Patents

Literature

725results about How to "Save disassembly time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

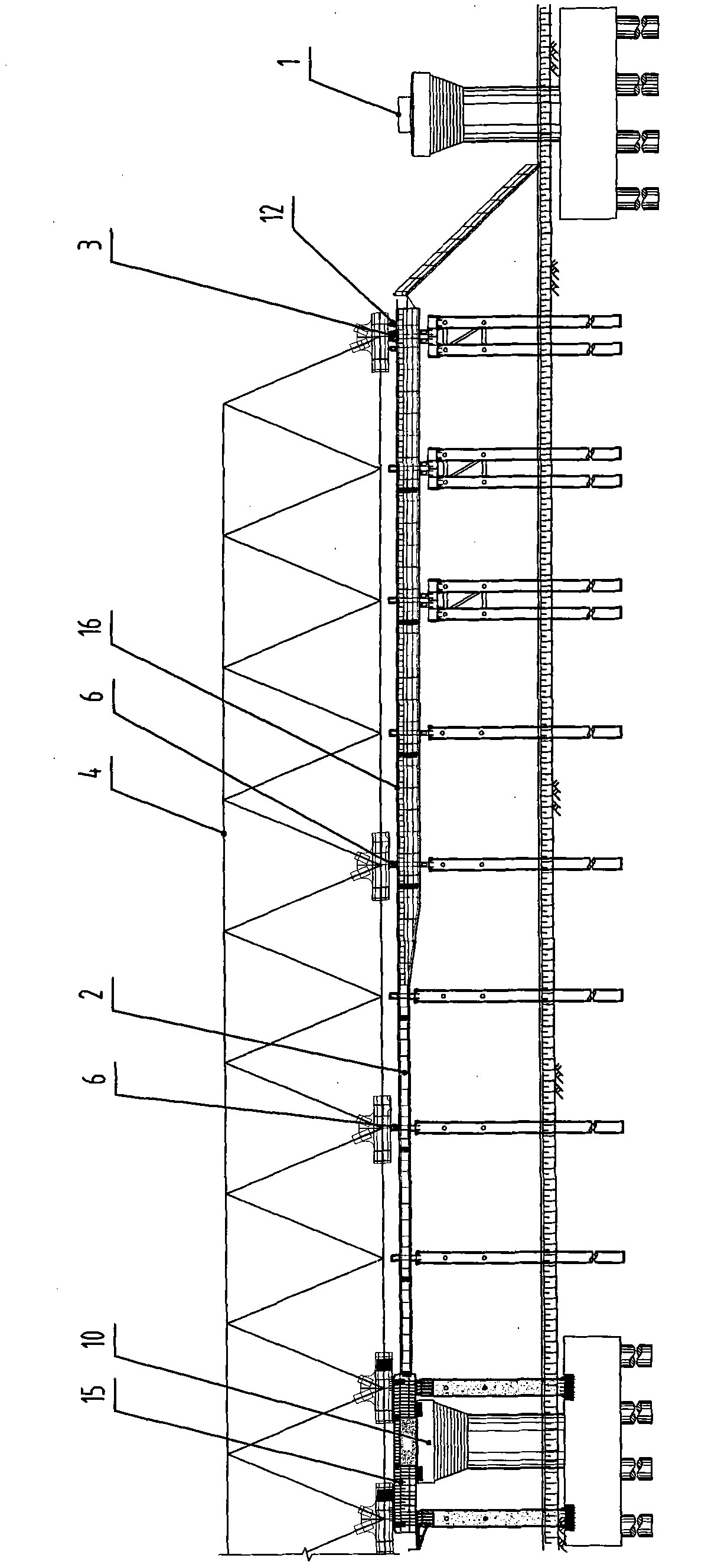

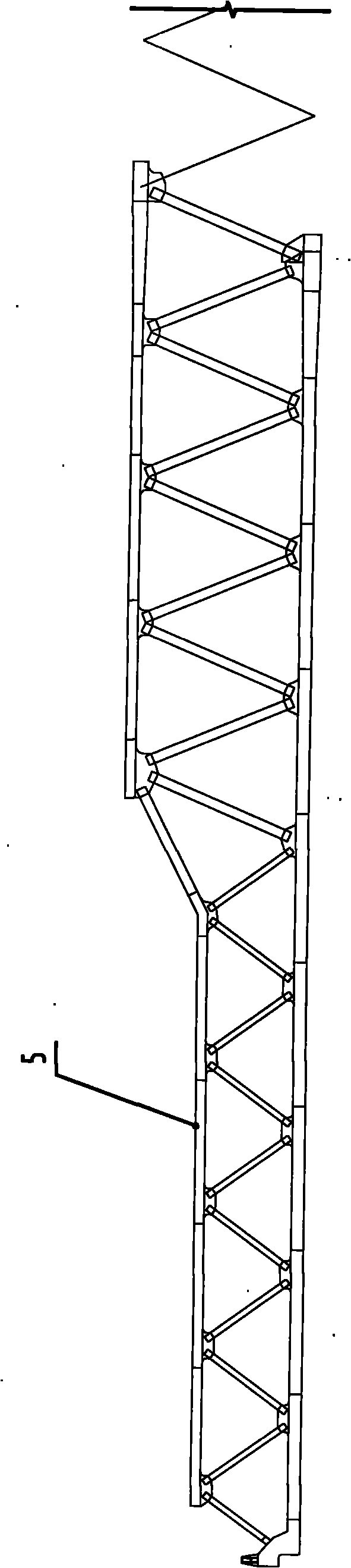

Multipoint synchronous push construction method for porous large-span continuous steel truss girder

ActiveCN101831874AEasy constructionReduce labor intensityBridge erection/assemblyControl systemEngineering

The invention discloses a multipoint synchronous push construction method for a porous large-span continuous steel truss girder, which comprises the following steps of: (1) assembling a steel truss girder assembling platform and a push slideway in a shoreside bridge pier position; (2) assembling a section of steel truss girder and a guide girder on the steel truss girder assembling platform; (3) installing a vertical jack for carrying out support conversion on the steel truss girder and then installing a continuous push jack, a steel strand and an electrohydraulic integrated control system; (4) operating the electrohydraulic integrated control system for carrying out push operation on the steel truss girder; and (5) after the push operation of the section of steel truss girder is finished, continuously assembling the steel truss girder on the steel truss girder assembling platform, carrying out next push operation, repeating the step for circulating operation and finishing the push construction of the porous large-span steel truss girder. The invention has the advantages of short construction period, safe construction, quality guarantee, low cost, and the like, realizes the push operation of the large-span steel truss girder, saves the construction cost, and reduces the pollution to a river channel.

Owner:1ST ENG OF CHINA ZHONGTIE MAJORBRIDGE GROUP +1

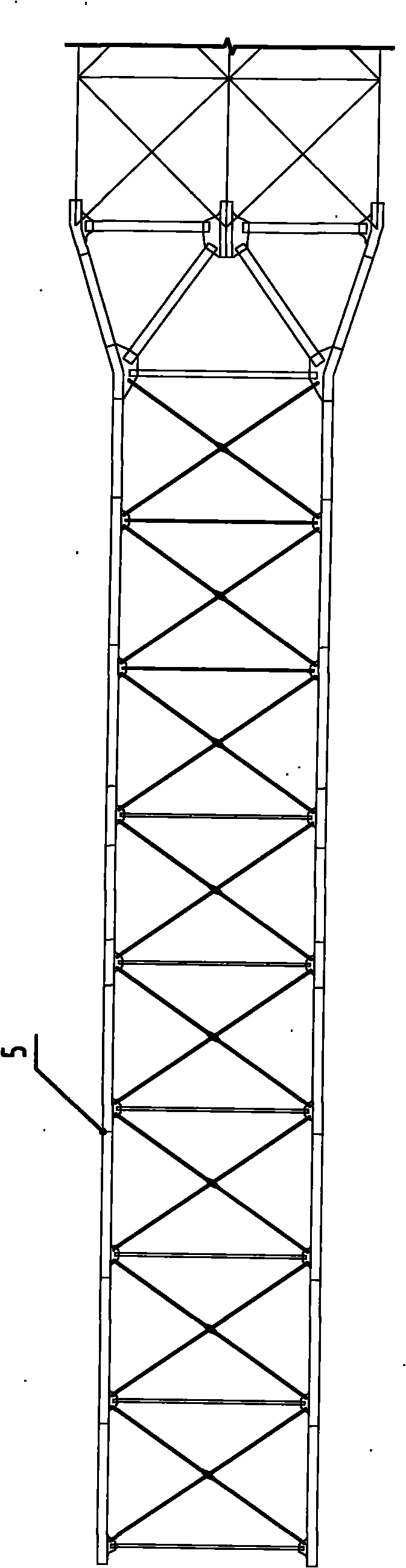

Mold supporting structure for variable cross-section cast-in-place box girder at section combining horizontal and longitudinal curves, and construction method of the mold supporting structure

ActiveCN104963290ARealize three-way stereo controlMonitor stress changesBridge erection/assemblyFalseworkBox girder

The invention relates to a mold supporting structure for a variable cross-section cast-in-place box girder at a section combining horizontal and longitudinal curves. The mold supporting structure mainly comprises an all-round scaffold, adjustable inclined supports, synchronous hydraulic jacks, composite moulds and adjustable supporting bases, wherein the all-round scaffold is formed by the overlapping connection of scaffold sets; the synchronous hydraulic jacks and the adjustable supporting bases are uniformly arranged at the joints of longitudinal supporting beams and transverse supporting beams at the top; the synchronous hydraulic jacks and the adjustable supporting bases are used as an upper part supporting body system, and a bottom mold is mounted on the top surface; the mounting angle of each lateral mold is adjusted through the adjustable inclined supports, and the lateral molds are fixedly connected with the bottom mold and an inner mold; custom-made steel templates are arranged at chamfers and circular-arc parts of the variable cross-section cast-in-place box girder; a core mold of the variable cross-section cast-in-place box girder is supported by an internal scaffold, and is fixed to the lateral molds through opposite-pull screw rods. Through the adoption of the mold supporting structure disclosed by the invention, the three-dimensional control for the moulds of the cast-in-place box girder at the section combining horizontal and longitudinal curves is realized, and besides, the uniform stress for the scaffold during concrete pouring can be guaranteed. The invention further provides a construction method of the mold supporting structure for the variable cross-section cast-in-place box girder at the section combining horizontal and longitudinal curves.

Owner:CITIC GUOAN CONSTR GRP CO LTD

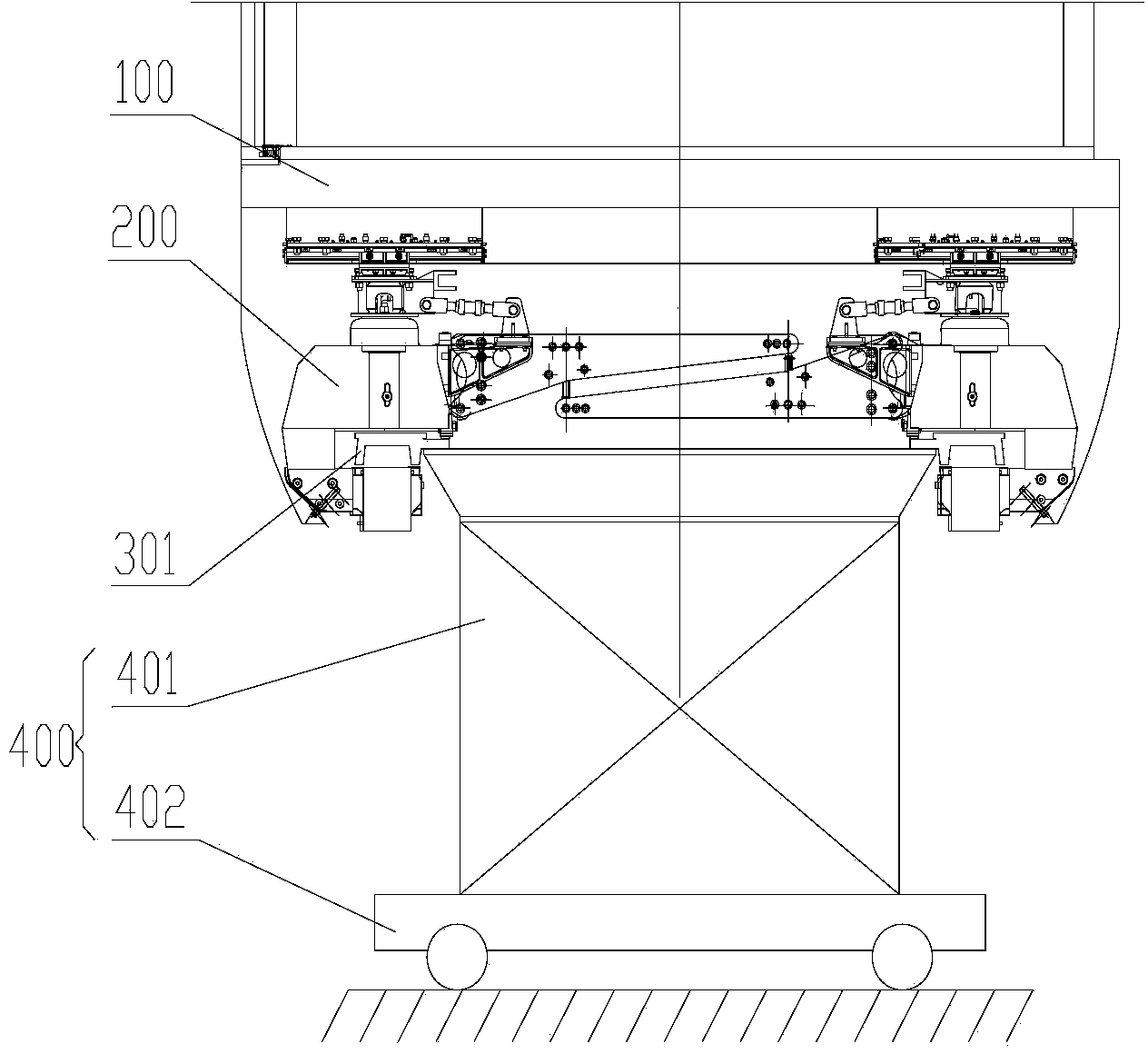

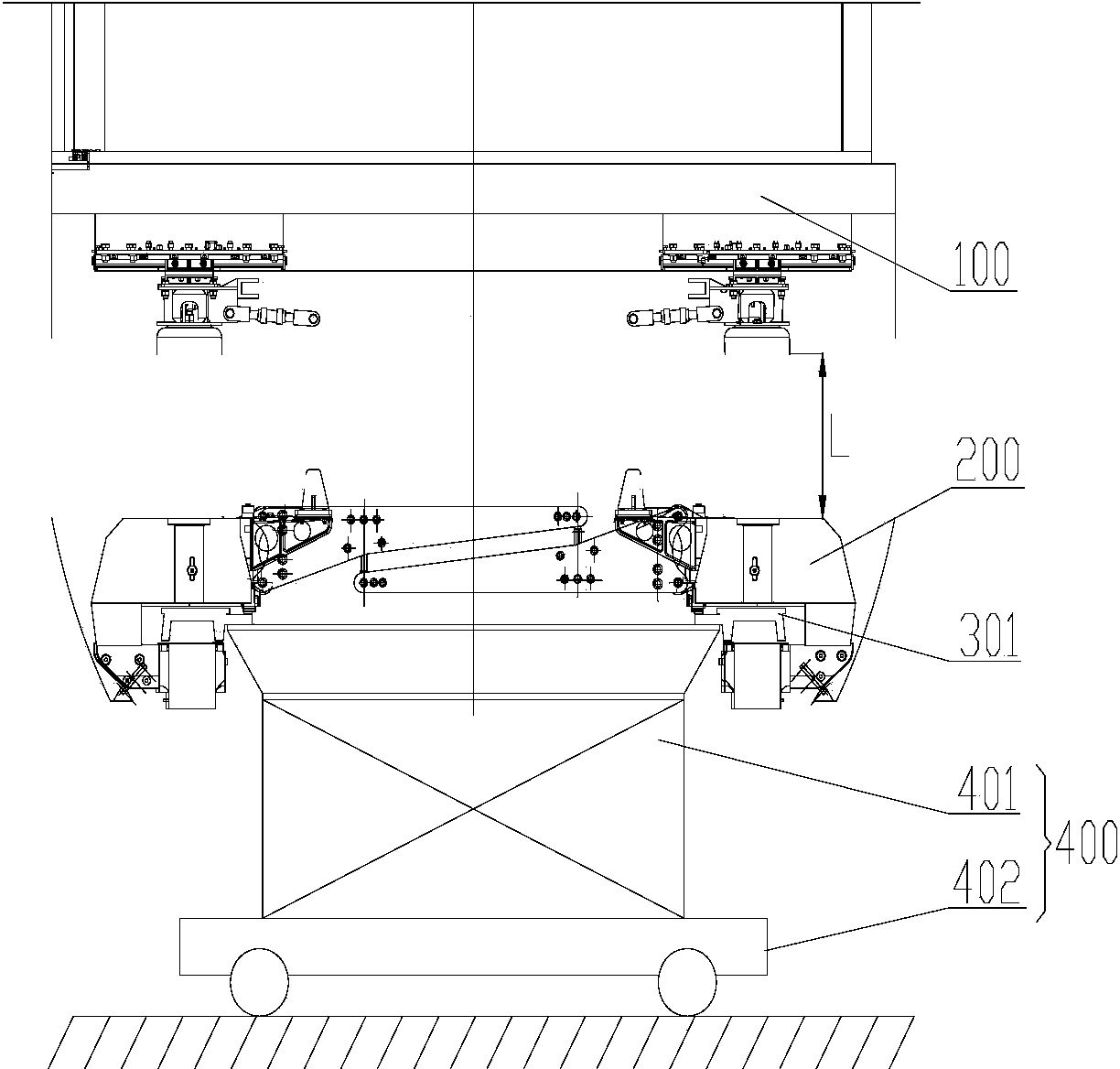

System and method for replacing bogie of magnetic levitation vehicle

InactiveCN104071173AImprove disassembly efficiencySave disassembly costBogiesMetal working apparatusBogieEngineering

The invention discloses a system for replacing the bogie of a magnetic levitation vehicle, which comprises a platform car arranged below the magnetic levitation vehicle, wherein a replacement track section butted with the fixed track section of the magnetic levitation vehicle is mounted on the platform truck; when the bogie is dismounted or mounted, the platform truck drives the replacement track section to separate from or move to a position, where the replacement track section is butted with the fixed track section. By adopting the replacement system for dismounting or mounting the bogie, the process of lifting the truck body by a lifting machine is eliminated, the dismounting and mounting cost and time are reduced, and the dismounting and mounting efficiency of the bogie is improved; the bogie is moved to a position beyond the running line, a new bogie can be mounted for recovering vehicle running, so that the influence on normal running of the vehicles is reduced. The invention further discloses a method for replacing the bogie of the magnetic levitation vehicle.

Owner:BEIJING ENTERPRISES HLDG MAGLEV TECH DEV +1

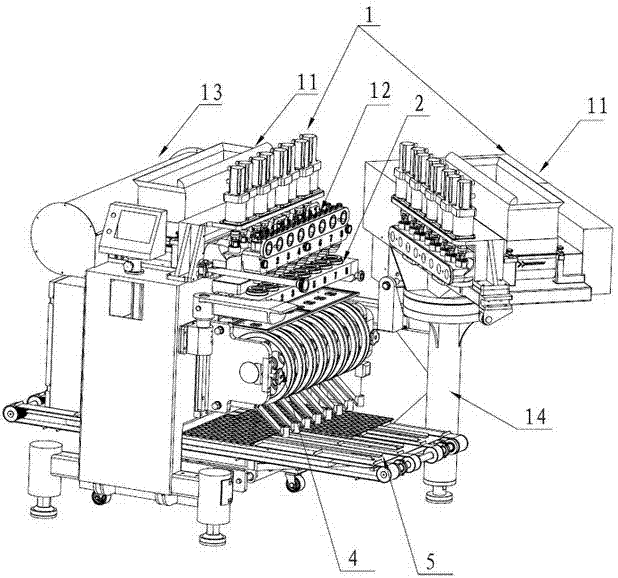

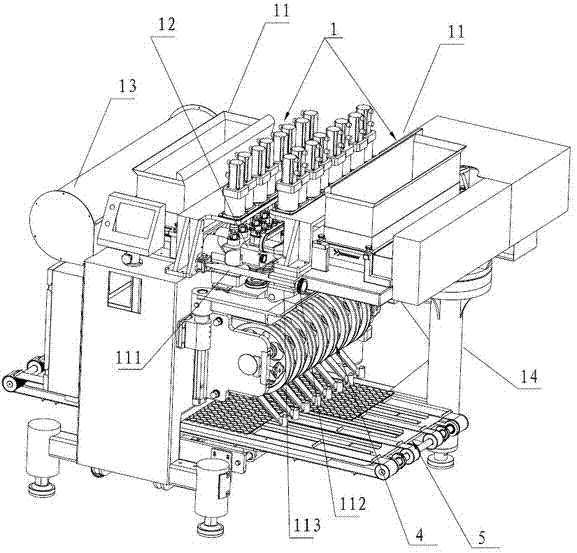

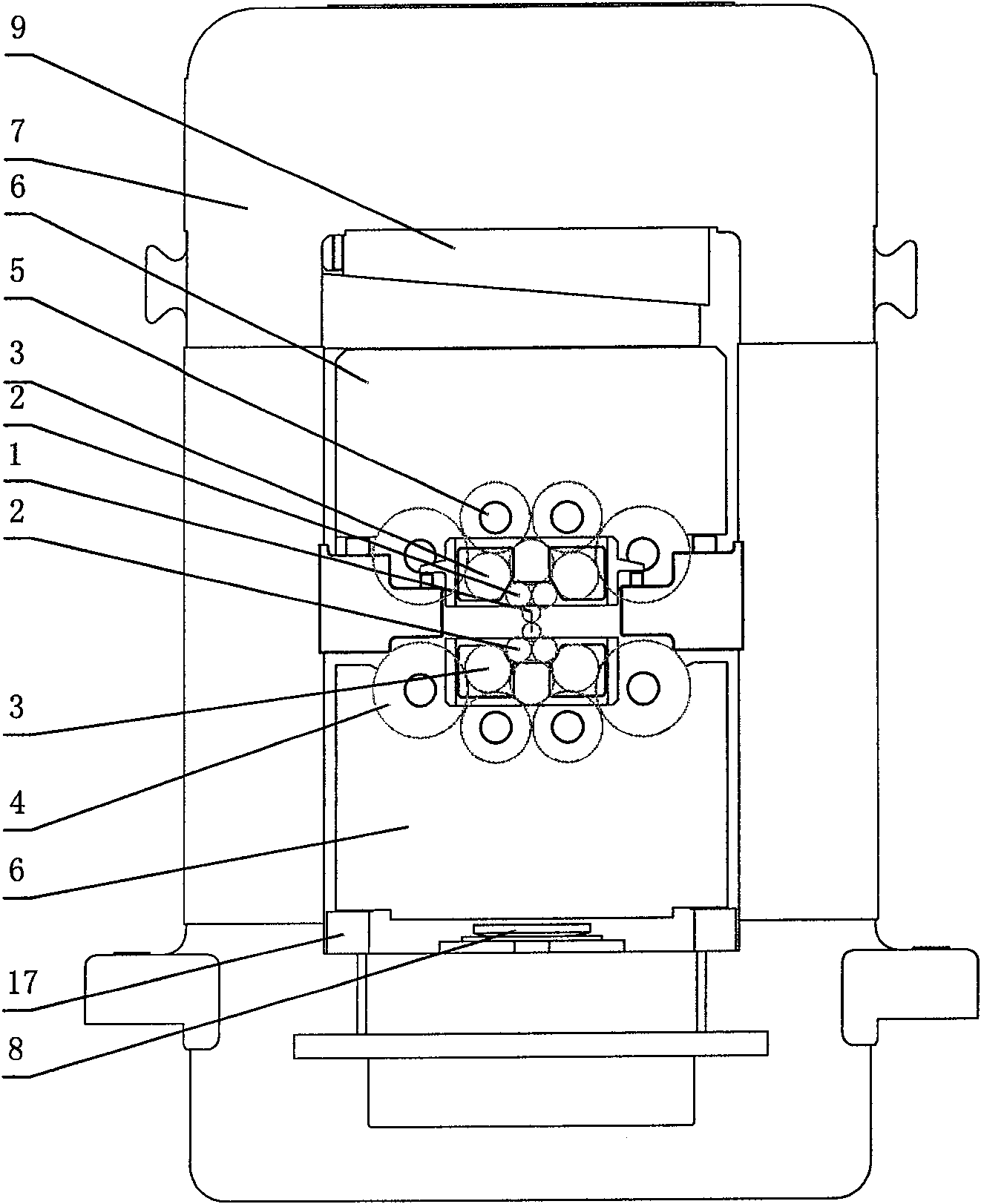

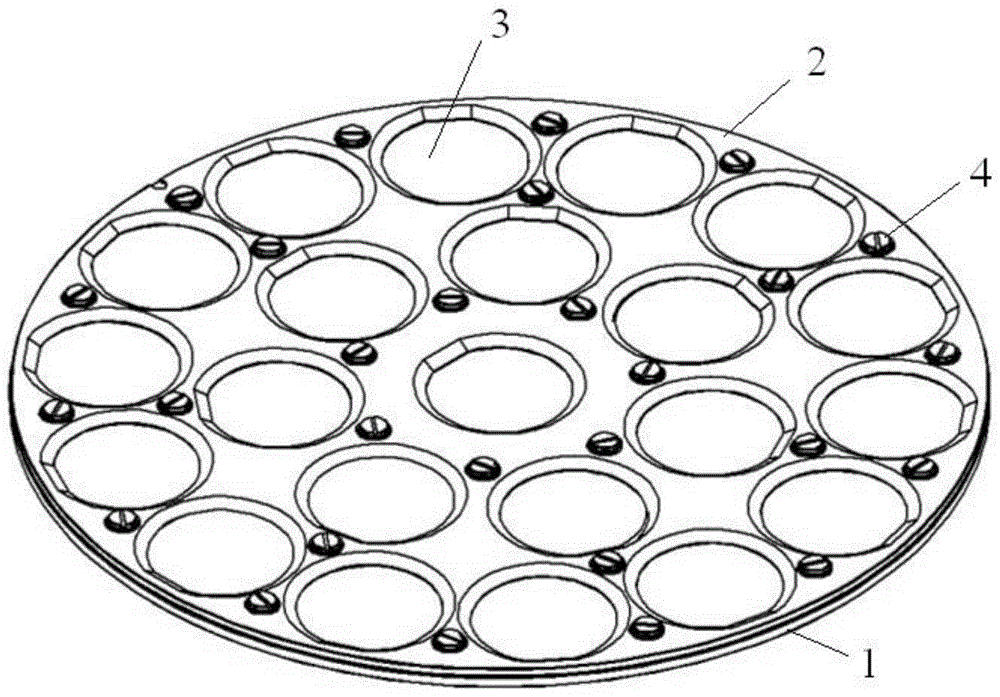

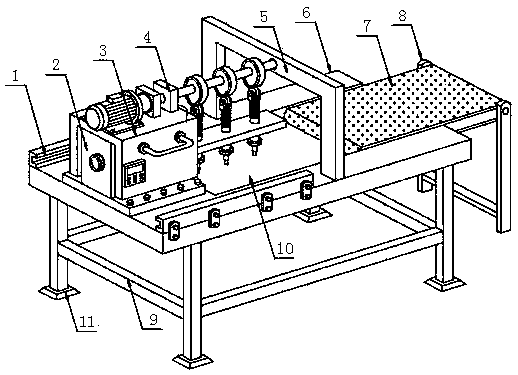

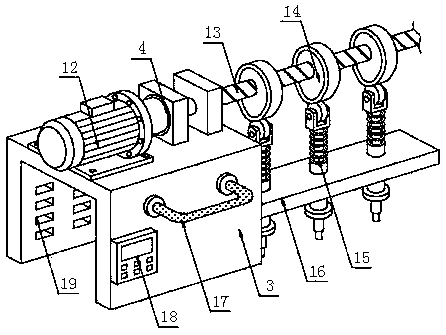

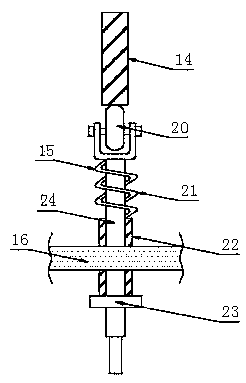

Molding method for food with round shape

ActiveCN102228305AEasy to disassembleEasy to installFood coatingFood shapingEngineeringIndependent feeding

The invention relates to the field of processing filling food, in particular to a molding method for food with round shape, comprising the following steps that: A, charging: skin and stuffing are added in feeding assemblies of a split type feeding system of a molding machine for food with round shape; B, compositing: the skin and stuffing of the feeding assembly are allowed to enter a skin-stuffing complex; C, cutting off: the skin and stuffing output by the skin-stuffing complex are cut off by a cutting assembly which is connected with a cutting lift assembly, the cutting assembly is driven by the cutting lift assembly to realize the cutting function and moving up and down simultaneously; D: ball-kneading: the cutting-off skin and stuffing are put into a ball-kneading device for kneading into balls; and E, discharging on the plate: the products obtained by ball-kneading are transferred to a discharging plate assembly from the ball-kneading device. According to the invention, the two independent feeding assemblies and the skin-stuffing complex have the advantages of simple disassembling and installation, when cleaning or maintaining the parts, only at least one feeding assembly needs be disassembled from the skin-stuffing complex to carry out the cleaning and the maintenance. Because the disassembling is realized by simple rotation, the present disassembling mode is simplified with saving the disassembling time and improving the work efficiency.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

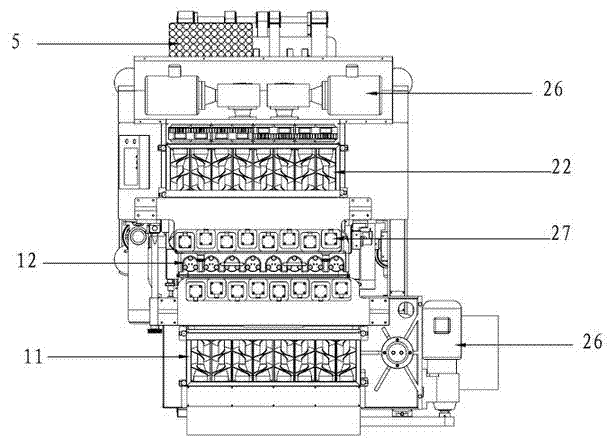

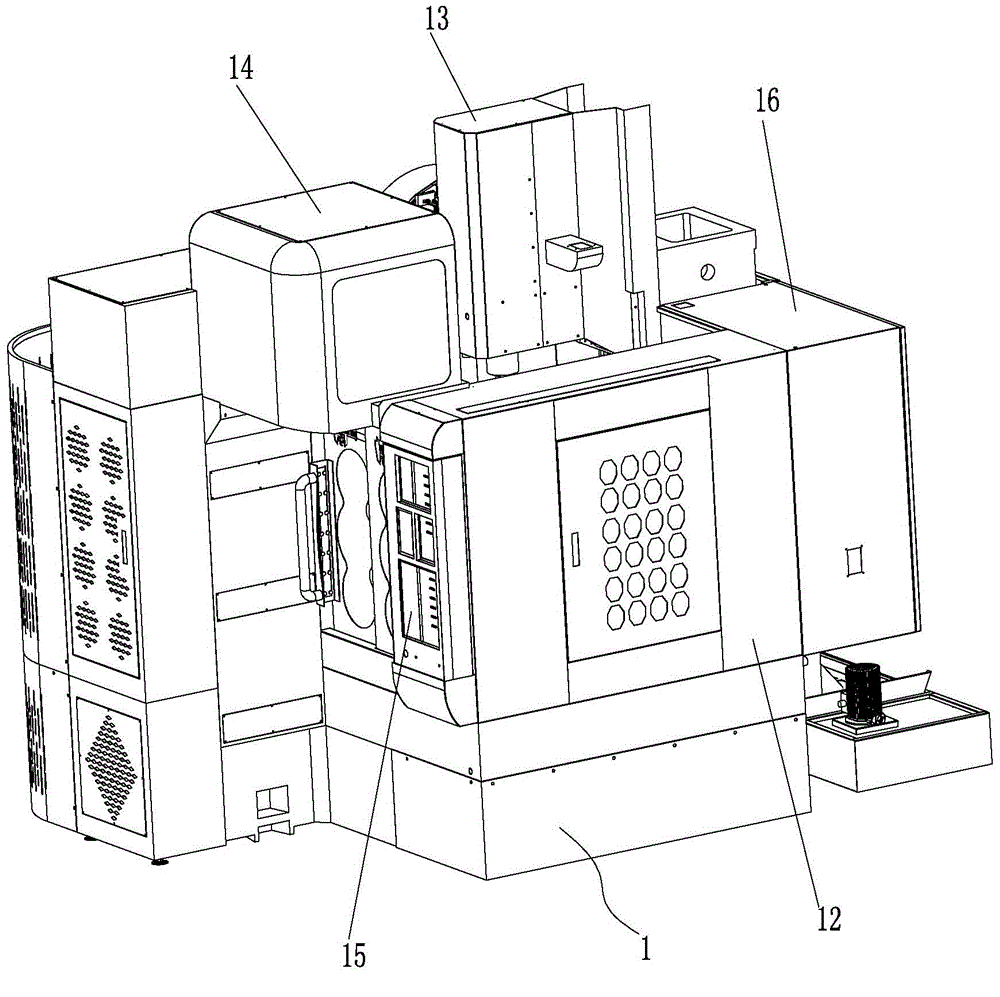

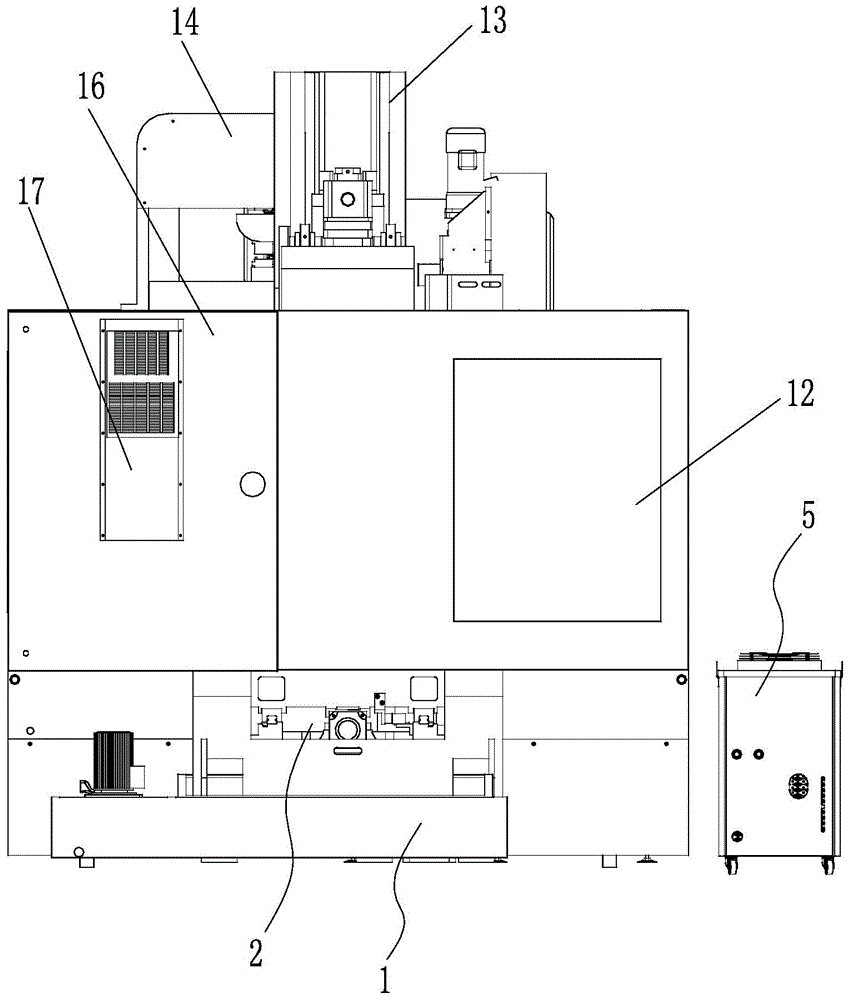

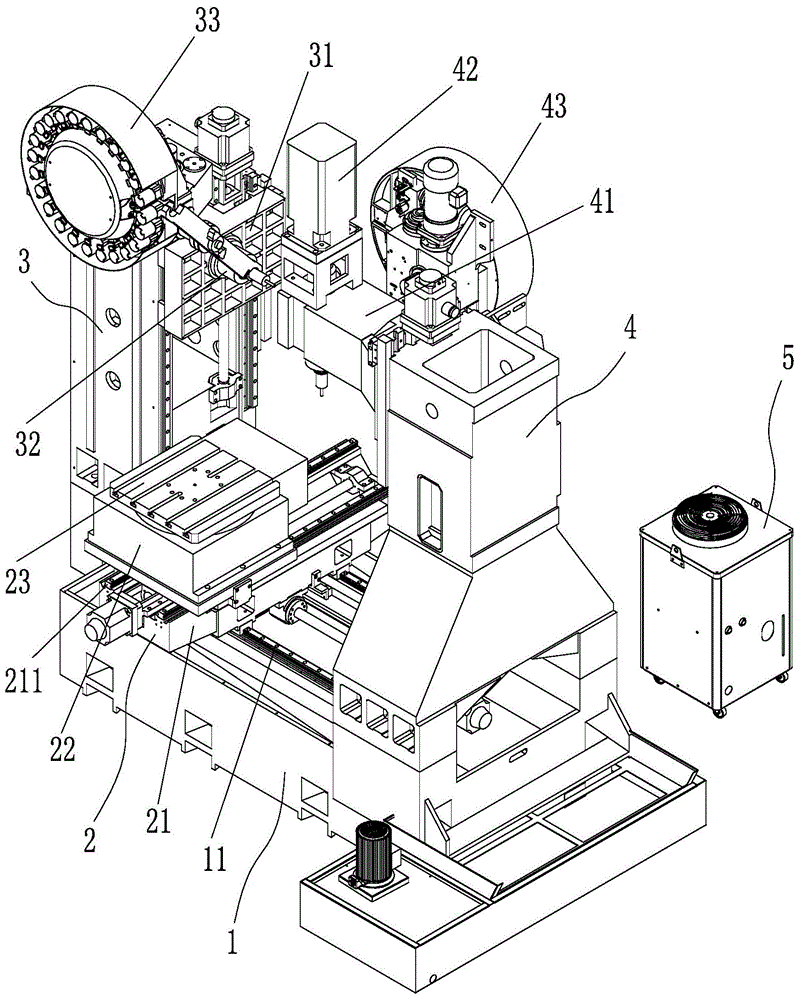

Vertical-horizontal composite multi-axis numerical control machining center

InactiveCN104002200ANo costSave disassembly timeLarge fixed membersMetal working apparatusComposite structureRotary stage

The invention relates to a vertical-horizontal composite multi-axis numerical control machining center. A machine base is provided. The numerical control machining center comprises a high-precision workbench, a horizontal upright post and a vertical upright post which are arranged on the machine base respectively, wherein the high-precision workbench comprises an x-axis sliding table arranged on the machine base, a y-axis sliding table arranged on the x-axis sliding table, and a high-precision turn table arranged on the y-axis sliding table; a horizontal spindle box is arranged on the horizontal upright post; a horizontal machining spindle and a first tool storage which is connected with the horizontal machining spindle are arranged on the horizontal spindle box; a vertical spindle box is arranged on the vertical upright post; a vertical machining spindle and a second tool storage which is connected with the vertical machining shaft are arranged on the vertical spindle box. According to the numerical control machining center, a vertical-horizontal composite structure is adopted, and workpieces can be machined at different positions and in different directions by using one machine without halting or dismounting, thereby saving a large amount of dismounting time and labor force, increasing the production machining efficiency and lowering the machining cost.

Owner:DONGGUAN HONGJINSHUN MACHINERY MFG

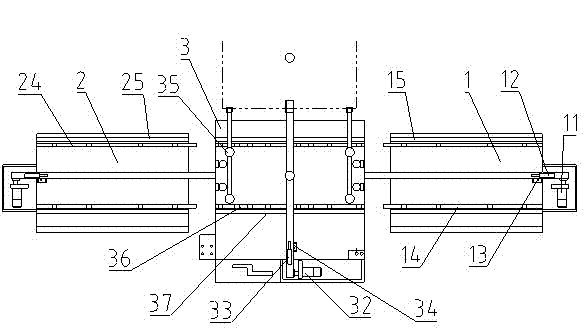

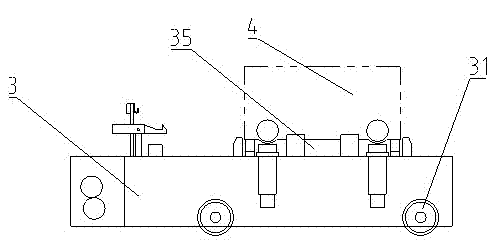

Die changing device

The invention discloses a die changing device, and belongs to the technical field of a conveying device. The die changing device comprises a first fixed die storing platform for storing a backup die, a second fixed die storing platform for storing a replaced die, and a lead rail die changing trolley for bearing the backup die or the replaced die in each working position of an equipment working table, wherein the lead rail die changing trolley can be operated among the equipment working table, the first fixed die storing platform and the second fixed die storing platform; and the die changing device further comprises a die seat for fixing the backup die or the replaced die in each working position of the equipment working table. The technical scheme provided by the invention has the beneficial effects that a die replacing operation and a die installing operation can be individually carried out, so that disassembling time can be saved, and a working cycle is reduced; the backup die can be precisely conveyed from a die storing table to the equipment working table, and an error in positioning precision is avoided; dies can be assembled in a plurality of working positions, thus, the error in positioning among different working positions can be avoided, working intensity of workers can be reduced, and danger is reduced.

Owner:SUOTE TRANSMISSION EQUIP

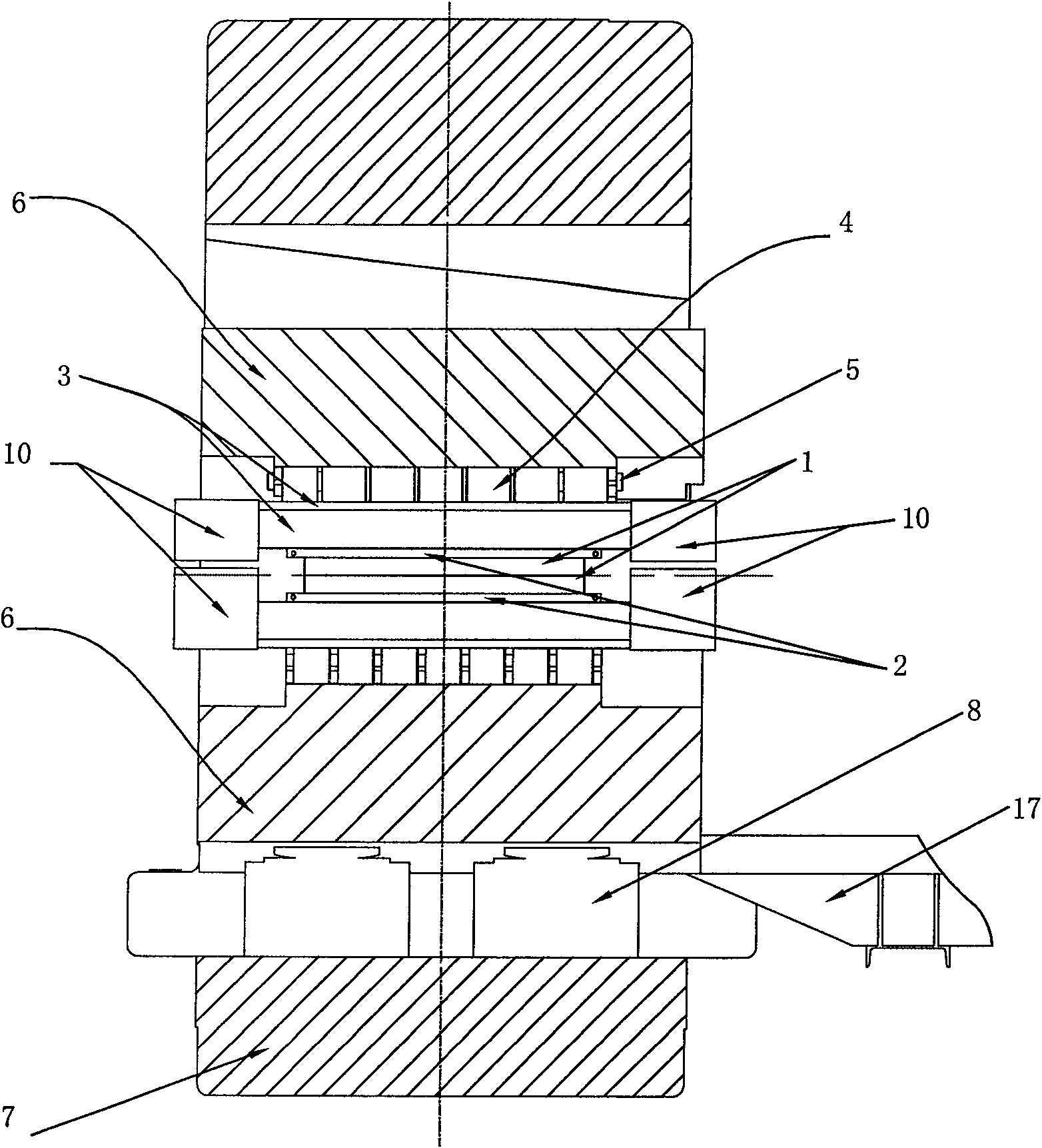

20-roll rolling mill comprising upper and lower splitting integrated roll box and method for replacing rolls thereof

ActiveCN101676041APrevent slippingAchieve replacementMetal rolling stand detailsMetal rolling arrangementsTowerBackup roll

The invention provides a novel technical method for a split-type 20-roll rolling mill comprising a tower-type roll system and 8 rows of backing bearings. The invention simplifies positioning devices in upper and lower box bodies and realizes the overall positioning of same-level backup rolls, while the invention dispenses with an independent suspension device for positioning the backup rolls, so that the roll system can be dismantled rapidly and conveniently for the maintenance and services of the 20-roll rolling mill. The invention improves the process for machining the mounting part of the backing bearings of the roll box, so that the roll box can be stable and reliable in the operating process. The other improvement of the invention provides a method for rapidly changing the rolls of the 20-roll rolling mill. The method can pull out backup rolls or working rolls in each layer and adjacent backup rolls thereof at the same time, thereby greatly reducing the time for changing rolls andimproving the operating efficiency.

Owner:王宇 +1

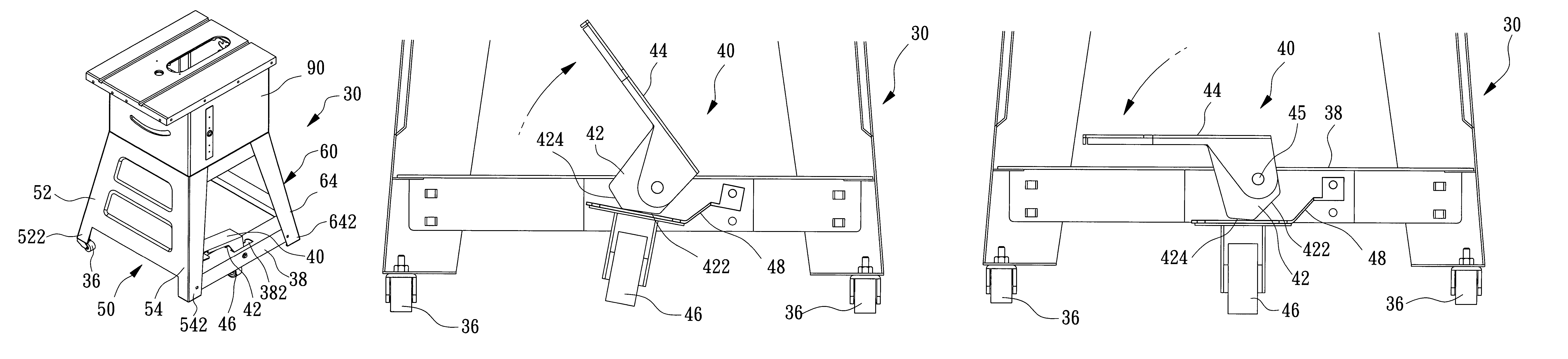

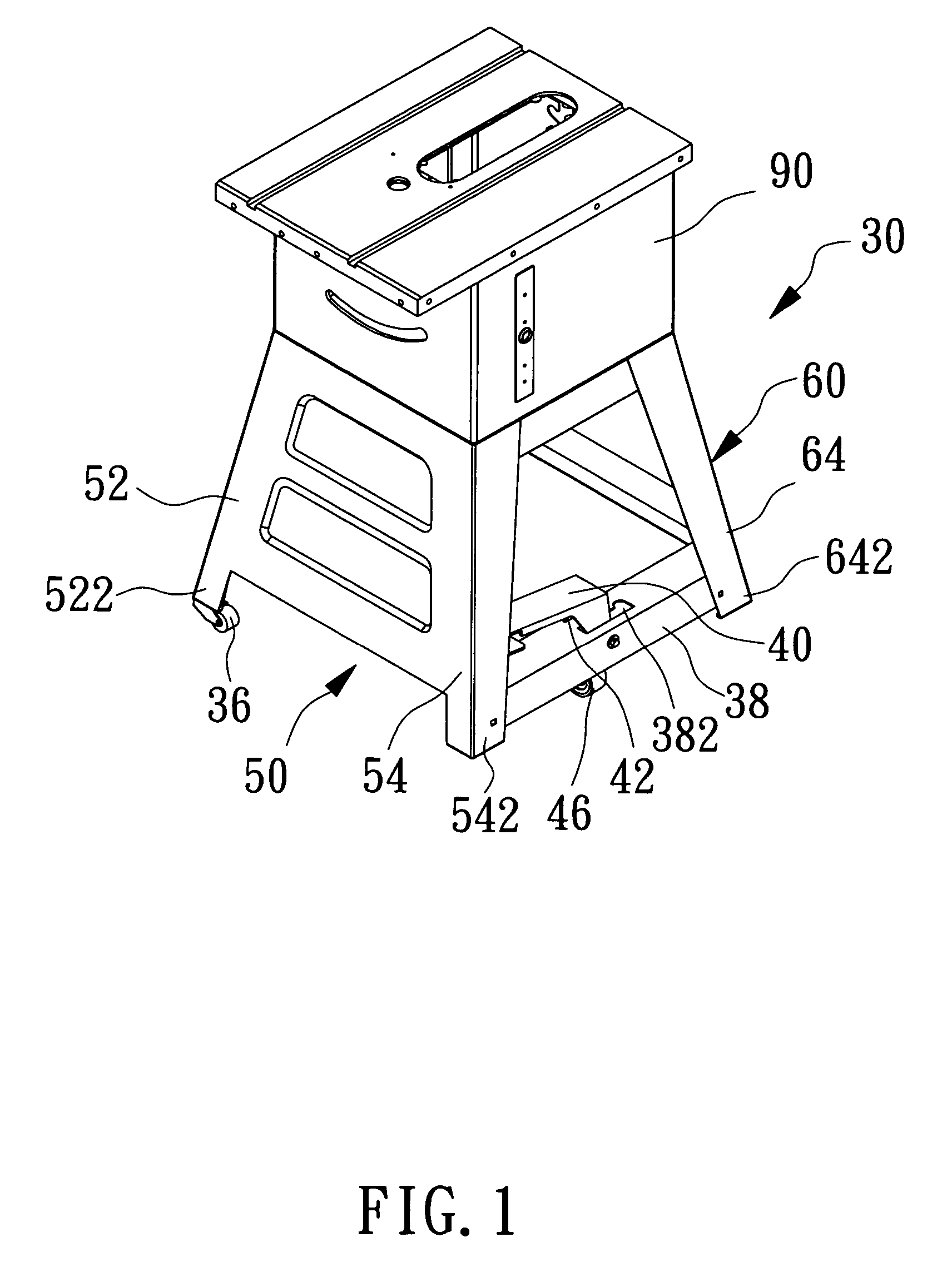

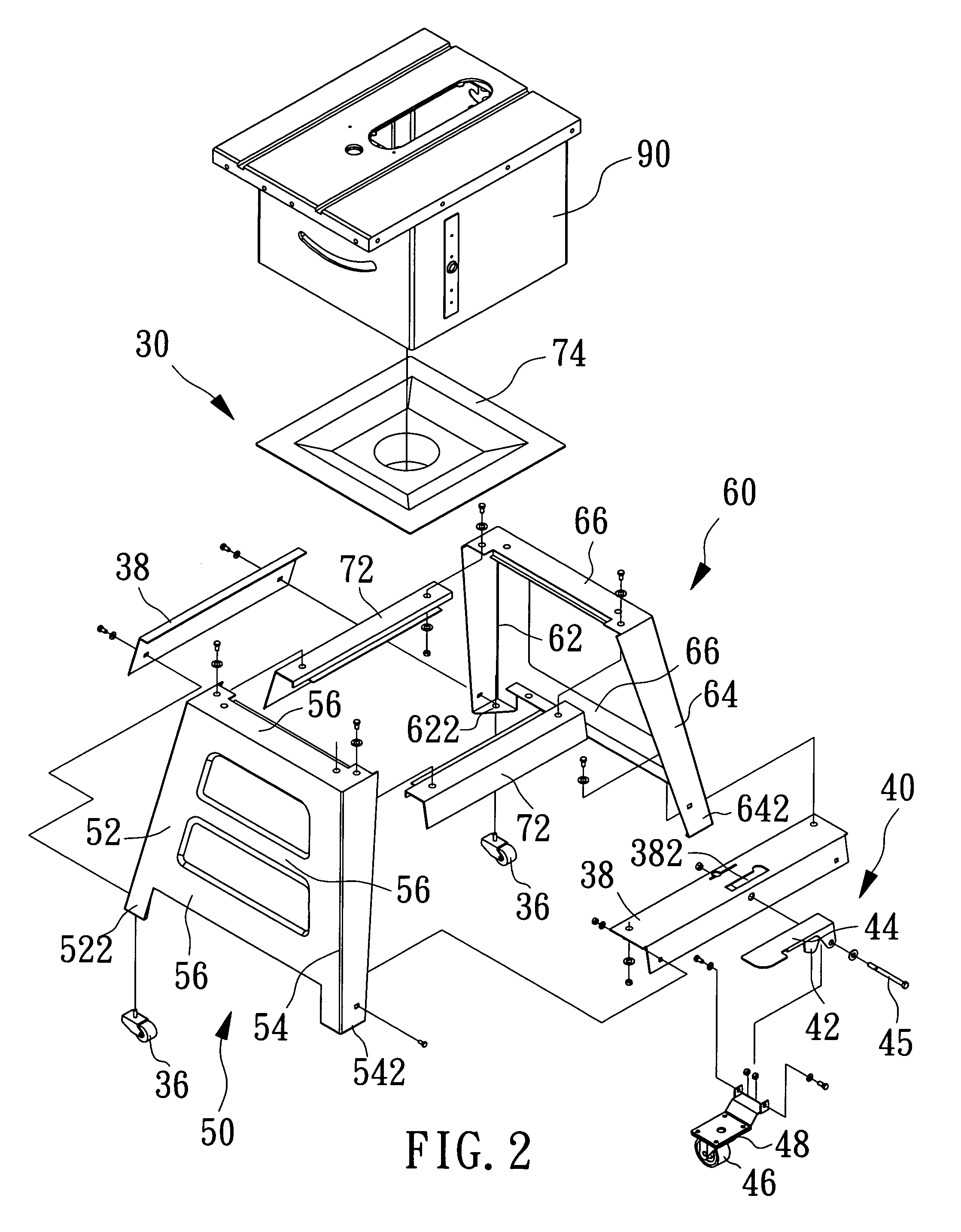

Mobile base

InactiveUS6997466B2Easy constructionSave disassembly timeCastorsUnderstructuresMechanical engineeringEngineering

Owner:WANG WANG TIEN

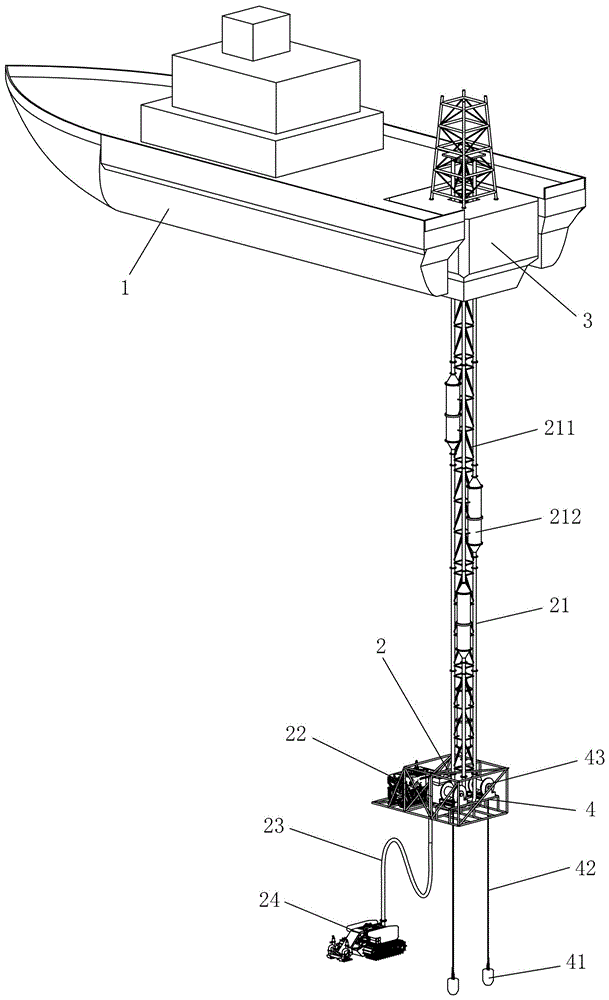

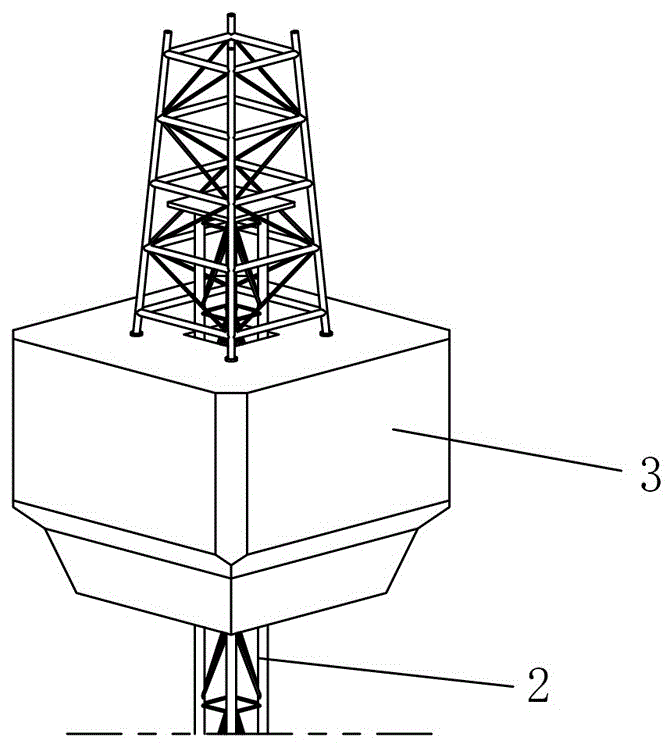

Deep sea mineral resource exploration system

ActiveCN105927229AReduce the difficulty of disassemblyReduce the impact of continuity of production operationsMineral miningEngineeringFloating platform

The invention discloses a deep sea mineral resource exploration system which comprises a mother operation ship, a mining system as well as a floating platform, wherein the floating platform is connected with the mother operation ship in a detachable manner; the mining system is connected with the floating platform; the mining system or the floating platform is connected with a submerging control device for enabling the floating platform to submerge under water. The deep sea mineral resource exploration system can shelter from the wind flexibly and conveniently without disassembling the whole system, can rapidly and flexibly respond to complex weather condition such as typhoon, and has the advantages of long service life, high production efficiency, good production operation continuity and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

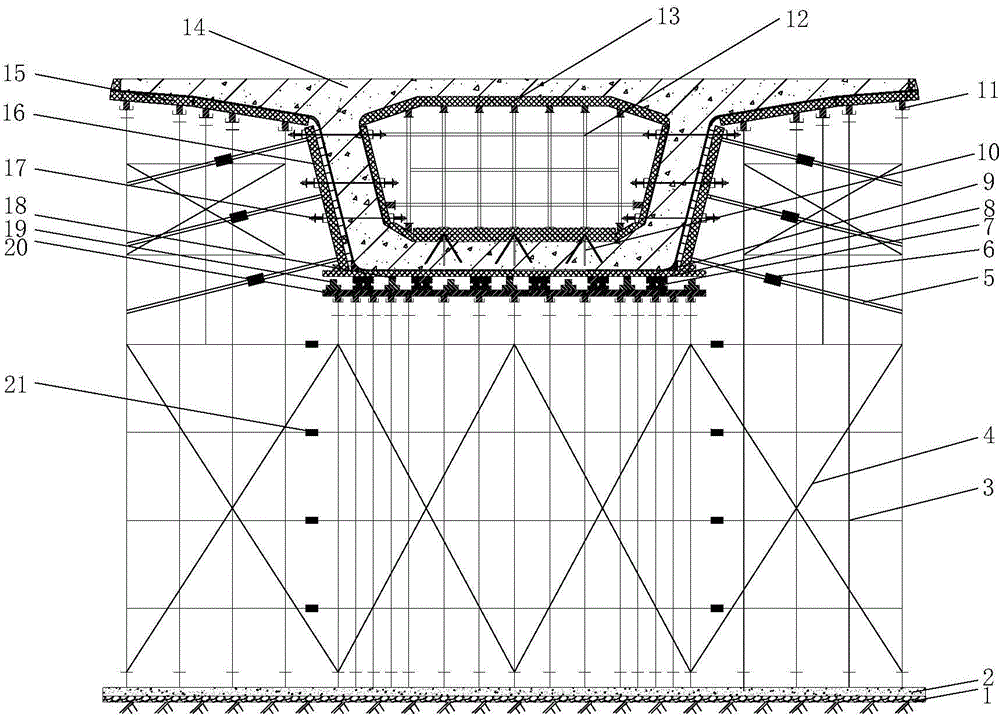

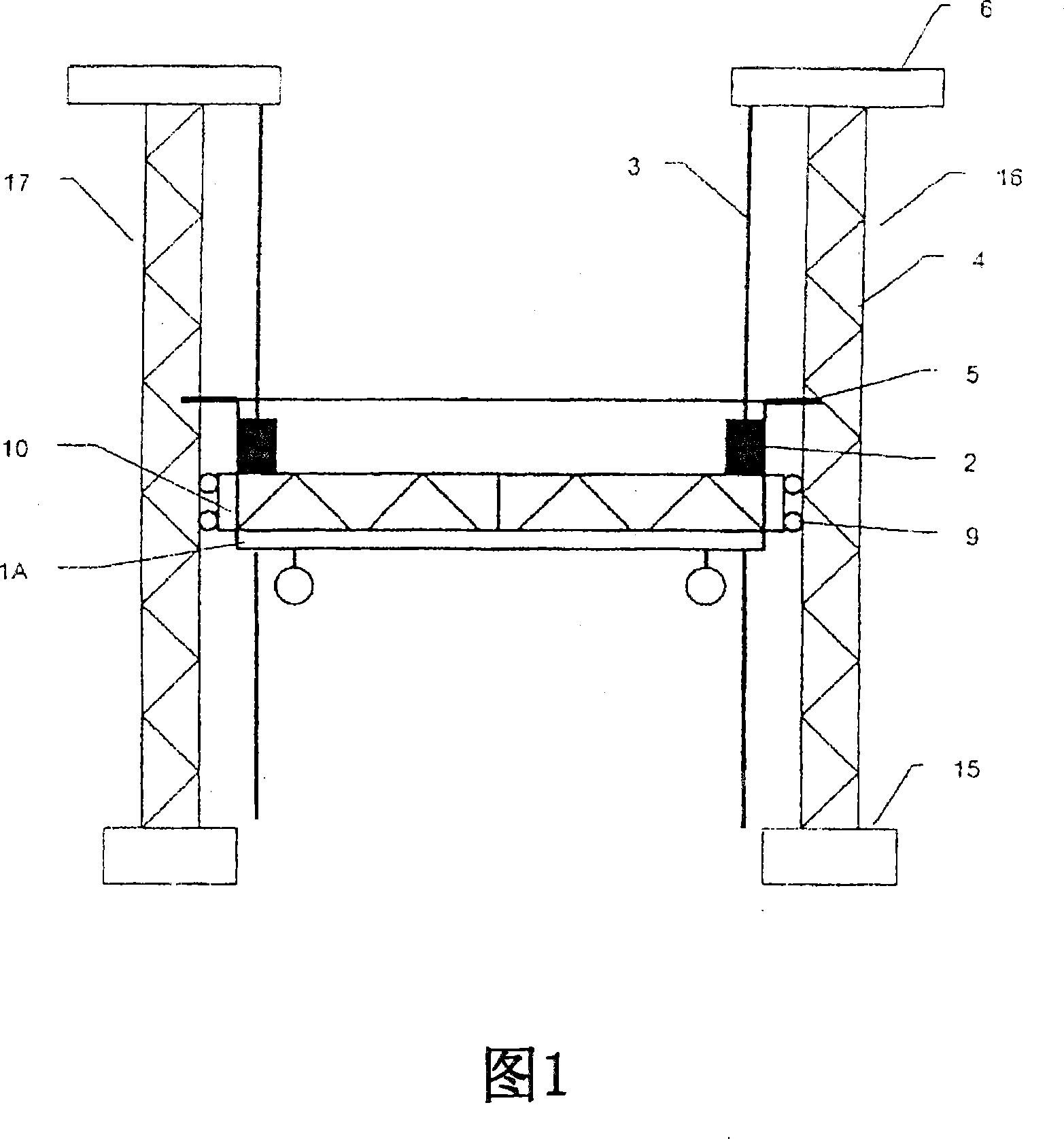

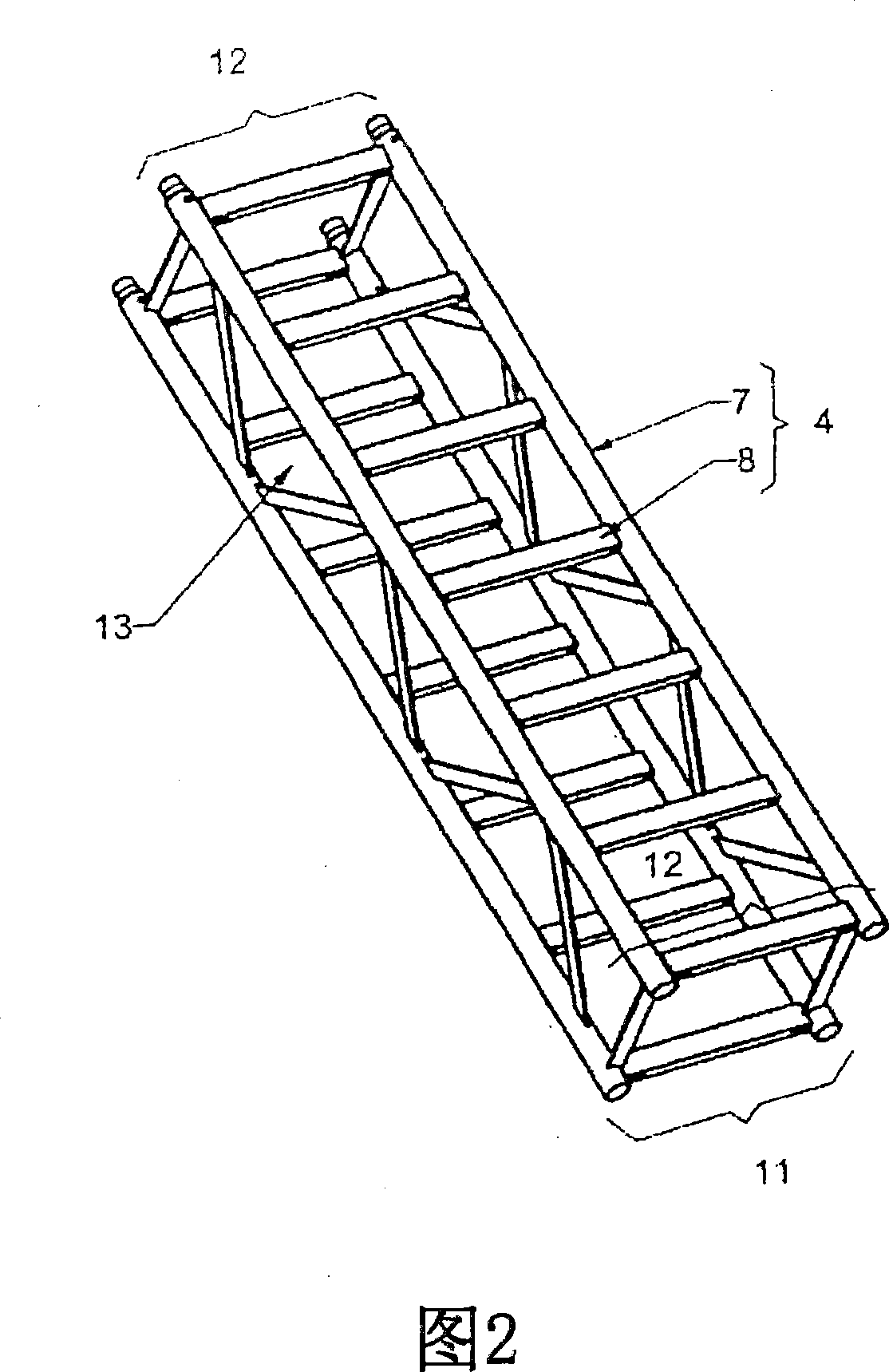

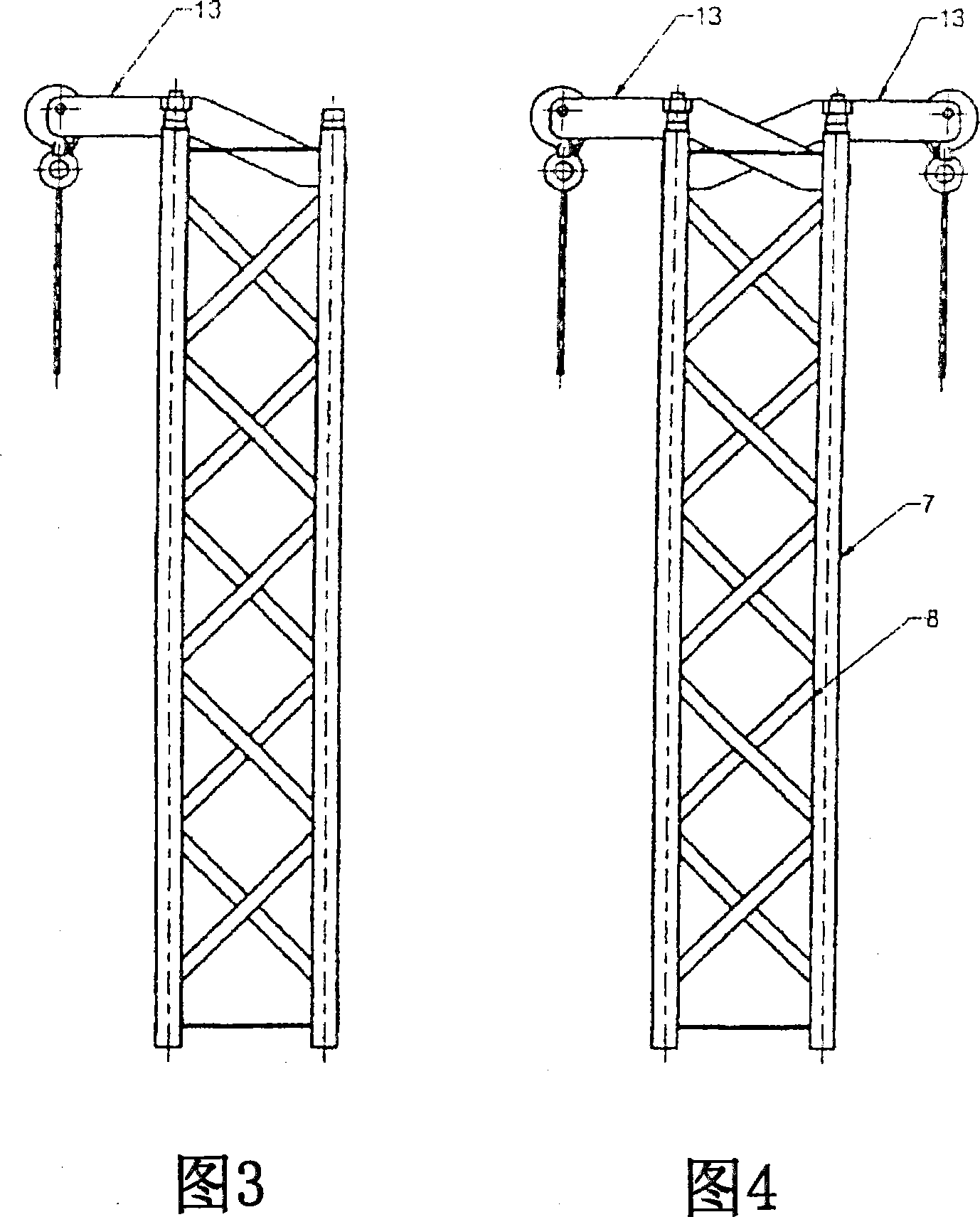

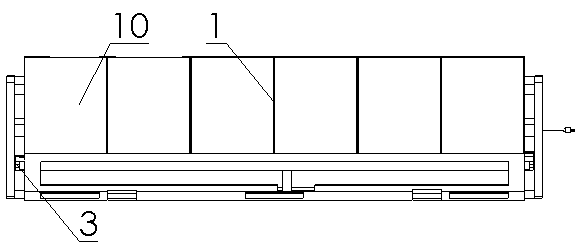

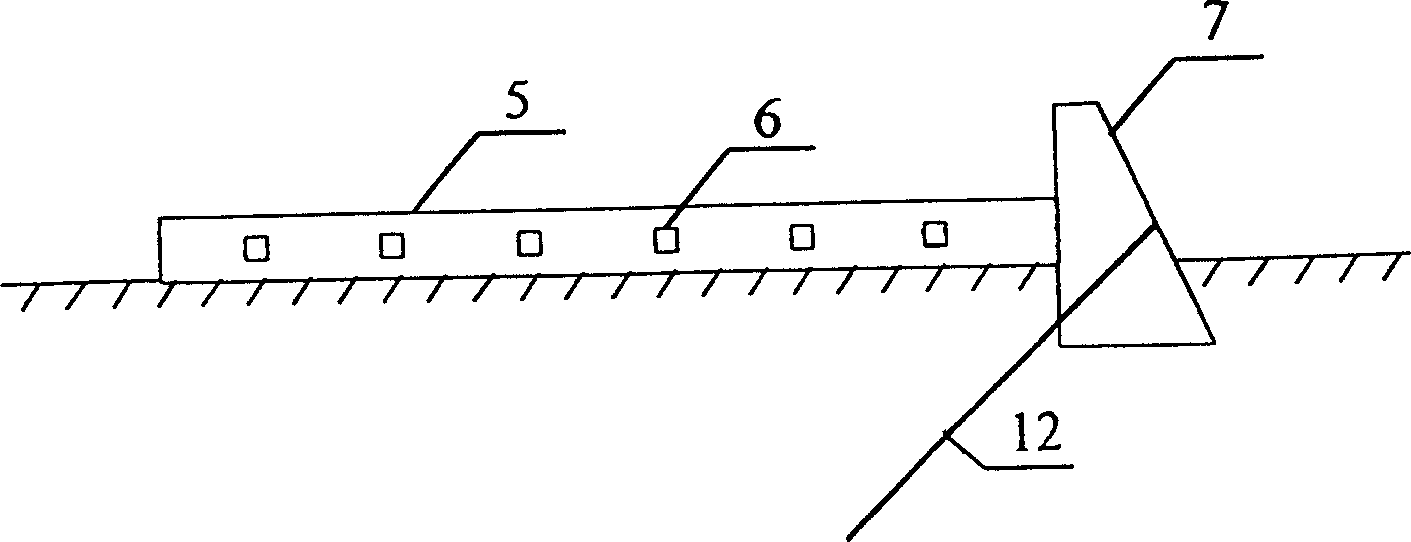

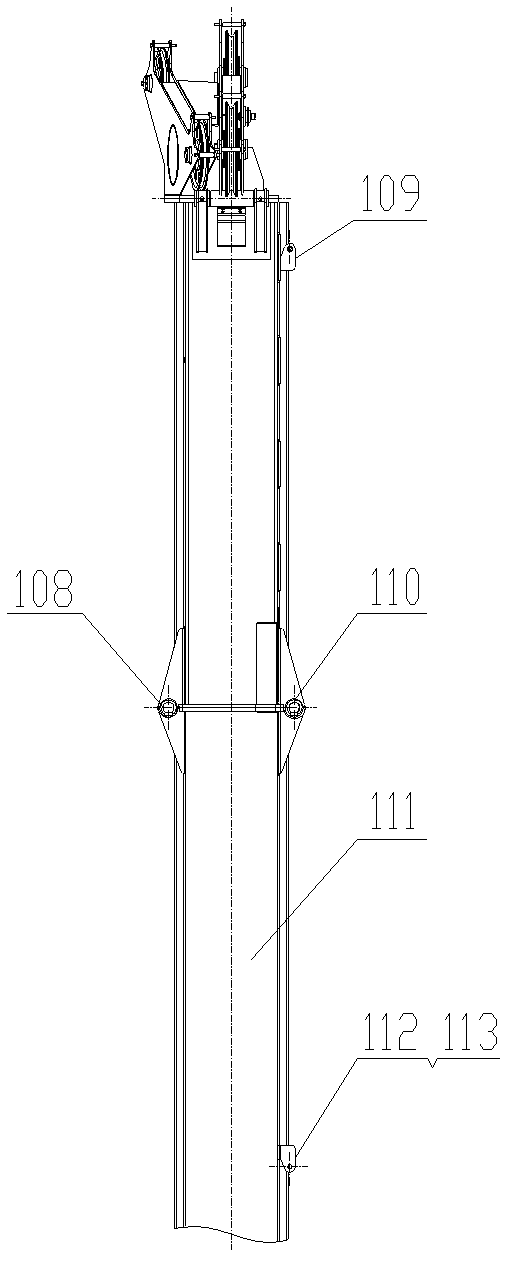

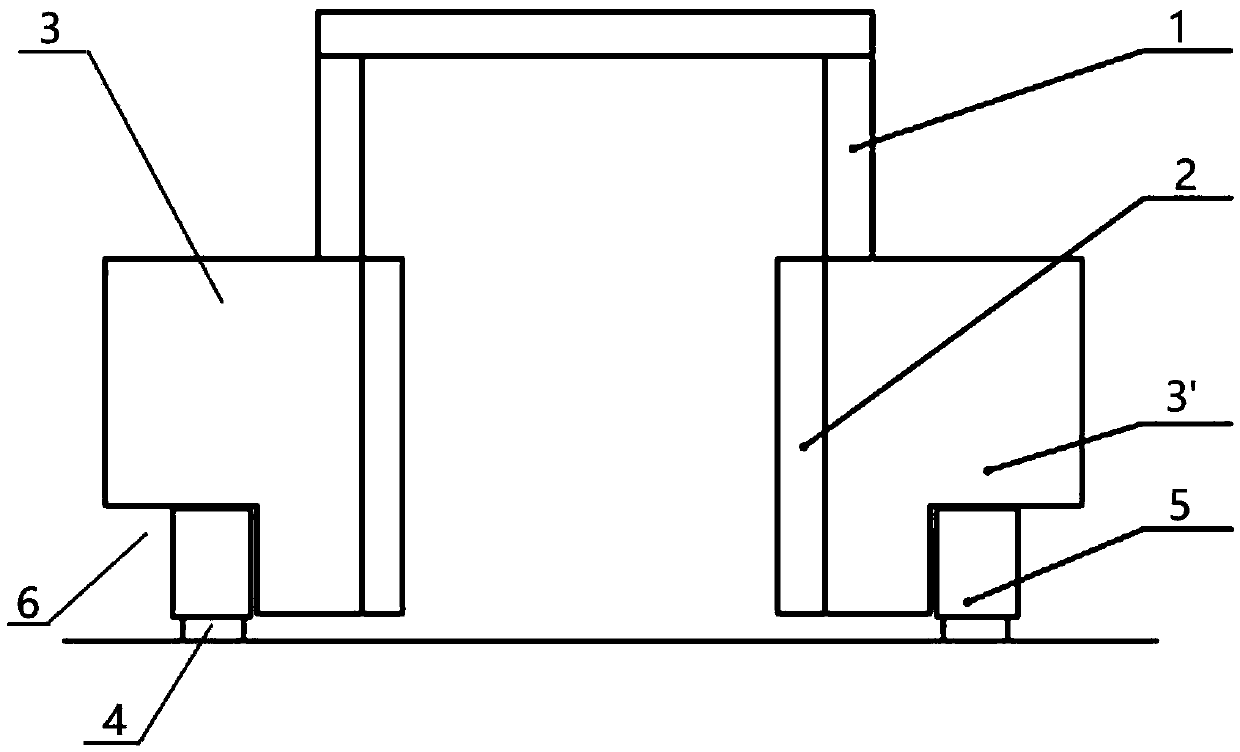

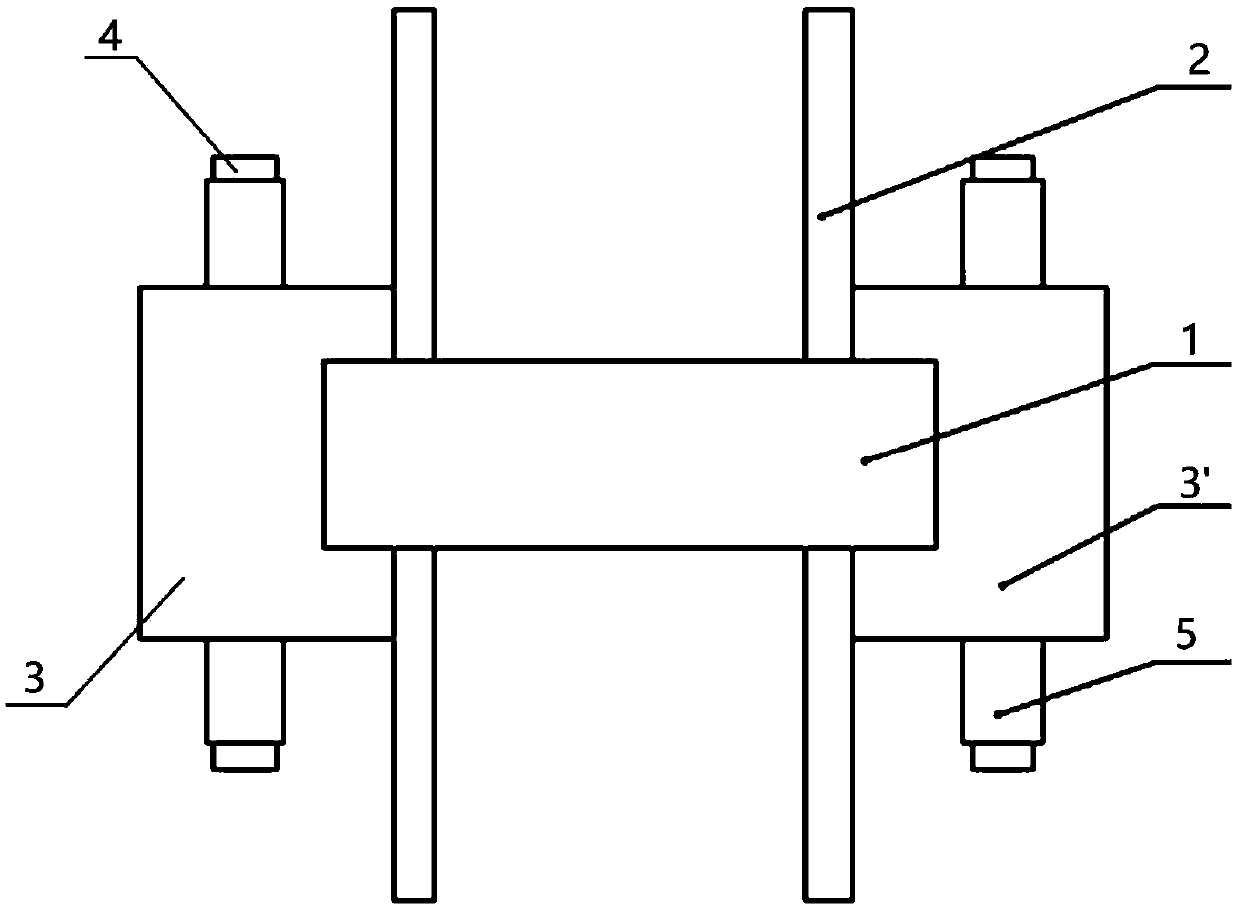

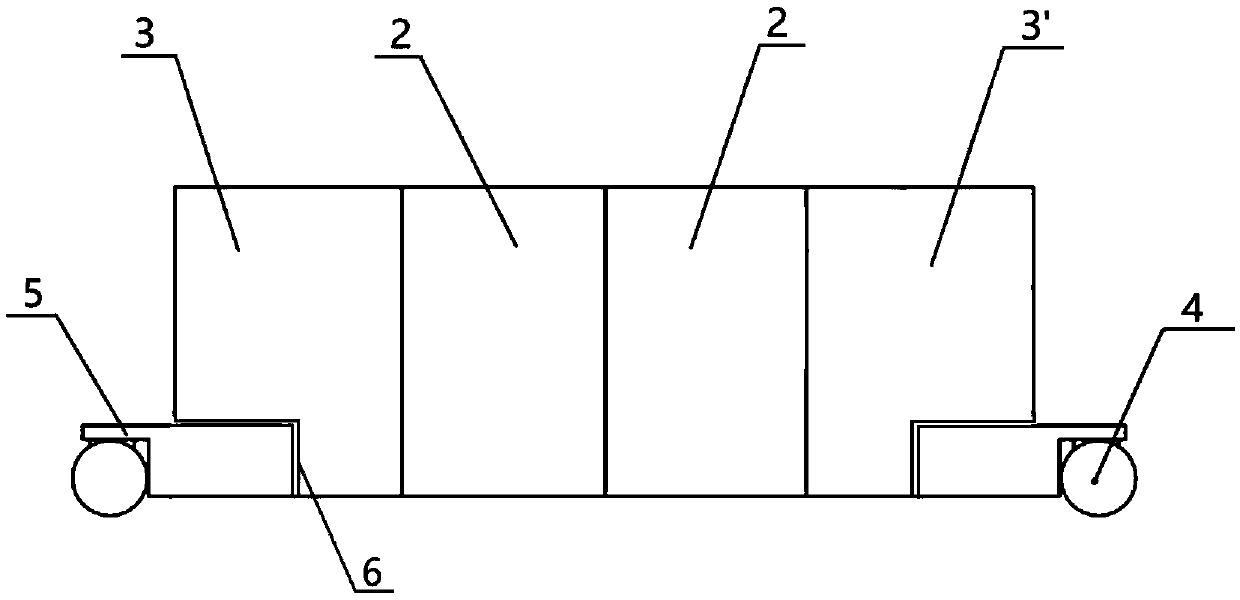

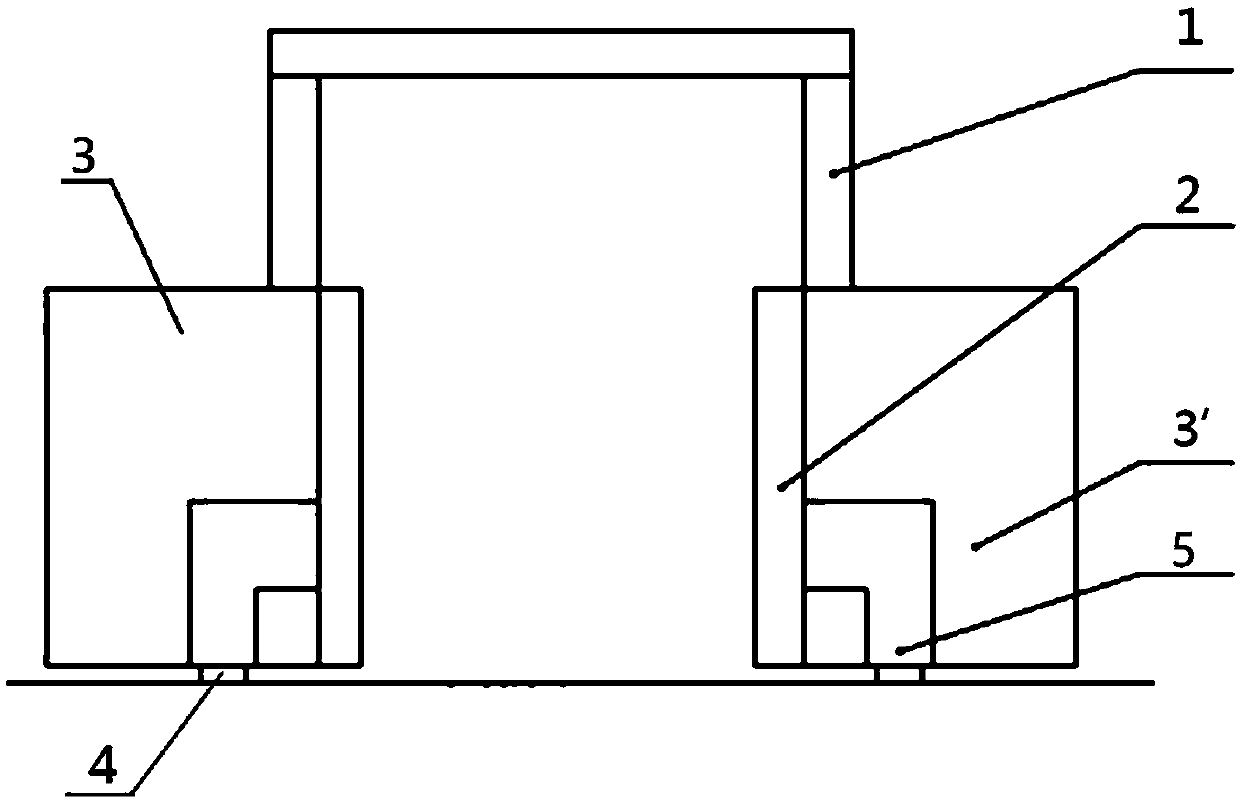

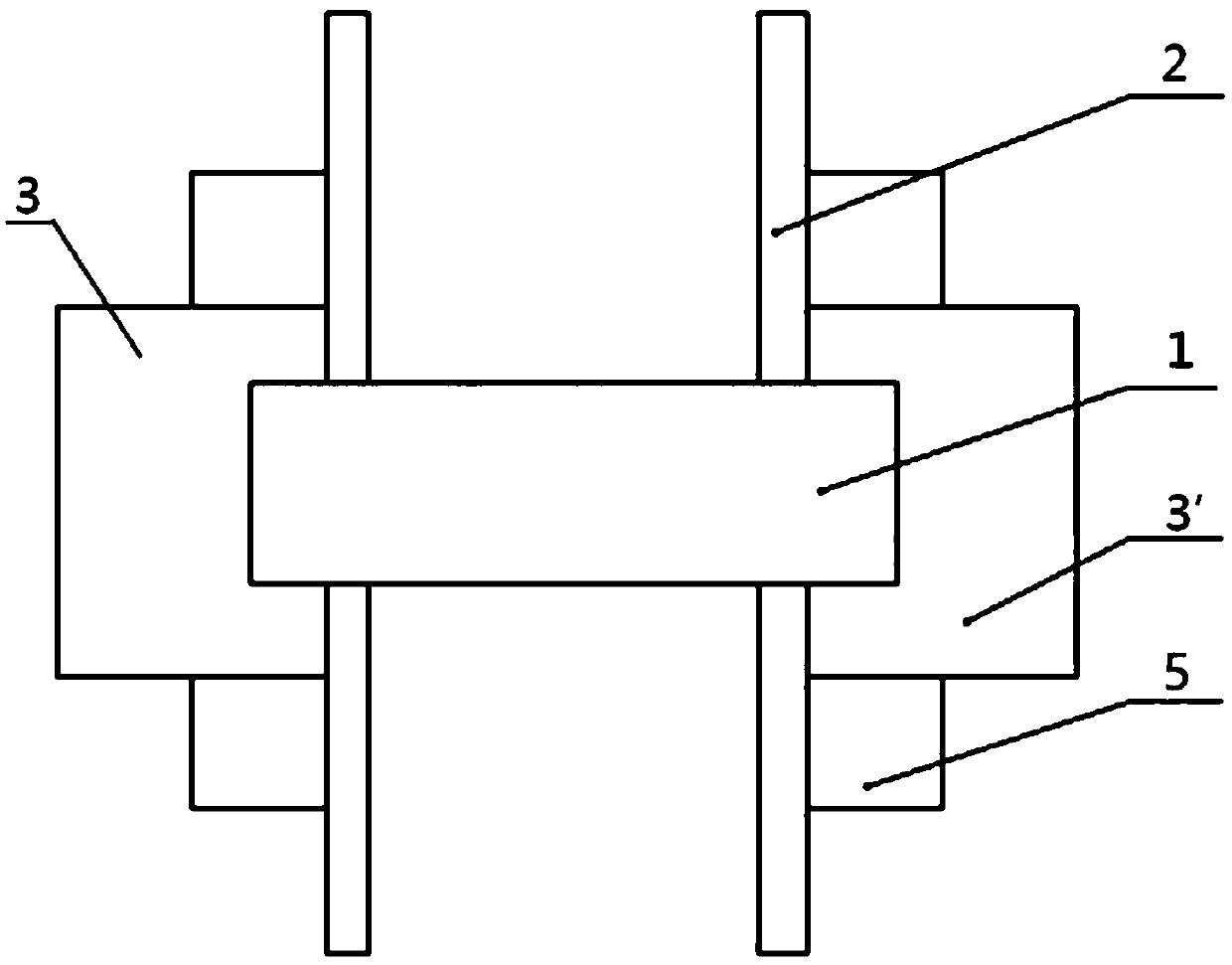

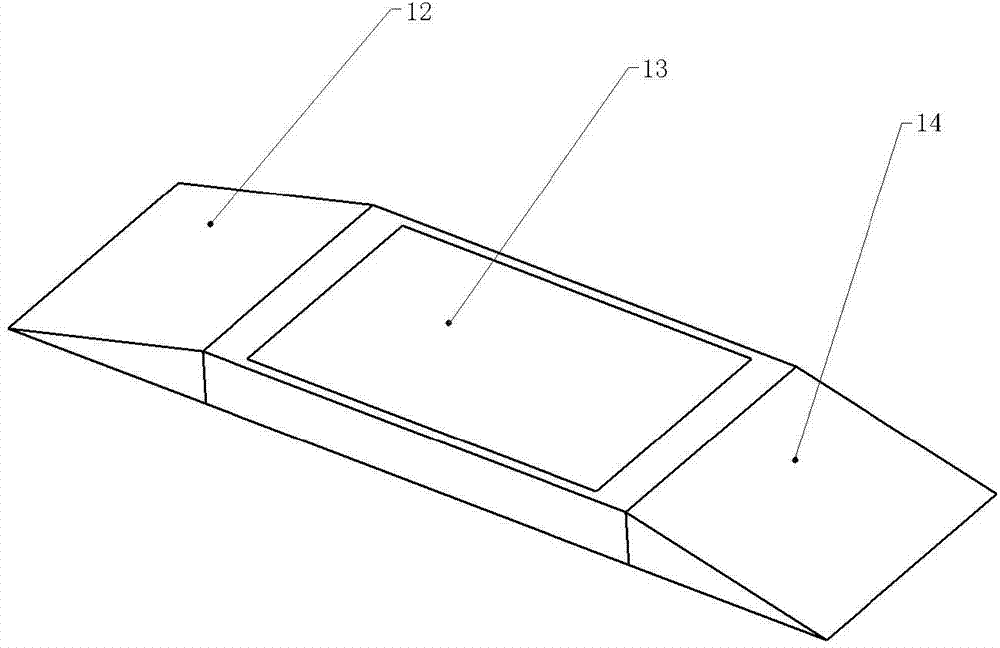

Platform support device for lifting loads or persons the height of a structure

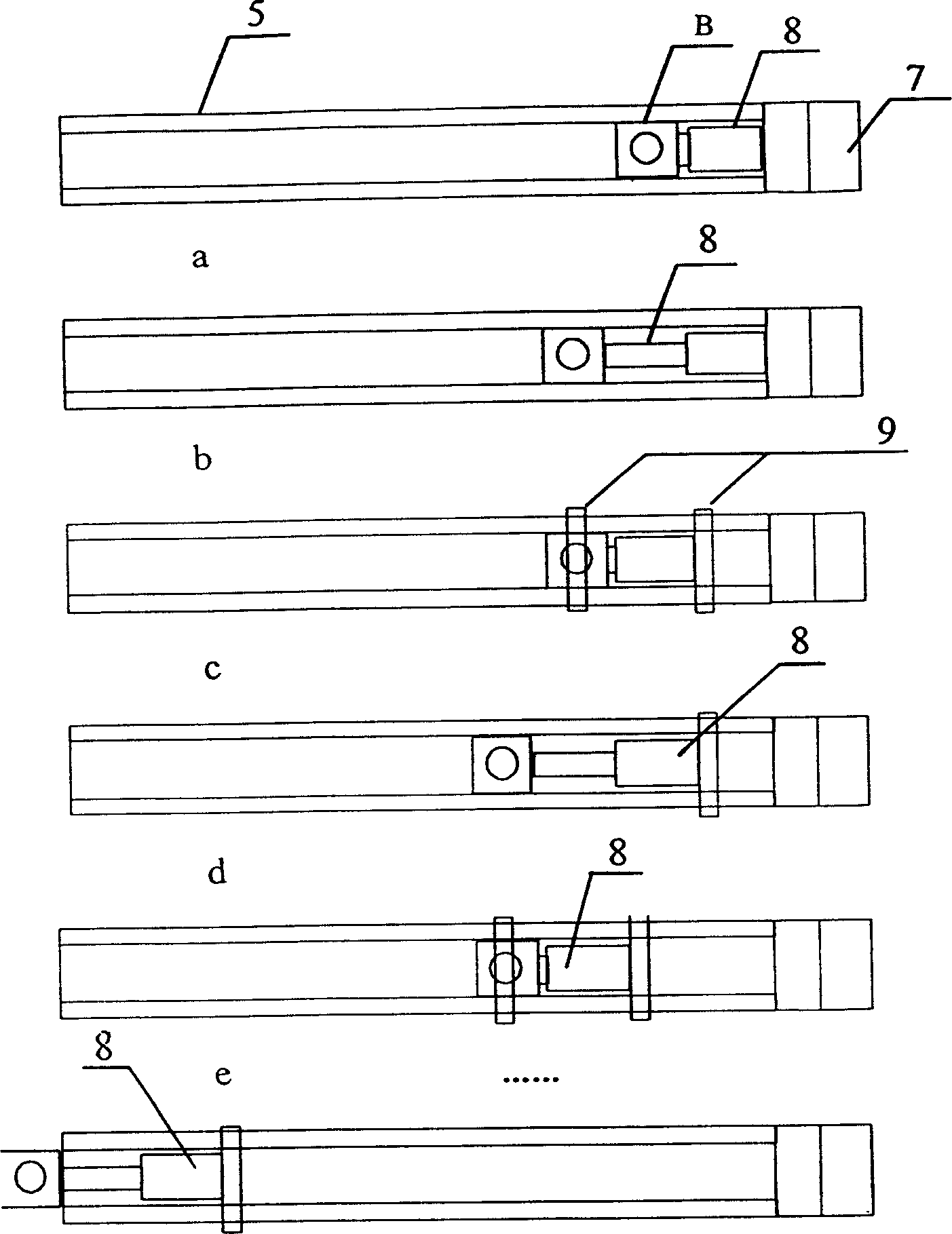

InactiveCN1997801ASave assembly timeSave disassembly timeLifting devicesBuilding liftsModularityEngineering

The invention relates to a device for supporting a platform (1A, 1B) that is used to lift loads or persons the height of a structure. Together with a platform (1A, 1B), the inventive device comprises winch-type platform-lifting elements (2, 3) and modular assemblable mast-forming elements (4, 6). According to the invention, each mast element (4, 6) is installed using the load platform (1A, 1B) which can be connected to the masts by means of: (i) the aforementioned winch-type lifting elements (2, 3) which can be disconnected at will from the masts, and (ii) means (5) for temporarily blocking the movement of the platform (1A, 1B) in relation to a modular element (4, 6) of each mast. In this way, when the movement of the platform (1A, 1B) is blocked, a modular element (4, 6) can be added to, or removed from the top of the masts in accordance with the desired platform (1A, 1B) lifting height. The invention is characterised in that the platform (1A, 1B) is positioned between two modular independent masts which form a lifting and guiding path (12), each mast having at least two guiding paths (11, 12) which are arranged in order to co-operate with a platform (1A, 1B), enabling the asynchronous movement of said platforms (1A, 1B).

Owner:FIXATOR

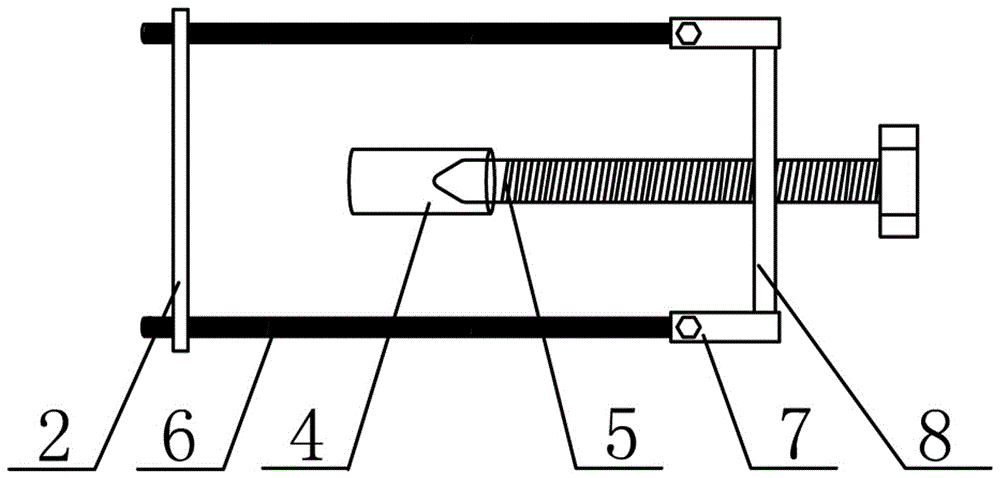

Dismounting tool of pluggable cable terminal

InactiveCN105977875ASave disassembly timeReduce disassembly damage rateApparatus for joining/termination cablesEngineeringScrew thread

The invention provides a pluggable cable terminal removal tool, which includes a fixing fixture, two adjusting pull rods, a connecting arm and a rotating screw rod, one end of the two adjusting pull rods is fixedly connected to both sides of the fixing fixture respectively, The other ends of the two adjusting pull rods are connected to the two ends of the connecting arm, and the middle part of the connecting arm is provided with a rotating screw hole, and the rotating screw is threadedly connected to the rotating screw hole. The removal tool is not only suitable for different manufacturers and different types of cable terminal accessories, but also can shorten the disassembly operation time, save human resources, avoid damage to the cable terminal equipment during disassembly, and solve the problem of difficult disassembly operations in a narrow space .

Owner:STATE GRID CORP OF CHINA +1

High-integration-level folding-type photovoltaic array

ActiveCN103474491AFast installationShorten the timePhotovoltaic supportsPhotovoltaic energy generationPhotovoltaic arraysStructural engineering

The invention discloses a high-integration-level folding-type photovoltaic array. The high-integration-level folding-type photovoltaic array comprises at least two photovoltaic module integration plates and at least one middle support structure, wherein at least two hinges are fixed on the middle support structure; the photovoltaic module integration plates are connected with the middle support structure by the hinges respectively; the at least two photovoltaic module integration plates are contacted with the ground; the total area of all photovoltaic modules on the photovoltaic array is greater than 18 square meters. According to the high-integration-level folding-type photovoltaic array, multiple components and parts including a foundation, a support, a cable, the photovoltaic modules, an inverter, a combiner box, an optimizer, a photovoltaic module power detection device, a plug and a socket can be integrated, and intermediate links are reduced, thus greatly increasing installation speed, expanding use range, and decreasing installation cost; due to the low appearance of the high-integration-level folding-type photovoltaic array after being expanded, anti-wind capability is greatly improved.

Owner:孙涛

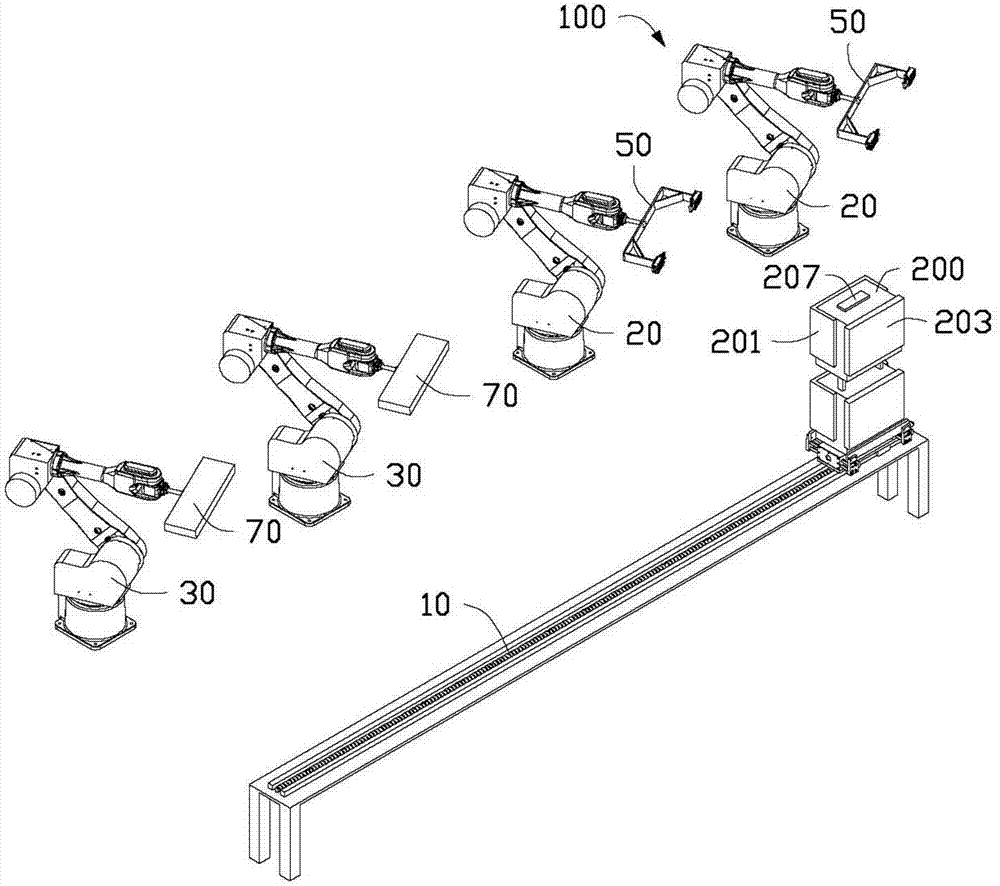

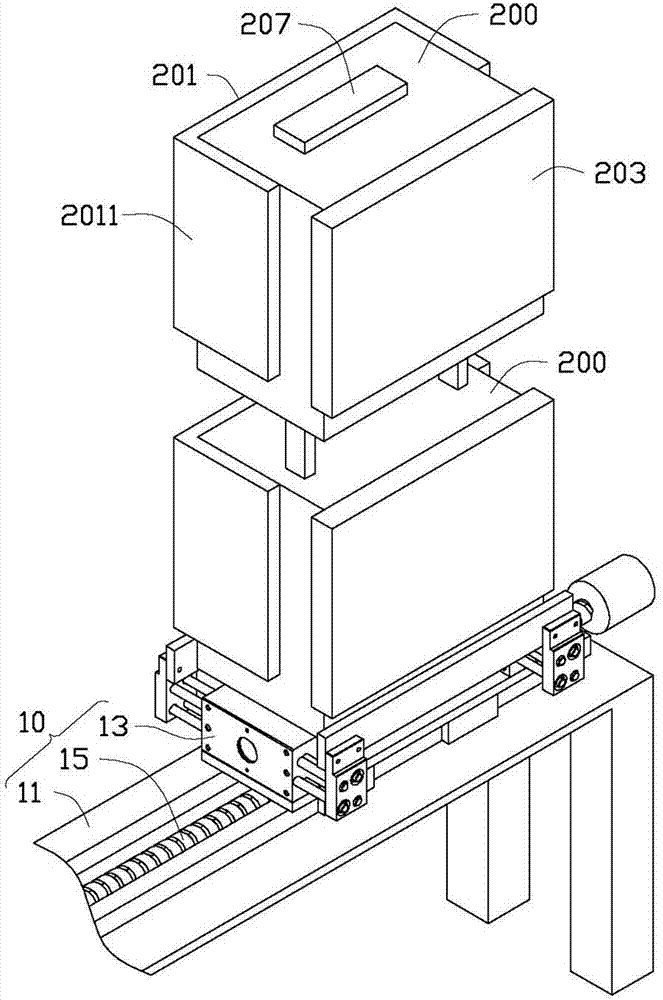

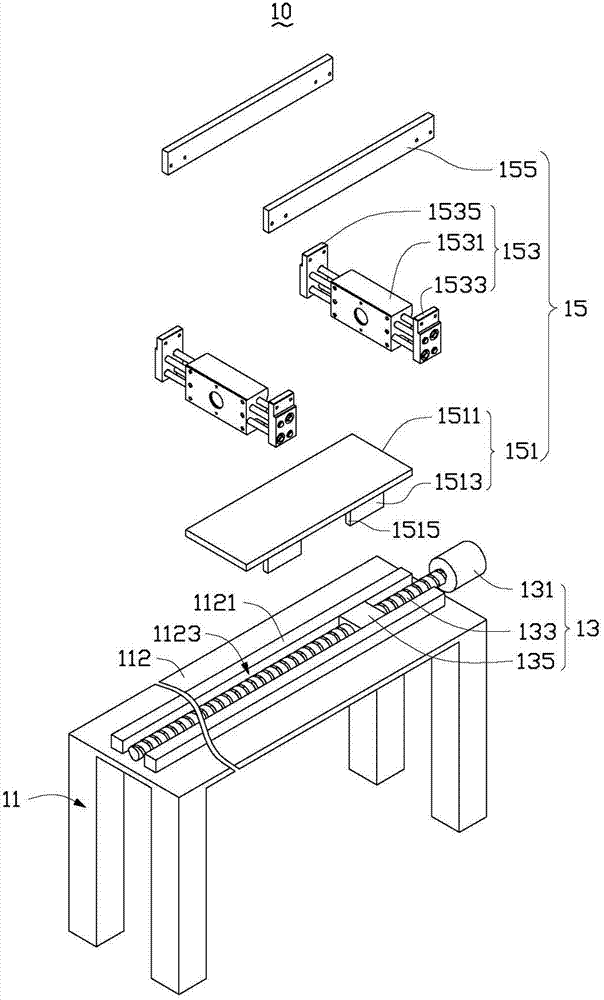

Demounting system

InactiveCN103707025ANo manual operationSave disassembly timeProgramme controlProgramme-controlled manipulatorAssembly lineManipulator

A demounting system comprises an automatic assembly line, a sliding rod, a controller, a rotating mechanism, multiple manipulators and multiple demounting mechanism. The automatic assembly line comprises a workbench, a transmission mechanism and a clamping mechanism, the workbench is positioned below the sliding rod, the transmission mechanism is arranged on the workbench, the clamping mechanism is arranged on the transmission mechanism, the rotating mechanism is mounted on the sliding rod and connected with a hanging tool, and is in same-speed moving with the transmission mechanism, the manipulators are arranged closely to the workbench at intervals, a sensor is mounted on each manipulator, and the controller is electrically connected with the transmission mechanism, the rotating mechanism, the sensors, the manipulators and the demounting mechanism. The sensor of one of the manipulators senses the hanging tool and transmits sensing information to the controller, the controller controls the manipulator and the transmission mechanism to move at a same speed, controls the demounting mechanism to demount a workpiece and controls the rotating mechanism to rotate the hanging tool to enable a workpiece in another direction on the hanging tool to face a next manipulator. The demounting system has the advantage of high demounting efficiency.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

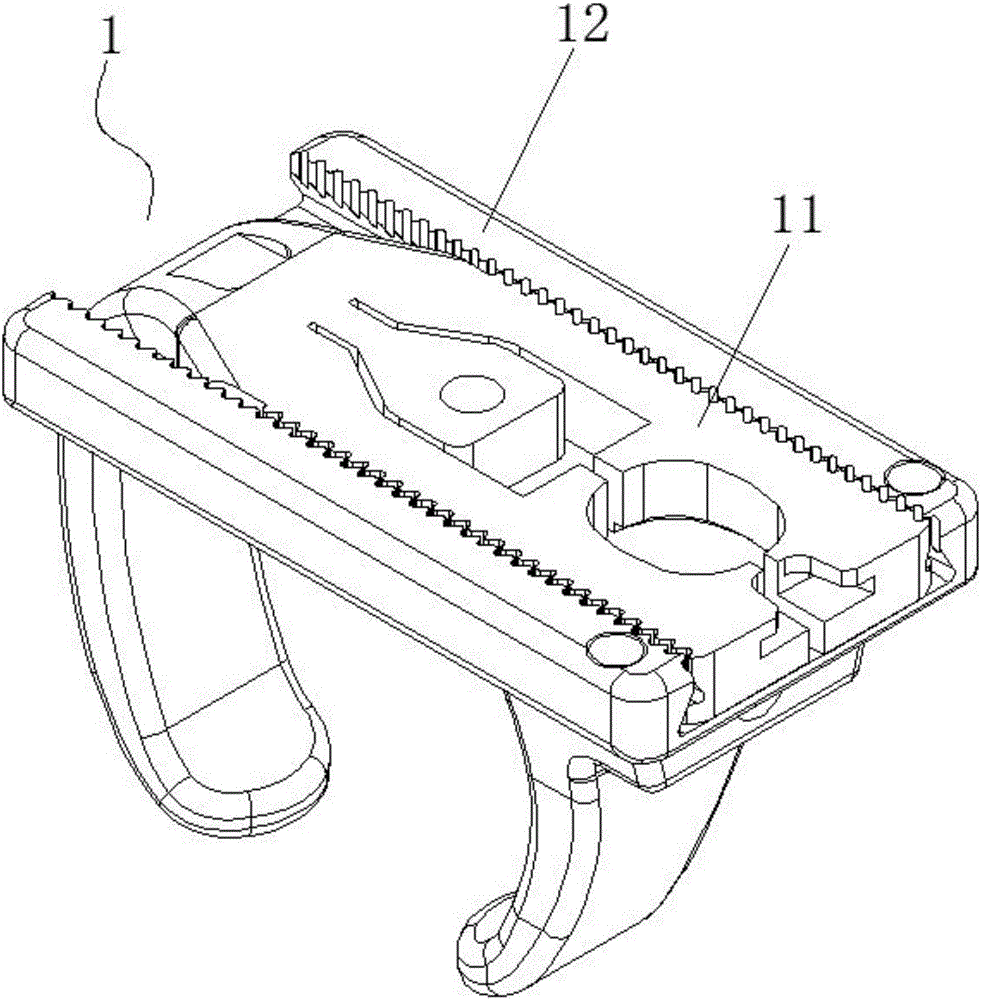

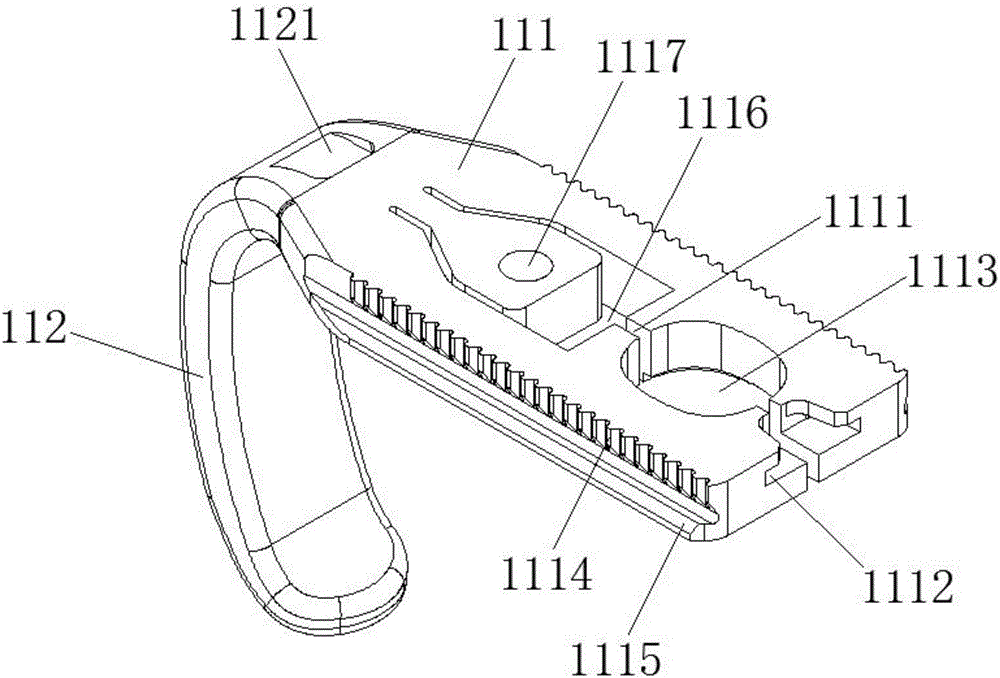

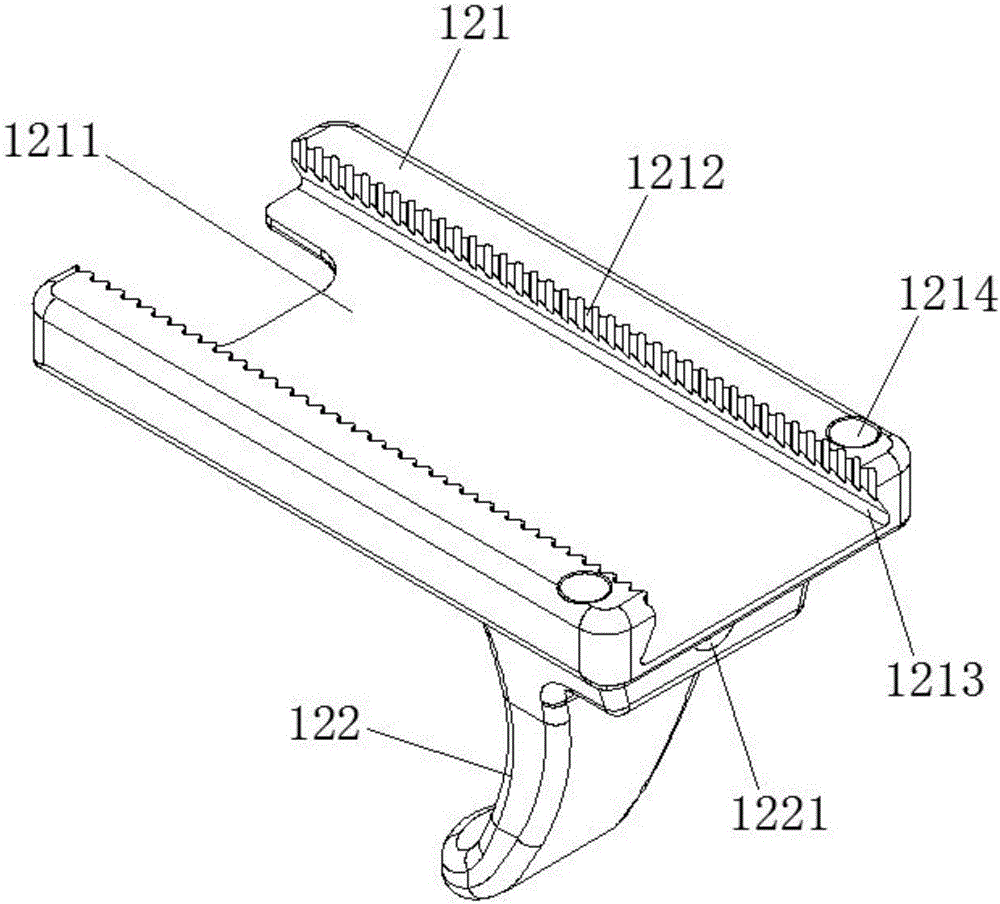

Surgical suite for sternal closure fixation

ActiveCN106108995AEfficient demolitionSolve the difficulty of dismantlingInternal osteosythesisBone platesOrthodontics

Owner:CHANGZHOU WASTON MEDICAL APPLIANCE CO LTD

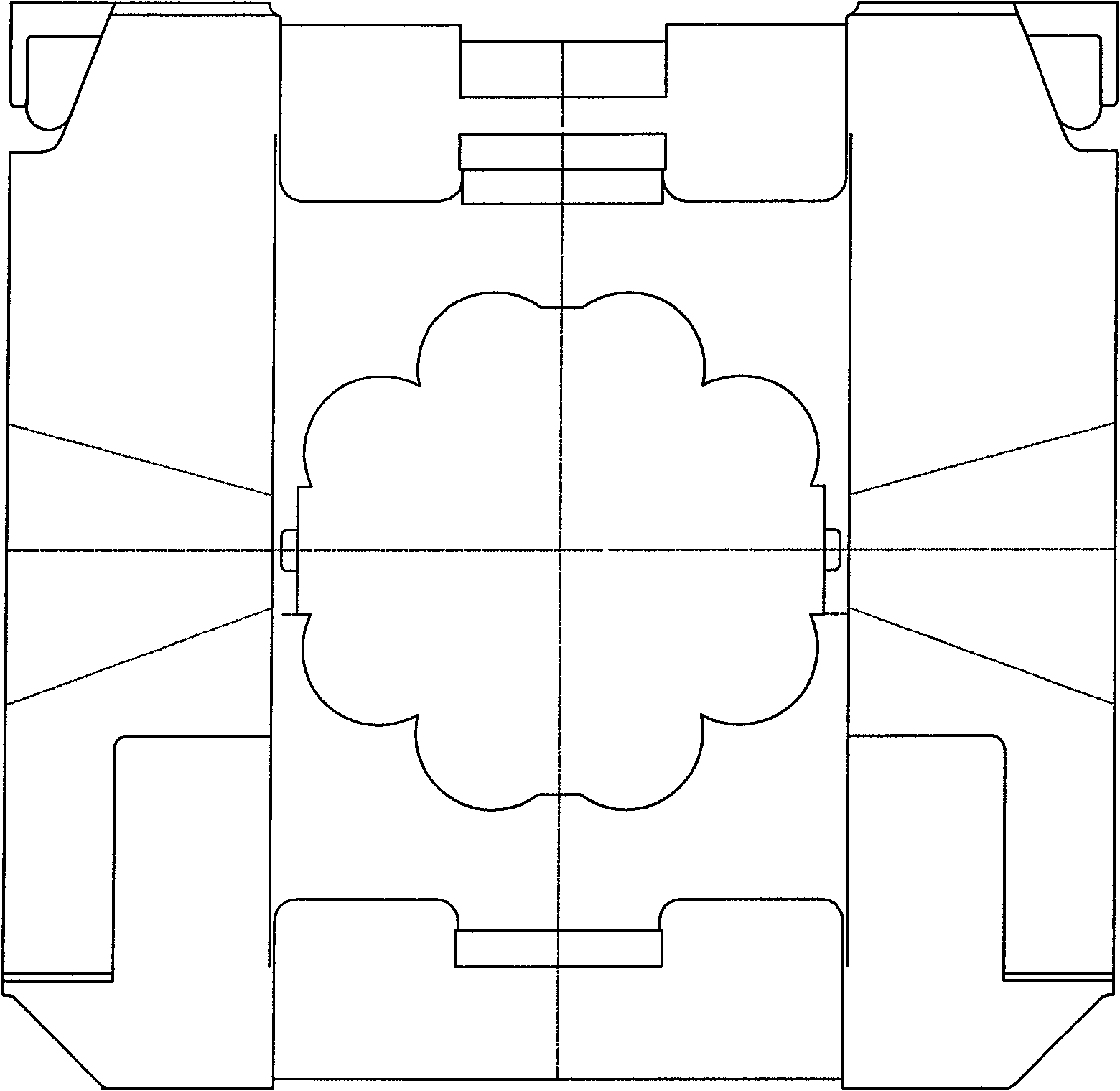

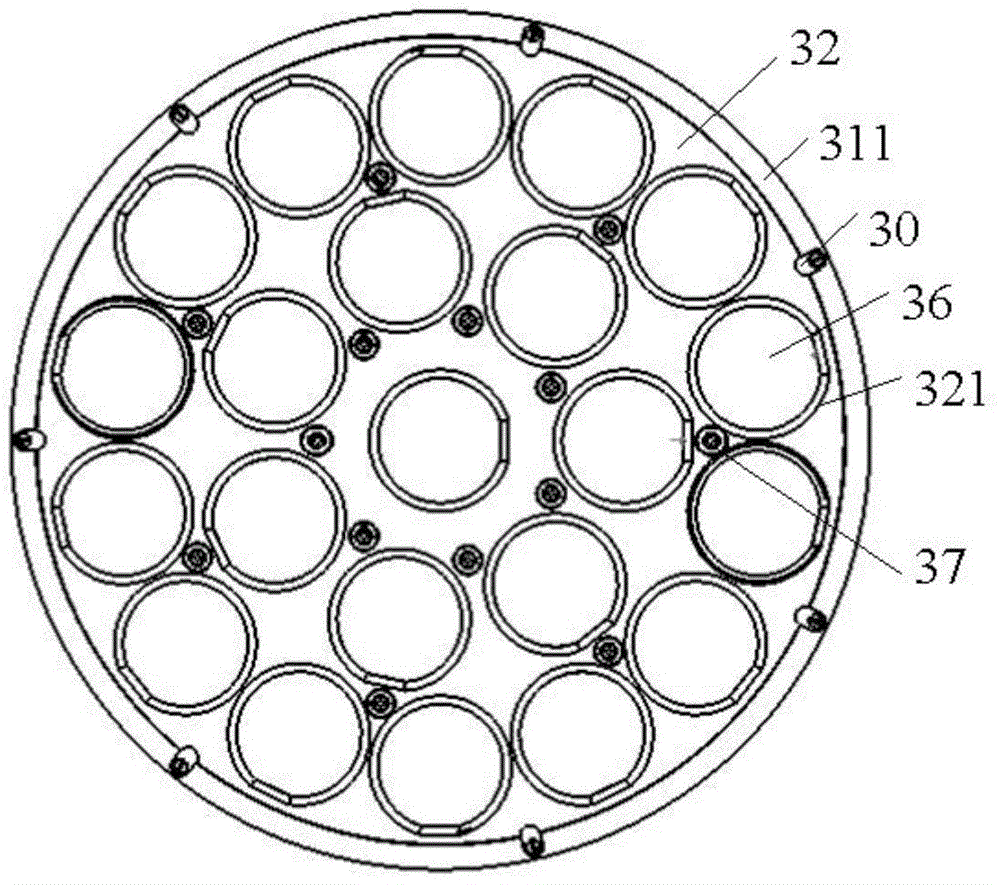

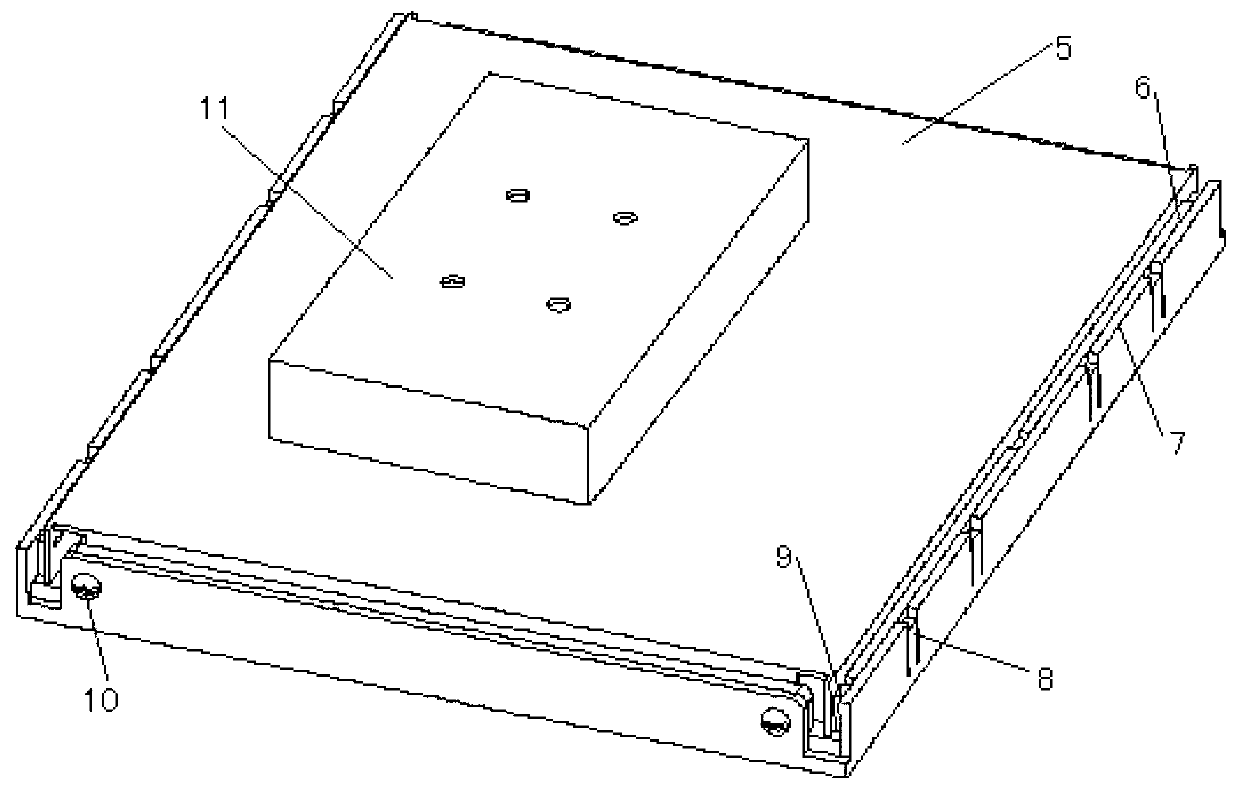

Clamping device and plasma processing device

ActiveCN104425337AExtended service lifeReduce use costElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringCantilever

The invention provides a clamping device and a plasma processing device. The clamping device comprises a tray, a cover plate and a fastening unit, wherein the fastening unit comprises a support part and a plurality of fastening components; the support part is of an annular structure, surrounds the outside of the cover plate and is connected with the tray; the plurality of fastening components are arranged on the support part and are arranged at intervals along the periphery of the cover plate; each fastening component comprises a pressing block, a fastening part and an elastic part; the pressing blocks are rotatably connected with the support part by virtue of the fastening parts; each pressing block is provided with a cantilever; the cantilevers are mutually superposed with the edge area of the cover plate when the cantilevers are driven to rotate to a first position by the pressing block; the cantilevers are mutually separated from the edge area of the cover plate when the cantilevers are driven to rotate to a second position by the pressing blocks; the fastening parts are used for applying elastic force to the upper surface of the tray by virtue of an elastic part, so that the cantilevers are used for pressing the edge area of the cover plate when in the first position. By virtue of the clamping device, the demounting time can be saved, the demounting steps can be simplified, and the cracking probability of the cover plate can also be reduced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

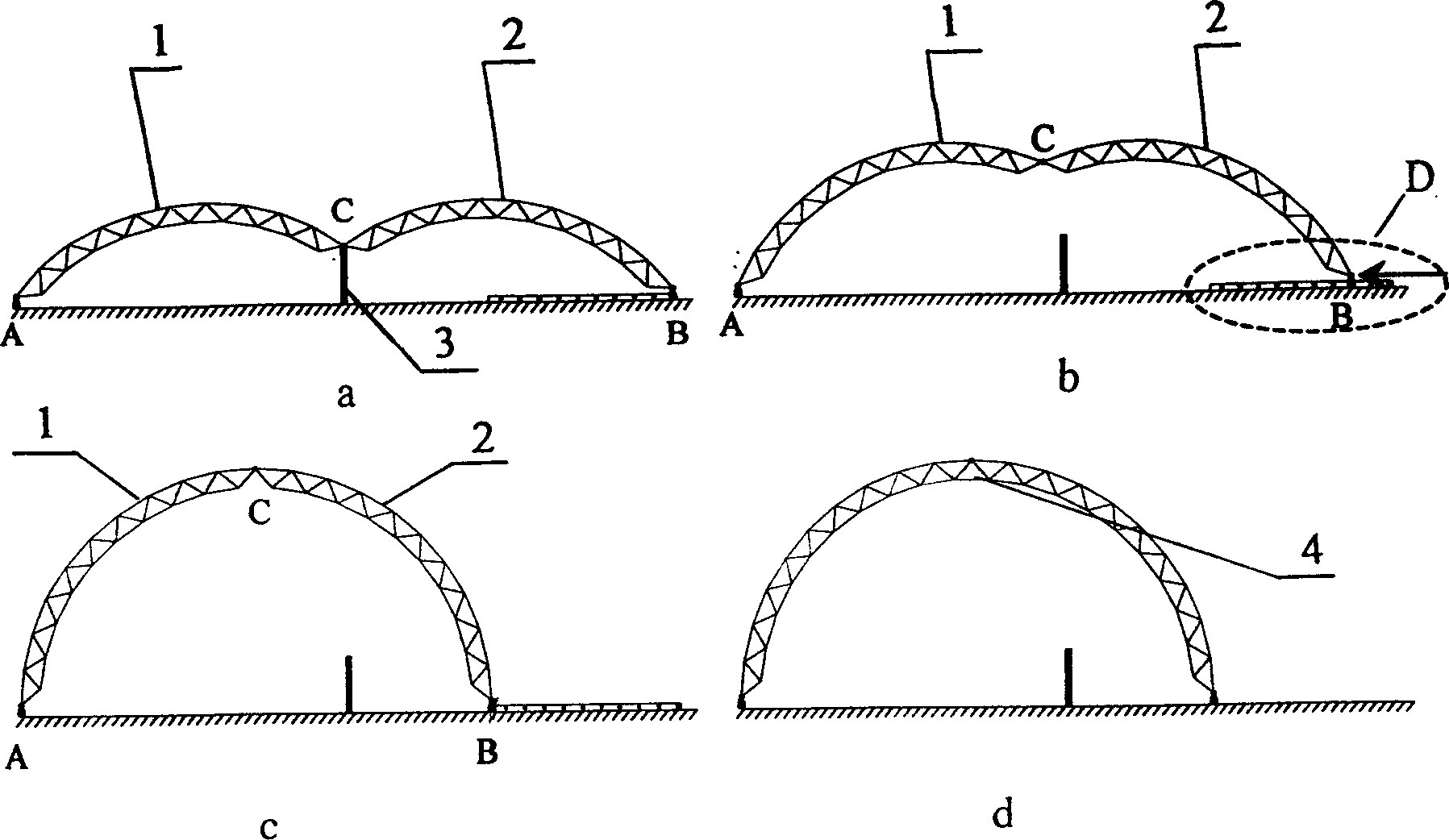

Whole forming method for cylindrical netting support with horizontal sliding structure

InactiveCN1472408AImprove installation accuracyGood construction qualityBuilding constructionsFixed hingeHinge angle

A construction method for integrally formed cylindrical reticulated shell with horizontal slide structure is disclosed. A cylindrical reticulated shell is divided into two segments for individual assembly. Its one end is a fixing hinge and its another end is a slide hinge in slide way. The hinged points between two segments are borne on temporary supporter. Both slide hinges are horizontally moving until they reach designed positions and the slide hinges are fixed to base. When hinged point reached designed height, a horizontal rod is linked to fix the hinged points. Its advantages are short period, and low cost.

Owner:浙江国盛钢结构有限公司

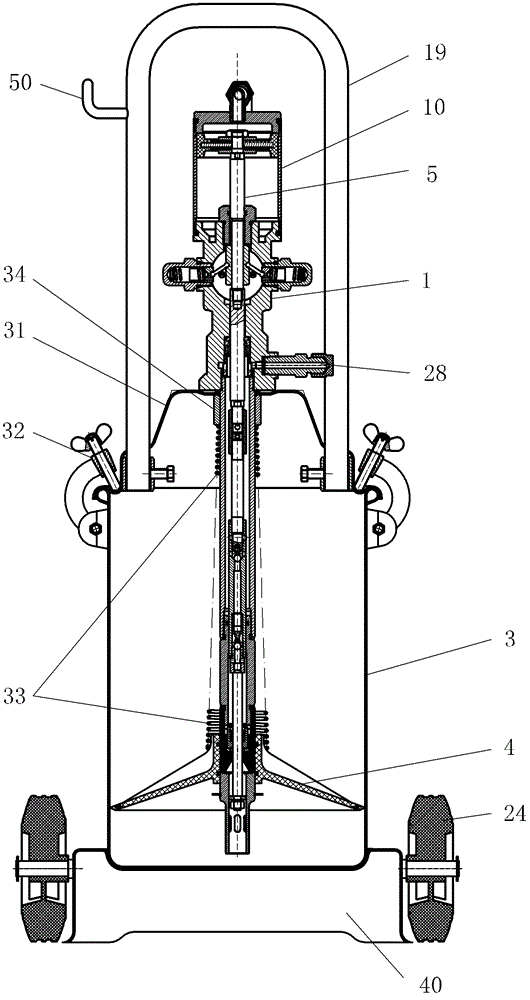

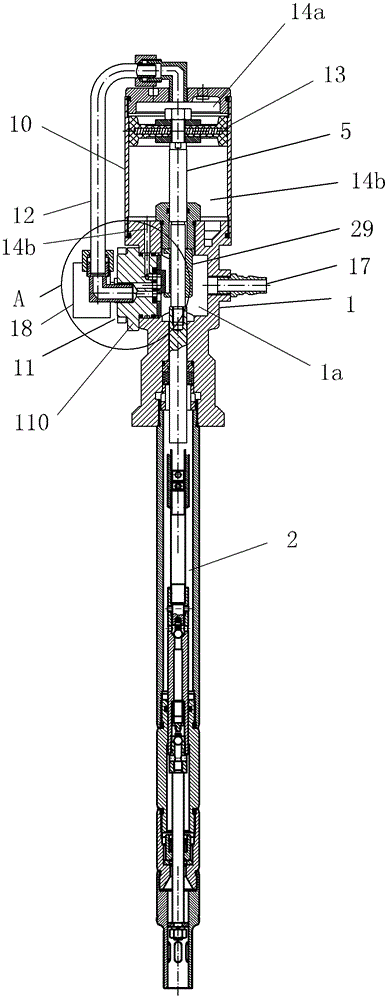

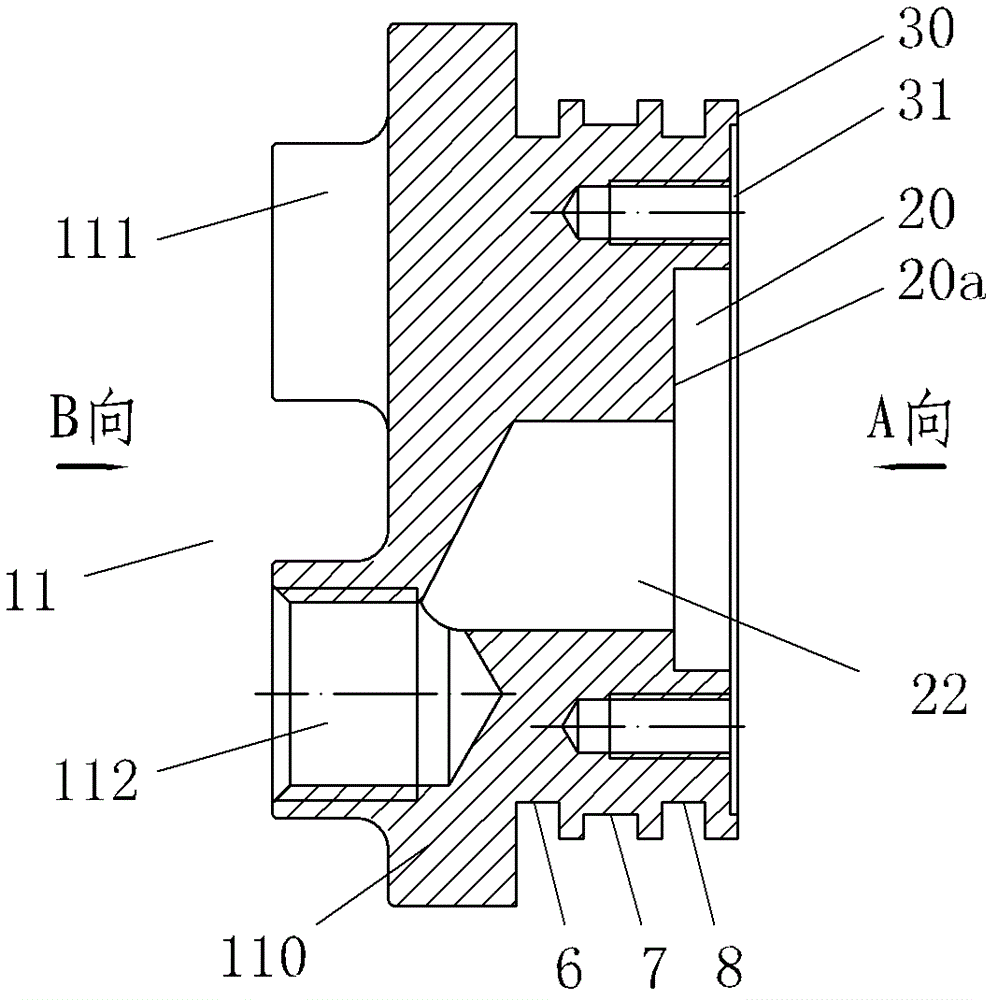

Pneumatic high-pressure oil filling device

The invention belongs to the technical field of grease machines and relates to a pneumatic high-pressure oil filling device. An oil filling pump, an oil filling gun connected with the oil filling pump, a push-and-pull armrest and a rolling wheel are arranged on a barrel body. Reciprocating motion of an air cylinder piston rod is achieved by a piston rod control reversing valve. The reversing valve comprises a gas distribution group cover, and an installing portion is arranged in the middle of the gas distribution group cover. A conduit connector, a silencer installing connector and a silencer are arranged on one side of the gas distribution group cover side by side, three annular grooves and three strip-shaped holes are arranged on a cylindrical face on the other side of the gas distribution group cover. The middle strip-shaped hole is communicated with the silencer installing connector, the strip-shaped hole on one side is communicated with the conduit connector and then communicated with an upper cavity of the piston, and the strip-shaped hole on the other side is communicated with a groove on the middle annular groove and then communicated with a lower cavity of the piston. Gas distribution sliding blocks are arranged in the cylindrical grooves and driven by a poking sleeve fixed on the piston rod, and seal rings are arranged on the annular grooves on two sides of the cylindrical face. The pneumatic high-pressure oil filling device has the advantages of being simple in structure, small in noise, convenient to disassemble and decorate and suitable for various oil filling devices.

Owner:ZHEJIANG REFINE WUFU AIR TOOLS

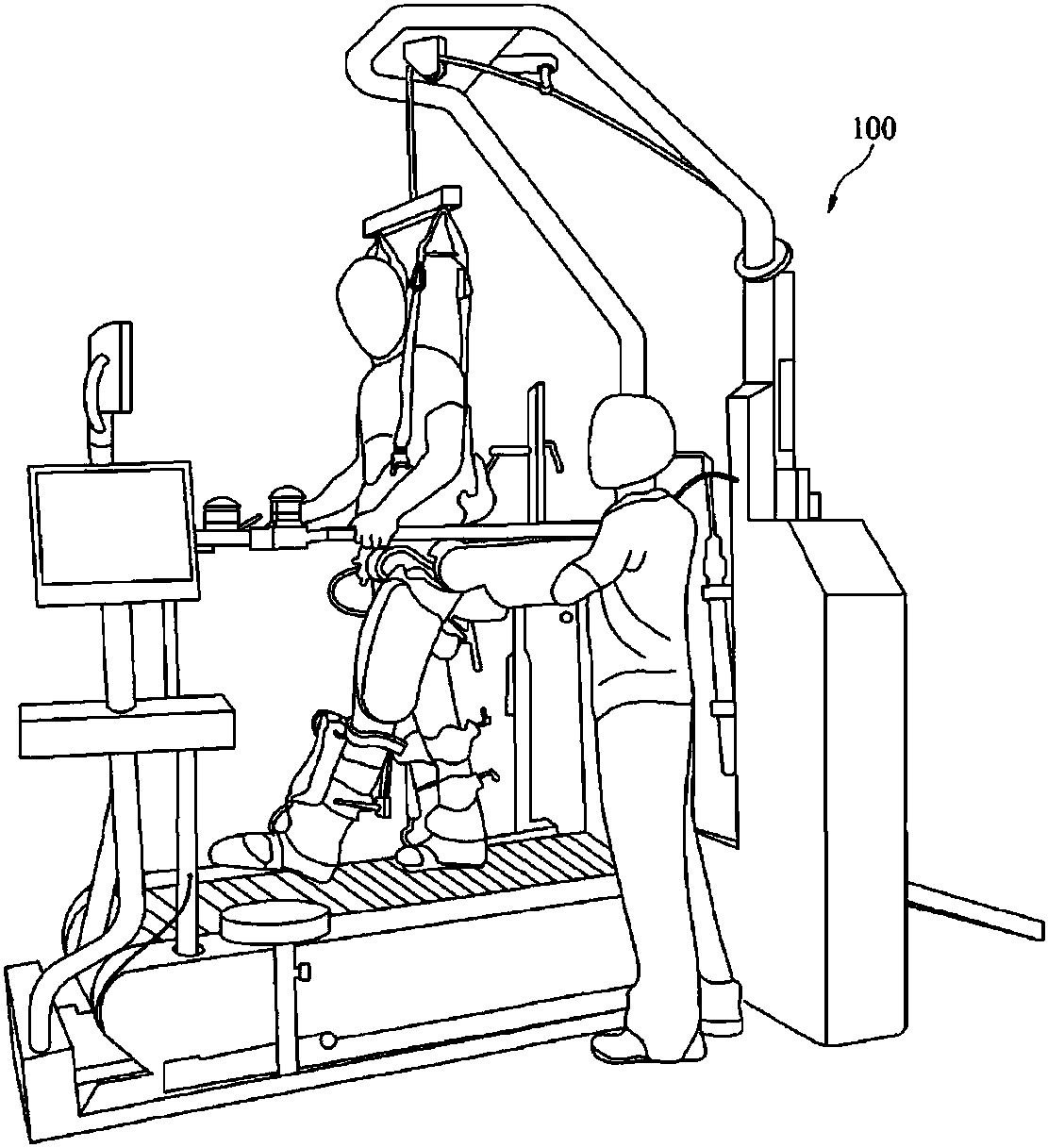

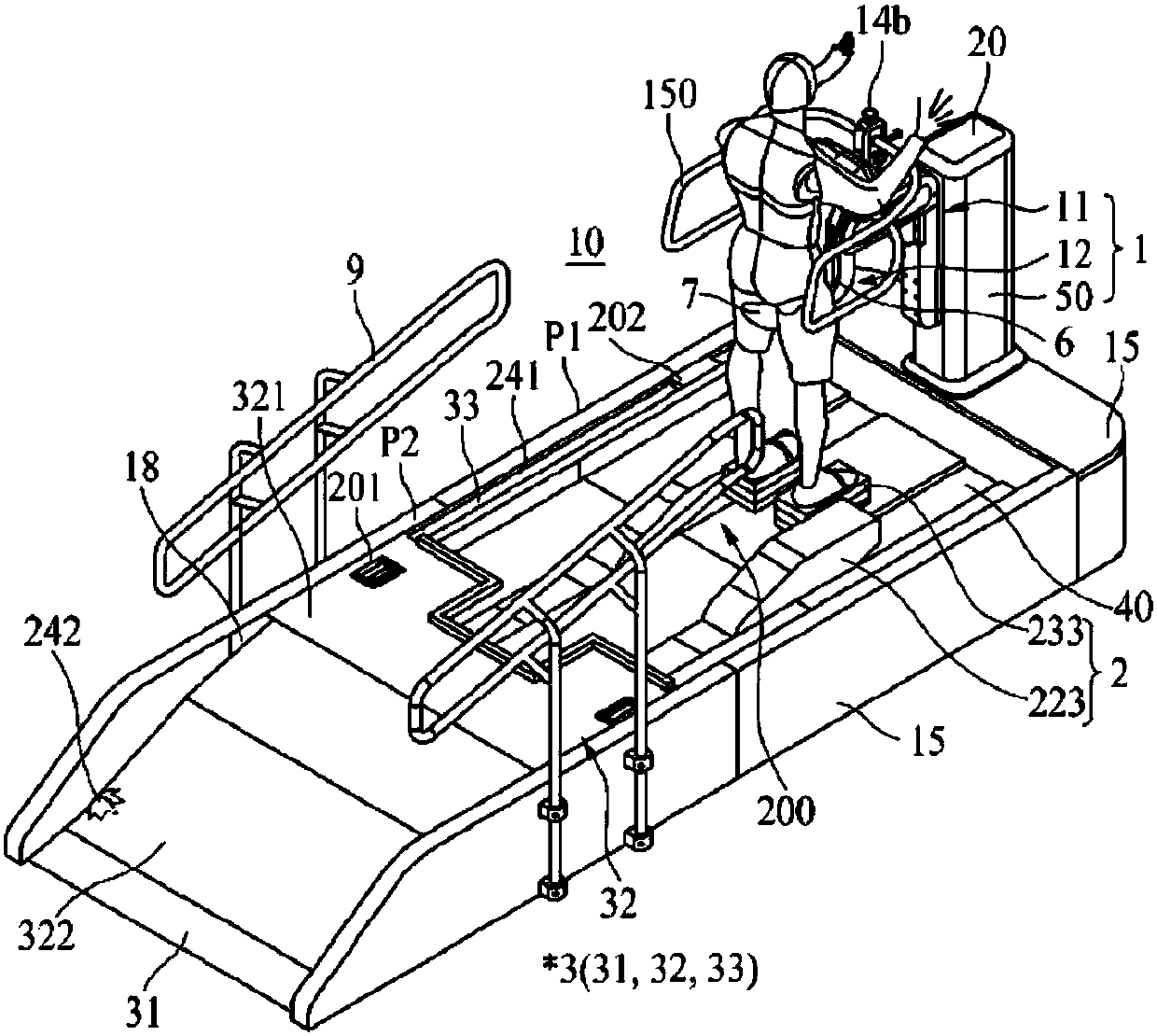

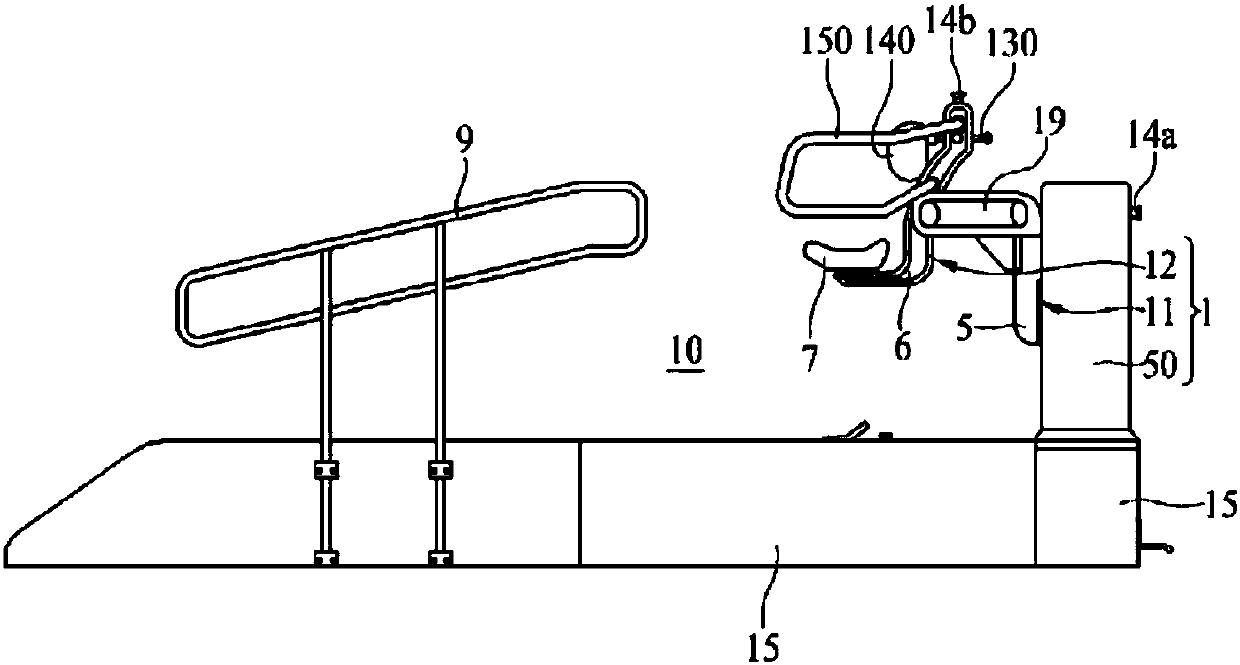

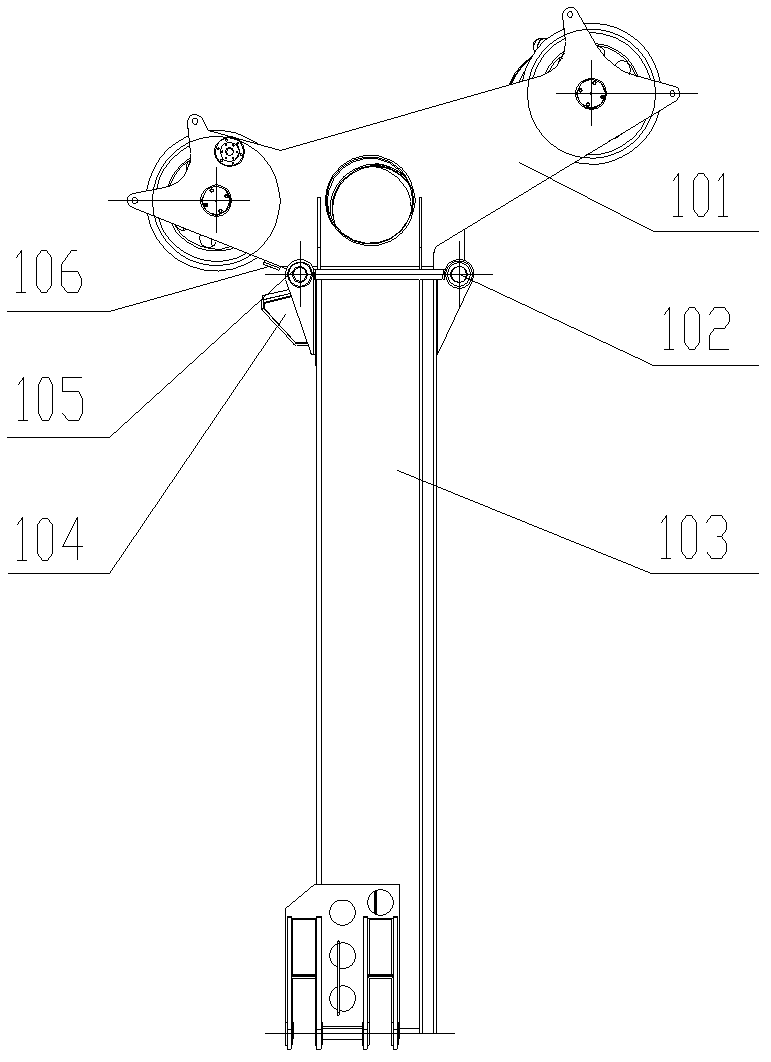

Seating-type rehabilitation robot for walking

ActiveCN107708641AImprove ease of useSave disassembly timeDiagnosticsChiropractic devicesEngineeringRehabilitation robot

The present invention relates to a seating-type rehabilitation robot for walking, comprising: a weight supporting part comprising an elevating and lowering part which is connected to a vertical support and moves up and down, and a seating part which is connected to the elevating and lowering part and supporting a trainee who sits on the seating part; and a walk actuating part which is connected tothe weight supporting part and is installed on the ground, with weight supporting links, which are connected to footrests to train the walking of the trainee, being separately mounted side by side onboth sides thereof, the walking actuating part comprising a uniaxial actuating part for forward and backward movements according to the walk tracking of each footrest, a biaxial actuating part for upward and downward movements of the footrests caused by rotation of the weight supporting links, and a triaxial actuating part for rotation of the footrests.

Owner:CUREXO

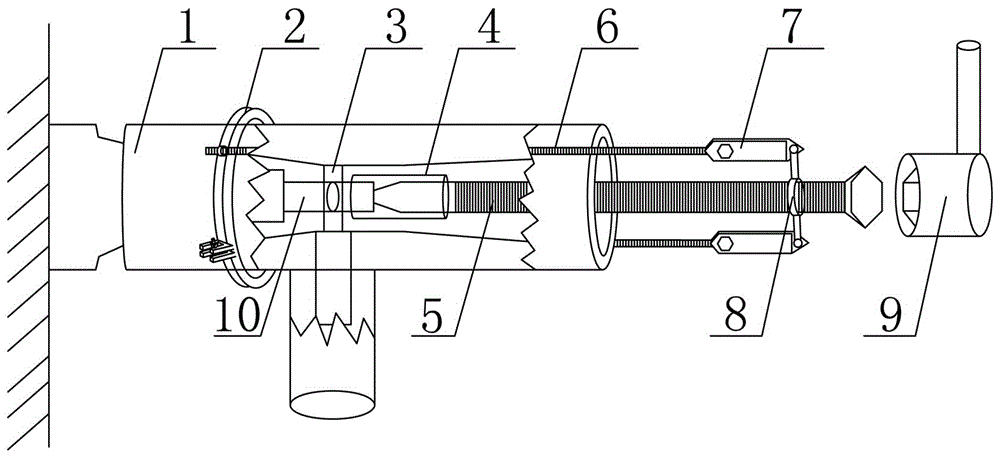

Rotary drilling rig and mast device thereof

The invention discloses a mast device for a rotary drilling rig. The mast device comprises a cathead, an upper mast hinged with the cathead, a middle mast hinged with the upper mast, an automatic cathead folding mechanism and an automatic upper mast folding mechanism, wherein the automatic cathead folding mechanism comprises a first folding oil cylinder arranged between the cathead and the upper mast; and the automatic upper mast folding mechanism is a connecting rod connecting device with a crank sliding block and two rockers. The cathead and the upper mast of the mast device can be automatically folded when the rotary drilling rig is used for transfer transportation, so that the mast device is conveniently assembled and disassembled by a user, time and labor are saved, and the transfer efficiency of the rotary drilling rig is greatly improved. The invention also discloses the rotary drilling rig with the mast device.

Owner:BEIJING CSR TIMES LOCOMOTIVE & ROLLING STOCK MECHANICS

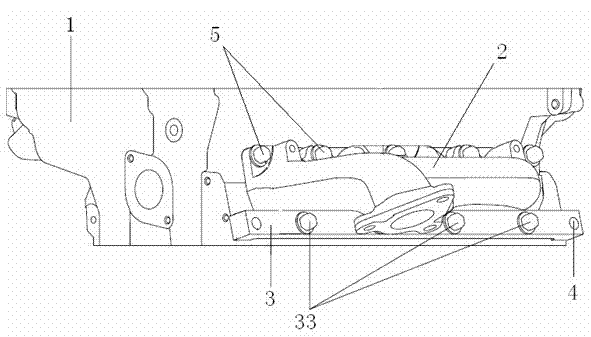

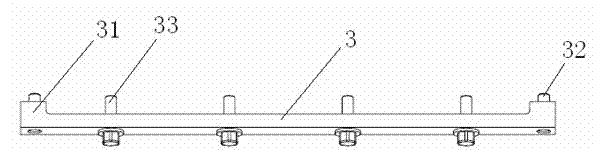

Exhaust manifold installation structure and method for assembling and disassembling same

InactiveCN102230415AReduce the number of installationsPrecise positioningExhaust apparatusSilencing apparatusFlangeExhaust manifold

The invention provides an exhaust manifold installation structure and a method for assembling and disassembling the same. The exhaust manifold installation structure comprises a cylinder cover, an exhaust manifold and an installation bracket, wherein bolt holes are formed on flange planes on the upper and lower sides of the exhaust manifold. Key points are that: bolt installation holes are formed on the cylinder cover opposite to the flange plane on one side of the exhaust manifold; positioning holes are formed on the cylinder cover opposite to the flange plane on the other side of the exhaust manifold; bolt holes on the side of the exhaust manifold, which is opposite to the positioning holes, are U-shaped installation holes; positioning pin holes are formed at the two ends of the installation bracket, which are opposite to the positioning holes; and positioning columns which face and protrude from the inner side of the installation bracket are arranged at positions which are opposite to the U-shaped installation holes. Due to the exhaust manifold installation structure, precise positioning can be ensured, the exhaust manifold installation structure is convenient to install and disassemble, installed bolts are reduced, disassembling time is saved, and the sliding probability of the bolts is reduced.

Owner:CHERY AUTOMOBILE CO LTD

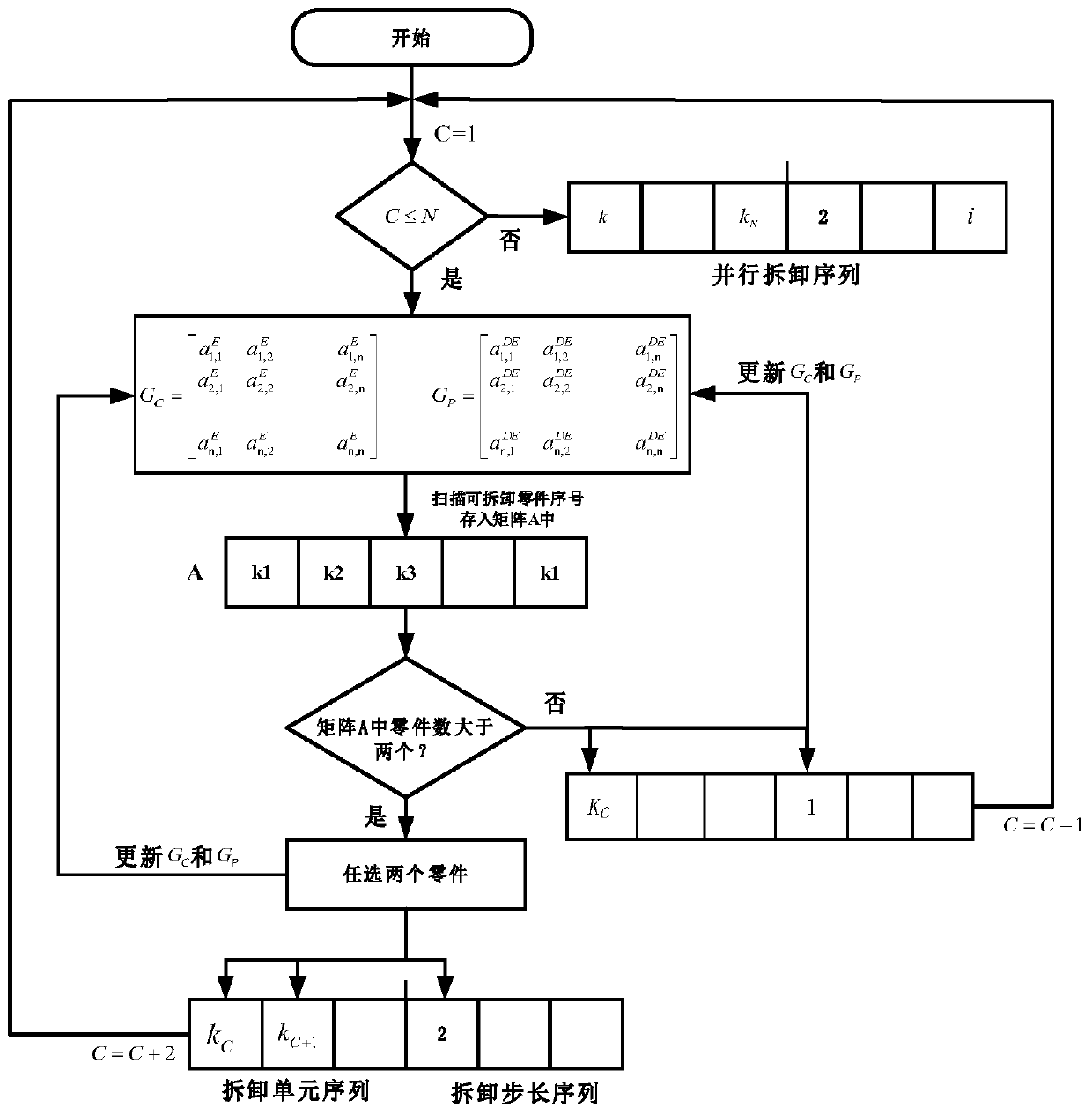

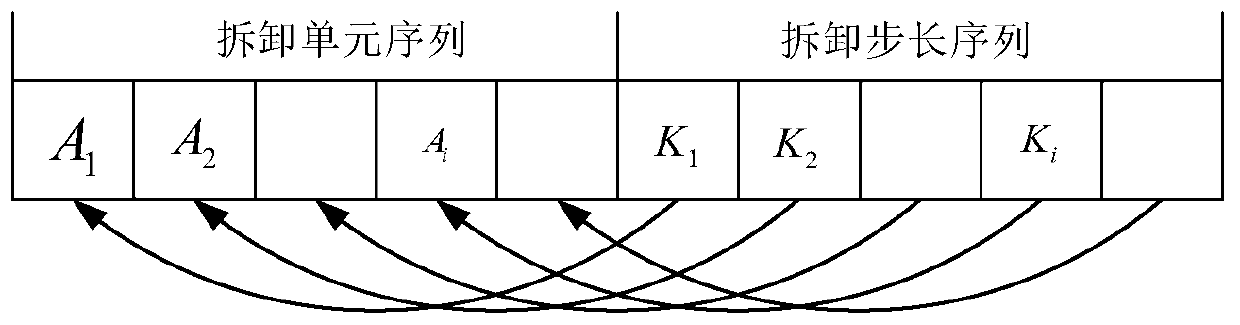

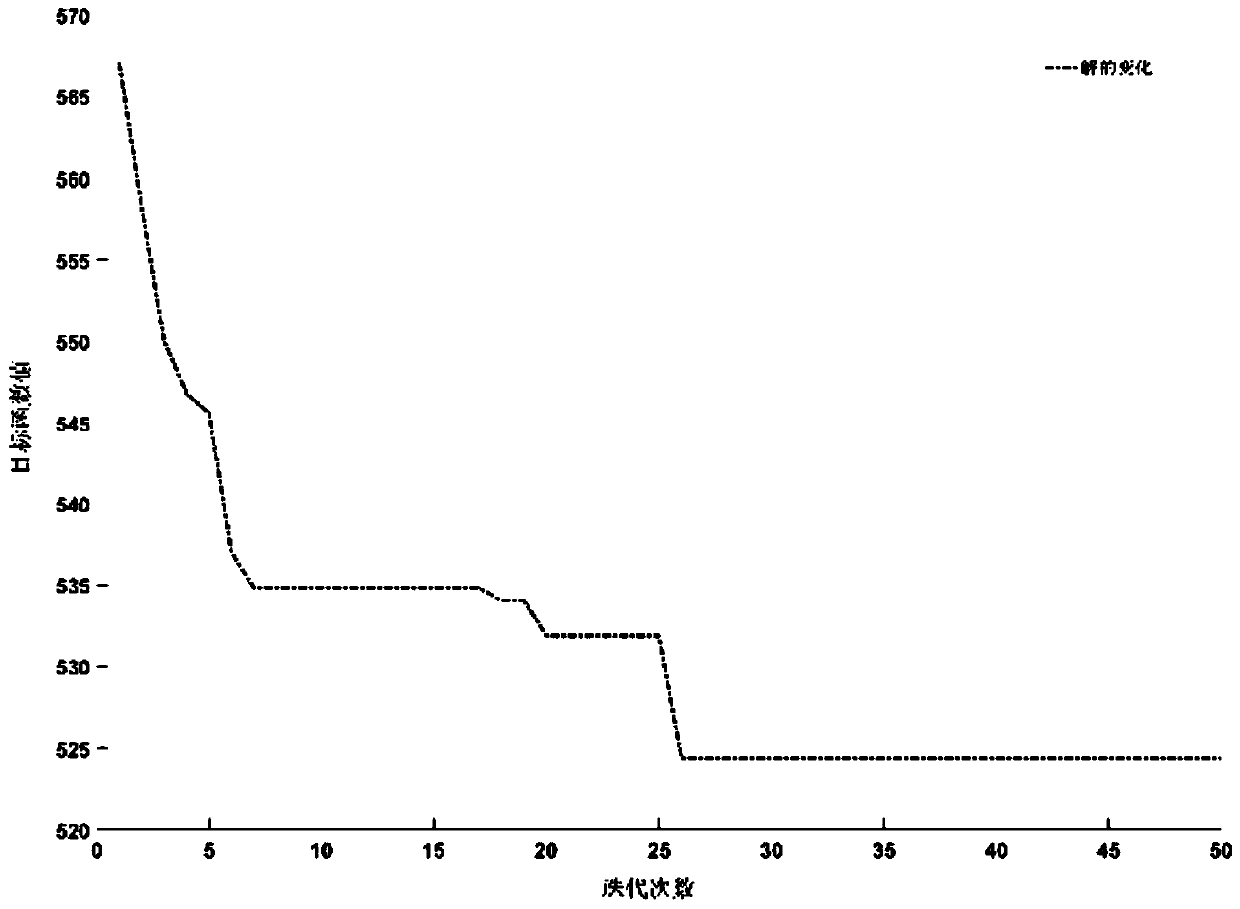

Low-carbon and high-efficiency parallel disassembly line balance optimization method

ActiveCN109814509AEmission reductionStrong convergence speedTotal factory controlProgramme total factory controlGenetic algorithmLine balancing

The invention discloses a low-carbon and high-efficiency parallel disassembly line balance optimization method. The method comprises the steps that a parallel disassembly model is established, and anoptimization model of parallel disassembly line balance is established. The optimization goal is to reduce carbon emission and reduce disassembly time, and belongs to multi-objective optimization; onthis basis, the parallel disassembly model is established, then practical constraints of a disassembly balance problem are comprehensively considered, the high-efficiency and low-carbon optimization method of a disassembly sequence is established, when the optimization problem is solved, a weight method is used for converting a multi-target problem into a single-target problem, finally a genetic algorithm is used for solving the disassembly line balance problem, it can be seen from a convergence graph that the genetic algorithm has a high convergence speed, and the model has a certain optimization effect on the disassembly time.

Owner:HEFEI UNIV OF TECH

Turret device for numerical control press

The invention relates to the technical field of numerical control press machining, and discloses a turret device for a numerical control press. The edge of the upper surface of a workbench is fixedlyconnected with a protection plate in the length direction, and a conveying belt is arranged on a second mounting support. The center of the edge of the upper surface of the workbench is further fixedly connected with a supporting frame. The bottom of a first mounting support is fixedly connected with anti-sliding legs. A turret assembly is clamped outside a square mounting base, and a driving assembly is arranged in the square mounting base. The turret assembly can reach higher punching frequency within identical time; meanwhile, a multi-station design manner is adopted, punching of three sections can be completed at the same time, and the punching efficiency is greatly improved; a traditional punching process is optimized, and the applicability is improved remarkably; and a worker can fast demount and mount the turret assembly through the driving assembly conveniently, the demounting and mounting time of the turret assembly is shortened, the worker can easily maintain the turret assembly and replace corresponding parts, and normal use is guaranteed.

Owner:烟台晟煊制冷设备有限公司

Scanning device and transition method thereof

PendingCN109521484AGet to work quicklyInput work shortenedMaterial analysis by transmitting radiationNuclear radiation detectionEngineering

The invention relates to a scanning device and a transition method thereof. The scanning device includes an arm stand (1) which is provided with multiple detectors and is used for forming an inspection channel, a first cabin (3) which is internally provided with a ray source and is connected with the arm stand (1), a protection wall (2) which is connected with the first cabin (3) or the arm stand(1) and is used for performing ray protection for a to-be-protected object, and a tire used for making the scanning device to move relative to the ground, wherein the arm stand (1), the first cabin (3) and the protection wall (2) are set to transport together in a connection state. The scanning device is advantaged in that when the scanning device needs transition, the link of re-mounting at the inspection site can be omitted, the dismounting time can be shortened, transition efficiency is improved, protection wall re-establishment and protection wall civil engineering works in the inspectionsite can be avoided, and the scanning device can be quickly put into work after being transported to the inspection site.

Owner:NUCTECH CO LTD +2

Liquid crystal display framework with initiative detachment function and initiative detachment device

InactiveCN102998825AConnection fails quicklyDamage will notCasings/cabinets/drawers detailsMetal working apparatusLiquid-crystal displayMolecular materials

The invention discloses a liquid crystal display framework with an initiative detachment function and an initiative detachment device. The liquid crystal display framework is characterized in that shell buckles, front bracket buckles, rear bracket buckles, shell screws and bracket screws are made from shape-memory high molecular materials and are arranged on an initiative detachment driving device which can generate driving force after being heated and stimulated; and a manner of heating stimulation enables a connection relation to be invalid and parts to be separated from one another. According to the liquid crystal display framework and the initiative detachment device, the detaching time of a liquid crystal display is greatly shortened and inner parts are not damaged. The liquid crystal display framework and the initiative detachment device are particularly suitable for large-batch recycling and detachment of liquid crystal displays.

Owner:HEFEI UNIV OF TECH

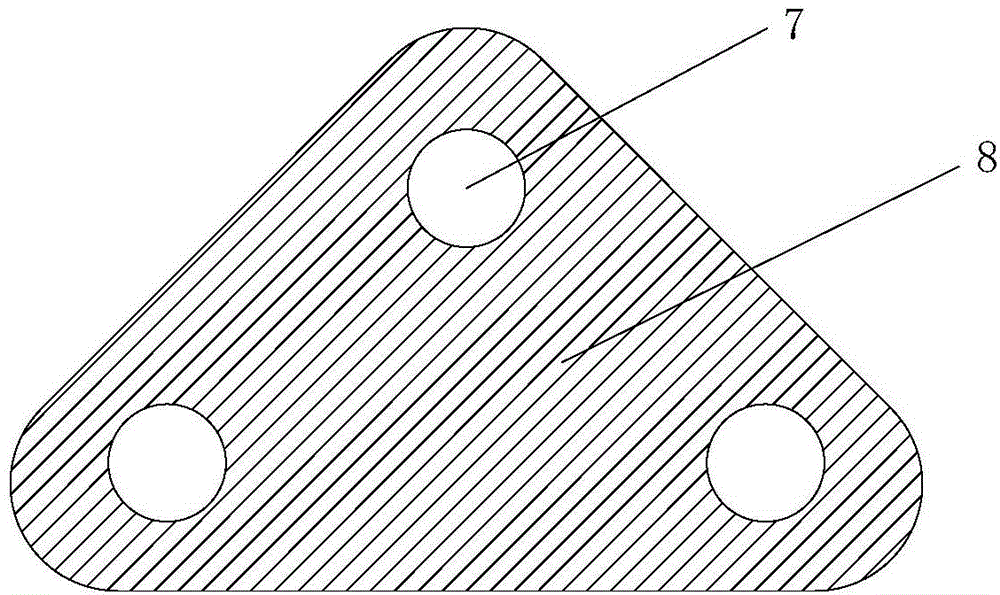

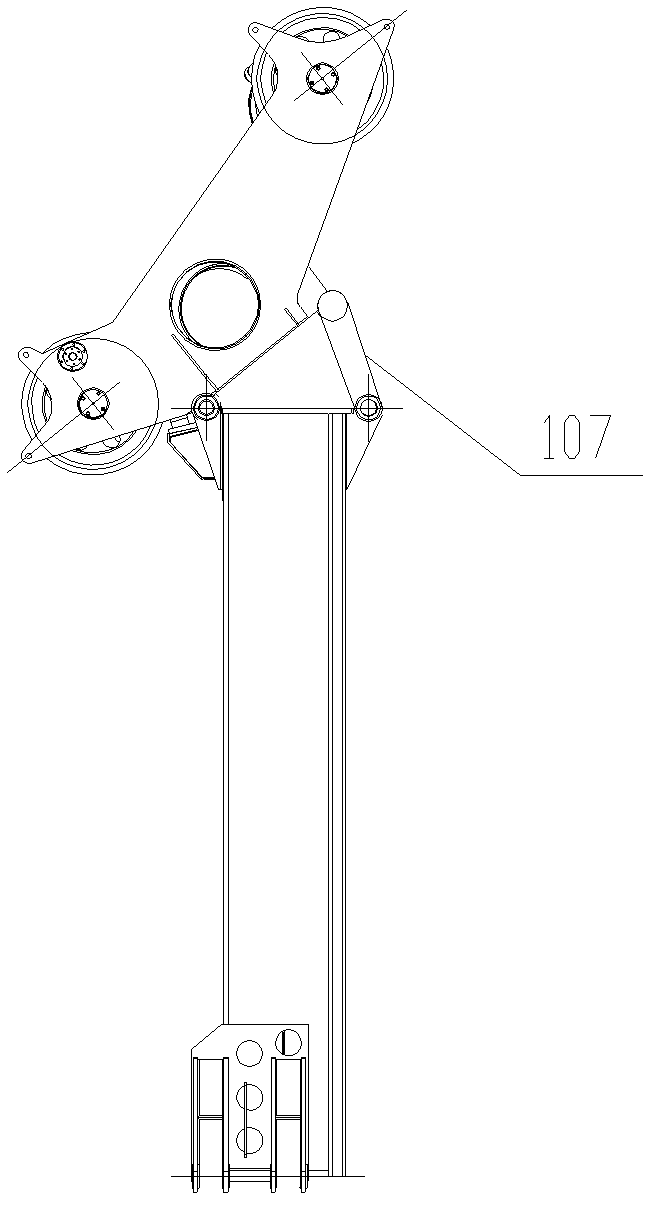

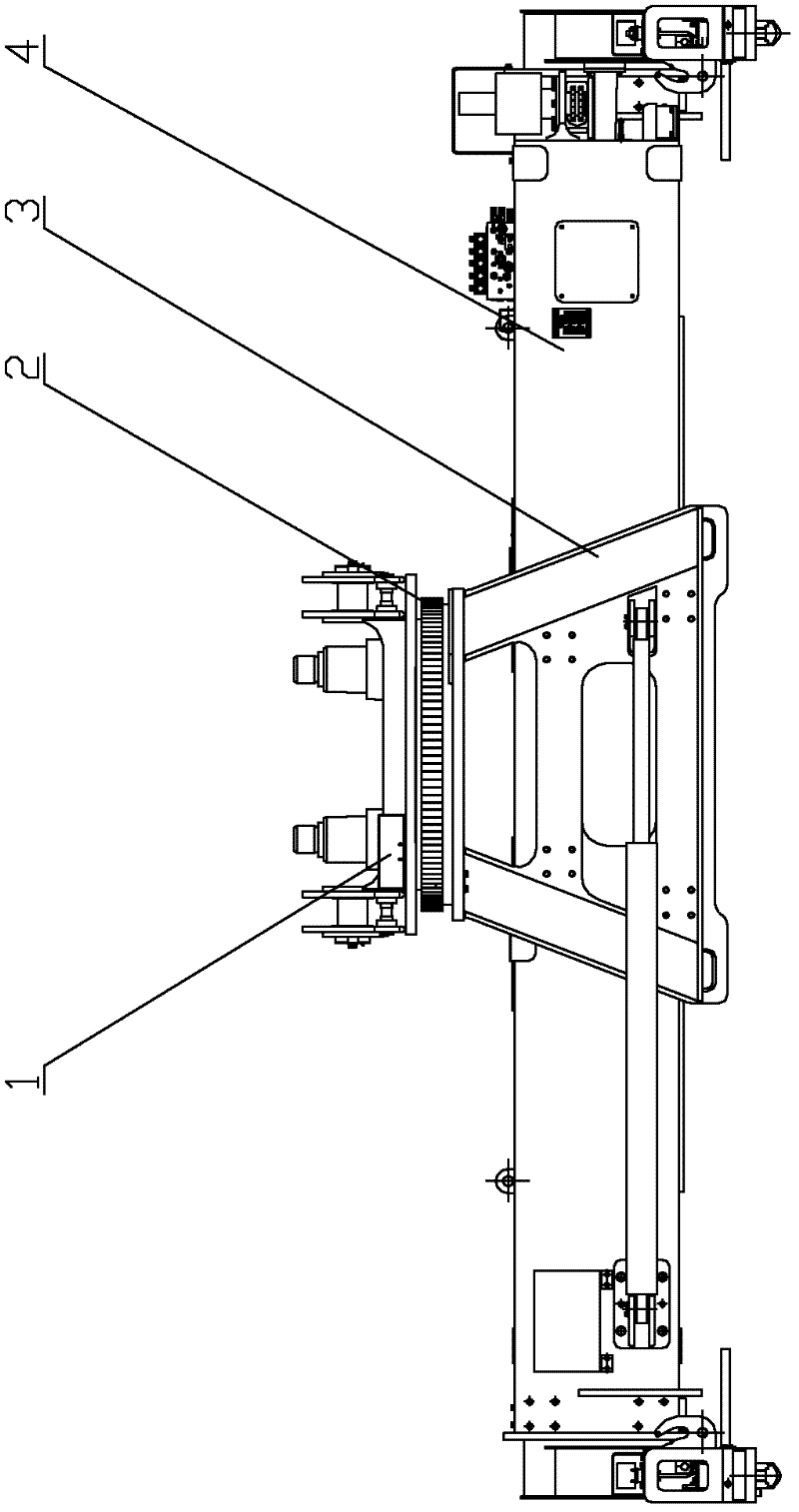

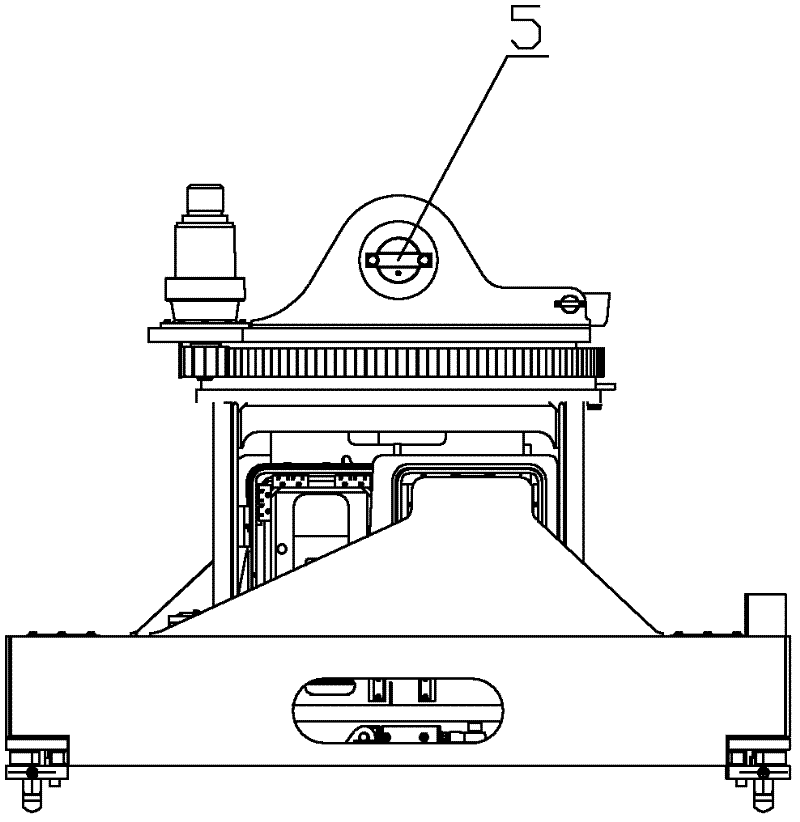

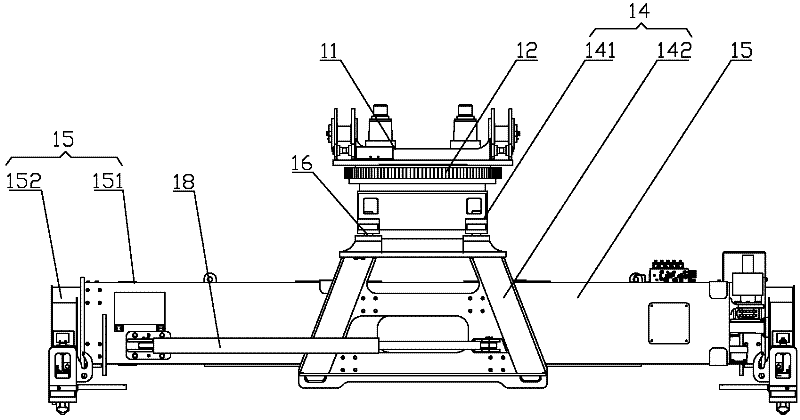

A kind of spreader and front hanger

ActiveCN102295223AEasy to assembleRealize the needs of different artifactsCranesLoad-engaging elementsEngineeringSlewing bearing

The invention discloses a lifting device of a front crane. The lifting device comprises an upper turntable (11) connected to a boom of the front crane, and a lower turntable (14) provided with a lifting crossbeam (15). The upper turntable (11) is connected to the lower turntable (14) through a slewing bearing (12), such that the upper turntable and the lower turntable can rotate relative to each other. The lower turntable (14) comprises an upper connecting frame (141) rigidly connected to the slewing bearing (12) and a lower cage (142) detachably connected to the upper connecting frame (141).The lifting crossbeam (15) is arranged on the lower cage (142). When the lifting device is disassembled, an oil cylinder and a damping pin between the turntables and the boom are not required to be disassembled. Therefore, disassembling is simplified, disassembling time is saved, and time for disassembling electric and hydraulic controlling pipelines on the turntables is saved. With the lifting device provided by the invention, assembling and disassembling are fast, and the work efficiency of the front crane is improved. Also, the invention provides a front crane with the lifting device.

Owner:SANY MARINE HEAVY IND +1

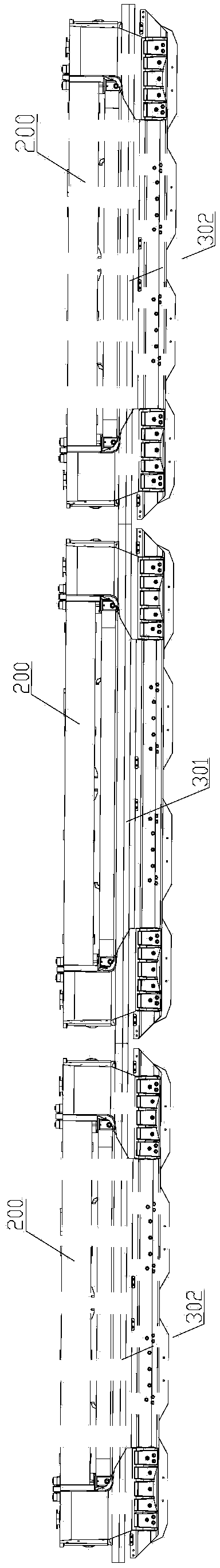

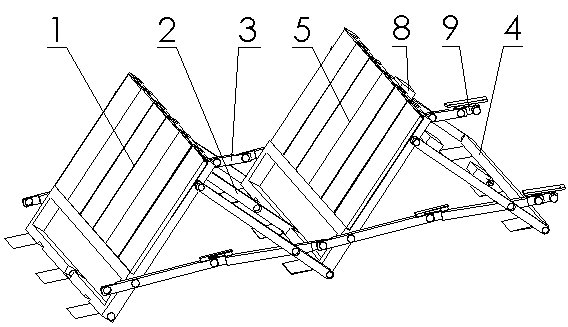

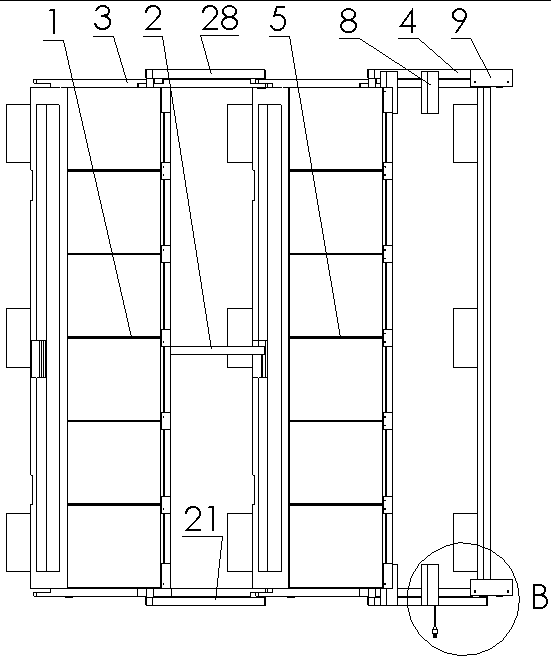

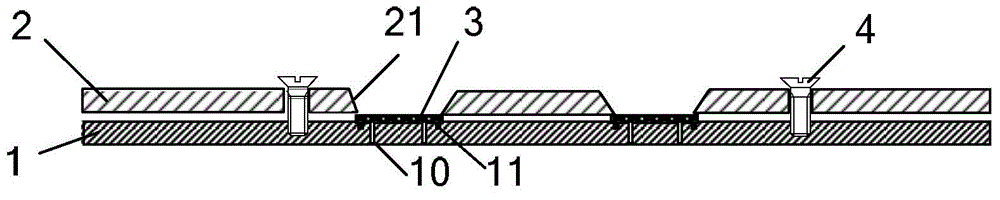

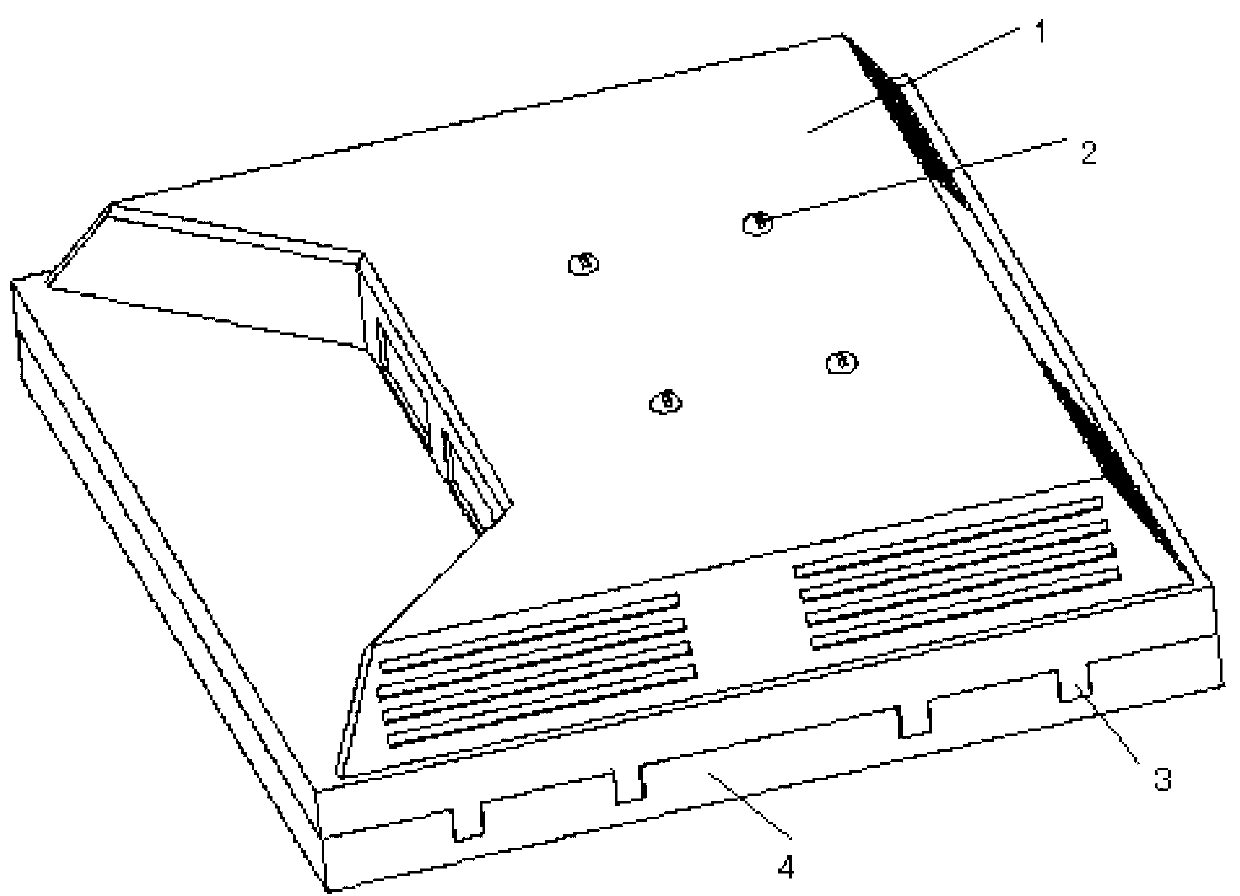

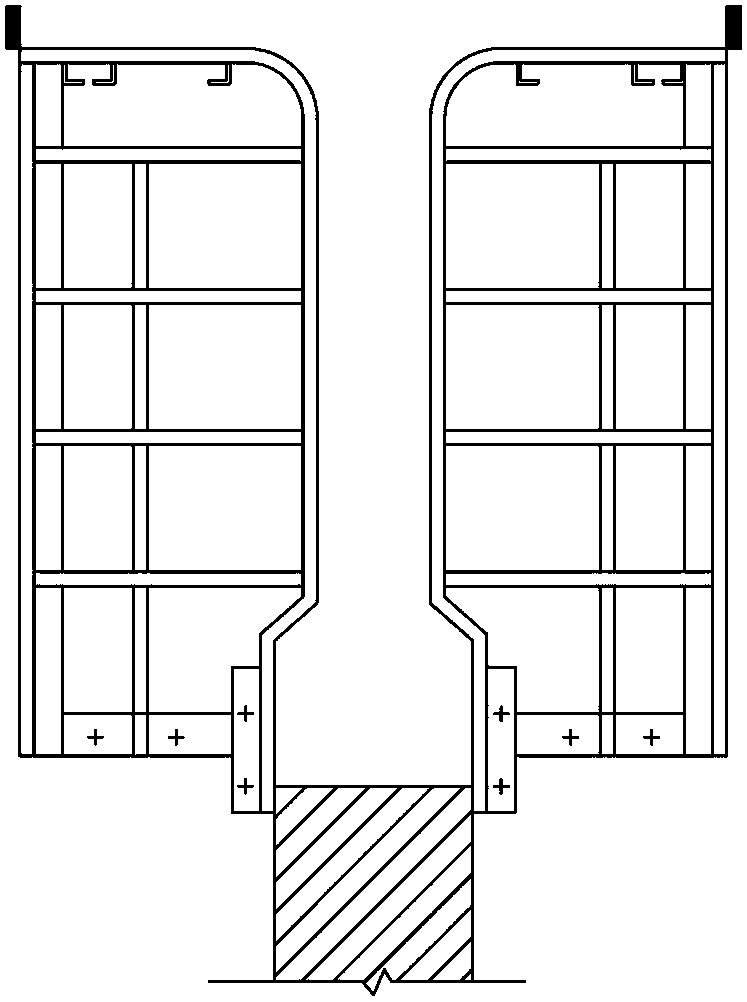

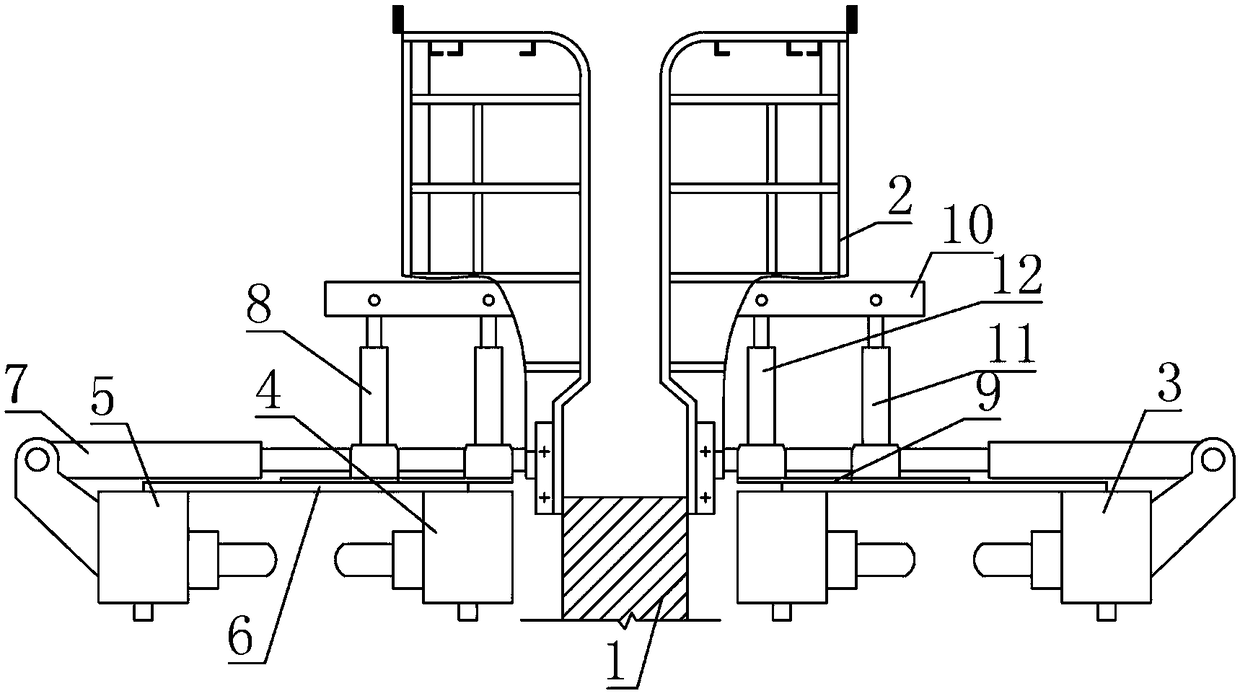

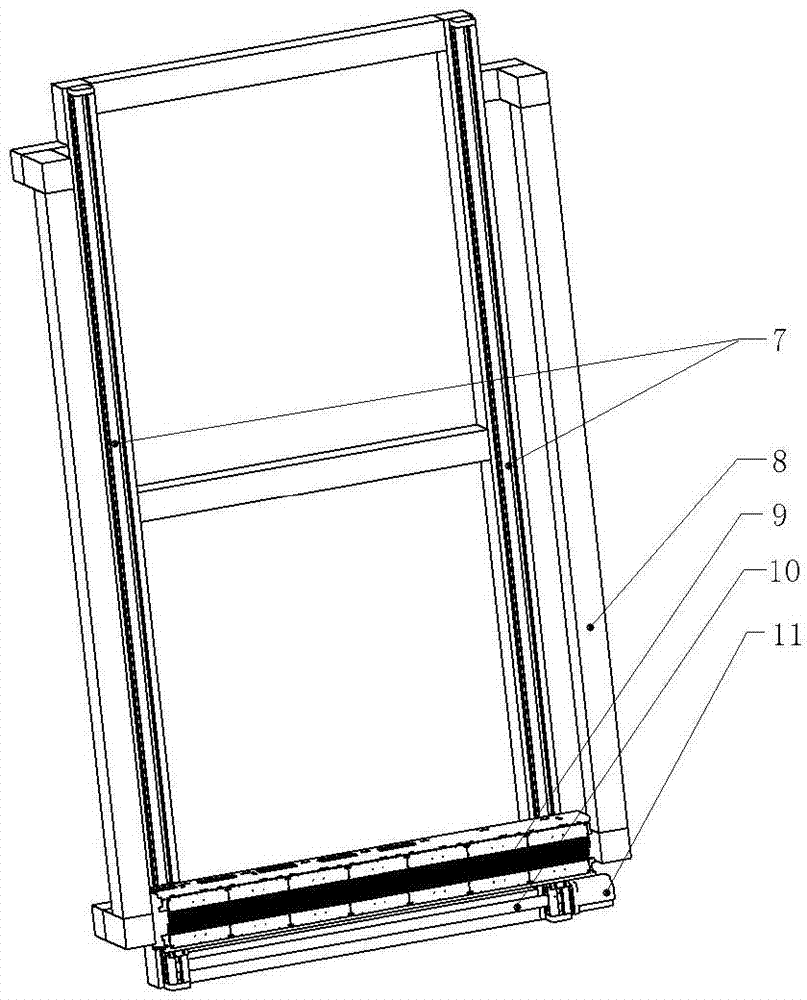

Prefabricated T-shaped beam hydraulic self-propelled integral formwork and construction method thereof

PendingCN108130863ASave installation timeSave disassembly timeBridge erection/assemblyShaped beamStructural engineering

The invention discloses a prefabricated T-shaped beam hydraulic self-propelled integral formwork and a construction method thereof. The problems that manual dismantling is prone to damaging the surface of a beam body and further affecting the appearance quality of the beam body in the production process of the existing prefabricated T-shaped beam, are solved. The prefabricated T-shaped beam hydraulic self-propelled integral formwork includes a T-shaped beam pedestal, and integral side formworks are symmetrically arranged at the two ends of the T-shaped beam pedestal. A driving end beam group is arranged on the lower portion of the integral side formworks, and is symmetrically arranged on the two sides of the T-shaped beam pedestal. The driving end beam group includes a first driving end beam and a second driving end beam, and the second driving end beam is arranged on the outer side of the first driving end beam. The first driving end beam is fixedly connected with the second driving end beam by a connecting frame. A horizontal hydraulic device is fixed on the upper portion of the outer end of the driving end beam group, and the horizontal hydraulic device is telescopically contacted with the integral side t formworks. A vertical hydraulic device is fixed on the upper portion of the first driving end beam, and the vertical hydraulic device is telescopically contacted with the integral side t formworks.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

Scanning device and transition method thereof

PendingCN109521485AGet to work quicklyShorten the timeNuclear radiation detectionEngineeringThermal protection

The invention relates to a scanning device and a transition method thereof. The scanning device includes an arm stand (1) which is provided with multiple detectors and is used for forming an inspection channel, a first cabin (3) which is internally provided with a ray source and is connected with the arm stand (1), a protection wall (2) which is connected with the first cabin (3) or the arm stand(1) and is used for performing ray protection for a to-be-protected object, and a tire used for making the scanning device to move relative to the ground, wherein the arm stand (1), the first cabin (3) and the protection wall (2) are set to transport together in a connection state. The scanning device is advantaged in that when the scanning device needs transition, the link of re-mounting at the inspection site can be omitted, the dismounting time can be shortened, transition efficiency is improved, protection wall re-establishment and protection wall civil engineering works in the inspectionsite can be avoided, and the scanning device can be quickly put into work after being transported to the inspection site.

Owner:NUCTECH CO LTD +2

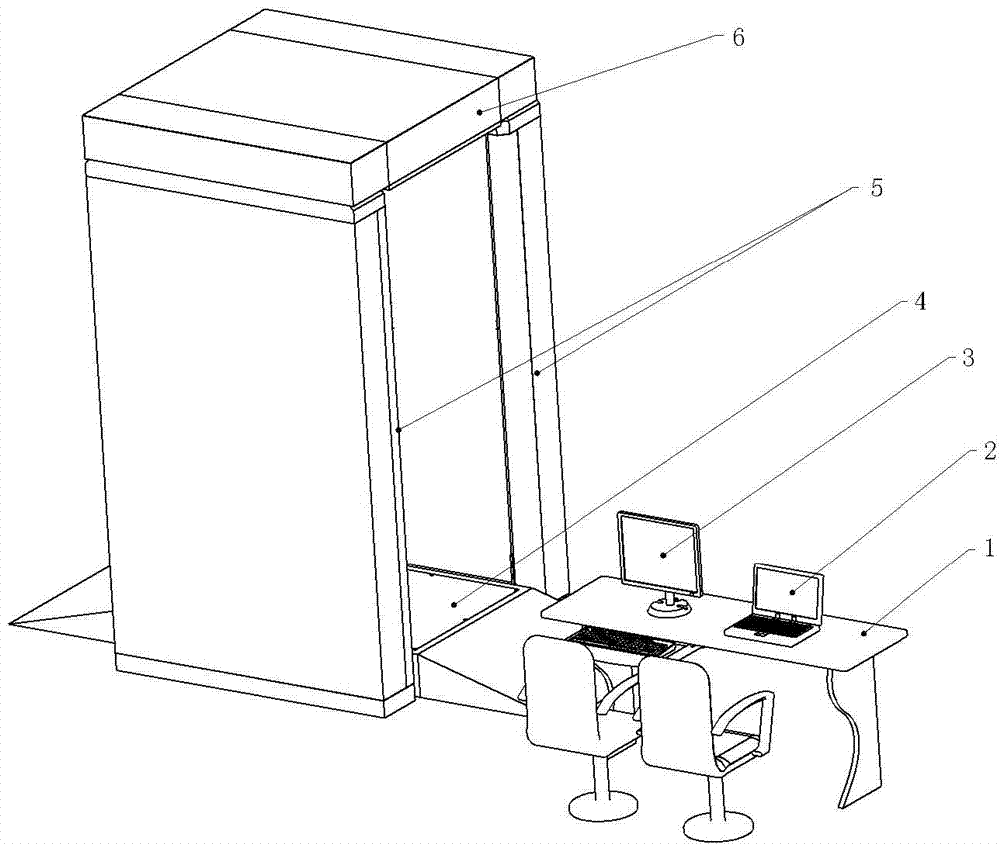

Modularized fast-assembly security inspection door

ActiveCN104502993ASimplify the disassembly procedureSave disassembly timeGeological measurementsDrive shaftDisplay device

The invention discloses a modularized fast-assembly security inspection door, which comprises a security inspection door body, a security inspection table, a protection plate, a fixed support, a display, a laptop and a working table, wherein the security inspection door body comprises a scanning antenna, a linear guide rail, a motor, a driving shaft, an aluminum profile frame and a packaging plate; and each of the security inspection door body, the security inspection table and the working table is a module respectively and independently. During the disassembly and movement process, disassembly of the complicated structure inside the security inspection door can be avoided, the parts are simply linked via interfaces and screws, and assembly and disassembly are convenient. Defects that assembly and disassembly of the traditional security inspection door is complicated and long in time consuming can be overcome; a shoe sole, which is the security inspection blind angle, of the inspected person can be inspected; and as the front door and the rear door perform scanning at the same time, the average security inspection time can be effectively reduced, the security inspection door application place can be expanded outdoors, and requirements on assembly conditions by the security inspection door are reduced.

Owner:BEIJING HUAHANG HAIYING NEW TECH DEV

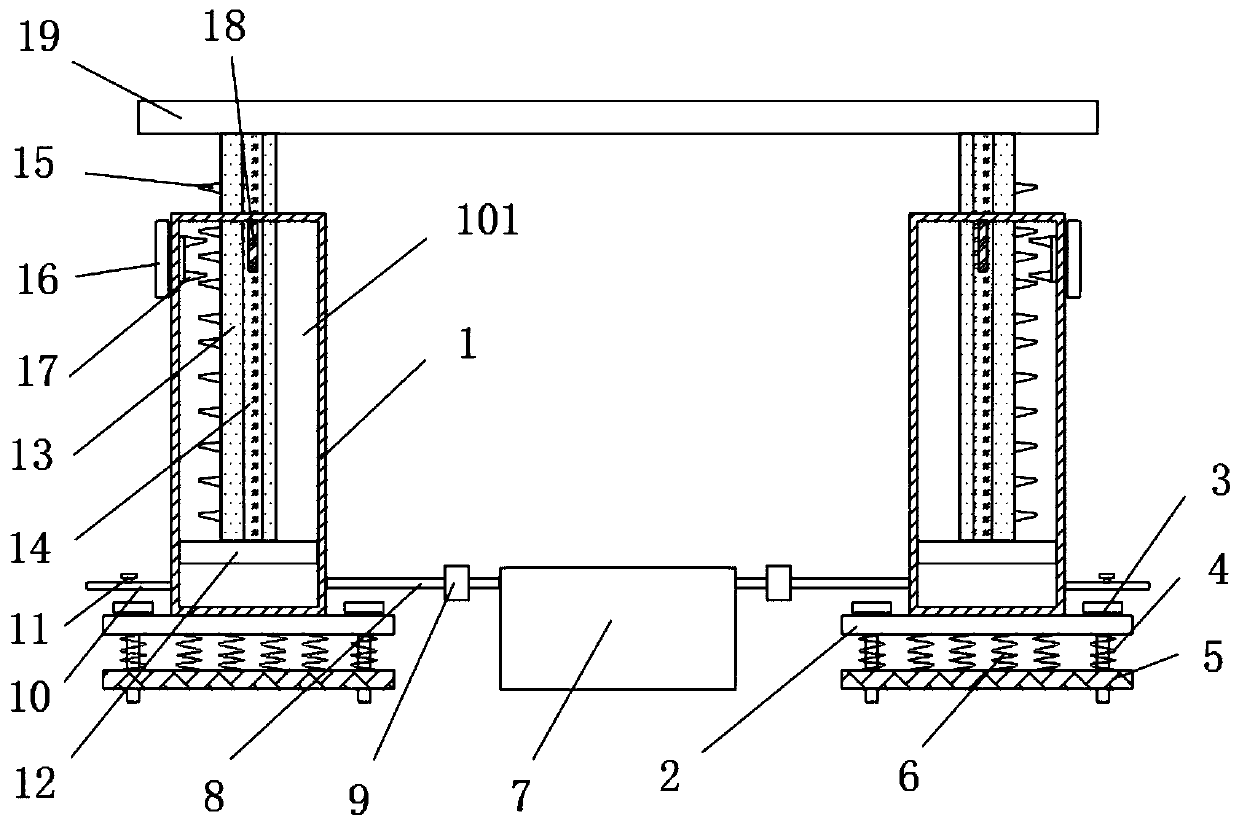

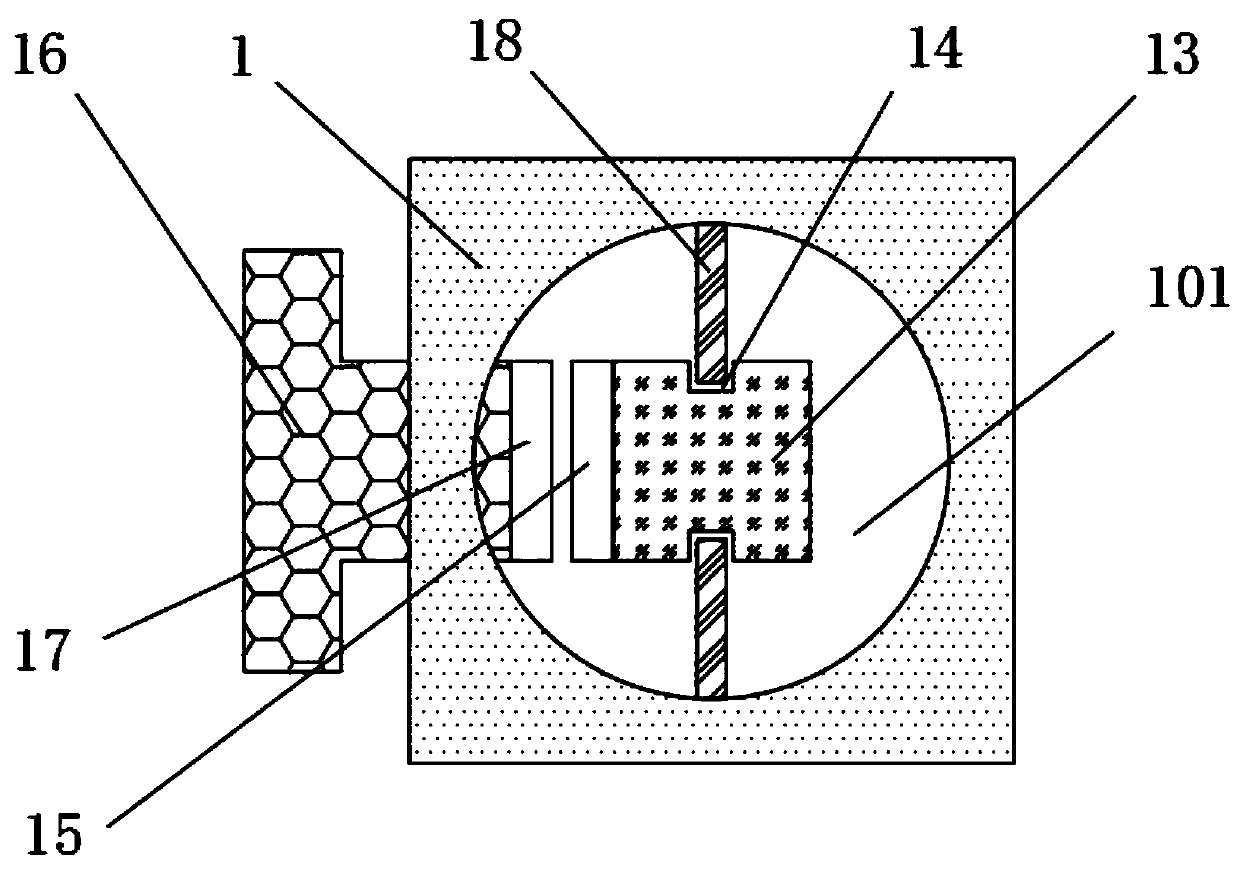

Adjustable automated equipment support

PendingCN107842693AHeight adjustableControl altitudeNon-rotating vibration suppressionStands/trestlesExhaust valveControl engineering

The invention discloses an adjustable automated equipment support. The adjustable automated equipment support comprises support columns, inner cavities, bottom boards, fixing bolts, first springs, rubber bases, second springs, an air pump, an air intake pipe, air valves, exhaust pipes, exhaust valves, sealing pistons, connecting rods, limiting sliding grooves, first tooth tips, clamp blocks, second tooth tips, limiting blocks and a placement board. The adjustable automated equipment support is reasonable in structure and novel in design. When in use, the adjustable automated equipment supportcan adjust the height of automated equipment at any time. Therefore, the placement height of the automated equipment can be controlled reasonably. Operation is simple. Meanwhile, stable application and stable placement of the automated equipment after height adjustment can be ensured. Therefore, a worker can conveniently perform operation so that working efficiency of the worker is increased. During application, vibration generated by the automated equipment can be effectively undermined. Connections among all structures are not affected by vibration generated from the automated equipment. Theservice lifetime is prolonged. The adjustable automated equipment support is highly practical and convenient to use.

Owner:HENAN LINXIAO SCI & TECH DEV

Carbon dioxide fracturing method

InactiveCN107782209ARapid outbreakStrong thrustDisloding machinesBlastingElectrical resistance and conductanceDetonation

The invention discloses a carbon dioxide fracturing method. The method includes the steps that first, carbon dioxide fracturing devices are assembled; second, an ohmmeter is used for detecting whetherthe resistance value between a filling valve and a release tube is normal or not; third, the carbon dioxide fracturing devices assembled in the first step are loaded and transferred to a mine after passing examinations; fourth, whether the resistance between each carbon dioxide fracturing device and a wire is normal or not is measured, a layer of blasting holes are drilled in the mine, and the carbon dioxide fracturing devices are put into the corresponding blasting holes; fifth, the hole opening of each blasting hole is covered with a bamboo chip and then is covered with a tarpaulin and earth bags; and sixth, a warning region is made around each carbon dioxide fracturing device, and an ignition device is pressed to start the carbon dioxide fracturing devices for detonation. By means of the carbon dioxide fracturing device, reuse can be realized, using cost is greatly reduced, powerful thrust generated momently is used for tearing materials, the same carbon dioxide fracturing devicescan be connected through the corresponding wires, and the advantages of being low in labor intensity, large in fracturing force, safe and good in fracturing effects are achieved.

Owner:浙江虹脉土石方工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com