Block For Forming Wall And The Wall Thus Formed

a technology of forming walls and blocks, applied in the field of blocks, can solve the problems of inconvenient use, shortening the service life of the building, and not solving the existing problem, and achieve the effects of improving the non-watertight and soil-keeping effect, avoiding water leakage, and avoiding water leakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103] The following are the further descriptions of the invention with reference to the figures. However, the figures, the ways described and the technical parameters cannot be understood as limitations to the present invention.

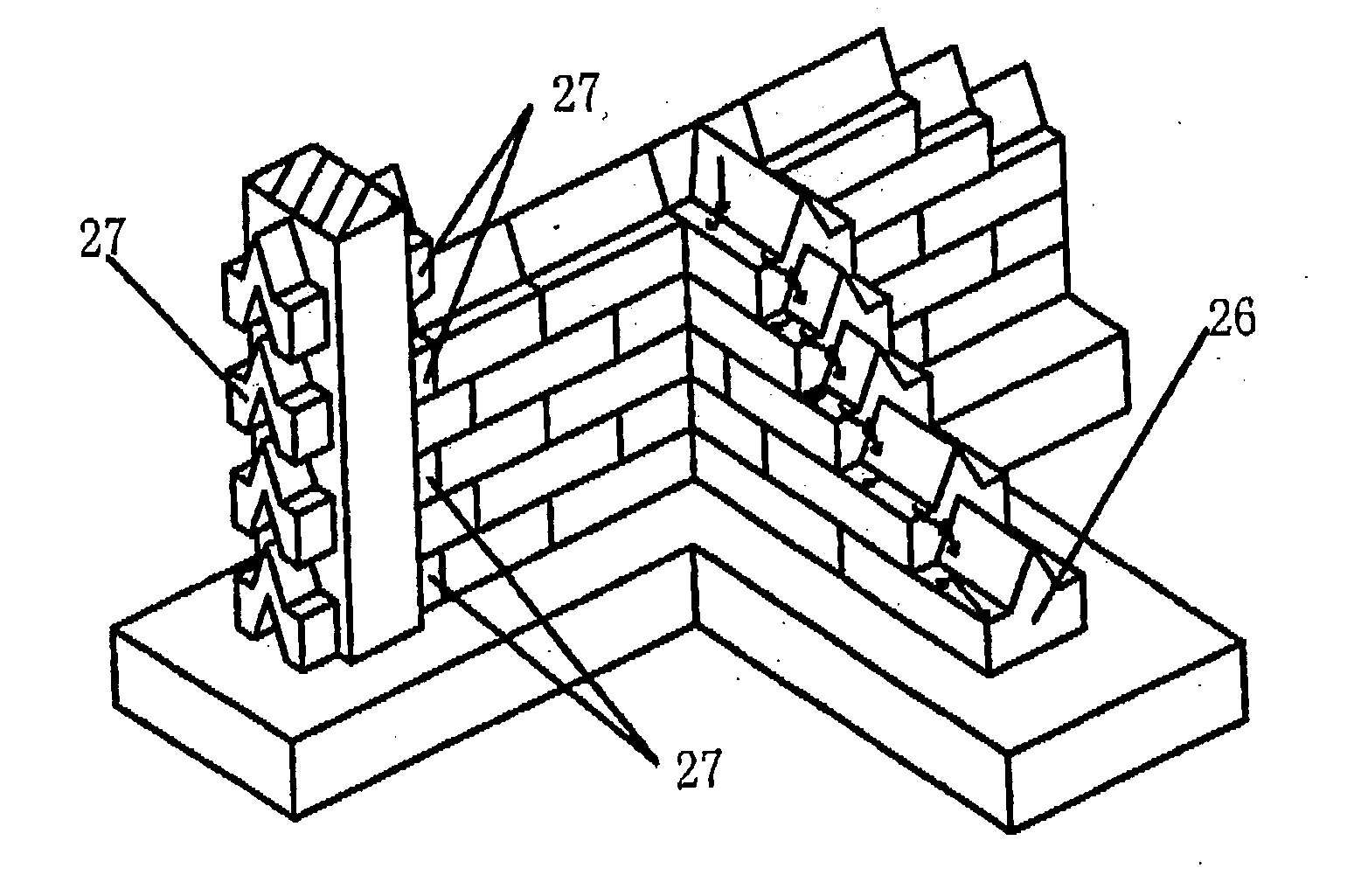

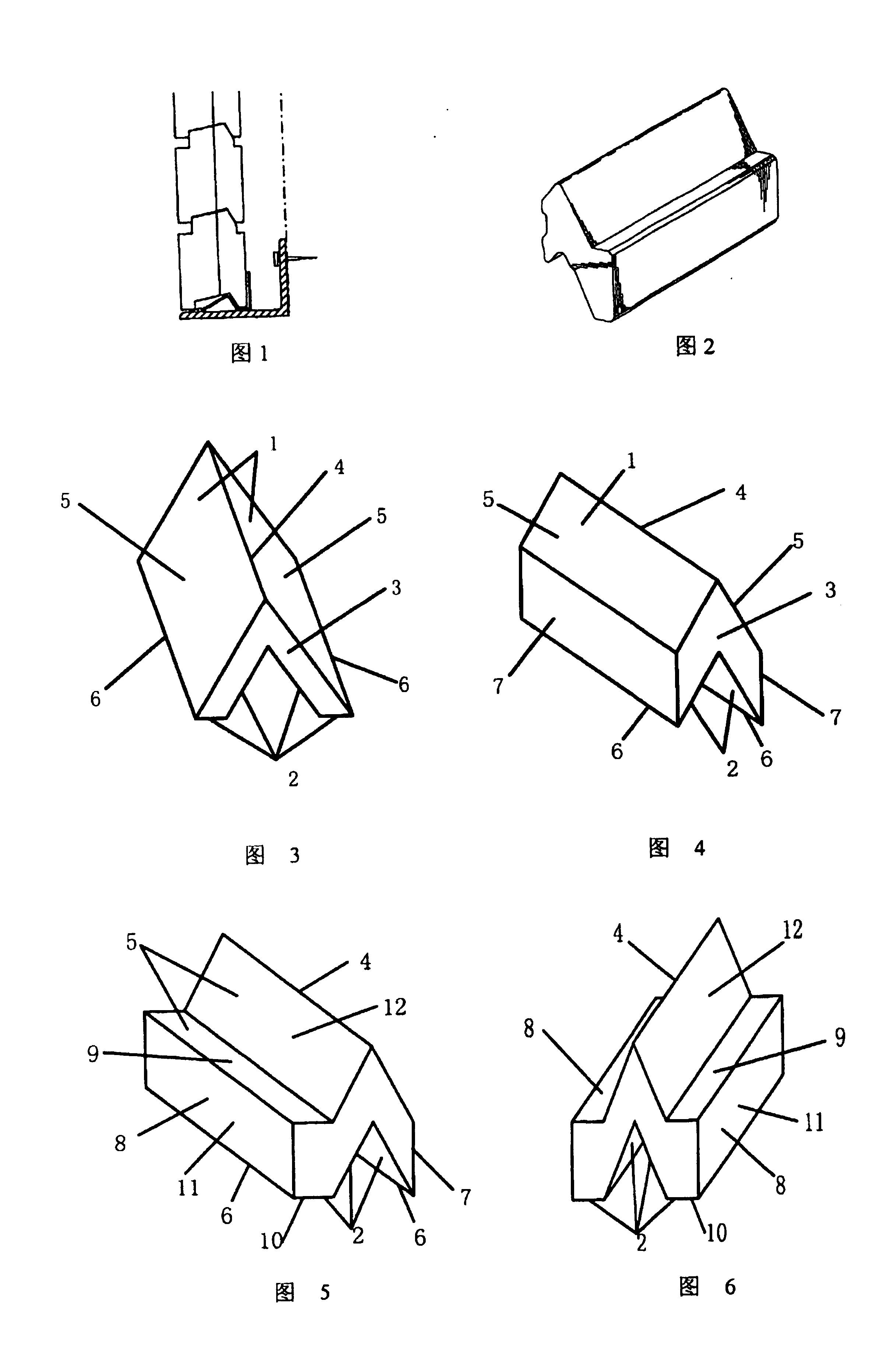

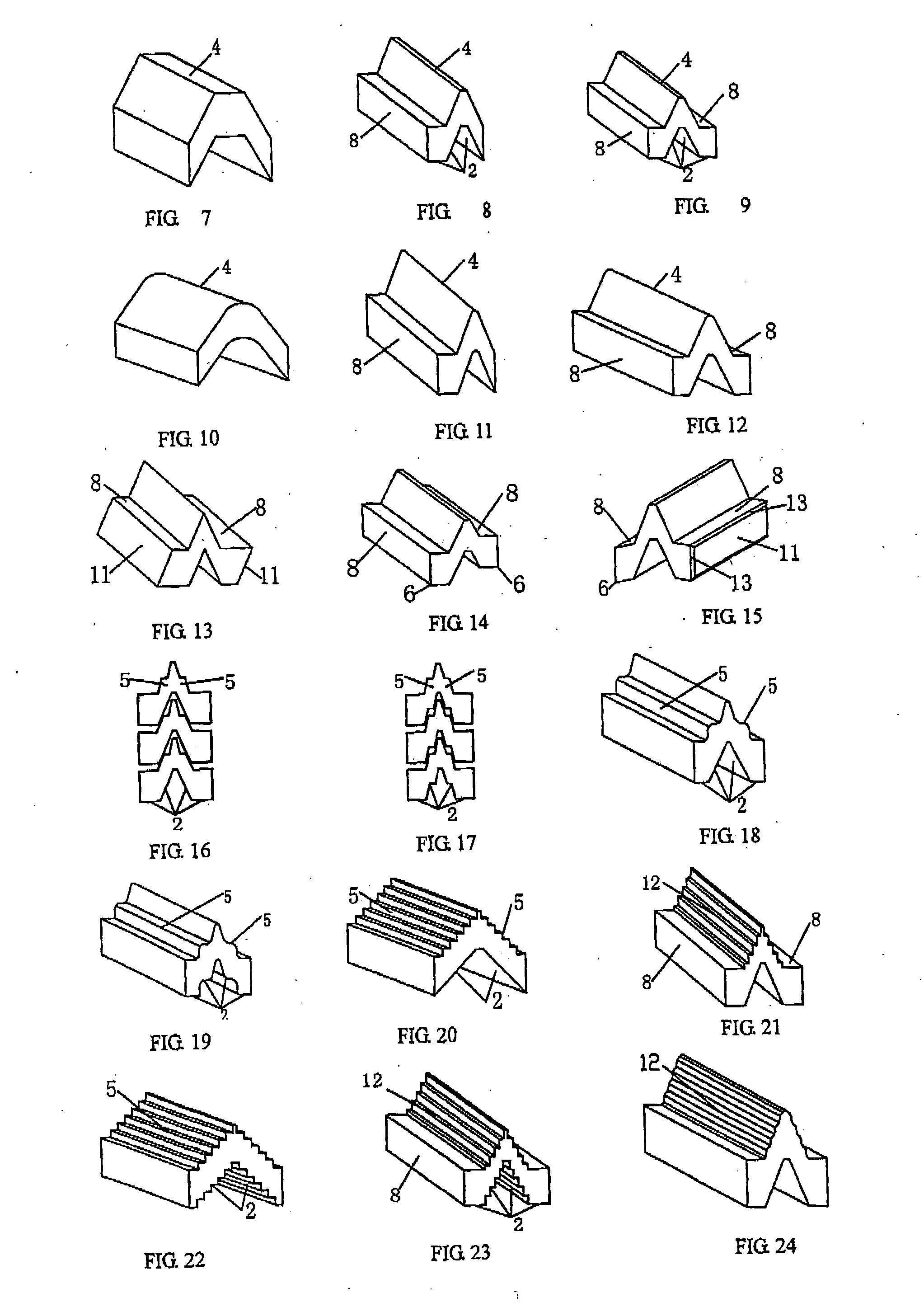

[0104]FIGS. 3 and 4 show the basic structural of the block of the invention. The block is a longitudinally formed (longitudinal profiled) product. The cross section of the block is of a downward-flared shape, and includes a top surface 1, a bottom surface 2 and two end surfaces 3. The top surface has a mid ridge 4 higher than the two sides of the surface so that a left supporting slope 5 and a right supporting slope 6 are formed. Both the top of the mid ridge and the bottom surface are of sharp-angled shape. As shown in FIG. 3, the planes at two sides of the bottom surface of the block are horizontal planes. Two bottom feet 6 are at the intersections between the top surface and the bottom surface. The block of FIG. 4 has a lateral connecting surface 7, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com