Patents

Literature

2911results about How to "Achieve replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quantum communication service station, quantum key management device, key configuration network, and key configuration method

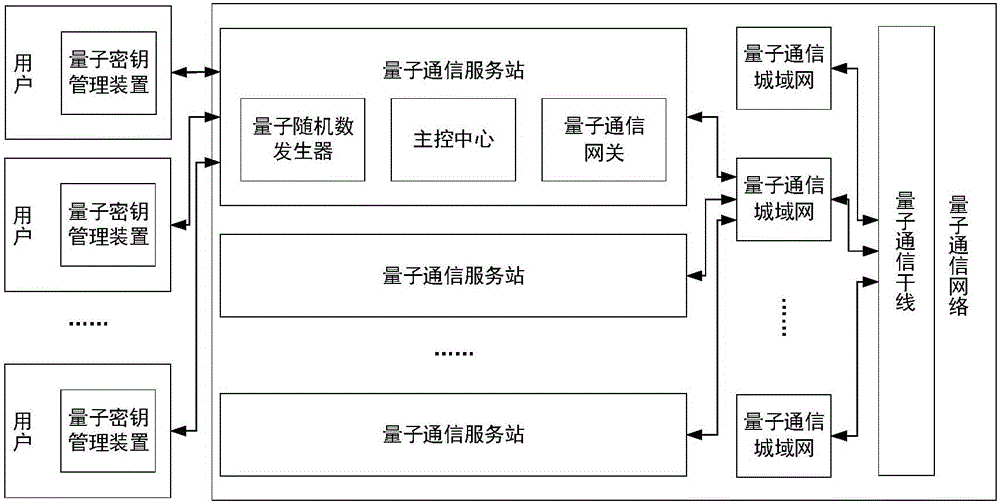

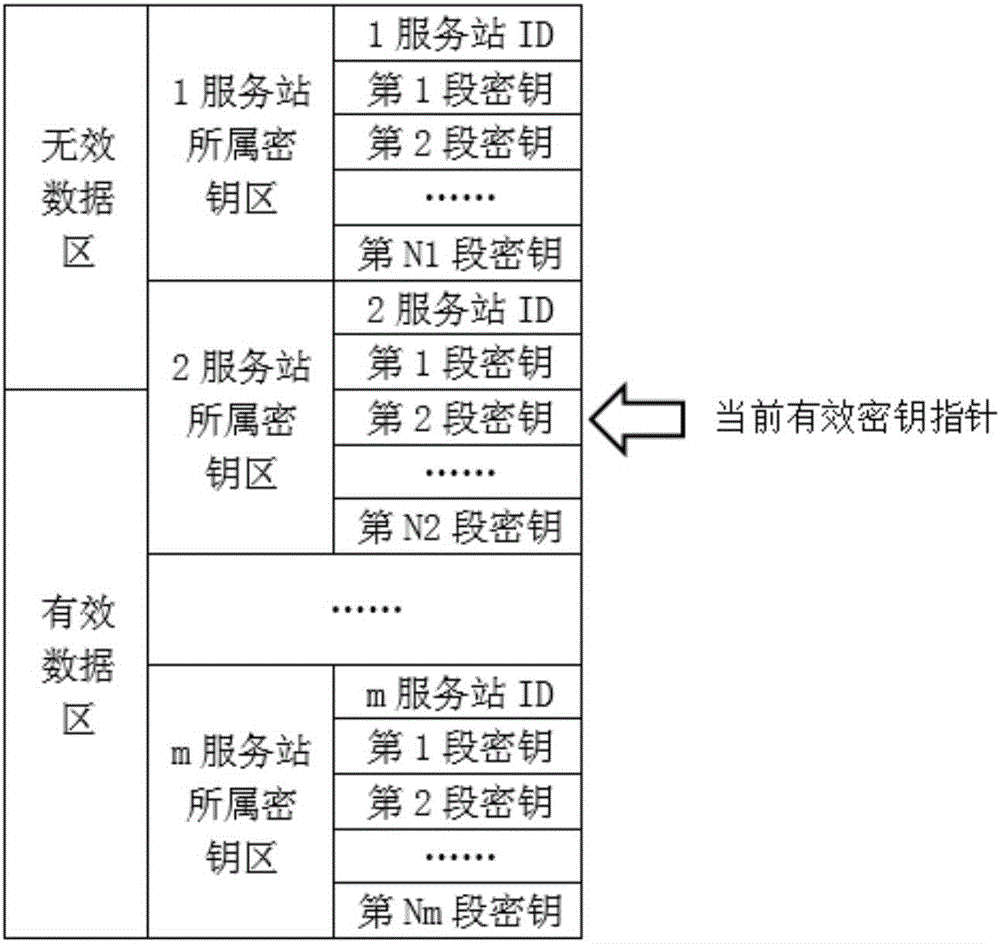

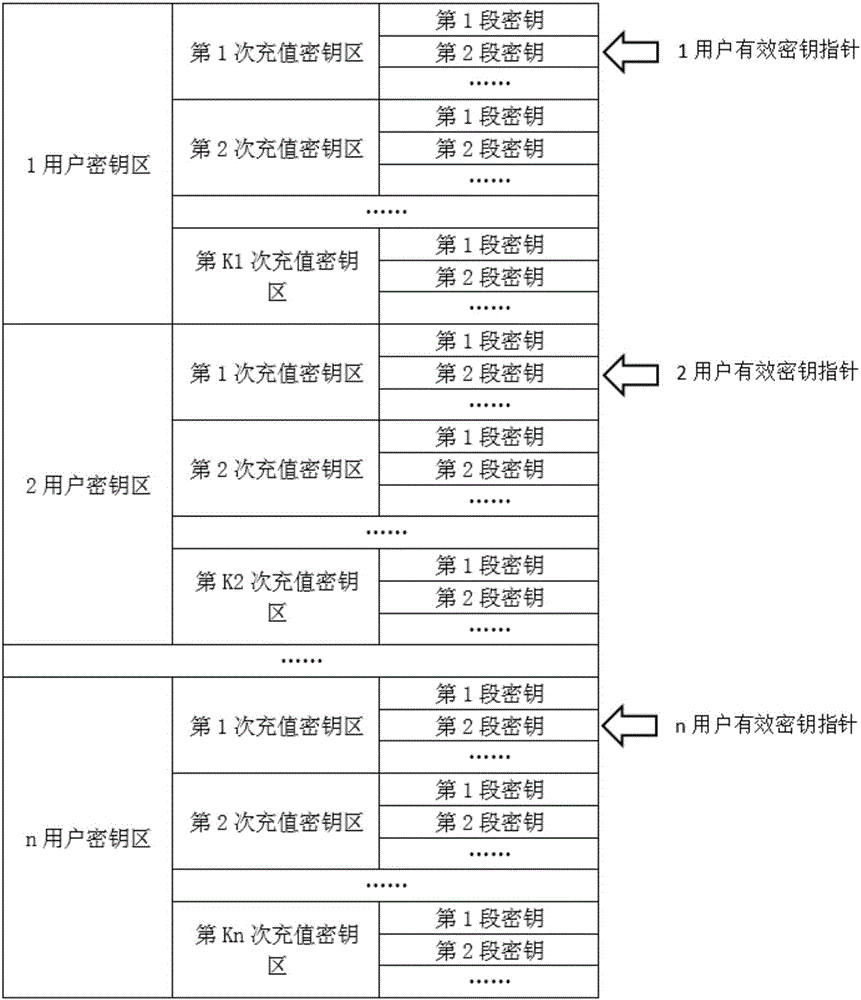

ActiveCN106452740AAddress access security issuesAchieve coverageKey distribution for secure communicationSecurity questionKey distribution

The invention discloses a quantum communication service station, a quantum key management device, a key configuration network, and a key configuration method. The key configuration method comprises the following steps: responding to a key distribution request; authenticating a user of the key distribution request; writing a key generated with a true random number into a quantum key management device of the authenticated user. The key configuration method is different from the existing quantum key distribution QKD method in that key distribution of ultra high security is realized by pairing quantum key management devices and service stations at the end of a quantum communication network, the problem about access security at the end of a quantum communication network is solved, and terminal access is not a weak link of a quantum communication scheme. The quantum communication network can completely cover and replace the classic communication network in service.

Owner:ZHEJIANG SHENZHOU QUANTUM NETWORK TECH CO LTD

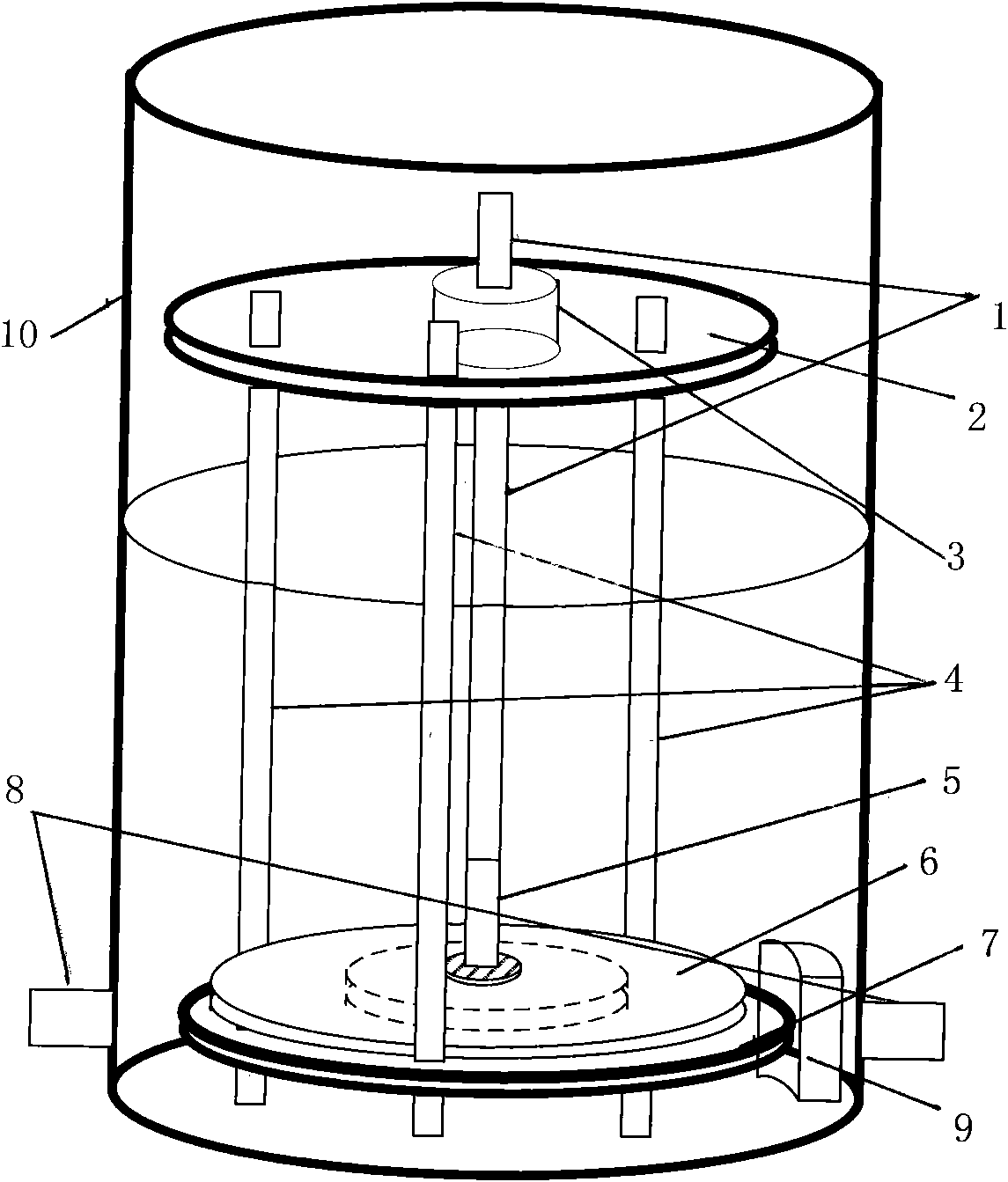

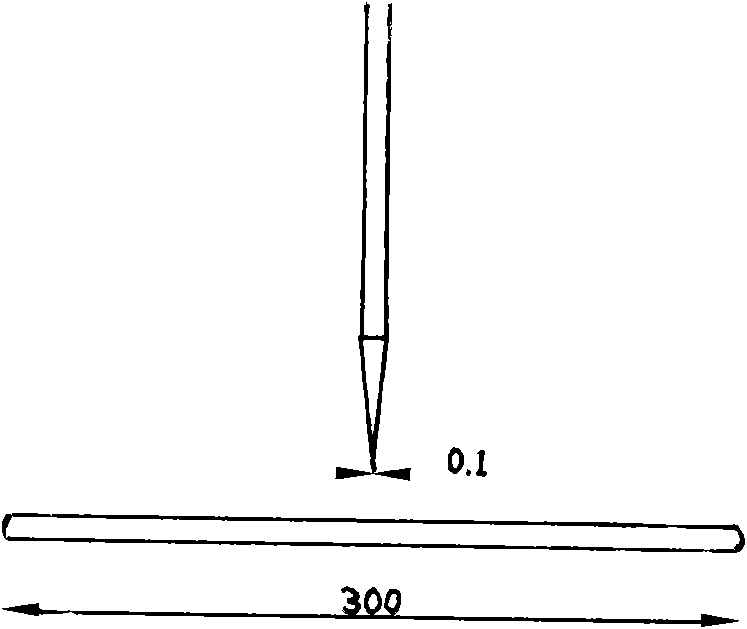

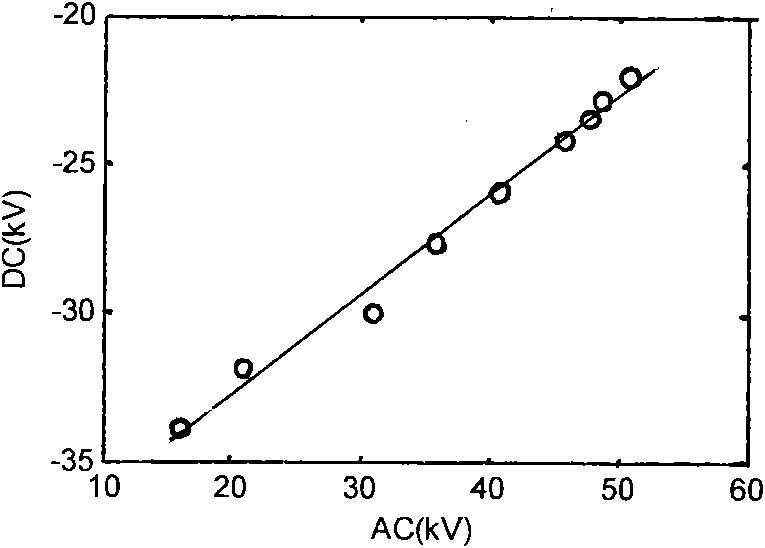

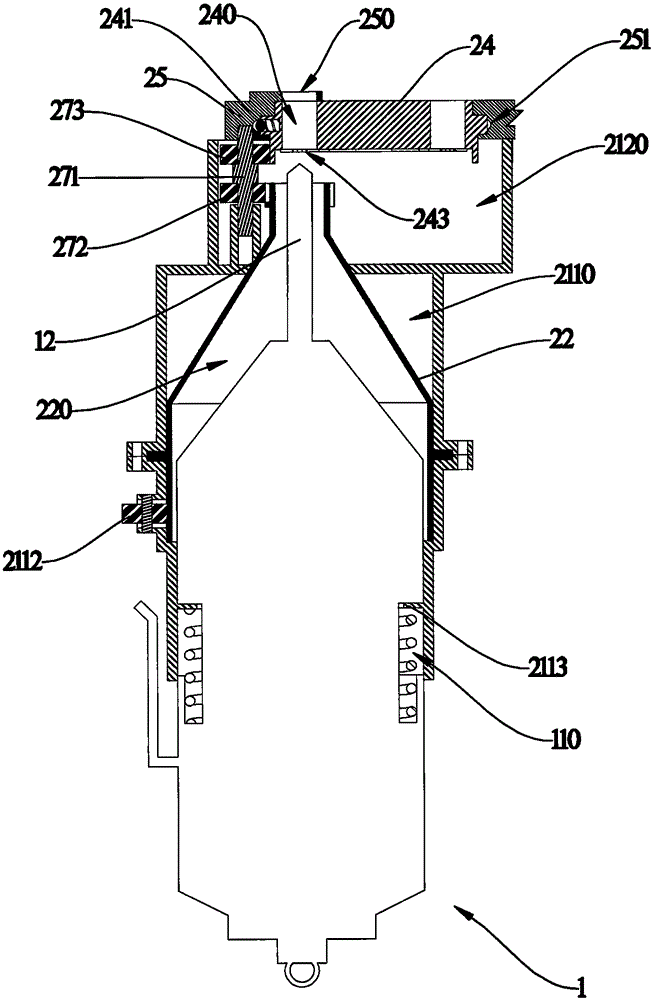

Device for testing insulating property of high-voltage oiled paper

ActiveCN101957423APrecise Electrode SpacingAdjust electrode spacingTesting vessel constructionPartial dischargeHigh pressure

The invention relates to the technical field of high voltage and insulation, in particular to a device for researching and testing an insulating property of high-voltage oiled paper. Aiming at the positions of frequent faults during the operation of a converter transformer, the device simulates a ball-board, a needle-board, a board-board, faces and suspension discharge electrode models; and the typical high-voltage oil / oiled paper insulating experiments can be realized under direct current (DC) voltage, alternating current (AC) voltage and AC-DC voltage so as to acquire partial discharge characteristics and breakdown characteristics of the major insulation of the converter transformer.

Owner:CHINA ELECTRIC POWER RES INST +1

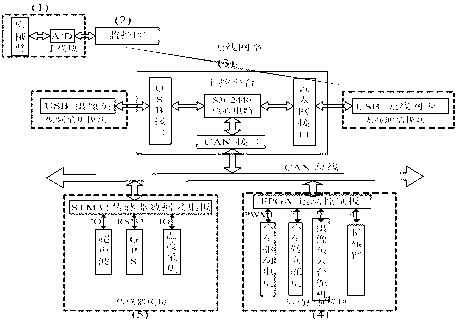

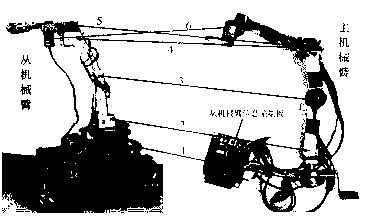

Robot control system and method based on principal and subordinate teleoperation mechanical arm

InactiveCN103273489ADoes not affect the additionDoes not affect deletionProgramme-controlled manipulatorData displaySystems engineering

The invention discloses a robot control system and method based on a principal and subordinate teleoperation mechanical arm. The robot control system comprises a principal mechanical arm and information collection plate, a monitoring center PC, a robot principal control panel, a subordinate mechanical arm and FPGA movement control panel and a site environmental information collection plate. The robot control method includes the steps of principal mechanical arm manufacturing and data collection, the control of a subordinate mechanical arm, a trolley and a cradle head, video collection and communication of the robot principal control panel, data collection and communication of the site environmental information collection plate and data display and communication of the monitoring center PC. Under the condition that the complexity of a system is not added, the mechanical arm can be controlled to achieve relatively complex movement. A modularized mode is designed to be used, and modules are in communication through CAN buses. An FPGA is used as a movement control panel, establishing and updating of the system are convenient, and the stability of the system is improved. A robot transmits the video information of a working site and the environmental information of the working site to a monitoring center so that the robot can be controlled to complete more complex operations.

Owner:SHANGHAI UNIV

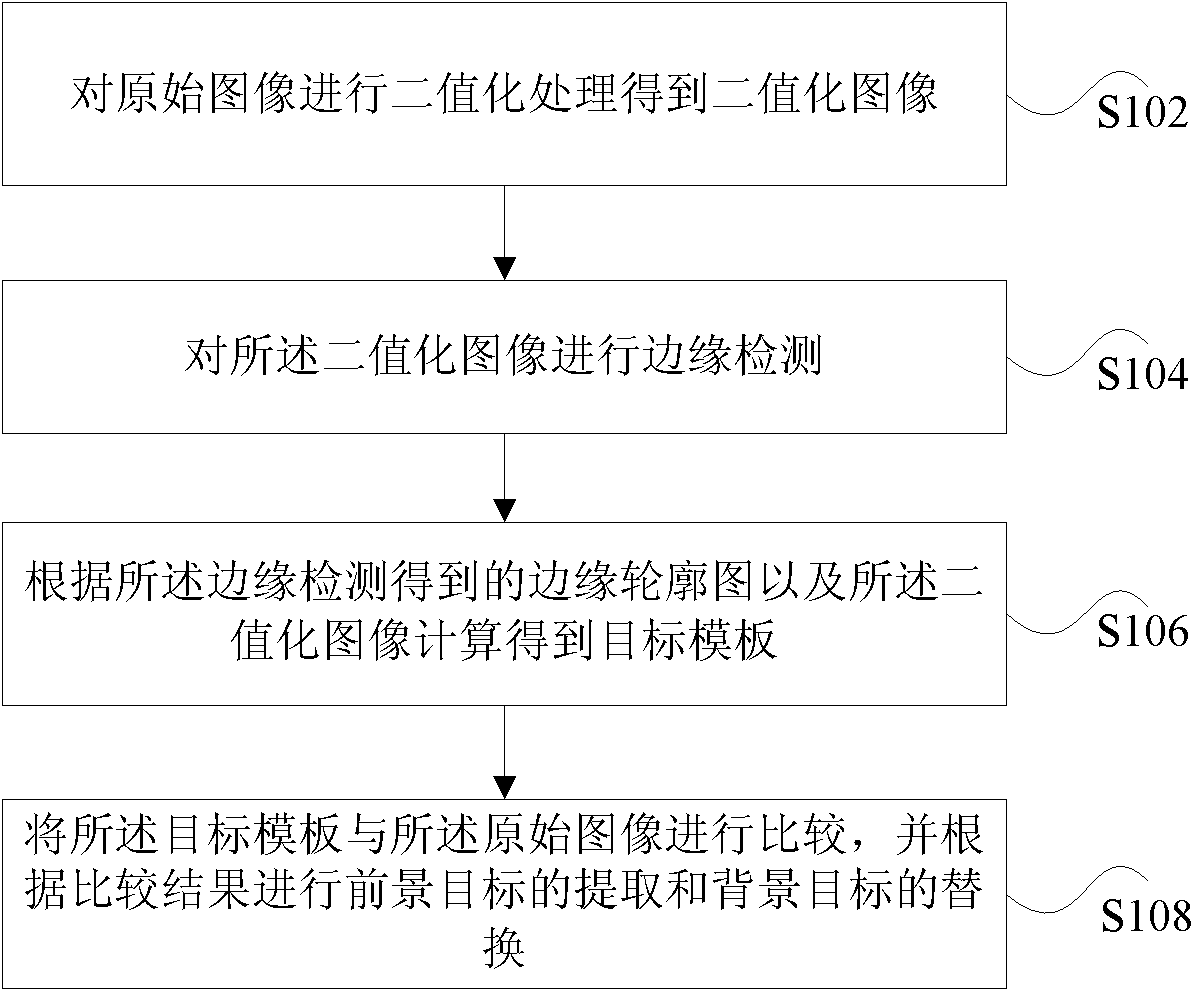

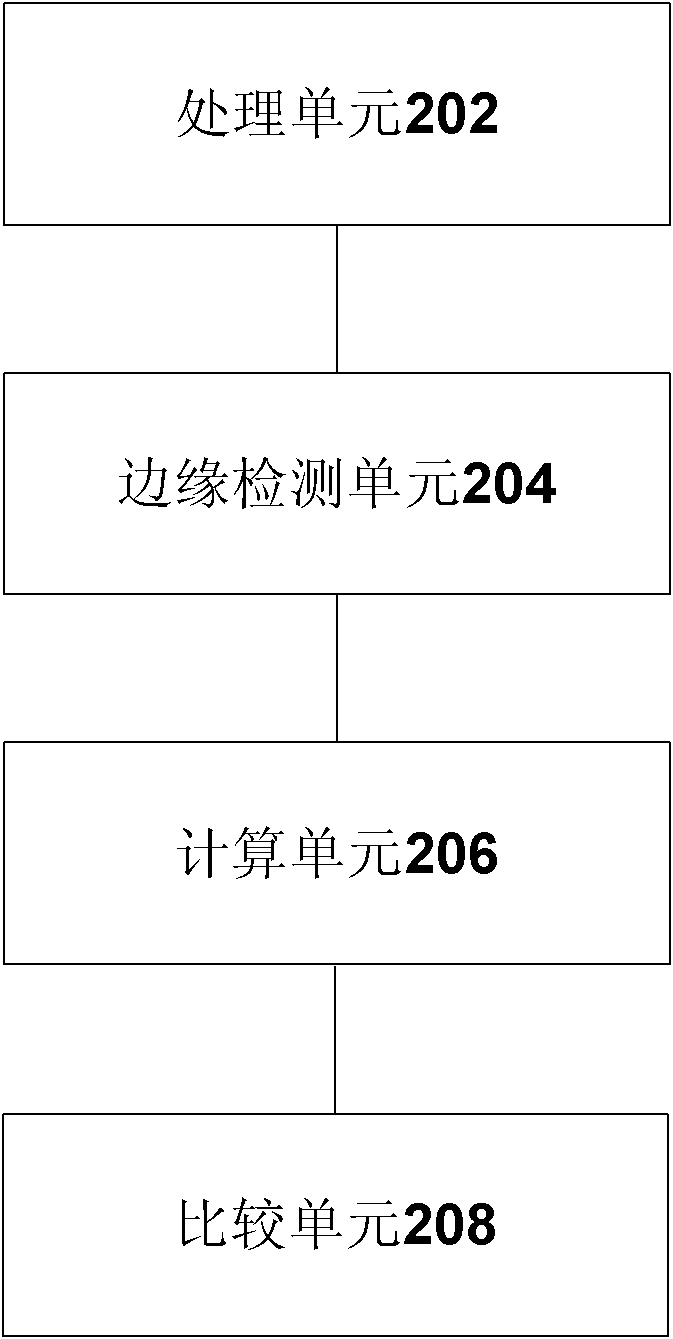

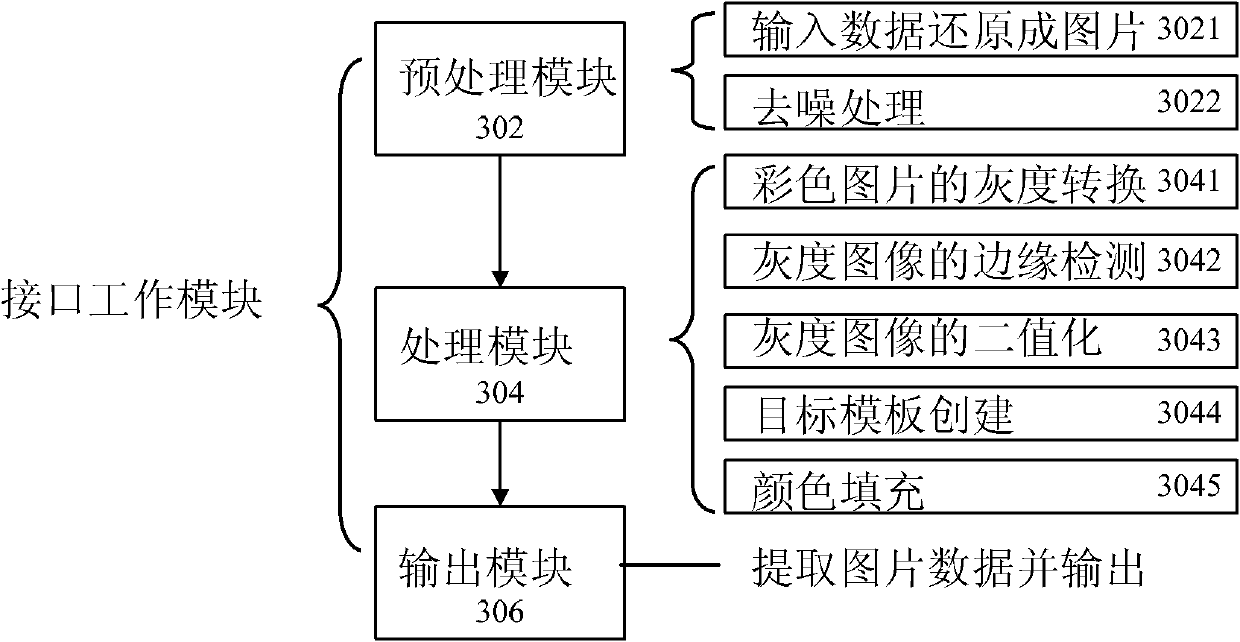

Method and device for replacing background target

InactiveCN102567727AAchieve replacementImage analysisCharacter and pattern recognitionRadiologyImage pair

The invention discloses a method and a device for replacing a background target. The method comprises the steps of binarizing an original image to obtain a binarized image; performing edge detection for the binarized image; calculating and obtaining a target template according to an edge contour map obtained by the edge detection and the binarized image; and comparing the target template with the original image and extracting a foreground target and replacing the background target according to the comparative result. The invention solves the problem that in the prior art, because the target is sensitive to the illumination change and relies on the shape and number of the mobile targets, the foreground target cannot be extracted well to replace the background target.

Owner:ZTE CORP

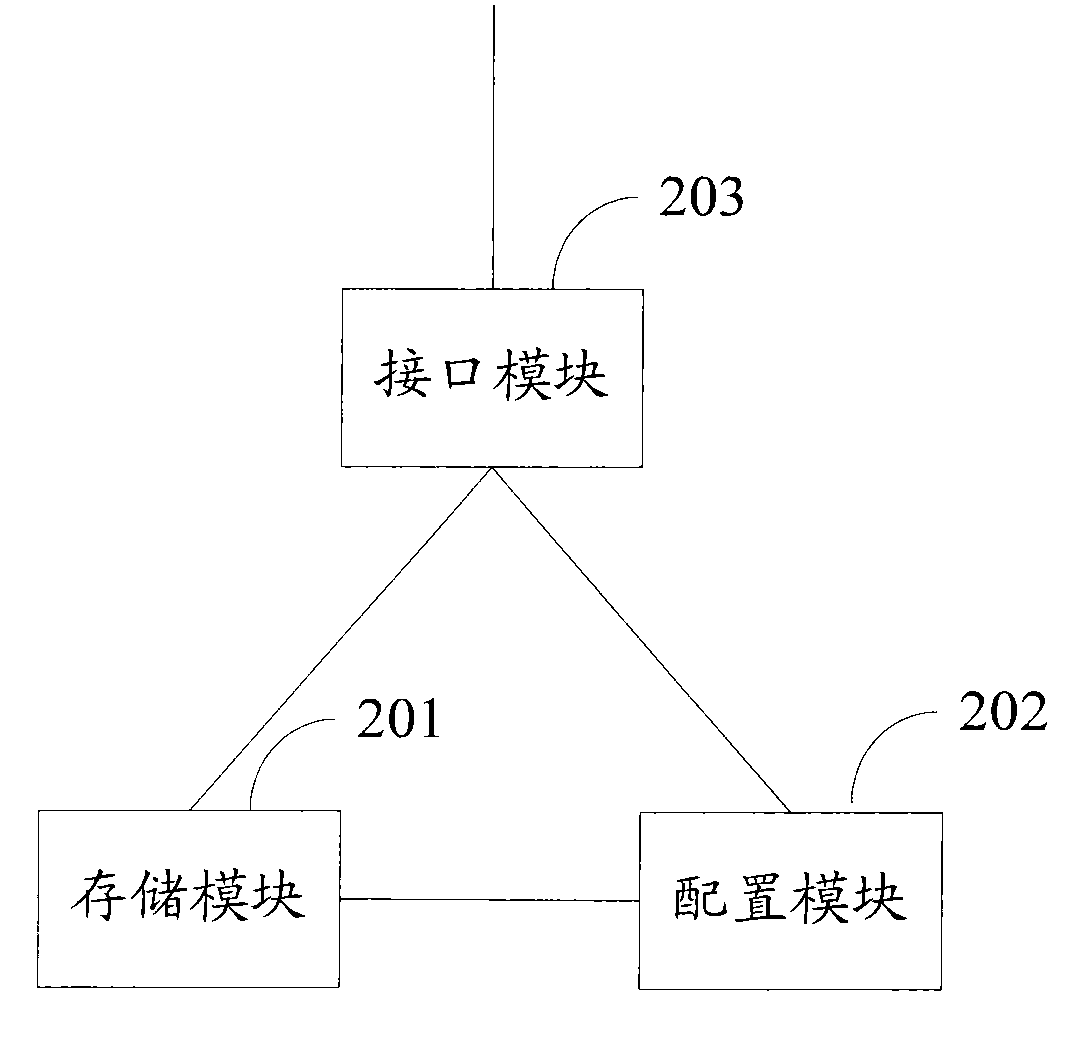

Method and device for replacement of main cell

The invention discloses a method and device for replacement of a main cell, which are used for realizing the replacement of the main cell in a carrier aggregation system. The method comprises the steps of: by means of UE (User Equipment), deleting configuration information of a source auxiliary cell when a main cell replacing command is received; obtaining the configuration information of a target main cell according to the configuration information of the target main cell carried by the main cell replacing command and the configuration information of the source main cell reserved by the main cell replacing command; and replacing the obtained configuration information from the source main cell to the target main cell. The invention also discloses a device used for realizing the method.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Greenhouse vegetable cultivation method for grapes

InactiveCN102293138AAchieving new resultsReduce pests and diseasesCultivating equipmentsGreenhousePoor quality

The invention discloses a greenhouse vegetable type culture method for grape, which comprises the steps of culture time, culture density, field planting ditch digging, small pit culture, planted exposed land management, management after greenhouse building, management after harvesting and the like. The greenhouse vegetable type culture method for grape has the advantages that the problems of small density and low yield, the problem of yield influence caused by variety replacement, the problems of low yield and poor quality caused by vine aging and the problem of unbalanced overground and underground growth are solved, simultaneously, the grape varieties can be changed every year according to requirements, branches in the greenhouse are all seasonable fresh branches and vines, the annual mother vine fruiting in each year is realized, the yield can not be influenced between years, and the acre yield reaches more than 4000kg.

Owner:刘冠义

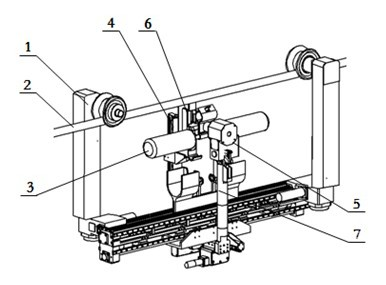

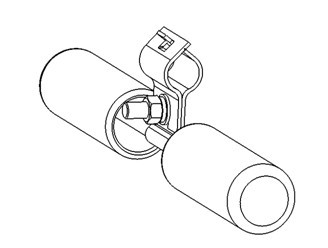

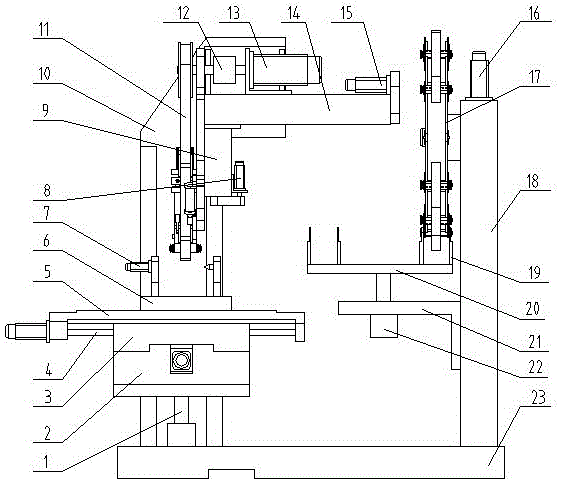

Mounting and dismantling device for dampers of high-voltage transmission lines

ActiveCN102581606AAchieve replacementImprove efficiencyMetal working apparatusManipulatorHigh pressureControl theory

The invention relates to a mounting and dismantling device for dampers of high-voltage transmission lines. The mounting and dismantling device comprises a clamping mechanical arm (4) and a nut screwing mechanical arm (5), wherein one end of the clamping mechanical arm is arranged on a walking robot (1) via a clamping mechanical arm driving mechanism, the clamping mechanical arm can be driven by the clamping mechanical arm driving mechanism to horizontally reciprocate and vertically move, one end of the nut screwing mechanical arm (5) is disposed on the walking robot (1) via a nut screwing mechanical arm driving mechanism, the nut screwing mechanical arm (5) can be driven by the nut screwing mechanical arm driving mechanism to horizontally reciprocate and vertically move, a clamping tail end component is arranged at the other end of the clamping mechanical arm (4), and a nut screwing tail end component is disposed at the other end of the nut screwing mechanical arm (5). The mounting and dismantling device has the advantages that 1, a damper can be replaced during maintenance of a high-voltage transmission line, a damper carried on the walking robot can be mounted on the line, and the damaged damper on the line also can be taken down; and 2, manual operation can be replaced, and the mounting and dismantling device is fine in effect, high in efficiency and low in cost.

Owner:GUANGDONG KEYSTAR INTELLIGENCE ROBOT CO LTD

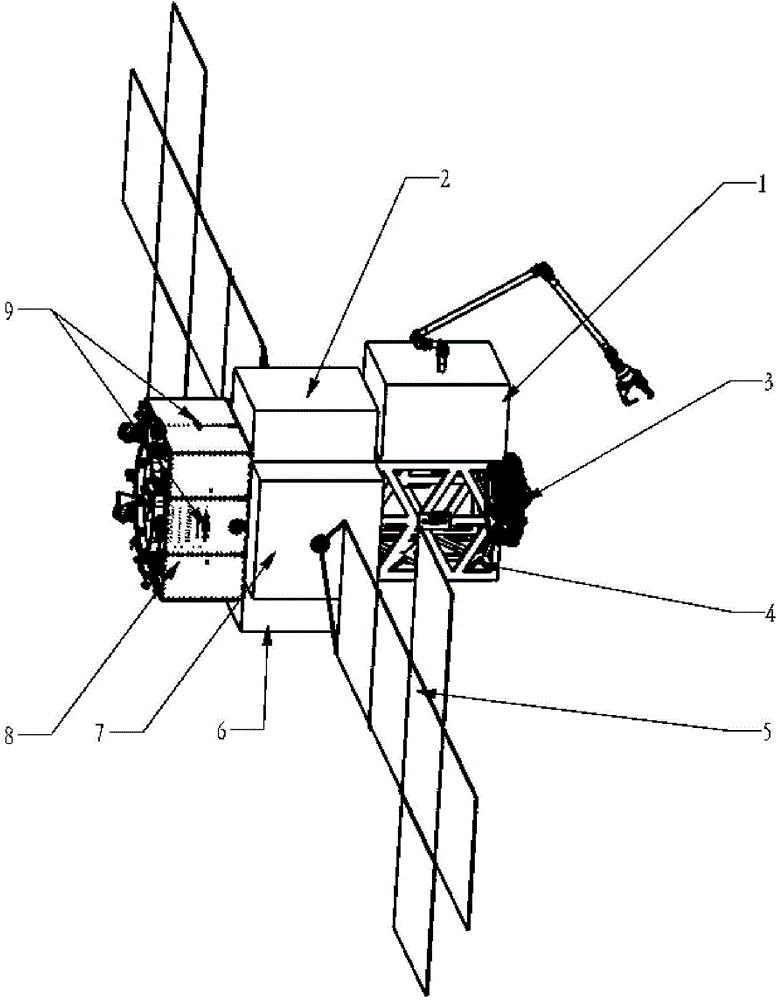

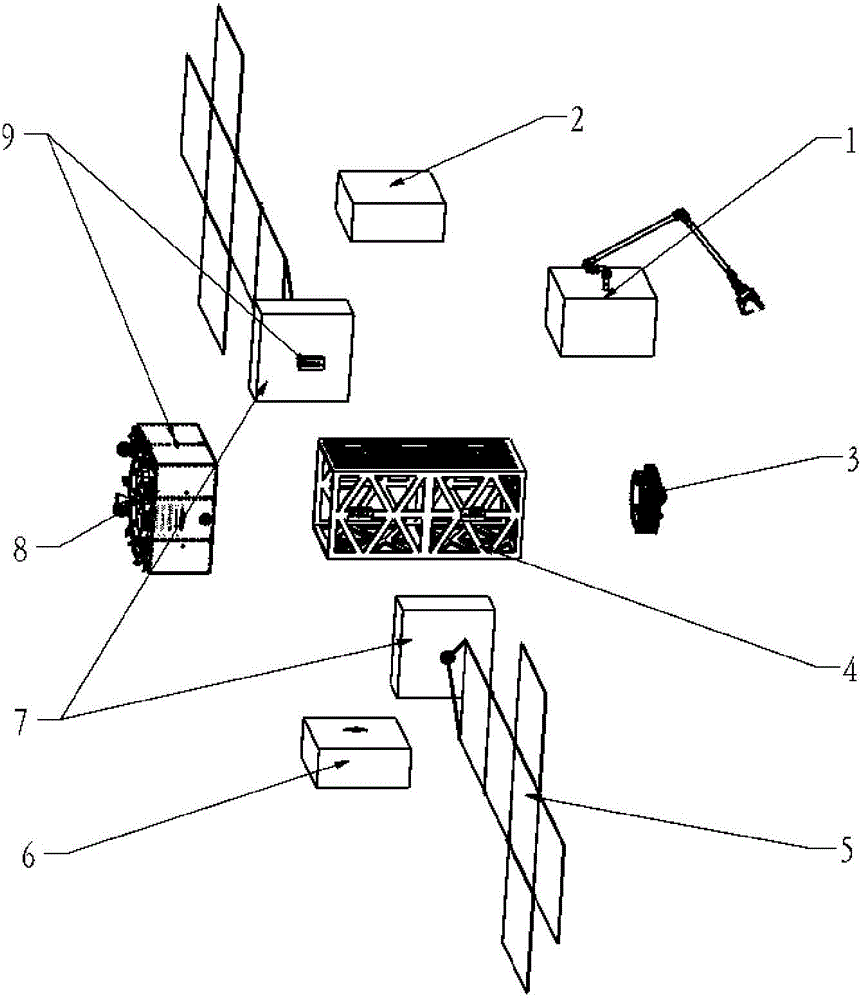

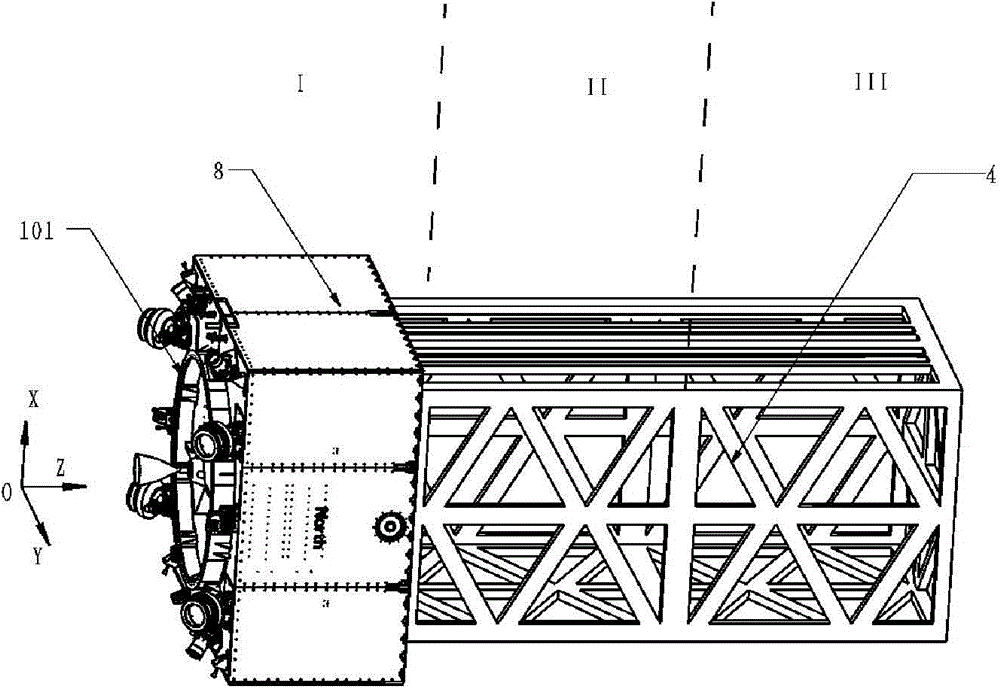

Space-based platform based on open structure

InactiveCN104691781AImprove survivabilityKeep technologically advancedCosmonautic vehiclesCosmonautic partsOpen structureAerospace engineering

A space-based platform based on an open structure comprises a free flying robot (1), a control cabin (2), an electromechanical liquid-gas integrated docking interface (3), a central truss extension level (4), solar wings (5), an electronic cabin (6), an energy cabin (7), a central truss foundation level (8) and cabin connecting interfaces (9), wherein the central truss foundation level (8) and the central truss extension level (4) are fixedly connected to constitute a central truss, the left side of the central truss extension level (4) is fixedly connected with the central truss foundation level (8), and the electromechanical liquid-gas integrated docking interface (3) for truss extension or aircraft docking is mounted on the right side. The cabin connecting interfaces (9) for cabin replacement or extension are arranged around the central truss extension level (4), the free flying robot (1), the control cabin (2), the electronic cabin (6) and the energy cabin (7) are fixed on the central truss extension level (4) through the cabin connecting interfaces (9), and the solar wings (5) are connected with the energy cabin (7) through SADA.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

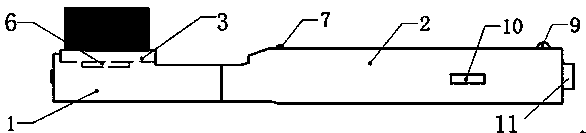

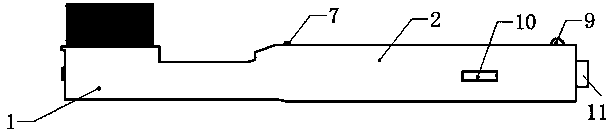

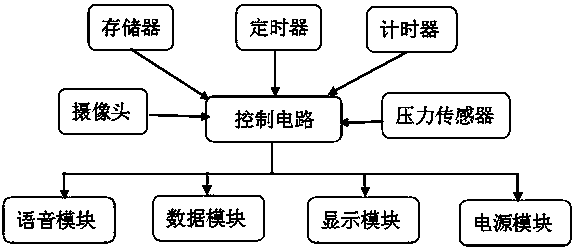

Intelligent toothbrush device

InactiveCN104305711ASimple structureEasy to implementBrushesDiagnostic recording/measuringEngineeringData transmission

The invention provides an intelligent toothbrush device. The intelligent toothbrush device comprises a toothbrush head and a toothbrush handle. According to a display module, a voice module, a data transmission module, a power supply module and a microcircuit controller arranged in a toothbrush, the tooth brushing habit can be fed back, the health indicators and physiological parameters of a user can be monitored, and the diet regulation can be prompted.

Owner:SICHUAN UNIV

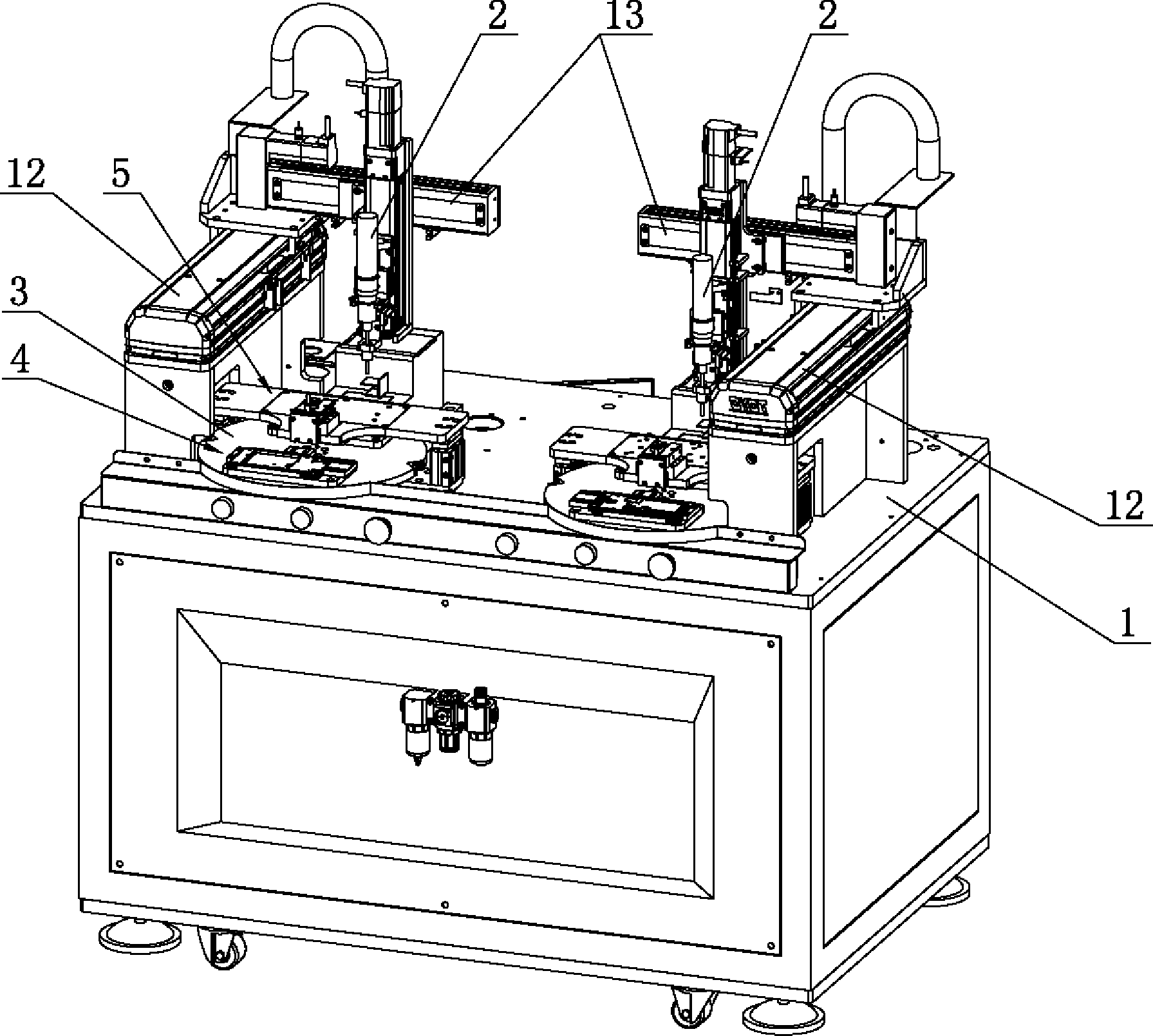

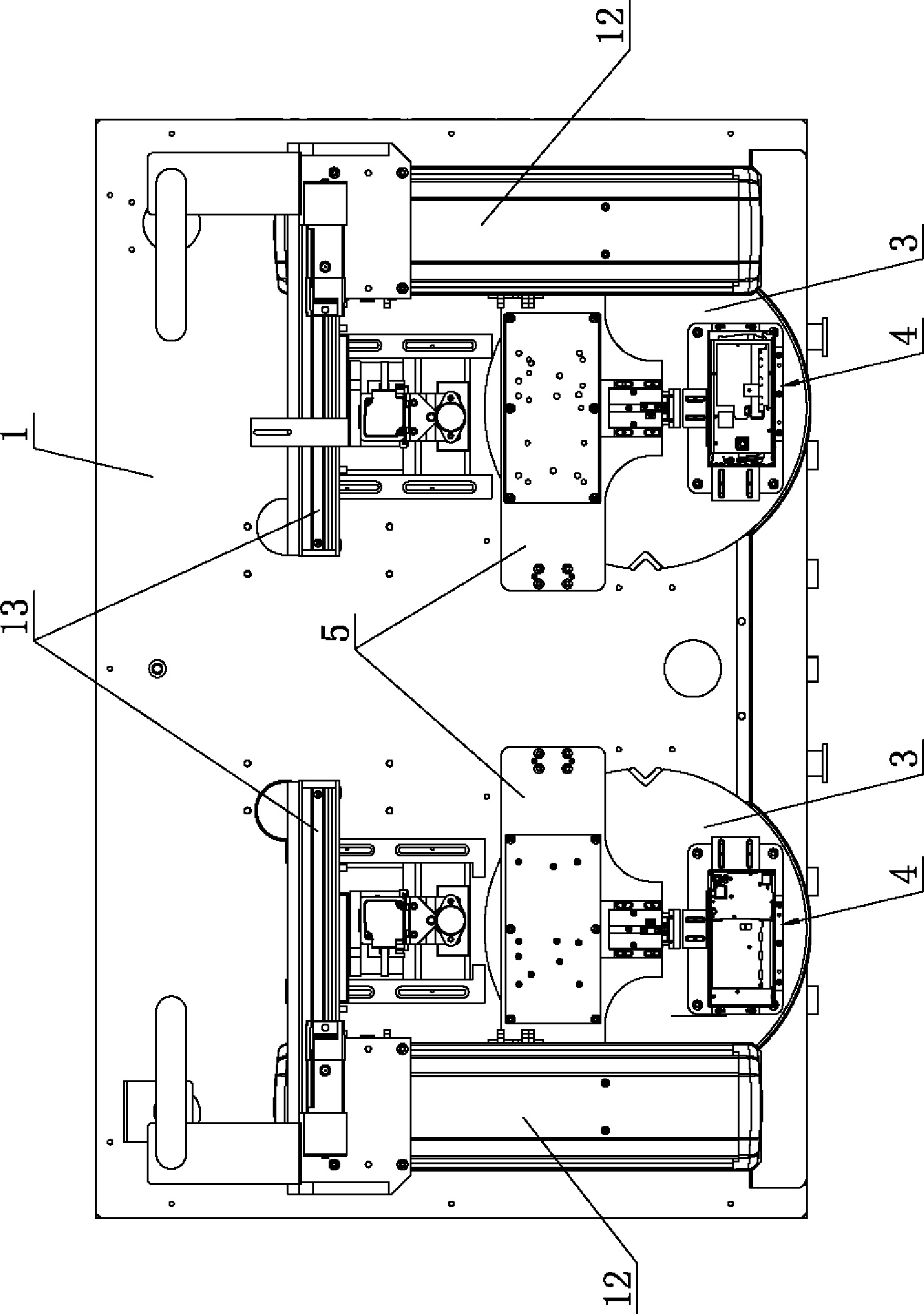

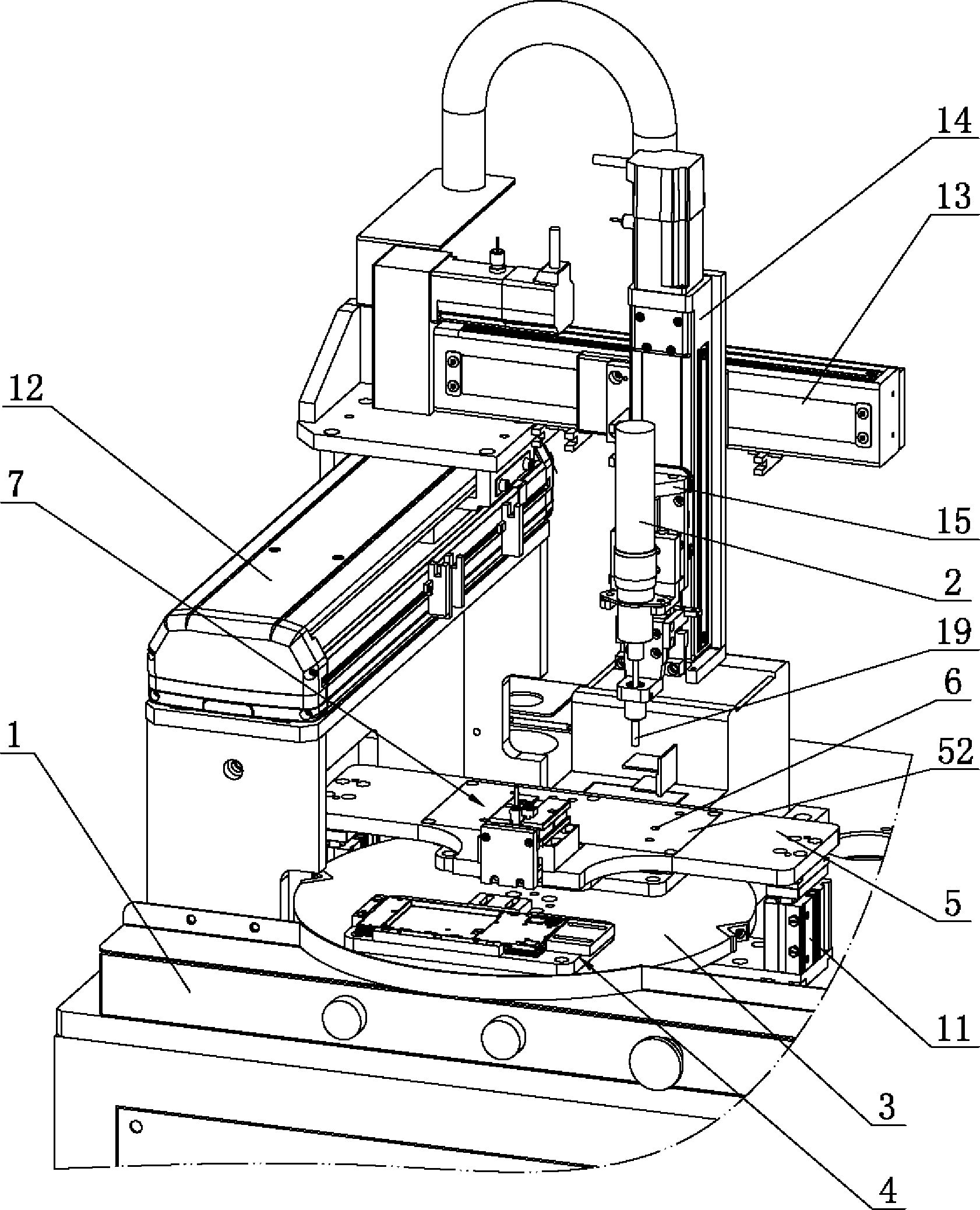

Biaxial suction type automatic lock screw feeder

ActiveCN103878577AImprove processing efficiencyAchieve loadingMetal working apparatusPersonal computerEngineering

The invention relates to the technical field of LED assembling and machining equipment, in particular to a biaxial suction type automatic lock screw feeder. The screw feeder comprises a machine frame and two triaxial moving assemblies arranged on the machine frame. Each triaxial moving assembly is provided with an electric screw driver, the lower portion of each triaxial moving assembly is provided with a clamp disc capable of rotating intermittently, and each clamp disc is provided with at least two workpiece clamps. In the lock screw machining process, equipment does not need to be shut down, loading, disassembling or replacement of workpieces can be achieved, and machining efficiency of the automatic lock screw feeder is greatly improved. In addition, the two triaxial moving assemblies carry out lock screw machining simultaneously, so that machining efficiency is further doubled, and practicability is high. The workpieces machined through the screw feeder can be mobile phone shells, tablet personal computer shells, navigator shells, routers, set top boxes and other electronic products.

Owner:DONGGUAN SHANGCHUAN AUTOMATIC EQUIP

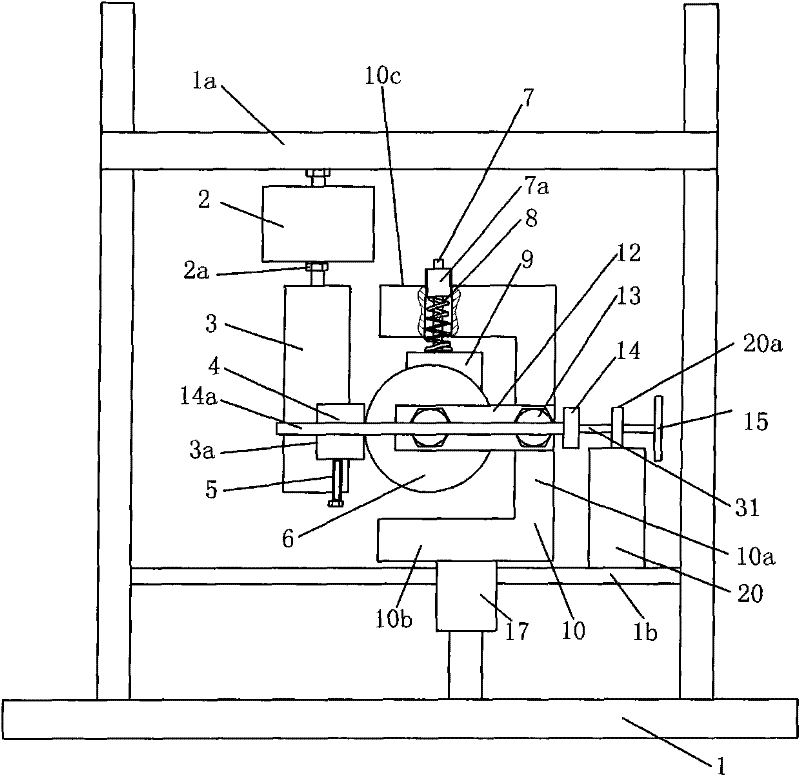

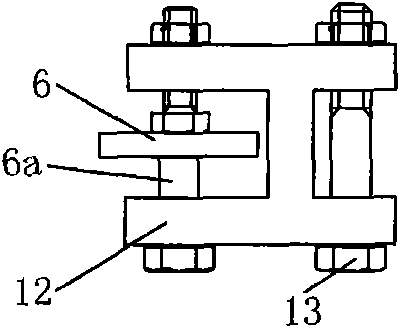

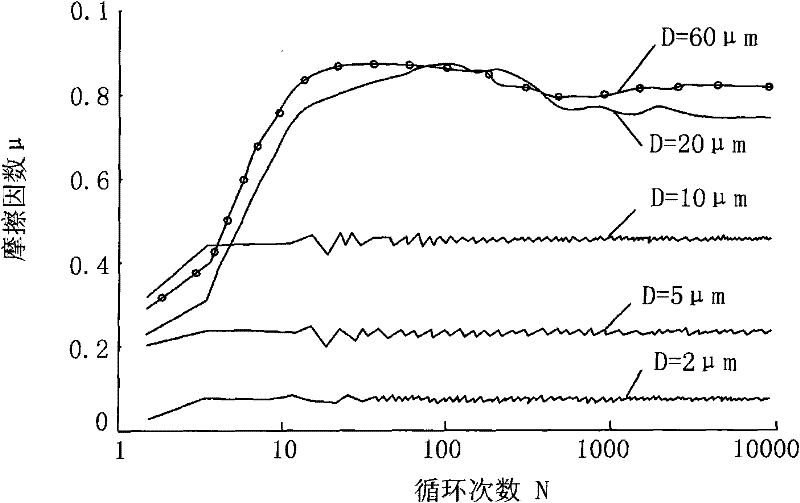

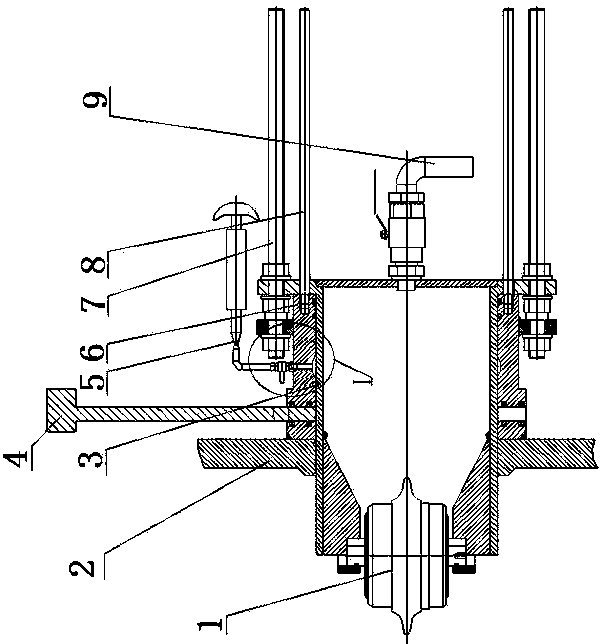

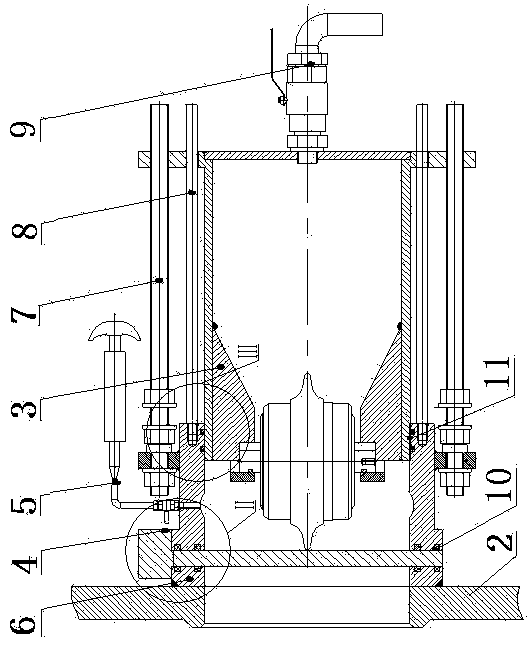

Small-displacement reciprocating rolling friction abrasion test device

InactiveCN101750259AAuthentic, reliable and effective simulationAuthentic, reliable and effective analysisInvestigating abrasion/wear resistanceRolling resistanceTangential force

The invention relates to a small-displacement reciprocating rolling friction abrasion test device. A plane sample clamp is fixedly connected below a cross beam of a hydraulic friction test machine by a tangential force sensor; a rolling sample clamp is positioned at the right side of the plane sample clamp and is fixed on a vertical column of a support frame; a bottom plate of the clamp support frame is connected on a hydraulic piston of the hydraulic friction test machine; the right side of the clamp support frame is provided with a normal force; a screw at the right side of the normal force sensor is connected on a support nut by threads, and the end part of the screw is connected with a rotating disc; the support nut is fixed on a work platform surface of the hydraulic friction test machine by a support seat; and a U-shaped connecting piece at the left side of the normal force sensor is sheathed on the vertical column of the clamp support frame. The small-displacement reciprocating rolling friction abrasion test device can simulate the friction abrasion between a plane sample and a rolling body more really and reliably, is convenient to microscopically analyze the test result, and has high degree of automation, simple and convenient operation, high accuracy of control and test and good repeatability of test data.

Owner:SOUTHWEST JIAOTONG UNIV

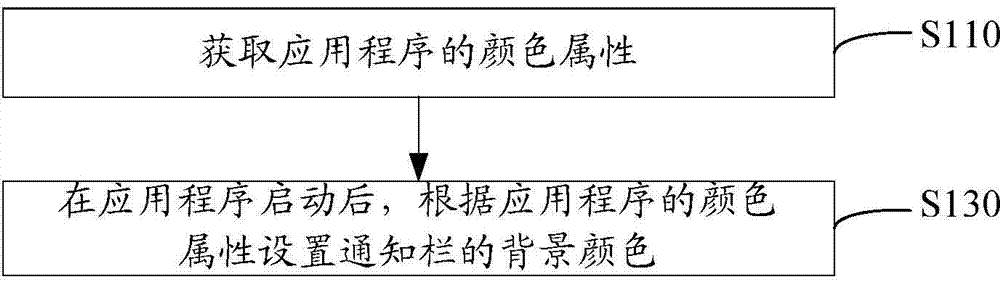

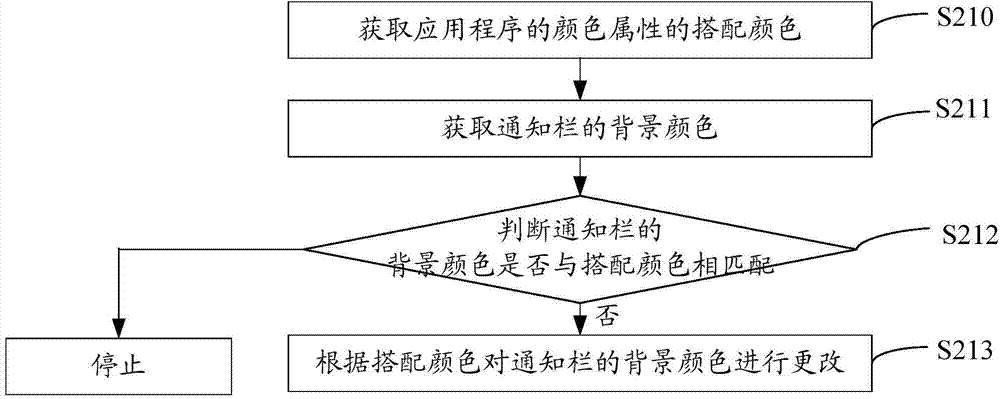

Interface display method and system

ActiveCN104850395AImprove visual effectsAchieve replacementSpecific program execution arrangementsComputer graphics (images)Background color

The invention relates to an interface display method and system. The interface display method comprises the following steps: acquiring the color attribute of an application; and setting the background color of a notification bar according to the color attribute of the application. The background color of the notification bar is set according to the color attribute of the application through acquisition of the color attribute of the application, so that the background color of the notification bar is matched with the color of the application; change of the background color of the notification bar is realized; and the visual effect of an interface is enhanced.

Owner:MEIZU TECH CO LTD

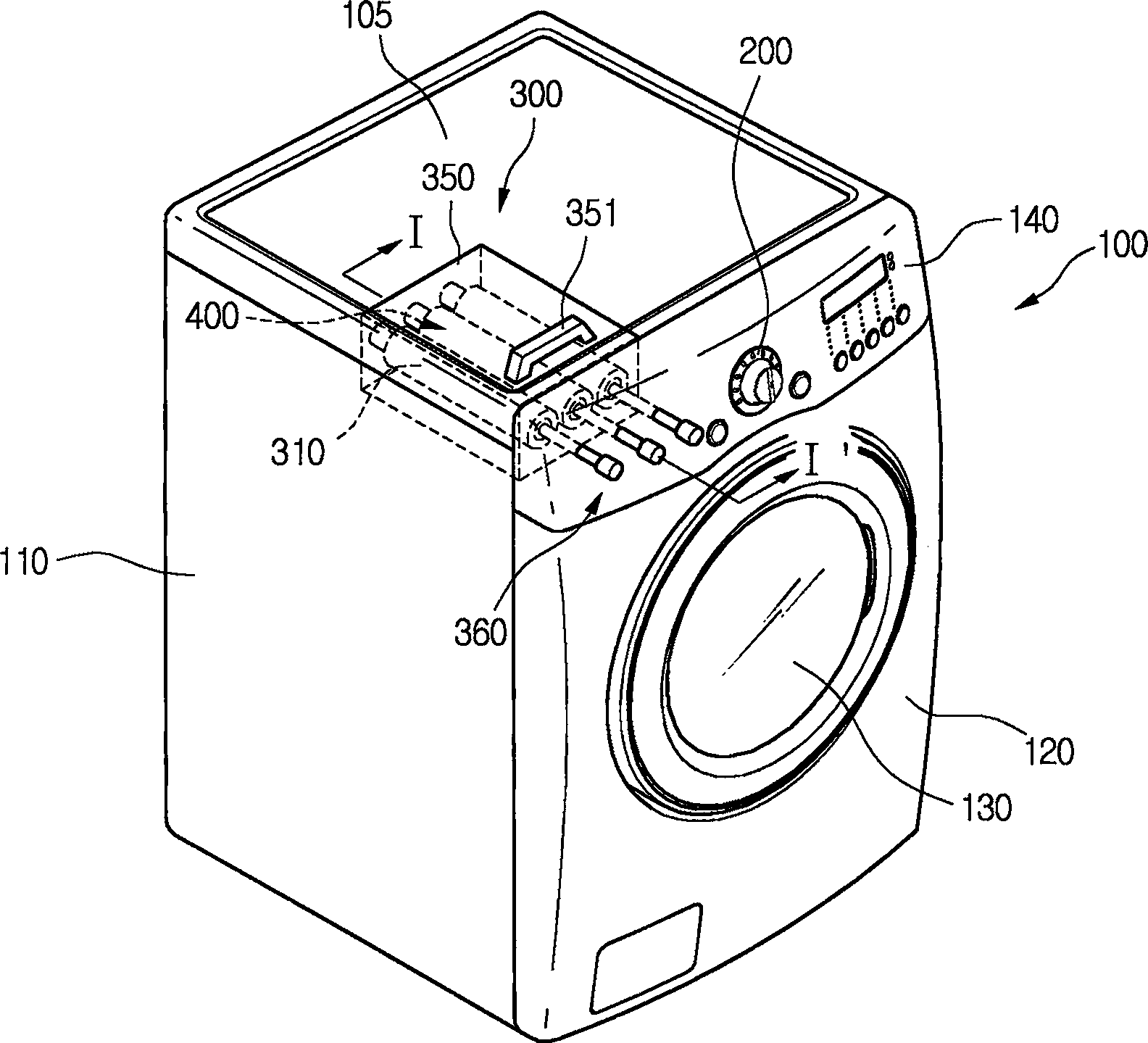

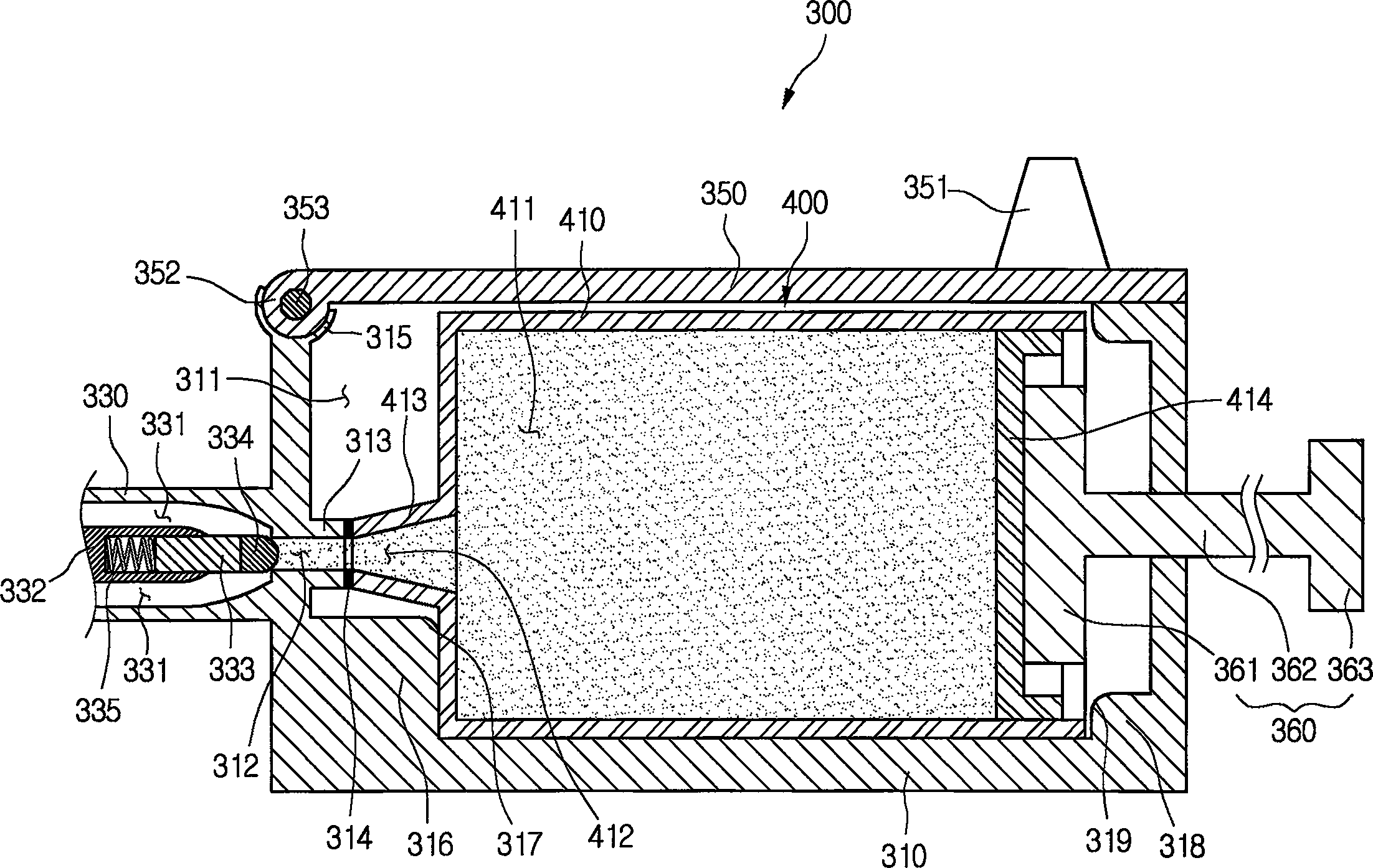

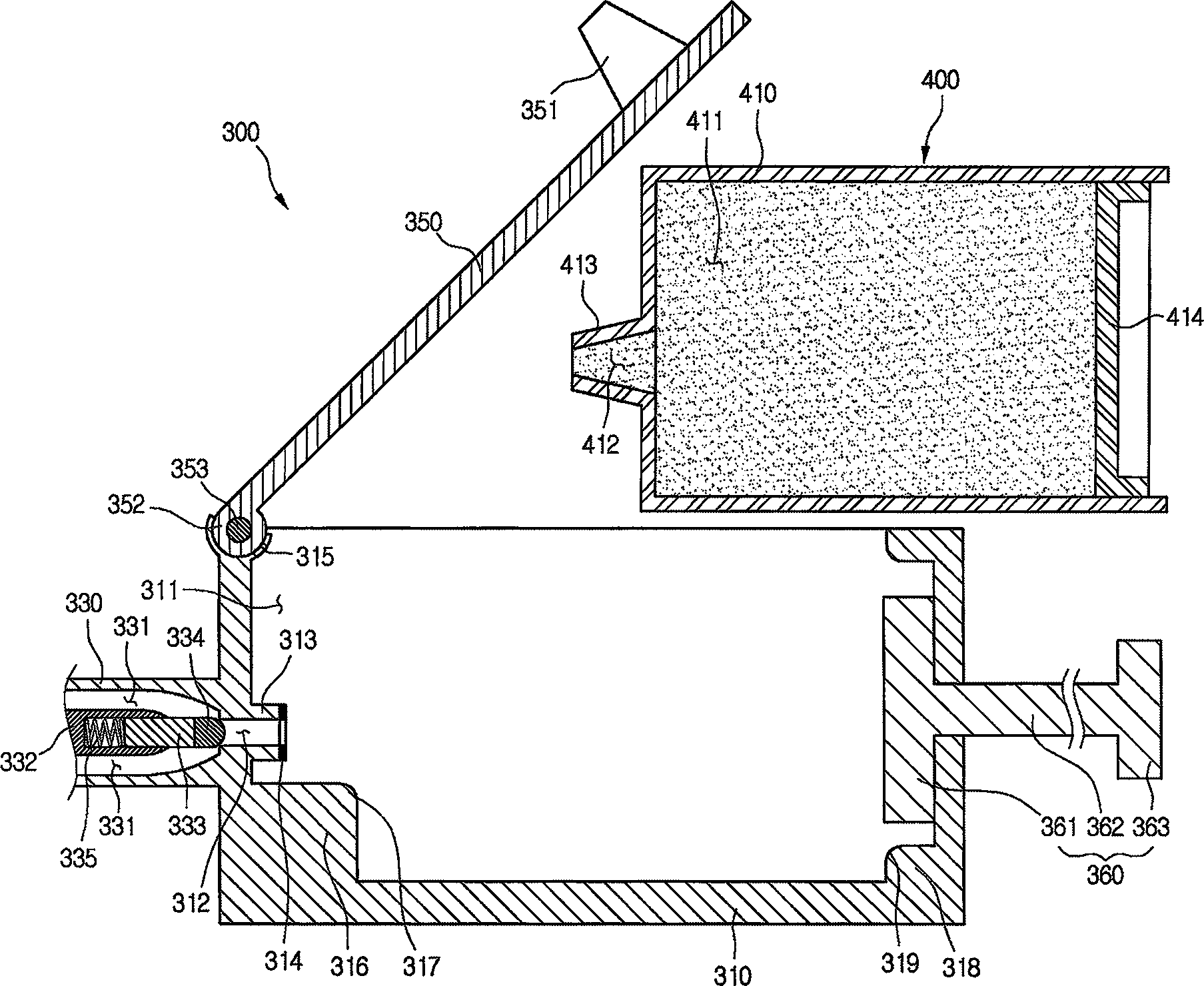

Detergent dispensing apparatus of washing machine

InactiveCN1873084ARealize distributionAchieve replacementOther washing machinesTextiles and paperEngineeringMechanical engineering

There is provided a detergent dispensing apparatus of a washing machine. The detergent dispensing apparatus includes a main body of the washing machine, a detergent cartridge separately received in the main body and storing a detergent therein, a detergent outlet formed on the detergent cartridge to define a detergent dispensing passage, and an opening / closing assembly for selectively opening and closing the detergent outlet.

Owner:LG ELECTRONICS INC

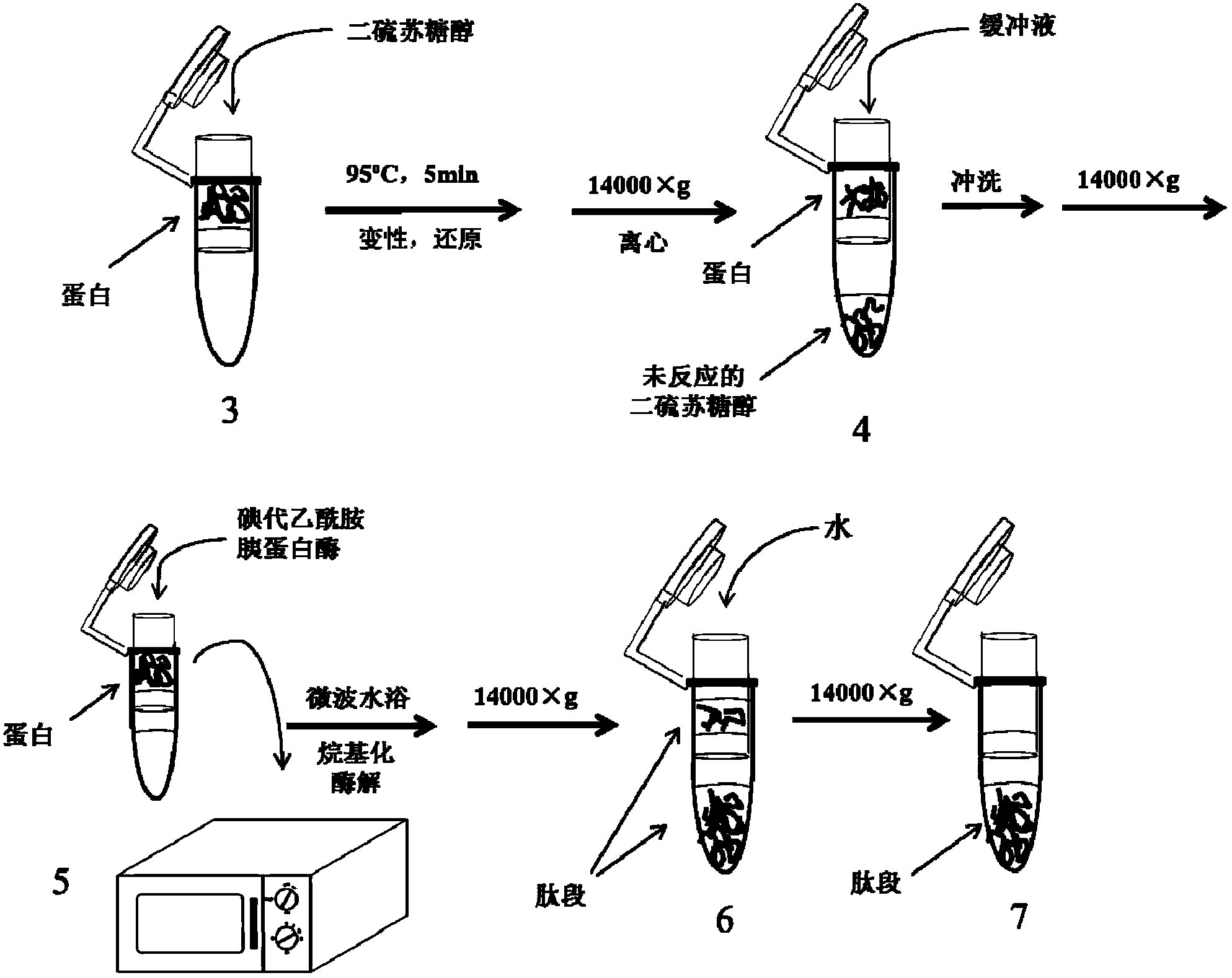

In-situ rapid preprocessing method for protein samples

ActiveCN104075931AReduce lossesAchieve replacementPreparing sample for investigationPretreatment methodUltrafiltration

The invention relates to an in-situ rapid preprocessing method for protein samples. The whole preprocessing process of the protein samples is carried out in a centrifugal ultrafiltration device in situ, the denaturation process, the reduction process, the solvent replacement process, the alkylate process, the enzymolysis process and the impurity removal process of the protein samples are integrated, and enzymolysis of the protein samples is accelerated under assistance of microwaves. The method can remarkably improve the preprocessing flux of the protein samples; meanwhile, the whole preprocessing process of the samples is carried out in situ, and the recovery rate is high. In addition, the centrifugal ultrafiltration device can conveniently and rapidly achieve the purification of the samples and replacement of solvents, and enzymatic hydrolysate does not need an additional purification process and can be directly combined with subsequent efficient liquid chromatogram separation and mass spectrum identification.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

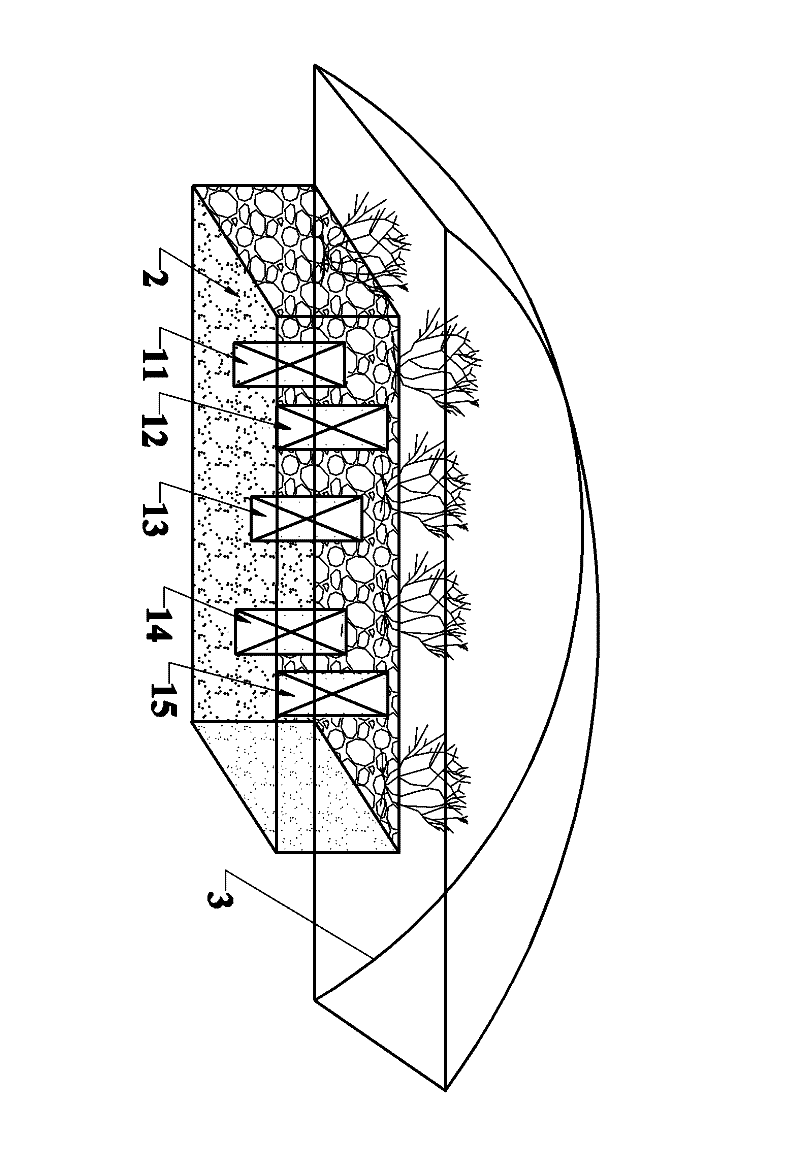

Constructed wetland with sewage treatment function

ActiveCN102491583AActiveAchieve removalMultistage water/sewage treatmentEnergy based wastewater treatmentConstructed wetlandOxygen

The invention relates to an environmental project able to treat sewage, especially to a constructed wetland with a sewage treatment function. According to the technical scheme of the invention, the constructed wetland with a sewage treatment function is characterized by comprising a wetland main body composed of a plant and a filling material. The wetland main body is provided with a heating functional device, an aerobic functional device, a carbon source adding and denitrification functional device, a physicochemical adsorption functional device and a sludge discharge functional device. The carbon source adding and denitrification functional device consists of a hollow filtering cavity and a carbon source substance displaced in the hollow part of the hollow filtering cavity. The physicochemical adsorption functional device includes a hollow filtering cavity and a fine-grained physicochemical adsorption filling material disposed in the hollow part of the hollow filtering cavity. By means of the above scheme, the invention overcomes problems existing in prior art, and provides a novel constructed wetland with a sewage treatment function, wherein, the constructed wetland has the advantages of high removal efficiency, stable operation, and difficult obstruction, etc.

Owner:贵州威尔森环保生物工程有限公司

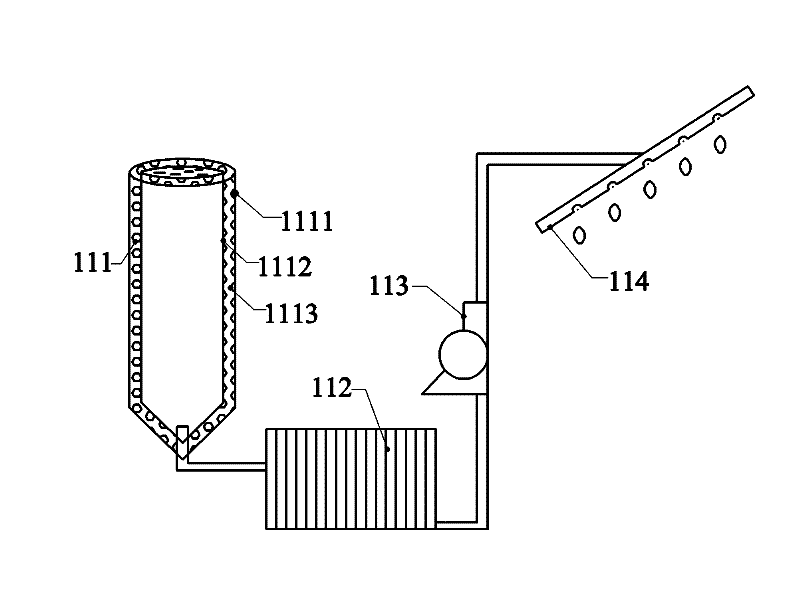

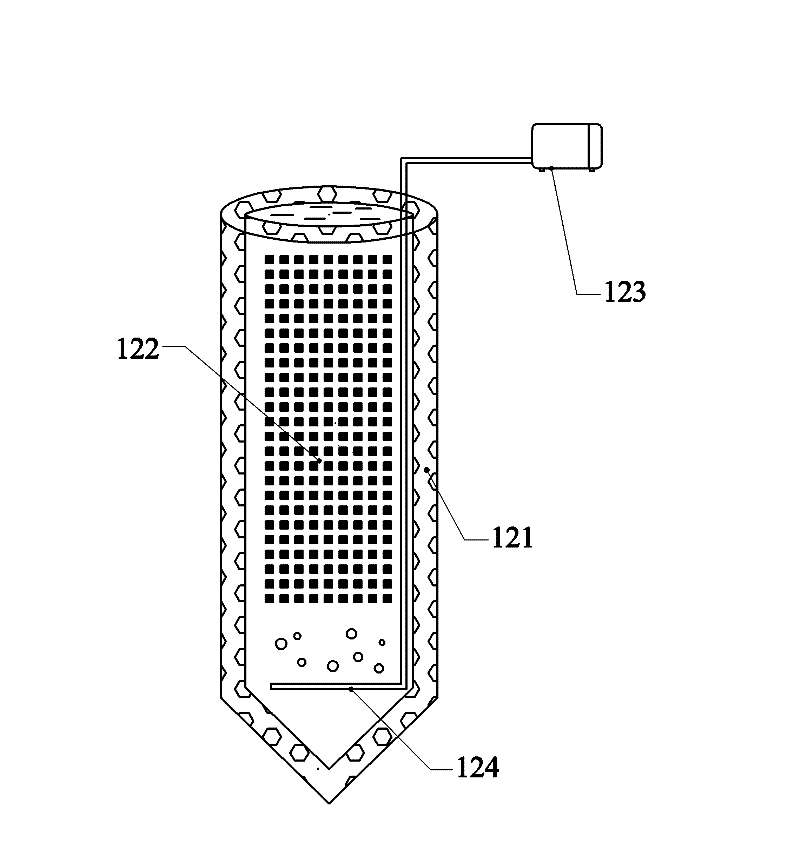

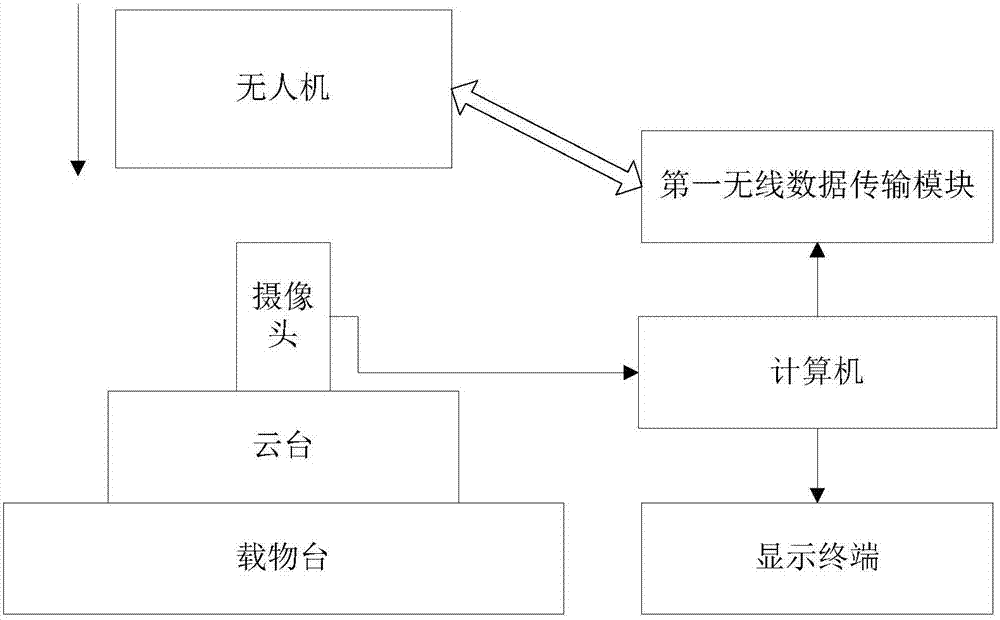

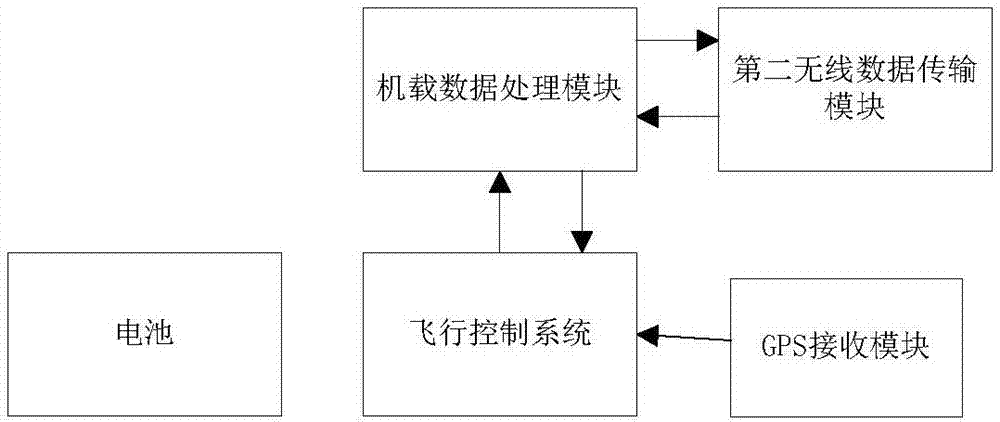

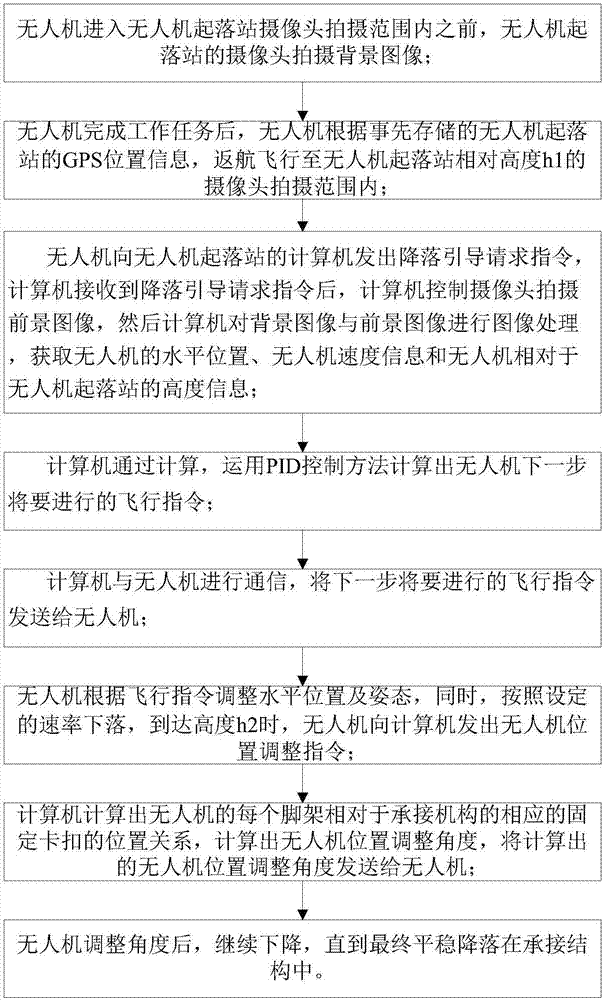

Unmanned aerial vehicle flight landing system and method based on image processing

ActiveCN106864751AFast recognitionFast falling speedAnchoring installationsLanding aidsCamera lensImaging processing

The invention discloses an unmanned aerial vehicle flight landing system and method based on image processing. The system comprises an unmanned aerial vehicle and an unmanned aerial vehicle take-off and landing station. The unmanned aerial vehicle take-off and landing station comprises a carrying table arranged on the ground. A precise positioning and fixing device assisting in landing of the unmanned aerial vehicle is mounted on the carrying table. A holder is mounted on the precise positioning and fixing device assisting in landing of the unmanned aerial vehicle. A camera is mounted on the holder, and a camera lens of the camera faces upward. The camera and the holder are both connected with a computer. The computer controls rotation of the holder to drive the camera to rotate, and accordingly the shooting direction of the camera is adjusted. The computer controls the camera to shoot pictures. The computer is in communication connection with the unmanned aerial vehicle through a first wireless data transmission module. The computer is further connected with a display terminal. The unmanned aerial vehicle flight landing system and method have the beneficial effect that an all-weather centimeter-level precise landing function of the multi-rotor unmanned aerial vehicle is achieved based on image processing by adoption of a multistratum PID control technology.

Owner:SHANDONG UNIV +1

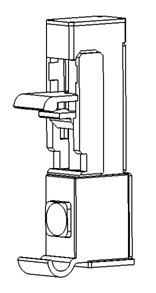

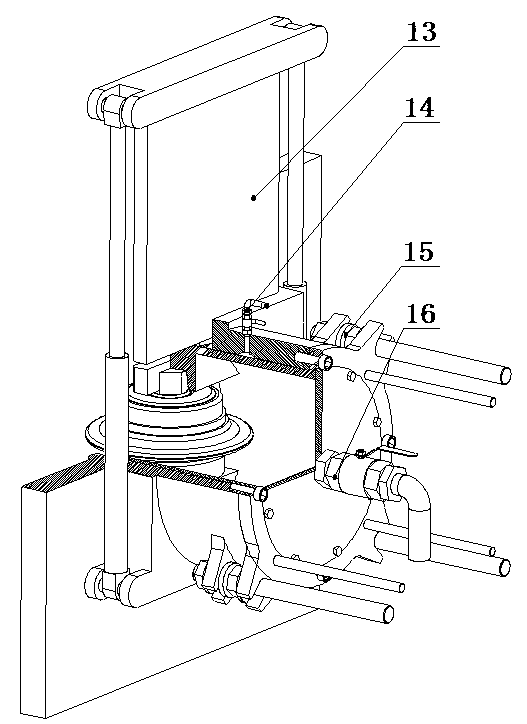

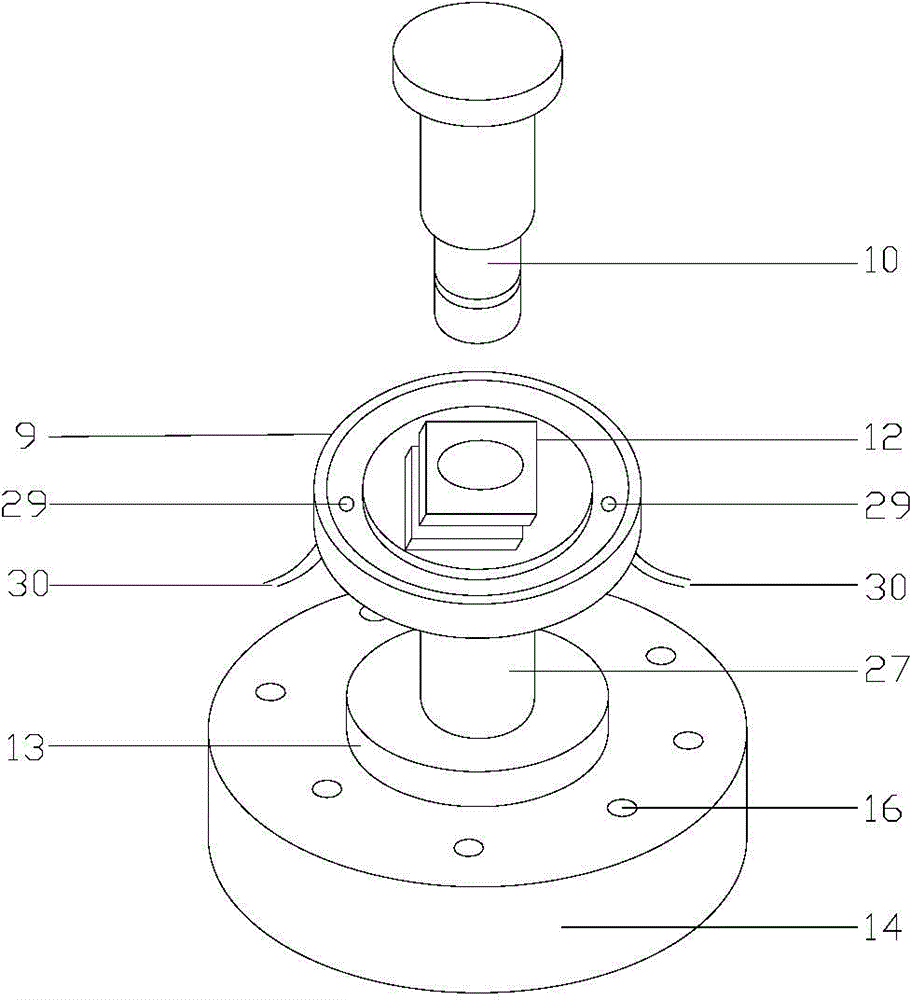

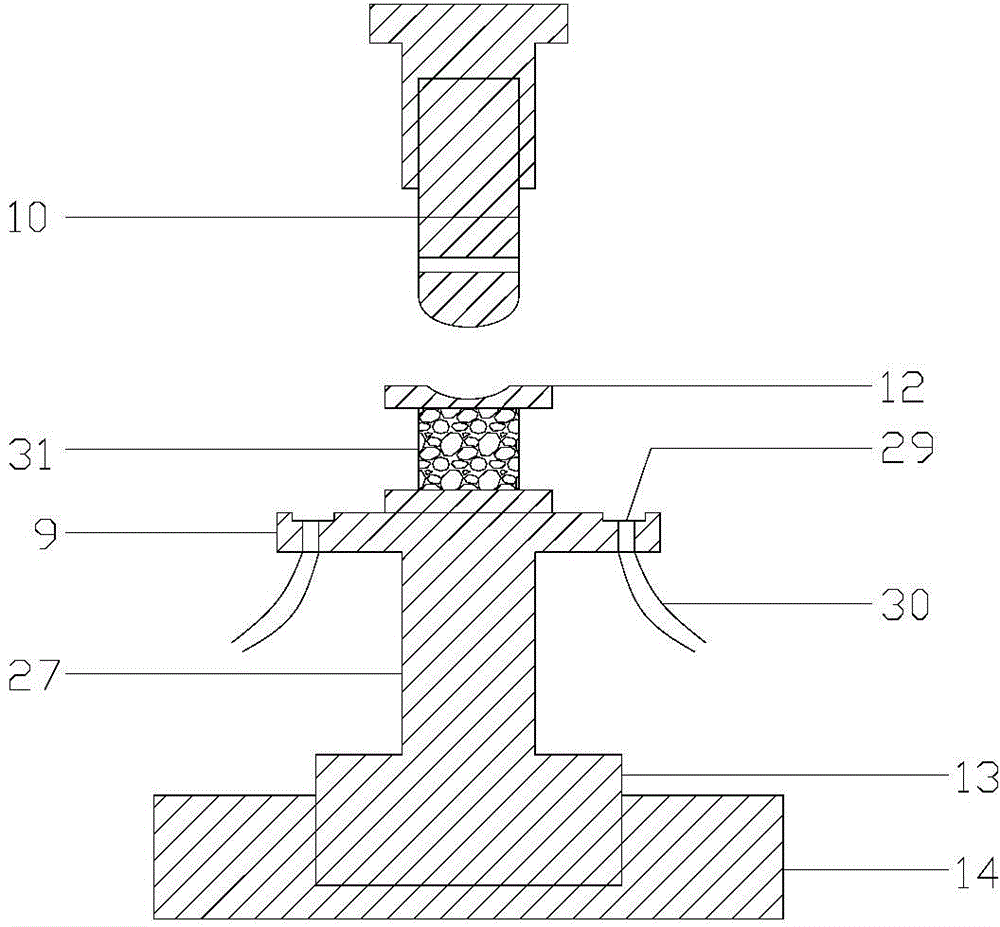

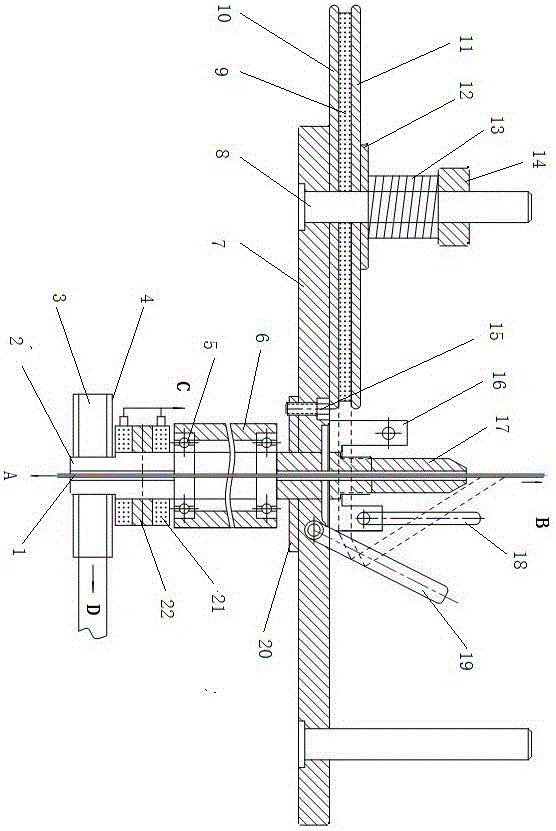

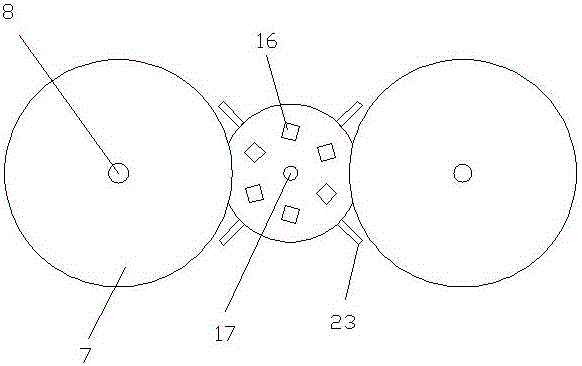

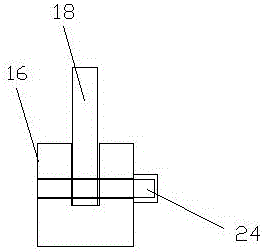

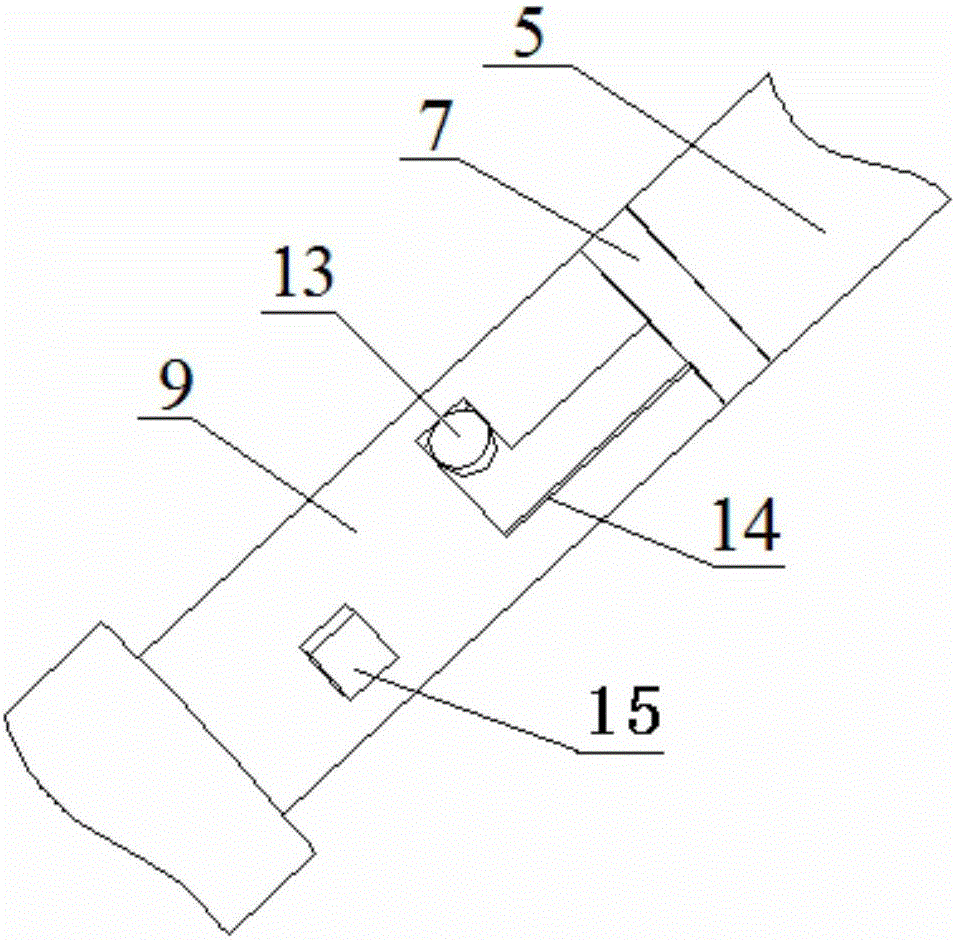

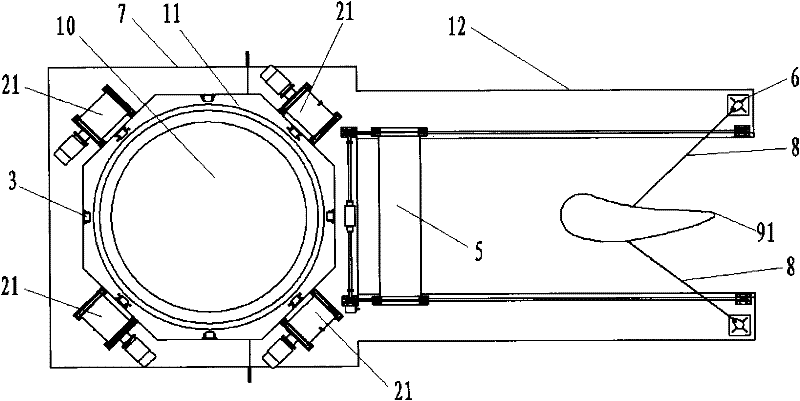

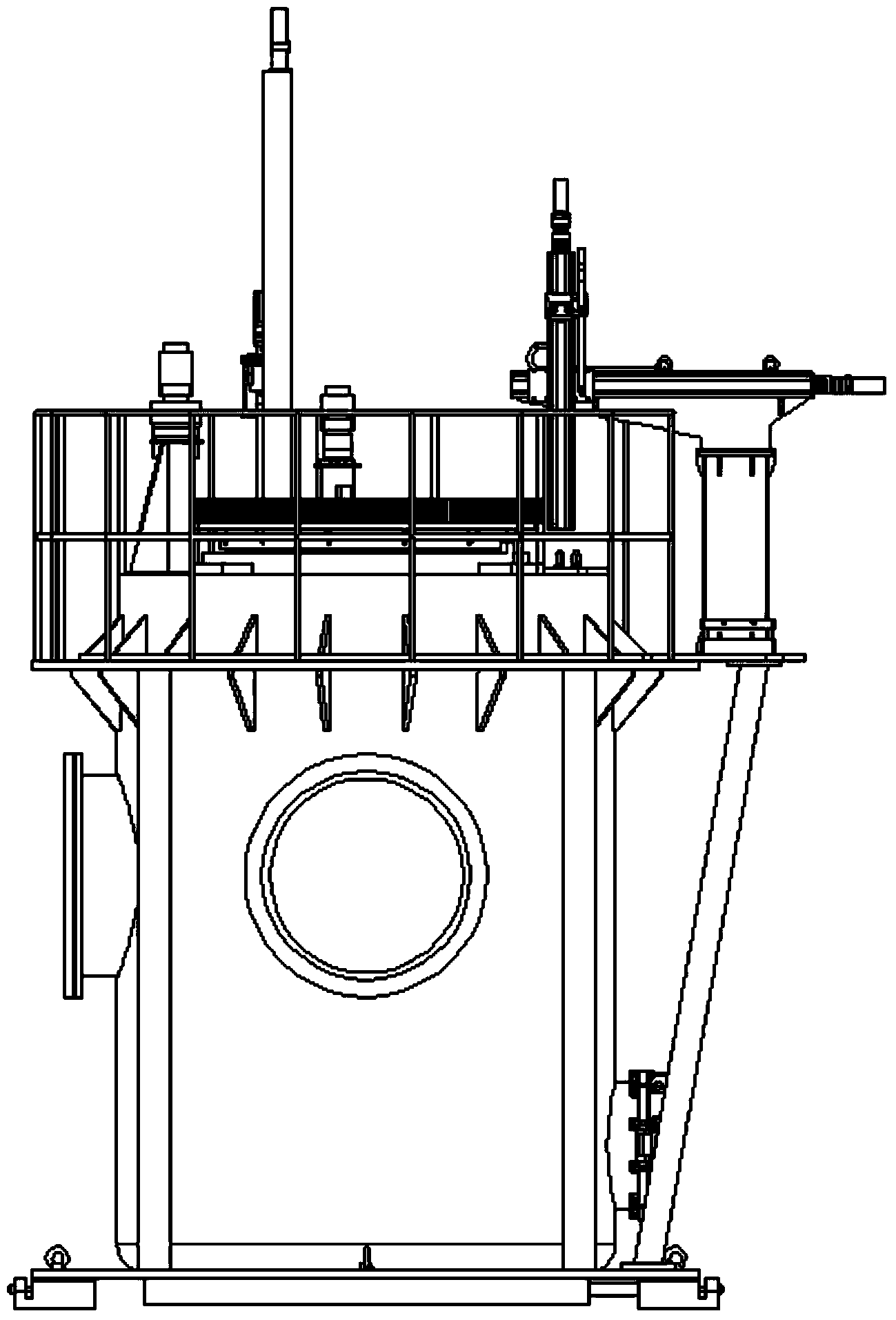

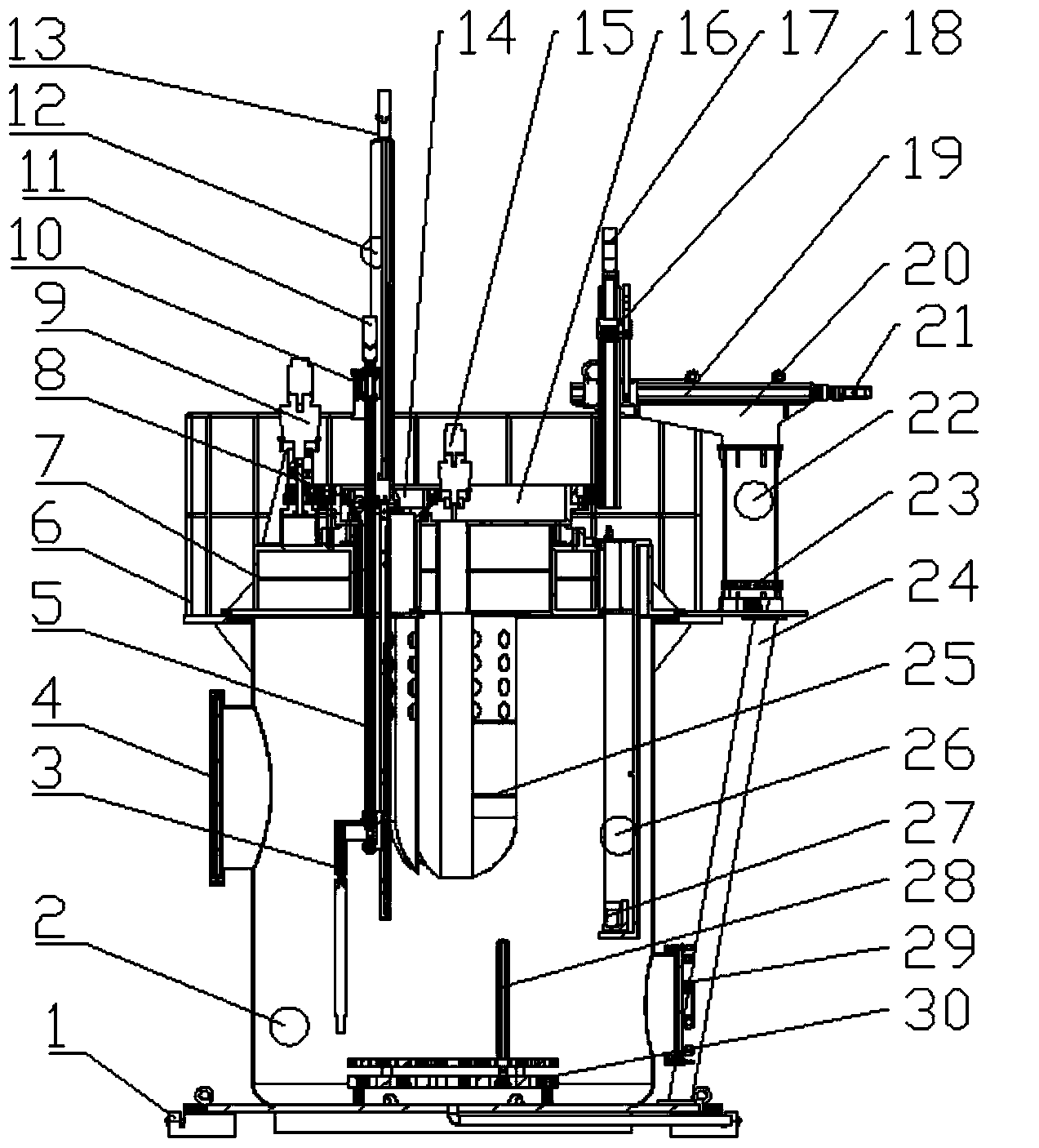

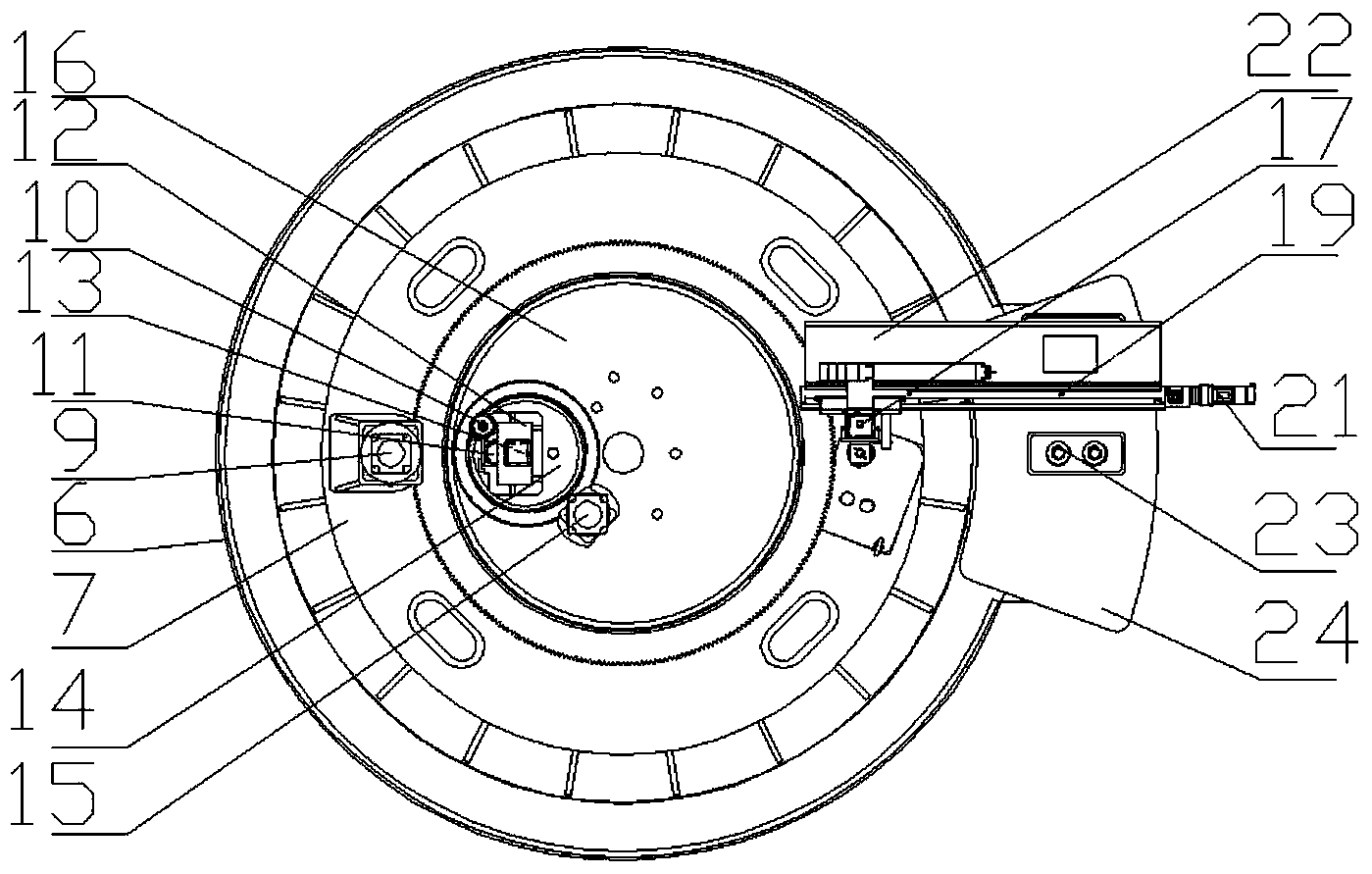

Normal-pressure hobbing cutter changing device

The invention discloses a normal-pressure hobbing cutter changing device. The device comprises a tool apron (3), a cutterhead panel (2) connected with the tool apron (3) and a hobbing cutter (1) arranged on the tool apron (3), wherein the tool apron (3) is connected with a pressure retaining device which is connected with a lubricating device (14) and a high-low pressure isolating device (13), and a pressure relieving device (16) and a tool apron detaching device (15) connected with the tool apron (3) are arranged at the tail part of the tool apron (3). According to the device, the hobbing cutter of a shield is changed under a pressure retaining condition in a normal pressure environment through close matching of the pressure retaining device, the lubricating device, the high-low pressure isolating device, the pressure relieving device arranged at the tail part of the tool apron and the tool apron detaching device connected with the tool apron 3, wherein the lubricating device and the high-low pressure isolating device are arranged on the pressure retaining device; therefore, the risk of change of the cuter under a high-pressure water condition in a construction process of tunnels crossing over rivers and oceans is effectively overcome, the physical health of cutter changing workers is protected, the construction progress is accelerated, the construction period is shortened and the construction cost is lowered.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

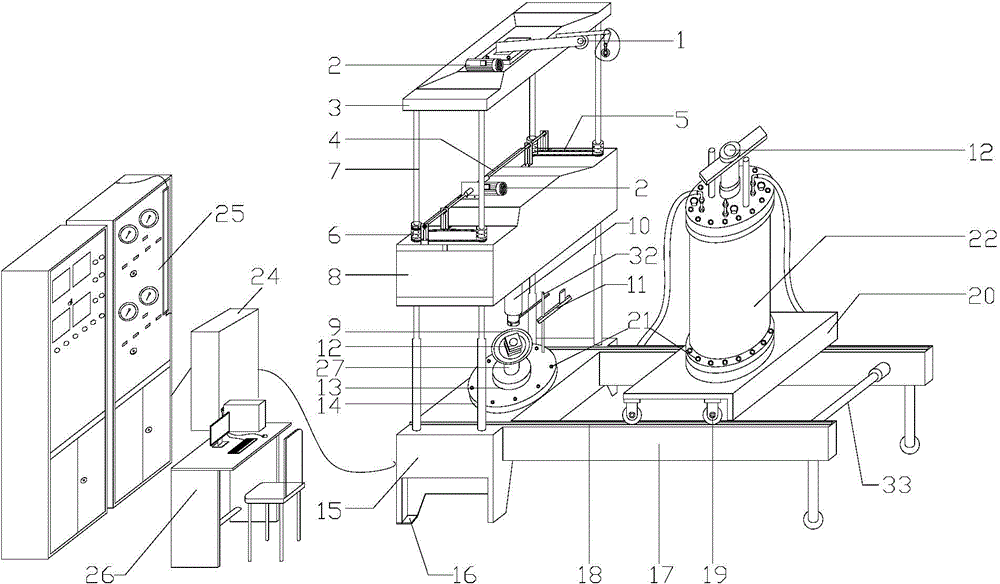

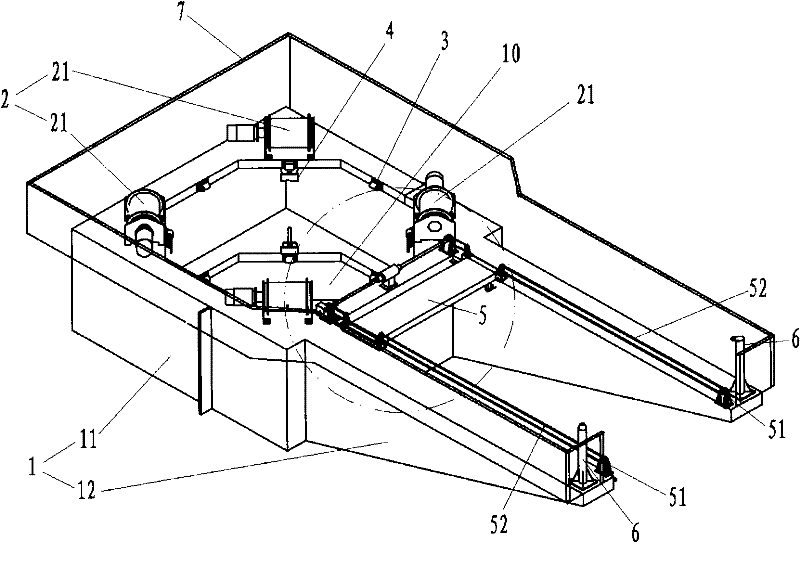

Large-sized fluid-solid-heat multi-field coupling test loading system

ActiveCN104458428AChange test loading spaceReduce R&D costsMaterial strength using tensile/compressive forcesAxial pressureMulti field

The invention relates to a large-sized fluid-solid-heat multi-field coupling test loading system. The large-sized fluid-solid-heat multi-field coupling test loading system consists of a loading framework main body, a loading platform, a pressure chamber inlet-outlet platform and a data acquisition system. The large-sized fluid-solid-heat multi-field coupling test loading system has the following advantages: firstly, the test loading space is changed by virtue of an adjustable central crossbeam, and the multi-field coupling test for test samples of different types and different sizes can be realized by selecting different pressure chambers for different test samples of different types; secondly, under the situation that the pressure chamber is not used, a hydraulic crack test for concrete and rock under high water pressure can be carried out, and a conventional material parameter of the material can be determined; thirdly, by adopting a pressure chamber hoisting device and a wheel inlet-outlet platform device, the replacement of different test samples and different pressure chambers can be conveniently realized; fourthly, by adopting the data acquisition device and data storage software, data such as water pressure, confining pressure, axial pressure and temperature variation can be fully automatically acquired, displayed and stored in real time in the whole process without interfering with each other.

Owner:HOHAI UNIV

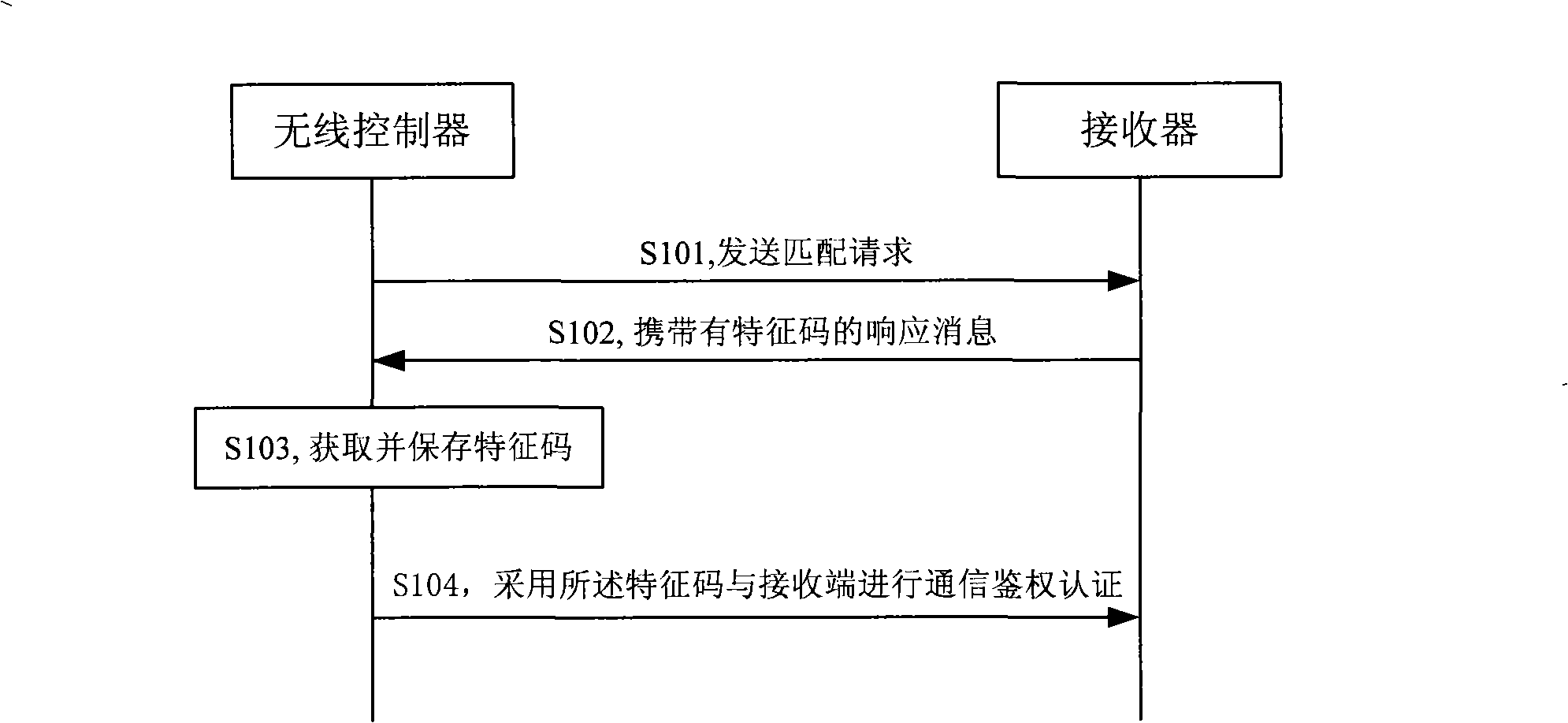

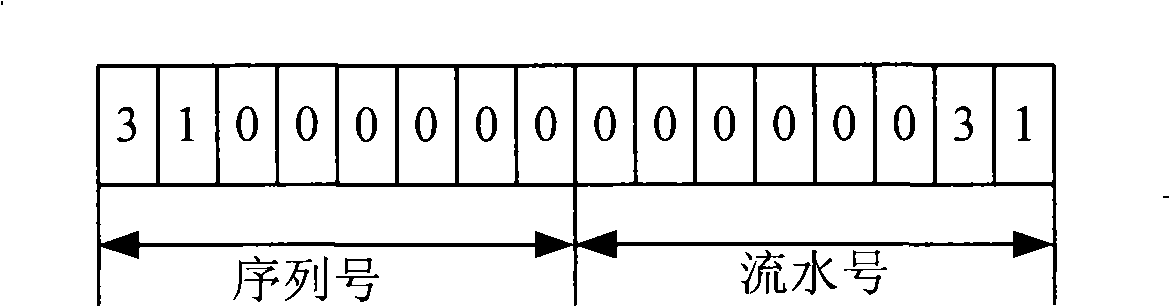

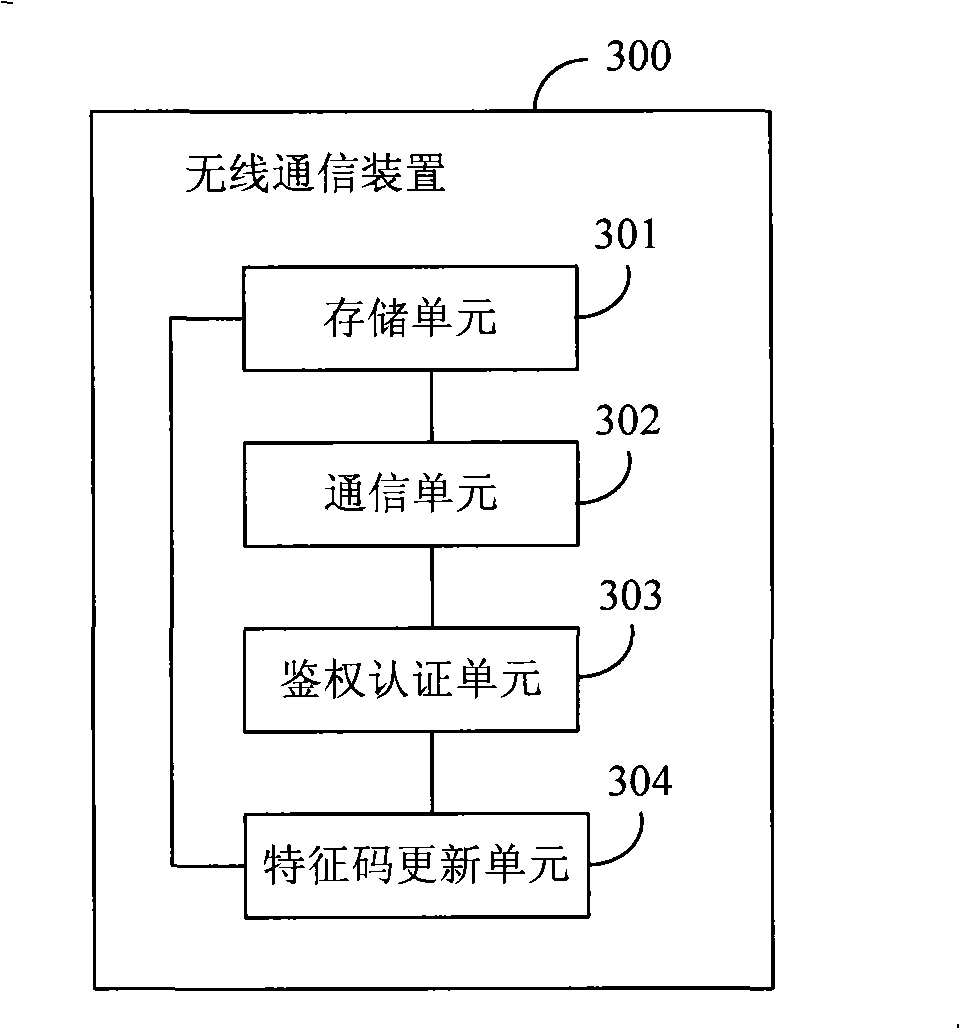

Matching authentication method, apparatus and system for radio communication apparatus

ActiveCN101309436AEasy curingRealize one-to-one correspondenceTelemetry/telecontrol selection arrangementsRadio/inductive link selection arrangementsCommunication unitCommunications system

The invention discloses a matching authentication method for wireless communication equipment. The method comprised the following steps: a device at the transmitting end sends a matching request to a device at the receiving end; the device at the transmitting end can be used for receiving the response messages feedback by the device at the receiving end, and the response messages are carried with feature codes; the feature codes are obtained through the end at the transmitting end, and the feature codes are taken as the authorization codes communicated with the receiving end. The invention also provides a wireless communication device with a function of matching authentication correspondingly. The wireless communication device comprises a memory unit, a communication unit, and an authorization unit and a feature code updating unit. The invention also provides a wireless communication system with the function of matching authentication. By adopting the method, the wireless controller is corresponding to the controlled equipment uniquely, thus the security of operational control can be ensured, and the interchangeability of the control equipment can be met.

Owner:SANY AUTOMOBILE MFG CO LTD

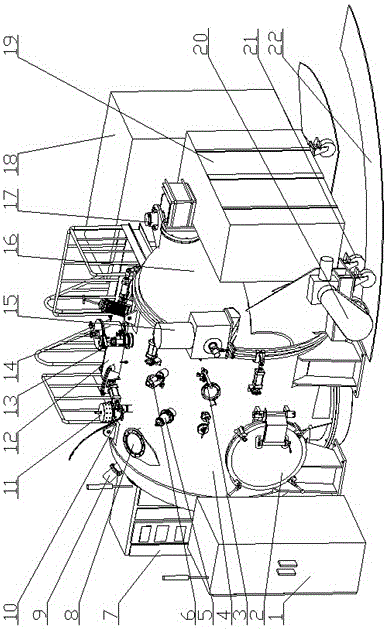

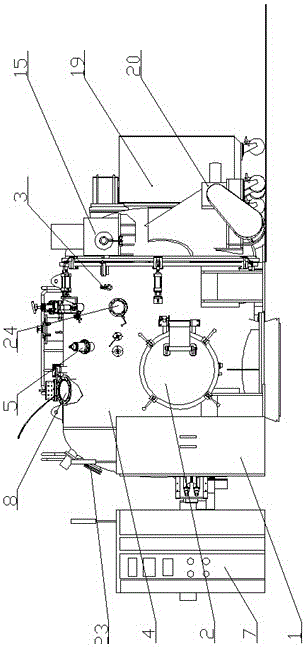

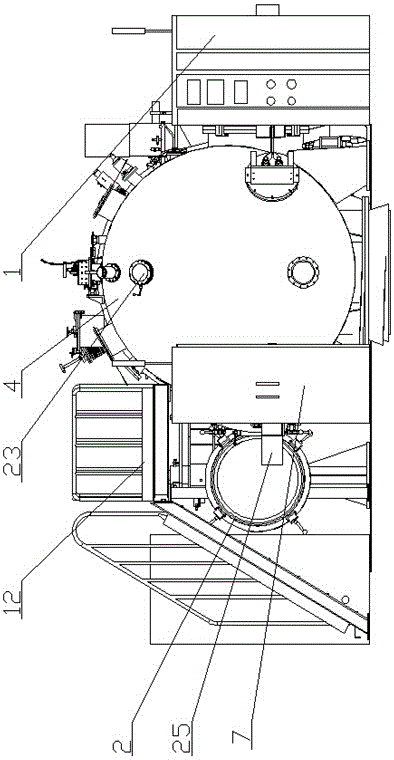

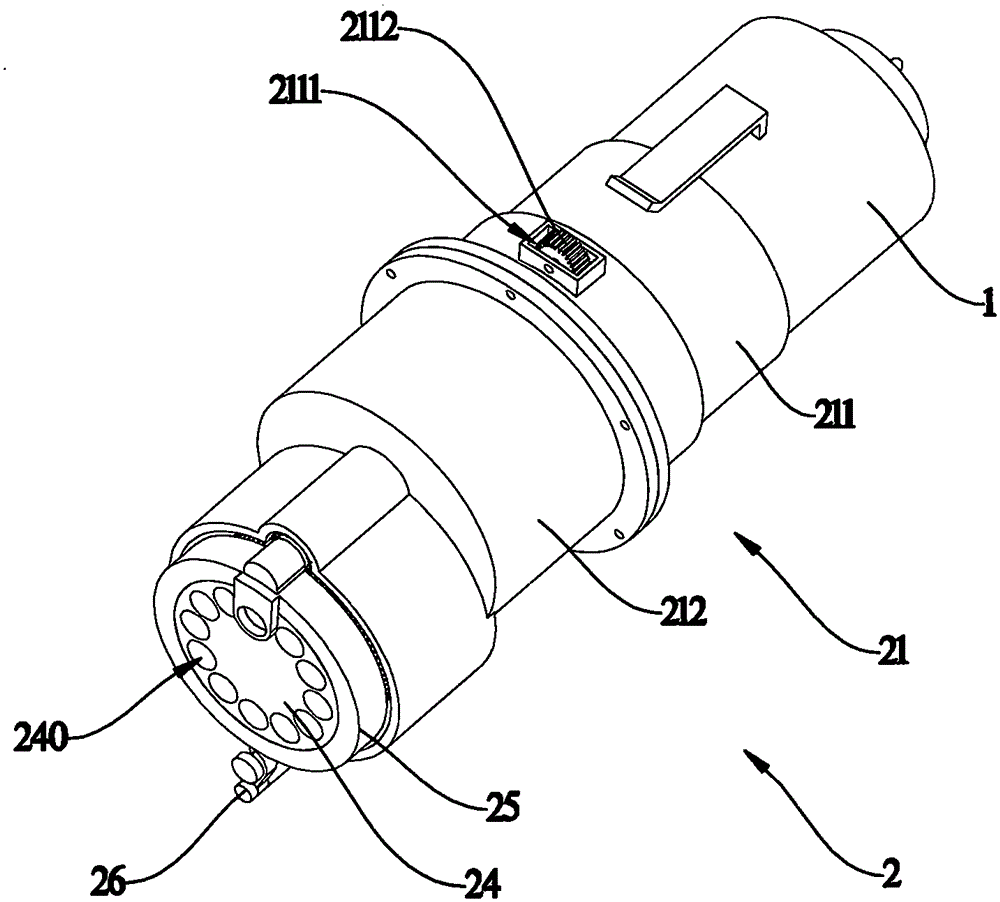

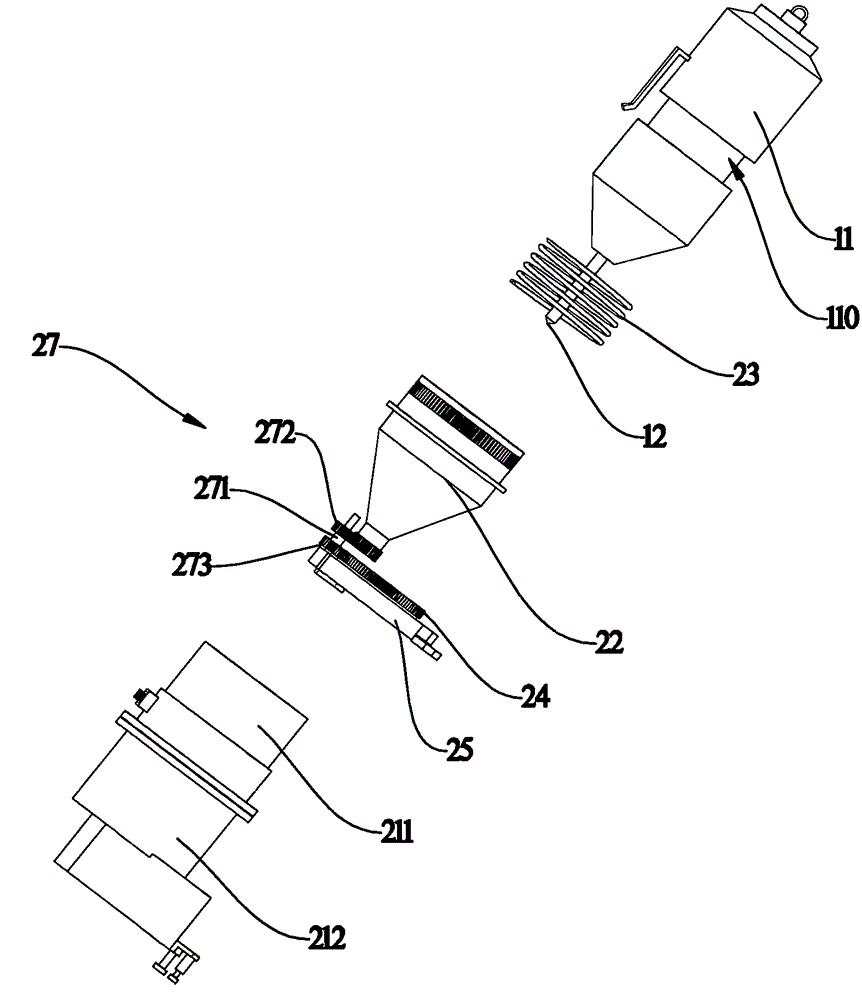

Vacuum melting gas atomization milling device

ActiveCN106077685ASimple structureAchieve replacementMelt-holding vesselsMaterials scienceFunctional module

The invention discloses a vacuum melting gas atomization milling device. The vacuum melting gas atomization milling device comprises a smelting furnace body, at least two tundish functional modules, a moving mechanism and an atomization device, wherein a melting crucible is arranged inside the smelting furnace body; the melting crucible pours materials into the tundish functional modules through a material pouring electric elevator; the tundish functional modules are mounted in the position, above the atomization device, inside the smelting furnace body; the tundish functional modules can perform horizontal sliding and / or up-down lifting motion inside the smelting furnace body through the moving mechanism; the moving mechanism is used for changing the tundish functional modules for utilization; and the tundish functional modules are connected with the atomization device. According to the vacuum melting gas atomization milling device, the structure is simple; the plurality of tundish functional modules and the matched moving mechanism are adopted, so that changing between the plurality of tundish functional modules is achieved, and the problem that in the prior art, when a tundish functional module breaks down, overhauling requires to be carried out under the condition of production halt and the vacuum melting gas atomization milling operation cannot be continuously carried out is solved; and the operation is convenient.

Owner:HUNAN JUTA TECH

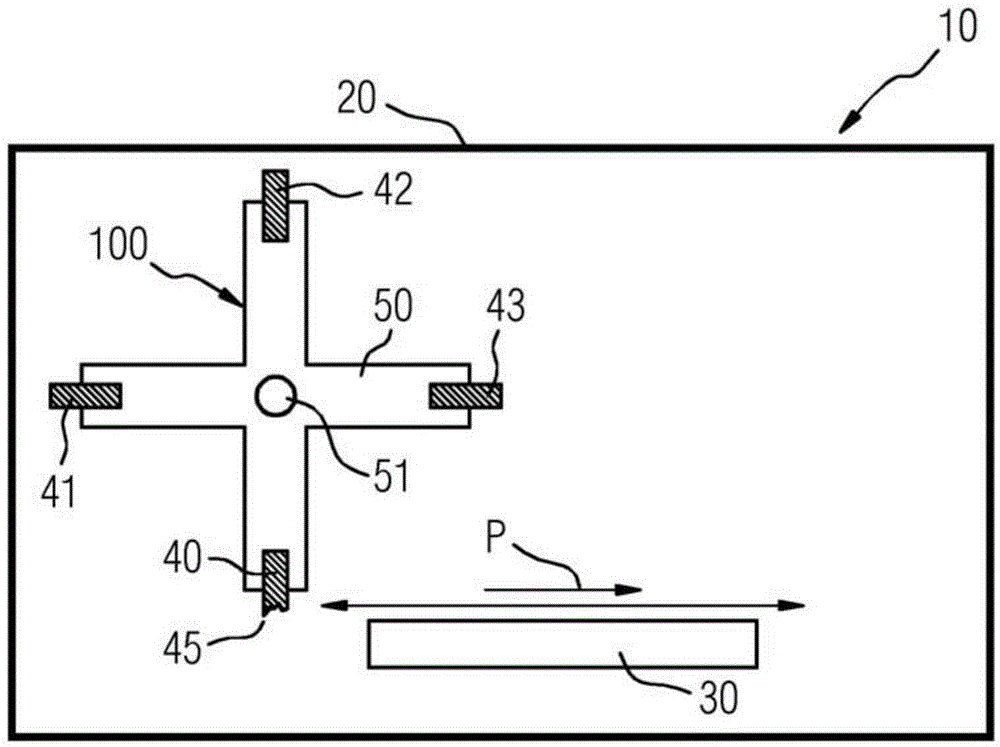

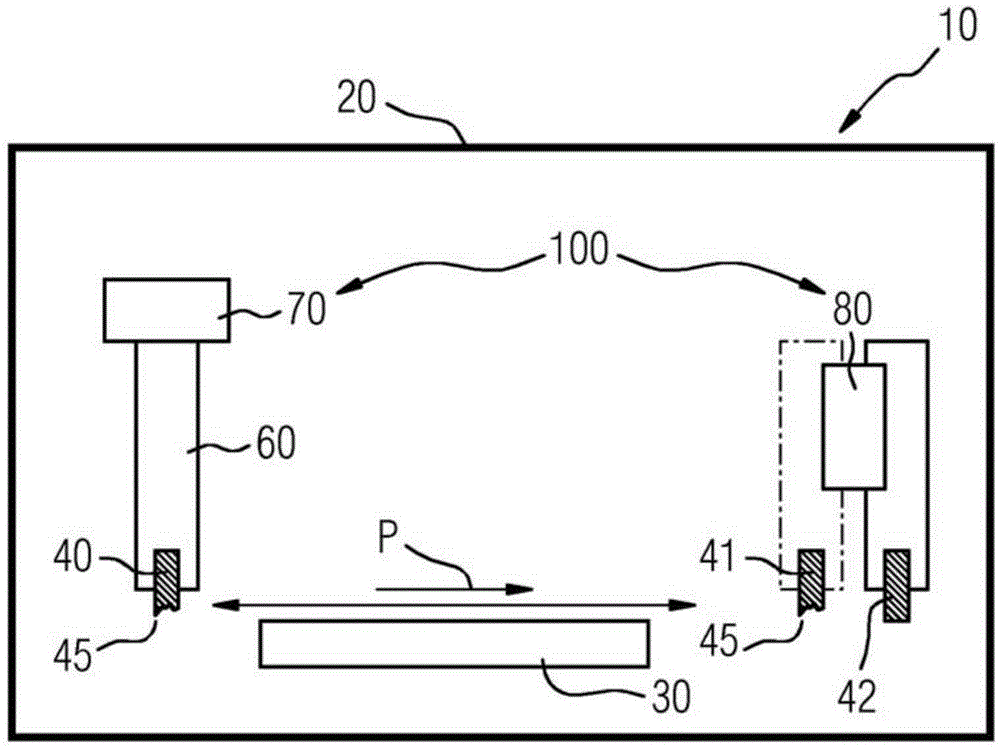

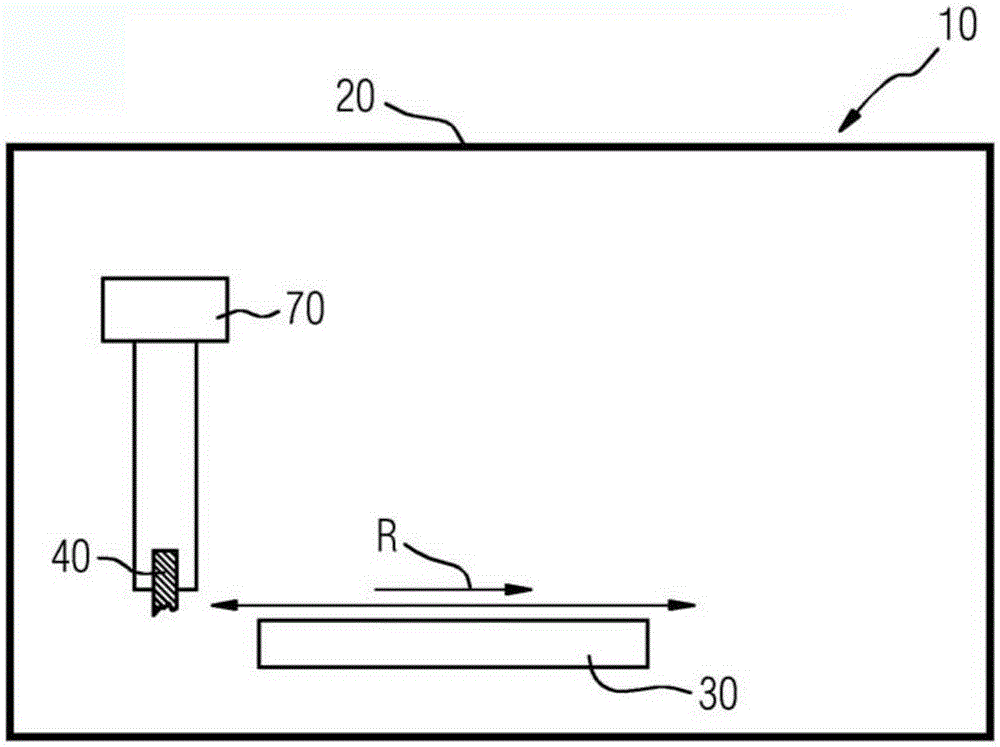

Arrangement for coating a powder

InactiveCN105408040AAchieve replacementPrevent openingAdditive manufacturing apparatusLiquid surface applicatorsMetal powderCoating

The invention relates to an arrangement (10) with a processing chamber (20), a coating platform (30) which can be found in the processing chamber (20), and a coating device with a coating element (40) which can be found in the processing chamber (20) for coating a powder, in particular a metal or ceramic powder. According to the invention, the arrangement (10) has an exchanging device (100) which is suited for exchanging at least one portion of the coating element (40) with another portion of the same coating element (40) or for exchanging the entire coating element (40) with another coating element (41, 42, 43) within the processing chamber (20) when the processing chamber (20) is closed. The exchanging device (100) can comprise a multiple head (50), in particular a pivoting head or a revolving head, an exchanging station (80), and / or a moving device (70) which allows a coating element (40) portion that is to be exchanged to be moved or pushed away. A part of the coating element (40) can also be rolled on a supply roller (230), and the coating element portion can be exchanged by unrolling the coating element from the supply roller (230). Together with the exchanging device (100), a wear determining device (300) is also preferably provided, said wear determining device being capable of measuring the wear of the coating element (40) and triggering an automatic coating element exchange or coating element portion exchange by means of the exchanging device (100).

Owner:SIEMENS AG

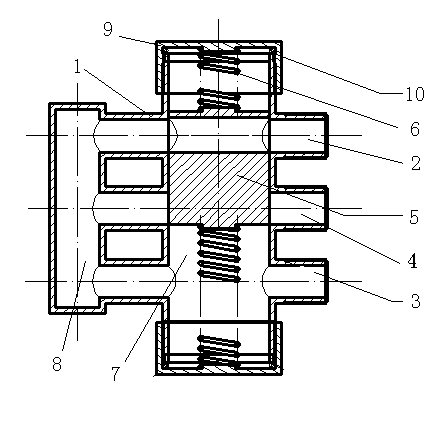

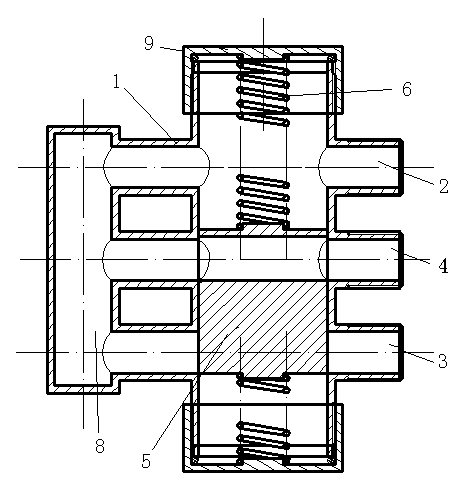

Automatic cold water and hot water diverting valve

InactiveCN103016790AEasy to repair and replaceSmooth transmissionOperating means/releasing devices for valvesMultiple way valvesThermodynamicsAutomatic control

The invention discloses an automatic cold water and hot water diverting valve, which comprises a valve body provided with a valve cavity, wherein the valve body is provided with a water inlet, a cold water outlet and a hot water outlet that are communicated with the valve cavity; a piston type valve core is further arranged in the valve cavity; two-way shape memory alloy is further connected between the valve core and the valve body; a phase transition temperature of the two-way shape memory alloy is 40-55 DEG C; when the temperature of the two-way shape memory alloy is less than the phase transition temperature, the valve core can block the hot water outlet and communicate the water inlet with the cold water outlet; and when the temperature of the two-way shape memory alloy is greater than the phase transition temperature, the deformation occurs so that the valve core can displace to block the cold water outlet and communicate the water inlet with the hot water outlet. The automatic cold water and hot water diverting valve can automatically divert a cold water part in a hot water supply pipe so as to save water and avoid waste; and further the automatic cold water and hot water diverting valve is simple and compact in structure, low in cost and convenient to install, and achieves the automatic control.

Owner:CHONGQING UNIV

Cable wrapping machine

ActiveCN106448948AAchieve replacementEasy to replaceInsulating conductors/cablesEngineeringGuide tube

The invention discloses a cable wrapping machine. The cable wrapping machine comprises a frame, a pay-off guide wheel and a take-up guide wheel. A vertical cable guide tube is arranged on the frame and in coaxial arrangement with a spindle, and a mounting seat is arranged on the spindle which is driven to rotate by a motor. Rotating plates are symmetrically fixed to two sides of the mounting seat, a wrapping belt mounting vertical shaft is vertically arranged on each rotating plate, and a wrapping belt lower tray, a wrapping belt and a wrapping belt upper tray sequentially sleeves each mounting vertical shaft. Two groups of belt guide shafts are arranged on the mounting seat; the first group of the belt guide shafts is arranged on the outer side of the cable guide tube, and an included angle between first belt guide shafts and the cable guide tube is adjustable in a range of 0-180 degrees; the second group of the belt guide shafts is arranged close to the rotating plates, and an included angle between second belt guide shafts and the cable guide tube is adjustable in a range of 0-90 degrees; each rotating plate corresponds to one of the first belt guide shafts and one of the second belt guide shafts. The cable wrapping machine has advantages that replacement of wrapping belts can be realized without cutting of cores when the wrapping belts are used up, convenience in replacement is realized, core wires are unaffected, and produced cables are high in quality.

Owner:SHANDONG KUNYU CABLE

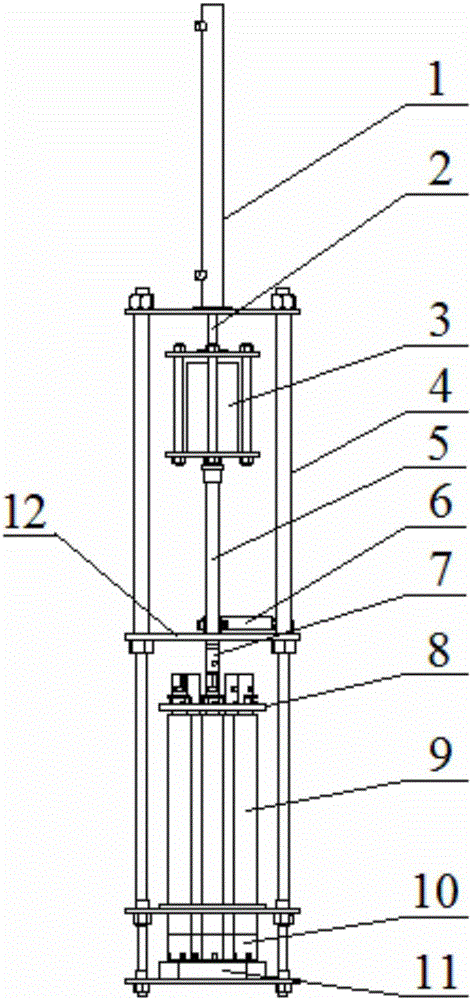

Small deep-sea multi-tube coring drilling rig

InactiveCN105863541AInhibit sheddingRapid positioningDrilling rodsUnderwater drillingRock coreOperation point

The invention relates to a small deep-sea multi-tube coring drilling rig which is equipment capable of being mounted on a deep-sea remotely-operated vehicle (ROV) or deep-sea human occupied vehicle (HOV) and other subsea equipment to obtain a seabed rock core through drilling and sampling. A feed oil cylinder, a power head, a drill rod bin and a drill rod conversion mechanism mounted on a rack are arranged on the drilling rig; the feed oil cylinder is connected with the power head through an oil cylinder piston rod; an output shaft of the power head is connected with a connecting head through an extension tube; the connecting head is connected with the drilling rig by using a clamping groove type quick plugging-connection structure; drill rods in the drill rod bin can be replaced by rotating the drill rod bin at a certain angle through the drill rod conversion mechanism. The drilling rig provided by the invention has advantages of compact structure, high reliability and high operation efficiency, can core multiple times at different operation points after entering water at a time, meets deep-sea shallow-hole coring operation requirements, and provides support for the investigation of deep-sea mineral resources.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

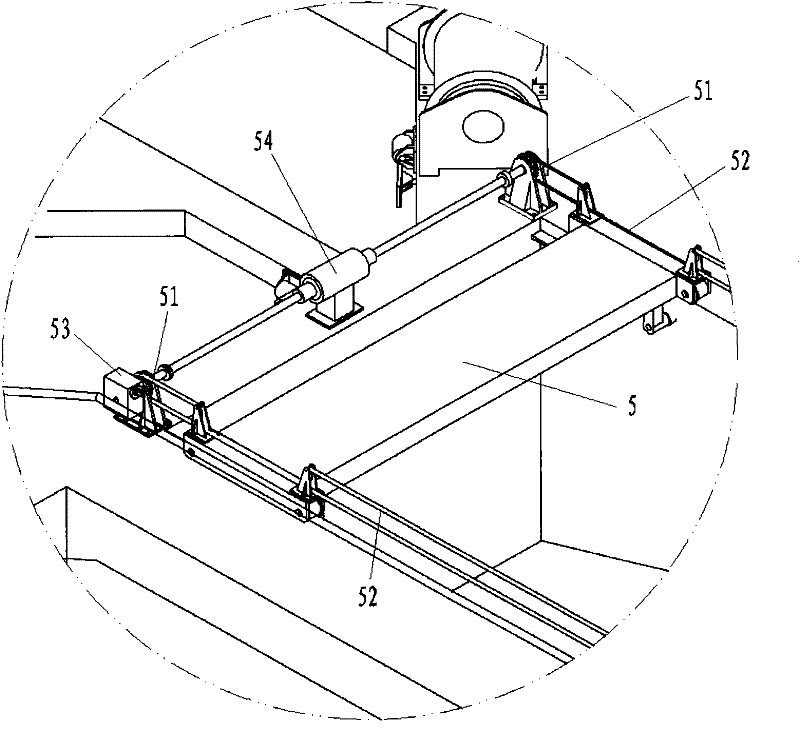

Wind turbine multifunctional platform and blade disassembly method

ActiveCN102275071AAchieve replacementThe geographical influence is smallEngine manufactureFinal product manufactureElectricityTurbine blade

The invention relates to a multifunctional platform of a wind turbine and a vane dismantling method. The multifunction platform comprises a platform frame, a winch mechanism, a plurality of tower barrel clamping mechanism, a mobile trolley and two vane adjusting supports and two groups of vane dragging mechanisms, wherein the platform frame comprises a base with an annular central hole, and two mutually parallel support arms; the winch mechanism is used for realizing up and down translation of a platform; the plurality of tower barrel clamping mechanism are annularly fixed on the periphery ofthe annular central hole of the platform and used for preventing the platform frame from rotating; the mobile trolley slides on the two support arms; and the two vane adjusting supports and the two groups of vane dragging mechanisms are used for dragging vanes to adjust the vanes to an appropriate height and angle. According to the method for vane dismantling by utilizing the multifunctional platform, the multifunctional platform is lift to the appropriate height of a tower barrel by utilizing the winch mechanism, working personnel are conveyed to all hoist point positions of the vane by the mobile trolley and tied up with straps, and the vane is dismantled and stably descends to a transport ship by utilizing a crane ship, a fan maintenance crane and the vane dragging mechanism.

Owner:SINOVEL WIND GRP

Semi-automatic screw feeding electric screwdriver

ActiveCN105082043AImprove work efficiencyAchieve replacementSpannersWrenchesSemi automaticEngineering

The invention provides a semi-automatic screw feeding electric screwdriver. The semi-automatic screw feeding electric screwdriver comprises a screwdriver body and a screw feeding device. The screw feeding device comprises an installing shell, a rotary table, a reset spring and a screw rotary table. The rotary table and the screw rotary table are rotationally arranged in the installing shell. The screwdriver body is movably arranged in a containing cavity of the rotary table, a drill bit at the front end of the screwdriver body is aligned with a screw hole in the screw rotary table, and the reset spring is arranged between the installing shell and the screwdriver body. When the installing shell is kept fixed and the screwdriver body is pushed forwards, the reset spring elastically deforms, the drill bit ejects a screw in the screw rotary table out, and when external force is removed, the installing shell and the screwdriver body are reset to the original position.

Owner:ANHUI KECHANG MACHINERY MFG

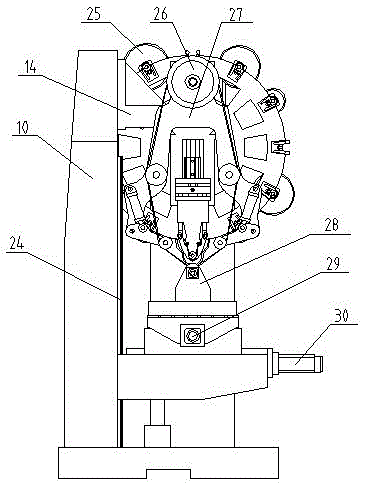

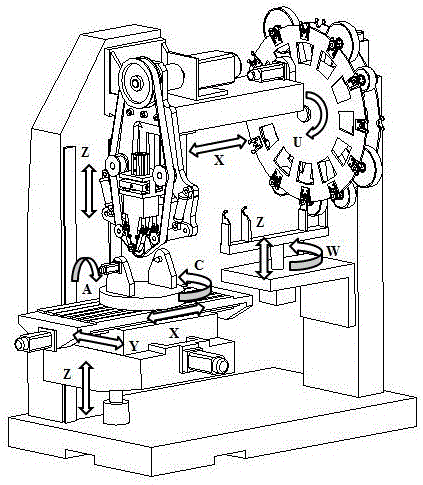

Abrasive belt grinding machining device with contact wheel depot

InactiveCN105058207AAxis position unchangedNo tape dropGrinding drivesBelt grinding machinesRotary stageSurface tooth

The invention discloses an abrasive belt grinding machining center with a contact wheel depot. The abrasive belt grinding machining center comprises a base, a stand column, a five-degree-of-freedom workbench, a power device, an abrasive belt supporting tensioning device, a grinding head device, the contact wheel depot and an automatic wheel replacing device. The five-degree-of-freedom workbench is composed of an X-direction saddle, a Y-direction saddle, a Z-direction saddle, a rotating table, a centre and a servo motor, and grinding machining of planes, revolution bodies and free curve faces can be achieved; an abrasive belt and a tensioning device are arranged on an abrasive belt supporting plate, and the abrasive belt is in the tensioning state all the time under the constant pressure effect of a tensioning air cylinder; the grinding head device can move in the X direction and the Z direction, so that the movement requirements in the grinding machining process and the wheel replacing process are met; contact wheels with different diameters, hardness degrees and surface tooth shapes are distributed on a rotary disc of the contact wheel depot in a circumferential manner; and an automatic wheel replacing mechanical arm is provided with four mechanical arm claws, and every two paired mechanical arm claws are used for clamping a contact wheel component to achieve the wheel replacing function. The abrasive belt grinding machining device is suitable for grinding machining of the planes, the revolution bodies and the free curve faces, and grinding machining with different surface quality requirements and different process requirements. The machining accuracy and the stability of parts are remarkably improved, the production period is shortened, and economic benefits are improved.

Owner:JILIN UNIV

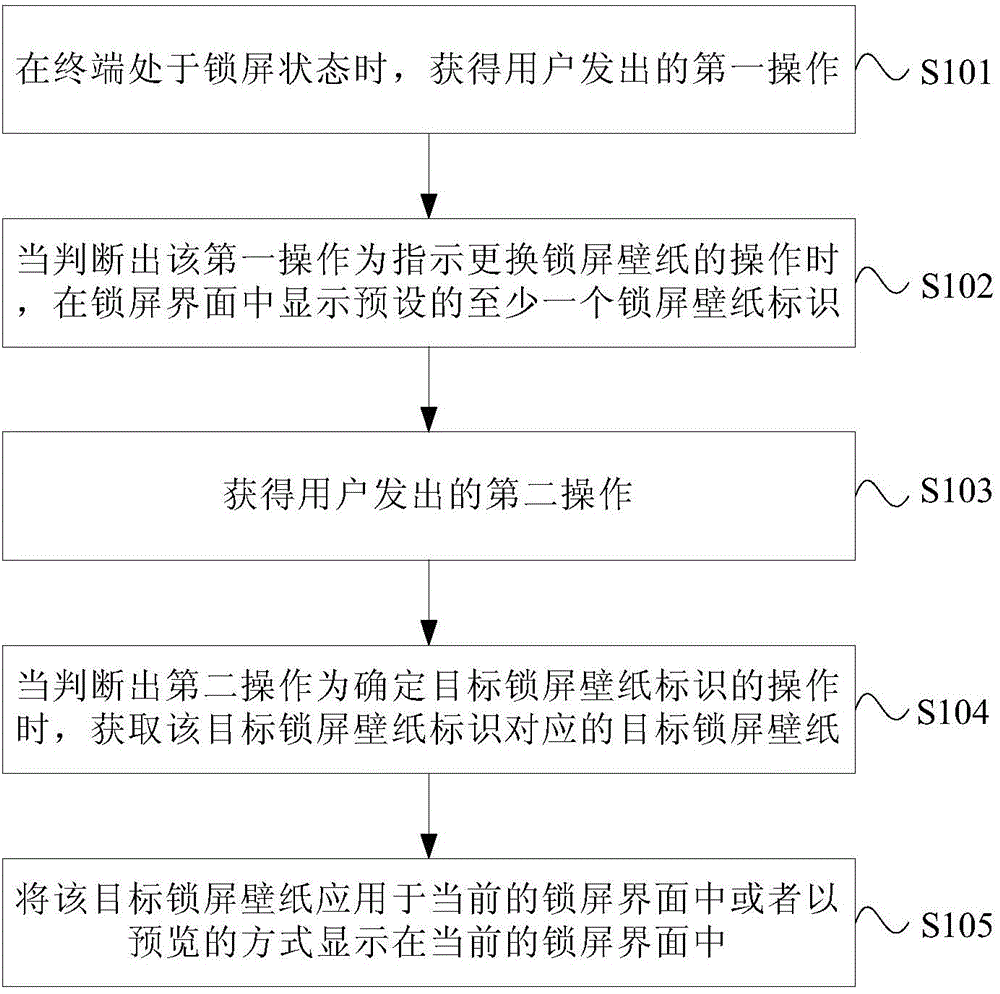

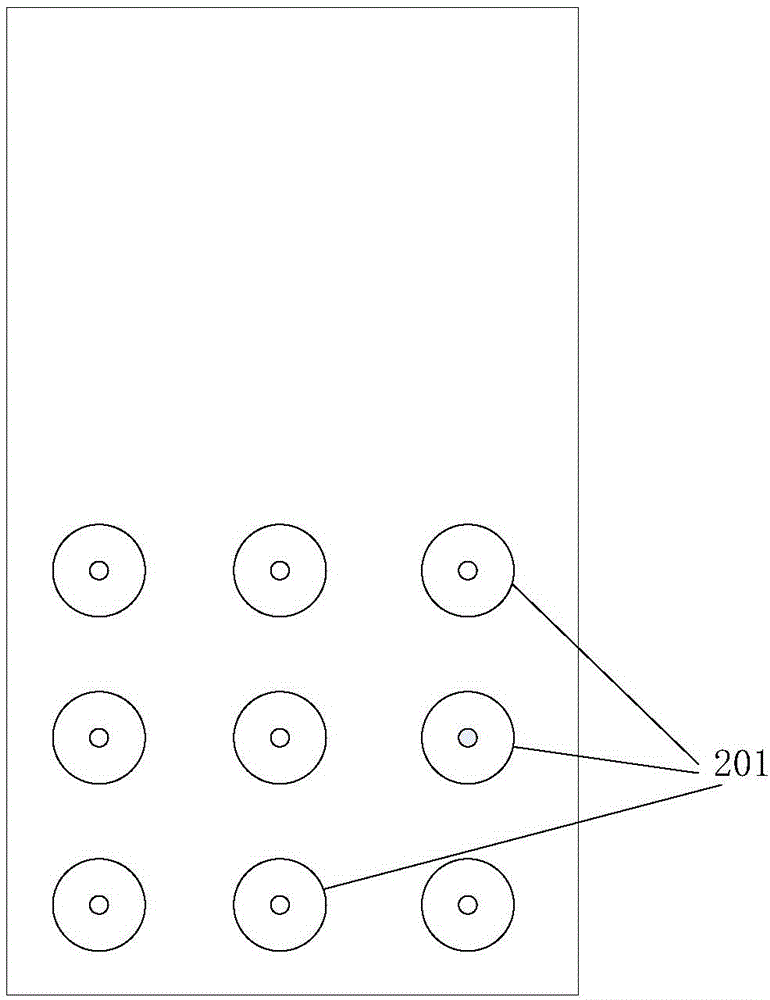

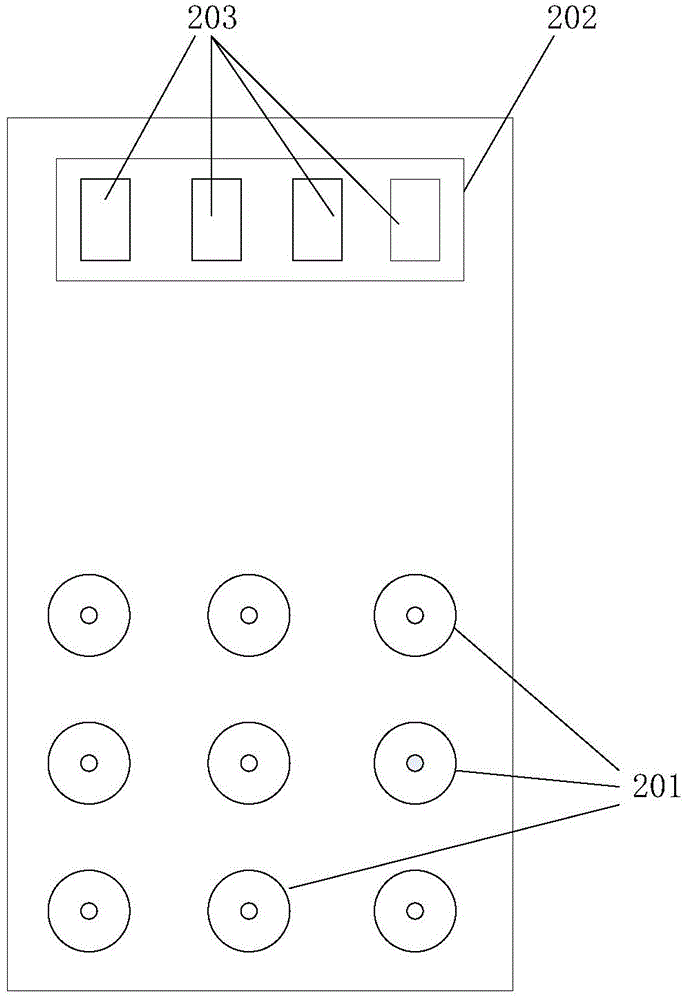

Lock-screen wallpaper replacement method and device

InactiveCN104423820AAchieve replacementImprove user experienceInput/output processes for data processingComputer terminalLock screen

An embodiment of the invention discloses a lock-screen wallpaper replacement method and device. The lock-screen wallpaper replacement method includes the steps: acquiring a first operation transmitted by a user when a terminal is in a lock-screen state; displaying at least one preset lock-screen wallpaper identifier in a lock-screen interface when judging that the first operation indicates lock-screen wallpaper replacement; acquiring a second operation transmitted by the user; acquiring target lock-screen wallpaper corresponding to a target lock-screen wallpaper identifier when judging that the second operation determines the target lock-screen wallpaper identifier; applying the target lock-screen wallpaper to the current lock-screen interface or displaying the target lock-screen wallpaper in the current lock-screen interface in a previewing mode. As the lock-screen wallpaper is replaced when the terminal is in the lock-screen state, corresponding lock-screen effects can be immediately displayed after the lock-screen wallpaper is replaced, and use experience of a user is improved.

Owner:BEIJING CHEETAH MOBILE TECH CO LTD +4

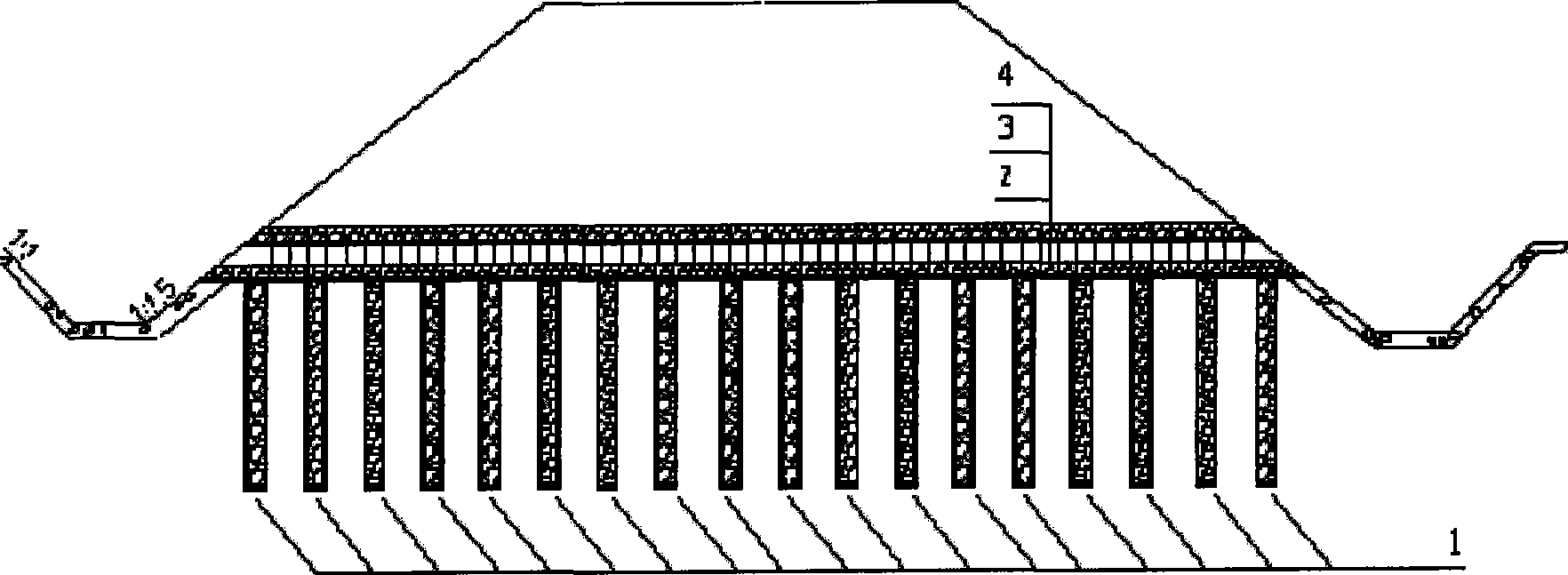

Bidirectional reinforcing and water drainage reinforcing means for highway soft soil foundation

The invention discloses a soft soil foundation two-way reinforcement and drainage reinforcement method for highways. The invention comprises the steps as follows: (1) the site is leveled and the pile positions are set out; (2) the construction is carried out by vibroflotation, hammering method, or vibrating tube sinking method to form a gravel pile; (3) the top of the pile is paved with Geocell coarse sand or gravel hardcore, the main composition body thereof is a Geocell layer with drain holes on the wall, the Geocell is filled with compact coarse sand or gravels, and the upper part and the lower part of the Geocell are respectively paved with drainage layers. By adopting the Geocell coarse sand or gravel hardcore and gravel pile two-way reinforcement and drainage structure, the method can realize a composite action of reinforcement, compaction, replacement and drainage on the soft foundation, effectively improve the strength and stability of the roadbed, reduce the differential settlement of the foundation and satisfy the requirement of traffic load increase on the bearing capacity and deformation of the roadbed.

Owner:HUNAN UNIV

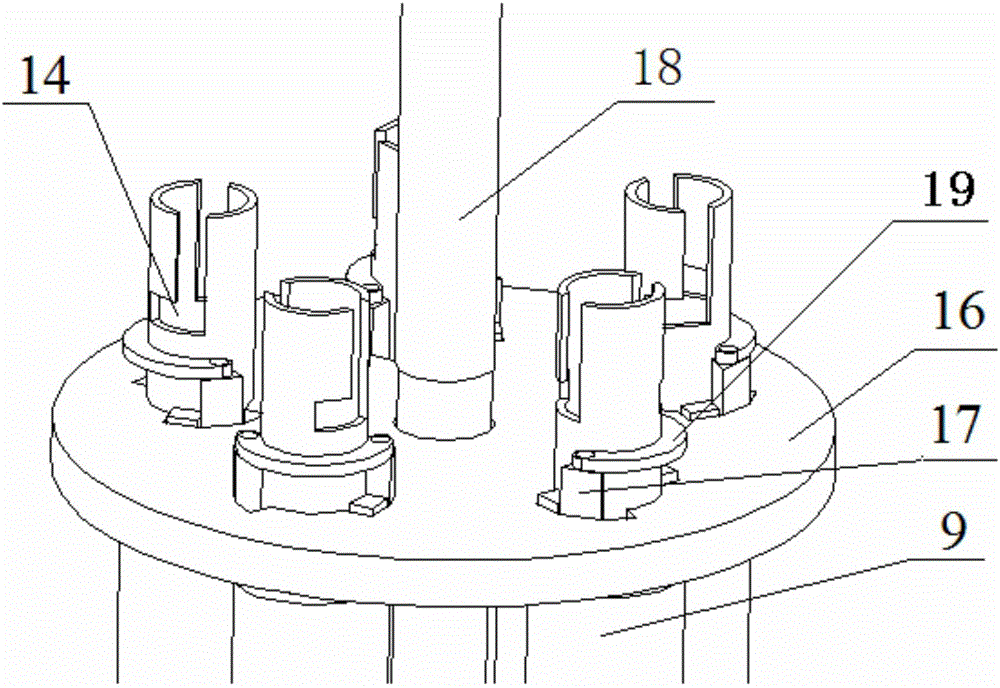

Verification device for in-pile refueling system in liquid-state heavy metal reactor

ActiveCN104269197AAchieve replacementSimple structureNuclear energy generationReactor fuel elementsElectric machineryDrive motor

The invention discloses a verification device for an in-pile refueling system in a liquid-state heavy metal reactor. The device mainly comprises a container tank, a reactor top cover, a cock and a drive mechanism, a refueling machine, an out-of-pile translation mechanism, a lifting machine, a simulated fuel assembly and a grid plate. The cock and the drive mechanism are concentrically arranged and supported on the reactor top cover, and mainly comprise a large cock, a large cock drive motor, a small cock, a small cock drive motor and a center measurement column; the small cock is eccentrically arranged on the large cock. The device is capable of simulating a refueling function of the refueling system in the liquid-state heavy metal reactor under a cold-state air environment, realizing replacement of a reactor core fuel assembly, and providing a verifying platform for design and parameter correction of the refueling system in the ADS liquid-state heavy metal reactor. The device is good in running performance, and verifies the feasibility of the refueling system in a double-cock split type central measurement cylinder reactor.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com