Patents

Literature

493results about How to "Environmental performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

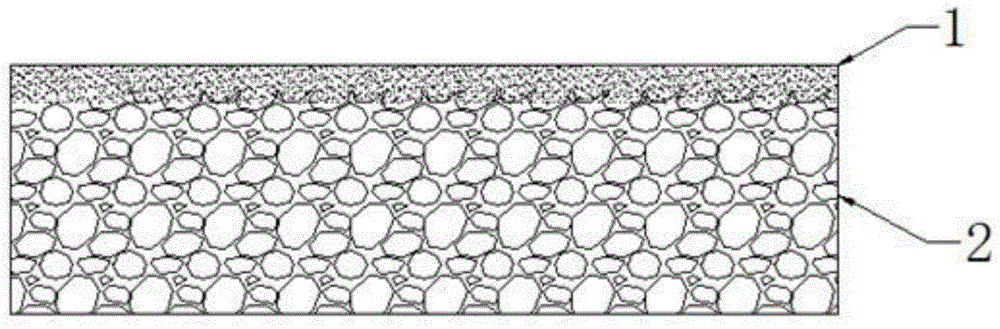

Water permeable brick and preparation method thereof

ActiveCN104452525AHigh porosityHigh strengthSolid waste managementSidewalk pavingsSolid componentBrick

The invention discloses a water permeable brick and a preparation method thereof. The water permeable brick comprises two parts, namely a surface layer and a base layer, wherein the material of the surface layer is prepared from the following components in percentage by mass: 60-70% of ceramic sand, 15-20% of sand and 15-20% of cement, and in addition to the solid components with the sum of 100% in percentage by mass, water accounting for 50-60% by mass of cement is further added; and the material of the base layer is prepared from the following components in percentage by mass: 45-65% of building silt unburned ceramsite, 10-15% of cement, 5-10% of fly ash, 10-15% of melon seed-shaped drug slices and 10-15% of sand, and in addition to the solid components with the sum of 100% in percentage by mass, the water accounting for 30-40% and a water reducer accounting for 1-1.5% relative to total mass of the cement and the fly ash are further added. The water permeable brick disclosed by the invention is prepared by using the building silt unburned ceramsite to replace natural aggregate or calcined ceramsite, on one hand, the using ways of the building silt unburned ceramsite can be expanded, the utilization rate of solid wastes is improved, and negative effects on an environment are reduced, and on the other hand, the obtained water permeable brick has excellent performance.

Owner:浙江合泽环境科技有限公司

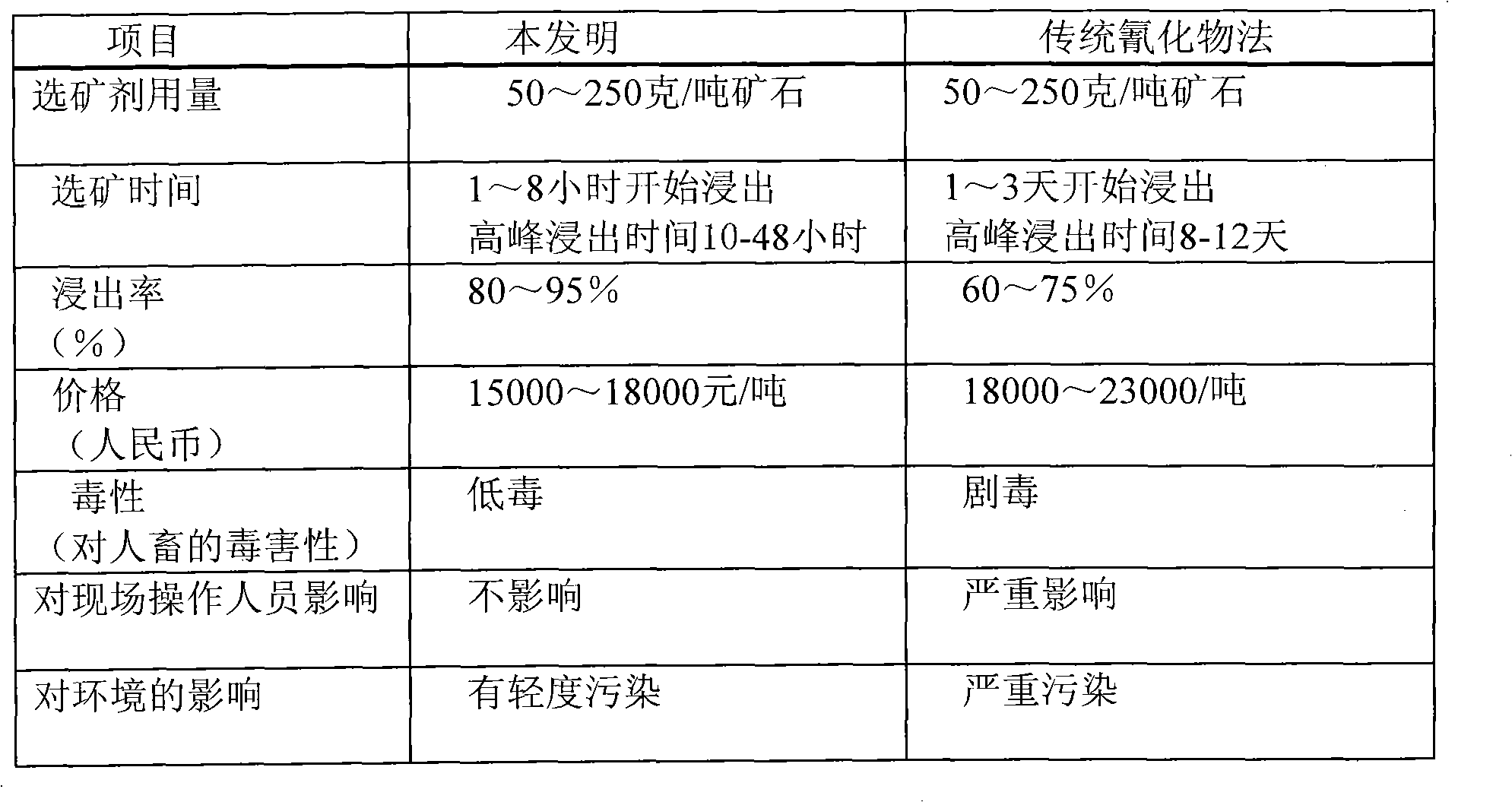

Production and using method of environmentally-friendly noble metal mineral processing reagent

ActiveCN102321807AEasy to produceAccurate ingredientsProcess efficiency improvementMolten stateCopper oxide

The invention discloses the production method of an environmentally-friendly noble metal mineral processing reagent. The method comprises the following steps: putting potassium ferrocyanide and urea after being mixed into a reactor; adding a pH regulator during the slow temperature rise process; heating to the molten state; taking a small amount of molten material detection samples, cooling and dissolving into water; measuring the pH value, enabling the molten material pH value to be 8-14; keeping the molten temperature for 5-60 minutes; and cooling to the normal temperature, thus the environmentally-friendly noble metal mineral processing reagent is obtained. The product obtained from the invention can be widely applied to the production of noble metal mine, such as the soaking, core spray of gold oxide ores, silver oxide ores and copper oxide ores, also can be used in industrial production industries such as electroplating, and used as medicaments for replacing toxic Cymag; and compared with all the other non-toxic or low-toxicity mineral processing reagents, the noble metal mineral processing reagent has the advantages of good effect, stable drug property, environmentally-friendly product, simple production method, low cost and the like.

Owner:广西地生金矿业科技有限公司 +2

Composite material and preparation method thereof

The invention discloses a composite material, the formula of the composite material consists of polylactic acid, straw fiber powder, a coupling agent, a heat stabilizer and a processing aid, wherein the polylactic acid is taken as a substrate, and the straw fiber is taken as a reinforcing agent; the modification is carried out on the surface of the straw fiber, thereby improving the compatibility with the substrate; and then the composite material of the polylactic acid and the straw fiber is manufactured by co-blending, melt extrusion, granulation and other processing technologies. The composite material has the advantages of low density and capability of being degraded completely.

Owner:CHERY AUTOMOBILE CO LTD

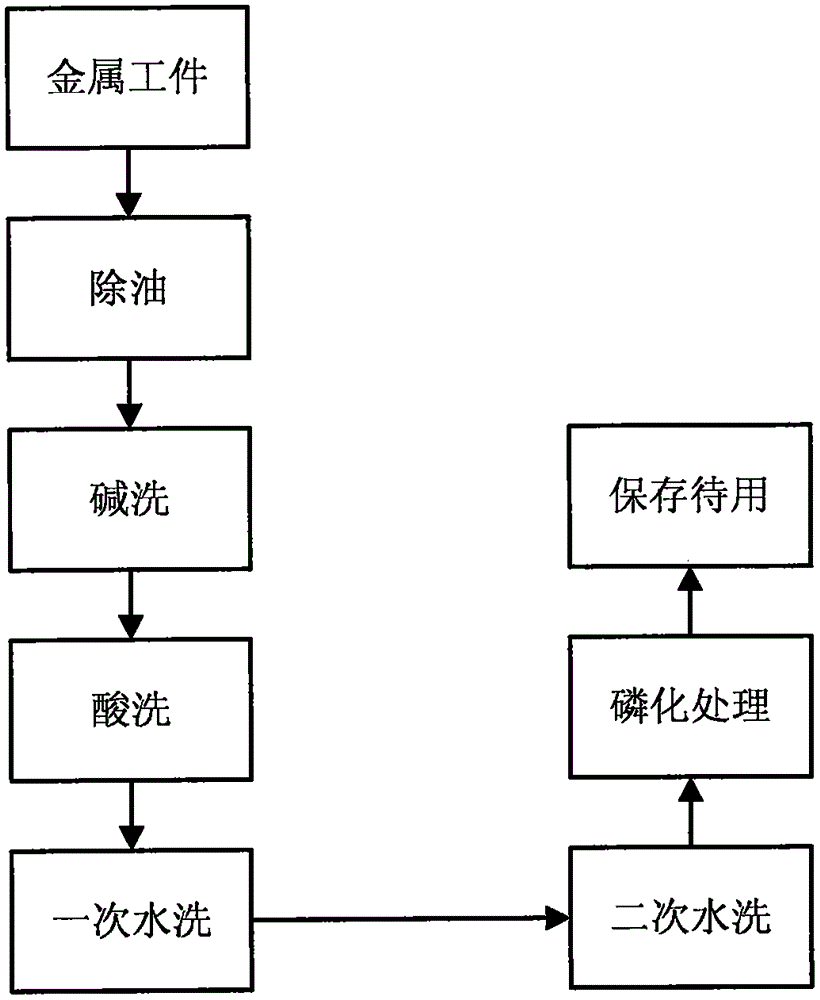

Before-coating metal surface treatment method

ActiveCN105369271AImprove permeabilityFast film formationMetallic material coating processesNonferrous metalAcid washing

The invention discloses a before-coating metal surface treatment method. The before-coating metal surface treatment method comprises such steps as oil removal, alkali washing, acid washing, two times of water washing and phosphorization. Adopted environment-friendly alkaline cleaning liquid has the technical effects of energy conservation and environmental protection, and has an excellent cleaning effect on both black metal and nonferrous metal; adopted phosphorization liquid has such advantages as quick film formation, strong paint film bonding force, good corrosion resistance, capability of operating through brushing or spraying, simple operation and low cost; the prepared phosphorization liquid reduces phosphorization liquid sediments, and guarantees the quality of phosphorized film; and the film layers are uniform and exquisite, so that the metal surface treatment method can realize the before-coating metal surface treatment more environment-friendly and more efficiently, and has active effects on the coating process and the coating quality.

Owner:苏州天成涂装系统股份有限公司

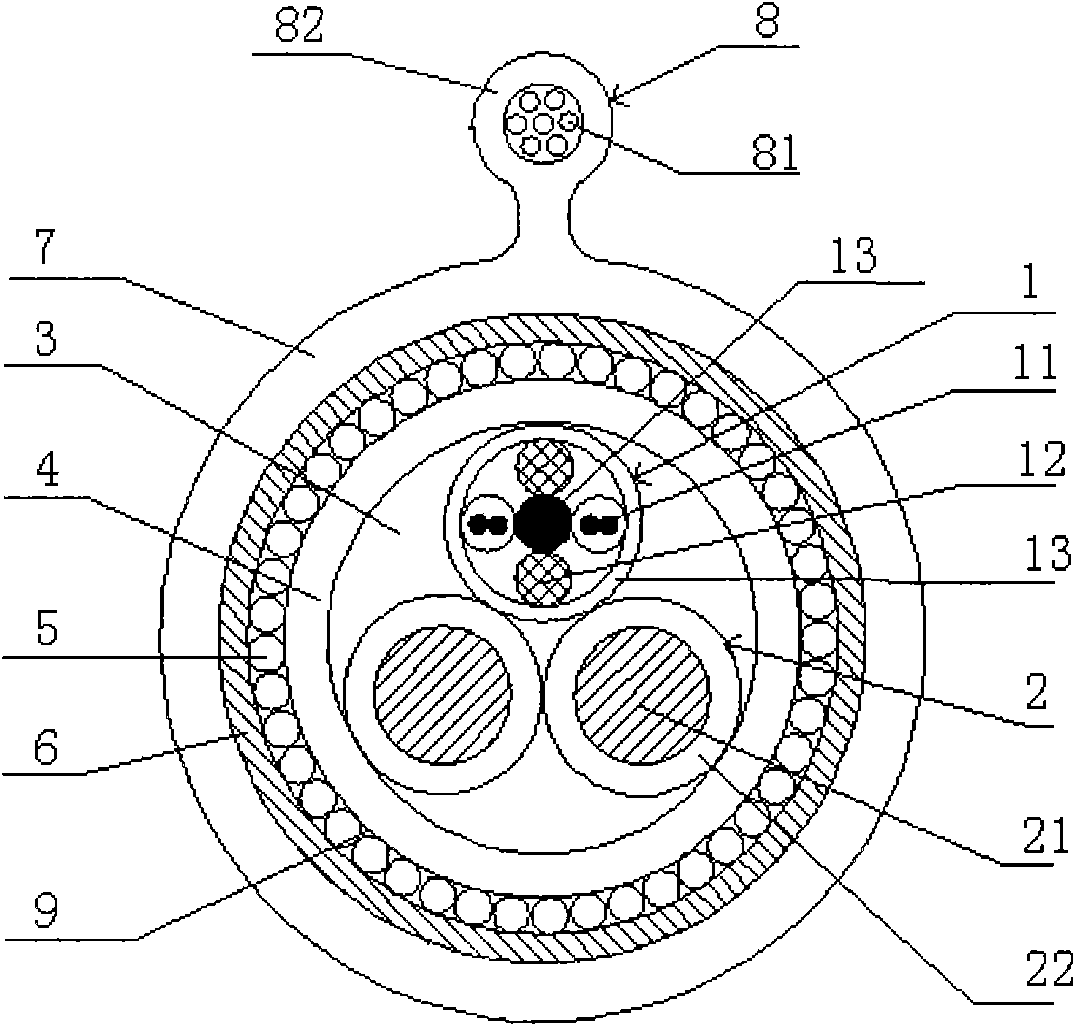

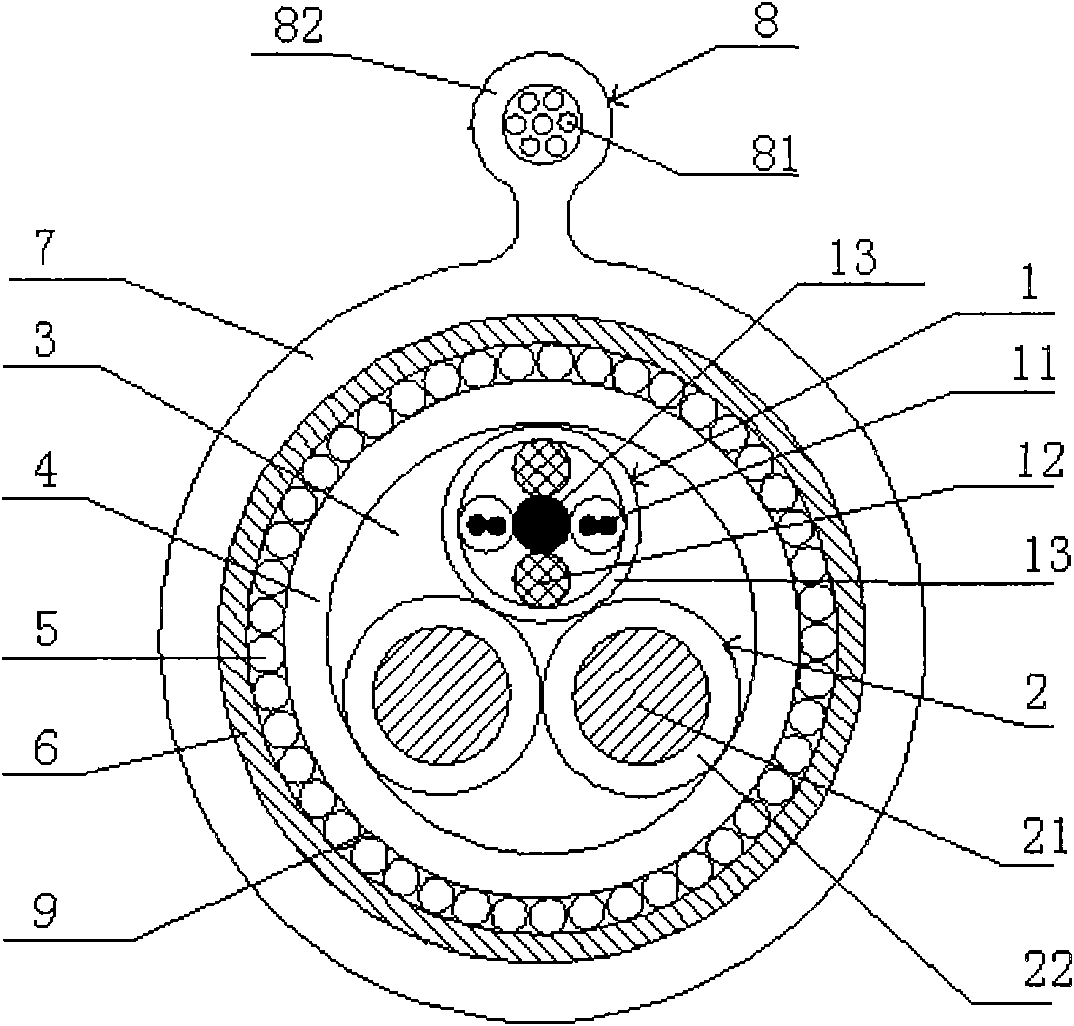

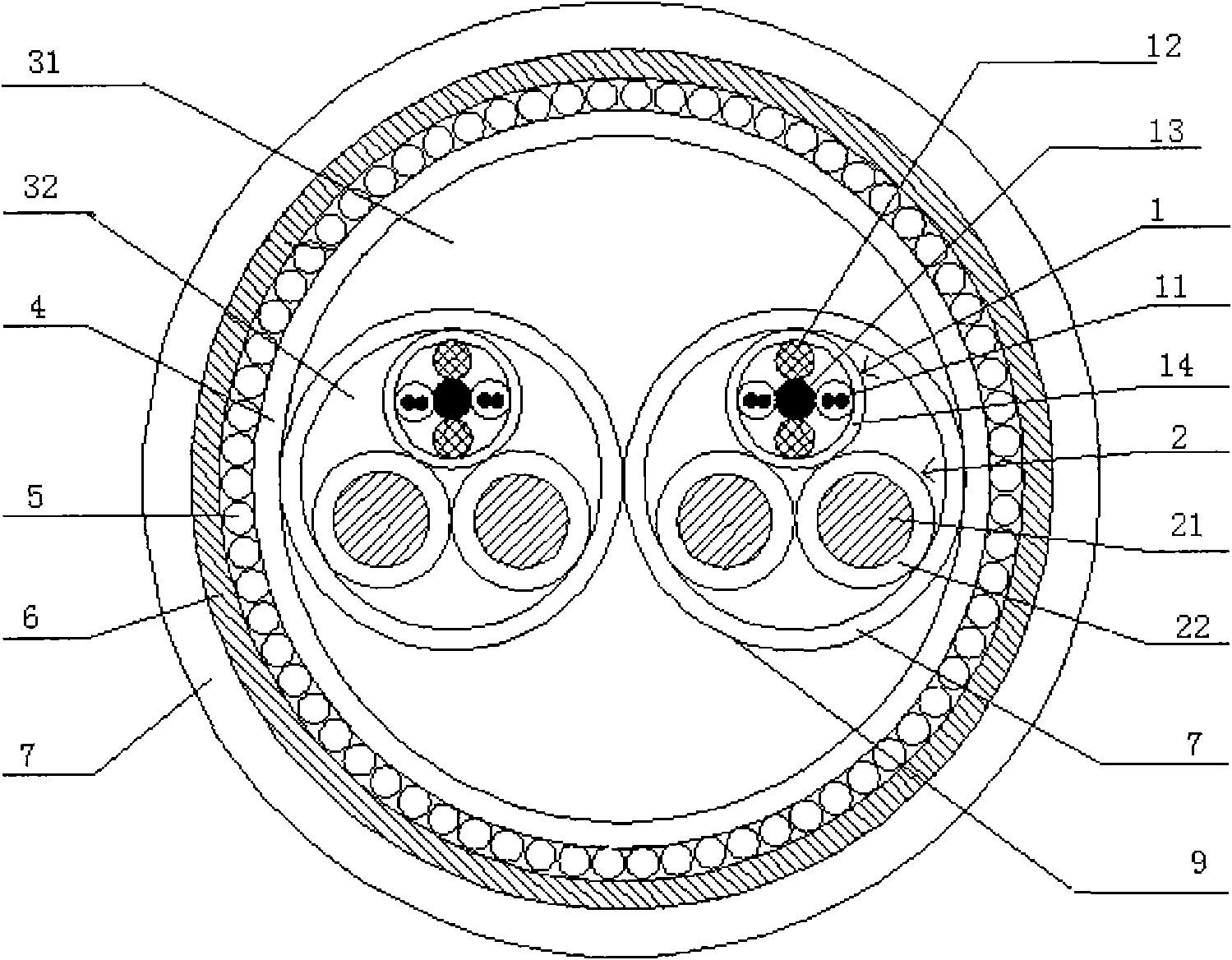

Self-supporting lightning-proof optical cable

ActiveCN101887781AMeet special climate requirementsEasy to layPlastic/resin/waxes insulatorsInsulated cablesShielded cableElectromagnetic field

The invention discloses a self-supporting lightning-proof optical cable. The self-supporting lightning-proof optical cable comprises a cable core, a covered layer and a suspension wire, wherein the cable core is used for transmitting an optical signal and power; the covered layer is covered with the cable core; and the suspension wire is connected with the covered layer. The covered layer comprises a shielding layer, an outer sheath and a ground layer, wherein the shielding layer shields the cable core; the outer sheath coats the shielding layer; and the ground layer is arranged between the cable core and the shielding layer. The self-supporting lightning-proof optical cable of the invention can prevent communication equipment from being damaged by thunder and lightening, effectively prevent an electromagnetic field generated by the shielding cable from disturbing other communication cable signals and prevent external electromagnetic field from disturbing the cable core.

Owner:JIANGSU ZHONGLI GRP CO LTD +3

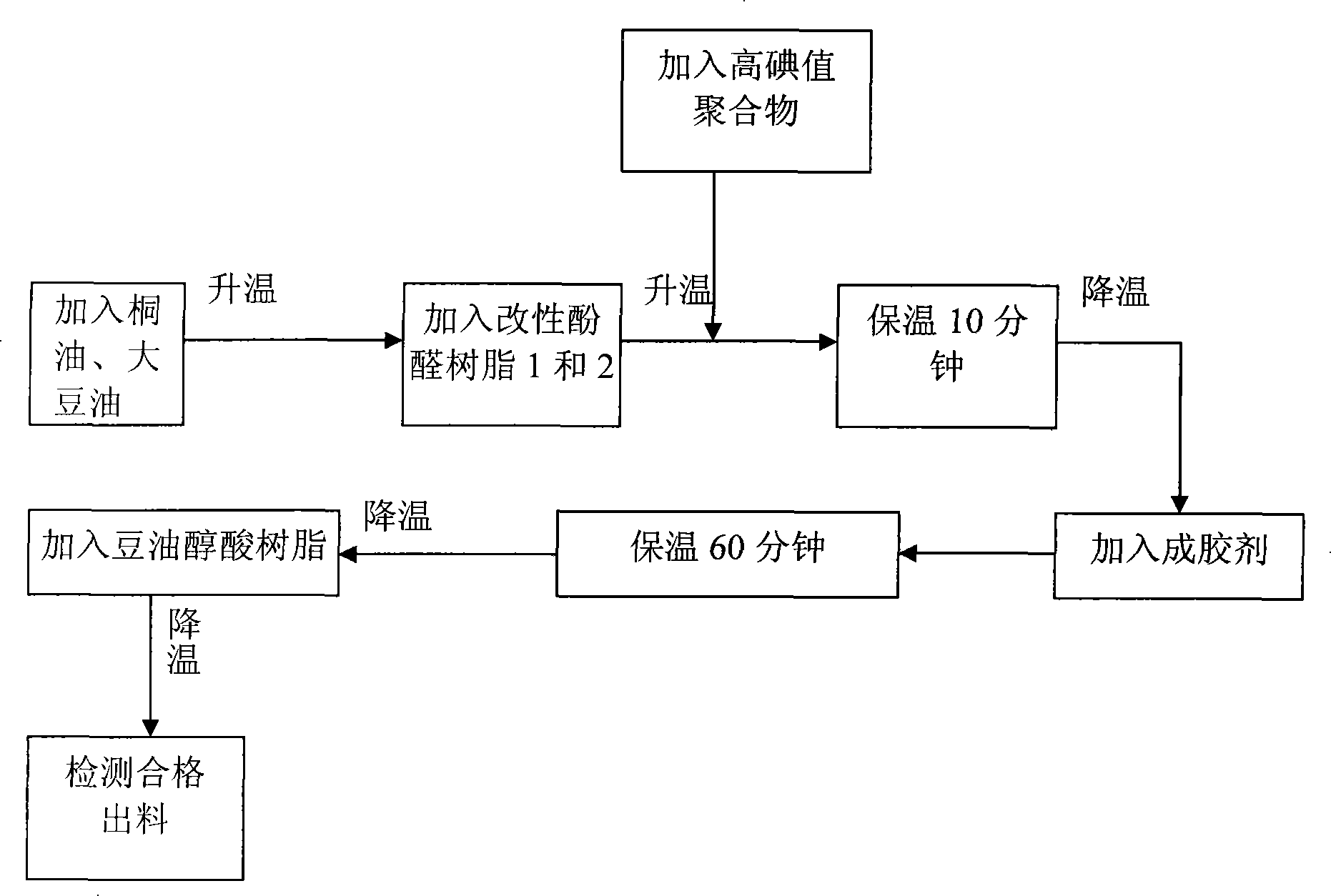

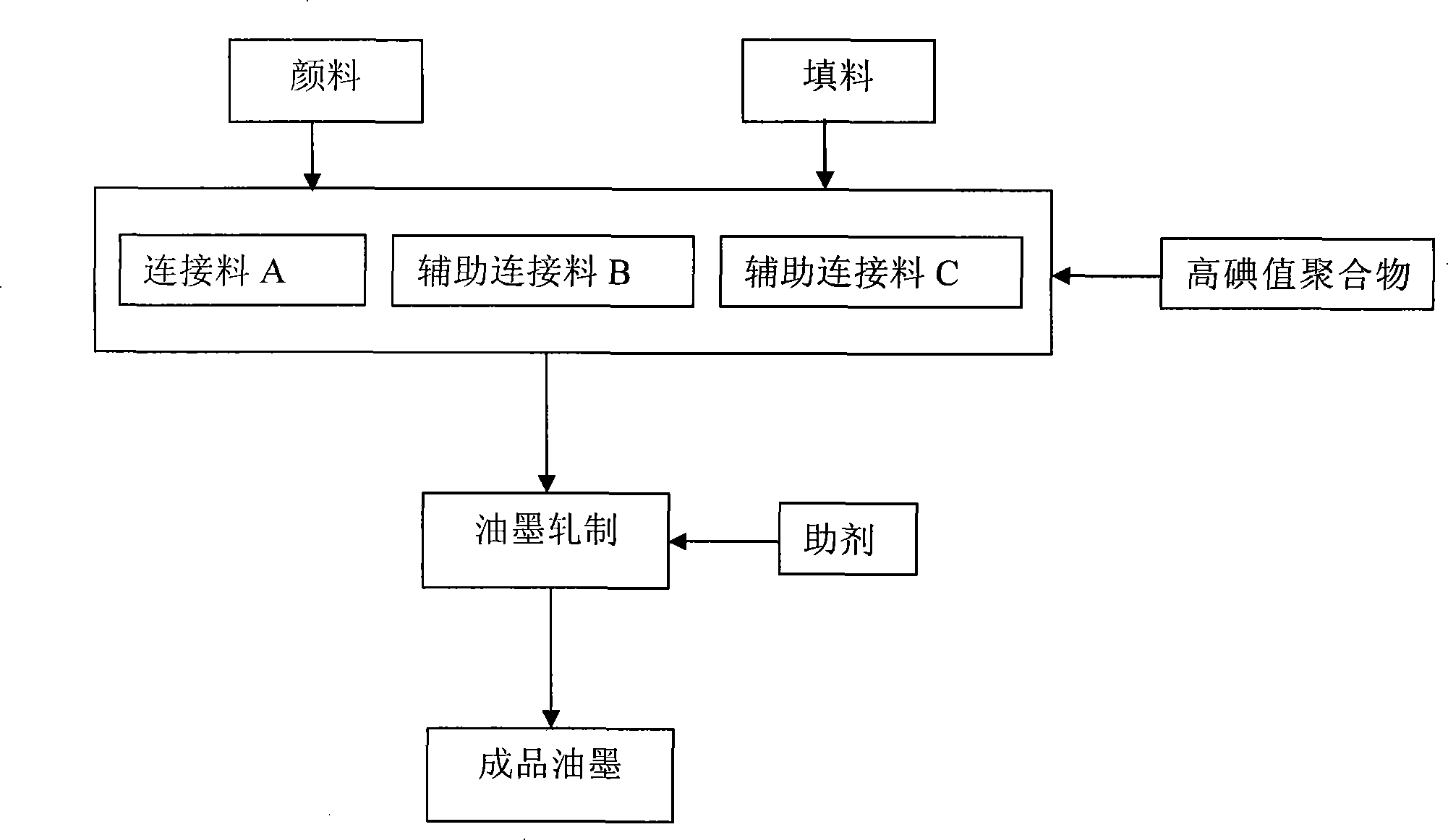

Soybean oil based hectographic ink and bonding material thereof

Soybean oil base offset printing ink and bonding material comprises bonding material A, auxiliary bonding material B and auxiliary bonding material C. The invention replaces most part or total petroleum mineral oil in printing ink with soybean oil, belonging to environment-friendly printing ink bonding material without significant petroleum components. The printing ink solves the technical problem that harmful contamination in the air and the surface of printing which is caused by large amount of petroleum solvent comprised in current common letterpress printing ink can further dangers the health of producers and users, has the advantages of environment-friendly, safety, extensive application range, excellent printability and prominent materialization index.

Owner:CHINA BANKNOTE PRINTING & MINTING

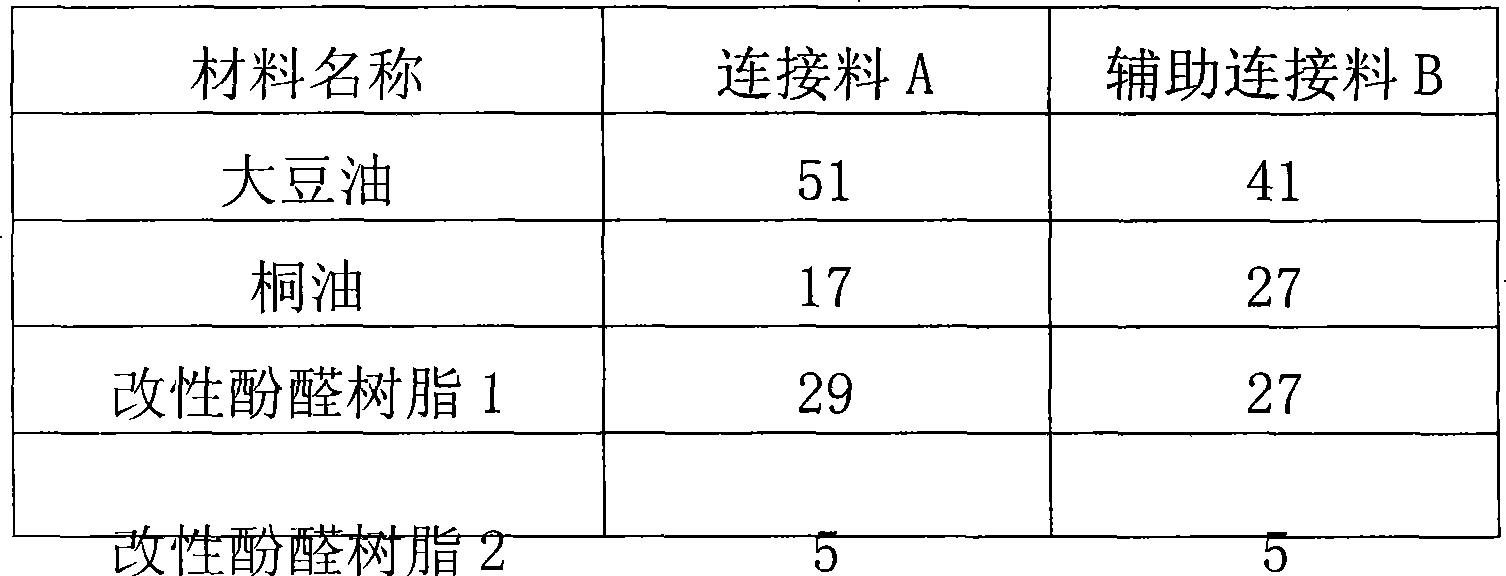

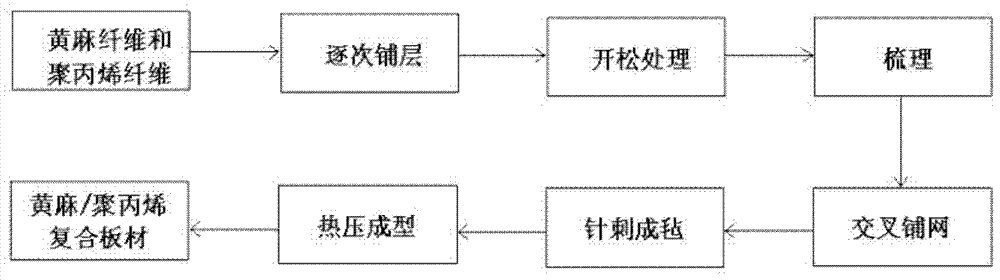

Natural fiber-reinforced thermoplastic composite material and preparation method and application thereof

ActiveCN102953231AEnvironmental performanceEasy to processVehicle componentsNon-woven fabricsAcute angleNatural fiber

The invention belongs to the technical field of composite materials, and relates to a thermoplastic composite material and a preparation method and application thereof. The thermoplastic composite material comprises the following components in percentage by mass: 40-60% of jute fiber and 40-60% of polypropylene fiber. Compared with the prior art, the composite material provided by the invention is environment-friendly and can be degraded naturally; with certain mechanical strength, the composite material can meet the requirement of the automotive trim material for strength; moreover, the composite material also has excellent processing performance and safety performance; and through the invention, the technological flow is shortened, the production efficiency is improved, and more importantly, the green and light automotive trim material is realized. Through the invention, the technological flow is simple, the composite material is easy to manufacture, and the raw materials are widely available and low in price, thereby being favorable for lowering the cost of the composite material; and moreover, a composite board has perfect toughness and does not form an acute-angle section after being broken, thereby being safe and reliable.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

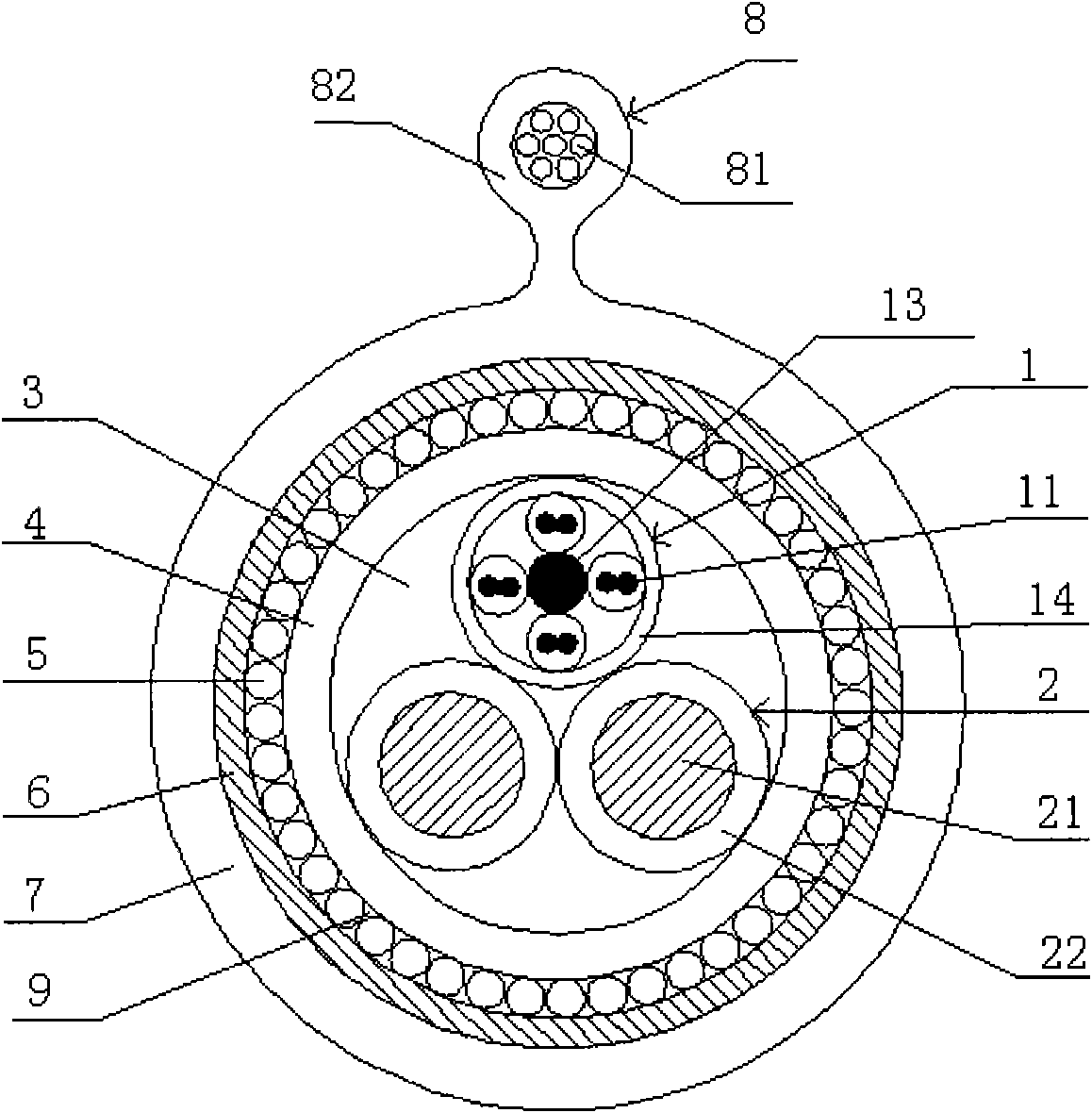

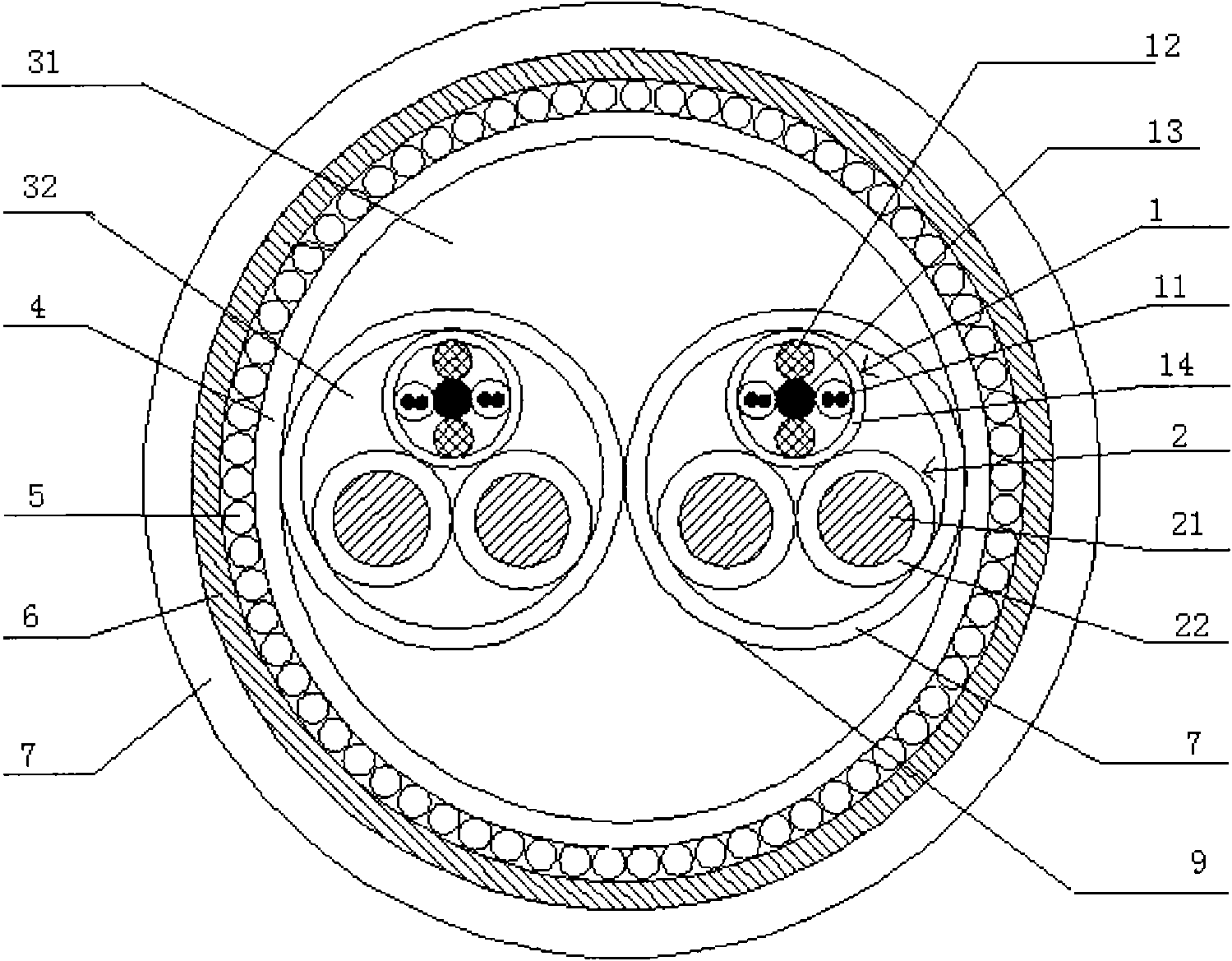

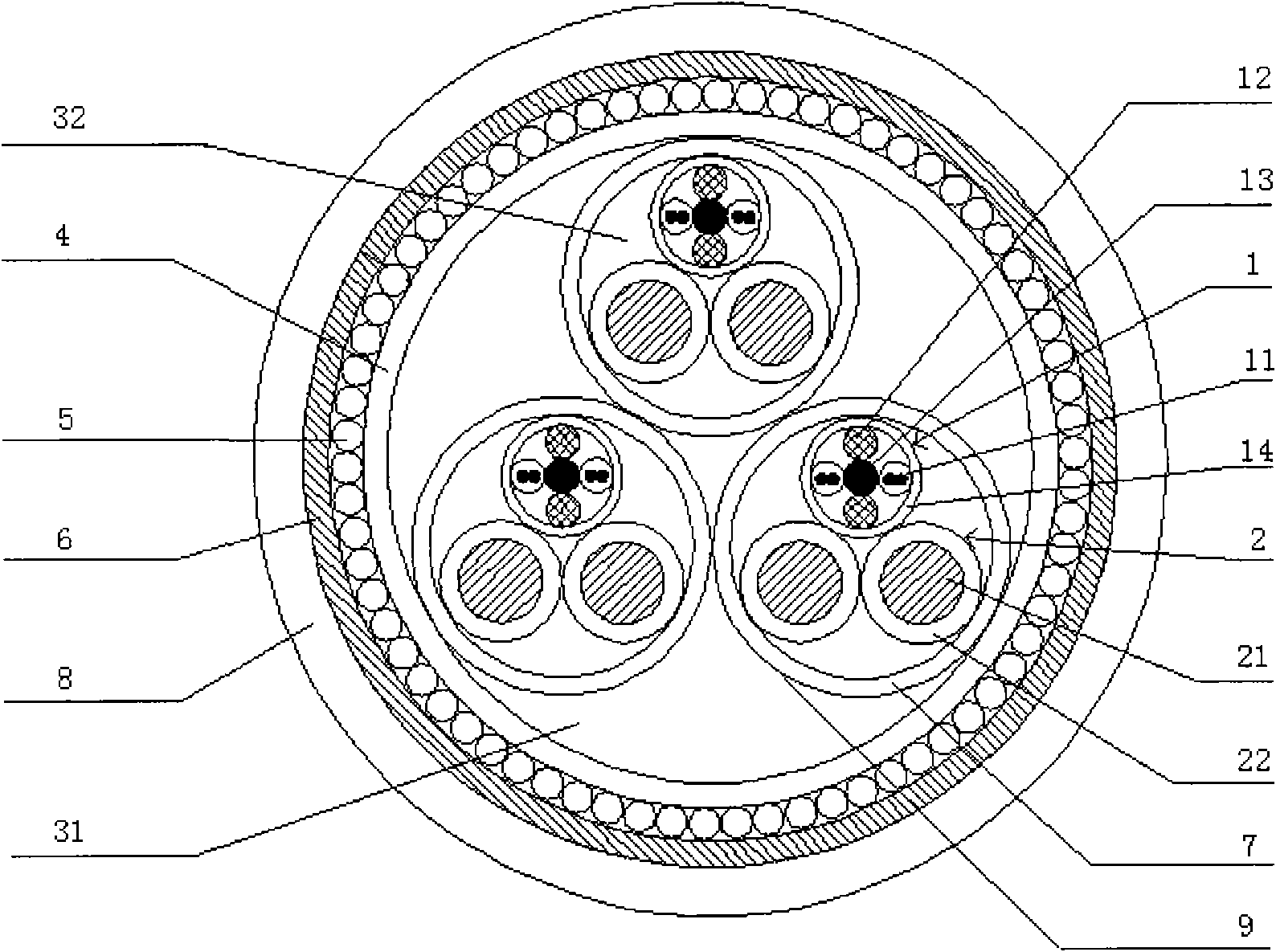

Multigroup lightning protection optical cable

ActiveCN101887780AMeet special climate requirementsImprove conductivityCoaxial cables/analogue cablesPlastic/resin/waxes insulatorsShielded cableEngineering

The invention discloses a multigroup lightning protection optical cable which comprises cables and a coating layer covering the cables, wherein the cables are made of multigroup cable cores covered by an inside liner; and the coating layer comprises a shielding layer for shielding the cables, an outer jacket covering the shielding layer and a grounding layer arranged between the inside liner and the shielding layer. The multigroup lightning protection optical cable can prevent lightning from damaging communication equipment, and can effectively shield the interference of an electric magnetic field generated by the cables on other communication cable signals and the interference of an external magnetic field on the cables.

Owner:JIANGSU ZHONGLI GRP CO LTD +2

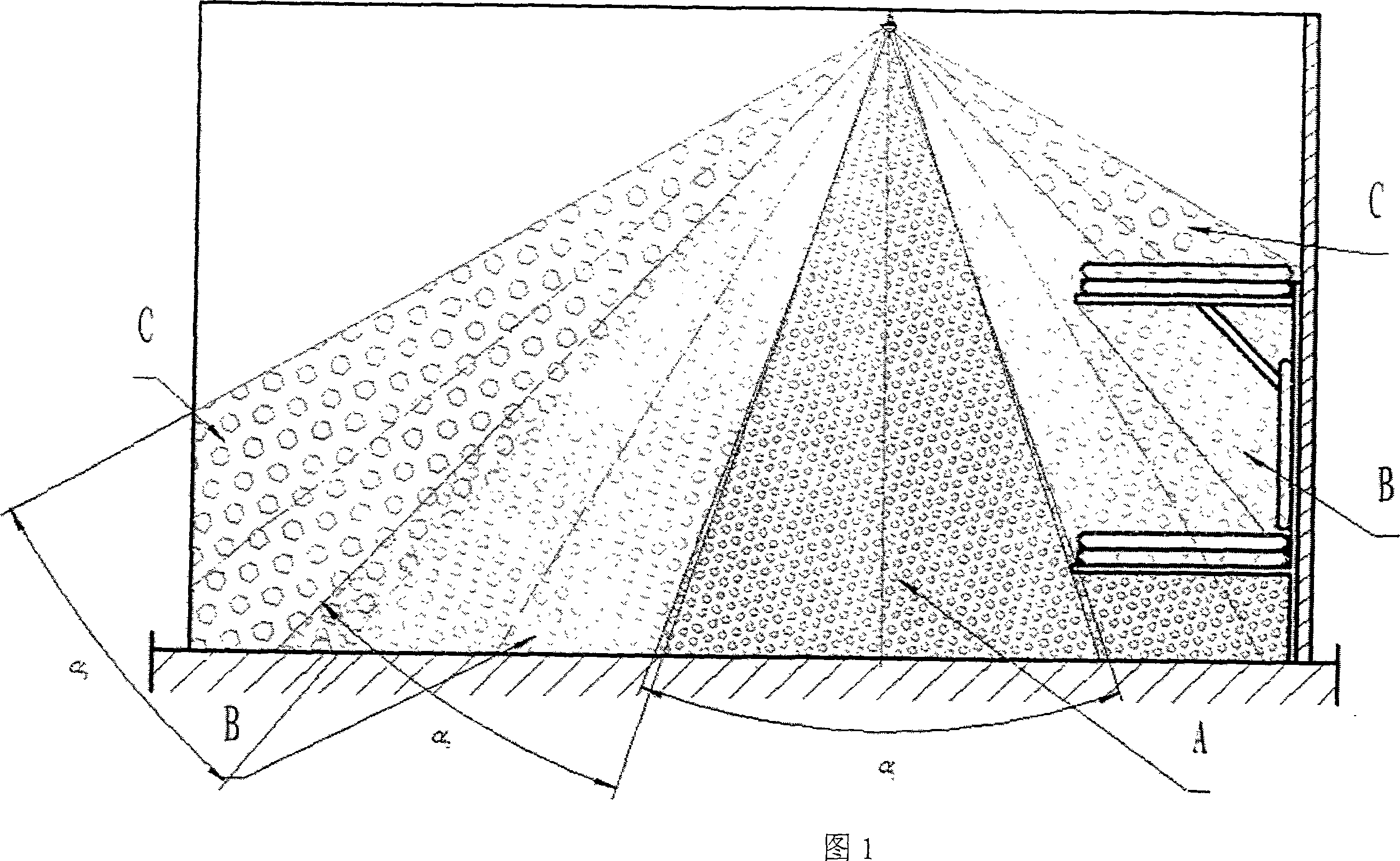

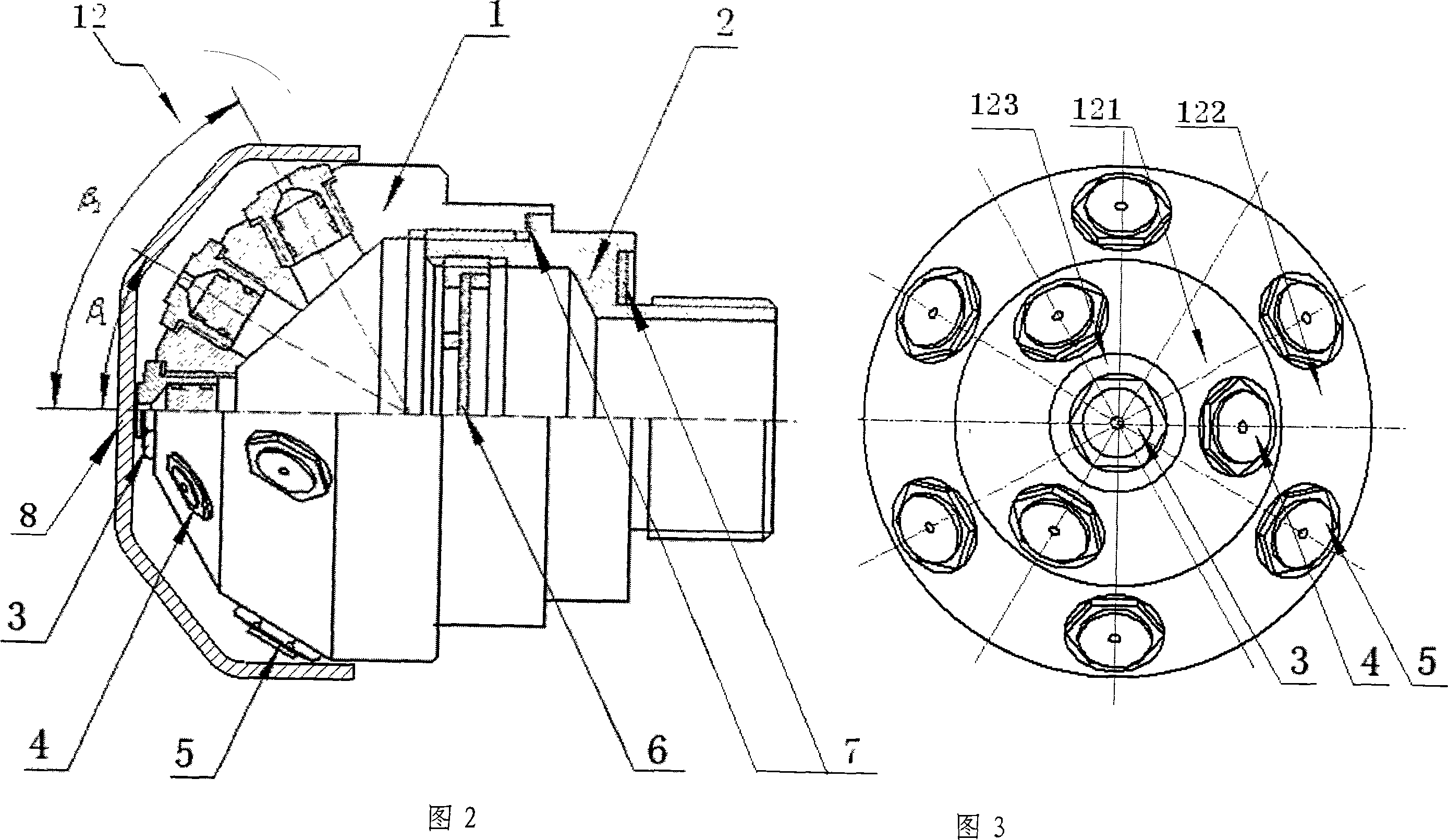

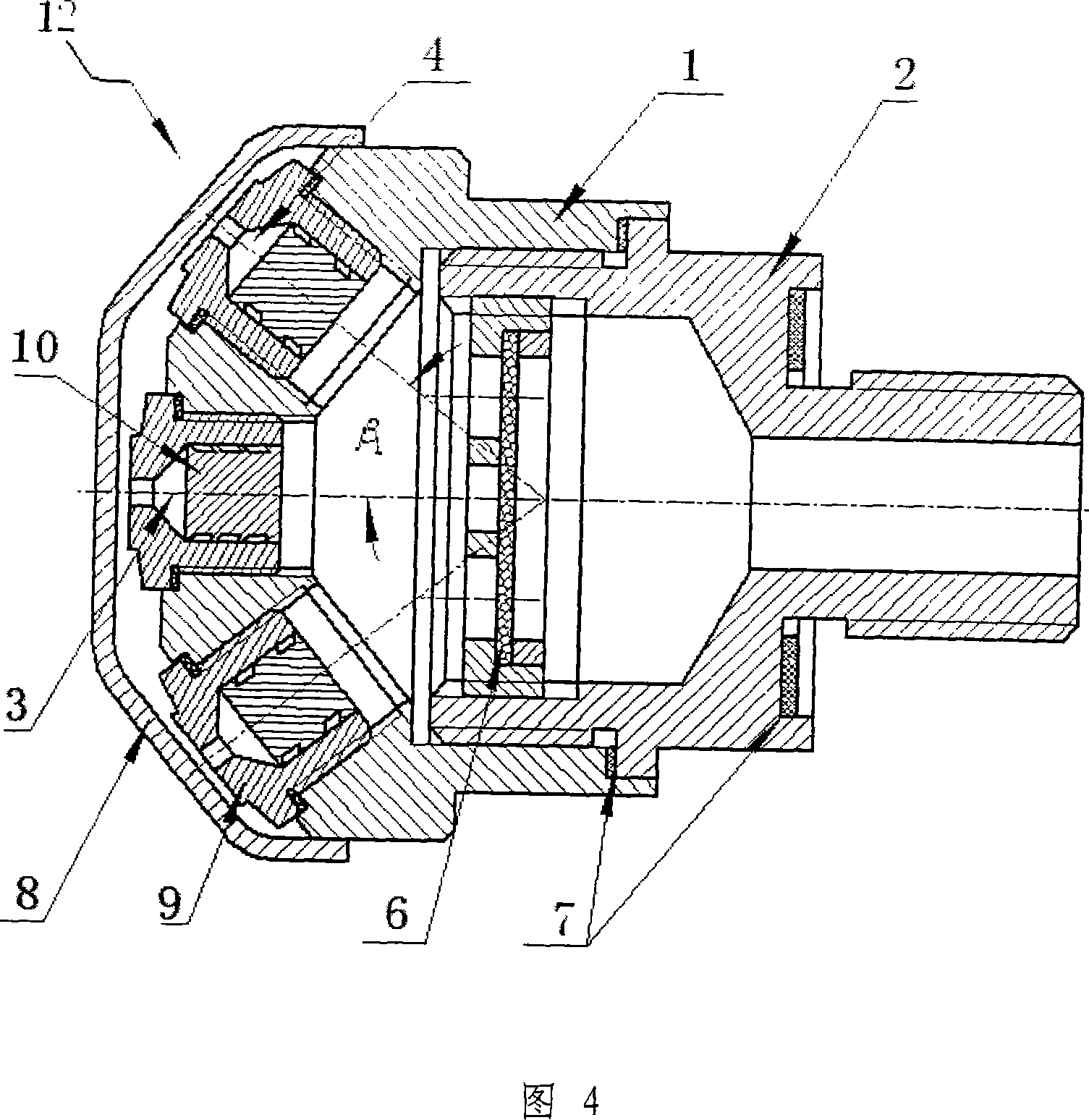

High-pressure extinguishing nozzle with fine spraying for submarine and ship habitation cabin

The invention discloses a high-pressure thin water spray fire-fighting injector used in submarine and ship, comprising injector shell, injector patchplug, central air spout, spherical air spout, outer air spout, internal filtering net, metallic sealing bale and dust shield. The shape of injector shell is two conical surfaces, the top of conical surface neat top part is plain, the central part is equipped with air spout; conical surface near to top is distributed with several spherical sir spouts; outer circle of conical surface near to top is next to another conical surface, a plurality of outer air spouts are installed on said conical surface. The air spouts on different installation surface are intercrossed, the injector shell and central air spout, spherical air spout and outer air spout, and injector shell and injector patch plug are all connected with each other through screw. The sealing employs metallic pad. The air spout is connected with the cavity of injector shell; the cavity of injector patch plug is equipped with stainless steel filtering net; another end of injector patch plug is connected with fire-fighting system through screw, and the injector shell is provided with dust cover.

Owner:BEIHANG UNIV

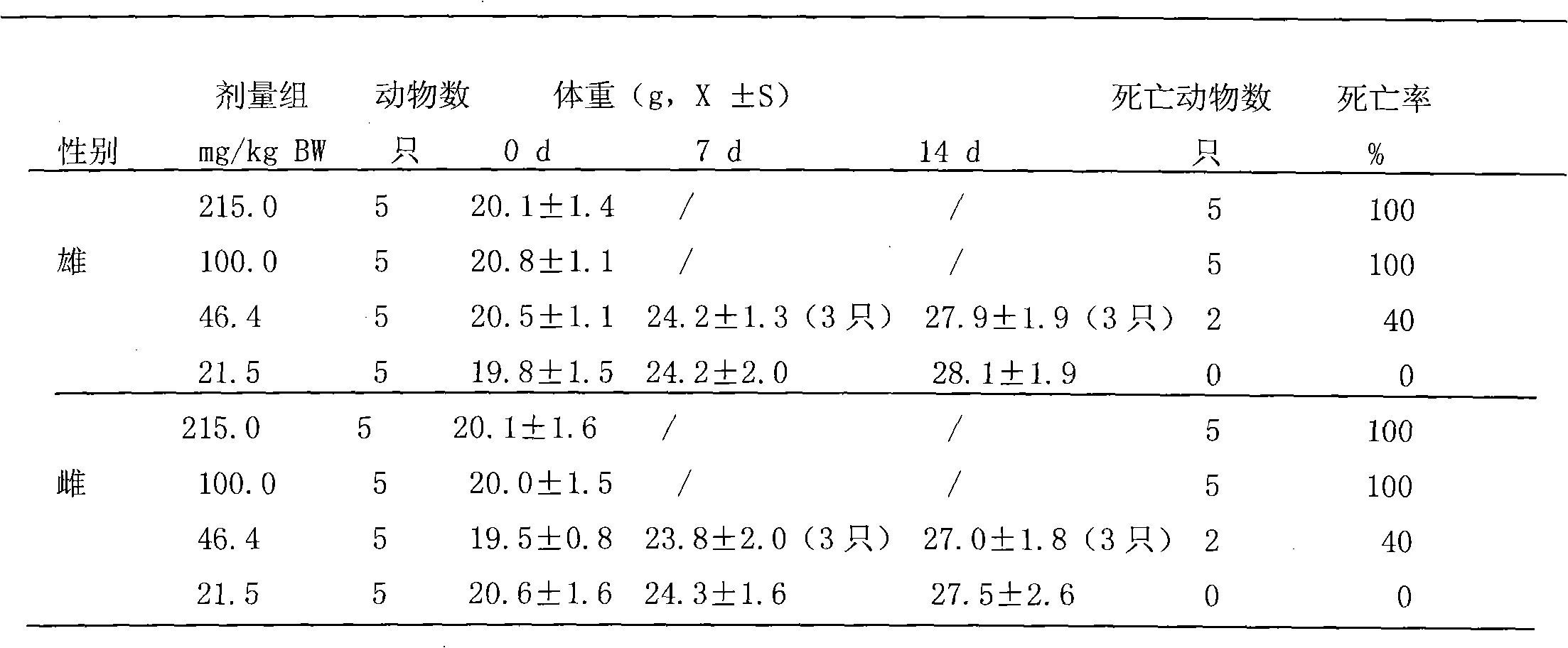

Preparation method of environment-friendly type precious metal beneficiation agent

ActiveCN103937986AAvoid pollutionEfficient leachingProcess efficiency improvementLead saltSodium cyanide

The invention relates to a preparation method of a low-toxic environment-friendly type novel precious metal beneficiation agent. Raw materials of the low-toxic environment-friendly type novel precious metal beneficiation agent comprise a cyanate, sodium hydroxide, sodium sulfate, sodium ferrocyanide, a bromide, and a lead salt. The preparation method comprises following steps: sodium cyanate, sodium hydroxide, sodium sulfate, and sodium ferrocyanide are mixed at a certain ratio; an obtained mixture is delivered into a smelting pot which is heated to be slightly red, and is heated to 650 to 750 DEG C so as to obtain a fused material, temperature is maintained to be 750 DEG C for 30 to 50min of reaction, and then an obtained product is collected and cooled; the obtained product is smashed, the bromide and the lead salt are added for stirring, and the environment-friendly type precious metal beneficiation agent is obtained via combination. The environment-friendly type precious metal beneficiation agent can be widely used for precious metal beneficiation metallurgy of nonferrous metals ores, contains no hypertoxic compounds, is safe for human and animal, and is friendly to the environment. Compared with other metal beneficiation agents, the environment-friendly type precious metal beneficiation agent is excellent in effects, stable in performance, and low in production cost; the preparation method is simple; and environmental protection can be realized.

Owner:广西河池鑫银环保科技有限公司

Phase-transition self-temperature-regulating heat-preserving facing brick of external wall and manufacturing method thereof

InactiveCN101705741AHigh quality light weight, compressive strengthLight in massCovering/liningsSolid waste managementBrickSilicon oxide

The invention relates to a phase-transition self-temperature-regulating heat-preserving facing brick of an external wall, which is an integrated structure compacted by a phase-transition heat-preserving layer and an inorganic facing layer, wherein the phase-transition heat-preserving layer is mixed by proportion and compacted by hull-type expanded perlite heat-preserving aggregates, phase-transition temperature-regulating aggregates and cements; the inorganic facing layer is mixed by quartz sand, calcium carbonate, calcium oxide, cement and silicon oxide powders; and the phase-transition temperature-regulating aggregate is made of phase-transition cores and encapsulated hulls. The manufacturing method not only effectively solves the encapsulation problem of the phase-transition material, leads the prepared phase-transition self-temperature-regulating heat-preserving facing brick of the external wall to have excellent heat-preserving performance, waterproof performance and permanent anti-ageing performance, but also radically solves the obsolescence of thermo-physical property and the leakage problem of phase-transition material in the circulation process. The facing brick has the advantages of light weight, strong adhesion strength, large compressive strength, heat insulation, heat preservation, waterproof and moisture-proof performances, obvious energy-saving effect, and the like.

Owner:信阳天意节能技术股份有限公司

Anticorrosive wear-resistant flexible ceramic powder coating

InactiveCN1743395AGood flexibilityImprove impact resistancePowdery paintsEpoxy resin coatingsEpoxyCeramic coating

The invention relates to an anticorrosive, wearproof flexible ceramic coating having A , B two components. It is characterized by: A component comprising epoxy resin, ceramic powder, pigment, solvent and additive. Its specific content is: using threeepoxy resins as film forming substance to improve anti-heat modification of coating layer, using silicon micropowder, titanium dioxide, lamprophyllite, titanium carbide, superfine zinc oxide as functional filler to increase wearproof and anticorrosion of coating layer, utilizing fibrous wollastonite to reinforce impact resistance of coating layer. B component is curing agent, phenol-amine compounds with long chain structure. It has outstanding properties of anticorrosion. wearproof, impact resiatance and sterilzing.

Owner:JIANGSU UNIV OF SCI & TECH

Spraying-free nano nylon 6 composite material

The invention discloses a spraying-free nano nylon 6 composite material. The spraying-free nano nylon 6 composite material is prepared from the following raw materials in parts by mass: 70 to 94 partsof a nano nylon 6 composite material, 4 to 10 parts of metal master batch, 1 to 10 parts of an antistatic agent and 1 to 10 parts of an antibacterial agent; the nano nylon 6 composite material is prepared from the following raw materials in parts by mass: 81 to 87 parts of caprolactam and 3 to 6 parts of montmorillonite. The composite material disclosed by the invention does not need to be sprayed, so that coating is saved and the working mount in a production process is reduced; the spraying-free nano nylon 6 composite material has an environment protection effect and also has the advantagesof good color and luster, high strength, strong wear resistance, antistatic performance, antibacterial performance and the like.

Owner:GUANGDONG XINHUI MEIDA NYLON

Novel coating

ActiveCN101058690AWidely applicableIncrease filling volumePolyurea/polyurethane coatingsEpoxy resin coatingsMaterials scienceCoating

Owner:HUAQIAO UNIVERSITY

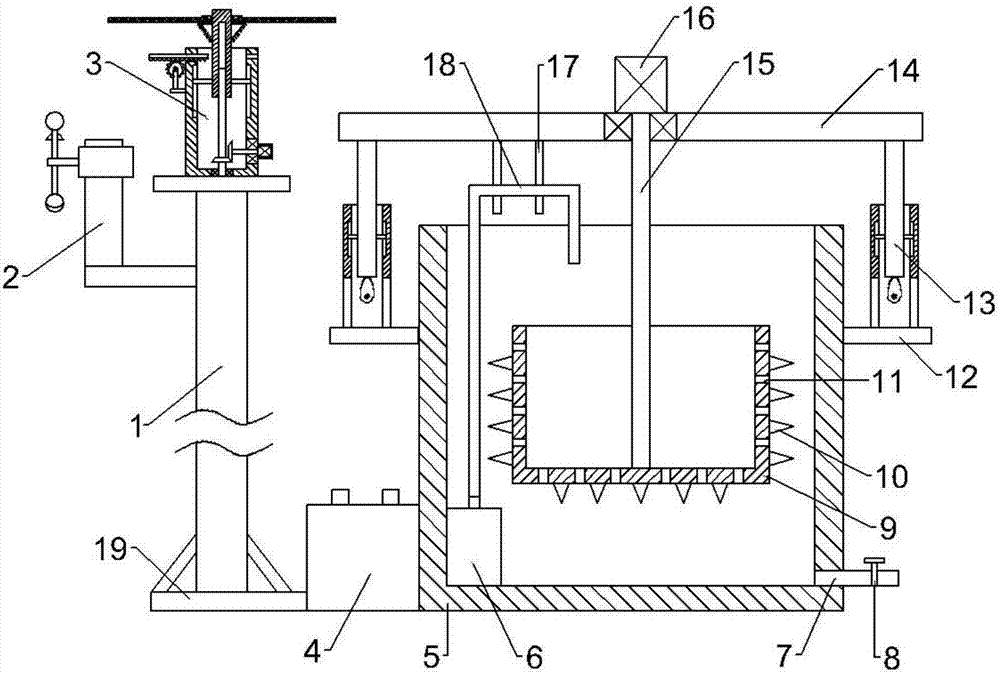

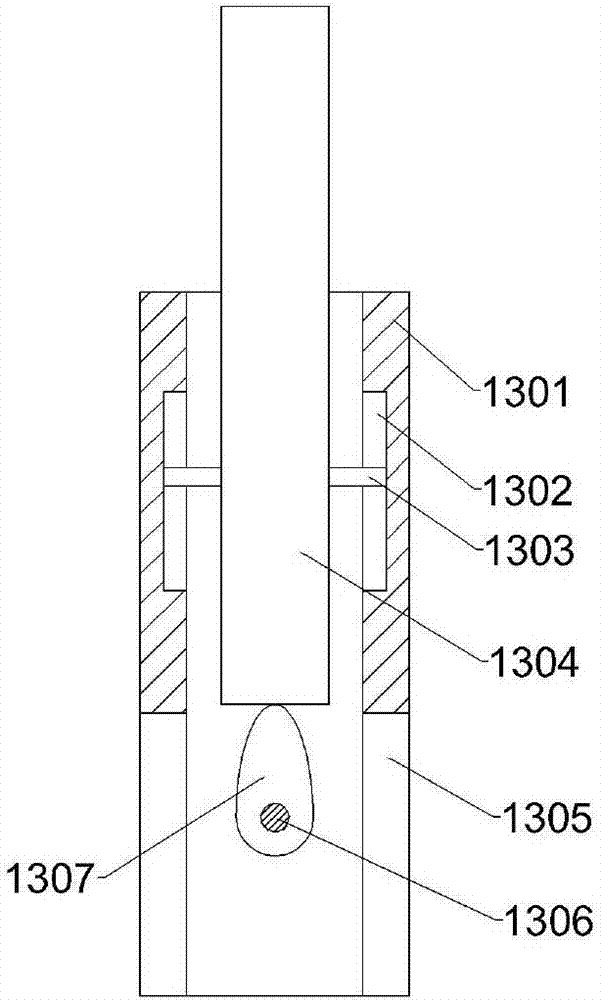

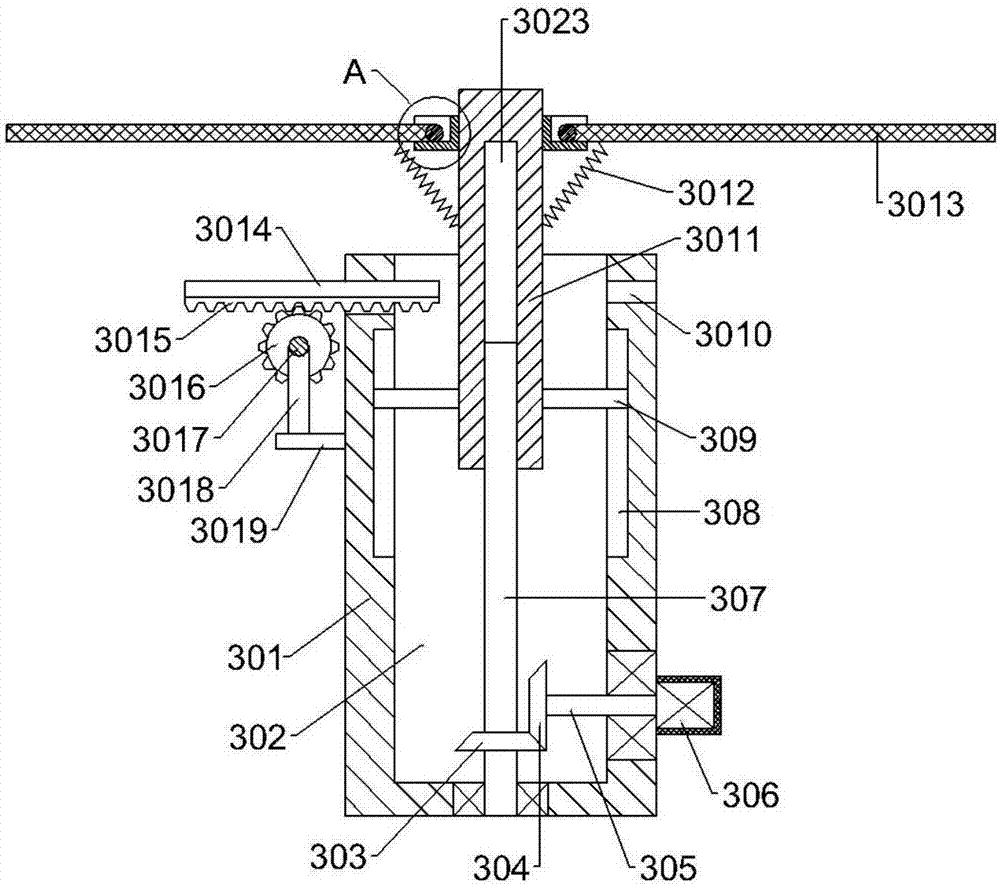

Water purifying plant based on complementary power supply by solar energy and wind energy

InactiveCN107265589AReduce erosionExtended service lifeWind motor with solar radiationWind energy with electric storageElectric power systemEngineering

The invention provides a water purifying plant based on complementary power supply by solar energy and wind energy. The water purifying plant comprises a mounting base; the upper side of the mounting base is fixedly connected with a support bar; the top end of the support bar is fixedly connected with a solar power generation device; the sidewall of the support bar is fixedly connected with a wind power generation device; the right side of the support bar is provided with a sewage treating device; the sewage treating device comprises a treating tank; the upper part of the treating tank is opened; the outer side wall of the treating tank is fixedly connected with two symmetric first installation seats; and the first installation seats are fixedly connected with a device carrying out reciprocating motion up and down. The water purifying plant provided by the invention has the following beneficial effects: solar cell panels in the solar power generation device can be hidden in rainy weather, so erosion of rain and water to the solar cell panels is reduced, and thus, the service life of the solar cell panels is prolonged; and the solar power generation device and the wind power generation device are employed for providing electric power sources to sewage treatment, so energy is effectively saved, and environmental protection is implemented.

Owner:邢均利

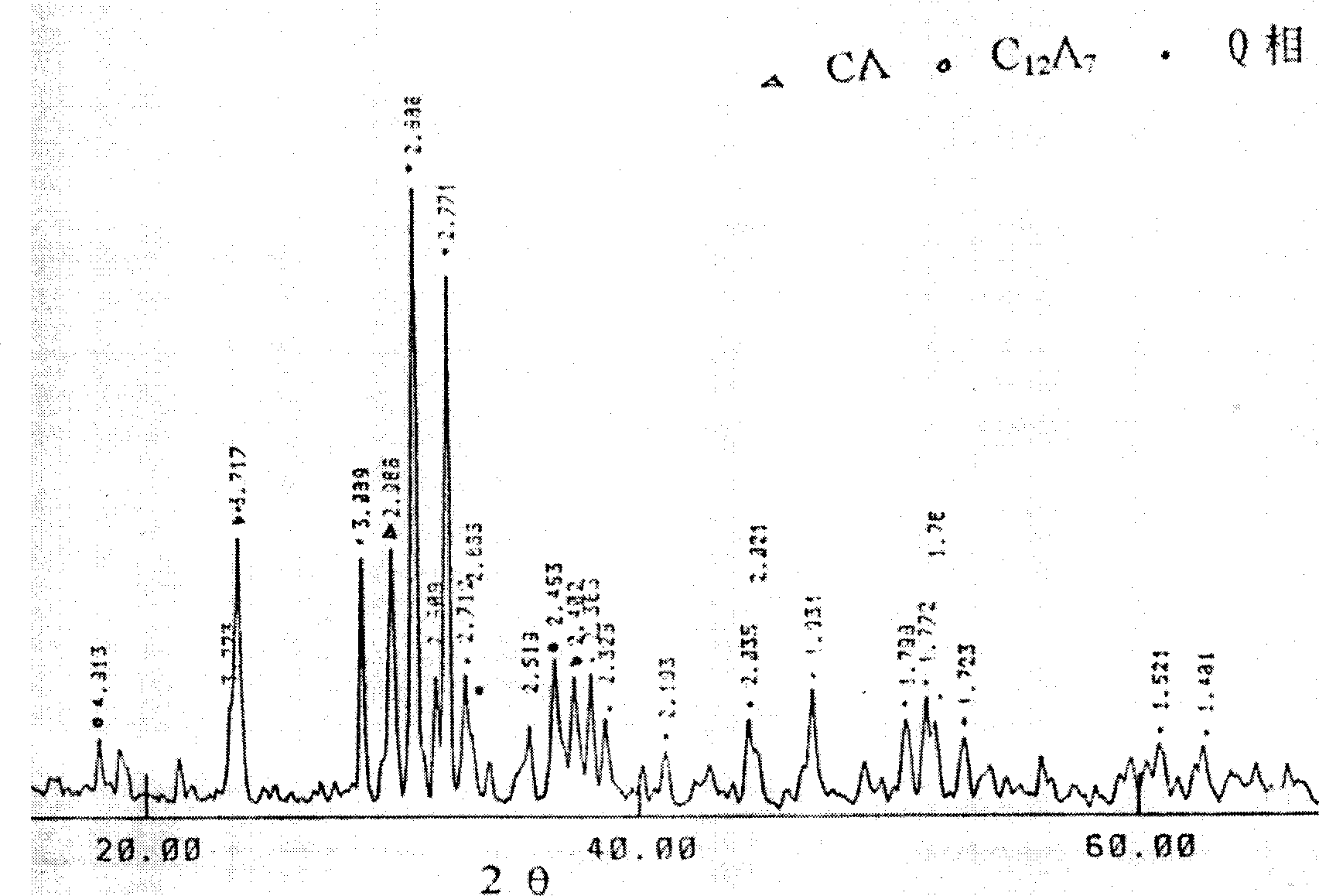

Aluminate cement material of containing mineral in Q phase

The invention provides an aluminate cement material containing. Q phase mineral that weight percenge is 40-80. The invention cement material has advantages of excellent functin of early strength and quick hardening, low firing temp., chalk containing magnesium-silicon and low-grade bauxite can be used as raw material to produce the cement material with high aluminium and low calcium.

Owner:UNIV OF JINAN

Coke passivator and preparation method thereof

ActiveCN101186853AReduce washoutReduced responseSolid fuelsHigh magnesiumCoke strength after reaction

The invention belongs to the technical field of ironmaking, in particular relating to a coke passivator and process for preparation. The coke passivator is produced by the raw materials at different part by weight, including 15-30 parts of boracic acid, 15-30 parts of borax, 30-50 parts of high magnesium powder, 5-15 parts of aluminum silicon powder, and 5-20 parts of calcium silicon powder. The coke passivator can uniformly form a layer of protective coating, which can reduce the erosion of the coke caused by CO2, decrease the reactivity of the coke, increase the coke strength after reaction, improve the utilization coefficient and the service life of the blast fumace and reduce the coke ratio. Utilizing the concentration of 0.3kg / t can reduce the reactivity of the coke by 5%, increase the coke strength after reaction by 7% and improve the production of the blast furnace by more than 3%-5%. The invention is an ideal product for blast furnace ironmaking which has the advantages of saving energy, reducing consumption, increasing production, improving benefits and protecting environment.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Method for preparation of waterborne polyurethane impregnated superfine fiber synthetic leather base

ActiveCN105155297AGood moisture permeabilityGood ventilationSynthetic resin layered productsLaminationEnvironmental resistanceMoisture permeability

The invention relates to a method for preparation of a waterborne polyurethane impregnated superfine fiber synthetic leather base. The method includes the steps: coating waterborne polyurethane slurry on release paper, pasting a superfine fiber nonwoven fabric and carrying out infrared heating and hot-air drying; after cooling, carrying out impregnation to obtain the waterborne polyurethane impregnated superfine fiber synthetic leather base. Since only moisture volatilization exists in a production process, environment friendliness is realized; no harmful gas is generated in a production environment, and operators are protected from health hazards; due to the fact that waterborne materials in the waterborne polyurethane impregnated superfine fiber synthetic leather base have hydrophilic groups, excellent moisture permeability is achieved; after alkali deweighting and splitting, the waterborne polyurethane impregnated superfine fiber synthetic leather base is excellent in breathability. Compared with a traditional methylbenzene deweighting process, the alkali deweighting process in production of the waterborne polyurethane impregnated superfine fiber synthetic leather base has the advantage of high sustainability.

Owner:ZHEJIANG FANSHENG MICROFIBER PROD

Bio-enzyme modified plant protein base timber adhesive and preparation method thereof

InactiveCN103709990AWidely plantedNot harmful to healthNon-macromolecular adhesive additivesProtein adhesivesHazardous substancePreservative

The invention discloses a bio-enzyme modified plant protein base timber adhesive and a preparation method thereof. The preparation method of the plant protein base adhesive is as below: conducting homogenization, pH adjusting, enzymolysis, pH readjusting and anti-corrosion treatment on the components of, by weight, 20-30 parts of biomass containing plant protein, 60-120 parts of water, 0.20-1.50 parts of biological enzyme, 0.3-0.8 part of acid, 0.2-2.0 parts of alkali and 0.24-1.10 parts of a preservative. The adhesive uses renewable material sources, contains no toxic or harmful substance, is green and environment-friendly, has water endurance bonding strength reaching the level of grade II adhesive (indoor), and can be used for manufacturing of various indoor man-made boards. The preparation method of the adhesive reduces the use of chemicals, and has the effects of energy saving and emission reduction; and the adhesive overcomes the problems of harm to the health of producers and users and environment pollution caused by chemicals in ordinary adhesive.

Owner:FUJIAN AGRI & FORESTRY UNIV

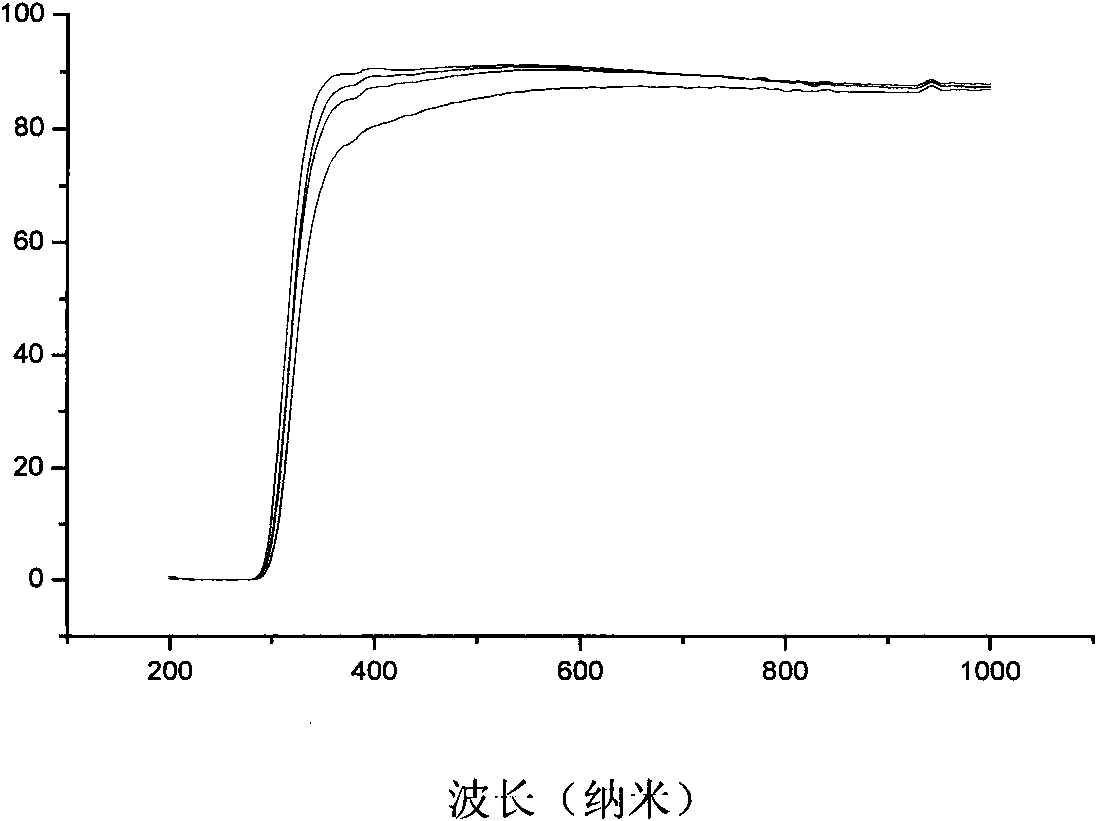

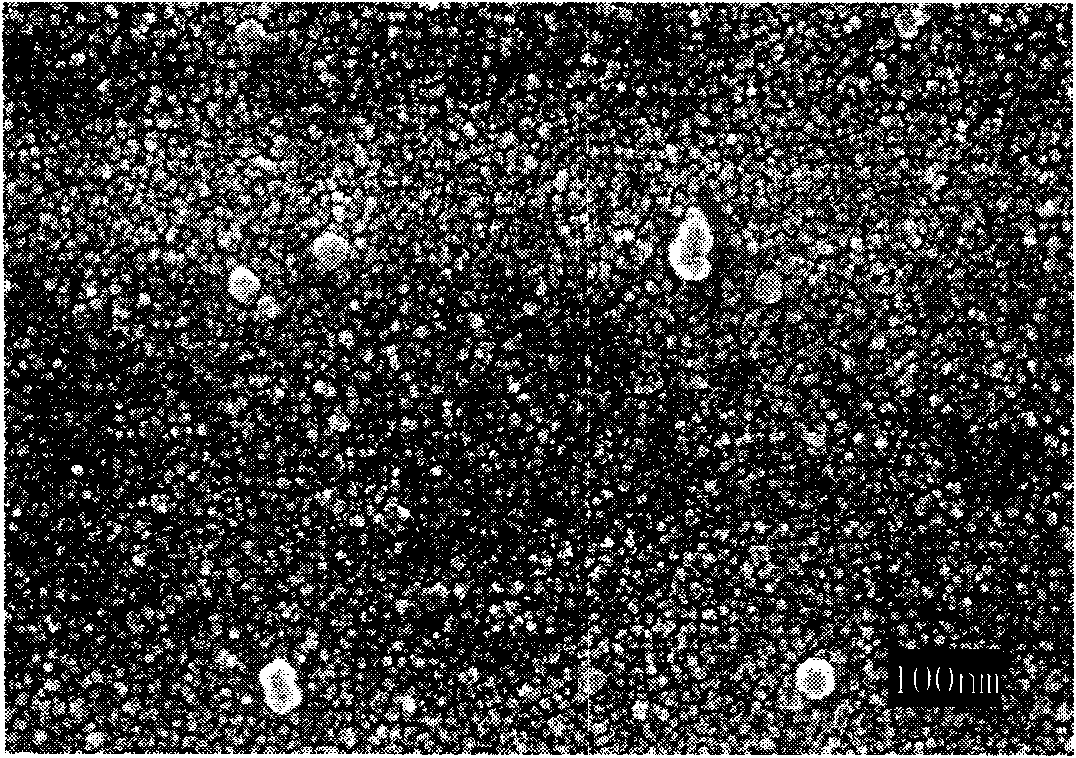

A method of nano self-cleaning glass production in the float glass production line

The invention relates to a method of nano self-cleaning glass production in the float glass production line. At the end of annealing kiln and above the area between the emergency transverse cutting machines in the float glass production line, the method need add the on-line spray equipment for spraying the nano self-cleaning paint across the float glass production line; evenly and directly spray the nano self-cleaning paint in fine mist on the non-tin surface of the glass at temperature 60-120 DEG C obtained at the end of the annealing kiln to form the nano self-cleaning coating; and then continue to follow the cold end manufacturing process of the float glass line to perform the on-line production to eventually obtain the nano self-cleaning glass. The method of invention saves the glass cleaning process before painting the nano self-cleaning paint during the traditional self-cleaning glass manufacturing. It uses the on-line clean glass obtained at end of the annealing kiln, directly sprays the nano self-cleaning paint on the non-tin glass surface to form the film; and saves the glass cleaning process as well as the resources.

Owner:北京中科华纳技术发展有限公司

Manufacturing method for impregnated wood and preparation method for impregnating resin

ActiveCN104526804AReduce polarityReduce acidityWood treatment detailsPretreatment apparatusMechanical propertyPolyresin

The invention provides a manufacturing method for impregnated wood and a preparation method for impregnating resin. The manufacturing method for the impregnated wood comprises the steps of primary drying, impregnating, secondary drying and hot and wet treatment. The mechanical property, the formaldehyde emission and the size stability of the impregnated wood manufactured through the method are obviously improved, and the impregnated wood can meet the using requirements of furniture and decoration such as cabinets, chests and doors and windows and wood floors. The preparation method for the impregnating resin comprises the steps of feeding, reacting and discharging, raw materials needed for preparing the resin are simple and easy to store, and under the condition that the water content of the wood is low, the resin can evenly impregnate the wood.

Owner:GUANGZHOU HOLIKE CREATIVE HOME FURNISHING

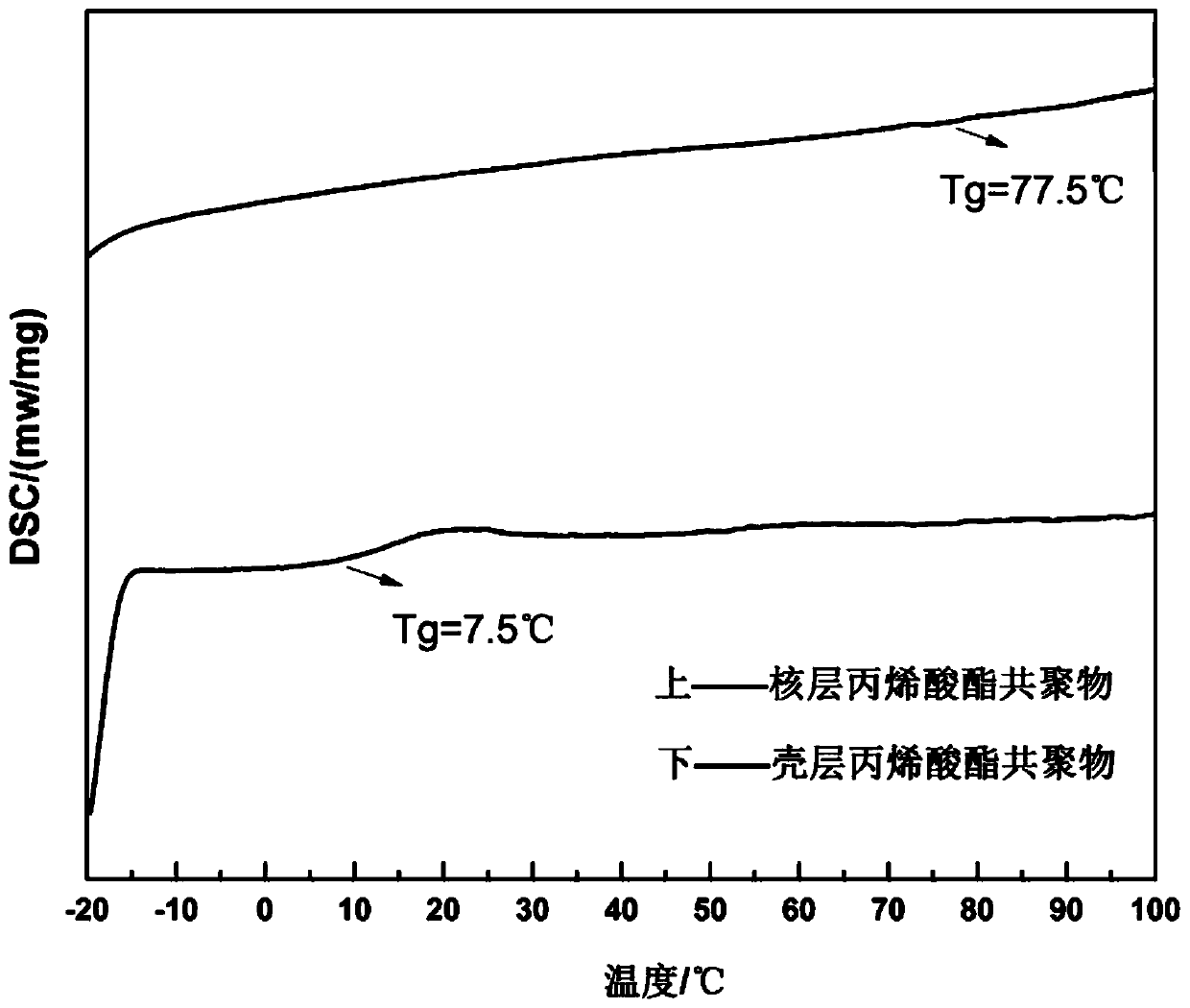

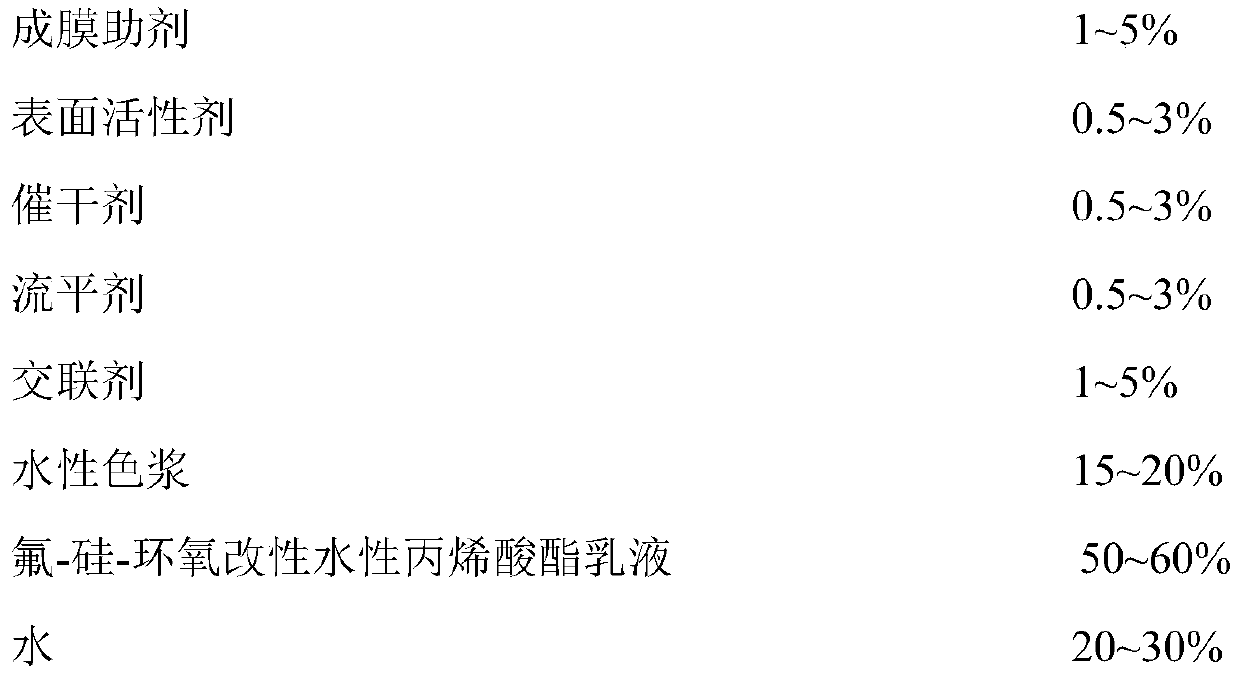

Fluorine-silicon-epoxy-modified aqueous acrylate emulsion ink special for PVC film and preparation method of ink

The invention discloses fluorine-silicon-epoxy-modified aqueous acrylate emulsion ink special for a PVC film and a preparation method of the ink. The ink consists of the following raw materials in parts by weight: 1-5% of a film forming additive, 0.5-3% of a surfactant, 0.5-3% of a drier, 0.5-3% of a leveling agent, 1-5% of a crosslinking agent, 15-20% of aqueous color paste, 50-60% of a fluorine-silicon-epoxy-modified aqueous acrylate emulsion and 20-30% of water. The fluorine-silicon-epoxy-modified aqueous acrylate emulsion ink takes the water as a solvent, so that the ink has no volatile odor; when the ink is applied to the PVC film, the wettability is good; an ink coating film with the thickness of 50 um can reach a surface drying state within 6 seconds at 50 DEG C, and the adhesion fastness reaches 99%; the ink can be scrubbed by 70% of an ethanol aqueous solution more than 100 times after curing completely, and the adhesion resistance reaches 95%; and the preparation process is simple, the production cost is low, and the ink is favorable for universal popularization and application.

Owner:SOUTH CHINA UNIV OF TECH

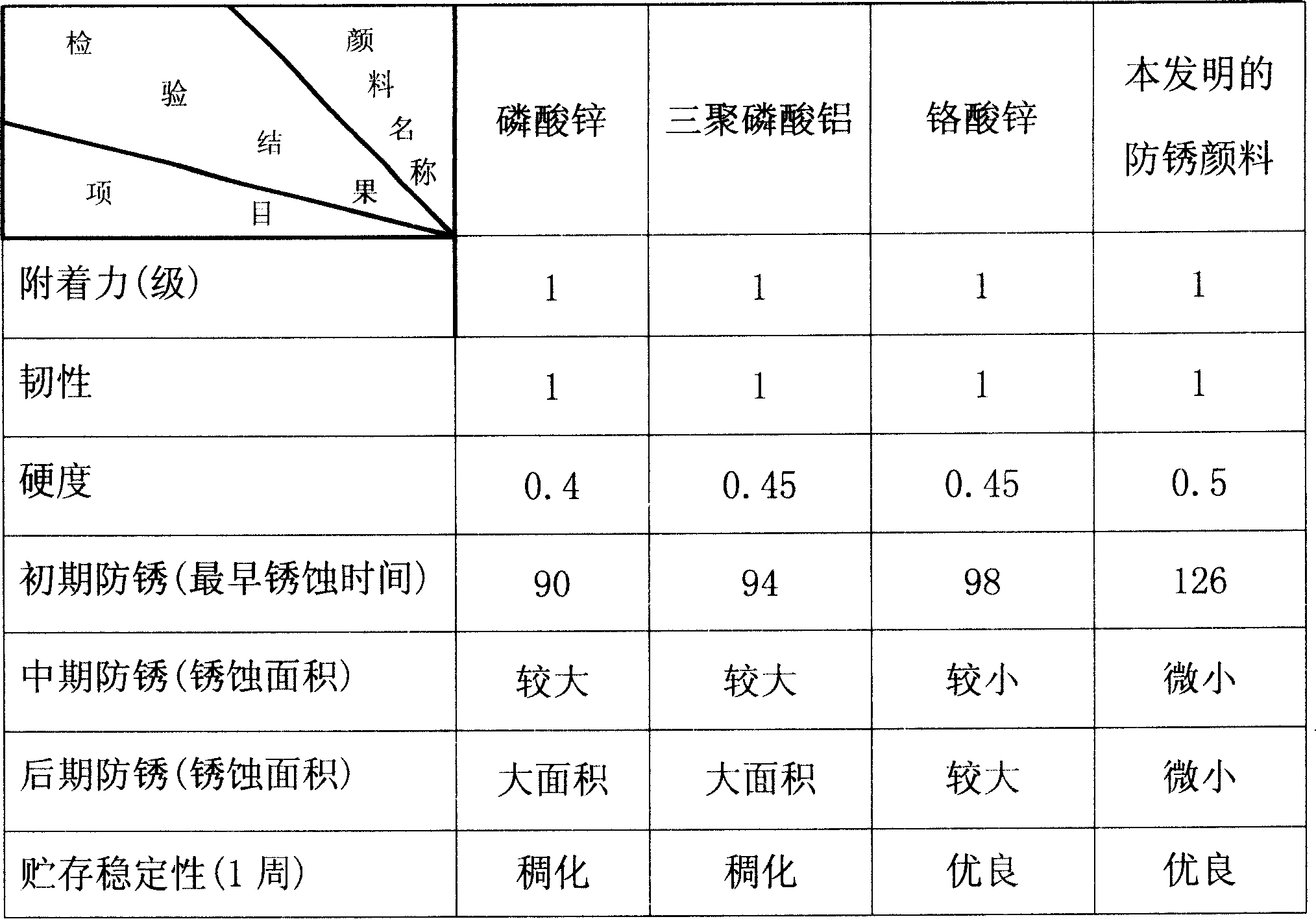

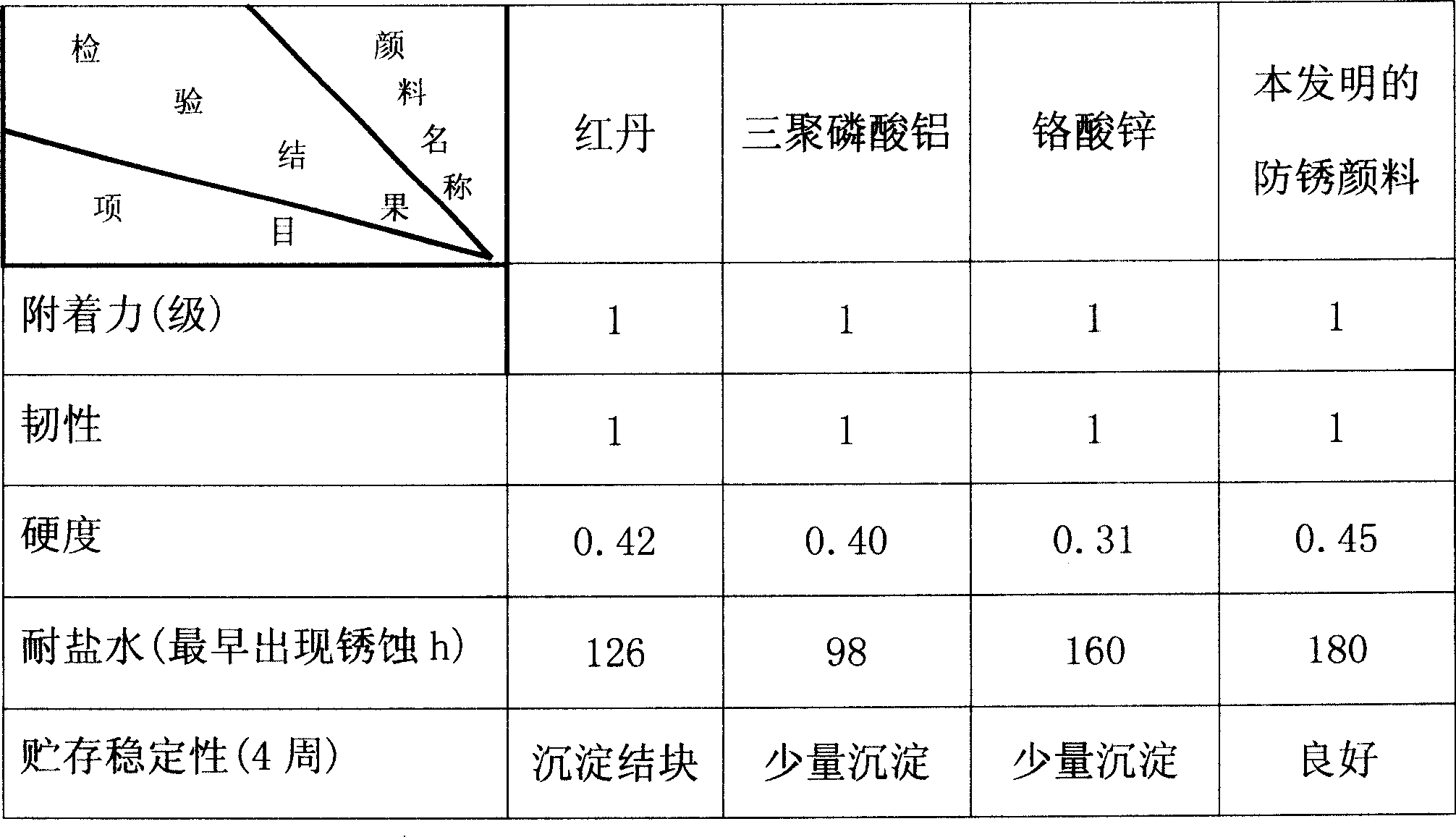

Rust-preventive pigment

InactiveCN101007918AEnvironmental performanceGood storage stabilityAnti-corrosive paintsPigment pastesOxidePigment

The invention belongs to chemical paint technolgy, and relates to a rust-preventive pigment. It comprises phytate and mica or mica ferric oxide or ferro-phosphorus powder packing material, and the weight ratio between them is 1: 1- 9. It is prepared through deposition and polymerization with mentioned raw materials. The rust-preventive pigment only contains phytic acid and non- toxic packing material, no lead, chromium, cadmium and arsenic, so the rigidity, flexibility and adhesive force are dramatically increased, and can be modified with other pigment, packing material and resin.

Owner:赵奎山

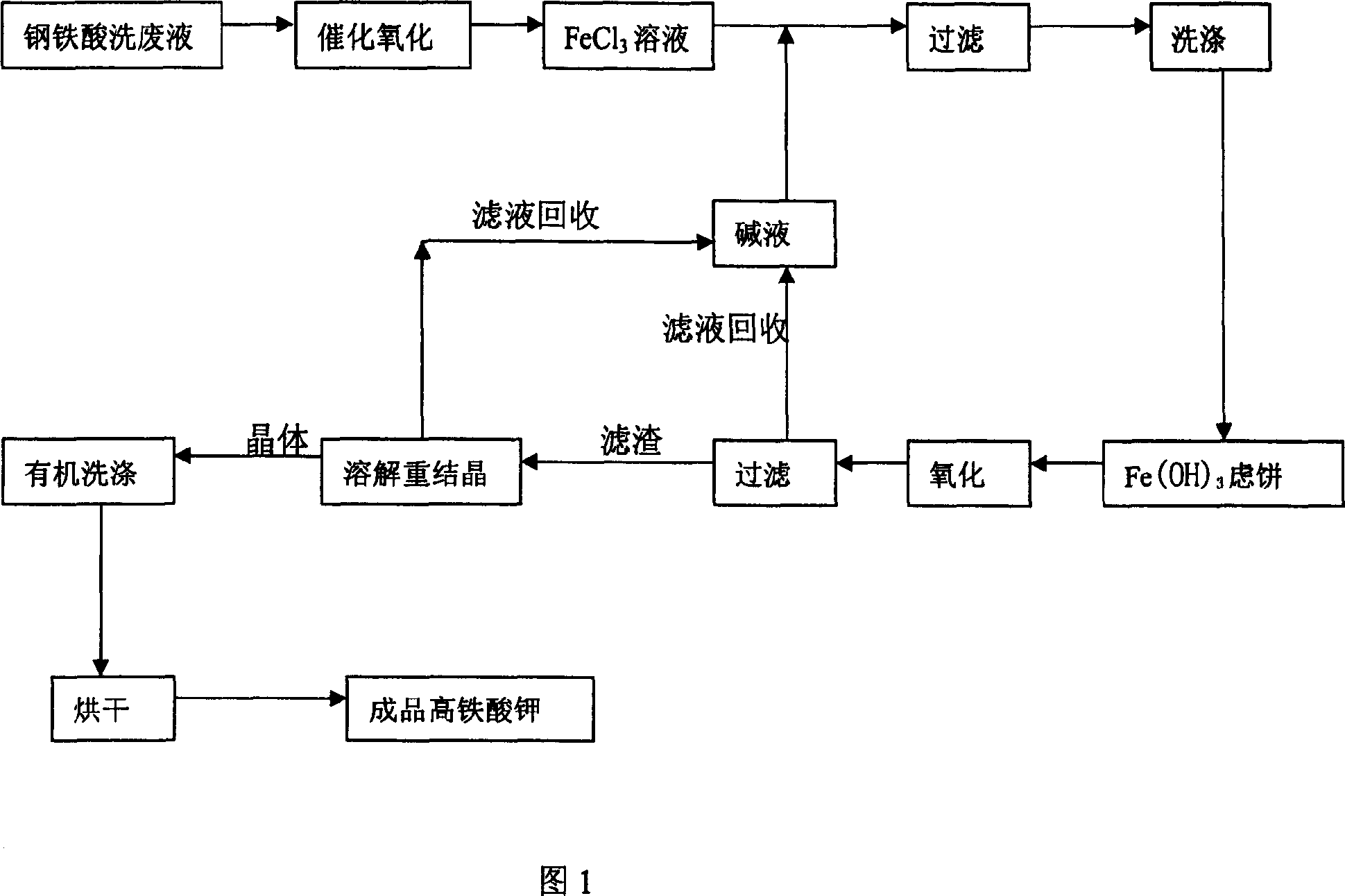

Method for preparing potassium ferrate by using waste liquid from acid washing steel

InactiveCN1958462AAvoid pollutionEasy to operateMultistage water/sewage treatmentIron compoundsOrganic solventAcid washing

This invention relates to a method preparing potassium ferrate from steel acid-washing waste liquid. The method comprises: oxidizing bivalent iron ions in steel acid-washing waste liquid into trivalent iron ions, precipitating trivalent iron ions to obtain Fe (OH) 3, and oxidizing Fe (OH) 3 by KClO in a strong alkaline condition to obtain potassium ferrate. The process mainly comprises: catalytically oxidizing, filtering the precipitate, oxidizing by KClO, recovering the filtrate, recrystallizing for purification, and washing with organic solvent. The method is environmentally friendly.

Owner:WUHAN UNIV OF TECH

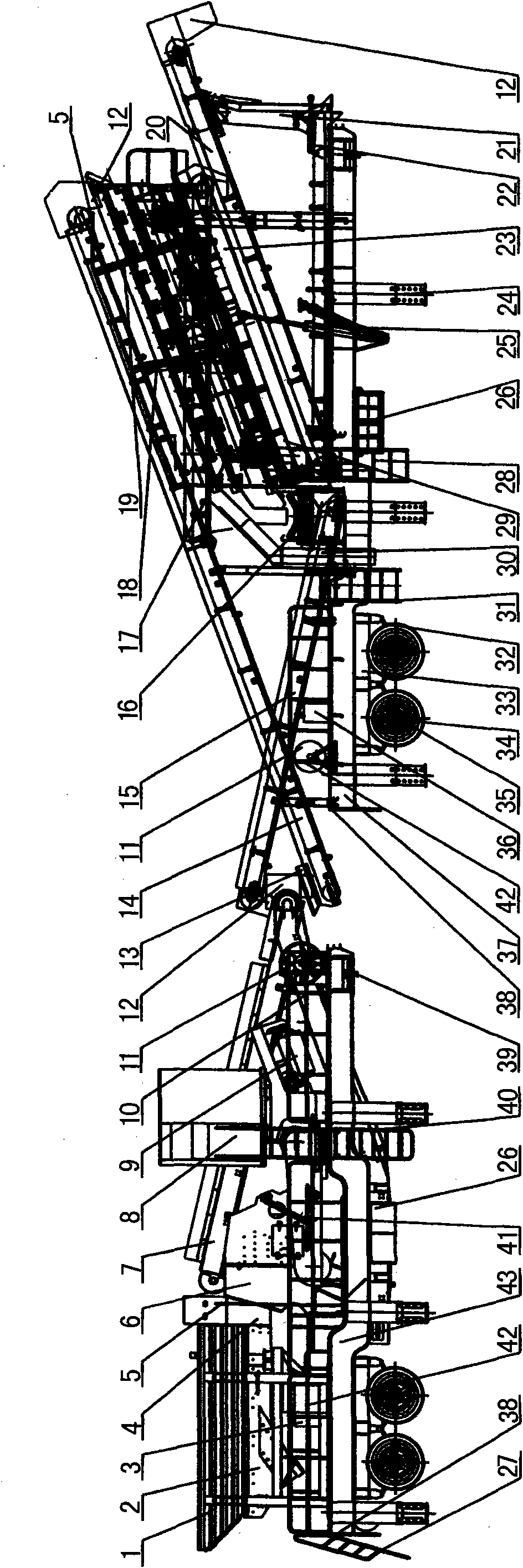

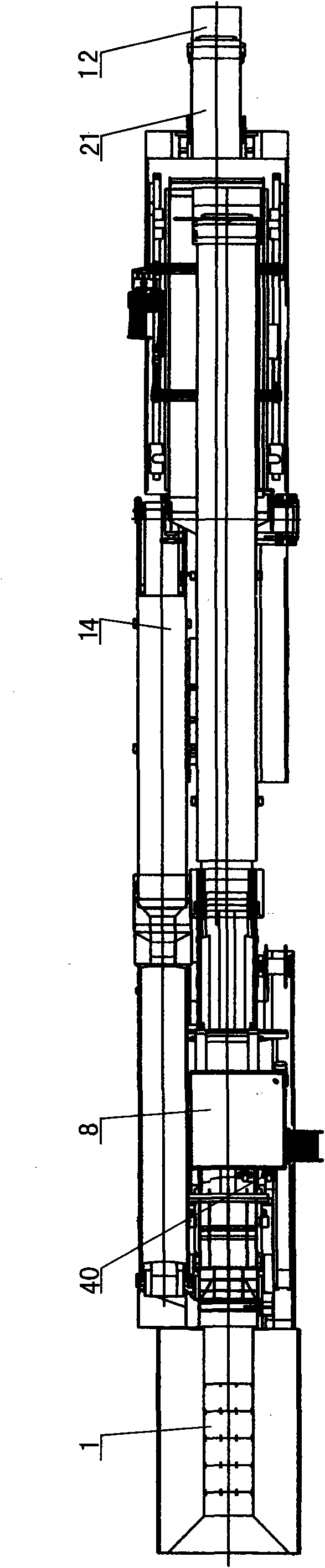

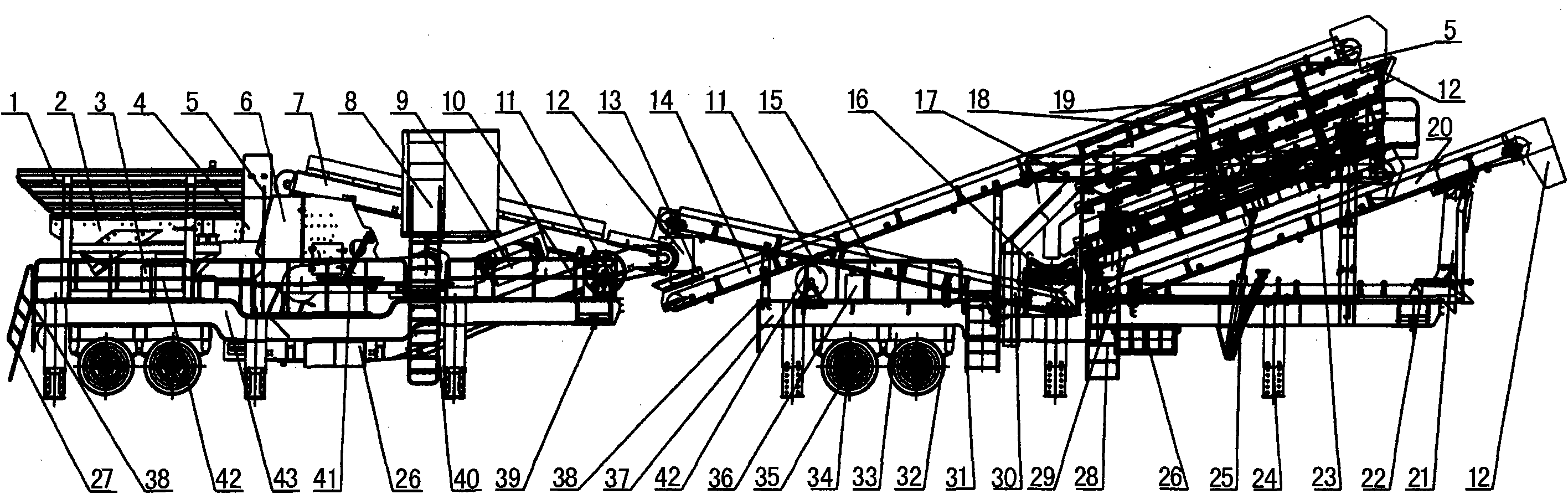

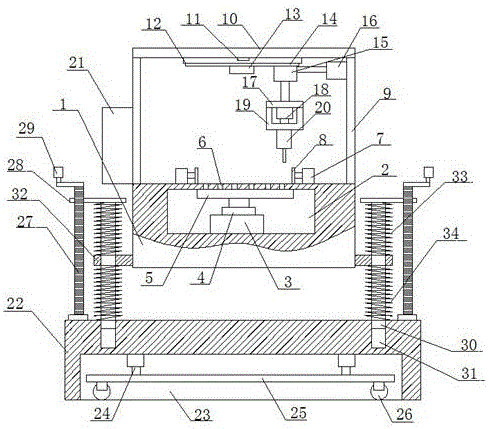

Mobile construction waste crushing station

InactiveCN101927256ASmall footprintReduce pollutionConstruction waste recoverySolid waste disposalTurning framesCrusher

The invention relates to construction waste crushing equipment, in particular to a mobile construction waste crushing station. In the mobile construction waste crushing station, a vibrating feeder (2) is arranged on the lower part of a raw material storage (1); a construction waste crushing machine feed hopper (4) is arranged on the upper middle part of another frame main beam (43) and is communicated with the raw material storage; the upper part of one end of a feeding belt conveyer A (10) is arranged on the lower part of a construction waste crushing machine A (6); a belt conveyer outlet hopper (12) at the other end of the feeding belt conveyer A is arranged above a feeding belt conveyer B (14); a belt conveyer receiving hopper (13) is connected with the feeding belt conveyer B; a returning belt conveyer A (7) is arranged on one side of the feeding belt conveyer A; and both of the tail part of the returning belt conveyer A (7) and the head part of a feeding belt conveyer B (15) are provided with a receiving hopper and a feed hopper. In the mobile construction waste crushing station, useful iron wires, reinforcing steel bars and various steel members are separated from the crushed construction waste, so occupied area of municipal refuse is effectively reduced and pollution is reduced.

Owner:洛阳凯兴矿山机械有限公司

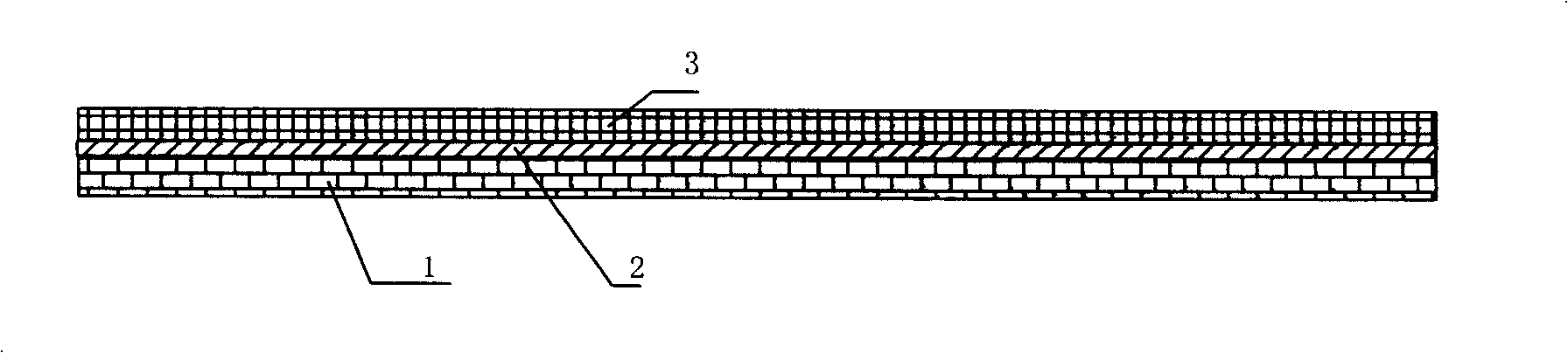

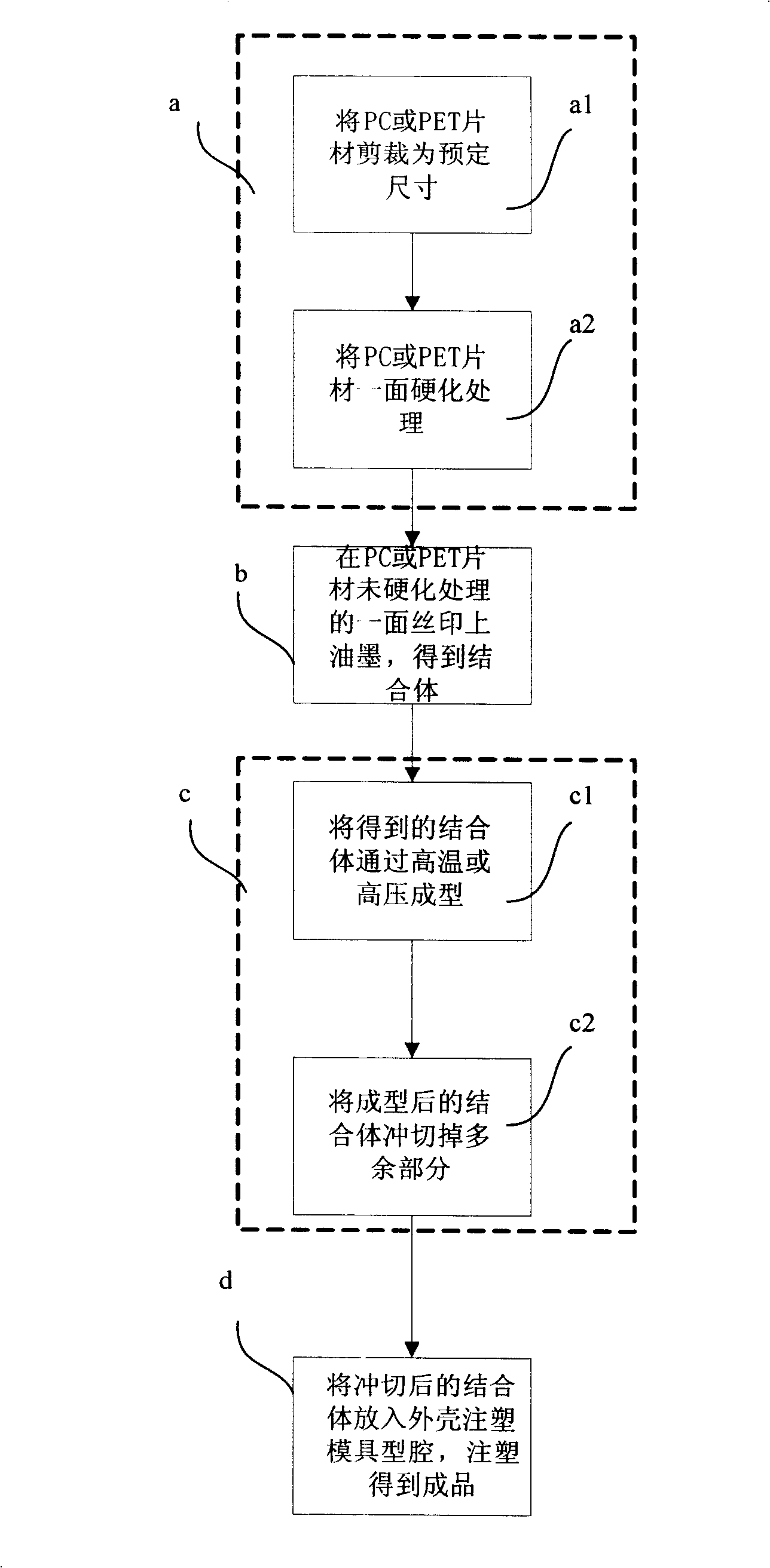

Notebook computer casing and shaping method

ActiveCN101256426ASo as not to damageNot easy to damageDigital data processing detailsSynthetic resin layered productsEngineeringComputer case

The invention relates to a notebook PC case, consists of a body (1) formed by injection molding, a protecting layer (2) attached to the body (1) when injection molded, and a middle layer (2) positioned therebetween. The invention also provides a method for manufacturing the notebook PC case, comprising: processing PC or PET sheet material used as the protecting layer; combining the middle layer with the protecting layer by printing; processing the combination of the middle layer and the protecting layer; putting the combination into an injection molding mould cavity of the case, injection molding and forming the body integrated with the middle layer and the protecting layer. The embodiment of the invention has the following beneficial effects: the outer surface of the case of the notebook computer is durable, not easy to damage or scrape, the printed pattern thereon is not easy to drop off or pollute and has environment-protecting effect.

Owner:QUNDA PLASTIC ELECTRONICS SHENZHEN

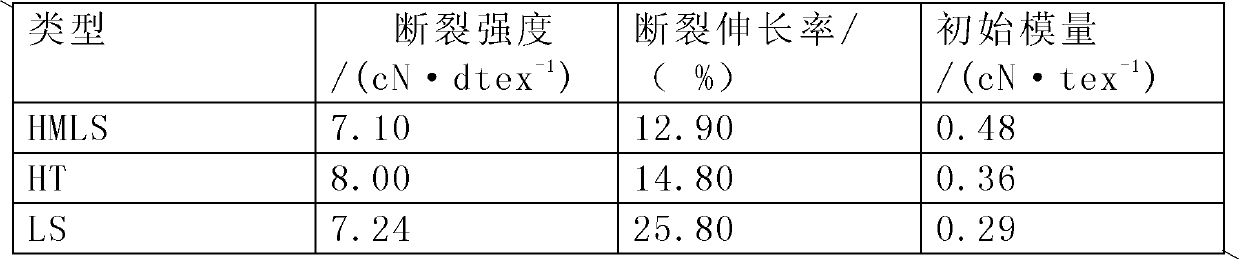

High-intensity environment-protection type textilene reeled silk

ActiveCN101994165AEnvironmental performanceHigh mechanical strengthFilament/thread formingYarnEnvironmental resistancePlastic materials

The invention provides high-intensity environment-protection type textilene reeled silk, which belongs to the technical field of weaving reeled silk and solves the problem that the traditional textilene has poor environment protection performance. The high-intensity environment-protection type textilene reeled silk is formed by twisting and reeling long textilene threads in different colors, the long textilene threads are compound threads in cladding structures, core bodies are terylene industrial filament yarns, and cover layers are environment-protection type plastic materials. The textilene reeled silk of the invention has the core bodies made of terylene industrial filament yarns and the cover layers made of the environment-protection type plastic materials, and has the environment protection performance and higher mechanical intensity.

Owner:TAIZHOU DONGHAI PLASTIC PRODS MFG +1

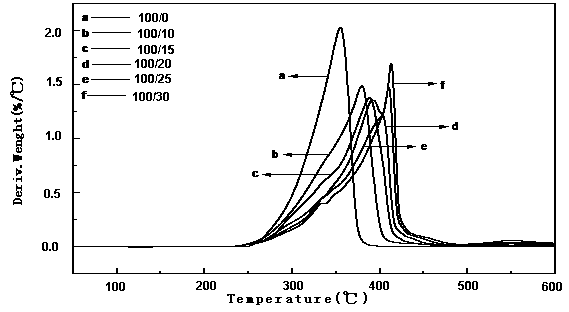

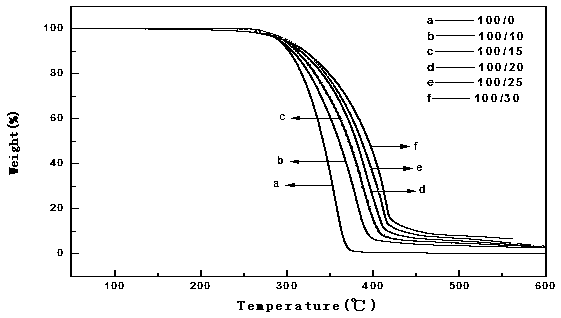

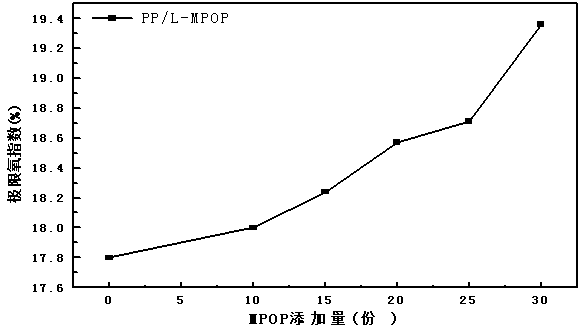

Preparation method of MPOP

InactiveCN105504292AHigh degree of polymerizationLow water solubilityOrganic chemistryFiltrationReaction temperature

The invention provides a preparation method of MPOP. The method comprises steps as follows: (1) preparation of an intermediate: urea phosphate is dissolved in water, the concentration of urea phosphate is controlled to range from 10% to 50%, a certain amount of melamine is added to react with urea phosphate, the molar ratio of urea phosphate to melamine is 1:(0.8-1.25), the reaction temperature is controlled within 25-100 DEG C, the reaction time is 0.5-2.5 h, filtration, washing and vacuum drying are performed, and the intermediate is obtained; (2) preparation of MPOP: the intermediate prepared in Step A is calcined at the temperature of 200-400 DEG C for 1-5 h, cooling, grinding and sieving are performed, and a flame retardant, namely, MPOP is obtained. The technology is simple, industrialization is easy to realize, the operation condition is mild, water is taken as a reaction medium, and the method is clean and pollution-free.

Owner:WENGFU (GRP) CO LTD +2

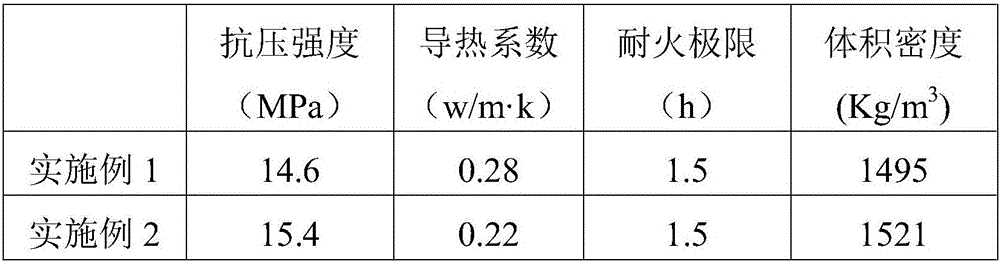

Lightweight fireproof building brick and preparation method thereof

InactiveCN106747496AEmission reductionEnvironmental performanceCeramic materials productionClaywaresBrickSludge

The invention discloses a lightweight fireproof building brick and a preparation method thereof. The brick is prepared from the following raw materials in parts by weight: 40 to 80 parts of industrial waste residues, 40 to 80 parts of building debris, 80 to 120 parts of wastewater, 10 to 65 parts of sludge, 10 to 50 parts of fly ash, 10 to 40 parts of river sand, 10 to 30 parts of cement, 5 to 30 parts of clay, and 1 to 20 parts of sintering aid, wherein the weight ratio of river sand to cement to clay is 2:1:1, and the sintering aid accounts for 1 to 3% of the total weight of the raw materials. The brick has a certain strength and fireproof effect. Comprehensive garbage is taken as the raw materials, wastes are recovered and utilized, the production cost is reduced, and the environment is protected.

Owner:KUNSHAN DINGNIU SHIZHENG CONSTR CO LTD

Multi-direction cutting plate shearing machine adjustable in damping performance

InactiveCN106541505AProtect your healthProtective elastic forceWorking accessoriesStone-like material working toolsMachiningAerospace engineering

The invention discloses a multi-direction cutting plate shearing machine adjustable in damping performance. The multi-direction cutting plate shearing machine comprises a workbench and a base. A cavity is formed in the workbench. A dust collecting box is arranged at the bottom of the cavity. A dust suction device is arranged on the upper side of the dust collecting box and connected with a dust suction hopper through a pipeline. Multiple dust suction openings are formed in the upper side of the workbench. A first longitudinal guide rail is arranged on the lower side of an installing plate and provided with a moving plate. A first air cylinder is arranged at the rear end of the upper side of the installing plate. The front end of the first air cylinder is connected with the rear side of the moving plate. A second longitudinal guide rail is arranged on the lower side of the moving plate, and a second air cylinder is arranged on the lower side of the second longitudinal guide rail. A third air cylinder is arranged at the right end below the installing plate. The left end of the third air cylinder is connected with the right end of the second air cylinder. A connecting plate is arranged at the lower end of the second air cylinder. A motor is arranged on the lower side of the connecting plate, and the output end of the motor is connected with a rotation support. The multi-direction cutting plate shearing machine is simple in structure and convenient to use, multi-direction machining can be achieved, and the function of dust suction is achieved as well.

Owner:江苏言诺机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com