Patents

Literature

807 results about "Alant starch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Synonym(s): alant starch, alantin, dahlin inulin /in·u·lin/ ( in´ūl-in ) a starch occurring in the rhizome of certain plants, yielding fructose on hydrolysis, and used in tests of renal function.

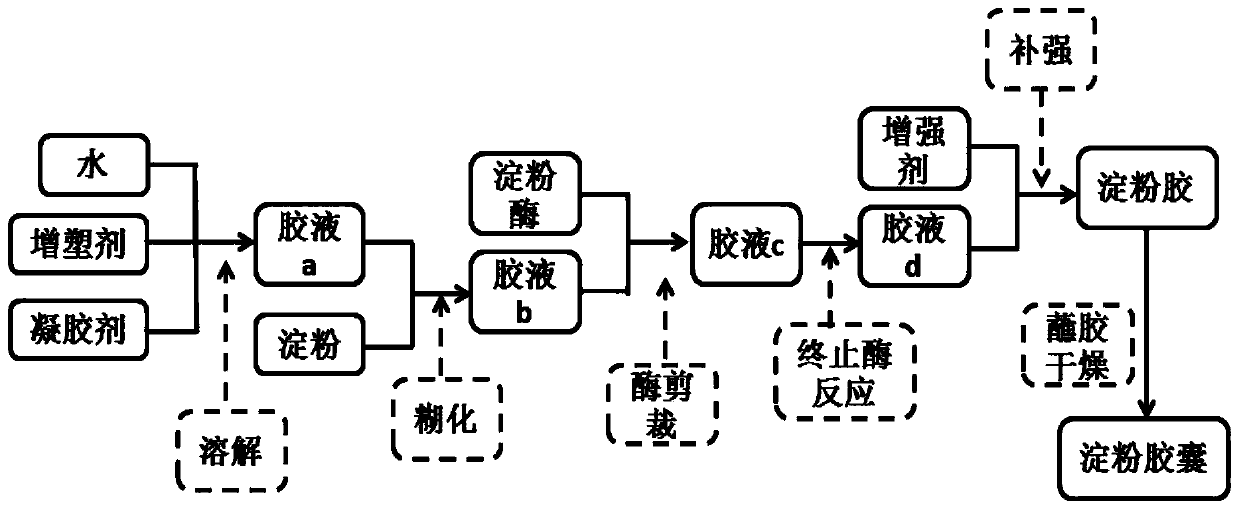

Production method of starch empty capsule

ActiveCN103830736AMeet the requirementsSimple processPharmaceutical non-active ingredientsCapsule deliveryStarch gelatinizationPlasticizer

The invention relates to a production method of a starch empty capsule. The raw material used is a low viscosity starch gel liquid. A preparation method of the low viscosity starch gel liquid comprises the following steps: mixing gel, a plasticizer and water; stirring and dissolving; then, adding starch or modified starch; and heating to gelatinize the starch. The preparation method is characterized by further comprising the step of adding amylase for enzyme reaction to obtain the gel liquid with the viscosity of 1000-7000cps. Production conditions such as dipping temperature, temperature of a gel disc and temperature of a drying tunnel which are strictly controlled are obtained when the hollow capsule is prepared by using the low viscosity starch gel liquid by means of repeatedly researching and testing the technological parameters of each step in production of the hollow capsule. By taking the starch as the raw material, a hollow plant capsule product which satisfies the requirements of pharmacopeia can be produced. The production method disclosed by the invention is simple in process and convenient to operate. Existing capsule production equipment can be directly utilized, so that the production method is suitable for industrialized production.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

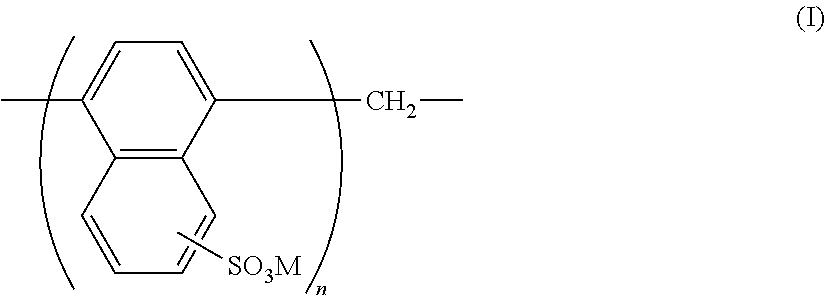

Preparation method of starch grafted copolymer inverse emulsion for drilling fluid

ActiveCN103113524AImprove the lubrication effectGood anti-collapse abilityDrilling compositionWater basedPotassium hydroxide

The invention relates to a preparation method of a starch grafted copolymer inverse emulsion for a drilling fluid. The method comprises the following steps of: adding an emulsifier sorbitan monooleate into white oil, and stirring, dissolving and introducing nitrogen to obtain an oil phase; dissolving potassium hydroxide in water, adding 2-acrylamidyl-2-methyl propanesulfonic acid, acrylamide, a vinyl monomer, a cationic monomer, polyoxyethylene sorbitan monooleate, ethylene diamine tetraacetic acid disodium salt and starch, and stirring to obtain an aqueous phase; adding the aqueous phase into the oil phase, adequately emulsifying, adjusting the pH value, introducing nitrogen, adding an initiator and a reducing agent; and stirring, heating, insulating heat, cooling, discharging and filtering under nitrogen protection to obtain the starch grafted copolymer inverse emulsion for the drilling fluid. The product serving as a drilling fluid treatment agent has good de-filtration effect, good thickening effect, a flow type regulating effect and good inhibition effect for dehydrating dispersion of clay and drillings, so that the quality of filter cakes is improved, the lubricity of the drilling liquid is improved and the processing cost of the drilling liquid is lowered, and the preparation method is suitable for various types of water-based drilling fluids.

Owner:CHINA PETROLEUM & CHEM CORP +1

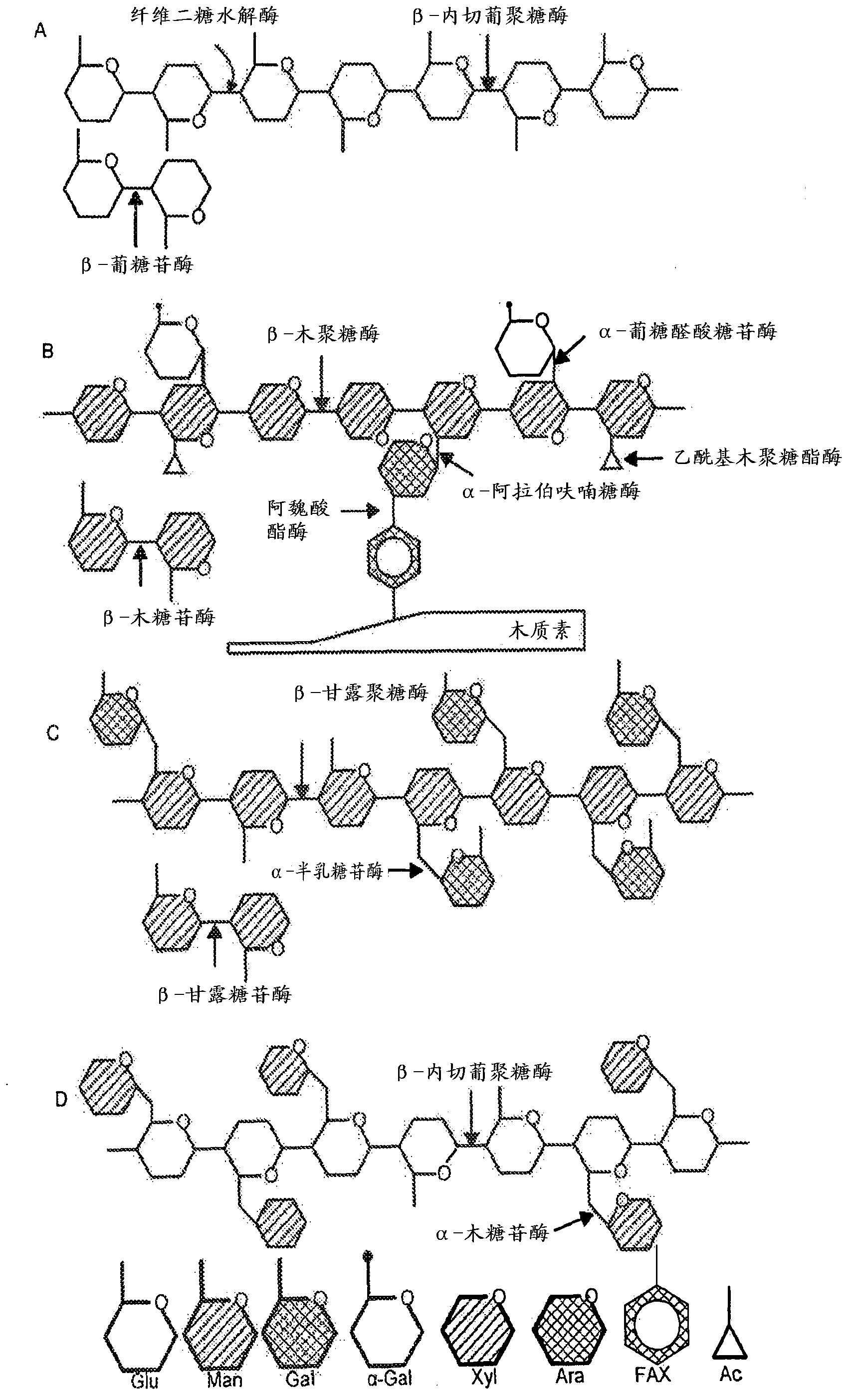

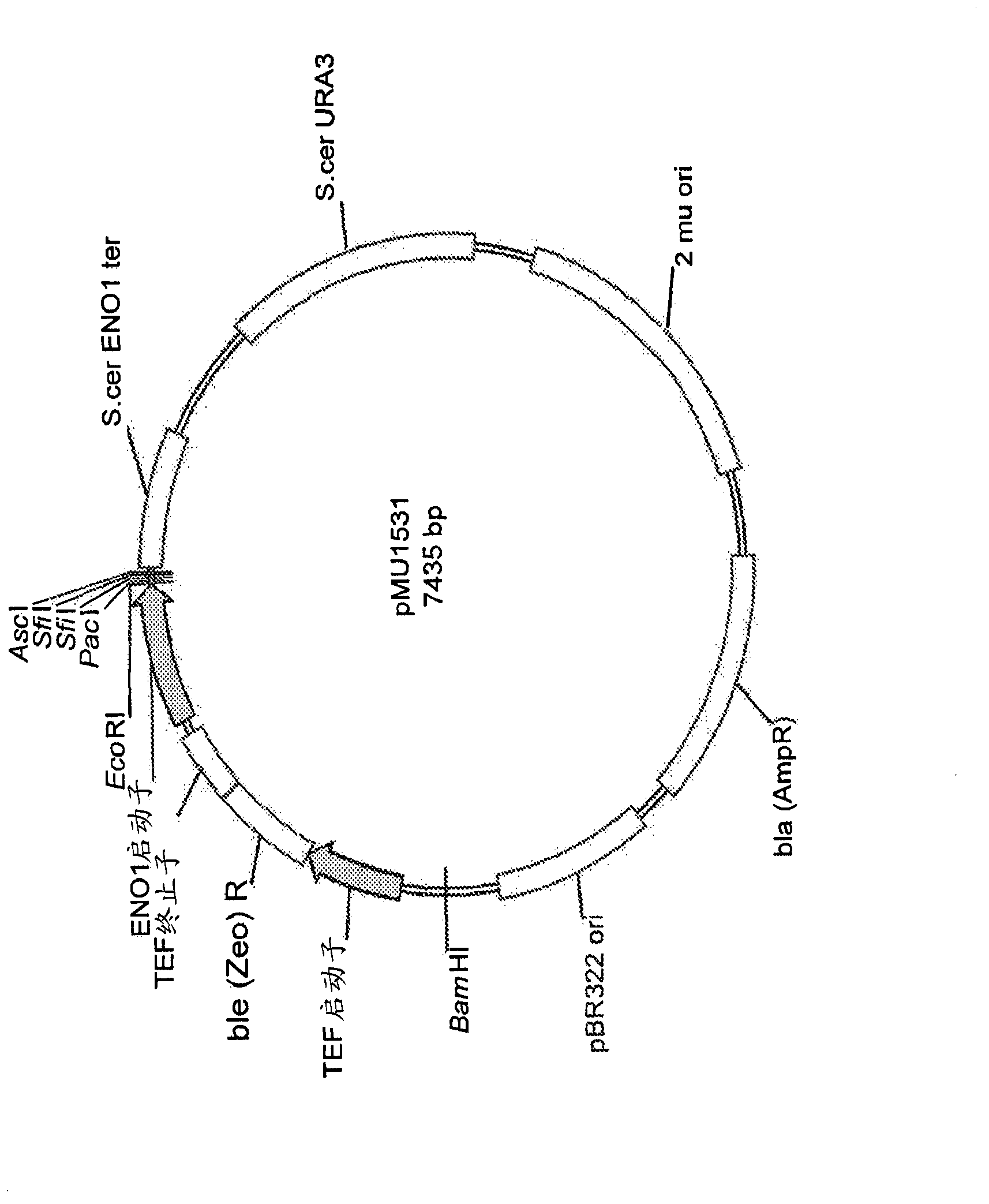

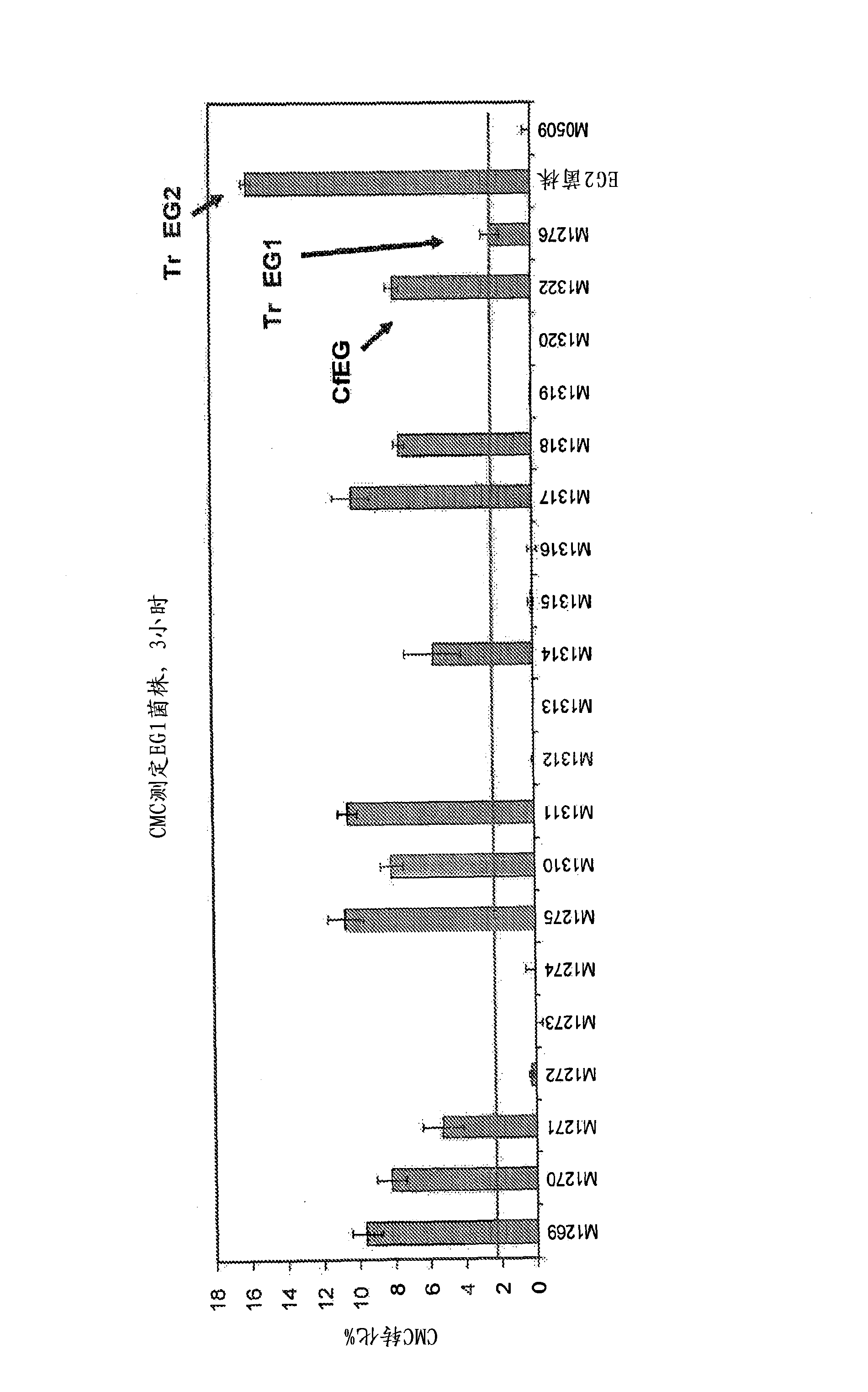

Yeast expressing saccharolytic enzymes for consolidated bioprocessing using starch and cellulose

The present invention is directed to a yeast strain, or strains, secreting a full suite, or any subset of that, full suite, of enzymes to hydrolyze com starch, corn fiber, lignocellulose, (including enzymes that hydrolyze linkages in cellulose, hemicelhiiose, and between lignin and carbohydrates) and to utilize pentose sugars (xylose and arabinose). The invention is also directed to the set of proteins that are well expressed in yeast for each category of enzymatic activity. The resulting strain, or strains can be used to hydrolyze starch and cellulose simultaneously. The resulting strain, or strains can be also metabolically engineered to produce less glycerol and uptake acetate. The resulting strain, or strains can also be used to produce ethanol from granular starch without liquefaction.; The resulting strain, or strains, can be further used to reduce the amount of external enzyme needed to hydrolyze a biomass feedstock during an Simultaneous Saccharification and Fermentation (SSF) process, or to increase the yield of ethanol during SSF at current saccharolytic enzyme loadings. In addition, multiple enzymes of the present invention can be co-expressed in cells of the invention to provide synergistic digestive action on biomass feedstock. In some aspects, host cells expressing different heterologous saccharolytic enzymes can also be co-cultured togetherand used to produce ethanol from biomass feedstock.

Owner:LALLEMAND HUNGARY LIQUIDITY MANAGEMENT LLC +1

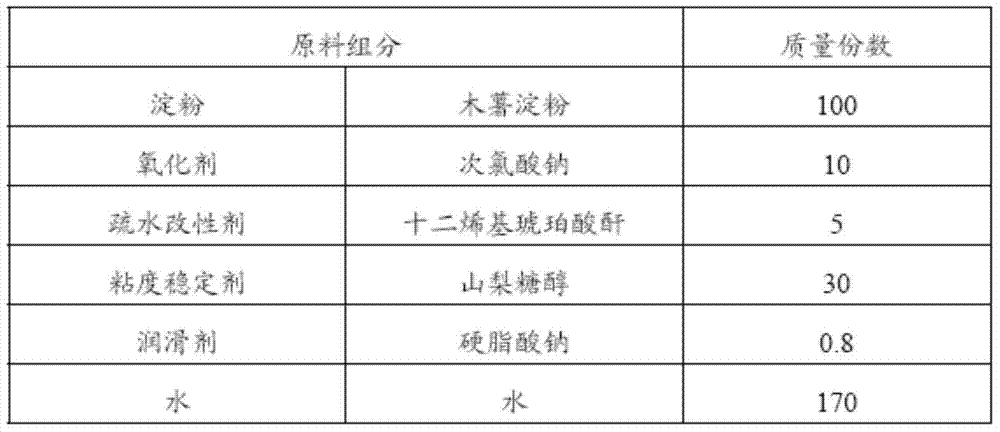

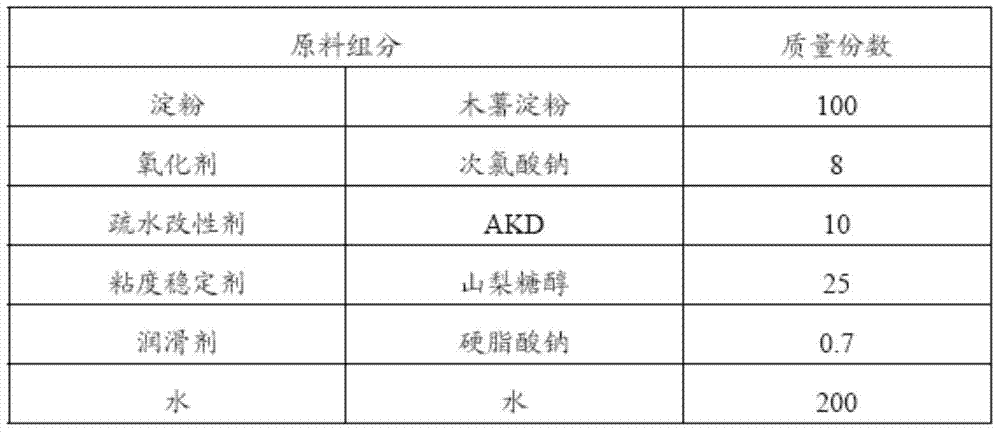

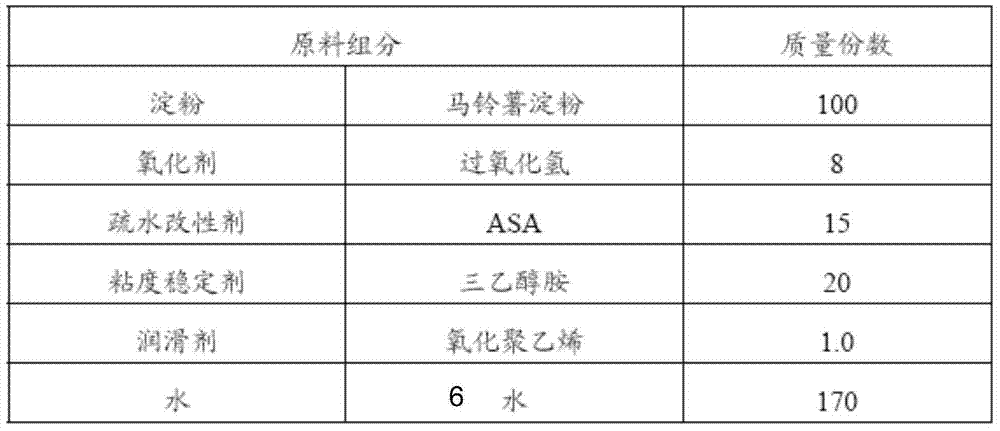

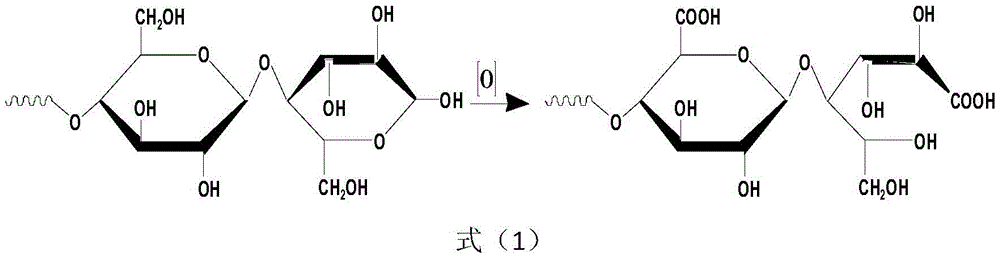

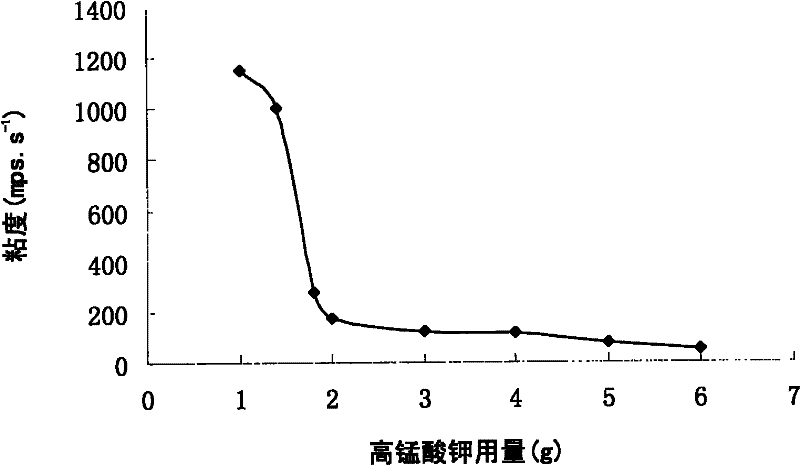

Latex for papermaking, preparation method and coating containing latex for papermaking

ActiveCN103757980AImprove performanceImprove water resistancePaper forming aids additionEpoxyPapermaking

The invention provides latex for papermaking. The latex contains starch, oxidants, hydrophobic modifying agents and water, wherein the dosage of the oxidants is 7-10% of the mass of starch; the dosage of the hydrophobic modifying agents is 5-20% of the mass of the starch; the hydrophobic modifying agents are selected from at least one of dodecenyl succinic anhydride, maleic anhydride, epoxy chloropropane, an alkyl ketene dimmer, alkenyl succinic anhydride, a styrene-acrylate copolymer, a silane coupling agent and a titanate coupling agent. The invention also provides a preparation method of the latex for papermaking and a coating containing the latex for papermaking. The problems that the wet strength of finished paper is poor and dusting happens easily because the paper is coated with the starch-based latex for papermaking in existing processes are solved.

Owner:GOLD HUASHENG PAPER SUZHOU IND PARK

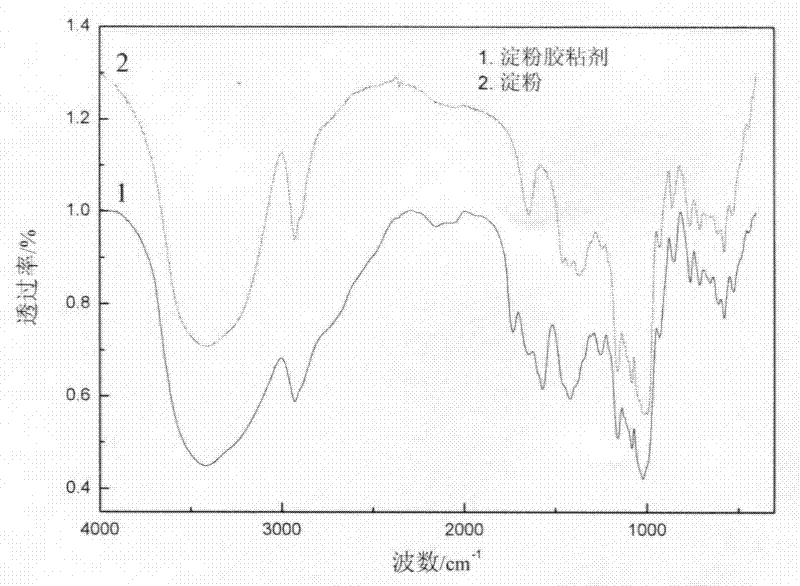

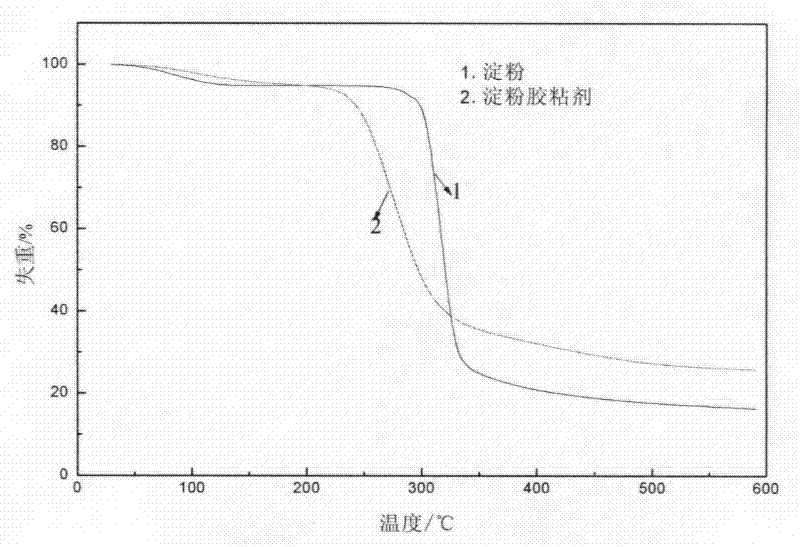

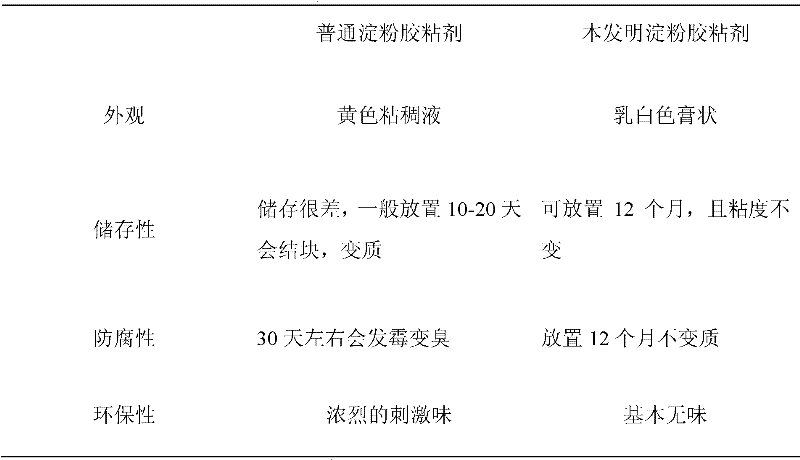

Starch adhesive with nanometer oxidized cellulose size as matrix and preparation method of starch adhesive

ActiveCN105542676AAvoid replacementPrevent drynessNon-macromolecular adhesive additivesStarch derivtive adhesivesPolymer scienceSlurry

The invention discloses a starch adhesive with nanometer oxidized cellulose size as the matrix. The starch adhesive is prepared from, by weight, 100 parts of nanometer oxidized cellulose size with the oxidation rate of 5-30%, 10-40 parts of starch, 2-5 parts of oxidizing agent, 0.1-2 parts of stabilizer, 0.1-2 parts of preservative and 0.1-2 parts of emulsified paraffin. The preparation method includes the steps of preparing nanometer oxidized cellulose size the with oxidation rate of 5-30%, adding starch and 2-5 parts of oxidizing agent to the prepared nanometer oxidized cellulose size in batches, adding stabilizer, preservative and emulsified paraffin after sufficient stirring, and sufficiently stirring the components at a temperature of 50-70 DEG C till all the components are evenly dispersed to obtain the starch adhesive. The starch adhesive is high in bonding strength and high in water resistance. By means of the preparation method, the solvent replacement and drying process is avoided, energy consumption is greatly lowered, and labor intensity is reduced.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Modified starch binder used for granulation of organic fertilizer and preparation method thereof

ActiveCN102477171ALow costImprove transportation efficiencyFertilizer mixturesCross-linkOrganic fertilizer

The invention provides a modified starch binder used for granulation of an organic fertilizer and a preparation method thereof. The method comprises the following steps: 1) subjecting plant starch to an oxidation reaction so as to obtain oxidized starch; 2) adding a gelatinizing agent into the oxidized starch and carrying out a cross-linking reaction so as to obtain the modified starch binder. Modified starch prepared by using the method has the advantages of low cost, environment friendliness and a good granulation bonding effect. Raw materials used for the binder are environment friendly and can degrade rapidly. When applied in granulation of an organic fertilizer, the binder enables the organic fertilizer to form granules, improves transport and usage efficiency of the organic fertilizer and strengthens popularization and application of the organic fertilizer.

Owner:北京永丰泰生物科技有限公司

Starch esters and method of preparation

A lipophilic starch is provided along with methods of making the same. The starch is prepared by modifying the starch with an organic acid anhydride reagent, such as octenyl succinic anhydride, drying the modified starch to a moisture content of less than 15% by weight, and then heat treating the dried starch at a temperature of at least 100° C. for at least one minute.

Owner:KANSAS STATE UNIV RES FOUND

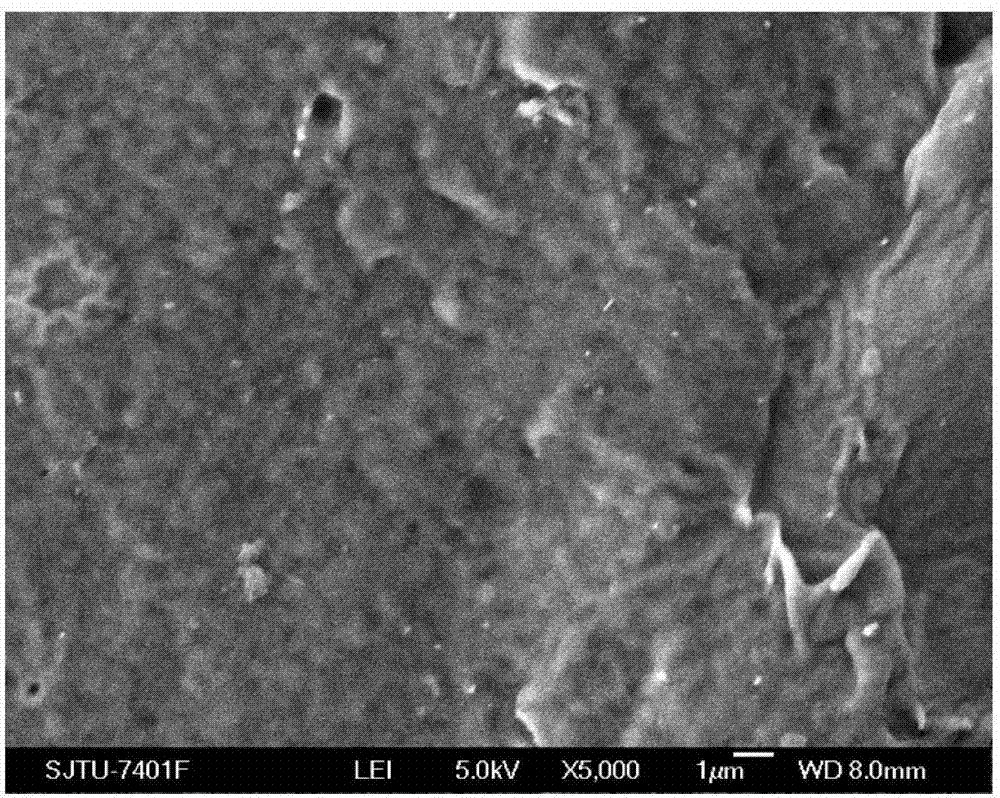

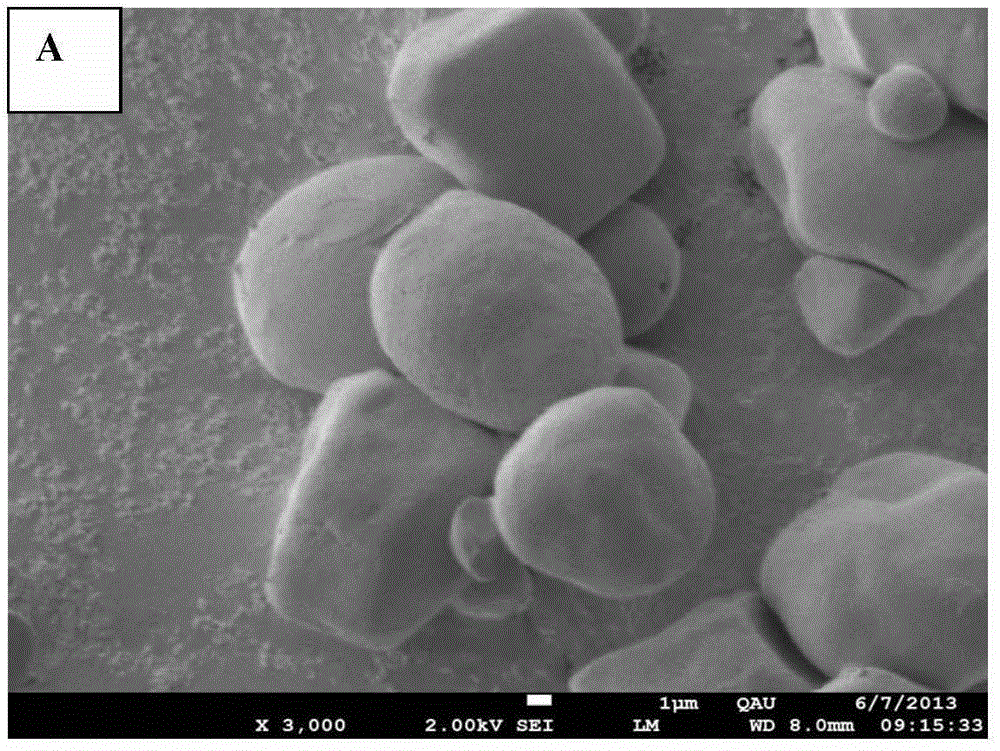

Preparation method of plastic starch-modified PBAT (poly(terephthalic acid-buthylene succinate)) biodegradable material

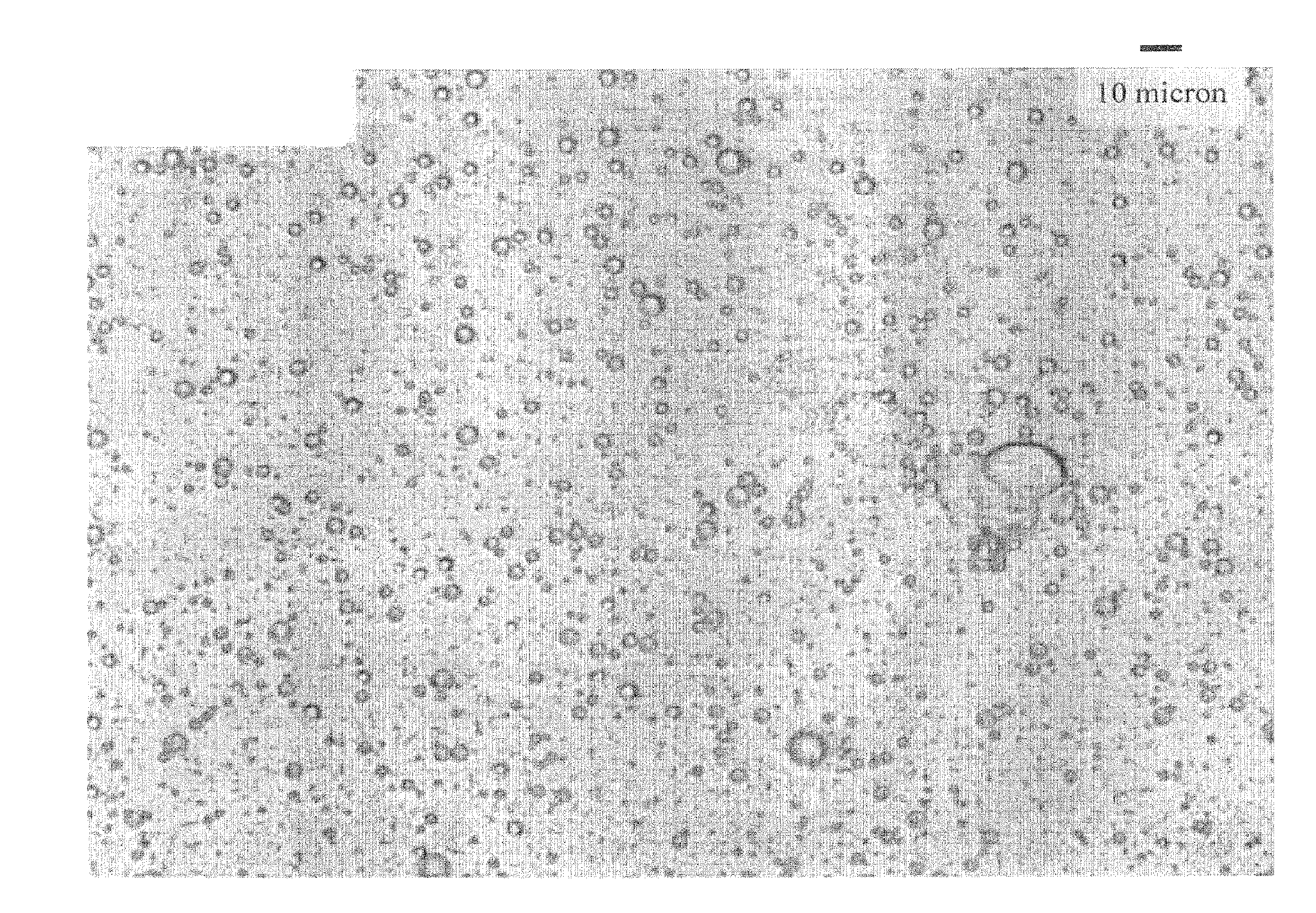

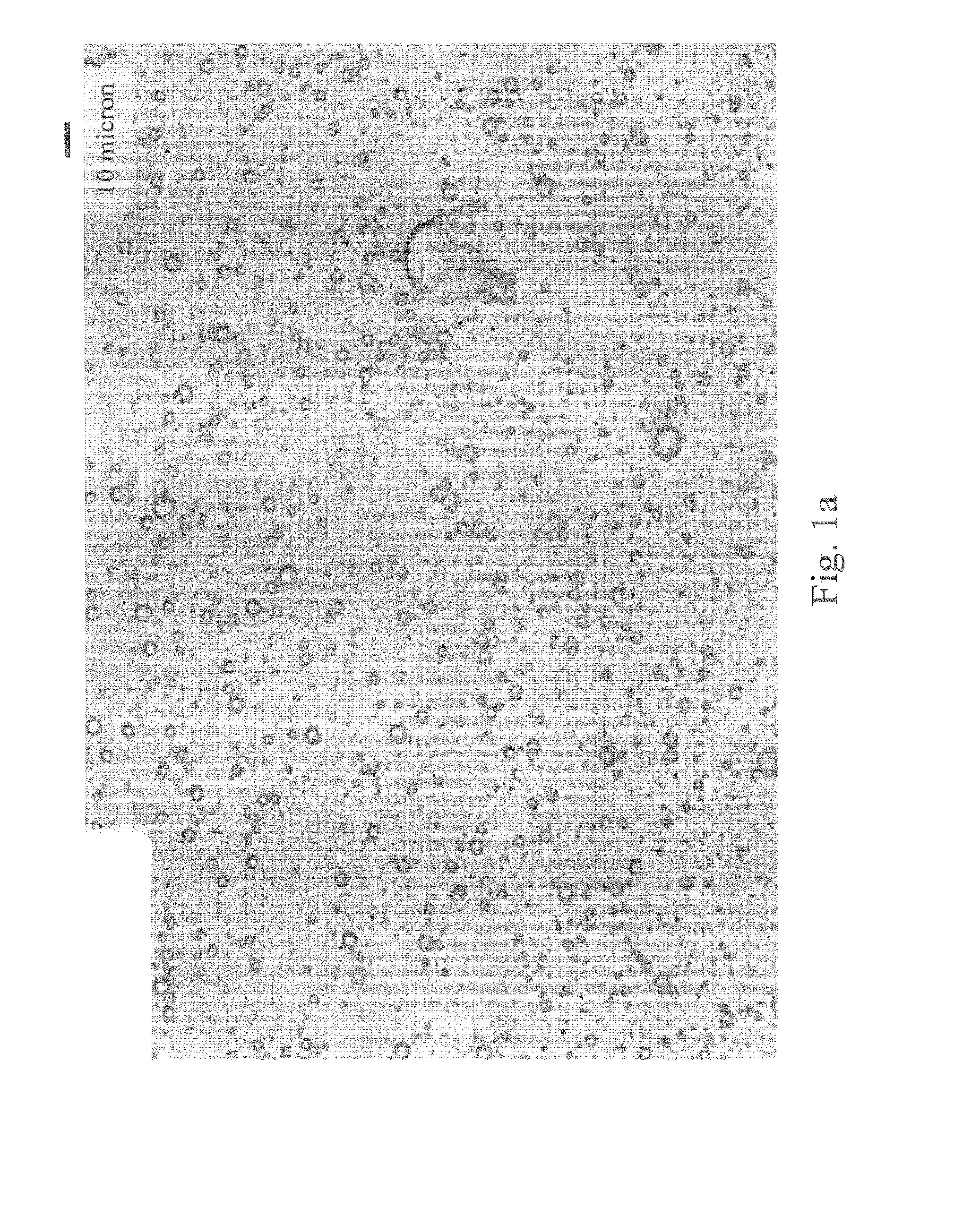

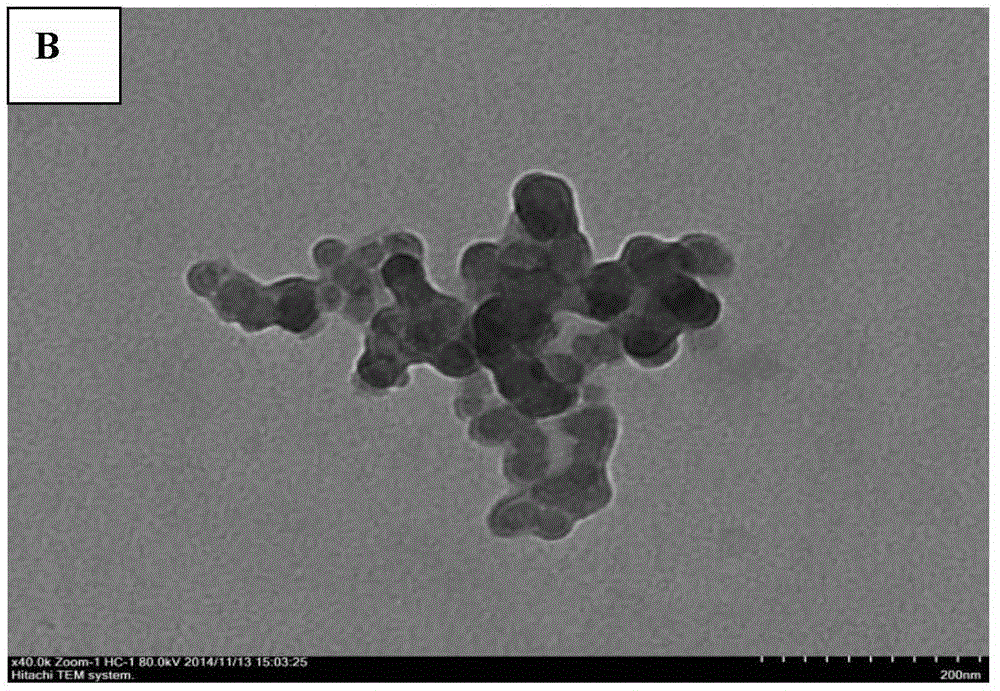

The invention relates to a preparation method of a plastic starch-modified PBAT (poly(terephthalic acid-buthylene succinate)) biodegradable material. The preparation method comprises the following three steps: preparing a plastic starch; performing melt blending on the plastic starch and PBAT; and processing the modified material. The plastic starch-modified PBAT biodegradable material can be applied through multiple processing measures of injection moulding, cast moulding, film casting, extrusion moulding and the like. In the modified material, the starch recycling rate is low, and the recycled starch has the particle diameter of 1-50 nm and is uniformly dispersed in a matrix; the tensile strength is 10-15 MPa, the elongation at break is 100-700%, and the melt index (150 DEG C, 2160g) is more than or equal to 1 g / 10 min; and under a composting condition, the plastic starch-modified PBAT biodegradable material is kept for 30 days at the temperature of 20-50 DEG C and the humidity of 30-60%, and 50-75% of the plastic starch-modified PBAT biodegradable material can be degraded. The plastic starch-modified PBAT biodegradable material integrates excellent mechanical properties and biodegradability and has a relatively large potential in industrial application.

Owner:SHANGHAI JIAO TONG UNIV +1

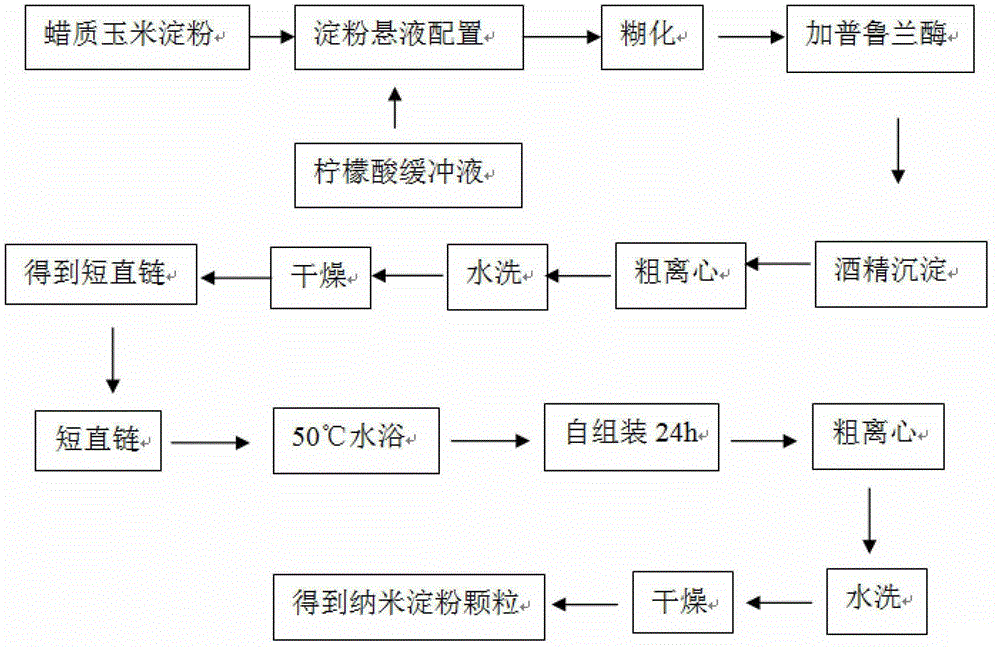

Process for moderate-temperature self-assembly preparation of nano starch from enzymolysis short amylose

The invention discloses a process for moderate-temperature self-assembly preparation of nano starch from enzymolysis short amylose. The process particularly comprises the following steps: (1) preparing a buffer solution; (2) preparing a starch water solution; (3) past-forming; (4) enzymolyzing, and then using anhydrous ethanol to precipitate the degreased starch solution; (5) preparing short amylose; (6) preparing nano starch. According to the process, enzyme hydrolysis starch is adopted to prepare nano starch at 30-70 DEG C in an anabiosis manner, the nano starch prepared by the method is high in productivity, low in cost, safer and more environment-friendly, and can serve as embedding materials of medicines, active ingredients and the like, and the application field of the process in the food industry is widened.

Owner:QINGDAO AGRI UNIV

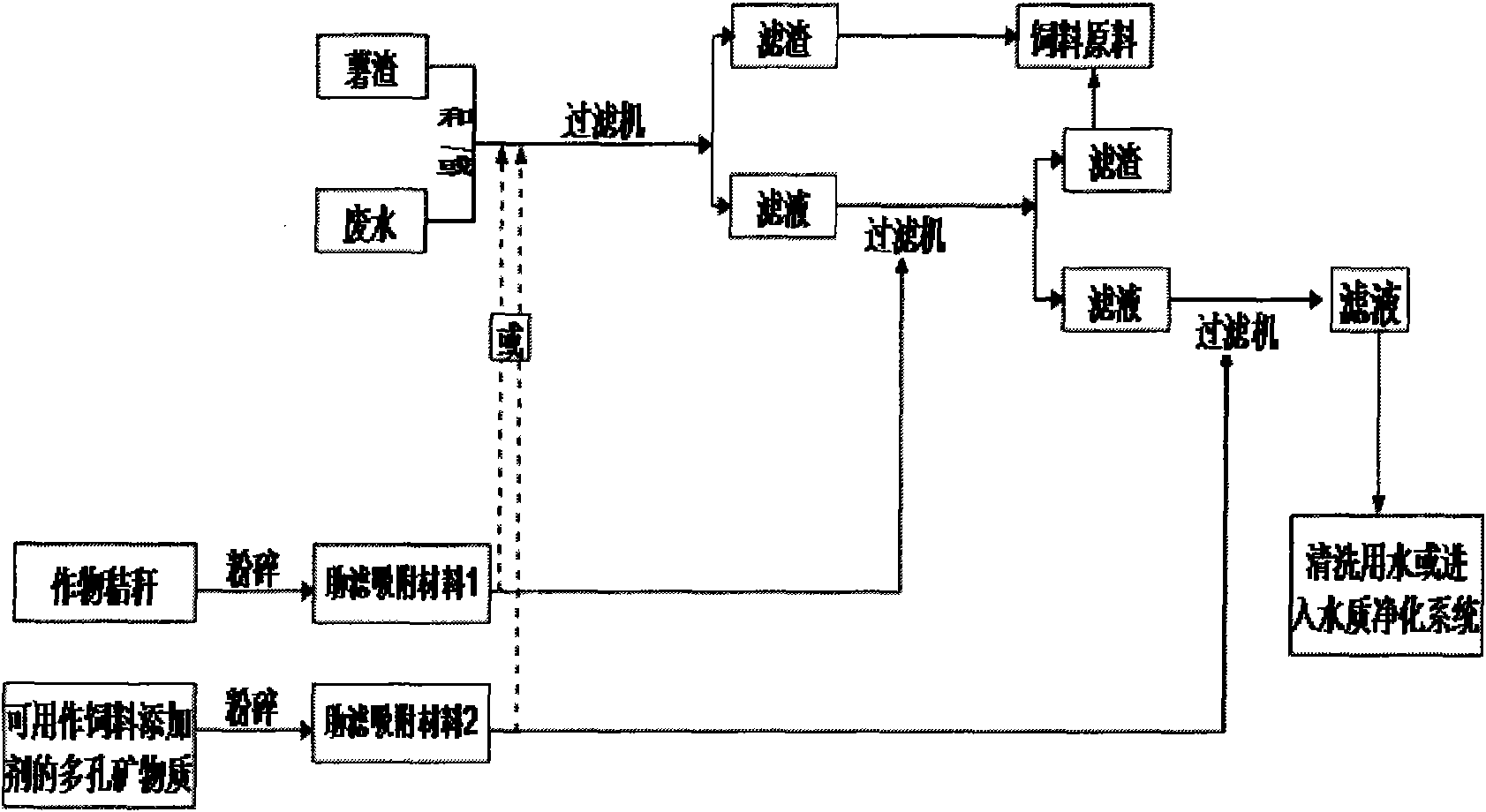

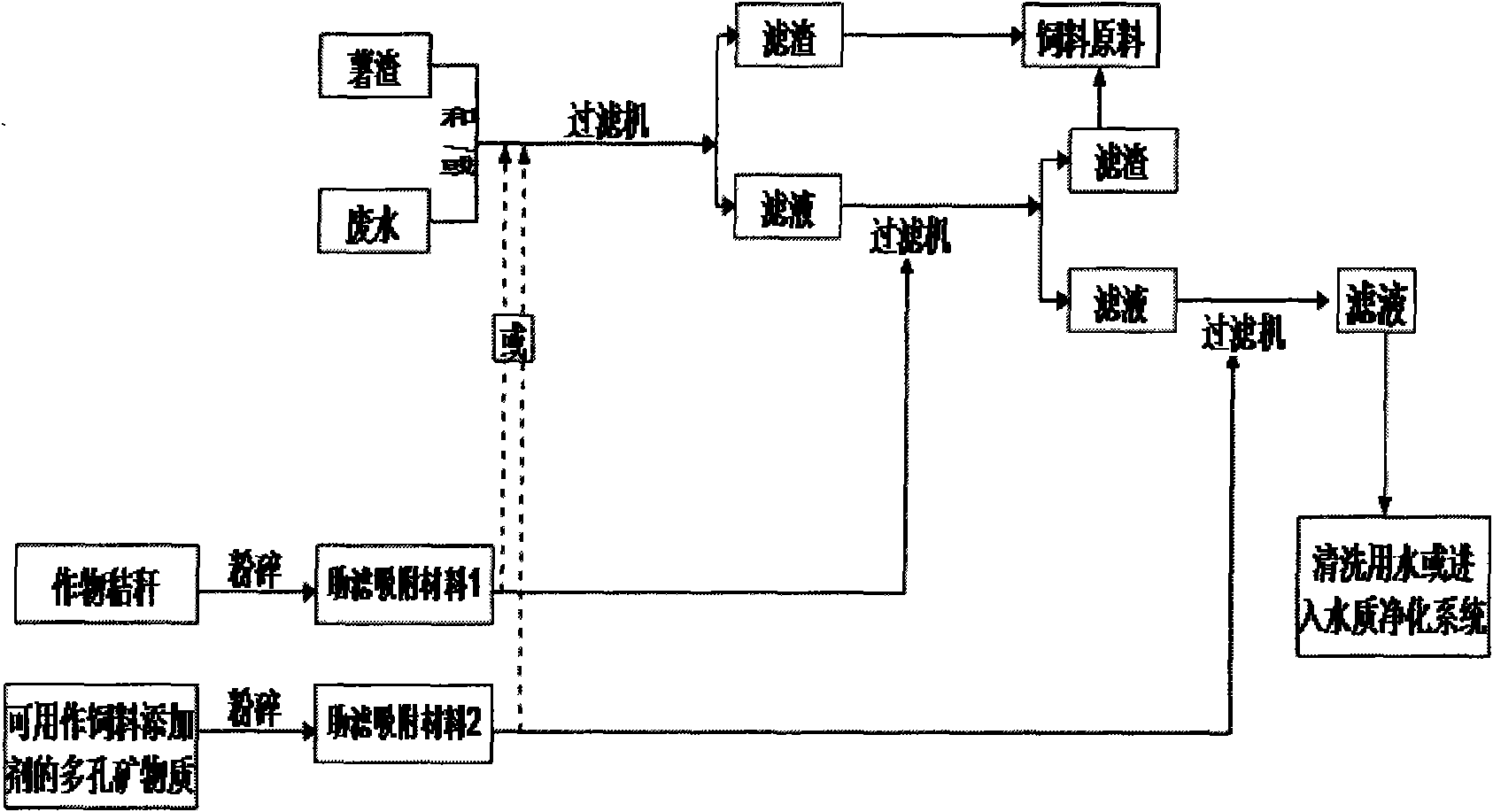

Method for recycling potato residue and waste water in production process of potato starch

InactiveCN101990987AReduce equipment costsLow running costOther chemical processesFood processingSubstance usePotato starch

The invention relates to the field of industrial production of potato starch and provides a method for recycling potato residue and waste water in the production process of potato starch. The method mainly comprises the following steps of: respectively pulverizing crop straws and porous mineral substances used as a feedstuff additive into certain size of particles as filtering-assisted adsorbing materials through a physical method; and carrying out filtering treatment by stages by utilizing the two filtering-assisted adsorbing materials in a process of recycling potato residue and waste water organic matters generated when processing the potato starch. The recycled organic matters, such as small particle starch, protein, polysaccharide, and the like and the filtering-assisted adsorbing materials can be together used as feedstuff materials, and the purpose of purifying the waste water is also achieved; and the purified water can be used as washing water for potato processing directly or through precipitating.

Owner:甘肃省农业科学院农产品贮藏加工研究所

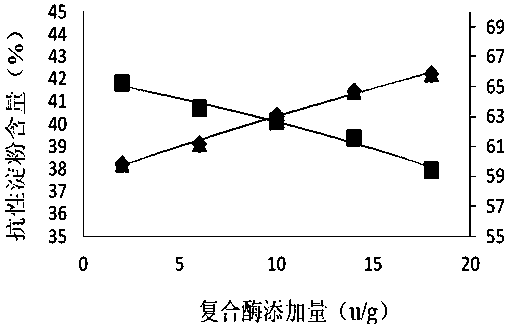

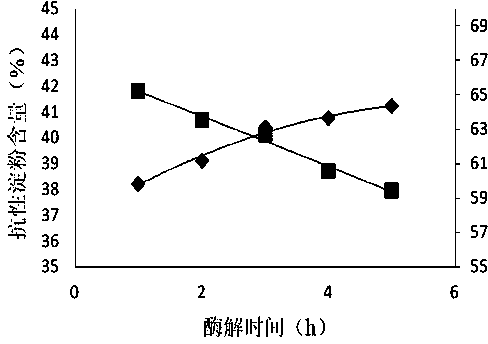

Processing method of slowly digestible and resistant starch-containing food raw material

ActiveCN103621870AWide variety of sourcesSimple processing technologyFood thermal treatmentLipidic food ingredientsOil and greaseGranularity

The invention discloses a processing method of a slowly digestible and resistant starch-containing food raw material. The processing method comprises the steps: crushing starch or a starch-containing food raw material, screening with a 60-100-mesh sieve, drying until the water content is 3-8 percent, adding grease which accounts for 5-25 percent of the dry basis weight of the starch, and uniformly mixing; heating to 40-60 DEG C, keeping stirring and mixing for 1-3h, adjusting the content of water in the obtained mixture to 10-40 percent, heating to 80-120 DEG C in a closed container, keeping stirring and mixing for 3-12h, and slowly cooling the mixture to the room temperature; and drying, crushing, and controlling the granularity of the material to obtain the slowly digestible and resistant starch-containing food raw material. The processing method provided by the invention has the advantages of simple process, advanced process, and the like; the safety of products processed by using the method is high; the obtained food raw material is rich in the slowly digestible and resistant starch, has the characteristics of nutrient enrichment and the like, and is widely applied to food processing fields such as functional foods and health-care products.

Owner:SOUTH CHINA UNIV OF TECH

Production technology for continuously extracting starch, oil and sugar from cyperus esculentus

The invention relates to agricultural product deep processing, and relates to a production technology for continuously extracting starch, oil and sugar from cyperus esculentus. The method comprises the steps that: raw materials are crushed and grinded into a first slurry; water with a volume two times than that of the residue from the previous step is added to the residue, and a second grinding step is carried out; an obtained slurry is separated such that a second slurry is separated from the residue; the first slurry and the second slurry are mixed for extracting starch and oil, and the residue is used for extracting sugar; oil is extracted through an aqueous enzymatic method; the obtained oil is layered through centrifuging and is enzyme-killed, such that upper layer oil and cyperus esculentus crude oil are obtained; sugar is extracted; extracted sugar is in a form of transparent light yellow syrup, and serves as a raw slurry for the preparations of various sugars.

Owner:CHANGCHUN UNIV

Low-viscosity starch glue for preparing starch capsules as well as preparation method and application of low-viscosity starch glue

InactiveCN103834066ALow viscosityMeet the requirements of automated productionPharmaceutical non-active ingredientsCapsule deliveryPlasticizerUltimate tensile strength

The invention discloses low-viscosity starch glue for preparing starch capsules as well as a preparation method and an application of the low-viscosity starch glue. According to the preparation method disclosed by the invention, a starch structure is sheared through amylase for the first time in a process of preparing the starch glue, thus preparing starch glue that viscosity is reduced to 1000-7000cps. Furthermore, the invention provides a preparation method of the low-viscosity starch glue, wherein the low-viscosity starch glue is prepared from starch or modified starch, gel and a plasticizer through such steps as dissolving at a low temperature, gelatinizing at a high temperature and enzymatically hydrolyzing at an intermediate temperature to control viscosity. To improve strength of the low-viscosity starch glue, the method disclosed by the invention initiates a way of adding a starch glue enhancer to the starch glue, so that tensile strength of the starch glue can reach 15-40MPa. The prepared starch glue disclosed by the invention is applicable to automatic production of various hollow capsules.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

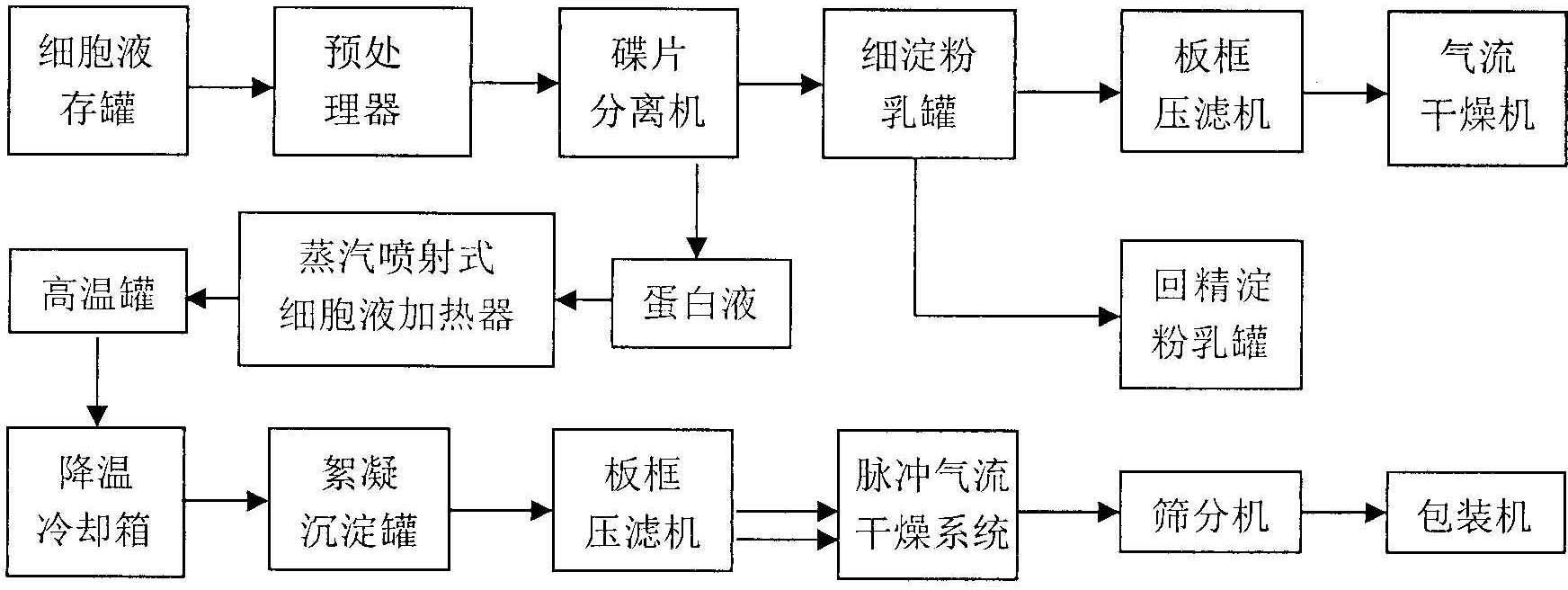

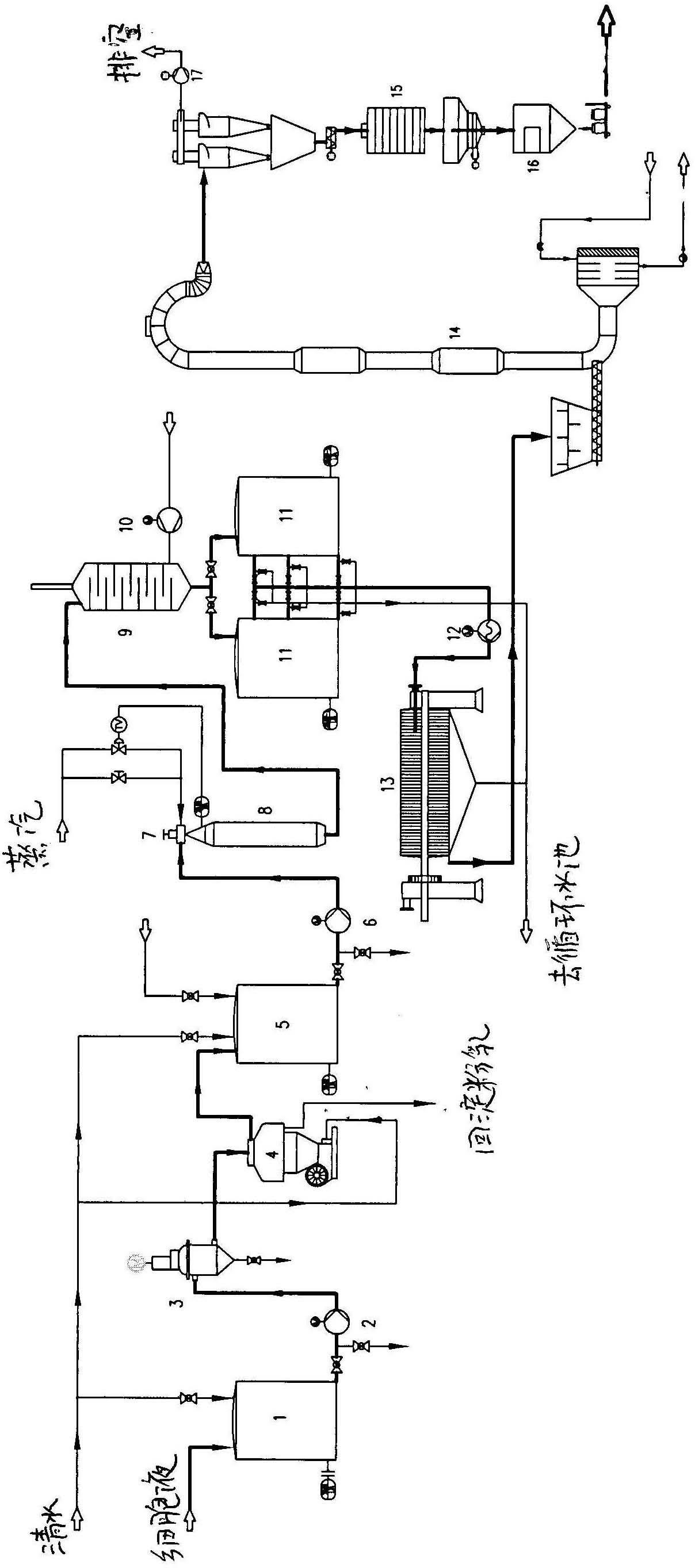

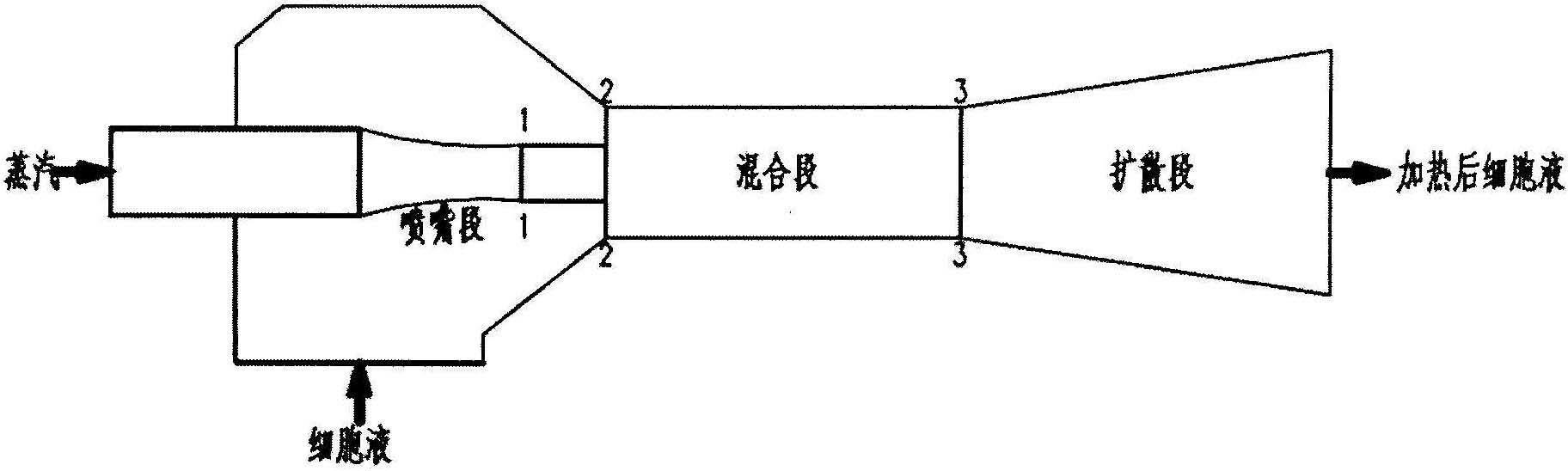

Process for extracting sweet potato protein by thermal deposition method

ActiveCN102558327ACompletely brokenEasy to separatePeptide preparation methodsPlant peptidesFiberSolubility

The invention relates to a process for extracting sweet potato protein by a thermal deposition method. The process is characterized by comprising the following steps of: treating cell sap to extract the sweet potato protein from the cell sap while producing sweet potato starch, separating and purifying by using a disc separator according to the difference of specific gravity of the protein and other substances such as starch and the like, removing fine fibers according to the solubility of the protein and the size of particles, and further purifying; purifying, concentrating, and degeneratingthe sweet potato protein to generate floccules according to the characteristic that the protein is degenerated at high temperature by a physical heating method; and concentrating, squeezing for dehydrating, drying, sieving, and performing aftertreatment to obtain a sweet potato protein commodity. The invention has the advantages that: (1) the sweet potato protein is degenerated by a steam jet cell sap heater, a moving part is not provided, and continuous production is ensured; (2) chemicals such as a flocculating agent and the like are not added, so that pollution is avoided, and subsequent treatment difficulty is reduced; and (3) the process is technically mature, and the industrial production capacity can be achieved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Corn starch adhesive for building and preparation method thereof

InactiveCN102391797AReduce consumptionReduce oxidationStarch derivtive adhesivesAcetic anhydrideAdhesive

The invention provides a corn starch adhesive for a building and a preparation method thereof. The adhesive is prepared from the following components in parts by mass: 10-30 parts of corn starch, 50-150 parts of tap water, 0.1-0.8 part of oxidant, 0.5-2 parts of esterifying agent, 0.4-0.8 part of alkali, 0.4-0.5 part of acid regulating agent, 0.1-0.2 part of preservative, 0.005-0.001 part of tributyl phosphate and 0.01-0.02 part of catalyst, wherein the oxidant is hydrogen peroxide; the esterifying agent is acetic anhydride, maleic anhydride or phthalic anhydride; and the catalyst is ferrous sulfate, copper sulfate or ferric chloride. The corn starch adhesive is a starch adhesive formed by directly gelatinizing oxidized and esterified starch, has good bonding effect and has the advantages of simple process, low cost, no environment pollution and the like.

Owner:SHANXI UNIV

Preparation process of rice high fructose syrup

InactiveCN101979643APromote deep processingUse valueFermentationIsomerizationHigh-fructose corn syrup

The invention relates to a preparation process of rice high fructose syrup, which belongs to the technical field of biological enzymolysis. The preparation process is characterized by comprising the following process steps of: washed rice soaking; thick fluid grinding; liquefaction and enzyme inactivation; rice dreg filtration; saccharification and enzyme inactivation; decolorization and filtration; ion exchange and concentration; isomerization; secondary decolorization and filtration; and secondary ion exchange and vacuum concentration, wherein when the syrup concentration reaches 70 to 75 percent, the concentration is stopped to obtain a finished product, namely 42% high fructose syrup. The preparation process directly takes rice as a raw material to produce the high fructose syrup through a biological enzymolysis technique, thereby not only saving a process step of preparing starch from foodstuff and greatly reducing the production cost, but also promoting intensive processing of the rice, bringing the utilization value of the rice into play to the utmost extent, and strongly promoting the diversified development of grain processing enterprises.

Owner:曾爱民

Method for pretreating cotton fabrics by adopting glucoamylase/glucose oxidase, pectinase and CBD (cellulose-binding domain)-lignin peroxidase

InactiveCN102154810AImprove qualityImprove dyeing qualityBiochemical fibre treatmentDry-cleaning apparatus for textilesChemical treatmentPectinase

The invention provides a method for pretreating cotton fabrics by adopting glucoamylase / glucose oxidase, pectinase and CBD (cellulose-binding domain)-lignin peroxidase, belonging to the technical field of cotton fabric dyeing and finishing pretreatment. The method is characterized in that the cotton fabrics are firstly treated in mixed enzyme solution containing the glucoamylase and the glucose oxidase and the glucoamylase catalyzes the starch size on the fabrics to be decomposed into glucose so as to eliminate the size; the glucose oxidase catalyzes the glucose and oxygen to act to generate hydrogen peroxide; the generated hydrogen peroxide not only plays a role of bleaching but also can damage the hydrophobic surface structure of the cotton to expose the lower pectic substances; then the cotton fabrics are treated in alkaline pectinase solution to remove the pectic substances through decomposition; and finally the cotton fabrics are treated in CBD-lignin peroxidase solution to finally remove the cotton seed hulls through decomposing the lignin in the cotton seed hulls. The method provided by the invention can replace the traditional chemical treatment method to realize full bio-enzyme pretreatment of the cotton fabrics, and at the same time the traditional hydrogen peroxide can be no longer adopted for bleaching.

Owner:JIANGNAN UNIV +1

Modified starch and manufacturing method and application of modified starch

ActiveCN102634049AReduce crystallinityImprove chemical reactivityOrganic solventOCTENYLSUCCINIC ACID

The invention discloses modified starch and a manufacturing method and application of the modified starch. The manufacturing method of the modified starch provided by the invention comprises the following steps: dispersing starch by an organic solvent, adding water and uniformly mixing to prepare a starch suspension, and performing the microwave or the ultrasonic treatment to obtain the modified starch. According to the invention, crystalline regions in modified starch granules are greatly reduced, and the crystallinity of the modified starch granules is decreased from 15-45% to 8-30%. After the crystallinity is decreased, cassava starch is used for manufacturing dialdehyde starch, hydroxypropyl starch and octenyl succinic anhydride starch ester and has obviously improved reactivity.

Owner:GUANGXI UNIV FOR NATITIES

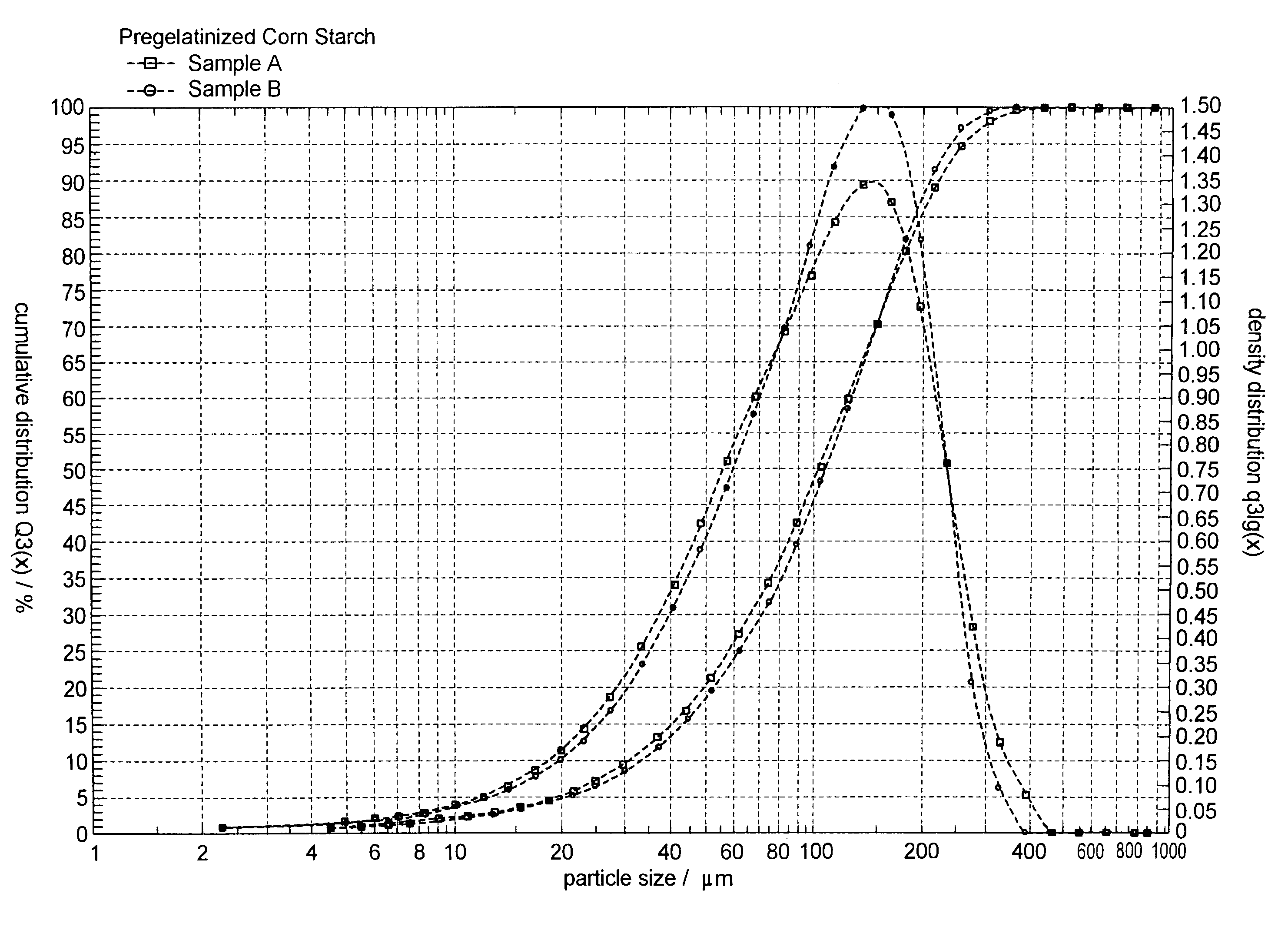

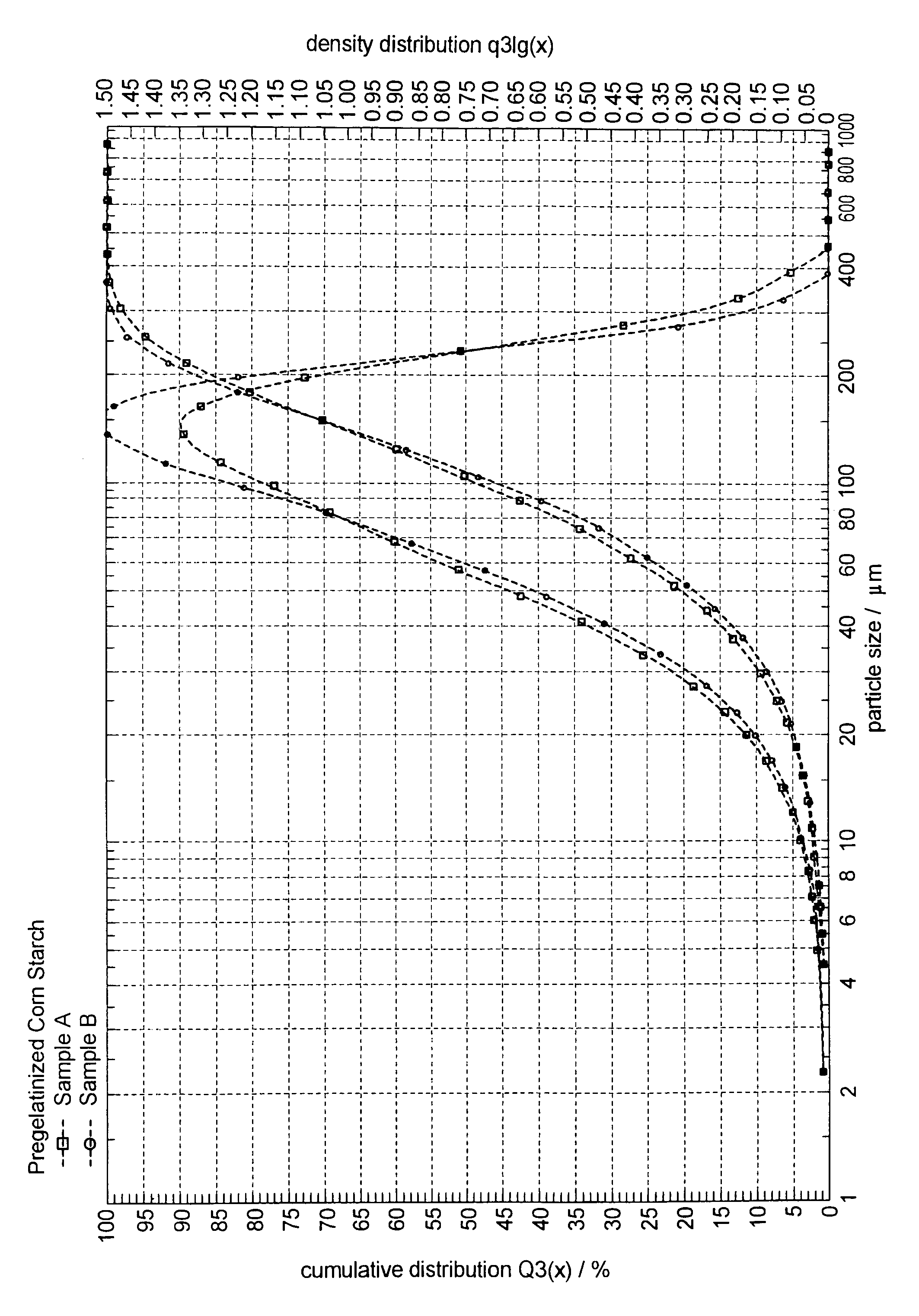

Method of water dispersing pregelatinized starch in making gypsum products

Owner:UNITED STATES GYPSUM CO

Novel starch-polyvinyl alcohol blend fully-degradable plastic film and preparation method thereof

InactiveCN104927093AScientific and reasonable particle sizeSmall particle sizeEnvironmental resistanceTert butyl

The invention discloses a novel starch-polyvinyl alcohol blend fully-degradable plastic film. The novel starch-polyvinyl alcohol blend fully-degradable plastic film is characterized by being prepared from the following raw materials in parts by weight: 60-65 parts of corn starch, 7-9 parts of nano montmorillonite, 0.6-0.7 part of peanut oil, 1.2-1.4 parts of tetrabutyl titanate, 12-14 parts of ramie sticks, 30-35 parts of polyvinyl alcohol, 2-3 parts of gelatin, 1-2 parts of magnesium stearate, 13-15 parts of acetyl tributyl citrate, 4-6 parts of nano titanium dioxide, and 1-1.5 parts of 2,6-di-tert-butyl-4- methyl phenol. The product disclosed by the invention is produced by a safe formula, and can be used for manufacturing a food packaging bag and the like; in use, the product is high in strength, waterproof, oil-resistant and durable in use, beneficial to realizing large-scale industrial production, easy to grasp, and convenient to popularize; and under the action of oxygen enrichment and microorganisms, the wasted product is automatically degraded and finally generates carbon dioxide and water, so that the novel starch-polyvinyl alcohol blend fully-degradable plastic film is ecological and environmentally-friendly.

Owner:TONGLING FOUNDER PLASTICS TECH

Method of preparing sugar by utilizing sweet potato residues

ActiveCN102559811AIncrease synergistic enzymolysisPromote digestionFermentationLiquid productAdditive ingredient

The invention relates to filed of biology and in particular relates to a method of preparing sugar by utilizing biomass sweet potato residues, used for microbial fermentation, as a sugar source. The method comprises the following steps of: adjusting the pH of sweet potato residue powder or wet residue to be 5.5-8.0, and carrying out heat preservation by adding alpha-amylase; adjusting the pH to be 3.0-5.5, carrying out enzyme removal after carrying out heat preservation at 40-65 DEG C by adding saccharifying enzyme, acid protease and cellulose; and carrying out solid-liquid separation on a feed liquid, and concentrating the liquid to obtain a sugar liquid product, wherein the ingredient of the sugar liquid product is basically the glucose. The preparation method is simple in process, highin specificity, high in product quality, and high in yield, can be used for solving the problem that the environment is severely polluted by the sweet potato residues, and is good in industrial application prospect.

Owner:SHANDONG BIO SUNKEEN

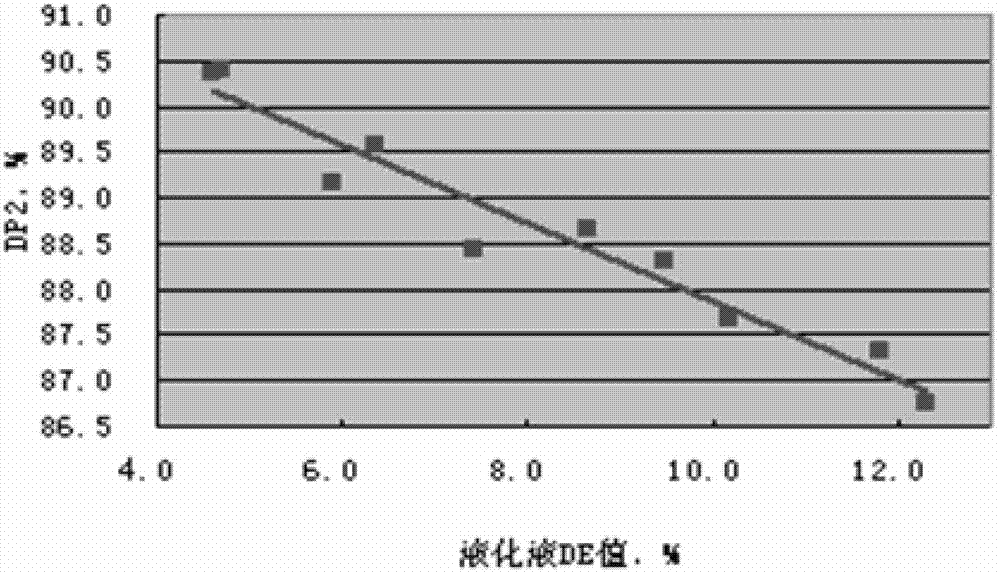

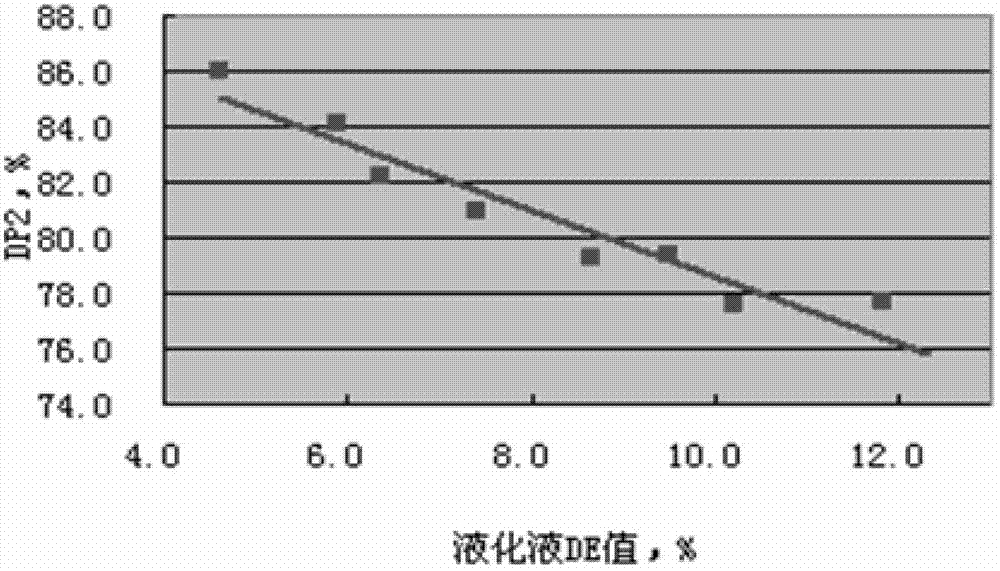

Preparation method for ultrahigh-content malt syrup

InactiveCN102766666AOptimal Hydrolysis Substrate ConditionsDiversified means of adjustmentFermentationAmylaseFiltration

The invention relates to a preparation method for ultrahigh-content malt syrup, which includes the following steps: (1) grain starch as material is added with water and produced into slurry, the dry matter concentration of the slurry is regulated to be 20 to 30 percent, the pH value of the slurry is regulated to be 5.8 to 6.2, and thermostable amylase is added into the slurry; (2) a cooker is used for cooking the slurry under 108 DEG C to 110 DEG C for 5 to 6 minutes, so that starch paste is obtained, the starch paste is liquefied to be hydrolyzed, the liquefaction time is 30 to 150 minutes, and after the temperature is increased to kill enzyme, aqueous maltodextrin solution is obtained; (3) the pH value of the aqueous maltodextrin solution is regulated to 5.0 to 5.2, the aqueous maltodextrin solution is added with diastatic enzyme, the bienzyme method or the trienzyme method is adopted to saccharify the aqueous maltodextrin solution, the saccharification time is 50 to 60 hours, and after the temperature is increased to kill enzyme, the ultrahigh-content malt syrup is obtained. According to the preparation method, low-DE value maltodextrin without needing filtration can be stably obtained, more than 85 percent of maltose can be obtained, and the method has a good application prospect.

Owner:SHANGHAI EAST TIDE BIOLOGICAL TECH DEV

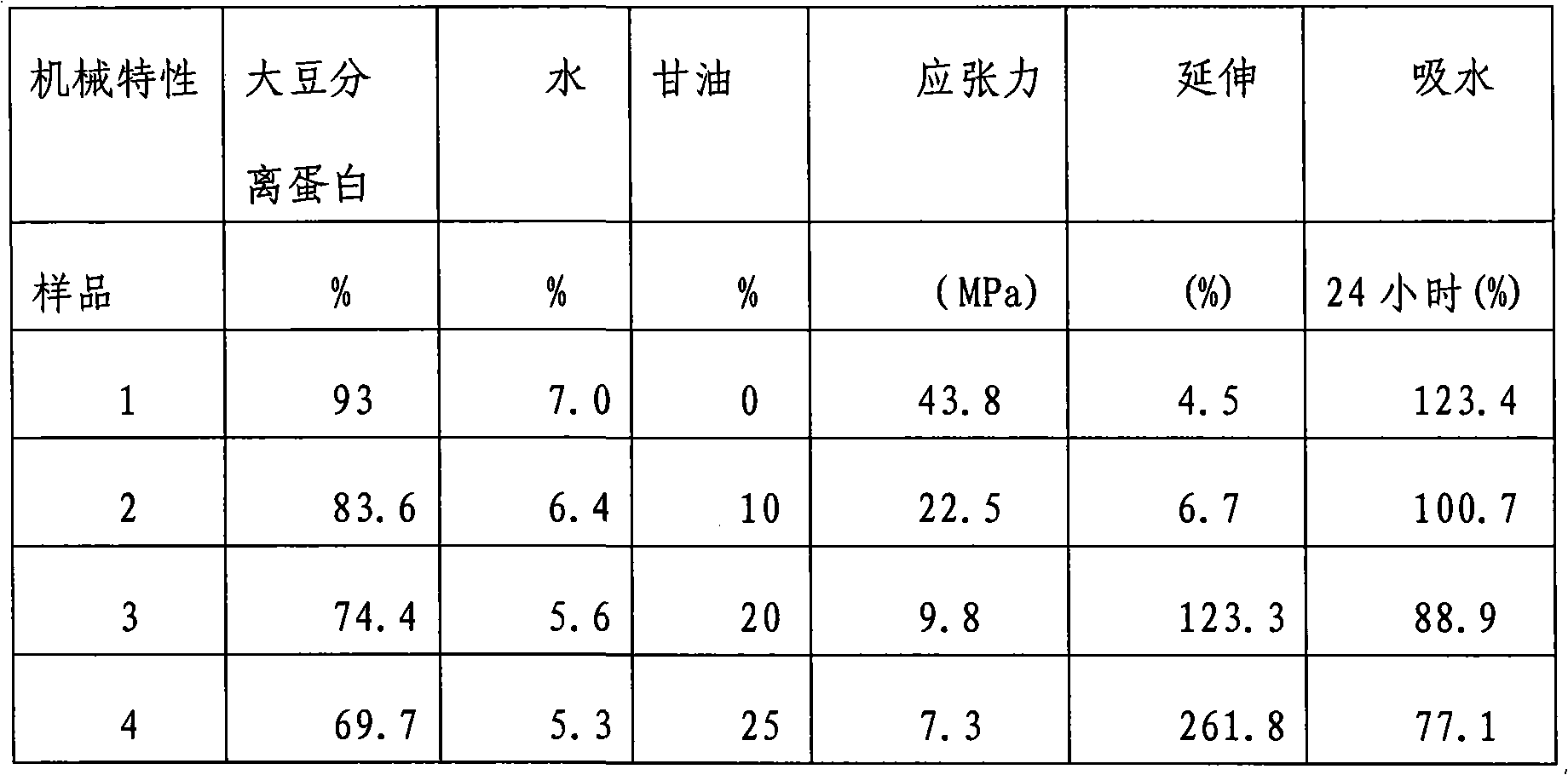

Prescription of biodegradable soybean protein thermoplastic material

The invention provides a prescription of a biodegradable soybean protein thermoplastic material, which comprises the following components in percentage by weight: 25-65 percent of protein, 30-40 percent of starch filler, 5-35 percent of plasticizer, 0.5-2.5 percent of reducing agent and 5-25 percent of water. The components have high flowability needed by machining, form a curing object with high tensile strength and high water resistance by extrusion or injection moulding and can be biodegraded.

Owner:SHANDONG WONDERFUL IND GROUP

Preparation method of low-viscosity cation starch

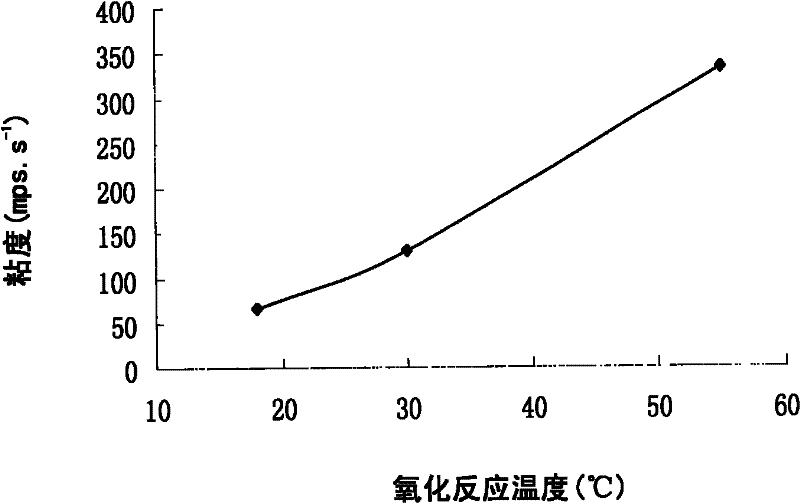

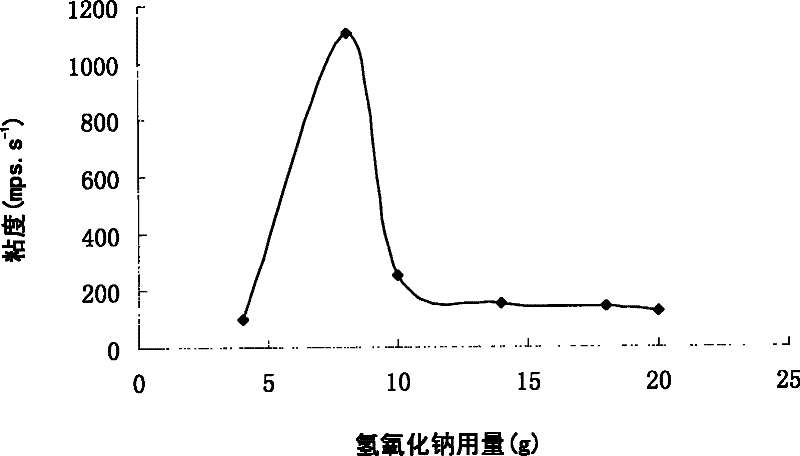

InactiveCN102161708AStrong positive chargeLow viscosityWater-repelling agents additionPapermakingSurface strength

The invention relates to a preparation method of low-viscosity cation starch, comprising the following steps: 1) preparing native starch into a 35-40% starch suspension by clear water, successively adding an inhibitor, an activated viscosity breaking agent and a metal ion catalyst under the state of stirring, heating to 42DEG C, adding a cation etherifying agent activated by an alkaline activator, keeping the temperature of 42-52DEG C, and reacting for 0.5-3 hours; 2) continuously adding an oxidant A in a flowing mode, and reacting for 2-5 hours; 3) cooling to 30-35DEG C, adjusting pH to 8.5 by hydrochloric acid, continuously adding an oxidant B in a flowing mode, adjusting the pH of the starch suspension to 8.5-9.5 by a base catalyst, keeping the temperature of 30-38DEG C, and reacting for 0.5-1.5 hours; and 4) adjusting the pH of the suspension to 6.5 by the hydrochloric acid, adding a stabilizer, washing after 20 minutes, dewatering and drying to obtain the product. The starch particle has strong positive charge, paste has the characteristics of low viscosity, good rheological property and high adhesive strength and is used for high-density surface sizing for papermaking, and the surface strength and the printability of paper can be obviously improved.

Owner:广西农垦明阳生化有限公司

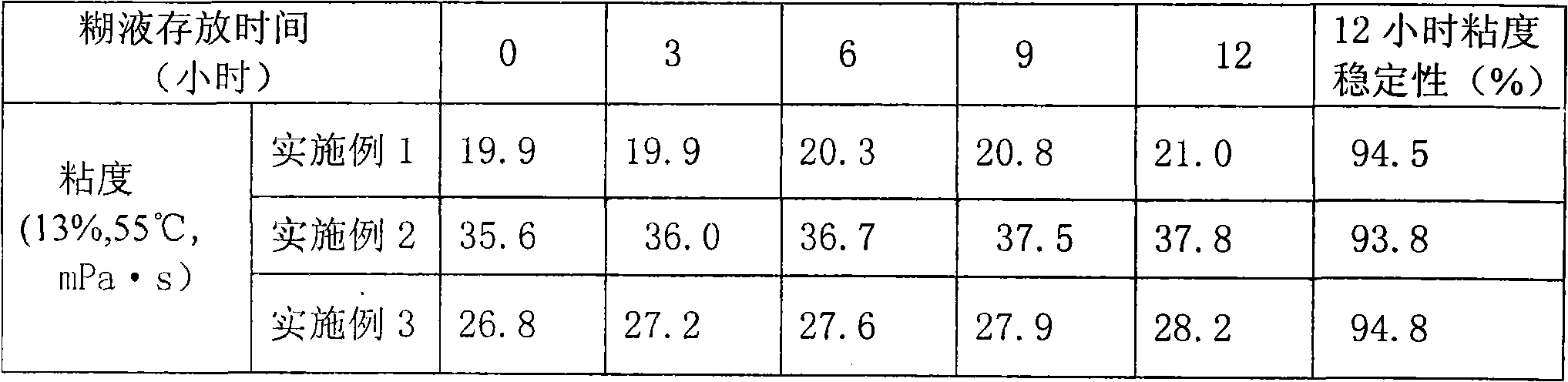

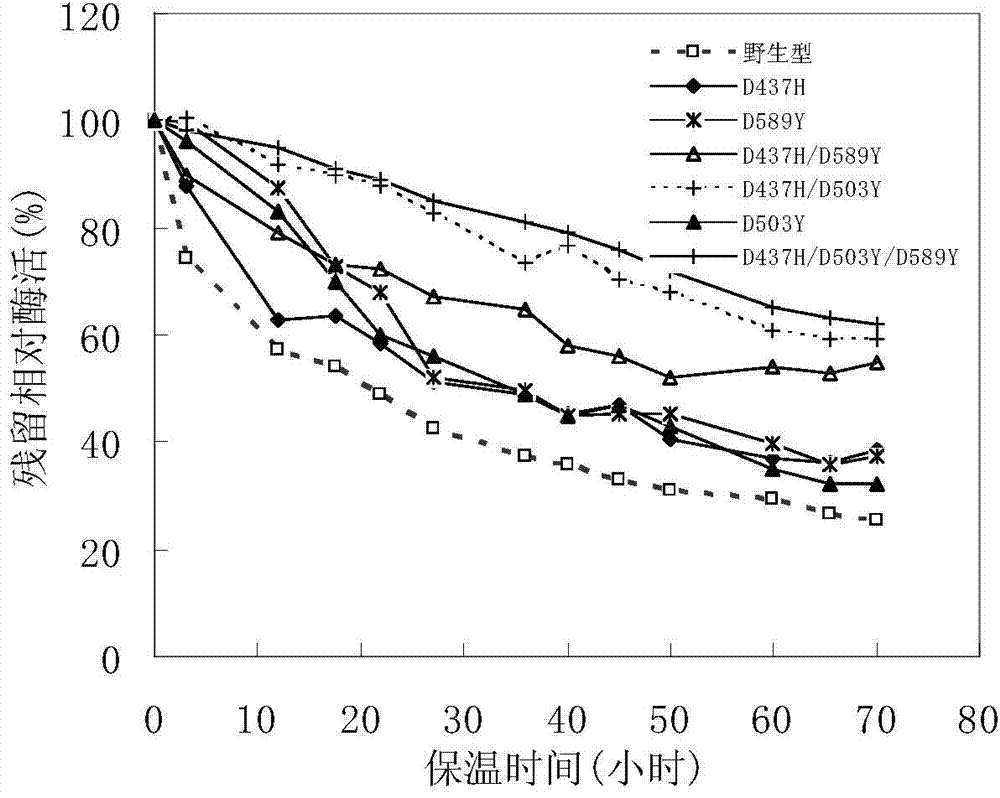

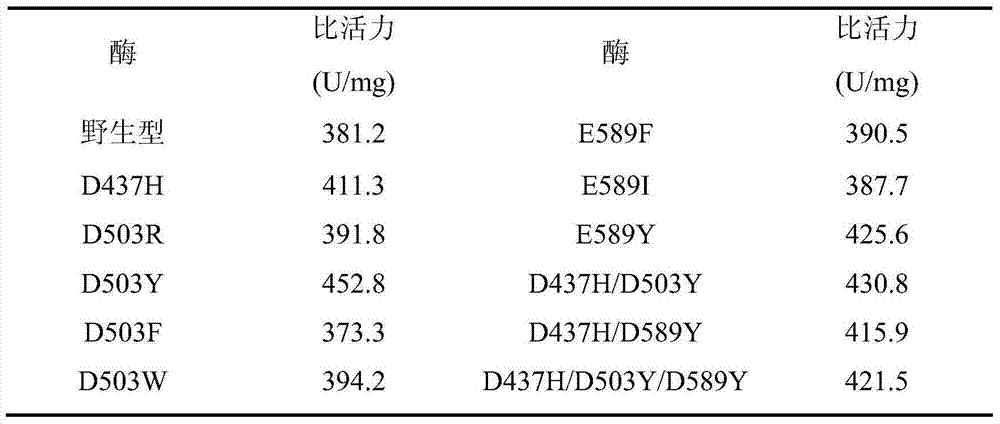

Pullulanase mutant and preparation method thereof

ActiveCN103484443AHigher than vitalityHigh activityMicroorganism based processesFermentationArginineWild type

The invention discloses a pullulanase mutant having a high specific activity and a high thermal stability, and a preparation method thereof. The mutant comprises one, two or three substituents relative to debranching Bacillus spp Pullulanase active amino acid residues and related with the thermal stability of pullulanase; and the active amino acid residues comprise 503th aspartic acid, and can be mutated to form arginine, phenylalanine and tryptophan or tyrosine, the above mutation improves the high specific activity and the high thermal stability of the pullulanase, and at least one of the cases comprising the rise of a best reaction temperature, the improvement of the thermal stability at a pH value of 4.0-5.0 and the improvement of the specific activity at a pH value of 4.0-5.0 is realized. The mutant is more suitable for the starch saccharification production process than wild pullulanase.

Owner:JIANGNAN UNIV

Polylactic acid/starch biologic degradable composite material and preparation method thereof

The invention discloses a polylactic acid / starch biologic degradable composite material which is prepared from the following components in percentage by weight: 30-94% of polylactic acid, 0.1-10% of phenol epoxy compounds, 5-60% of natural starch, 0-1% of an antioxidant, 0-5% of a lubricant, 0-1% of a catalyst and 0-1% of a hydrolysis resisting agent. The composite material is safe and non-toxic, biodegradable and excellent in mechanical performance. The invention further discloses a preparation method of the polylactic acid / starch biologic degradable composite material. The preparation method comprises the following steps: uniformly mixing the polylactic acid, the phenol epoxy compounds, the natural starch and various assistants; then, adding the mixed materials into a phenol epoxy compounds for melt blending; then, bracing and dicing; and drying to obtain the polylactic acid / starch biologic degradable composite material. The preparation method is simple, easy to control and implement, strong in operability and low in production cost, and the prepared composite material can be applied to the fields of thin films and disposable tableware and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

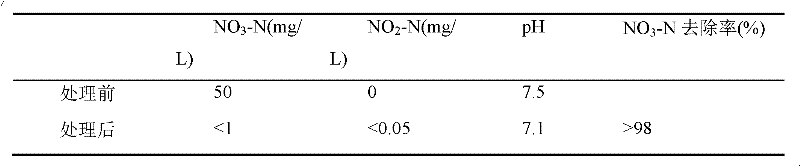

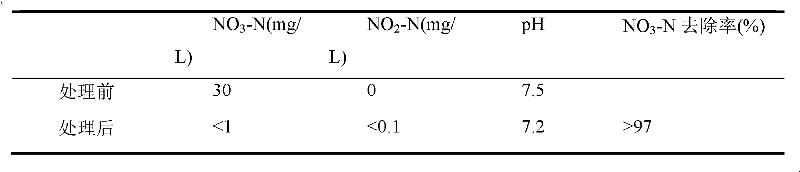

Starch and polycaprolactone blend and preparation method and application thereof

InactiveCN102212259AReduce the cost of denitrificationAvoid the process of thermoplasticizationTreatment with anaerobic digestion processesSolid carbonSurface water

The invention discloses a starch and polycaprolactone blend, a preparation method thereof and application of the blend used as a solid carbon source to the removal of nitrate from water. The preparation method comprises the following steps of: adding additives such as a plasticizer and the like into starch and polycaprolactone which are taken as raw materials, stirring and mixing uniformly, performing one-time extrusion by using a twin-screw extruder, and pelleting to obtain a product. The starch / polycaprolactone blend can be synchronously taken as a denitrification carbon source and a biofilm carrier in water treatment, so that the disadvantages of the use of the conventional liquid denitrification carbon source are overcome; moreover, the cheap starch is added into the blend, so the method has a remarkable economic advantage compared with a method in which the polycaprolactone is used as the solid carbon source. The blend can be applied to biological denitrification fields of surface water containing nitrates which exceed the standard, underground water, advanced treatment of sewage treatment plants and the like.

Owner:PEKING UNIV

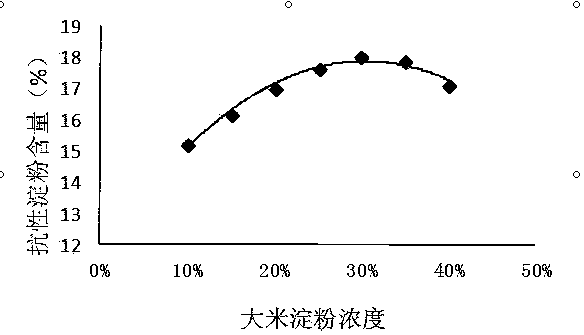

Production method for preparing resistant rice starch

ActiveCN103918872ARealize industrial productionImprove the utilization level of deep processingProtein foodstuffs working-upAmylaseDietary fiber

The invention relates to a production technology of resistant rice starch. A production method for preparing resistant rice starch comprises the following steps: firstly, gelatinizing, debranching and crystallizing the rice starch, and then drying the extracted resistant rice starch to obtain the resistant rice starch; improving the content of amylase in the rice starch by debranching treatment; controlling the concentration of the gelatinized rice starch at 20-50%, the debranching enzyme content at 12-25U / g, the debranching temperature at 45-55 DEG C and the debranching time at 12-20 hours; crystallizing under the condition of 2-12 DEG C after debranching is ended, and then extracting the resistant rice starch, and drying under the condition of 50-70 DEG C. The excessive rice resources such as broken rice and early indica rice can be reasonably utilized, the economic value of the potential resources is increased, and the produced resistant rice starch can overcome the defects of the traditional dietary fibers. By adopting the production method disclosed by the invention, the deep processing utilization level of the rice starch in China can be improved, and the method has important significance on development of grain storage enterprises and rural economy.

Owner:HENAN MINGYE BIOTECH

Preparation method of resistant dextrin

InactiveCN106755203AReduce the difficulty of subsequent separation and purificationReduce manufacturing costFermentationChromatographic separationDietary fiber

The invention relates to a preparation method of resistant dextrin. The method comprises the following steps: (1) adding starch dry powder into an acid solution, and stirring uniformly to obtain a starch acid treatment sample; (2) carrying out predrying pyrolysis reaction on the starch acid treatment sample to obtain a pyrolysis product; (3) carrying out polymerization reaction on the pyrolysis product to obtain the resistant dextrin crude product; (4) dissolving the resistant dextrin crude product in water, carrying out high-temperature alpha-amylase and composite saccharifying enzyme enzymolysis, and carrying out decolorization, ion exchange, concentration, chromatographic separation, secondary ion exchange, secondary concentration and drying to obtain the resistant dextrin. The starch dry powder is subjected to two dextrinization reaction stages and enzymolysis reaction to obtain the resistant dextrin with different dietary fiber contents by controlling the reaction conditions, thereby lowering the subsequent separation purification difficulty, lowering the production cost, optimizing the components of the resistant dextrin, and enhancing the product quality.

Owner:BAOLINGBAO BIOLOGY

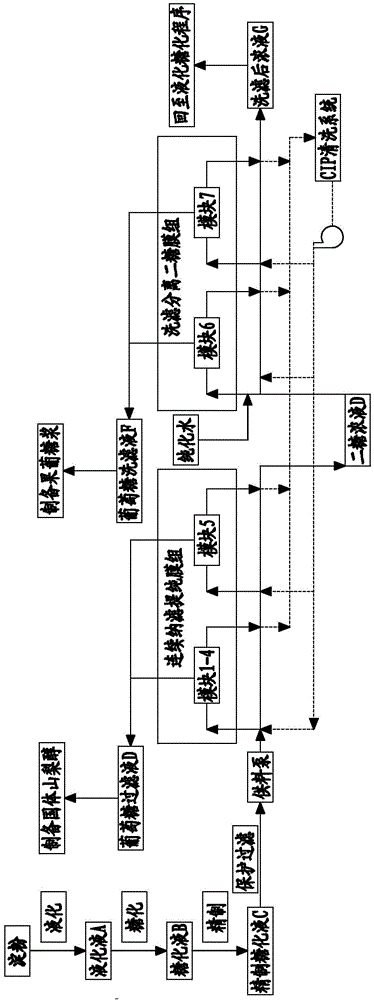

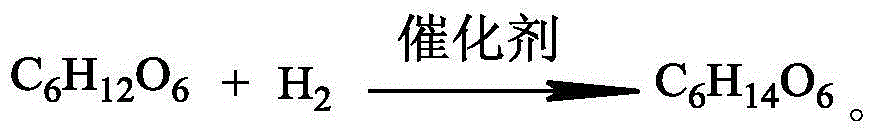

Process for preparing neosorb and coproducing fructose-glucose syrup

The invention discloses a process for preparing neosorb and coproducing fructose-glucose syrup. The process comprises the steps of (1) preparing a saccharified liquid from starch, and removing impurities to obtain a refined saccharified liquid; (2) carrying out nanofiltration treatment on the refined saccharified liquid to respectively obtain glucose filtrate and a disaccharide-concentrated liquid; (3) preparing neosorb from glucose filtrate; (4) carrying out nanofiltration treatment on the disaccharide-concentrated liquid to respectively obtain a glucose washing and filtering liquid and a washed and filtered concentrated liquid; and (5) preparing the fructose-glucose syrup from the glucose washing and filtering liquid, and mixing the washed and filtered concentrated liquid and the starch in the step (1) to prepare the saccharified liquid. According to the process, a continuous nanofiltration separation technology is adopted, the refined saccharified liquid is separated into several components with different glucose contents, then, products such as neosorb and the fructose-glucose syrup are respectively prepared according to different contents of all the components, and a low-content glucose solution is recycled, so that the whole process has the advantages that the saccharified liquid is efficiently utilized, and no resources are wasted.

Owner:ZHEJIANG HUAKANG PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com