Arrangement for coating a powder

A technology of equipment and powder, which is applied in the field of equipment, can solve problems such as coating quality degradation and wear, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

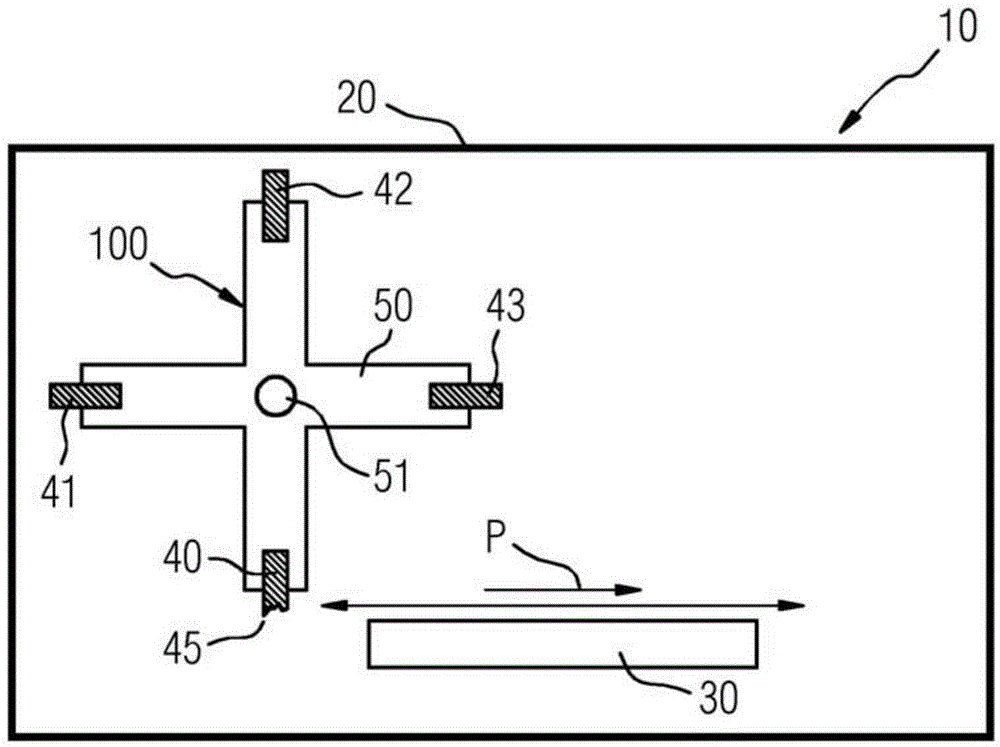

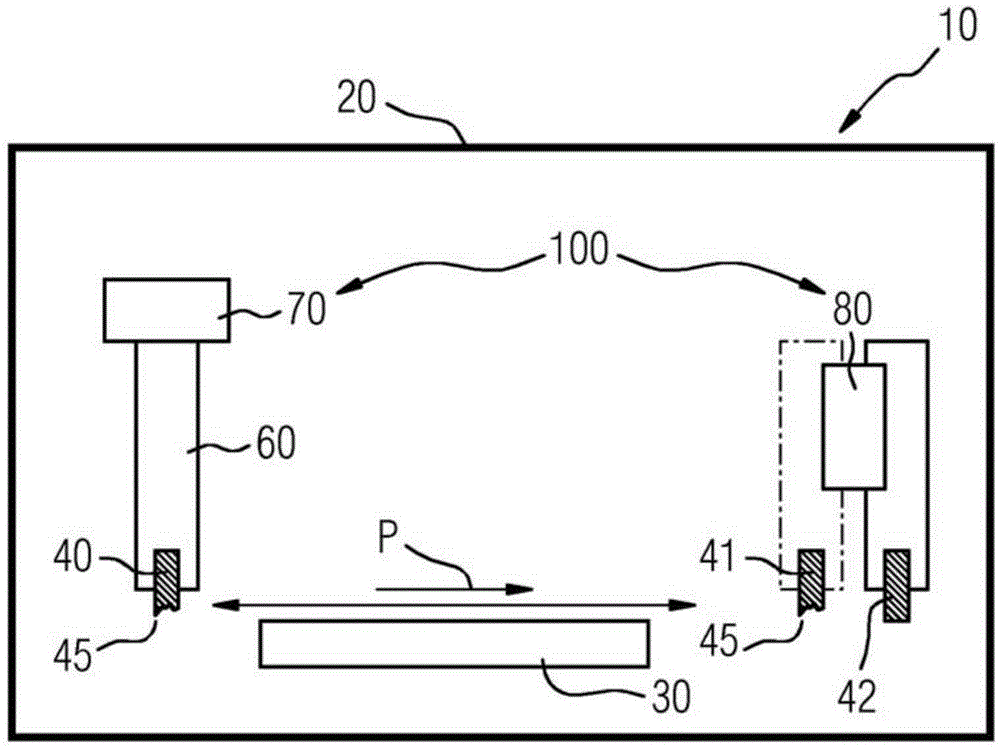

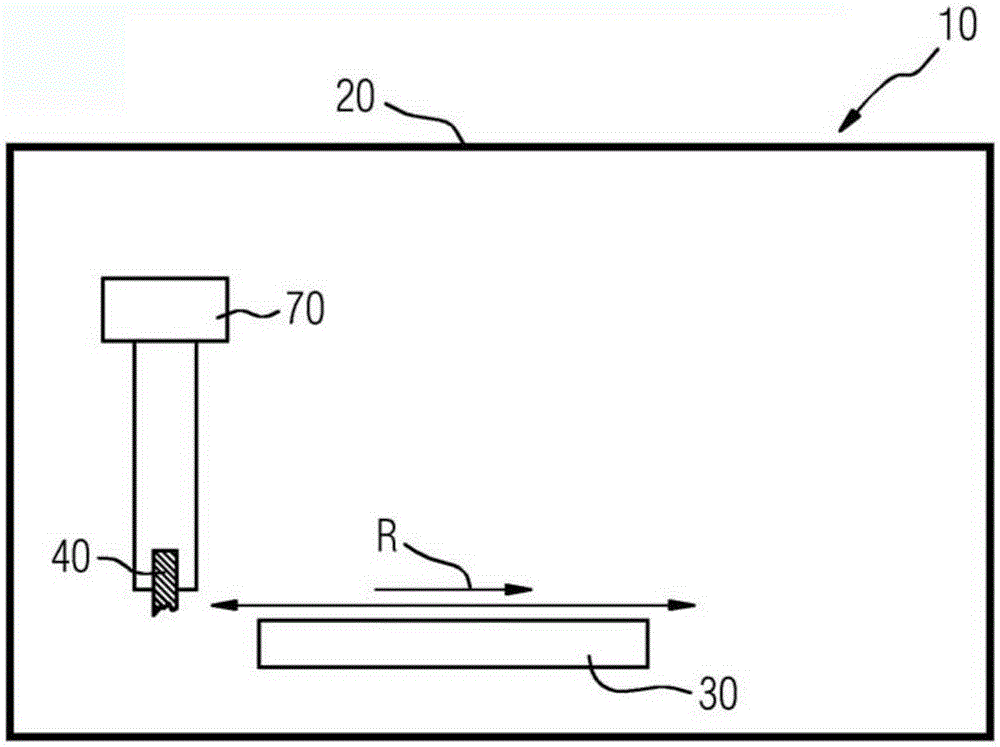

[0037] figure 1An apparatus 10 for knife coating powder is shown. The device 10 comprises a process chamber 20 in which a coating platform 30 and a doctor blade element 40 in the form of a doctor blade lip are located. The doctor-coating element 40 is held by a multiplex head 50 in the form of a rotating or turret head, on which other doctor-coating elements 41 , 42 and 43 are mounted.

[0038] The apparatus 10 can be used to draw down powders as follows:

[0039] First, for the powder coating, the knife coating element 40 is guided over the coating platform 30 in the direction of the arrow P, whereby powder, in particular in the form of metal powder or ceramic powder, is applied to the coating platform 30 and possibly already on the coating platform 30. Layer on top of the powder layer on the platform. In the area of powder application, wear of the application element 40 can occur in the region of the active doctor blade 45 , which interacts directly with the coating pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com