Preparation method of high-thermal-conductivity flexible phase-change material and battery module

A phase change material and battery module technology, which is applied in heat exchange materials, battery pack components, secondary batteries, etc., can solve the problems of easy leakage, poor thermal conductivity and brittleness of phase change materials, and improve The effect of flexibility and toughness, improving anti-leakage performance and latent heat value, and improving the degree of densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment 1 provides a method for preparing a highly thermally conductive flexible phase change material and the prepared flexible phase change material:

[0031] The raw materials include styrene-butadiene-styrene block copolymer, paraffin wax and thermal conductivity enhancer, and the preparation steps are as follows:

[0032] Step 1: Soak the styrene-butadiene-styrene block copolymer in an organic solvent for 2-3 hours. The mass ratio of the styrene-butadiene-styrene block copolymer to the organic solvent is 5: 5-7, during soaking, stirring until forming a colloidal solution of styrene-butadiene-styrene block copolymer;

[0033] Step 2: Dissolve the paraffin in an oil bath at a temperature of 60°C. When the paraffin is completely dissolved, add a thermal conduction enhancer. The mass ratio of paraffin to the thermal conduction enhancer is 5-8:0.7-1.2, at 1000rad / Stir at a speed of s. After stirring evenly, pour it into a mold for curing to obtain a composite ...

Embodiment 2

[0042] Embodiment 2 illustrates the preparation process of a highly thermally conductive flexible phase change material in combination with the specific components of the raw materials, as follows:

[0043] Step 1: Place 15g of styrene-butadiene-styrene block copolymer in 20g of carbon tetrachloride solution and soak for 2-3 hours. During the soaking, stir until forming styrene-butadiene-benzene Colloidal solution of ethylene block copolymer;

[0044] Step 2: Dissolve 32g of paraffin in an oil bath at a temperature of 60°C. When the paraffin is completely dissolved, add 3g of expanded graphite and stir at a speed of 1000rad / s. After stirring evenly, pour it into the mold Carry out curing to obtain the composite phase-change material of 35g;

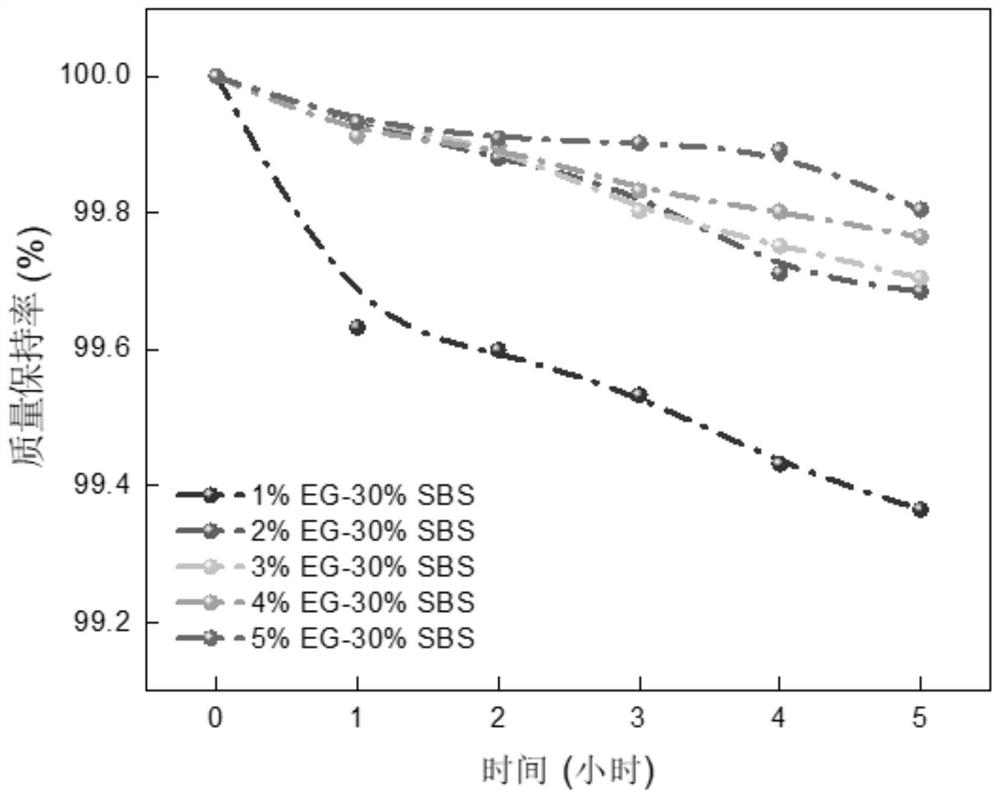

[0045] It should be noted that the thermal conductivity enhancer is expanded graphite, which can not only effectively improve the thermal conductivity of the phase change material, but also have a certain adsorption effect on paraffin, a...

Embodiment 3

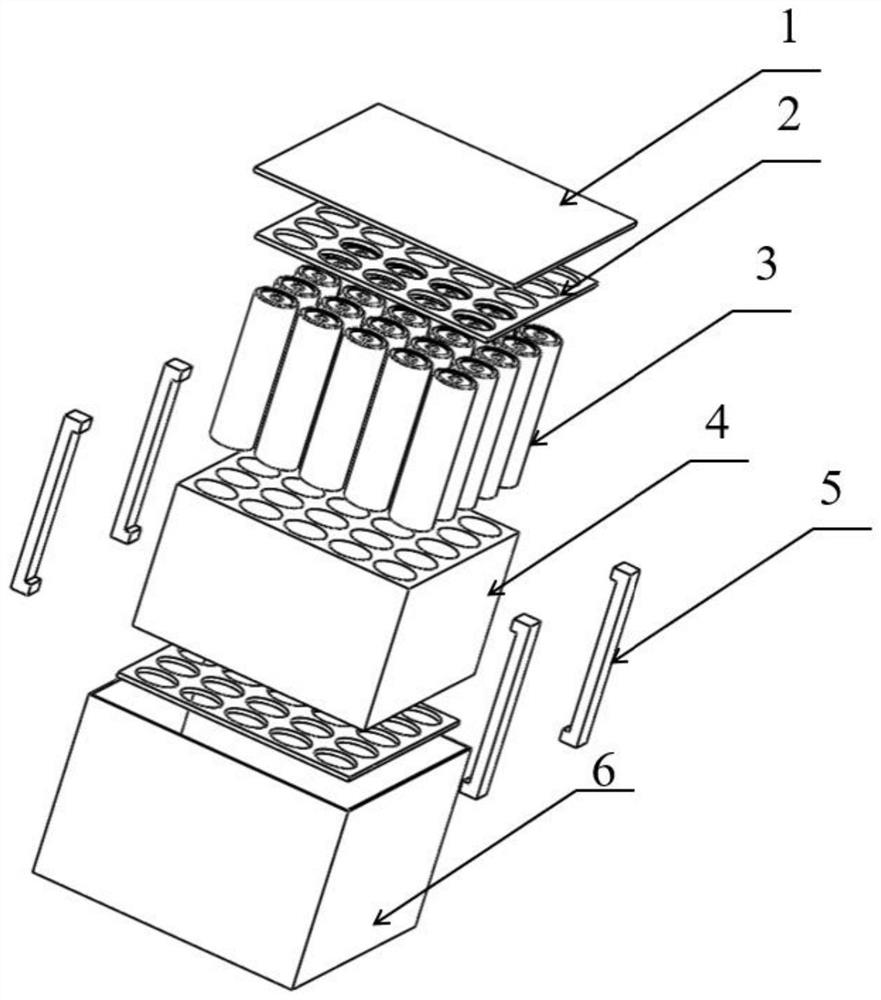

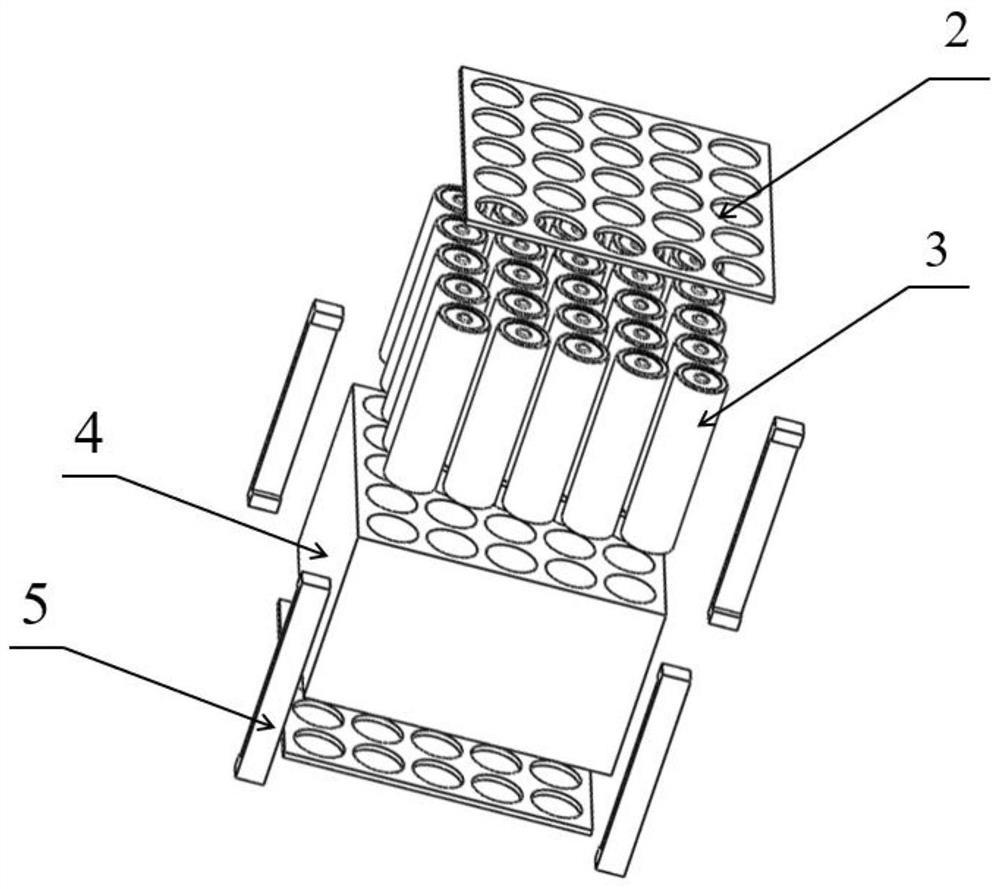

[0048] Embodiment 3 provides a battery module, refer to Figure 2-Figure 4 , this embodiment applies the high thermal conductivity flexible phase change material prepared by the method for preparing the high thermal conductivity flexible phase change material in the above embodiment, which includes a box body 6 and a battery rack 4; several batteries 3 are arranged in the box body 6; The battery frame 4 is made of a flexible phase-change material. The battery frame 4 is provided with a loading hole adapted to the structure of the battery 3, and the battery 3 is inserted into the loading hole.

[0049] It can be understood that in this embodiment, the battery frame 4 is provided and the loading hole is opened on the battery frame 4 to insert the battery 3, so that the battery 3 can be in contact with the flexible phase change material, and the structure of the battery frame 4 is more stable. It can provide a shock absorption effect for the battery 3, and can effectively ensure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com