Wind turbine multifunctional platform and blade disassembly method

A multi-functional technology for wind turbines, applied in wind turbine components, wind power generation, wind turbines, etc., can solve problems such as difficulty in maintenance and reduction of wind turbines, and achieve the effects of reducing replacement costs, comfortable working environment, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

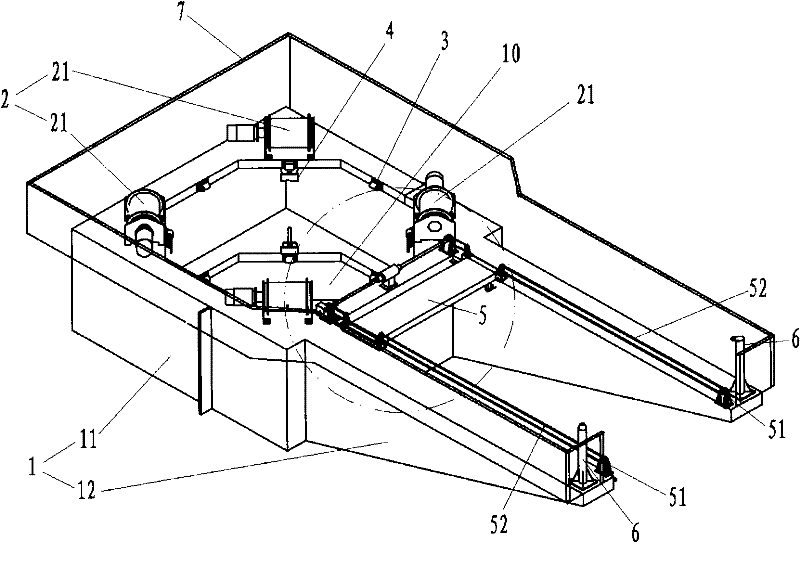

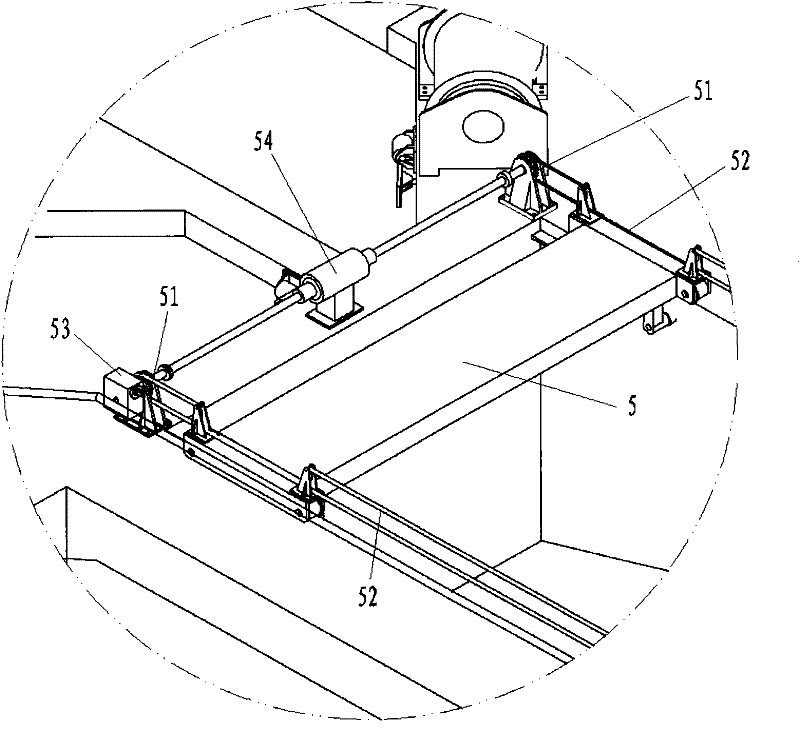

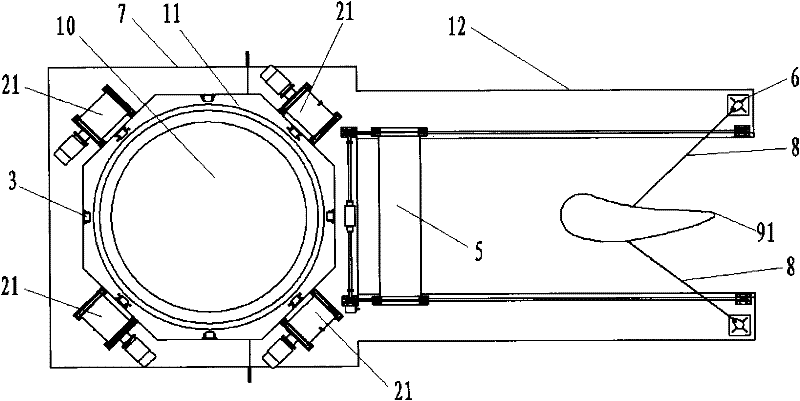

[0047] The present invention provides a multifunctional platform, such as figure 1 , Figure 1A , figure 2 As shown, the platform consists of the following parts:

[0048] 1. Platform frame 1: It is the installation basis of each functional component, and provides an operating platform for the operator to facilitate the work of the operator; the platform frame 1 adopts a split structure, which is divided into two parts arranged front and rear. Connected by bolts to facilitate transportation and installation; in this embodiment, the platform frame 1 includes a base 11 with an annular central hole 10 and two parallel arms 12 extending from one side of the base 11;

[0049] 2. Hoisting mechanism 2: used to realize the up and down translation of the platform, the hoisting mechanism 2 includes at least three electric hoisting machines 21 distributed around the annular center hole 10 and fixed on the base 11; in this embodiment, the electric hoisting machines 21 The number is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com