Method for preparing slowly digestible wheat starch through coordination of biological enzyme and low-temperature freeze-thawing

A wheat starch and biological enzyme technology, applied in the direction of fermentation, can solve the problems of unsuitable thermal processing, high production cost, high technical difficulty, etc., to reduce postprandial insulin reaction, ensure food safety, and have broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

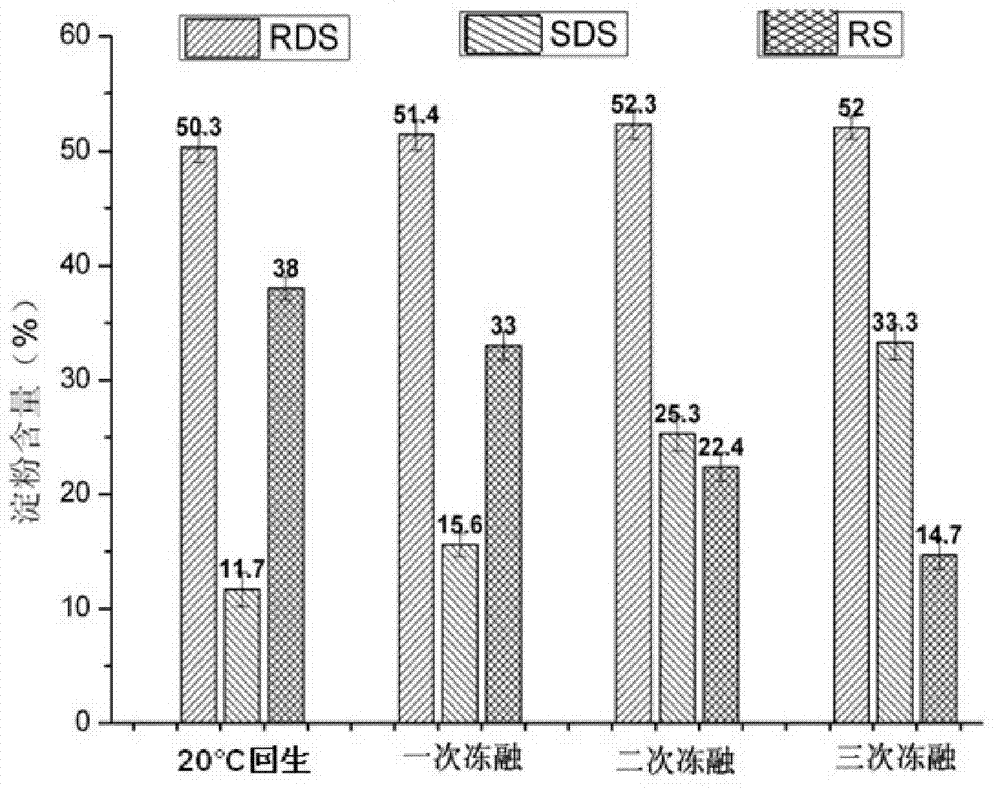

[0033] 1. Weigh 1kg of wheat starch, add a buffer solution with a pH value of 4.3 (prepared from 0.2M disodium hydrogen phosphate solution and 0.1M citric acid solution), and prepare a starch suspension with a concentration of 10%. Heating in a water bath for 60 minutes to obtain starch milk, cooling at room temperature to a temperature of 58°C, adding pullulanase and glucosidyl transferase to the starch milk, the addition amount of pullulanase and glucosidyl transferase is 2 ×10 4 ASPU, 3×10 3 U, enzymatic hydrolysis for 16 hours under stirring, after the enzymatic hydrolysis, use an autoclave to sterilize the enzyme at a pressure of 0.07Mpa and a temperature of 110°C for 15 minutes, and then store it at 20°C for 6h to form a starch gel.

[0034] 2. Freeze the starch gel at -5°C for 8 hours, then thaw it to room temperature, and repeat the freeze-thaw process 3 times. The starch gel after three freeze-thaw treatments was vacuum-dried at 40°C for 3 hours, then air-dried at 4...

Embodiment 2

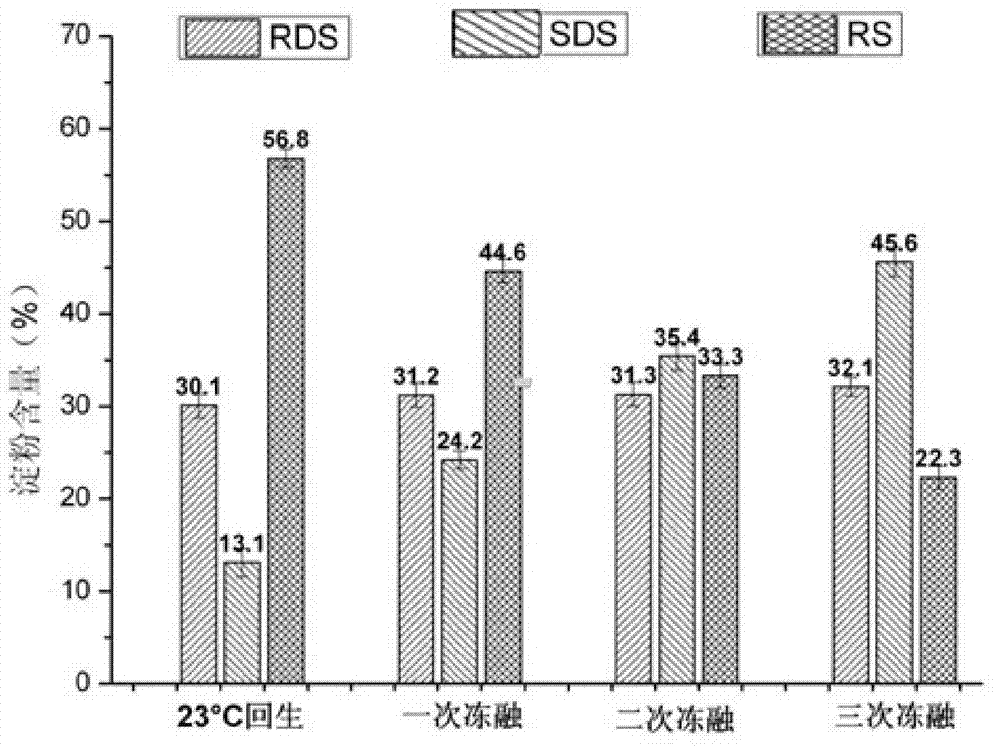

[0037] 1. Weigh 1kg of wheat starch, add a buffer solution with a pH value of 4.3 (prepared from 0.2M disodium hydrogen phosphate solution and 0.1M citric acid solution), and prepare a starch suspension with a concentration of 10%. Heating in a water bath for 60 minutes to obtain starch milk, cooling at room temperature to a temperature of 58°C, adding pullulanase and glucosidyl transferase to the starch milk, the addition amounts of pullulanase and glucosidyl transferase were 4 per liter of starch milk ×10 4 ASPU, 4×10 3 U, enzymatic hydrolysis with stirring for 18 hours, after the end of the enzymatic hydrolysis, use an autoclave to sterilize the enzyme at a pressure of 0.07Mpa and a temperature of 110°C for 15 minutes, and then store it at a temperature of 23°C for 15 hours to form a starch gel.

[0038] 2. Freeze the starch gel at -15°C for 16 hours, then thaw it to room temperature, and repeat the freeze-thaw process 3 times. The starch gel after 3 freeze-thaw treatment...

Embodiment 3

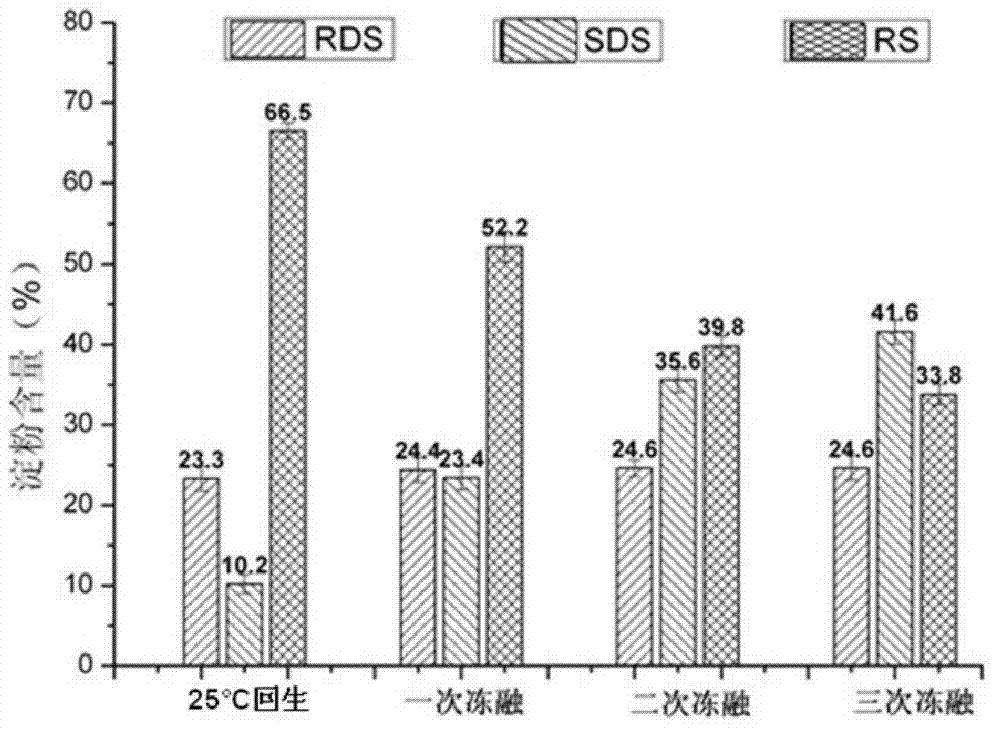

[0041] 1. Weigh 1kg of wheat starch, add a buffer solution with a pH value of 4.3 (prepared from 0.2M disodium hydrogen phosphate solution and 0.1M citric acid solution), and prepare a starch suspension with a concentration of 10%. Heating in a water bath for 60 minutes to obtain starch milk, cooling at room temperature to a temperature of 58°C, adding pullulanase and glucosidyl transferase to the starch milk, the addition amounts of pullulanase and glucosidyl transferase were 6 ×10 4 ASPU, 5×10 3 U, enzymatic hydrolysis with stirring for 20 hours, after the end of the enzymatic hydrolysis, use an autoclave to sterilize the enzyme at a pressure of 0.07 MPa and a temperature of 110°C for 15 minutes, and then store it at a temperature of 25°C for 24 hours to form a starch gel.

[0042] 2. Freeze the starch gel at -20°C for 24 hours, then thaw it to room temperature, and repeat the freeze-thaw process 3 times. The starch gel after 3 freeze-thaw treatments was vacuum-dried at 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com