Die changing device

A technology of traction device and lifting device, which is applied in the field of mold changing devices, can solve problems such as high labor intensity and unsafety, delay in operation cycle, and reduce production efficiency, so as to reduce labor intensity and unsafety, and avoid positioning accuracy errors , to avoid the effect of positioning error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

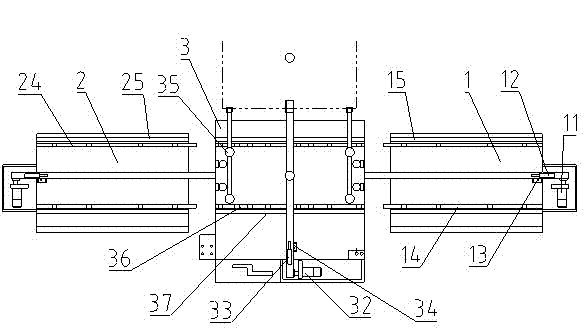

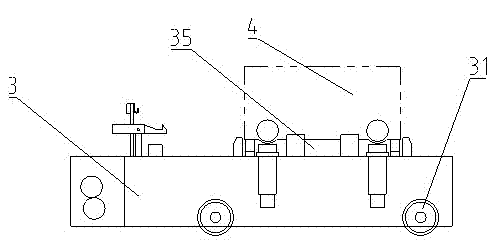

[0022] Such as figure 1 and figure 2 As shown, an embodiment of a mold changing device of the present invention, which includes a first fixed mold storage table 1 for storing spare molds, a second fixed mold storage table 2 for storing replaced molds, and a carrying device The spare molds of each station of the workbench (not shown in the drawings) or the replaced molds run between the equipment workbench, the first fixed mold storage table 1 and the second fixed mold storage table 2. Guide rail mold change vehicle 3 , the guide rail mold changing vehicle 3 transports the replaced mold from the equipment table to the second fixed mold storage table 2, and transports the spare mold from the first fixed mold storage table 1 to the equipment table; it also includes a fixed equipment table The sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com