Preheating equipment for metal wire hot dip galvanizing process

A metal wire and equipment technology, applied in the field of metal wire hot galvanizing process preheating equipment, can solve the problems of unable to achieve synchronous adjustment, less clamping wheel structure, unadjustable guide frame, etc., to ensure the uniformity of heating, guarantee Stability and accuracy, consistent effect of adjustment angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

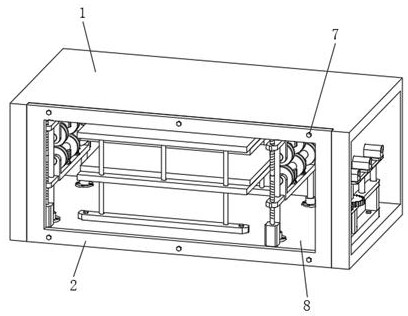

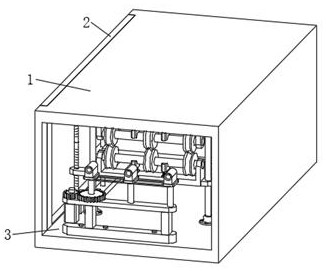

[0031] Such as Figure 1-8 As shown, a metal wire hot galvanizing process preheating equipment includes a main body 1 of the equipment, a side plate 2 is arranged on the main body 1 of the equipment, and an inner cavity 3 is opened on the main body 1 of the equipment, and the inner cavity 3 on the main body 1 of the equipment A heating structure 5 is fixedly installed, and the heating structure 5 includes a mounting plate 501, a support rod 502, a first horizontal plate 503, a second horizontal plate 504, a heating plate 505 and fastening bolts 506, and the support rod 502 is fixed on the mounting plate 501 , the first horizontal plate 503 and the second horizontal plate 504 are installed on the support rod 502, the heating plate 505 is fixedly installed on the first horizontal plate 503 and the second horizontal plate 504, and the inner cavity 3 on the main body 1 of the equipment is provided with a clamp A holding mechanism 4, a guiding structure 6 is fixedly installed in th...

Embodiment 2

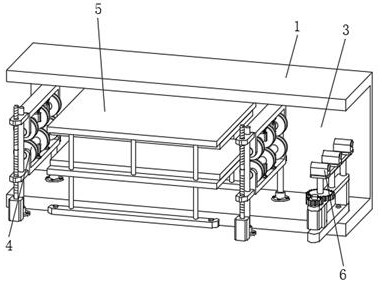

[0034] like Figure 1-8 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is: as Figure 4 , 5 As shown, the clamping mechanism 4 includes a fixed sleeve 401, a guide post 402, a first connecting frame 403, a second connecting frame 404, a rotating shaft 405, a clamping wheel 406, a stabilizing frame 407, a first lifting plate 408, and a second lifting plate 409. The servo motor 410, the screw rod 411, the guide post 402 are arranged on the fixed sleeve 401, and the two sets of rotating shafts 405 are respectively fixed on the first connecting frame 403 and the second connecting frame 404. The two groups of rotating shafts 405 are used in conjunction with each other. The holding wheel 406 is fi...

Embodiment 3

[0037] like Figure 1-8 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the third embodiment and the first embodiment is: as Figure 7 , 8 As shown, the guide structure 6 includes a connecting rod 601, a welding rod 602, a mounting rod 603, a stepper motor 604, a driving gear 605, a guide frame 606 and a driven gear 607, and the mounting rod 603 is arranged on the upper end of the welding rod 602, stepping The motor 604 is connected with the driving gear 605, and the stepper motor 604 is arranged on the mounting rod 603, the guide frame 606 is installed on the mounting rod 603, the connecting rod 601 and the welding rod 602 are welded together, and the connecting rod 601 There are screws on the top, and the connecting rod 601 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com