Verification device for in-pile refueling system in liquid-state heavy metal reactor

A liquid heavy metal and verification device technology, which is applied in the direction of reactor fuel elements, reactors, and greenhouse gas reduction, can solve the problems of no verification device, no refueling positioning system component fixed structure verification, etc., to achieve wide applicability, structure Simple, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

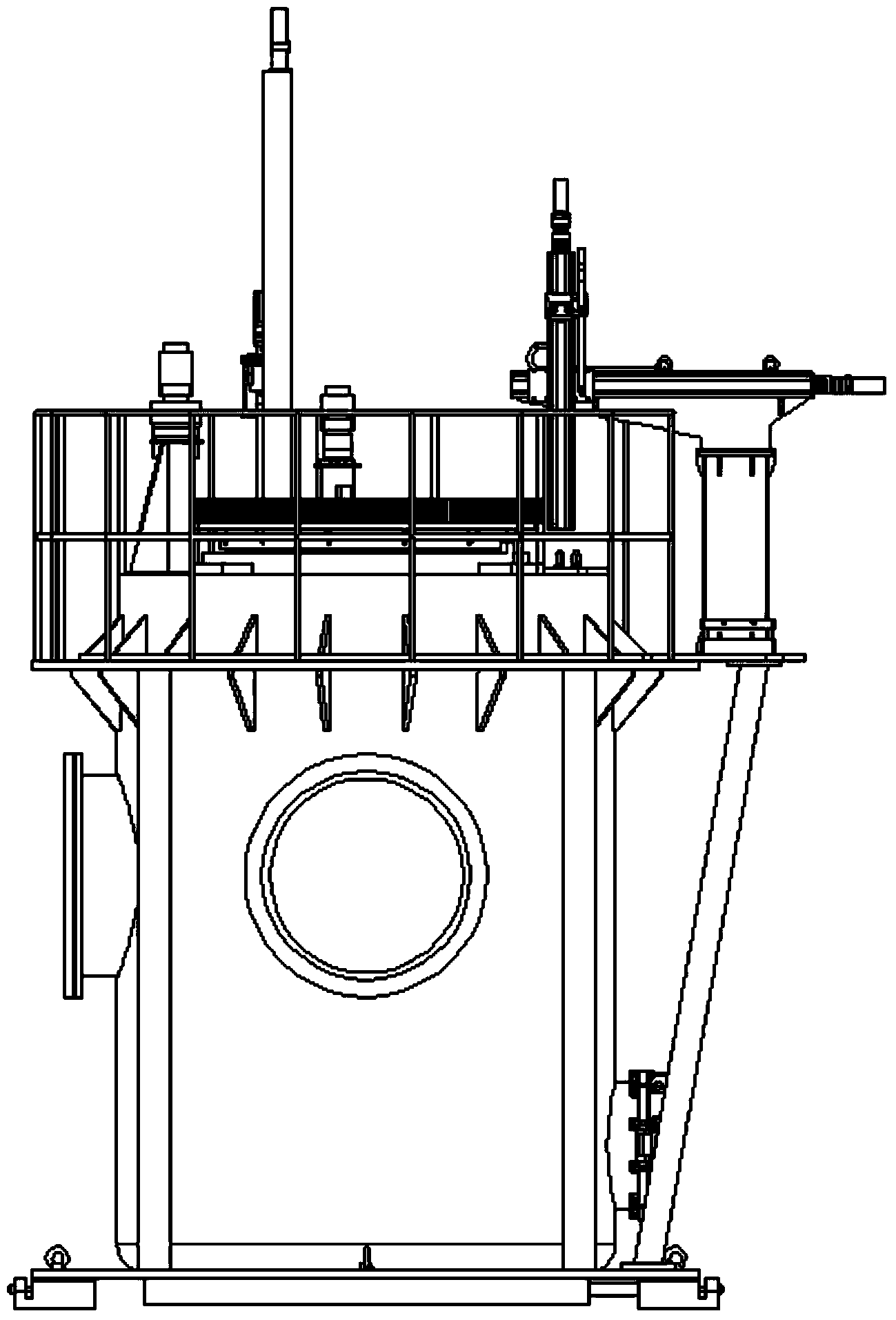

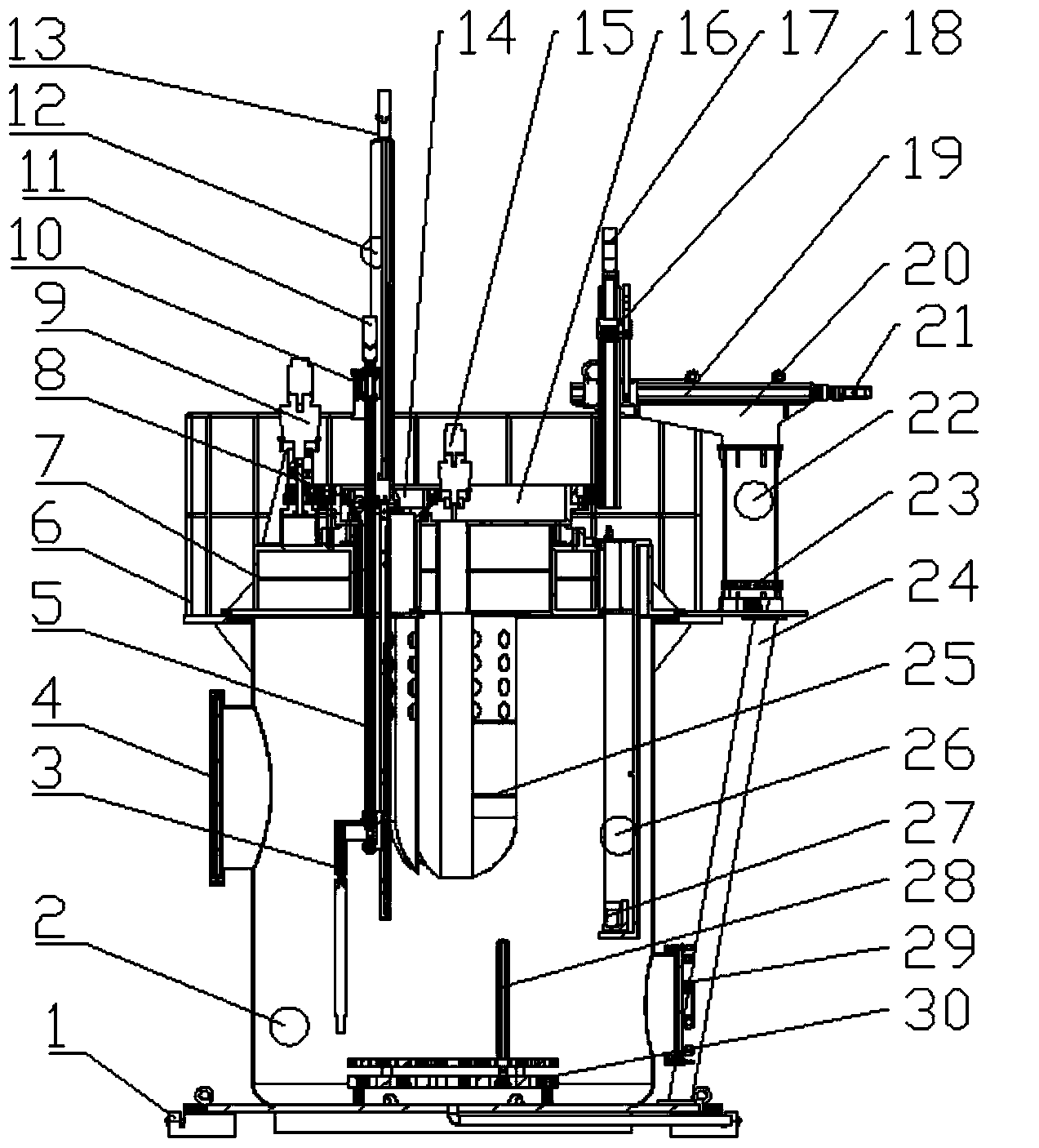

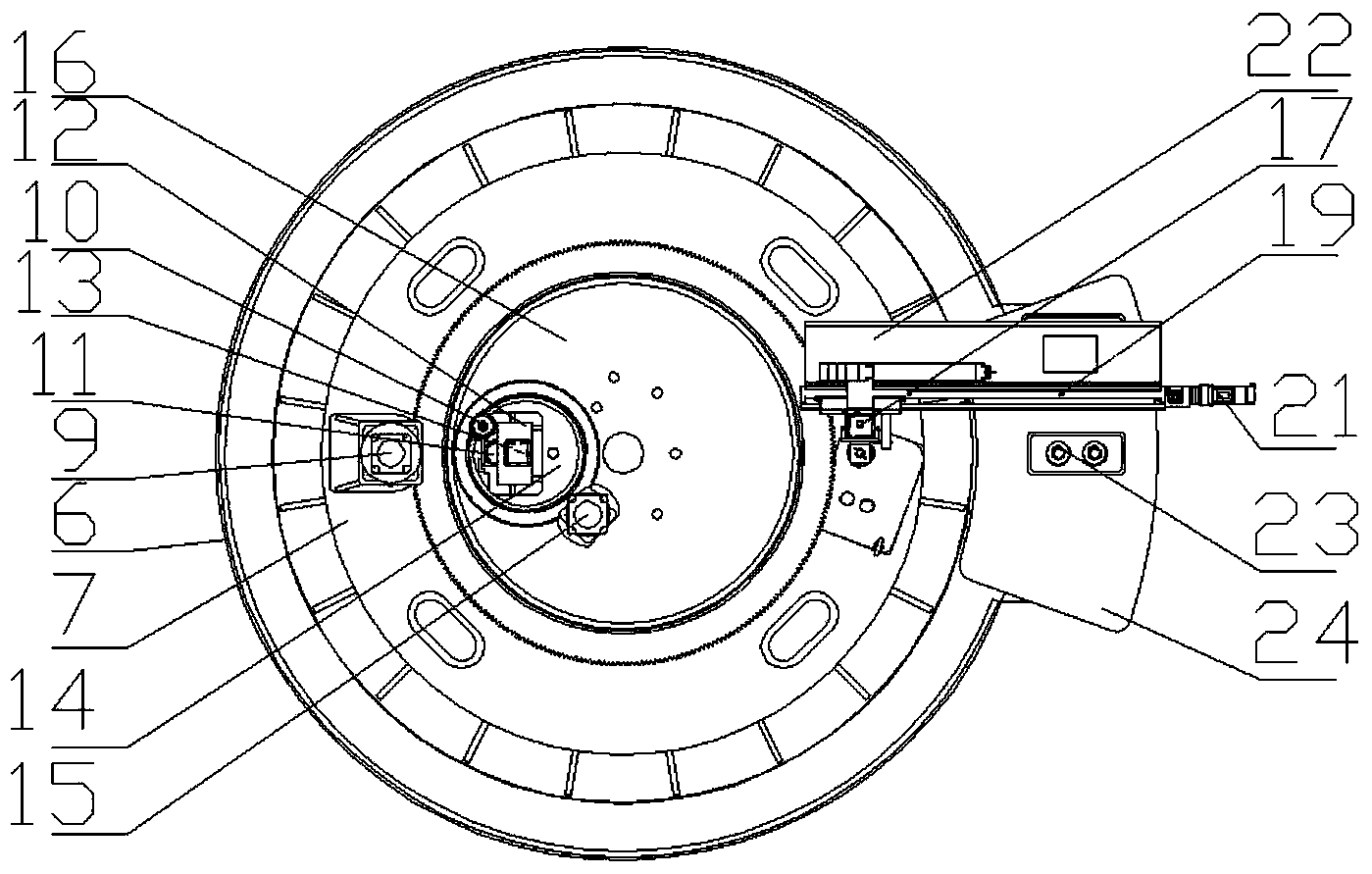

[0025] Such as Figure 1~3 As shown, this embodiment illustrates a verification device for the refueling system in a liquid heavy metal reactor, which mainly consists of a container tank 2, a stack top cover 7, a cock and a driving mechanism 8, a refueling machine 12, an external translation mechanism 22, The elevator 26, the simulated fuel assembly 28 and the grid plate 30 are composed.

[0026] The cock and the driving mechanism 8 are concentrically installed and supported on the stack top cover 7, and are mainly composed of a large cock 16, a large cock drive motor 9, a small cock 14, a small cock drive motor 15 and a central measuring column 25, and the small cock 14 is eccentrically installed on the large cock. Cock 16 on.

[0027] The refueling machine 12 is eccentrically and fixedly installed on the small cock 14, and is mainly composed of the refueling machine spindle 5, the refueling machine grip 3, the refueling machine rotating motor 10, the refueling machine gripp...

Embodiment 2

[0033] Such as Figure 4~6 As shown, this embodiment describes in detail the work flow steps of a verification device for a liquid heavy metal reactor refueling system.

[0034] Positioning step: After selecting the analog components that need to be replaced, the large cock drive motor 9 drives the large cock 16 to rotate, the small cock drive motor 15 drives the small cock 14 to rotate, and the refueling machine rotating motor 10 drives the refueling machine gripper 3 turns With the rotation of the main shaft 5 of the refueling machine, through the combined movement of the large and small cocks and the refueling machine, the gripper 3 of the refueling machine is positioned directly above the target simulated fuel assembly 28, and the target simulated fuel assembly 28 is placed on the grid plate 30 On, the elevator rotating slot 27 parked at the upper end of the elevator 26 moves down to the lower end;

[0035] Grabbing steps: the lifting motor 13 of the refueling machine drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com