Preparation method of plastic starch-modified PBAT (poly(terephthalic acid-buthylene succinate)) biodegradable material

A starch modification and plasticity technology, applied in the field of preparation of biodegradable materials, can solve the problems of not being able to be used as a continuous phase and losing value, and achieve the effects of great social significance and economic benefits, uniform dispersion and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The example adopts PBAT chip (Mw160000, MI 0.5g / 10min (150 ℃, 2160g)) 84wt%, tapioca starch 10wt%, plasticizer total content is 6wt%, including glycerin 2.4wt%, formamide 1.2wt%, urea 2.4 wt%.

[0021] The starch gelatinization temperature is 85°C, and the twin-screw extrusion rate is 10r / min; when the plastic starch and PBAT are dried, the vacuum degree is 1.3KPa, the drying temperature is 90°C, and the temperature is maintained for 9 hours; the melt blending temperature is 115°C, and extrusion Speed 15r / min.

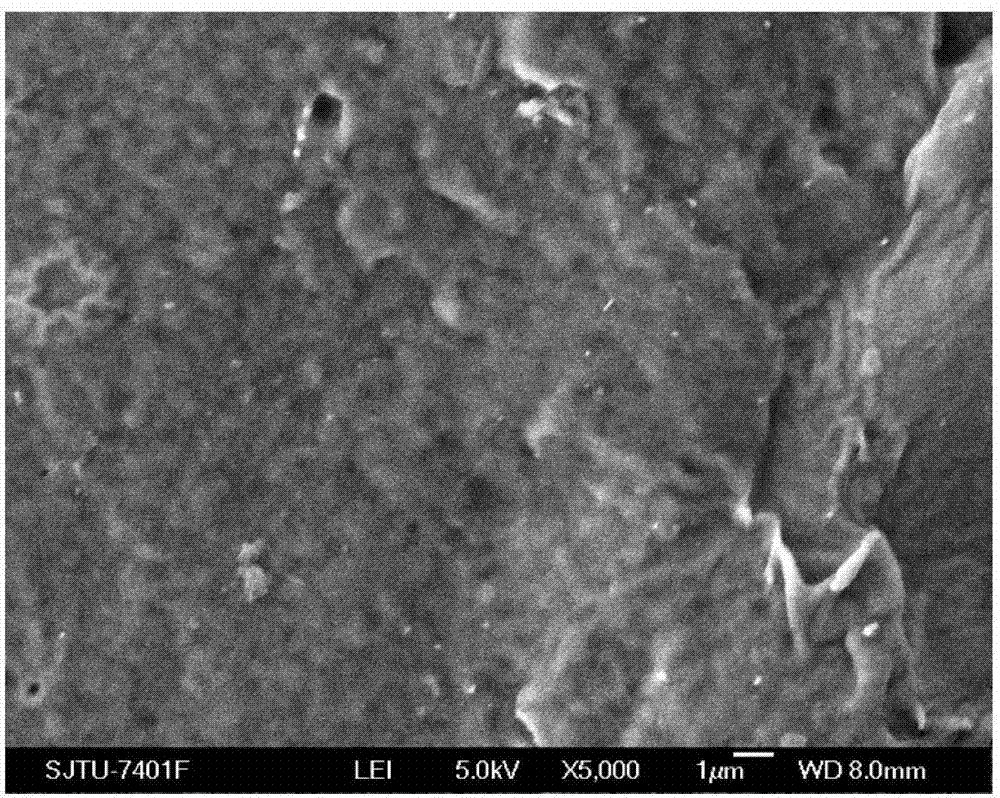

[0022] The prepared samples were hot-pressed into plates to prepare finished products, and the scanning electron micrograph of the cross-section is shown in figure 1 As shown, the control pressure is 20MPa and the temperature is 140°C. Finally, a biodegradable sheet with a thickness of 1mm was prepared. The starch particle size in the sample was 1-50um and uniformly dispersed, the tensile strength was 15MPa, and the elongation at break was 600%. Days, the d...

Embodiment 2

[0024] Example adopts PBAT chip (Mw130000, MI 3g / 10min (150 ℃, 2160g)) 55wt%, cornstarch 30wt%, plasticizer total content is 15wt%, wherein comprises glycerin 15wt%, formamide 0wt%, urea 0wt%.

[0025] The gelatinization temperature of starch is 80°C, and the twin-screw extrusion rate is 50r / min; when the plastic starch and PBAT are dried, the vacuum degree is 1.0KPa, the drying temperature is 80°C, and kept for 12 hours; the melt-blending temperature is 115°C, and the extrusion Speed 50r / min.

[0026] The prepared samples were melt-injected to prepare finished products at a temperature of 150°C. Finally, a biodegradable product with a thickness of 2.5mm is prepared. The starch particle size in the prepared sample is 1-50um and uniformly dispersed, the tensile strength is 10MPa, the elongation at break is 100%, and the compost is at 20°C and the humidity is 30%. Keeping it for 30 days, the degree of degradation reaches 55%.

Embodiment 3

[0028] The example adopts PBAT chip (Mw160000, MI 2.0g / 10min (150 ℃, 2160g)) 70wt%, potato starch 20wt%, plasticizer total content is 5wt%, including glycerol 0wt%, formamide 1.5wt%, urea 3.5 wt%; deionized water 5wt%.

[0029] The starch gelatinization temperature is 130°C, and the twin-screw extrusion rate is 50r / min; when the plastic starch and PBAT are dried, the vacuum degree is 1.0KPa, the drying temperature is 85°C, and kept for 12 hours; the melt blending temperature is 150°C, and the extruded Speed 10r / min.

[0030] The prepared samples were melt-casted to prepare finished products at a temperature of 150°C. The starch particle size in the final prepared sample is 1-50um and uniformly dispersed, the tensile strength is 12MPa, the elongation at break is 305%, and the degree of degradation reaches 50% after being kept for 30 days at a compost temperature of 30°C and a humidity of 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com