Before-coating metal surface treatment method

A surface treatment, pre-metal technology, applied in the direction of metal material coating process, etc., can solve the problems of environmental treatment burden of phosphate, short service life of phosphating solution, and high phosphating temperature, reducing phosphating solution slag and low cost. , The effect of good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

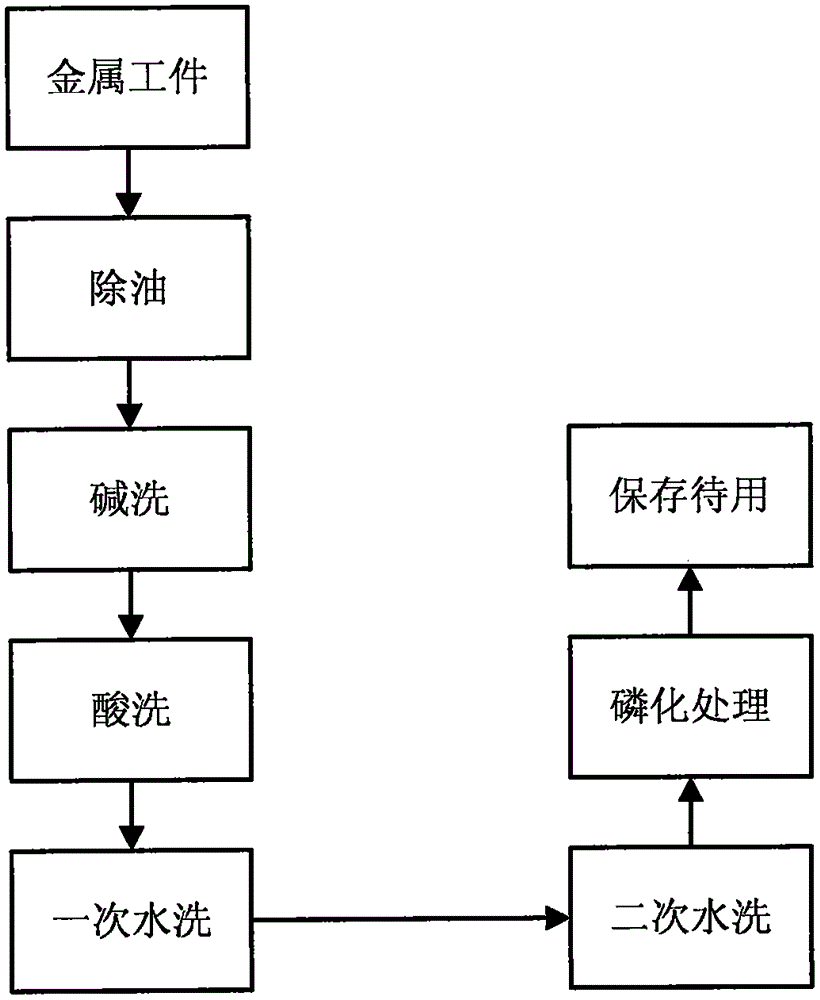

[0019] Such as figure 1 Shown, a kind of metal surface treatment method of the present invention mainly comprises the following steps:

[0020] Step 1) Degreasing: soak the metal workpiece to be treated in an acetone solution, use an ultrasonic cleaner to clean it for 10-15 minutes, and fully clean the oil stain;

[0021] Step 2) Alkali cleaning: immerse the workpiece to be treated in an alkaline cleaning solution or use an alkaline cleaning solution for spraying;

[0022] Step 3) pickling: the above-mentioned metal workpieces after alkali washing are pickled, and the pickling solution used is 150mL / L of H 2 SO 4 , a mixed solution of 50mL / L HF and 30mL / L triethanolamine, the temperature is controlled at about 25°C, and the pickling time is about 2min; the pickling solution used is 150mL / L H 2 SO 4 , a mixed solution of 50mL / L HF ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com