Cable wrapping machine

A technology of cable wire and wrapping machine, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, circuit, etc. It can solve the problems of tape scrapping, welding difficulties, easily damaged tape reels and conductors, etc. good quality cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

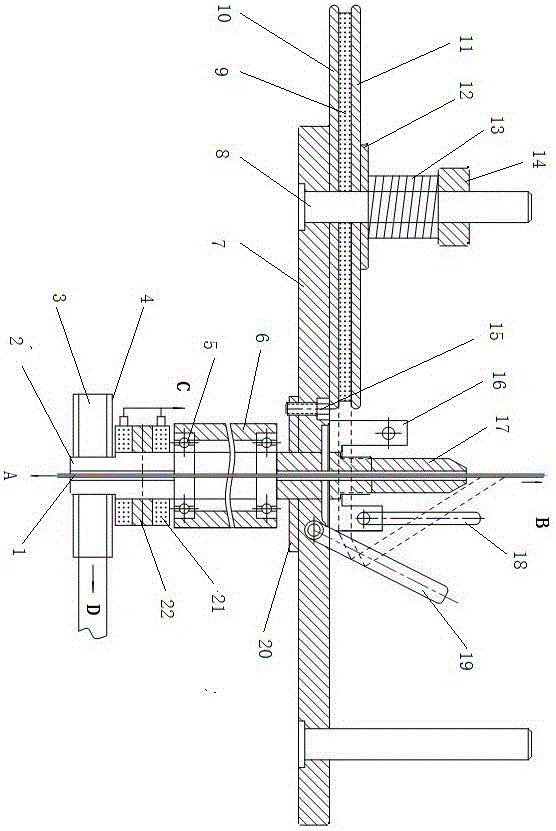

[0018] The cable wrapping machine of the present invention comprises a frame, a wire-releasing guide wheel and a wire-receiving guide wheel, and the structures of the frame, the wire-releasing guide wheel and the wire-receiving guide wheel are prior art, and there is no schematic diagram in the figure. Main shaft 2 is fixed with support 6 through bearing 5, and support 6 is fixed on the frame.

[0019] The cable core wire 1 enters from the direction indicated by A, and enters the take-up guide wheel from the direction indicated by B.

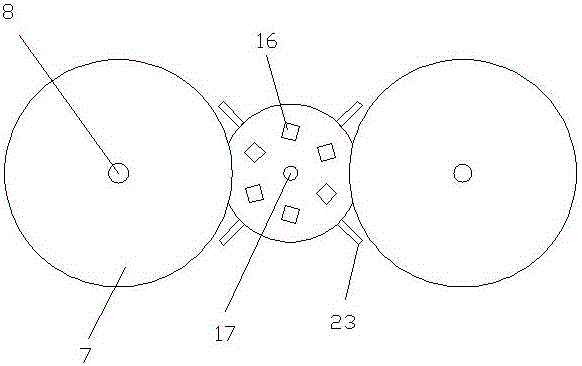

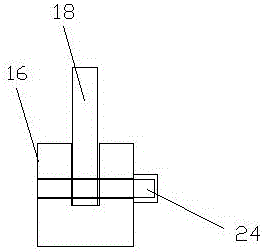

[0020] The cable lead-in pipe 17 is vertically arranged on the frame, the cable lead-in pipe 17 is coaxially arranged with the main shaft 2, the main shaft 2 is connected with the transmission wheel 4, and the driving motor drives the transmission wheel 4 through the belt 3, thereby driving the main shaft 2 to rotate. The main shaft 2 is provided with a mounting seat 20, which rotates together with the main shaft 2, and the two sides of the moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com