Patents

Literature

653results about How to "Change temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Condensation and humidity sensors for thermoelectric devices

ActiveUS8256236B2Improve thermal performanceChange temperatureAir-treating devicesSeat heating/ventillating devicesCapacitanceControl system

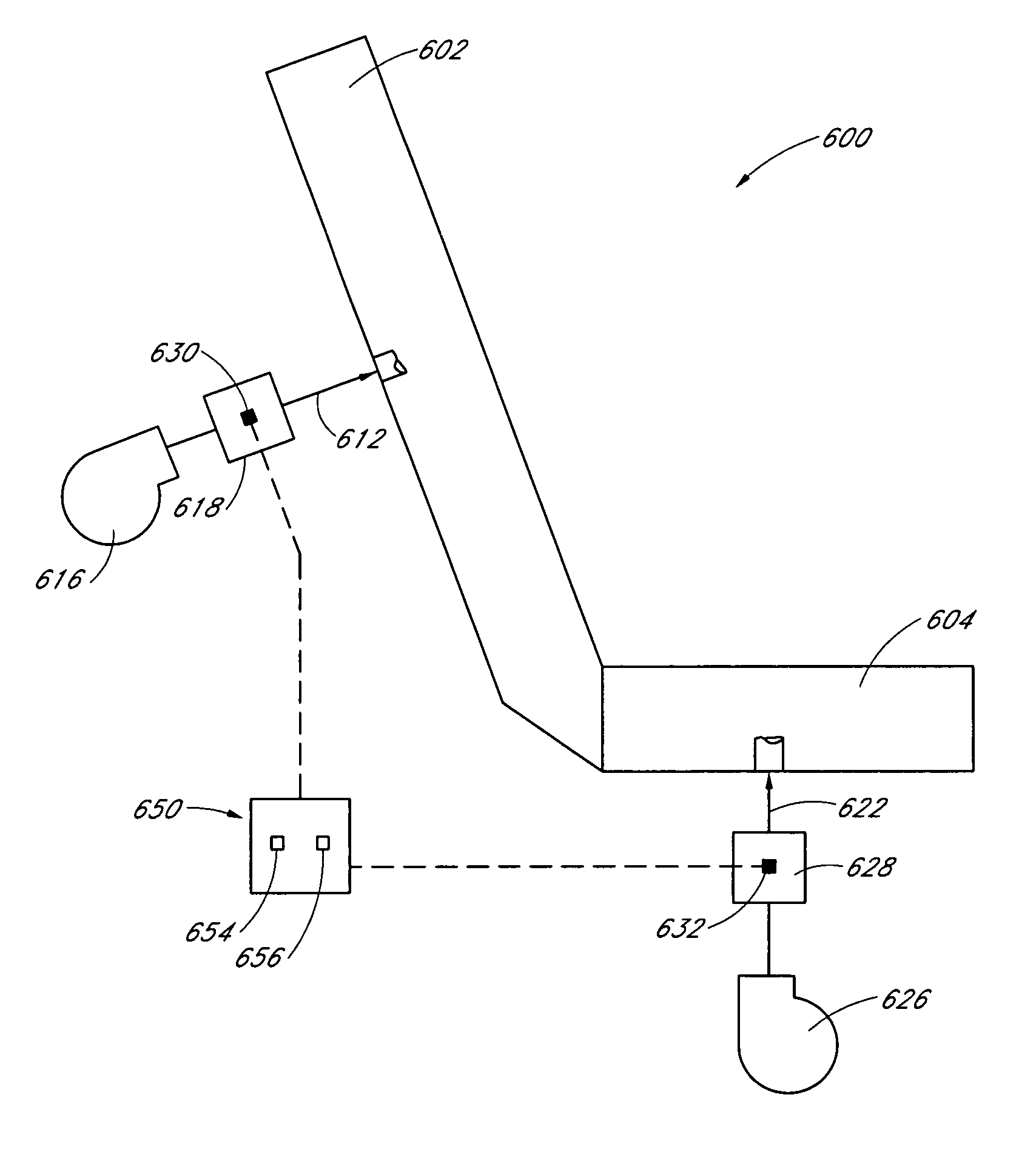

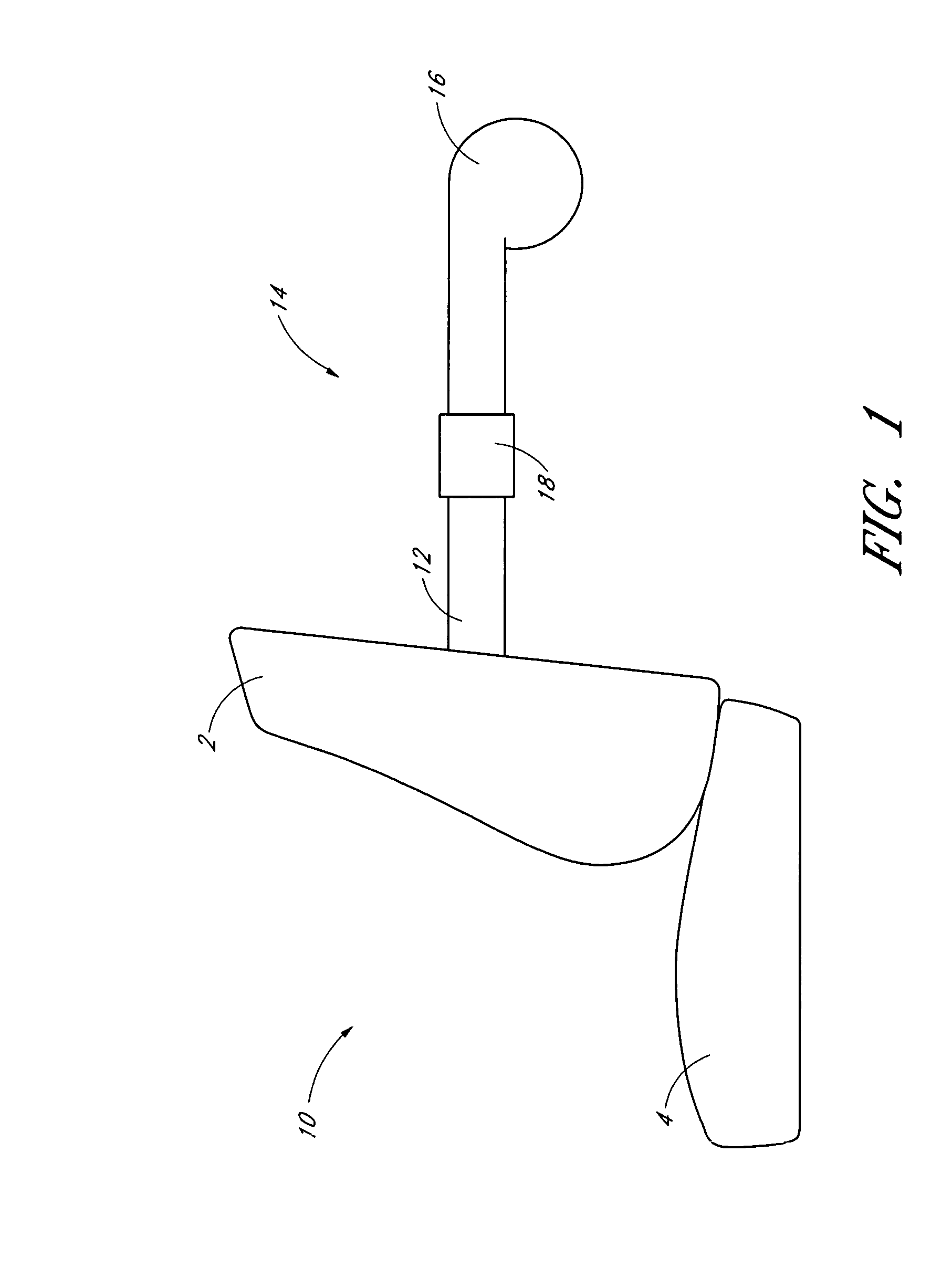

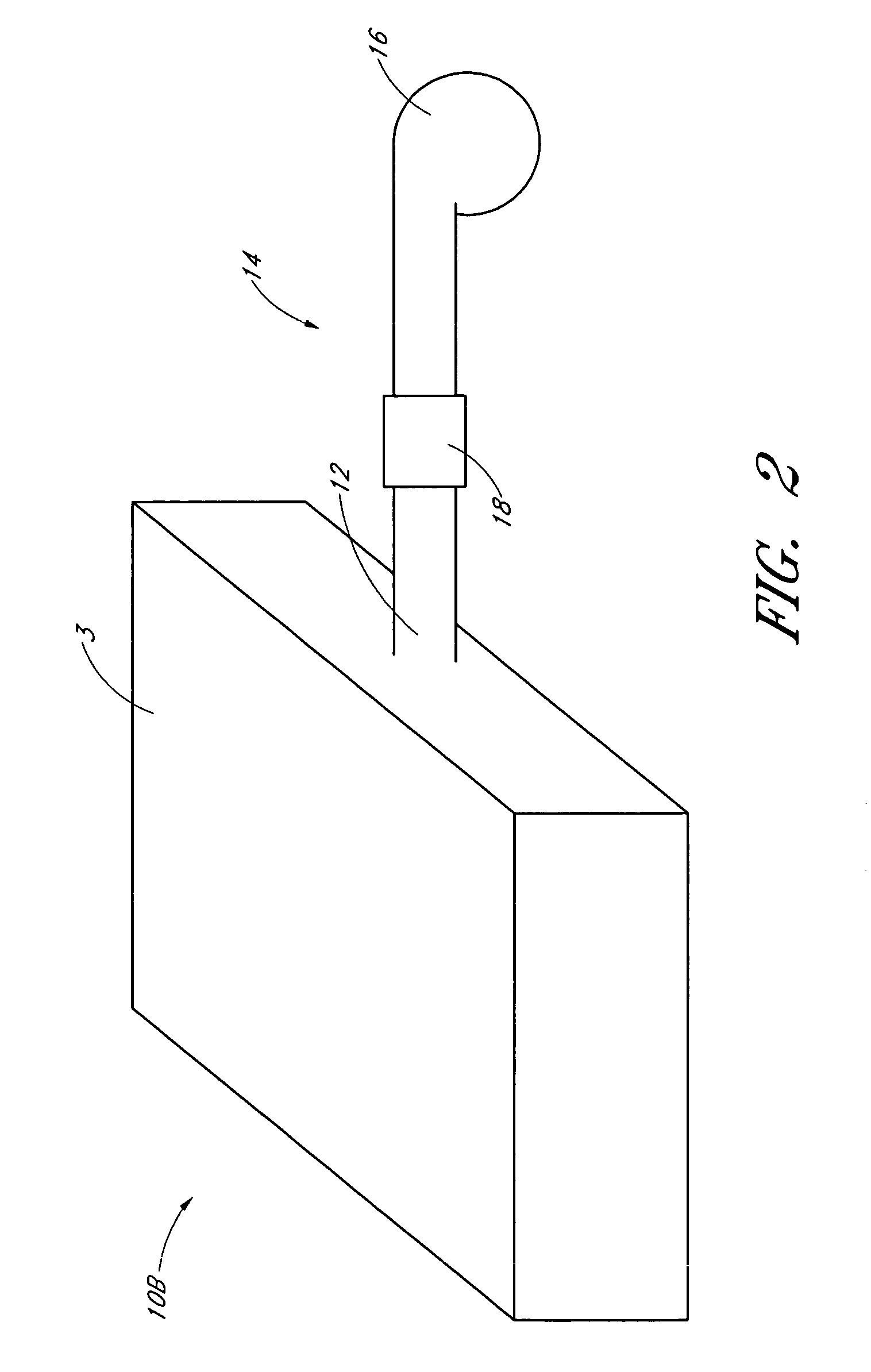

According to certain embodiments disclosed in the present application, a climate controlled seating assembly includes a thermal module. The thermal module comprises at least one inlet channel, at least one outlet channel and a thermoelectric device (e.g., Peltier circuit) positioned upstream of the outlet channel. In one embodiment, the seating assembly includes a sensor positioned within an interior of the thermal module and configured to detect the presence of a liquid, such as water, condensation or other fluids, on or near said sensor. In certain arrangements, the sensor is configured to detect the presence of a liquid by measuring an electrical resistance or capacitance across a portion of the sensor. A climate control system can include a separator gasket located within a housing of a fluid module and at least partially between the cold passage and the hot passage. In some embodiments, the separator gasket comprises one or more wicking materials. The separator gasket can be configured to transport liquids from the cold passage to the hot passage.

Owner:GENTHERM INC

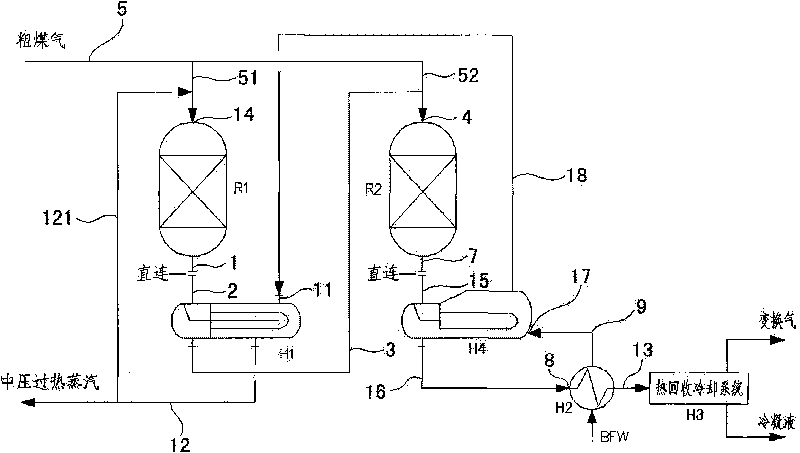

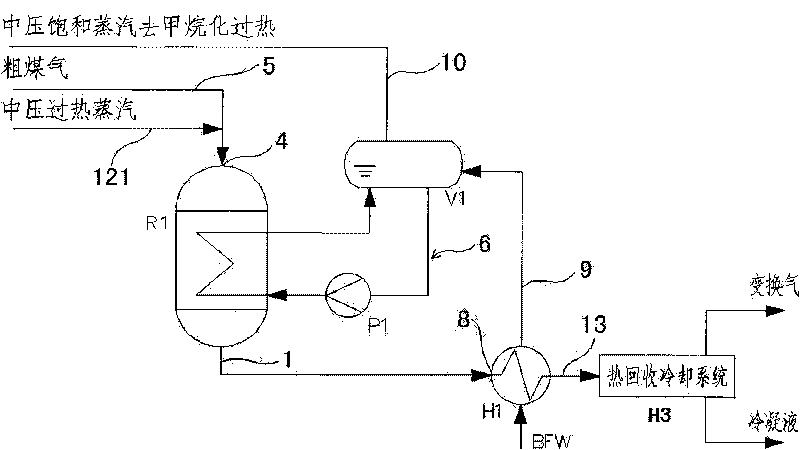

Shunting-type isothermal sulfur-tolerant conversion process and equipment thereof

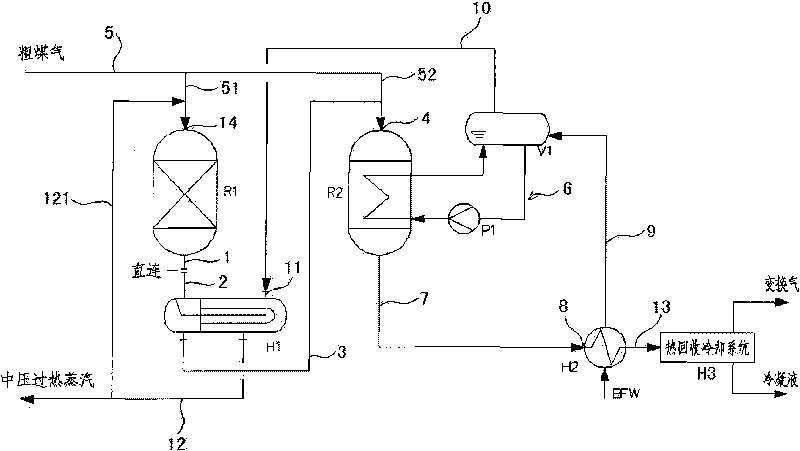

ActiveCN101704513ASatisfy conversion rate requirementsMeet the requirements of adiabatic conversion control temperature riseHydrogenChemical industryShunt typesSulfur

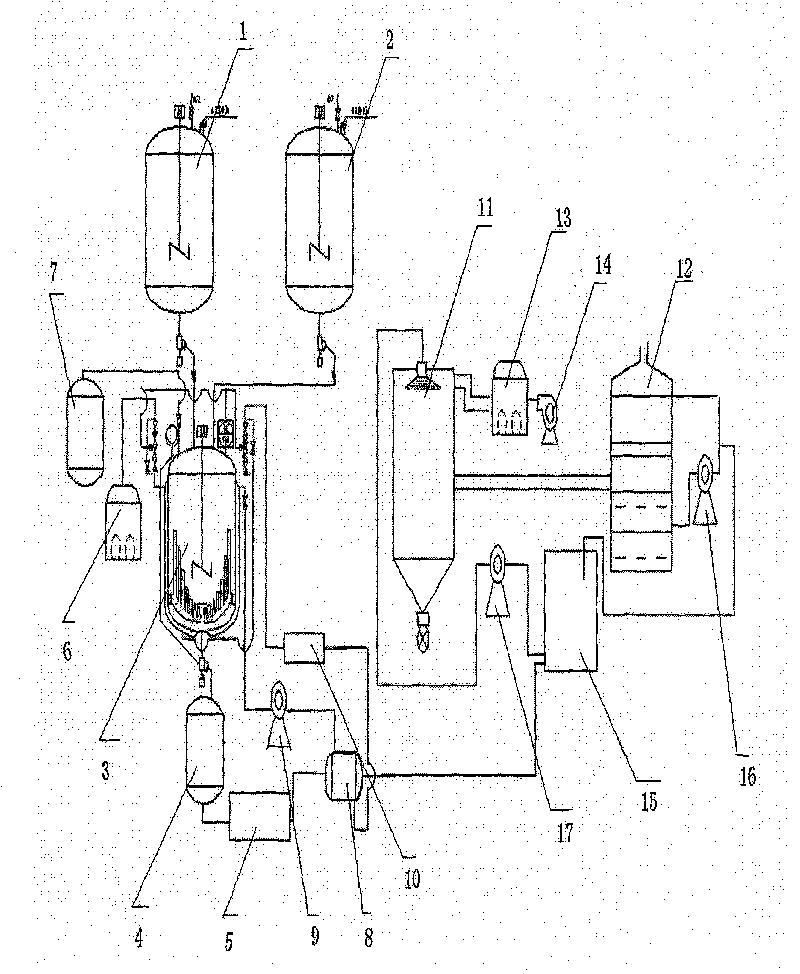

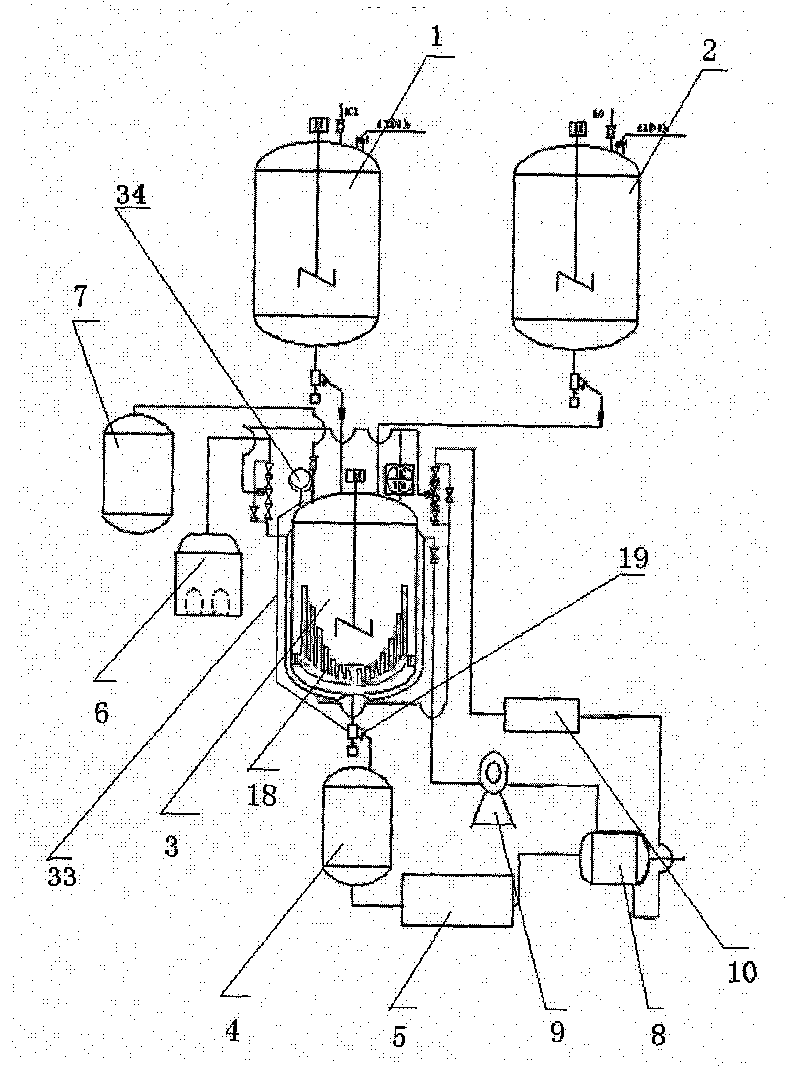

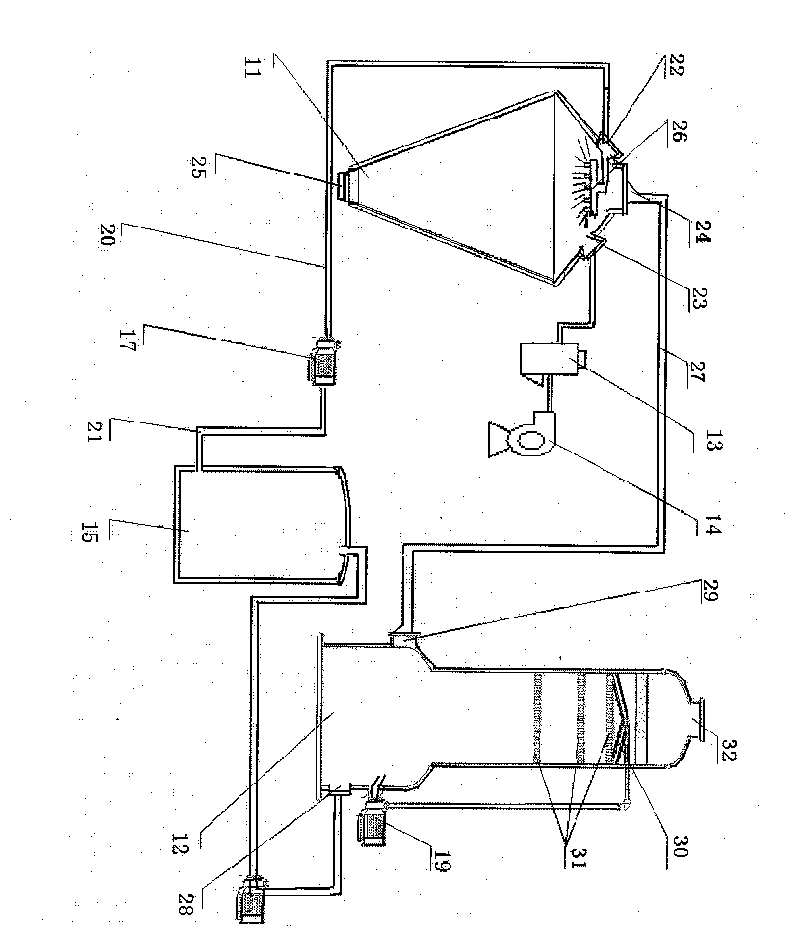

The invention discloses a shunting-type isothermal sulfur-tolerant conversion process. The process comprises the following steps: shunting raw coal gas from exterior into at least two parts; leading overheat stream in the first part of the raw coal gas to increase the temperature to 200-300 DEG C; and then entering a first-stage conversion reaction step to carry out a conversion reaction and generate first conversion gas; and conveying the other part of the raw coal gas to next-stage conversion reaction step to carry out a conversion reaction. The catalyst bed of a shift converter has the advantages of stable temperature, simple control, convenient operation and low output CO content. The invention has the advantages of short conversion flows, few equipment, reduced resistance, great byproduct stream amount, high overheat temperature, stream pressure and heat recovery rate, and the like, thereby achieving the aims of reducing conversion stages, equipment number and resistance fall, decreasing investment, having great byproduct stream amount and high overheat temperature, stream pressure and heat recovery rate, reducing conversion stream consumption and outward wastewater discharge, protecting the environment and easily maximizing the device equipment. The invention also discloses shunting-type isothermal sulfur-tolerant conversion equipment used by the process.

Owner:SHANGHAI INT ENG CONSULTING

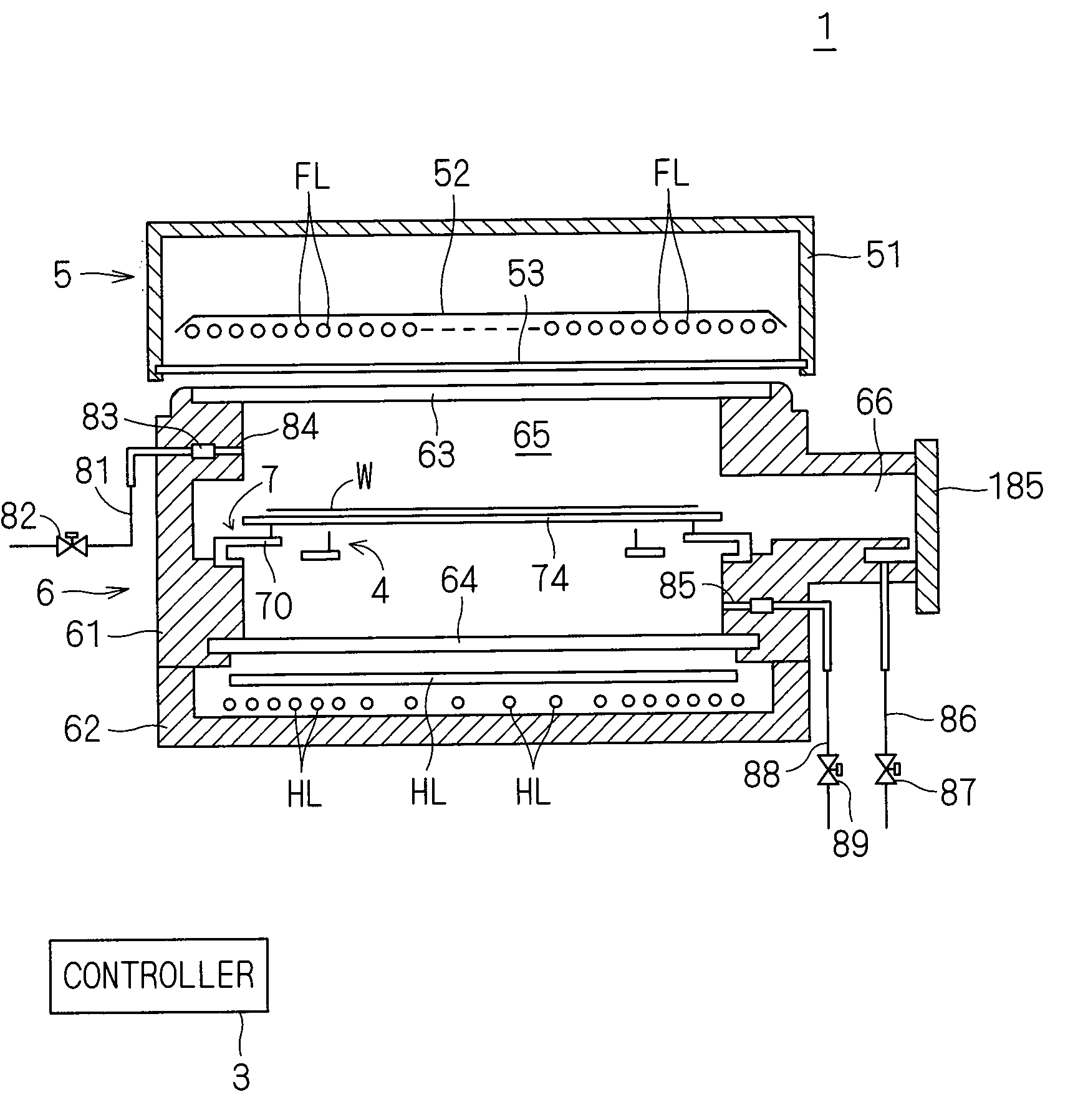

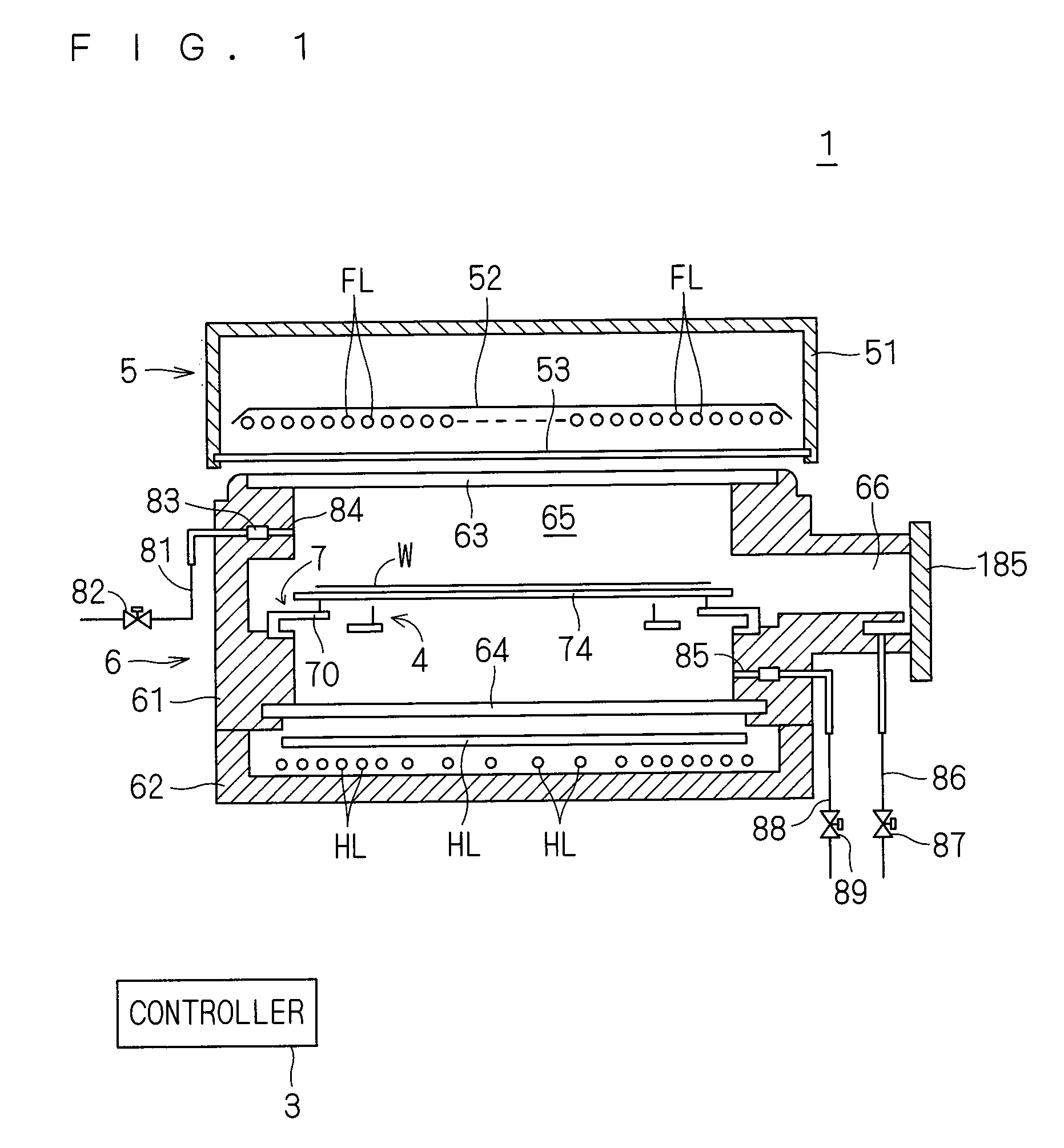

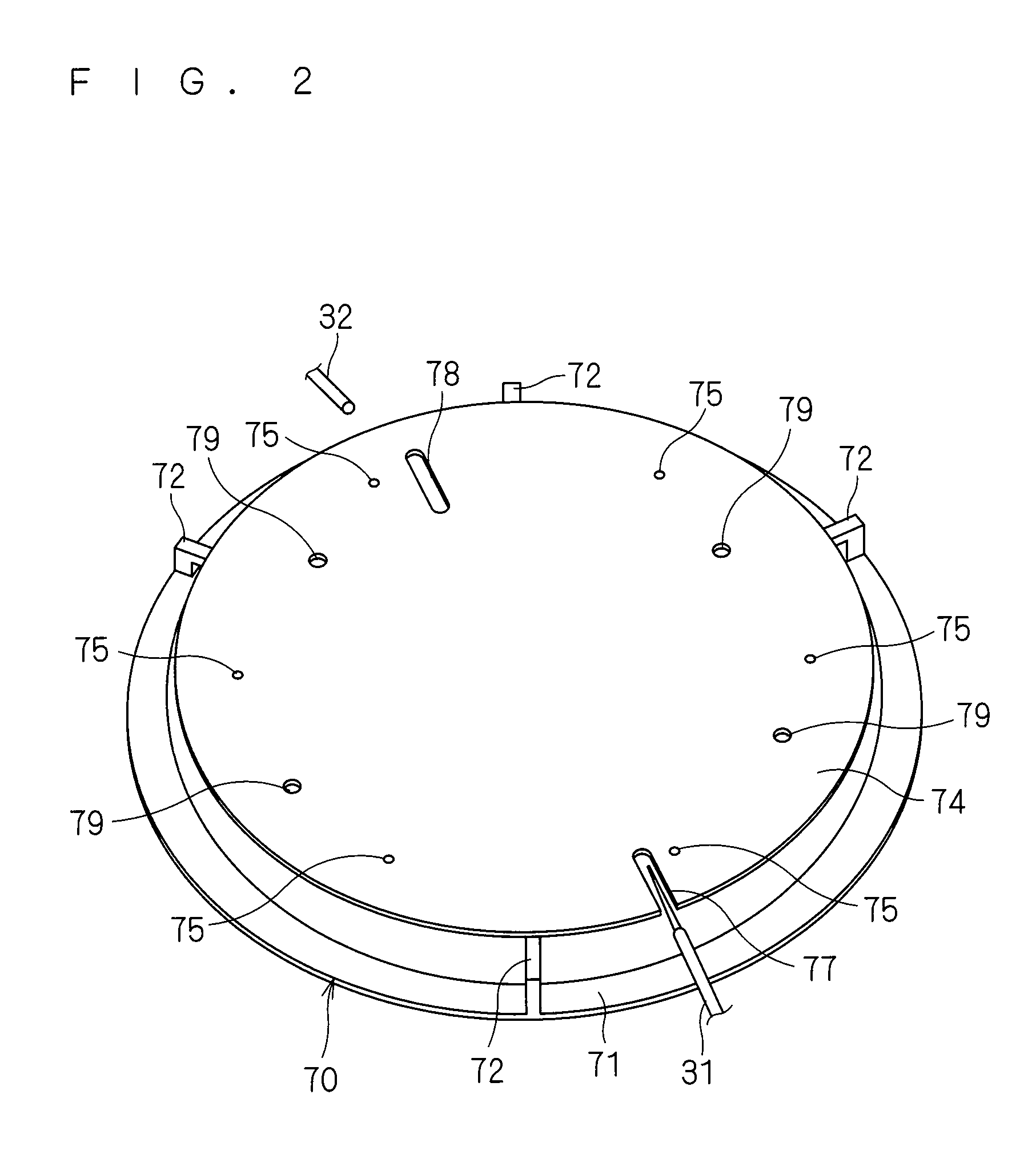

Heat treatment apparatus for heating substrate by exposing substrate to flash light

InactiveUS20090175605A1Suppresses temperature changesPrevent treatment failureSemiconductor/solid-state device manufacturingHigh-frequency/infra-red heating bakingElectrical resistance and conductanceSusceptor

A semiconductor wafer to be treated is placed in a horizontal position on a holding plate held by a susceptor. Six bumps are mounted upright on the upper surface of the holding plate. The semiconductor wafer is supported by the six bumps in point contacting relationship, and is held at a distance ranging from 0.5 mm to 3 mm from the upper surface of the holding plate. Light is directed from halogen lamps onto the semiconductor wafer held by the holding plate to preheat the substrate until the temperature of the semiconductor wafer is increased up to a predetermined temperature. Thereafter, flash light is directed from flash lamps onto the semiconductor wafer. A thin gas layer lying between the back surface of the semiconductor wafer and the upper surface of the holding plate acts as a resistance to suppress the motion of the semiconductor wafer, thereby preventing a crack in the semiconductor wafer.

Owner:DAINIPPON SCREEN MTG CO LTD

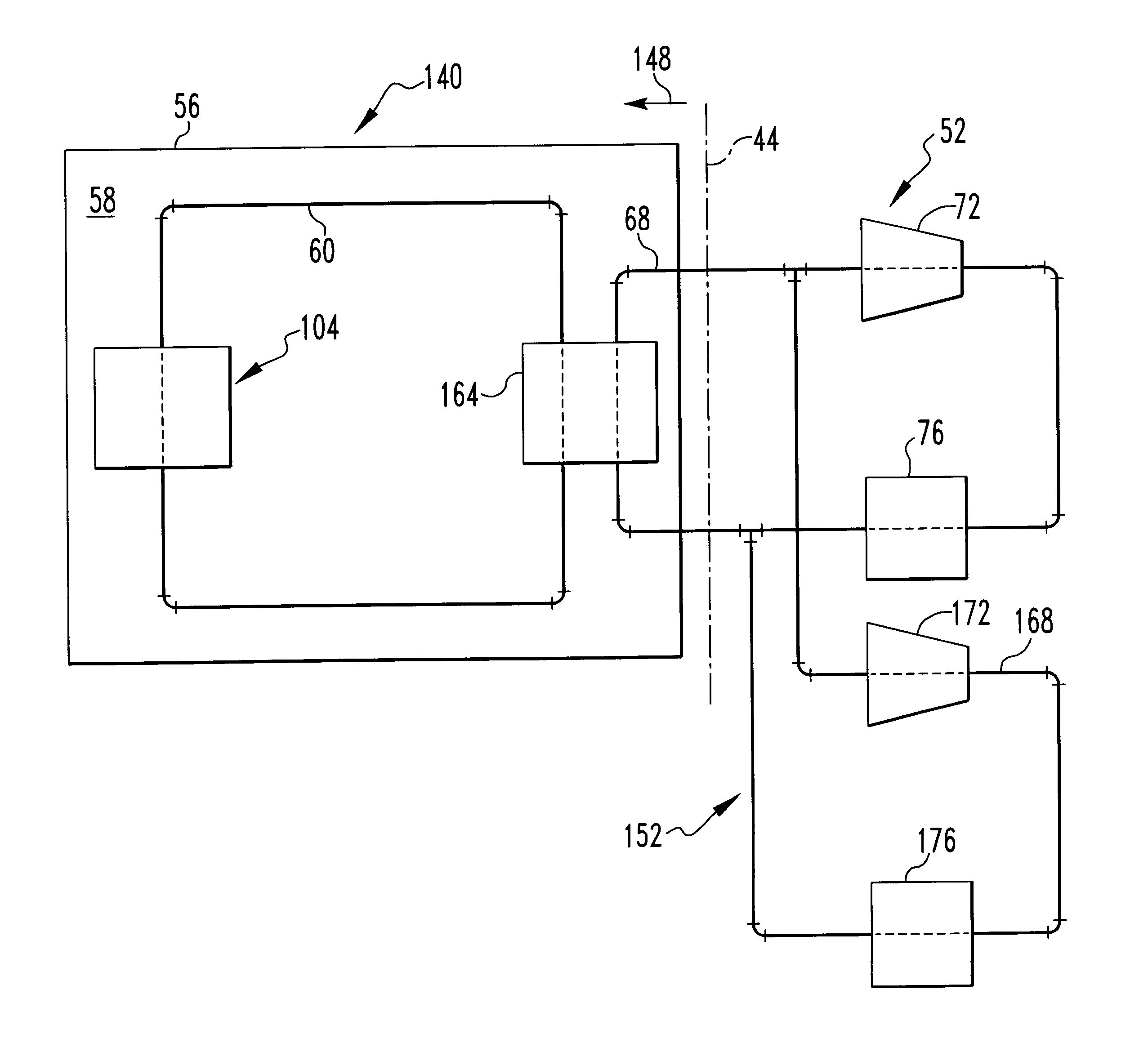

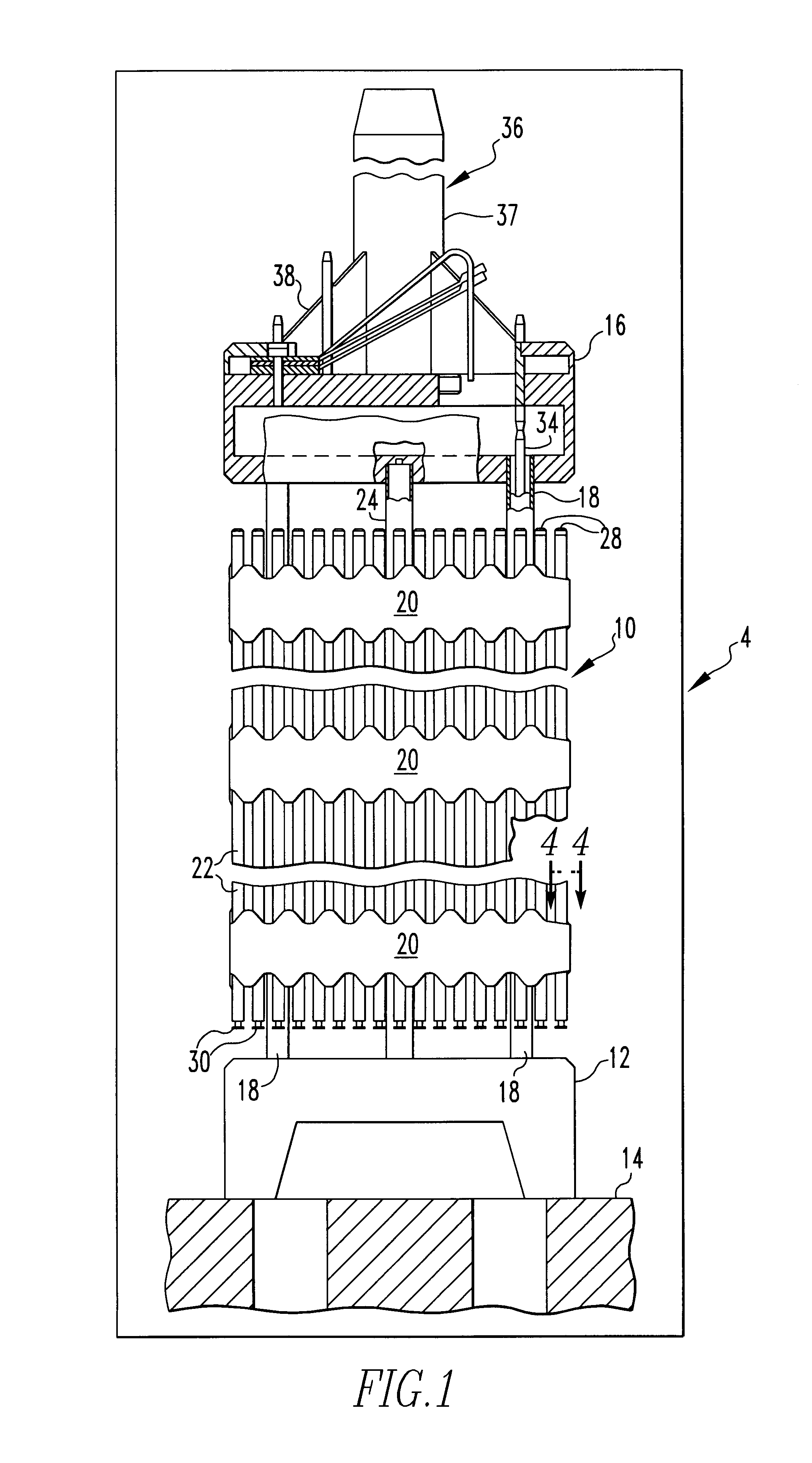

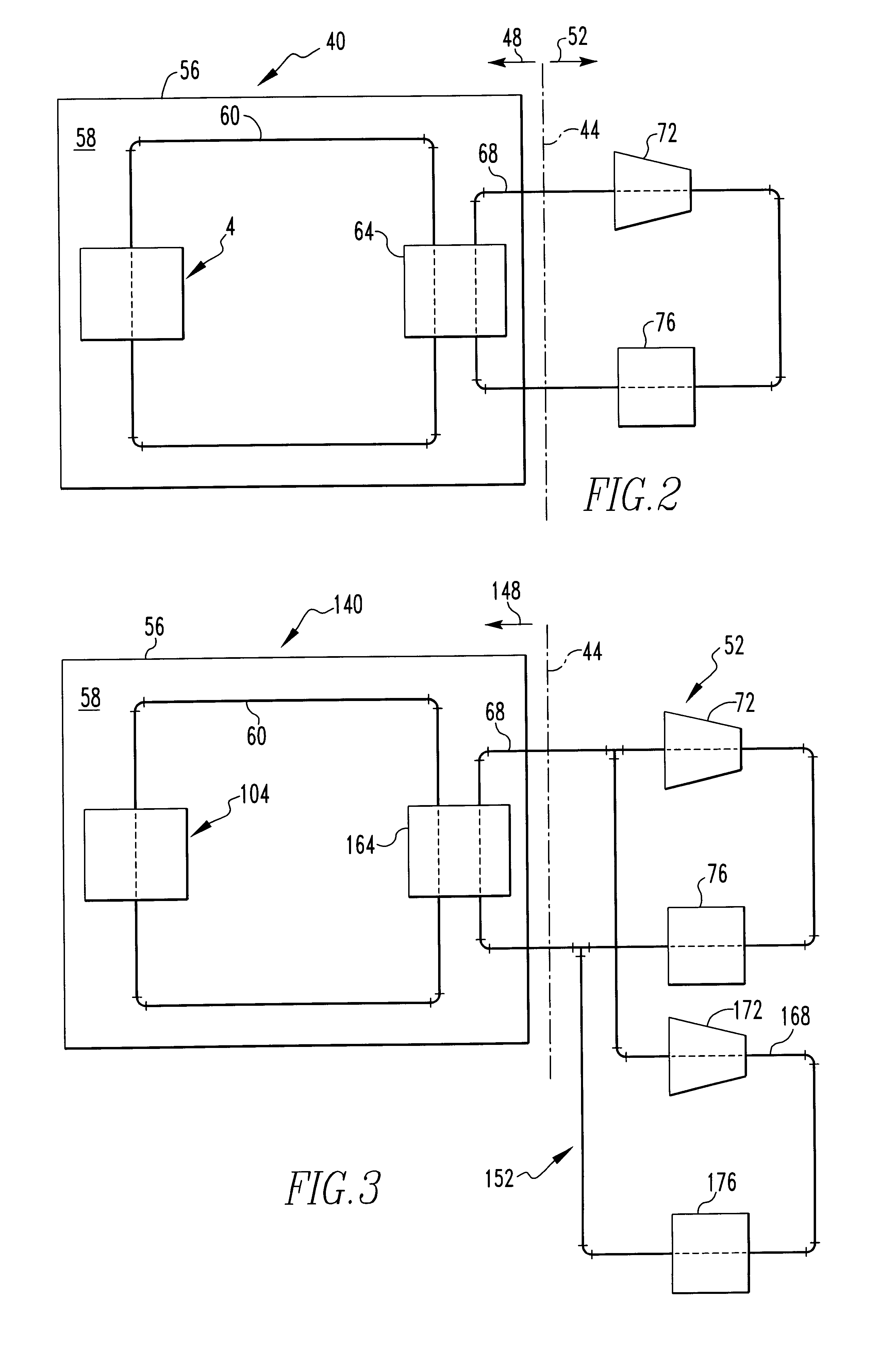

Method of uprating an existing nuclear power plant

InactiveUS6909765B2Increased power outputThermal power of be increaseNuclear energy generationNuclear engineering problemsNuclear engineeringSurface-area-to-volume ratio

An improved method of increasing the power output of an existing nuclear power plant includes increasing the thermal power output of the plant's nuclear island and constructing of an auxiliary BOP to handle the increased thermal power. The thermal power of the nuclear island can be increased such as by increasing the thermal power of the plant's reactor, by replacing the plant's steam generator with one that is more efficient, and by increasing the flow rate and / or change in temperature of a coolant in a secondary cooling loop of the plant. The thermal power of the reactor can be increased such as by replacing existing cylindrical fuel rods with fuel rods having a relatively greater surface area to volume ratio and / or by increasing the flow rate and / or the change in temperature of a coolant of a primary cooling loop. The auxiliary BOP can be constructed while the plant is in operation, and can then be connected with the nuclear island during a maintenance operation on the reactor.

Owner:WESTINGHOSE ELECTRIC CORP

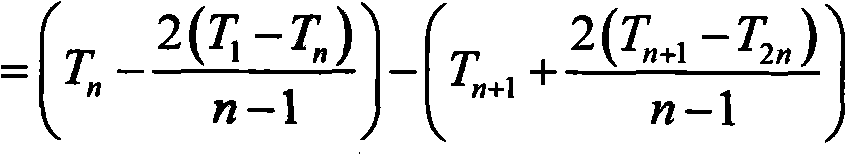

Thermal contact resistance testing method and equipment

The invention discloses a thermal contact resistance testing method belonging to the technical field of tests and comprising the steps of: preparing for test samples and equipment, heating the samples and acquiring the temperatures of test points of the samples, calculating the average temperature of the adjacent samples in the contact interface, and carrying out temperature compensation on the contact interface of the samples; and calculating contact conductance and thermal contact resistance according to the temperature drop of the contact interface of the adjacent samples and the axial heat flow of the samples. According to the requirement of the tests, the heating temperature of a heating device or loading stress of a stress loading device can be regulated, and the thermal contact resistances under different temperatures and stress conditions are tested. The testing method can be used for testing the thermal contact resistances of the test samples under different temperatures and stress conditions, and is easy and simple in implementation.

Owner:BEIHANG UNIV

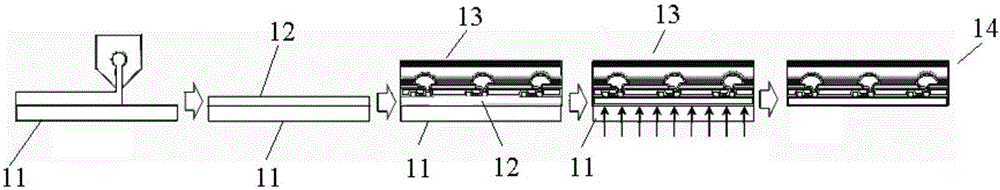

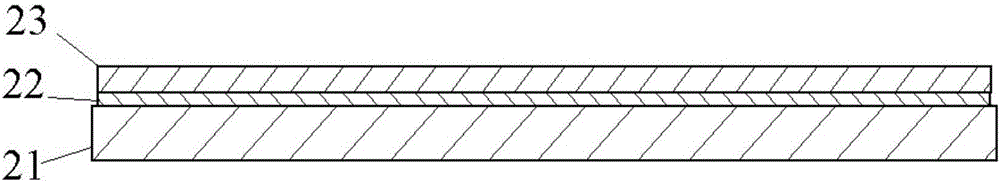

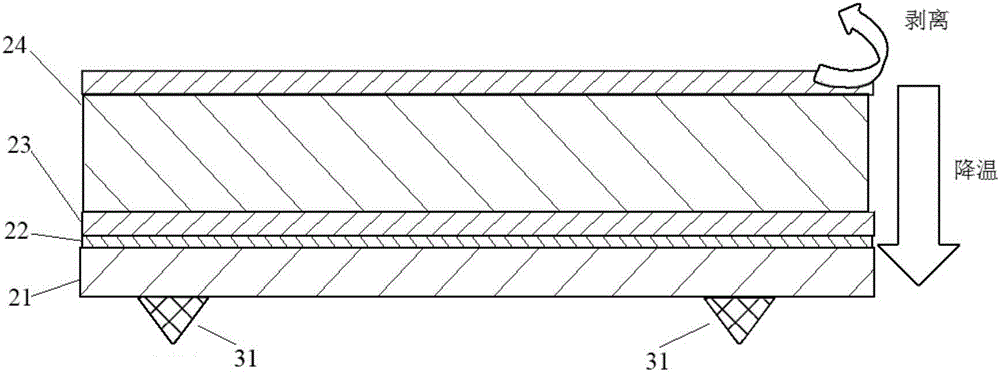

Flexible display screen substrate and preparation method thereof and preparation method of flexible display screen

InactiveCN106847862AAvoid harmChange temperatureLamination ancillary operationsSolid-state devicesDisplay deviceEngineering

The invention discloses a flexible display screen substrate. The substrate comprises a support base and a flexible base. An adhesive gel layer is arranged between the support base and the flexible base. The adhesive gel layer is used for pasting the flexible base on the support base. The adhesive force of the adhesive gel layer changes with the change of the environment. The invention further discloses a preparation method of the flexible display screen substrate. The method comprises the steps of firstly taking glues which have the adhesive force changing with the change of the environment, smearing the glues on the support base to form the adhesive gel layer. The invention further discloses a preparation method of a flexible display screen. According to the flexible display screen substrate and the preparation method thereof and the preparation method of flexible display screen, the environmental temperature is changed to achieve the detachment of the flexible base from the support base, the feature is different from the traditional laser detachment technology, and the damage caused by laser to the flexible base is avoided.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

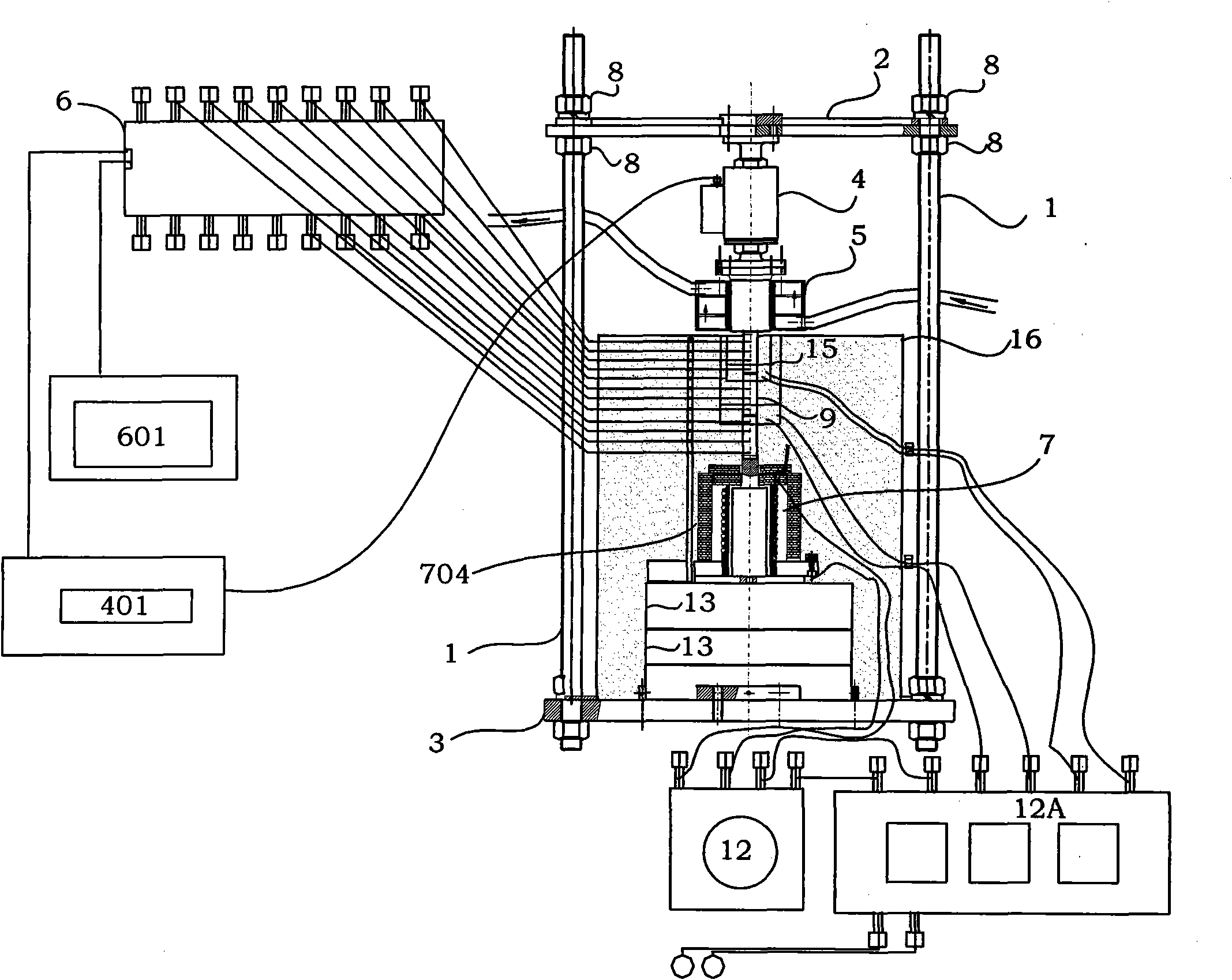

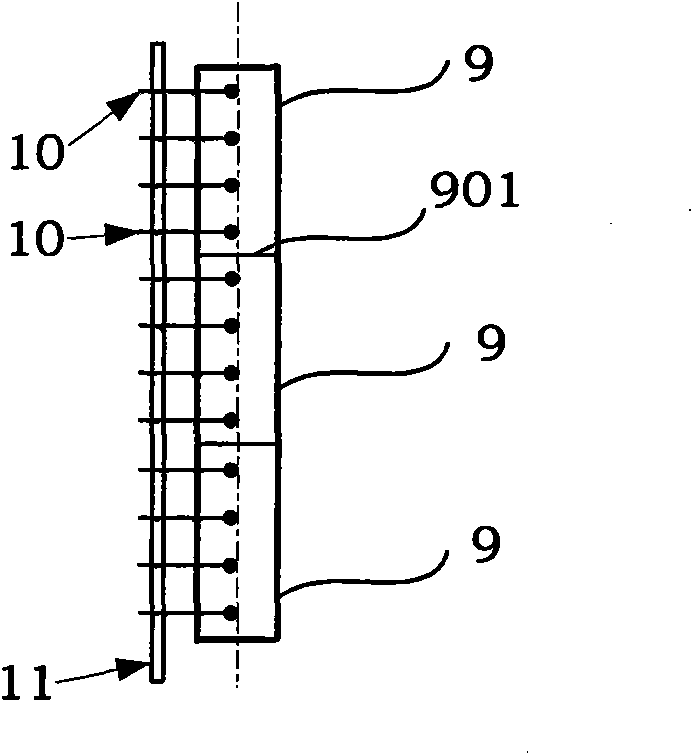

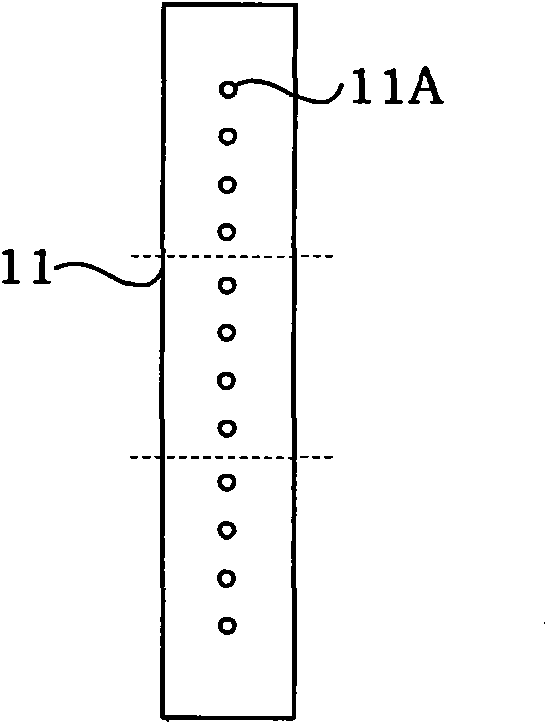

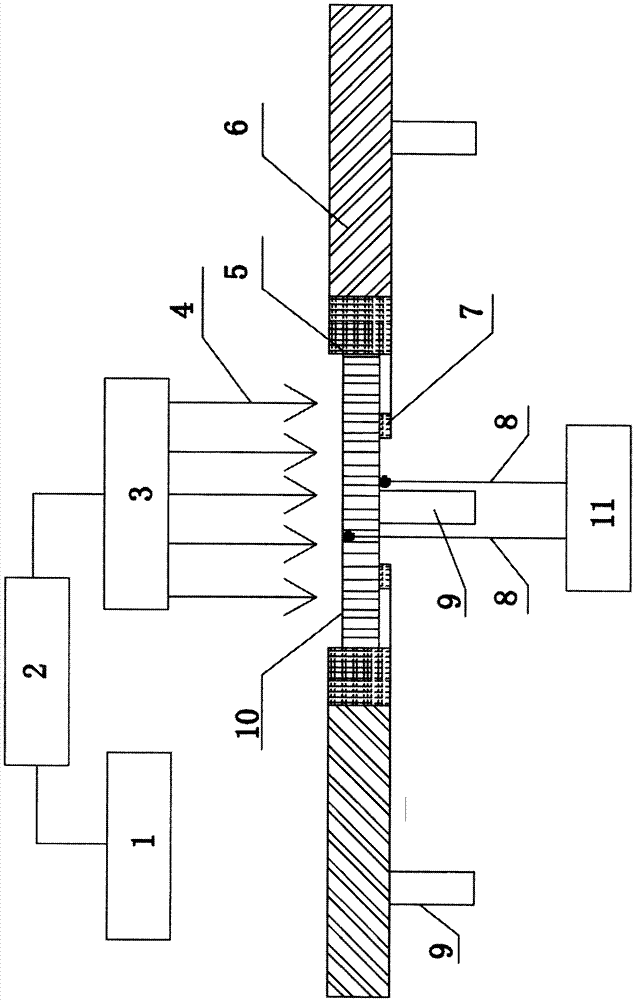

Thermal contact resistance test equipment

InactiveCN101907590AChange temperatureAvoid lostMaterial heat developmentThermometers using electric/magnetic elementsMonitoring siteTest sample

The invention discloses thermal contact resistance test equipment, which mainly comprises a bracket, a top plate, a bottom plate, a stress loading device, a data acquisition system and a heating device, wherein the heating device, a test sample and the stress loading device are arranged sequentially from the bottom up between the bottom plate and the top plate; the stress loading device is fixed in the centre of the top plate and adjusts four groups of nuts on the top plate; a stress transfer bar of the stress loading device is in contact with the top end of the test sample to load stress to the top end of the test sample; and the bottom plate adjusts a horizontal angle and a vertical height through the four groups of nuts, and is provided with the heating device used for heating the test sample. The equipment provided by the invention can perform thermal contact resistance test experiments under high temperature and high-contact stress, continuously change the temperature (less than or equal to 1,000 DEG C) of a hot end and adjust the loaded stress (less than or equal to 500 MPa), and simultaneously detect, record, analyze and count the temperatures of monitoring points of a plurality of channels so as to avoid errors caused by the loop record of each channel.

Owner:BEIHANG UNIV

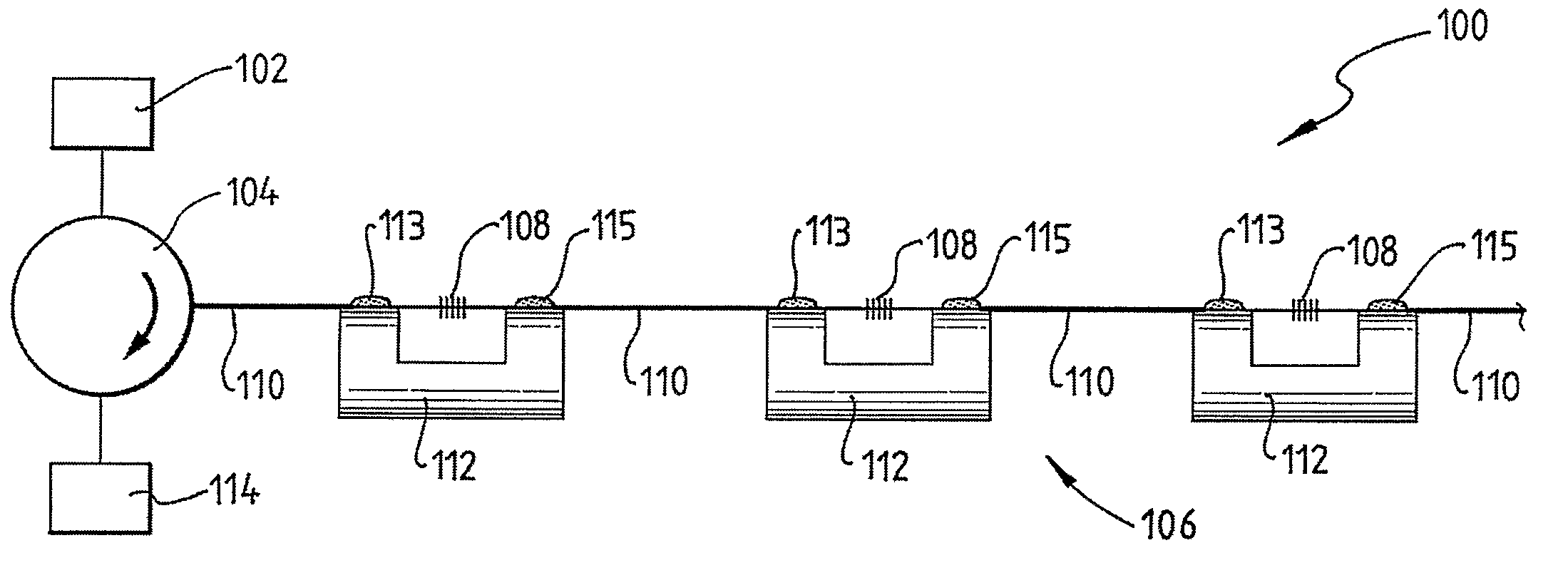

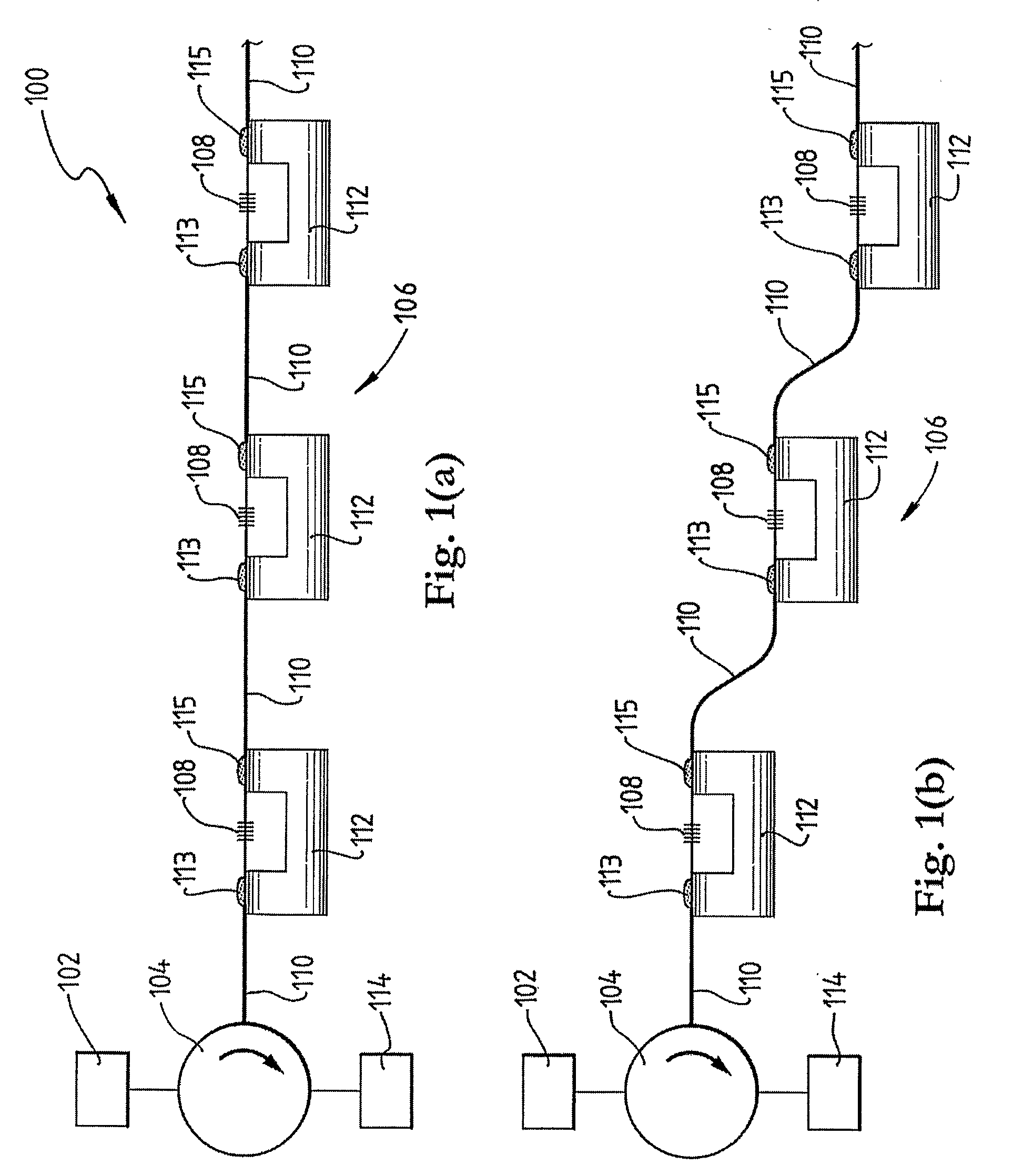

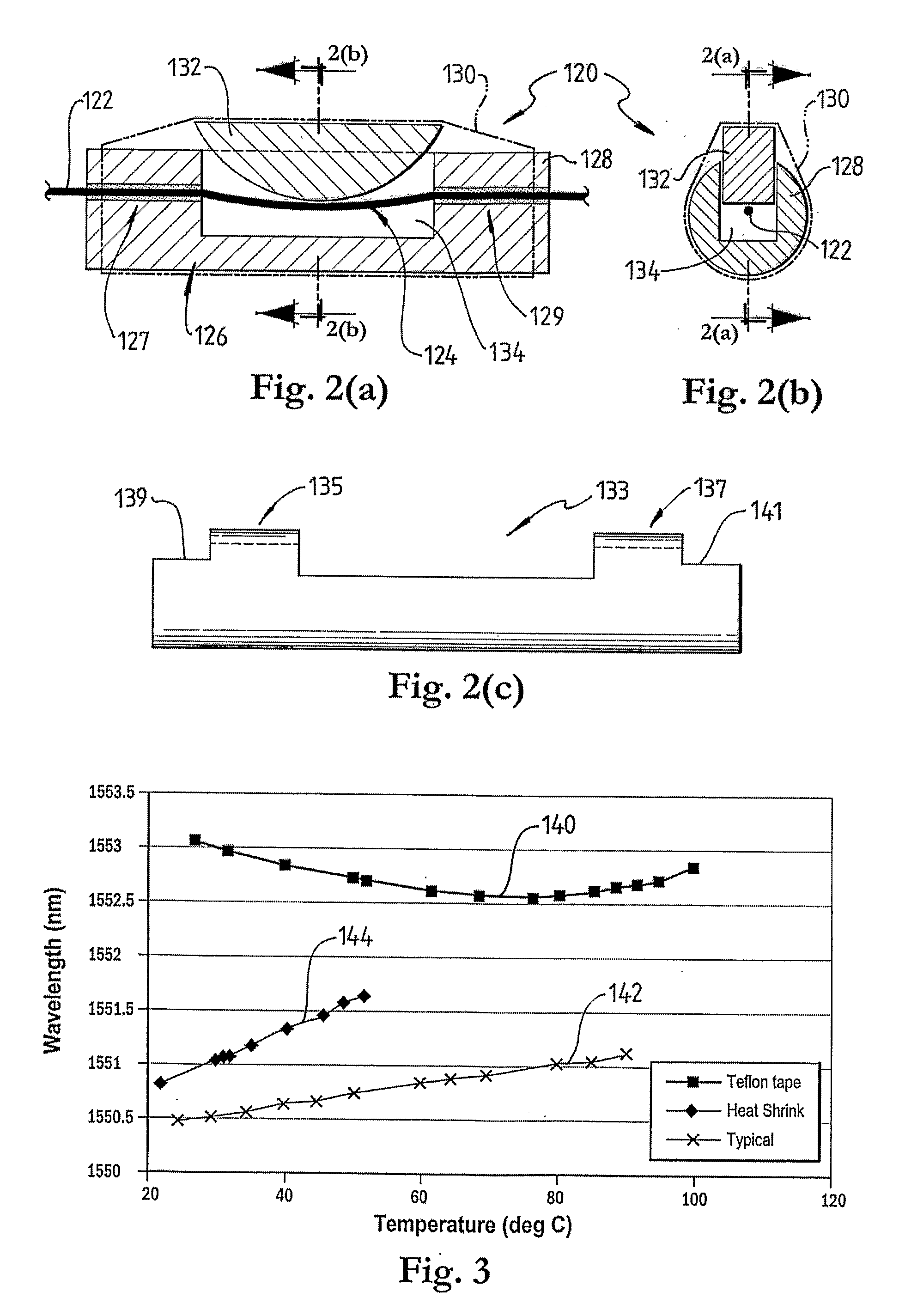

Optical Device

InactiveUS20080281209A1Compact designReduce temperature changesGlass making apparatusForce measurementGratingLight guide

The present invention provides an optical device which comprises a light guide incorporating a Bragg grating. The apparatus also comprises a moveable wall portion which is coupled to the Bragg grating so that a movement of the wall portion causes a force that effects a change in strain of the Bragg grating and thereby effects a change in an optical period of the Bragg grating. A temperature related change in the optical period of the Bragg grating is reduced by a temperature related change in the force on the Bragg grating by the moveable wall portion.

Owner:COMMONWEALTH SCI & IND RES ORG

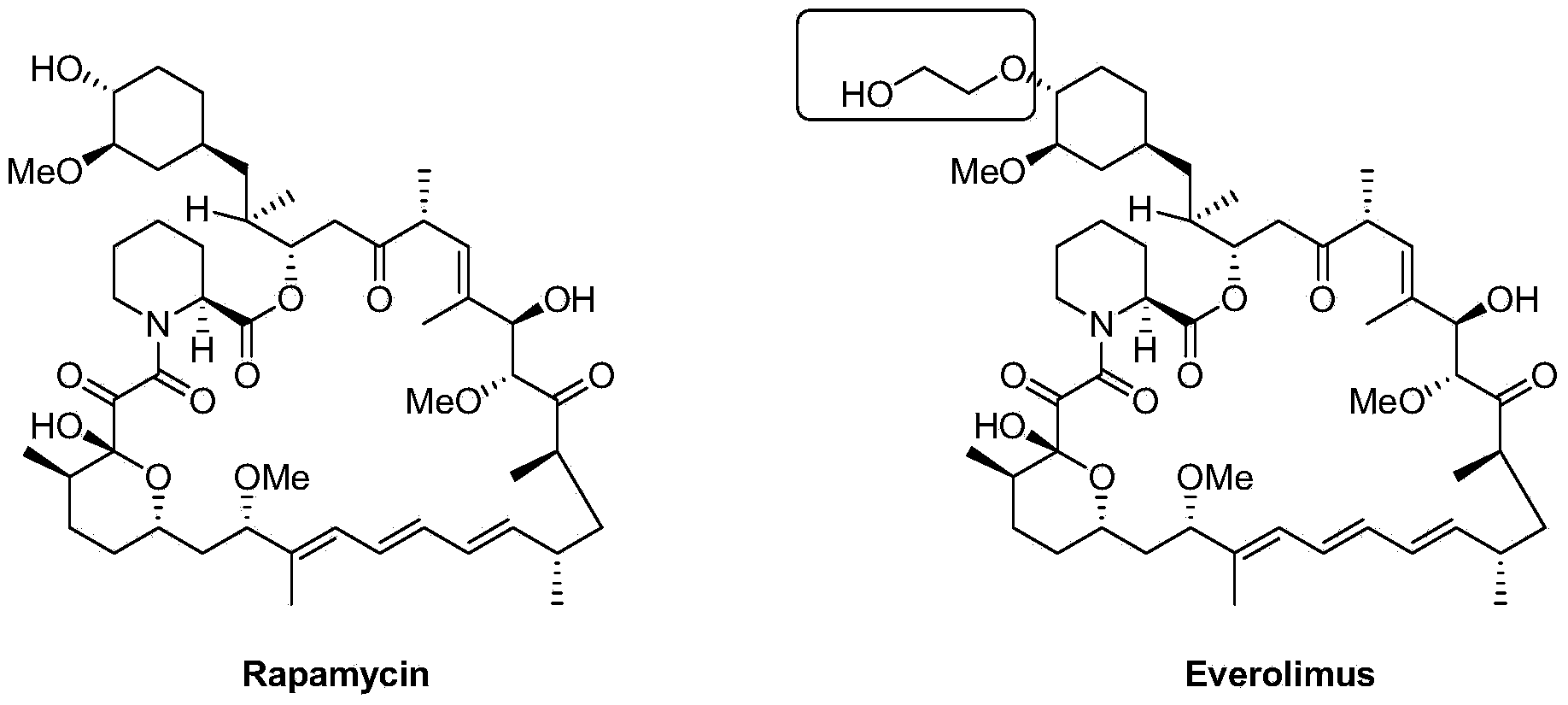

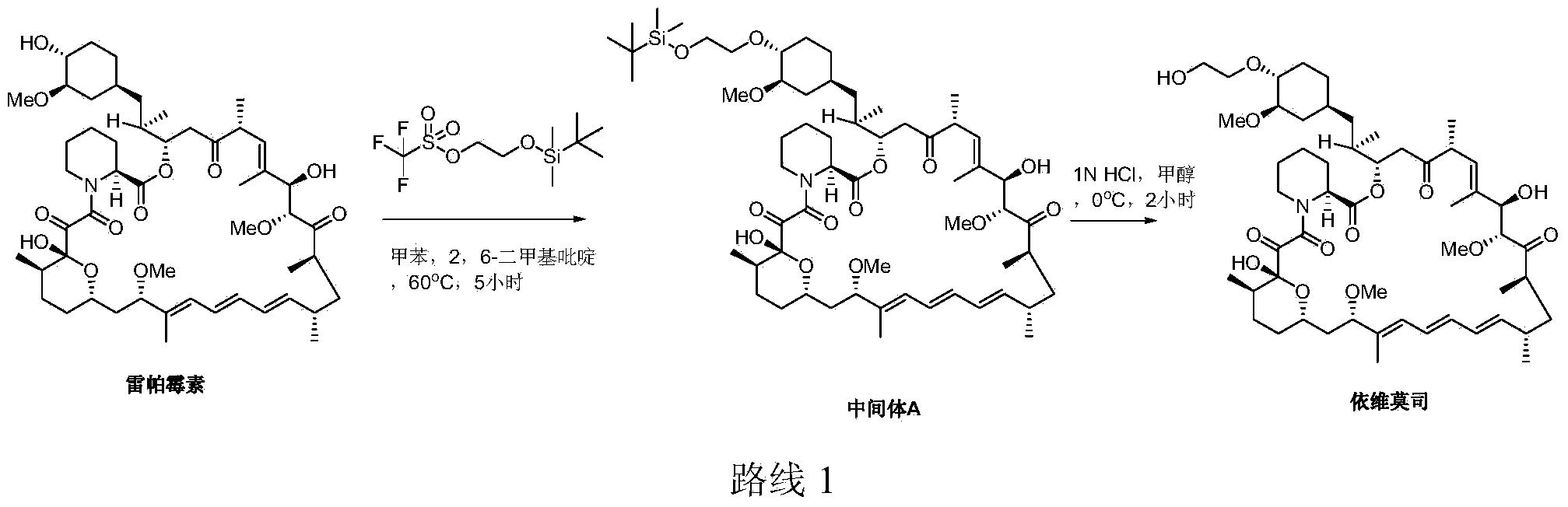

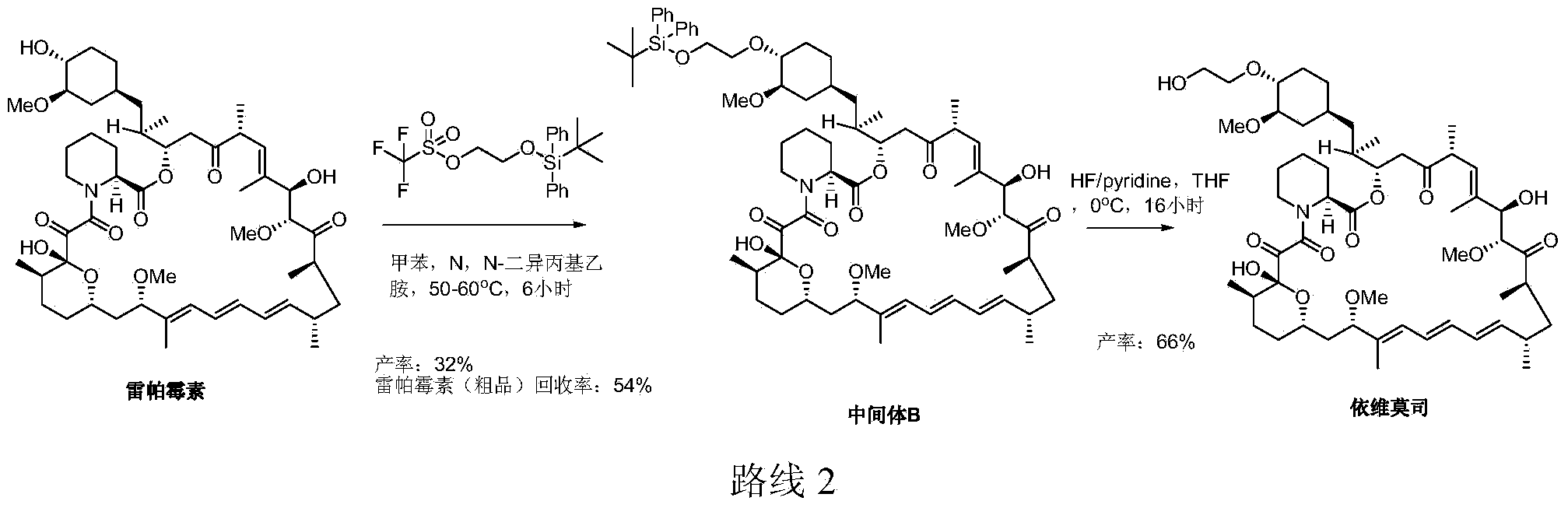

Preparation technology for everolimus

The invention provides a preparation technology for everolimus. The preparation method comprises the two steps of: 1) reacting sirolimus with 2-(tert-butyldiMethylsilyloxy) ethyl trifluoromethane sulfonate in the presence of proper solvent and organic base, to obtain an intermediate A; 2) reacting the intermediate A with inorganic acid in an organic solvent to obtain everolimus, wherein the organic base used in the step 1) is selected from large-steric hindrance or non-nucleophilic bases such as triethylamine, N,N-diisopropylethylamine, 1,8-diazabicycloundec-7-ene or N-methylmorpholine, acid used in the step 2) is hydrochloric acid, sulfuric acid or phosphoric acid. According to the technology, the total yield in the two steps and the purity of a final product are greatly improved as compared with those reported by the existing literature, the process route is short, the reaction conditions are mild, and the reaction result is also stable and reliable.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

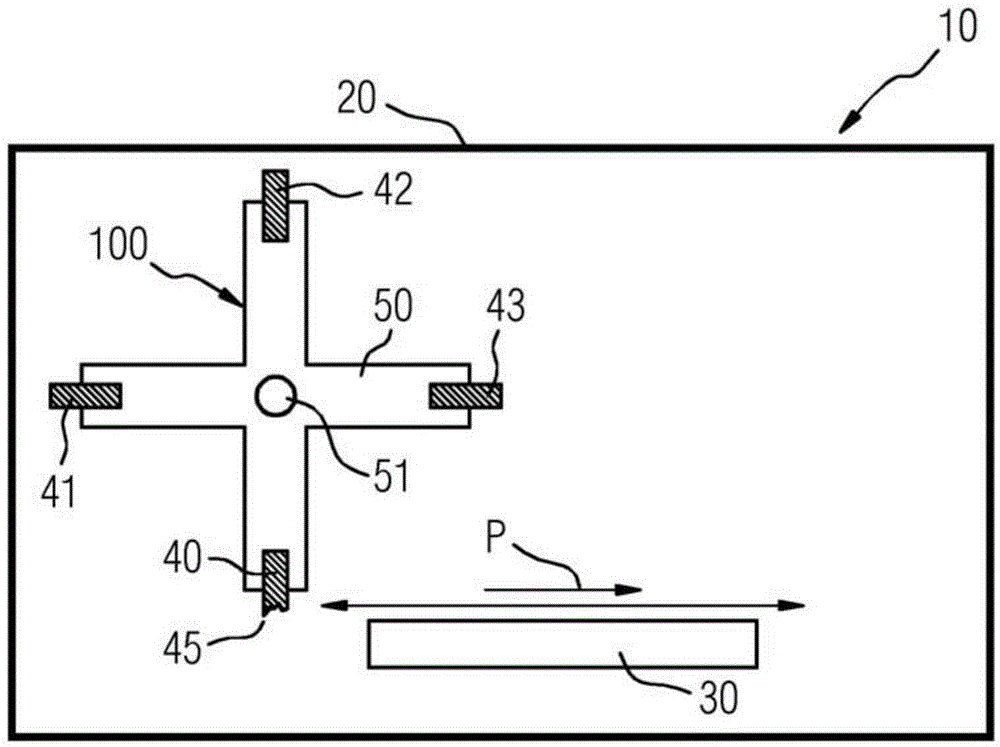

Arrangement for coating a powder

InactiveCN105408040AAchieve replacementPrevent openingAdditive manufacturing apparatusLiquid surface applicatorsMetal powderCoating

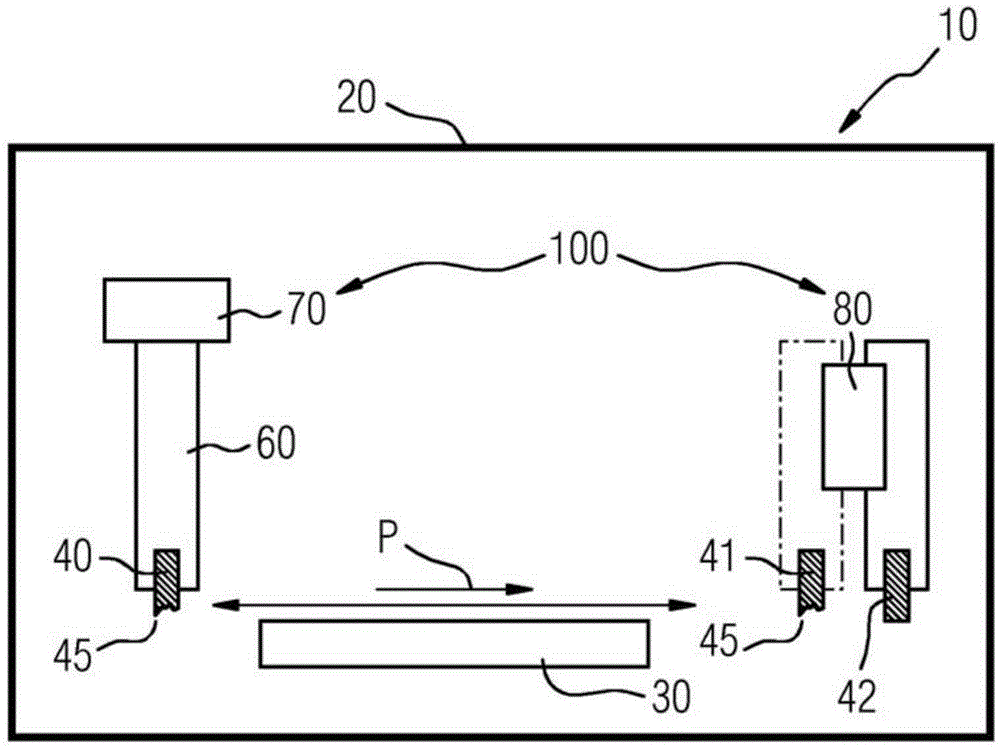

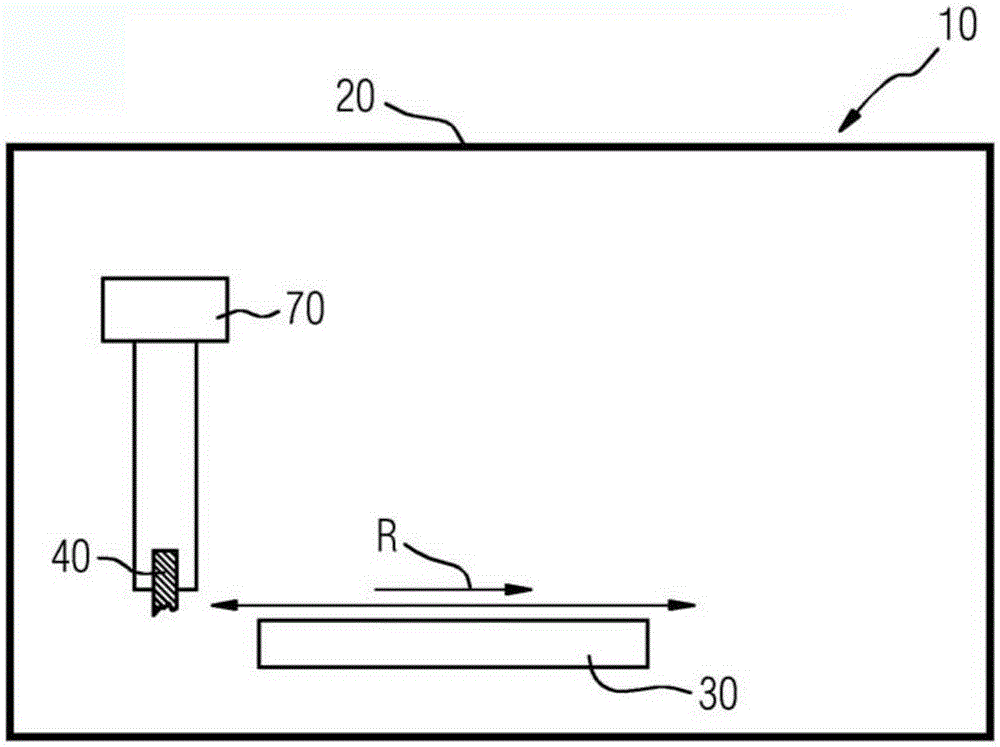

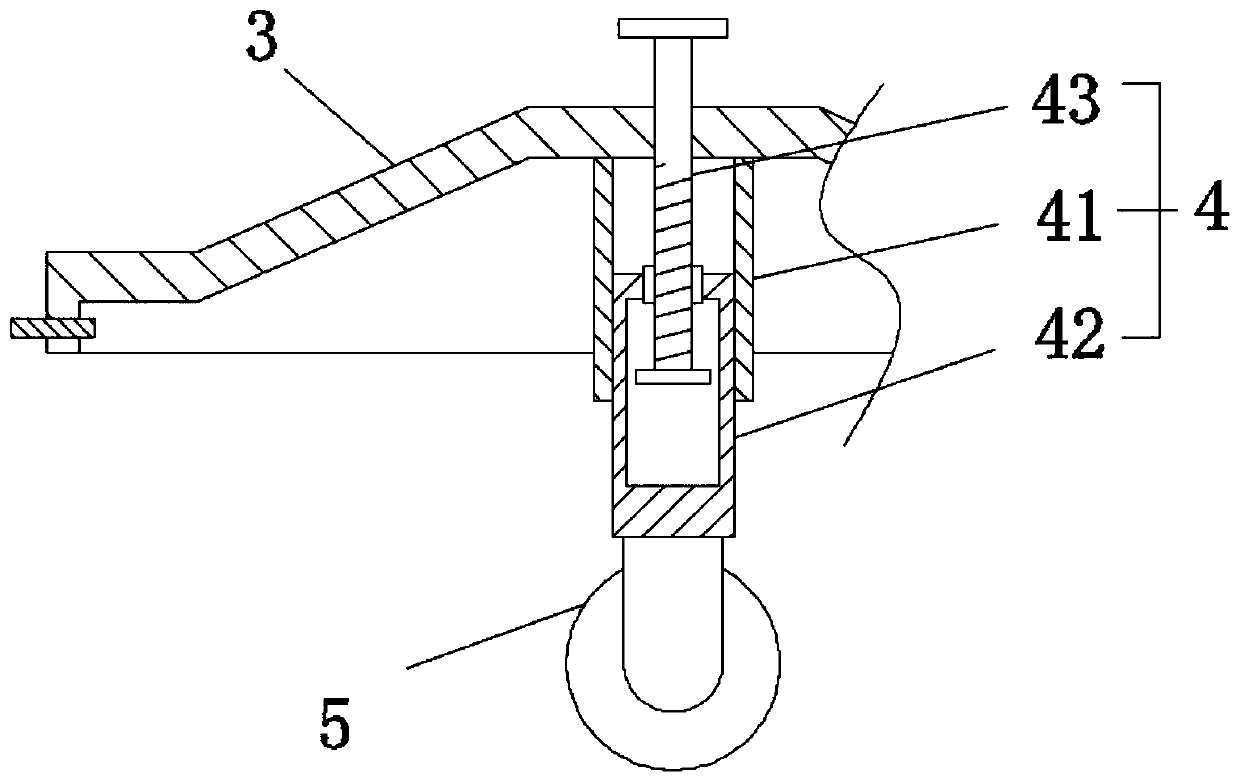

The invention relates to an arrangement (10) with a processing chamber (20), a coating platform (30) which can be found in the processing chamber (20), and a coating device with a coating element (40) which can be found in the processing chamber (20) for coating a powder, in particular a metal or ceramic powder. According to the invention, the arrangement (10) has an exchanging device (100) which is suited for exchanging at least one portion of the coating element (40) with another portion of the same coating element (40) or for exchanging the entire coating element (40) with another coating element (41, 42, 43) within the processing chamber (20) when the processing chamber (20) is closed. The exchanging device (100) can comprise a multiple head (50), in particular a pivoting head or a revolving head, an exchanging station (80), and / or a moving device (70) which allows a coating element (40) portion that is to be exchanged to be moved or pushed away. A part of the coating element (40) can also be rolled on a supply roller (230), and the coating element portion can be exchanged by unrolling the coating element from the supply roller (230). Together with the exchanging device (100), a wear determining device (300) is also preferably provided, said wear determining device being capable of measuring the wear of the coating element (40) and triggering an automatic coating element exchange or coating element portion exchange by means of the exchanging device (100).

Owner:SIEMENS AG

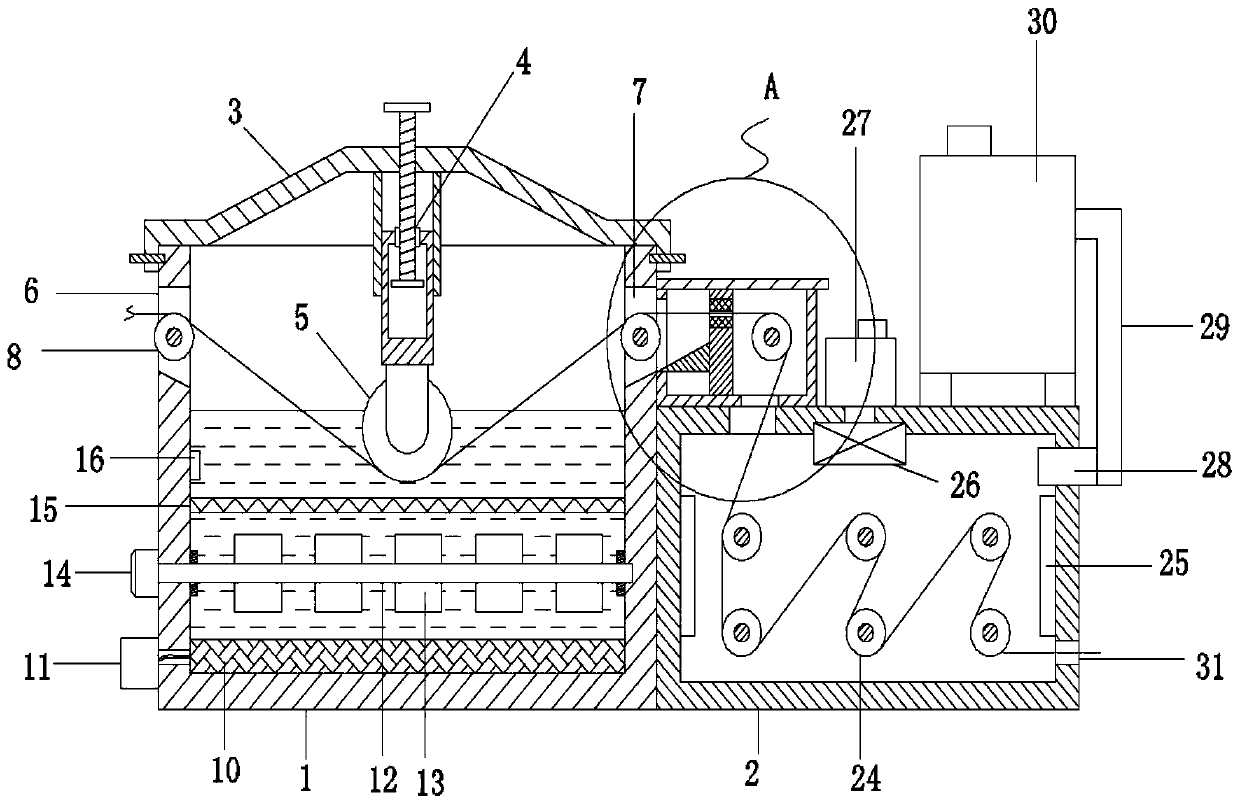

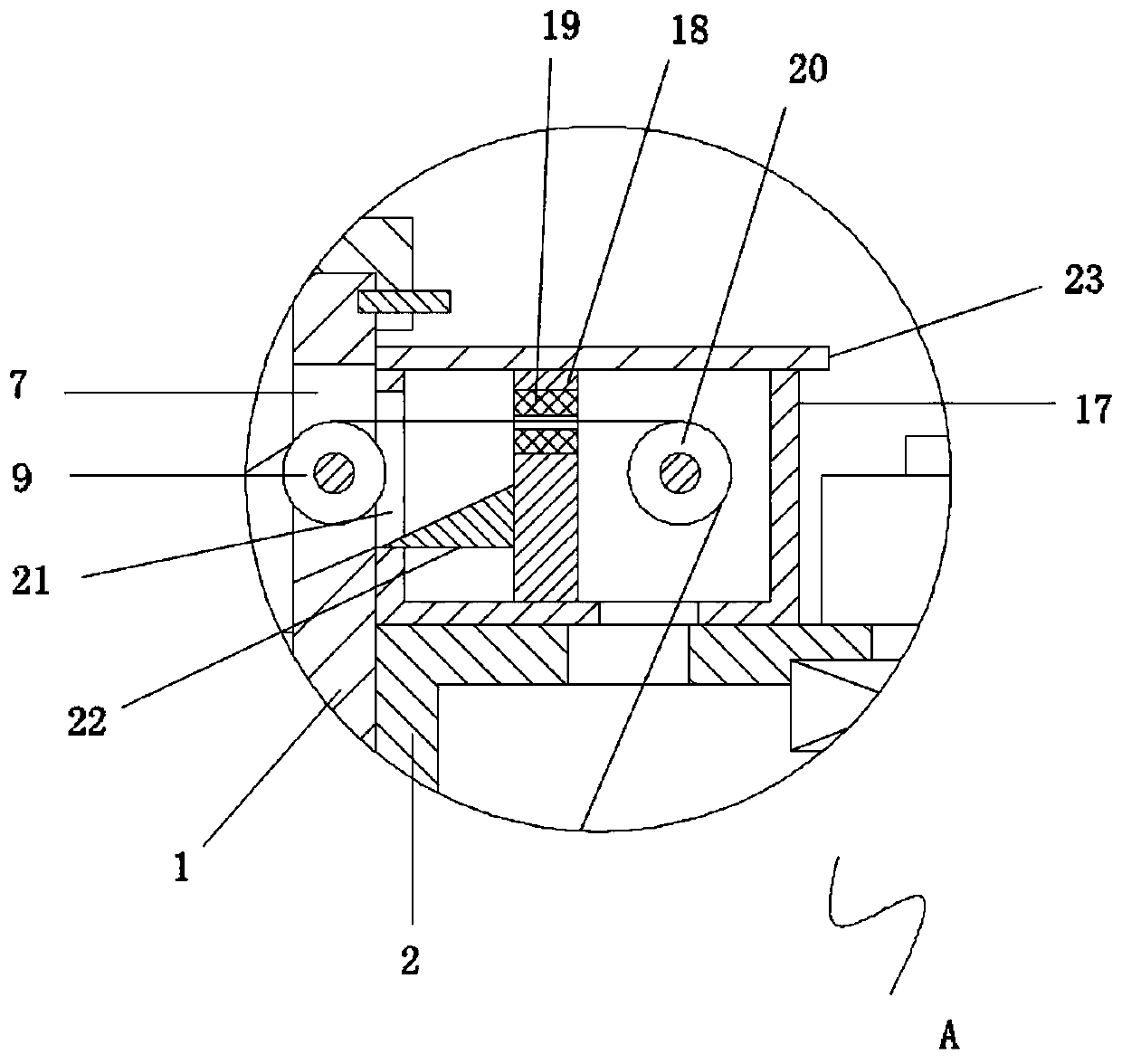

Nonwoven fabric dyeing device for clothing production

InactiveCN110004622AAvoid layered settlementImprove dyeing effectTextile treatment containersSucessive textile treatmentsLiquid temperatureDyeing

The invention discloses a nonwoven fabric dyeing device for clothing production in the technical field of nonwoven fabric production. The nonwoven fabric dyeing device comprises a dyeing tank and a drying tank, and the drying tank is fixedly connected to the right side wall of the dyeing tank. Dyeing liquid can be stirred by a stirring mechanism to avoid layered settlement; by arrangement of a heating plate and a component thereof, dyeing liquid temperature can be changed; by arrangement of an end cover and a telescopic mechanism, convenience in mounting of a nonwoven fabric in the dyeing tankis achieved; by arrangement of a protective screen, the problem of fabric loss caused by contact of the nonwoven fabric and the stirring mechanism can be avoided; by the drying tank and dyeing tank integrated structure, fabric dyeing and drying processes are integrated, a fabric dyeing process is simplified, and processing cost is reduced; by arrangement of array cloth rollers, two surfaces of the nonwoven fabric can be dried completely, and drying effects are improved; by arrangement of a filter tank, waste gas generated in dyeing and drying can be purified.

Owner:安徽职业技术学院

Device and method for preparing high-purity nano polyaluminium chloride with high efficiency, energy saving and environmental protection

InactiveCN101734703AEasy dischargeEfficient heat dissipationEnergy inputAluminium chloridesAluminium chlorohydrateProcess engineering

The invention relates to a device for utilizing the residual heat of tail gas in the production of polyaluminium chloride, which comprises a drying part of the liquid material of the polyaluminium chloride. The device is characterized in that the drying part of the liquid material of the polyaluminium chloride is provided with a drying tower 1 and a tail gas absorption tower 2, wherein a device for recovering the residual material of the tail gas and recycling the residual heat is arranged in the tail gas absorption tower 2; the utilization method of the device comprises a drying technology and a tail gas absorption technology. The method is characterized in that part of the liquid material is still in an atomization state after the liquid material is dried, and enters the tail gas absorption tower 2 along with the tail gas together, the circulation of the liquid material is carried out in the tail gas absorption tower 2 at any moment by a circulation pump 18, and the liquid material is heated and concentrated by the residual heat of the tail gas. The invention has the advantages that the liquid material is concentrated by utilizing the tail gas, the residual material and the residual heat of the tail gas are fully utilized, energy resources are saved, the mass output rate is enhanced, the discharge of the waste gas and the waste heat is reduced, the pollution is reduced, and the cost is lowered.

Owner:TIANJIN RUNWO WATER SUPPLY INSTALLATION ENG

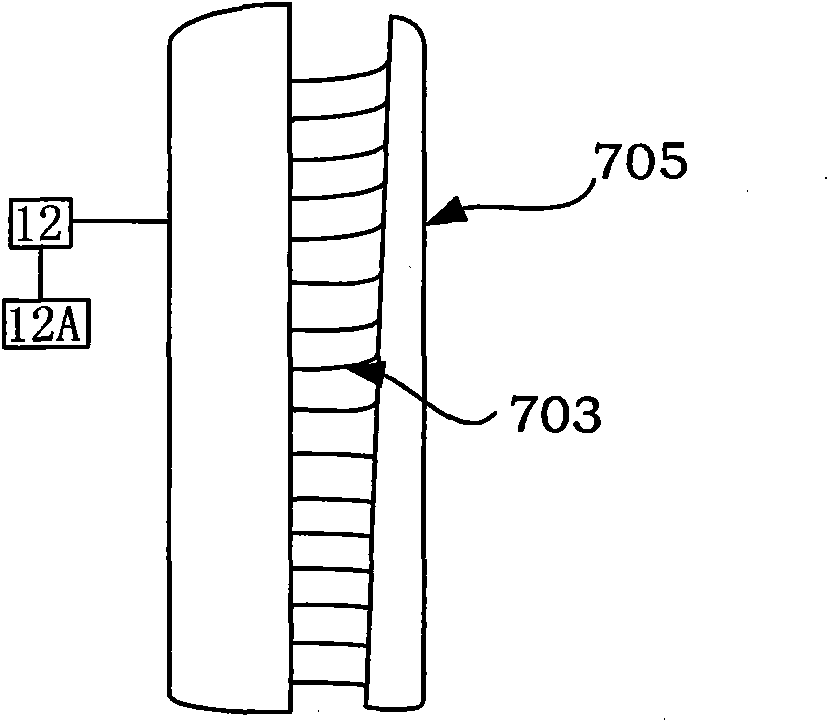

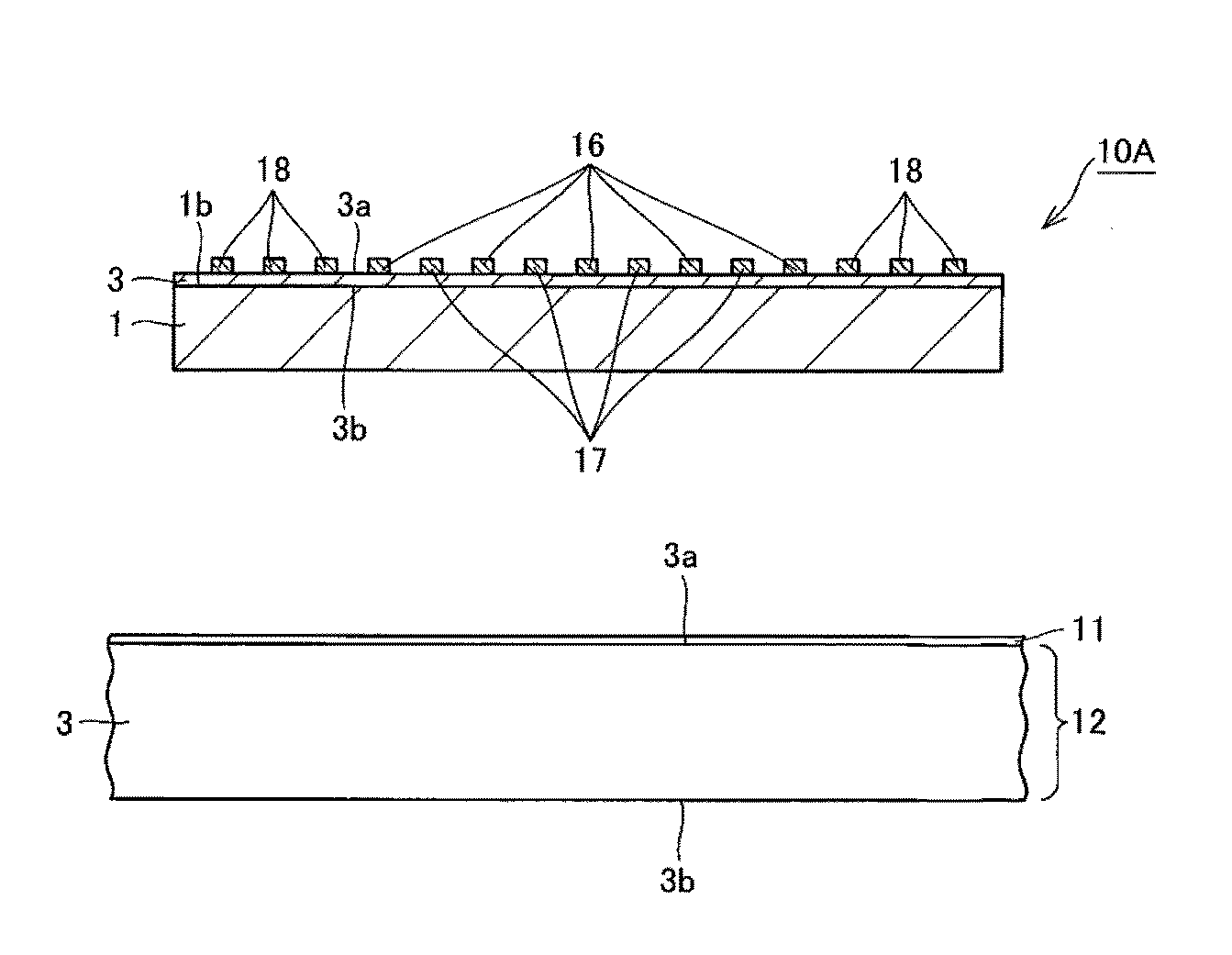

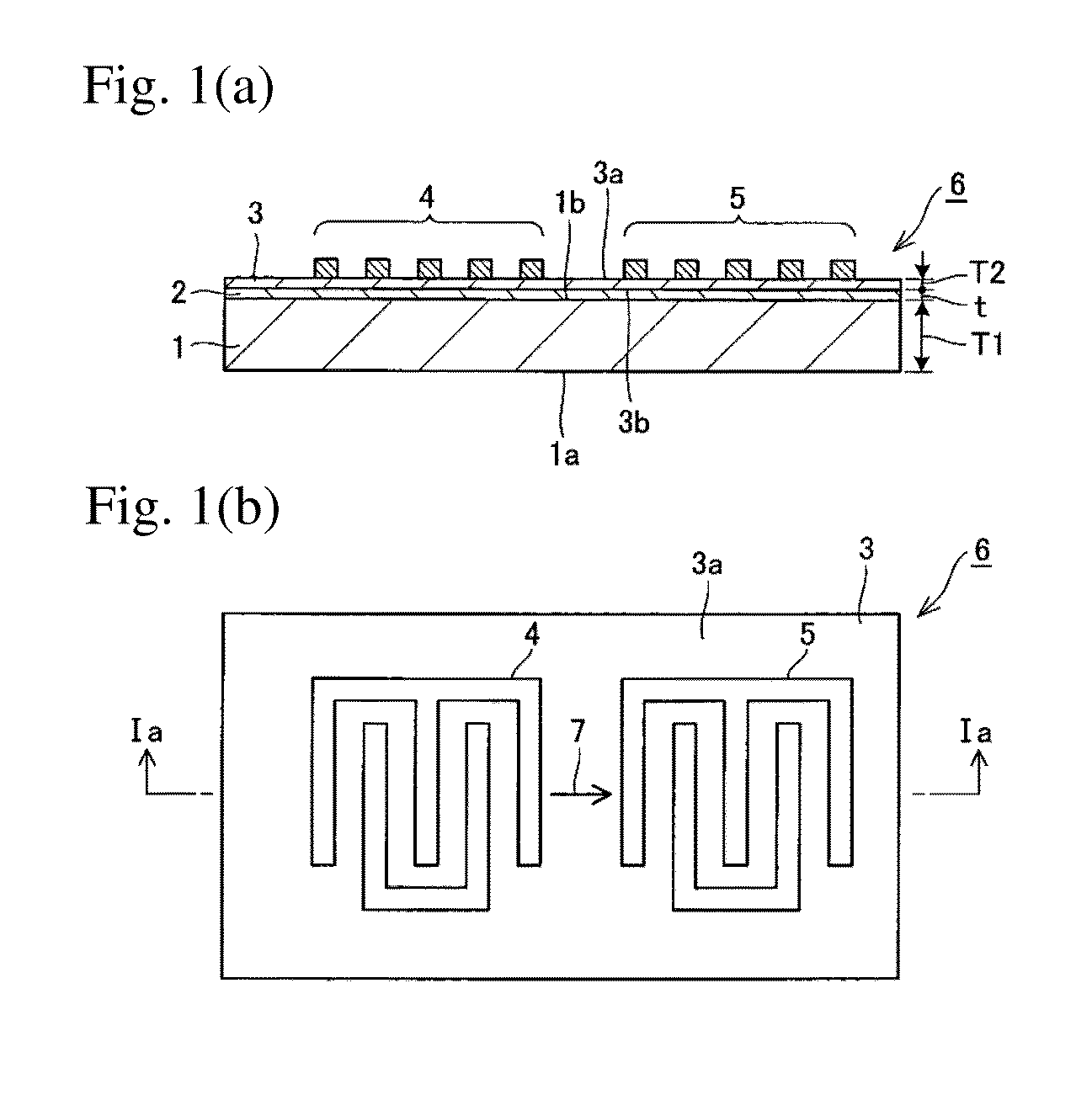

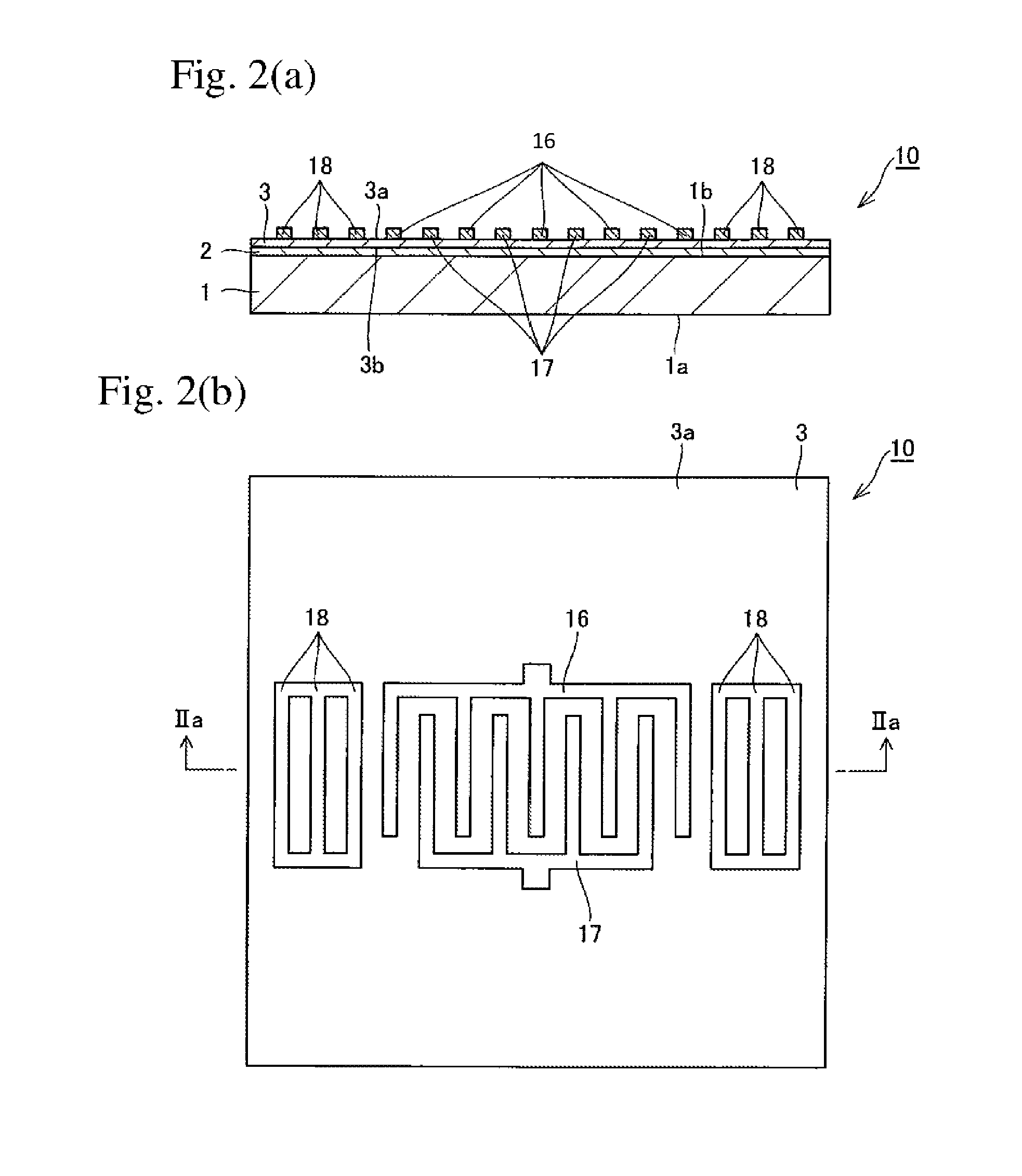

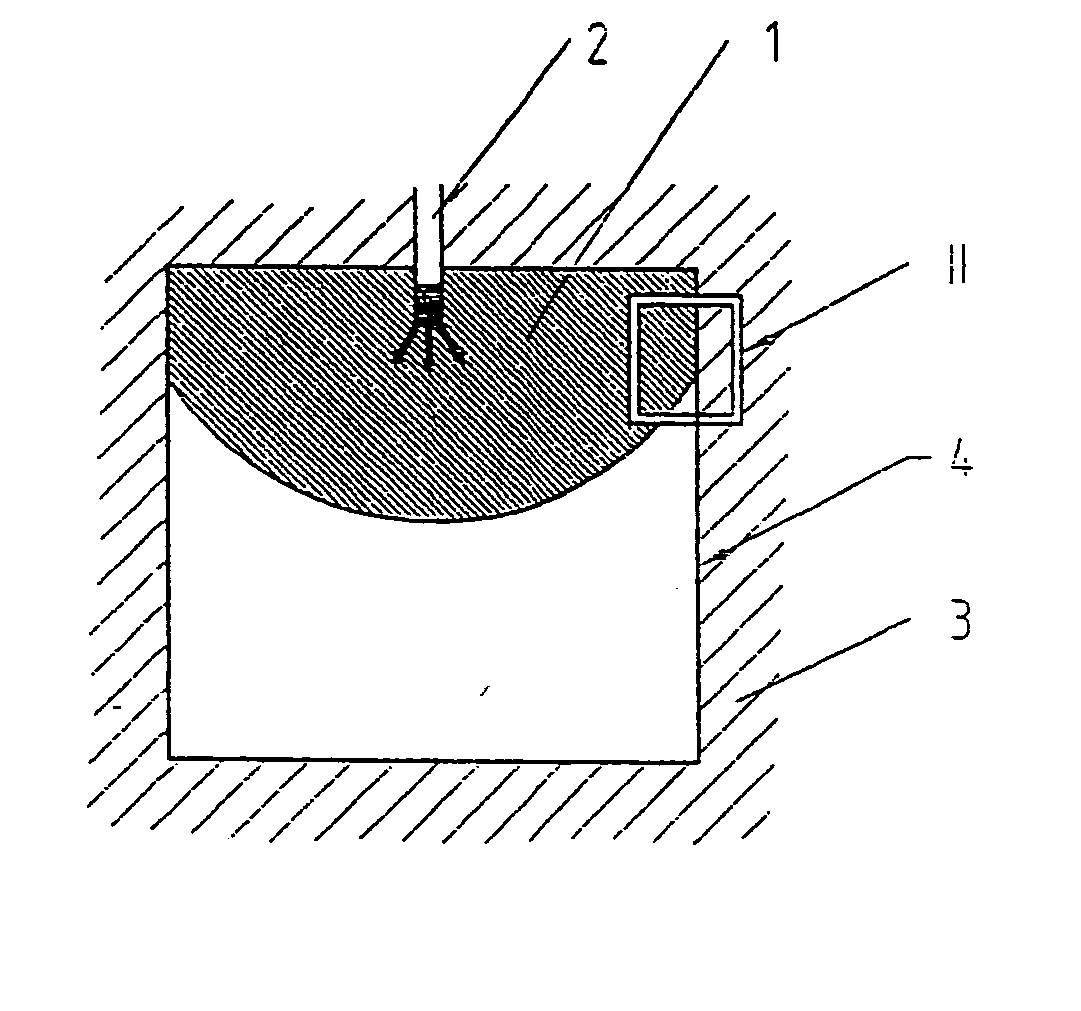

Composite substrates for acoustic wave elements, and acoustic wave elements

ActiveUS9438201B2Change temperatureReduce thicknessImpedence networksComposite substrateAcoustic wave

A composite substrate for an acoustic wave element includes a support substrate 1 and a propagation substrate 3 for propagating an acoustic wave. The propagation substrate is bonded to the support substrate 1 and composed of a piezoelectric single crystal. The propagation substrate 3 includes a surface lattice distortion layer 11 in which crystal lattices of the piezoelectric single crystal are distorted.

Owner:NGK INSULATORS LTD

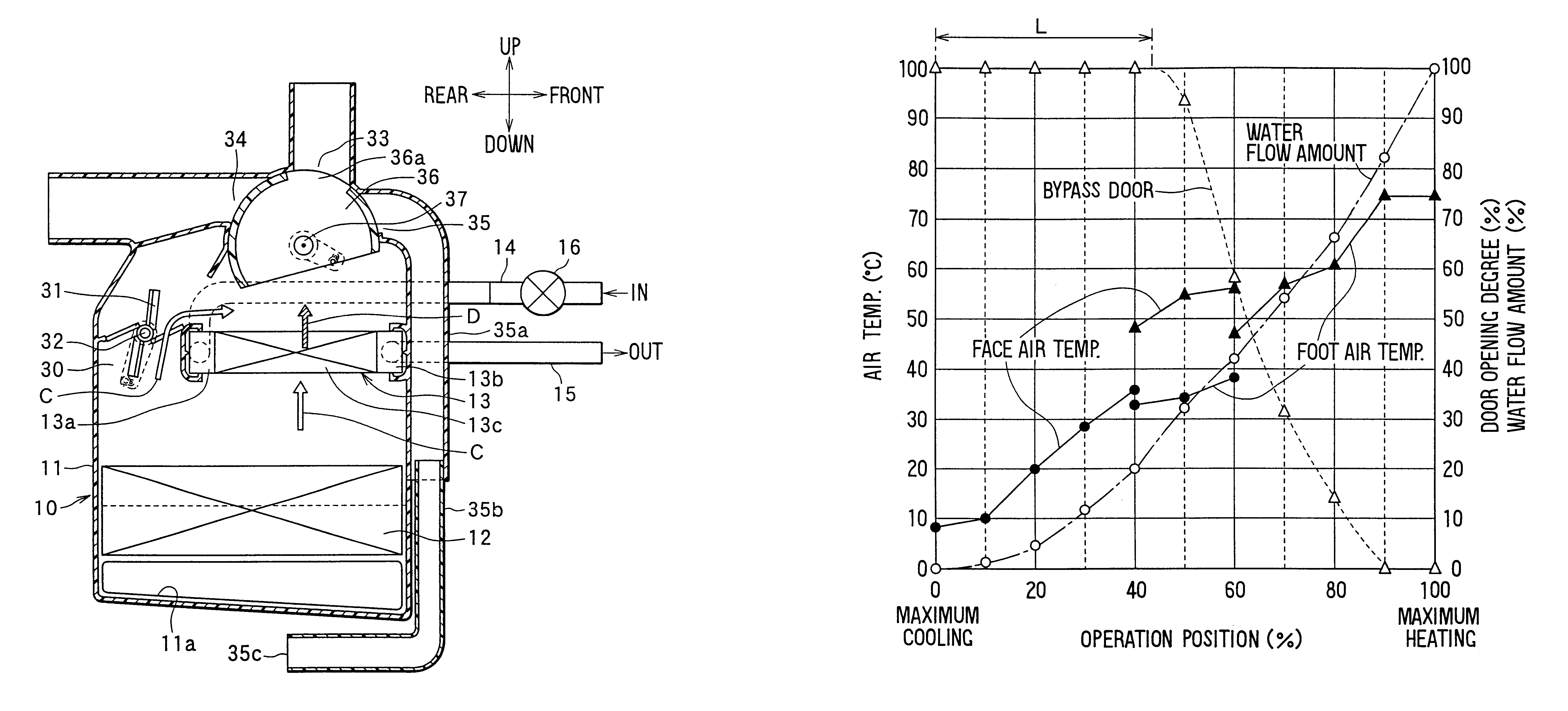

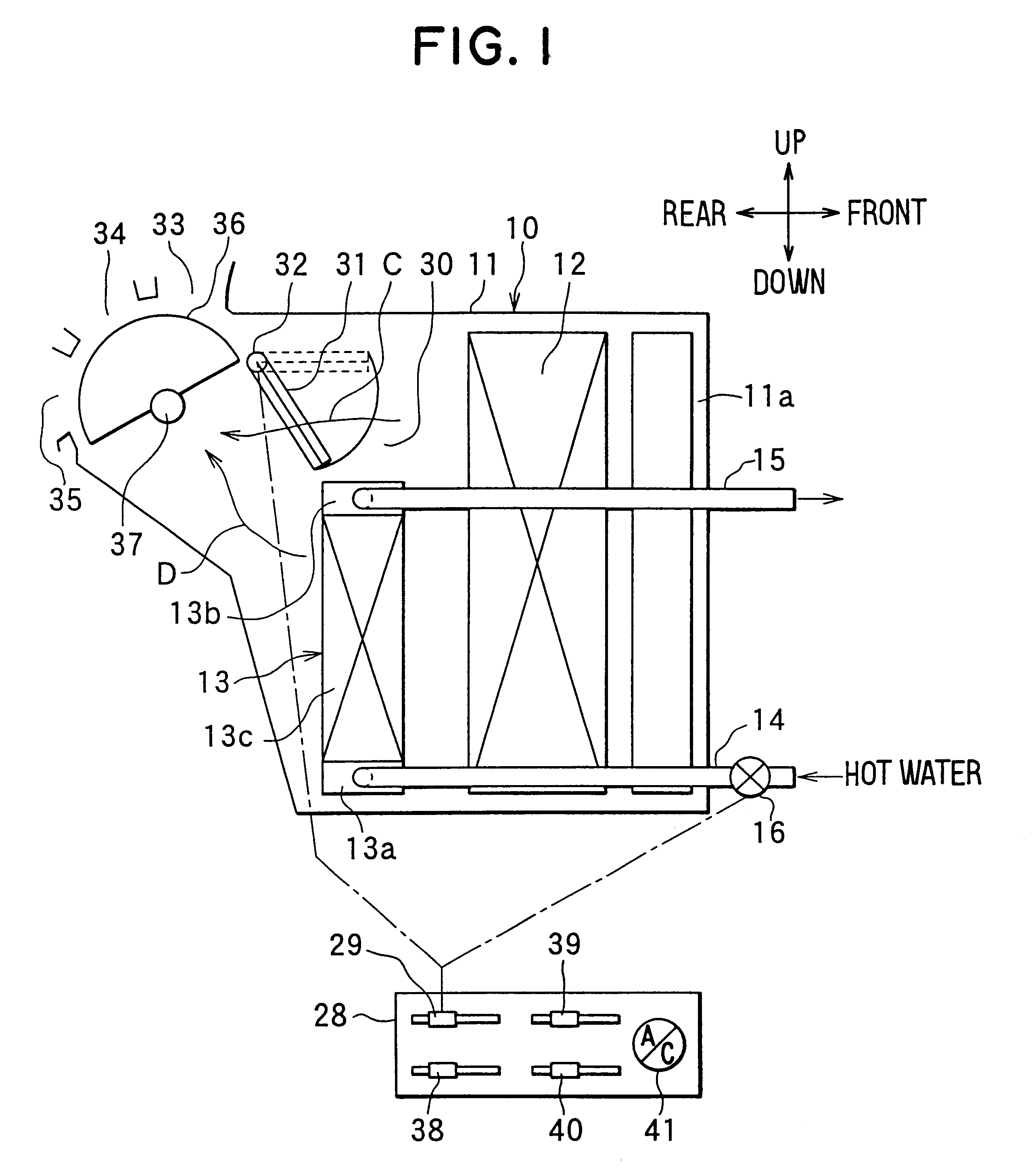

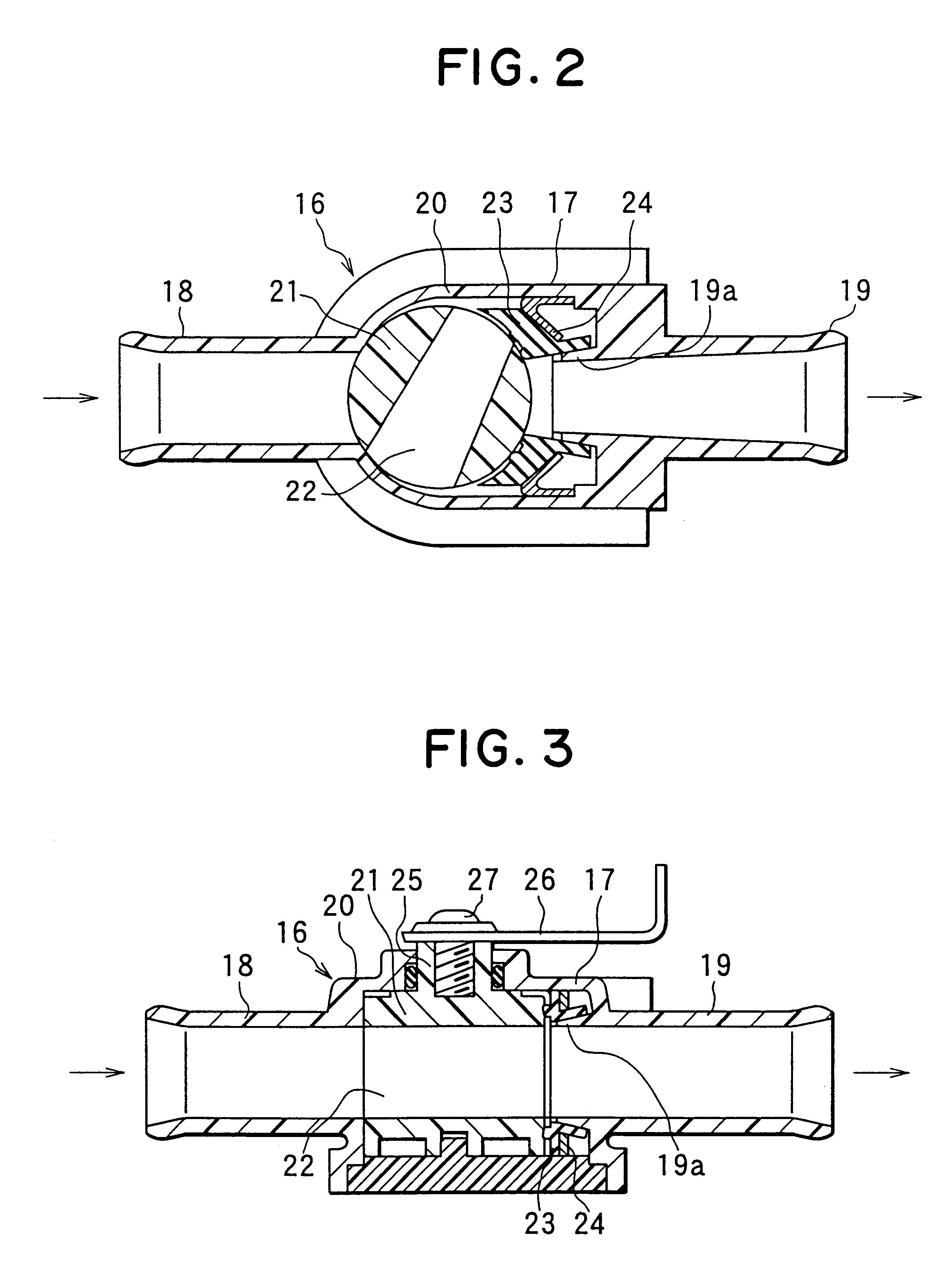

Air conditioning apparatus with air-temperature adjustment

InactiveUS6352208B1Easy to adjustReduce flow noiseAir-treating devicesRailway heating/coolingWater flowEngineering

A vehicle air conditioning apparatus includes a hot water valve for adjusting a flow amount of hot water flowing into a heating heat exchanger, a bypass passage through which air bypasses the heating heat exchanger, and a bypass door for opening and closing the bypass passage. In a high-temperature side area where temperature of air blown into the passenger compartment becomes higher, the temperature of air to be blown into the passenger compartment is adjusted by a hot-water flow adjustment of the hot water valve while the bypass door is operated at a fully closed position. On the other hand, in a low-temperature side area where temperature of air blown into the passenger compartment becomes lower, the temperature of air to be blown into the passenger compartment is adjusted by combining the hot-water flow adjustment of the hot water valve and the air flow adjustment of the bypass door. Thus, even in a minute flow area of hot water flowing into the heating heat exchanger, the temperature of air blown into the passenger compartment is accurately adjusted.

Owner:DENSO CORP

Method for making high-sensitivity optical fiber grating temperature sensor working in high and low temperature

InactiveCN101298999AChange temperatureThermometers using physical/chemical changesOptical waveguide light guideGratingFiber gratings

The invention provides a manufacturing method of a high-sensitivity optical fiber grating temperature sensor working in the high temperature and the low temperature, wherein the sensor adopts the duplex metal structure, and the temperature for the sensor to work is adjusted through adjusting the pre-loose length of the optical fiber grating. The method solves the problems that the high-sensitivity optical fiber grating temperature sensor can not work in the high and low temperature, and has wide application foreground in the temperature measuring field.

Owner:NAT INST OF NATURAL HAZARDS MINISTRY OF EMERGENCY MANAGEMENT OF CHINA +1

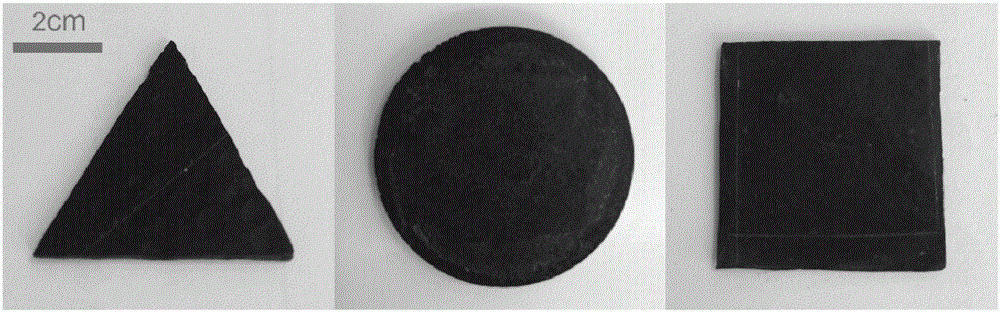

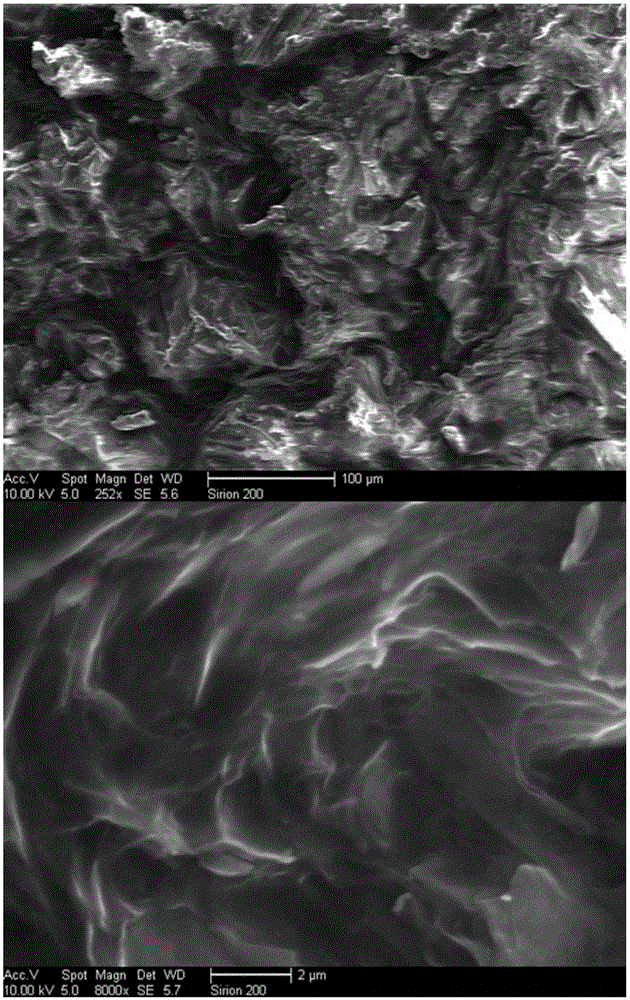

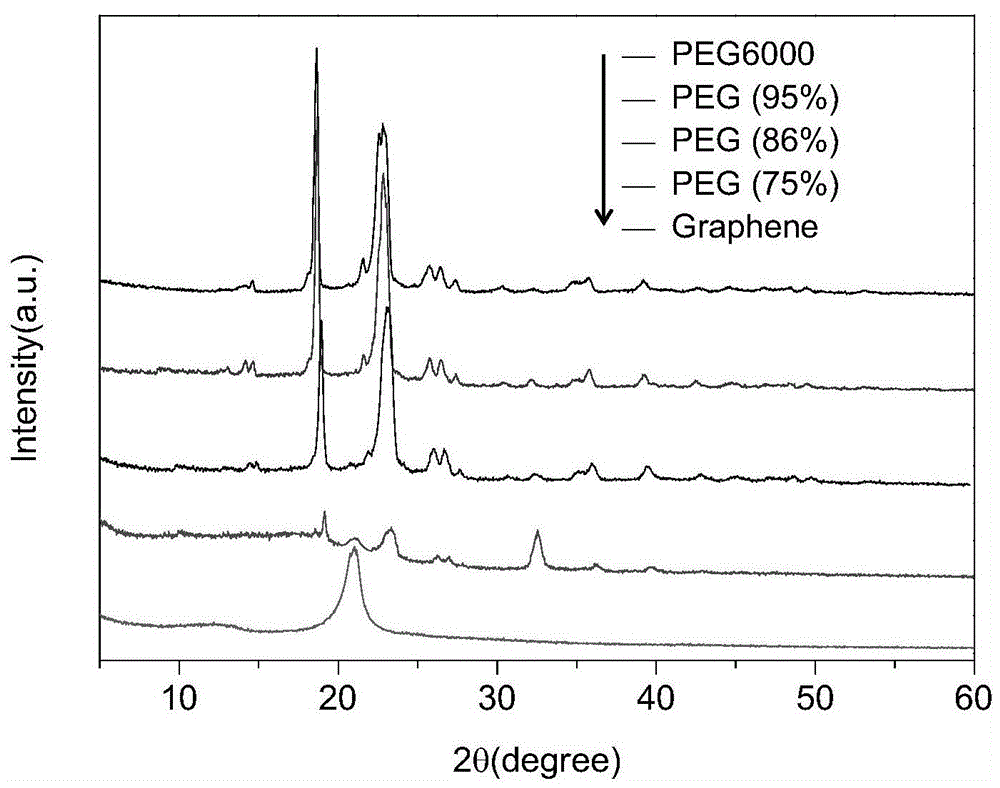

Energy-saving type three dimensional graphene skeleton composite phase change material with heat storage and release performances, and preparation method thereof

ActiveCN105112021APrevent leakageHigh thermal conductivityHeat-exchange elementsComposite phase change materialGraphene

The invention discloses an energy-saving type three dimensional graphene skeleton composite phase change material with heat storage and release performances, and a preparation method thereof. The phase energy-saving type three dimensional graphene skeleton composite phase change material is obtained through self-assembling graphen in an organic phase change material in a three dimensional skeleton interconnection form, and comprises 5-95 mass% of the organic phase change material, and the balance of graphene. The graphene composite phase change material can effectively solve the leakage problem of the organic phase change material, the three dimensional skeleton network distributed graphene greatly improves the heat conductivity of the phase change material, and provides a rapid transmission channel for heat energy collection and storage and later heat energy use; the preparation method has the advantages of simple operation, low cost and easy popularization; and the heat storage ability and the phase change temperature of the graphene composite phase change material prepared through the method depend on different selected phase change materials to meet different application channels, so wide prospect is provided for future application of the material.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

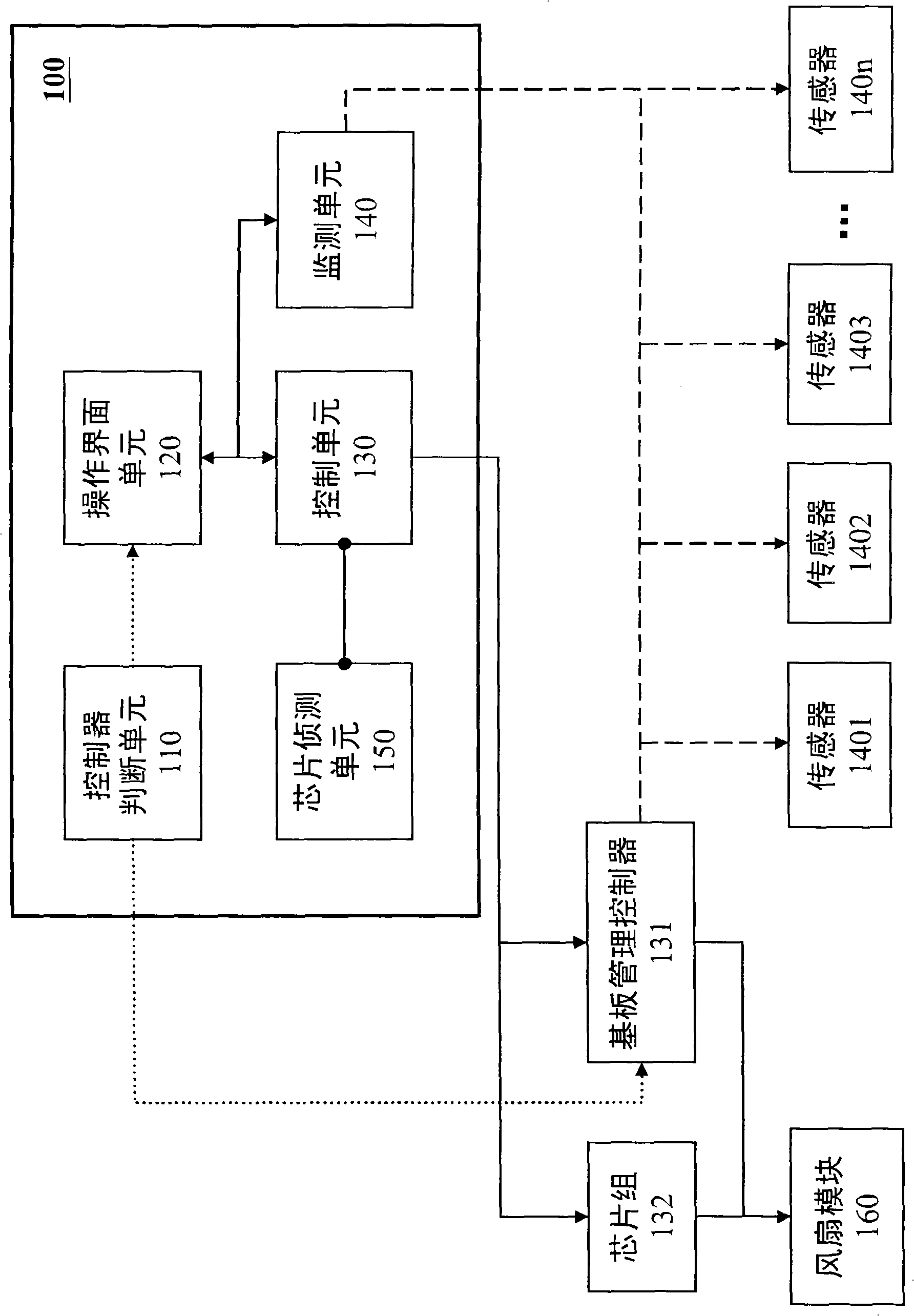

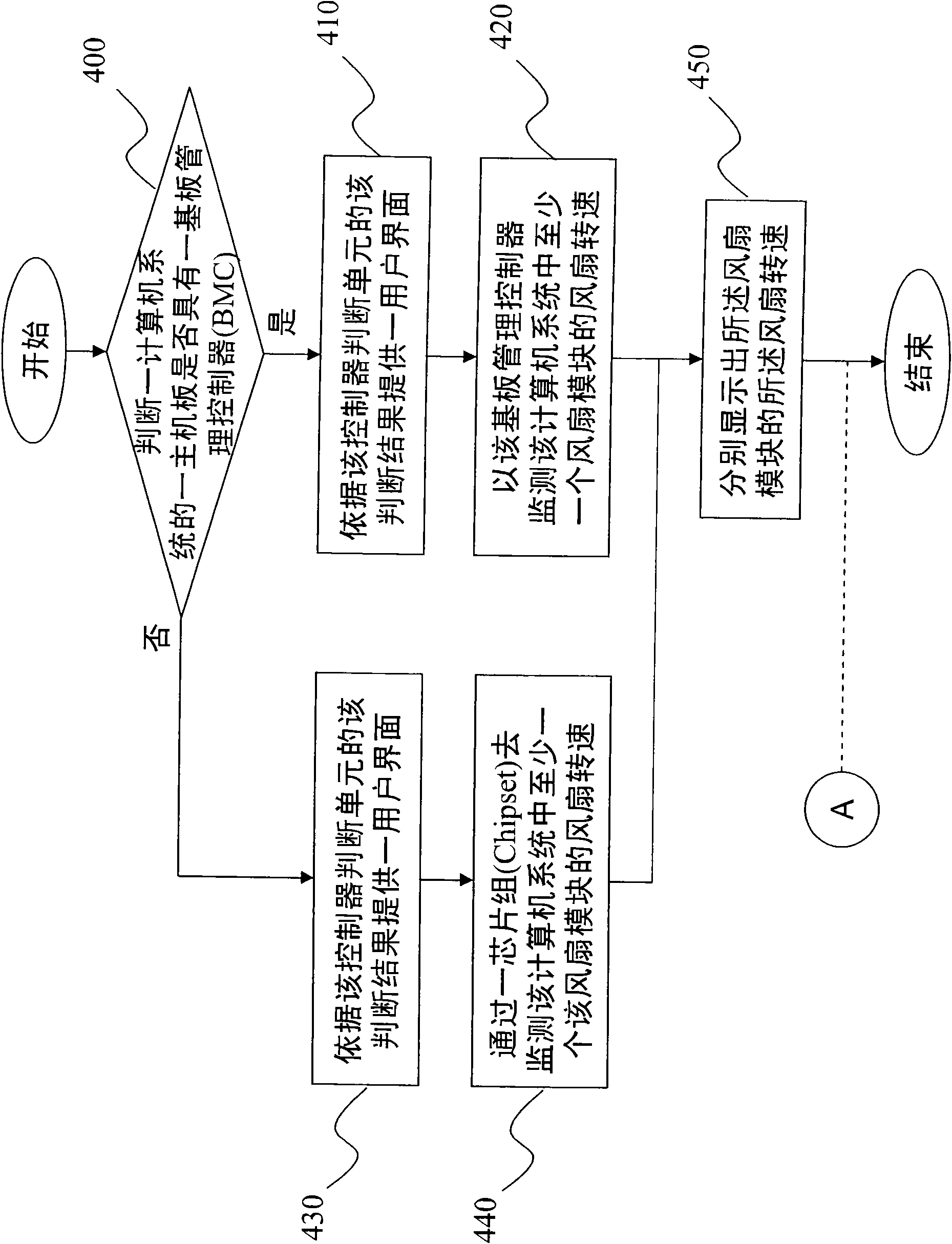

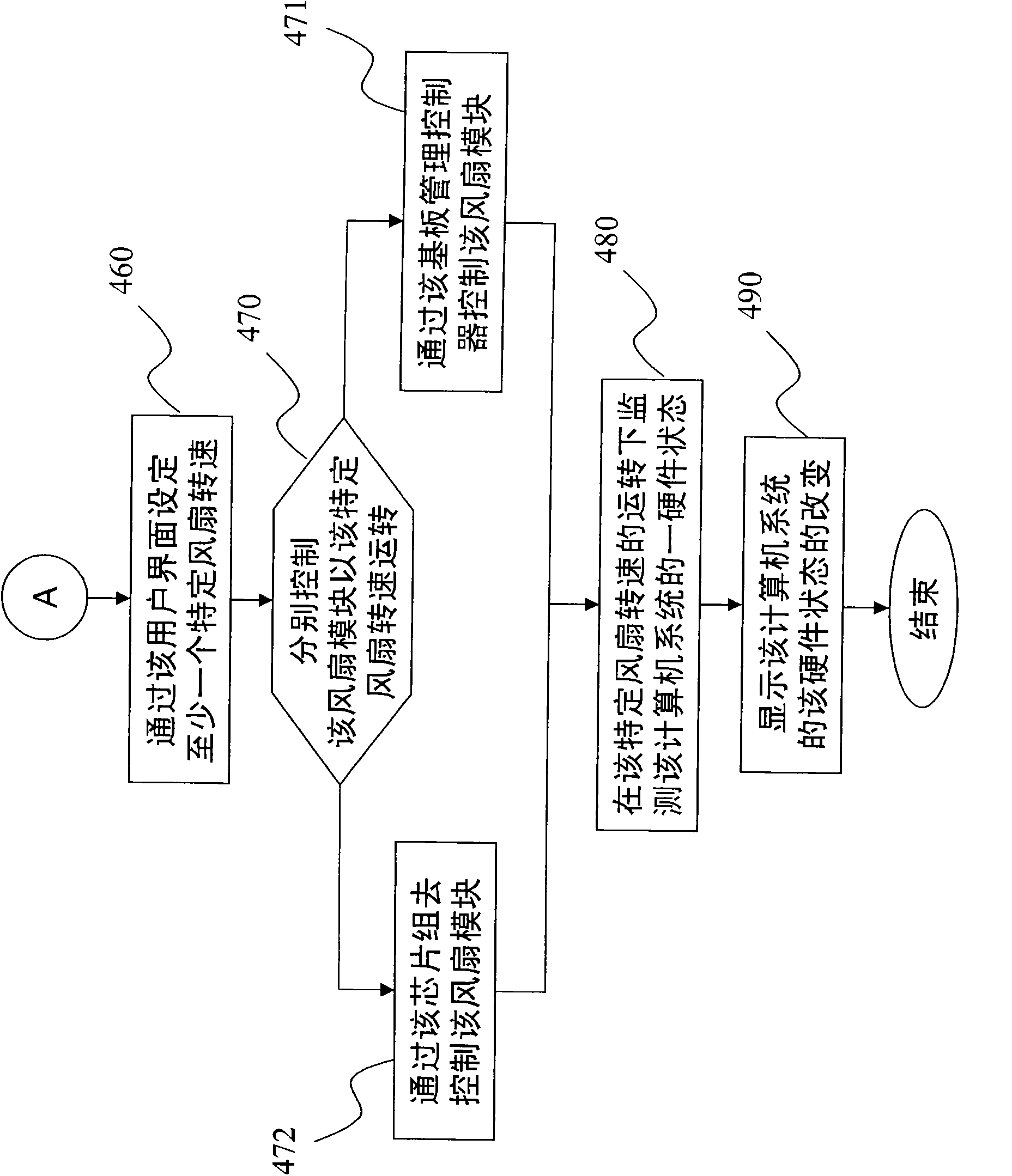

System hardware monitoring and simulation testing module and method thereof

InactiveCN101609424AChange CPU temperatureChange temperatureHardware monitoringComputer hardwareComputerized system

The invention relates to a system hardware monitoring and simulation testing module and a method thereof, which provide an operation interface for a user to set system hardware monitoring and simulation testing. Hardware in a computer system is controlled through a substrate management controller or a chip set on a mainboard, and the changes of the other hardware states of the computer system are monitored by controlling one hardware state.

Owner:刘玉梅

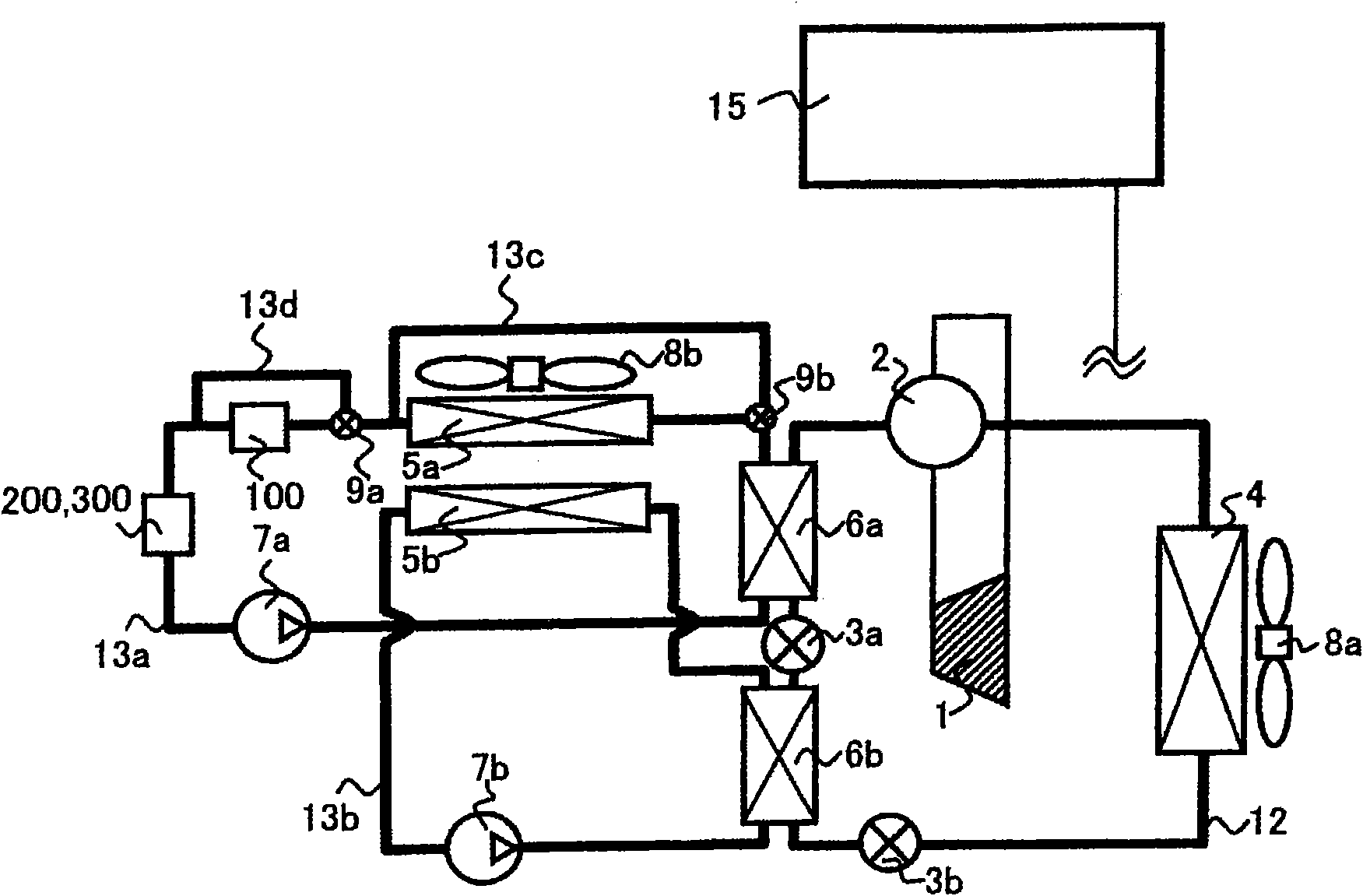

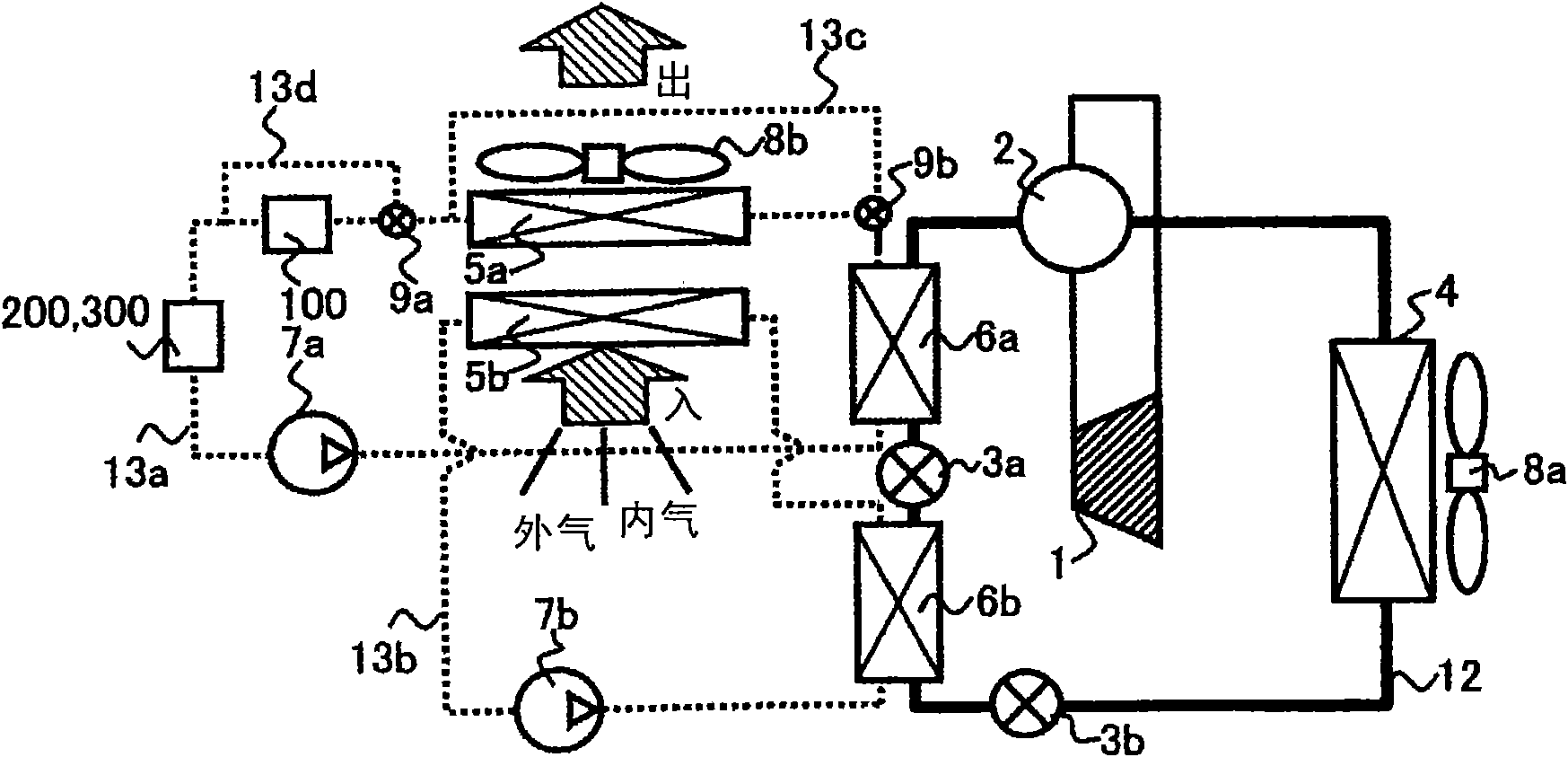

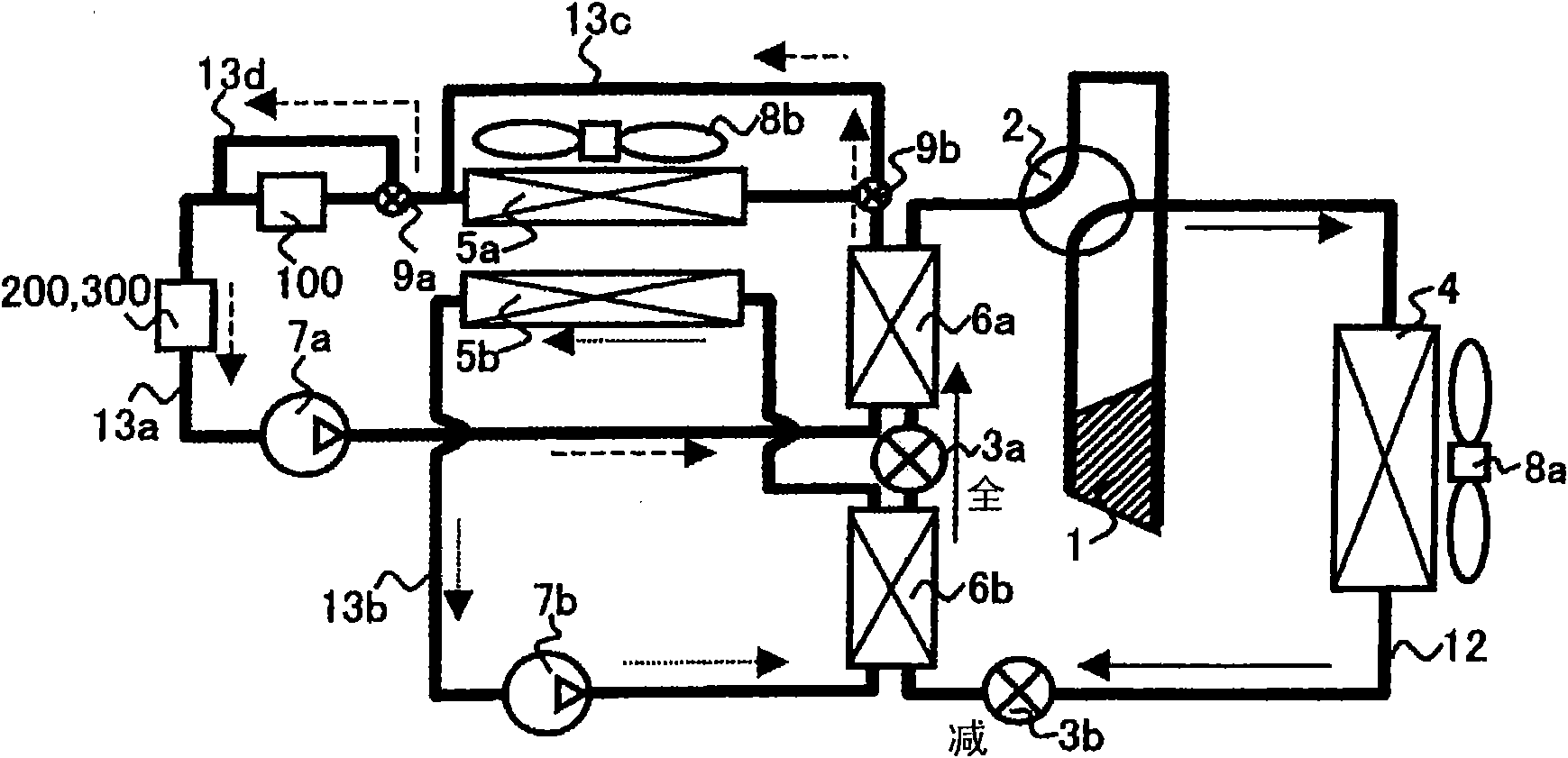

Thermodynamic cycle system for a vehicle

InactiveCN102029873AGood energy saving effectSuppress energyAir-treating devicesElectric machinesMobile vehicleIntermediate heat exchanger

A thermodynamic cycle system for a moving vehicle, including a refrigeration cycle system through which a refrigerant flows, a first heat-transferring system through which a heat-transferring medium flows, the heat-transferring medium being used for adjusting temperatures of heat-liberation components, a second heat-transferring system through which a heat-transferring medium flows, the heat-transferring medium being used for adjusting an indoor air state, an intermediate heat exchanger (6a) provided between the refrigeration cycle system and the first heat-transferring system, an intermediate heat exchanger (6b) provided between the refrigeration cycle system and the second heat-transferring system, an indoor heat exchanger (5a) provided in the first heat-transferring system, and an indoor heat exchanger (5b) provided in the second heat-transferring system.

Owner:HITACHI LTD

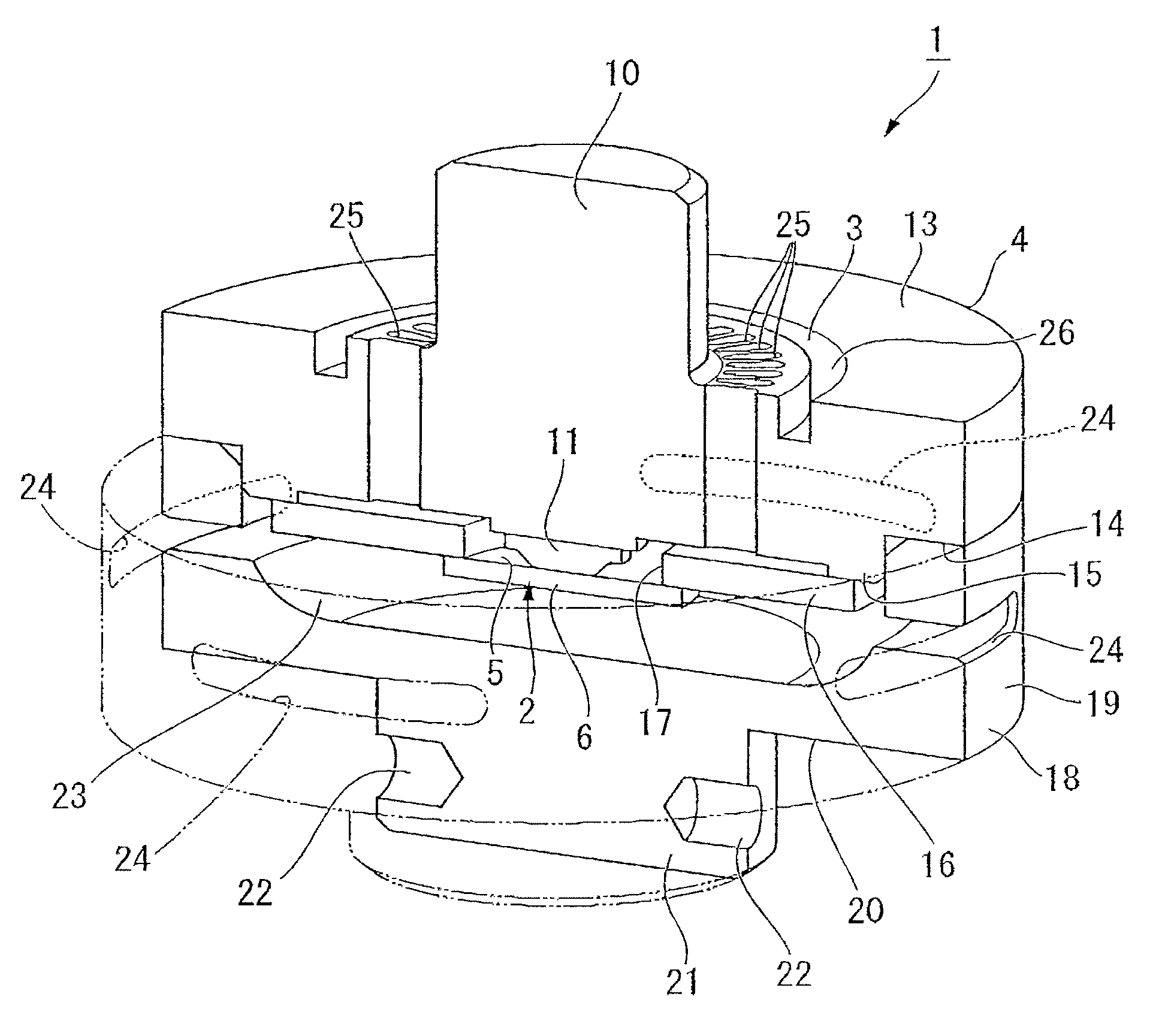

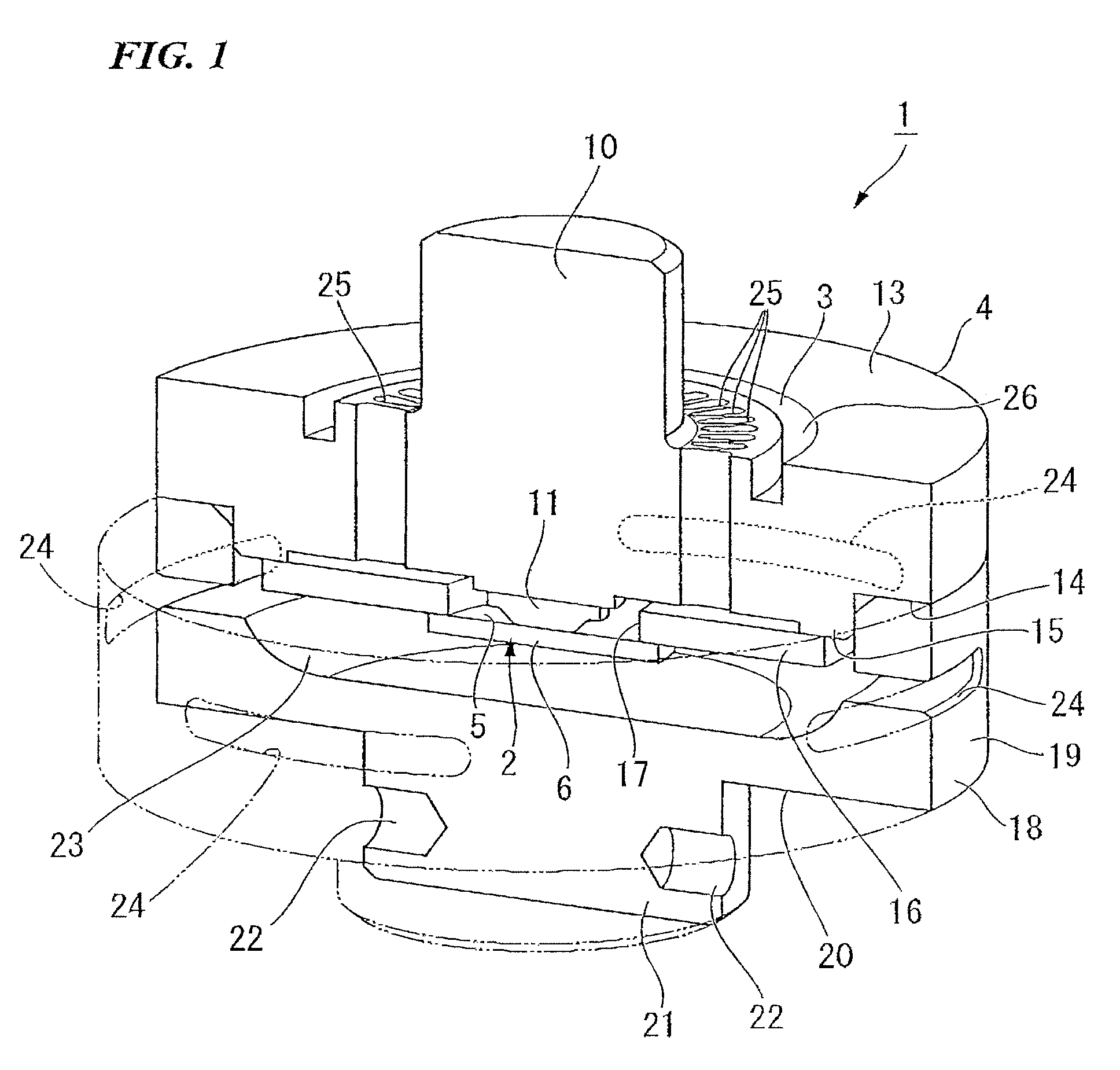

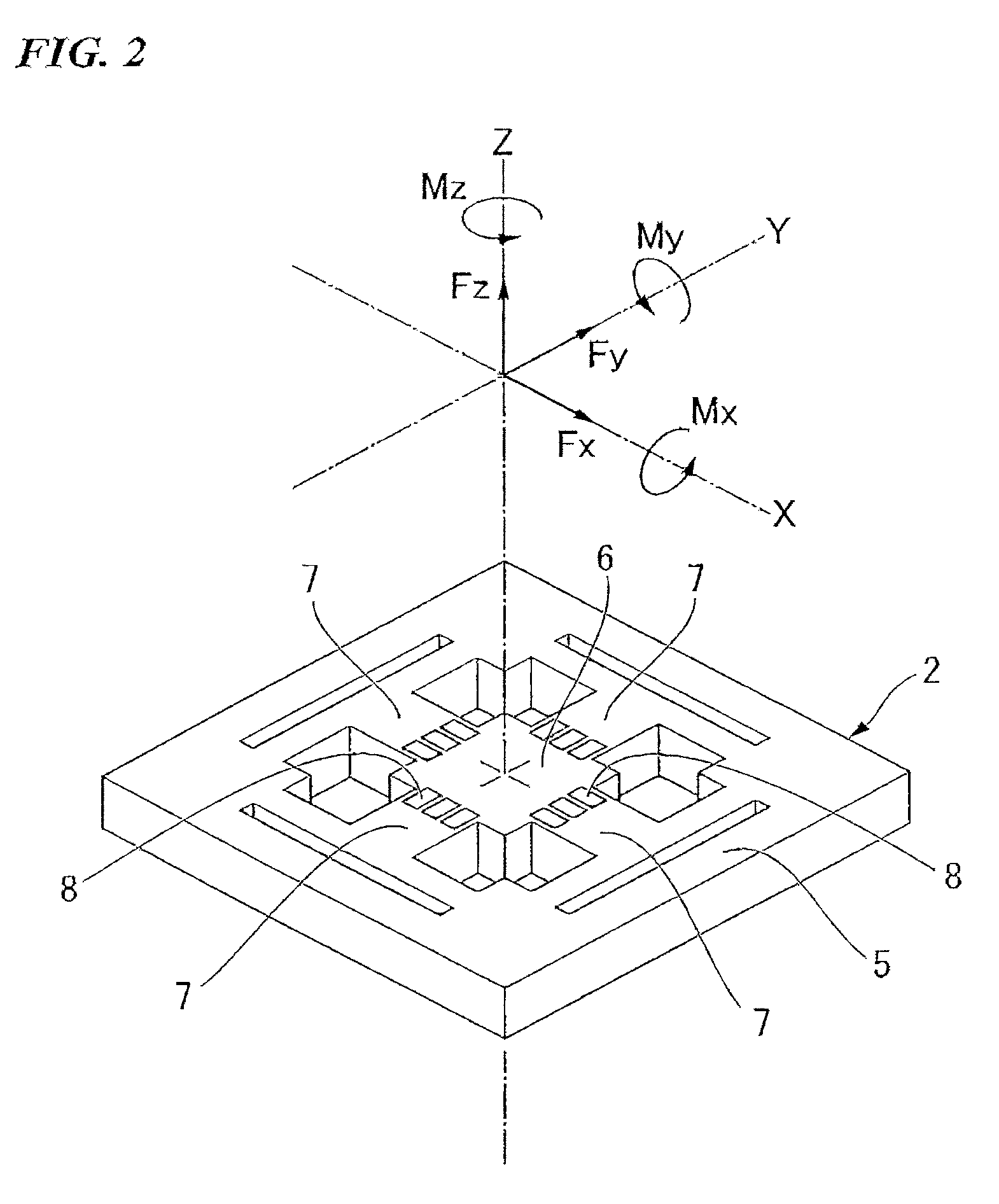

Force sensor unit

ActiveUS8196477B2Improve detection accuracyChange temperatureUsing electrical meansForce measurement using piezo-resistive materialsEngineeringForce sensor

Owner:HONDA MOTOR CO LTD

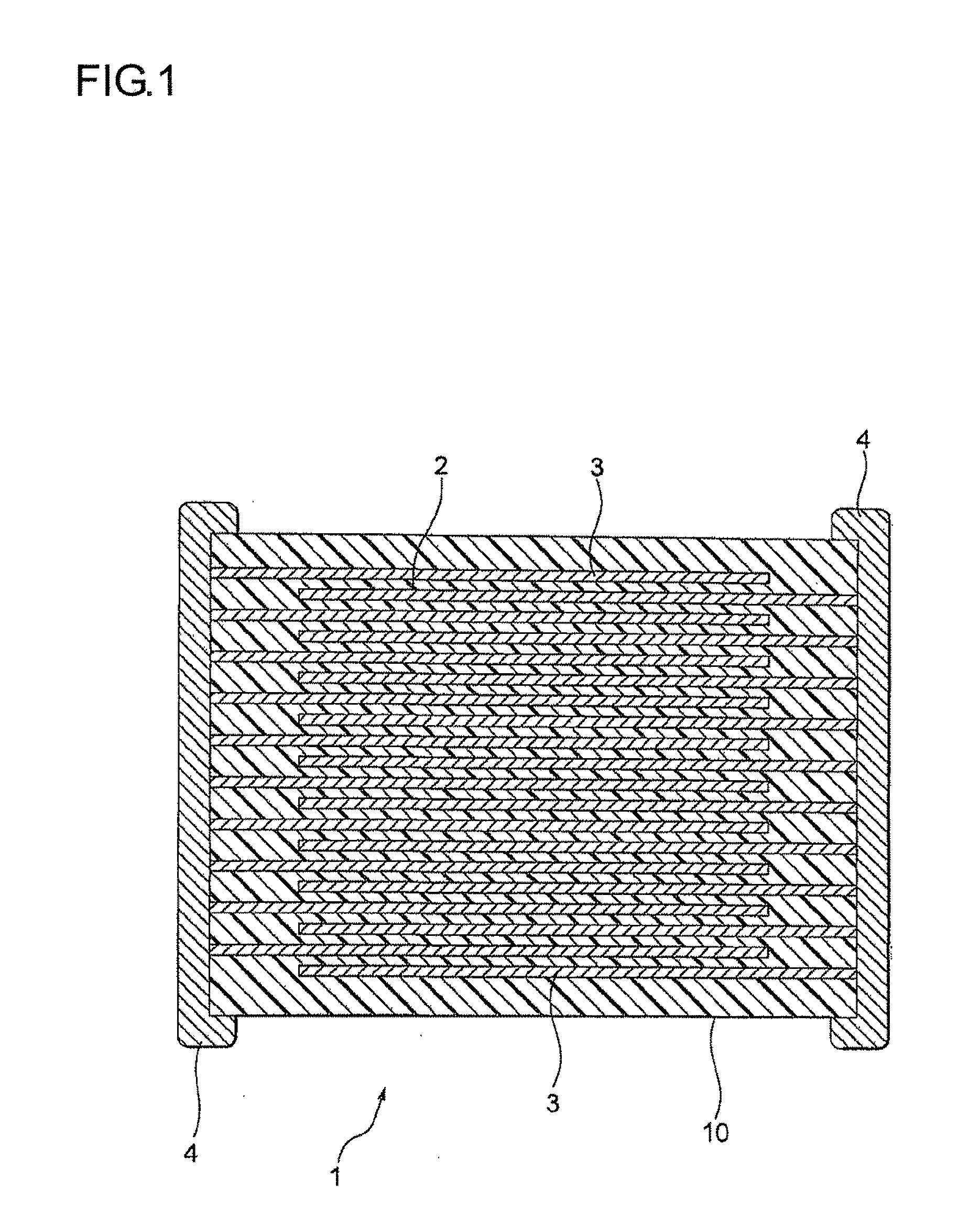

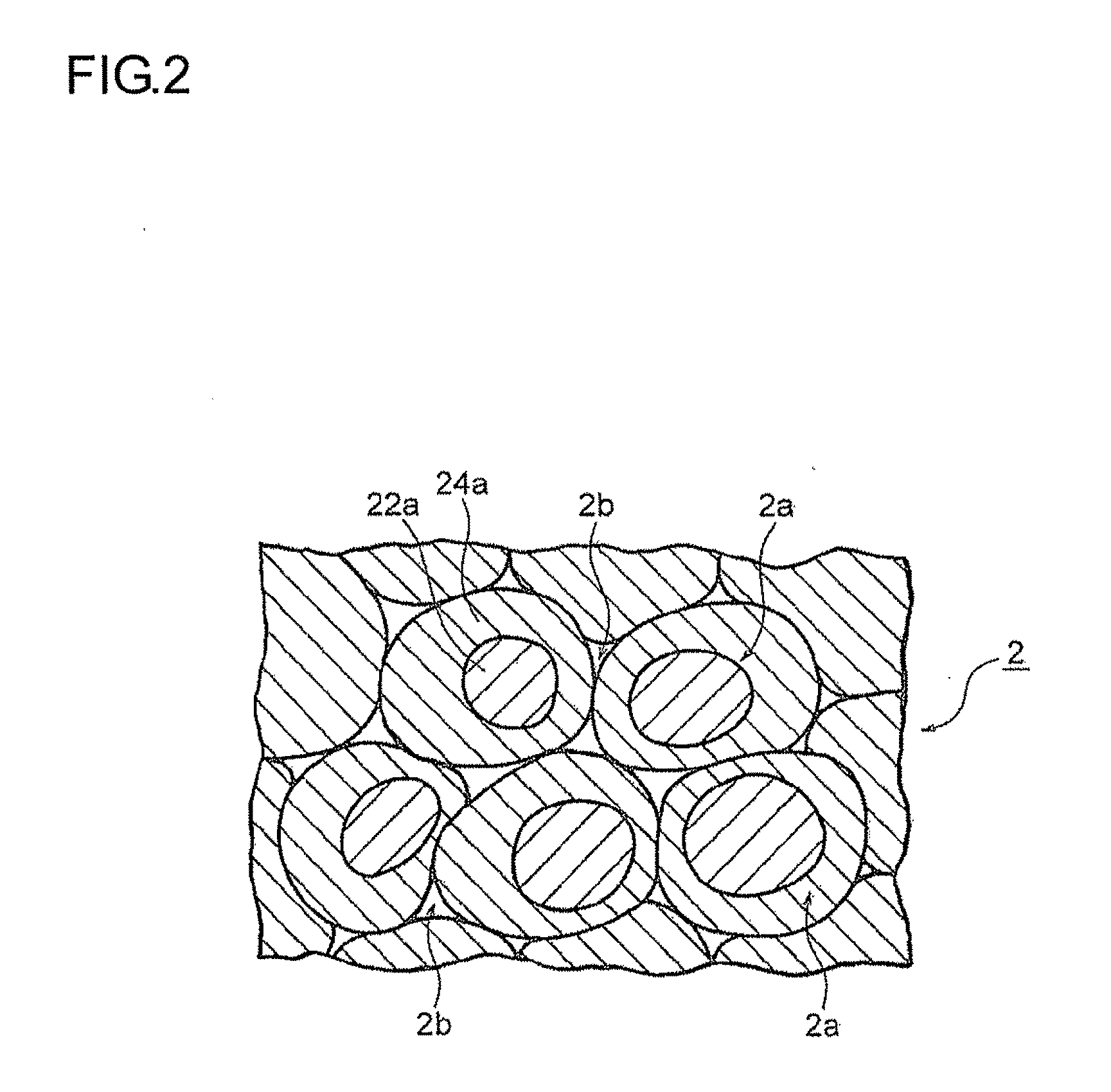

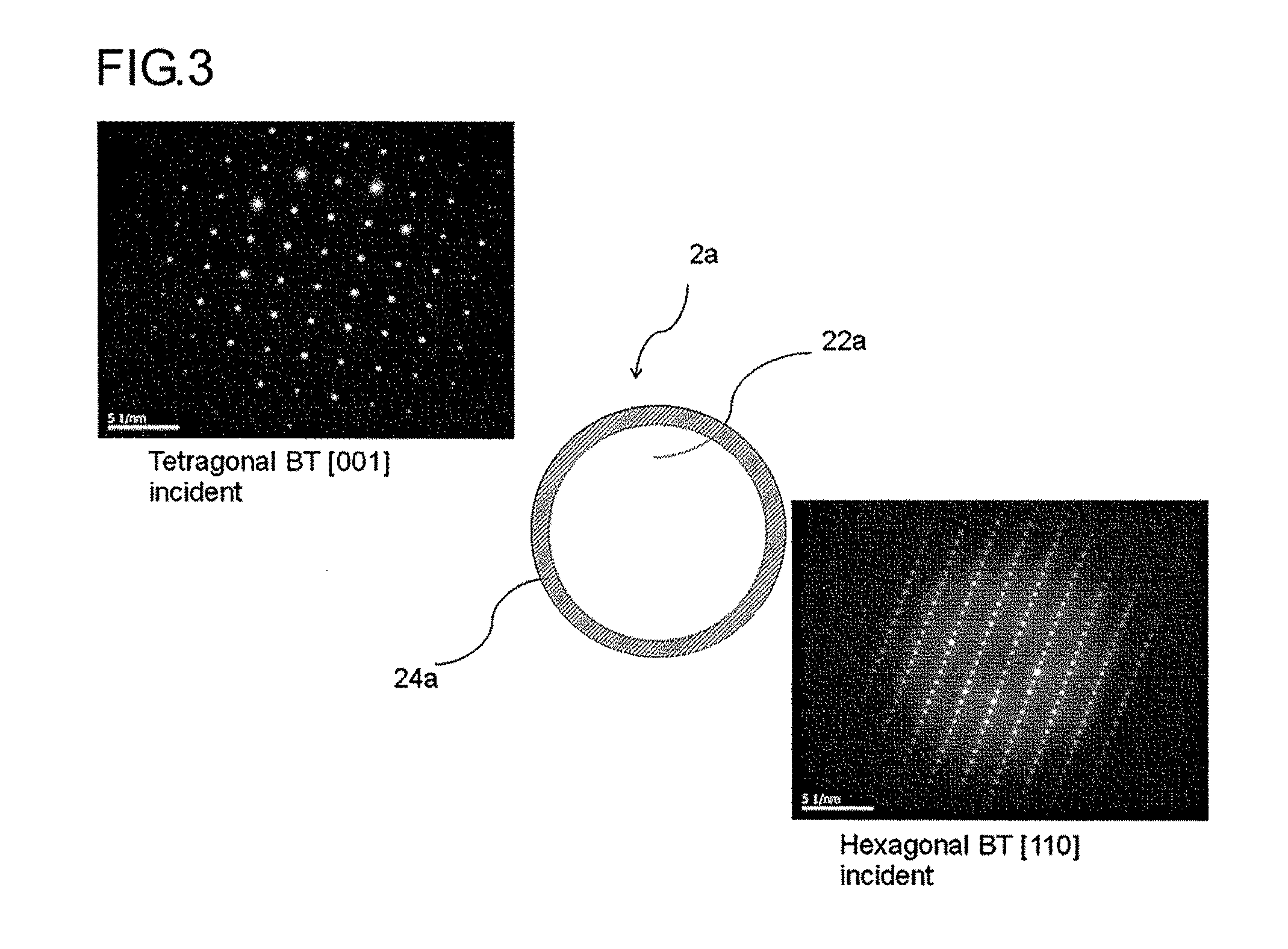

Dielectric ceramic composition and electronic component

InactiveUS20110111947A1Improve balanceLow dielectric constantAlkaline earth titanatesStacked capacitorsBarium titanateCeramic capacitor

The disclosed is a dielectric ceramic composition in which dielectric particles 2a are formed. The dielectric particle 2a has a core 22a comprised of hexagonal barium titanate, and a shell 24a formed on an outer circumference of the core 22a and comprised of cubical or tetragonal barium titanate. The purpose of the present invention is to provide a new dielectric ceramic composition, in which permittivity is hardly lowered due to size effect, a good balance between high insulation resistance and permittivity can easily be achieved, and changes in insulation resistance and specific permittivity due to temperature are small; and an electronic component such as a multilayer ceramic capacitor using the dielectric ceramic composition as its dielectric layer.

Owner:TDK CORPARATION +1

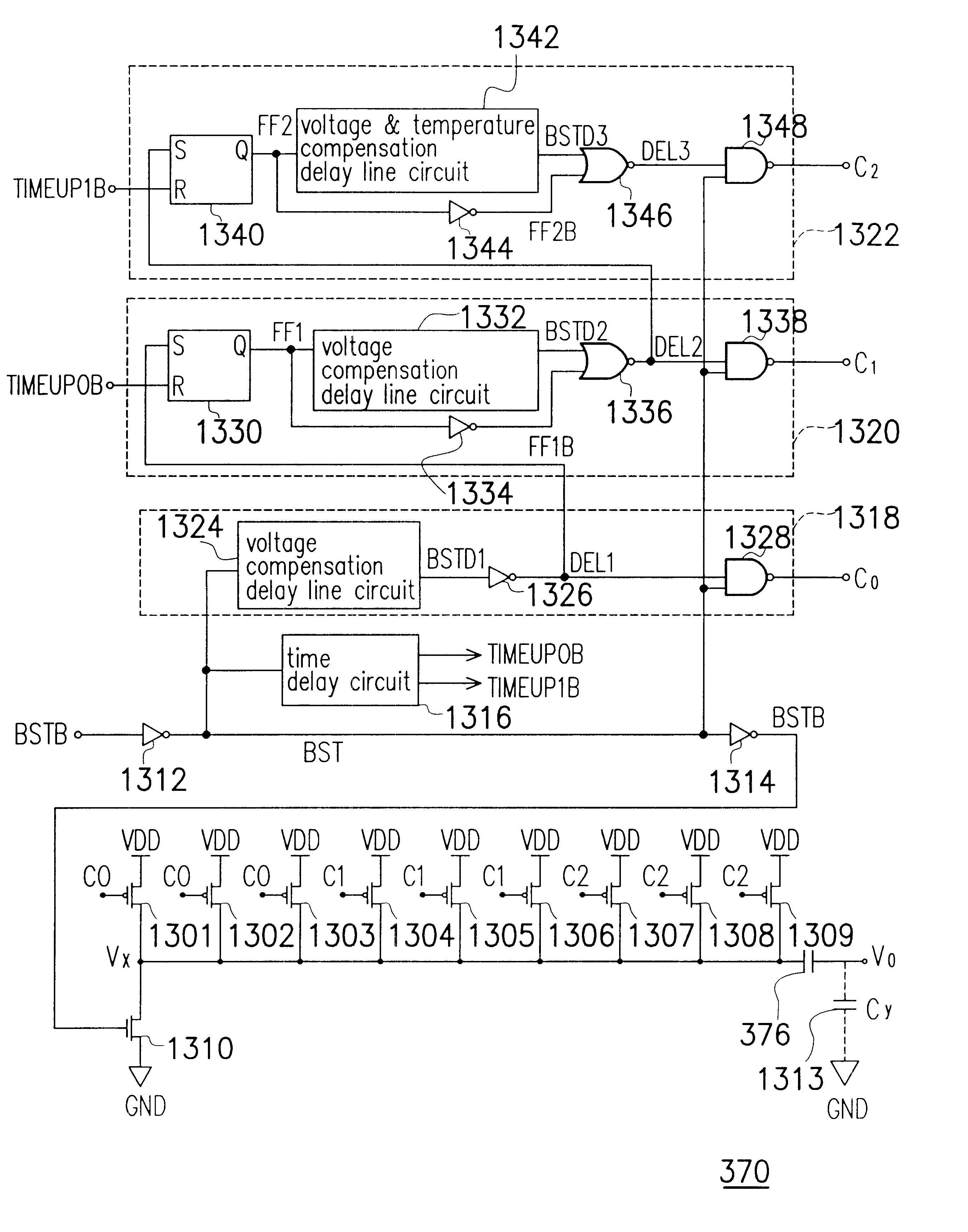

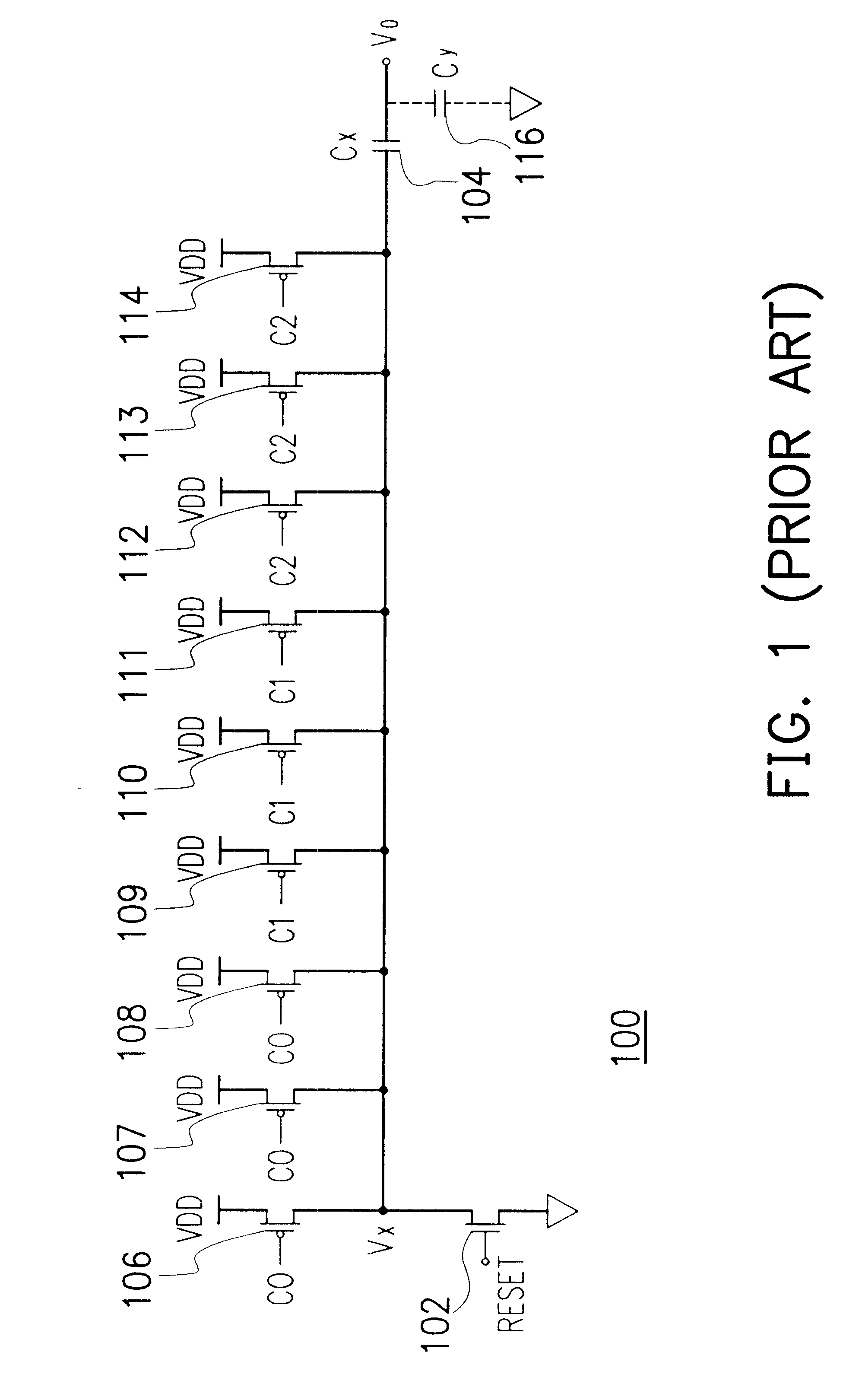

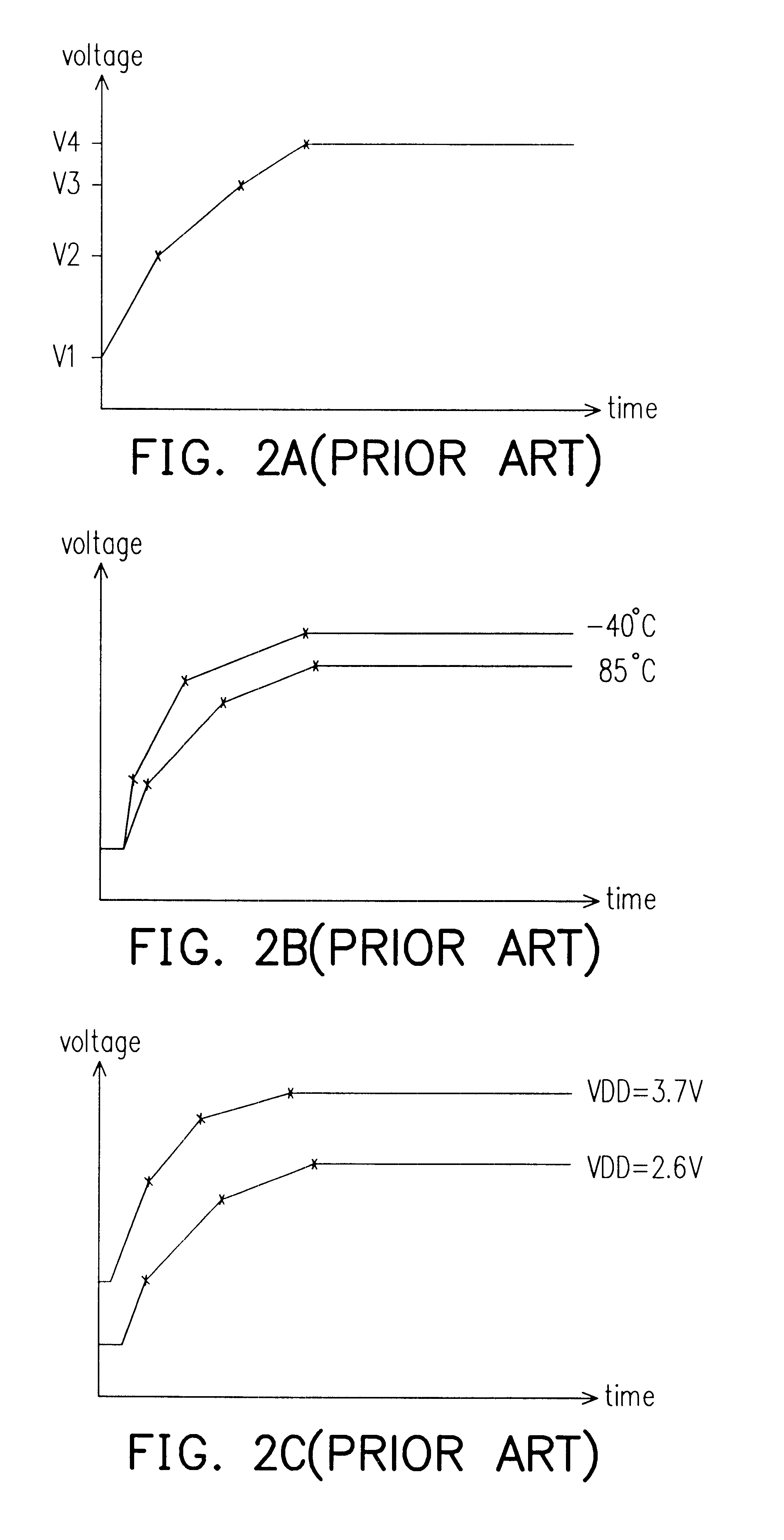

Voltage-boosting generator for reducing effects due to operating voltage variation and temperature change

InactiveUS6580287B2Reduce operating voltageReduce the effect of temperatureReliability increasing modificationsElectronic switchingControl signalTime delays

A voltage-boosting generator for reducing the effects due to operating voltage variation and temperature change. The generator comprises a delay line circuit and a voltage boosting circuit. The delay line circuit is used to perform a time delay according to an initial boosting signal and to produce a control signal. The voltage boosting circuit is used to boosted voltage according to the control signal.

Owner:MACRONIX INT CO LTD

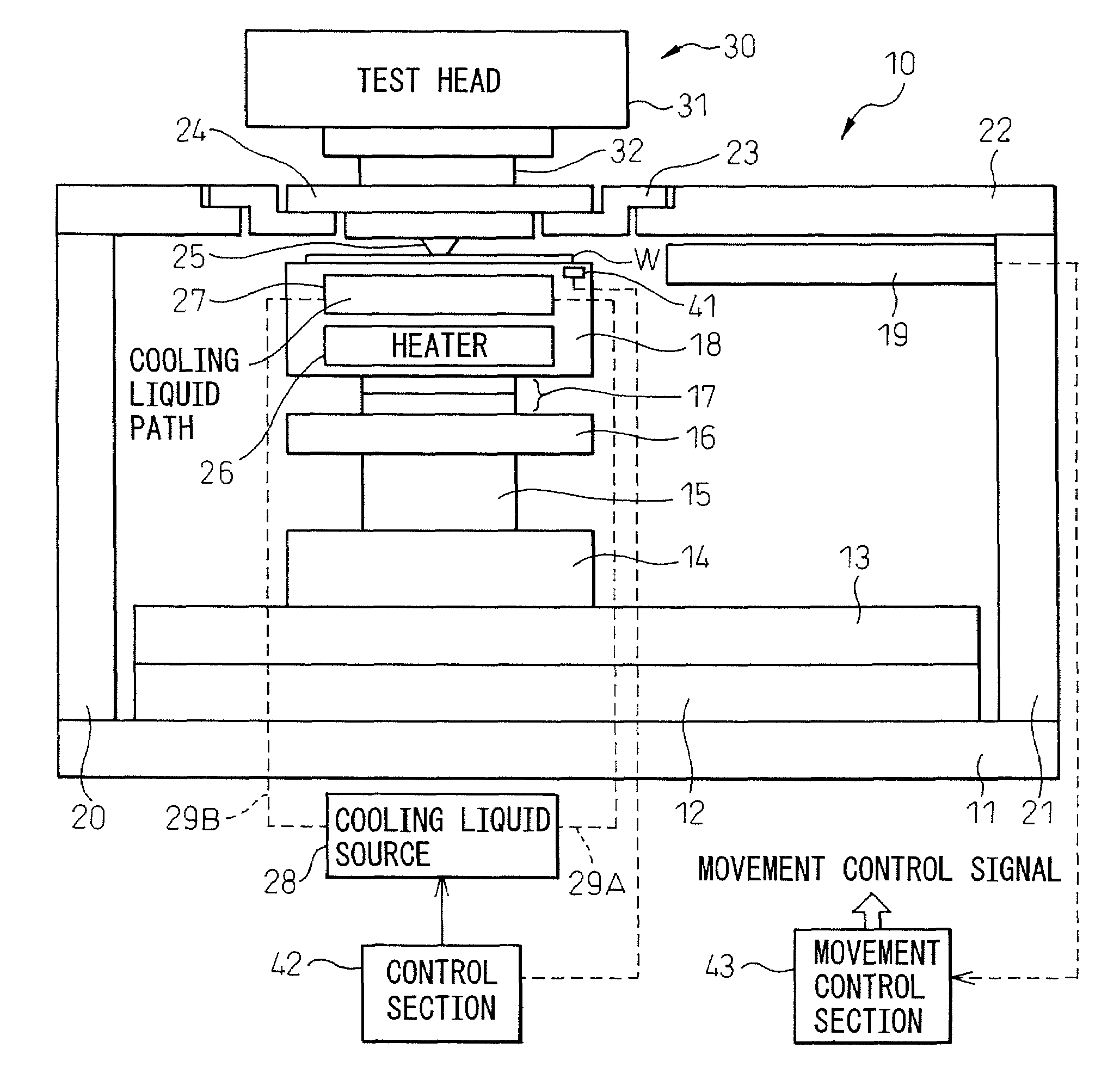

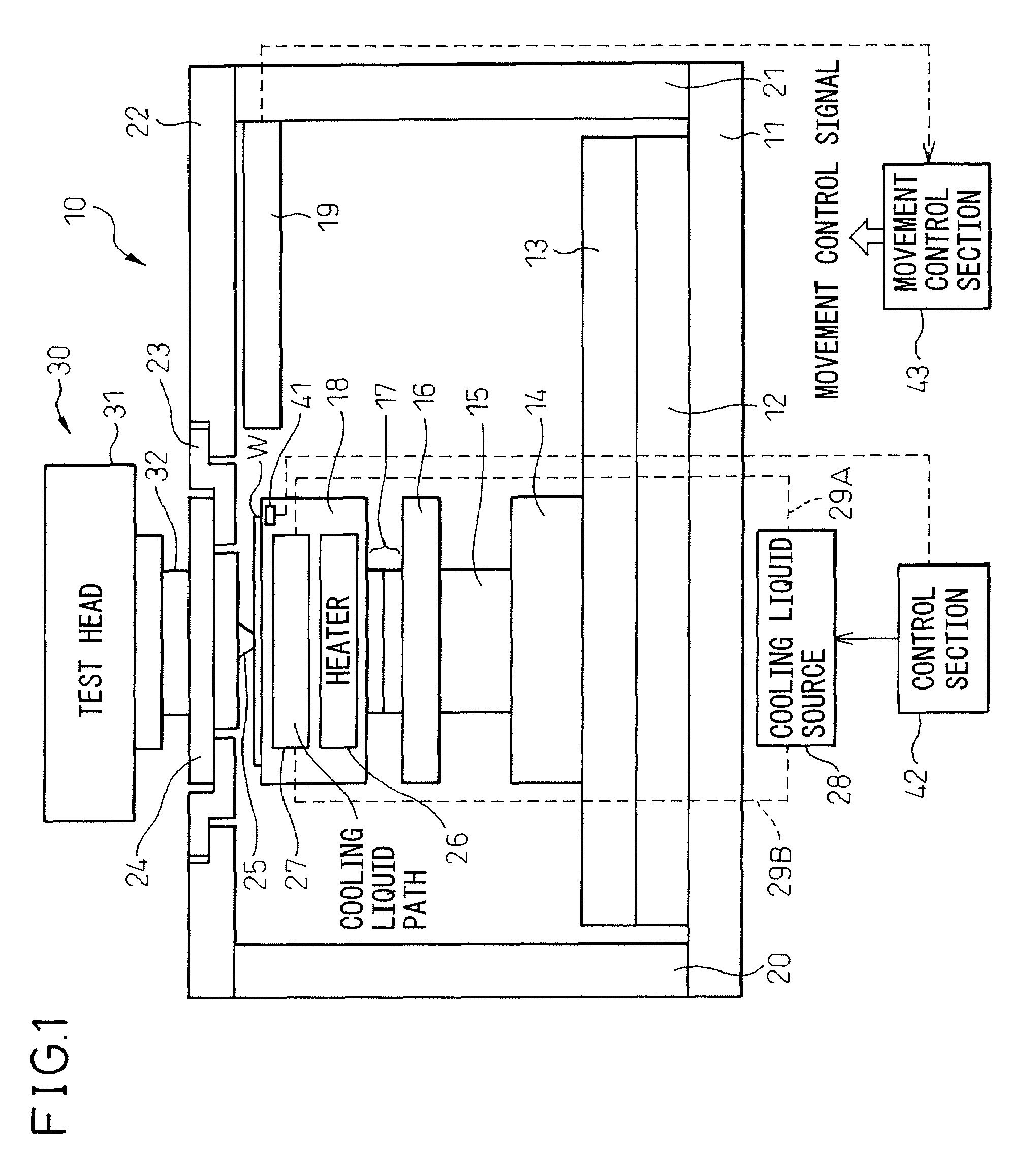

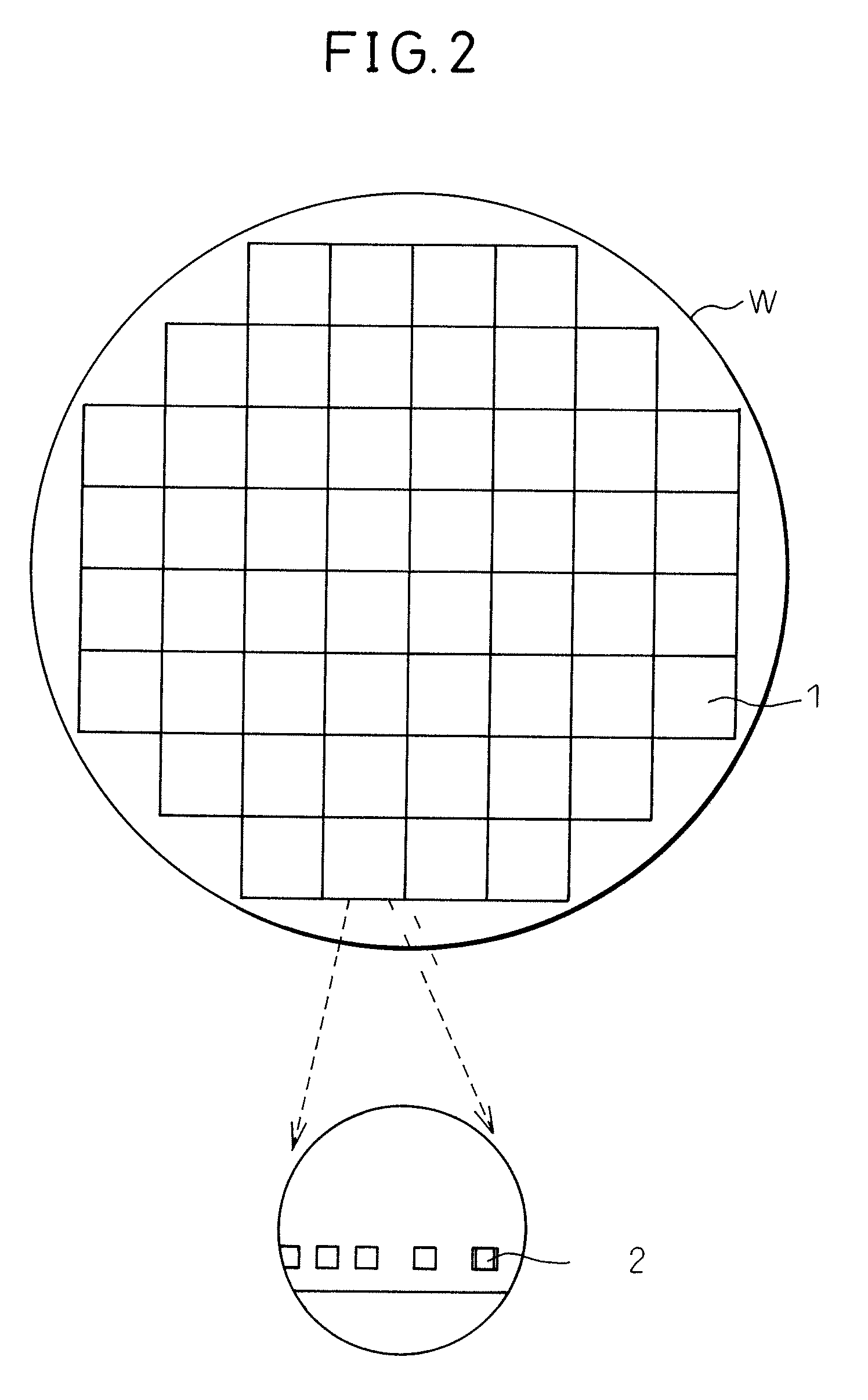

Prober and probe contact method

InactiveUS20080018352A1Shorten the timeReduce throughputSemiconductor/solid-state device testing/measurementElectrical measurement instrument detailsContact methodMovement control

A prober and a probe contact method for reducing errors in the contact position between a probe and an electrode without lowering throughput when conducting a probing test of a wafer at a high or low temperature have been disclosed. The prober comprises: a wafer chuck that holds a wafer; a movement mechanism that moves the wafer chuck; a temperature adjustment mechanism that adjusts the temperature of the wafer chuck to maintain the wafer at a predetermined temperature; an alignment means for measuring a positional relationship between the electrode of the device of the wafer and the probe; and a movement control section that calculates the amount of movement to touch the electrode to the probe based on the positional relationship between the electrode and the probe measured by the alignment means and controls the movement mechanism based on the calculated amount of movement, wherein: a wafer temperature sensor that detects the temperature of the wafer before it is held on the wafer chuck is further provided; and the movement control section comprises: a temperature change data storage section that stores in advance the wafer temperature changes after the wafers at various temperatures are held on the wafer chuck and the data about the changes in dimension; and a movement amount correction means for predicting the change in temperature after the wafer is held on the wafer chuck from the temperature of the wafer detected by the wafer temperature sensor and the data stored in the temperature change data storage means and corrects the calculated amount of movement in accordance with the predicted change in temperature when making an inspection while maintaining the temperature of the wafer chuck at a low or high set temperature.

Owner:TOKYO SEIMITSU

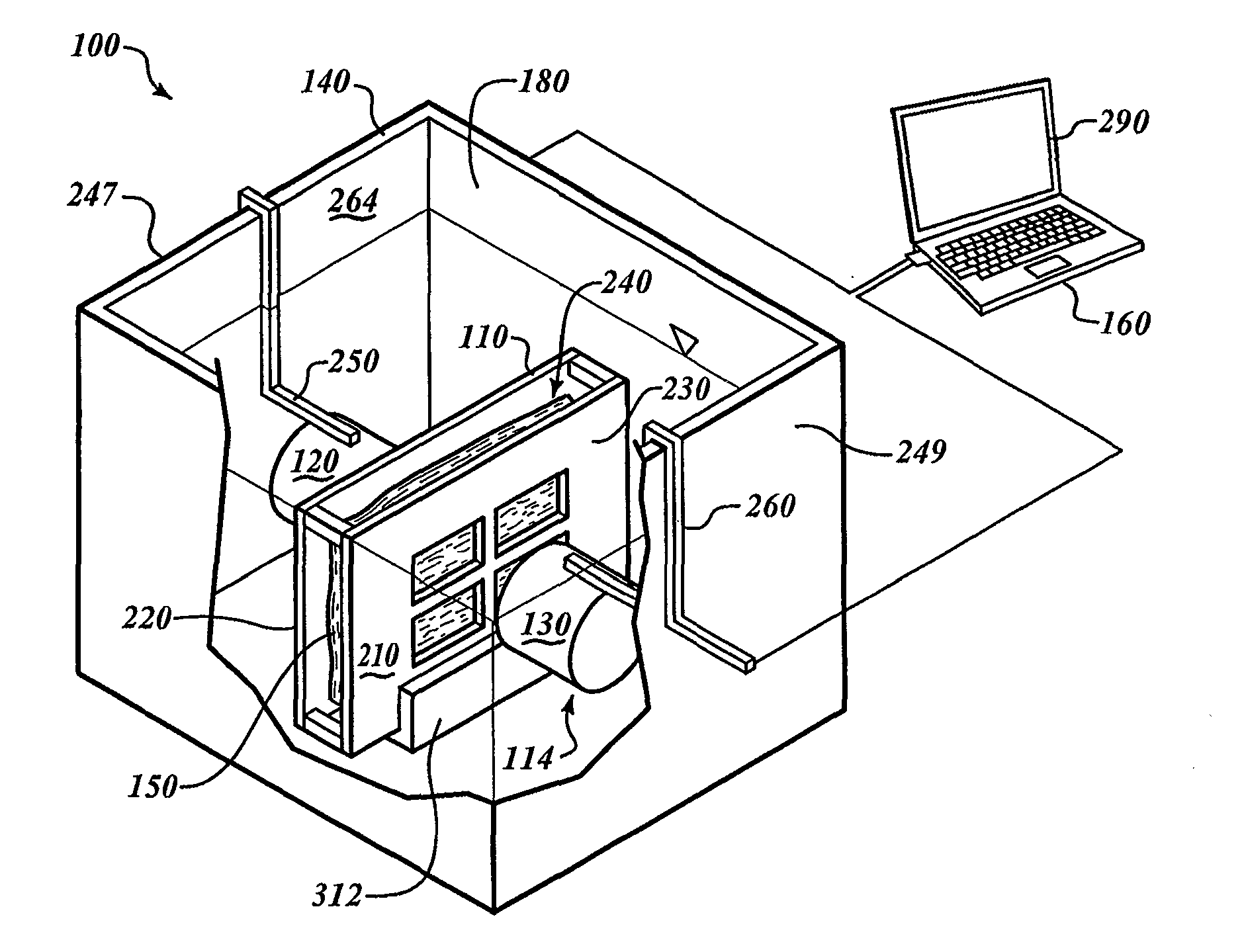

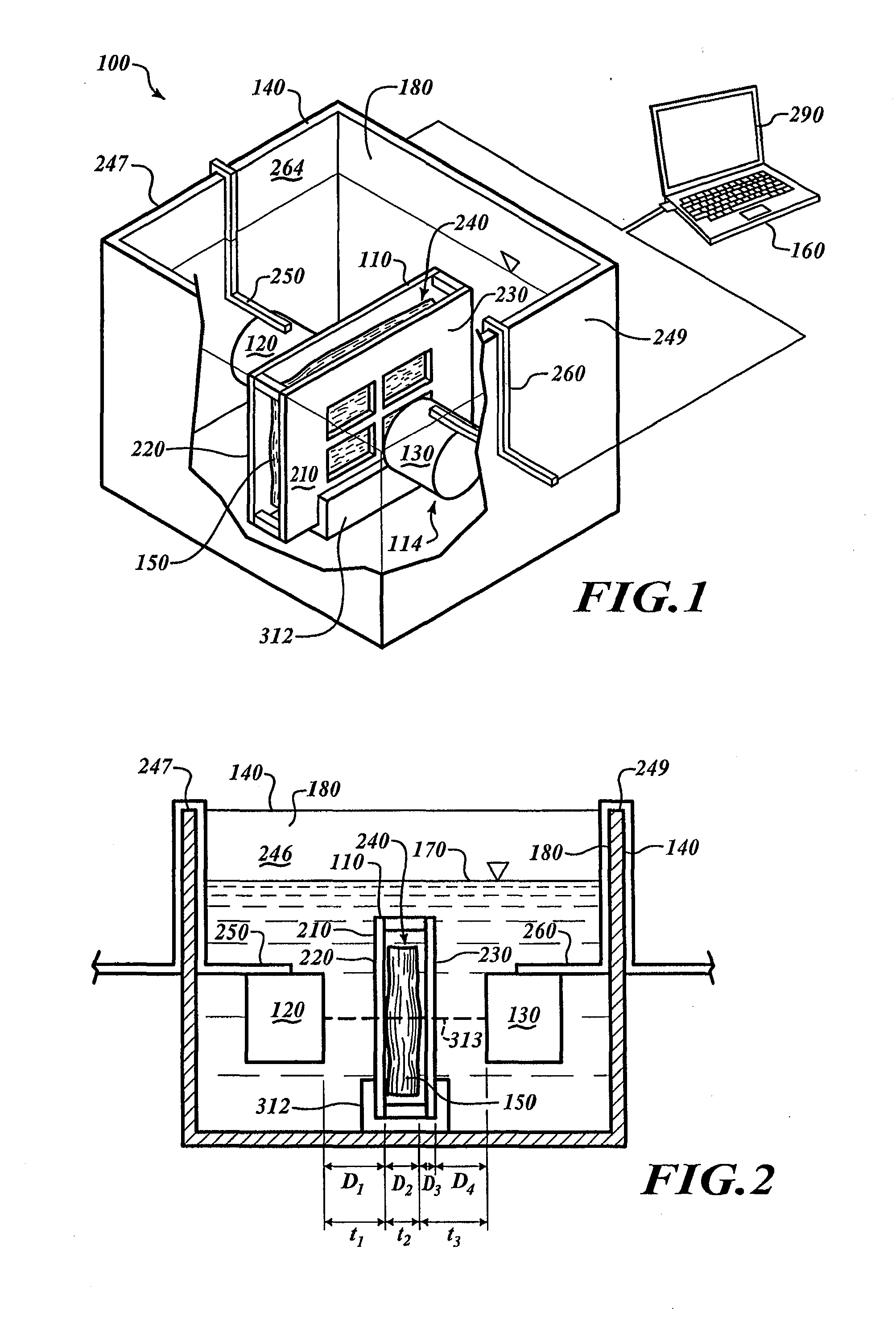

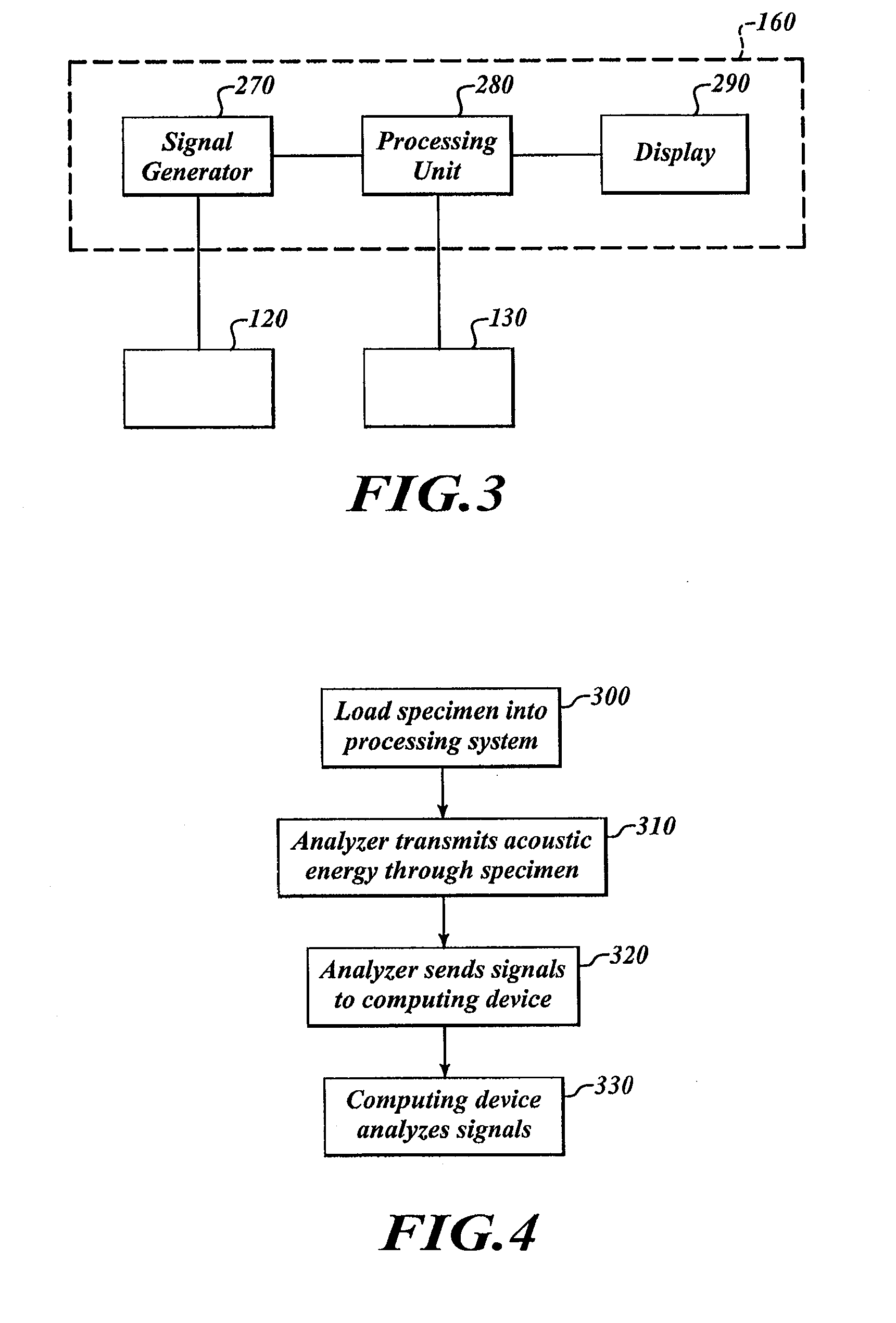

Processing system for processing specimens using acoustic energy

ActiveUS20120329088A1Improve consistencyReduce processing timeBioreactor/fermenter combinationsAnalysing solids using sonic/ultrasonic/infrasonic wavesAcoustic energyEnergy based

A method for fixing a biological sample includes delivering energy through a biological sample that has been removed from a subject, while fixing the biological sample. A change in speed of the energy traveling through the biological sample is evaluated to monitor the progress of the fixation. A system for performing the method can include a transmitter that outputs the energy and a receiver configured to detect the transmitted energy. A computing device can evaluate the speed of the energy based on signals from the receiver.

Owner:VENTANA MEDICAL SYST INC

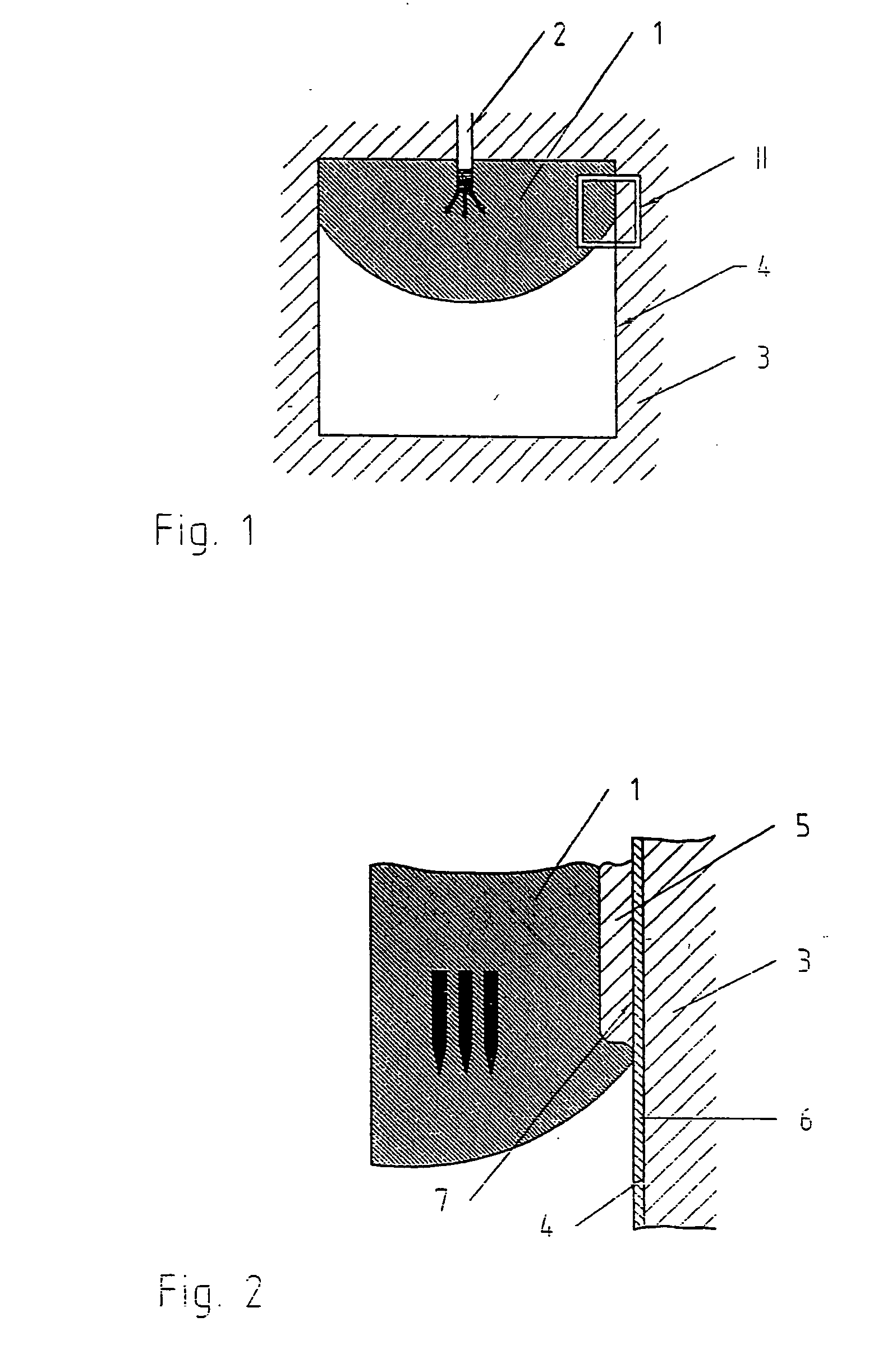

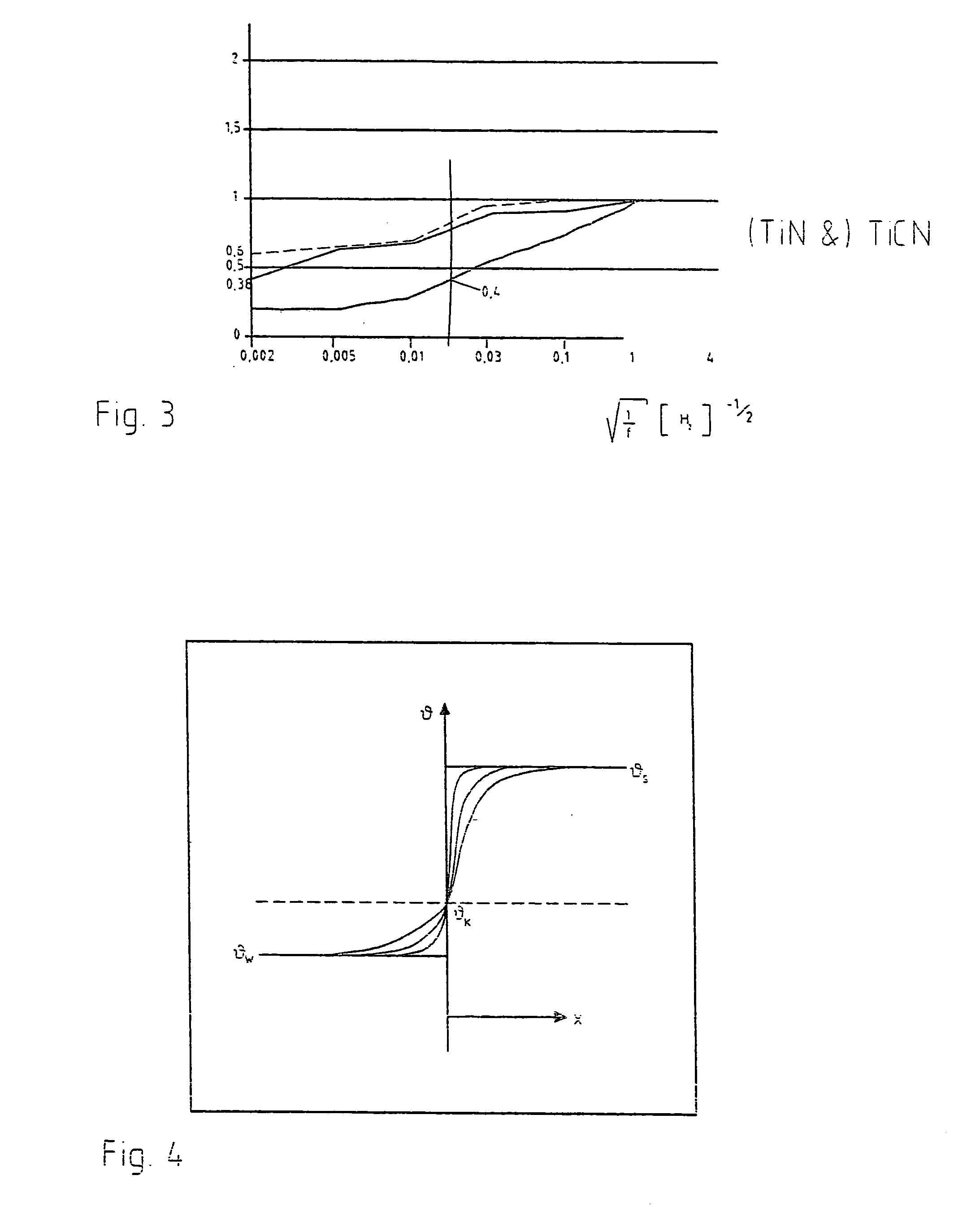

Gloss level adjustment

ActiveUS20050133962A1Highly accurate reproductionAvoid differencesDischarging arrangementMouldsTemperature controlHeat penetration

In a method for injection molding molten materials, especially plastic, in a mold that has a mold surface which comes into contact with the material, at least one coating on the mold surface and a temperature-control means for the mold surface, the mold surface is cooled by the temperature-control means so that the molten material solidifies at the interface with the coating and an injection-molded part can be removed from the form. During this process the molten material is brought into contact with the coating on the mold surface, the thickness of said coating being selected in coordination with the heat penetration coefficient of the coating material such that a specified 60° gloss level and / or color value L is obtained for the injection-molded part.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

Device for semiconductor refrigeration and heating of fruit juice and ice cream

PendingCN107616292AChange temperatureAdjustable temperatureFrozen sweetsStrainersFruit juiceEngineering

The invention discloses a juicer with a heat-preserving barrel and capable of manufacturing ice cream. The juicer comprises a juicer main body and the heat-preserving barrel, wherein the heat-preserving barrel and the juicer main body are connected into a whole, or are in plugging cooperation through male and female connectors; and the bottom part of the heat-preserving barrel is provided with a semiconductor refrigeration and heating chip used for refrigerating or heating an object in the heat-preserving barrel. The device provided by the invention can realize the purpose of changing the temperature of fruit juice according to self-requirements by addition of the semiconductor refrigeration and heating chip for refrigeration and heating of the heat-preserving barrel. The device avoids discomfort of people during drinking of the fruit juice in different seasons due to influence of an external temperature. After semiconductor refrigeration and heating, the temperature of the heat-preserving barrel can be adjusted, an a heat-preserving material or a vacuum layer can preserve heat for the heat-preserving barrel.

Owner:ZHEJIANG GEMCORE TECH

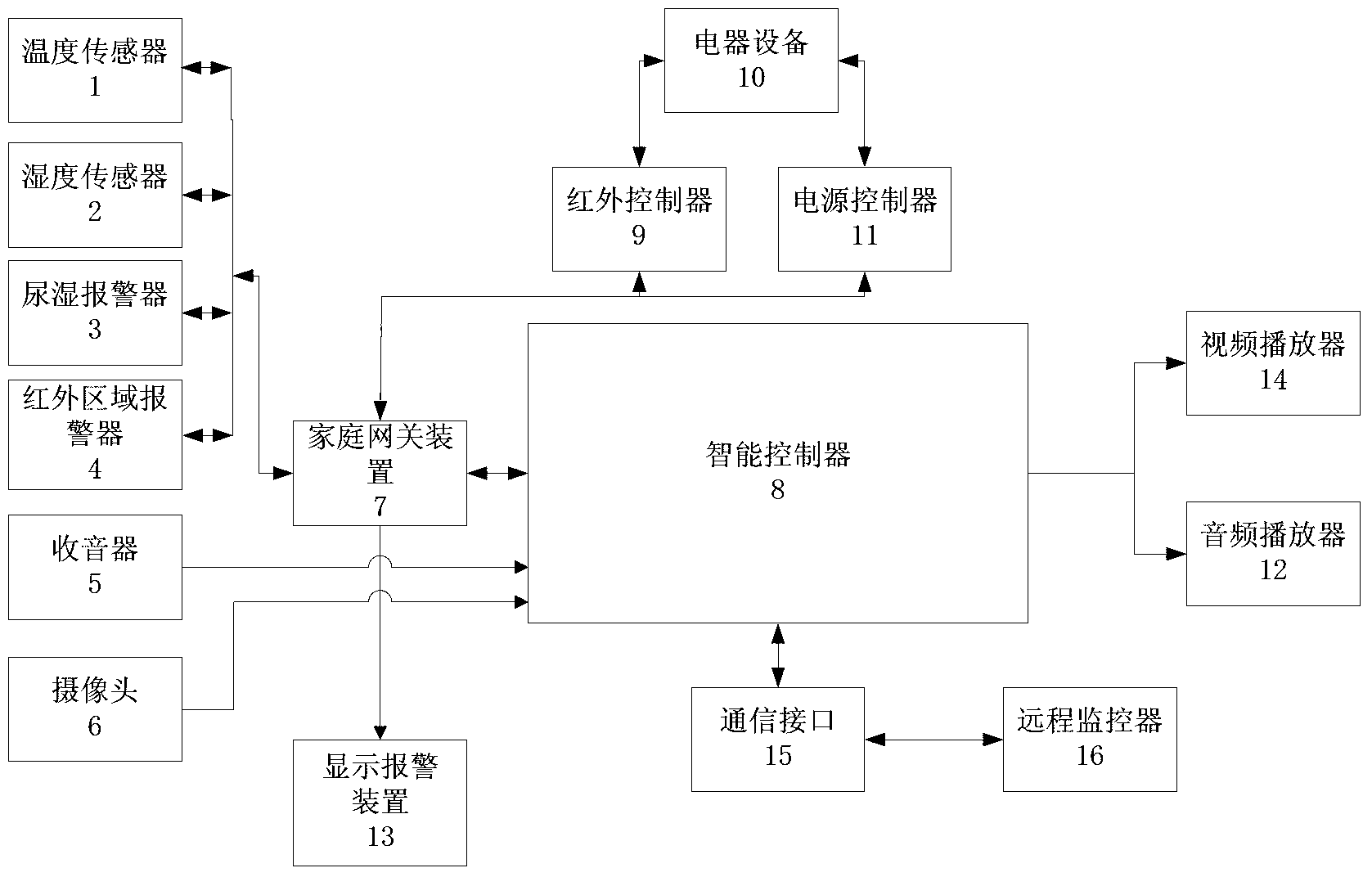

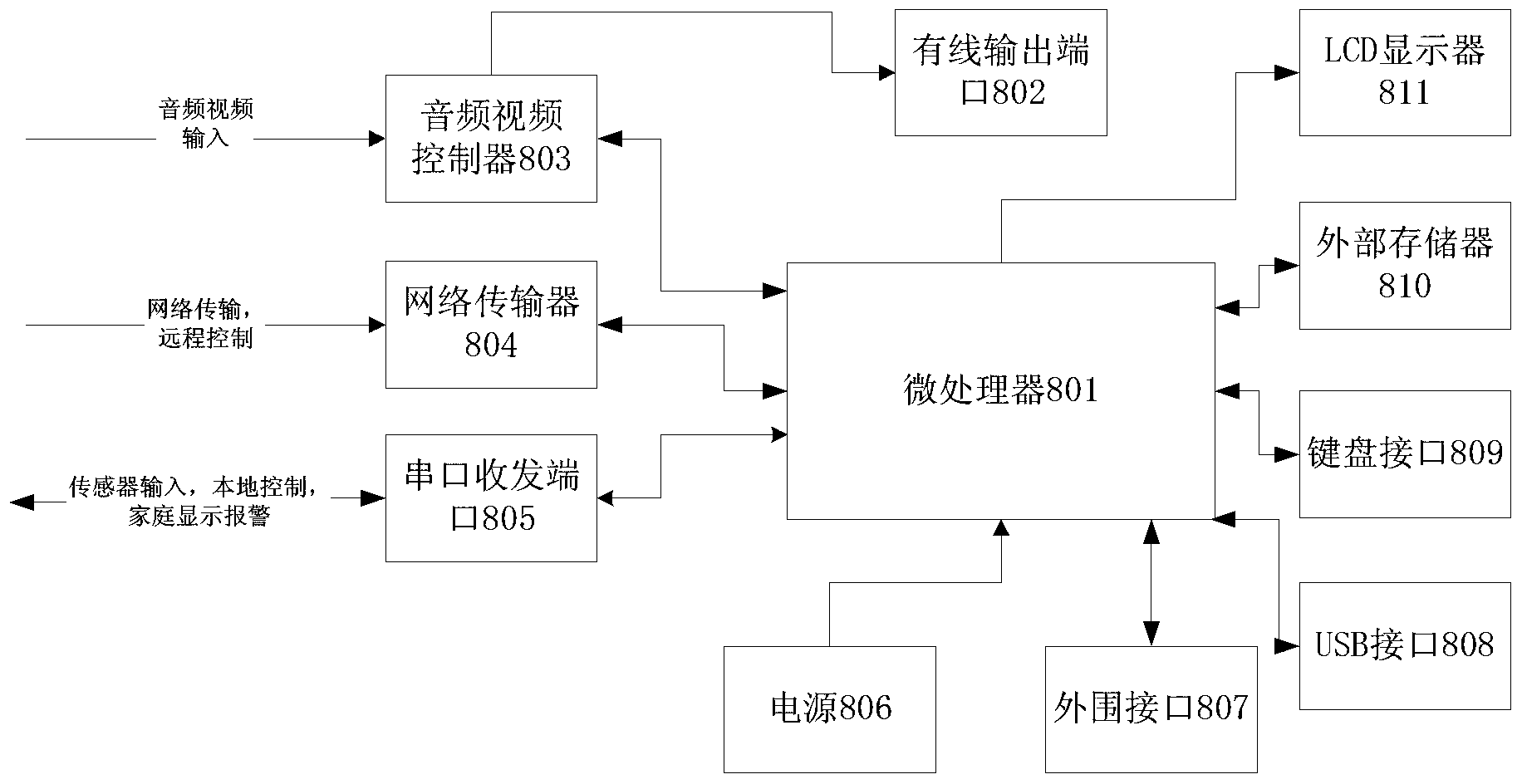

Intelligent baby room monitoring device

ActiveCN103268100AChange temperatureChange humidityProgramme total factory controlPower controllerCommunication interface

The invention relates to an intelligent baby room monitoring device. The intelligent baby room monitoring device comprises a temperature sensor, a humidity sensor, a urine-wetting alarm, an infrared area alarm, a sound receiver, a camera, a family gateway device, an intelligent controller, an infrared controller, an electric appliance, a power source controller, an audio player, a display alarm, a video player, a communication interface and a remote controller, wherein the family gateway device is respectively connected with the temperature sensor, the humidity sensor, the urine-wetting alarm, the infrared area alarm, the intelligent controller, the infrared controller, the power source controller and the display alarm, the infrared controller is connected with an infrared control device in the electric appliance, the power source controller is connected with a power source control device in the electric appliance, the sound receiver and the camera are connected with the intelligent controller, the intelligent controller is connected with the audio player and the video player, and the intelligent controller is connected with the remote controller through the communication interface. The intelligent baby room monitoring device can be widely applied to intelligent monitoring of a baby room.

Owner:NORTH CHINA INST OF SCI & TECH

Resin composition and molded or formed product

InactiveUS6342557B1Low rateFormed with easeInorganic material magnetismMixingShell moldingFerrite powder

A resin composition comprising a synthetic resin and a powdered magnetic material, wherein (1) the powdered magnetic material is soft ferrite powder having a rate of permeability change by temperature ranging from -0.040 to 0.010% / ° C. in a temperature range of from 20° C. to 80° C. and an average particle diameter ranging from 2 to 1,000 mum, and (2) the powdered magnetic material is contained in a proportion of 50 to 1,400 parts by weight per 100 parts by weight of the synthetic resin, and a molded or formed product which is formed from the resin composition and exhibits a permeability stable to changes in environmental temperature.

Owner:KUREHA KAGAKU KOGYO KK

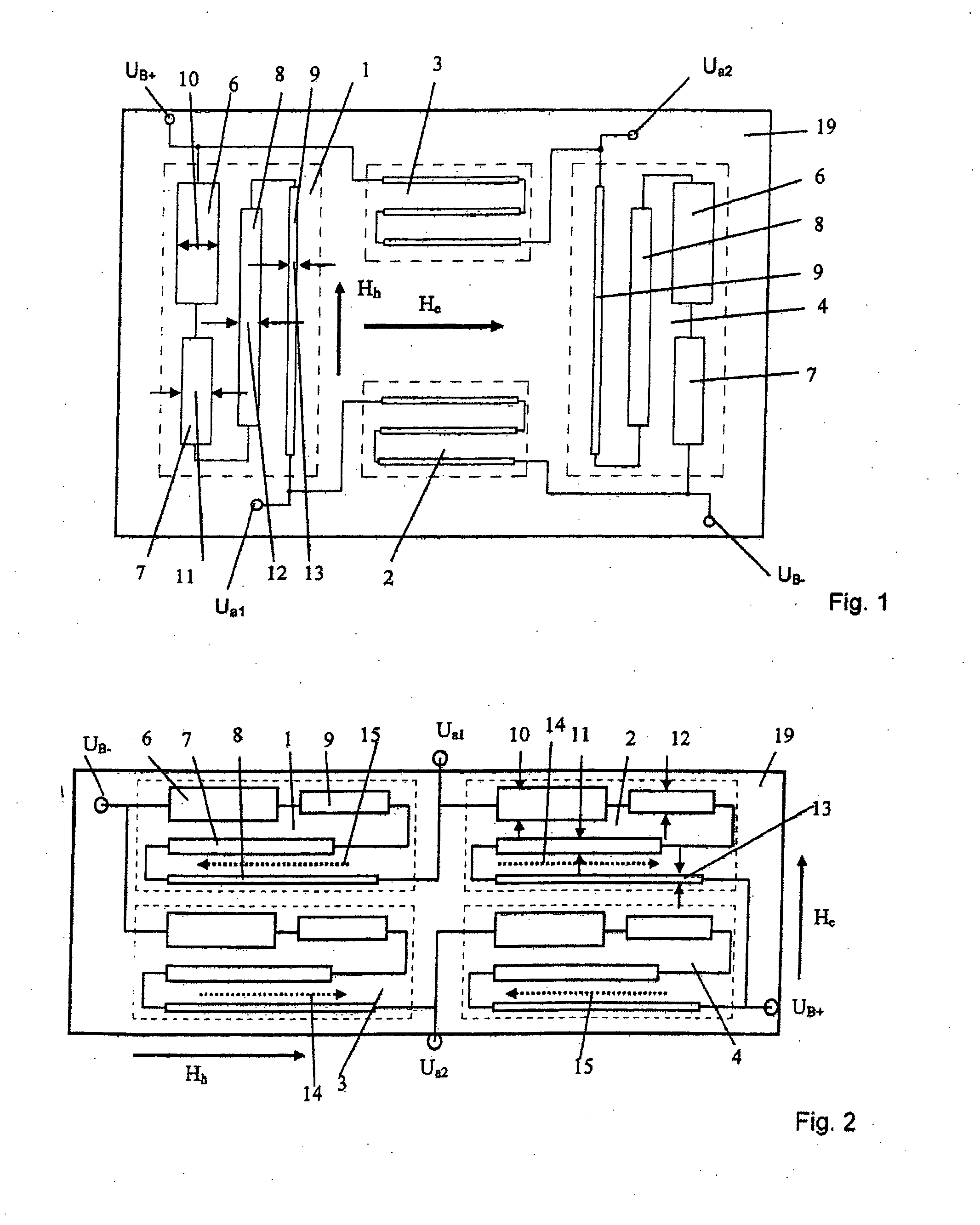

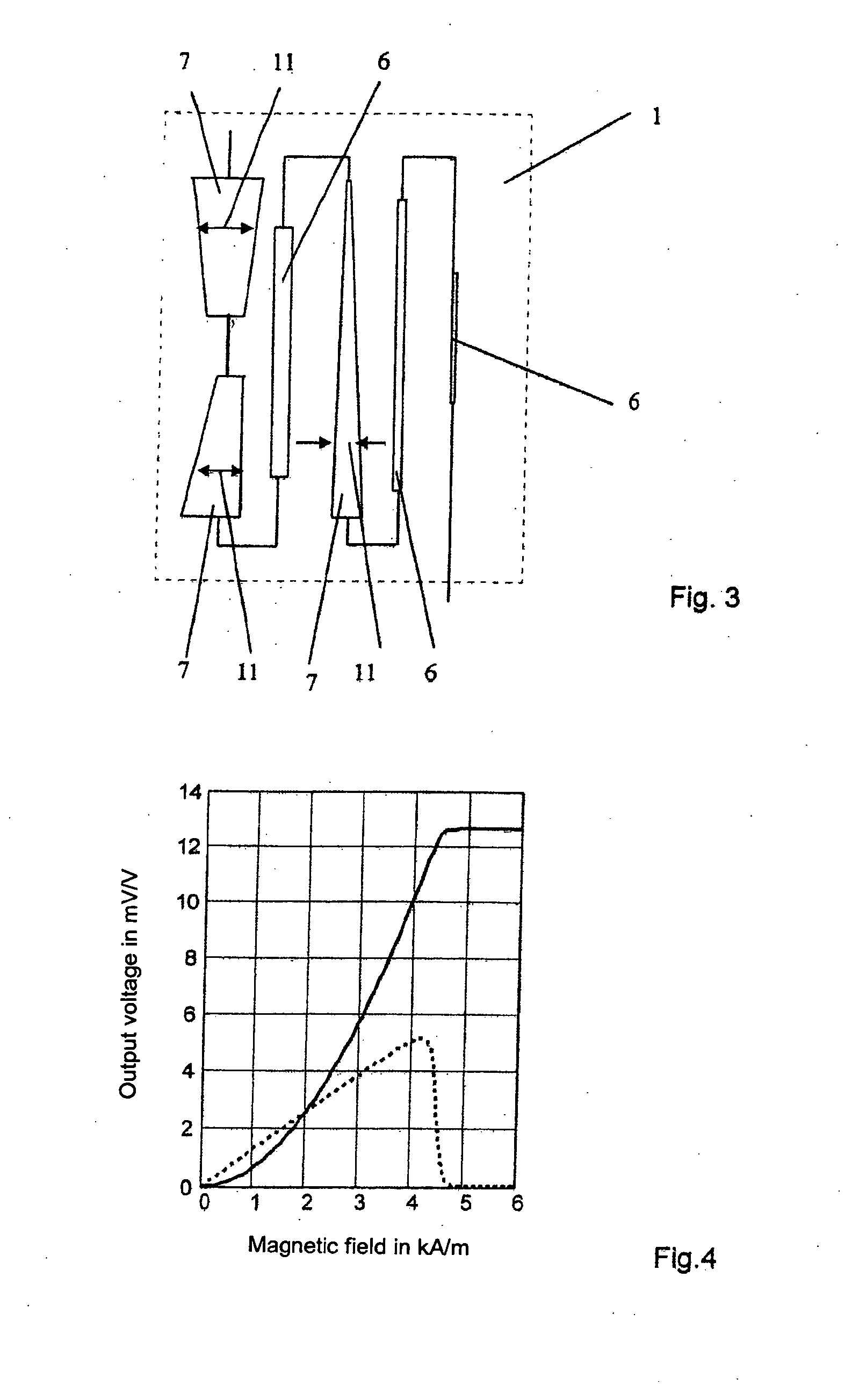

Magneto-resistive sensor for measuring magnetic fields

ActiveUS20120262164A1Smooth rotationSensitivity of sensorMagnitude/direction of magnetic fieldsElectrical resistance and conductanceResistive sensors

Magneto-resistive sensors based on the AMR or GMR effect exhibit substantially enlarged linear characteristic curve regions as a result of the fact that their resistances are composed of magneto-resistive layer strips of differing anisotropic forms. Differing anisotropic forms can be achieved by different strip widths, strip thicknesses, strip intervals or strip materials. The temperature compensation for the output voltage of the magneto-resistive sensors, at least at one point on the characteristic curve, is achieved by the series connection of an additional layer strip with a temperature coefficient that differs from that of the magneto-resistive material to at least one magneto-resistive resistance of the sensor.

Owner:MEAS DEUTLAND

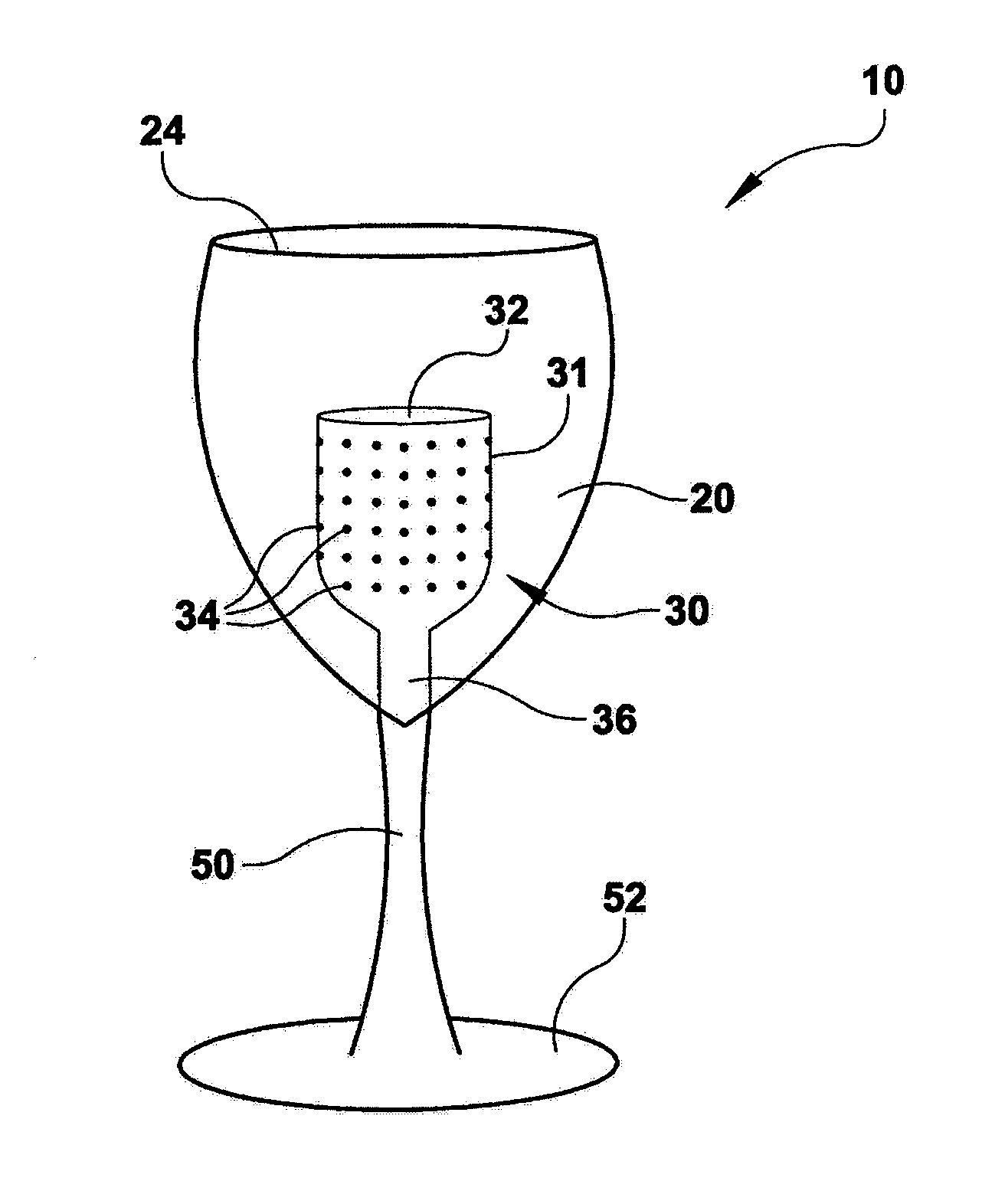

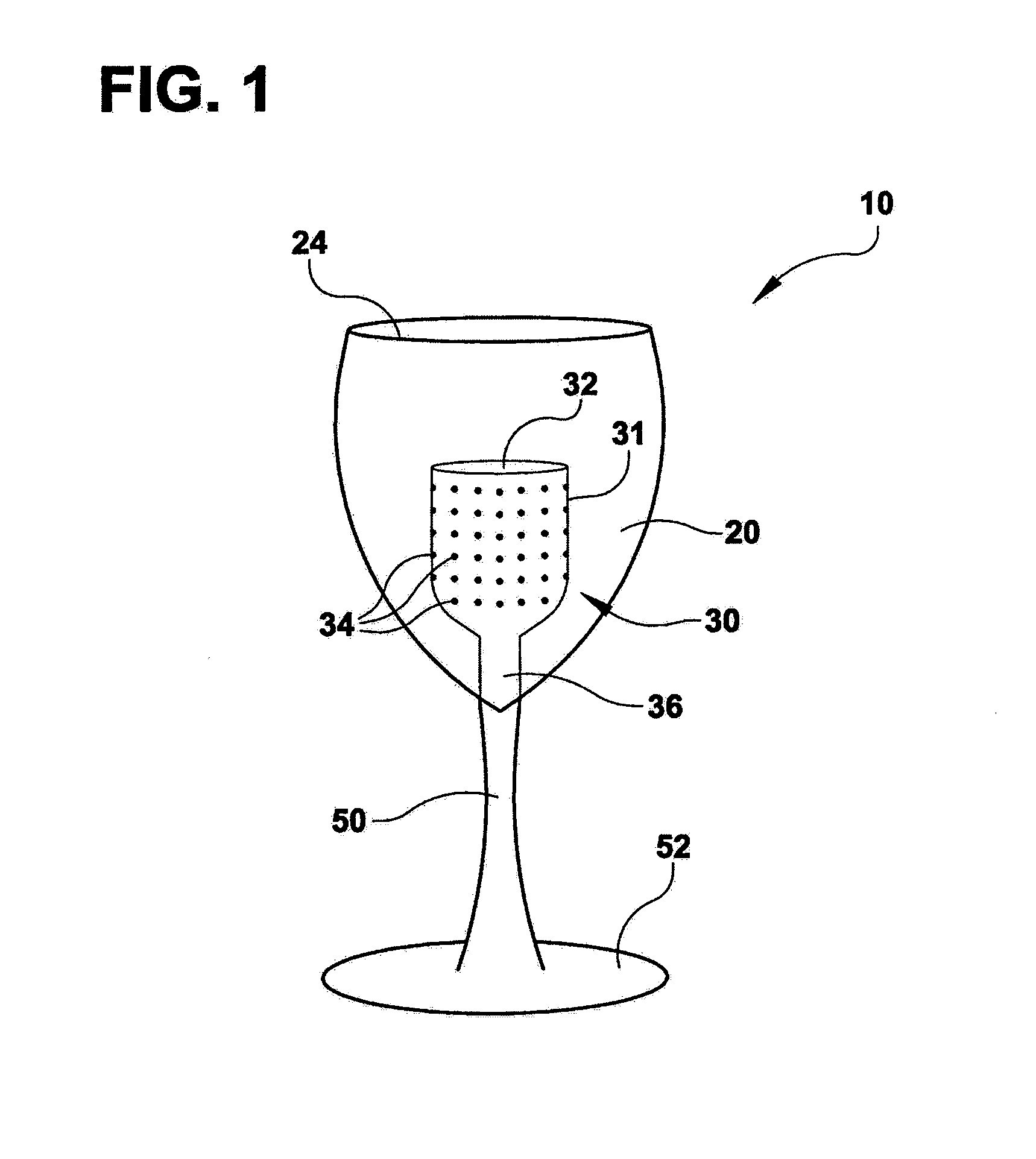

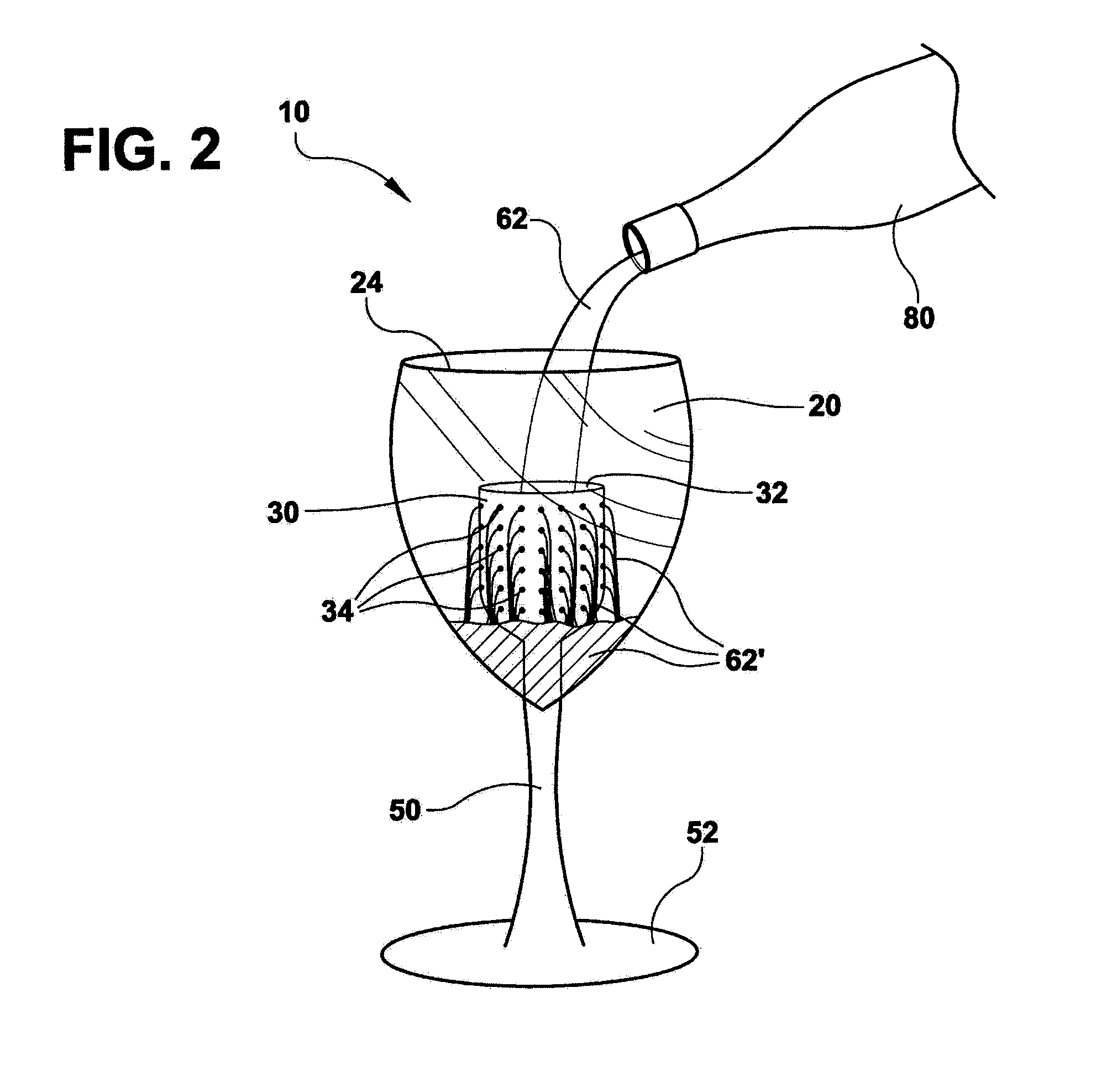

Beverage glass with internal decanting, filtering, mixing and aerating cell

ActiveUS20120167775A1Change temperatureTransportation and packagingMixing methodsEngineeringMaterial Perforation

A drinking container for decanting, filtering, mixing and / or aerating a beverage. The drinking container comprises a bowl having an upper opening and an aerating cell having a wall, an upper opening along the top of the cell and a plurality of openings or perforations through the wall. The cup-shaped cell has an upwardly facing hollow or concave configuration, optionally with a central upwardly extending protrusion, and is attached to and within the bowl, to decant, filter, mix and / or aerate a beverage that is poured through the bowl upper opening and into the cell upper opening, and subsequently flows through the at least one perforation into the bowl. Preferably, the drinking container is a wine glass having a base and stem supporting the bowl and the beverage is wine.

Owner:CHEVALIER HLDG LLC

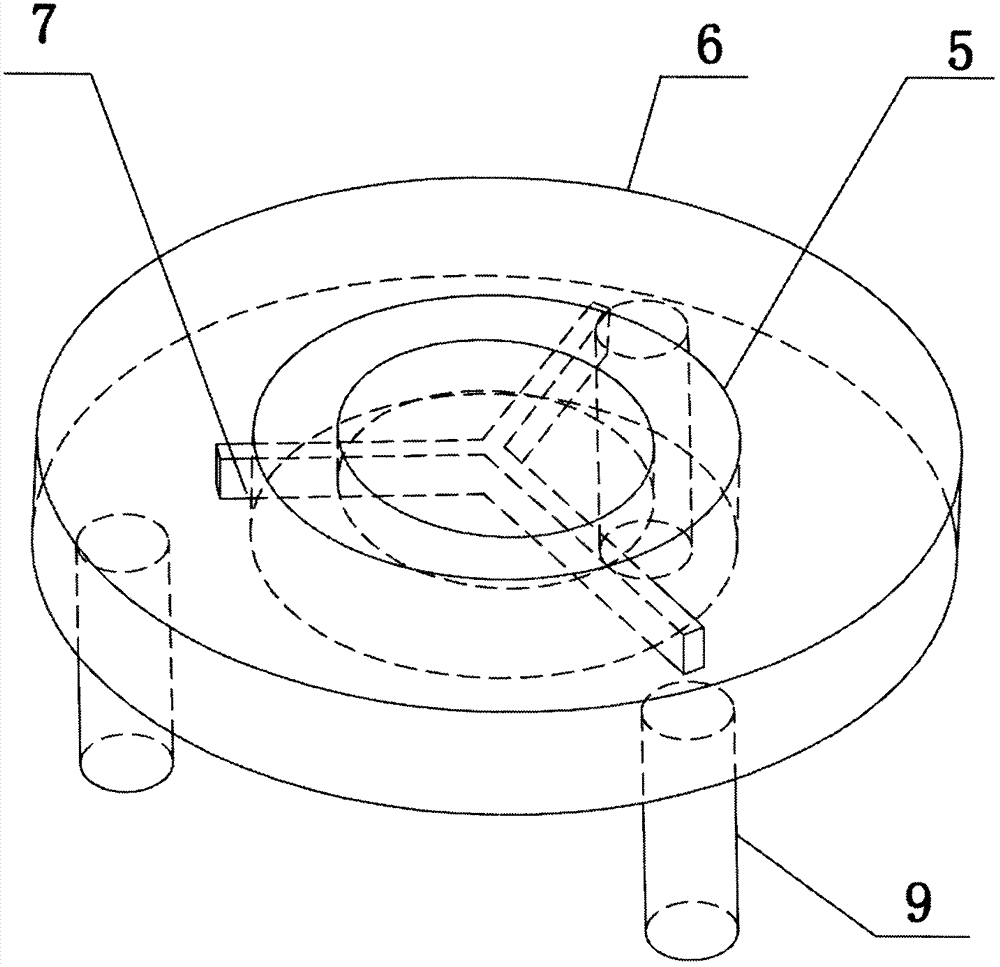

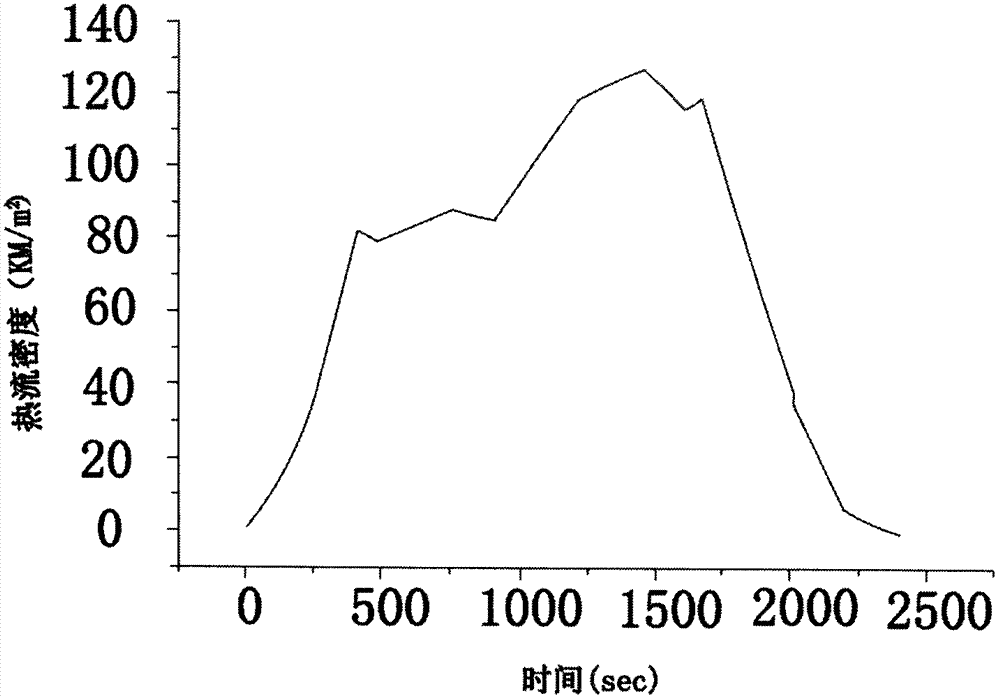

Test apparatus and test method for heat insulation performance of honeycomb panel

InactiveCN103196943AReduce energy consumptionEasy to operateMaterial heat developmentHeat fluxData acquisition

The invention discloses a test apparatus and a test method for the heat insulation performance of a honeycomb panel. A test piece to be tested is a high temperature alloy honeycomb panel. The test apparatus comprises a laser, a controller, an optical path adjusting device, a test fixture, a temperature sensor and a data acquisition system. The test method provided by the invention comprises the following steps: disposing the high temperature alloy honeycomb panel in the test fixture; adjusting the laser, the controller and the optical path adjusting device to allow laser output to exactly satisfy requirements for a heating range of the test piece to be tested; compiling a laser power control program according to a heat flux density curve to be simulated in testing; adjusting the laser power control program, confirming that the test apparatus is completely right and then starting testing; and collecting testing data from the data acquisition system connected with the temperature sensor and disposing and analyzing the data. The test apparatus and the test method for the heat insulation performance of the honeycomb panel in the invention have the following advantages: small energy consumption, simple operation, capacity of convenient and rapid changing of a temperature and capability of accurate and effective testing of the heat insulation performance of the honeycomb panel.

Owner:胡增荣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com