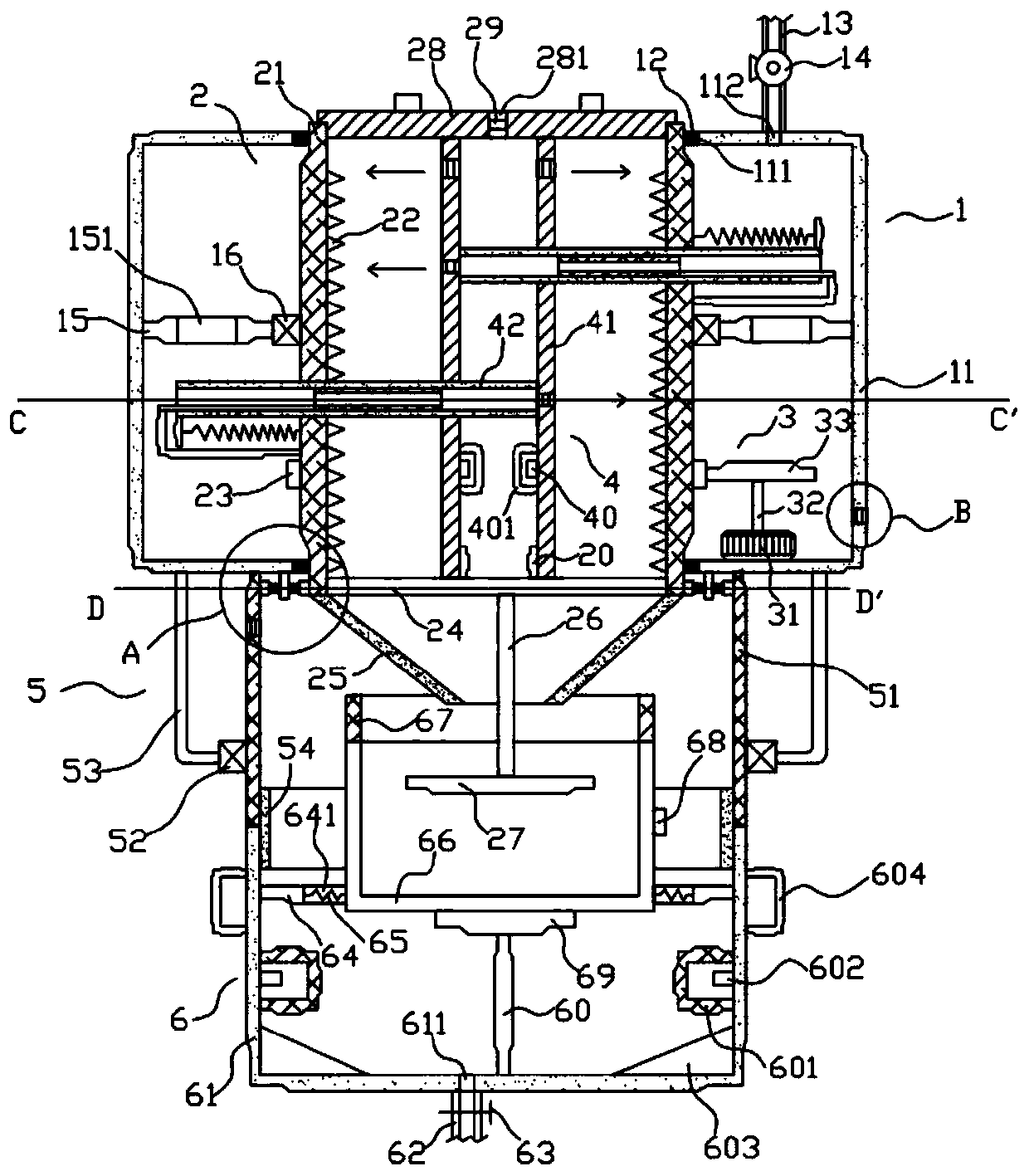

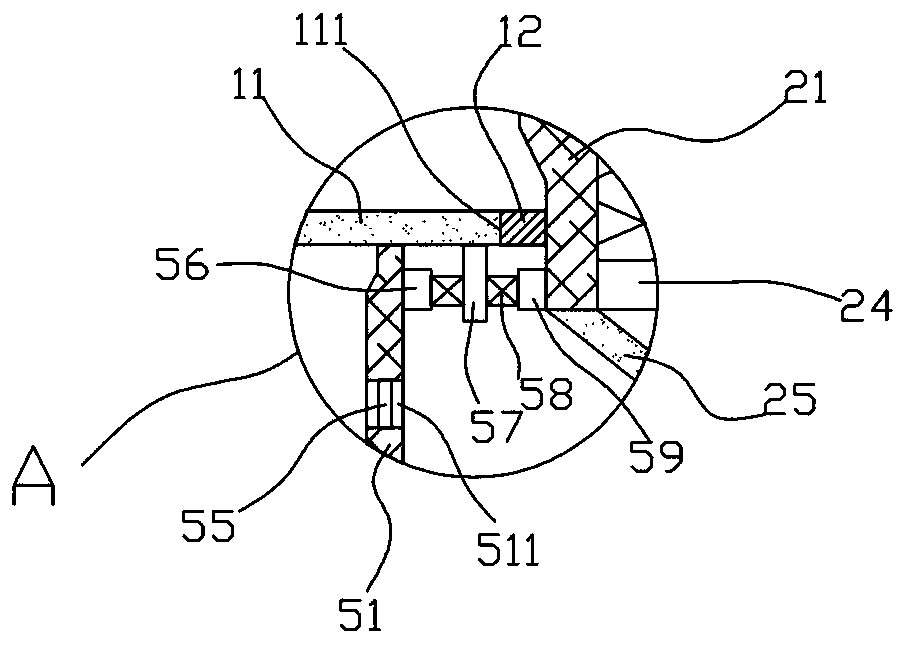

Steel strand retractor

InactiveCN101004096AFast constructionSmooth throughBuilding reinforcementsBuilding material handlingEngineeringPre stress

The present invention relates to a stranded wire puller. It includes an anchor main body and a pulling ring connected with stranded wire. It is characterized by that said anchor main body is made into the form of cylinder body whose interior is formed into cone form. In the interior of said anchor main body two clips and one pull rib are mounted, the end portion of said pull rib is connected with pulling ring. Said invention can be used in the superlong post-stressed concrete construction, and can be used for making stranded wire be smoothly passed through corrugated pipe.

Owner:BEIJING URBAN CONSTR GROUP

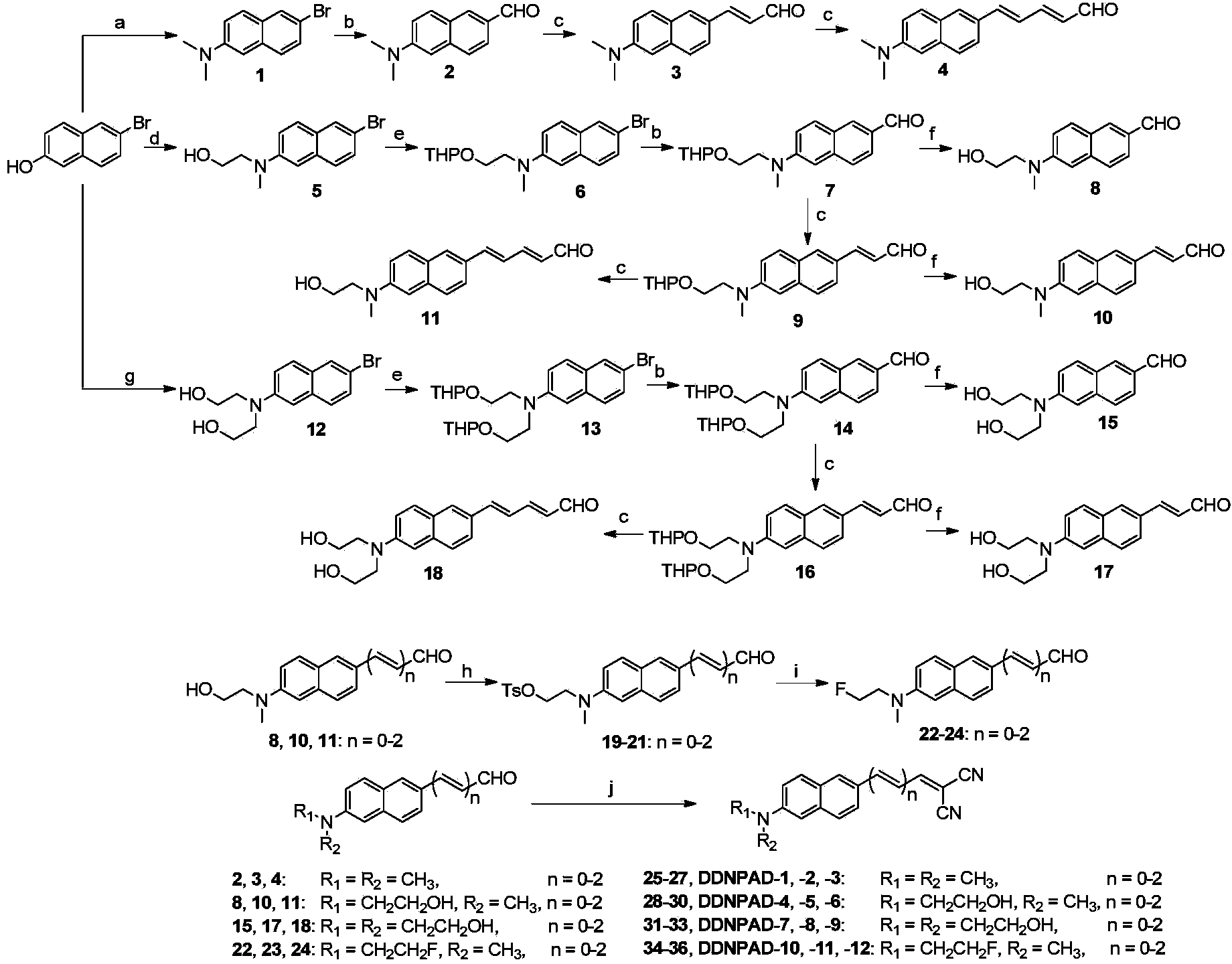

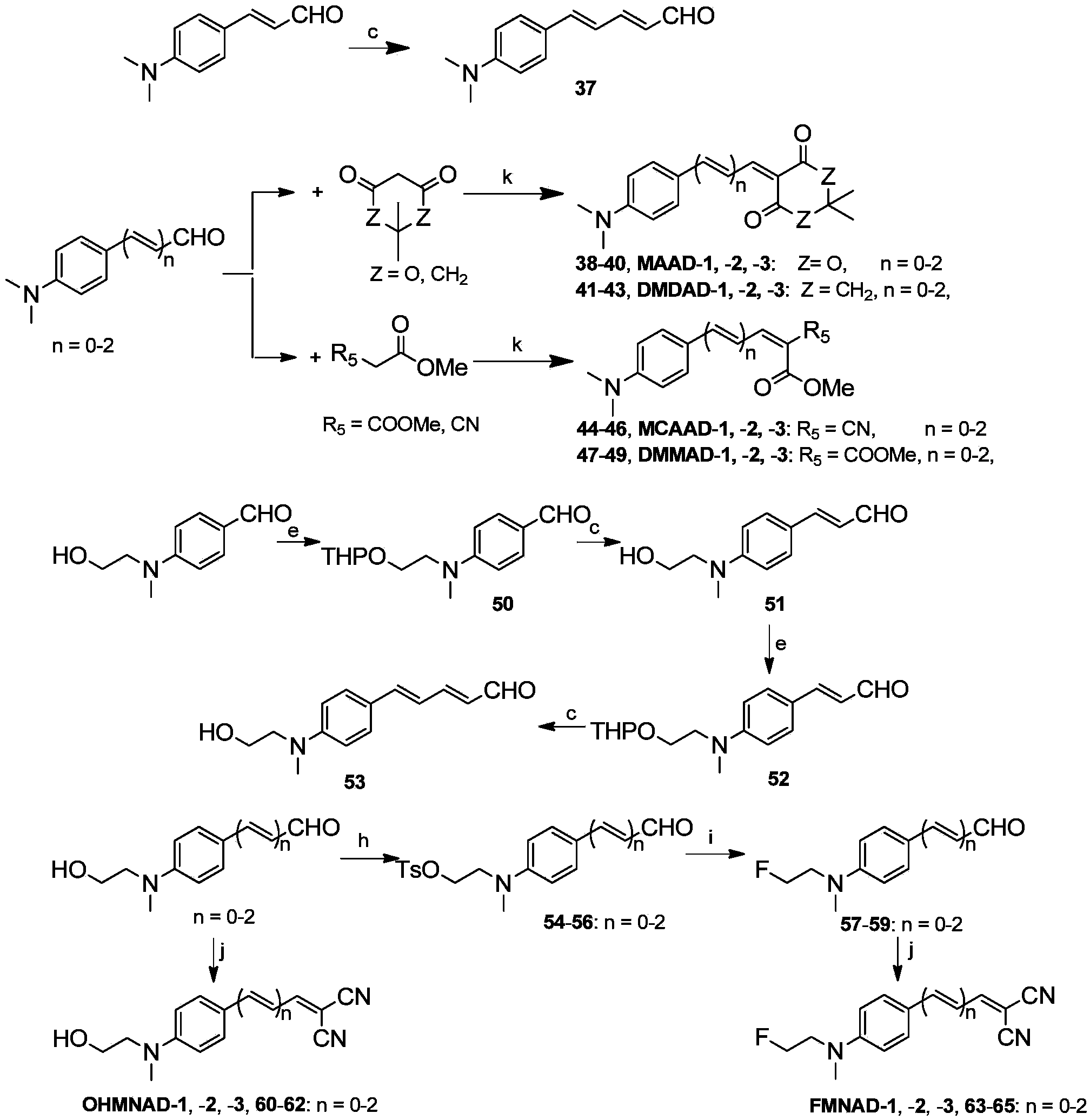

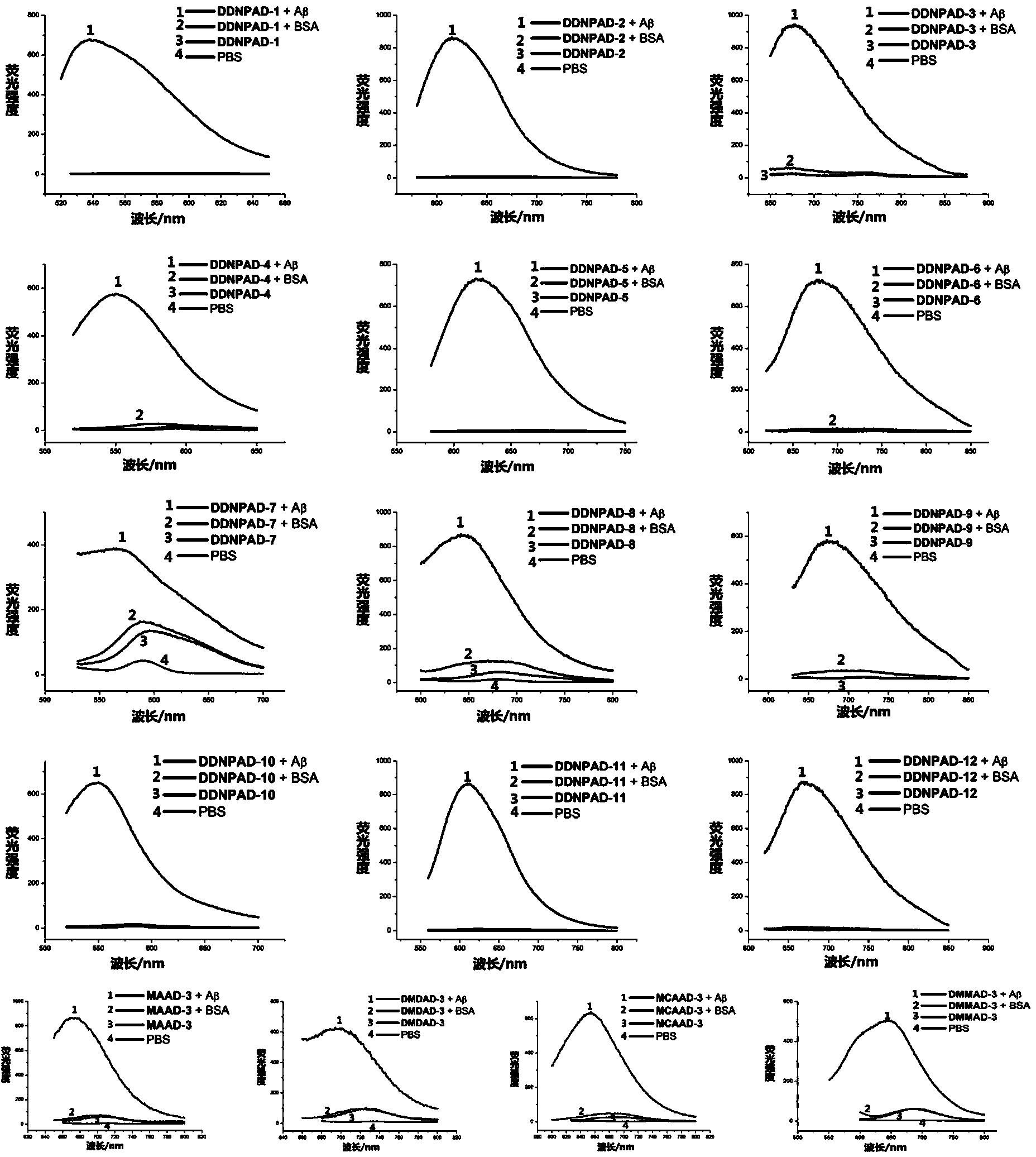

Compound provided with good affinity and tangled with Abeta plaque and nerve fiber and preparation method thereof

ActiveCN104140381AHigh affinityFast throughCarboxylic acid nitrile preparationOrganic compound preparationDiseaseIsotope

The invention provides a compound provided with good affinity and tangled with an Abeta plaque and a nerve fiber. The structural general formula (I) of the compound is as shown in the specification, wherein W is a benzo-hexahydric aromatic ring or a hexahydric aromatic ring; R1 and R2 independently represent CH3, 11CH3, aryl, heteroaryl or (CH2)n'R4; n' is 2-6; R4 is H, OH, F or Cl; F is 18F or 19F; R3 is as shown in the specification; n is 0-5; and carbon-carbon double bonds are trans double bonds. The invention also provides a preparation method and an application of the compound. The compound can be directly used as a near-infrared probe for detecting entanglement of amyloid protein sediments and the nerve fiber in a body or a tissue sample, and needs to be marked by appropriate radioactive isotopes when being applied to nuclear medicine imaging. The compound is especially suitable for diagnosis of patients with the disease of entanglement of the amyloid protein sediments and the nerve fiber, including the alzheimer disease.

Owner:BEIJING NORMAL UNIVERSITY

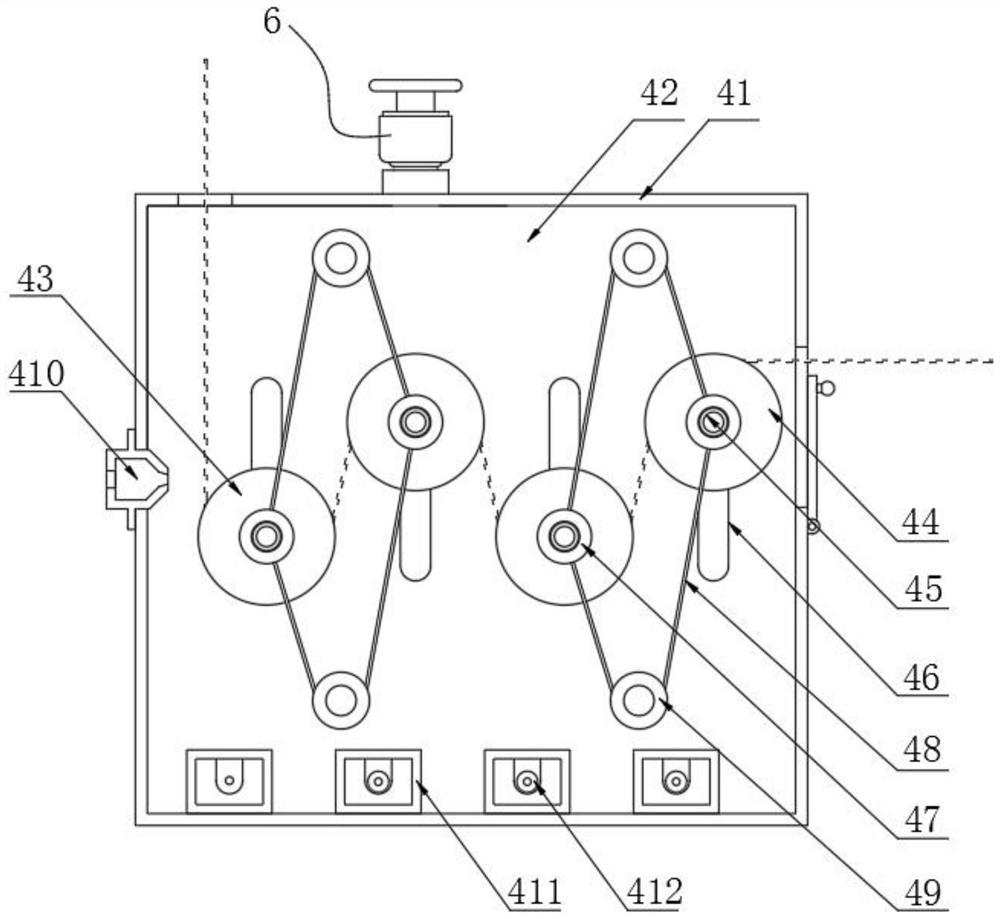

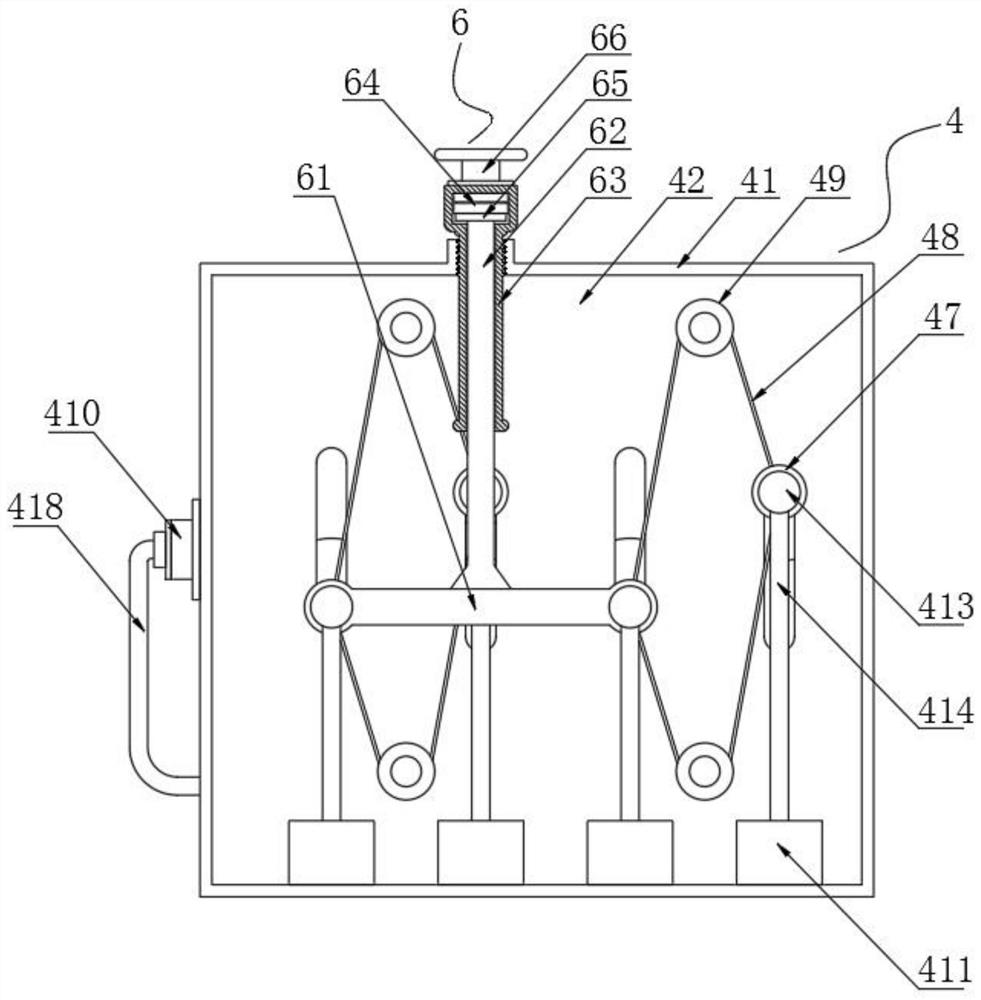

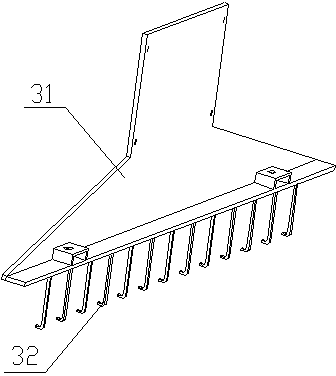

Wire winding device for spinning

ActiveCN106892303AImprove winding efficiencyImprove work efficiencyFilament handlingEngineeringFiber

The invention discloses a wire winding device for spinning. The wire winding device for spinning comprises a base; the top of the base is fixedly connected with the bottom of a wire separating device, and is fixedly provided with a fixed block on one side of the wire separating device; the top of the fixed block is fixedly connected with the bottom of a motor box; a motor is fixedly mounted in the motor box; the wire separating device comprises a shell; a groove is formed in the bottom of the shell; one side of the inner wall of the groove is fixedly connected with one side of a wire separating plate; and a bearing is embedded in one side, far from the inner wall of the groove, of the wire separating plate. The wire winding device for spinning is provided with the wire separating device; the wire separating plate, a wire separating rod, a baffle plate and a wire separating hole are matched with each other; a winding cylinder for winding chemical fibers is fixed on the wire separating rod; each chemical fiber singly penetrates through the wire separating hole, so that the chemical fibers cannot be wound together during separating; and meanwhile, multiple sets of chemical fibers can be synchronously wound, so that the wire winding efficiency is greatly improved.

Owner:绍兴市欣明家居有限公司

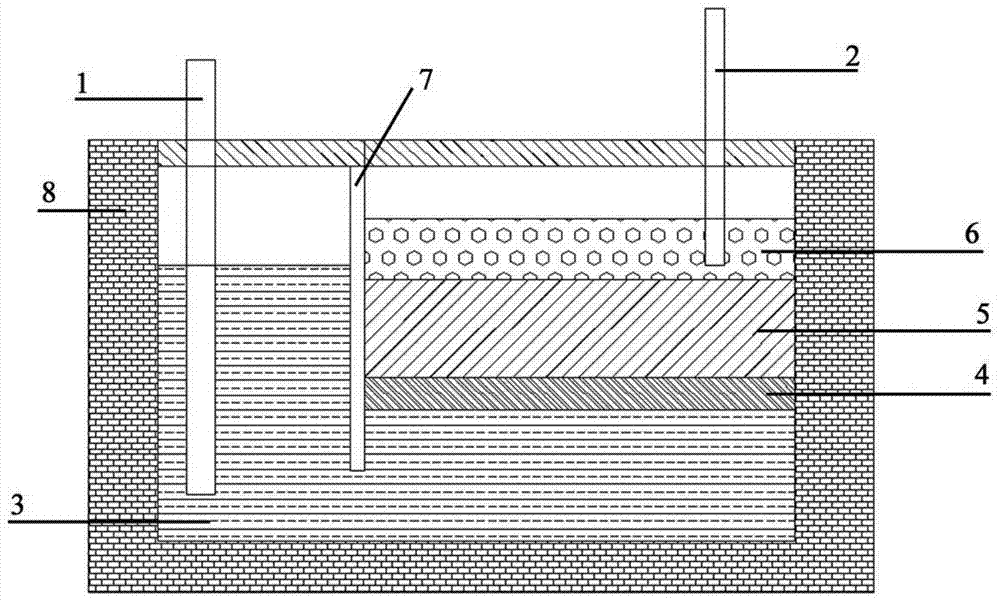

Method for producing calcium metal by performing electrodeposition and refining synchronously

The invention belongs to the technical field of molten salt electrolysis, and discloses a method for producing calcium metal by performing electrodeposition and refining synchronously. According to the method, three stable liquid layers with different densities are established in an electrolytic cell, wherein the three stable liquid layers respectively are light-phase calcium-containing molten salt of which the density is higher than calcium metal, heavy-phase calcium-containing molten salt of which the density is higher than the light-phase calcium-containing molten salt, and a molten calcium alloy intermediate phase of which the density is between the density of the heavy phase and the density of the light phase; the molten calcium alloy intermediate phase is taken as a bipolar electrode, the side of the molten calcium alloy intermediate phase, which is in contact with the heavy-phase calcium-containing molten salt is used as a liquid cathode for dissolving calcium metal generated by electrodeposition, and the side of the molten calcium alloy intermediate phase, which is in contact with the light-phase calcium-containing molten salt is used as a soluble anode for precipitating element calcium out of the heavy-phase calcium-containing molten salt in the form of calcium metal at the cathode. By adopting the method, the electrodeposition and refining of calcium metal are realized at the same time in one electrolytic cell, and physical isolation of the heavy phase from the light phase as well as holding of impurities are realized through the intermediate phase, so that the purity of the finished product of calcium metal is improved.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI

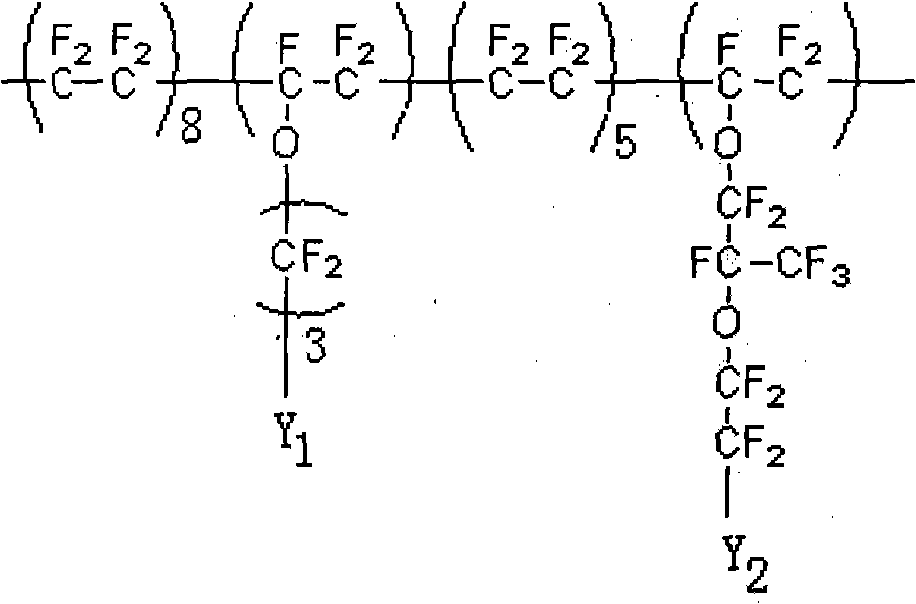

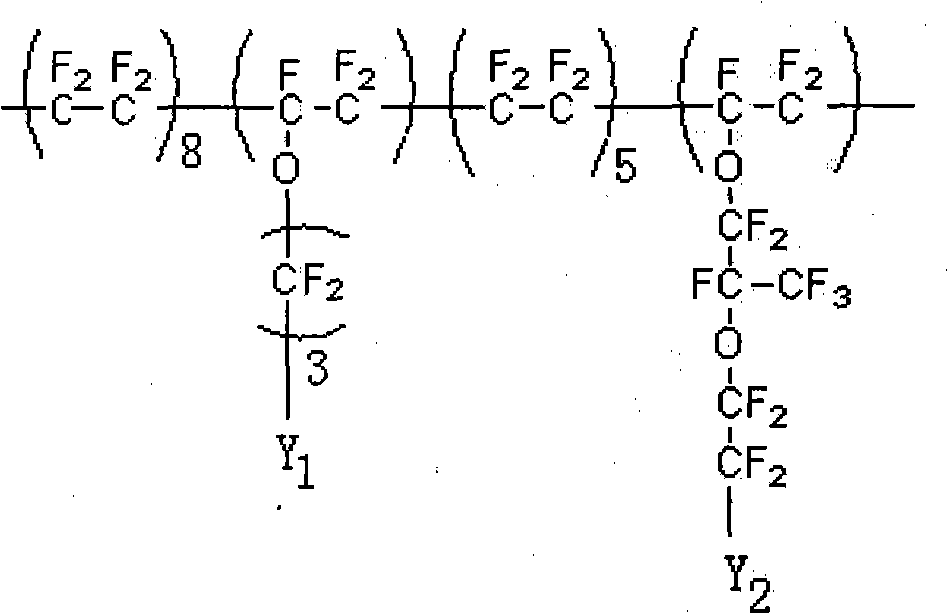

Inorganic metal ion mixing with fluorine proton exchange membrane and preparing method thereof

ActiveCN101773792AImprove ionic conductivityIncrease profitSemi-permeable membranesFinal product manufactureIon mixingSurface modification

The invention relates to an inorganic metal ion mixing with fluorine proton exchange membrane for a fuel cell and a preparing method thereof. In the fluorine proton exchange membrane, inorganic metal ion takes ion conductivity ceramics as a carrier to be distributed in fluorinion exchange resin. The preparing procedures of the fluorine proton exchange membrane are as follows: the ion conductivity ceramics material is purified, and thermoplastic resin is used to embellish the surface of the ion conductivity ceramics material, preparing inorganic metal compound taking the ion conductivity ceramics as the carrier, and preparing the inorganic metal ion mixing with fluorine proton exchange membrane used for the fuel cell. The proton exchange membrane used for the fuel cell has higher conductivity and stronger mechanical intensity, thus facilitating the improvement of the performance of the fuel cell.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

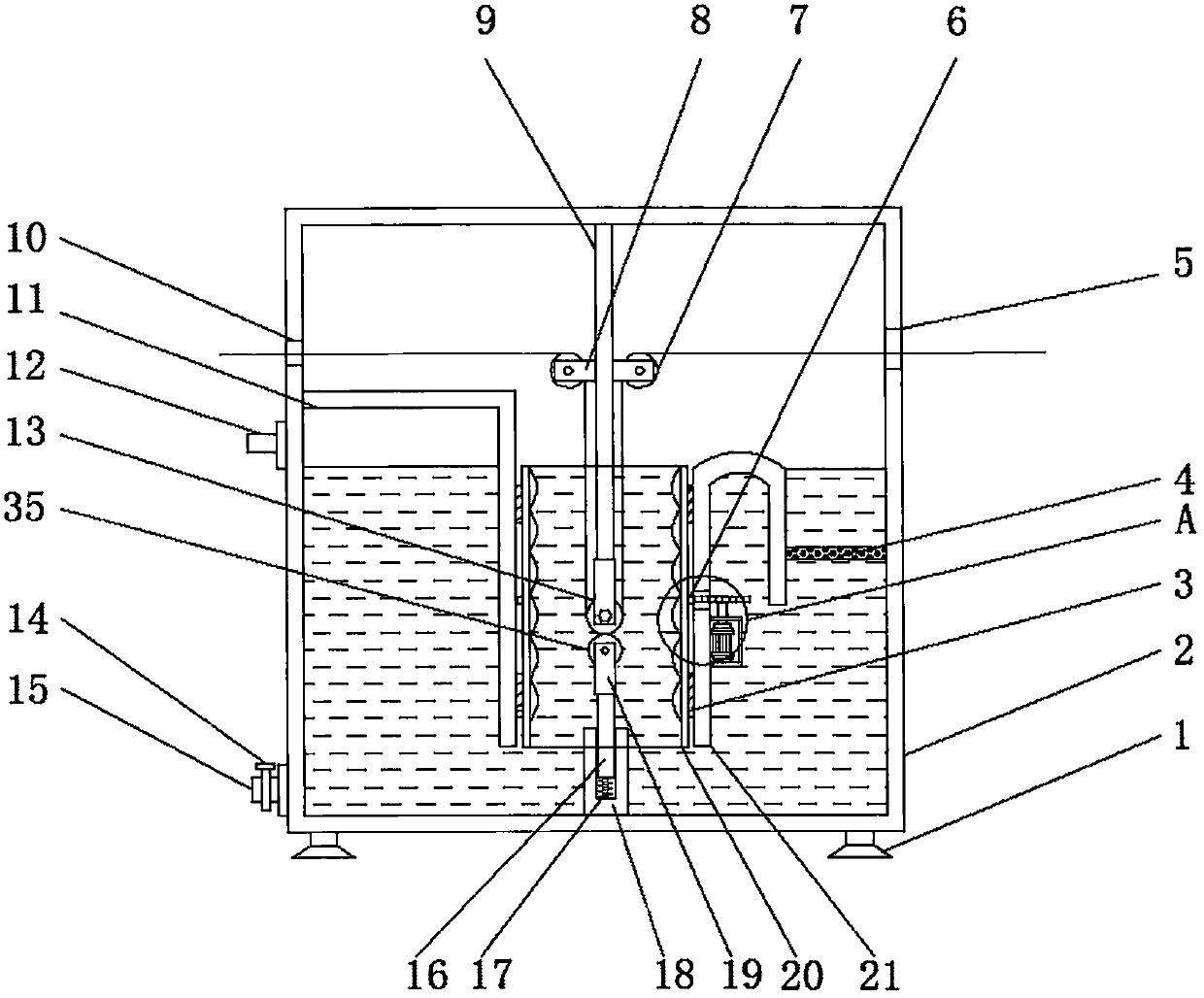

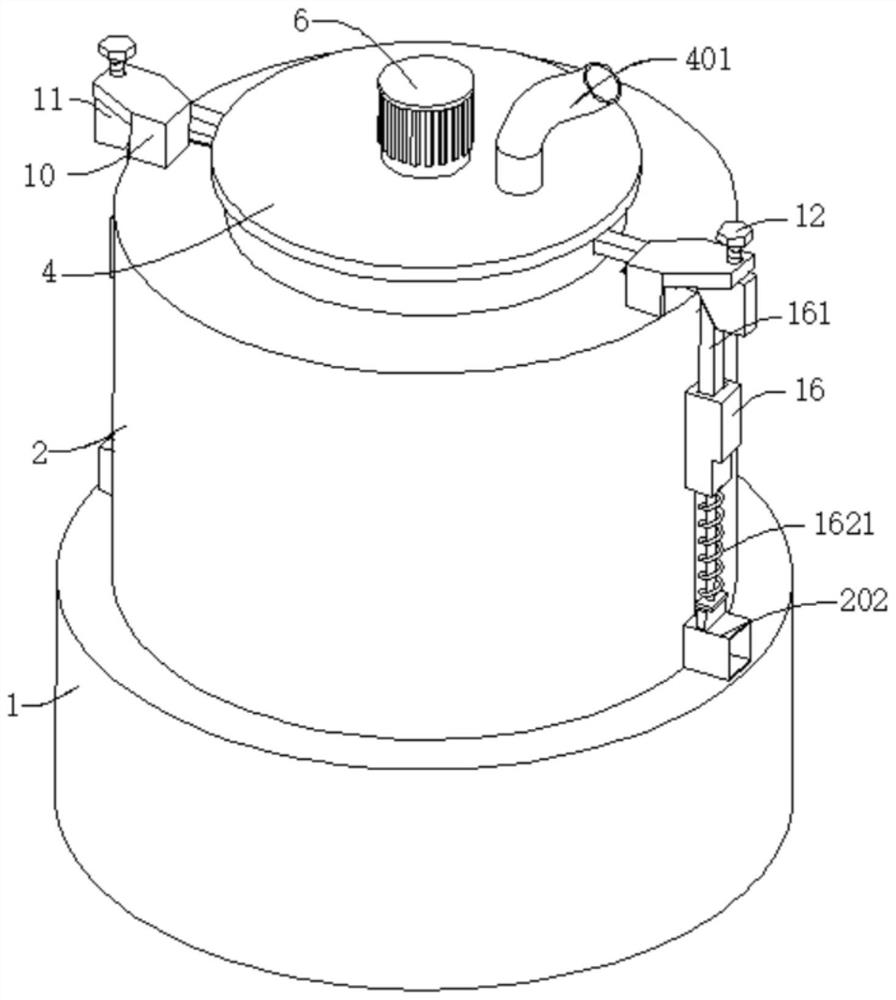

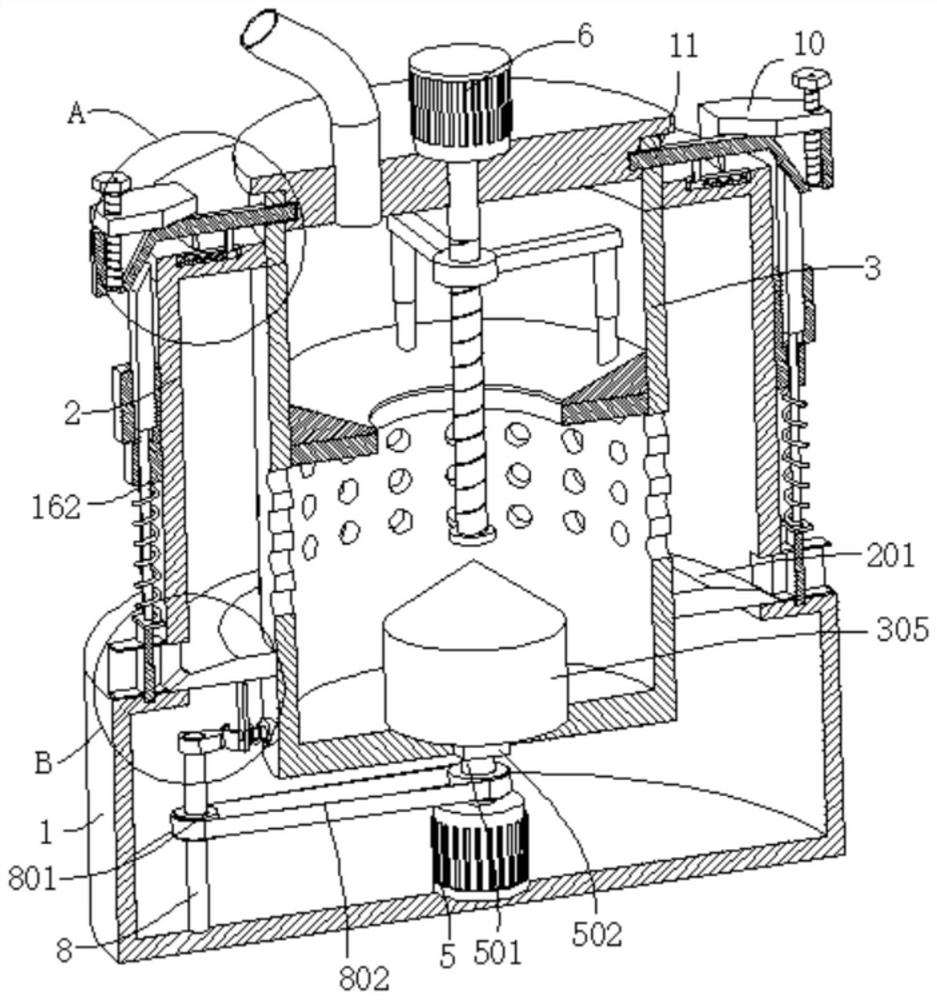

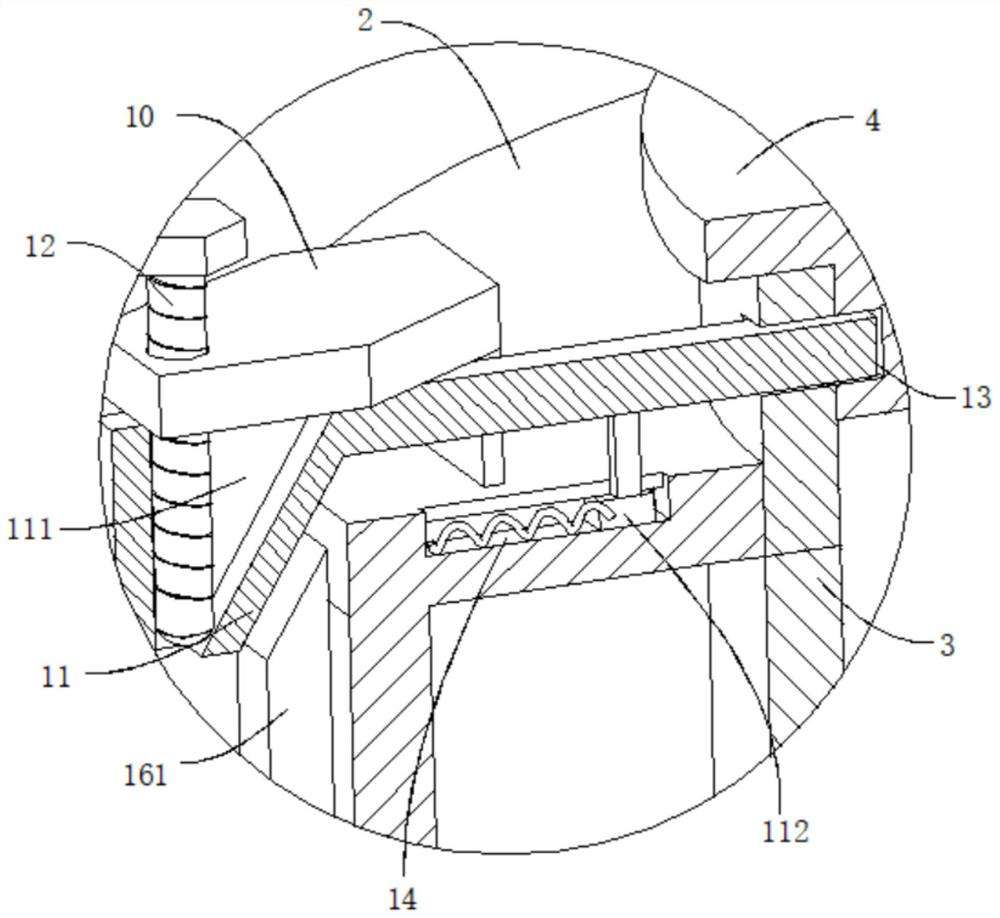

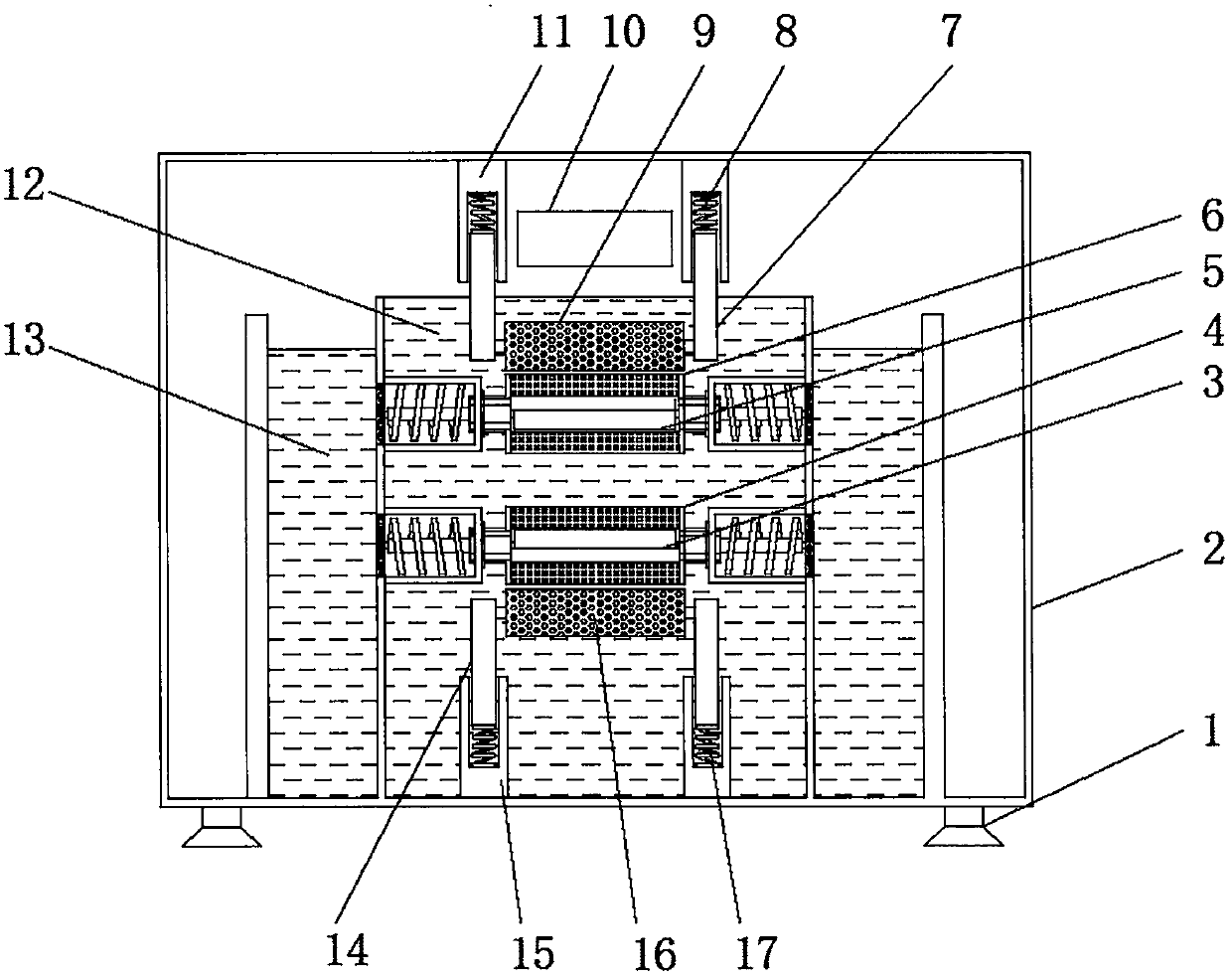

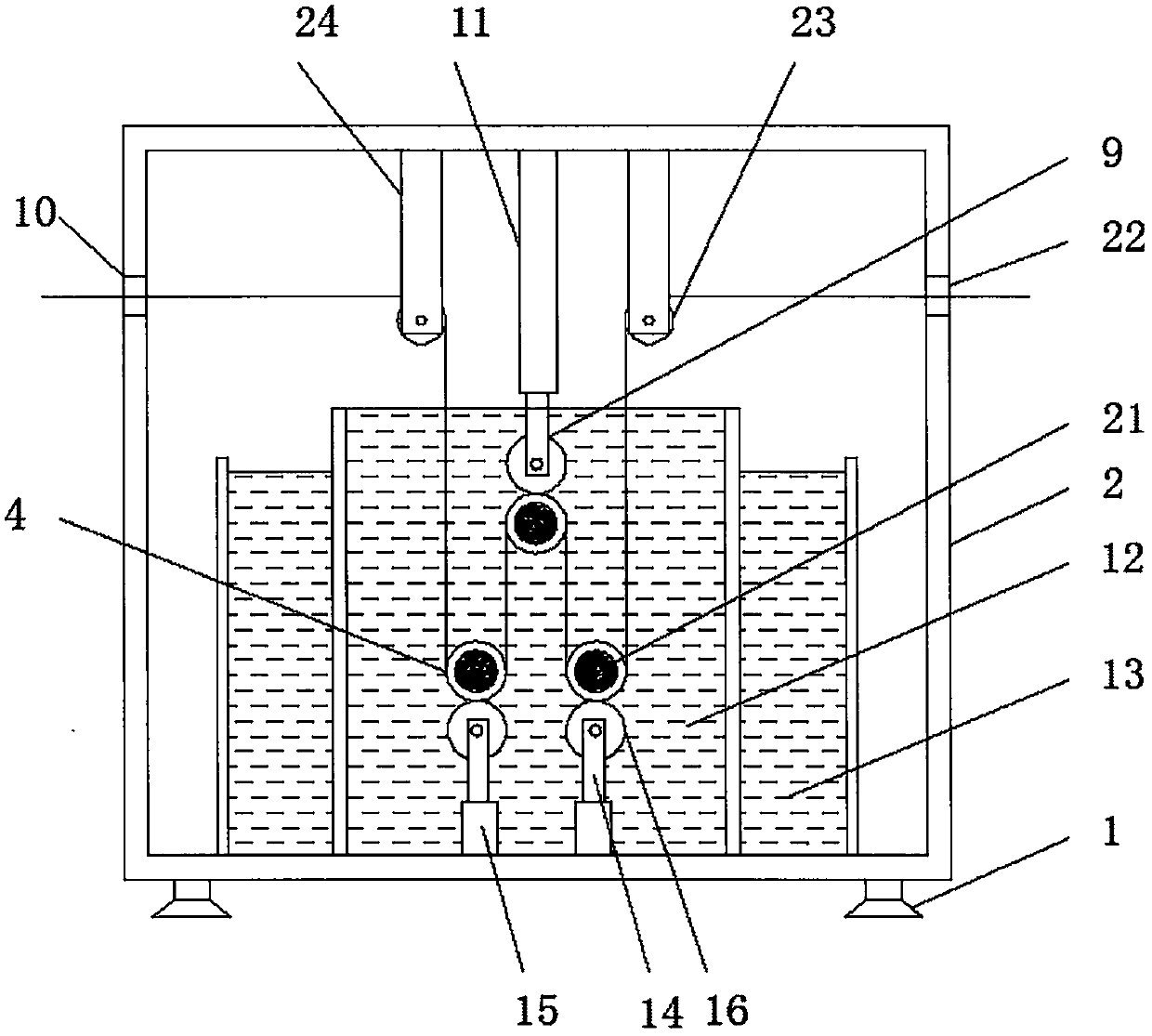

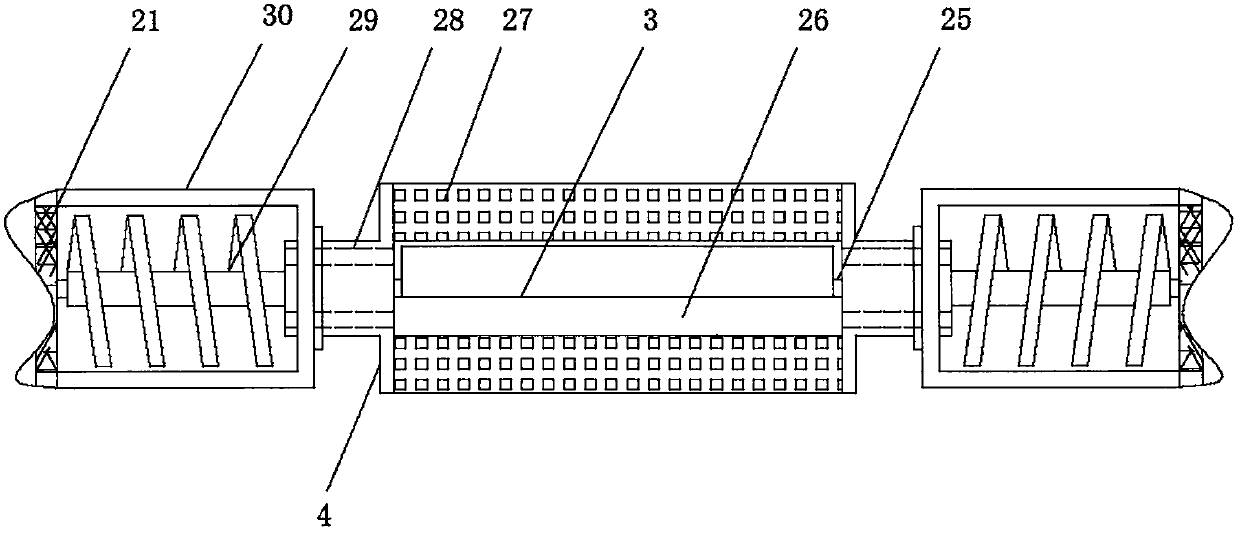

Sewage treatment device

ActiveCN112321126AEasy to handleEasy to separateSludge treatmentMoving filtering element filtersElectric machineryDrive motor

The invention discloses a sewage treatment device, and relates to the technical field of fecal treatment. The sewage treatment device comprises a shell, a first treatment mechanism, a second treatmentmechanism and a pressing adjusting mechanism, a treatment cavity is formed in the shell, the first treatment mechanism comprises a first driving motor and a first treatment assembly, and the second treatment mechanism comprises a second driving motor and a second treatment assembly; the second driving motor is installed at the upper end of the shell and is in transmission connection with the second treatment assembly, a feeding funnel is arranged at the upper end of the shell and communicates with the first treatment assembly, a liquid discharging pipe is arranged at the lower end of the shell, a discharging opening is formed in one end of the shell, and the pressing adjusting mechanism comprises a pressing assembly and an auxiliary discharging assembly; the pressing assembly is installedat the discharging opening, and the auxiliary discharging assembly is installed on the pressing assembly. Through two times of treatment, the excrement water separation effect can be improved, subsequent sewage treatment is facilitated, and the device can be suitable for treating excrement with different humidity.

Owner:烟台嘉特生物技术有限公司

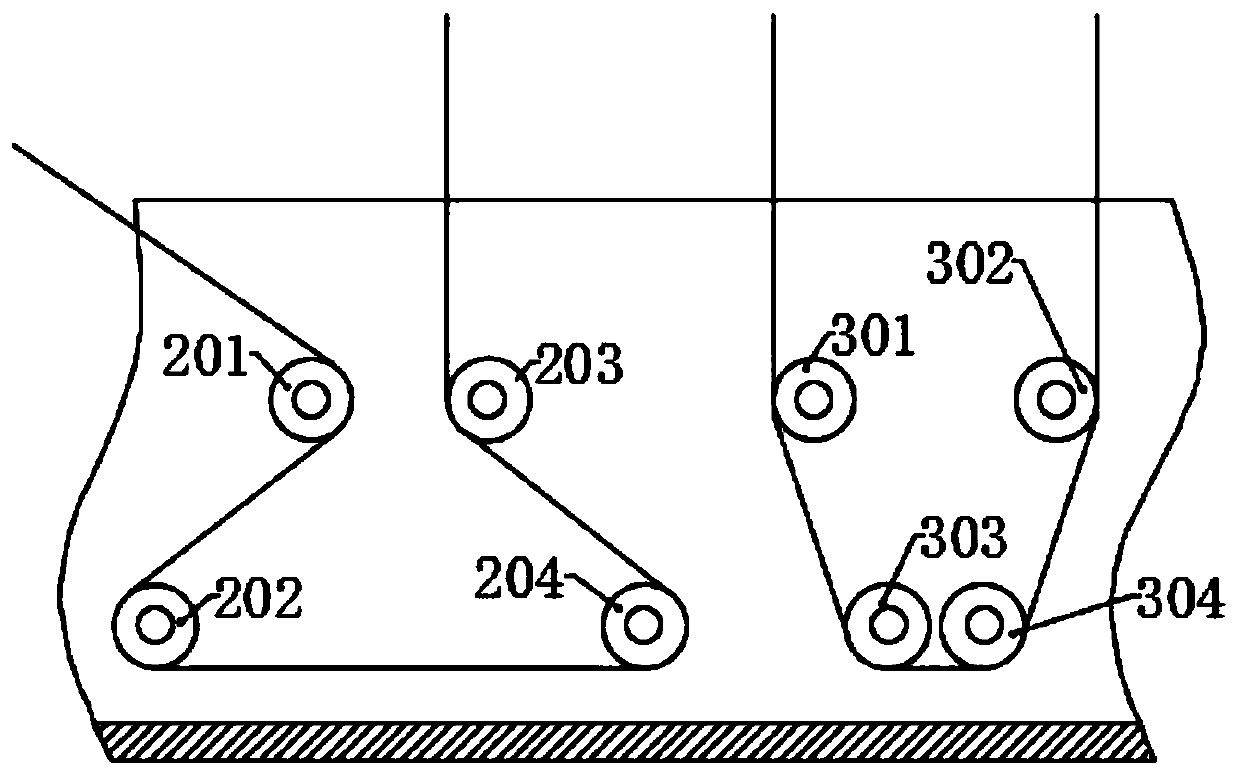

Textile fabric dyeing device with good dyeing uniformity

ActiveCN110878454AIncrease pressureIncrease contact areaTextile treatment machine arrangementsLiquid/gas/vapor treatment of indefinite length materialsPolymer scienceEngineering

The invention discloses a textile cloth dyeing device with good dyeing uniformity, which comprises a housing, a second guide roller support, a sleeve and an inner spiral pipe; a cloth feeding port isarranged at the top of one side of the housing, a cloth discharging port is arranged at the top of the other side of the housing, an L-shaped retainer is arranged on the inner wall of the housing below the cloth feeding port, and an n-shaped retainer is arranged in the housing at one side of the cloth feeding port. The second guide roller is driven to rotate through the transmission of cloth, a dye liquor is pressed into a cavity and is sprayed from a second outlet, the contact area between the cloth and the dye liquor is increased, and the dyeing efficiency is improved; in addition, the dye liquor inside the inner spiral pipe is rotated and surges upward; when the dye liquor rotates, the dye liquor can penetrate the cloth, so that the dyeing efficiency for the cloth is further improved, the cloth is uniformly dyed, and a dye in the dye liquor is prevented from precipitating; when the dye liquor surges upward, impurities floating on the surface of the dye liquor move to the other sideof the n-shaped retainer and are filtered so that the dye liquor is kept clean, the service life of the dye liquor is prolonged, and the cost is reduced.

Owner:JIANGSU SHUANGSHAN GRP

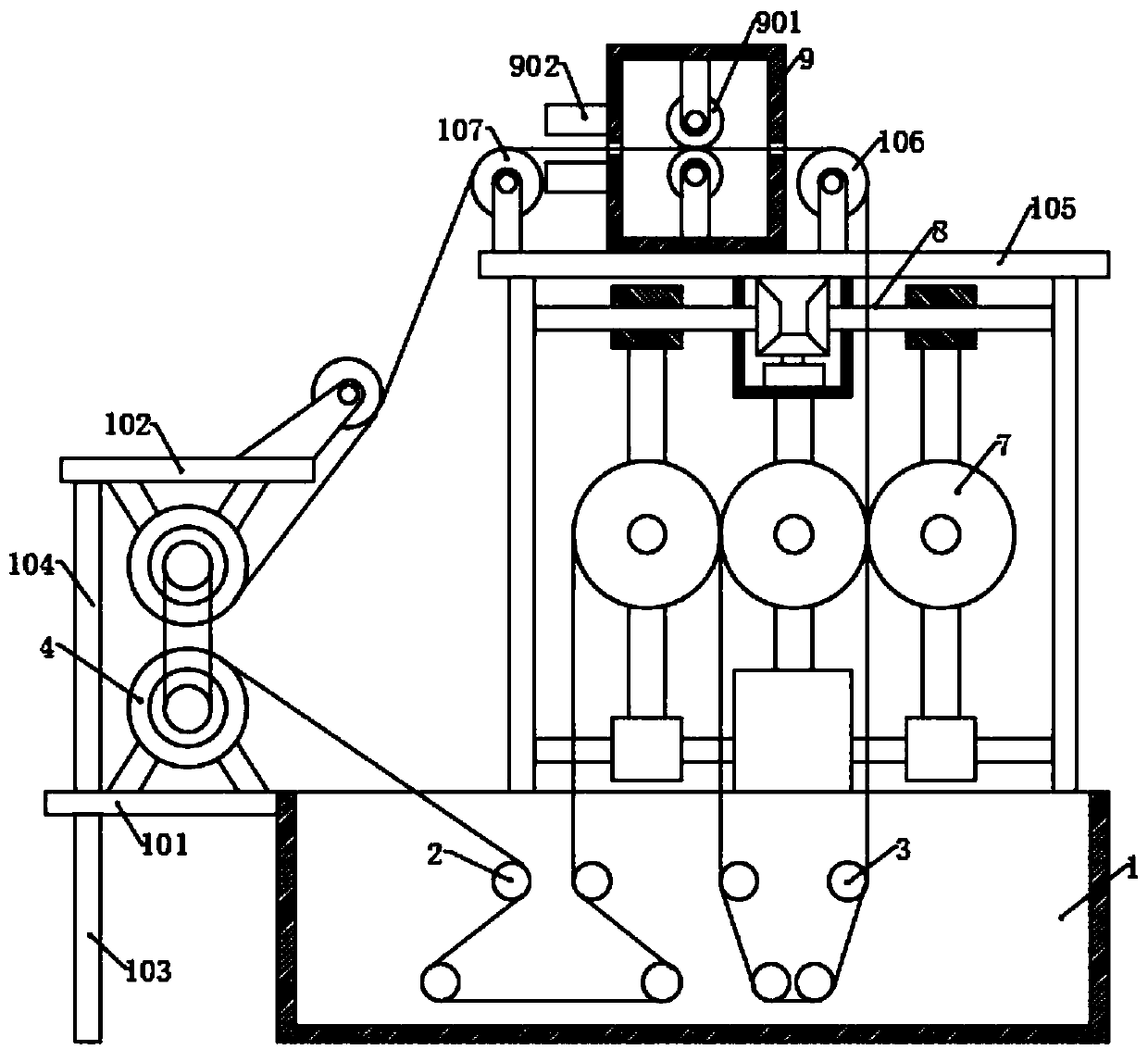

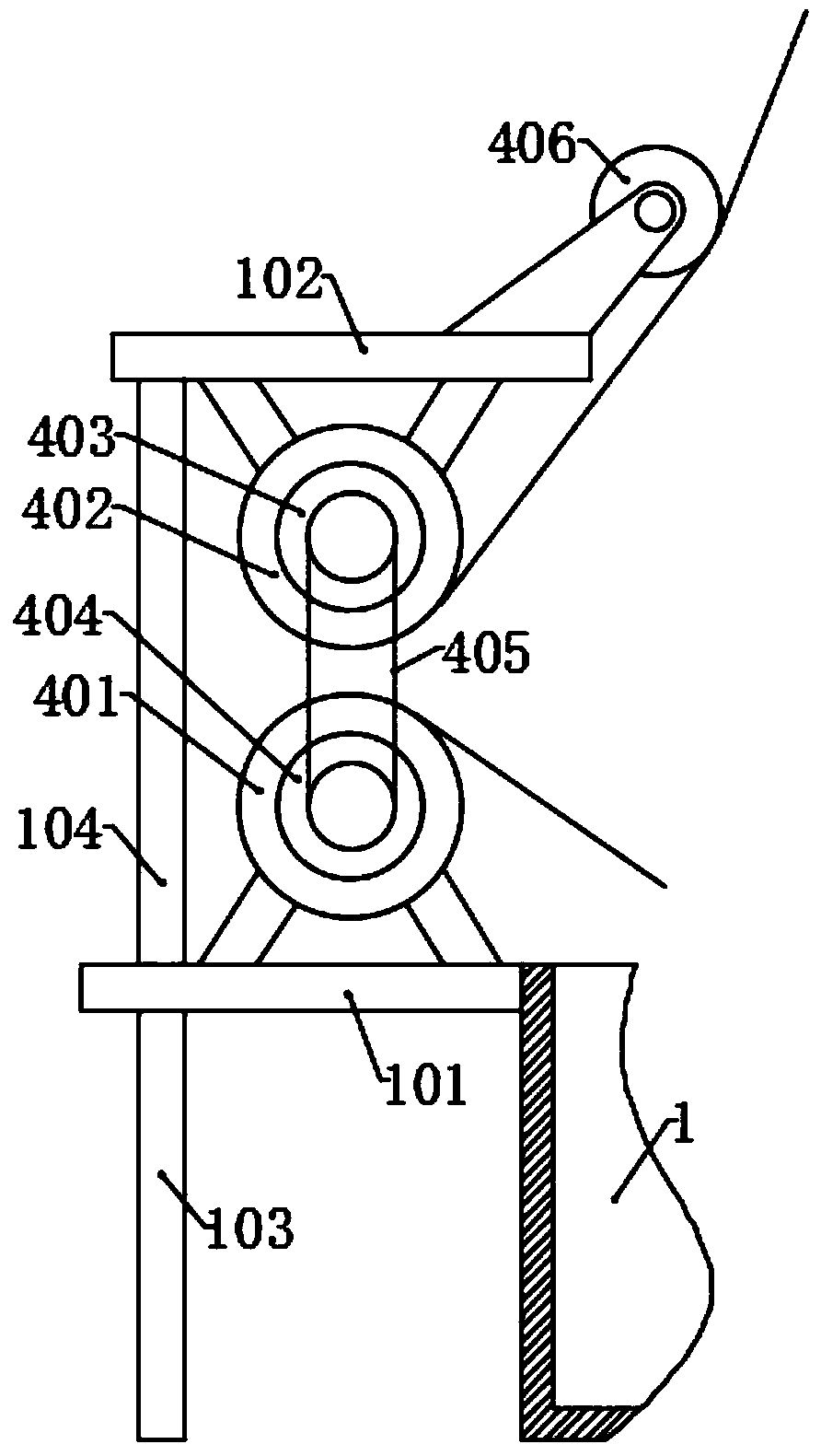

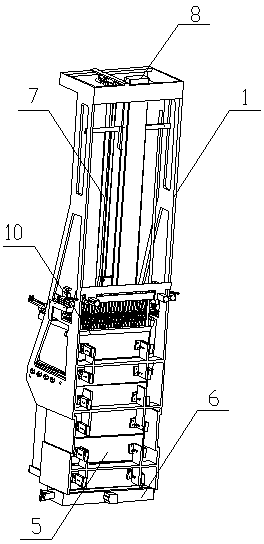

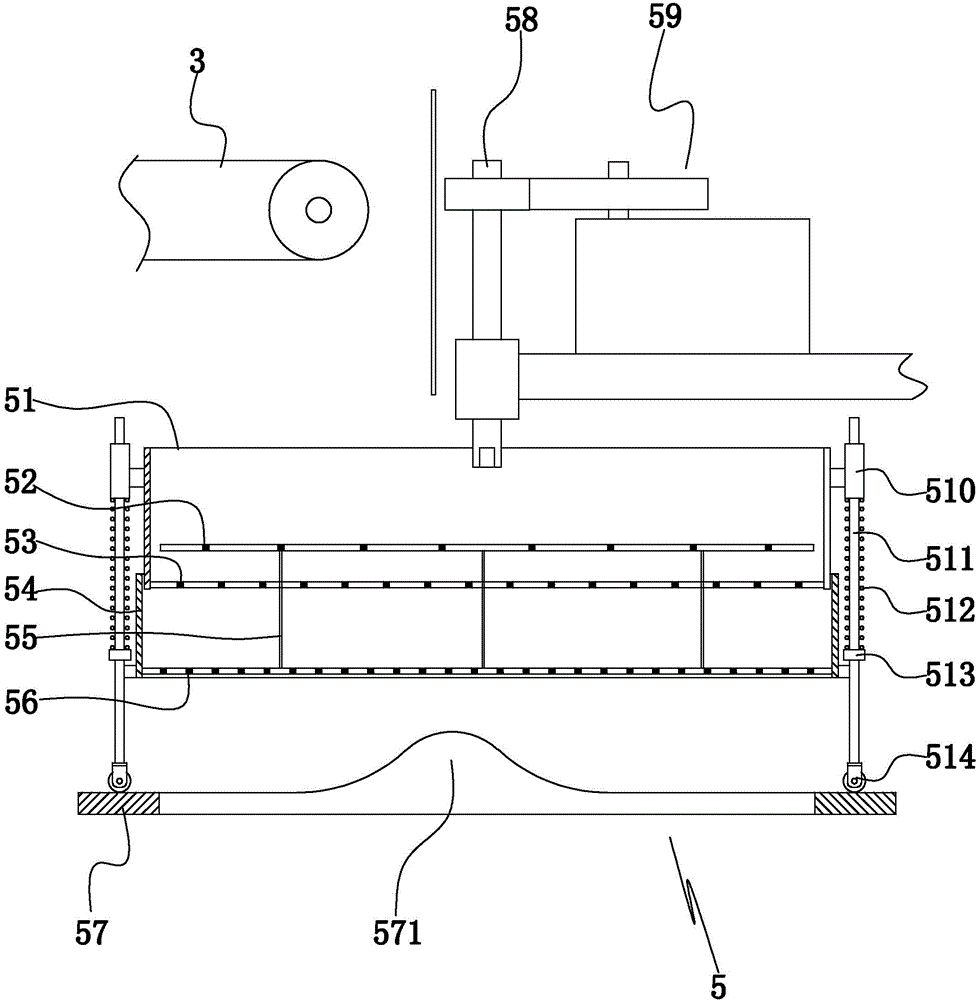

Production system of ultra-low shrinkage bright FDY and operation method thereof

ActiveCN111926403AHeight adjustableControl tensionNew-spun product collectionArtificial thread manufacturing machinesFiberIndustrial engineering

The invention discloses a production system of ultra-low shrinkage bright FDY and an operation method thereof. The production system comprises a spinneret box, an oil rolling tank, a network box, a heating shaping box and a package mechanism, wherein the spinneret box is fixedly connected to the top of the oil rolling tank. The invention relates to the technical field of textile equipment. According to the production system of the ultra-low shrinkage bright FDY and the operation method thereof, pulleys are arranged to be matched with digging ropes to connect two heating rollers and two shapingrollers correspondingly, when switching to a working mode, fiber filaments move in an S shape between the heating rollers and the shaping rollers, contact area is enough for heating shaping, before processing, a group of heating rollers and shaping rollers are pulled up by a lifting device, and a horizontal gap can be formed between the upper and lower two groups of heating rollers and shaping rollers, under the blowing of airflow, the fiber filaments can quickly pass through the heating rollers and the shaping rollers to extend to the right side, and traction and limit of the filaments are quick and convenient without the need of turning on equipment, the chance of dust pollution is reduced, and the efficiency is improved.

Owner:杭州辰泽新材料有限公司

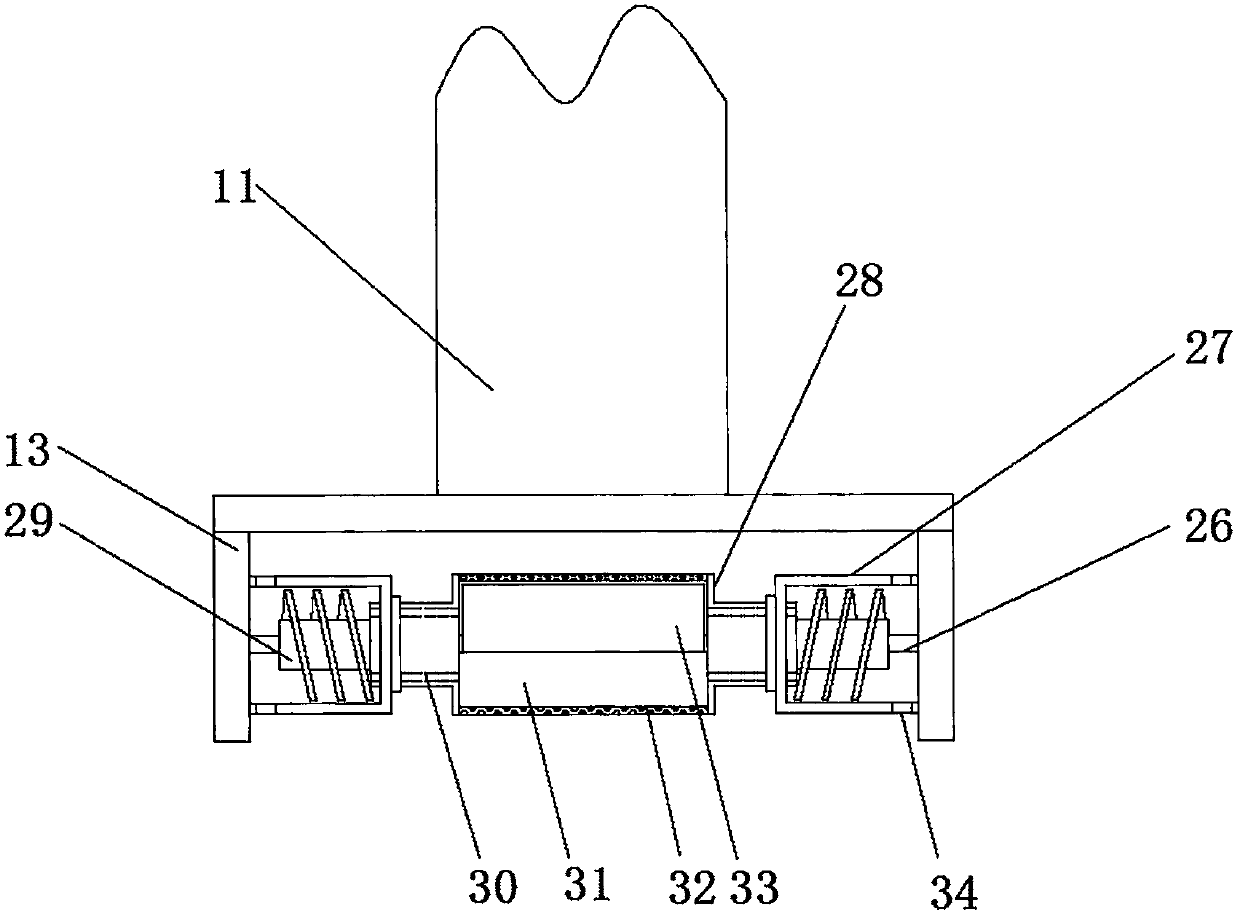

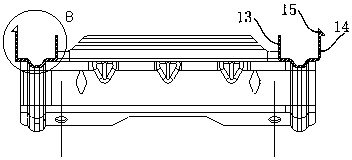

Yarn sizing and shaping equipment for textile processing

InactiveCN110923990AImprove sizing effectAvoid position shiftTextile treatment carriersTextile treatment rollersTextile yarnHeat setting

The invention discloses yarn sizing and shaping equipment for textile processing in the technical field of textile processing. The yarn sizing and shaping equipment comprises a sizing pool, a first sizing mechanism, a second sizing mechanism, a material winding mechanism, an extrusion mechanism and a shaping box. Spinning yarns are fed by a feeding tube, are subjected to primary sizing by the first sizing mechanism in the sizing pool, then enter a yarn guide groove of a first press roller, are subjected to primary extrusion action by an extruding table of a second press roller, then downwardsmove to be subjected to secondary sizing by the second sizing mechanism, and next upwards enter a yarn guide groove of the third press roller to be subjected to secondary extrusion by the extruding table of the second press roller; twice sizing and twice extrusion are performed; after sizing, the yarns enter the shaping box through a first guide wheel; the yarns are subjected to hot shaping by using a heating roller, and are finally rolled on a material collecting tube; the yarns always move along the yarn guide groove, so that position deviation when the yarns move is avoided; and through thesecond press roller, the yarns at the two sides are extruded at the same time.

Owner:安徽云至信电子商务有限公司

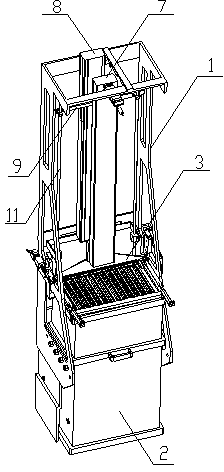

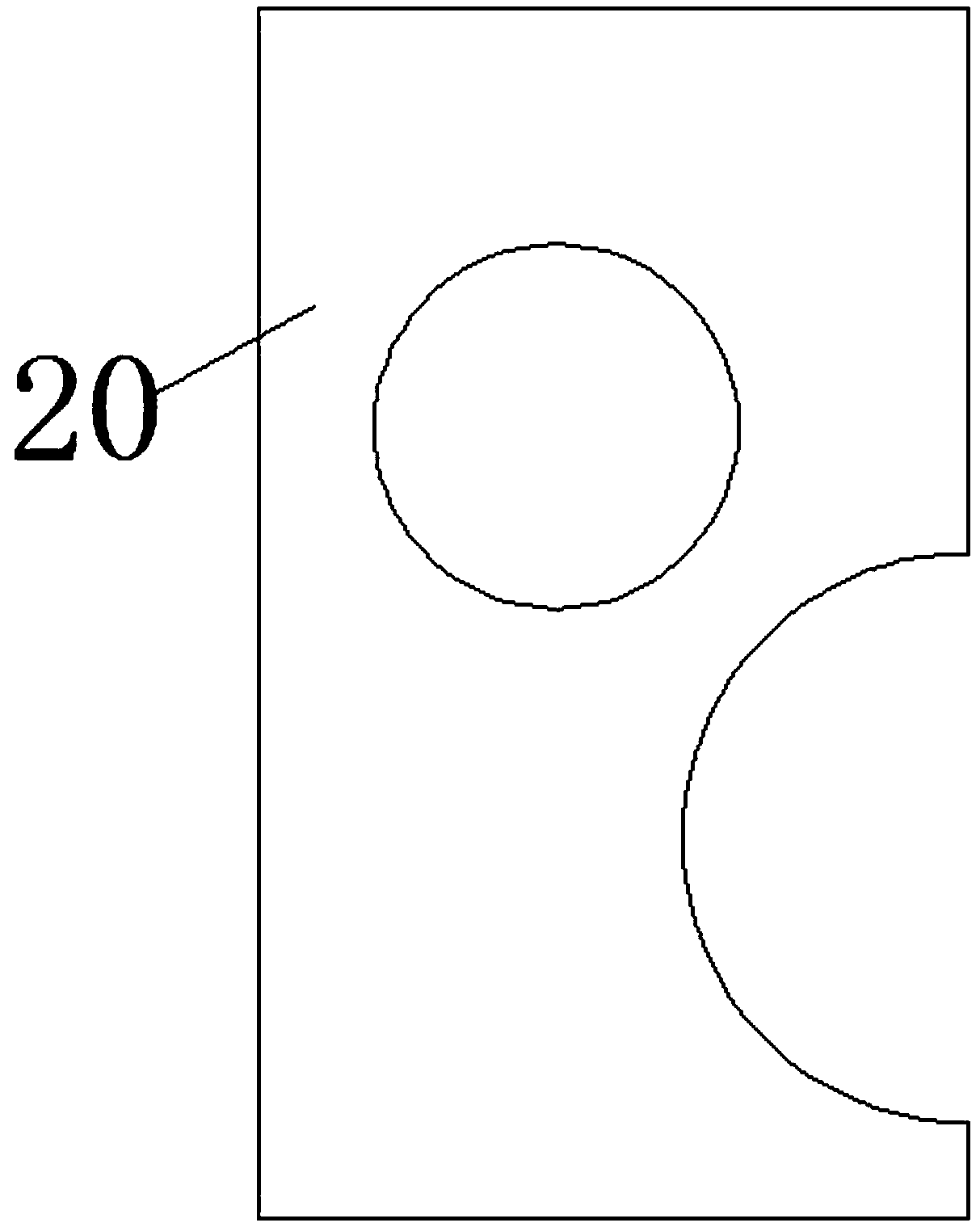

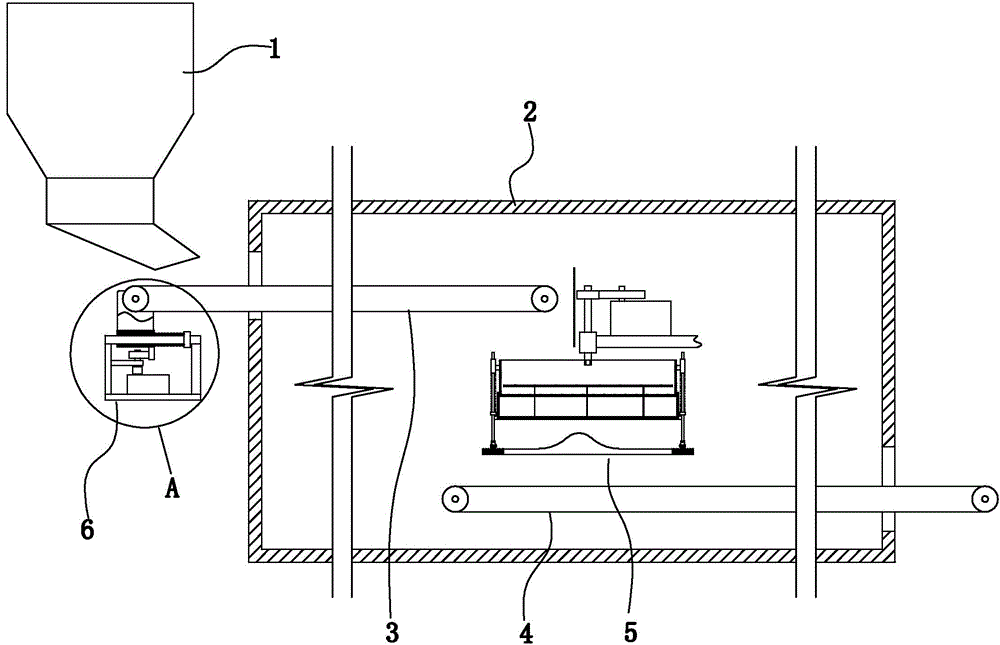

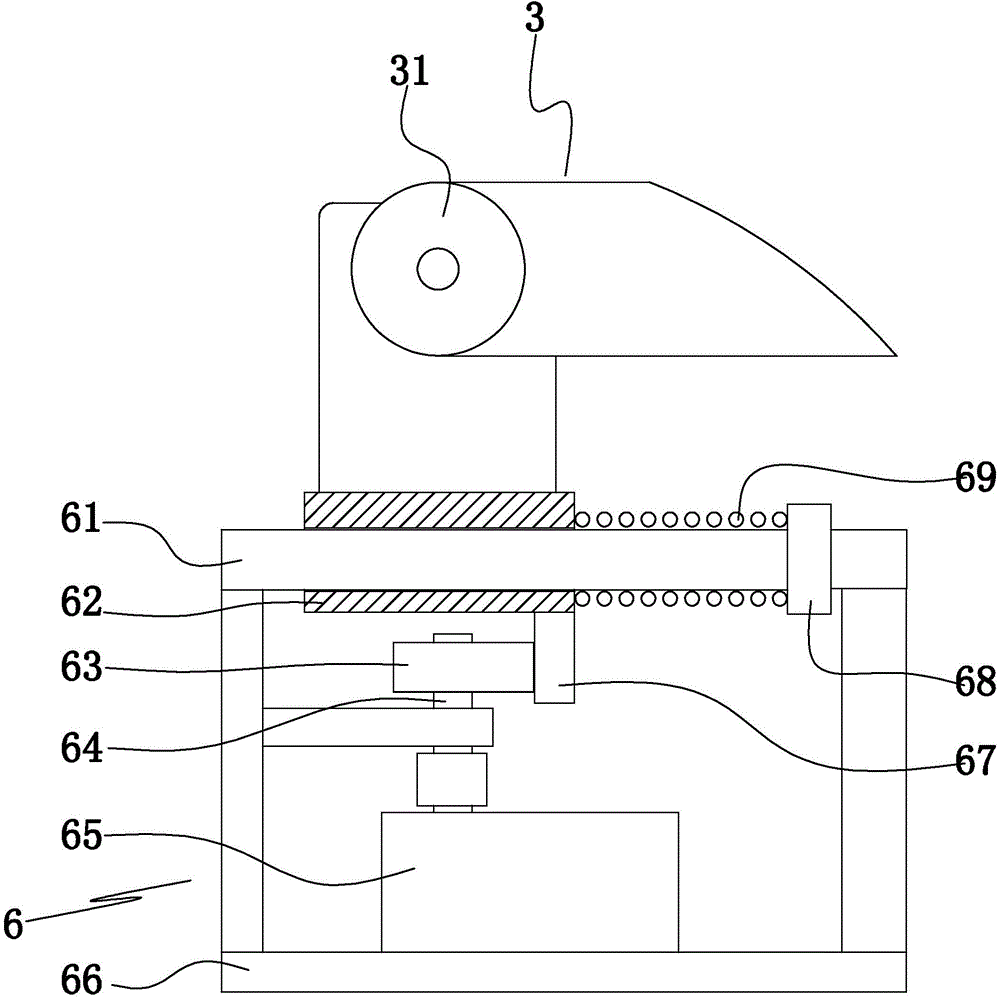

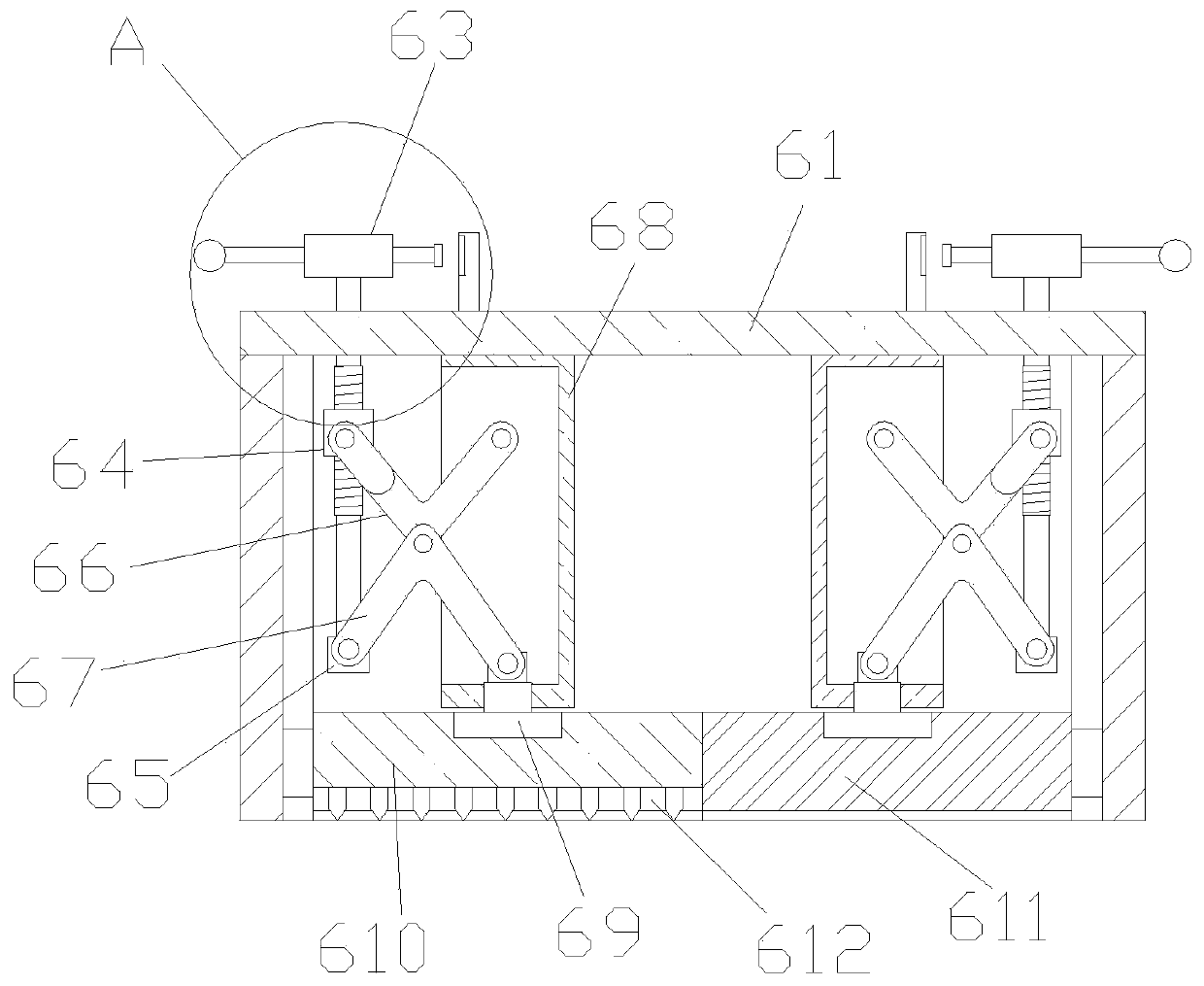

Air-conditioner heat dissipation copper pipe drawing-inserting mechanism

InactiveCN103170551AGrow fastRealize up and down positioningMetal-working feeding devicesHeat exchange apparatusEngineeringCopper tubing

The invention discloses an air-conditioner heat dissipation copper pipe drawing-inserting mechanism which comprises a rack, a work bin, a pothook mechanism, a heat dissipation copper pipe clamp mechanism, a guide mechanism and a heat dissipation copper pipe end opening aligning mechanism. According to the air-conditioner heat dissipation copper pipe drawing-inserting mechanism, the fact that a heat dissipation copper pipe is rapidly lifted can be achieved, bending of the heat dissipation copper pipe in pipe penetrating is avoided, aligning of the end opening of the opening end of the heat dissipation copper pipe can be carried out, so that automatic pipe penetrating of the heat dissipation copper pipe is achieved, labor intensity of workers is greatly reduced, and working efficiency is improved.

Owner:重庆伟略智能系统集成技术有限公司

Method for planting calliopsis on side slope

ActiveCN105917897ARich biodiversityImprove germination rateBiocideBioloigcal waste fertilisersEmulsionPre treatment

The invention discloses a method for planting calliopsis on a side slope. The method comprises the following steps: preparing slope surface; backfilling nutrient soil on the slope surface, and laying non-woven fabrics or coarse sand on the nutrient soil; pouring ecological concrete and covering a plastic thin film for maintenance, wherein the ecological concrete is prepared from gravels, cement, micro silicon dioxide powder or fly ash, a water reducing agent and water according to a weight proportion by uniform mixing under stirring; sowing calliopsis seeds and carrying out watering for maintenance, wherein the calliopsis seeds are pretreated through the following steps before sowing: adding starch and 6-benzyl aminopurine into an extract obtained by mixing rhubarb and traditional Chinese medicinal clove, then carrying out stirring so as to obtain an emulsion, and soaking the calliopsis seeds in the emulsion for use. The method provided by the invention enriches diversity of plants cultivated on the ecological concrete; meanwhile, the calliopsis seeds undergo soaking pretreatment in the emulsion of the extract containing rhubarb and traditional Chinese medicinal clove before sowing, so the disease-resisting ability and the survival rate of the calliopsis seeds are improved.

Owner:WUHAN BOTANICAL GARDEN CHINESE ACAD OF SCI

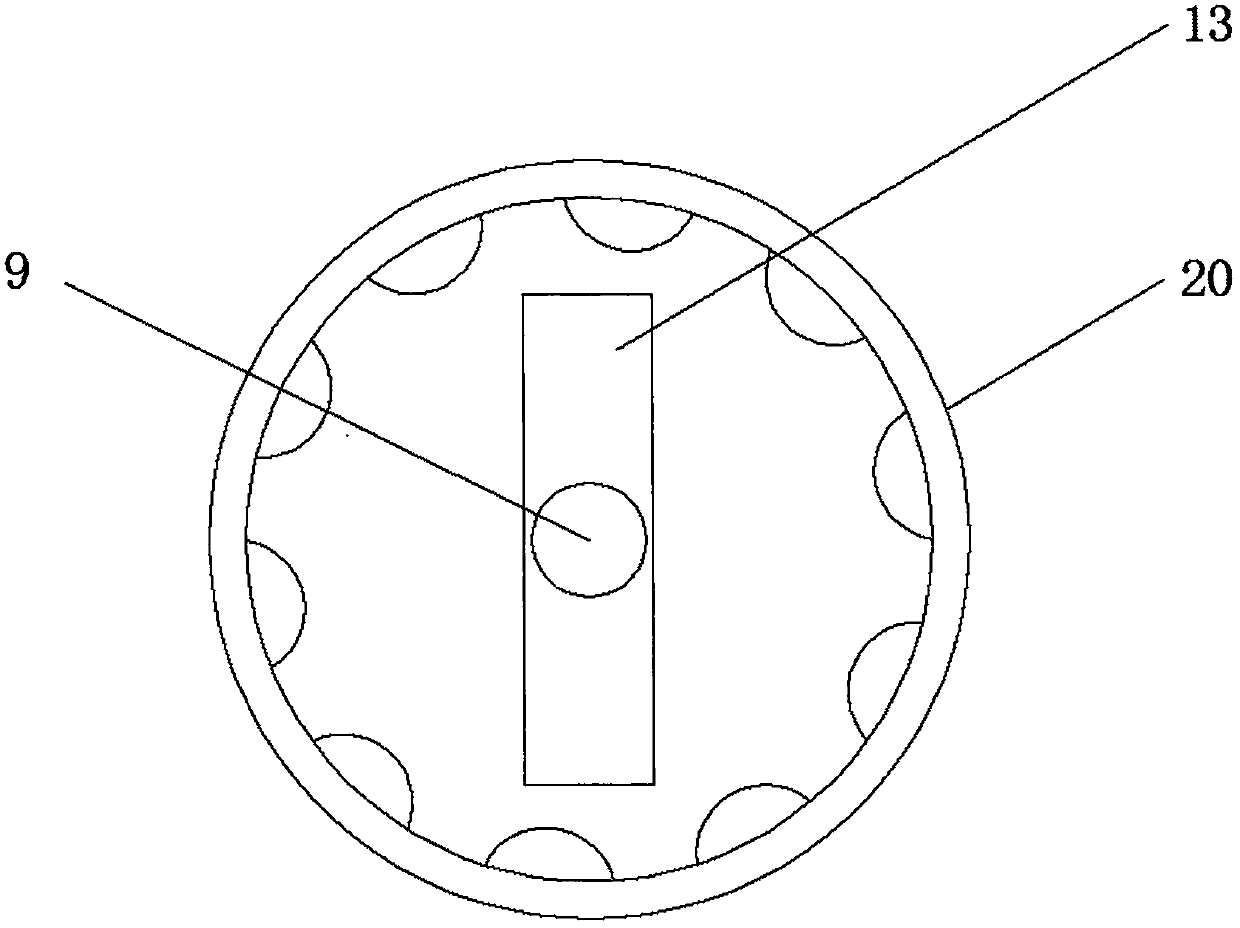

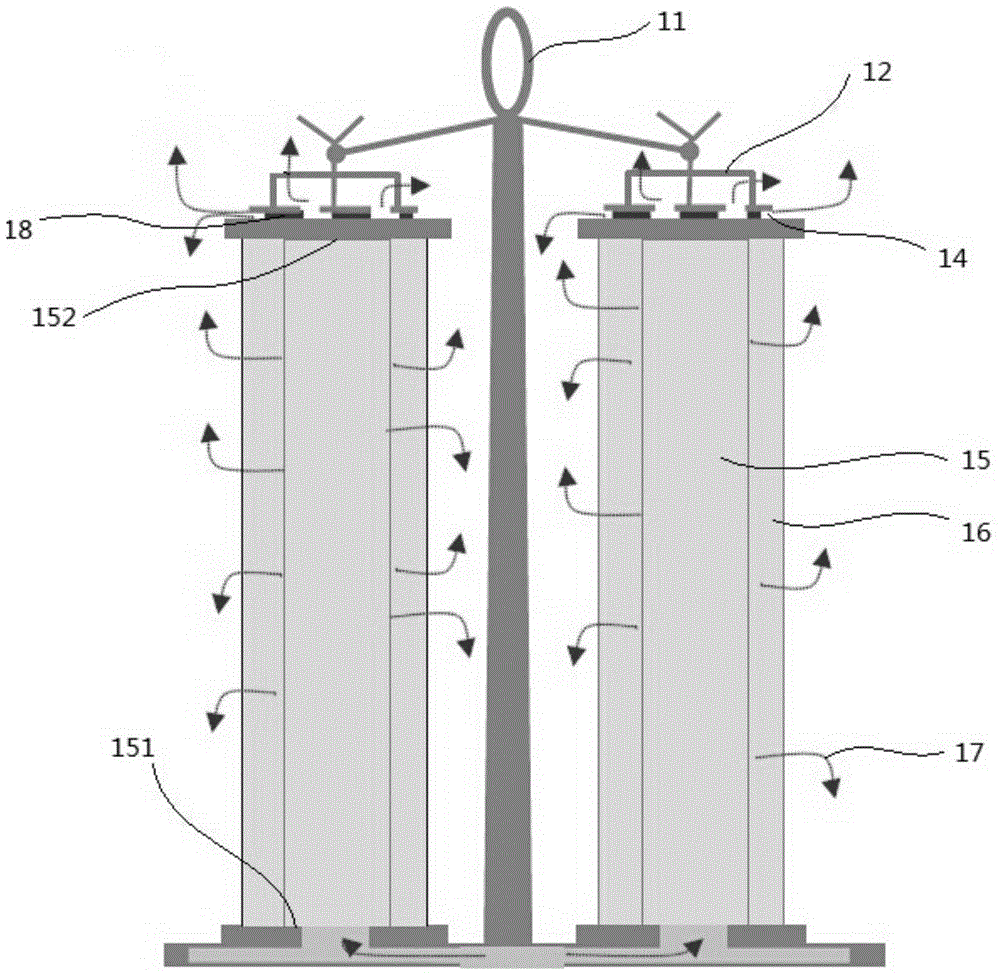

Sewage treatment device facilitating residue removal

PendingCN112456664AAvoid mesh cloggingEasy to pass throughSpecific water treatment objectivesTreatment involving filtrationElectric machineryStructural engineering

The invention discloses a sewage treatment device facilitating residue removal, and belongs to the technical field of sewage treatment. A sewage treatment device facilitating residue removal comprisesa shell base, a shell is connected to the top of the shell base, a partition plate is connected to the inner wall of the shell, drainage pipes are fixedly connected to the outer walls of the two sides of the shell, the drainage pipes are connected to the outer wall of the top of the shell base, and a filter screen cylinder is detachably connected into the shell; a first motor is connected to theinner wall of the bottom of the shell base, a first rotating shaft is connected to the output end of the first motor, a square block is connected to the end, away from the first motor, of the first rotating shaft, a square groove matched with the square block is dug in the outer wall of the bottom of the filter screen cylinder, and filter screen holes are formed in the outer wall of the filter screen cylinder; and the inner wall of the bottom of the filter screen cylinder is also connected with a convex block. Meshes can be prevented from being blocked, sewage can conveniently and quickly penetrate through the meshes, residues can be collected and treated, and the working efficiency of sewage residue removal is improved.

Owner:陈时云

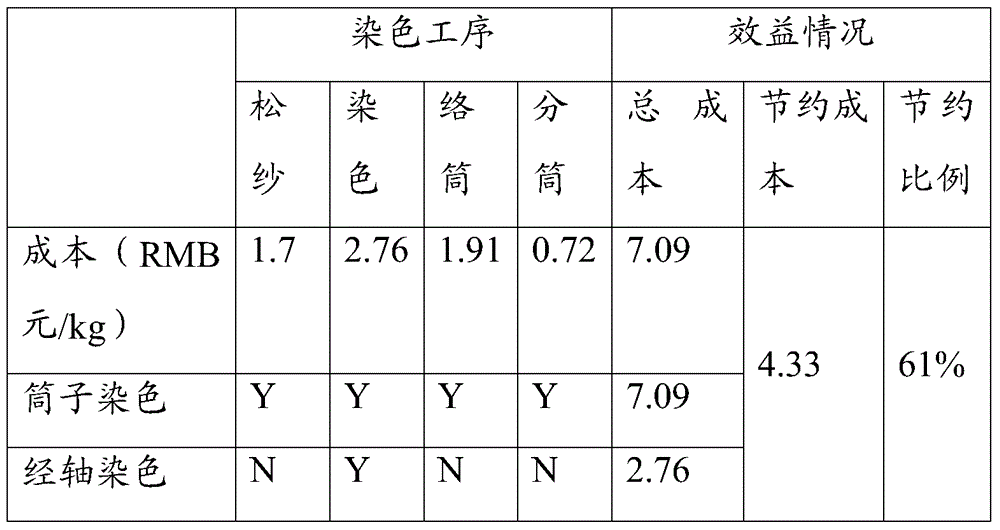

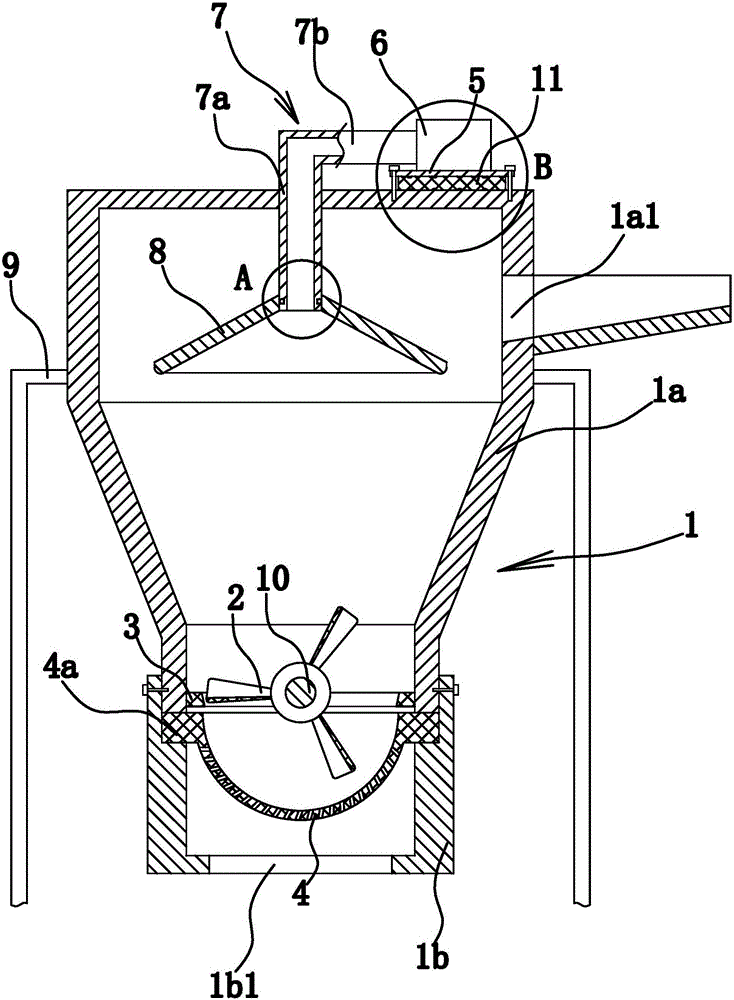

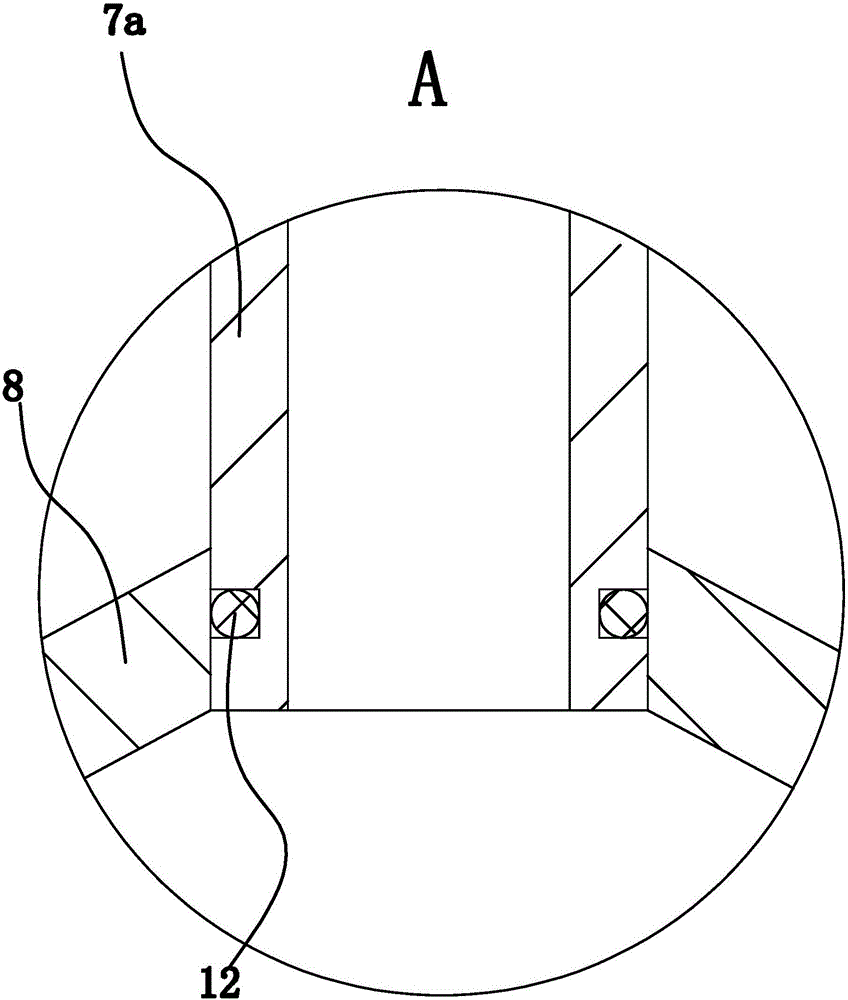

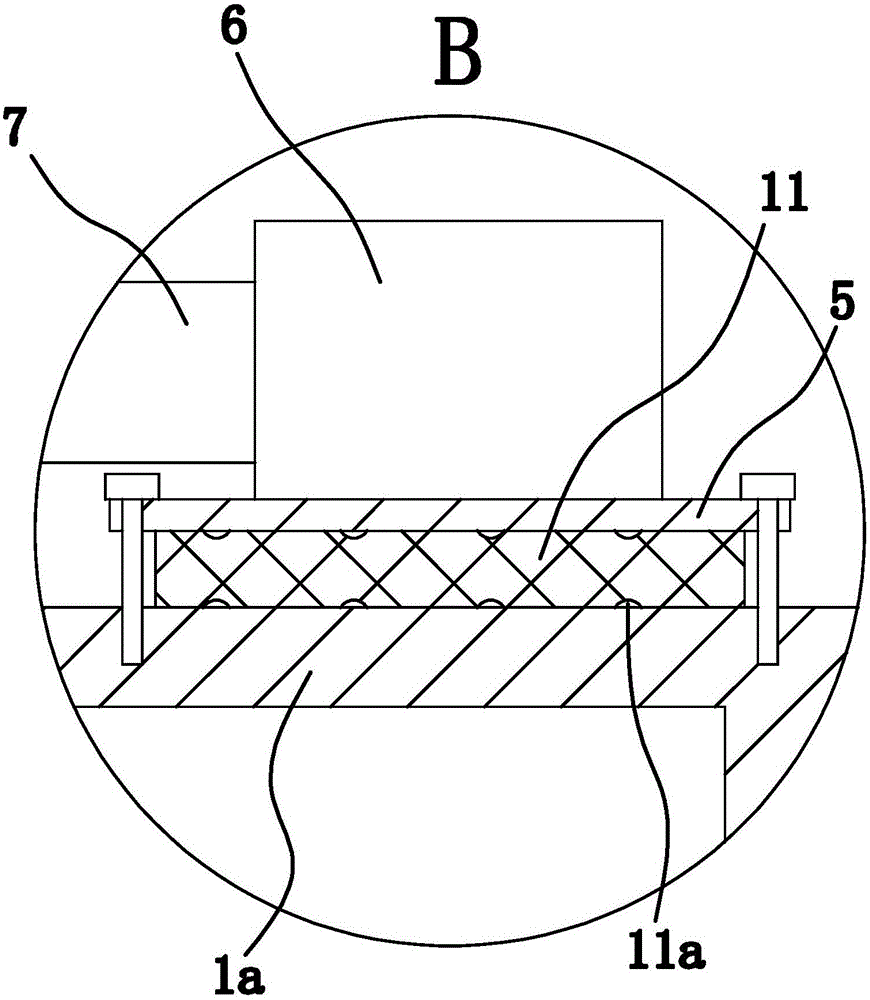

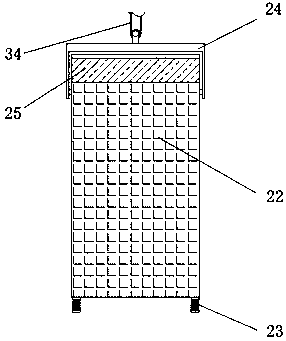

Warp beam cage with baking function and method for baking warp beam yarns or fabrics

ActiveCN104480663ASmooth circulationFast throughSolvent-treatmentTextile treatment carriersYarnEngineering

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

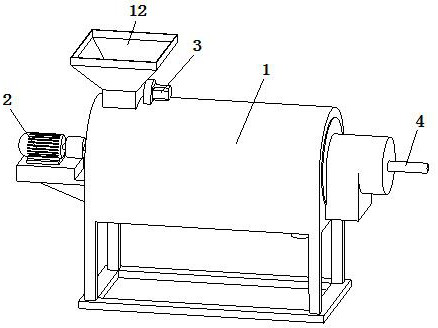

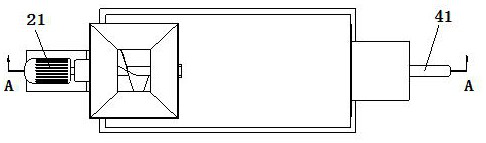

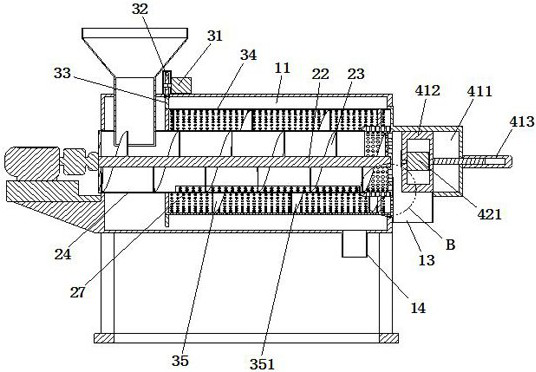

Medicinal material smashing device for pharmacy

The invention provides a medicinal material smashing device for pharmacy and belongs to the technical field of machines. The medicinal material smashing device solves the problem that an existing peel smashing machine for pharmacy is poor in stability. The medicinal material smashing device for pharmacy comprises a shell. A feeding opening is formed in one side of the shell. A discharging opening is formed in the bottom of the shell. Rotatable stirring blades, annular fixed blades and a hemi-spherical filter screen are arranged in the shell. The top wall of the shell is a plane, and a supporting plate is fixed to the top wall of the shell. A rubber plate is arranged between the supporting plate and the shell. The two side walls of the rubber plate lean on the supporting plate and the shell correspondingly. An air supply fan is fixed to the upper side face of the supporting plate. An air supply pipe in an L shape is arranged on one side of the air supply fan. One end of the air supply pipe communicates with an air outlet of the air supply fan, and the other end of the air supply pipe extends into the shell. A conical air guide cylinder is arranged in the shell and directly faces the filter screen. The upper end of the air guide cylinder communicates with the lower end of an air outlet part. The medicinal material smashing device for pharmacy has the beneficial effect of being good in working stability.

Owner:广东嘉韩药业有限公司

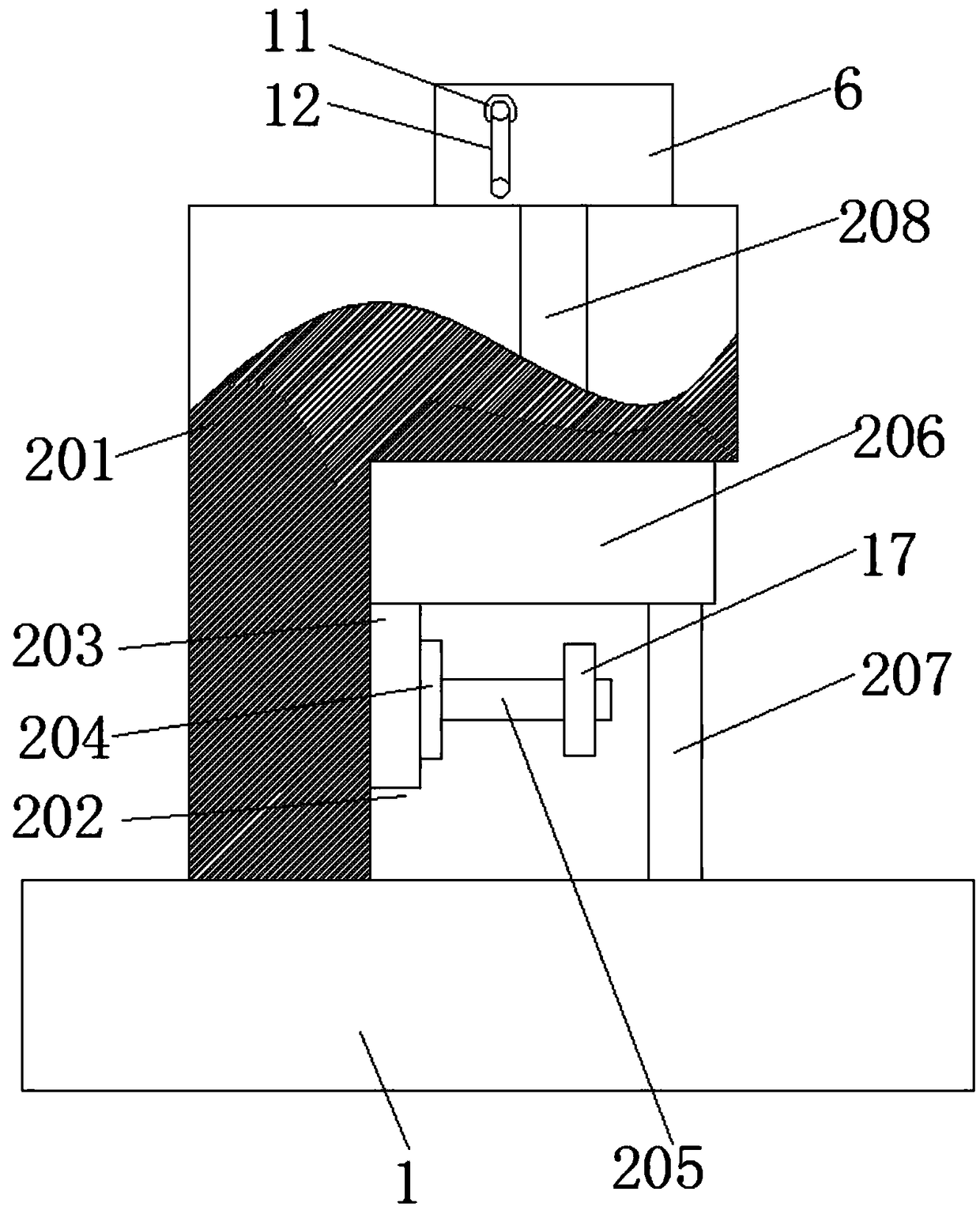

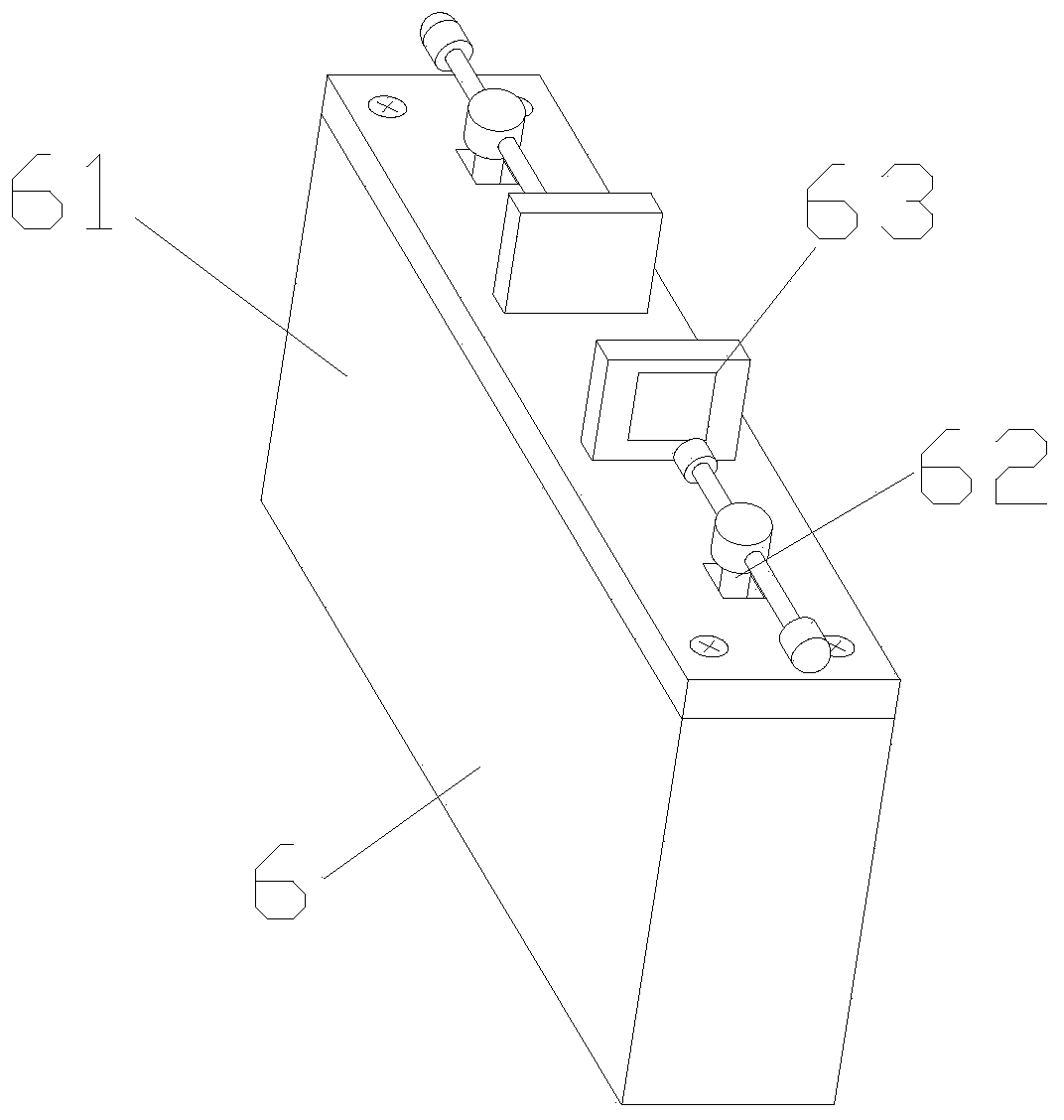

Tire clamping mechanism for land leveller

The invention discloses a tire clamping mechanism for a land leveller. The tire clamping mechanism comprises a supporting cylinder body, a connecting rod and a limiting structure. A baffle is installed in the supporting cylinder body and fixedly provided with a motor. The output end of the motor is connected with a rotating plate after penetrating through the baffle. A plurality of horizontal grooves are uniformly formed in the other end of the supporting cylinder body, and clamping claws are arranged in the horizontal grooves in a sliding mode. One end of the connecting rod is hinged to the bottom of the rotating plate, and the other end of the connecting rod is hinged to the end portions of the clamping claws. Rectangular blind holes are formed in the inner walls of the horizontal grooves, and a plurality of idler wheels are installed in the rectangular blind holes. The limiting structure is arranged on the baffle. The idler wheels in the horizontal grooves can change sliding friction between the clamping claws and the groove walls into rolling friction, loss between the horizontal grooves and the clamping claws can be reduced, and the moving speed of the clamping claws can be increased. In the rotating process, the motor rotates horizontally at a constant oscillation angle, and therefore the clamping claws can move in the horizontal grooves fast.

Owner:CHENGDU HAILINGDA MACHINERY

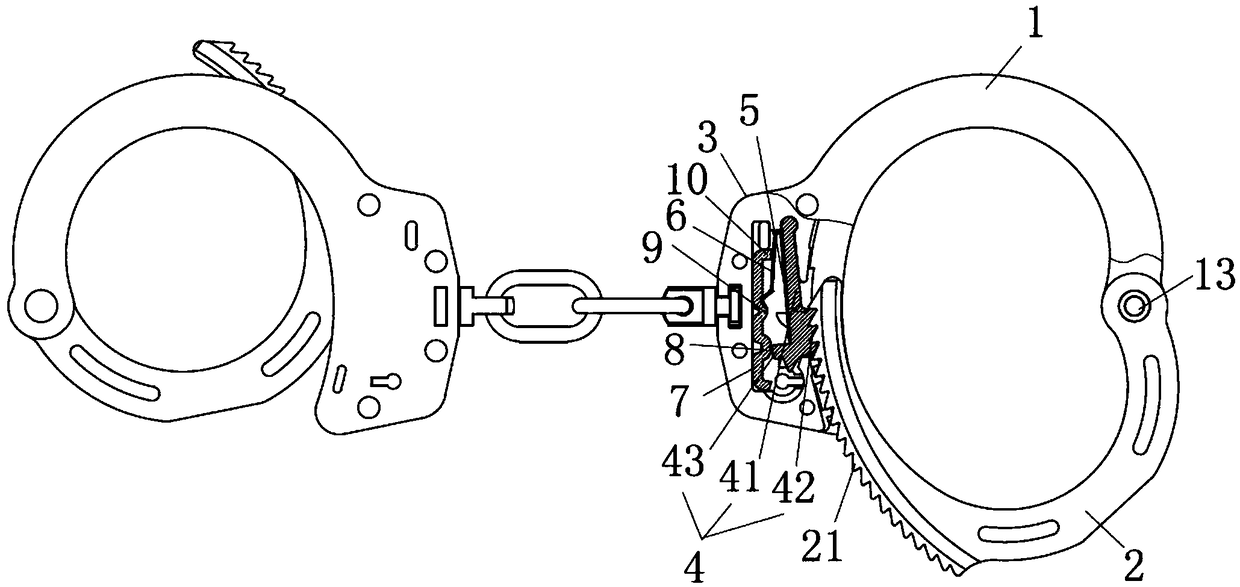

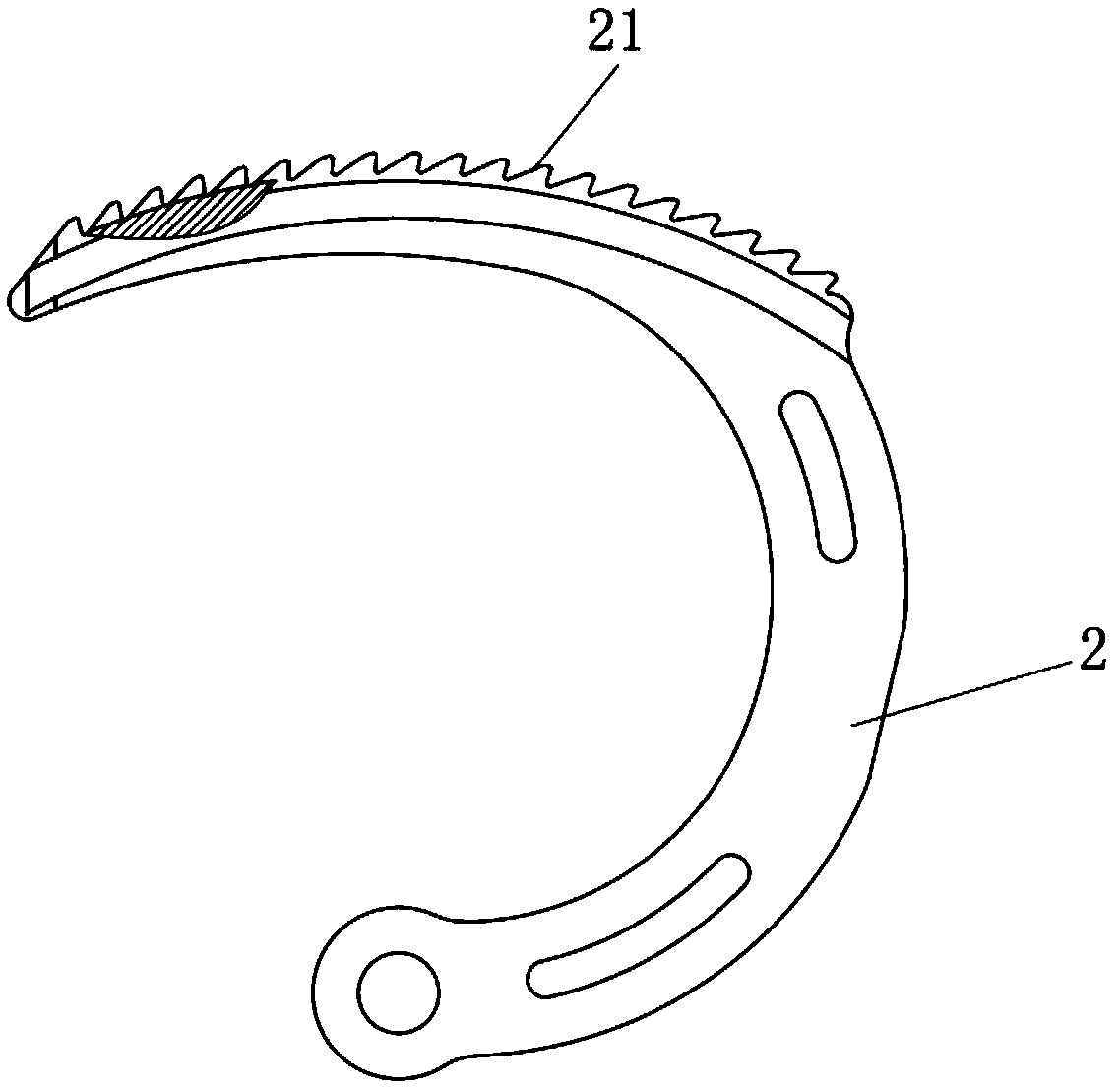

Police handcuffs capable of flexible use

Owner:温州弘德仪器科技有限公司

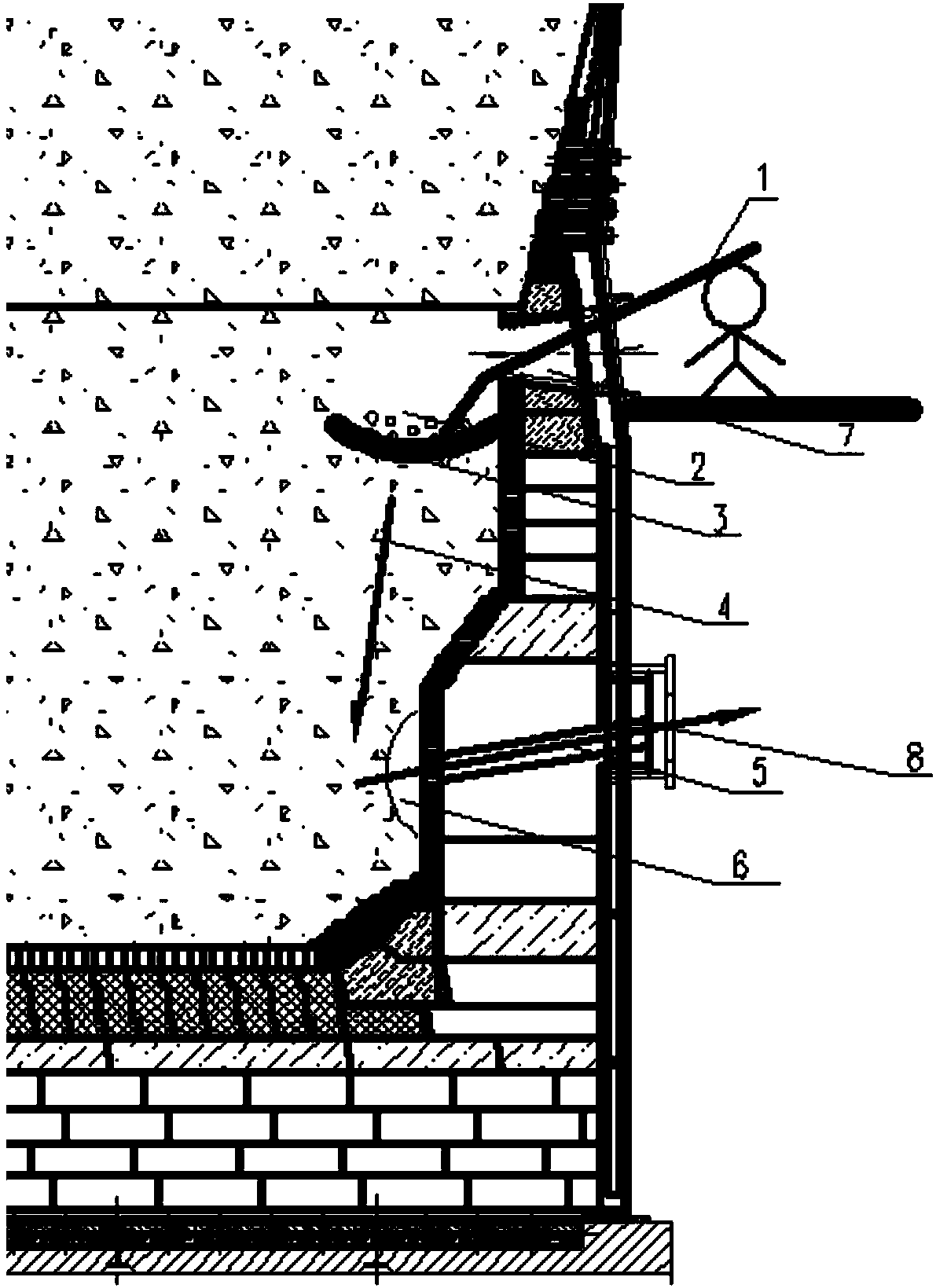

Method for communicating blast furnace tuyere and taphole

ActiveCN108977601AIncrease temperatureGuaranteed continuityBlast furnace componentsBlast furnace detailsEmesis basinIngot

The invention discloses a method for communicating a blast furnace tuyere and a taphole. The technical problems that the method for communicating the blast furnace tuyere and the taphole in the priorart is low in efficiency and high in cost are solved. According to the technical scheme, the method for communicating the blast furnace tuyere and the taphole comprises the steps that (1) a mud drum at the blast furnace taphole is drilled to be through, and a taphole pore passage of the blast furnace taphole is made smooth; (2) a medium-sized sleeve and a small sleeve of the blast furnace tapholeare removed, and coke at the front end of the blast furnace tuyere is clawed to form an emesis basin; (3) an aluminium ingot and coke are sequentially arranged at the emesis basin at the front end ofthe blast furnace tuyere; (4) oxygen burning operation is conducted at the emesis basin at the front end of the blast furnace tuyere; (5) when molten aluminium seeps out at the taphole pore passage ofthe blast furnace tuyere, oxygen burning operation is stopped. When the method is adopted for treating hearth chill of a blast furnace, the blast furnace tuyere and a high blast taphole can be made to communicate quickly, the time of oxygen burning in the front of the blast furnace is shortened, and the accident handling time is greatly shortened.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

A spinning device for textile

ActiveCN106892303BWinding won't happenImprove winding efficiencyFilament handlingFiberElectric machinery

The invention discloses a wire winding device for spinning. The wire winding device for spinning comprises a base; the top of the base is fixedly connected with the bottom of a wire separating device, and is fixedly provided with a fixed block on one side of the wire separating device; the top of the fixed block is fixedly connected with the bottom of a motor box; a motor is fixedly mounted in the motor box; the wire separating device comprises a shell; a groove is formed in the bottom of the shell; one side of the inner wall of the groove is fixedly connected with one side of a wire separating plate; and a bearing is embedded in one side, far from the inner wall of the groove, of the wire separating plate. The wire winding device for spinning is provided with the wire separating device; the wire separating plate, a wire separating rod, a baffle plate and a wire separating hole are matched with each other; a winding cylinder for winding chemical fibers is fixed on the wire separating rod; each chemical fiber singly penetrates through the wire separating hole, so that the chemical fibers cannot be wound together during separating; and meanwhile, multiple sets of chemical fibers can be synchronously wound, so that the wire winding efficiency is greatly improved.

Owner:绍兴市欣明家居有限公司

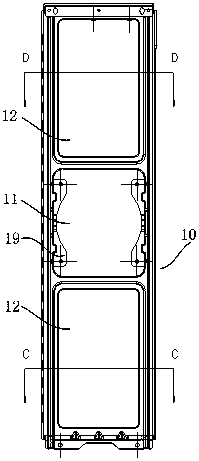

Air conditioner outdoor unit motor bracket

ActiveCN108302653AImprove structural strengthFast throughLighting and heating apparatusAir conditioning systemsEngineering

The invention relates to the technical field of air conditioners and provides an air conditioner outdoor unit motor bracket which comprises an upper fixing plate, a bracket main body and a lower fixing plate; and the bracket main body is provided with a hollow part for mounting a motor and a plurality of diversion holes which are arranged on the two sides of the hollow part respectively and are arranged in a length direction. The air conditioner outdoor unit motor bracket provided by the invention can solve the problems of high running noise, low performance of the whole machine, poor user experience and the like caused by the existing motor bracket to air flow retardation.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

Method for planting canna on slope

ActiveCN105900557ARich species diversityDoes not affect growthCultivating equipmentsPlant cultivationEcological environmentOfficinalis

The invention discloses a method for planting canna on a slope. The method comprises the steps of preparing the slope; sequentially laying a nutrition soil layer and a gravel soil layer on the slope from bottom to top; pouring ecological concrete and covering the slope with a plastic film for protection, wherein the ecological concrete is obtained by mixing and stirring gravels, cement, silicon dioxide micro powder or coal ash, a water reducing agent and water to be uniform according to a certain weight part ratio; sowing canna seeds, wherein the canna seeds are pretreated before sowing, first filter liquid extracted from semen cassia and second filter liquid extracted from cortex magnoliae officinalis are mixed to obtain mixed liquid, and the canna seeds are soaked in the mixed liquid; watering and protecting are carried out after sowing. By means of the method, variety diversity of cultivated plants on the ecological concrete is enriched, and the canna is high in tillering capacity, grows quickly and has high ornamental value; the canna planted on the slope can effectively fix slope soil, improve the ecological environment and can beautify the environment well.

Owner:WUHAN BOTANICAL GARDEN CHINESE ACAD OF SCI

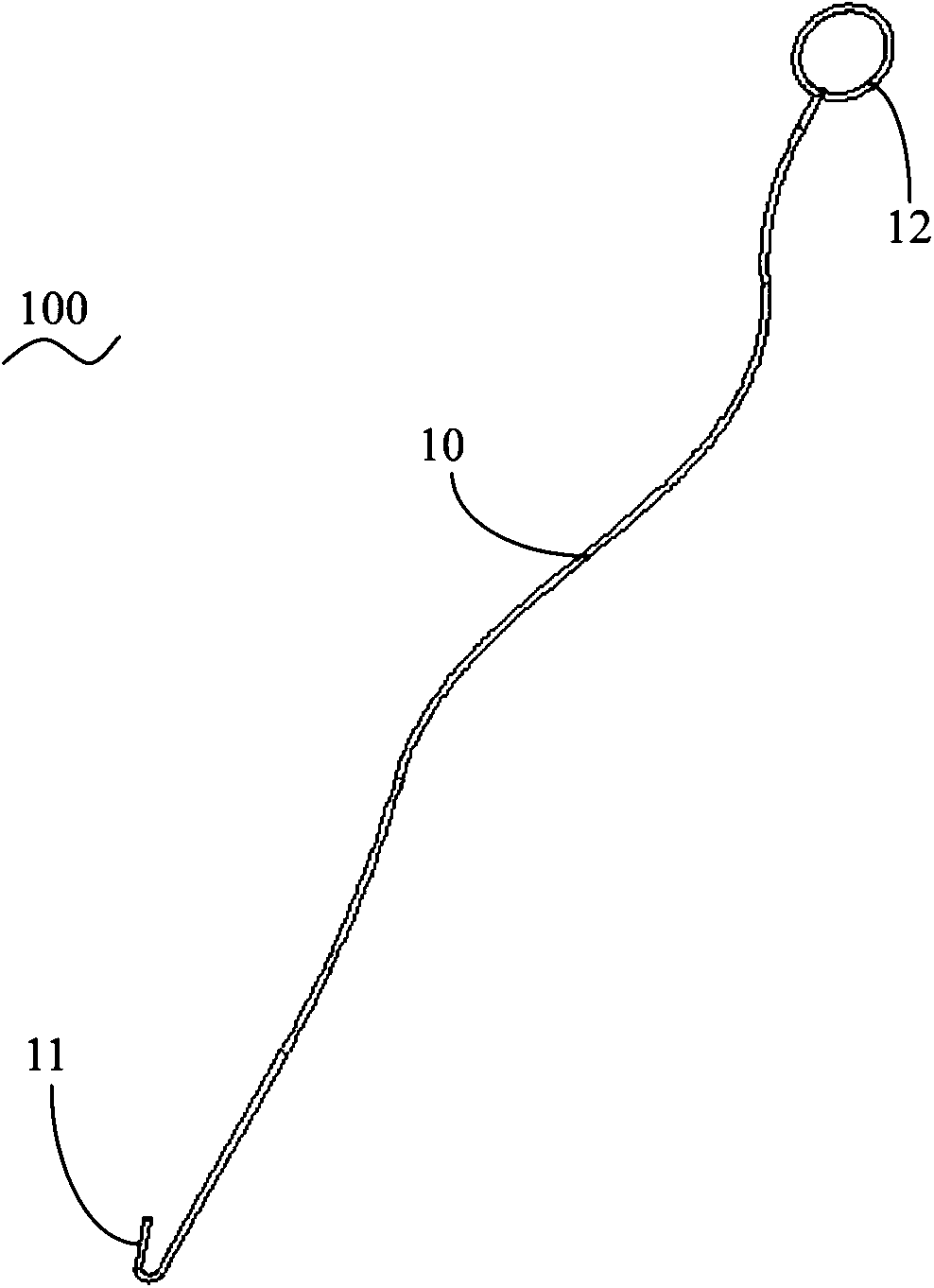

Electrode wire threading device

The invention provides an electrode wire threading device which comprises a body. A bent part is disposed at one end of the body. A hanging part is disposed at the other end of the body. The body, the bent part and the hanging part are integrally formed. By the electrode wire threading device, electrode wires can be threaded through threading holes fast. The electrode wire threading device is simple to operate and widely applicable, threading time is saved, and production efficiency is increased.

Owner:苏州市合昌电器有限公司

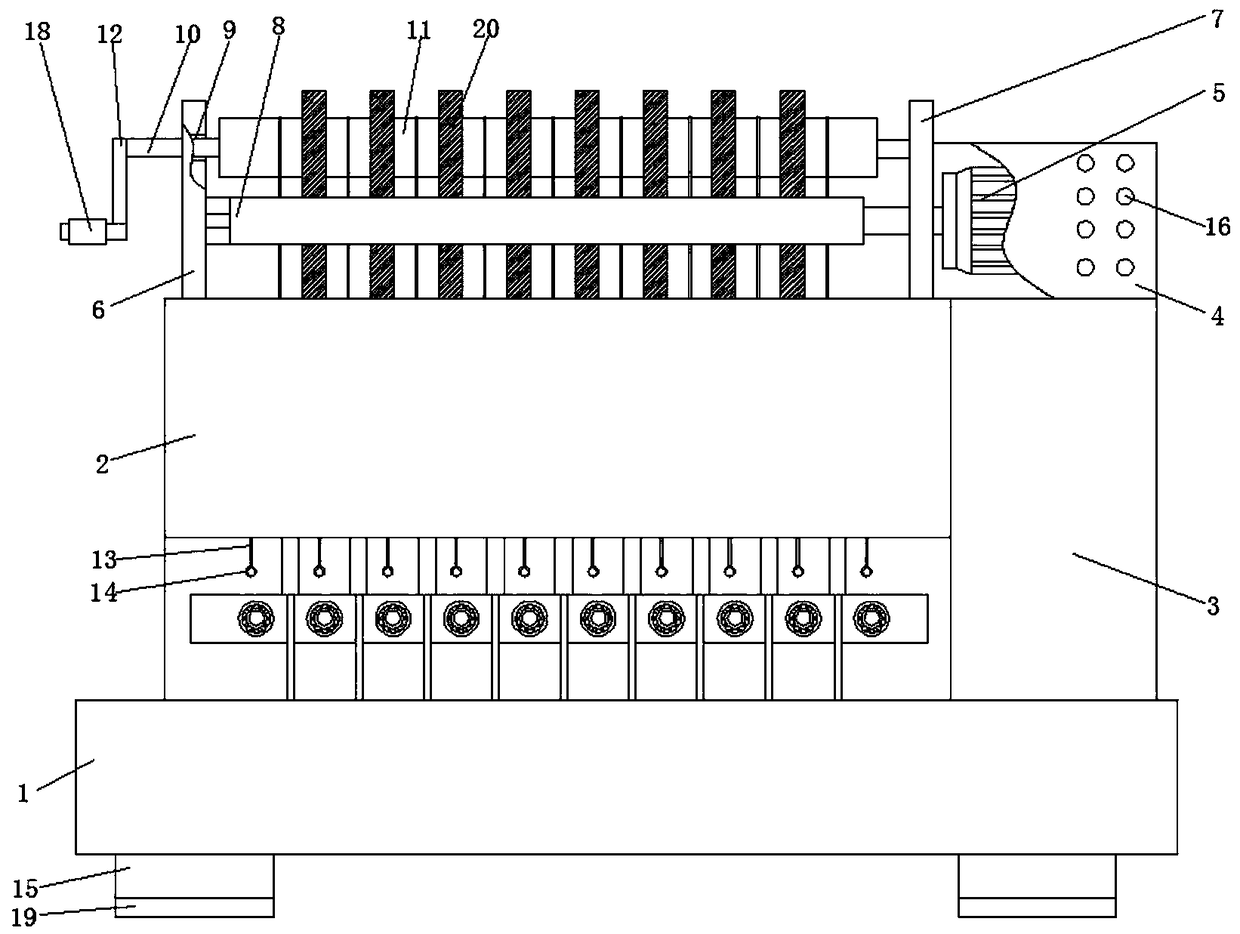

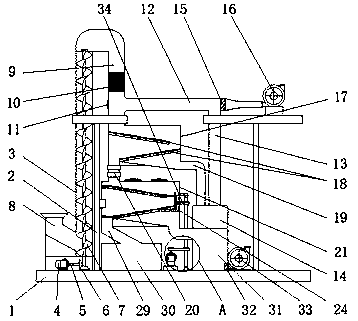

Wind screen type corn seed cleaning machine with double-screen-box function

PendingCN111097695AWith double screen box functionImprove cleaning efficiencySievingGas current separationAgricultural scienceAgricultural engineering

The invention discloses a wind screen type corn seed cleaning machine with a double-screen-box function. The machine comprises a base and a second belt, wherein a fixing frame is arranged at the top of the base, the left side of the fixing frame is provided with a feeding pipe, a first motor is arranged below the feeding pipe, the first motor is rotationally connected with a first motor shaft, thefirst motor shaft is rotationally connected with a spiral transmission group, the spiral transmission group is rotationally connected with a spiral conveyor, the spiral conveyor is arranged in the feeding pipe, the left side of the left bottom of the feeding pipe is connected with a feeding port, the top of the feeding pipe is connected with a discharging pipe, and a grid is arranged in the discharging pipe. According to the wind screen type corn seed cleaning machine with the double-screen-box function, the grid, a first filter screen, a second filter screen, a third filter screen, a first fan, a movable support and a second fan are arranged, corn seeds are thoroughly cleaned through pre-screening, wind screening type cleaning and vibrating type cleaning, the screening amount is improvedwhile the cleaning efficiency is kept, and use is more convenient.

Owner:甘肃酒玉种业有限公司

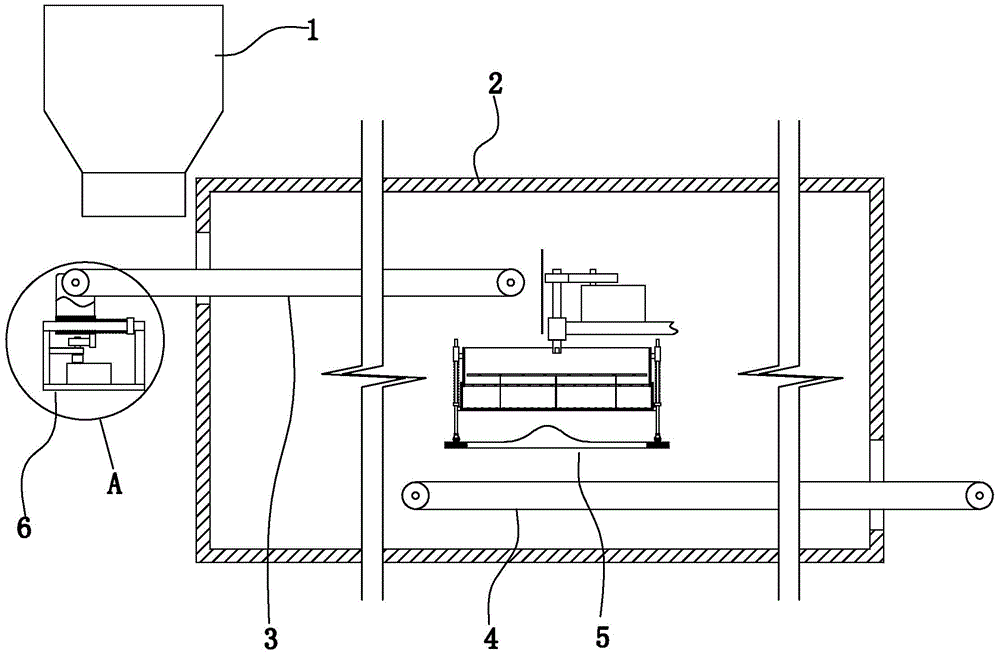

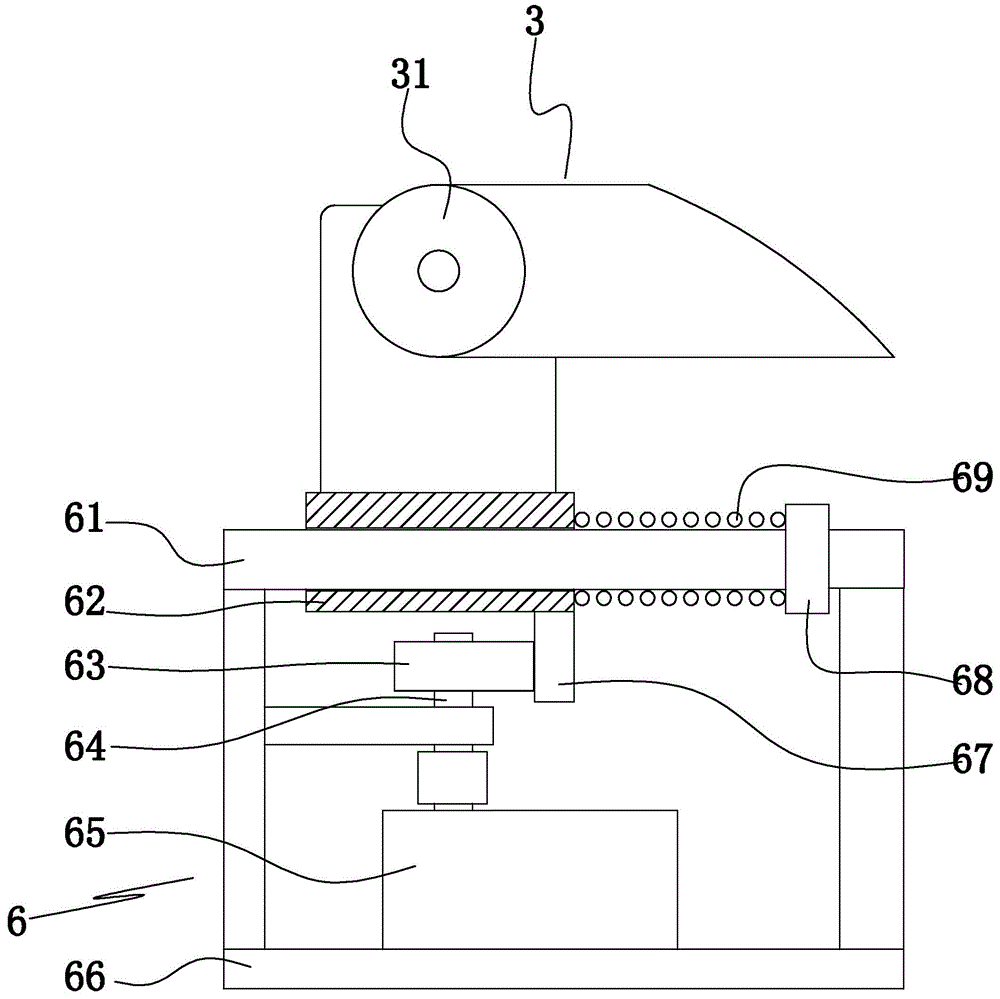

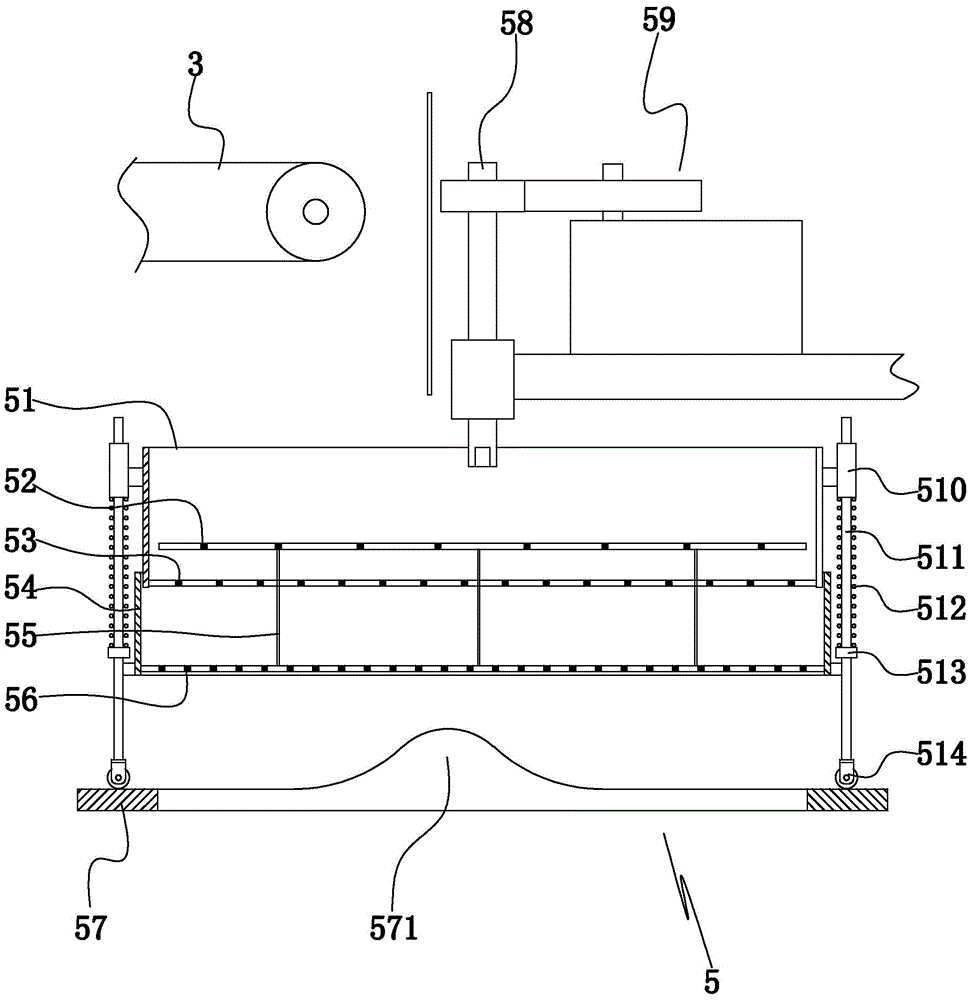

Formula of folium mori chrysanthemum tea as well as processing method and device for folium mori chrysanthemum tea

The invention discloses a formula of folium mori chrysanthemum tea as well as a processing method and processing device for the folium mori chrysanthemum tea, and aims to provide a formula of the folium mori chrysanthemum tea which has chrysanthemum fragrance and sweet and mellow taste, has the efficacies of dispelling wind and heat, clearing liver and improving vision, is suitable for prevention, treatment and health care of various people, especially hypertensive patients. The folium mori chrysanthemum tea comprises the following raw materials: folium mori powder, chrysanthemum liquid extract, honey and stevioside. The processing method of the folium mori chrysanthemum tea sequentially comprises the following steps: mixing, granulating, and drying. The processing device for the folium mori chrysanthemum tea comprises a granulator and a drying device, wherein the drying device comprises a drying chamber and a belt conveying device; conveyor belts of the belt conveying device penetrate through the drying chamber.

Owner:ZHEJIANG CHINESE MEDICAL UNIV MEDICAL PIECES

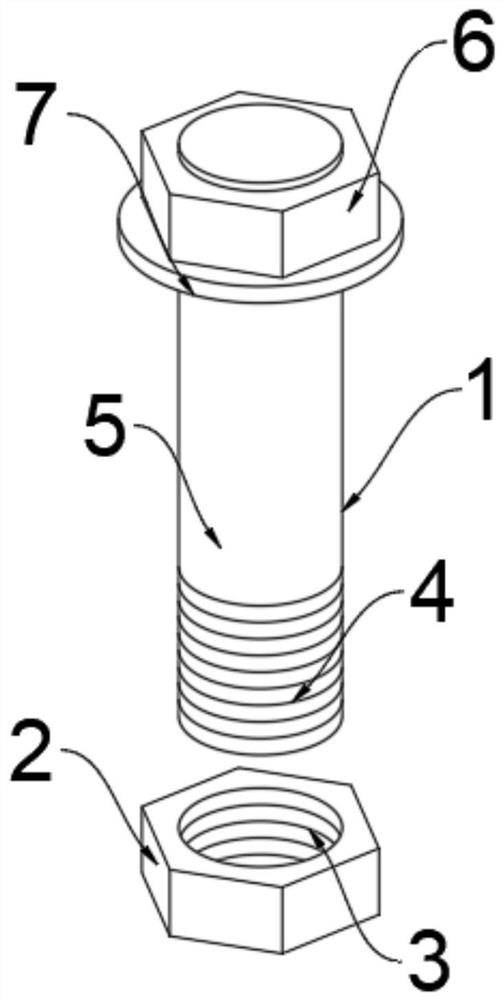

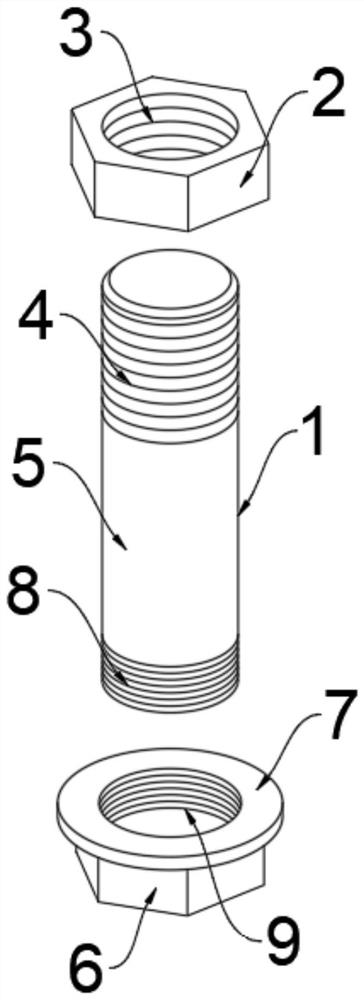

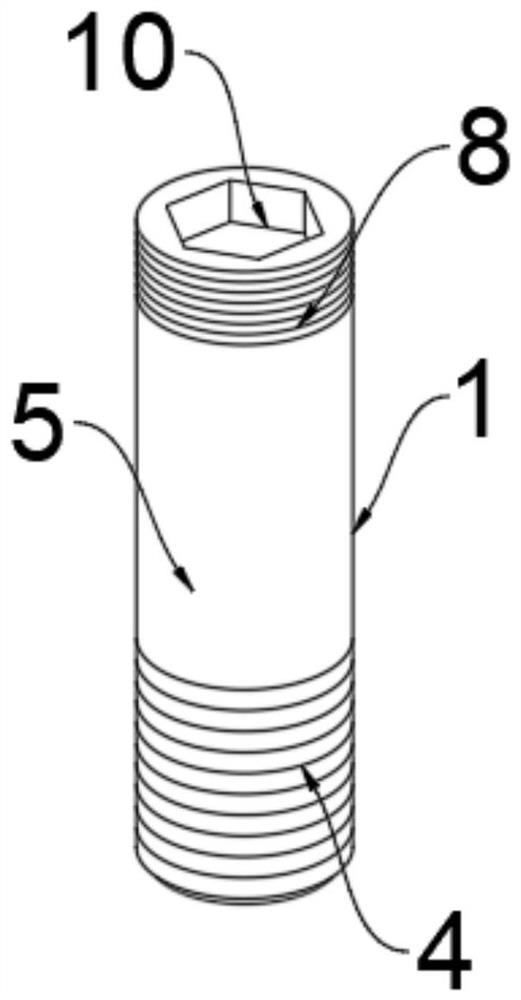

Fastening bolt capable of being rapidly disassembled and assembled

The invention discloses a fastening bolt capable of being rapidly disassembled and assembled, relates to the technical field of bolts, and aims to solve the problems that in the prior art,in the usingprocess, a bolt can be independently used as a connecting piece and can also cooperate with a nut to achieve fixing, sometimes, in the process of achieving disassembling and assembling by cooperatingwith the nut, the thickness of a fixed piece is small, consequently, the rotating torque of the nut or the bolt is too long, and consequently consumed time is increased. A hexagon nut is arranged below a metal screw, a nut threaded hole is formed in the inner side of the hexagon nut, a hexagon screw cap is arranged above the metal screw, a pre-tightening gasket is arranged at the bottom of the hexagon screw cap, the pre-tightening gasket is connected with the hexagon screw cap in a welded mode, and the metal screw comprises a resistance-free rod body. A long-distance threaded groove is formedin one end of the resistance-free rod body, a short-distance threaded groove is formed in the other end of the resistance-free rod body, the metal screw rod is rotationally connected with the hexagonnut through the long-distance threaded groove, and a screw cap threaded hole is formed in the hexagon screw cap.

Owner:宁波市鄞州利华电器有限公司

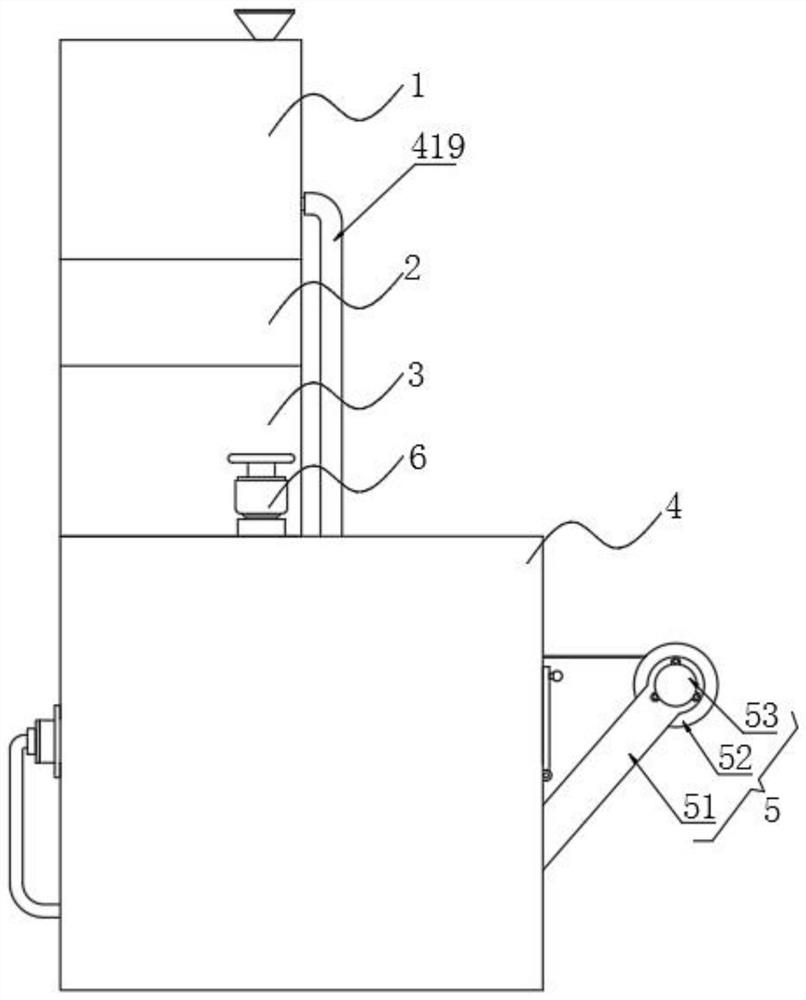

Environment-friendly medical waste disposal equipment

ActiveCN111451248AEasy to crushRealize solid-liquid separationSolid waste disposalTransportation and packagingMedical wasteRefuse Disposals

The invention discloses environment-friendly medical waste disposal equipment. The equipment comprises a first casing structure, a rotating structure arranged on the first casing structure, a drivingstructure arranged outside the rotating structure, an extruding structure arranged on the rotating structure, a second casing structure located below the first casing structure and a separate disinfection structure arranged below the second casing structure. According to the equipment, a rotating frame can be arranged on a first casing, so that the rotating frame can rotate on the first casing conveniently; and the rotating frame is a cylinder, meanwhile, a cuboid cavity is formed in the rotating frame, thus the double purposes that the rotating frame rotates and an extruding plate moves in the rotating frame conveniently to crush garbage can be achieved, and the garbage can be crushed sufficiently.

Owner:郑利娟

Formula, processing method and processing device of peppermint and green gram seed-coat tea

The invention discloses a formula, a processing method and a processing device of peppermint and green gram seed-coat tea, and aims to provide the formula, the processing method and the processing device of peppermint and green gram seed-coat tea which has fragrant and mellow taste of peppermint and the effects of dispelling wind and heat, clearing brain and eyes, clearing heat, removing toxicity, relieving summer heat and inducing diuresis and is suitable for prevention, treatment and health effects of different people in summer. According to the formula, the tea is prepared from the following raw materials: peppermint leaf fine powder, green gram seed-coat fluid extract and stevioside. The processing method sequentially comprises the steps of mixing, granulating and drying. The processing device comprises a granulator and a drying device, wherein the drying device comprises a baking chamber and a belt conveying mechanism; and the conveying belt of the belt conveying mechanism passes through the baking chamber.

Owner:ZHEJIANG CHINESE MEDICAL UNIV MEDICAL PIECES

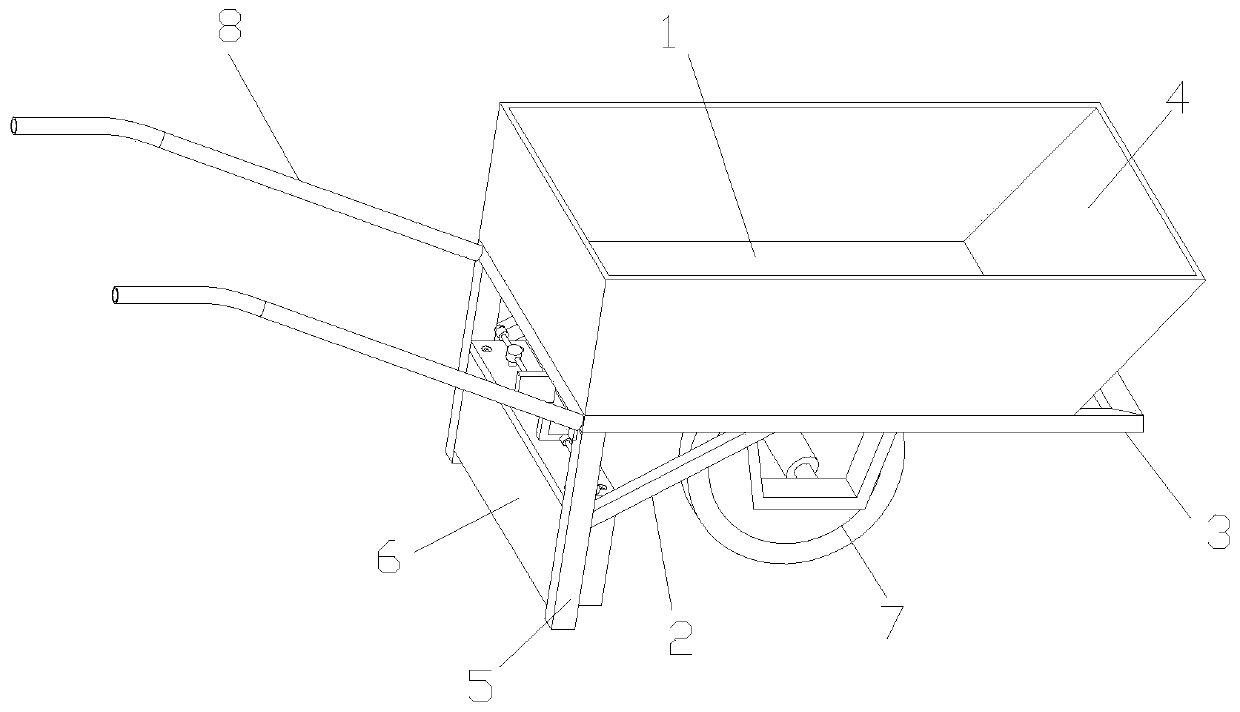

Improved type building aerated block carrying device

InactiveCN110843872AImprove stabilityImprove placement stabilityHand carts with one axisArchitectural engineeringStructural engineering

Owner:刘斌

High-efficiency textile fabric dyeing device

ActiveCN110878453AFast absorptionIncrease contact areaTextile treatment machine arrangementsLiquid/gas/vapor treatment of indefinite length materialsPolymer scienceEngineering

The invention discloses a high-efficiency textile fabric dyeing device, comprising a housing, a first dye liquor chamber, a second dye liquor chamber and a screw; a cloth feeding port is formed in oneside of the housing; the other side of the housing is provided with a cloth discharging port, the middle of the inside of the housing is provided with the first dye liquor chamber; the second dye liquor chamber is arranged in the housing outside the first dye liquor chamber; a second guide roller is arranged at the top end of the inside of the first dye liquor chamber; two first guide rollers arearranged in the first dye liquor chamber below the second guide roller; a cavity is formed in each of the second guide roller and the first guide rollers. The transmission of fabric drives the firstguide rollers, the second guide roller, a first rubber extrusion roller and a second rubber extrusion roller to rotate, a dye liquor is sprayed out of second liquid outlets of the first guide rollersand the second guide roller, the dye liquor is sprayed out of first liquid outlets of the first rubber extrusion roller and the second rubber extrusion roller, the dye liquor quickly penetrates the fabric, and the dyeing efficiency and uniformity are improved; meanwhile, impurities floating on the surface of the dye liquor in the first dye liquor chamber are guided into the second dye liquor chamber.

Owner:YANCHENG HUAGUAN TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com