Abrasive belt grinding machining device with contact wheel depot

A processing device and abrasive belt grinding technology, which is applied in the direction of grinding drive devices, abrasive belt grinders, metal processing equipment, etc., to achieve the effect of convenient wheel replacement and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

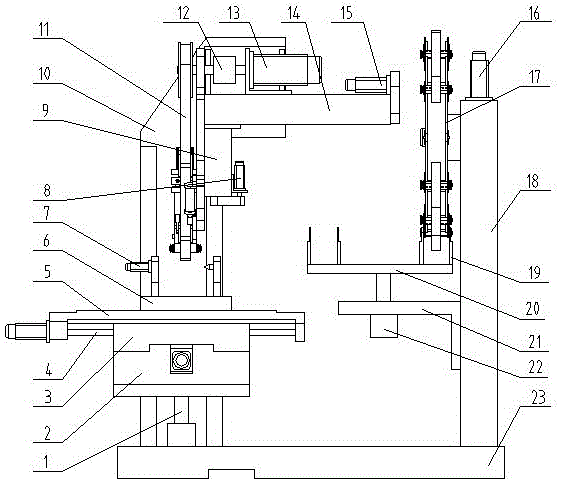

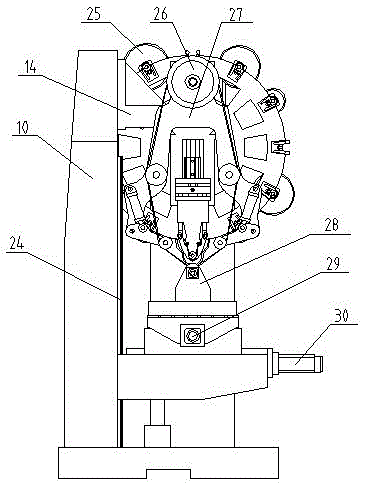

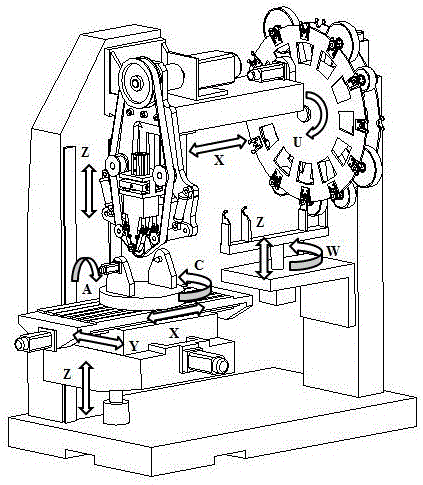

[0047] see Figure 1 to Figure 16 As shown, it is an embodiment of the present invention, including a lifting screw 1, a Z-direction lifting saddle 2, a Y-direction moving saddle 3, a worktable X-direction driving screw 4, an X-direction mobile worktable 5, and a rotating table 6 , A-direction drive motor 7, grinding head Z-direction lifting drive motor 8, grinding head X-direction moving ram 9, first column 10, abrasive belt 11, coupling 12, abrasive belt drive motor 13, grinding head support beam 14 , Grinding head X-direction drive motor 15, contact wheel storehouse turntable drive motor 16, contact wheel storehouse turntable 17, second column 18, wheel-changing mechanical claw 19, wheel-changing mechanical arm 20, wheel-changing device base 21, wheel-changing drive motor 22. Base 23, workbench lifting guide rail 24, contact wheel part 63, abrasive belt drive wheel 26, abrasive belt support plate 27, fixture 28, worktable X-direction movement drive motor 29, workbench Y-dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com