Method for making high-sensitivity optical fiber grating temperature sensor working in high and low temperature

A technology of temperature sensor and optical fiber grating, which is applied in the field of bimetallic optical fiber grating temperature-enhancing sensor design, can solve the problem of limited range of high-sensitivity optical fiber grating temperature sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

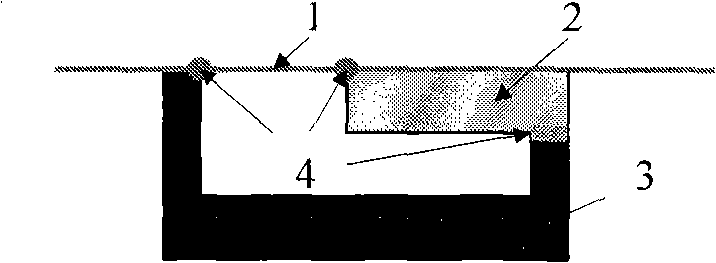

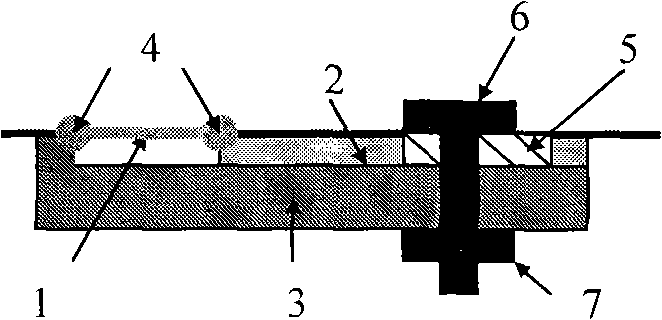

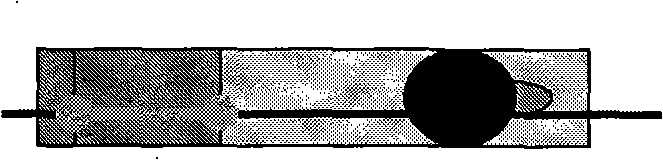

[0030] Example 1: In an environment of 20°C, make a sensor with an initial working temperature of 120°C. The sensor is mainly composed of the following parts: a fiber grating, aluminum with a large thermal expansion coefficient (α=22*10 -6 / K) base, small coefficient of thermal expansion invar (α=0.5*10 -6 / K) strip, where a strip hole, a set screw and a nut are made on the invar strip. according to figure 2 and image 3 In the way shown, first fix the aluminum base and the invar strip together with screws and nuts. Then use epoxy glue to paste the two ends of the fiber grating to the aluminum base and the end points of the invar strip respectively. Then, you can determine d by moving the invar bar, and choose different Δd according to different Ts.

[0031] Might as well set L=500mm, d=15mm. At this time, the pre-loose length of the fiber grating should be:

[0032] Δd=[α 2 L-α 1 (L-d)](Ts-Tr)≈1.05mm

[0033] The temperature sensitivity of the sensor is:

[0034] ...

example 2

[0036] Example 2: In an environment of 20°C, make a sensor with an initial working temperature of -80°C. The sensor is mainly composed of the following parts: a fiber grating, an invar base with a small thermal expansion coefficient, a long aluminum strip with a large thermal expansion coefficient, and a long hole, a fixing screw and a nut are made on the aluminum strip. according to figure 2 and image 3In the way shown, the invar base and the aluminum bar are first fixed together with screws and nuts. Then use epoxy glue to paste the two ends of the fiber grating to the invar base and the ends of the aluminum bar respectively. Then, d can be determined by moving the aluminum strip, and different Δd can be selected according to different Ts.

[0037] Might as well set L=500mm, d=15mm. At this time, the pre-loose length of the fiber grating should be:

[0038] Δd=[α 2 L-α 1 (L-d)](Ts-Tr)≈1.04mm,

[0039] The temperature sensitivity of the sensor is:

[0040] Δλ B / Δ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com