Bidirectional reinforcing and water drainage reinforcing means for highway soft soil foundation

A technology for weak soil foundations and highways, applied in soil protection, foundation structure engineering, construction, etc., can solve the problems of piles not being able to drain, reducing foundation settlement, and soil reinforcement between piles is small, so as to improve foundation stability and bearing capacity, reducing foundation differential settlement, and post-construction settlement reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

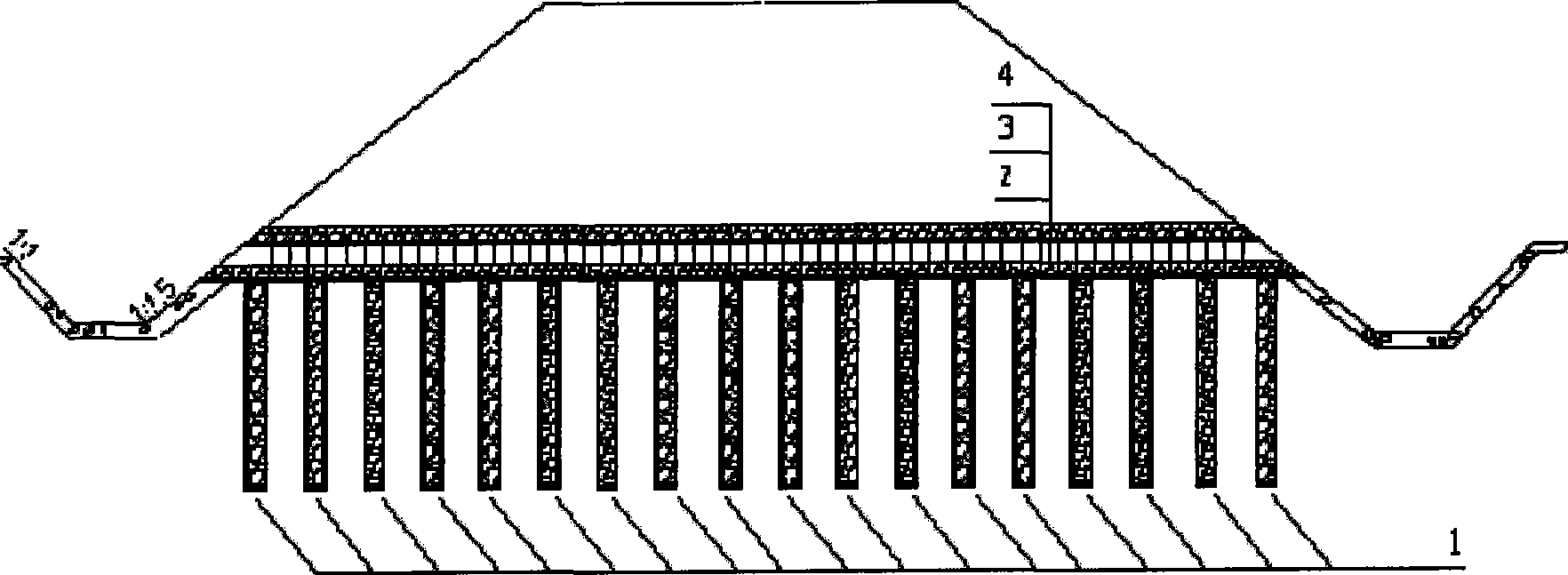

[0019] (1) Level the site, set out the pile positions, arrange piles in plum blossom shape, and the pile spacing is 1.8m.

[0020] (2) The gravel pile 1 is formed by vibro-construction, the diameter of the gravel pile is 0.9m, and the length is 15m;

[0021] (3) Lay the lower drainage layer 2 on the top surface of the gravel pile 1, use gravel (the particle size of the gravel is 2cm ~ 5cm) as the material, and loosely lay the thickness h 1 23cm, layered rolling, thickness ΔH after compaction 1 20cm;

[0022] (4) Lay a geocell with a thickness of 12cm and a drainage hole on the wall above the lower drainage layer 2, fill the room with coarse sand and compact to form the geocell layer 3;

[0023] (5) Lay the upper drainage layer 4 on the geocell layer 3, use gravel (the departure of the gravel is 2cm ~ 5cm) as the material, and loosely lay the thickness h 2 22cm, layered rolling, thickness ΔH after compaction 2 It is 20cm.

Embodiment 2

[0025] (1) Level the site, set out the pile positions, arrange piles in a square, and the pile spacing is 1.2m.

[0026] (2) Utilize the construction of vibrating sinking pipe method to form gravel pile 1, and the diameter of the gravel pile is 0.4m and the pile length is 12m;

[0027] (3) Lay the lower drainage layer 2 on the top surface of the gravel pile 1, use coarse sand as the material, and roll it layer by layer, and the thickness after compaction is 20cm;

[0028] (4) Lay a geocell with a thickness of 18cm and a drainage hole on the chamber wall above the lower drainage layer 2, fill the room with coarse sand and gravel (the volume content of the gravel accounts for 50%) and compact to form the geocell layer 3;

[0029] (5) Lay the upper drainage layer 4 on the geocell layer 3, use coarse sand as the material, and roll it layer by layer, and the thickness after compaction is 20cm.

Embodiment 3

[0031] (1) Level the site, set out the pile positions, arrange piles in plum blossom shape, and the pile spacing is 1.5m.

[0032] (2) The gravel pile 1 is formed by hammering the pipe sinking method, the diameter of the gravel pile is 0.4m, and the pile length is 10m;

[0033] (3) Lay the lower drainage layer 2 on the top surface of the gravel pile 1, use coarse sand as the material, and roll it layer by layer, and the thickness after compaction is 20cm;

[0034] (4) Lay a geocell with a thickness of 15cm and a drainage hole on the wall above the lower drainage layer 2, fill the room with coarse sand and gravel (the volume content of the gravel accounts for 30%) and compact to form the geocell layer 3;

[0035] (5) Lay the upper drainage layer 4 on the geocell layer 3, use crushed stone (the particle size of the crushed stone is 2cm ~ 5cm) as the material, and roll it layer by layer, and the thickness after compaction is 40cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com