Patents

Literature

721results about "Alkaline earth titanates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

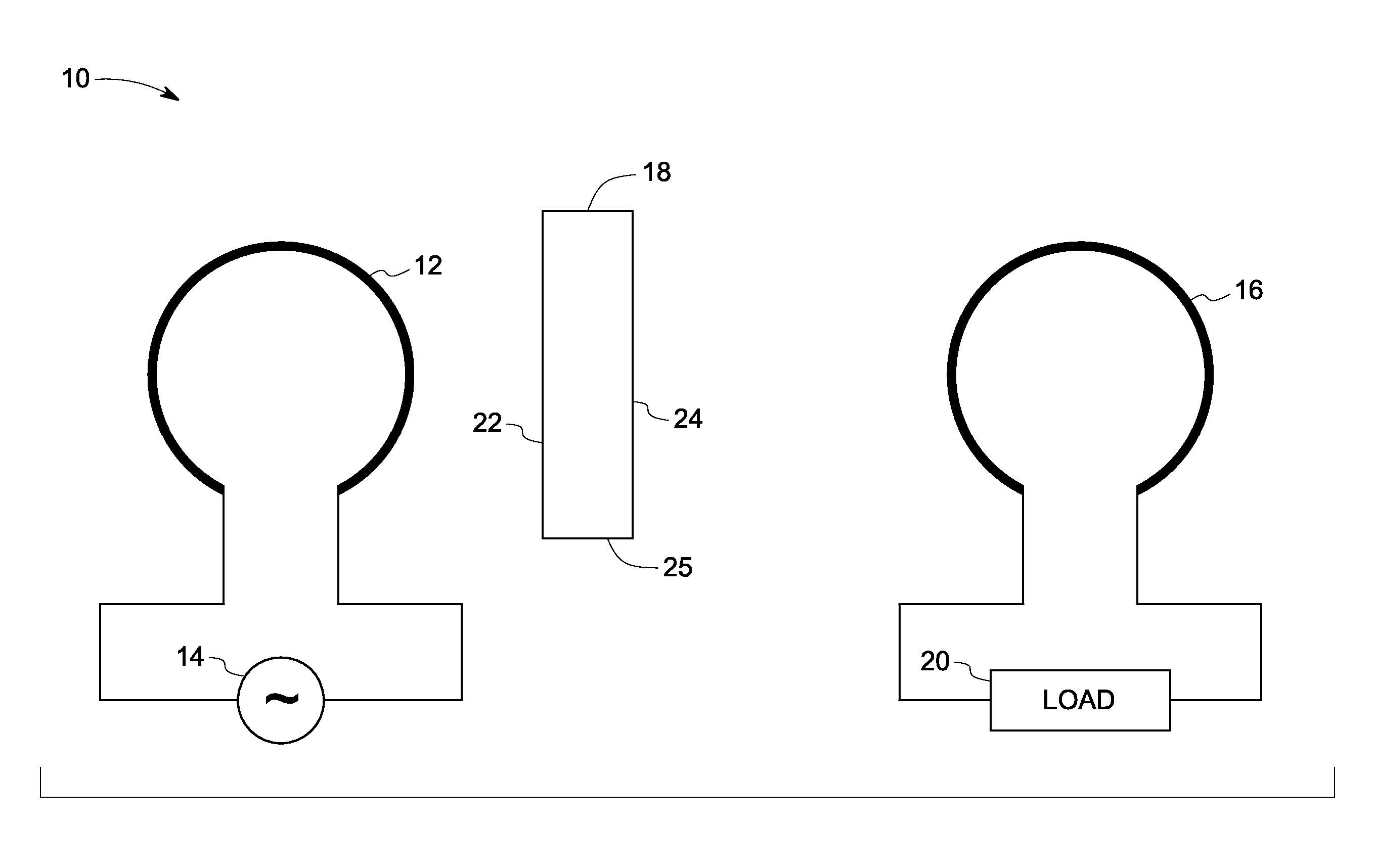

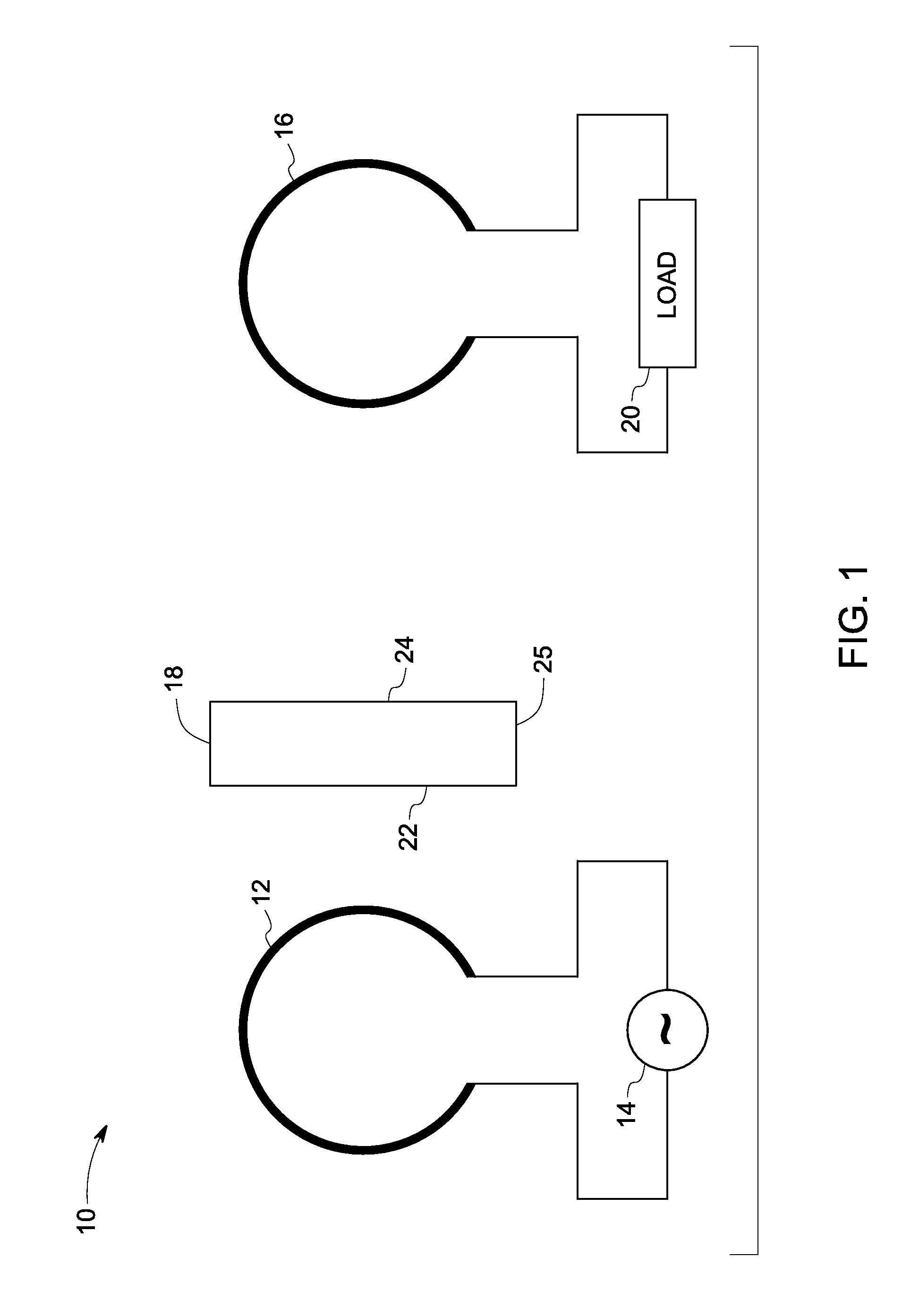

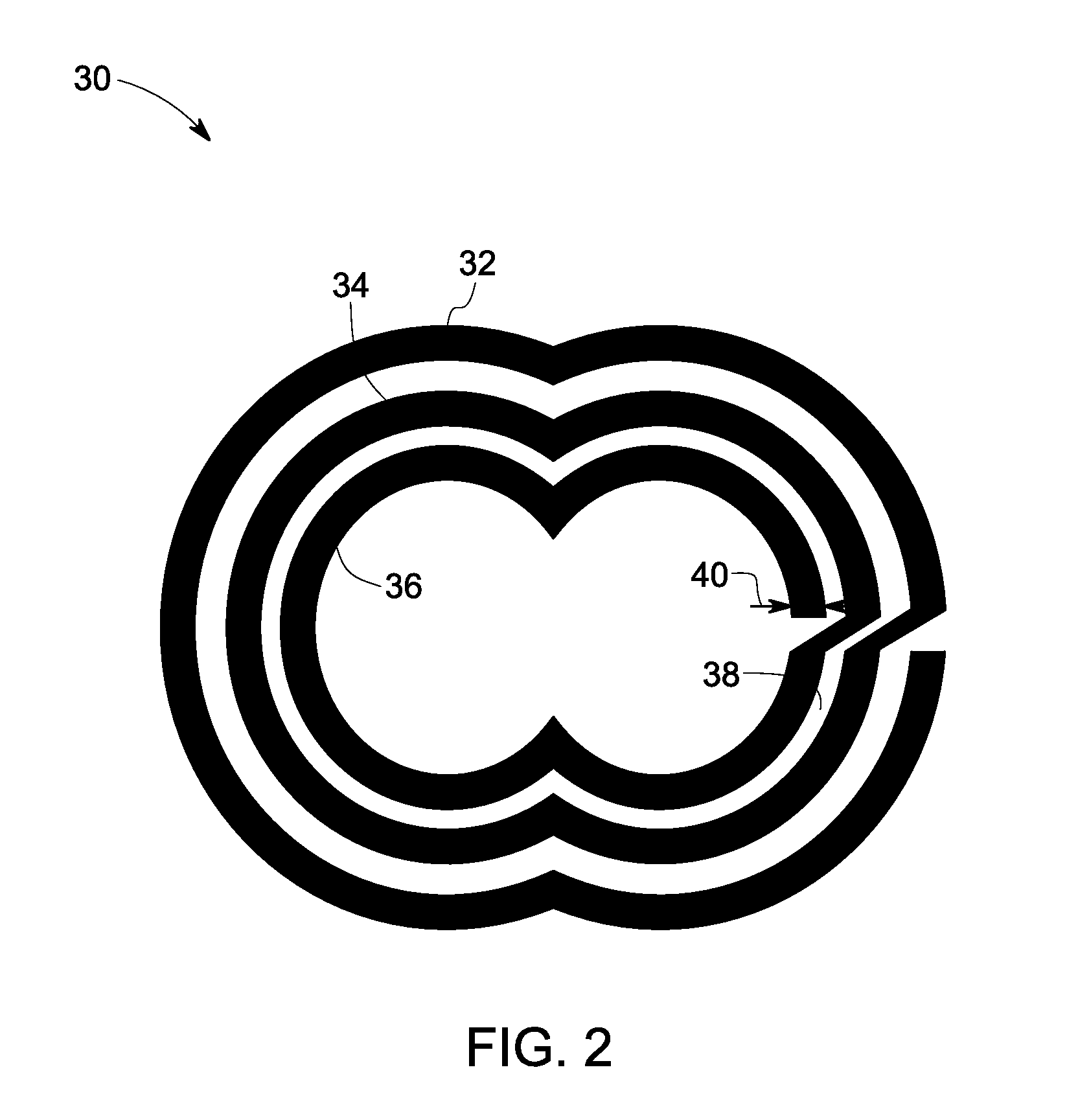

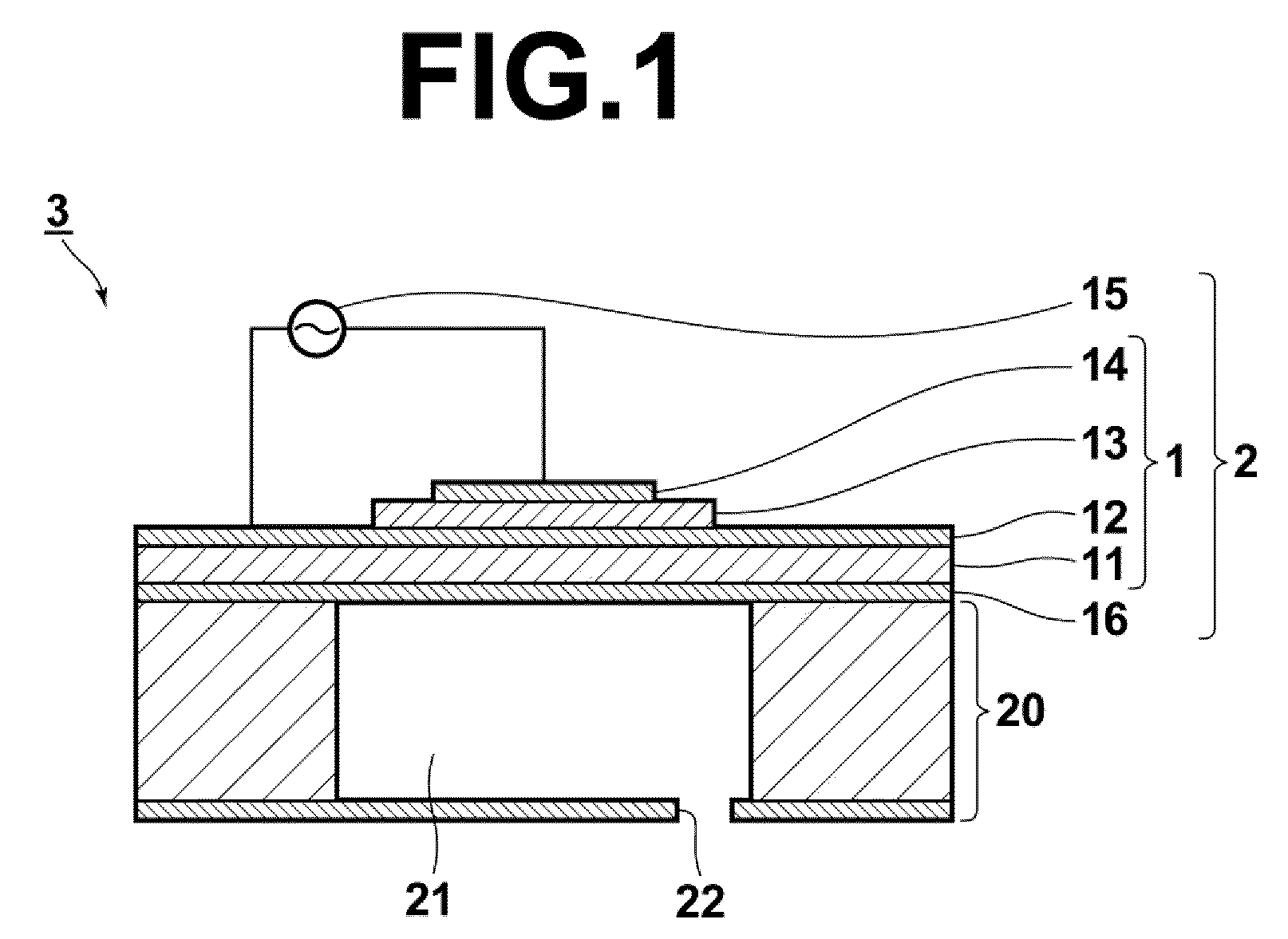

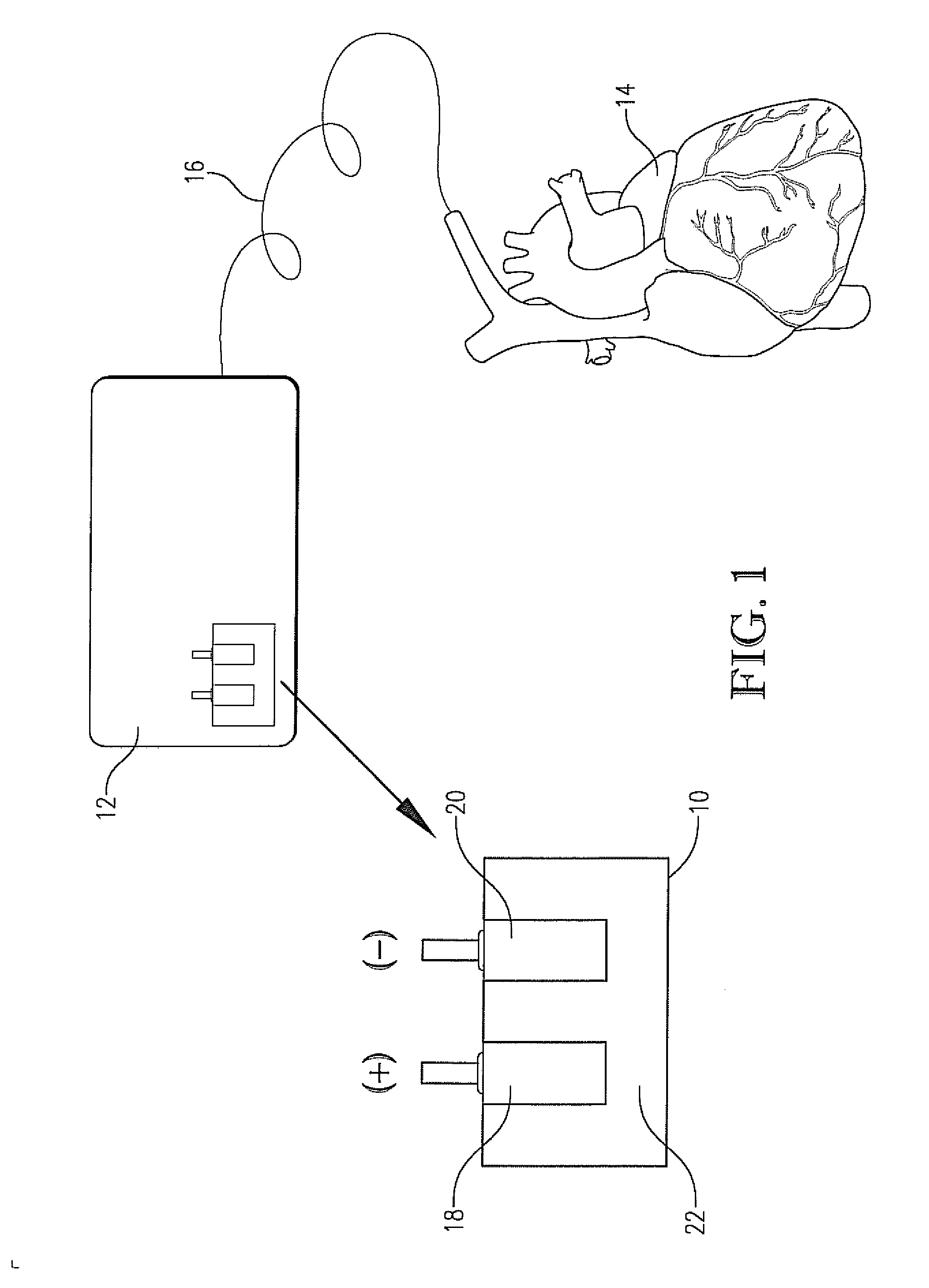

Dielectric materials for power transfer system

A contactless power transfer system is proposed. The power transfer system comprises a field-focusing element comprising a dielectric material. The dielectric material comprises a composition that is selected from the family of (Ba,Sr)TiO3 or CaCu3Ti4O12. The compositions of the (Ba,Sr)TiO3 include the materials such as Ca1-x-yBaxSryTi1-zCrzO3-δNp, wherein 0<x<1; 0<y<1; 0≦z≦0.01; 0≦δ≦1; and 0≦p≦1. The compositions of the CaCu3Ti4O12 include the materials such as Ca1-x-yBaxSry (Ca1-zCuz)Cu2Ti4-δAlδO12-0.5δ, wherein 0≦x<0.5; 0≦y<0.5; 0≦z≦1; and 0≦δ≦0.1.

Owner:GENERAL ELECTRIC CO

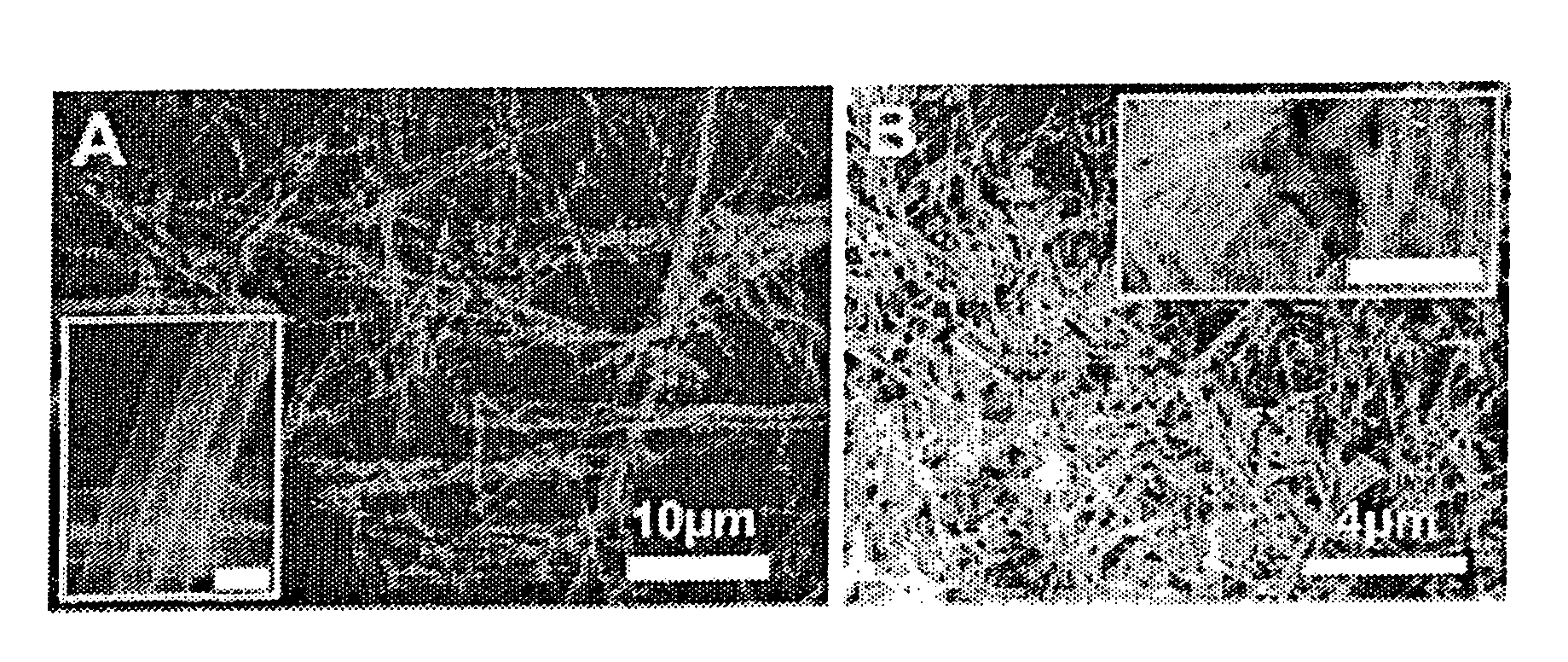

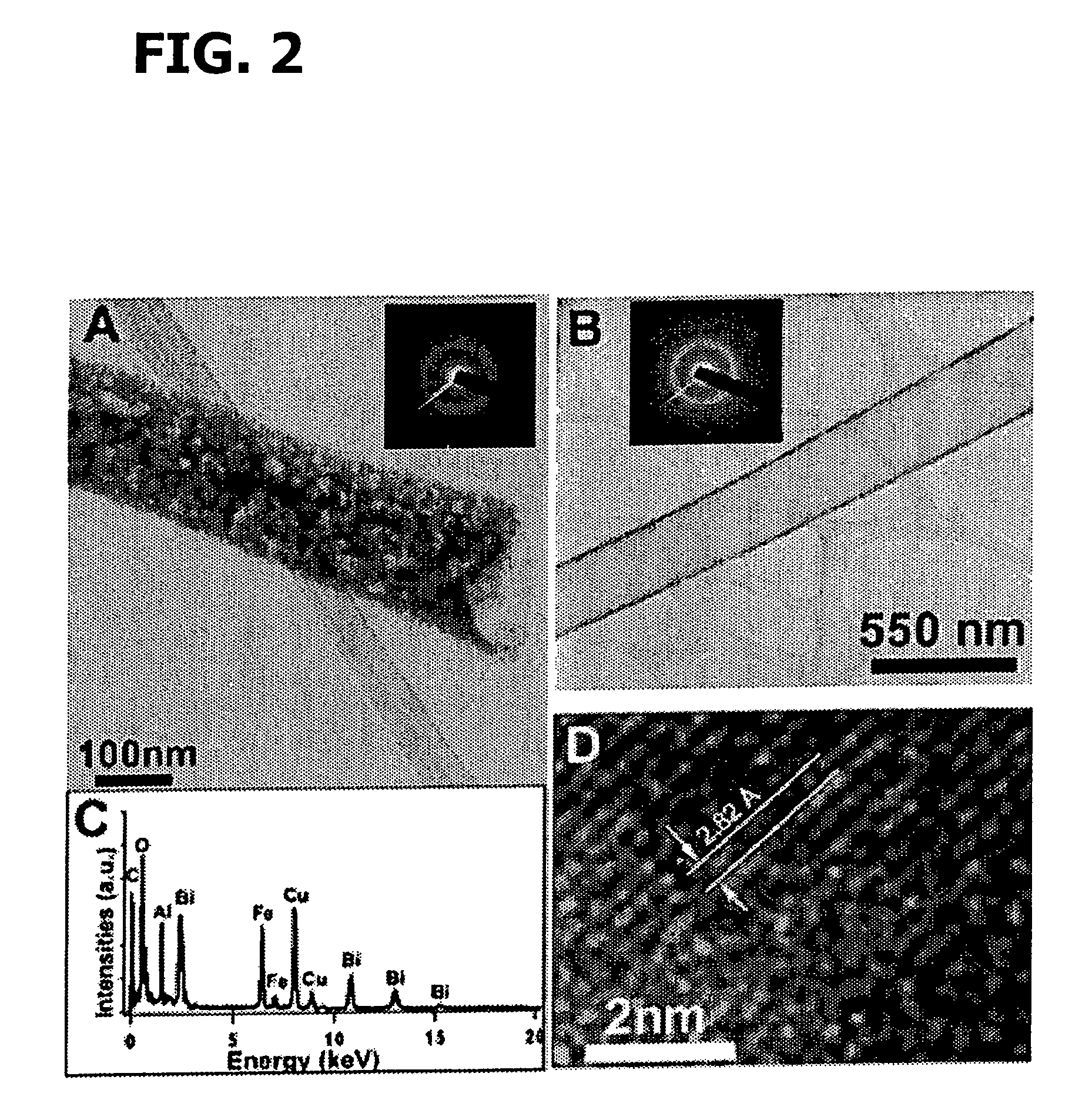

Ternary oxide nanostructures and methods of making same

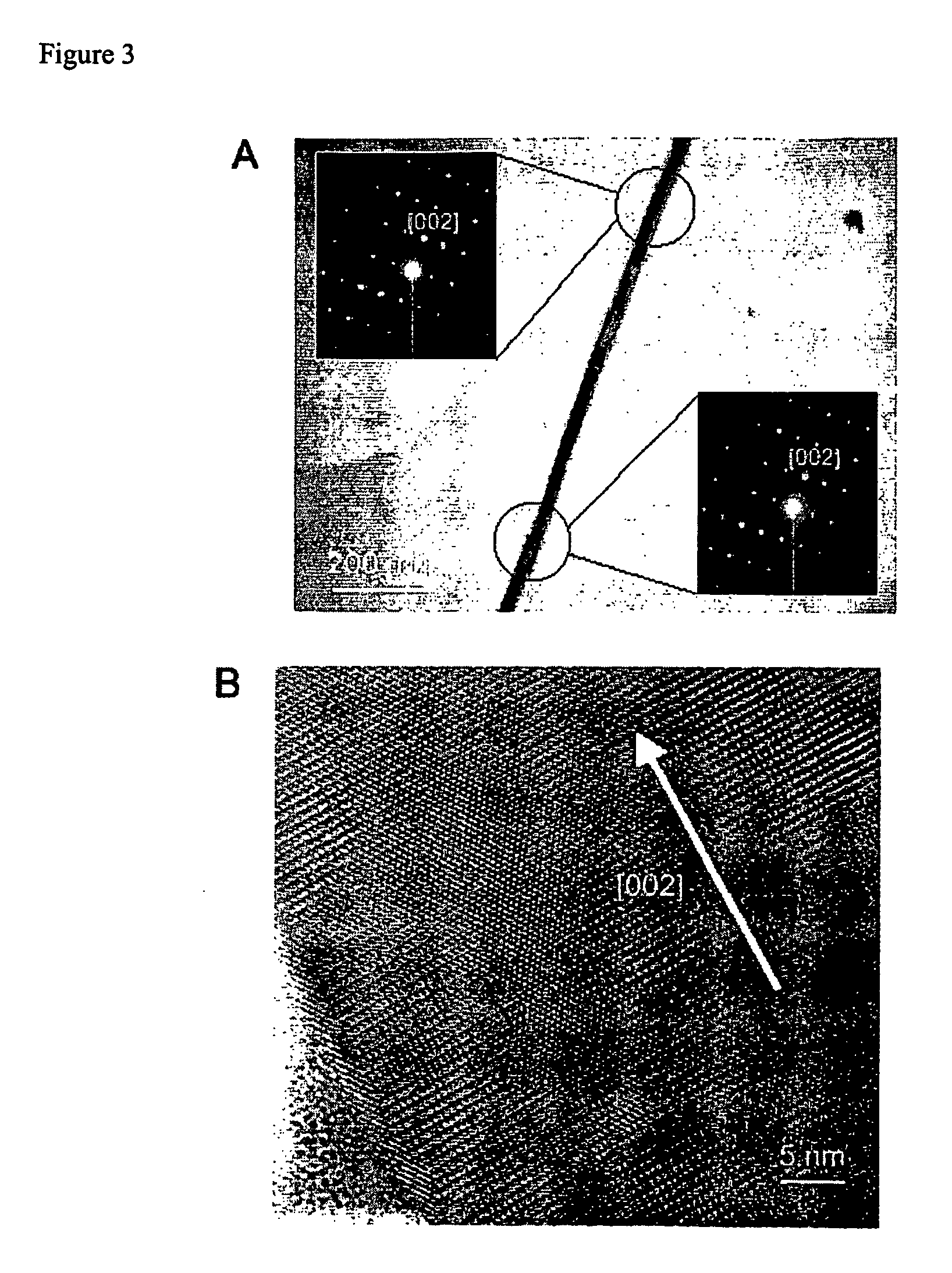

InactiveUS20070138459A1Suitable for preparationFrom gel stateAlkaline earth titanatesNanostructureDislocation

A single crystalline ternary nanostructure having the formula AxByOz, wherein x ranges from 0.25 to 24, and y ranges from 1.5 to 40, and wherein A and B are independently selected from the group consisting of Ag, Al, As, Au, B, Ba, Br, Ca, Cd, Ce, Cl, Cm, Co, Cr, Cs, Cu, Dy, Er, Eu, F, Fe, Ga, Gd, Ge, Hf, Ho, I, In, Ir, K, La, Li, Lu, Mg, Mn, Mo, Na, Nb, Nd, Ni, Os, P, Pb, Pd, Pr, Pt, Rb, Re, Rh, Ru, S, Sb, Sc, Se, Si, Sm, Sn, Sr, Ta, Tb, Tc, Te, Ti, Ti, Tm, U, V, W, Y, Yb, and Zn, wherein the nanostructure is at least 95% free of defects and / or dislocations.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

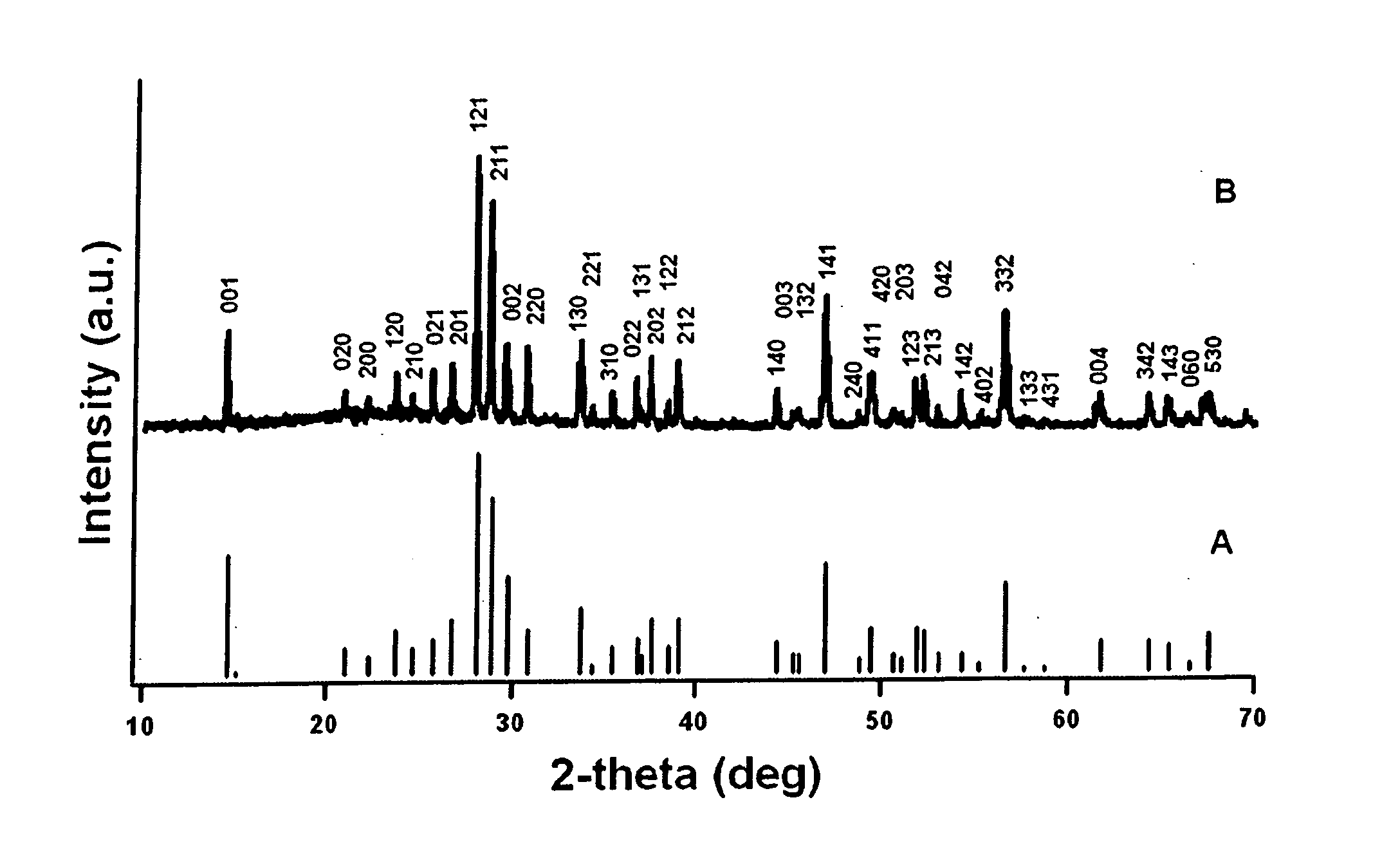

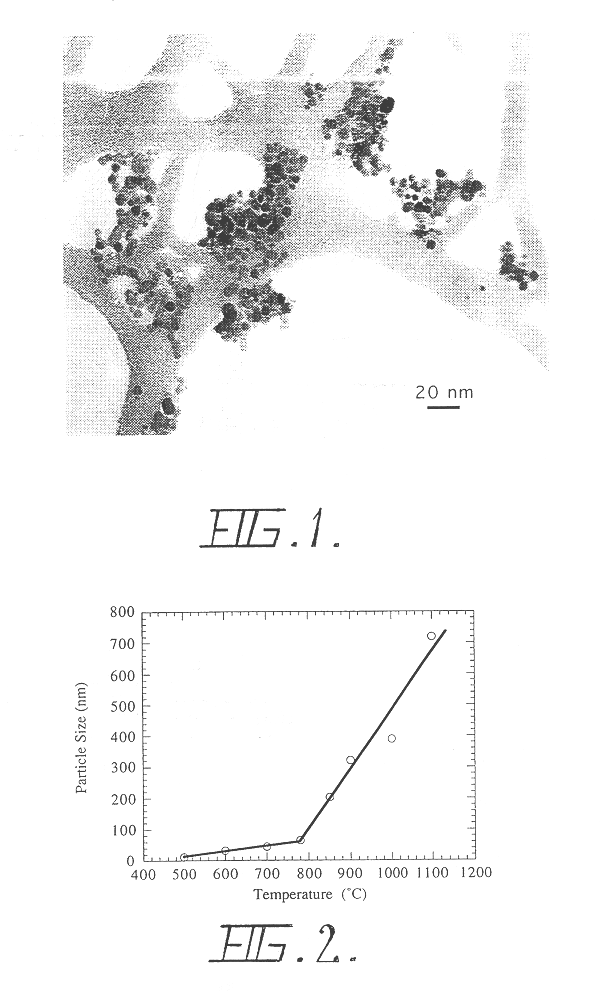

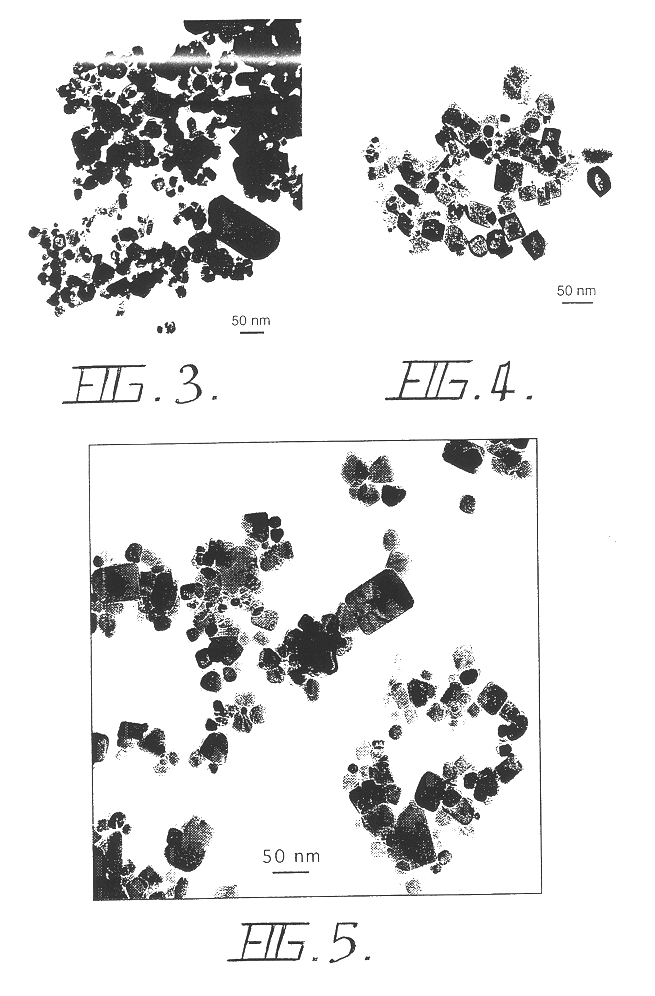

Process for the production of ultrafine powders of metal oxides

InactiveUS6503475B1Low costHigh yield rateAlkaline earth titanatesMaterial nanotechnologyDiluentBiological activation

A process for the production of ultrafine powders that includes subjecting a mixture of precursor metal compound and a non-reactant diluent phase to mechanical milling whereby the process of mechanical activation reduces the microstructure of the mixture to the form of nano-sized grains of the metal compound uniformly dispersed in the diluent phase. The process also includes heat treating the mixture of nano-sized grains of the metal compound uniformly dispersed in the diluent phase to convert the nano-sized grains of the metal compound into a metal oxide phase. The process further includes removing the diluent phase such that the nano-sized grains of the metal oxide phase are left behind in the form of an ultrafine powder.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD +1

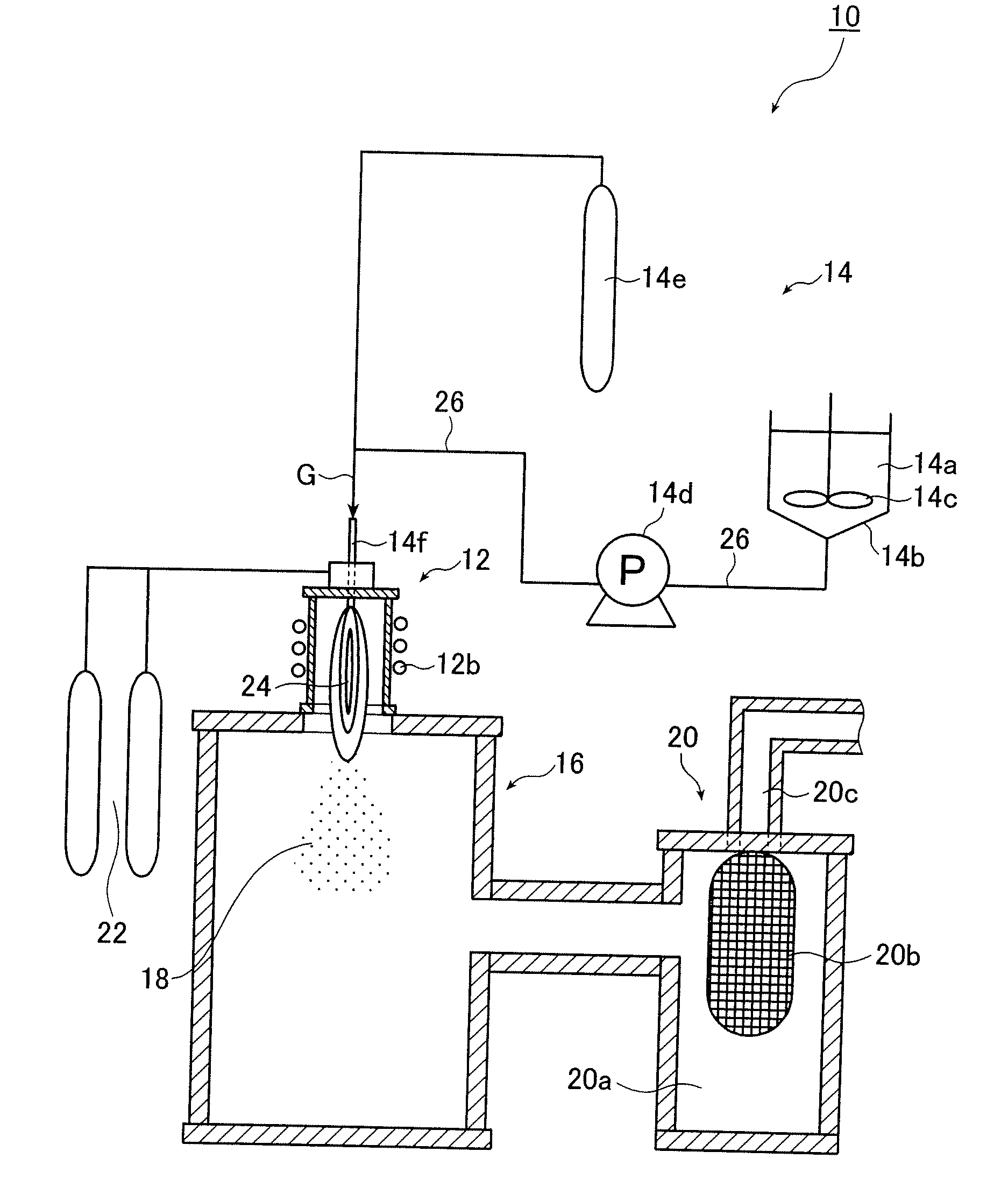

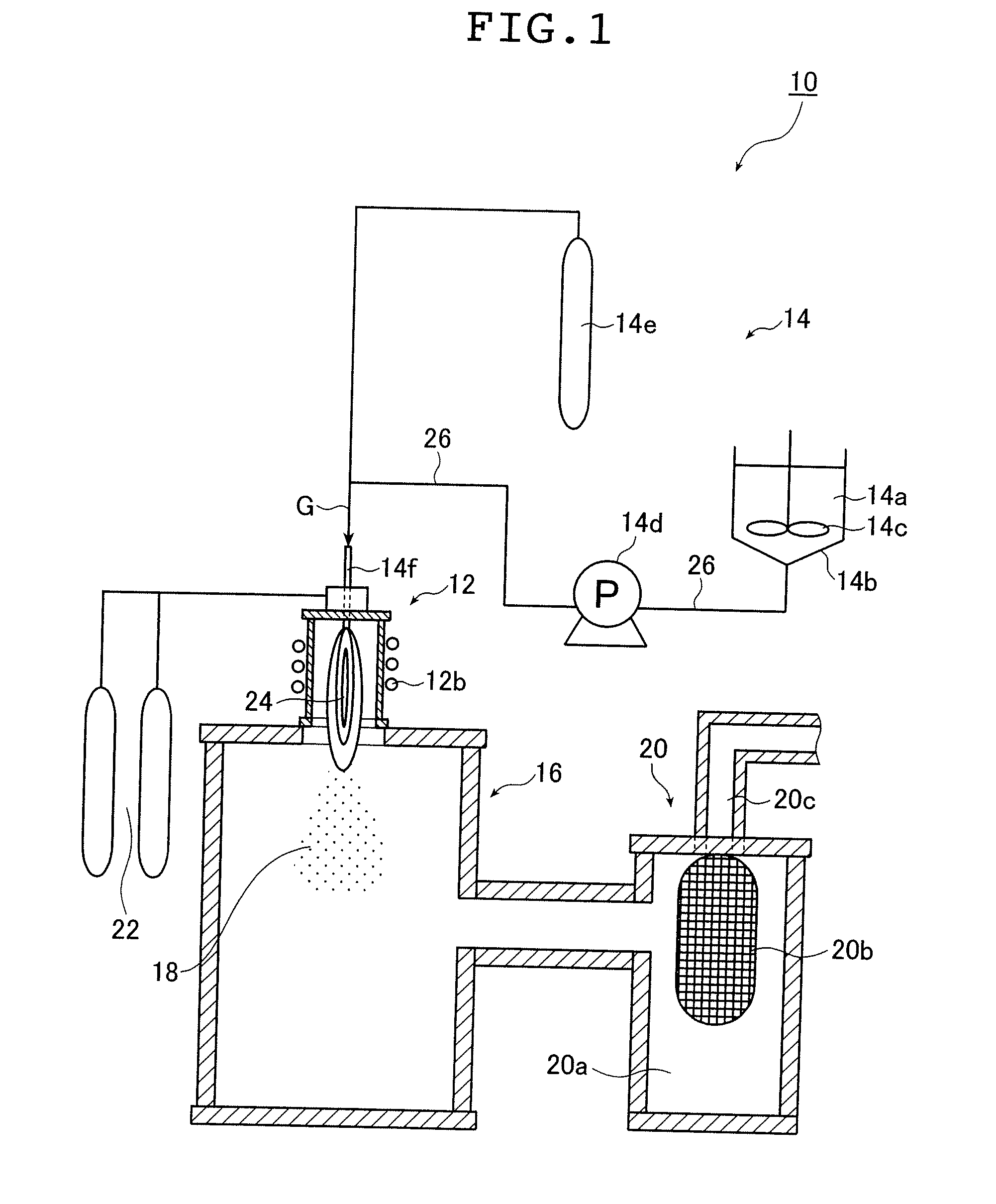

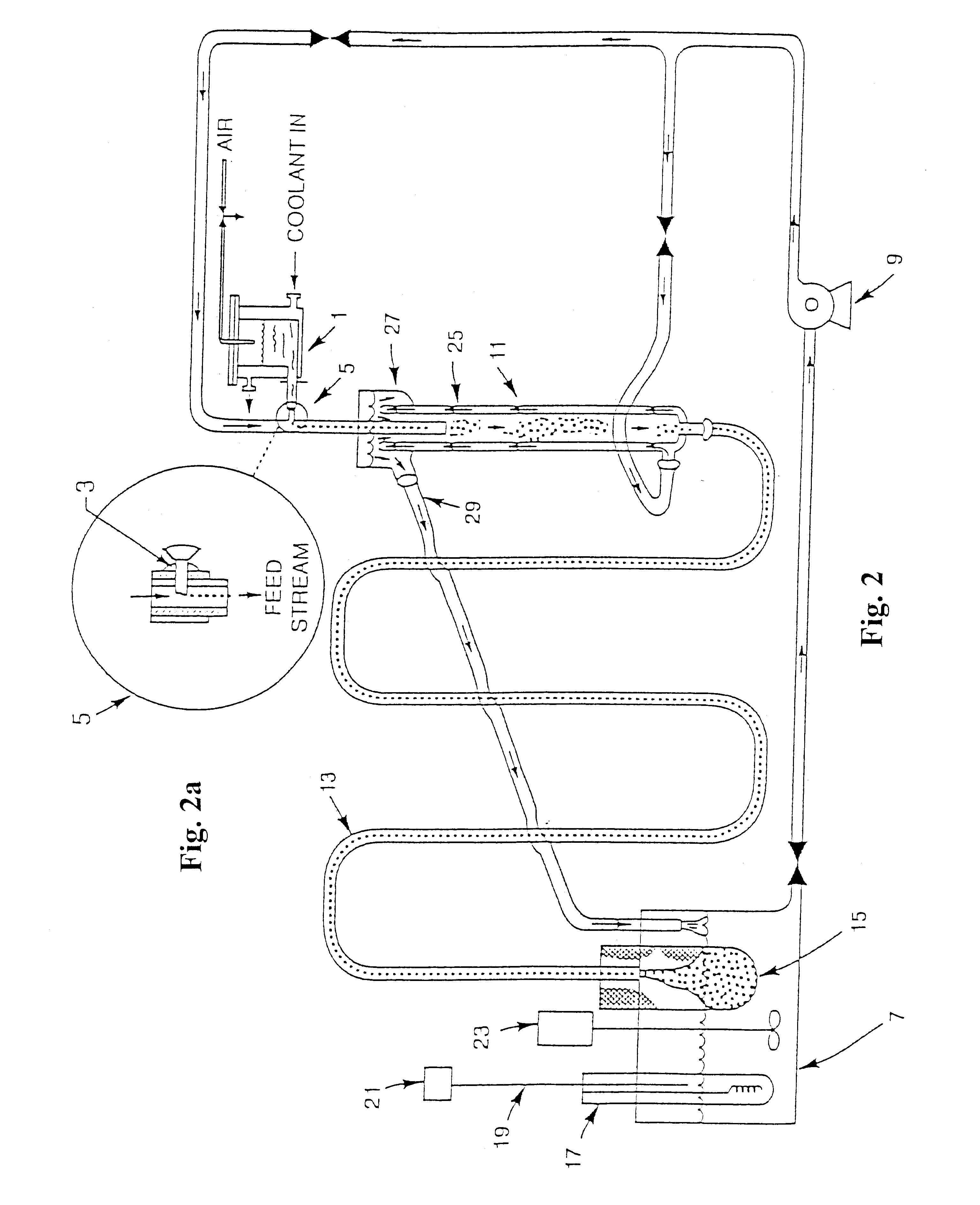

Process and Apparatus for Producing Fine Particles

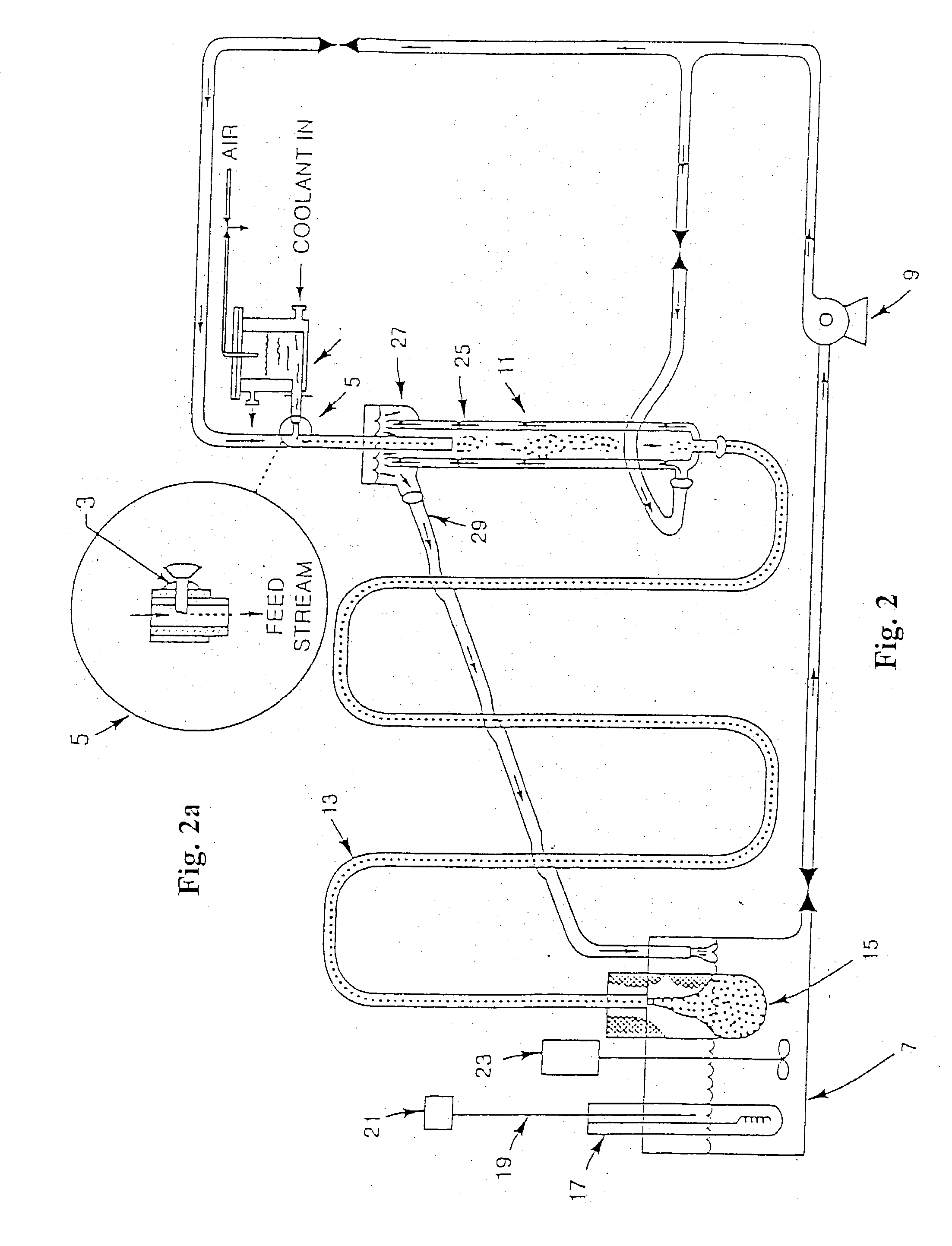

ActiveUS20080006954A1Improve productivityFunction increaseAlkaline earth titanatesMaterial nanotechnologyGas phaseSlurry

A fine particle producing process introduces a material for producing fine particles into a thermal plasma flame to make a vapor-phase mixture and quenches the vapor-phase mixture to form the fine particles. In the process, the material for producing the fine particles is dispersed or dissolved in a dispersion medium or solvent, preferably containing a combustible material to prepare a dispersion such as a slurry, a colloidal solution or a dissolution solution, the dispersion is made into a form of droplets, or the material for producing the fine particles is dispersed with a carrier gas and a combustible material and the dispersion in a droplet form or the dispersed material is introduced into the thermal plasma flame. In the fine particle producing process and apparatus, a gas of an amount sufficient to quench the vapor-phase mixture is supplied toward a tail of the thermal plasma flame. In the process and apparatus, primary fine particles are introduced into a cyclone to be subjected to cooling and classification and secondary fine particles having a particle size of 100 nm or less which are left upon removal of coarse particles are recovered.

Owner:NISSHIN SEIFUN GRP INC +1

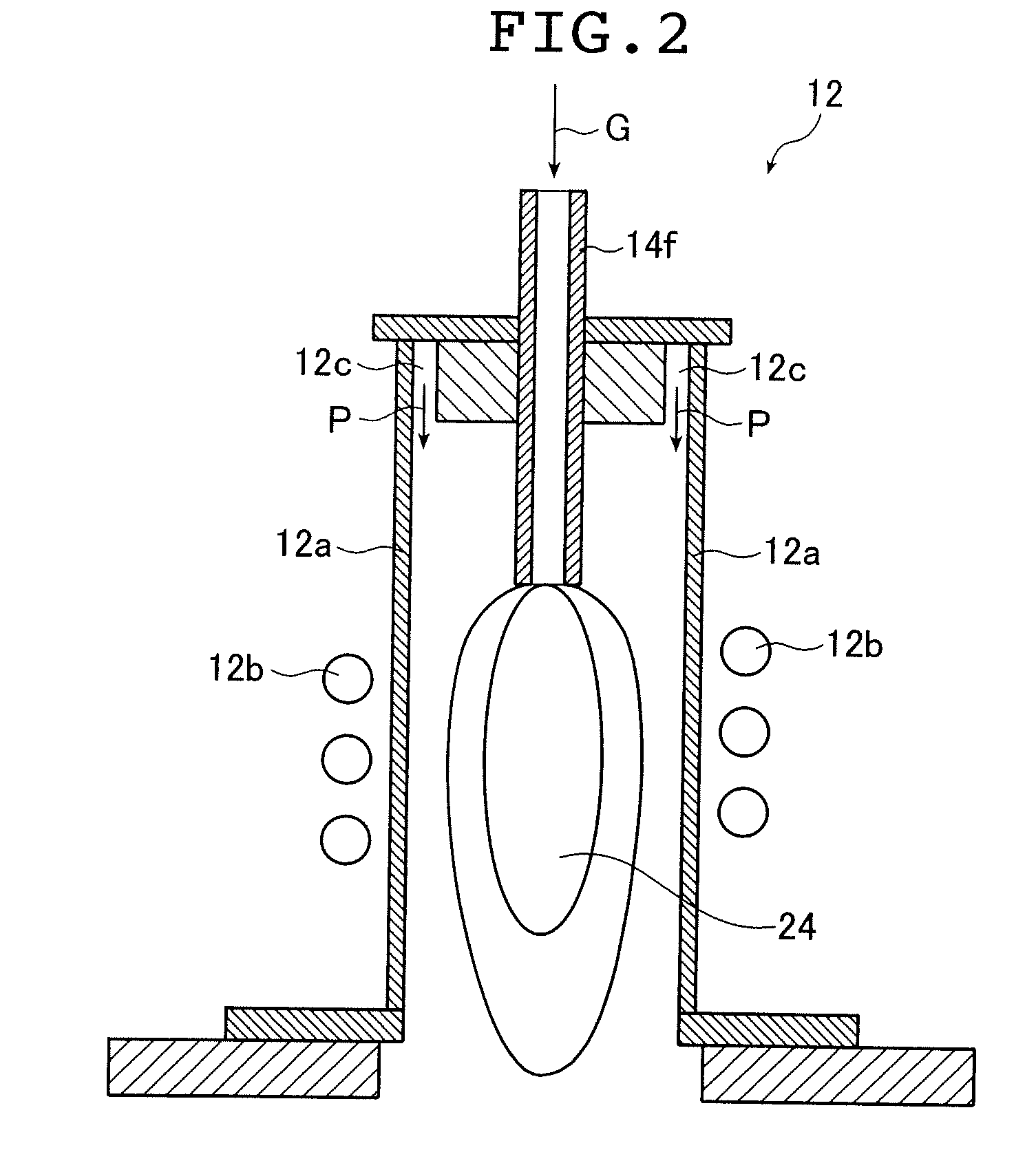

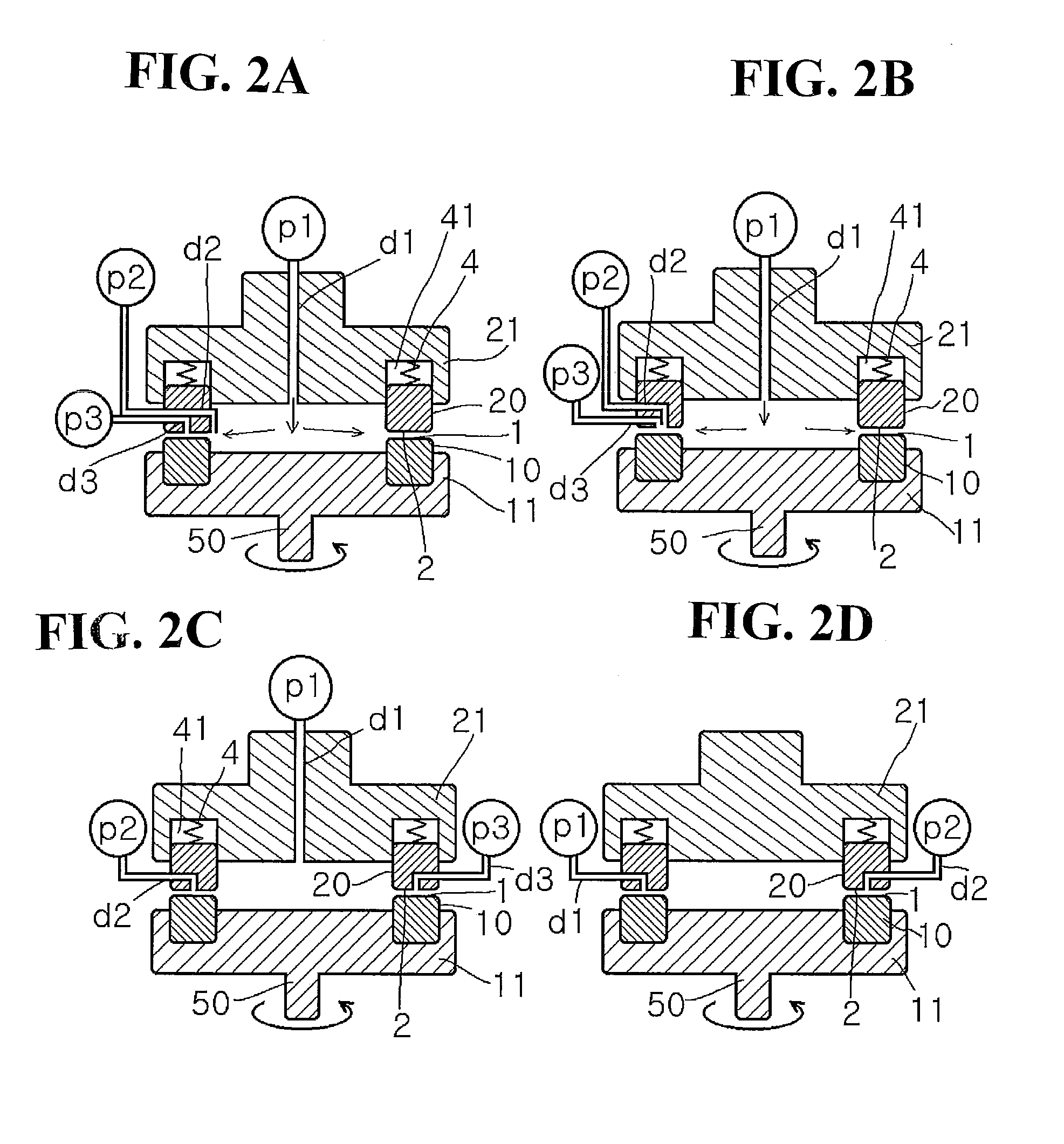

Electromechanical actuators

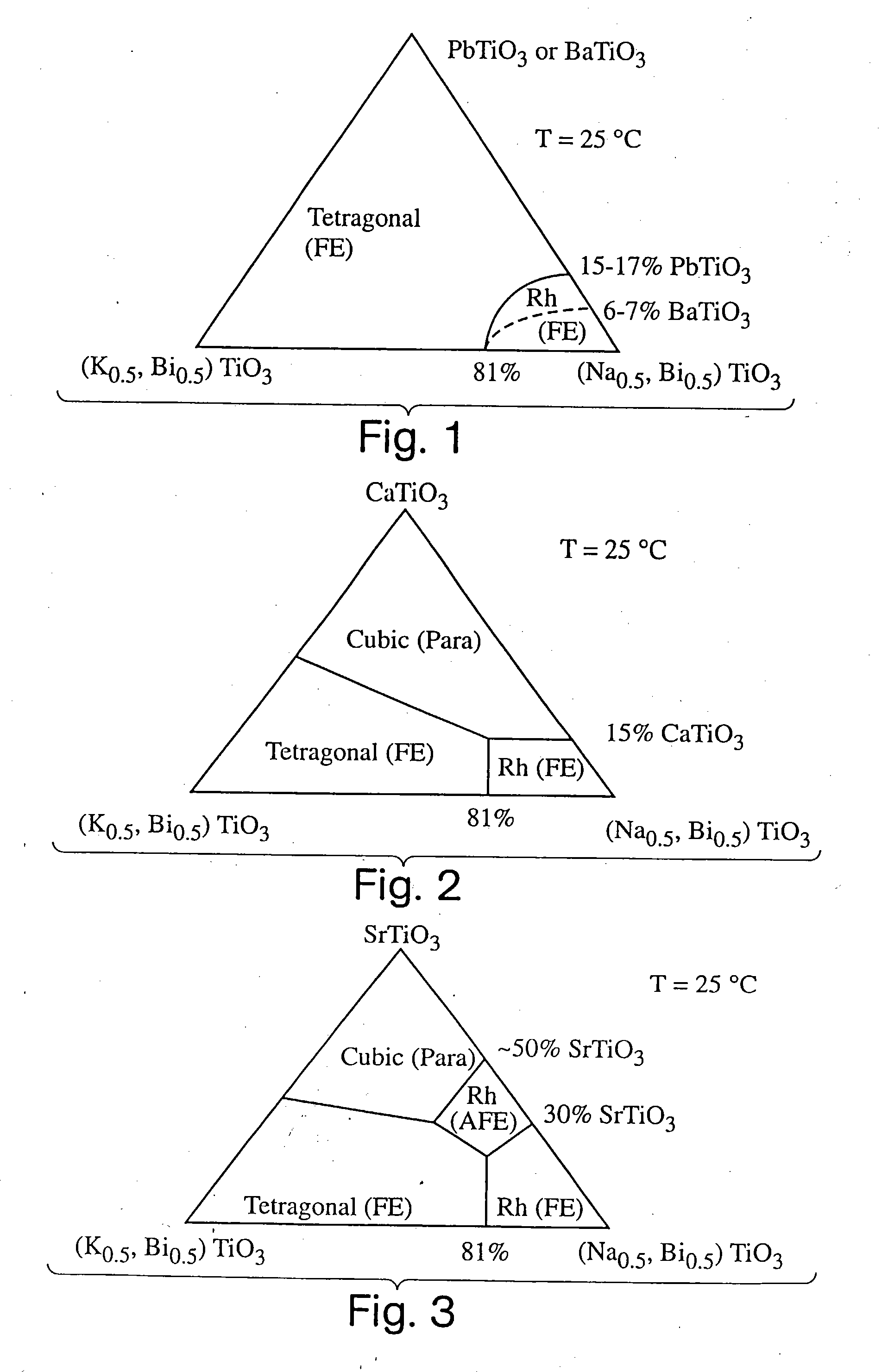

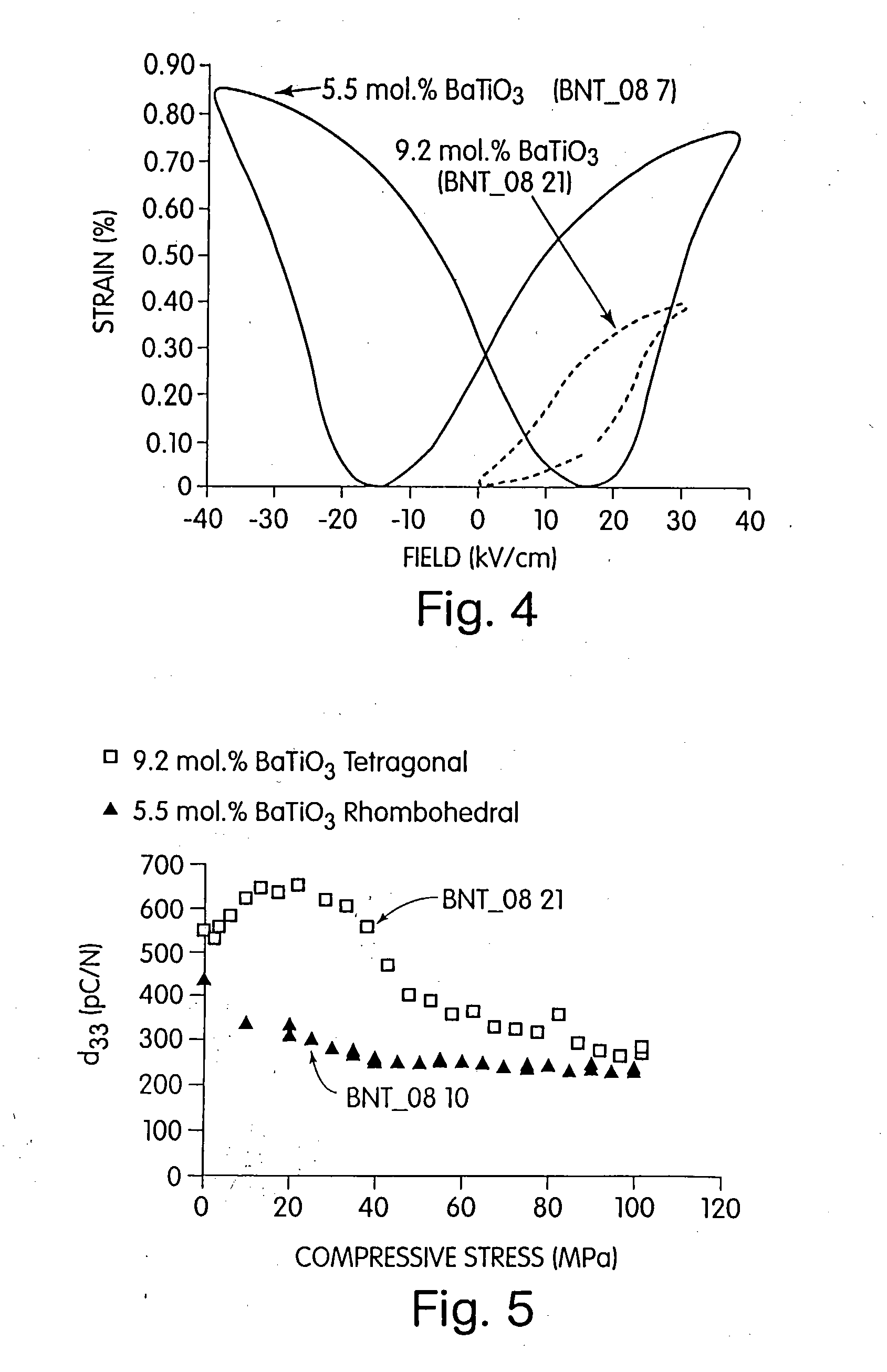

InactiveUS7090785B2Increased doping of BaTiOImprove propertiesAlkaline earth titanatesLighting support devicesElectroactive materialsMaterials science

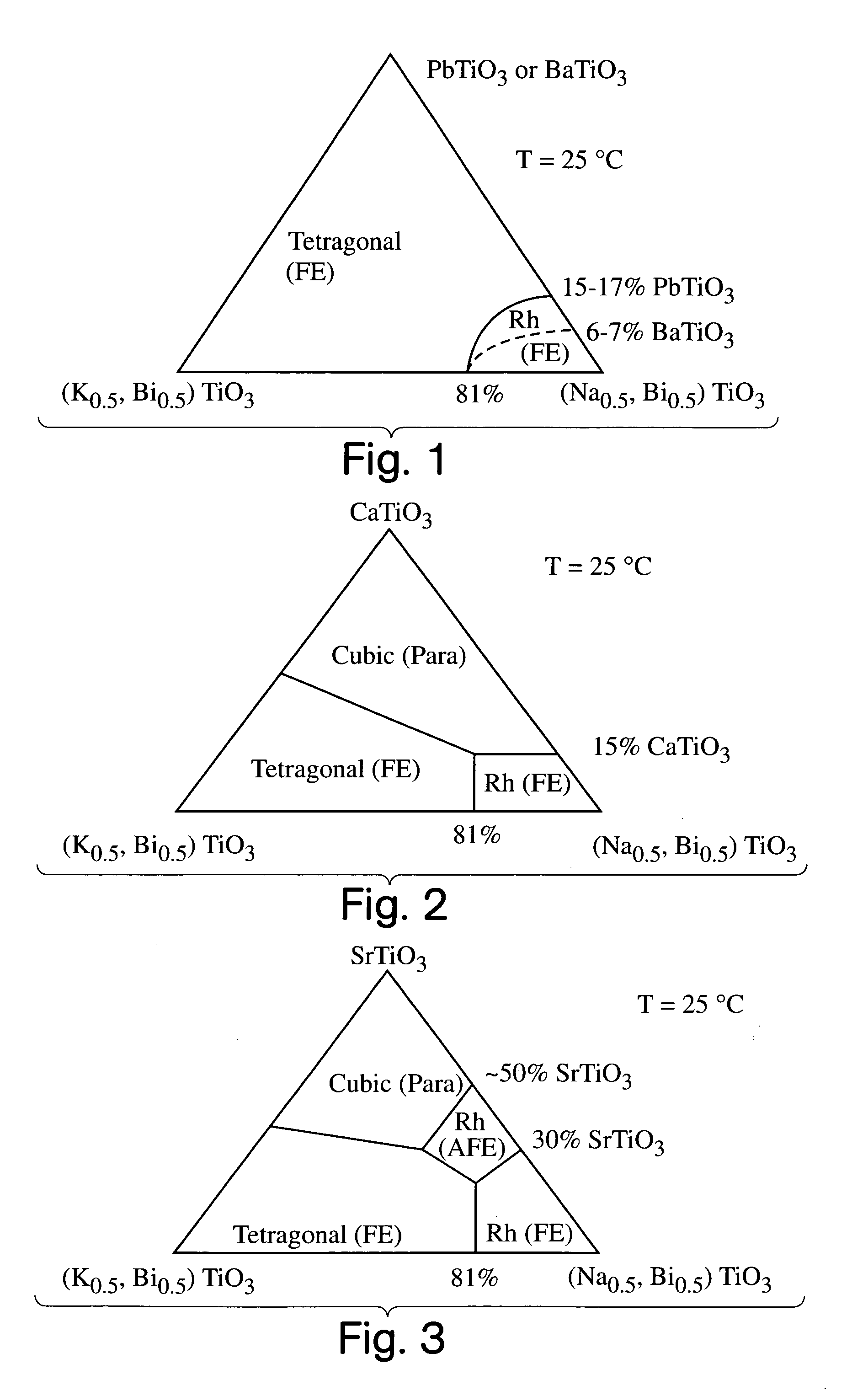

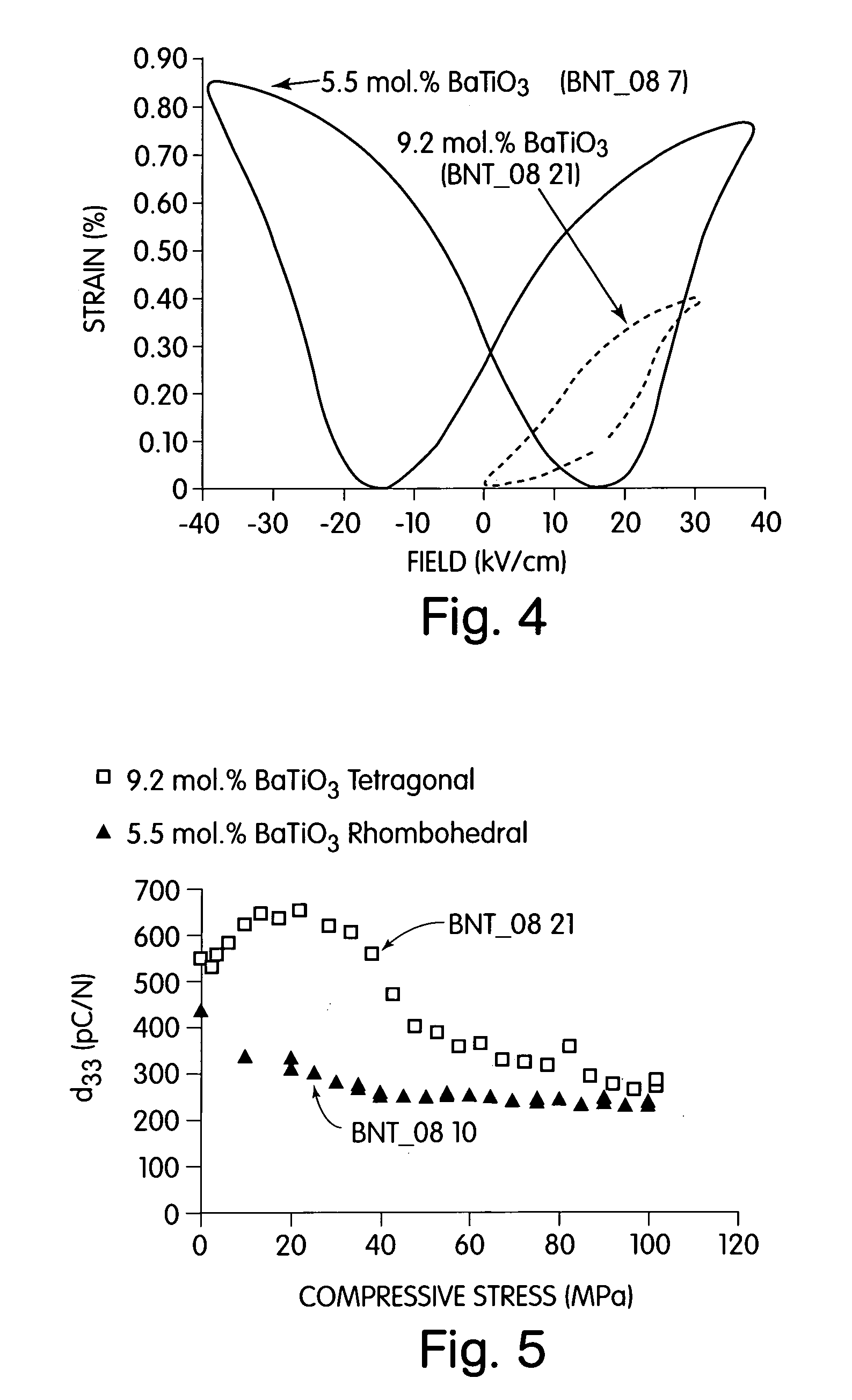

A perovskite compound of the formula, (Na1 / 2Bi1 / 2)1-xMx(Ti1-yM′y)O3±z, where M is one or more of Ca, Sr, Ba, Pb, Y, La, Pr, Nd, Sm, Eu, Gd, Th, Dy, Ho, Er, Tm, Yb and Lu; and M′ is one or more of Zr, Hf, Sn, Ge, Mg, Zn, Al, Sc, Ga, Nb, Mo, Sb, Ta, W, Cr, Mn, Fe, Co and Ni, and 0.01<x<0.3, and 0.01<y<0.3, and z<0.1 functions as an electromechanically active material. The material may possess electrostrictive or piezoelectric characteristics.

Owner:MASSACHUSETTS INST OF TECH

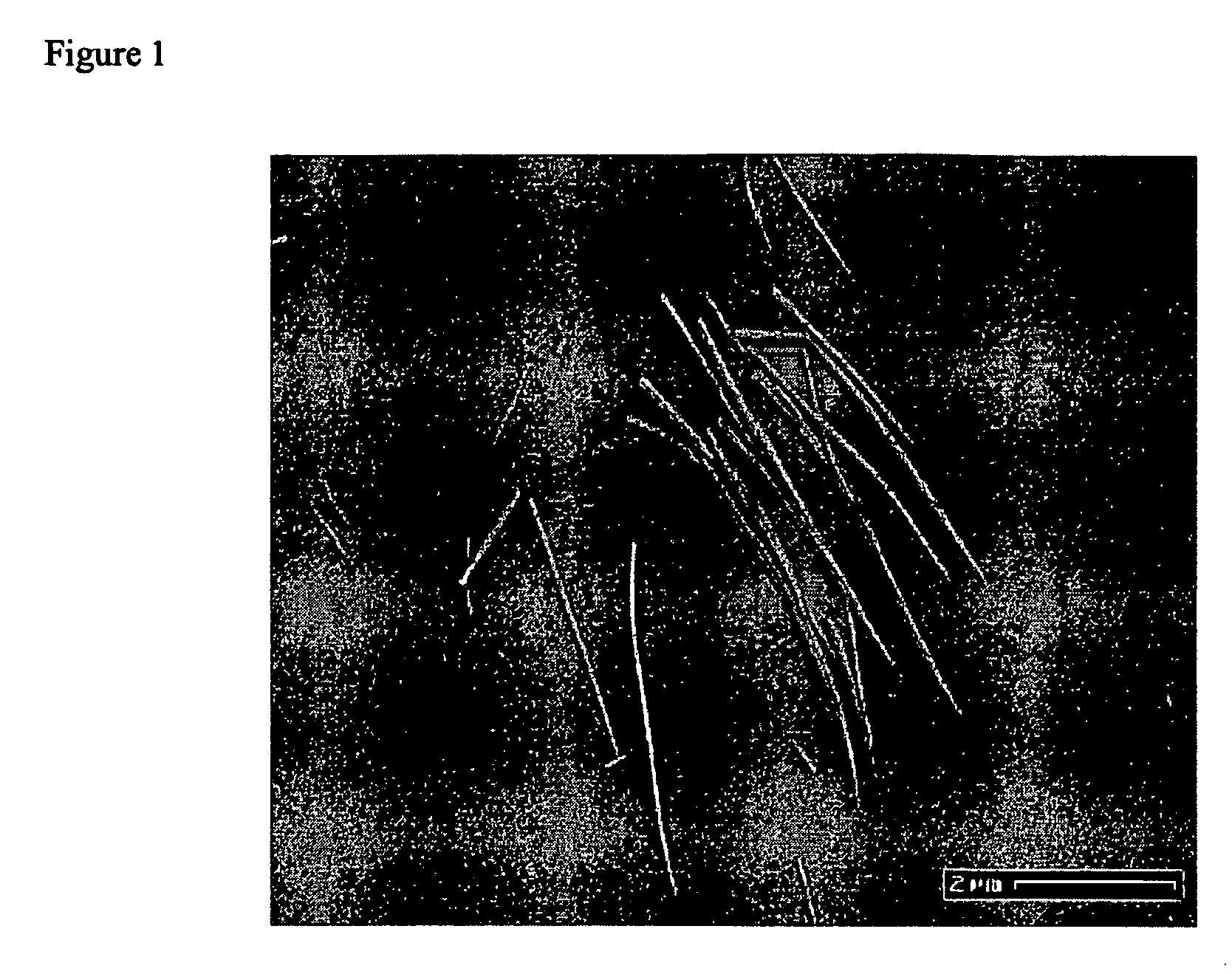

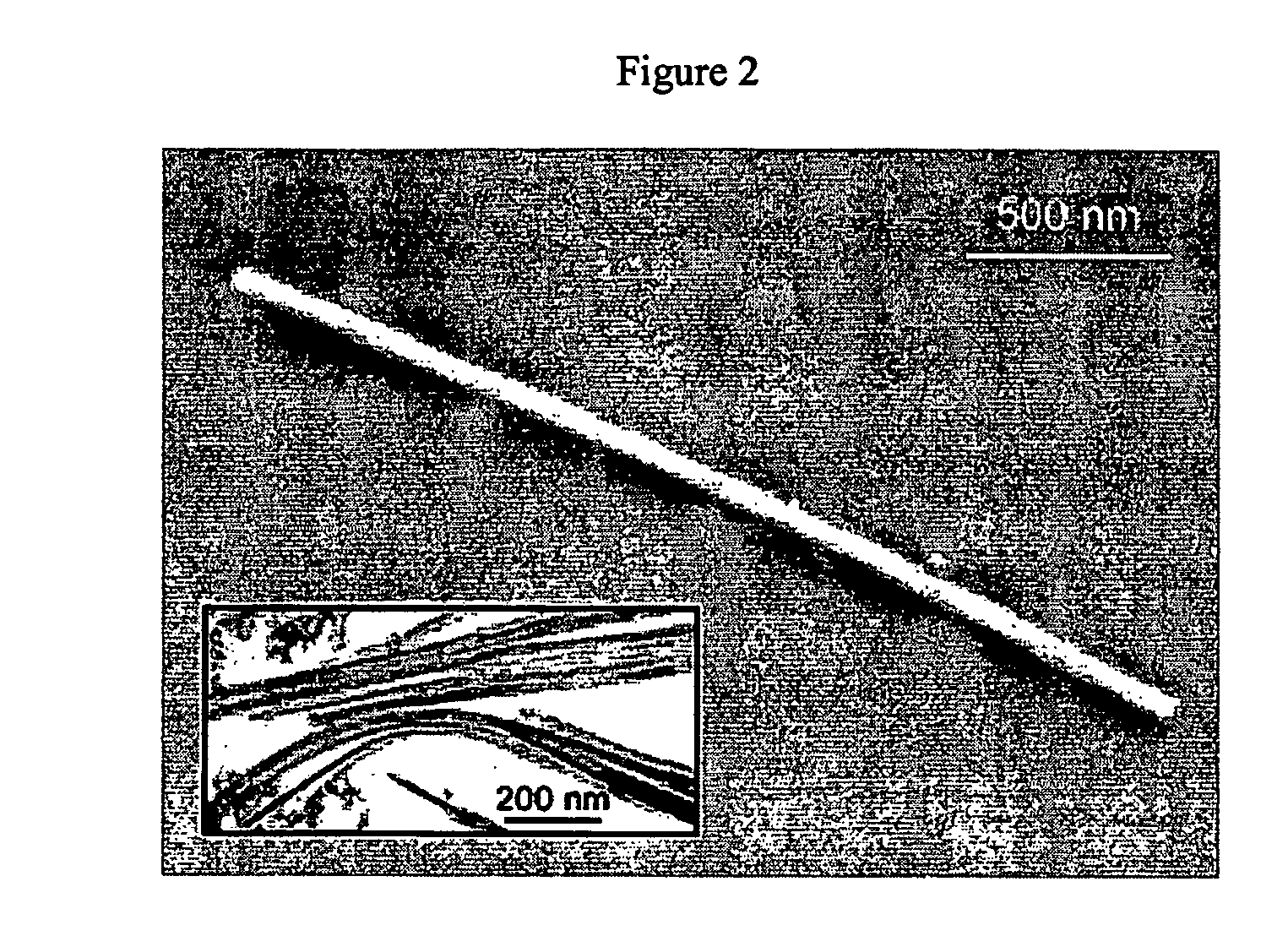

Transition metal oxide nanowires

Nanowires are disclosed which comprise transition metal oxides. The transition metal oxides may include oxides of group II, group III, group IV and lanthanide metals. Also disclosed are methods for making nanowires which comprise injecting decomposition agents into a solution comprising solvents and metallic alkoxide or metallic salt precursors.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

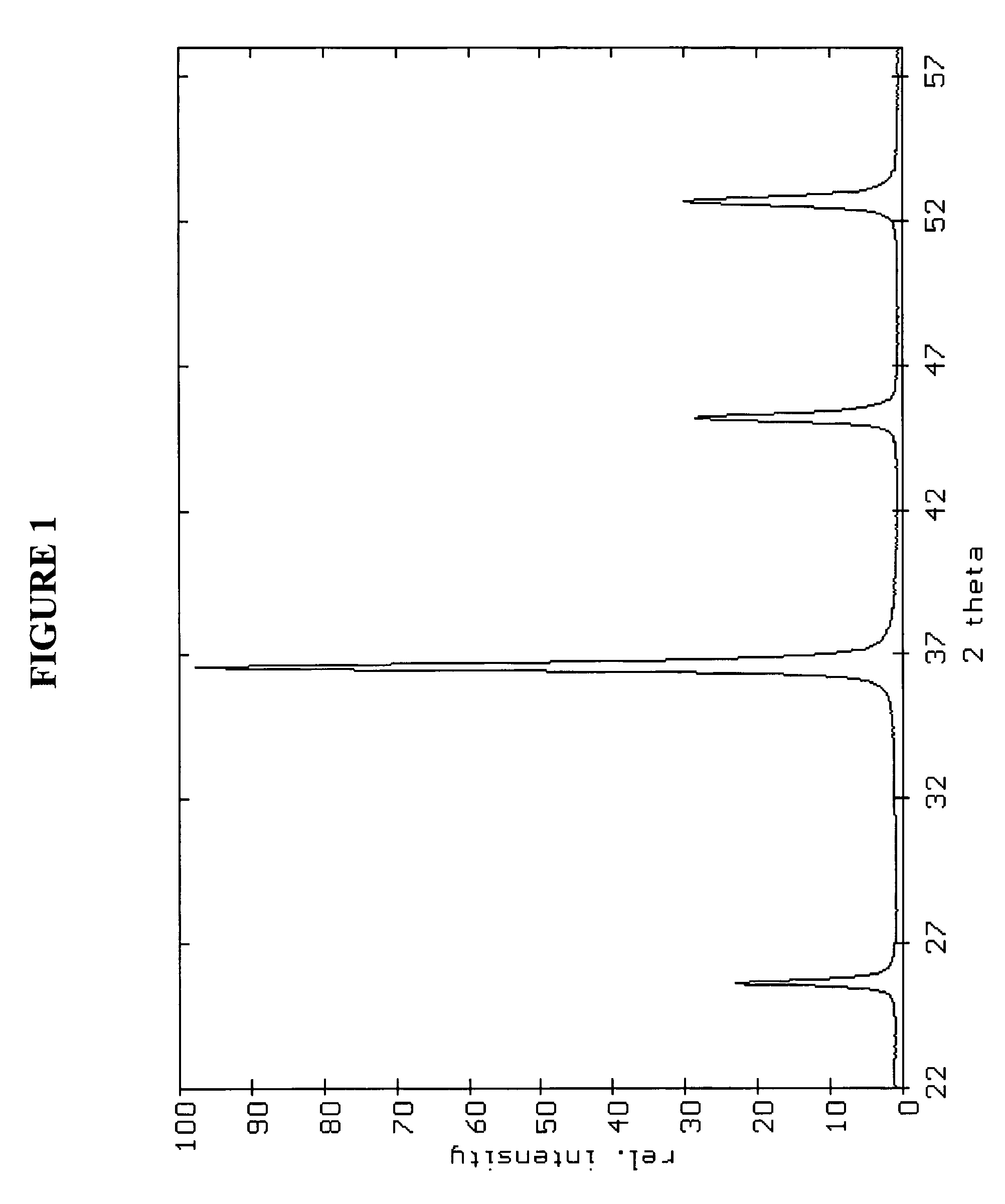

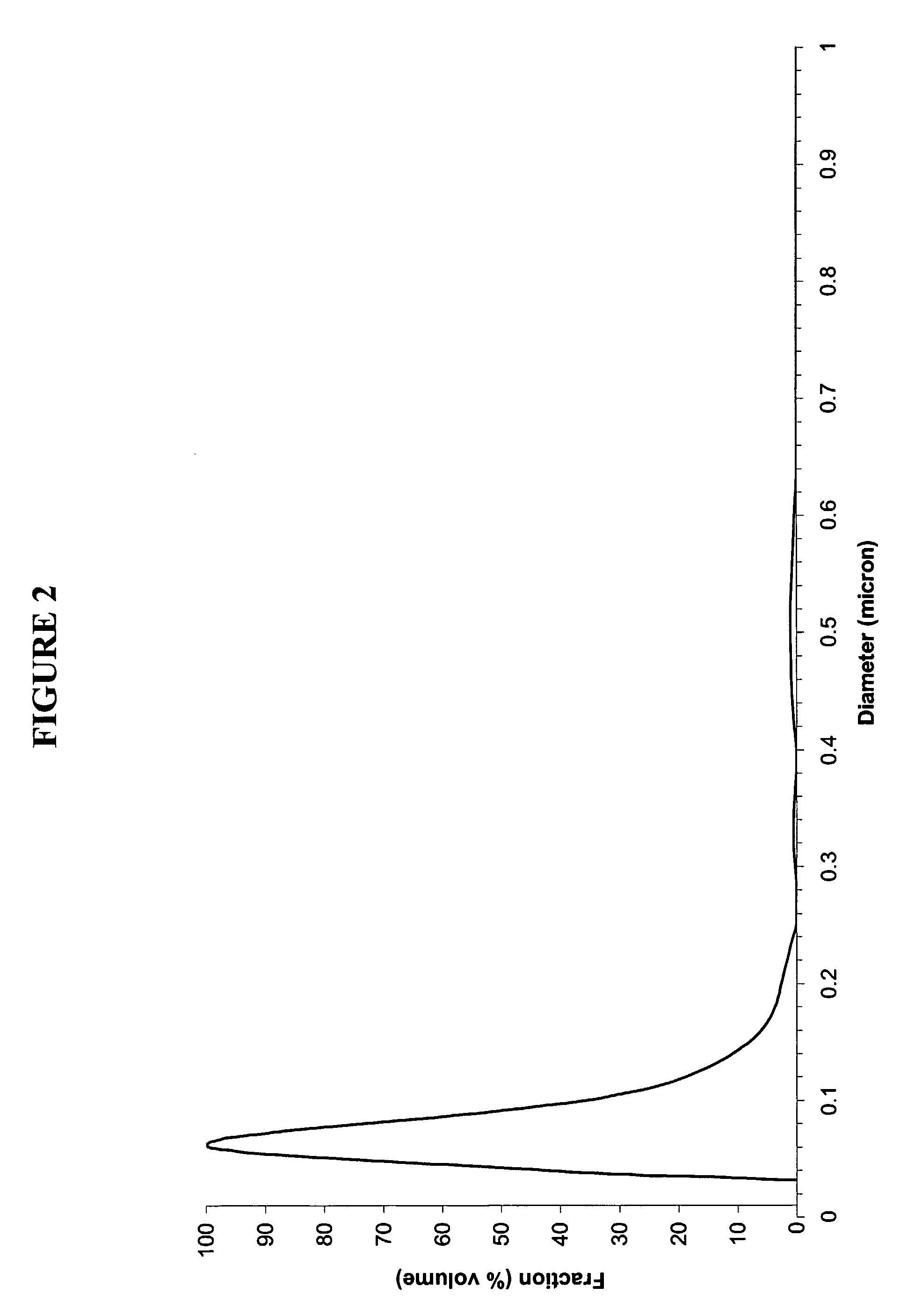

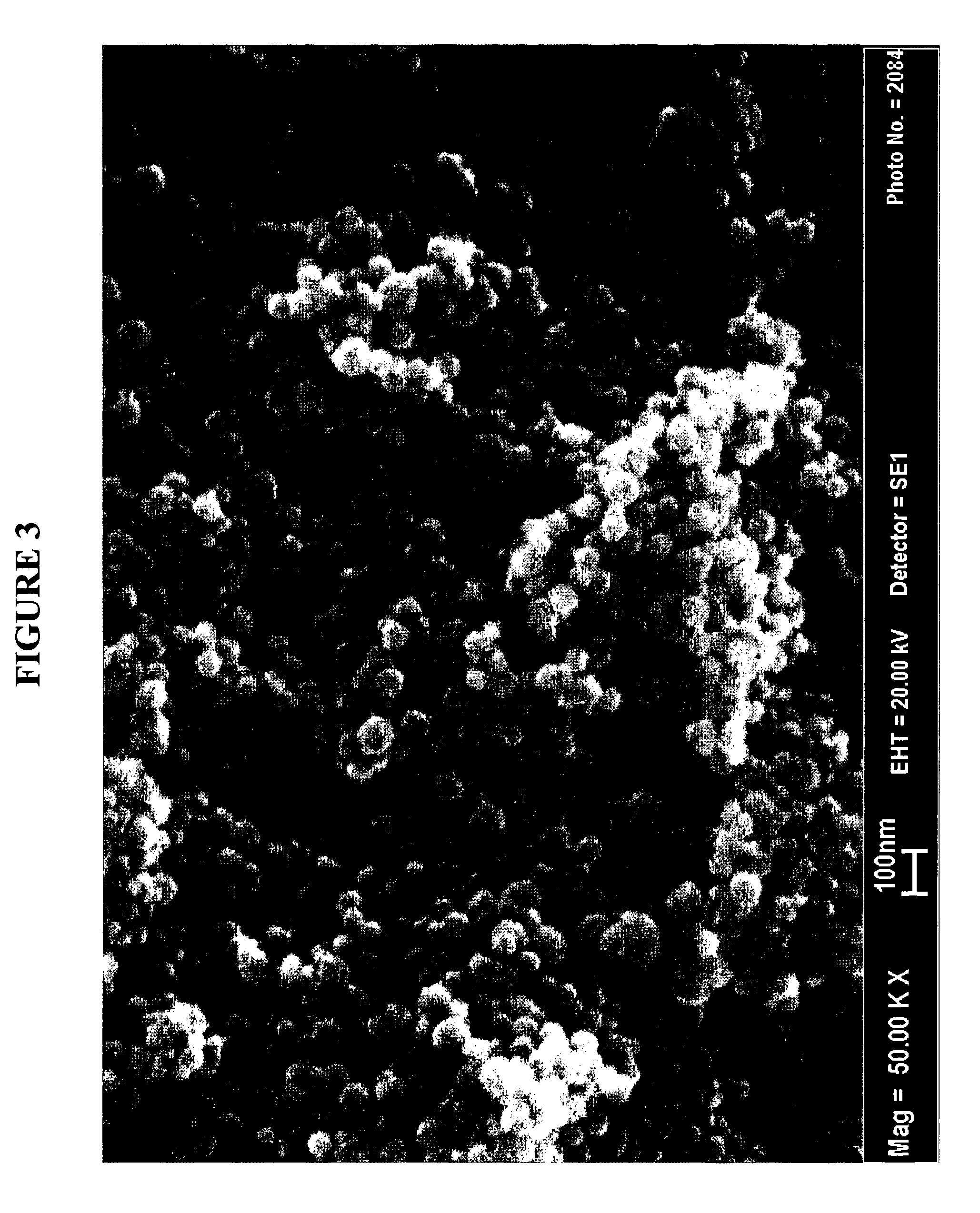

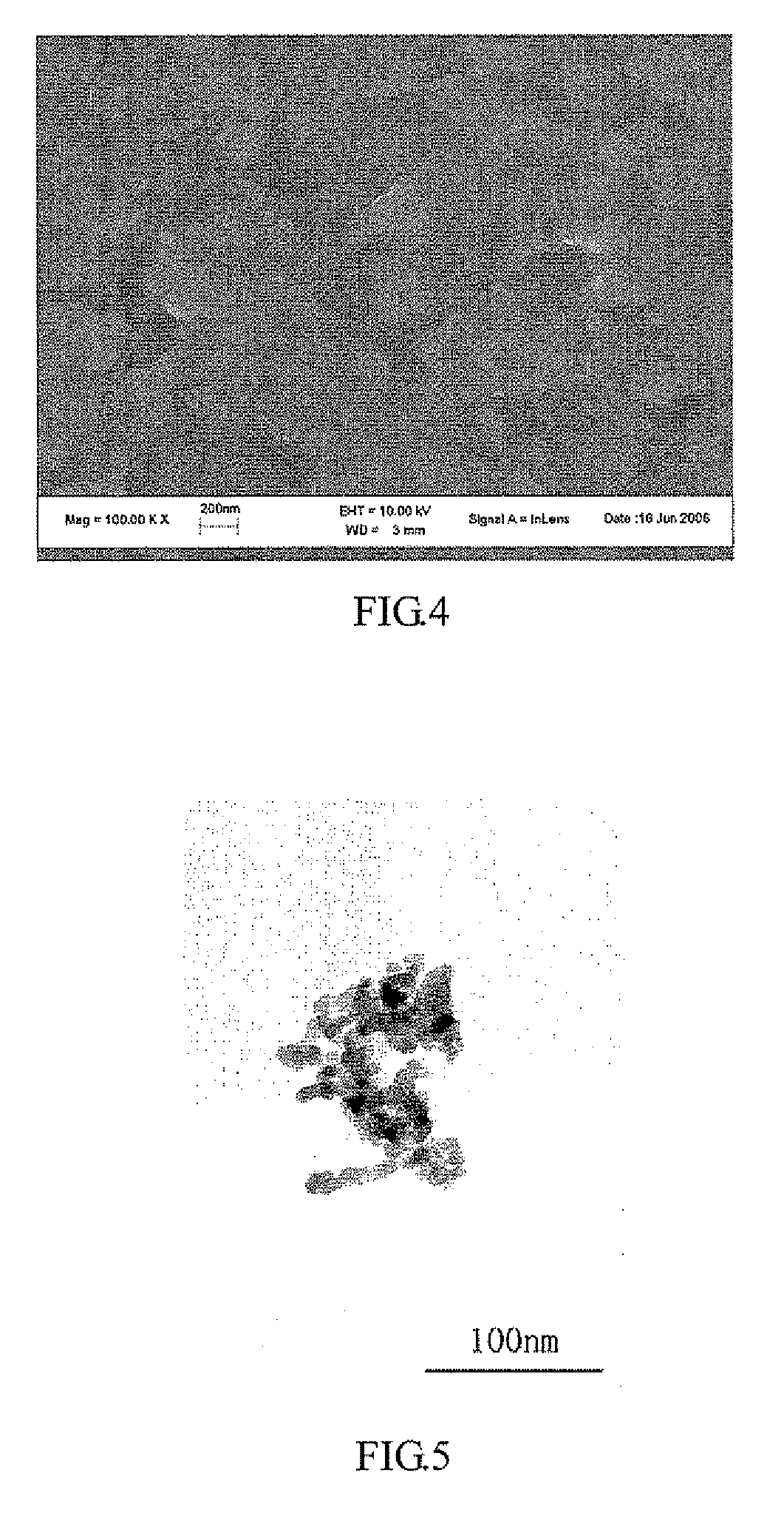

Production Of Barium Titanate Compounds

InactiveUS20070202036A1High purityLow costMaterial nanotechnologyAlkaline earth titanatesBarium titanateSpherical shaped

An ultrafine powder of barium titanate including solid solutions and doped compounds that meets up to specific characteristics is produced by method comprising two main steps. The first step is a reaction, typically in a Segmented Flow Tubular Reactor, between reactants to produce cubic-structure barium titanate composed of non-agglomerated ultrafine particles having a shape of given aspect ratio, usually a generally spherical shape, of low density corresponding at most to 90% of the intrinsic density, all particles being smaller than 1 micron and having a narrow particle size distribution and wherein the ratio of Ba:Ti including substitutents and dopants is very close to the ideal stoichiometry. This is followed by subjecting the powder produced in the first step to a second stage solvothermal post treatment typically in an autoclave at temperature less than 400° C. to convert the cubic-structure particles of low density to ultrafine tetragonal particles of increased density corresponding to at least 90% of the intrinsic density while maintaining the same aspect ratio, and maintaining the size of all particles below 1 micron, the narrow particle size distribution span, and the given ideal stoichiometry. The produced particles can have a non-spherical facetted shape such as cube-like.

Owner:JONGEN NATHALIE +1

Preparation of catalyst and use for high yield conversion of methane to ethylene

InactiveUS7250543B2Maintain activityAlkaline earth titanatesHydrocarbon by hydrocarbon condensationAlkaline earth metalSlurry

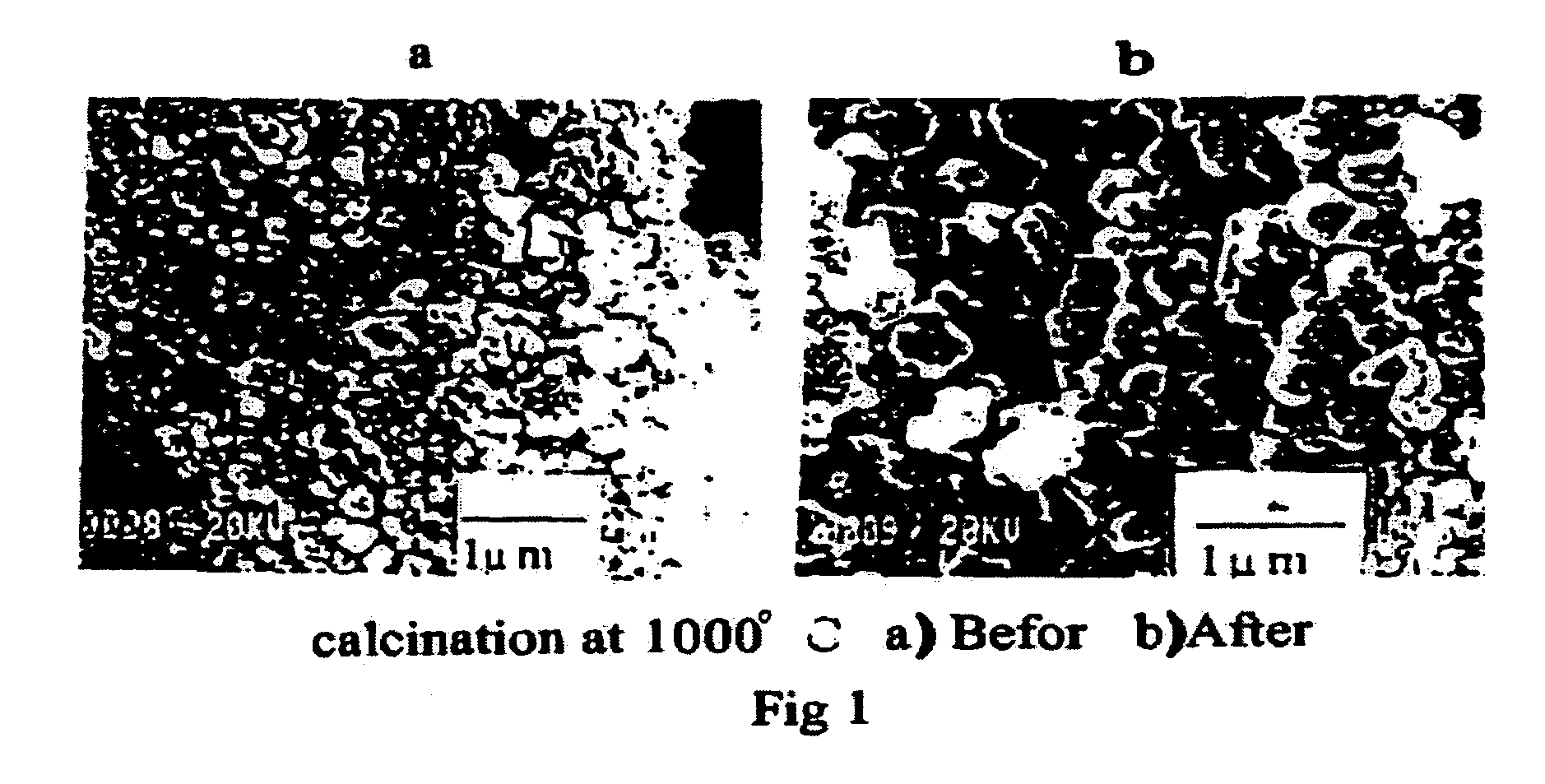

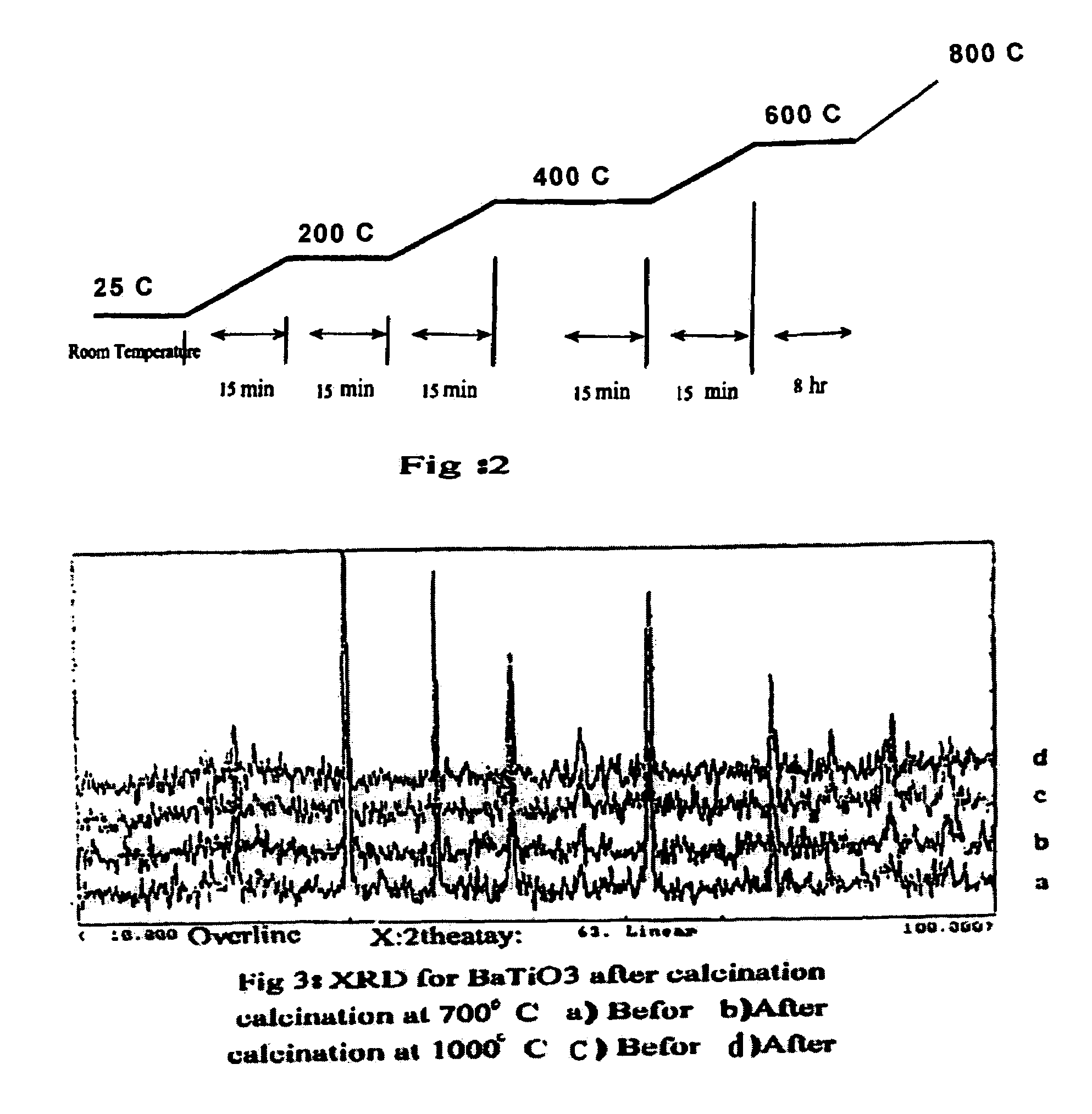

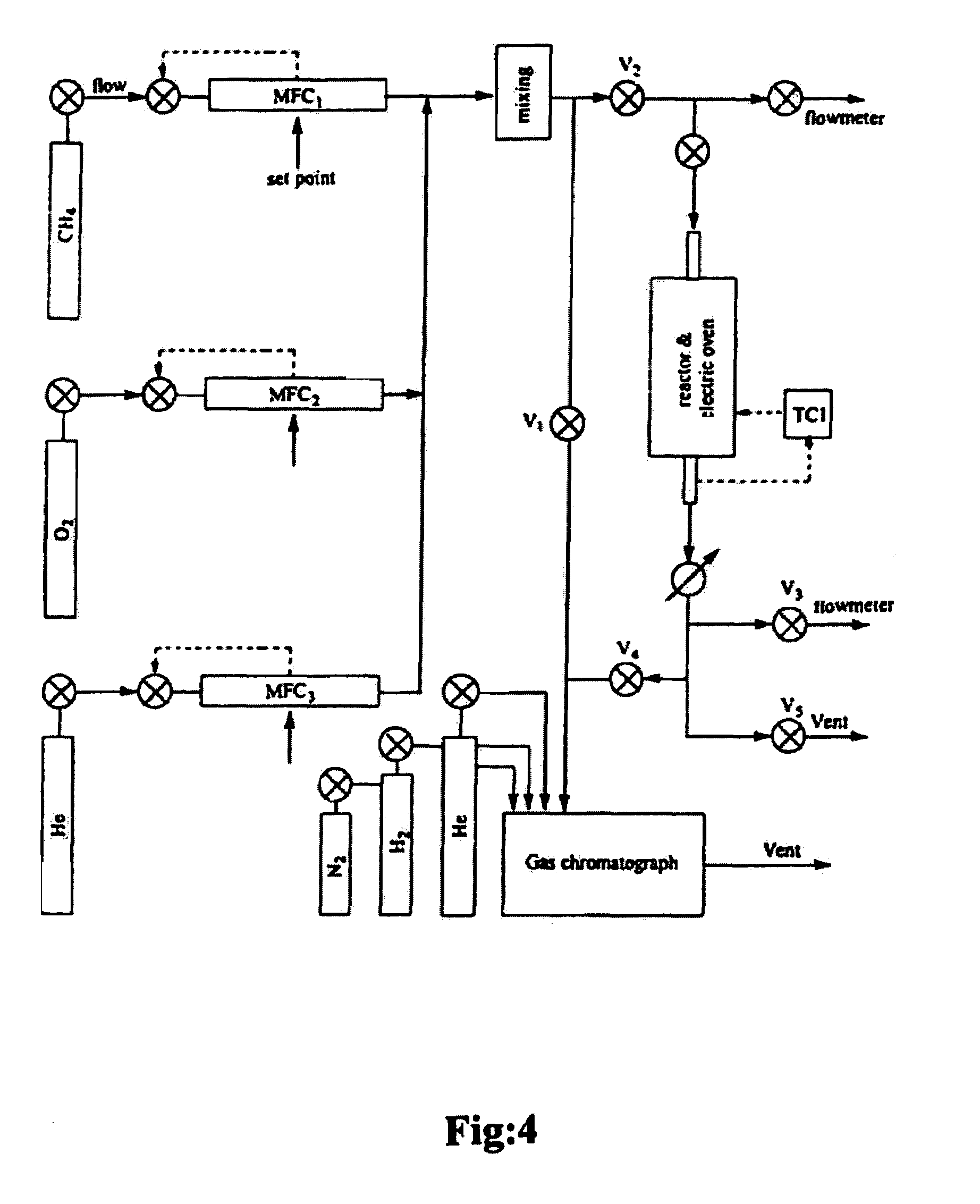

A perovskite catalyst is prepared using a ceramic sol-sol methodology comprising preparing slurry in water of an alkaline earth metal salt, a powdered metal salt and a powdered transition metal oxide, adding a polymeric binder to form a paste, drying and comminuting the paste into a powder and heating the powder with a temperature profile to calcination temperatures. In one embodiment the slurry is formed of titanium oxide with barium carbonate and tin chloride in deionized water, and more specifically by a mixture according to Ba (1-0.05x)+TiO2+SnCl2(0.05x) where x is in moles. The perovskite catalyst is preferably used in a process for oxidative coupling of methane. Catalyst performance is enhanced through the addition of halides to the feed gas in the reaction.

Owner:HRD CORP

Electromechanical actuators

InactiveUS20050109263A9Improve the overall coefficientImprove electromechanical performanceAlkaline earth titanatesLighting support devicesMaterials science

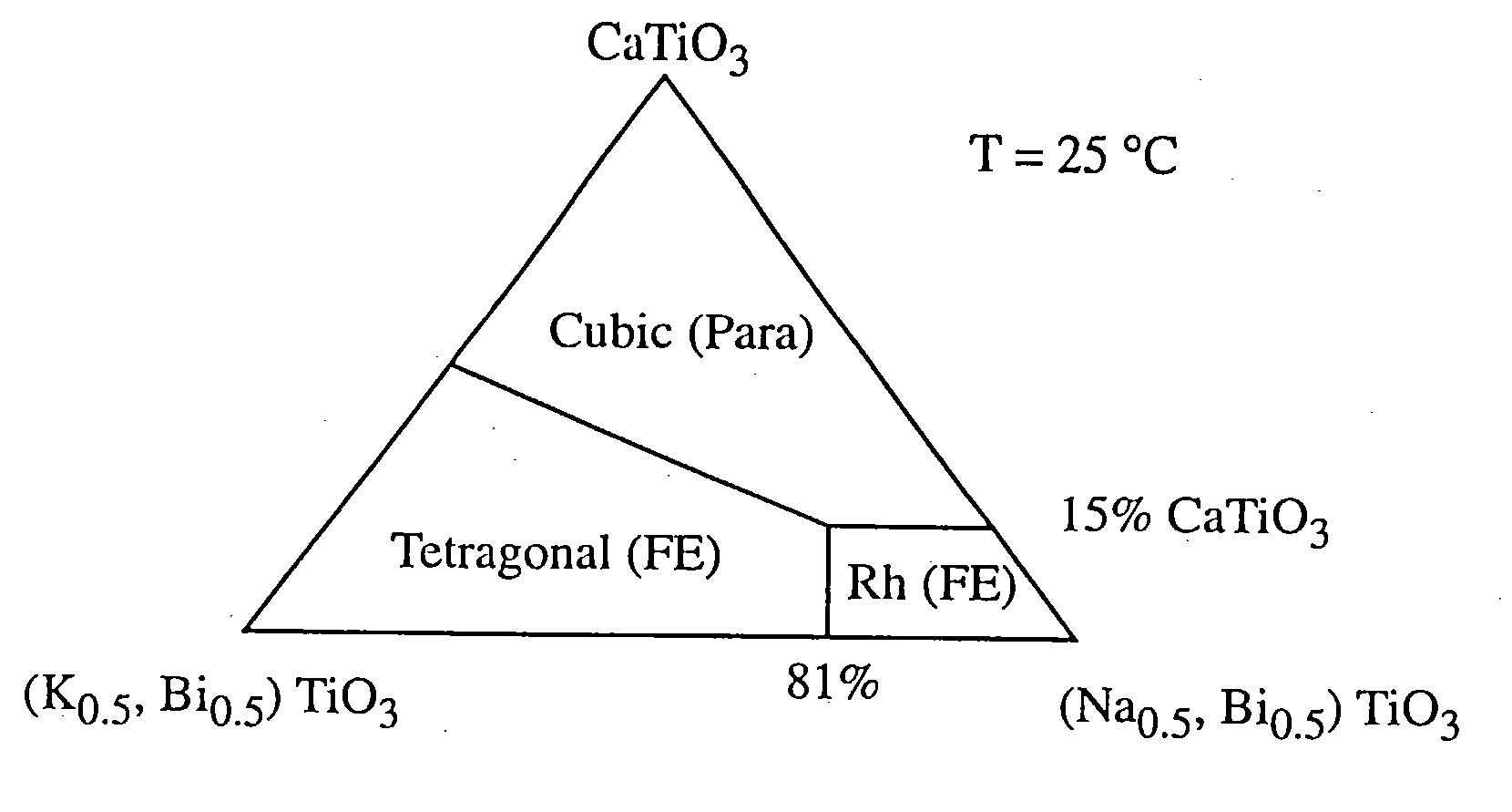

A perovskite compound of the formula, (Na1 / 2Bi1 / 2)1-xMx(Ti1-yM′y)O3±z, where M is one or more of Ca, Sr, Ba, Pb, Y, La, Pr, Nd, Sm, Eu, Gd, Th, Dy, Ho, Er, Tm, Yb and Lu; and M′ is one or more of Zr, Hf, Sn, Ge, Mg, Zn, Al, Sc, Ga, Nb, Mo, Sb, Ta, W, Cr, Mn, Fe, Co and Ni, and 0.01<x<0.3, and 0.01<y<0.3, and z<0.1 functions as an electromechanically active material. The material may possess electrostrictive or piezoelectric characteristics.

Owner:MASSACHUSETTS INST OF TECH

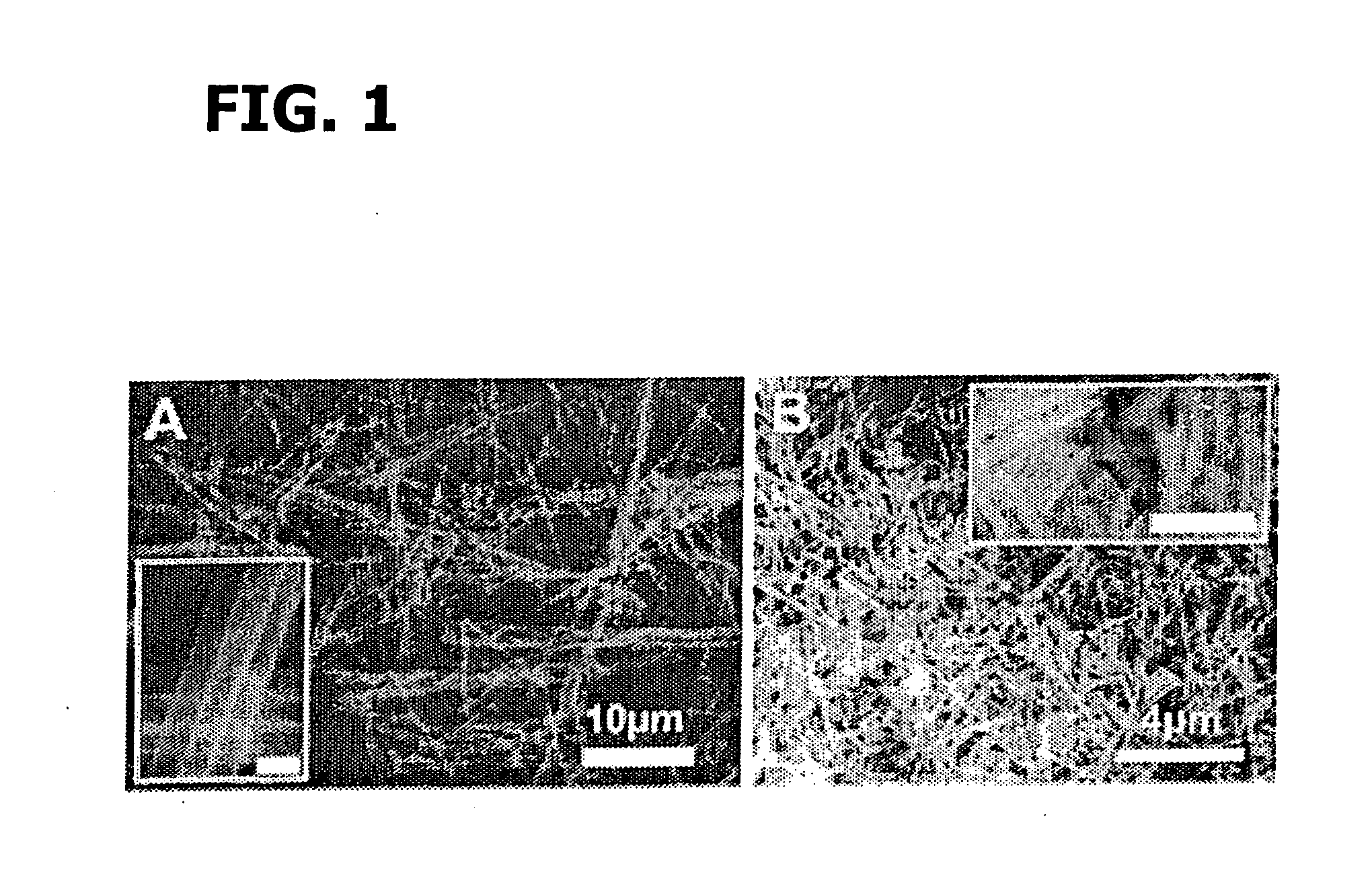

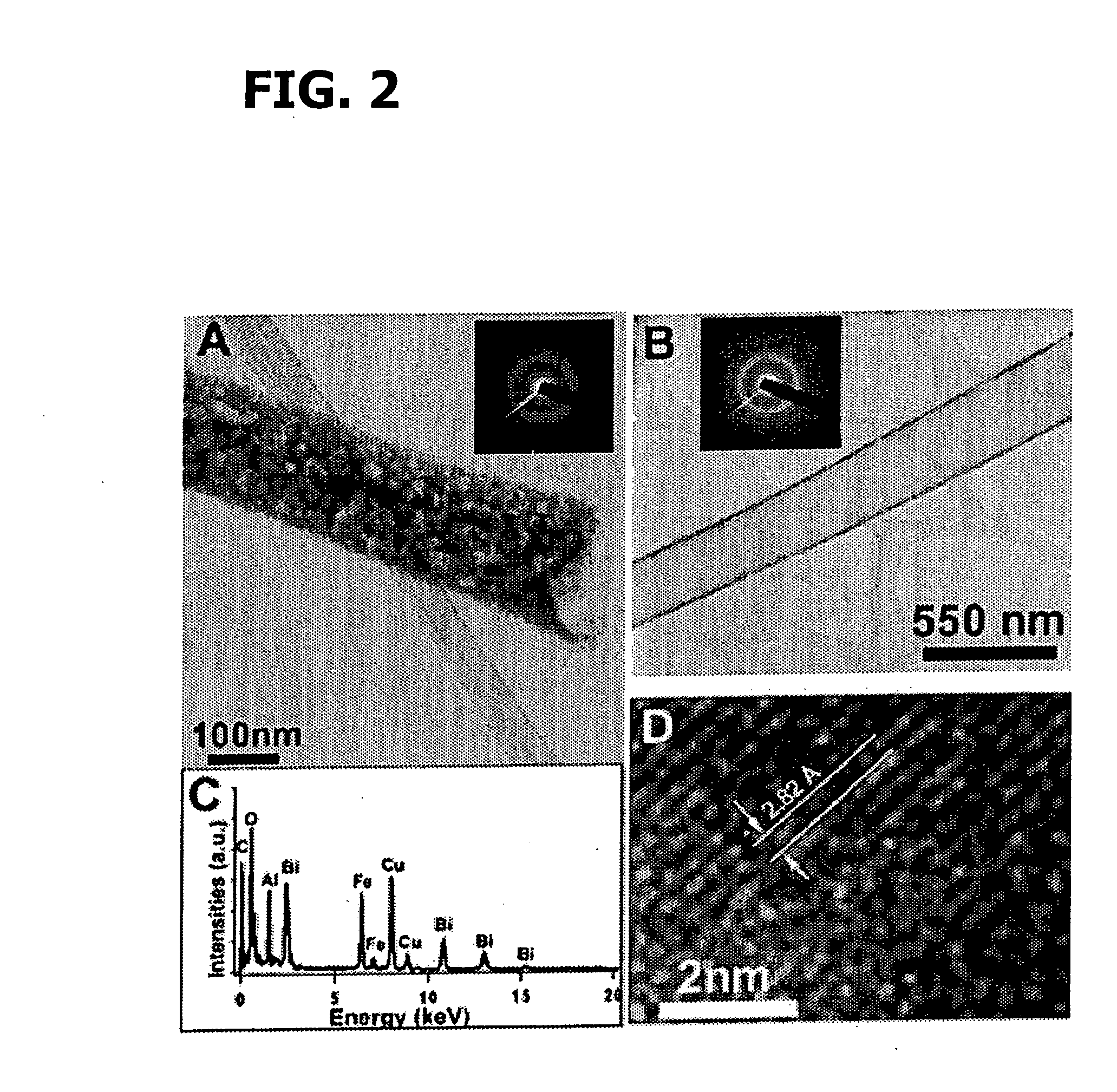

Ternary oxide nanostructures and methods of making same

InactiveUS7585474B2Suitable for preparationFrom gel stateAlkaline earth titanatesSingle crystalNanostructure

A single crystalline ternary nanostructure having the formula AxByOz, wherein x ranges from 0.25 to 24, and y ranges from 1.5 to 40, and wherein A and B are independently selected from the group consisting of Ag, Al, As, Au, B, Ba, Br, Ca, Cd, Ce, Cl, Cm, Co, Cr, Cs, Cu, Dy, Er, Eu, F, Fe, Ga, Gd, Ge, Hf, Ho, I, In, Ir, K, La, Li, Lu, Mg, Mn, Mo, Na, Nb, Nd, Ni, Os, P, Pb, Pd, Pr, Pt, Rb, Re, Rh, Ru, S, Sb, Sc, Se, Si, Sm, Sn, Sr, Ta, Tb, Tc, Te, Ti, Tl, Tm, U, V, W, Y, Yb, and Zn, wherein the nanostructure is at least 95% free of defects and / or dislocations.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

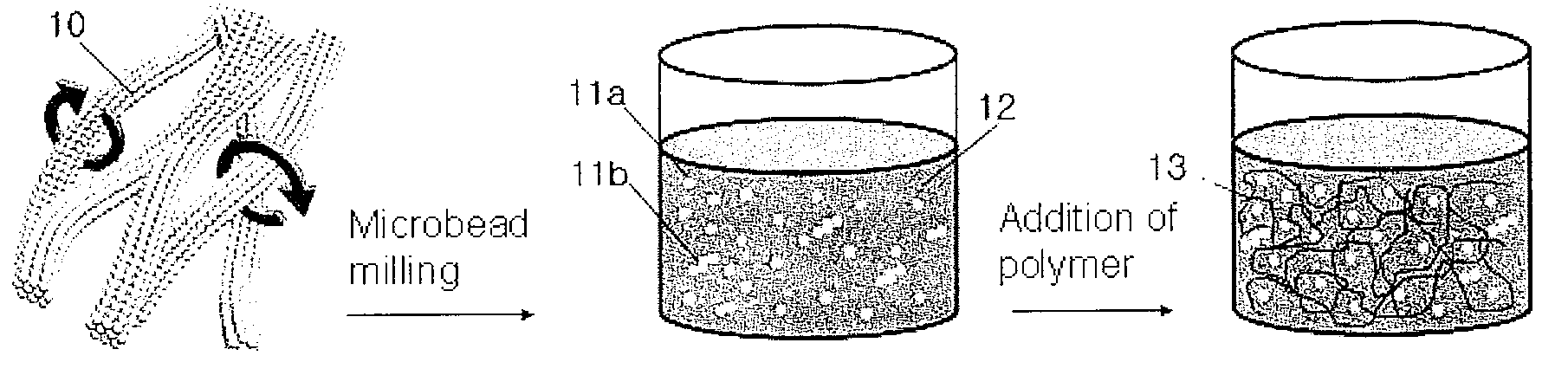

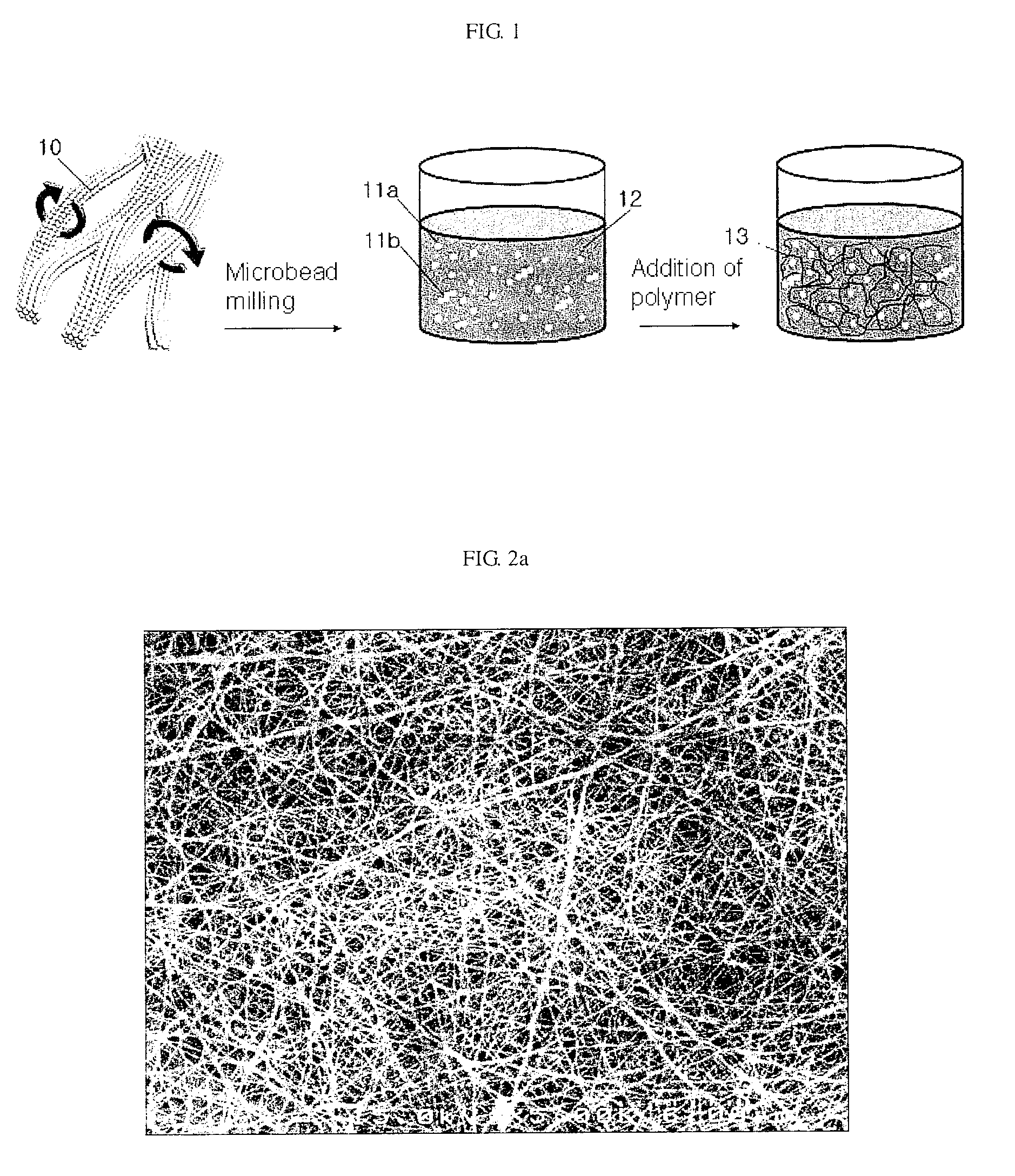

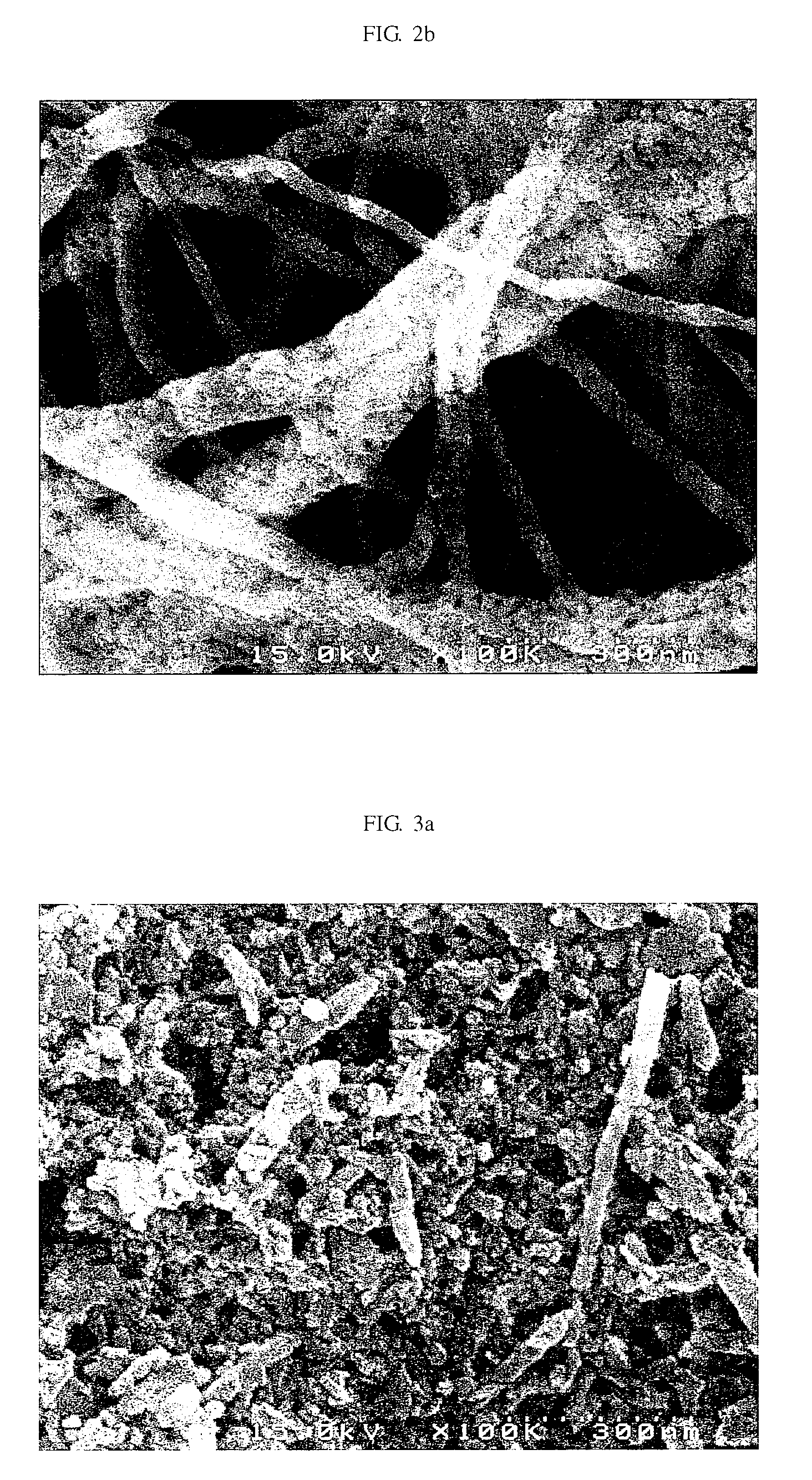

NANO powder, NANO ink and micro rod, and the fabrication methods thereof

InactiveUS20100167078A1Easy to makeOvercome problemsAlkaline earth titanatesPigmenting treatmentFiberMicro rods

Disclosed are a method for fabricating nanopowders, nano ink containing the nanopowders and micro rods, and nanopowders containing nanoparticles, nano clusters or mixture thereof, milled from nano fiber composed of at least one kind of nanoparticles selected from a group consisting of metal, nonmetal, metal oxide, metal compound, nonmetal compound and composite metal oxide, nano ink containing the nanopowders and microrods, the method comprising spinning a spinning solution containing at least one kind of precursor capable of composing at least one kind selected from a group consisting of metal, nonmetal, metal oxide, metal compound, nonmetal compound and composite metal oxide, crystallizing or amorphizing the spun precursor to produce nano fiber containing at least one kind of nanoparticles selected from a group consisting of metal, nonmetal, metal oxide, metal compound, nonmetal compound and composite metal oxide, and milling the nano fiber to fabricate nanopowders containing nanoparticles, nano clusters or mixture thereof.

Owner:KOREA INST OF SCI & TECH

Manufacturing methods for nanomaterial dispersions and products thereof

InactiveUS20060016371A1Increase volumeLow cost productionMaterial nanotechnologyAlkaline earth titanatesManufactured nanomaterialsApplications of nanotechnology

Methods for manufacturing nanomaterial dispersions, such as nanomaterial concentrates, and related nanotechnology are provided. The nanomaterial concentrates provided can be more cheaply stored and transported compared to non-concentrate nanomaterial forms.

Owner:PPG IND OHIO INC

Process for preparing perovskite-type crystalline compound powders

InactiveUS20060045840A1Alkaline earth titanatesMaterial nanotechnologyRare earthParticle-size distribution

A process for preparing perovskite-type compound Ax(BO3)y powders involving reacting a solution containing A and a solution containing B, or a combined solution comprising A and B, with an alkaline solution in a high-gravity reactor at a temperature ranging from about 60° C. to about 100° C. A is one or more metal elements selected from the group consisting of Li, Na, K, Mg, Ca, Sr, Ba, Pb, Sm, La, Nd, Bi, and other rare-earth metal elements. B is one or more metal elements selected from the group consisting of Ti, Zr, Sn, Hf, Nb, Ce, Al, Zn, Mn, Co, Ni, Fe, Cr, Y, Sc, W, Ta, and the like. The resulting mixture is then filtered, rinsed and dried to obtain the desired powders. The obtained perovskite-type compound Ax(BO3)y powders have a small average particle size with a narrow particle size distribution, a perfect crystal form and a uniform particle shape, and is suitable for use as raw material for making dielectric, piezoelectric, anti-ferroelectric, pyroelectric, pressure-resisting, sensing, microwave media, and other ceramics.

Owner:BEIJING UNIV OF CHEM TECH +1

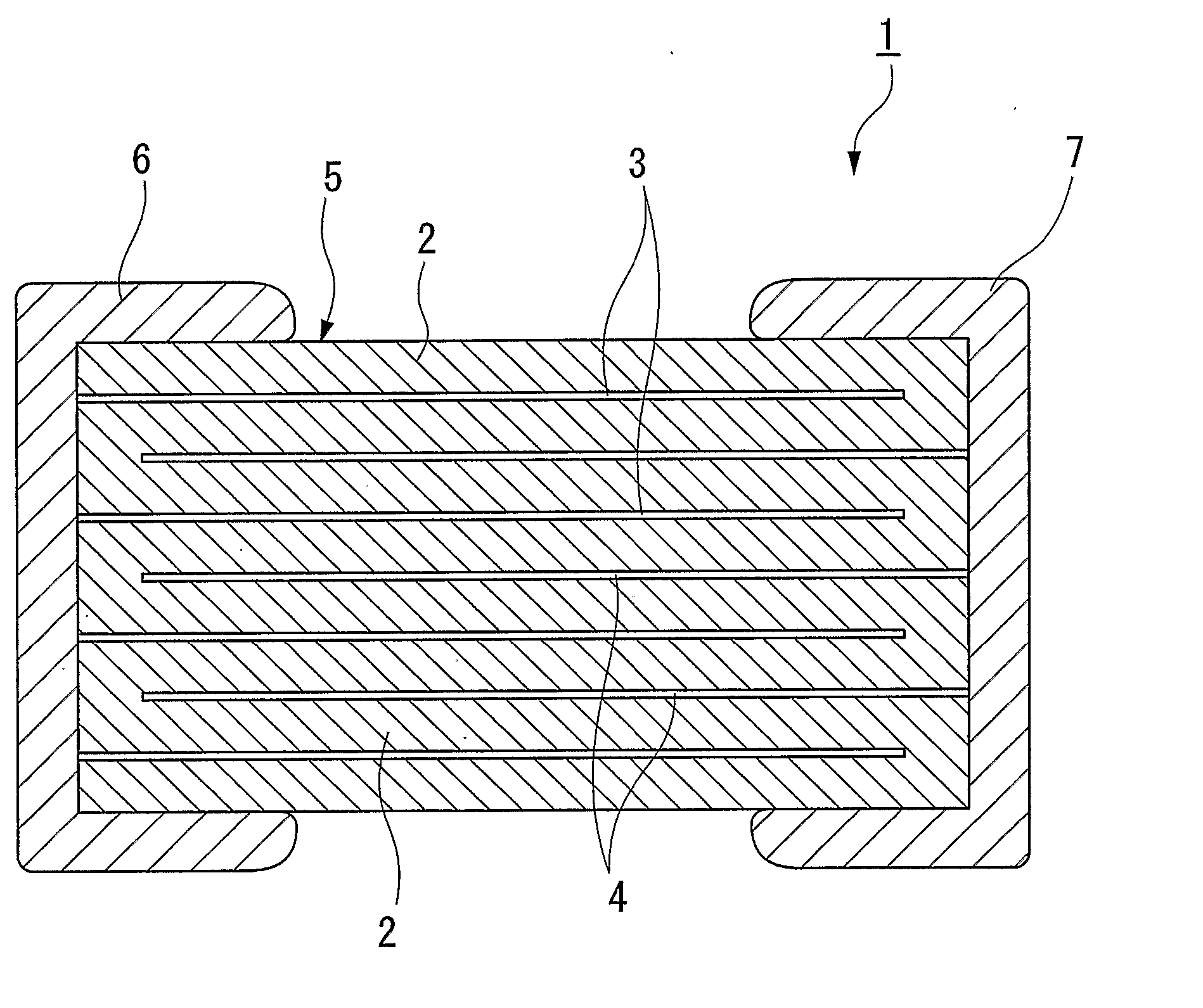

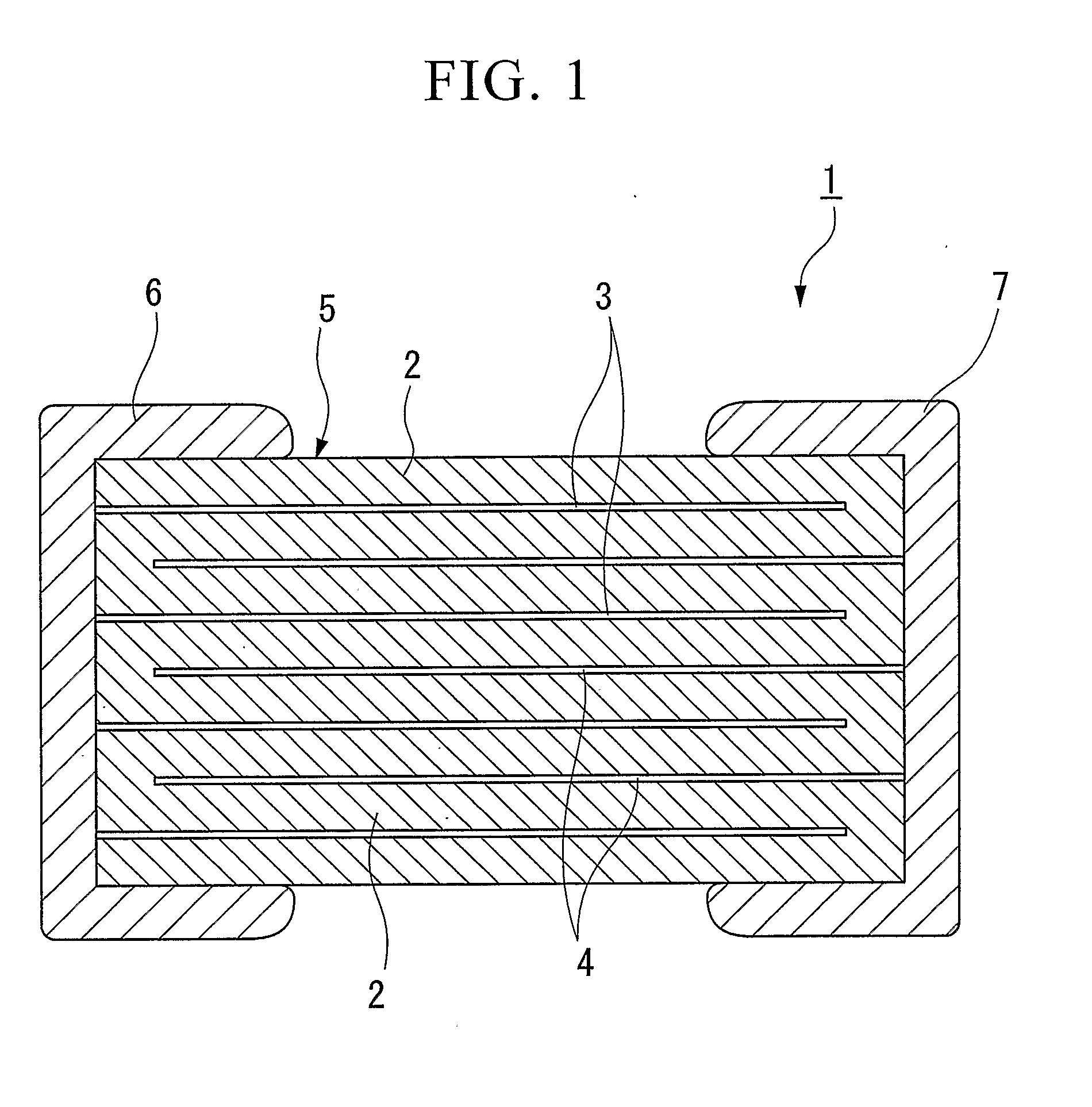

Dielectric ceramic and multilayer ceramic capacitor using the same

ActiveUS20090207551A1Increased Curie temperatureSmooth changeAlkaline earth titanatesFixed capacitor dielectricDielectricCeramic capacitor

A dielectric ceramic is provided which is can be stably used for a multilayer ceramic capacitor even at a high temperature of approximately 175° C. The dielectric ceramic includes a perovskite type compound represented by the composition formula (B1-x-yCaxSny)m(Ti1-zZrz)O3 (where x, y, z, and m satisfy 0≦x≦0.20, 0.02≦y≦0.20, 0≦z≦0.05, and 0.990≦m≦1.015, respectively) as a primary component; and RE as an accessory component (where RE is at least one selected from the group consisting of Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, and Lu), wherein 0.5 to 20 molar parts of RE is contained with respect to 100 molar parts of the primary component.

Owner:MURATA MFG CO LTD

Metal delivery system for nanoparticle manufacture

ActiveUS20060229197A1Improve productivityWell mixedRare earth metal oxides/hydroxidesMolten spray coating2-Ethylhexanoic acidMetallacarboxylic acid

Described is a method for the production of pure or mixed metal oxides, wherein at least one metal precursor that is a metal carboxylate with a mean carbon value per carboxylate group of at least 3, e.g. the 2-ethyl hexanoic acid salt, is formed into droplets and e.g. flame oxidized. The method is performed at viscosities prior to droplet formation of usually less than 40 mPa s, obtained by heating and / or addition of one or more low viscosity solvents with adequately high enthalpy.

Owner:ETH ZURICH THE SHORT NAME OF EID GENOSSISCHE TECHN HOCHSCHULE ZURICH

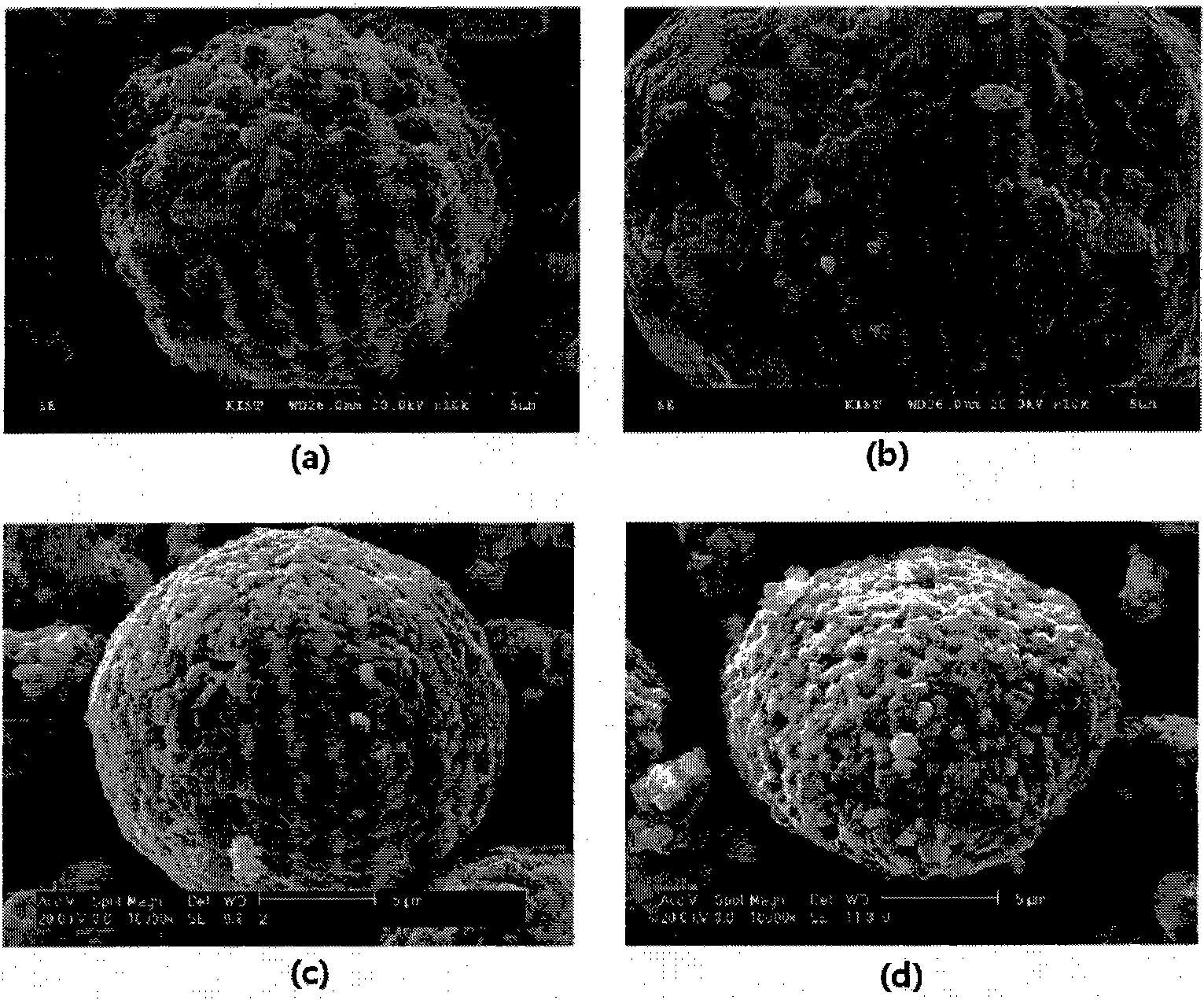

Dielectric composite materials and method for preparing

InactiveUS6600645B1Maximize volumetric packing densityQuantity maximizationAlkaline earth titanatesFixed capacitor dielectricPorositySpherical shaped

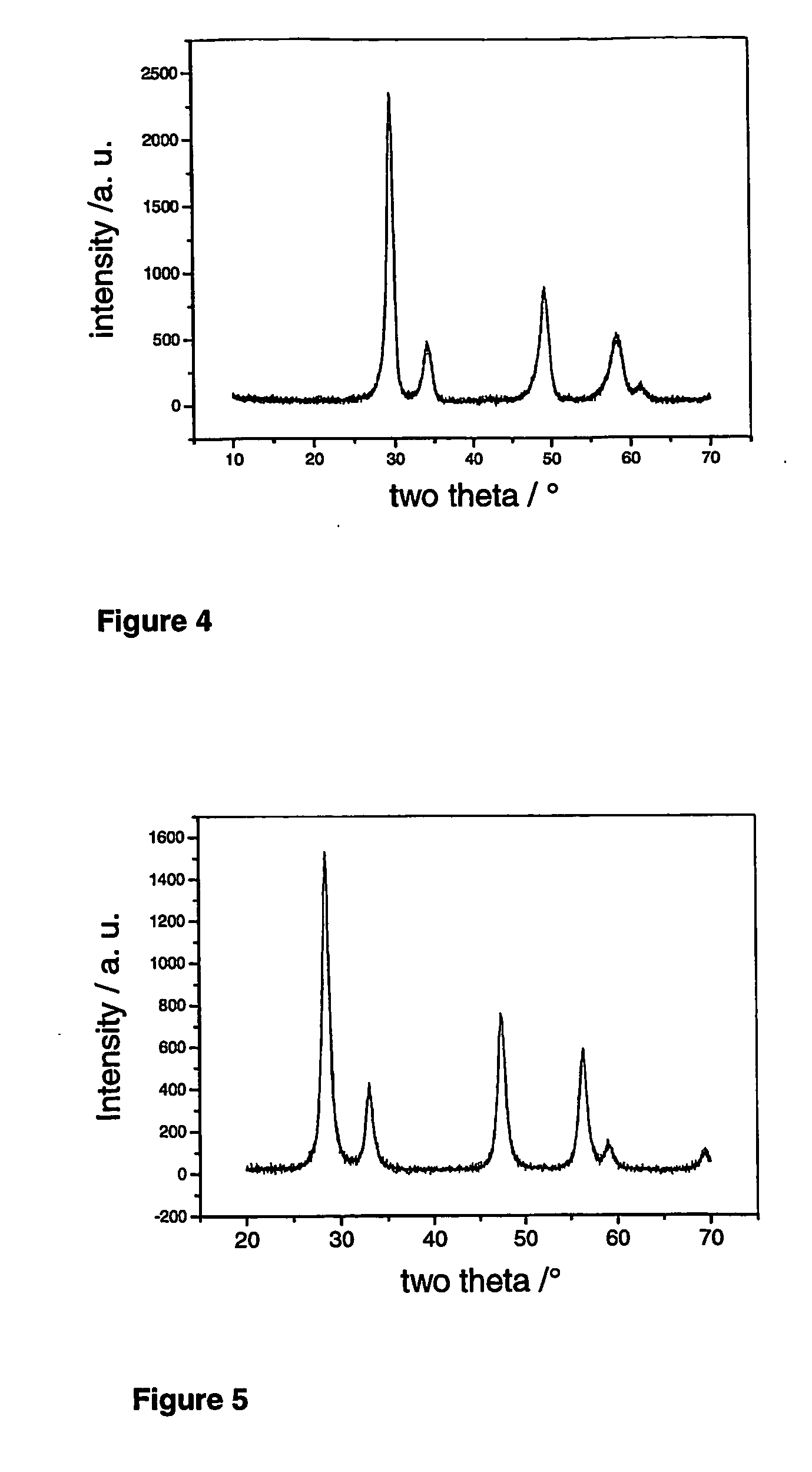

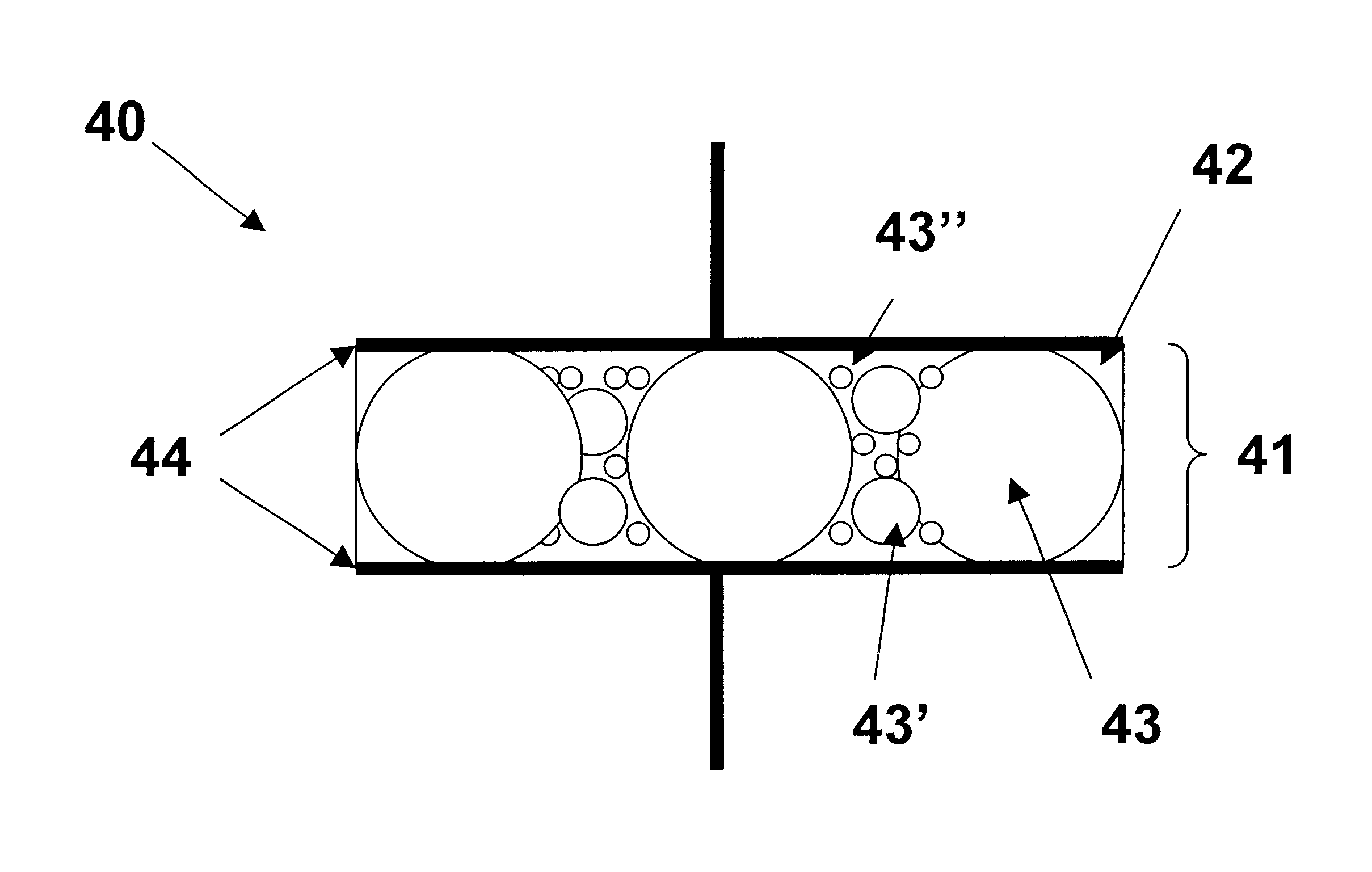

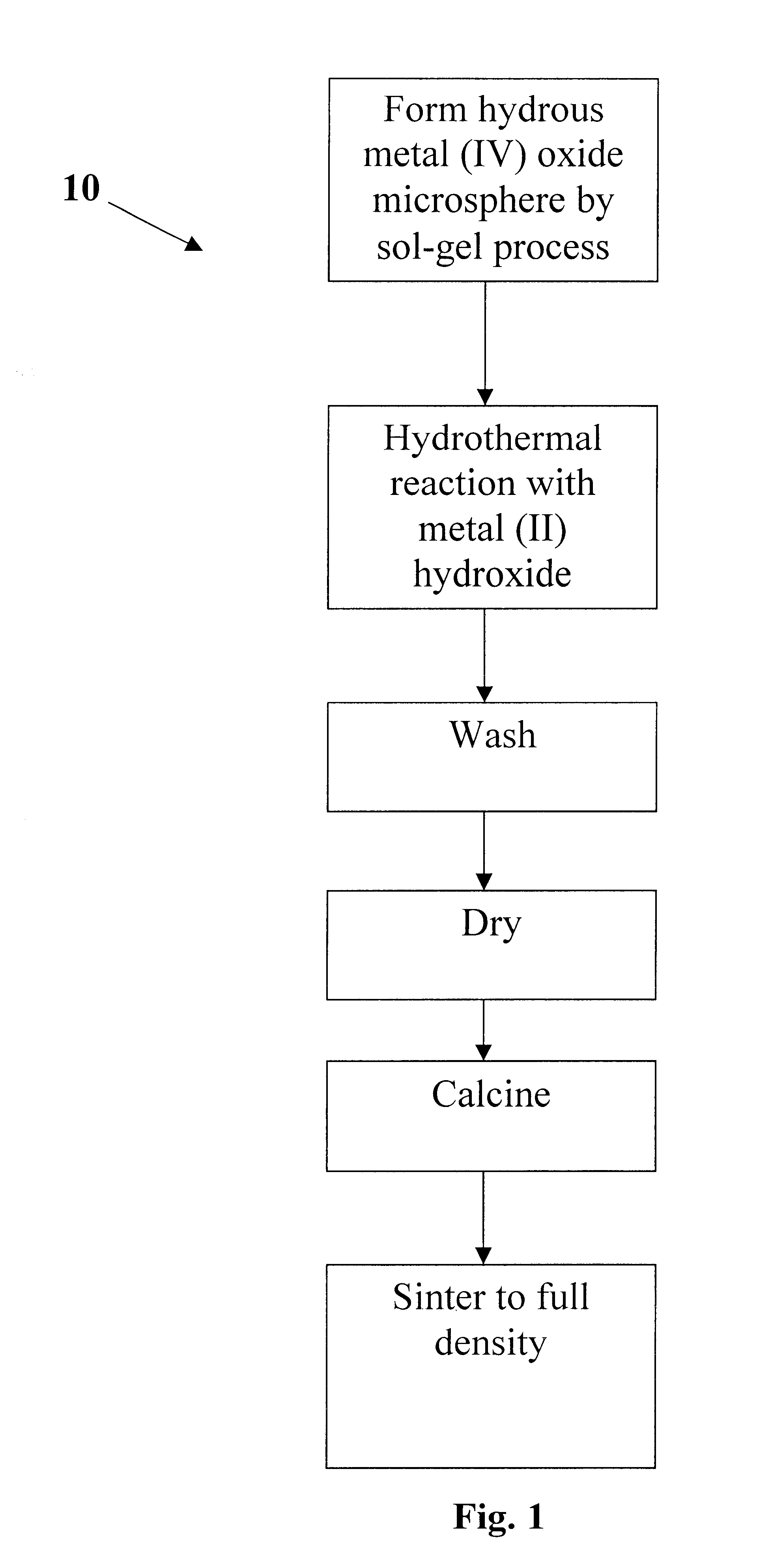

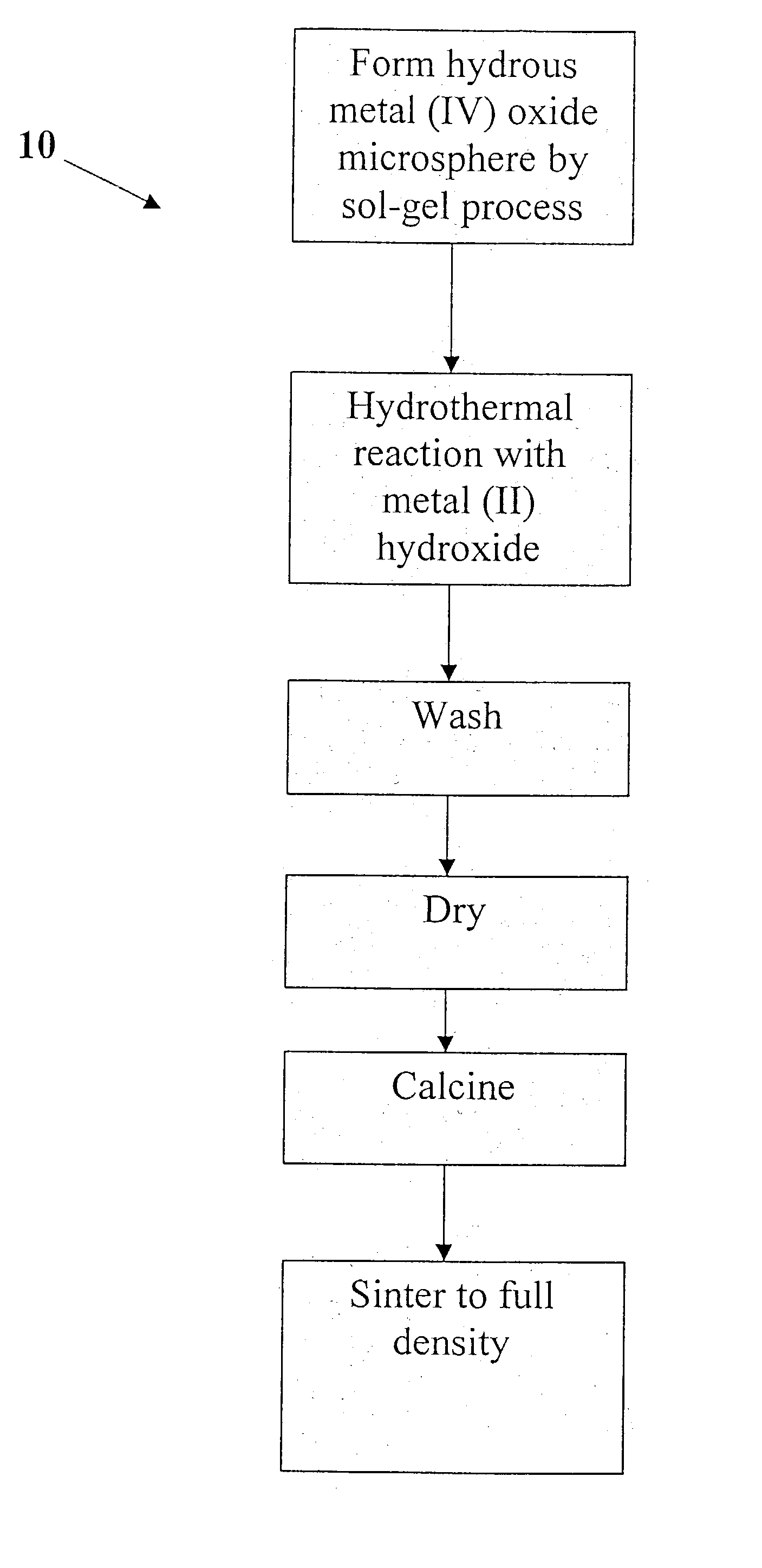

The invention allows the fabrication of small, dense beads of dielectric materials with selected compositions, which are incorporated into a polymeric matrix for use in capacitors, filters, and the like. A porous, generally spherical bead of hydrous metal oxide containing titanium or zirconium is made by a sol-gel process to form a substantially rigid bead having a generally fine crystallite size and correspondingly finely distributed internal porosity. The resulting gel bead may be washed and hydrothermally reacted with a soluble alkaline earth salt (typically Ba or Sr) at elevated temperature and pressure to convert the bead into a mixed hydrous titanium- or zirconium-alkaline earth oxide while retaining the generally spherical shape. Alternatively, the gel bead may be made by coprecipitation. This mixed oxide bead is then washed, dried and calcined to produce the desired (BaTiO3, PbTiO3, SrZrO3) structure. The sintered beads are incorporated into a selected polymer matrix. The resulting dielectric composite material may be electrically "poled" if desired.

Owner:EI DU PONT DE NEMOURS & CO +1

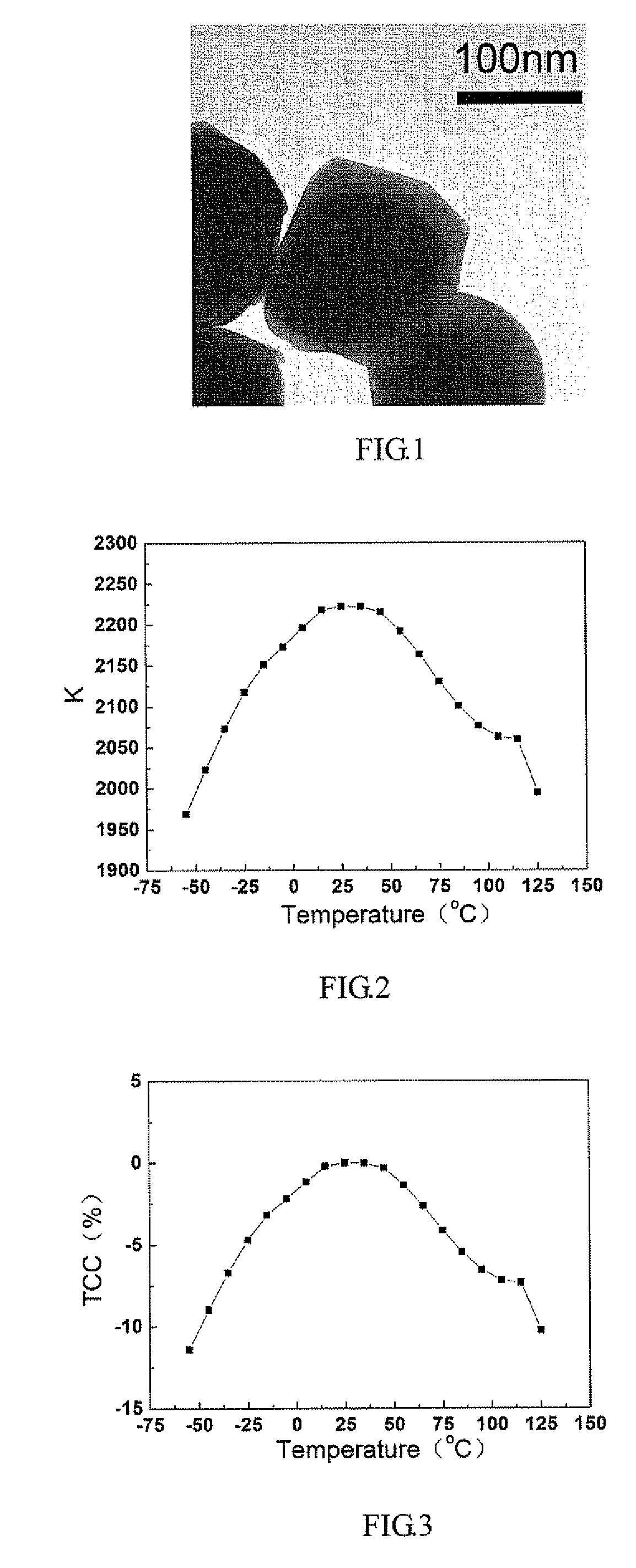

NANO complex oxide doped dielectric ceramic material, preparation method thereof and multilayer ceramic capacitors made from the same

InactiveUS20090135546A1High insulation resistanceInsulation resistance can be improvedAlkaline earth titanatesMaterial nanotechnologyDopantBarium titanate

The present invention provides a nano complex oxide doped dielectric ceramic material used for a multilayer ceramic capacitor using a base metal as a material of internal electrodes. The doped dielectric ceramic material comprises barium titanate and a nano complex oxide dopant, wherein the molar ratio of the barium titanate to the nano complex oxide dopant is in the range of (90˜98):(2˜10), the average particle size of the barium titanate is 50˜300 nm and the nano complex oxide dopant has the following formula (1): w A+x B+y C+z D. The present invention also provides processes for preparing the nano complex oxide doped dielectric ceramic material and ultrafine-grained and temperature-stable multilayer ceramic capacitors using the nano complex oxide doped dielectric ceramic material as the material of dielectric layers.

Owner:TSINGHUA UNIV

Inorganic dielectric powder for composite dielectric material and composite dielectric material

InactiveUS20070049485A1High dielectric constantSatisfactory filling propertyAlkaline earth titanatesFixed capacitor dielectricBarium titanateRadio frequency

It is an object of the present invention to provide an inorganic dielectric powder used for a composite dielectric material, the inorganic dielectric powder having high filling properties and expressing a high dielectric constant when used as a composite dielectric. It is another object of the present invention to provide a composite dielectric material having a high dielectric constant, the composite dielectric material being used for dielectric layers of electronic components, such as printed circuit boards, semiconductor packages, capacitors, antennae for radio frequencies, and inorganic electroluminescent devices. In an inorganic dielectric powder according to the present invention used for a composite dielectric material mainly containing a polymeric material and the inorganic dielectric powder, the inorganic dielectric powder includes perovskite compound oxide particles in which a subcomponent element is dissolved in barium titanate particles, wherein the perovskite compound oxide particles are prepared by wet-reaction of a titanium compound and a barium compound with a compound containing the subcomponent element and then calcining the resulting reaction product.

Owner:NIPPON CHECMICAL IND CO LTD +1

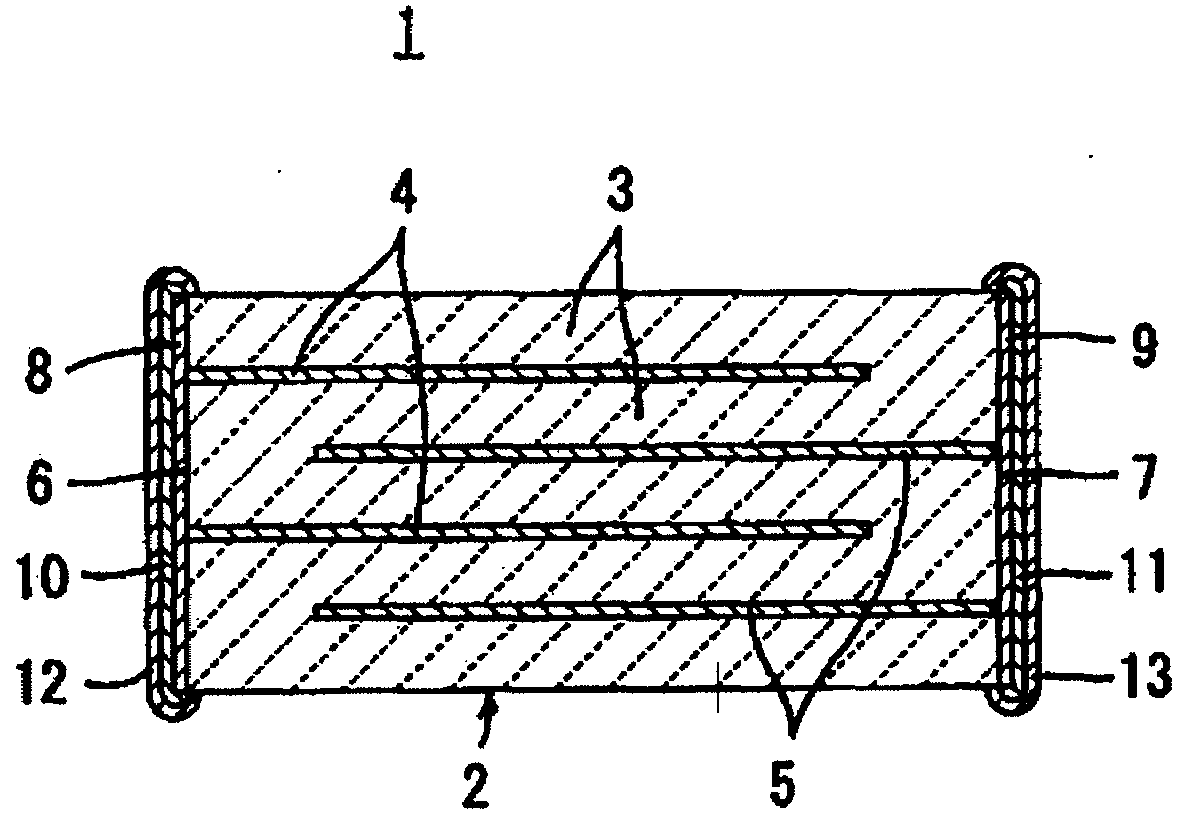

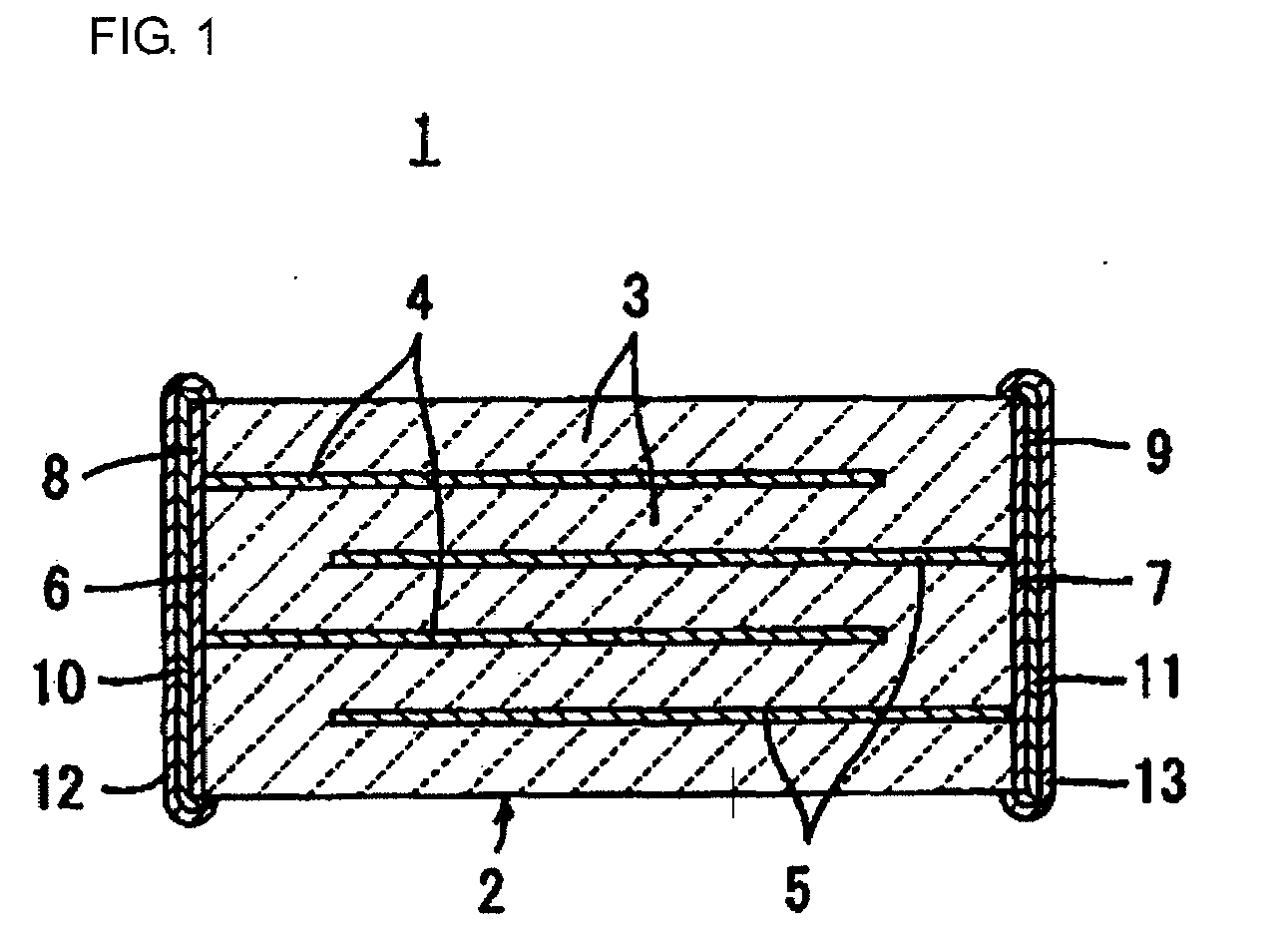

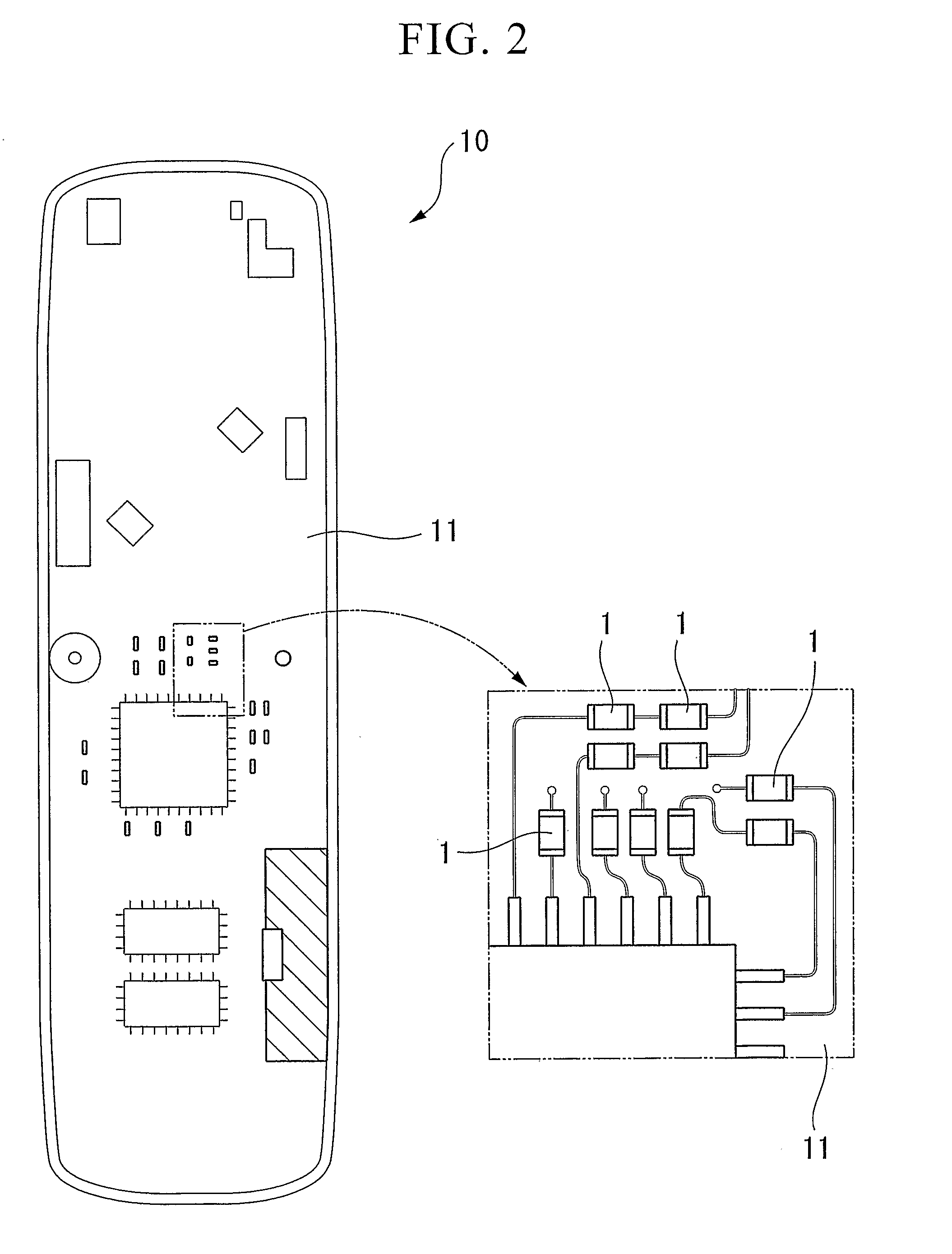

Multilayer ceramic capacitor and method for producing the same

ActiveUS20160118188A1High dielectric constantIncrease the electric field strengthAlkaline earth titanatesFixed capacitor electrodesRare-earth elementCeramic capacitor

A dielectric ceramic that forms dielectric ceramic layers of a multilayer ceramic capacitor contains a Ba and Ti containing perovskite compound, Ca, R (R denotes a rare earth element, such as La), M (M denotes Mn or the like), and Si. The Ca content ranges from 0.5 to 2.5 molar parts, the R content ranges from 0.5 to 4 molar parts, the M content ranges from 0.5 to 2 molar parts, and the Si content ranges from 1 to 4 molar parts, based on 100 molar parts of Ti. In perovskite crystal grains, the Ca diffusion depth is 10% or less of the average grain size of the crystal grains, and the Ca concentration in a Ca diffusion region is 0.2 to 5 molar parts higher than the Ca concentration near the center of each of the crystal grains.

Owner:MURATA MFG CO LTD

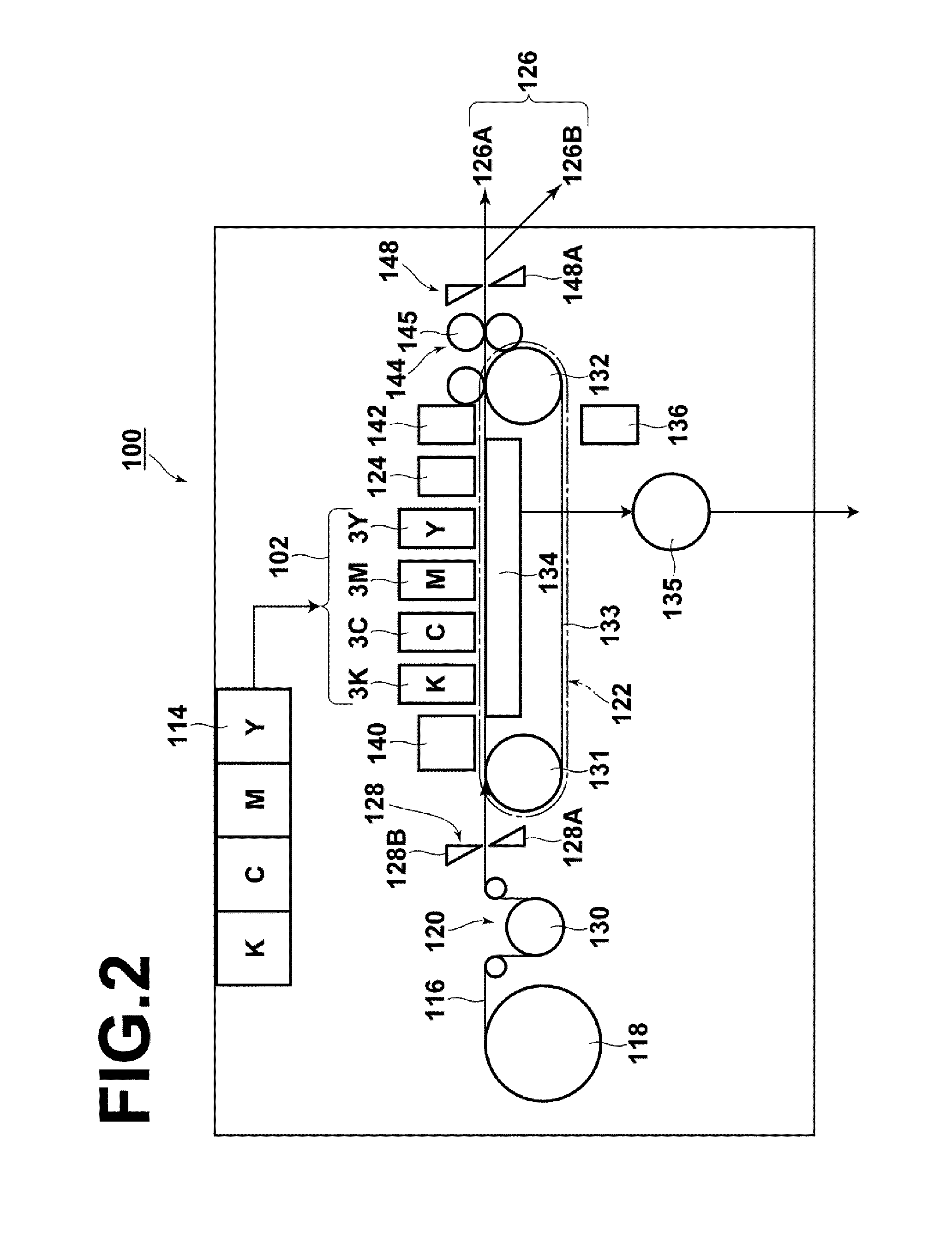

Perovskite oxide material, ferroelectric compound, piezoelectric body, piezoelectric device, and liquid discharge device

ActiveUS20110007115A1Reduce contentSimple compositionAlkaline earth titanatesPiezoelectric/electrostriction/magnetostriction machinesOxygenFerric

A perovskite oxide material containing: BiFeO3 as a first component; a second component containing at least one perovskite oxide which is constituted by A-site atoms having an average ionic valence of two and has a tendency to form a tetragonal structure; and a third component containing at least one perovskite oxide which has a tendency to form one of monoclinic, triclinic, and orthorhombic structures; where each perovskite oxide in the first component, the second component, and the third component contains A-site atoms, B-site atoms, and oxygen atoms substantially in a molar ratio of 1:1:3, and the molar ratio can deviate from 1:1:3 within a range

Owner:FUJIFILM CORP

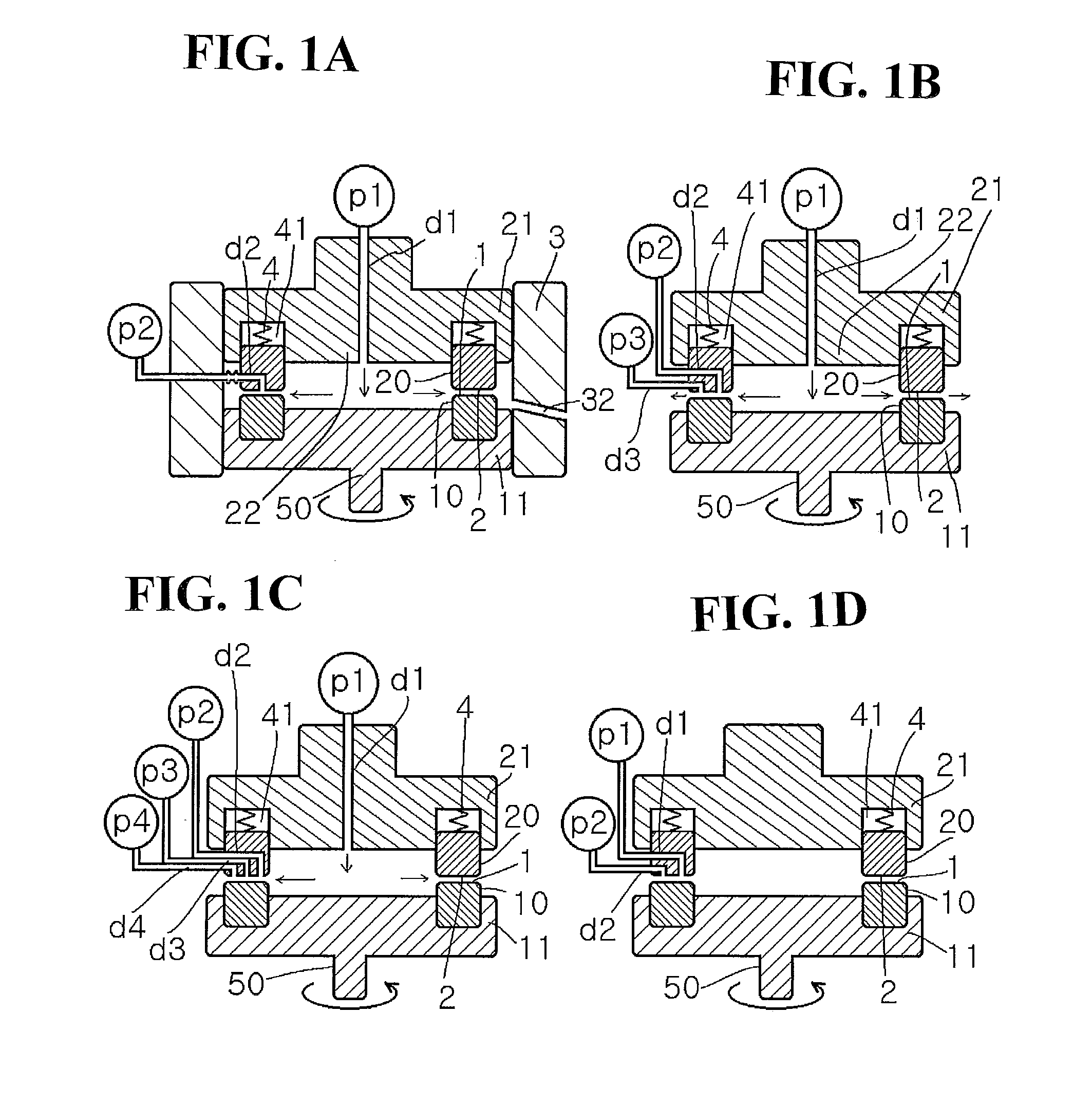

Method for producing ceramic nanoparticles

ActiveUS20110015054A1Improve production efficiencyIncrease in sizeMaterial nanotechnologyAlkaline earth titanatesMetallurgyNanoparticle

The invention provides a method for producing ceramic nanoparticles, which comprises hydrolyzing a ceramic material in a thin film fluid formed between processing surfaces arranged to be opposite to each other so as to be able to approach to and separate from each other, at least one of which rotates relative to the other.

Owner:M TECHN

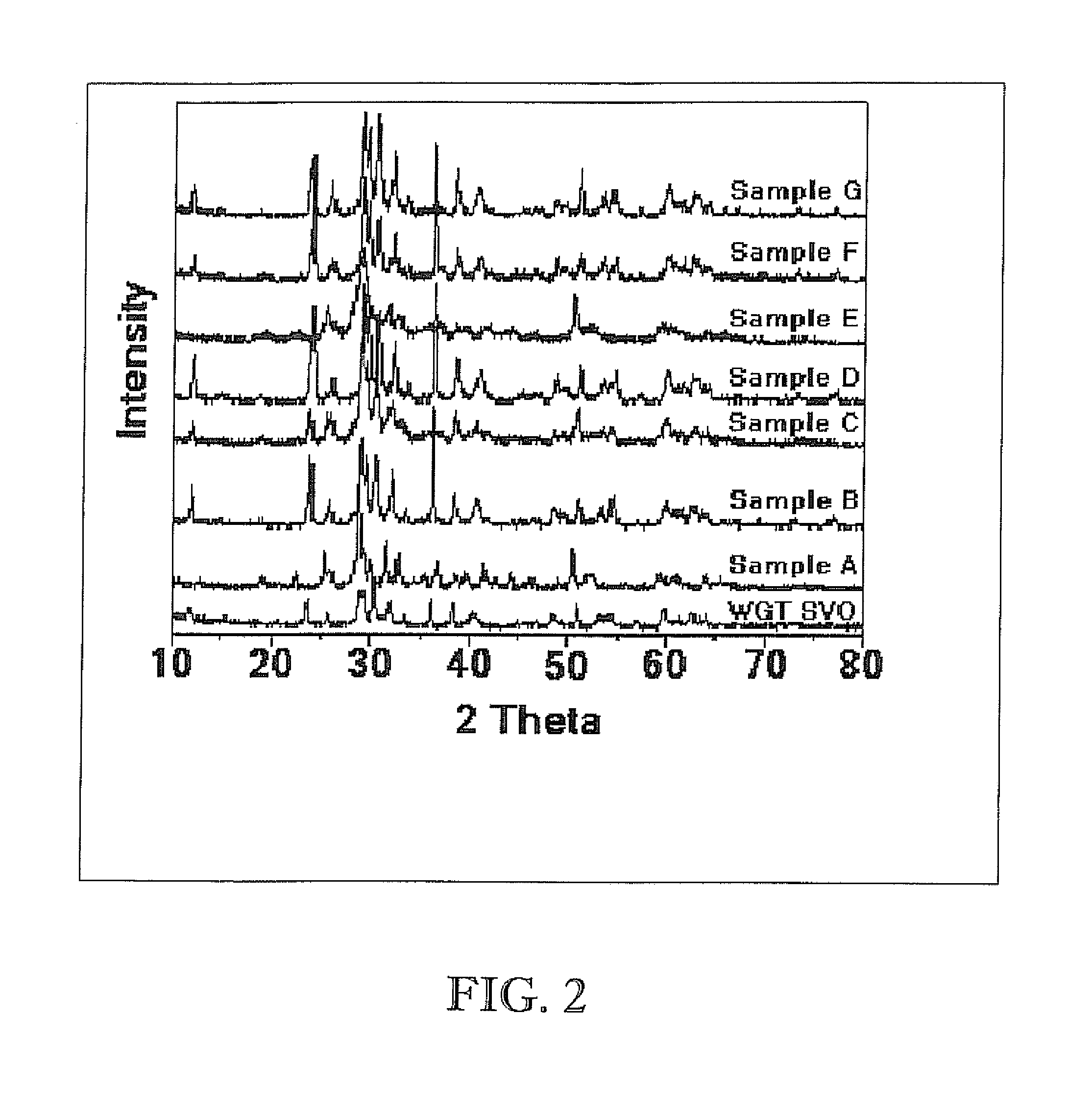

Synthesis of high surface area nanocrystalline materials useful in battery applications

InactiveUS20070286796A1Alkaline earth titanatesMaterial nanotechnologyElectrochemical cellMedical device

An improved mixed metal oxide material suitable for use in electrochemical cells is provided. The mixed metal oxide material generally exhibits high surface area and pore volume than conventionally manufactured materials thereby imparting improved electrochemical performance. Batteries manufactured using the mixed metal oxide material are particularly suited for use in implantable medical devices.

Owner:TIMILON TECH ACQUISITIONS LLC

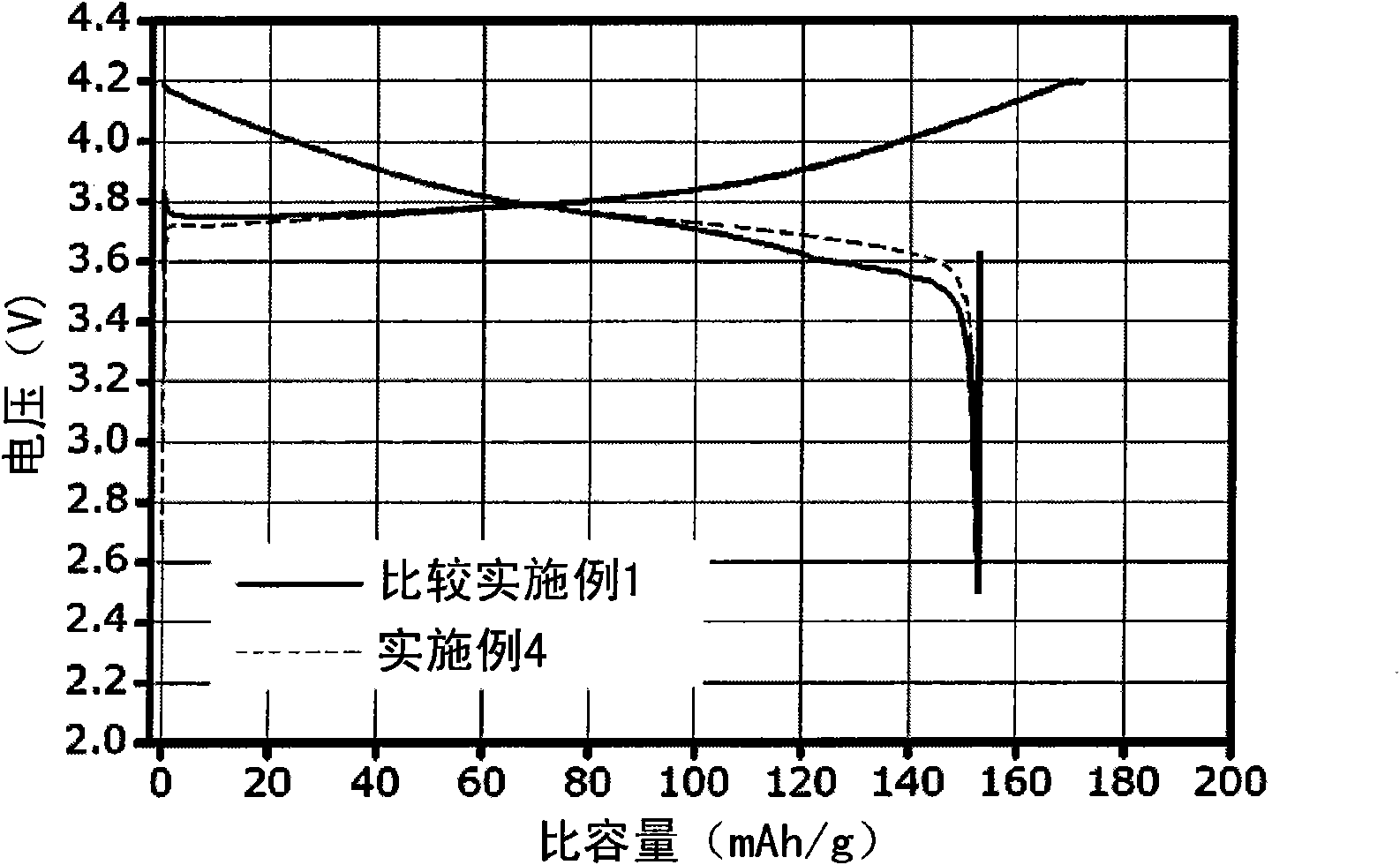

Cathode active material for lithium secondary batteries with high safety and method of preparing for the same and lithium secondary batteries comprising the same

ActiveCN101884126AHigh yieldGood reproducibilityAlkaline earth titanatesMaterial nanotechnologyBarium titanateLithium metal

A cathode active material for a lithium secondary battery includes a lithium metal oxide secondary particle core formed by agglomerating lithium metal oxide primary particles; and a shell formed by coating the secondary particle core with barium titanate and metal oxide. This cathode active material allows making a lithium secondary battery having improved safety, particularly in thermal stability and overcharging characteristics.

Owner:SOLE SOLAR TECH KOREA CO LTD

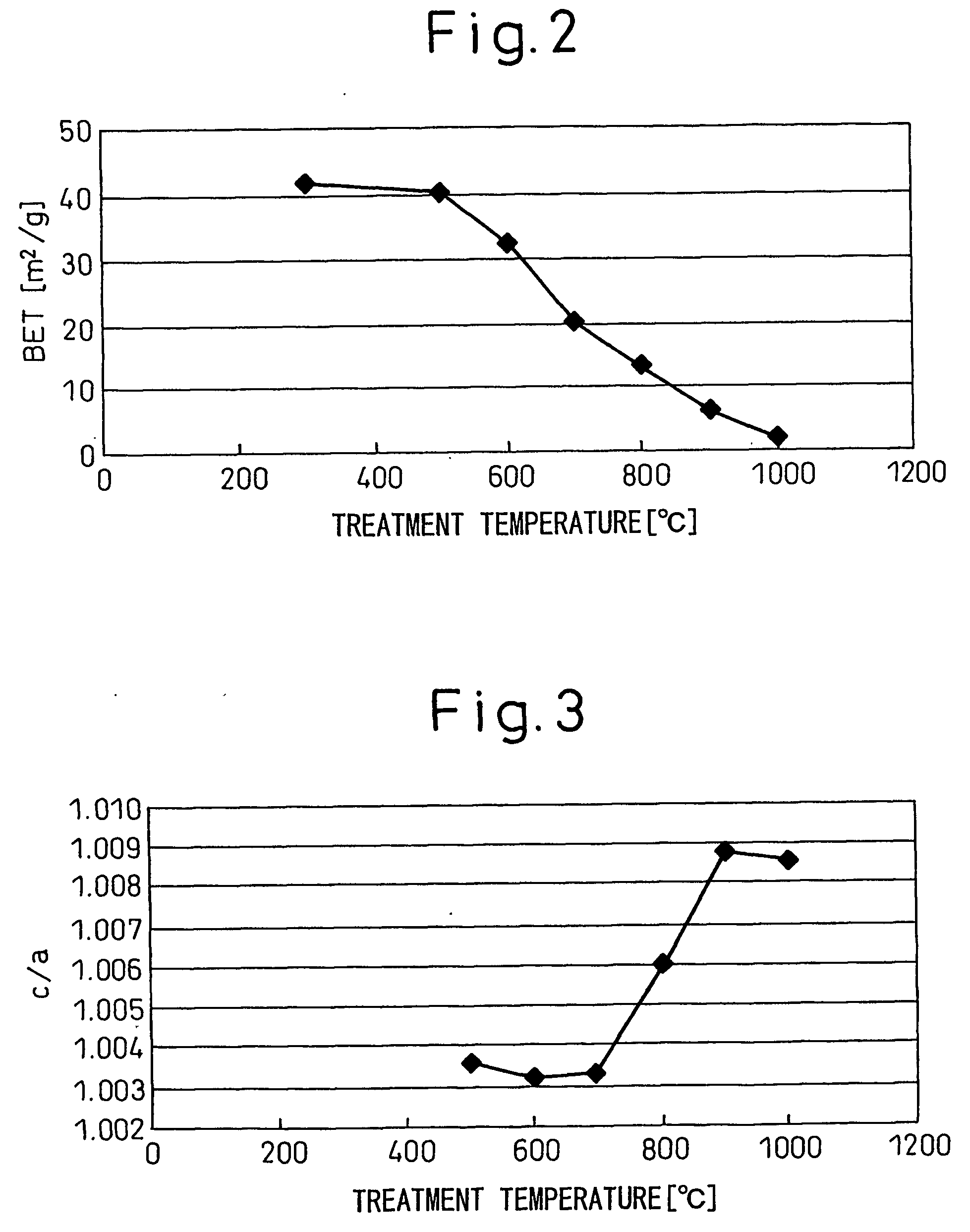

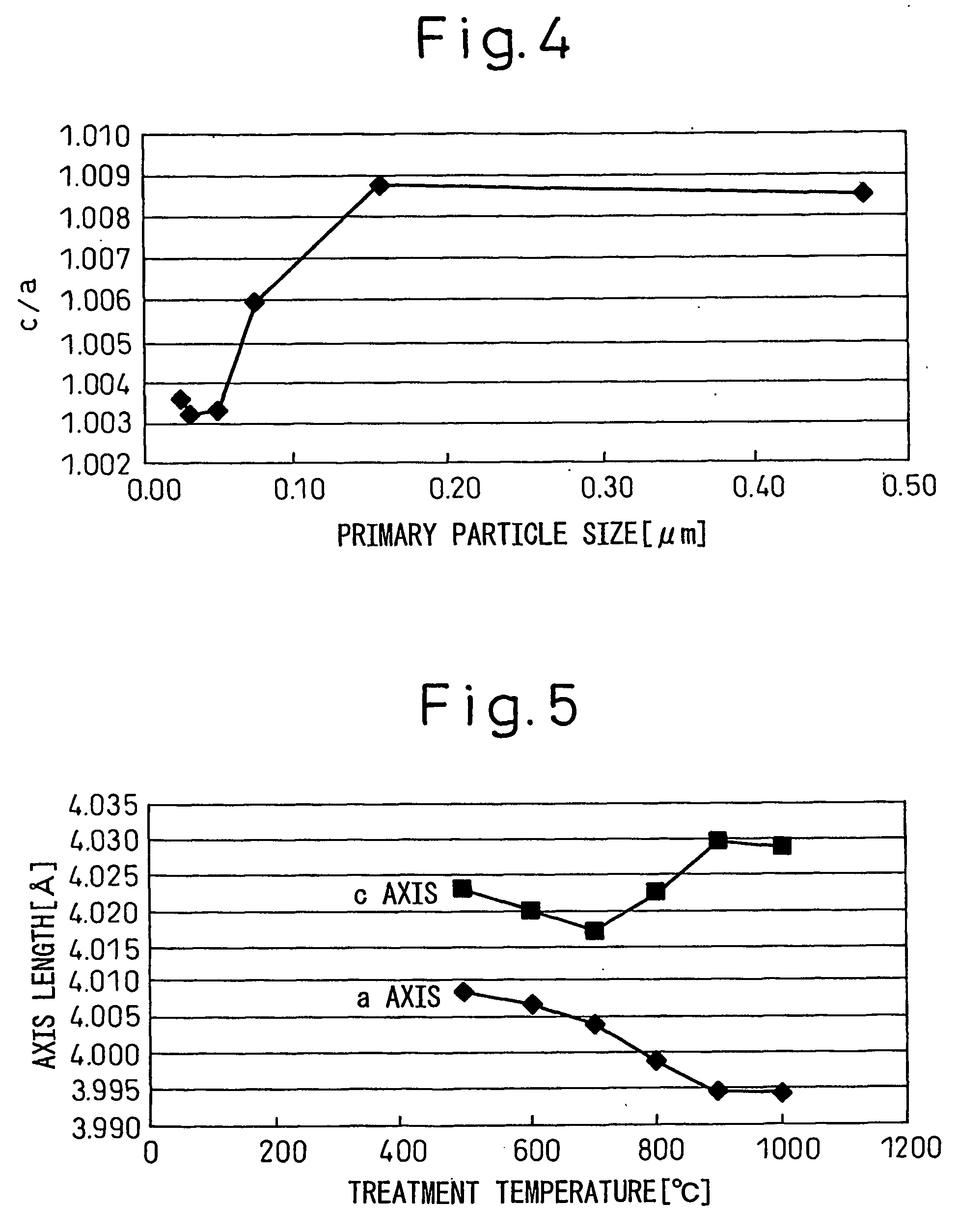

Perovskite titanium-containing composite oxide particle, production process and uses thereof

InactiveUS20060078492A1Large particle sizeGood dispersionMaterial nanotechnologyAlkaline earth titanatesTitaniumComposite oxide

The present invention provides a perovskite titanium-containing composite oxide fine particle represented by the formula: (A1XA2(1−X))YTiO3±δ (wherein 0≦X≦1, 0.98≦Y≦1.02, 0≦δ≦0.05, A1 and A2 each is an atom selected from a group consisting of Ca, Sr, Ba, Pb and Mg and are different from each other), wherein the specific surface area is from 1 to 100 m2 / g and the D2 / D1 value is from 1 to 10.

Owner:SHOWA DENKO KK

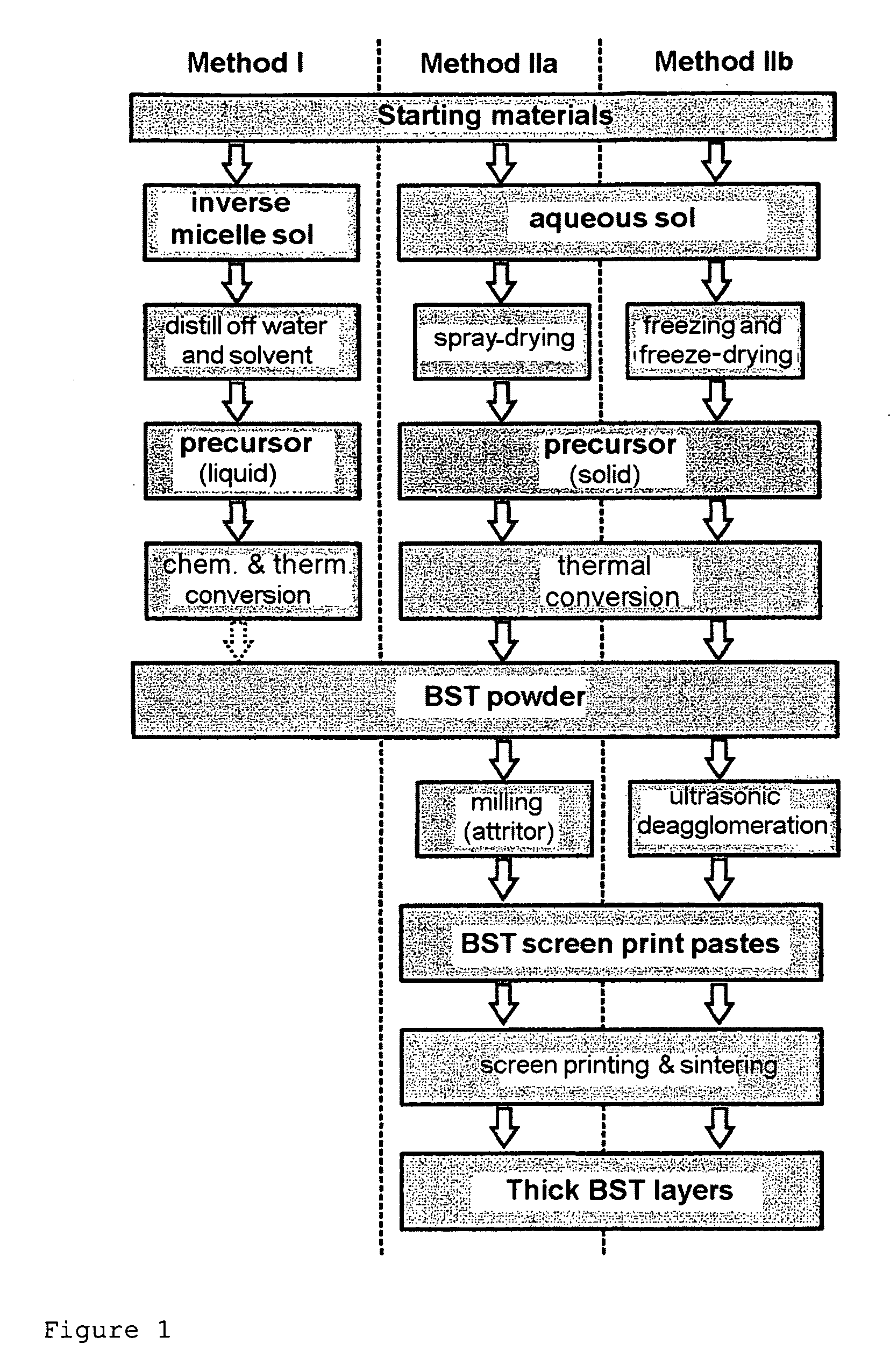

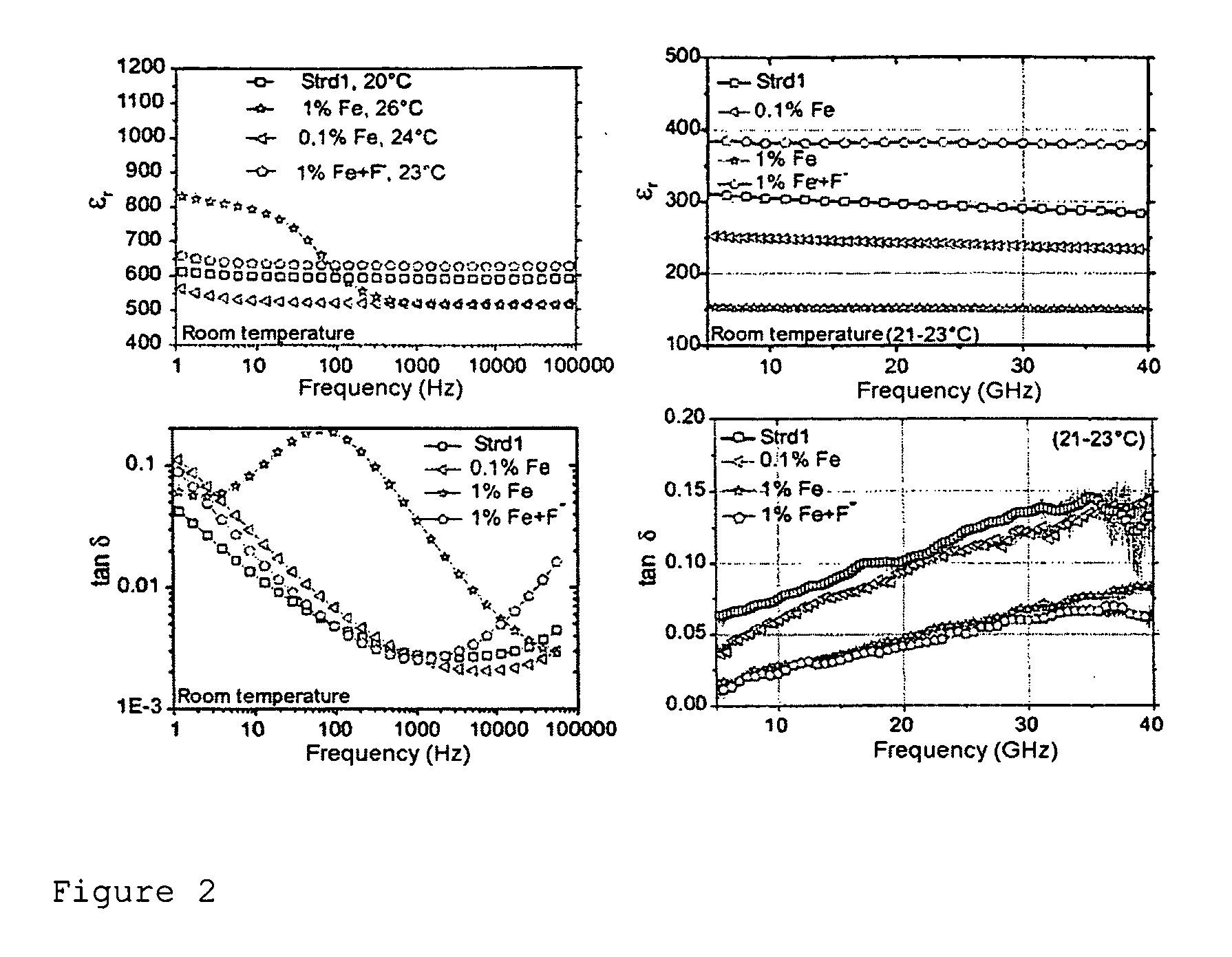

Ceramic dielectric or thin and/or thick layers containing at least one ceramic dielectric method for production and use thereof

InactiveUS20090297804A1Improve efficiencyAlkaline earth titanatesVacuum evaporation coatingDielectric ceramics

The present invention relates to dielectric ceramics, thin and / or thick layers produced therefrom and a method for the production thereof and the use of the dielectrics and of the thin and / or thick layers.

Owner:KERNFORSCHUNGSZENTRUM KARLSRUHE GMBH

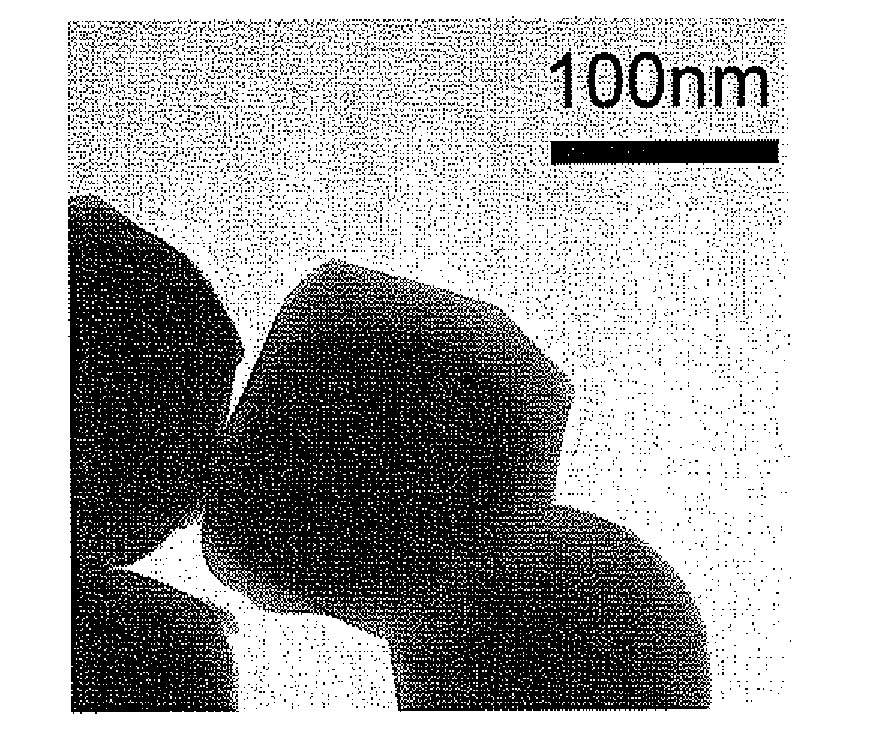

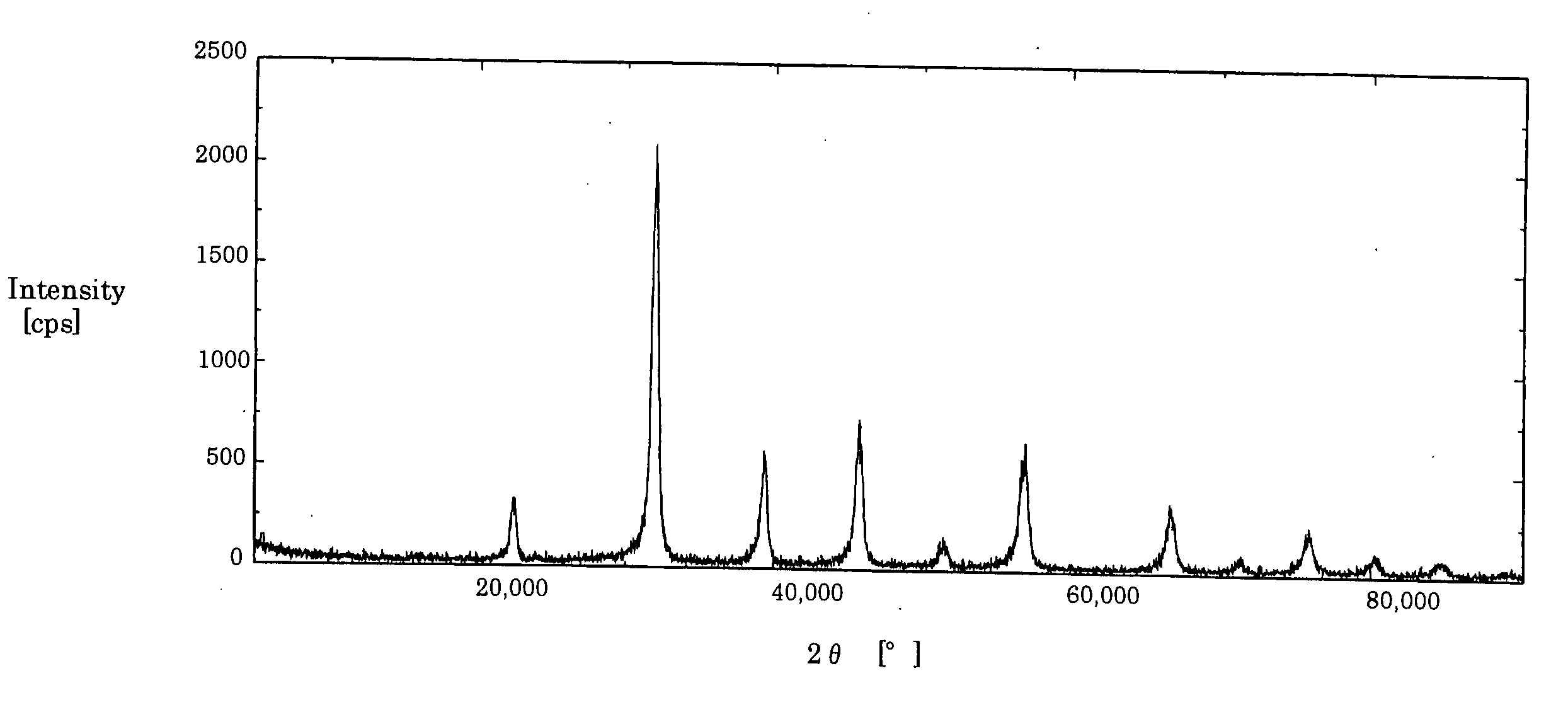

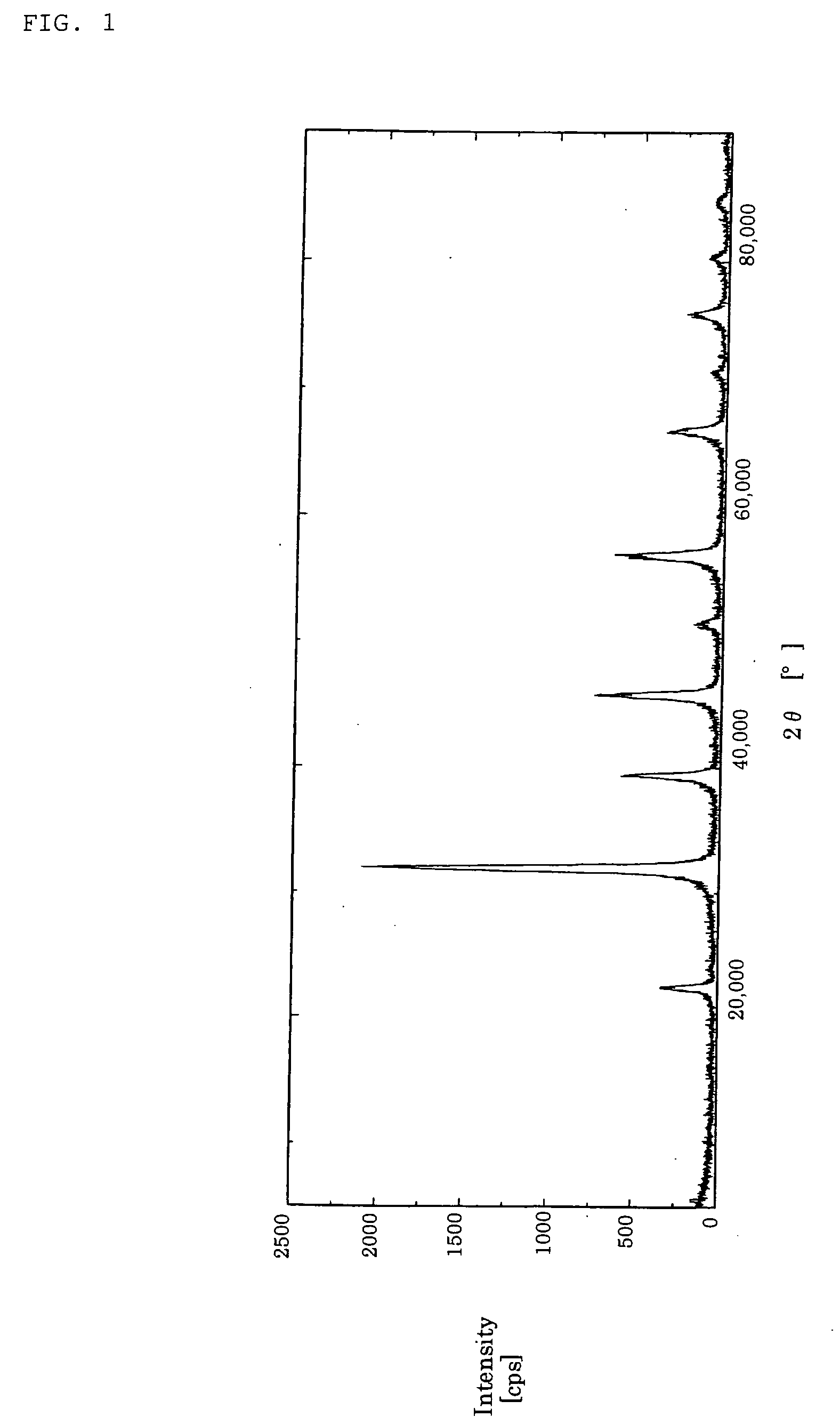

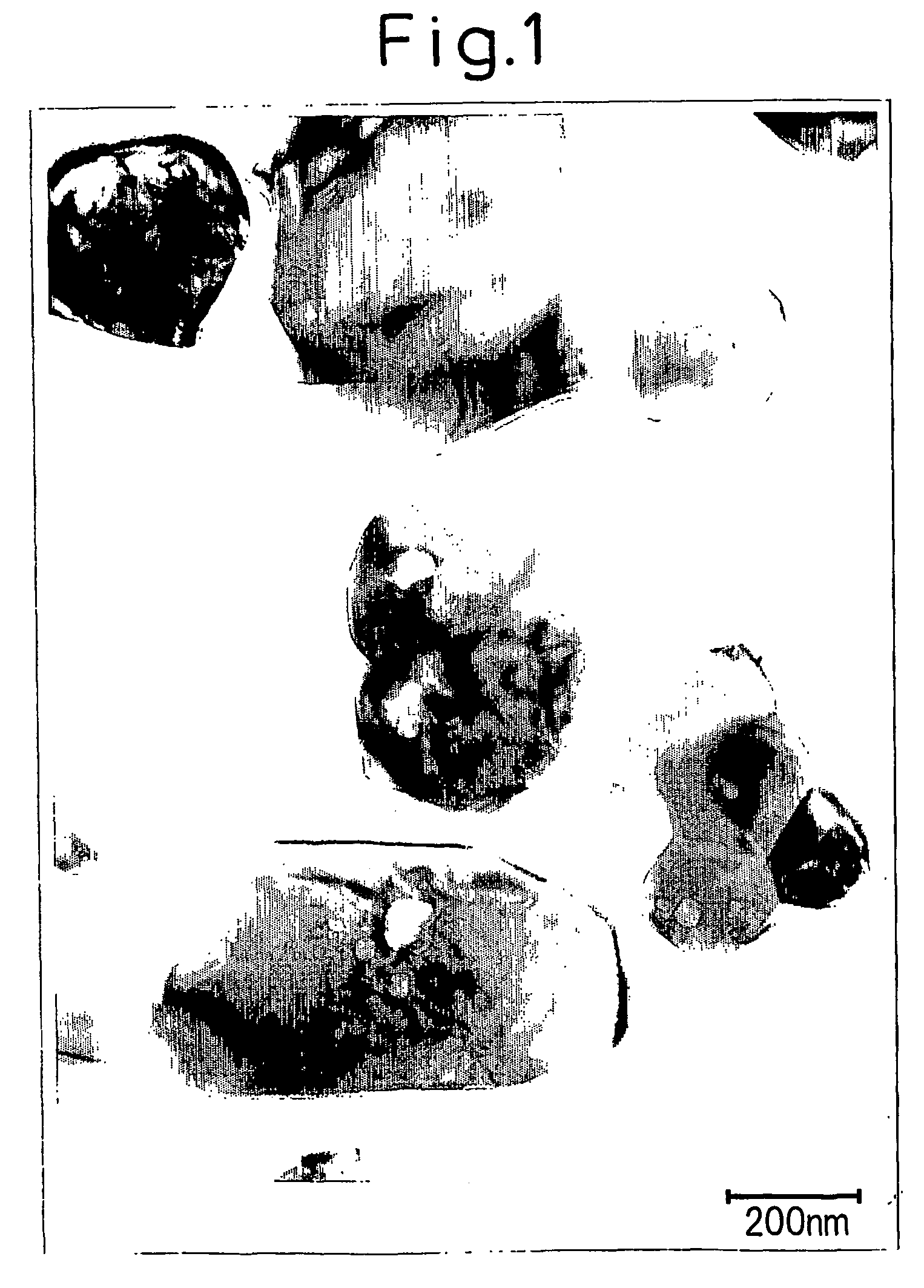

Barium titanate and electronic parts using the material

InactiveUS20060172880A1Small particle sizeMaterial nanotechnologyAlkaline earth titanatesBarium titanateSingle crystal

A barium titanate, which is single crystal in the form of particles, said particles comprising particles without a void having a diameter of 1 nm or more in an amount of 20% or more by number of the total particles. A dielectric material comprising the barium titanate as well as a capacitor comprising the dielectric material.

Owner:SHOWA DENKO KK

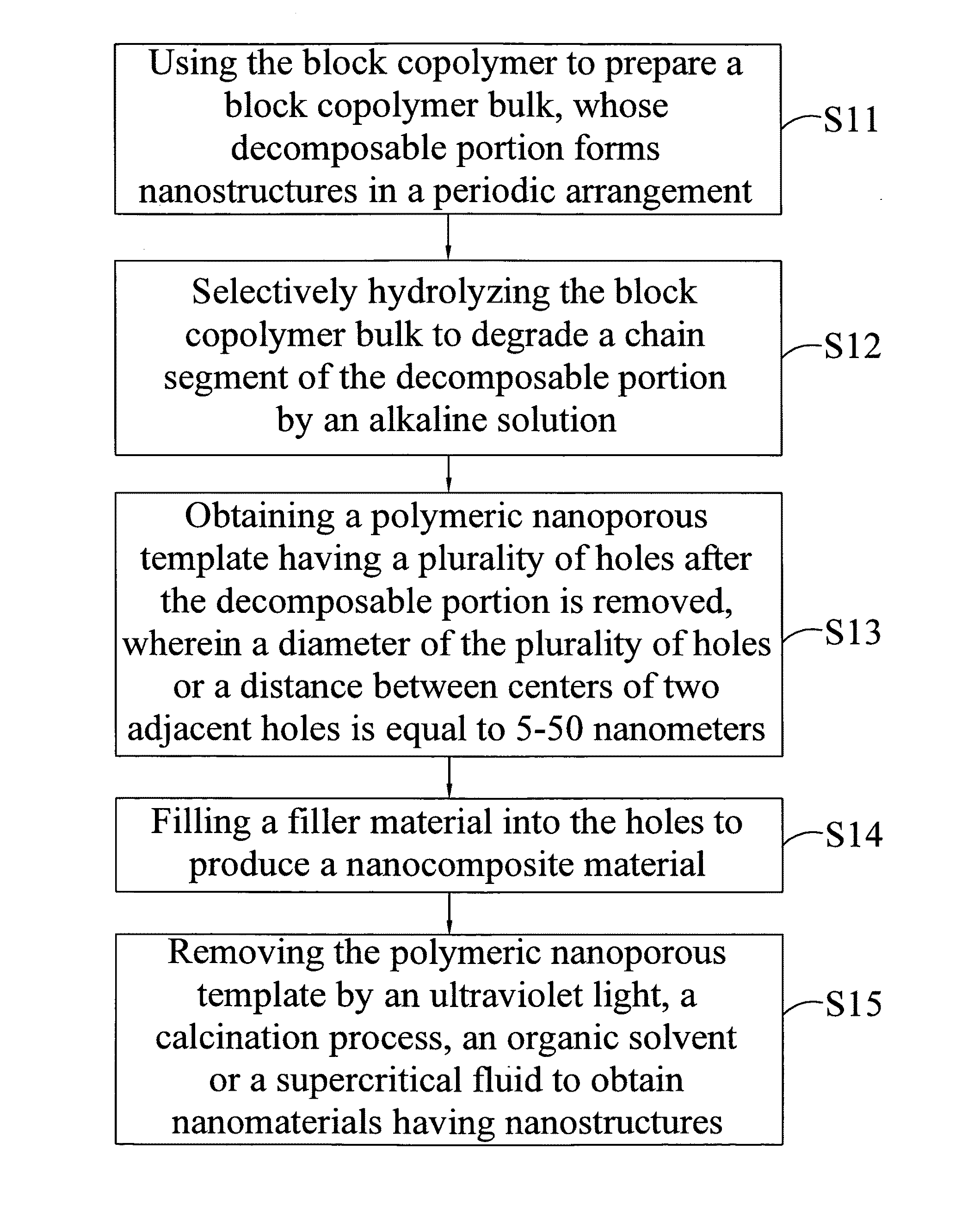

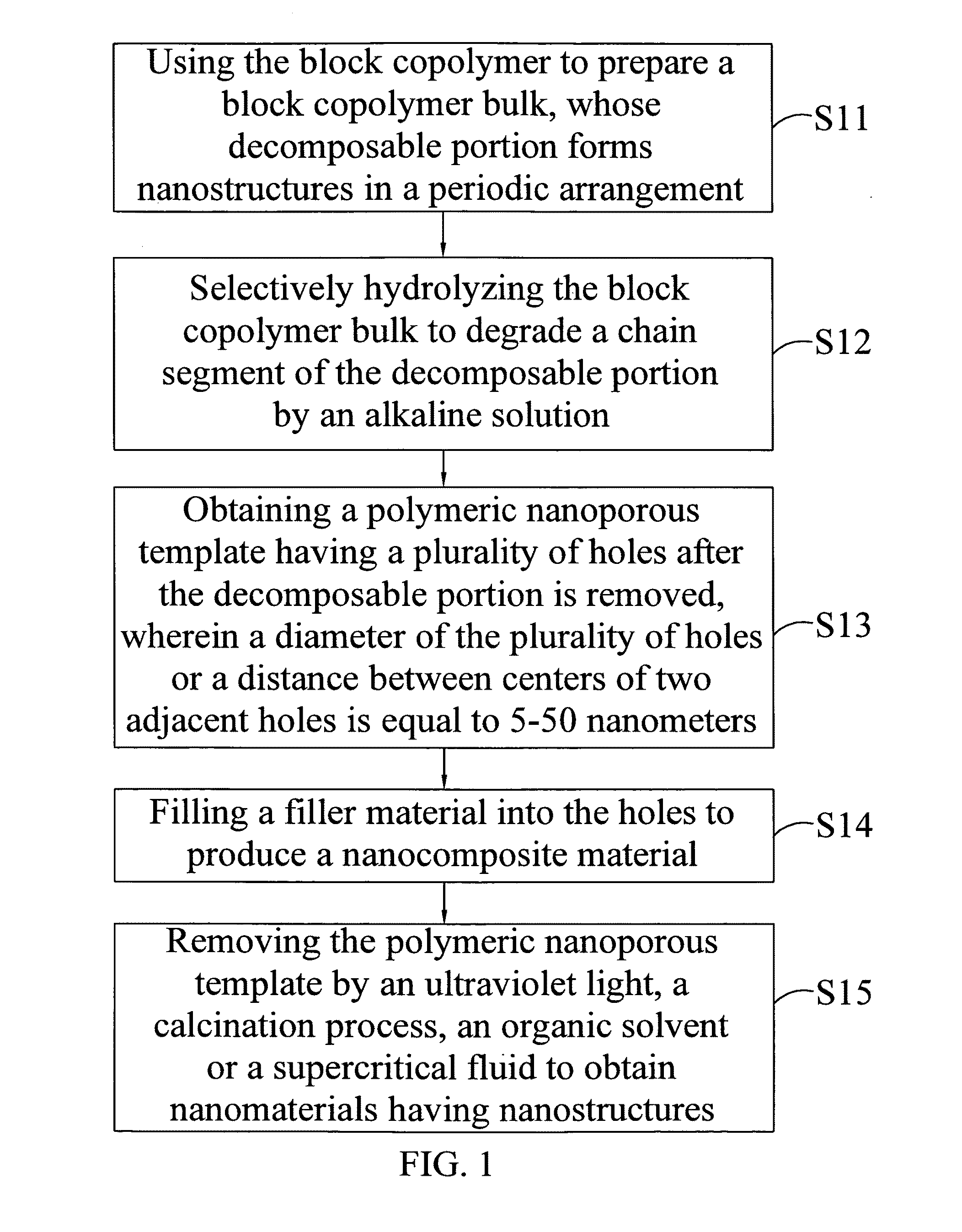

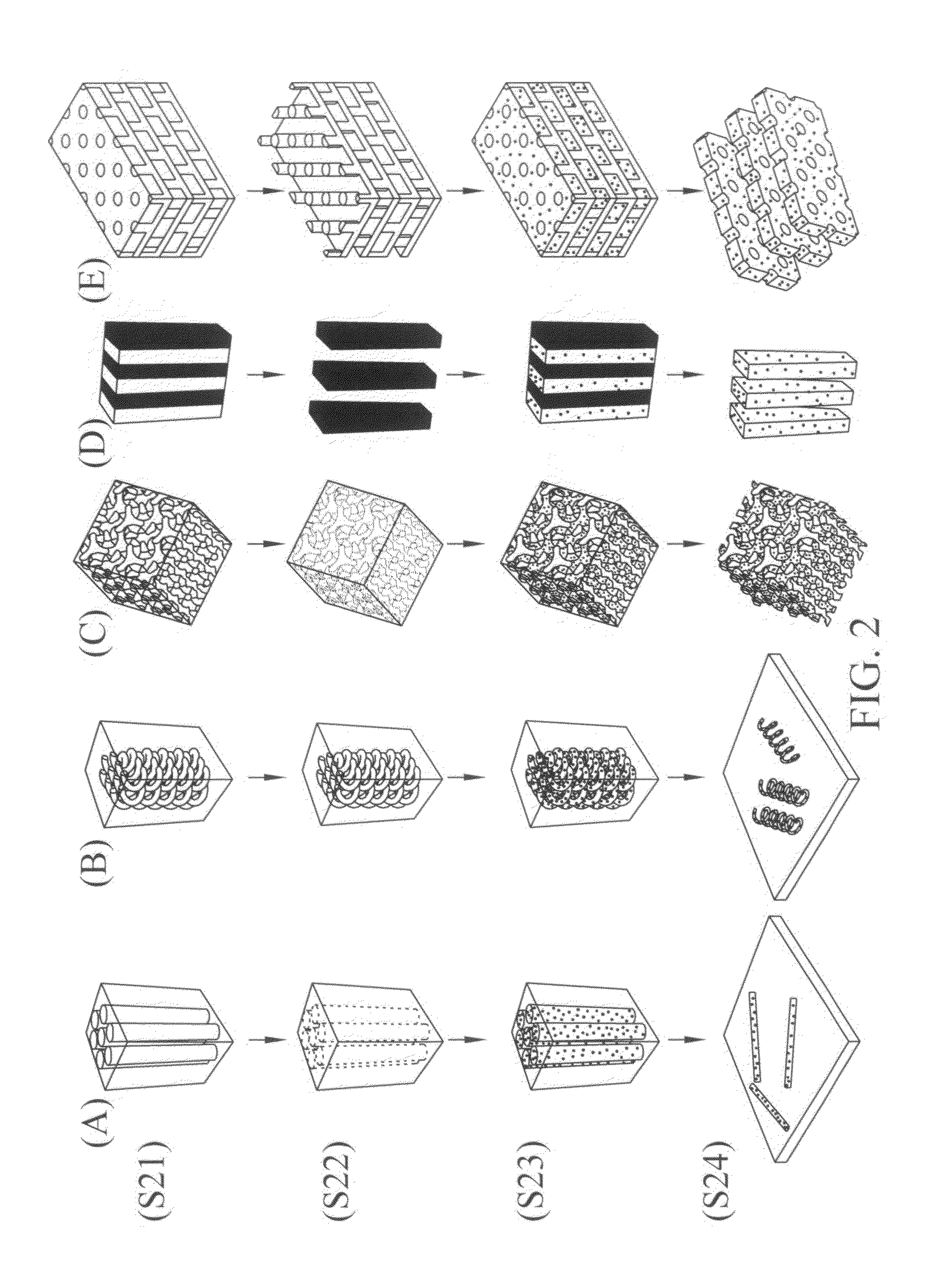

Fabrication method of nanomaterials by using polymeric nanoporous templates

InactiveUS20110003069A1Easy to manufactureLow costAlkaline earth titanatesSilicaNanoreactorFilling materials

Owner:NATIONAL TSING HUA UNIVERSITY

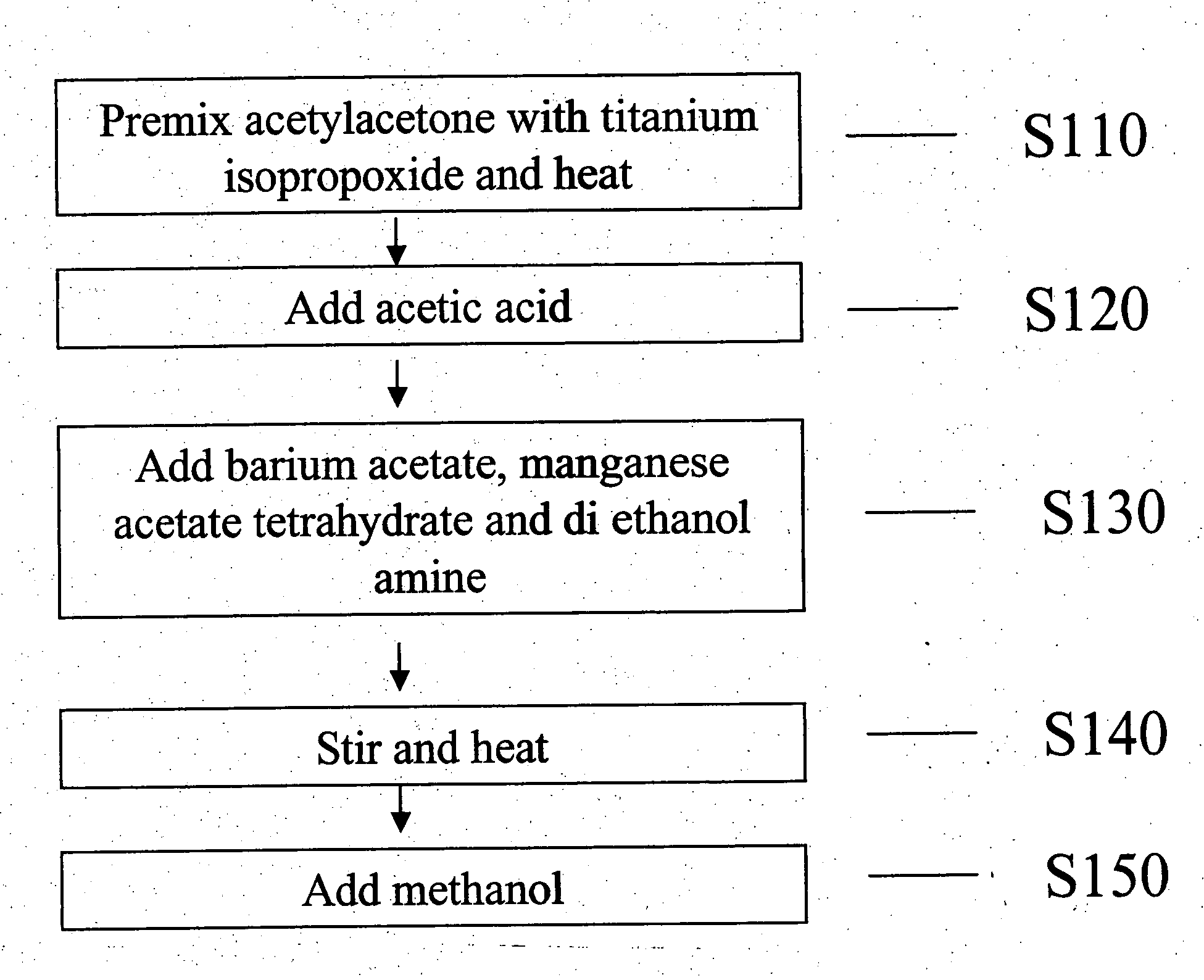

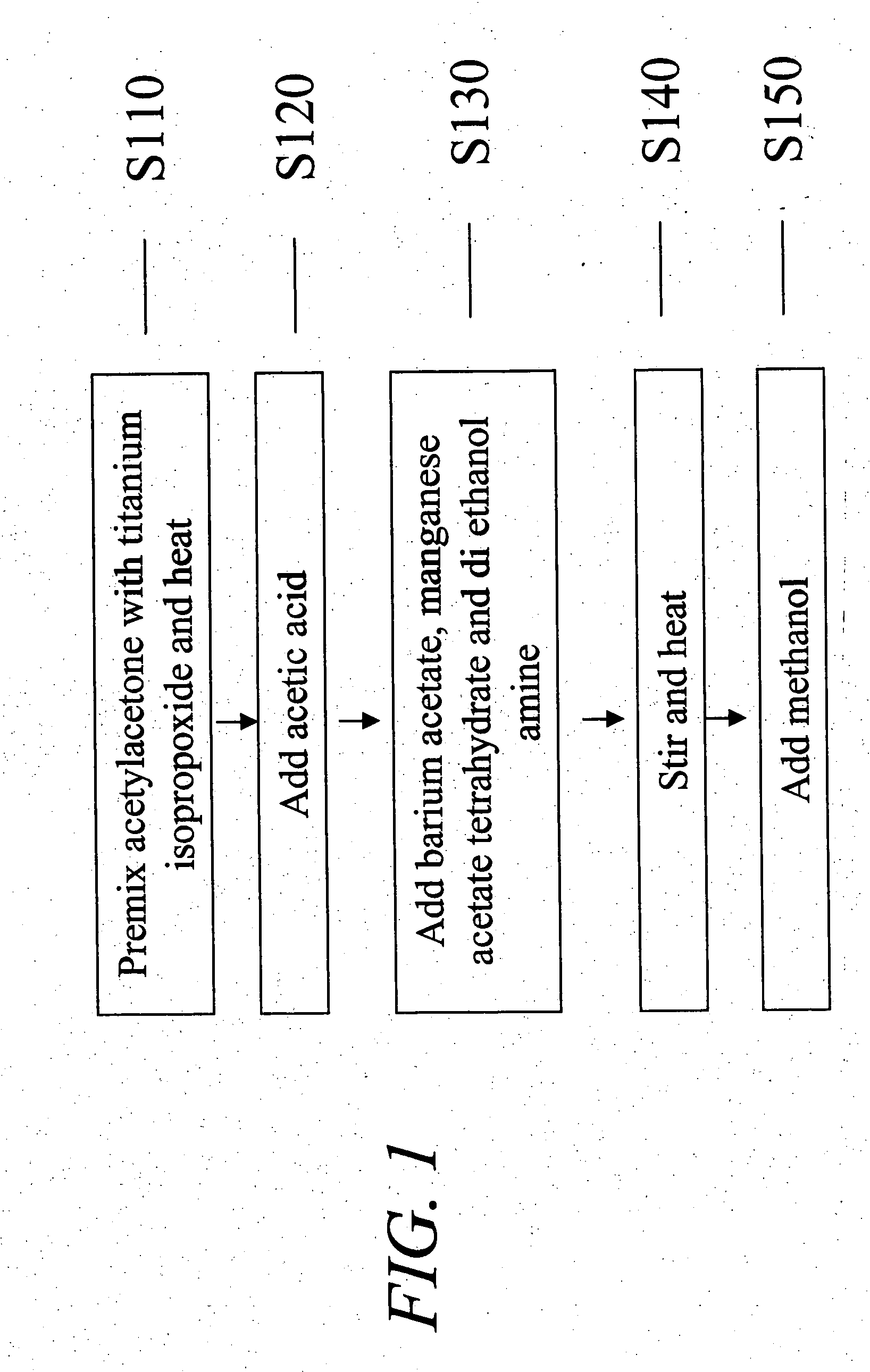

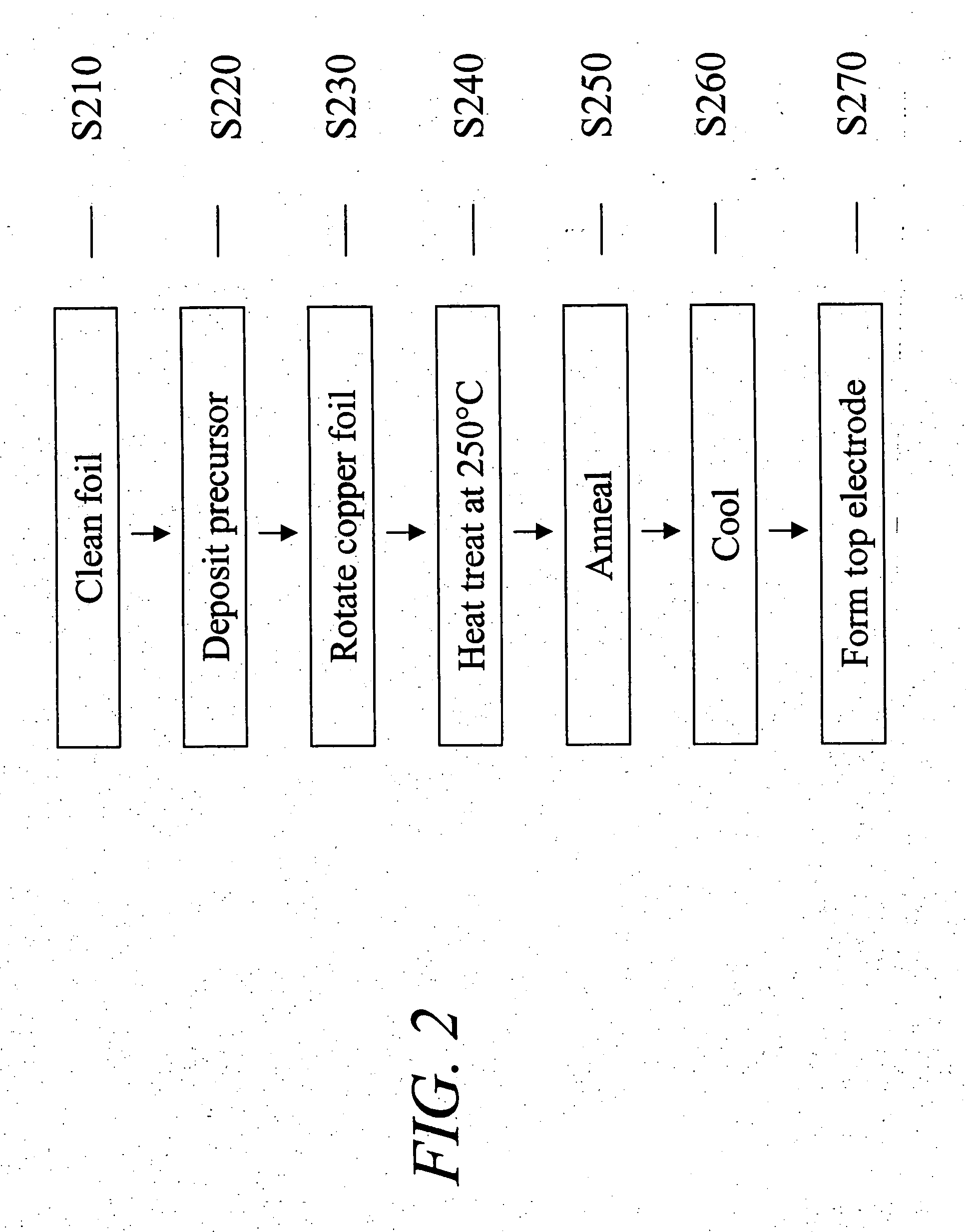

Manganese doped barium titanate thin film compositions, capacitors, and methods of making thereof

The present invention is directed to a dielectric thin film composition comprising: (1) one or more barium / titanium-containing selected from (a) barium titanate, (b) any composition that can form barium titanate during firing, and (c) mixtures thereof; dissolved in (2) organic medium; and wherein said thin film composition is doped with 0.002 to 0.05 atom percent of a manganese-containing additive.

Owner:EI DU PONT DE NEMOURS & CO +1

Barium Calcium Titanate, Production Process Thereof and Capacitor

InactiveUS20070253145A1Good dispersionReduce the presence of impuritiesAlkaline earth titanatesPiezoelectric/electrostrictive device manufacture/assemblyBarium titanatePhysical chemistry

A barium calcium titanate of the present invention has a remarkable effect that a fine barium calcium titanate powder having excellent dispersibility, reduced impurities and high crystallinity and being solid-dissolved at an arbitrary ratio, and a production process thereof are provided. The barium calcium titanate represented by the compositional formula: (Ba(1-X)CaX)YTiO3 (wherein 0<X<0.2 and 0.98≦Y≦1.02), which contains 3 mol % or less (including 0 mol %) of an orthorhombic perovskite compound and in which the specific surface area D is from 1 to 100 m2 / g.

Owner:SHOWA DENKO KK

Dielectric composite materials and method for preparing

InactiveUS20040060730A1Maximize volumetric packing densityQuantity maximizationAlkaline earth titanatesFixed capacitor dielectricMaterials scienceCrystallite

The invention allows the fabrication of small, dense beads of dielectric materials with selected compositions, which are incorporated into a polymeric matrix for use in capacitors, filters, and the like. A porous, generally spherical bead of hydrous metal oxide containing titanium or zirconium is made by a sol-gel process to form a substantially rigid bead having a generally fine crystallite size and correspondingly finely distributed internal porosity. The resulting gel bead may be washed and hydrothermally reacted with a soluble alkaline earth salt (typically Ba or Sr) at elevated temperature and pressure to convert the bead into a mixed hydrous titanium- or zirconium-alkaline earth oxide while retaining the generally spherical shape. Alternatively, the gel bead may be made by coprecipitation. This mixed oxide bead is then washed, dried and calcined to produce the desired (BaTiO3, PbTiO3, SrZrO3) structure. The sintered beads are incorporated into a selected polymer matrix. The resulting dielectric composite material may be electrically "poled" if desired.

Owner:UT BATTELLE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com