Patents

Literature

93results about How to "Less sediment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional assistant plating additive for hot dip plating process, preparation and use method thereof

ActiveCN101328568AReduce lossImprove stabilityHot-dipping/immersion processesDissolutionLiquid metal

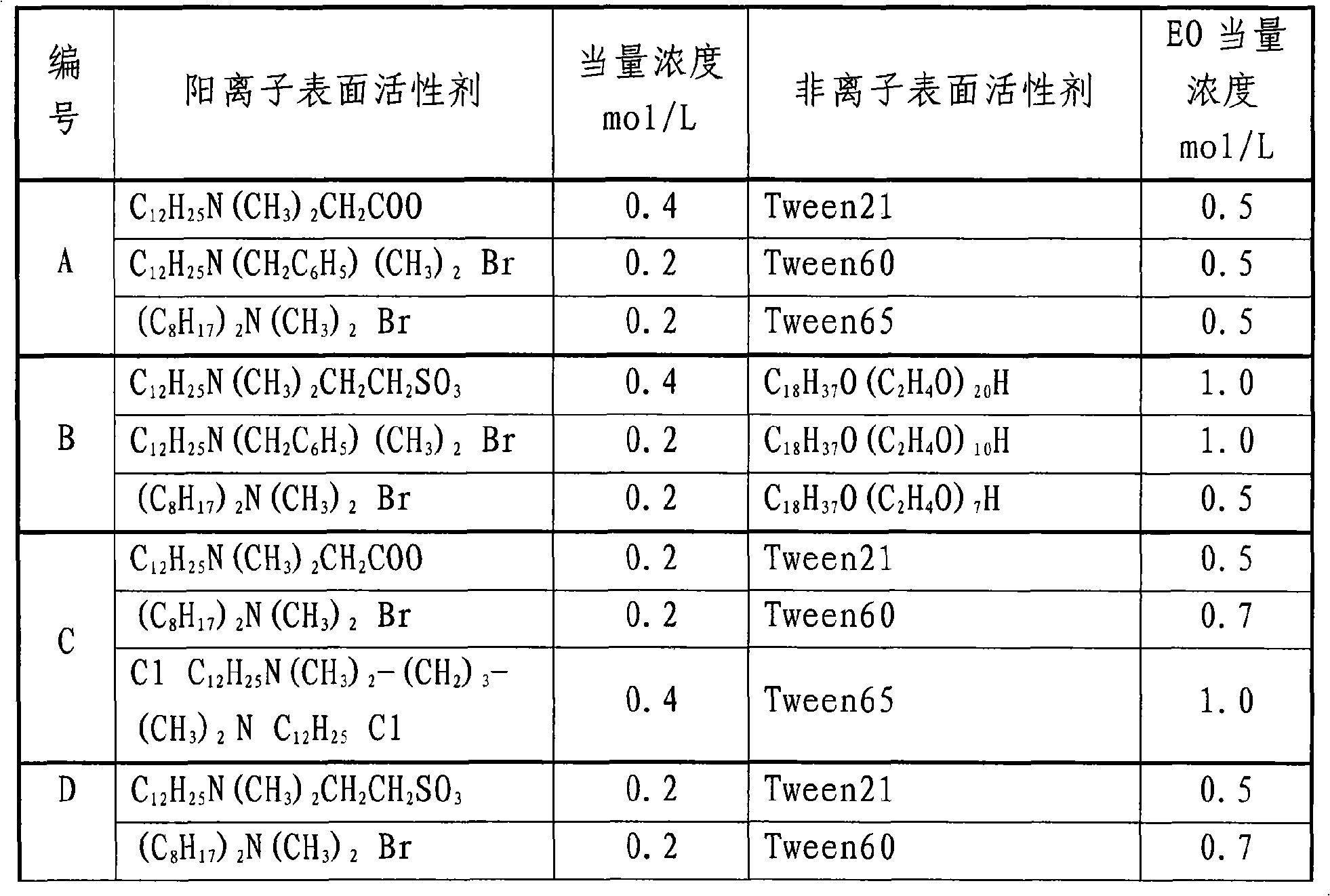

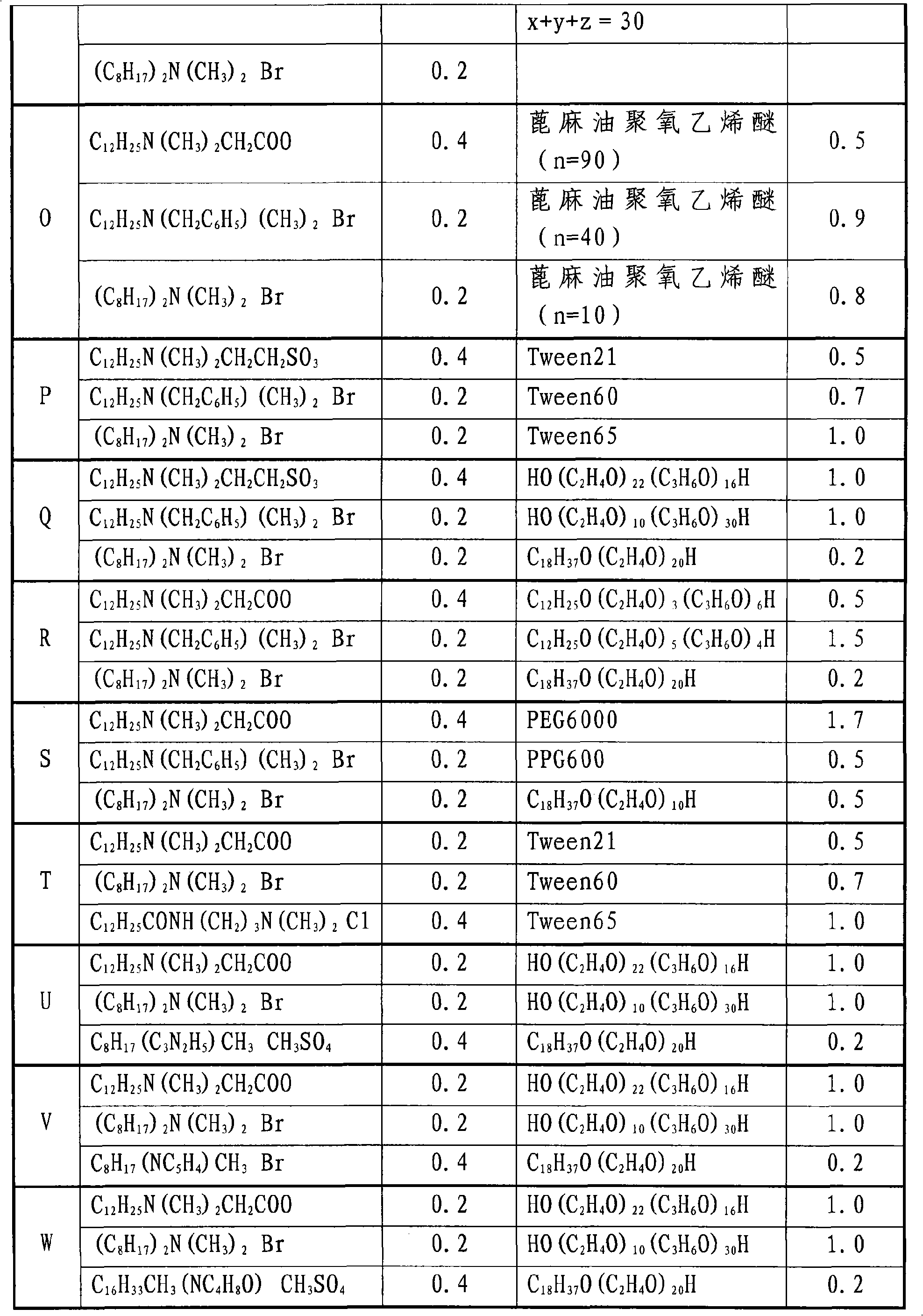

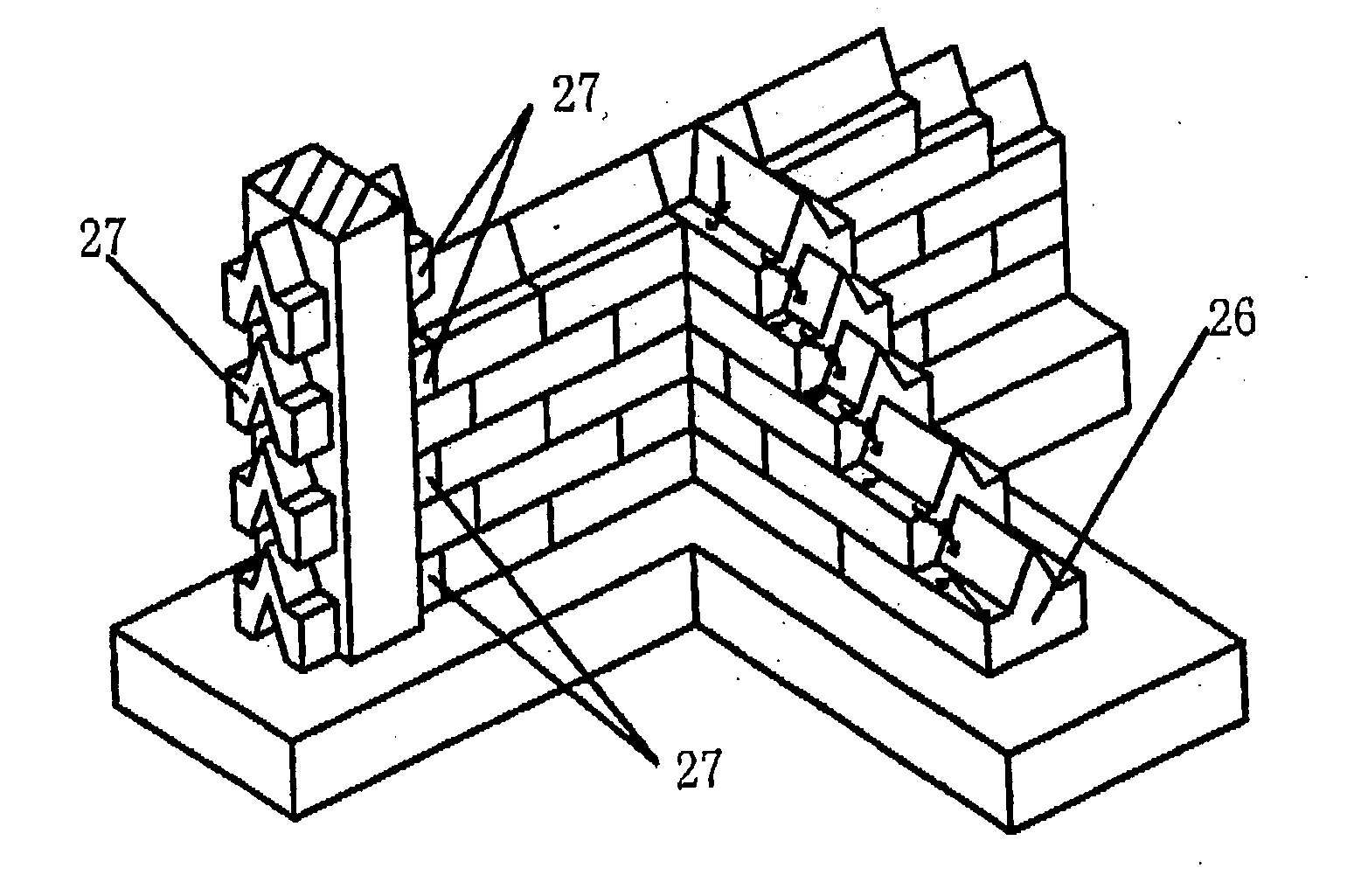

The invention relates to a multifunctional plating assisting additive for a hot dipping metallization process and a preparation and application method thereof, and belongs to the metal material anticorrosive technical field for providing multiple plating assisting efficacy. The technical proposal of the invention comprises that: a plurality of cations or an amphoteric surfactant ( an equivalent concentration of a quaternary ammonium group is between 0.1 and 2 mol / L) and nonionics (an equivalent concentration of a polyoxyethylene group is between 0.5 and 5 mol / L) are dissolved in deionized water. The method can improve the wetting quality between a liquid-state metal and a workpiece, and the adhesive uniformity and continuity of the plating assisting additive, reduces the drying time, prevents the liquid-state metal from falling and splashing, shortens the dipping and plating time, saves raw materials, improves a residue form, reduces an ash content, increases an ash discharge speed, isolates air, stops oxidation, disperses residual dirt and is suitable for a plurality of processes of hot galvanizing, hot plating zinc-aluminum alloy, hot plating aluminum, etc. The preparation steps comprise dissolution, cubage determination, cooling, keeping stand and filling; when the multifunctional plating assisting additive is used, the multifunctional plating assisting additive is directly added into a plating assisting additive solution and is evenly stirred.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

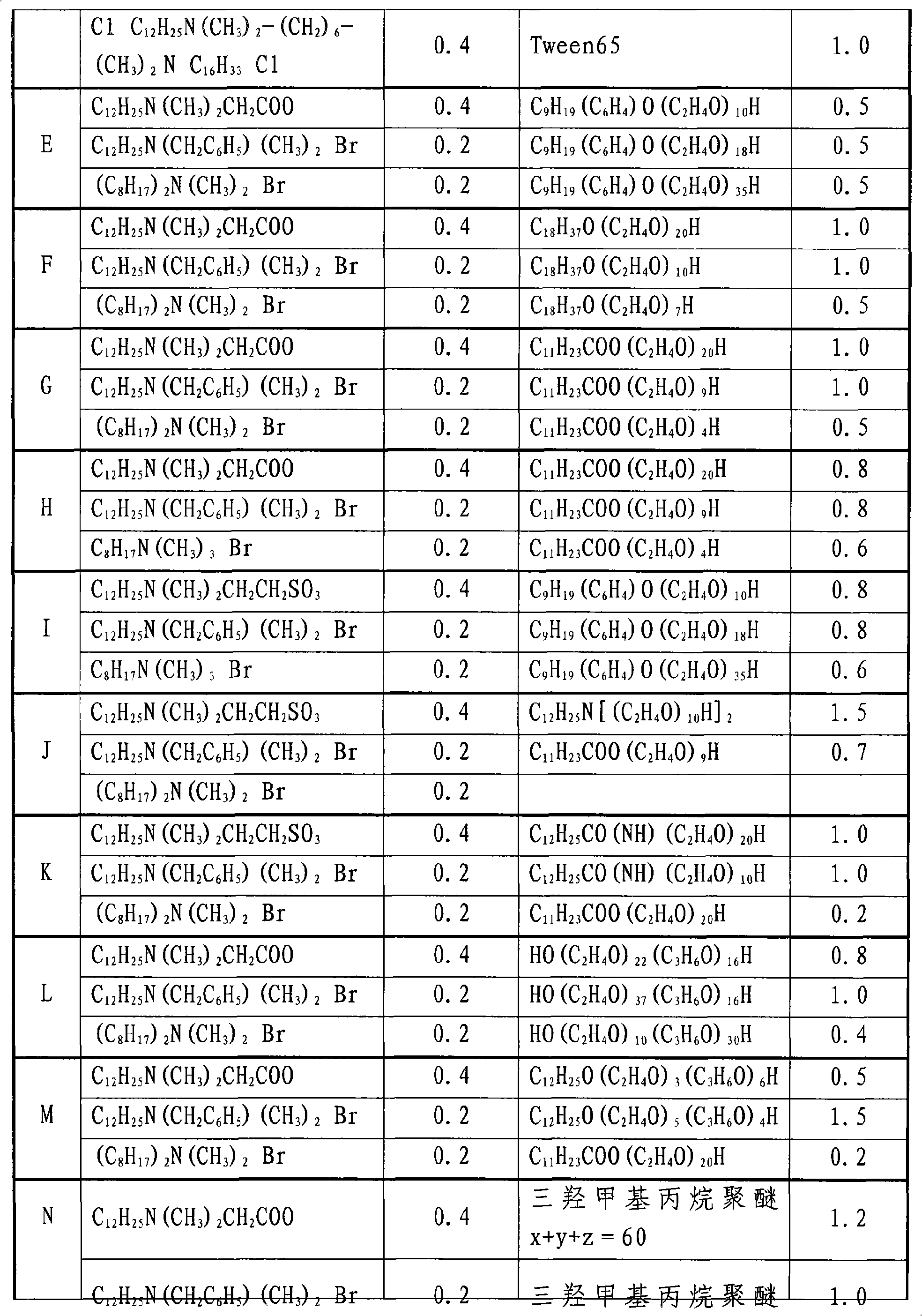

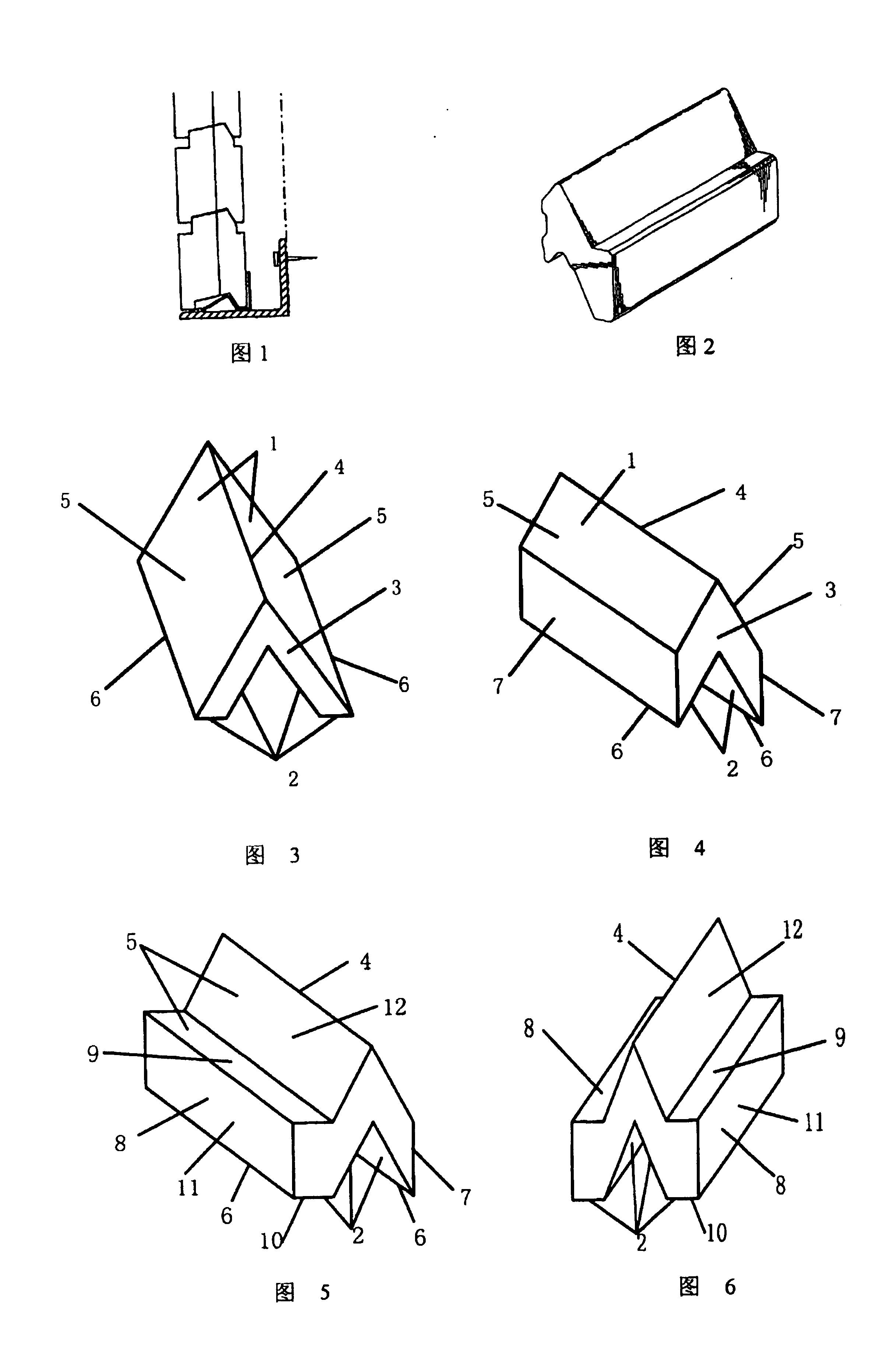

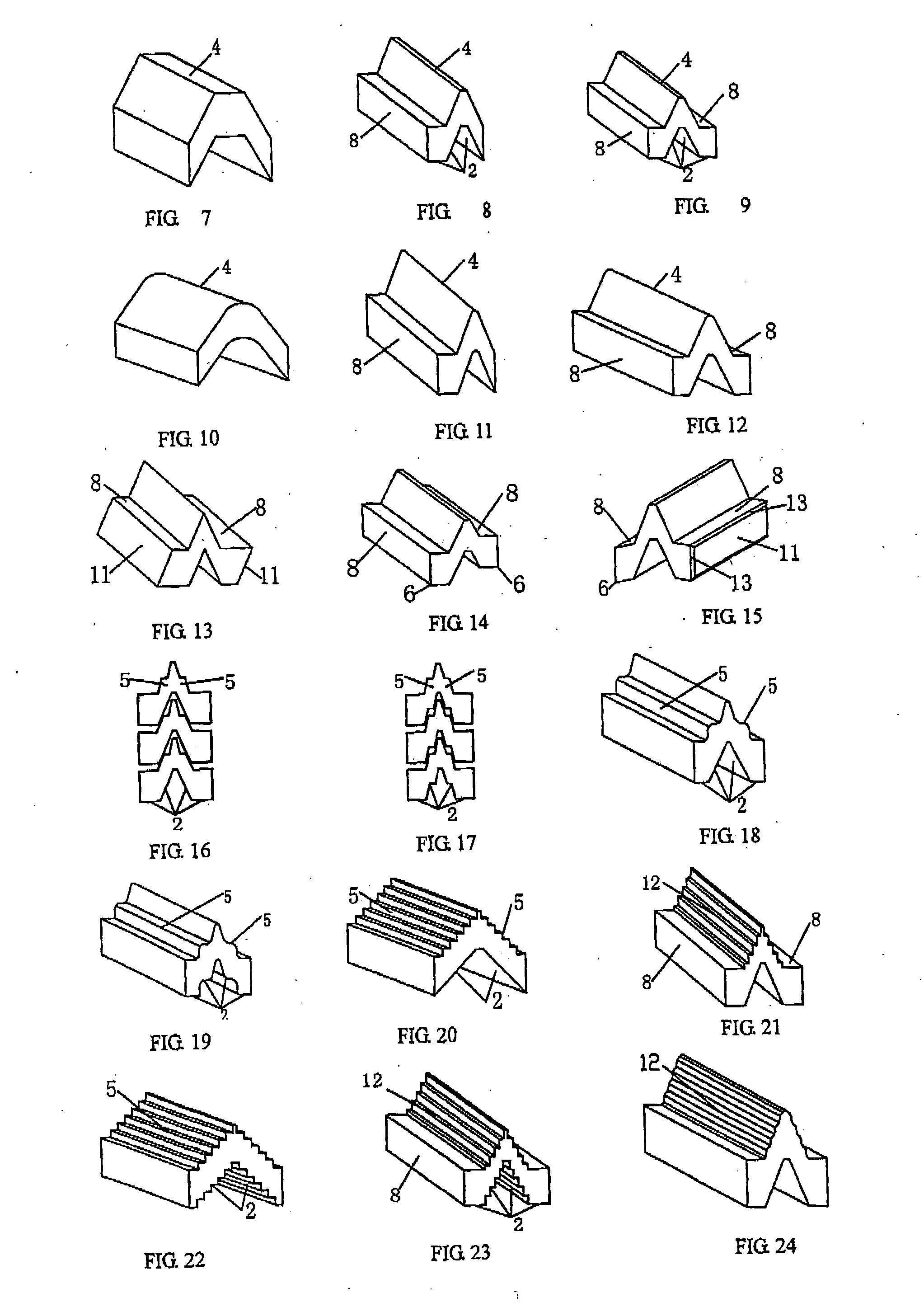

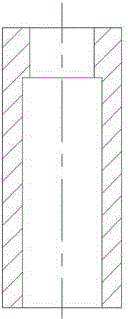

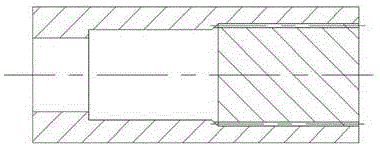

Block For Forming Wall And The Wall Thus Formed

InactiveUS20070199273A1Improve leak resistanceLess sedimentBuilding roofsConstruction materialEngineeringBlock structure

A kind of block for building wall and the wall built with said blocks. There are many analogous blocks laid to overlap and stagger with upper / nether block continuously in said wall. The block extends lengthways and comprises top surface (1), bottom surface (2) and two end surfaces (3); the cross section thereof on the whole is a converse trumpet shape; the top surface (1) has a mid ridge (4) higher than the two sides of the surface so as to form the left / right supporting slope (5); the top surface (1) and the bottom surface (2) are formed in this way: when a block overlap with a analogous block thereunder to form a wall, the left and right supporting slope (5) become a blocking structure to lock the two blocks neighbored up and down, the raised dimension of the mid ridge (4) can cut off space-time trochoid. This invention also provides the assistant blocks, which cooperate with said blocks when building wall.

Owner:WANG RONGXUN

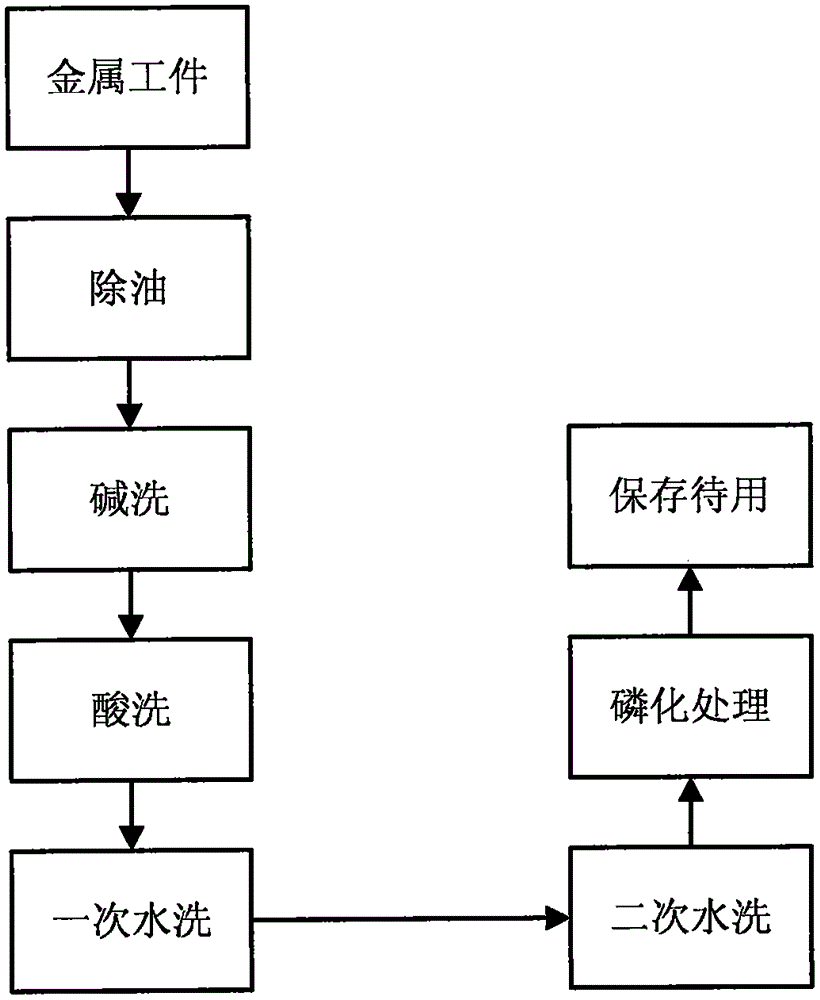

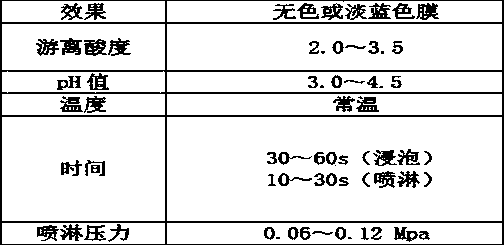

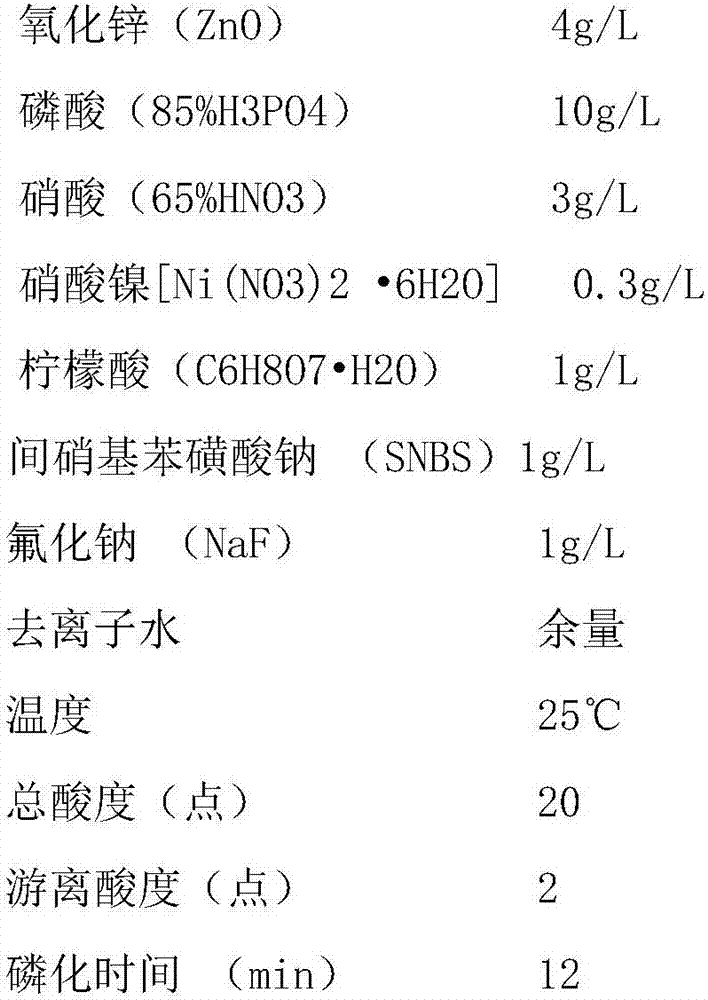

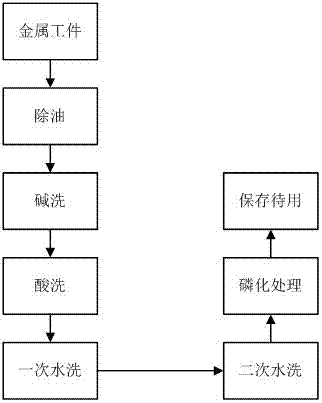

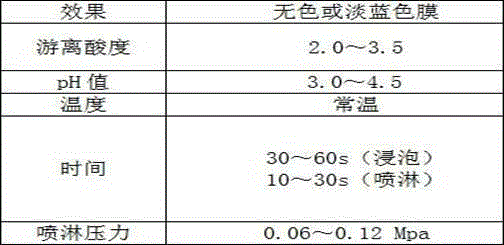

Before-coating metal surface treatment method

ActiveCN105369271AImprove permeabilityFast film formationMetallic material coating processesNonferrous metalAcid washing

The invention discloses a before-coating metal surface treatment method. The before-coating metal surface treatment method comprises such steps as oil removal, alkali washing, acid washing, two times of water washing and phosphorization. Adopted environment-friendly alkaline cleaning liquid has the technical effects of energy conservation and environmental protection, and has an excellent cleaning effect on both black metal and nonferrous metal; adopted phosphorization liquid has such advantages as quick film formation, strong paint film bonding force, good corrosion resistance, capability of operating through brushing or spraying, simple operation and low cost; the prepared phosphorization liquid reduces phosphorization liquid sediments, and guarantees the quality of phosphorized film; and the film layers are uniform and exquisite, so that the metal surface treatment method can realize the before-coating metal surface treatment more environment-friendly and more efficiently, and has active effects on the coating process and the coating quality.

Owner:苏州天成涂装系统股份有限公司

Manganese phosphating liquor, preparation and use thereof

InactiveCN101328583AImprove adhesionImprove corrosion resistanceMetallic material coating processesCalcium hydroxidePhosphoric acid

The invention provides a manganese phosphating solution, a preparation method thereof and an application. The compositions in percentage by mass of the manganese phosphating solution are: 5.0 to 15.0 percent of phosphoric acid, 5.0 to 20.0 percent of manganese biphosphate, 1.0 to 18.0 percent of nitric acid, 0.1 to 3.0 percent of calcium hydroxide, 0.2 to 5.0 percent of zinc oxide, 1.0 to 5.0 percent of tartaric acid and the balance being water. Water, phosphoric acid, pasty zinc oxide, nitric acid and phosphoric acid mixture, calcium hydroxide and tartaric acid are added in a reaction kettle in turn, and are stirred continuously so as to prepare the phosphating solution. The manganese phosphating solution is used in surface treatment of oil well pipe coupling. The manganese phosphating solution can be formed into a compact black crystallized phosphating film on metal surface, thereby effectively improving the abrasion resistance, thread gluing-proof property and seizure resistance of metal surface and increasing the performance of oil well pipe coupling to 4 to 10 times; moreover, the manganese phosphating solution, the preparation method thereof and the application ensure simplified operation and convenient maintenance, and can be effectively used in practical industrialized production.

Owner:BAOSHAN IRON & STEEL CO LTD

Process for cold extrusion forming of one-way device spline sleeve

InactiveCN104148888AEliminates drilling/boring stepsDrilling/boring steps meetEngineeringUltimate tensile strength

The invention provides a process for cold extrusion forming of a one-way device spline sleeve. The process comprises the steps of utilizing hollow pipes to serve as raw materials, performing blanking according to specified dimensions, sequentially performing annealing, head flattening, shot blasting, phosphatization and saponification treatment, cold extrusion shaping, cold extrusion spline forming, machining, quenching, tempering, shot blasting, cleaning and grinding machine processing, and obtaining finished product one-way device spline sleeves. The one-way device spline sleeves obtained through the process are high in precision, small in individual differences, good in strength performance and long in service lives.

Owner:宁波惠山汽配制造有限公司

Magnesium alloy chromium-free fluorine-free phosphorization solution and phosphorization method

InactiveCN101851755AProcess stabilityFew ingredientsMetallic material coating processesChromium freeSal ammoniac

The invention relates to magnesium alloy chromium-free fluorine-free phosphorization solution and a phosphorization method. Each liter of the magnesium alloy chromium-free fluorine-free phosphorization solution comprises 1 to 50 g of dihydric phosphate, 0 to 30 g of nitrate and 0.1 to 5 g of additive. The processed magnesium alloy workpiece is soaked and stood in the phosphorization solution of which the pH value is adjusted to be 2.0 to 5.0 by using phosphoric acid and ammonia water and is subjected to phosphating treatment at the temperature of between 30 and 100 DEG C for 1 to 60 minutes to form a phosphate coating. The magnesium alloy is phosphated by the phosphorization solution and the process, a uniform phosphate conversion coating with high corrosion resistance can be obtained on the surface of the magnesium alloy and the phosphate coating can effectively improve the adhesion and the protective property of the subsequent coatings. The phosphorization solution on the surface ofthe magnesium alloy has the advantages of few components and simple preparation. The phosphorization method of the phosphorization solution has the advantages of easy control, stable process, low cost and little sediment.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Steel normal-temperature blackening solution composite film-forming accelerator, steel normal-temperature blackening solution and preparation method of steel normal-temperature blackening solution

InactiveCN102899650ASimple preparation processReduce manufacturing costMetallic material coating processesComposite filmPhosphate

The invention discloses a steel normal-temperature blackening solution composite film-forming accelerator which comprises the following components in parts by weight: 1-3 parts of calcium nitrate, 4-8 parts of cobalt nitrate, 2.5-5 parts of sodium borate and 0.3-0.6 part of metanitrobenzene sulfonic acid. The adhesive force and corrosion resistance of a blackening film are obviously improved, and the film-forming speed is also increased. The invention also discloses a steel normal-temperature blackening solution. The steel normal-temperature blackening solution takes water as a solvent, has a pH value of 2-3 and comprises the main components of 2-8 g / L copper sulfate, 3-6.5 g / L selenium dioxide, 2-10 g / L potassium dihydrogen phosphate, 2-6 g / L zinc nitrate, 1-3 g / L nickel sulfate, 2-6 g / L composite film-forming accelerator, 3-8 g / L urea and 0.5-8 g / L complexing agent. The invention also discloses a preparation method of the steel normal-temperature blackening solution. The blackening film of the prepared blackening solution has firm adhesive force, high corrosion resistance and less sediment.

Owner:田康

Phosphating liquor of manganses series

InactiveCN101063199AGood stabilityLess sedimentMetallic material coating processesSoftened waterSodium nitrite

The invention discloses a manganese series liquid phosphide in surface chemical technical domain, which comprises the following steps: allocating with mass ratio as 2. 0-8. 0 phosphoric acid, 1-10 horse sun husband salt, 2-8 sodium nitrate, 0. 5-5 zinc nitrate, 3. 0-5. 0 nickel nitrate, 1-4 sodium nitrite, 0. 5-6 hydrogen dioxide solution and 45-60 softened water; getting the product. This invention can improve wear resistance and prolong durability of gear.

Owner:宋晨玮

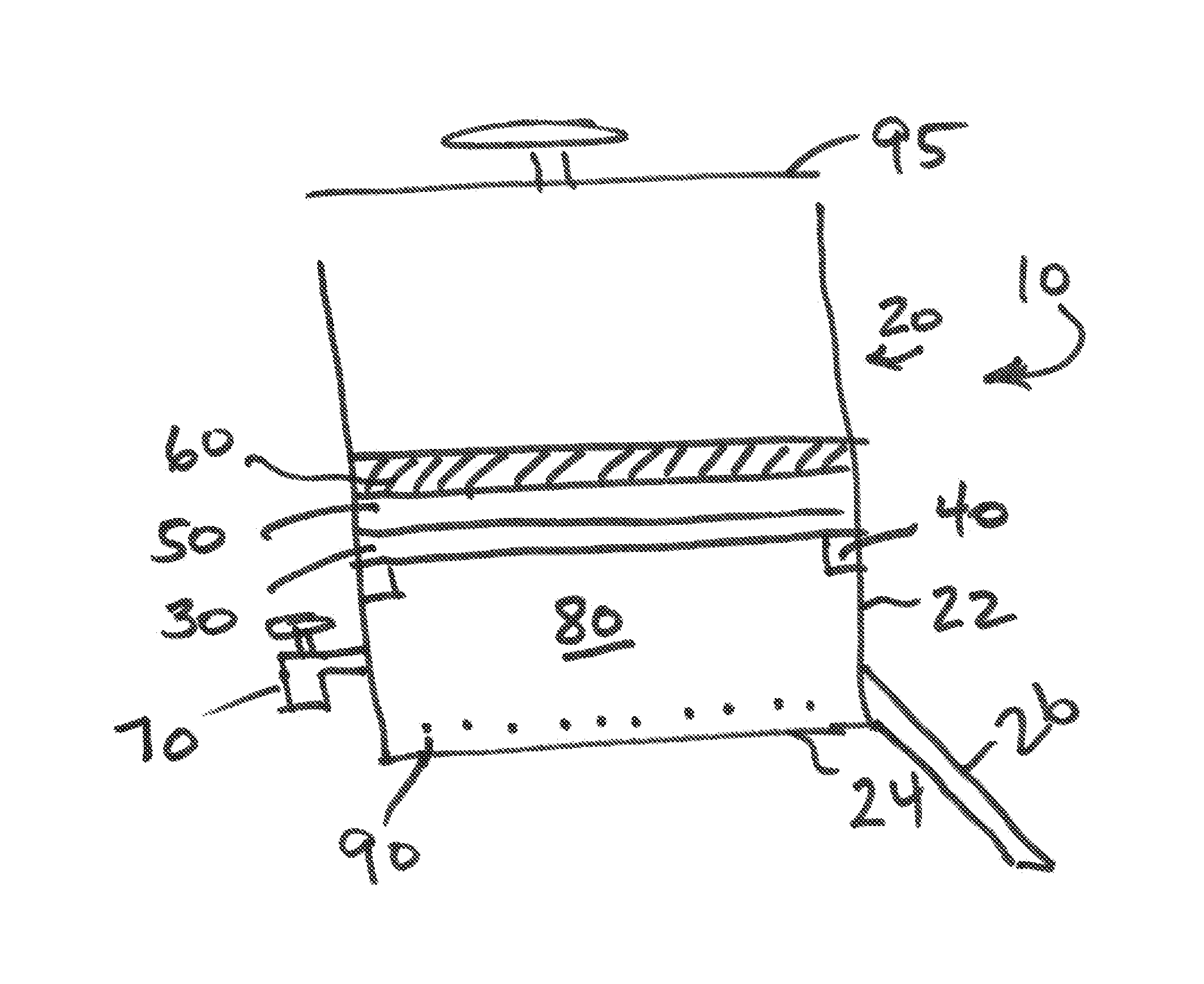

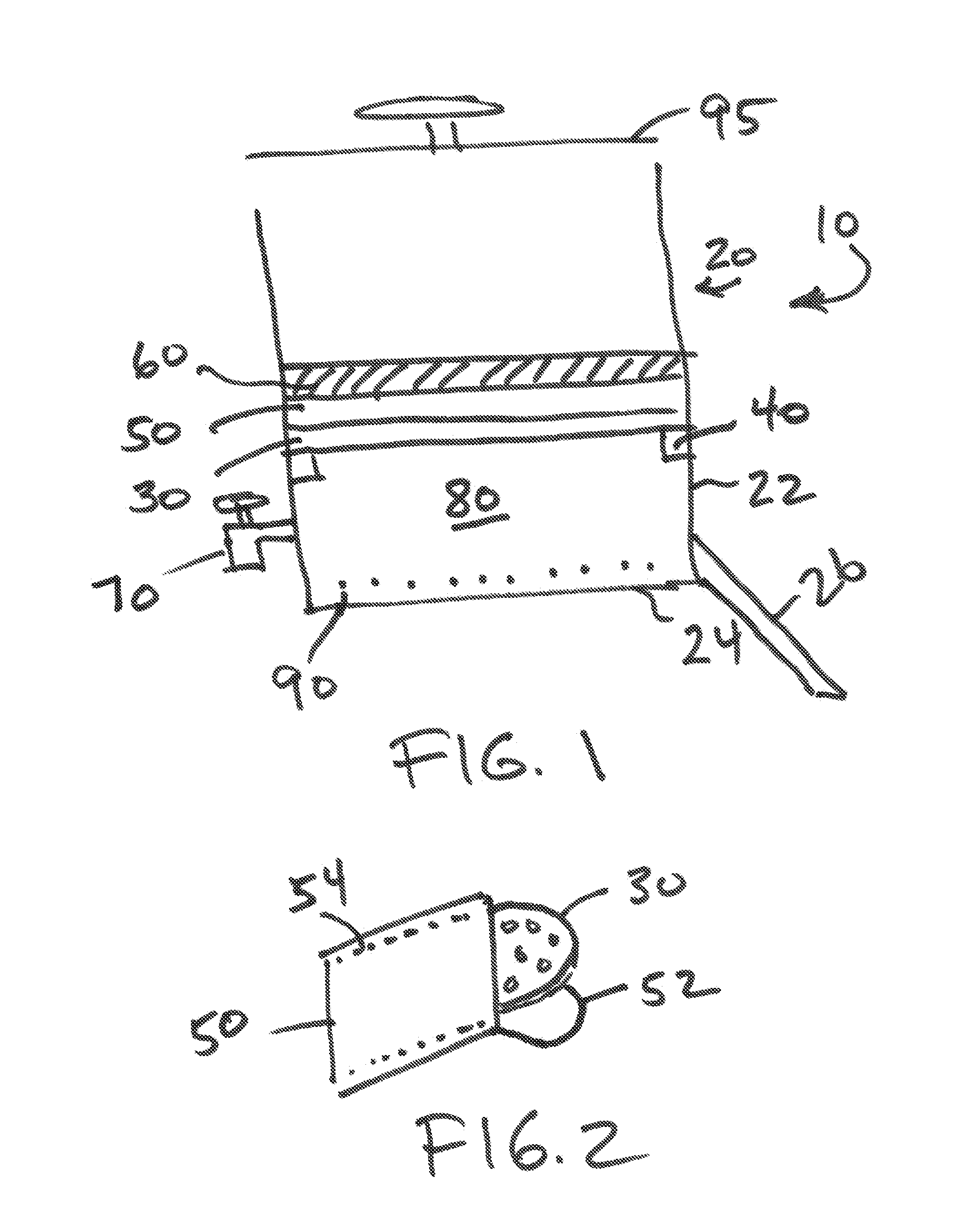

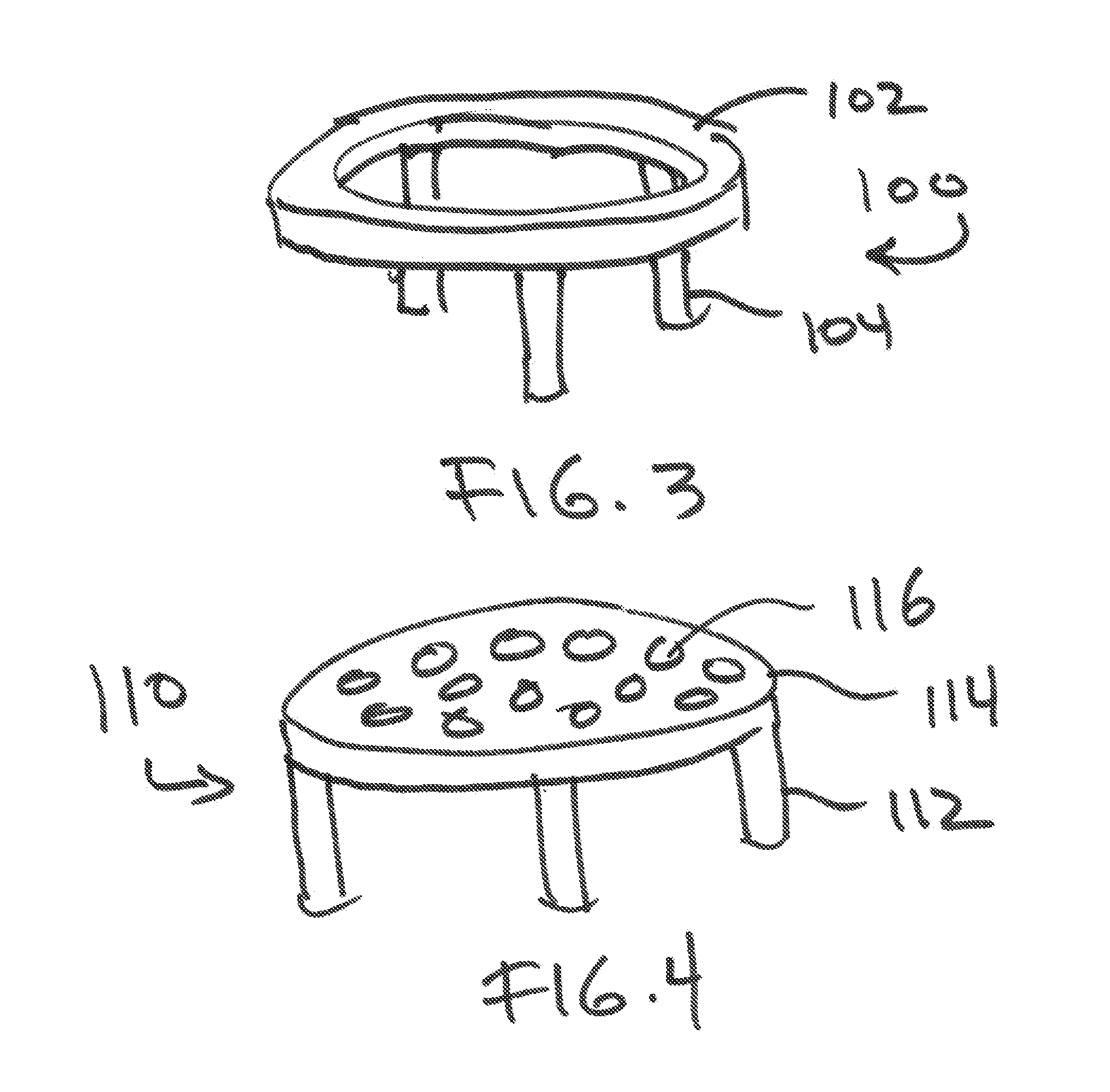

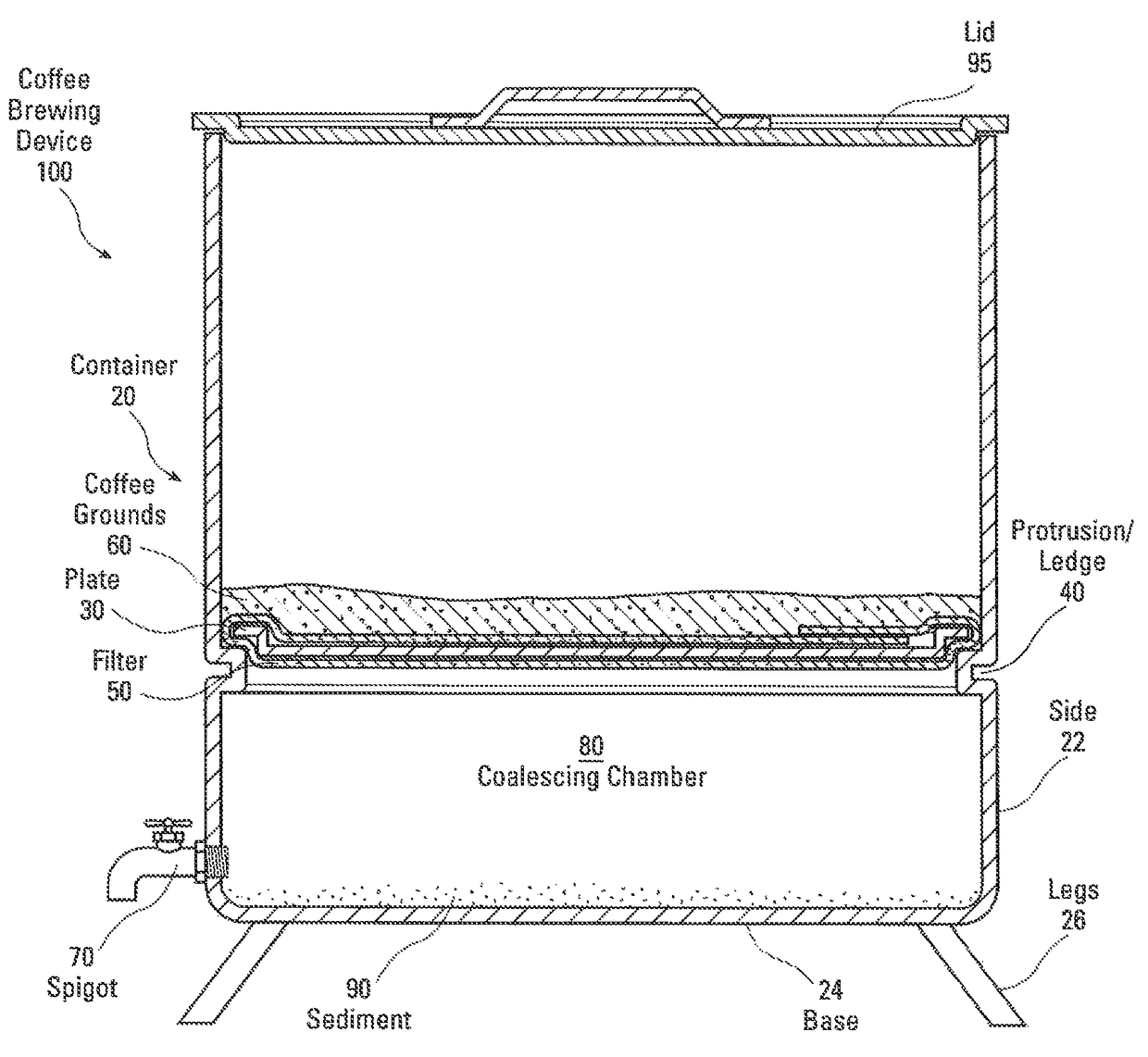

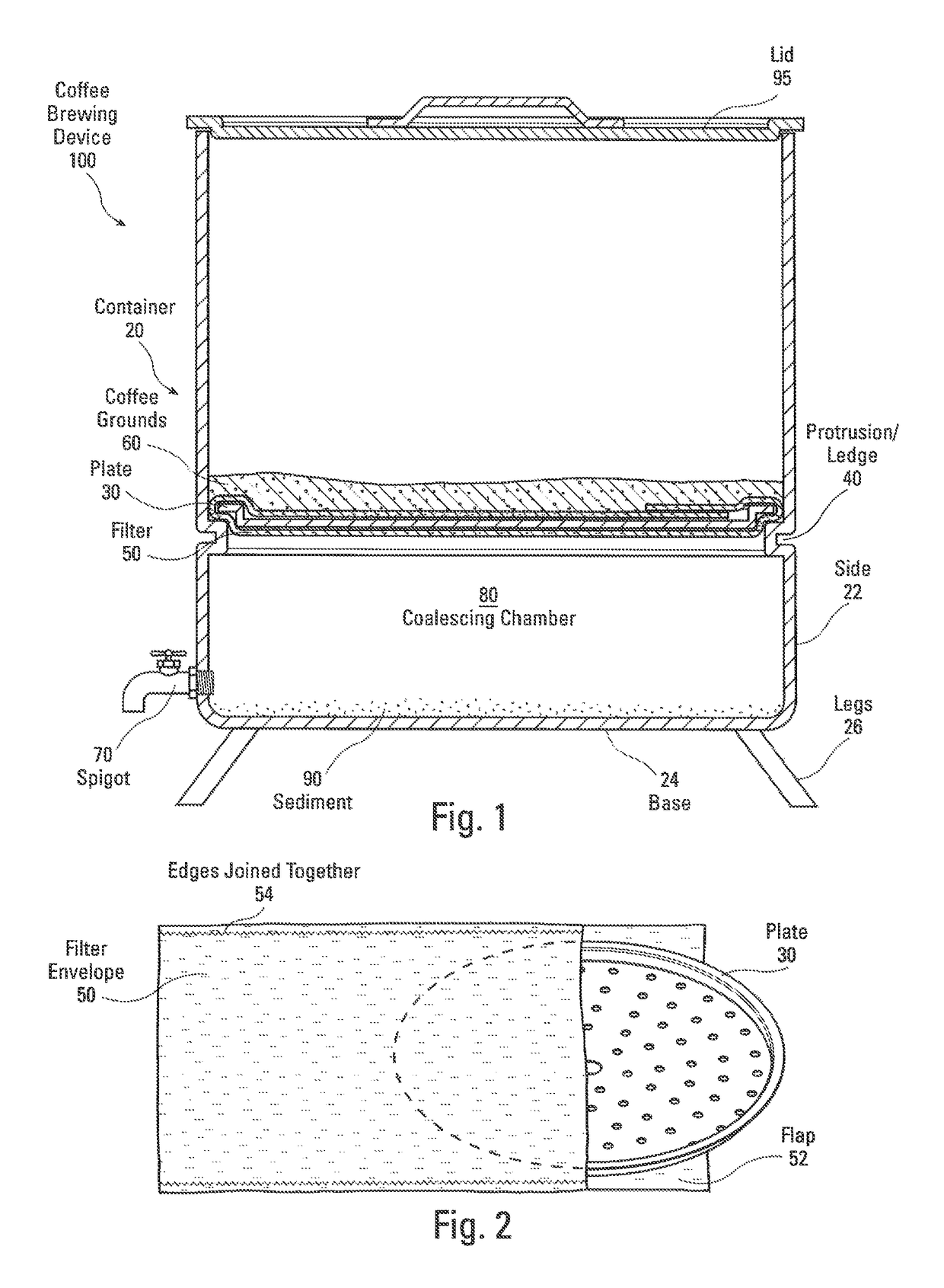

Cold coffee brewing device and methods thereof

ActiveUS20160183713A1LessExcessively polishedBeverage vesselsMetal working apparatusFilter paperSediment

A coffee brewing device, such as a cold coffee brewing device and related methods are disclosed. The device includes a container, a supported horizontal plate that holds filter paper in place, and a spigot below the horizontal plate. Coffee grounds are placed on the filter, then water is added to the container such that minimal disturbance of the coffee ground bed occurs. When the spigot is opened, liquid is removed in a north / south (up / down) direction through the coffee ground bed. The coffee ground bed serves as a first filter, the filter serves as a second filter, and the chamber below the horizontal plate serves as a coalescing chamber where sediment drops out thus serving as a third filter. The resulting liquid dispensed from the spigot is amber in color and clear.

Owner:TODDY LLC

Chromium-free coating agent and preparation method thereof

ActiveCN103938199AImprove adhesionImprove corrosion resistanceMetallic material coating processesChromium freeZirconium oxychloride

The invention relates to the field of a metal surface treatment agent, and particularly relates to a chromium-free coating agent and a preparation method thereof. The chromium-free coating agent is prepared from the following raw materials by mass percent: 2-6% of hexafluorozirconic acid, 1.7-6.7% of composite silane coupling agent, 0.8-1.5% of zirconium oxychloride, 0.5-1% of citric acid and the balance of water. The chromium-free coating agent does not contain chromium ions, has the characteristics of being short in treatment time, less in sediments, compact in crystal, stable in bath solution, easy to manage and the like, and is especially applicable to surface treatment of aluminum and aluminum alloy before coating. A layer of colorless corrosion-resistant passivation layer can be formed on the aluminum surface in a spraying or soaking manner, so that the adhesive force between a coating and a matrix and the corrosion resistance of the matrix are greatly improved.

Owner:HUNAN JINYU CHEM

Magnetic material phosphating solution

ActiveCN104962895AImprove corrosion resistanceFast phosphatingMetallic material coating processesPhosphatePhosphoric acid

The invention discloses a magnetic material phosphating solution, which consists of the following components: 20-200g / L of zinc dihydrogen phosphate, 50-200g / L of manganous dihydrogen phosphate, 50-200g / L of zinc nitrate, 100-303g / L of phosphoric acid, 100-303g / L of nitric acid, 5-20g / L of complexing agent, 50-100g / L of a buffering agent, 10-30g / L of an auxiliary film-forming agent and 50-120g / L of a promoting agent. A phosphating film formed by the phosphating solution disclosed by the invention is high in corrosion resistance and can be used as an ultimate treatment protection film layer, and no subsequent coating treatment is required. The phosphating speed of the phosphating solution is high, the film layer is fine in crystallization, the solution is stable, and sediment is settled; the shortcomings that too much sediment is settled in a high-temperature phosphating process of a common phosphating solution and the formed phosphating film is low in corrosion resistance are overcome.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

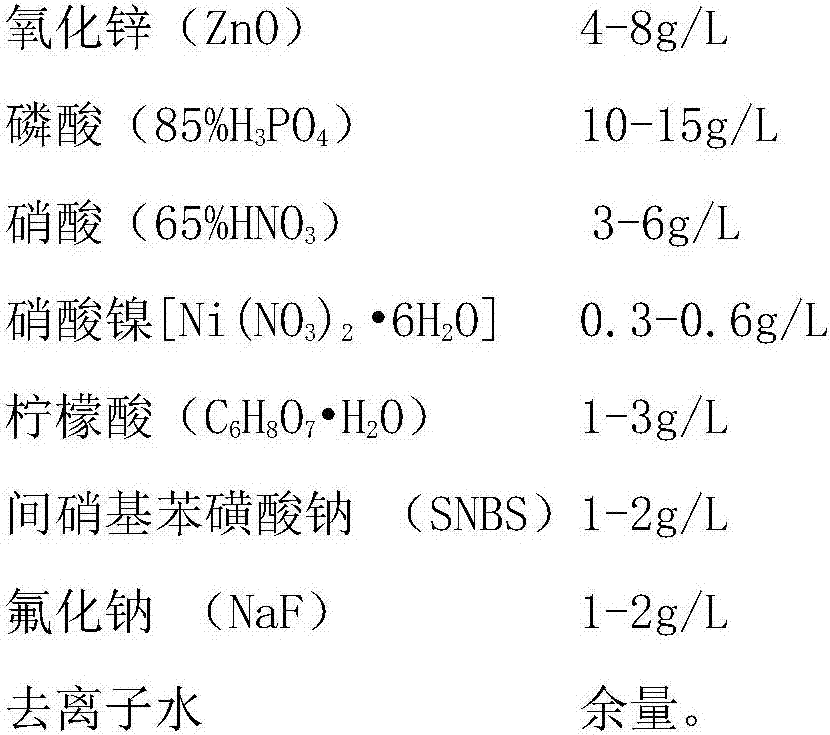

NdFeB zinc series phosphating solution and application method thereof

InactiveCN105695974AImprove corrosion resistancePrevent precipitationMetallic material coating processesSaline waterTime range

The invention discloses an NdFeB zinc series phosphating solution. The NdFeB zinc series phosphating solution is composed of Zn2+, PO43-, NO3-, F-, an accelerant and Ni2+, wherein the amount-of-substance concentration ratio of Zn2+ to PO43- to NO3- to F- to the accelerant is (54-74) :(163-183) :(126-146) :(50-70) :(3-5), the concentration of the accelerant ranges from 0.1 g / L to 1.3 g / L, and the concentration of Ni2+ ranges from 0.01 g / L to 0.2 g / L. The phosphating solution and water are prepared into a work solution according to the ratio of 1:10. According to work parameters, the free acidity ranges from 5% to 8%, the total acidity ranges from 30% to 40%, the phosphating temperature ranges from 50 DEG C to 55 DEG C, the phosphating time ranges from 10 minutes to 15 minutes, NdFeB is treated to generate a light grey or grey phosphating film, the soaking time of 3% neutral saline water is three hours or above, the cross-cut test of a paint film obtained after cathode electrophoresis is the degree 0, and the time of the neutral salt spray test of the paint film obtained after cathode electrophoresis is 550 hours or above. The phosphating solution is high in film-forming thickness and fine in film layer crystallization on treated workpieces, the surface is smooth and dense, the corrosion resistance is excellent, the solution is stable, less sediment is generated, and the time of the salt spray test is longer; and meanwhile no organic complexing agent is included in the formula, the enterprise cost is reduced, and the environment is protected.

Owner:QINGDAO XINPURUI DETECTION TECH CO LTD

Light scent type surface treating agent for aluminum alloy

InactiveCN104099591APromote environmental protectionImprove protectionMetallic material coating processesBenzoic acidButanedioic acid

The invention discloses light scent type surface treating agent for aluminum alloy. The light scent type surface treating agent comprises the following raw materials in parts by weight: 0.6-1 part of benzoic acid, 0.3-1 part of cobalt aluminate, 2-3 parts of alkyl succinic acid, 2.2-4 parts of potassium dichromate, 0.2-0.5 part of citronellol, 1-2.6 parts of maleic anhydride, 2-3 parts of glycerinum, 0.1-0.2 part of pine tar, 0.3-1 part of tetrabutylammonium bromide, 1-2 parts of palm wax, 0.1-0.2 part of hydrotalcite powder, 0.1-0.3 part of chromium carbide, 2-4 parts of coalescing agent, 16-20 parts of 3-amido propyl trimethoxy silane, and110-130 parts of de-ionized water. The surface treating agent has the advantages of good environmental protecting performance, less treated sediment and light scent, can improve the antibacterial and antiseptic property, and can enhance the workpiece protecting effect.

Owner:RUIZHAN TONGLING TECH

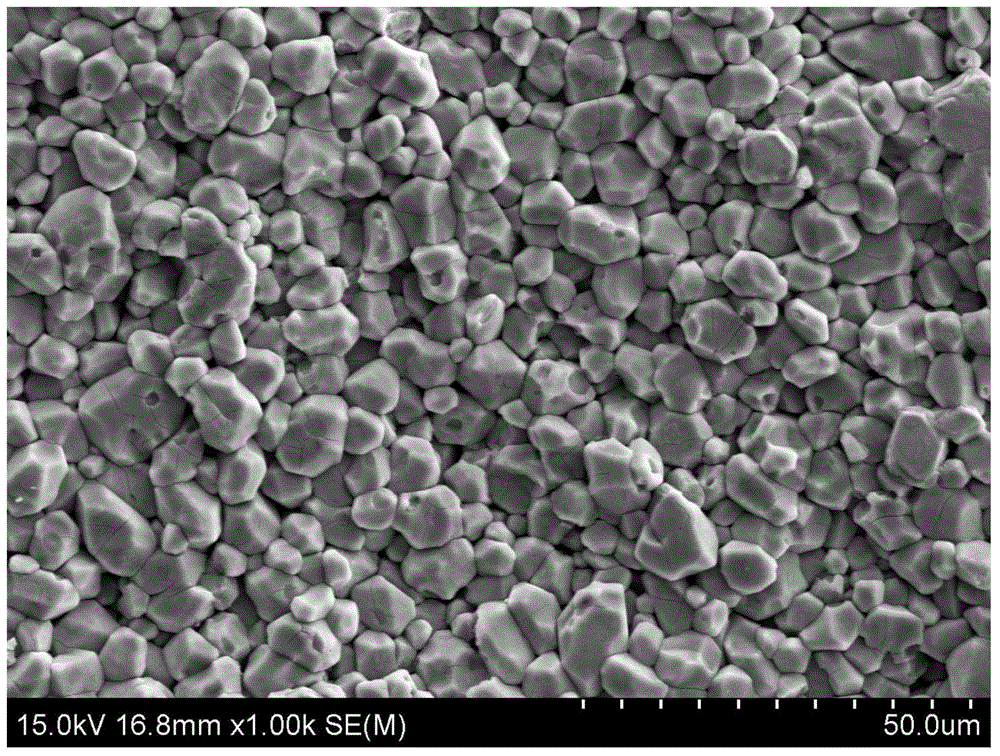

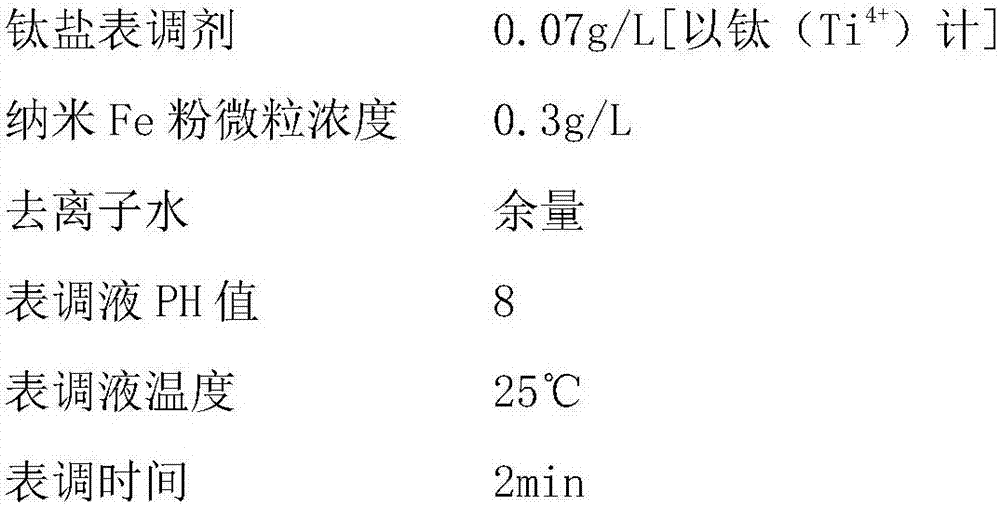

Method for improving corrosion resistance of sintered neodymium iron boron permanent magnet phosphating film

ActiveCN107164754AImprove corrosion resistanceExcellent adhesionMetallic material coating processesFiltrationTitanium

The invention discloses a method for improving corrosion resistance of a sintered neodymium iron boron permanent magnet phosphating film. The method comprises the steps that a machined and formed neodymium iron boron magnet is subjected to chamfering processing and is subjected to oil removing, acid pickling and water washing processing in sequence; in the stirring situation, the magnet is placed into surface conditioning liquid at the temperature of 20-30 DEG C for surface conditioning for 1-3 minutes, and the surface conditioning liquid is composed of a titanium salt surface conditioning agent, nanometer Fe powder particles and deionized water; and finally, the magnet is placed into a phosphating solution at the temperature of 20-40 DEG C for phosphating treatment for 10-20 minutes, and circulating filtration is performed. After the magnet is subjected to jointed surface conditioning by the titanium salt solution mixed with the nanometer Fe powder particles, the surface of the magnet is uniformly provided with a plurality of activated points and film forming factors, therefore the magnet can obtain the more uniform, more fine and more complete phosphating film in the phosphating reaction process, and thus corrosion resistance of the magnet is greatly improved.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

Low chromium anticorrosive chemical conversion treating fluid on surface of constructive aluminium profile and use method thereof

InactiveCN101597758BLow in chromateLess sedimentMetallic material coating processesRare earthPotassium ferricyanide

Owner:佛山科富科技有限公司

Zinc series phosphating solution for aluminum alloys

ActiveCN104404489ALower working temperatureLess sedimentMetallic material coating processesAlloy substrateZinc

The invention relates to a zinc series phosphating solution for aluminum alloys. The zinc series phosphating solution comprises the following components: Zn<2+> 15-18 g / l, PO4<3-> 15-20 g / l, Cu<2+> 0.001-0.003 g / l,Fe<2+> 1-2.5 g / l, F<-> l-2.5 g / l, Ni<2+> 0.5-1.5 g / l. The components are mixed with deionized water so as to prepare the zinc series phosphating solution. The phosphating solution provided by the invention doesn't employ chromium so as to avoid the problem of chromium poison to environment and people, works at a low temperature (35-45 DEG C) so as to save energy, produces few sediments during working, can form a uniform and compact phosphating film with favorable corrosion resistance and the effects such as antifriction and lubrication at a high speed, and increases the bonding strength of a synthetic coating and an aluminum alloy substrate. Besides, the components of the phosphating solution are simple, and the raw materials are easy to purchase.

Owner:CHONGQING YUEJIN MACHINERY

Medium-low temperature high corrosion resistant black phosphating solution on steel surface

InactiveCN101200799AQuality assuranceExtended service lifeMetallic material coating processesAcetic acidNitrate

A middle and low temperature high corrosion black phosphating liquid on steel surface is characterized in that one liter of phosphating liquid contains 40-50g / L of dihydrogen phosphate Mn, 60-70g / L of zinc nitrate, 1-2g / L nickel nitrate, 3-4ml / L acetic acid (36 percent), 2-3g / L of ammonium citrate and 1-2g / L bismuth molybdate, and the rest is water. The phosphating liquid can produce film and then produce 18-22 Mu m of phosphating films after 20m at the temperature of 60-65 DEG C. the invention has the advantages of low phosphating temperature, small energy consumption, less sediment, reduced pollutions, environment protection, uniform and dense phosphating films and good appearance color sensory characters, and especially that the corrosion resistance complies with the national relative standard.

Owner:XIAN TECHNOLOGICAL UNIV

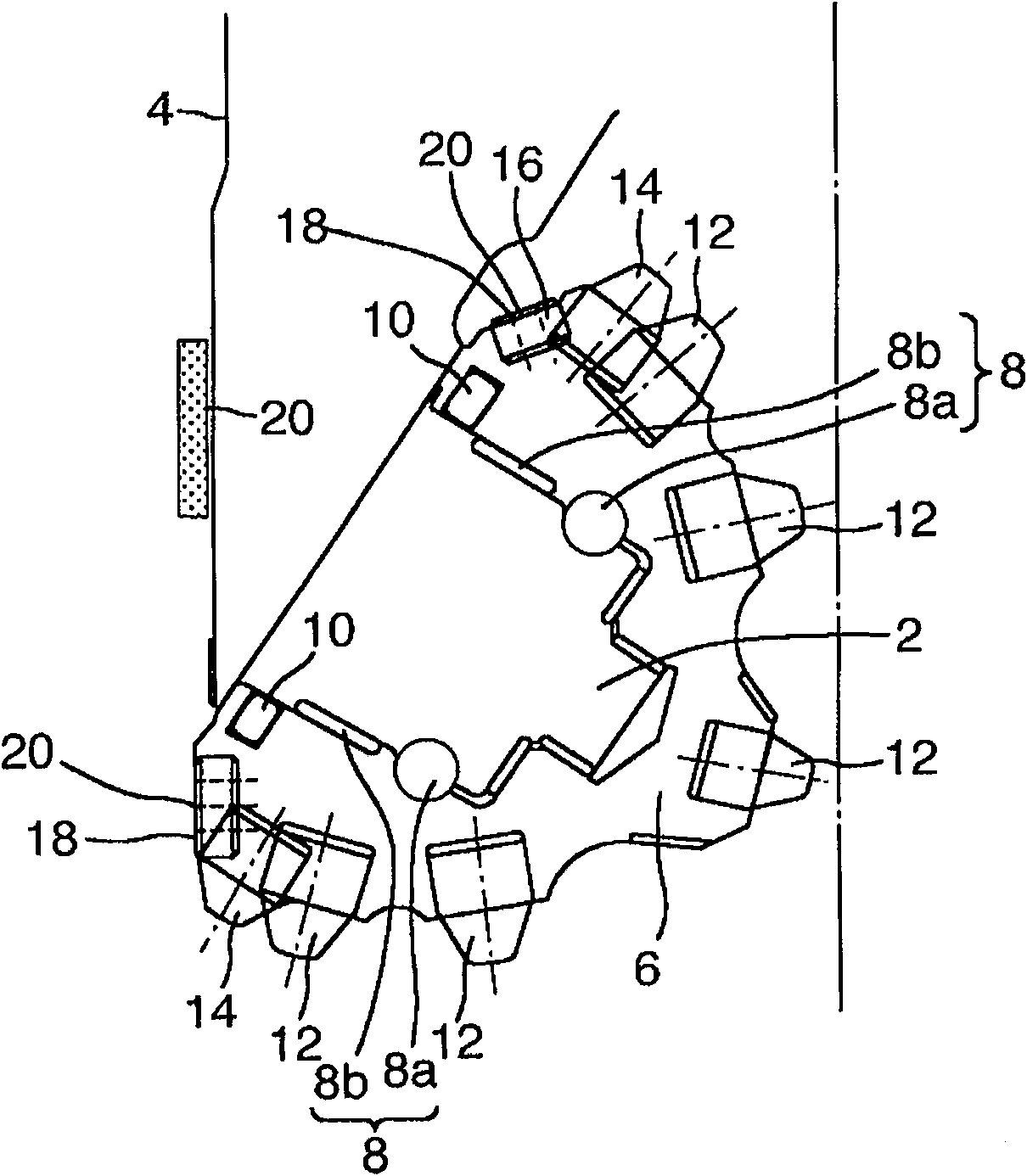

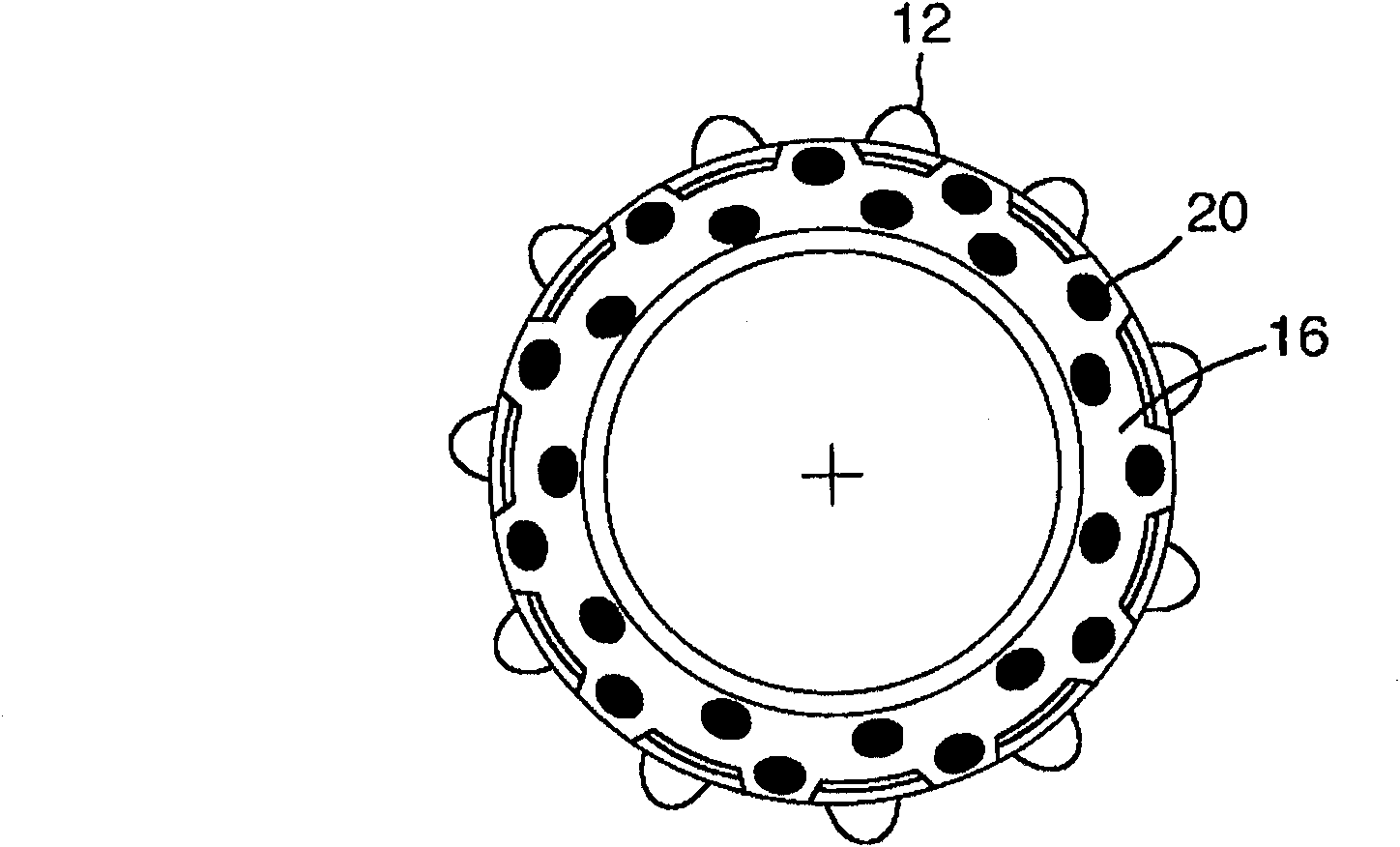

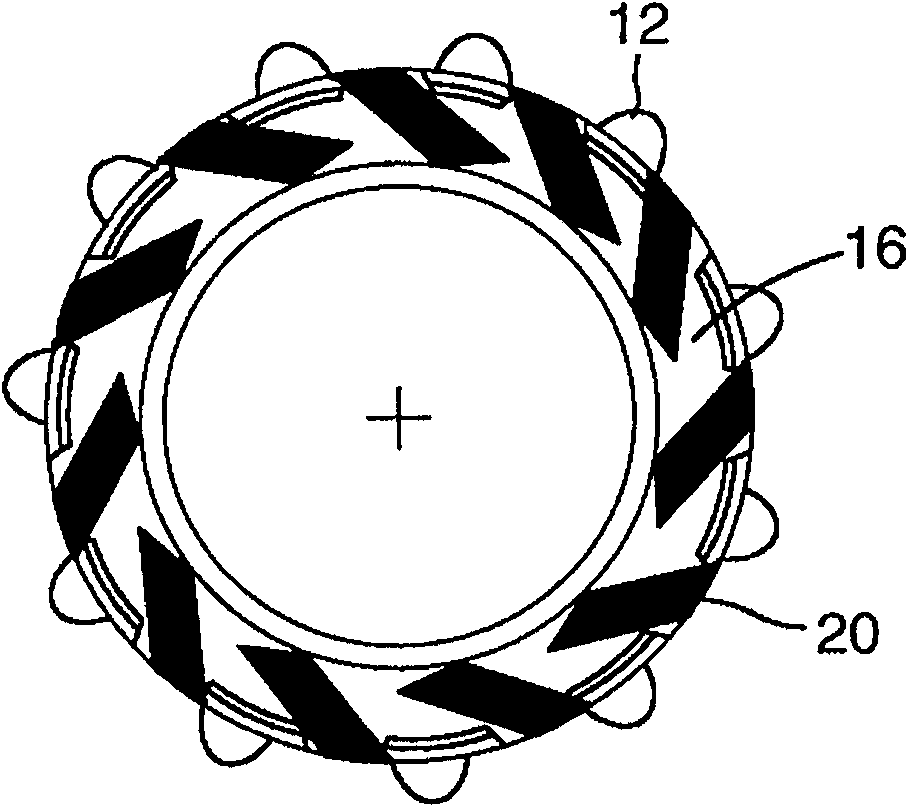

Rock bit

The present invention provides a rock bit which enables a reduction in surface pressure from a well wall and which allows possible vibration to be suppressed. A first of the present invention provides a rock bit including a bit body with a journal portion, a cone portion configured to be rotatable with respect to the bit body, a bearing portion located between the cone portion and the journal portion, and a seal provided between the cone portion and the journal portion to seal the bearing portion, wherein the cone portion includes a gauge surface that contacts a side wall of a well, and a diamond composite material is preferably disposed extensively and smoothly on the gauge surface. In a second aspect of the present invention, a ring bit is provided at an outer peripheral portion of a bit body. Furthermore, a cone portion of a tri-cone bit includes no gauge tip or surface chip that contacts the side wall of the well but only cemented carbide tips that contact a bottom of the well.

Owner:TIX HLDG COMPANY

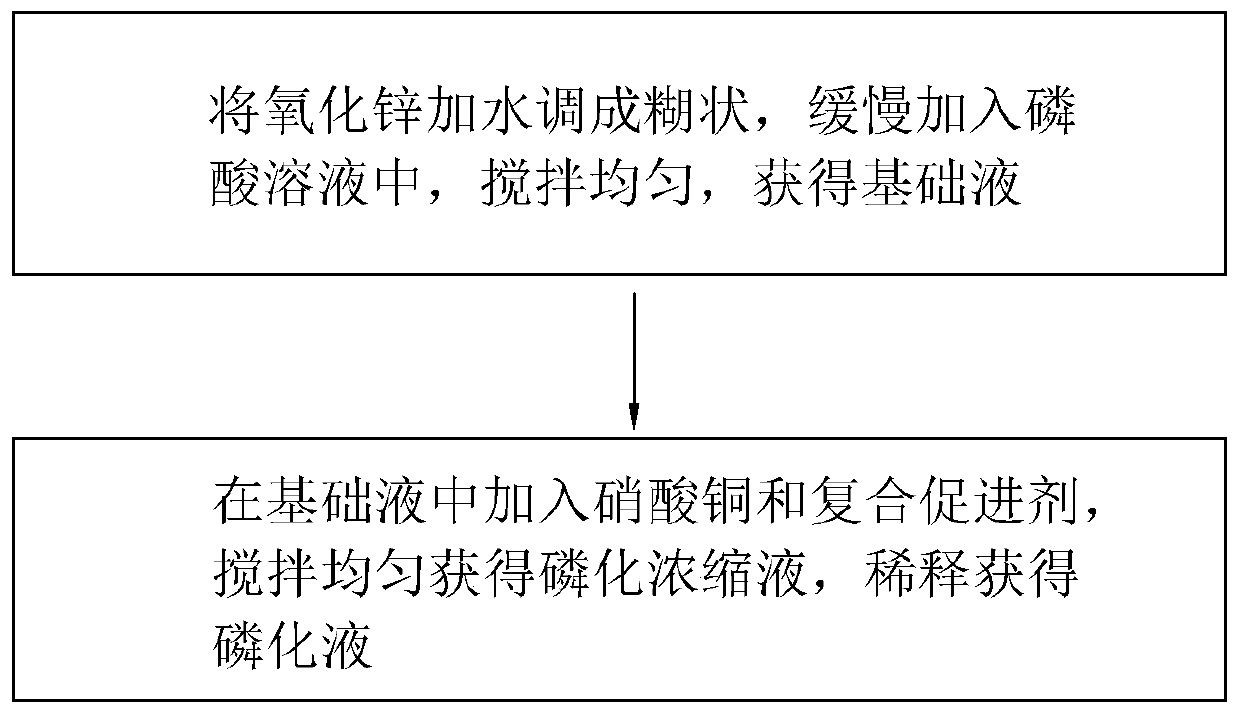

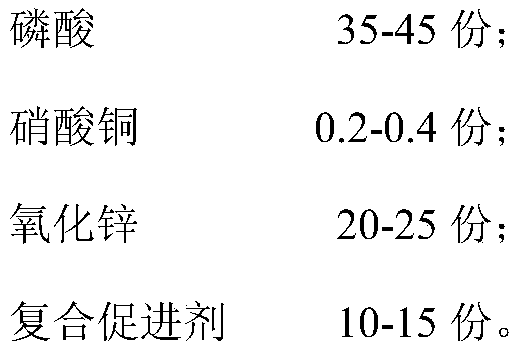

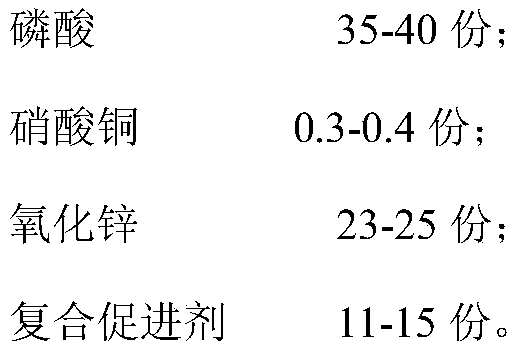

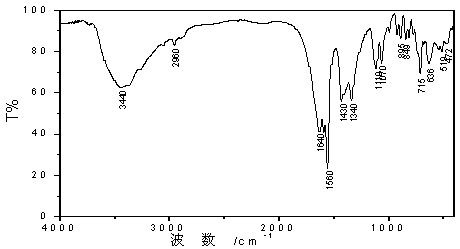

Anti-seismic prefabricated house

InactiveCN109778161AImprove film qualityPromotes electrochemical reactionsMetallic material coating processesElectrode potentialElectrochemical response

The invention discloses an anti-seismic prefabricated house, comprising a plurality of steel plates, wherein the outer side of each steel plate is treated by a phosphating solution to form a phosphating film, and the phosphating solution comprises the following components in parts by weight: 35-45 parts of phosphoric acid, 0.2-0.4 parts of copper nitrate, 20-25 parts of zinc oxide, and 10-15 partsof compound accelerant. The anti-seismic prefabricated house provided by the invention has the advantages: as the main film-forming materials, the phosphoric acid and zinc oxide can form a continuous and uniform phosphating film on the surface of the processed. Meanwhile, the addition of the compound accelerator further improves the film forming speed and film forming quality of the phosphatingfilm. In addition, because the electrode potential of copper is higher than that of iron, copper ions are reduced and deposited on the surface of a phosphated hinge body, so the cathode area on the surface is increased; the electrochemical reaction of phosphating is further promoted, the formation of phosphating crystal nucleus is accelerated, crystal grains are refined, and the phosphating film is compact and uniform; meanwhile, the phosphating speed is improved, the phosphating temperature is reduced, and finally the phosphating film has the advantages of compact film formation and strong adhesive force.

Owner:浙江华锦建筑装饰设计有限公司

Environmentally-protective slag reducing agent of phosphating solution

ActiveCN102965662ALess sedimentImprove corrosion resistanceMetallic material coating processesEthylene diamineRegenerative process

The invention discloses an environmentally-protective slag reducing agent of a phosphating solution. The agent contains ethylene diamine tetraacetic acid, hydroxy ethylidene diphosphonic acid, tartrate and phytic acid. The agent mainly uses a principle of a composite complexing agent, and can perform complexation for part heavy metal easy to produce slag in the phosphating solution, thereby obviously reducing the amount of slag during a regenerative process. The complexing agent also has an effect of improving corrosion resistance of metal phosphide films. When the phosphating solution is to be discarded or is discarded all ready, the agent is added in a proportion of 0.1 to 0.3 %, and sediment of the phosphating solution can be greatly reduced; and the quality of the newly transformed phosphating solution fully meet production demands.

Owner:DALIAN BETRUST ENVIRONMENTAL PROTECTION TECH CO LTD

Method for coating normal-temperature black phosphating film on steel surface

The invention relates to a method for coating a film on a steel surface, particularly a method for coating a normal-temperature black phosphating film on a steel surface. The black phosphating solution is composed of organic acid antimony, 5-10 g / L zinc oxide, 30-60 g / L phosphoric acid, 20-40 g / L manganese dihydrogen phosphate, 1-3 g / L nickel nitrate and the balance of water. A cathode electrolysis phosphating process is adopted to perform normal-temperature phosphating on the steel surface, wherein the current density is 0.5-3 A / dm<2>, and the time is 5-20 minutes. The method has the advantages of energy saving, environment friendliness, stable phosphating solution, simple phosphating technique, high film-forming speed, black color of the film layer, and favorable corrosion resistance, and is convenient to operate and suitable for various steel surface treatment.

Owner:SHENYANG UNIV

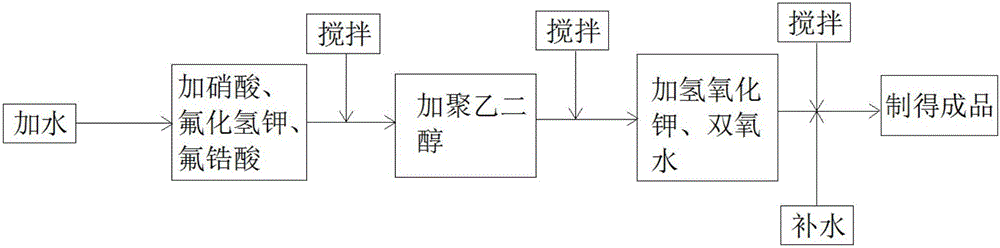

Formation agent and preparation method

InactiveCN106245017AReduce health hazardsStrong environmental protectionMetallic material coating processesPolyethylene glycolManganese

The invention provides a formation agent. The agent is prepared from specific components as follows: nitric acid with the concentration being 50%, an accelerant, hexafluorozirconic acid, polyethylene glycol in the analytically pure specification, a pH regulator, a bactericide and pure water. The invention further provides a preparation method of the formation agent. According to the formation agent and the preparation method, hexafluorozirconic acid is used as a film-forming agent, harmful metal ions such as zinc, manganese, nickel, phosphorus, chromium and the like are not contained, and the formation agent is high in environmental protection performance, has little damage to human health and has little sediment.

Owner:NIPPON PAINT CHONGQING CHEM CO LTD

Phosphorizing liquid and production method thereof

InactiveCN102691058AExtended cathode rangeFast growthMetallic material coating processesChemical treatmentCompound organic

The invention belongs to the technical field of chemical treatment of metal surfaces and particularly relates to a novel green normal-temperature rapid phosphorizing liquid suitable for phosphorizing treatment on the surface of a steel member. The phosphorizing liquid integrates the functions of oil removing, derusting, phosphorizing and passivating and is suitably applied to automobiles, large iron stands and other equipment under severe outdoor environment. The phosphorizing liquid is composed of the following substances in percentage by mass: 20-30% of phosphoric acid, 0.1-0.3% of zinc oxide, 0.001-0.04% of composite organic-acid film-forming aid, 8-12% of organic solvent, 0.15-0.4% of sodium molybdate, 0.1-0.3% of grain refiner, 0.1-0.2% of inert metal salt, 0.002-0.004% of nonionic surfactant and the balance of softened water. The phosphorizing liquid disclosed by the invention has the advantages that operation is simple, film forming strength is high, binding force is strong and corrosion resistance is good.

Owner:XIAMEN GUANDAXIN ENVIRONMENTAL PROTECTION TECH

Alkaline washing solution, phosphating solution and metal surface treatment method

ActiveCN107345297AImprove permeabilityFast film formationMetallic material coating processesPhysical chemistryStrong binding

The invention discloses an alkaline washing solution, a phosphating solution and a metal surface treatment method. The metal surface treatment method comprises the steps of deoiling, washing via alkaline, washing via acid, washing twice via water and phosphating. The adopted environment-friendly alkaline washing solution has the technical effects of energy economization and environment protection and also has excellent washing effects on ferrous metals and non-ferrous metals; the adopted phosphating solution has the advantages of rapid film formation, strong binding force of coating films, high corrosion resistance, capability of operating by brushing or spraying, simple operation and low cost; according to the prepared phosphating solution, the sediment of the phosphating solution is reduced; the quality of phosphating films is ensured; film layers are uniform, fine and smooth; therefore, the metal surface treatment method is capable of more environmentally friendly and more efficiently achieving metal surface treatment before coating and has positive influence on the coating process and the coating quality.

Owner:威海赤那思电子材料有限公司

Method for pre-treating dyed wastewater by coagulation

ActiveCN108408963AEfficient removalGood removal effectWater contaminantsTreatment involving filtrationMetal saltsEnvironmental chemistry

The invention relates to the field of sewage treatment, in particular to a method for pre-treating dyed wastewater by coagulation. The method comprises the following steps: filtering the dyed wastewater and then adding a coagulant containing metal salt modified graphene oxide for settling; then adding an adsorbent for adsorption settlement. The coagulant is obtained by modifying graphene, then introducing metal ions such as iron, calcium, aluminum, magnesium, copper and zinc on the surface to prepare the metal salt modified graphene oxide, and then mixing the metal salt modified graphene oxidewith soluble natural polysaccharides. The applicability to the dyed wastewater is high. By combination of coagulation of the coagulant and adsorption of the adsorbent, turbid substances in the dyed wastewater are removed effectively, the coagulant has three-in-one coagulation and flocculation effects, applicability to coagulation pretreatment of the dyed wastewater is high, dyestuff which is small in relative molecular weight and cannot be in the shape of colloid easily can be removed effectively, by a further flocculation effect, organic wastes in the dyed wastewater are coagulated and are subjected to flocculating settling, the feeding amount is small, dregs are less, and the pretreatment cost is low.

Owner:长兴科创科技咨询有限公司

One-step oil-removal rust-removal phosphatization technology of steel workpiece

InactiveCN104250780ANo heating requiredSave energyMetallic material coating processesThioureaPhosphate

The invention discloses a one-step oil-removal rust-removal phosphatization technology of a steel workpiece. A phosphatization liquid used by the one-step oil-removal rust-removal phosphatization technology comprises 165-175g / L of phosphoric acid having a concentration of 85%, 22-28g / L of nickel dihydrogen phosphate, 14-18g / L of zinc dihydrogen phosphate, 6-8g / L of cobalt dihydrogen phosphate, 6-8g / L of sodium chlorate, 2-4g / L of sodium 3-nitrobenzene sulfonate, 2-4g / L of potassium ferrocyanide, 1-3g / L of ammonium molybdate, 2-4g / L of thiourea, 11-15g / L of tartrate, 6-10g / L of OP-10 and the balance water. The one-step oil-removal rust-removal phosphatization technology comprises the following steps of preparing the phosphatization liquid from the above components, adjusting free acidity to 14-20 and total acidity to 200-240, keeping a temperature of the phosphatization liquid in a range of 15-35 DEG C, putting a steel workpiece into the phosphatization liquid for phosphatization treatment for 25-35min, taking out the treated steel workpiece and carrying out airing in a ventilated place.

Owner:WUXI LUOSHE TECH VENTURE

Chromium-free coating agent and preparation method thereof

ActiveCN103938199BImprove adhesionImprove corrosion resistanceMetallic material coating processesChromium freeZirconium oxychloride

The invention relates to the field of a metal surface treatment agent, and particularly relates to a chromium-free coating agent and a preparation method thereof. The chromium-free coating agent is prepared from the following raw materials by mass percent: 2-6% of hexafluorozirconic acid, 1.7-6.7% of composite silane coupling agent, 0.8-1.5% of zirconium oxychloride, 0.5-1% of citric acid and the balance of water. The chromium-free coating agent does not contain chromium ions, has the characteristics of being short in treatment time, less in sediments, compact in crystal, stable in bath solution, easy to manage and the like, and is especially applicable to surface treatment of aluminum and aluminum alloy before coating. A layer of colorless corrosion-resistant passivation layer can be formed on the aluminum surface in a spraying or soaking manner, so that the adhesive force between a coating and a matrix and the corrosion resistance of the matrix are greatly improved.

Owner:HUNAN JINYU CHEM

High-efficiency preparation method of novel phosphating solution

InactiveCN103572275ASolution to short lifeLess sedimentMetallic material coating processesO-Phosphoric AcidHydroxylamine

The invention discloses normal-temperature phosphating solution free from nitrite and heavy metal; the film forming speed of the phosphating solution is rapid; phosphating film grains are rapidly refined; and the corrosion resisting property of the phosphating solution is greatly increased. The technical scheme provided by the invention is as follows: the phosphating solution is composed of six main components including phosphoric acid, zinc oxide, calcium nitrate, barium nitrate, hydroxylamine sulphate and nitric acid. The novel phosphating solution disclosed by the invention has the advantages that: the phosphating solution is free from nitrite and heavy metal; about 2 g of French grey, uniform and compact phosphating films per square metre can be generated by immersing at 5-40 DEG C and phosphating for 5-10 min; the dropping time of CuSO4-resistant solution is up to 90-140 s; the immersion time of 3% sodium chloride resistant solution is 240 min; first-stage clean phosphating production is realized; furthermore, the service life of the phosphating solution is longer; little sediment is generated; the generated phosphating film has good quality; and the novel phosphating solution disclosed by the invention can be used for coating the surface of steel.

Owner:TIANJIN JIANFA PRECISION MACHINERY MFG

Cold coffee brewing device and methods thereof

ActiveUS9924827B2Excessively polishedHighly finished/polishedBeverage vesselsCoffee extractionEngineeringFilter paper

Owner:TODDY LLC

Anti-corrosion treatment agent for metal material surface

InactiveCN105349984AImprove efficiencySimple process controlMetallic material coating processesEpoxyPhosphate

The invention discloses an anti-corrosion treatment agent for a metal material surface. The anti-corrosion treatment agent comprises 20 to 30 parts of manganous dihydrogen phosphate, 20 to 30 parts of zinc dihydrogen phosphate, 1 to 3 parts of potassium fluozirconate, 1 to 3 parts of phytic acid, 3 to 5 parts of citric acid, 0.5 to 1 part of emulsifying agent, 1 to 2 parts of vinylsilane, 2 to 4 parts of epoxy silane, and proper amount of phosphatizing accelerator. The anti-corrosion treatment agent can overcome the shortages in the prior art, and is stable in a solution, simple in process control process, and high in corrosion resistance; meanwhile, the heavy metal ions can be decreased. The anti-corrosion treatment agent is small in VOC (Volatile Organic Compounds) and sediment amount, small in pollution, high in efficiency, and wide in applicable scope.

Owner:ANHUI HONGQIAO METAL MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com