Patents

Literature

99 results about "Perfect crystal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crystalline materials (mainly metals and alloys, but also stoichiometric salts and other materials) are made up of solid regions of ordered matter (atoms placed in one of a number of ordered formations called Bravais lattices). These regions are known as crystals. A perfect crystal is the one that contains no point, linear, or planar imperfections. There are a wide variety of crystallographic defects.

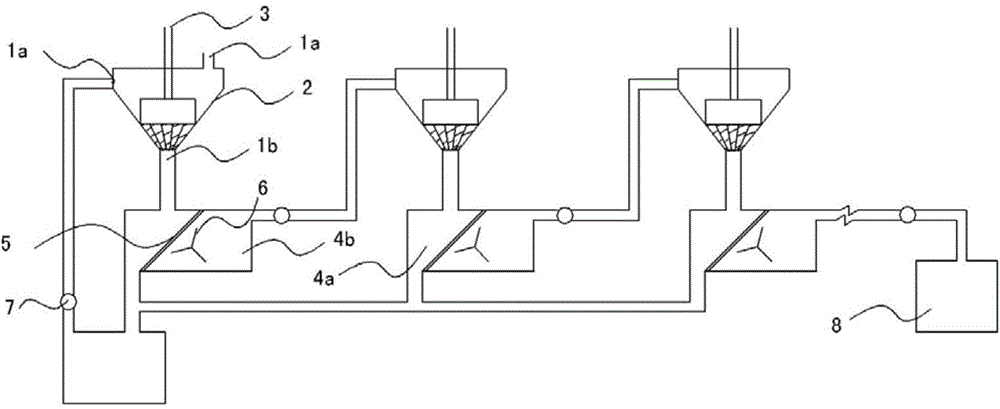

Machine-like stripping device for ton-scale production of graphene and production method of machine-like stripping device

The invention discloses a machine-like stripping device for ton-scale production of graphene and a production method of the machine-like stripping device. The machine-like stripping device is characterized by comprising one or more stages of stripping devices which are connected in series, wherein each stripping device comprises a material bin, a rotor, a material distribution bin and the like, the lower part of the rotor is matched with that of the material bin, and when the rotor rotates, relative friction is formed at the matching position between the outer surface of the rotor and the inner surface of the material bin. During use, graphite raw material receives the shearing action of a friction force at the matching position, and Van der Waals forces among graphite layers of the graphite collapse so that the graphite is stripped and thinned into graphene which is fed into the material distribution bin. The machine-like stripping device for ton-scale production of graphene is simple to operate and can realize batch production of graphene, and the obtained graphene has a perfect crystal structure, a large specific surface area and good conductivity.

Owner:合肥微晶材料科技有限公司

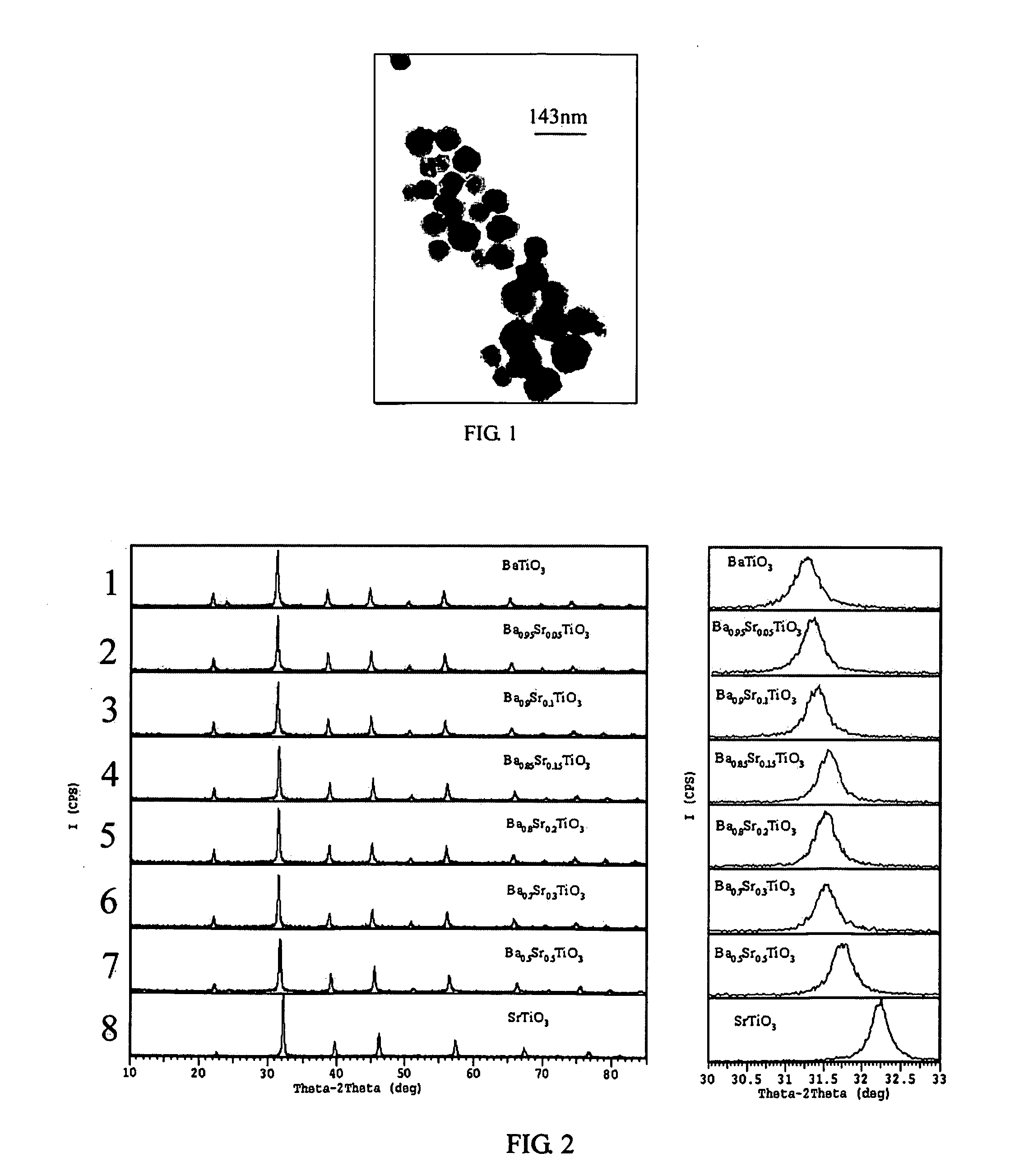

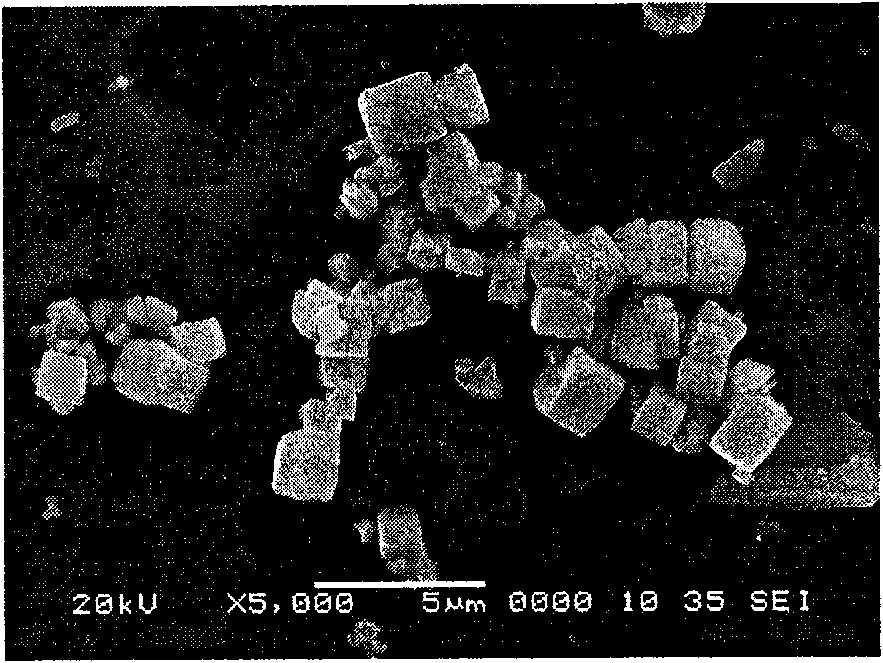

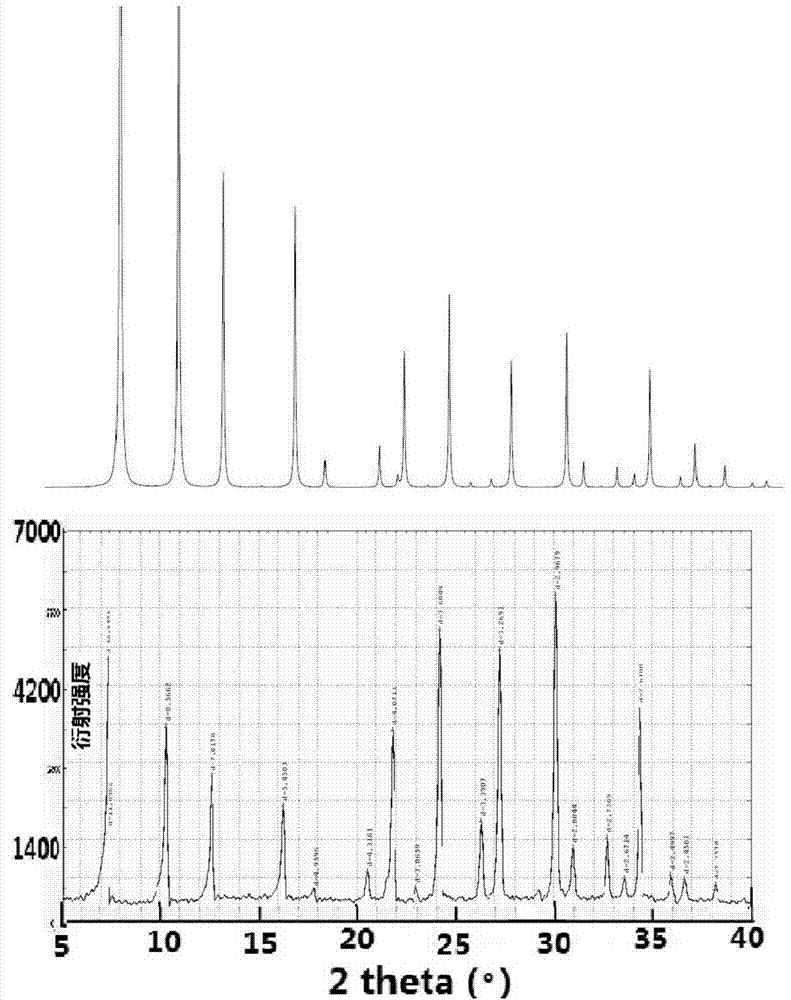

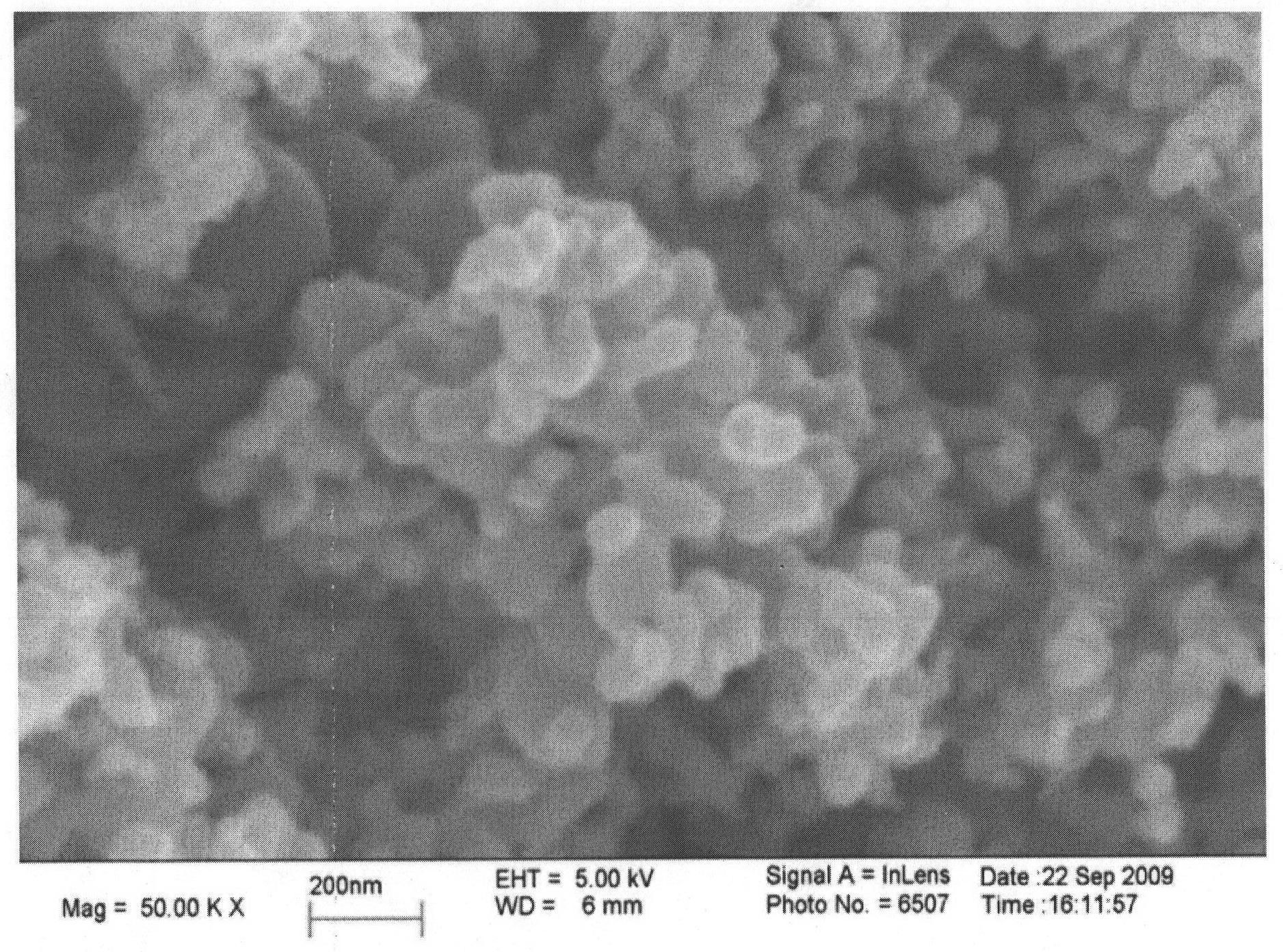

Process for preparing perovskite-type crystalline compound powders

InactiveUS20060045840A1Alkaline earth titanatesMaterial nanotechnologyRare earthParticle-size distribution

A process for preparing perovskite-type compound Ax(BO3)y powders involving reacting a solution containing A and a solution containing B, or a combined solution comprising A and B, with an alkaline solution in a high-gravity reactor at a temperature ranging from about 60° C. to about 100° C. A is one or more metal elements selected from the group consisting of Li, Na, K, Mg, Ca, Sr, Ba, Pb, Sm, La, Nd, Bi, and other rare-earth metal elements. B is one or more metal elements selected from the group consisting of Ti, Zr, Sn, Hf, Nb, Ce, Al, Zn, Mn, Co, Ni, Fe, Cr, Y, Sc, W, Ta, and the like. The resulting mixture is then filtered, rinsed and dried to obtain the desired powders. The obtained perovskite-type compound Ax(BO3)y powders have a small average particle size with a narrow particle size distribution, a perfect crystal form and a uniform particle shape, and is suitable for use as raw material for making dielectric, piezoelectric, anti-ferroelectric, pyroelectric, pressure-resisting, sensing, microwave media, and other ceramics.

Owner:BEIJING UNIV OF CHEM TECH +1

High-density spherical iron phosphate and manufacture method thereof

InactiveCN101269807AHigh crystallinityImprove crystal structurePhosphorus compoundsPhosphatePhosphoric acid

The invention relates to a high-density spherical ferric phosphate and a preparation method thereof, and preparation materials are mainly used for preparing ferrous phosphate lithium which is the anode material of a lithium ion battery. The preparation method takes an iron source and an additive as raw materials, and the raw materials are dissolved by vaal water to be made into a mixed solution A; the preparation method takes phosphate and a neutralizing agent as raw materials, and the raw materials are dissolved by the vaal water to be made into a mixed solution B. The solution A and the solution B are mixed and reacted, preparation materials are washed and parched, and the high-density spherical ferric phosphate the average grain diameter of which is 1.5-5micron, the tap density is not less than 0.95g / cm<3>, the grains are dispersed and the sizes are symmetrical is obtained. The ferrous phosphate lithium prepared by the high-density spherical ferric phosphate has perfect crystal structure, lithium ion intercalation / de-intercalation channel is normal, and the discharge capacity can reach 140mAh / g under the condition of 1C. The preparation method has simple process and is easy to technologize, and the ferrous phosphate lithium synthetized by the ferric phosphate has good crystallinity and crystal structure and can increase the electrochemical properties of the ferrous phosphate lithium.

Owner:GUANGZHOU RONGJIE MATERIAL TECH

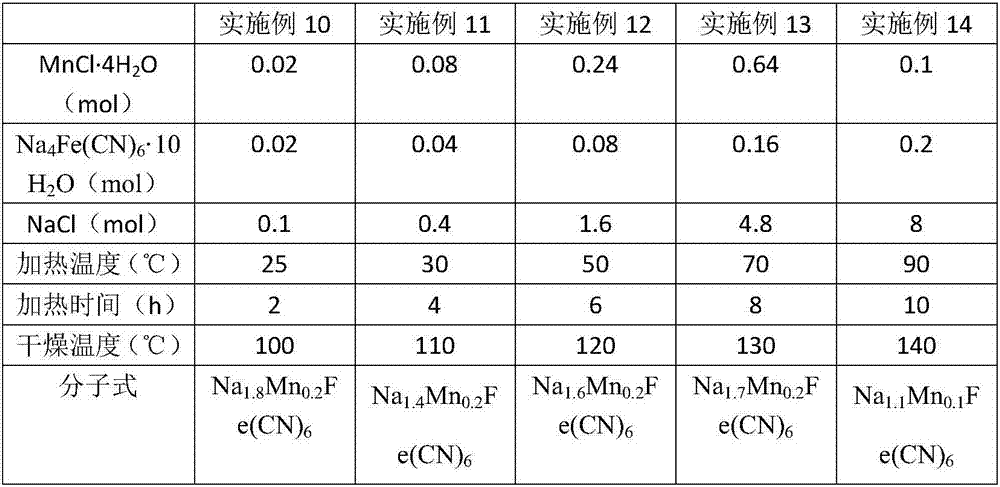

Prussian blue positive electrode material and sodium ion battery

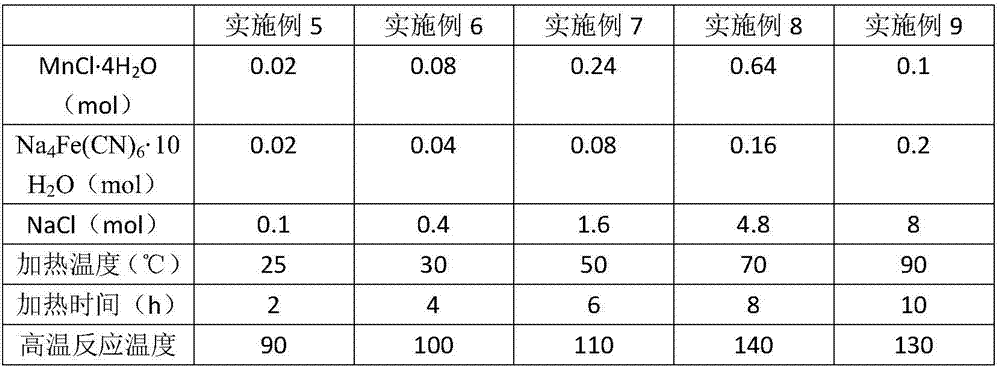

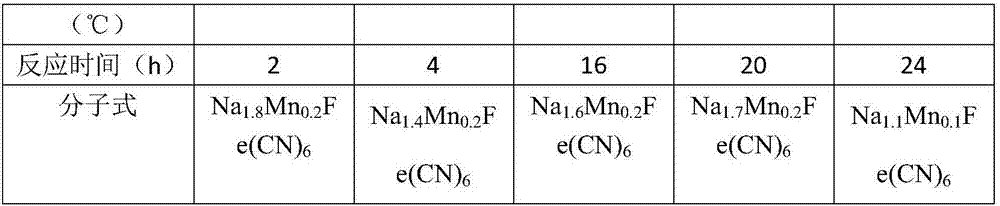

InactiveCN107364874AImprove crystal structureFew defectsIron cyanidesCell electrodesSodium-ion batteryHigh pressure

The invention discloses a Prussian blue positive electrode material and a sodium ion battery. The preparation method comprises that the salt solution of M creeps to the mixed solution of Na4Fe(CN)6 and a sodium salt, the obtained solution is heated in a protective atmosphere to obtain a Prussian blue intermediate, the intermediate solution is transferred into a high-pressure reaction kettle, and a heating reaction is performed at a certain temperature to obtain the Prussian blue positive electrode material, or the intermediate solution is subjected to high-temperature spray drying to obtain the Prussian blue material powder. According to the present invention, through the high-temperature and normal pressure reaction and the high-pressure and high-pressure heating reaction, the prepared material has advantages of perfect crystal structure, less defect and low water content, and can improve the specific capacity and the stability of the battery in the application as the sodium ion battery positive electrode material; and the preparation method is simple, and is suitable for continuous large-scale production.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

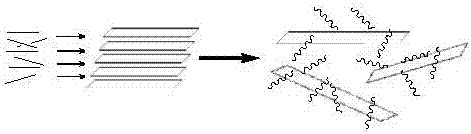

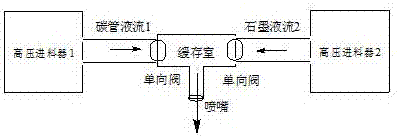

Preparation and dispersion method and equipment of graphene/carbon nanotube composite conductive paste

InactiveCN107317034ASimple preparation processImproved rate cycle performanceCell electrodesSecondary cellsConductive pasteCarbon nanotube

The invention belongs to the technical field of a lithium ion battery conductive agent, and relates to a preparation method of graphene / carbon nanotube composite conductive paste. The preparation method comprises the following steps of S1, dispersing a dispersing agent in a solvent, adding and uniformly stirring carbon nanotubes, and performing initial grinding and dispersing to form a carbon nanotube dispersion liquid A; S2, dispersing the dispersing agent in the solvent, adding graphene, and performing per-dispersion processing, namely, mechanical stirring is performed until uniform stirring is achieved, and cutting and dispersing are performed by a high-speed cutting machine to form a graphite dispersion liquid B; and S3, clashing two stands of high-voltage liquids of the carbon nanotube dispersion liquid A and the graphite dispersion liquid B in clash equipment in a coaxial opposite runner, namely, the two strands of liquids of the carbon nanotube dispersion liquid A and the graphite dispersion liquid B are combined, a linear carbon tube is embedded into graphene sheet layers to form a carbon tube insertion-layer graphite middle body, extremely high pressure difference (reach 3,000bar) is instantaneously formed when the liquid is released from a nozzle, so that graphite is exploded to form perfect crystal-structure graphene, and meanwhile, the carbon tubes are uniformly arranged on a surface of the graphene to form the graphene / carbon nanotube composite conductive paste C.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD

Production method for silicon single crystal and production device for single crystal ingot, and heat treating method for silicon crystal wafer

InactiveUS7141113B1Stable supplyQuality improvementPolycrystalline material growthAfter-treatment detailsSingle crystalIngot

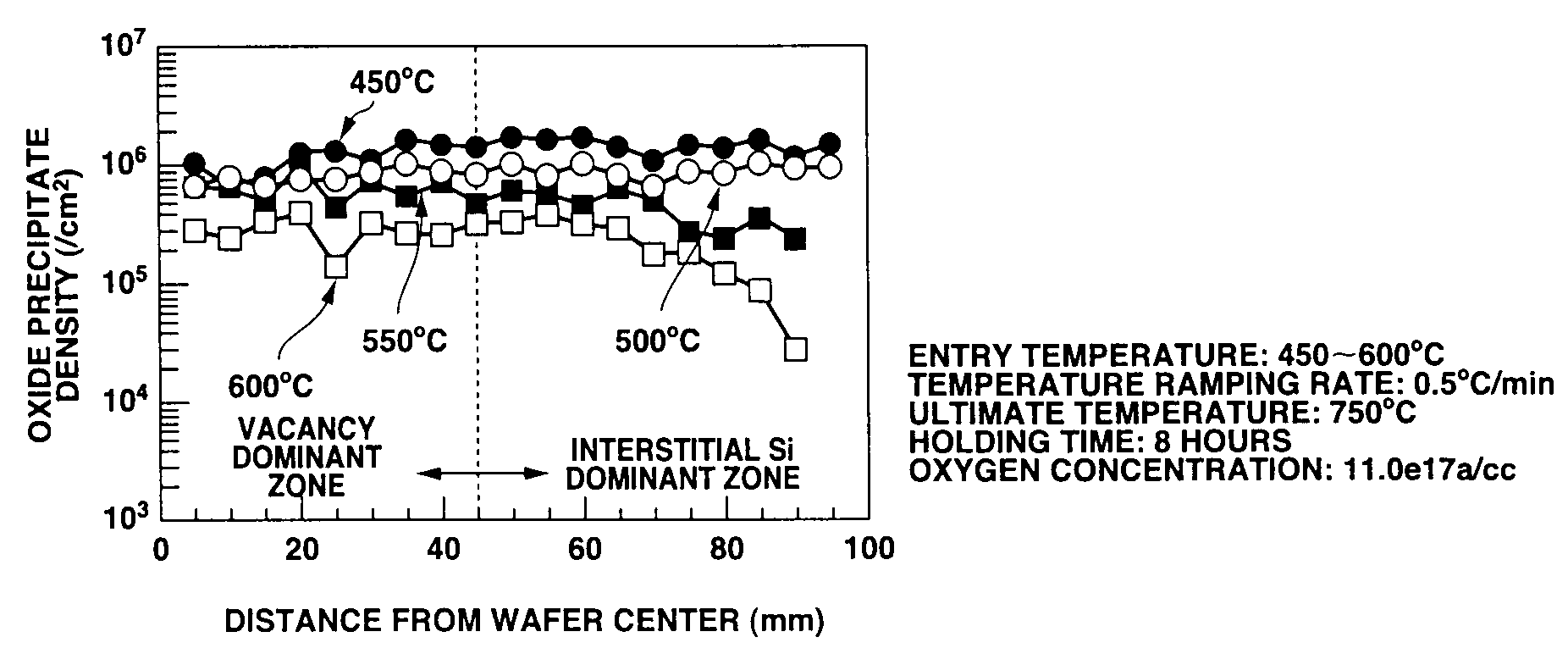

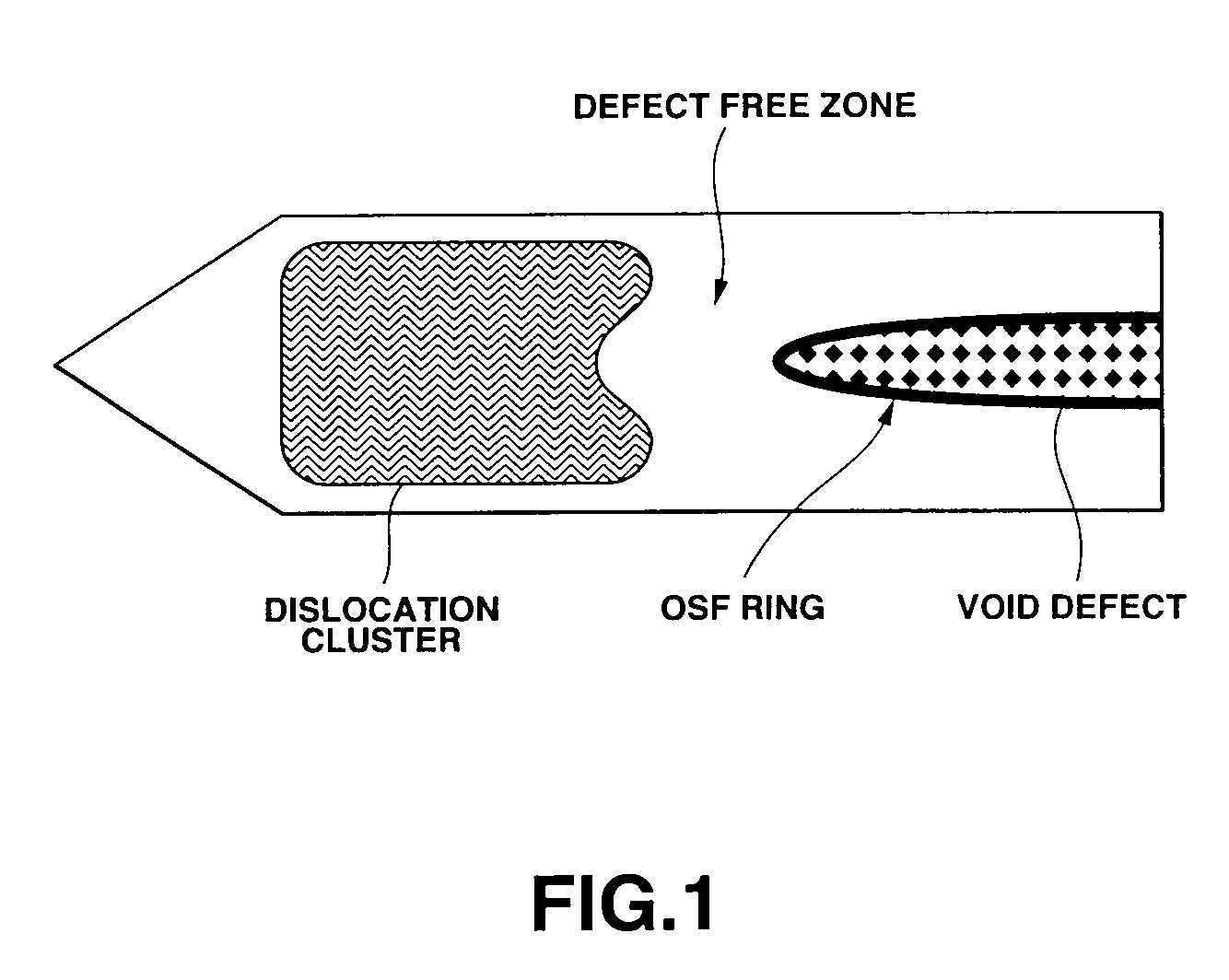

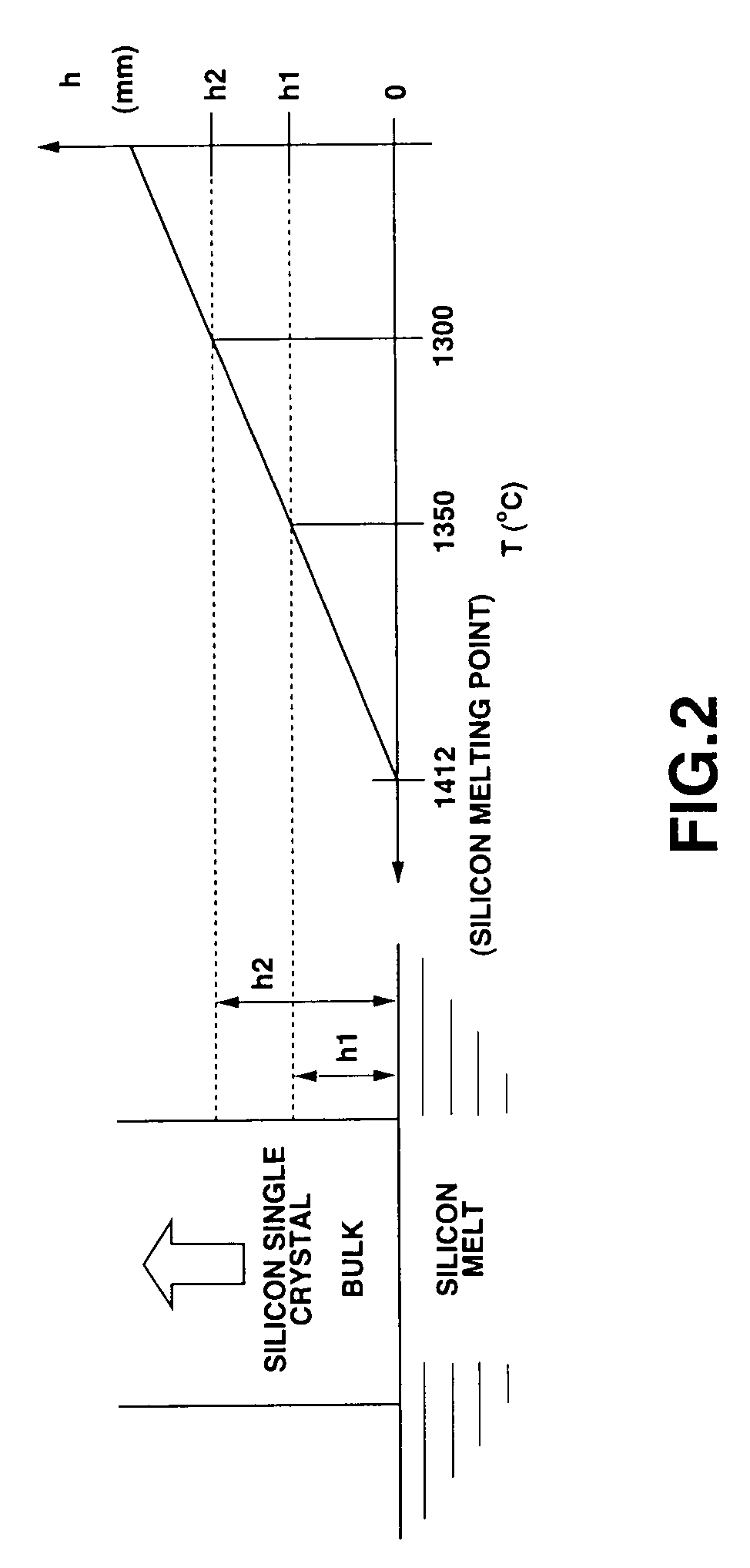

A method for growing a silicon crystal by a Czochralsky method, wherein, let a pulling speed be V (mm / min) and an average value of an in-crystal temperature gradient in a pulling axis direction within a temperature range, a silicon melting point to 1350° C., be G (° C. / mm), V / G ranges from 0.16 to 0.18 mm2 / ° C. min between a crystal center position and a crystal outer periphery position, and a ratio G outer / G center of an average value G of an in-crystal temperature gradient in a pulling axis direction within a temperature range, a silicon melting point to 1350° C., at a crystal outer surface to that at a crystal center is set to up to 1.10 to thereby obtain a high-quality perfect crystal silicon wafer. Such a perfect crystal silicon wafer, wherein an oxygen concentration is controlled to up to 13×1017 atoms / cm3, an initial heat treatment temperature is at least up to 500° C. and a temperature is raised at up to 1° C. / min at least within 700 to 900° C., thereby making uniform a wafer radial distribution to an arbitrary oxygen precipitation density level.

Owner:SUMCO TECHXIV

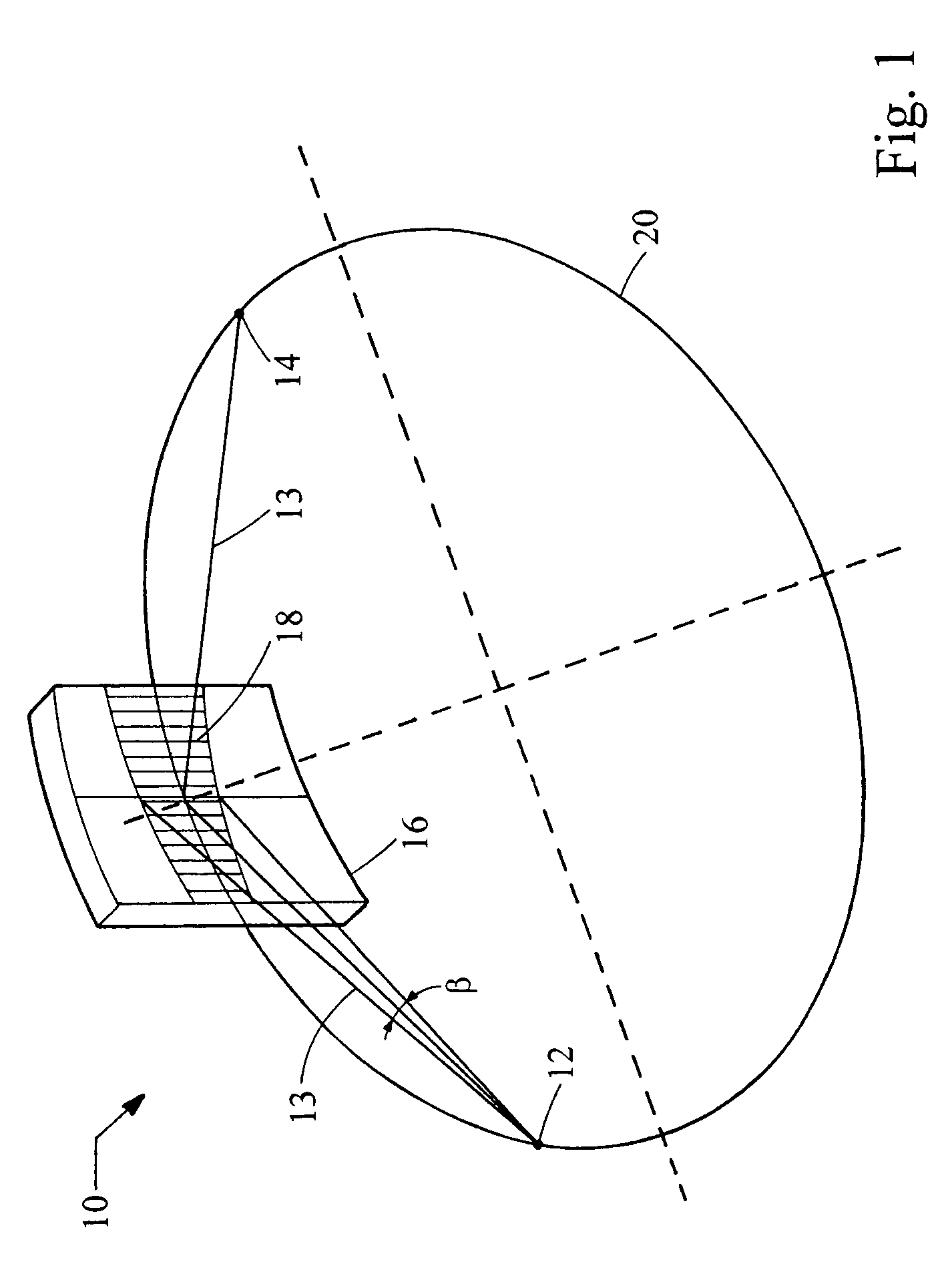

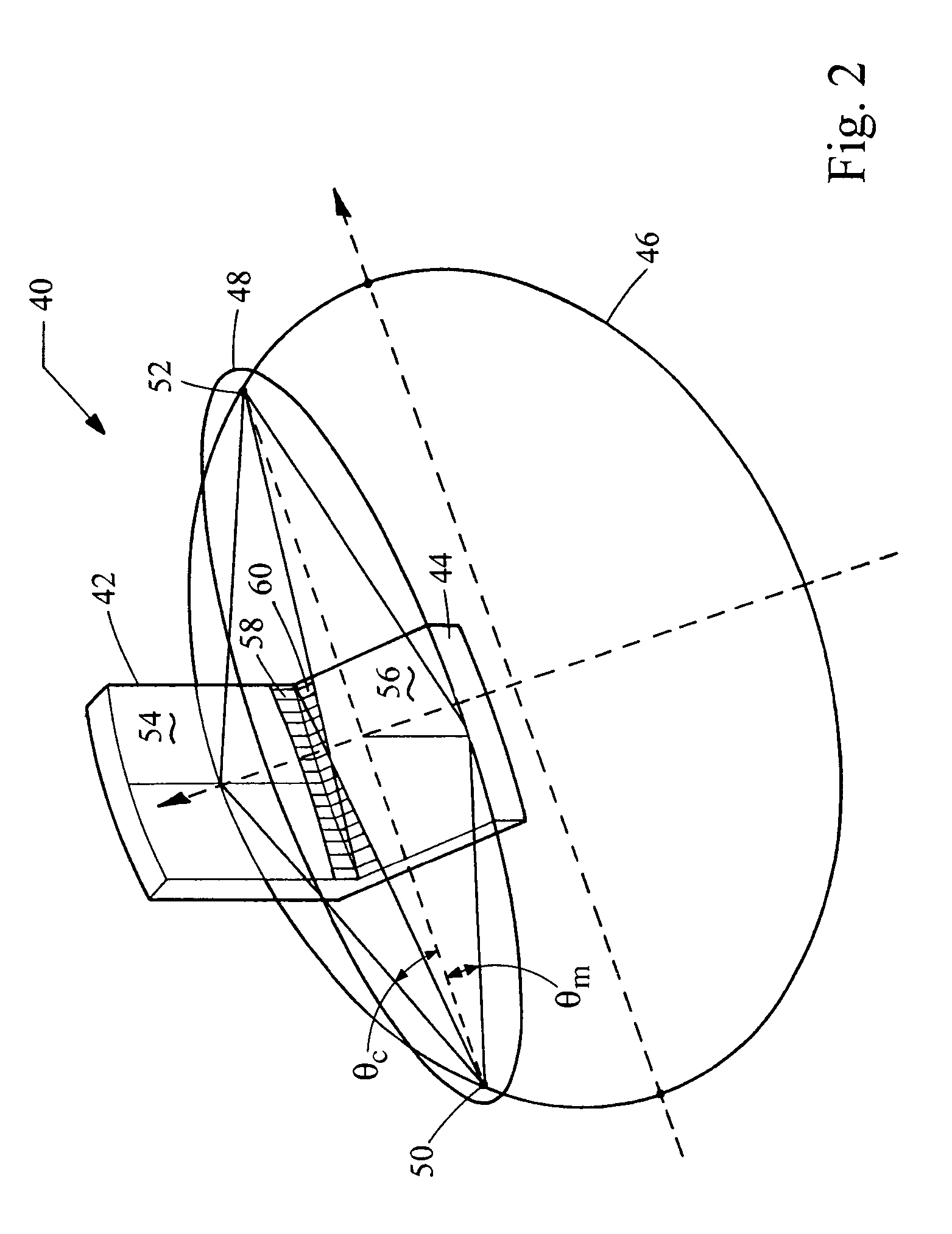

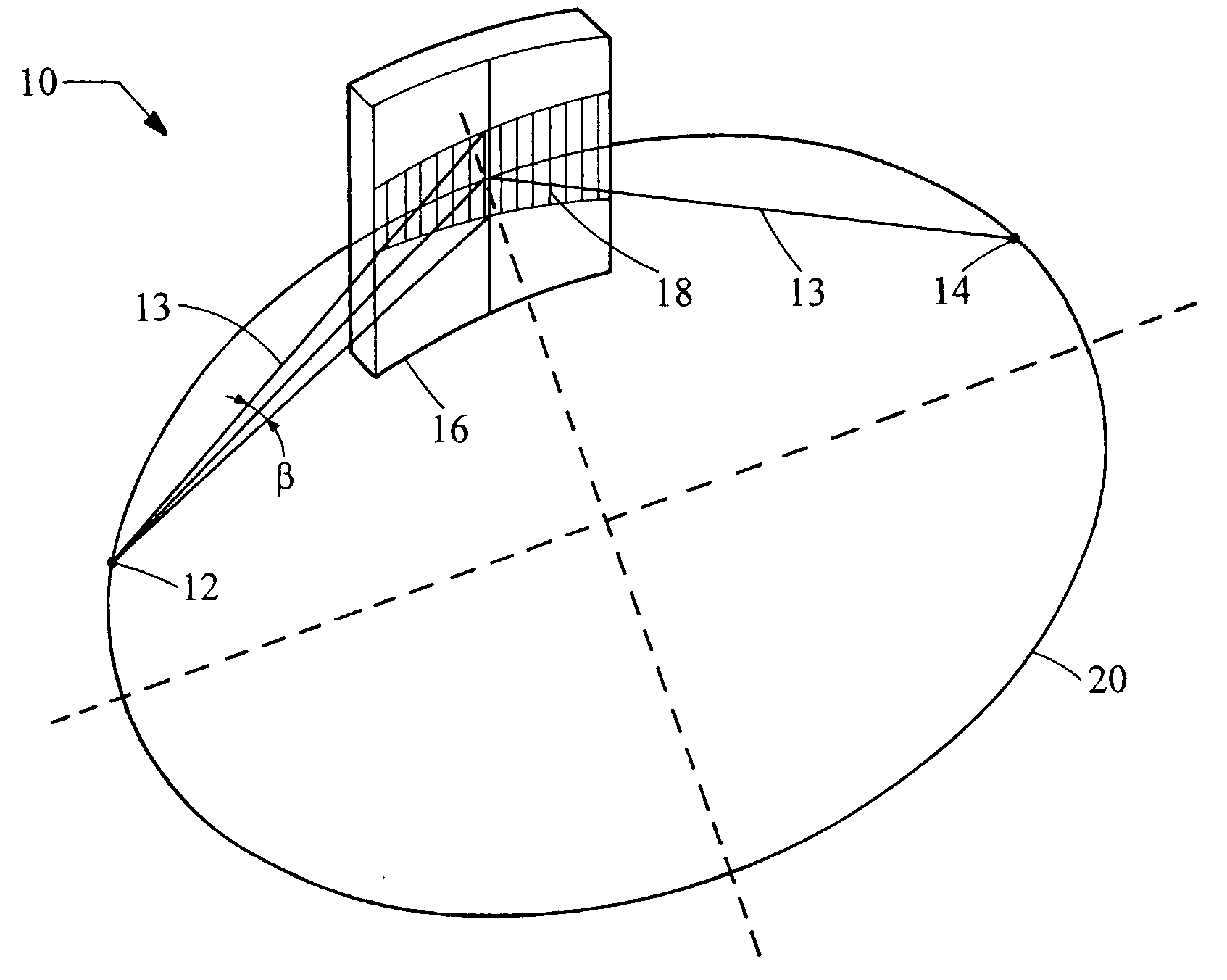

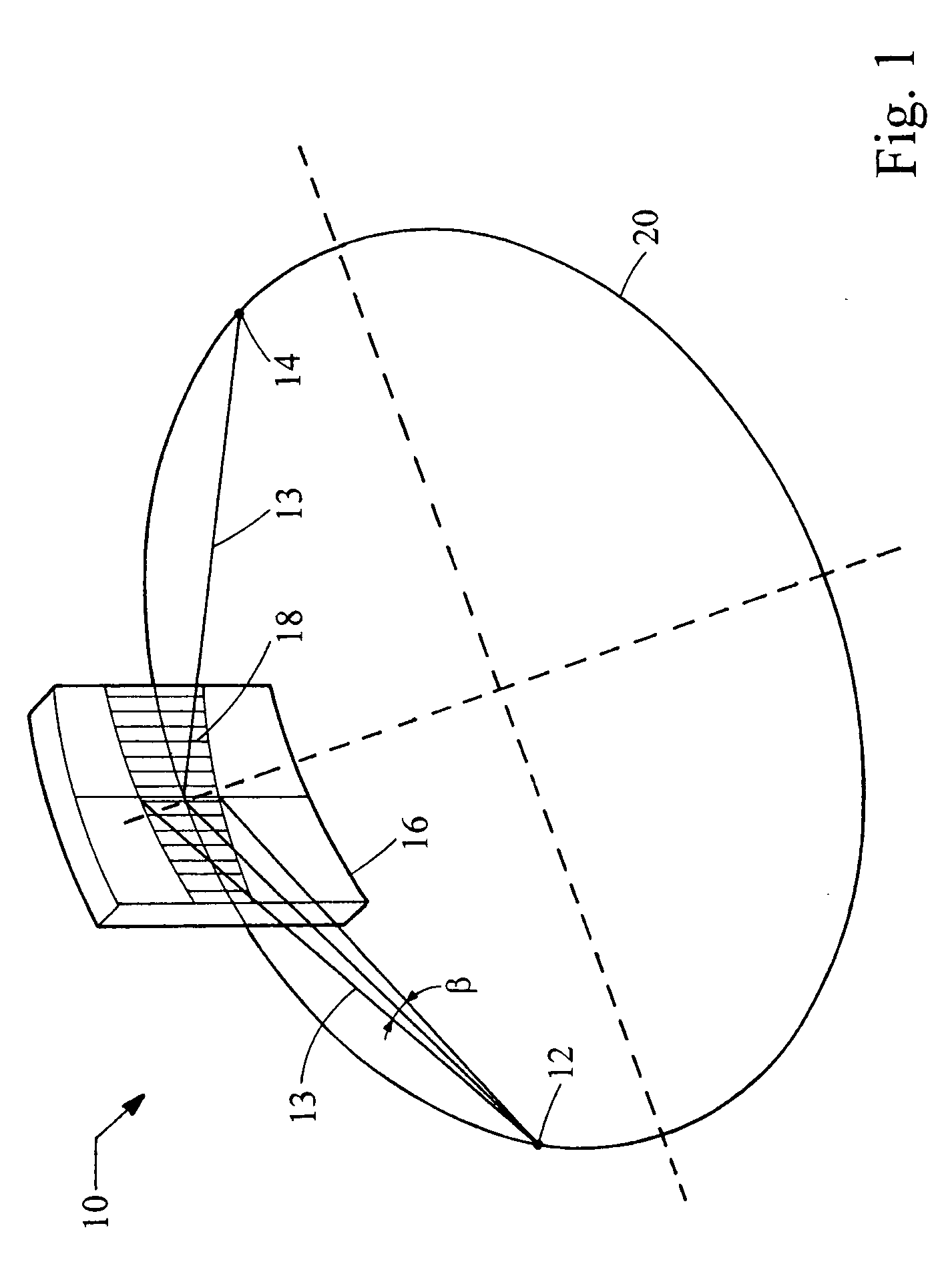

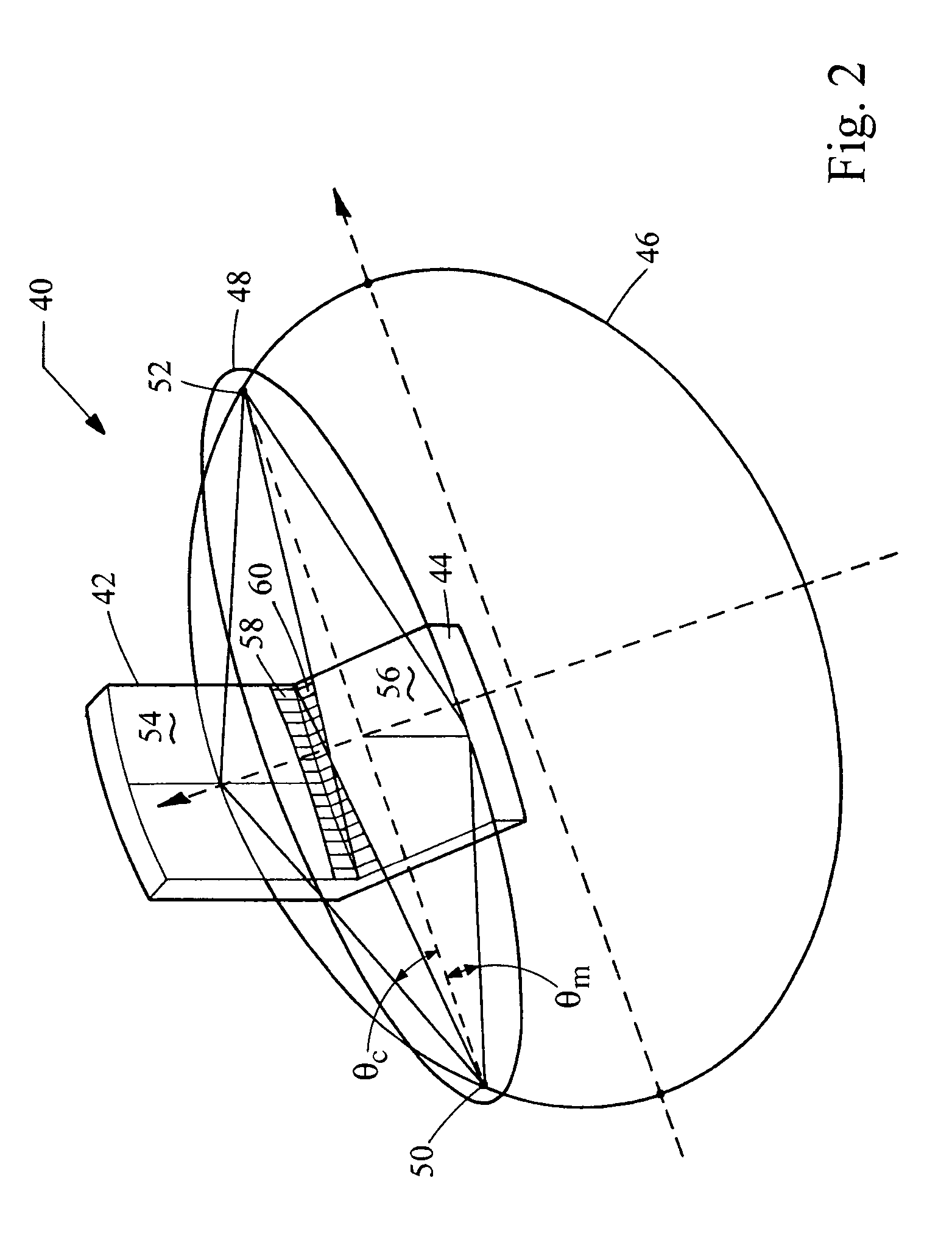

Beam conditioning system

ActiveUS7076026B2NanoinformaticsHandling using diffraction/refraction/reflectionLight beamOptoelectronics

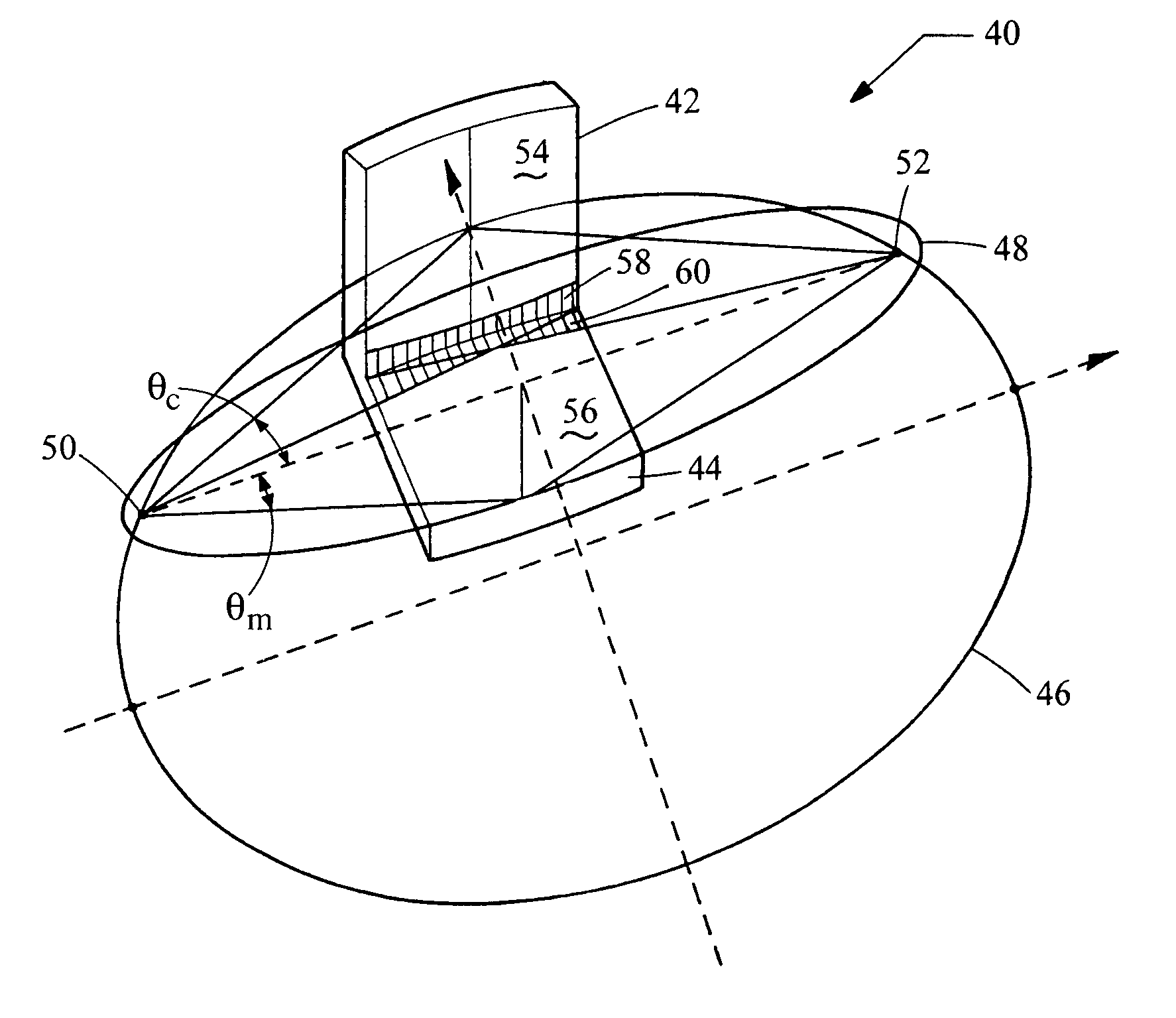

The present invention provides an x-ray beam conditioning system with a Kirkpatrick-Baez diffractive optic including two optical elements, of which one of the optical elements is a crystal. The elements are arranged in a side-by-side configuration. The crystal can be a perfect crystal. One or both diffractive elements can be mosaic crystals. One element can be a multilayer optic. For example, the multilayer optic can be an elliptical mirror or a parabolic mirror with graded d-spacing. The graded d-spacing can be either lateral grading or depth grading, or both.

Owner:OSMIC INC

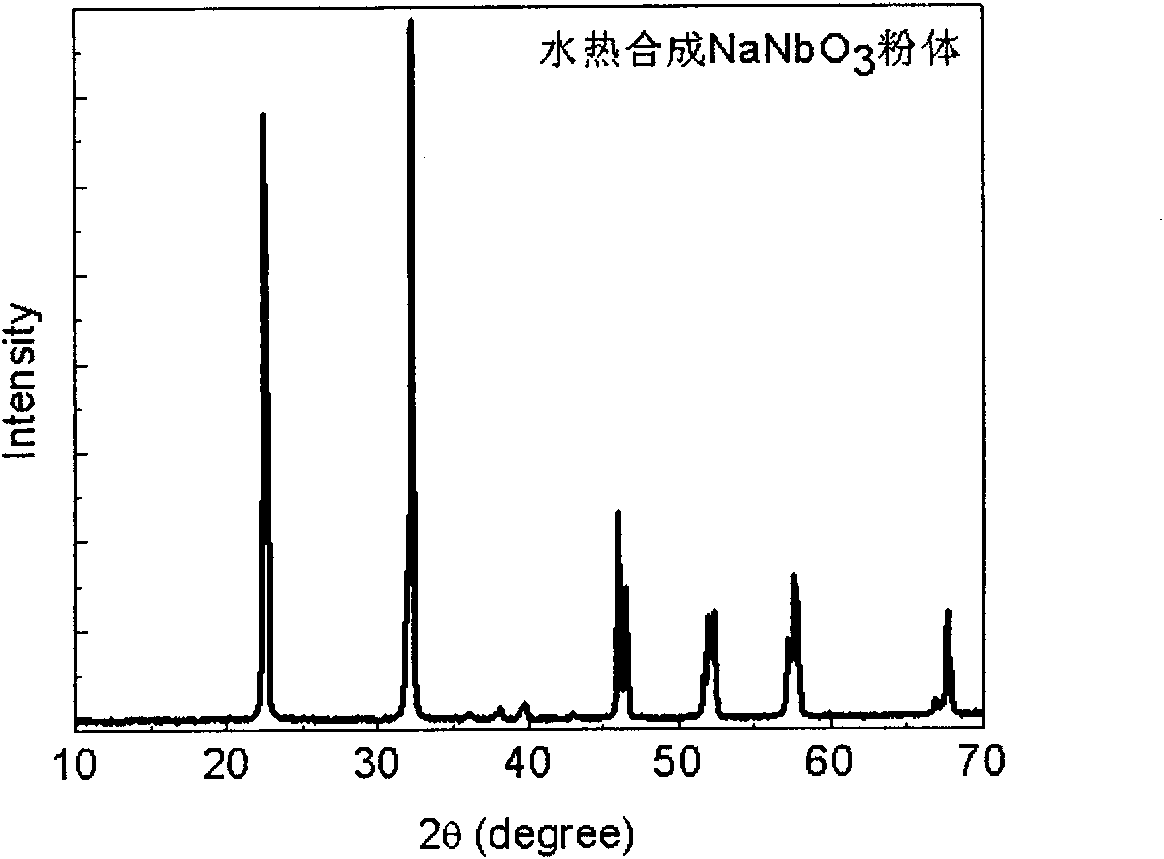

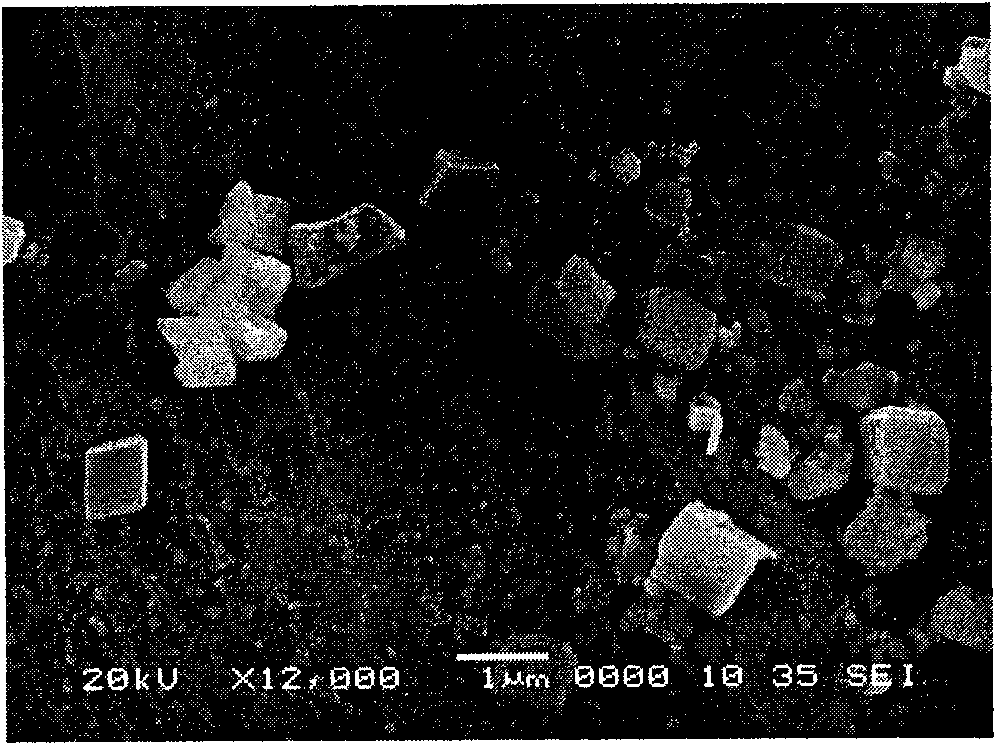

Hydrothermal synthesis method for sodium niobate powder

The invention discloses a hydrothermal synthesis method for sodium niobate powder, which comprises the following steps: putting niobium pentaoxide and sodium hydroxide in a molar ratio of 0.05-10 into an autoclave, and adding deionized water into the autoclave according to a filling rate between 50 and 90 percent to adjust the concentration of the sodium hydroxide to between 0.1 and 15 mol / L; sealing the autoclave, putting the autoclave into a pit furnace or an oven, raising the temperature to between 120 and 240 DEG C in a temperature rise rate of 1 to 5 DEG C per minute, preserving heat for 4 to 72 hours, and then cooling along with the furnace; and taking out and opening the autoclave, pouring an obtained product into a beaker, repeatedly filtering and washing with deionized water until the washed solution is neutral, putting obtained powder into an oven, and baking at a temperature of between 40 and 100 DEG C for 6 to 24 hours. The method is simple, saves energy, reduces emission, has low cost, and is suitable for mass production; and the prepared sodium niobate powder has high purity, good fluidity, narrow particle size distribution, low degree of particle agglomeration, and perfect crystal growth.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Beam conditioning system

ActiveUS20050025281A1NanoinformaticsHandling using diffraction/refraction/reflectionLight beamOptoelectronics

The present invention provides an x-ray beam conditioning system with a Kirkpatrick-Baez diffractive optic including two optical elements, of which one of the optical elements is a crystal. The elements are arranged in a side-by-side configuration. The crystal can be a perfect crystal. One or both diffractive elements can be mosaic crystals. One element can be a multilayer optic. For example, the multilayer optic can be an elliptical mirror or a parabolic mirror with graded d-spacing. The graded d-spacing can be either lateral grading or depth grading, or both.

Owner:OSMIC INC

Method for preparing nano metal oxides and nano metal powder

ActiveCN108128815AReunion inevitableEffective isolationMaterial nanotechnologyTransportation and packagingDecompositionPotassium

The invention discloses a method for preparing nano metal oxides and nano metal powder. The method comprises the steps that: nano potassium sulphate is used for dispersing and isolating metal oxide precursor particles in xylene, a drying material is subjected to high-temperature calcination and decomposition after centrifugal precipitation, after washing, the dispersed nano metal oxides can be obtained, and the calcined product is secondarily calcined in a reducing atmosphere and the dispersed nano metal powder can be obtained after water washing. The method for preparing the nano metal oxidesand the nano metal powder can rapidly prepare nano metal oxides or nano metal powder with good dispersion and perfect crystals in batch.

Owner:SOUTHEAST UNIV

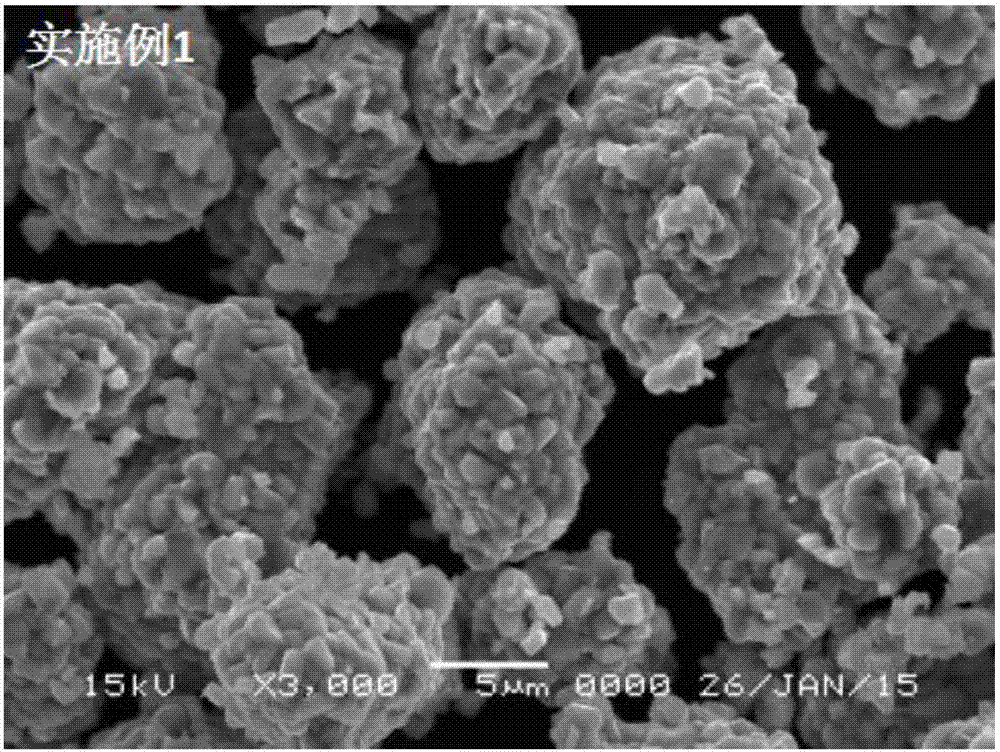

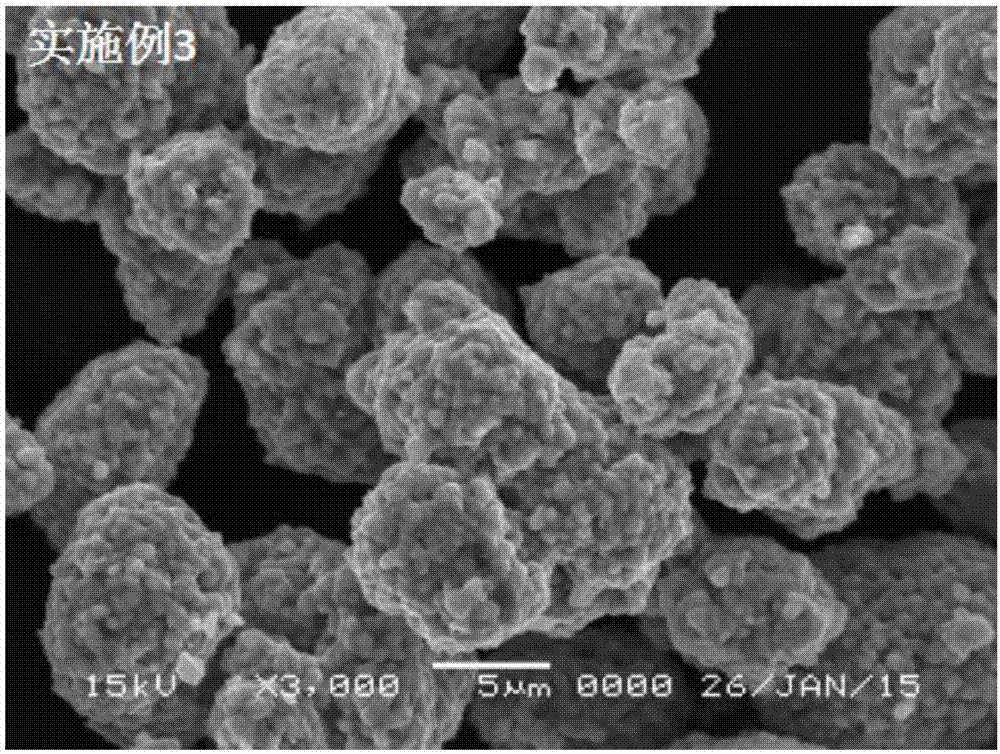

Nickel cobalt lithium aluminate positive electrode material as well as preparation method and application thereof

ActiveCN107403930ALow free lithium contentShape is easy to controlCell electrodesSecondary cellsPower batteryCrystal structure

The invention relates to a nickel cobalt lithium aluminate positive electrode material as well as a preparation method and application thereof. The positive electrode material has a chemical formula of LixNiaCobAlcMdO2, wherein x is greater than or equal to 0.95 but smaller than or equal to 1.06; a is greater than or equal to 0.80 but smaller than or equal to 0.82; b is greater than or equal to 0.09 but smaller than or equal to 0.17; c is greater than or equal to 0.01 but smaller than or equal to 0.06; d is greater than or equal to 0 but smaller than or equal to 0.03; the sum of the a, the b and the c is 1.0 to 1.03; M is a doping element; the content of free lithium ions in the positive electrode material is lower than 0.1 weight percent of the positive electrode material. The positive electrode material is prepared through work procedures of mixing raw materials containing nickel cobalt aluminum precursors and lithium salts, performing high-temperature crushing at 300 to 400 DEG C and performing sintering, crushing and the like. The preparation process has the advantages that the material selection is wide; the production intensity is high; the physical diffusion is uniform, and the like. The preparation process can be widely used in positive electrode material production. The positive electrode material prepared by the method has the characteristics of low free lithium content, perfect crystal structure, high specific capacity and the like. Compared with the existing positive electrode material, the positive electrode material prepared by the technology provided by the invention shows the excellent electrochemical performance; the power battery energy density improvement, the service life prolonging and the like are facilitated.

Owner:湖南金富力新能源股份有限公司

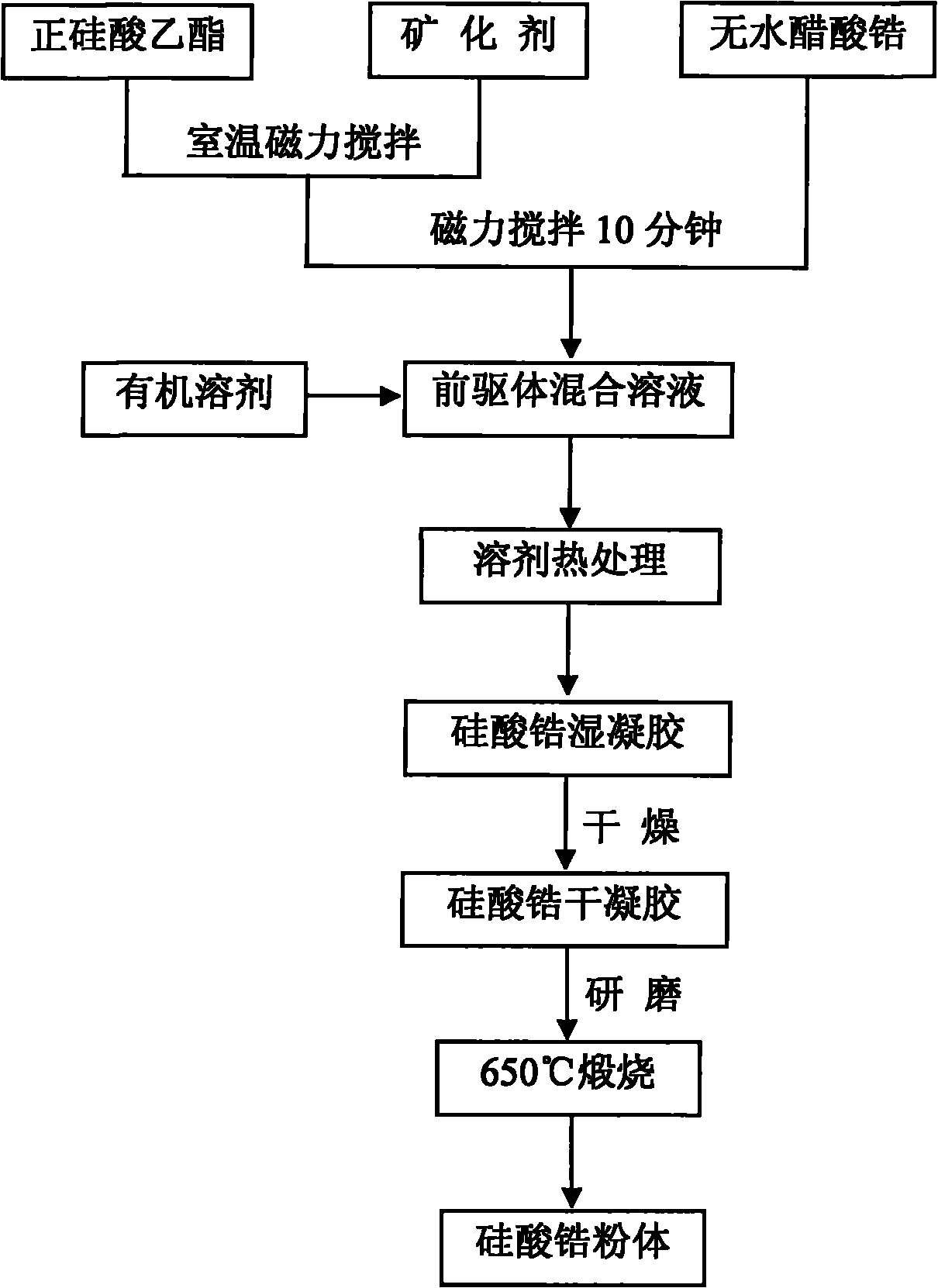

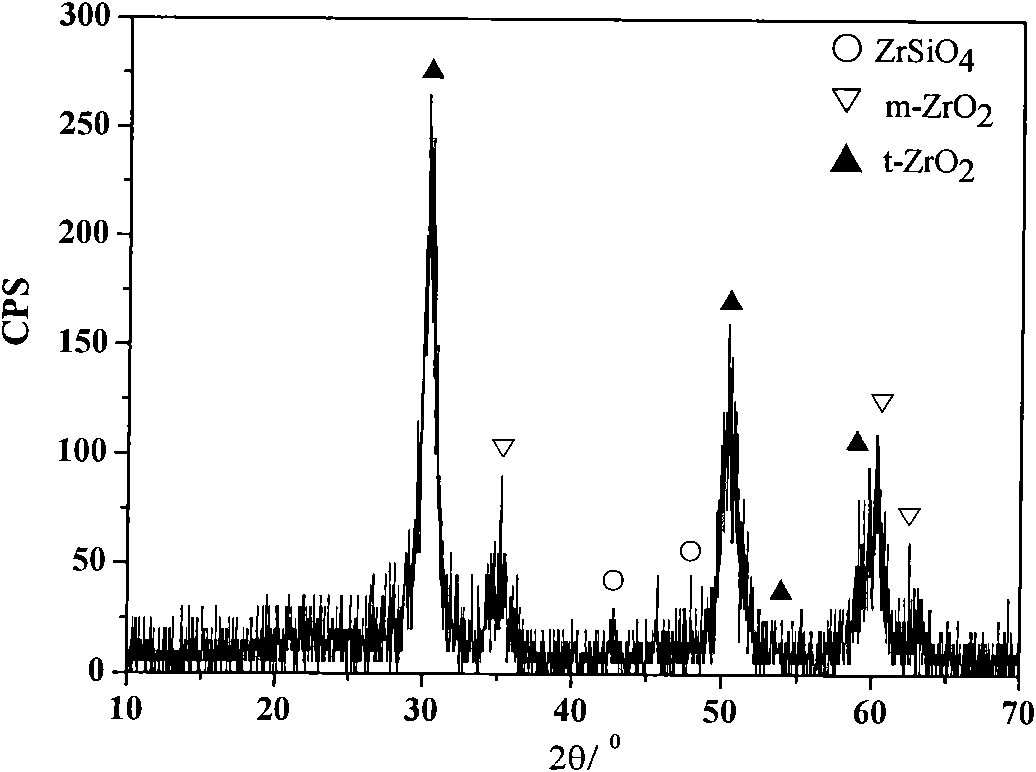

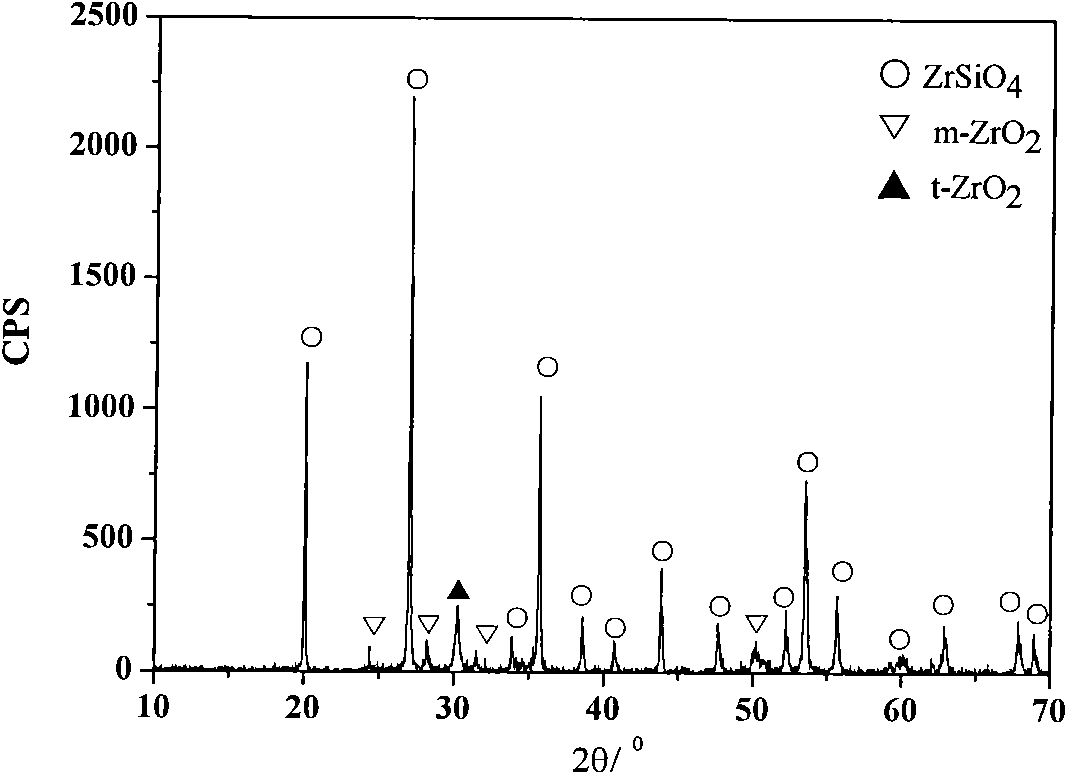

Method for low-temperature synthesis of zirconium silicate powder through non-hydrolytic sol-gel reaction by using zirconium acetate as zirconium source

The invention discloses a method for the low-temperature synthesis of zirconium silicate powder through non-hydrolytic sol-gel reaction by using zirconium acetate as a zirconium source. The method comprises the following steps of: by using ethyl orthosilicate and anhydrous zirconium acetate as precursors, LiF or MgF2 as a mineralizer, and chloroalkane or anhydrous lower alcohol as a solvent, mixing the precursors, the mineralizer and the solvent in proportion to prepare precursor mixed solution; feeding the solution into a hydrothermal synthesis reactor to perform the thermal treatment to form a zirconium silicate solid wet gel; and drying, grinding and sintering the zirconium silicate solid wet gel at the temperature of 650 DEG C to obtain the zirconium silicate powder with less powder agglomeration and perfect crystal form growth. The method has the advantages of further reducing the synthesis temperature of zirconium silicate and avoiding the emission of HCl corrosive gas along with simple process and convenient operation.

Owner:JINGDEZHEN CERAMIC INSTITUTE

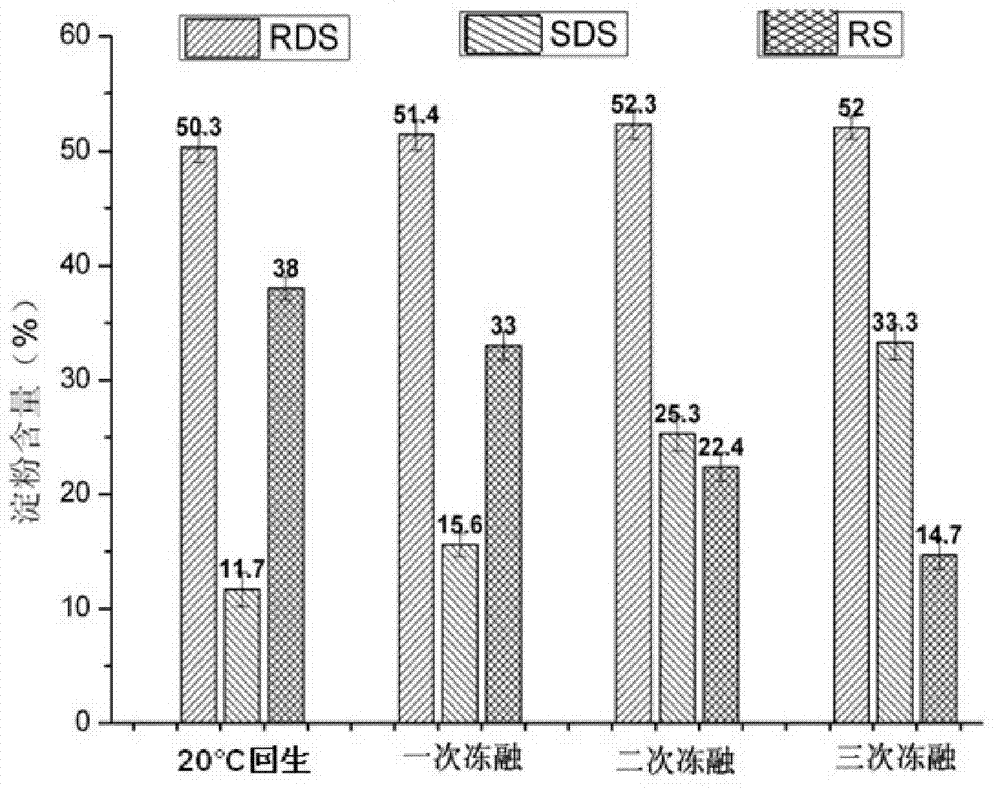

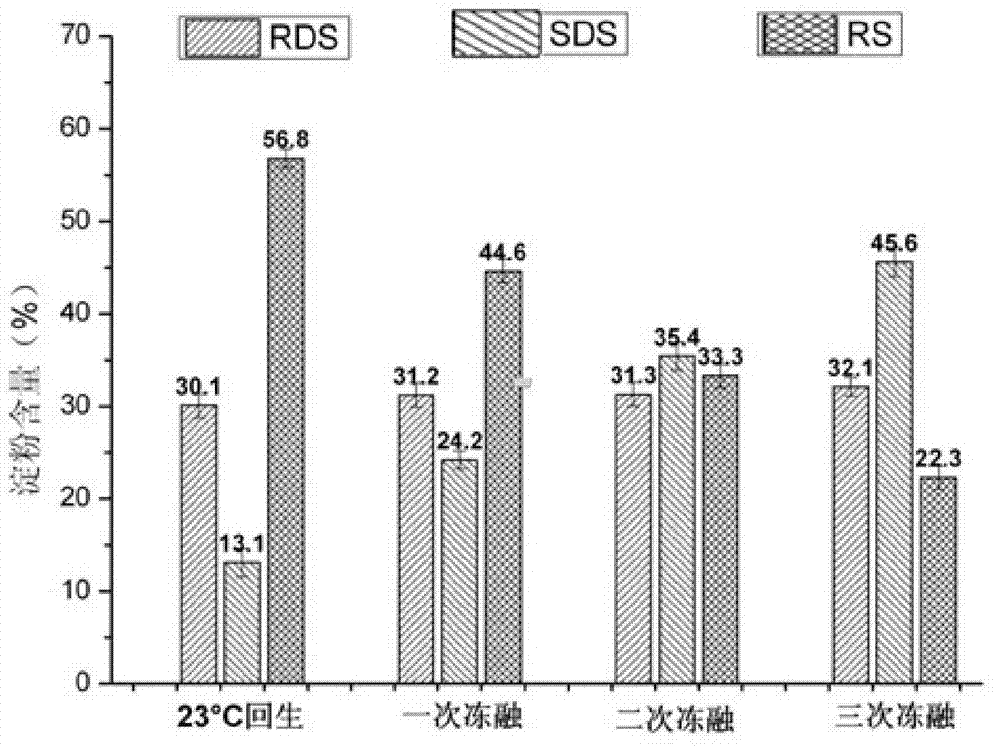

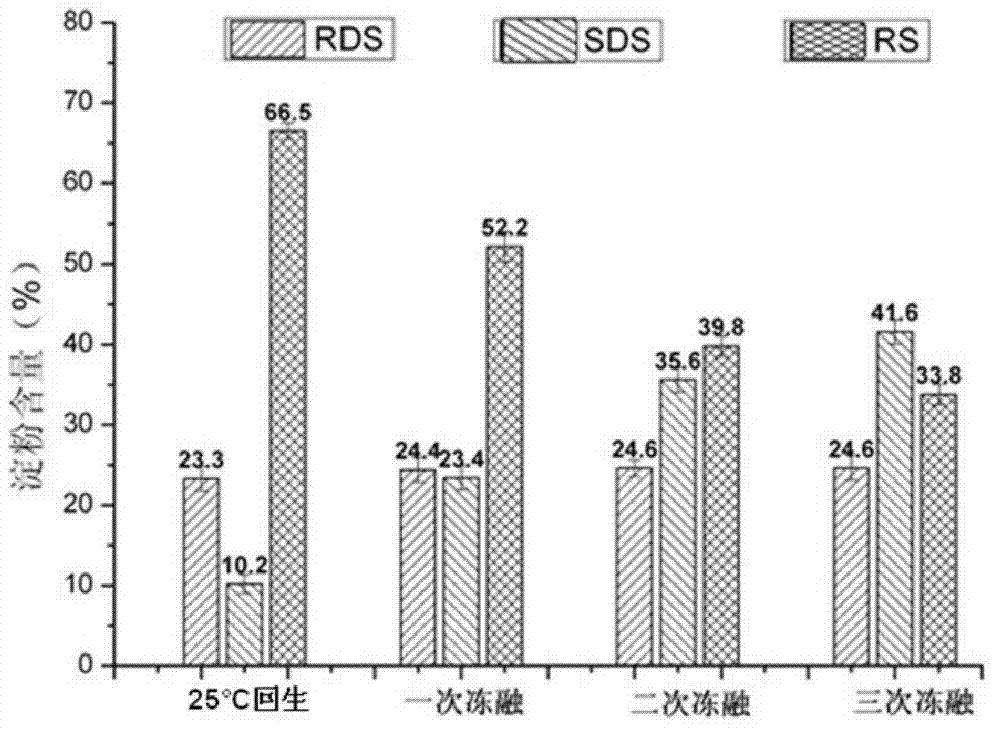

Method for preparing slowly digestible wheat starch through coordination of biological enzyme and low-temperature freeze-thawing

The invention discloses a method for preparing slowly digestible wheat starch through the coordination of a biological enzyme and low-temperature freeze-thawing, which comprises the following steps: performing debranching treatment on starch through a biological enzyme method; forming a structure the most of which is in the form of a compact perfect crystal under retrogradation action; and performing low-temperature repeated freeze-thawing treatment to destroy the perfect crystal of the starch so as to form a structure the most of which is in the form of an imperfect crystal, thus increasing content of the slowly digestible starch. The slowly digestible starch content in the slowly digestible wheat starch is no less than 30%; and after high-temperature cooking (at 100 DEG C), the residual content of the slowly digestible starch is up to 95% or above. Thus, the slowly digestible wheat starch is especially suitable for being developed into a food for diabetics, has the characteristics of stable property, high safety, low blood sugar generation index, high glucose utilization rate and the like, and is easy to realize industrial production.

Owner:HEFEI UNIV OF TECH

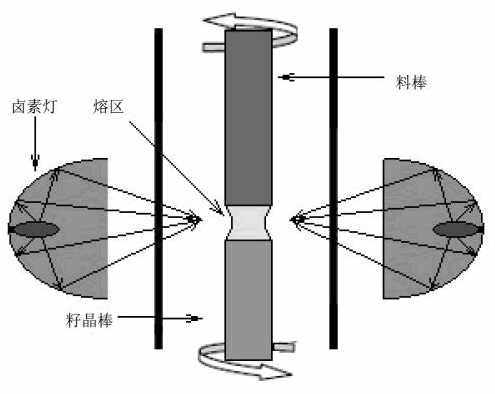

Method for growing RFeO3 photomagnetic function crystal by secondary melting method

InactiveCN102011188AQuality improvementImprove the finishPolycrystalline material growthBy zone-melting liquidsCzochralski methodPhysical chemistry

The invention relates to the field of research on growth of RFeO3 photomagnetic function crystal, an optical floating zone secondary melting method is a brand new and efficient growth method for the materials at present. In the method, high-purity ferric oxide and rare earth oxide are used as raw materials to prepare a material bar through processes of milling, sintering, isostatic pressing and the like according to chemical proportion, and then, the material bar is placed in an optical floating zone furnace to grow in air atmosphere. A surface of a single crystal prepared by the method has ideal surface finish, density and uniformity, a characteristic peak of the single crystal is obviously increased, and FWHM is obviously reduced, so that crystallization quality of the crystal is greatly improved, a pure-phase integral RFeO3 crystal can be obtained more easily; simultaneously, the method has high efficiency and can appropriately adjust growth speed in a rang of 1-9mm / h according to different application goals, that is unachievable to traditional methods, such as a pulling method, a hydrothermal method, a descending method and the like.

Owner:SHANGHAI UNIV

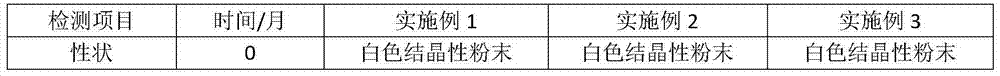

Cefuroxime sodium powder preparation for injection

ActiveCN104771372ALess impuritiesImprove stabilityAntibacterial agentsOrganic active ingredientsSodium acetateFiltration

The present invention discloses a cefuroxime sodium powder preparation for injection. The preparation is prepared by the following steps: (1) preparing a sodium acetate solution by dissolving sodium acetate with a solvent for standby; (2) adding the solvent and water, and adding cefuroxime acid with stirring until complete dissolution; adding activated carbon, decolorizing, filtering, mixing with the solvent, washing the residue and a filter bottle, and filling a crystallization tank with the filtrate; (3) applying the particle process morphology and molecular assembly process crystal product molecular assembly and shape-state optimization technology by Hebei Huamin Pharmaceutical Co. Ltd. of North China Pharmaceutical Co. Ltd., controlling the temperature and stirring speed, and dropwise adding sodium acetate solution; and adding a solvent agent according to the flow rate; (4) carrying out pumping filtration, washing, vacuum drying, weighing, and packing; and 5) packing the preparations in different specifications to obtain the cefuroxime sodium for injection. The cefuroxime sodium powder prepared by the method has the advantages of excellent hydrodynamic performance, perfect crystal shape, uniform particle size distribution, and greatly improved color grade, clarification, purity and stability.

Owner:NORTH CHINA PHARMA HEBEI HUAMIN PHARMA

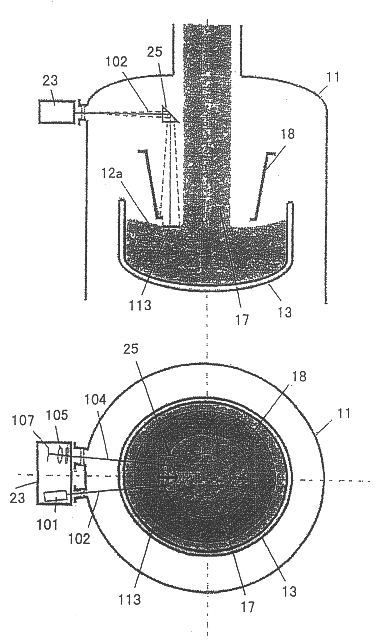

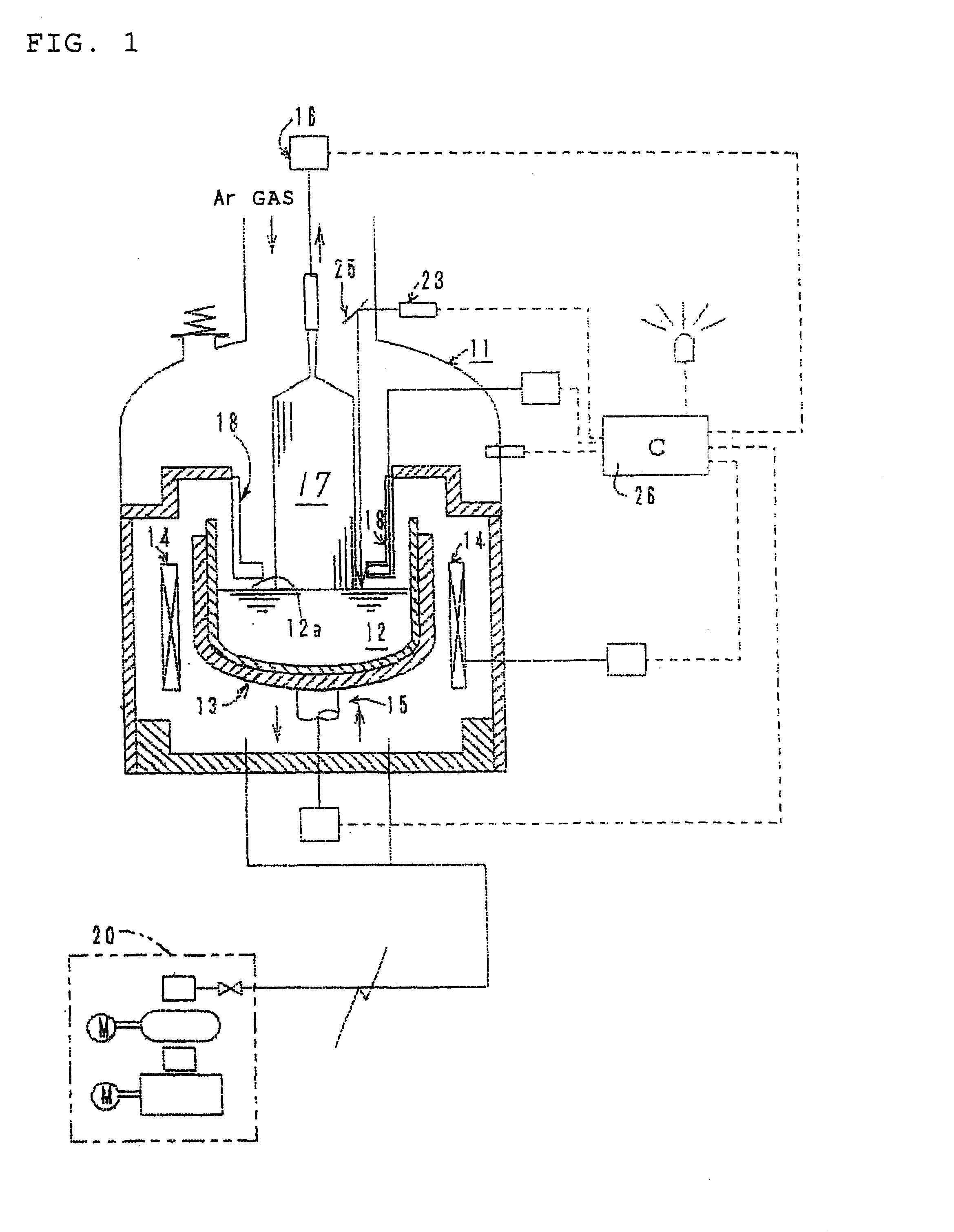

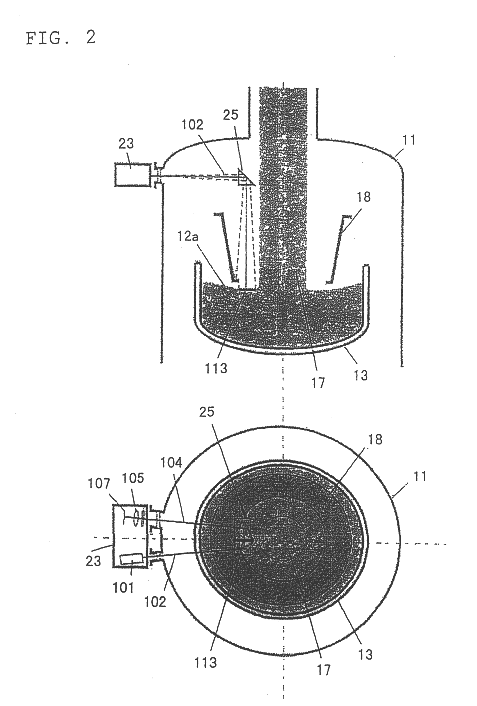

System for manufacturing a single-crystal ingot employing czochralski technique, and method of controlling the system

InactiveUS6458203B1Increase ratingsIncrease temperaturePolycrystalline material growthSemiconductor/solid-state device manufacturingSingle crystalIngot

There are provided a CZ system for manufacturing a single-crystal ingot, which produces a perfect crystal with good reproducibility through growth of a single-crystal ingot, as well as a method of manufacturing the single-crystal ingot. A system of manufacturing a single-crystal ingot by pulling a single-crystal ingot from molten raw material by means of a Czochralski technique, the system including measurement means for measuring the distance between the level of molten raw material and the bottom of a heat-shielding member. On the basis of the thus-measured distance, the temperature gradient of area G1 of the single-crystal pulled silicon ingot is controlled so as to produce a perfect crystal with good reproducibility, by means of controlling any factor for pulling a single-crystal silicon ingot selected from the group comprising the amount of heat applied to silicon melt, the level of silicon melt, and the pull rate of a single-crystal silicon ingot.

Owner:SUMCO TECHXIV

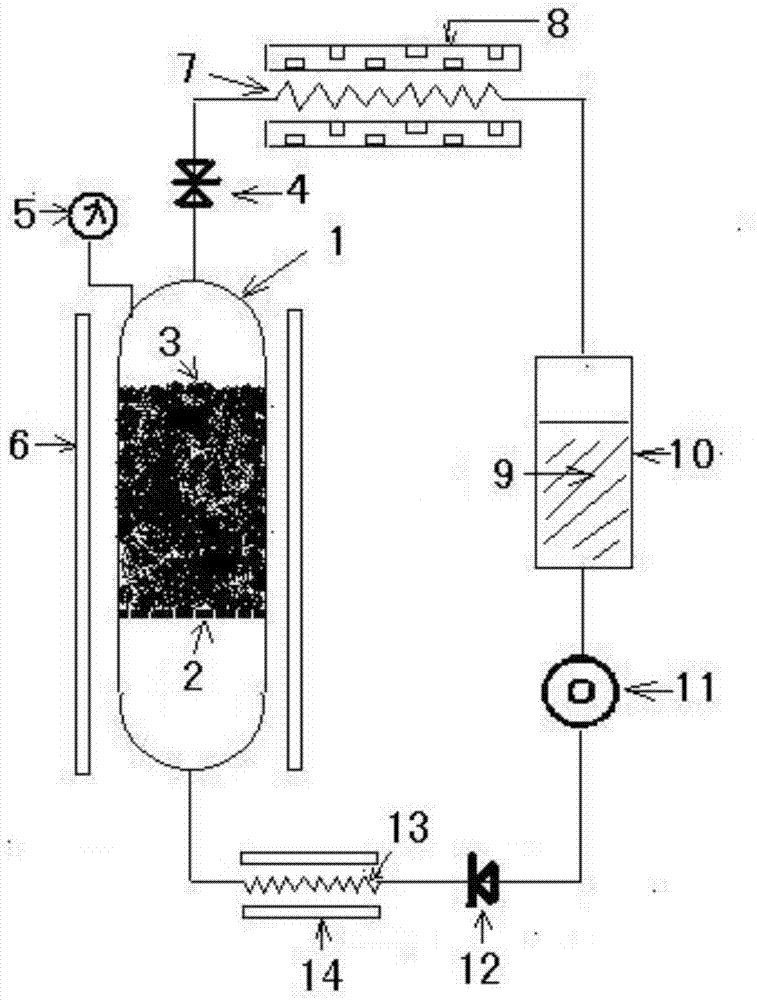

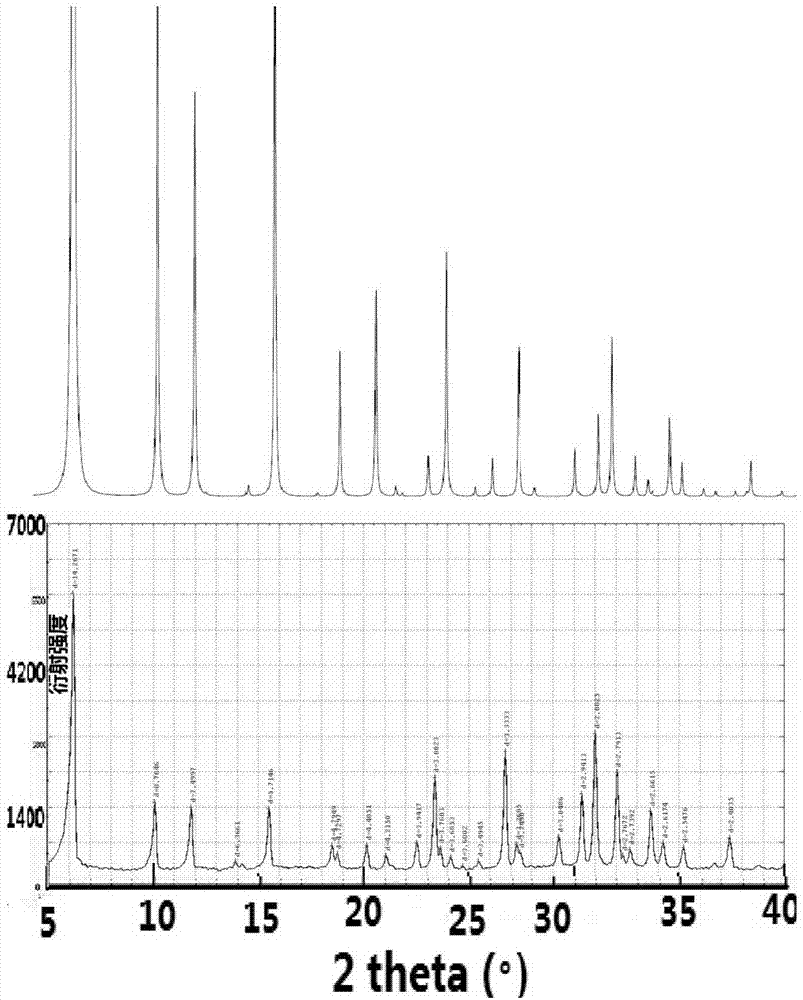

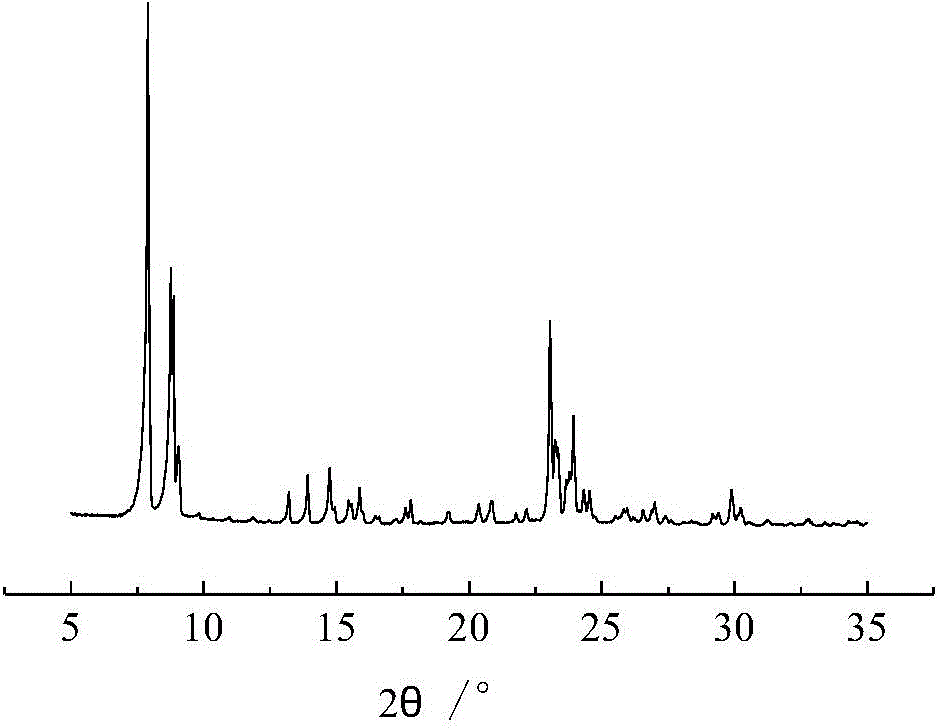

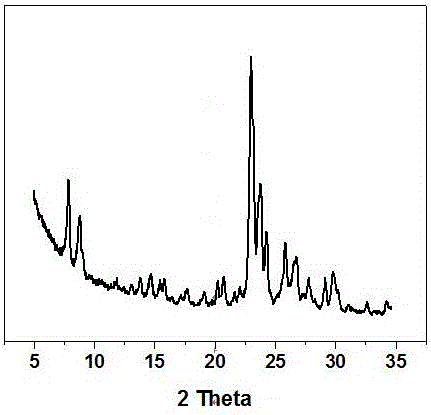

Method for synthesizing zeolite molecular sieve or SAPO molecular sieve, and apparatus thereof

InactiveCN104760970ANo emissionsImprove the crystallization processFerrierite aluminosilicate zeoliteFaujasite aluminosilicate zeoliteReaction temperatureEngineering

The invention belongs to the technical field of chemical engineering, and concretely relates to a method for synthesizing zeolite molecular sieve or SAPO molecular sieve, and an apparatus thereof. The synthesis method is characterized in that a gas-solid phase reaction of amorphous nonmetal oxide reactant dry glue in a pressure reactor is carried out in continuously flowing directing agent steam to form the zeolite molecular sieve or SAPO molecular sieve, the liquid hourly space velocity of the continuously flowing directing agent steam before vaporization is 1-50hr<-1>, the pressure in the pressure reactor is 0.1-1.5MP, and the reaction temperature is 100-200DEG C; and the directing agent steam discharged from the outlet of the reactor undergoes pressure reduction to normal pressure, and is cooled to a liquid which can be recycled. The synthesis reaction temperature and pressure, the composition of the above directing agent and the flow velocity of the steam can be adjusted, the crystallization process can be accelerated, and the obtained product has the advantages of pure phase, perfect crystal form, and small and uniform crystal grain size. The directing agent can be recycled, no waste gas or waste liquid is discharged, and realization of low-cost environmentally friendly large-scale industrial production is facilitated.

Owner:SHANGHAI FUYU NEW MATERIAL TECH

Method for preparing high whiteness A-type zeolite from coal gangue

InactiveCN101214973AHigh crystallinityHigh purityAluminosilicate zeolite type-AInorganic saltsPerfect crystal

A process for preparing high-whiteness A-type zeolite by gangue comprises the gangue, alkali fusion agent and inorganic salt via mixing and high-temperature reaction, water dissolving alkali fusant, aging additional supplied aluminum salt, further heating up to crystallize the aluminum salt, and then obtaining dried A-type zeolite with high quality via filtering and washing the product of crystallization. The invention sufficiently activates active constituents of silica-alumina in the gangue inclusive of quartz, mixed calcining the inorganic salt, the gangue and alkali, adding complexing agent to whiten in the process of crystallization and obtaining A-type zeolite with high crystallinity, high purity and high whiteness via hydro-thermal synthesis. The process for synthesizing zeolite of the invention is simple, convenient and feasible, and the synthesized A-type zeolite has narrower grain size distribution, quite perfect crystal shape and high whiteness and crystallinity.

Owner:CHINA RES INST OF DAILY CHEM IND

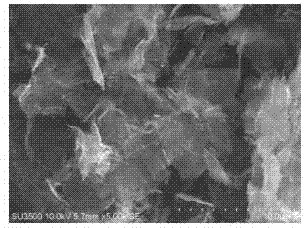

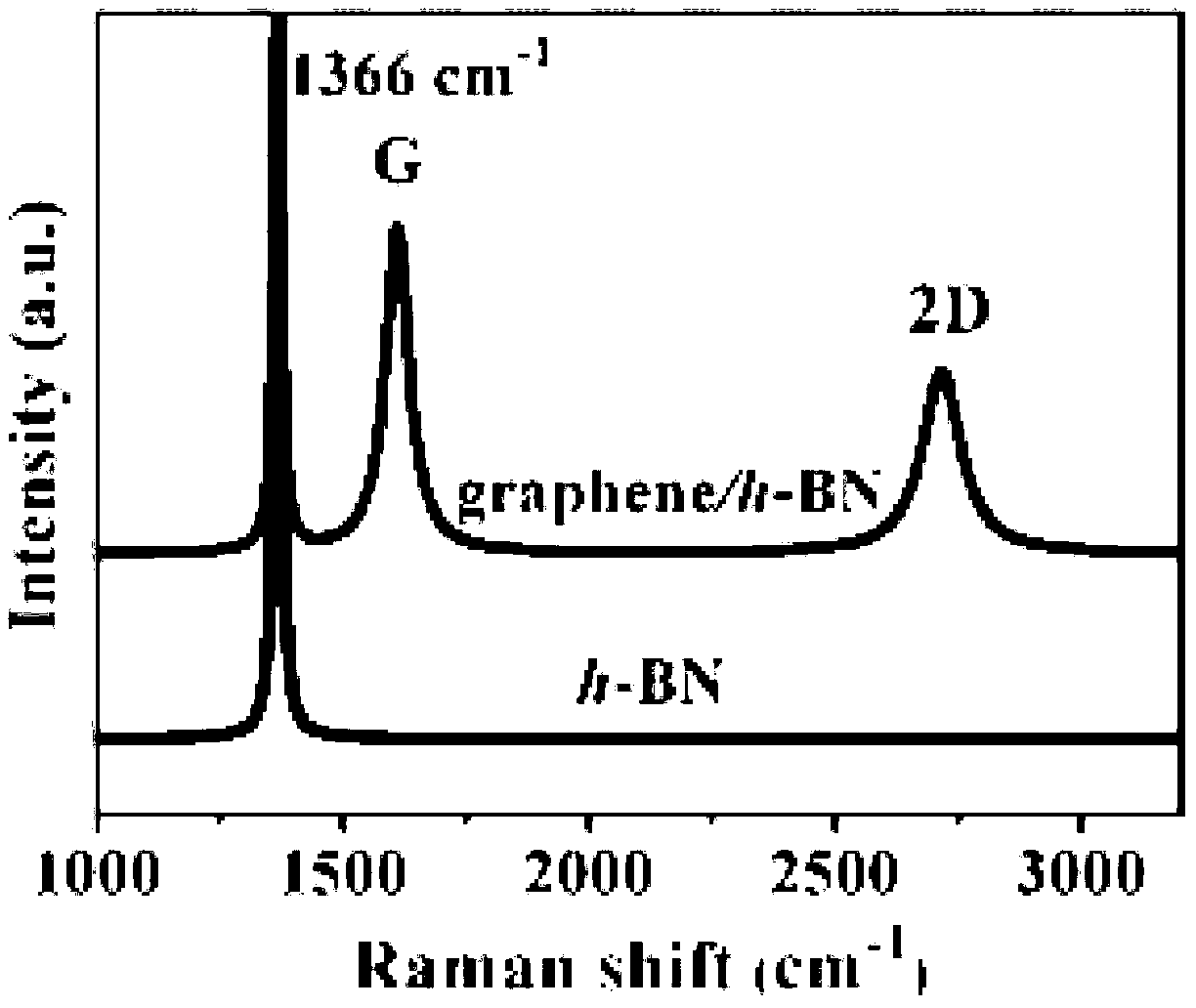

Large-size graphene stack structure wafer and preparation method thereof

InactiveCN103227194AImproved lattice structurePreserve ultra-high mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesHexagonal boron nitrideCharge carrier

The invention discloses a large-size graphene stack structure wafer which is characterized in that a wafer structure comprises a graphene single crystal layer, an h-BN (hexagonal boron nitride) single crystal layer, an h-BN buffer layer and SiO2 / Si wafer substrates from the top down sequentially. The wafer and the preparation method have the benefits that the wafer can be compatible with a production technique of the available silicon substrate semiconductor device sufficiently, and can take full advantage of the characteristic of a hexagonal boron nitride substrate material; growing graphene has a most perfect crystal structure and a carrier transport environment with the weakest scattering; the super-high mobility of carriers in graphene is kept at the utmost; and the performance of a graphene substrate electronic device is improved greatly.

Owner:XIDIAN UNIV

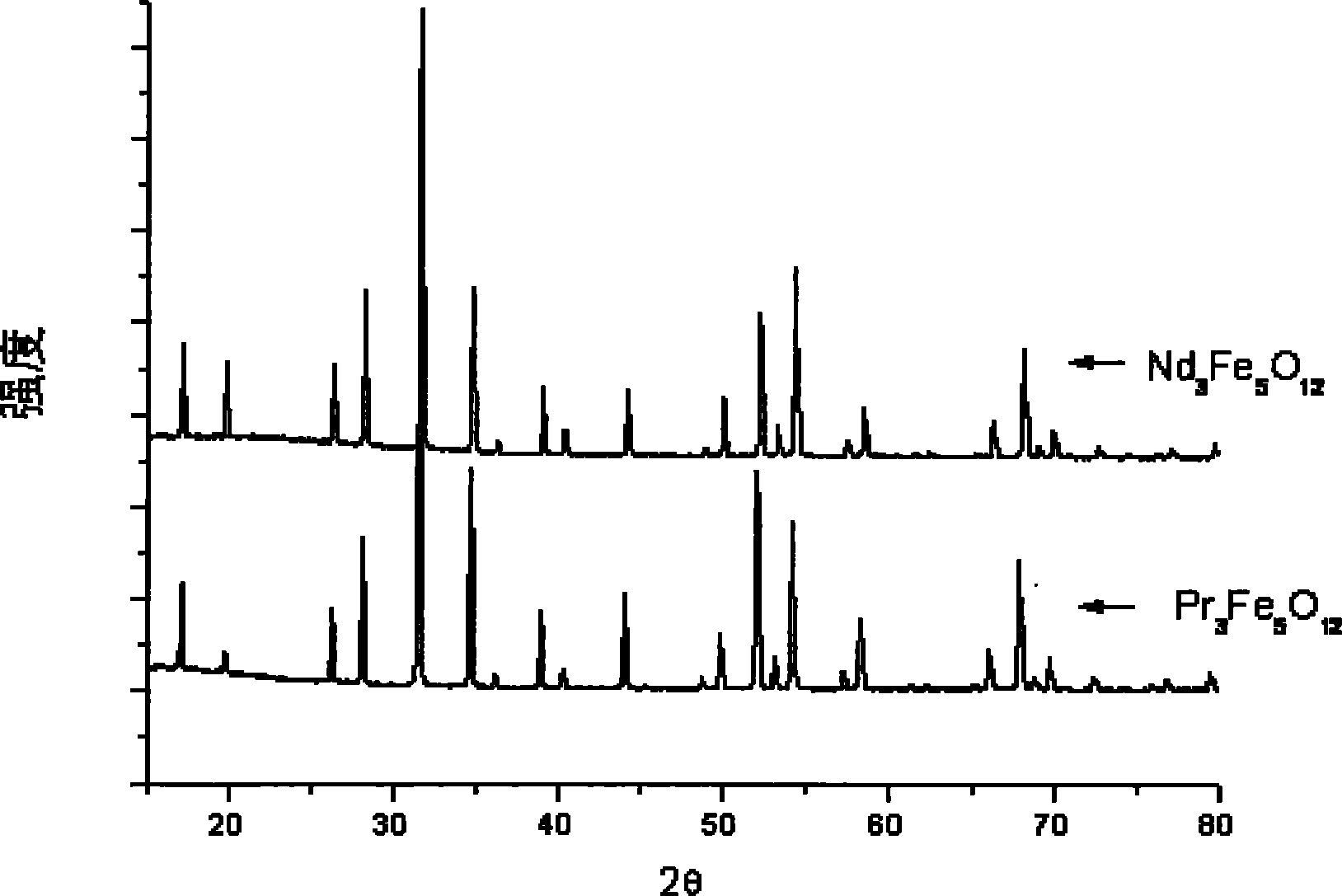

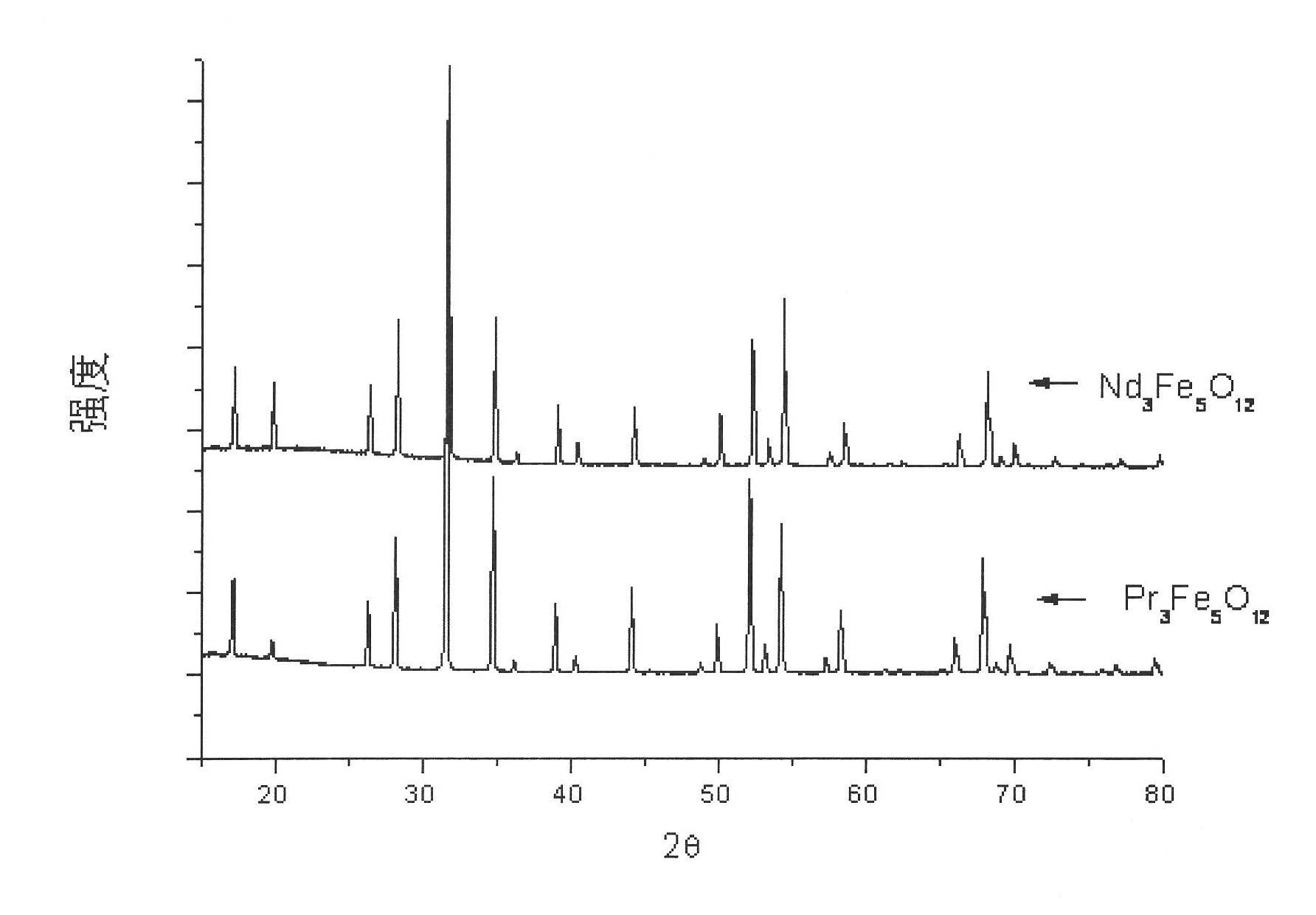

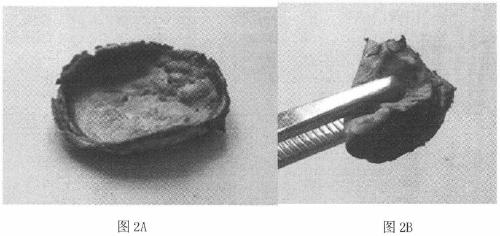

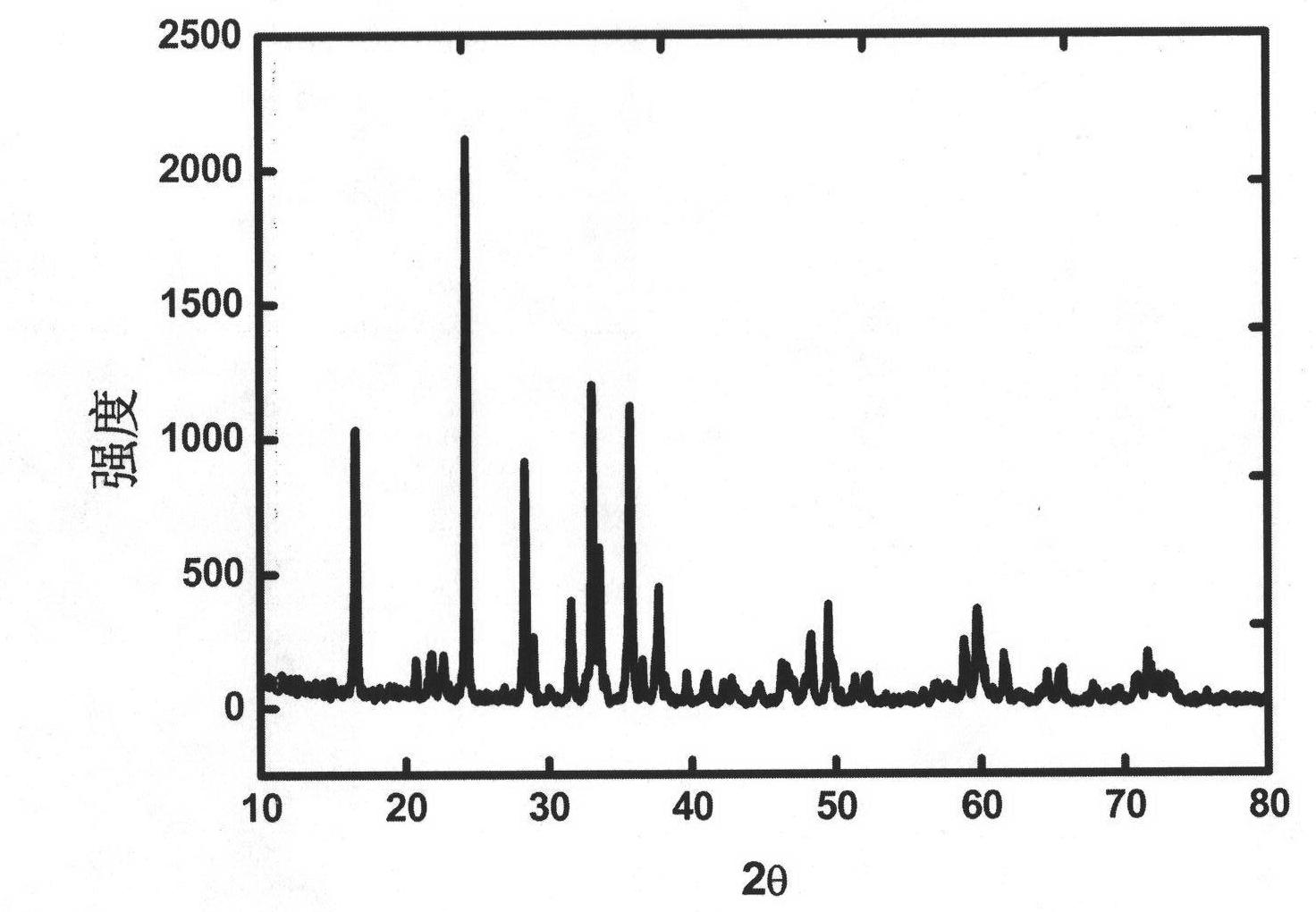

Rare earth garnet type ferrite compound and preparation method thereof

InactiveCN101811738ALow costImprove high frequency performanceIron compoundsRare earthHydrothermal reaction

The invention discloses a rare earth garnet type ferrite compound and a preparation method thereof, which belong to the technical field of inorganic materials and preparation processes thereof. The rare earth garnet type ferrite compound comprises R3Fe[5-y]MyO12, wherein R is Pr, Nd, Sm or Eu, M is Mn, Cr or V and y is more than or equal to 0 and less than3; and calcium or strontium can be doped at C bit. In the preparation method, trivalent rare earth nitrate and Fe(NO3)3 used as reactants, MnCl2 and the like as doped metal salts and KOH as a mineralizing agent are mixed, stirred and are subjected to alkalinity adjustment and hydrothermal reaction in the presence of a large amount of mineralizing agents. The invention discloses a preparation method of the rare earth garnet type ferrite compound which is difficult to synthesize and is unstable at high temperature and has the characteristics of simple operation, mild conditions, high reaction speed, good repeatability, low cost and the like; and in addition, by using the preparation method, a pure phase product with smooth and perfect crystal can be synthesized, the grain diameter of the product is small to several hundreds of nanometers and the monocrystal X-ray analysis can be carried out when the grain diameter is approximately dozens of micrometers.

Owner:JILIN UNIV

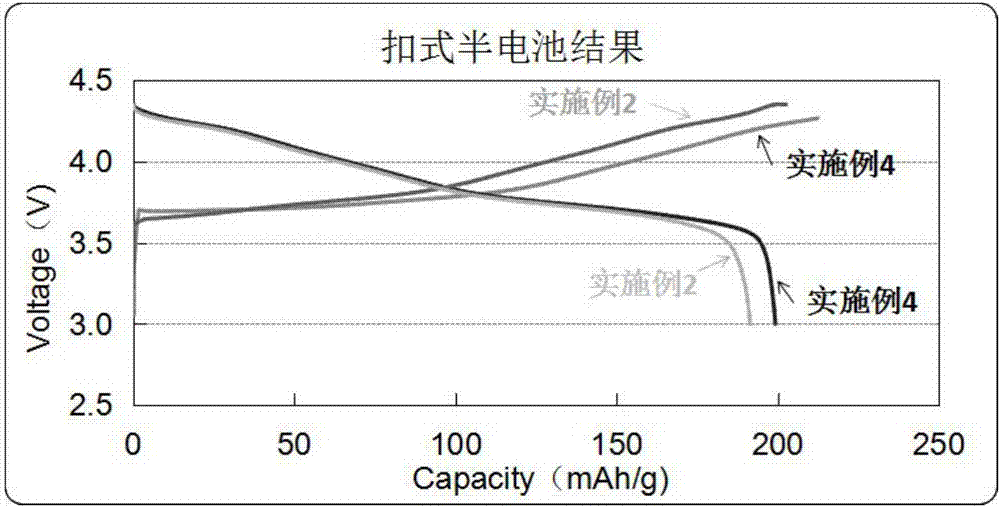

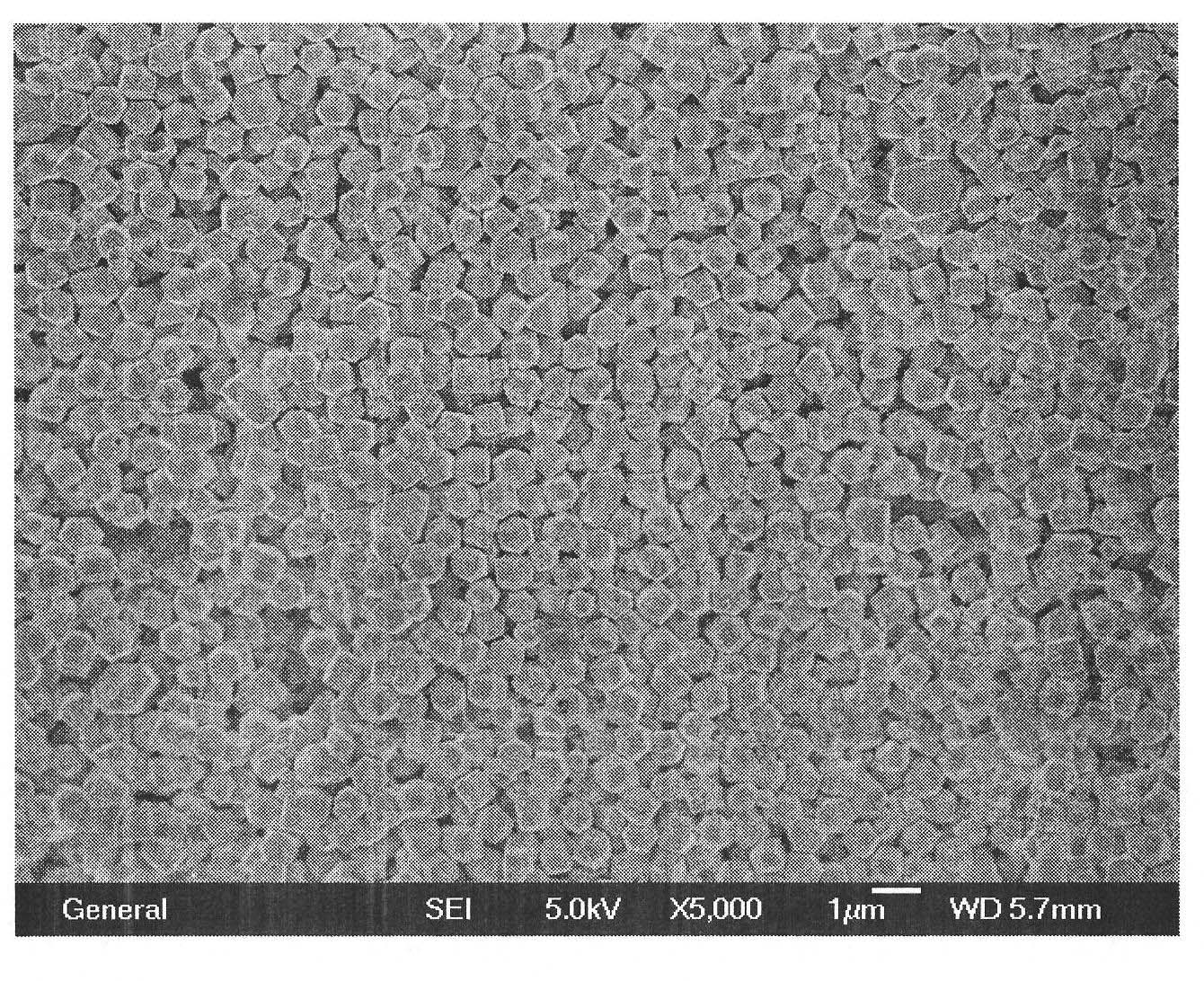

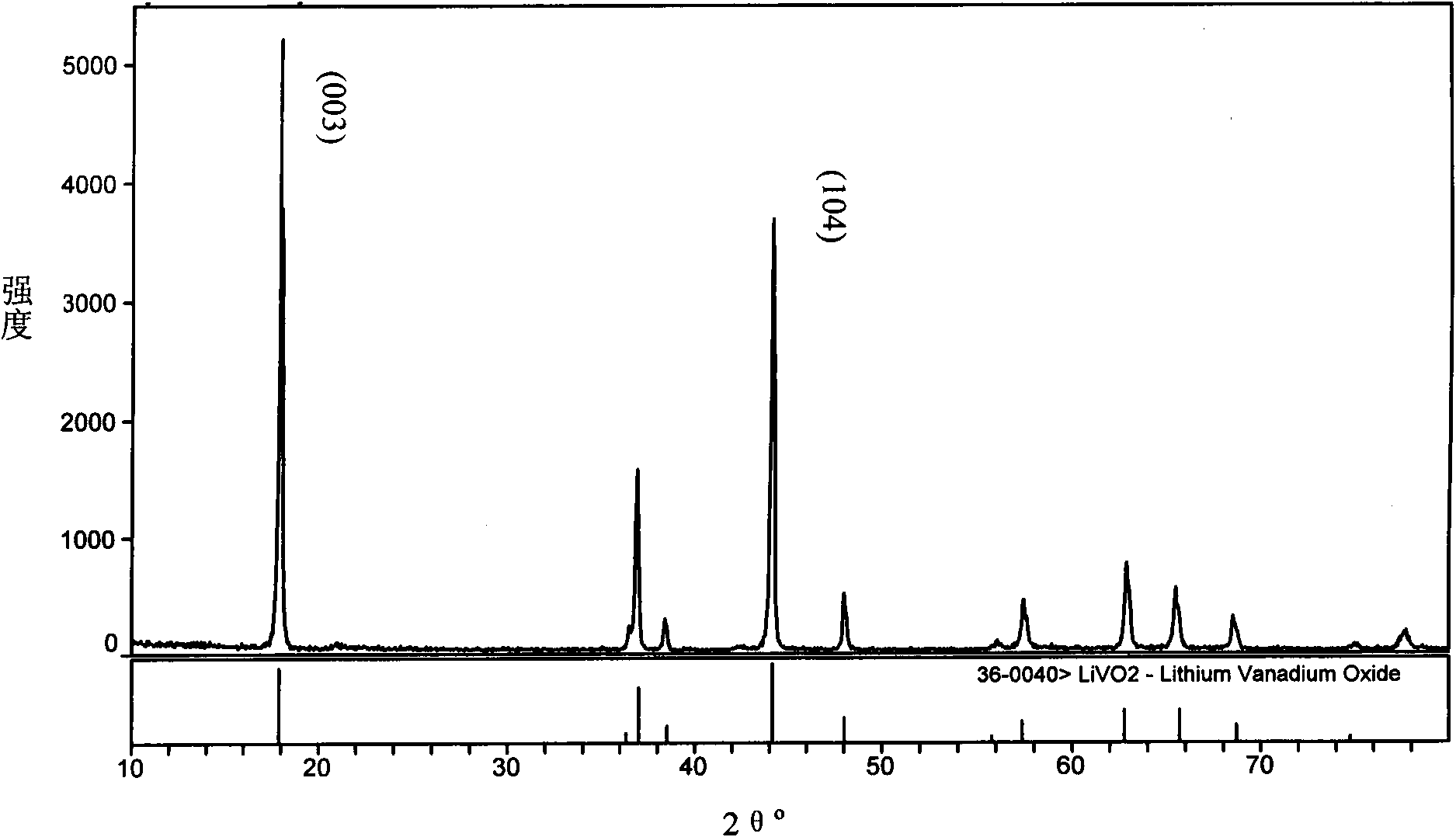

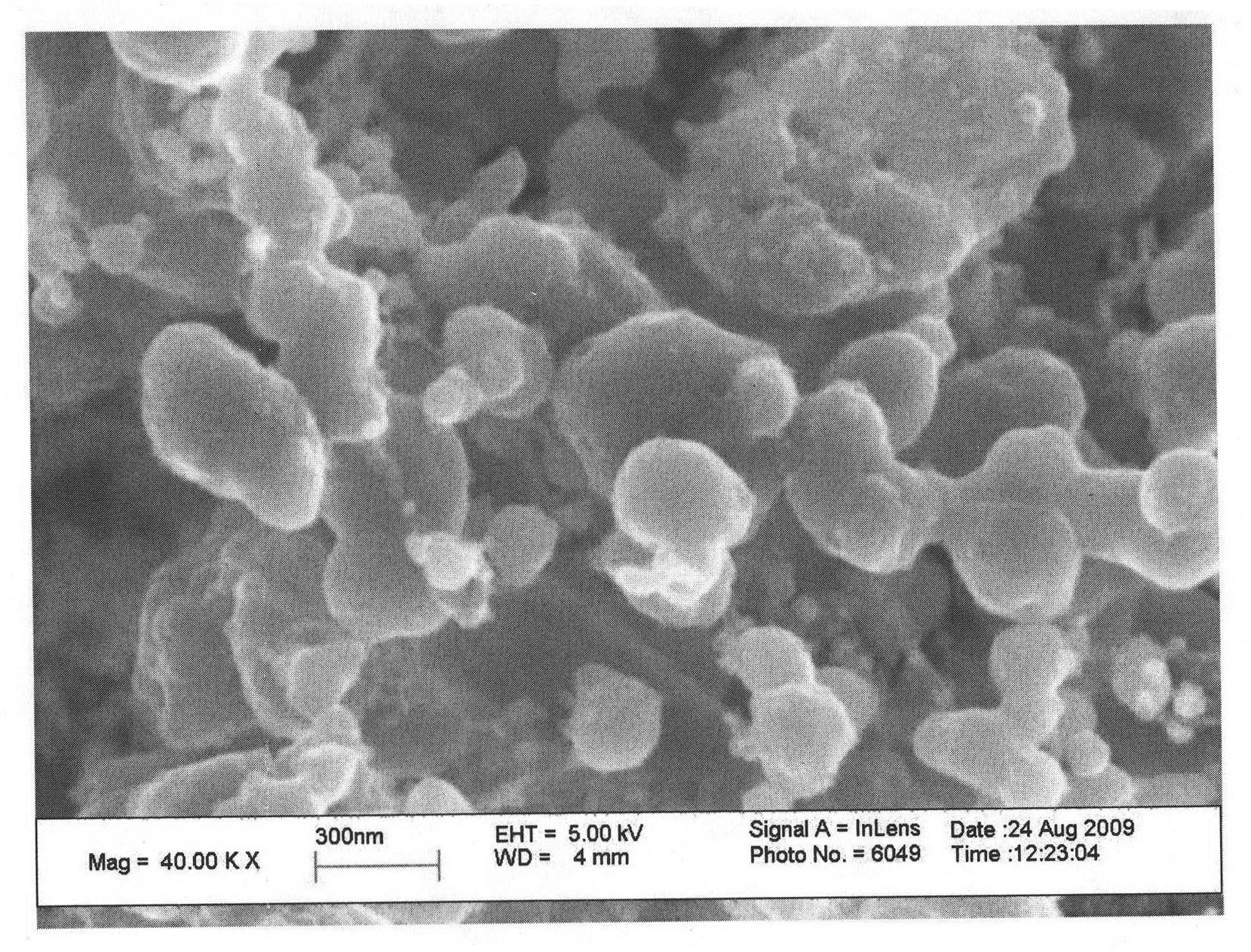

Cathodic active material as well as preparation method and battery thereof

InactiveCN101853939AHigh tap densityGood crystal shapeElectrode manufacturing processesFinal product manufactureMass ratioFull width at half maximum

The invention provides a cathodic active material comprising LiVO2, wherein the tap density of a LiVO2 material is 1.5 to 2.2g / cm3, the ratio of the intensity I003 of the diffraction peak of a 003 crystal face to the intensity I104 of the diffraction peak of a 104 crystal face is 0.9 to 1.8, and the full width at half maximum of the diffraction peak of the 003 crystal face is 0.17 to 0.25. The material has large tap density, perfect crystal form and superior electrochemical performance, and the capacity of the mass ratio of the prepared battery is very large and can reach 339mAh / g, which is beneficial to the development of traditional small-sized and light-duty batteries and meets the development requirements of the traditional battery. Moreover, the invention provides a preparation method of the material. The process is simple, solves the corrosion of a traditional preparation method to equipment well, enhances the rate of finished products, saves the cost and is beneficial to the industrial scale.

Owner:BYD CO LTD

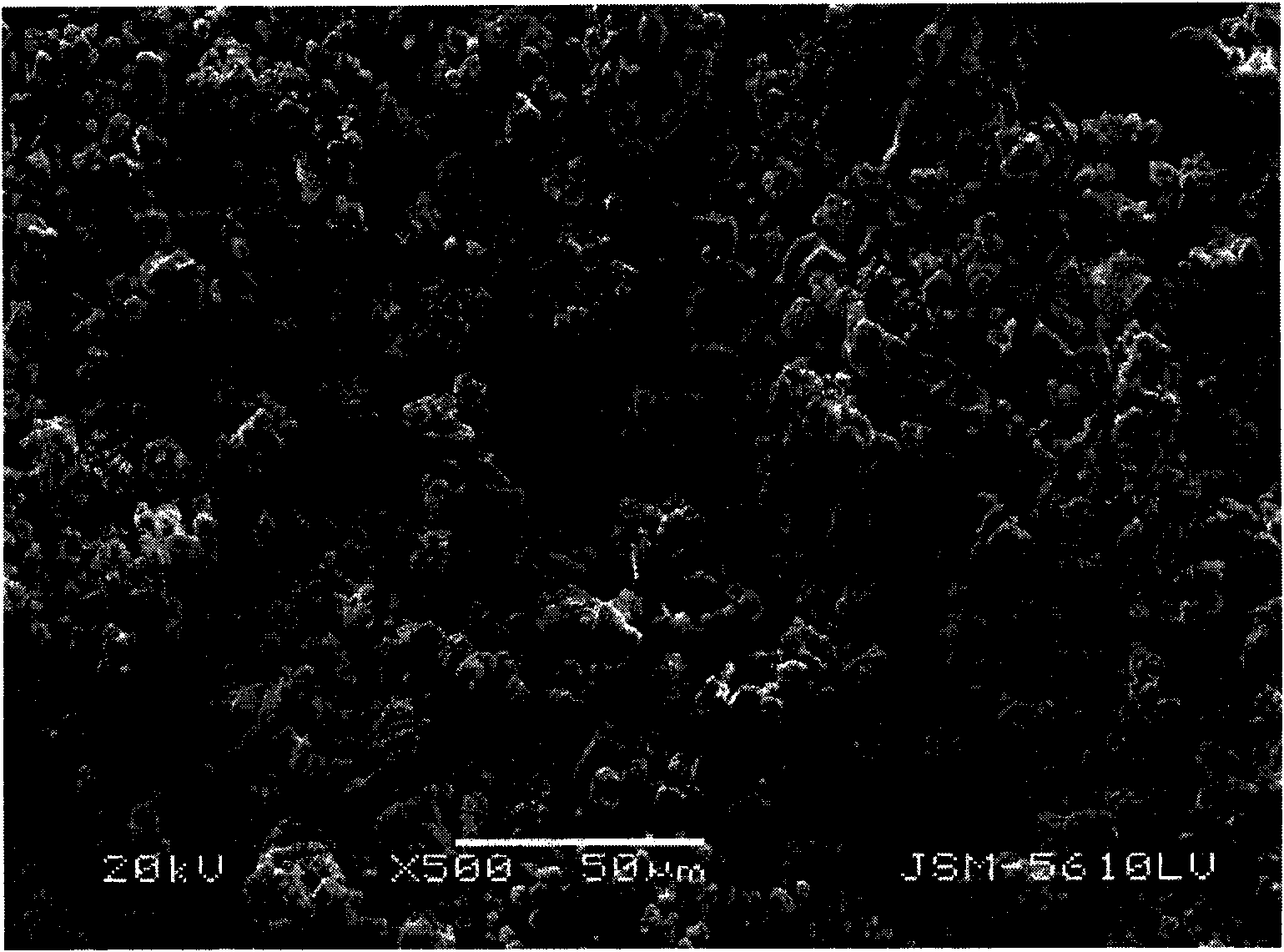

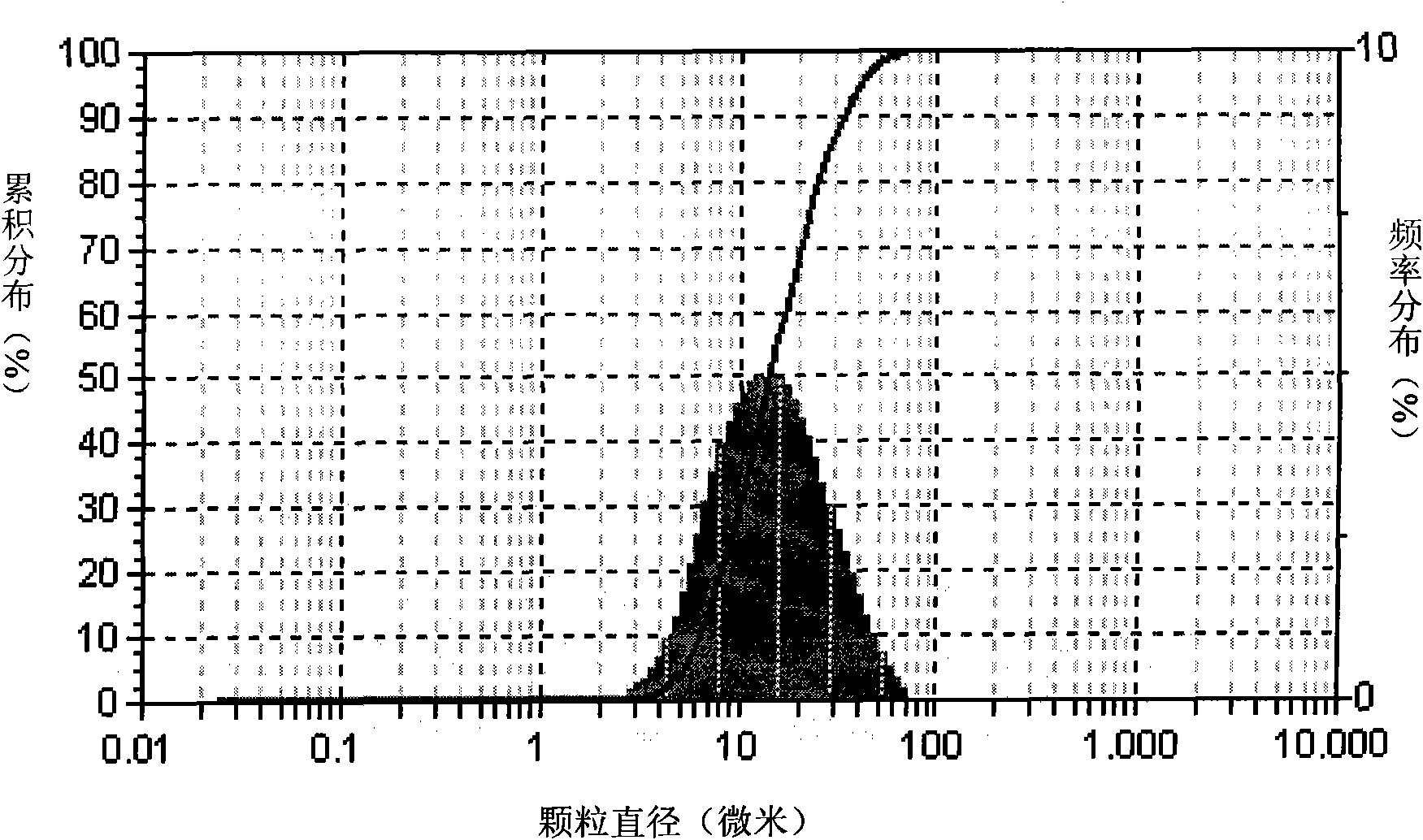

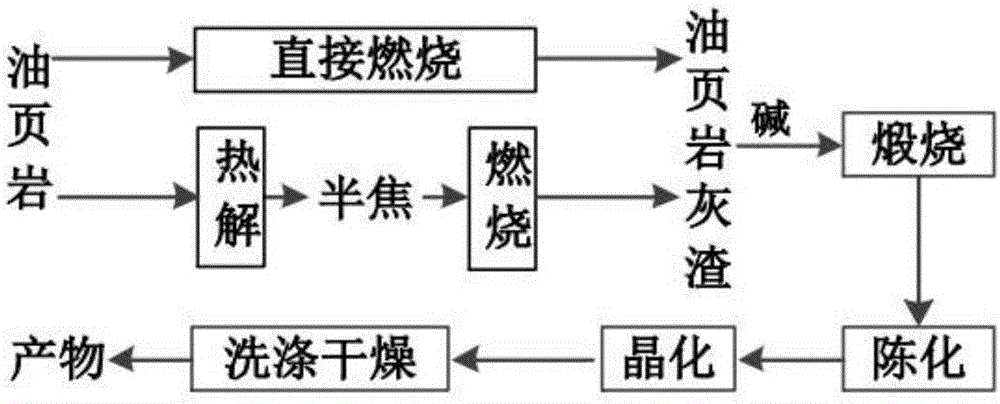

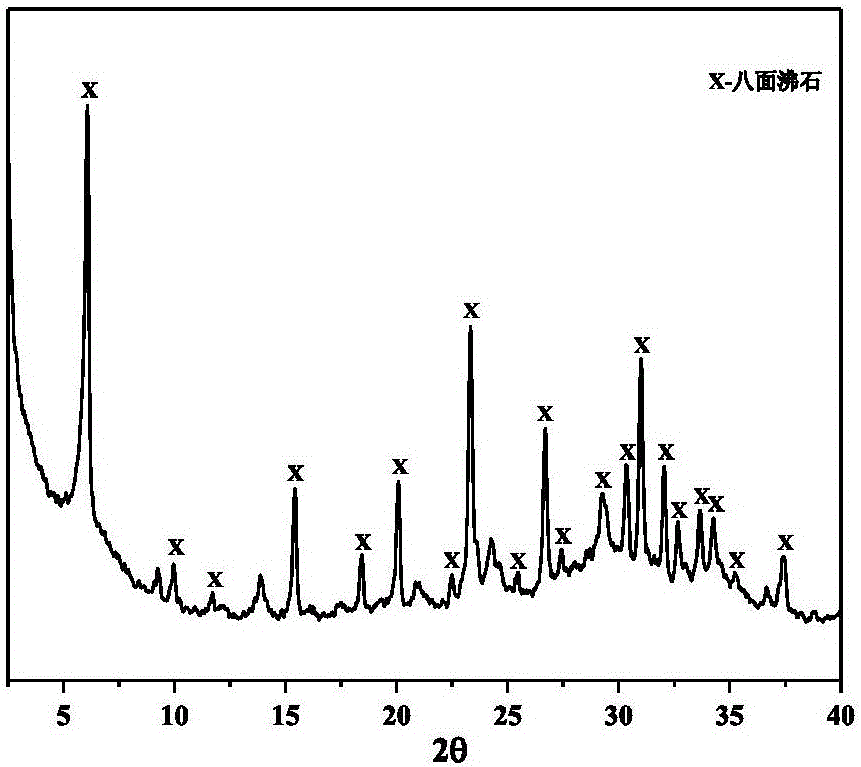

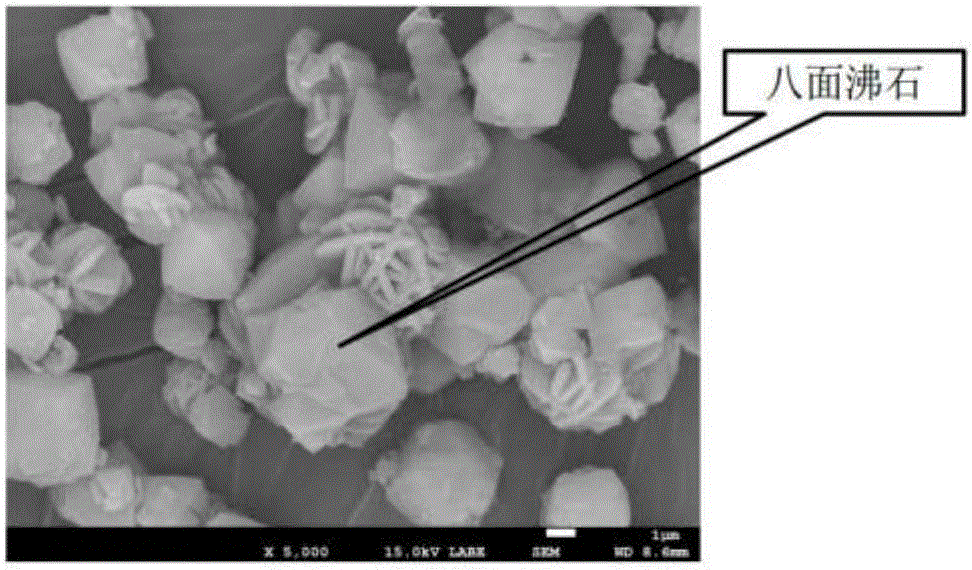

Method for preparation of faujasite from oil shale residue

InactiveCN106241829ASimple processLow costFaujasite aluminosilicate zeoliteResource utilizationFixed bed

The invention relates to a method for preparation of faujasite from oil shale residue. The method comprises the steps of: subjecting the semi-coke generated by pyrolysis of oil shale at 300-700DEG C to combustion in an industrial boiler like circulating fluidized bed and the like or directly subjecting oil shale to combustion in an industrial boiler like a fixed bed or circulating fluidized bed and the like, and taking the generated oil shale residue as the raw material, taking oil shale residue below 200 meshes, fully grinding and mixing the oil shale residue with alkali in a mass ratio of 1: 0.8-1:1.5 evenly, then calcining the mixture at 550-700DEG C for 0.5-2h, letting the calcined object cool naturally to room temperature, then performing grinding, adding distilled water according to a liquid-solid ratio of 3:1-7:1 (ml / g), fully stirring the substances at room temperature for 3-24h, conducting sealing and carrying out crystallization at 60-110DEG C for 6-48h, washing the crystallization product with distilled water until the pH value of the washing liquid reaches 7-8, and performing drying so as to obtain a faujasite product. The method for synthesis of faujasite has the advantages of simple process, low cost and good repeatability, and the prepared faujasite has perfect crystal form and good crystallinity, thus providing a new way for high grade resource utilization of oil shale residue.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

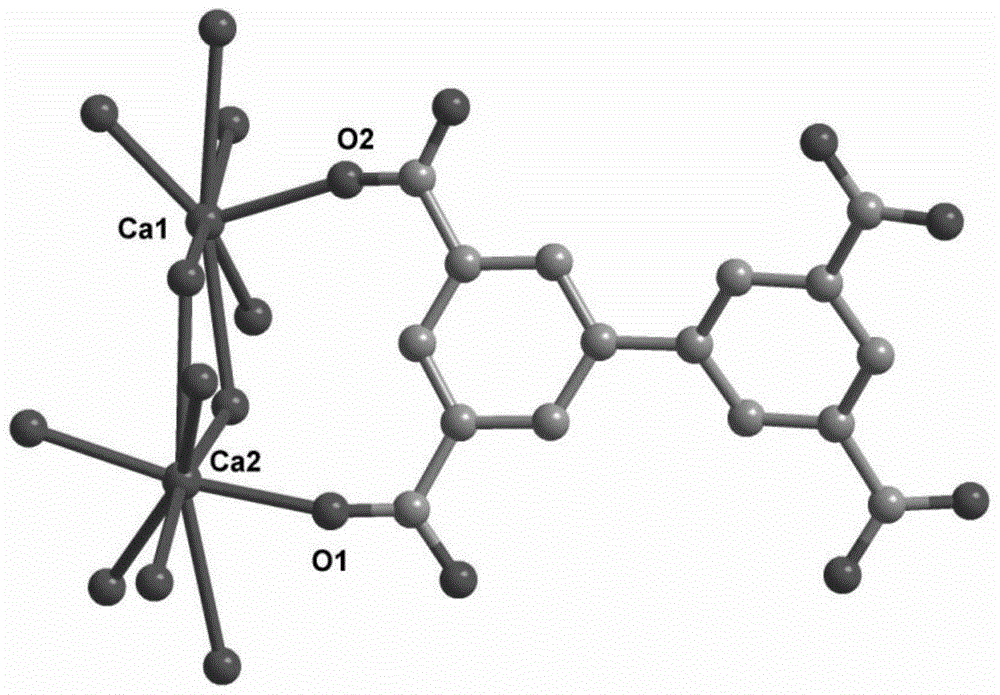

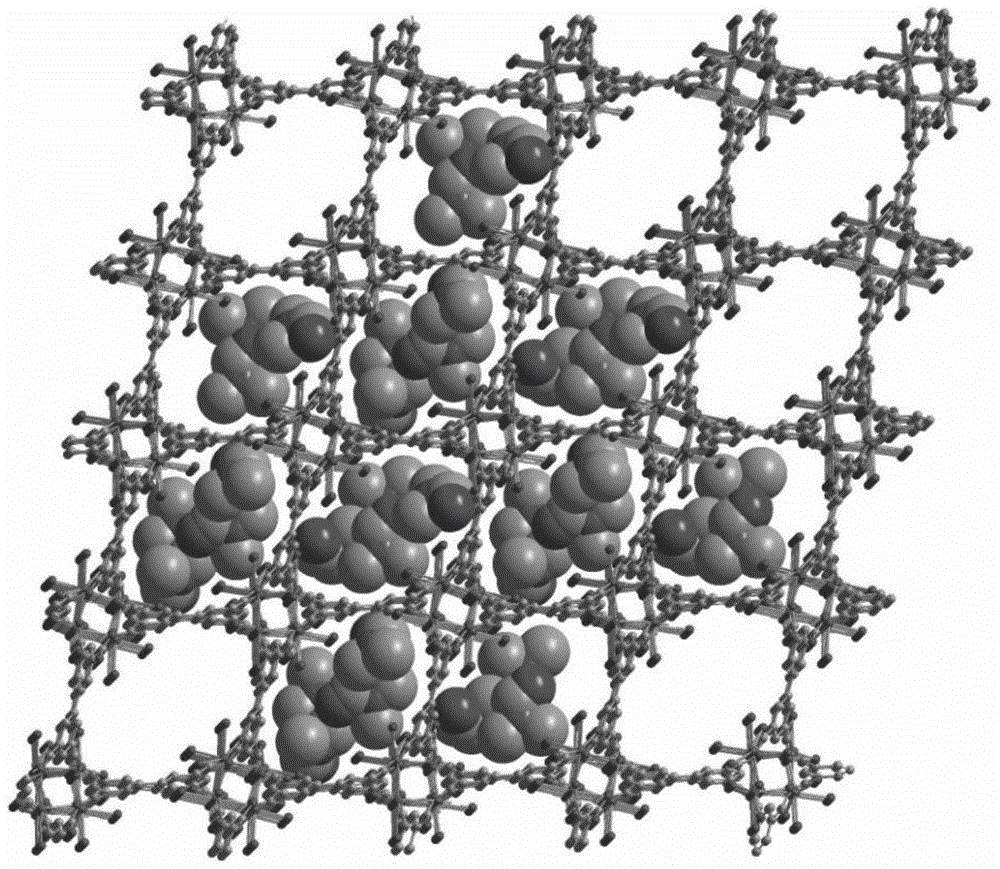

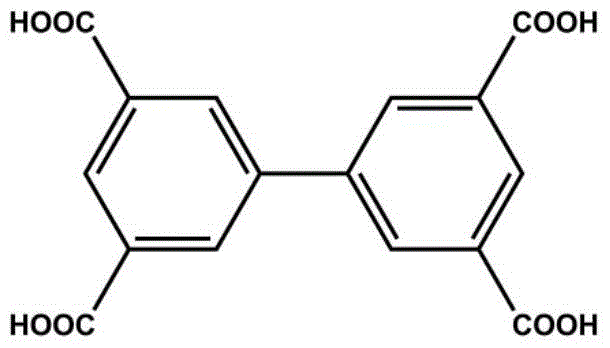

Calcium metal-organic coordination polymer and preparation method thereof

InactiveCN105646185AHigh yieldGood chemical stabilityOrganic compound preparationOrganic chemistry methodsSpace groupSolvent

The invention provides a calcium metal-organic coordination polymer and a preparation method thereof, belonging to the field of coordination chemistry. The chemical formula of the calcium metal-organic coordination polymer is [C22H21N2O13Ca2] which belongs to an orthorhombic system; the space group is P2[1]2[1]2[1]; and the cell parameters are as follows: a=13.883(11)A, b=13.883A, c=17.739(14)A, alpha=90.00 degrees, beta=90.00 degrees, gamma=90.00 degrees, and V=3419(4)A<3>. The metal organic coordination polymer is synthesized by a solvothermal process, thereby being beneficial to quickly obtaining the perfect crystals with fewer defects and uniform orientation. The preparation method is simple, and the metal ions preferably adopt pollution-free harmless calcium ions, so the raw material is accessible and economical. The obtained polymer has the advantages of high yield and favorable chemical stability, and has excellent application potential in the fields of gas adsorption and separation, catalysis, identification, optics and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

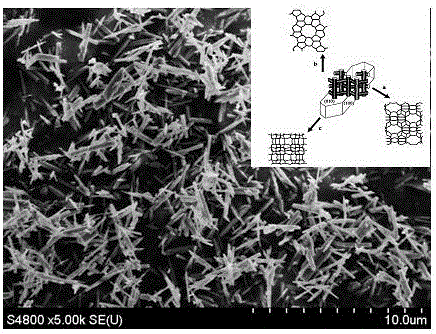

Preparation method of chrysotile nanotube in direction arrangement

InactiveCN101607714AImprove crystal structureWith weak magneticMagnesium silicatesNano sio2Distilled water

The invention discloses a preparation method of chrysotile nanotubes in direction arrangement, comprising the following steps: 1) placing NaOH solution in a hydrothermal reaction kettle; 2) preparing water solution doped with magnetic ions, adding the water solution in the hydrothermal reaction kettle; 3) separately weighting active MgO and nano-SiO2 powder according to a molar ratio of 3 to 2, adding the active MgO and nano-SiO2 powder in the hydrothermal reaction kettle in turn, then adding distilled water in the reaction system, adjusting the pH value of the reaction system to 11-13.8; 4) sealing the hydrothermal reaction kettle and placing the kettle in a magnetic field; meanwhile, heating the hydrothermal reaction kettle and keeping temperature to perform a reaction for 15-80h, cooling; then opening the cooled hydrothermal reaction kettle, sucking up the upper clear liquid slowly and adding distilled water slowly for washing until the washing water which is sucked up is neutral; then heating and drying the product after opening the kettle to obtain the nanotubes of the invention. The method is simple, and the produced chrysotile nanotubes are pure with a perfect crystal structure so that the method is applicable to the nano-assembly and can be used in the preparation of nano-submicron devices.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Production method of ultrafine tungsten carbide powder with good dispersity, perfect crystals and high purity

InactiveCN110127703AGood dispersionCrystallization intactTungsten/molybdenum carbideDispersityAmmonium paratungstate

The invention discloses a production method of ultrafine tungsten carbide powder with good dispersity, perfect crystals and high purity. The production method of the ultrafine tungsten carbide powderwith the good dispersity, the perfect crystals and the high purity comprises the steps of (1) using ammonium paratungstate as a raw material, and conducting calcination to generate a tungsten oxide precursor; (2) conducting hydrogen reduction on the tungsten oxide precursor obtained in the step (1) through an automatic pusher four-tube furnace to obtain tungsten powder; and (3) conducting carbon addition on the tungsten powder produced in the step (2), using carbon black as a C source, adopting a planetary ball mill for dry-milling, placing a material subjected to ball milling in a tube atmosphere furnace, and conducting carbonation in a hydrogen atmosphere to produce the ultrafine tungsten carbide powder. According to the production method of the ultrafine tungsten carbide powder with thegood dispersity, the perfect crystals and the high purity, the ammonium paratungstate is used as the raw material, by adjusting and controlling a calcination technology, the ultrafine tungsten oxideprecursor is obtained, furthermore, in the reduction process, synchronous crystallization of tungsten crystals is controlled, a fast and complete carbonation process is achieved, meanwhile, impurity elements are monitored, a gas deoxygenation technology is used, the key impurity content and the oxygen content are controlled, and finally, the ultrafine tungsten carbide powder with the good dispersity, the perfect crystals and the high purity is obtained.

Owner:蓬莱市超硬复合材料有限公司

Preparation method of reduced graphene oxide base composite membrane

PendingCN110117004AHigh degree of reductionImprove crystal structureMaterial nanotechnologySiliconSupercritical dryingFreeze-drying

The invention discloses a preparation method of a reduced graphene oxide base composite membrane. The method comprises the steps that graphene oxide is adopted as a raw material and mixed with other substances in water or other solvents, the reduced graphene oxide base composite membrane or a reduced graphene oxide base composite gel membrane is prepared through a hydrothermal reaction or a solvothermal reaction in a reaction kettle, and the reduced graphene oxide base composite gel is converted into the composite membrane through freeze drying or supercritical drying. The synthesized composite membrane can be wetted and dried in a solvent to obtain a thinner composite membrane. The reduced graphene oxide base composite membrane can be reduced through high temperature to obtain the reducedgraphene oxide base composite membrane with the higher graphene reducing degree and the perfect crystal structure.

Owner:庄鹏宇

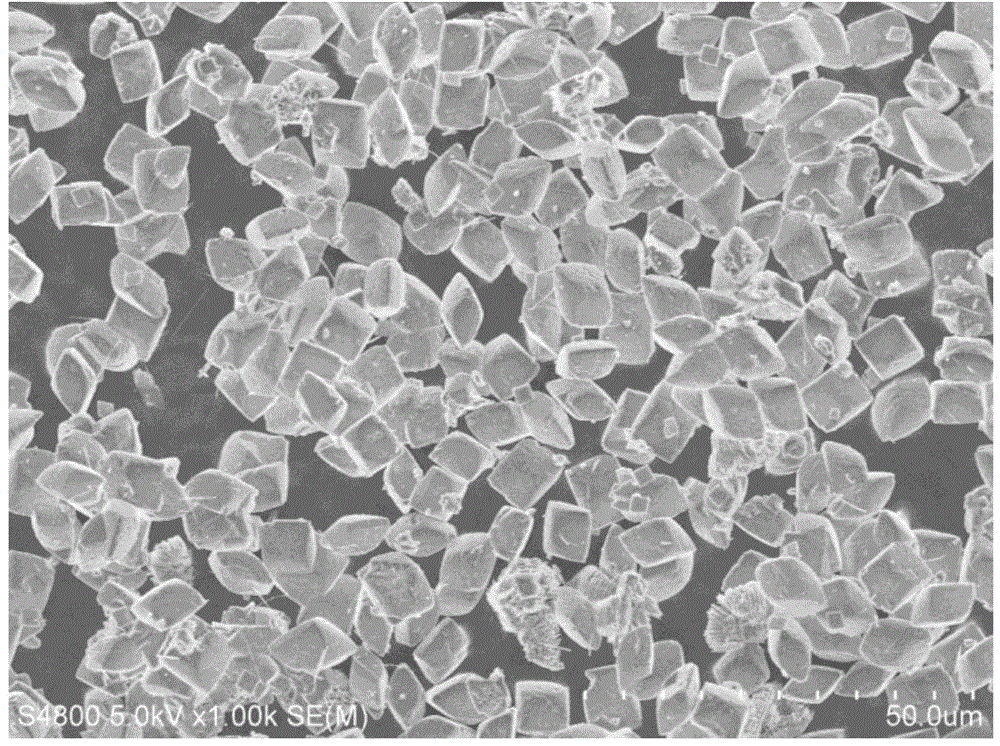

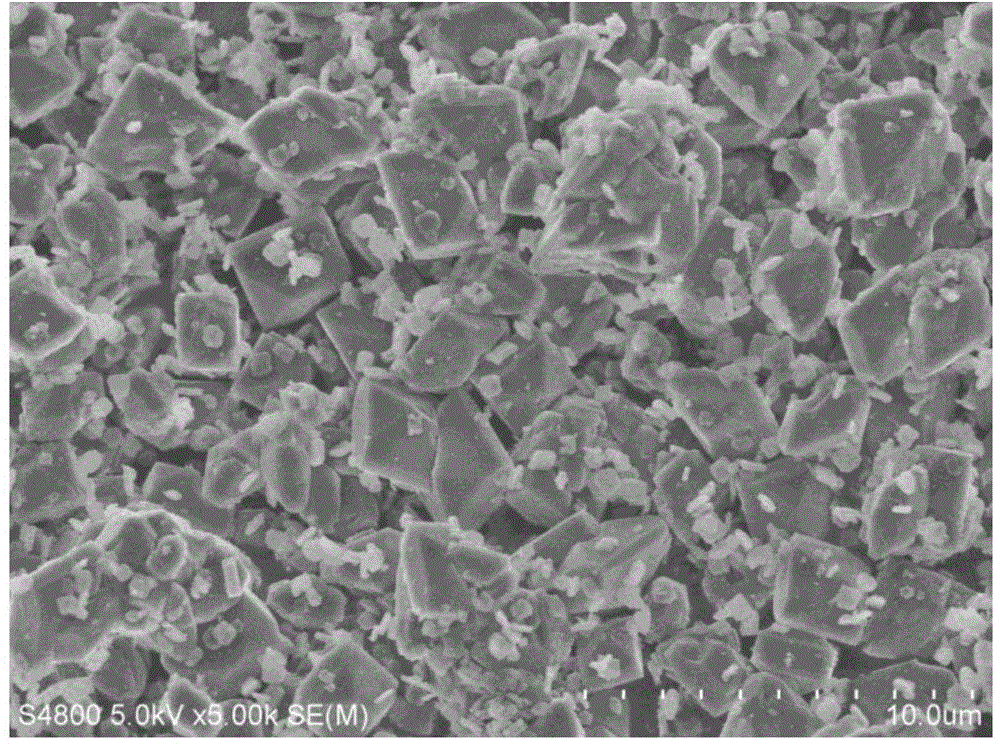

Synthesis method for Silicalite-1

ActiveCN105858672ADie intactSilicaMolecular-sieve and base-exchange compoundsTetramethylammonium iodideTetramethylammonium bromide

The invention discloses a synthesis method for a Silicalite-1 molecular sieve, wherein the method comprises the following steps: (1) mixing evenly a silicon source, a structure directing agent, a mineralizer and water, to obtain a reaction mixture with the molar ratio of OH<->:SiO2:R:F:H2O=(0.05-5):1:(0.05-0.39):(0.05-5):(2-100), wherein R represents the mole number of the structure directing agent, F represents the mole number of the mineralizer, and the structure directing agent is at least one selected from the group consisting of tetraethylammonium hydroxide, tetraethylammonium bromide, tetraethylammonium chloride, tetraethylammonium fluoride, tetraethylammonium iodide and triethylamine; (2) transferring the reaction mixture obtained in the step (1) to a pressureproof airtight container, crystallizing for 0.5-60 days at the temperature of 80-200 DEG C and at the self-generated pressure, to obtain a crystallized product; and (3) recycling the crystallized product obtained in the step (2). By the synthesis method, the Silicalite-1 molecular sieve with uniform and perfect crystal grains can be synthesized under the action of the novel structure directing agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anode active material and preparation method thereof

The invention provides an anode active material. The structural formula is LiyMxM'1-xSiO4-0.5zFz, wherein x is more than or equal to 0 and less than or equal to 1; y is more than or equal to 2 and less than or equal to 2.2; z is more than or equal to 0.01 and less than or equal to 0.1; M is selected from one or more of Mn, Fe, Ni and Co; and M' is selected from one or more of Mn, Fe, Ni and Co. The anode active material has good electric conductivity, excellent multiplying power discharge performance, stable structure, excellent cycle performance and high capacity at the same time. Meanwhile, the invention provides a preparation method for the anode active material, which comprises the following steps of: a, mixing and ball-milling a lithium source, an M source, an M' source, a fluorine source and a silicate radical source; b, performing ultrasonic treatment on the ball-milled substances of the step a, and drying; and c, sintering the substances obtained in the step b under inert atmosphere. The method is simple and easy to implement, and the prepared material has the advantages of perfect crystal form, no agglomeration, and uniform granule diameter distribution.

Owner:BYD CO LTD

Production method of compound sweetener

InactiveCN110179096AUniform sweetnessConsistent particlesFood ingredient as mouthfeel improving agentFood additiveInulin

The invention discloses a production method of a compound sweetener, and relates to the technical field of production of food additives. The method comprises the following steps: dissolving erythritol, inulin, stevioside and mogroside in purified water to obtain a mixed solution, heating the mixed solution to 80-100 DEG C, keeping the temperature for 0.5-1 hour, then performing cooling and crystallizing, and drying the crystallized matter in an oven to obtain the compound sweetener. The compound sweetener obtained by the method has the advantages of consistent particle size, perfect crystal form particle size, good fluidity, uniform sweetness dispersion and good mouth feel.

Owner:江苏科乐欣生物有限公司

Synthesis method of high-silicon b-oriented ZSM-5 nanosheets

InactiveCN106185978AHigh activityHigh silicon b-orientationPentasil aluminosilicate zeoliteInorganic saltsSynthesis methods

The invention discloses a synthesis method of high-silicon b-oriented ZSM-5 nanosheets. The method is characterized by comprising the following steps: mixing an aluminum source with ammonia water, inorganic salts and water, stirring, slowly and dropwisely adding a silicon source, adding a template and a crystal seed at a uniform speed, and carrying out crystallization reaction at 120-190 DEG C for 24-48 hours; and after the reaction finishes, filtering, and drying to obtain the high-silicon b-oriented ZSM-5 nanosheets. Compared with the prior art, the ZSM-5 nanosheets have the advantages of high activity, ultrathin crystal grains, high silicon b-orientation, adjustable silica-alumina ratio, controllable thickness, perfect crystals and high hydrothermal stability, well overcome the defect that the preparation of the nanosheet zeolite catalyst requires the use of the specific-structure high-price structure guide agent or secondary template, have the characteristics of lower preparation cost and high synthesis yield, and have certain industrialized application prospects and obvious economic value.

Owner:EAST CHINA NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com