Patents

Literature

1177 results about "Latent heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

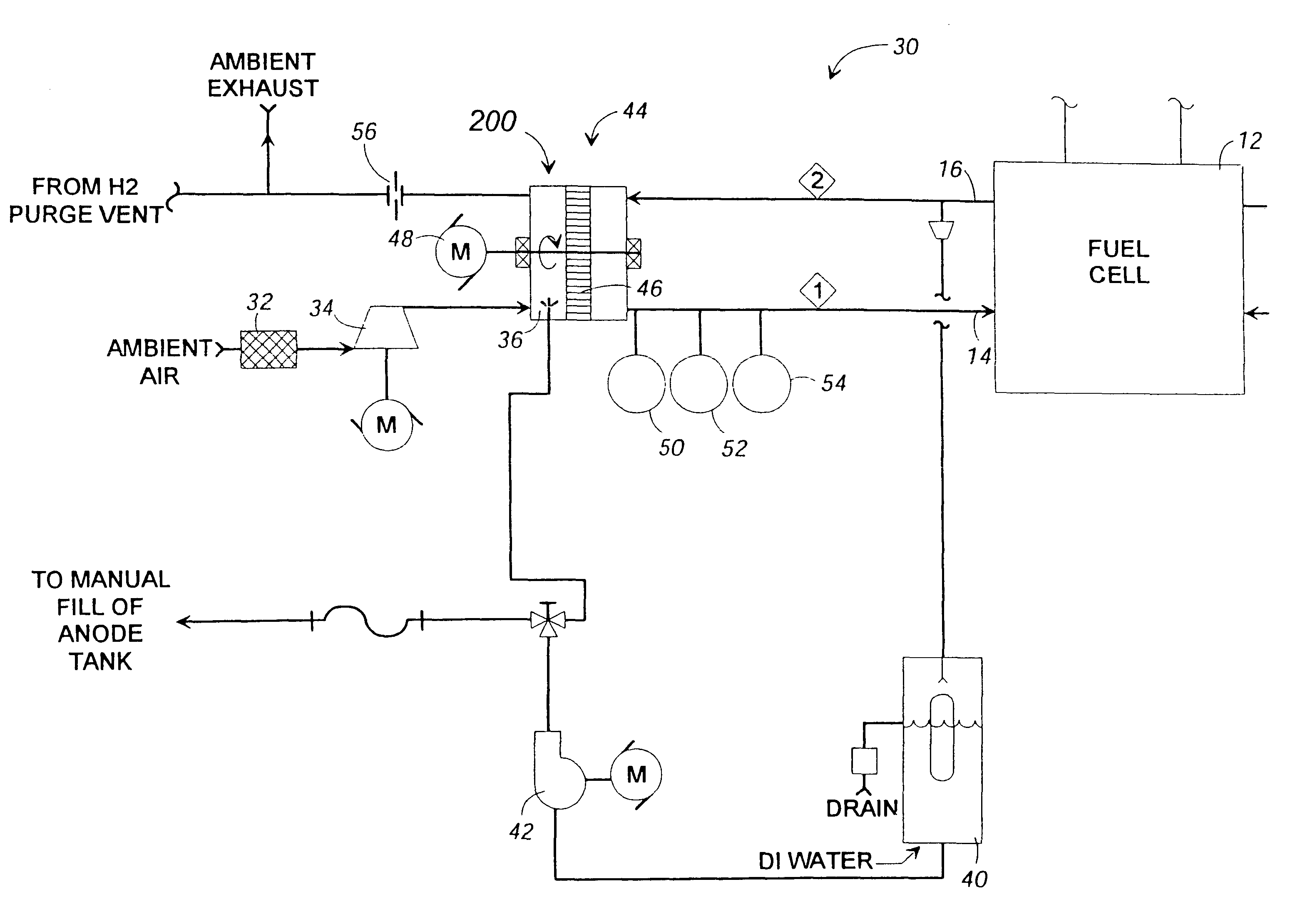

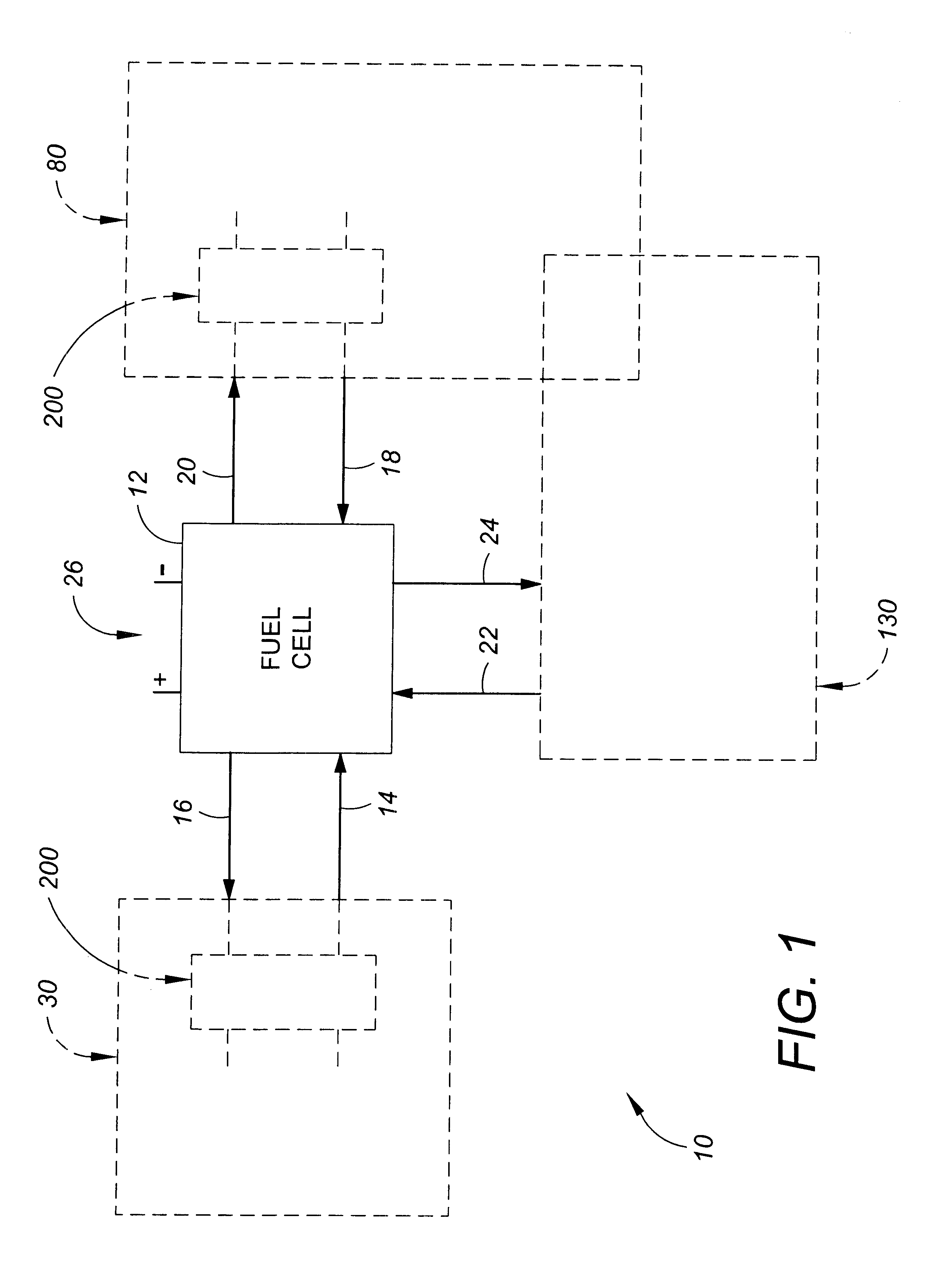

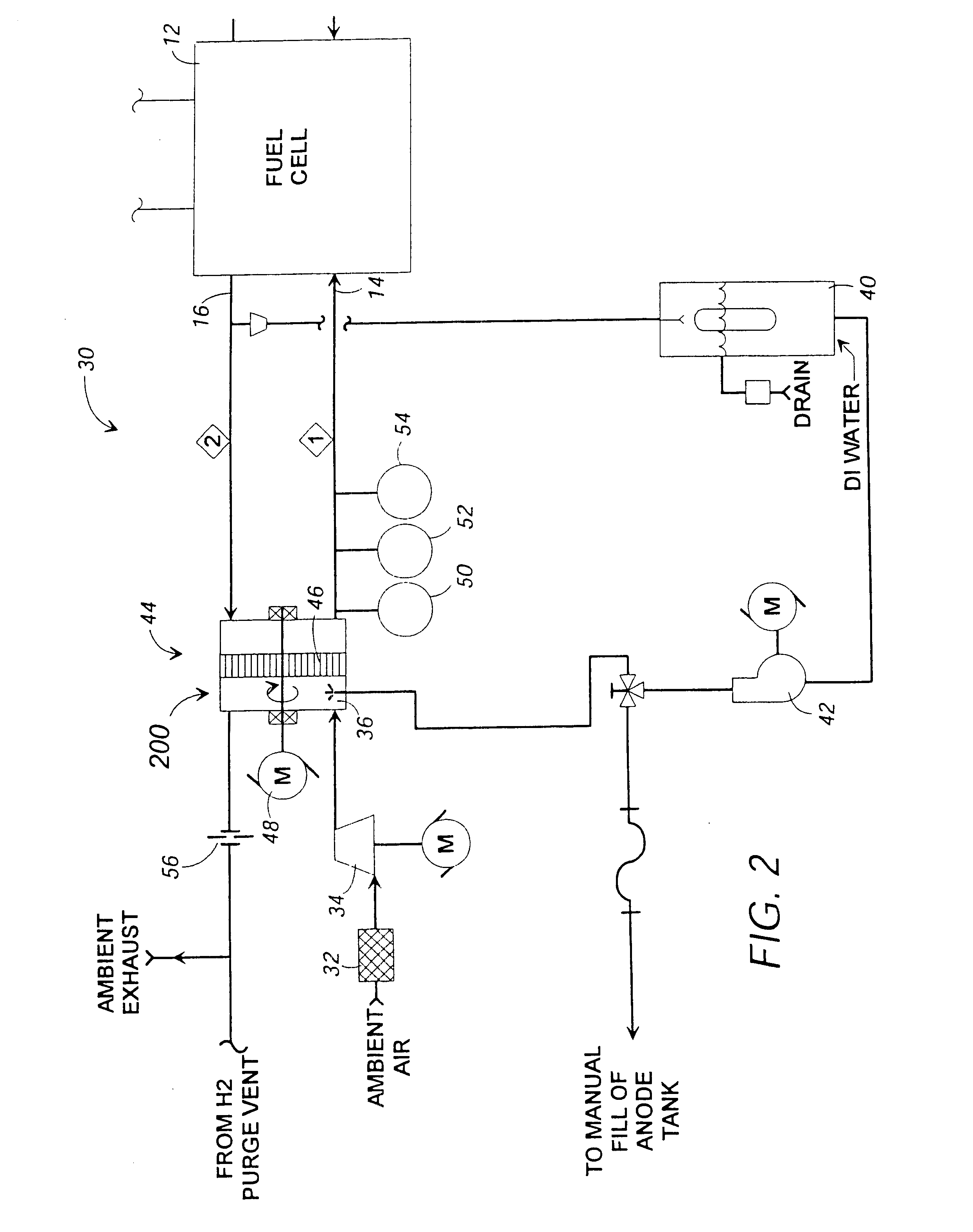

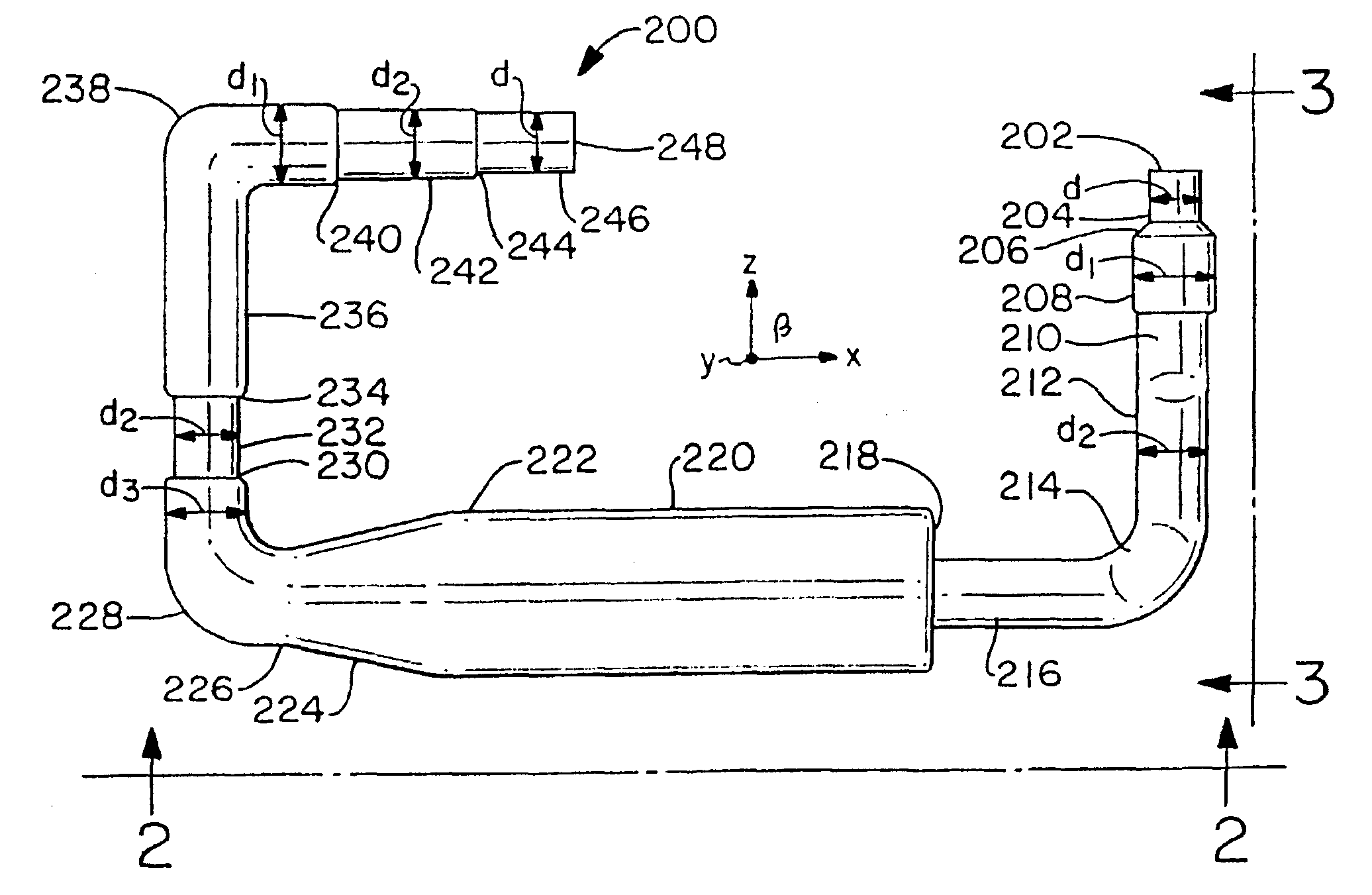

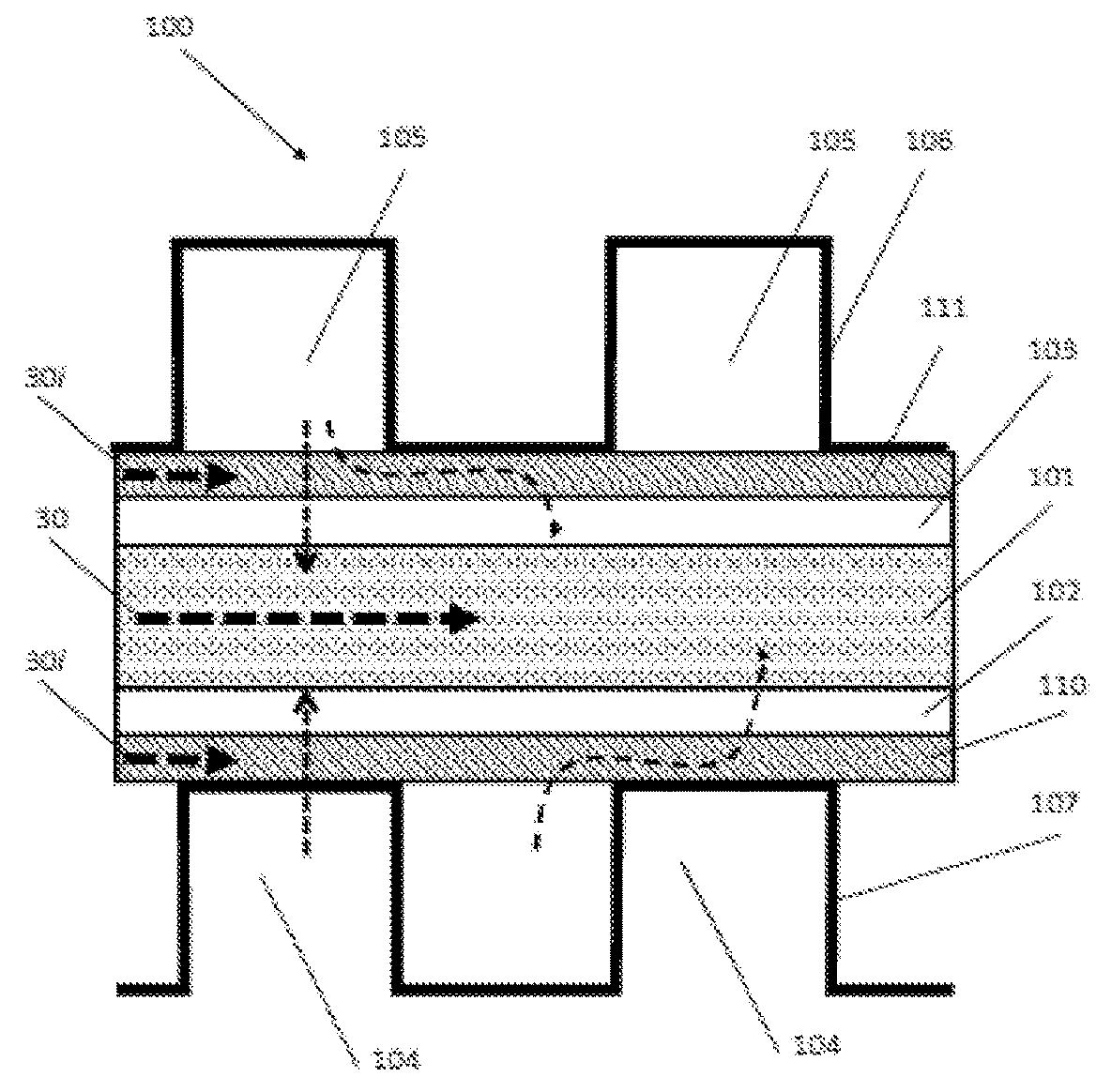

Fuel-cell engine stream conditioning system

A stream conditioning system for a fuel cell gas management system or fuel cell engine. The stream conditioning system manages species potential in at least one fuel cell reactant stream. A species transfer device is located in the path of at least one reactant stream of a fuel cell's inlet or outlet, which transfer device conditions that stream to improve the efficiency of the fuel cell. The species transfer device incorporates an exchange media and a sorbent. The fuel cell gas management system can include a cathode loop with the stream conditioning system transferring latent and sensible heat from an exhaust stream to the cathode inlet stream of the fuel cell; an anode humidity retention system for maintaining the total enthalpy of the anode stream exiting the fuel cell related to the total enthalpy of the anode inlet stream; and a cooling water management system having segregated deionized water and cooling water loops interconnected by means of a brazed plate heat exchanger.

Owner:EMPRISE TECH ASSOC

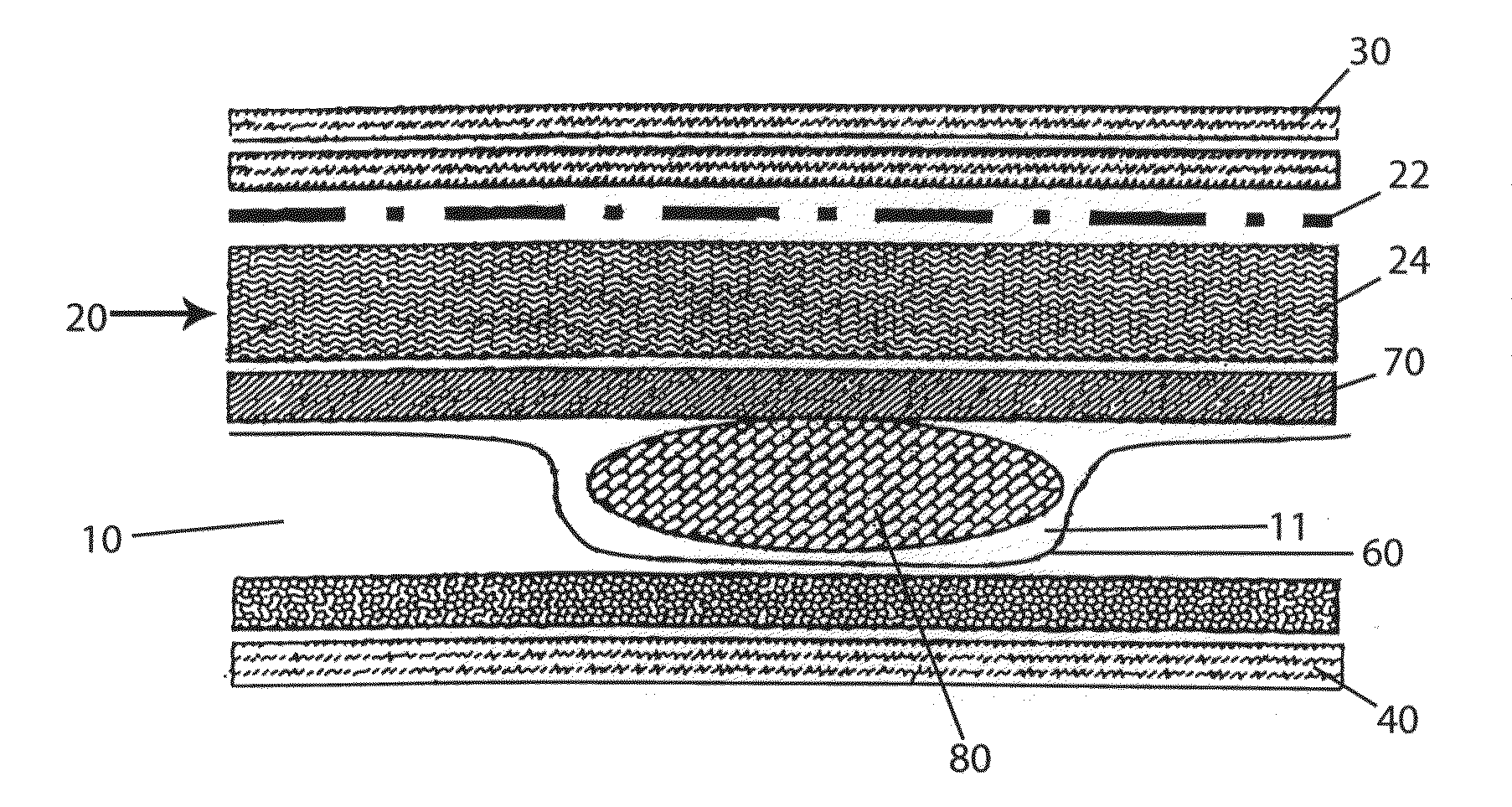

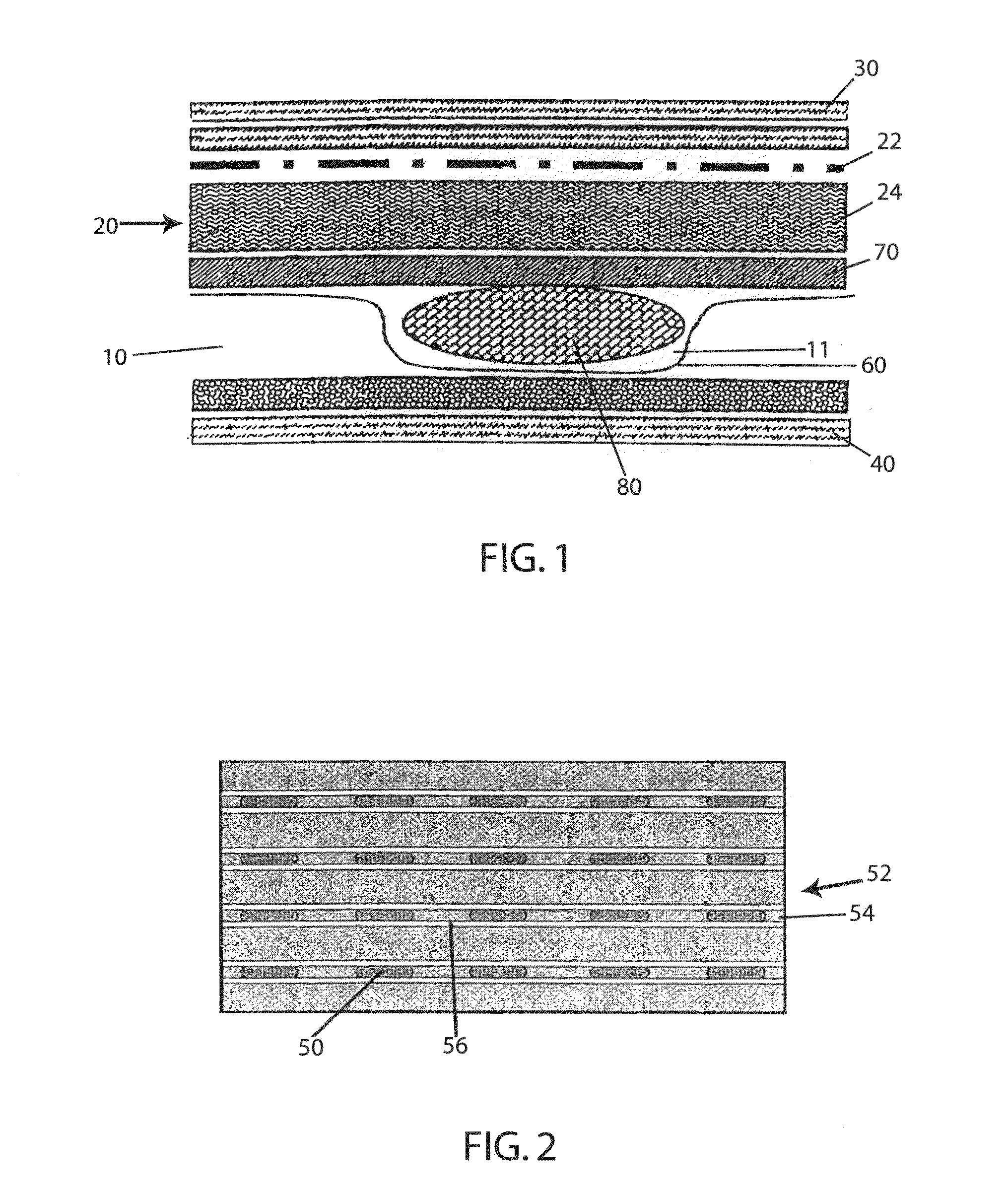

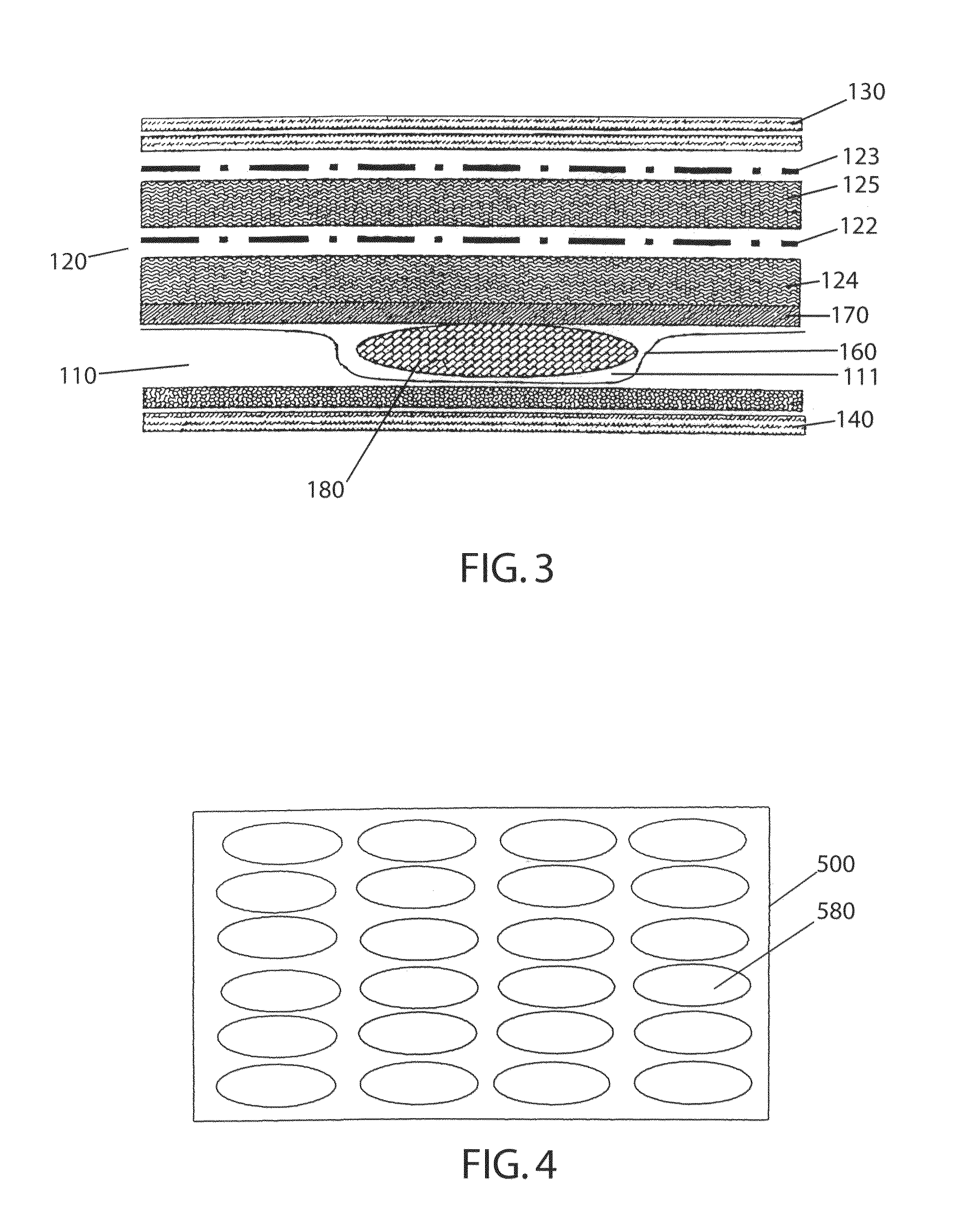

Fibers and articles having combined fire resistance and enhanced reversible thermal properties

A fabric, fiber or article comprising a plurality of fiber bodies, the plurality of fiber bodies including a first fiber material and a second fiber material, wherein the first fiber material comprises a cellulosic material and a phase change material dispersed in the cellulosic material, the phase change material forming a plurality of domains dispersed in the cellulosic material, the phase change material having a latent heat of at least 5 Joules per gram and a transition temperature in the range of 0° C. to 100° C., the phase change material providing thermal regulation based on at least one of absorption and release of the latent heat at the transition temperature. Wherein the second fiber material comprises a fire resistant material.

Owner:OUTLAST TECH LLC

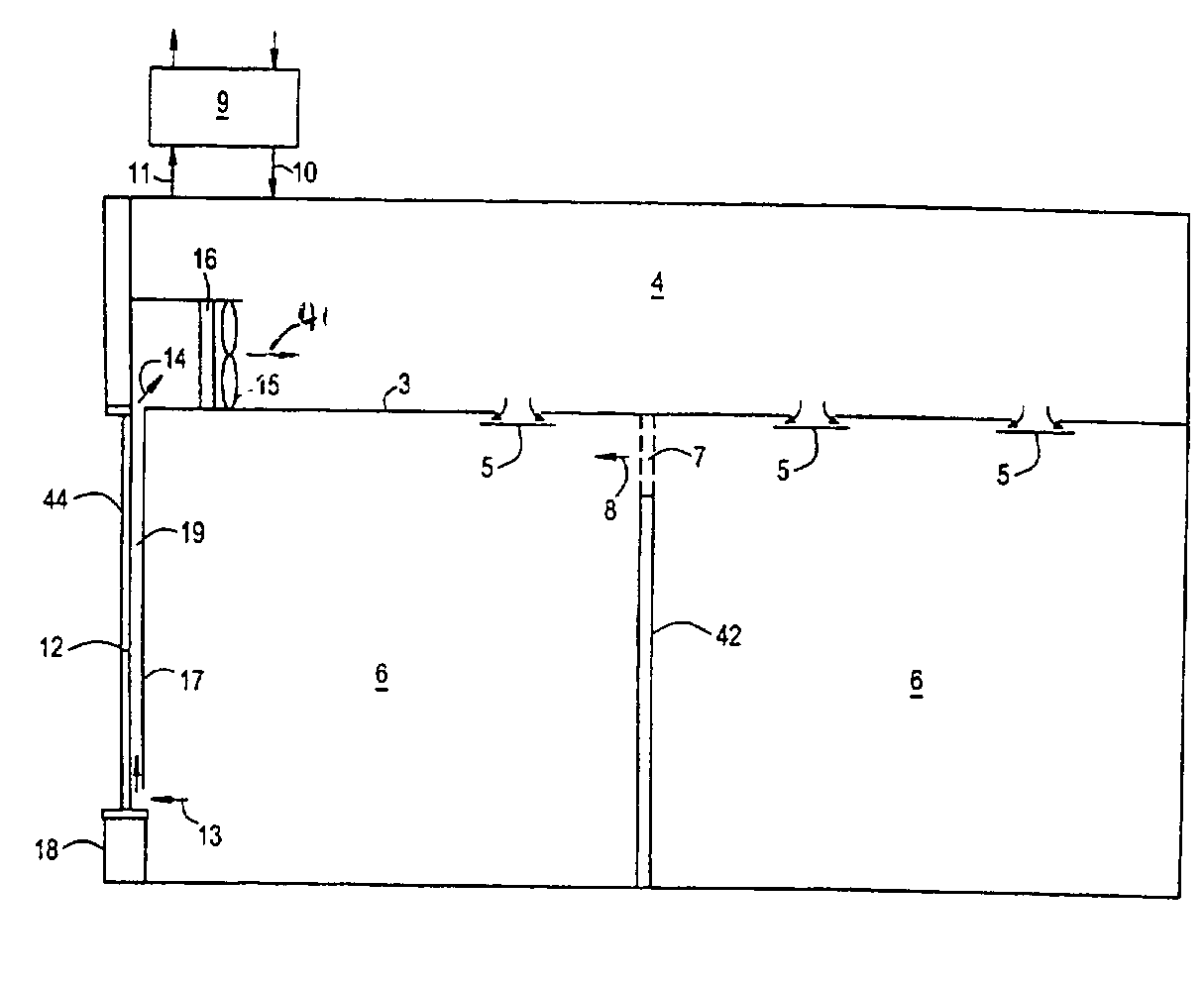

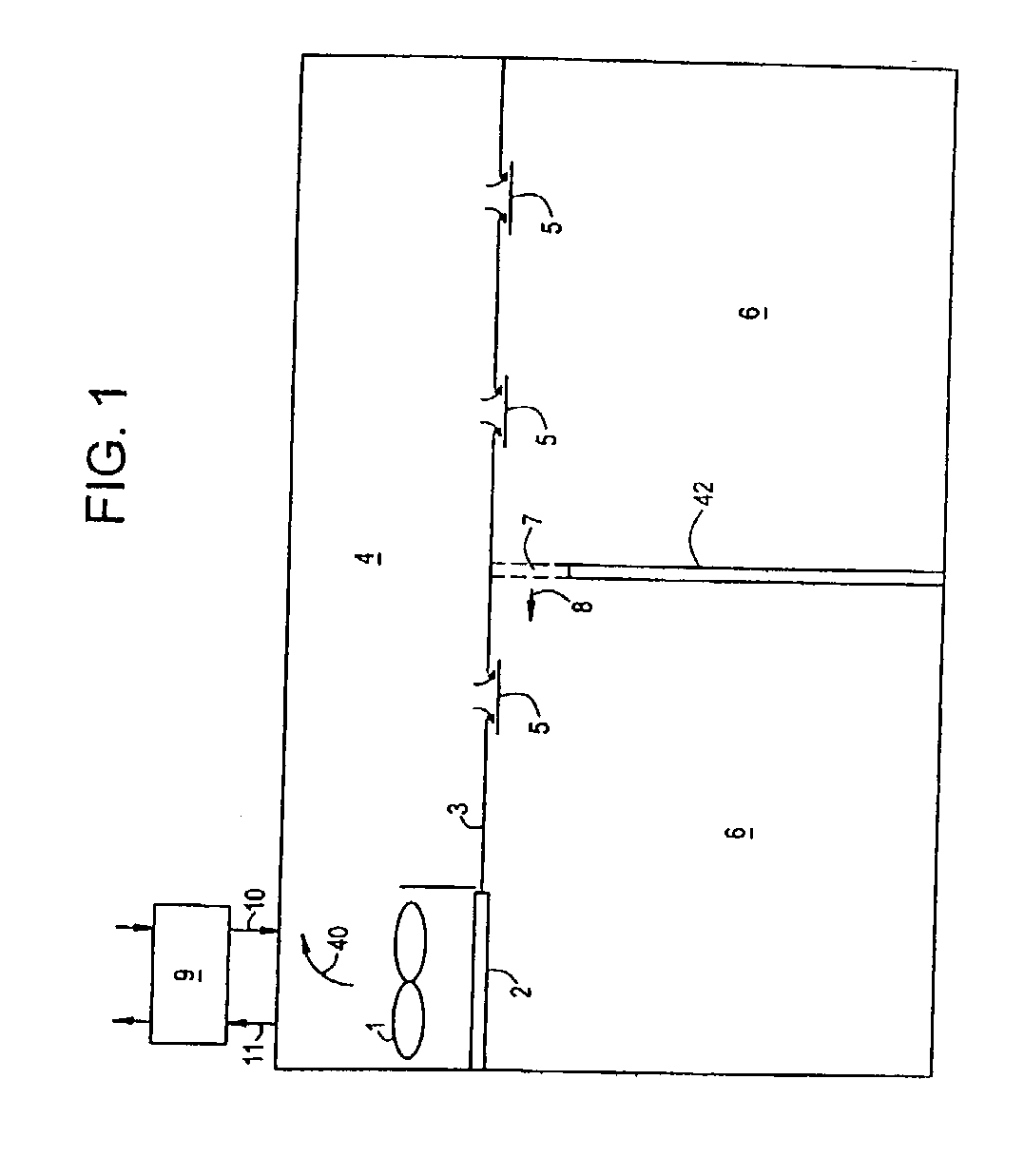

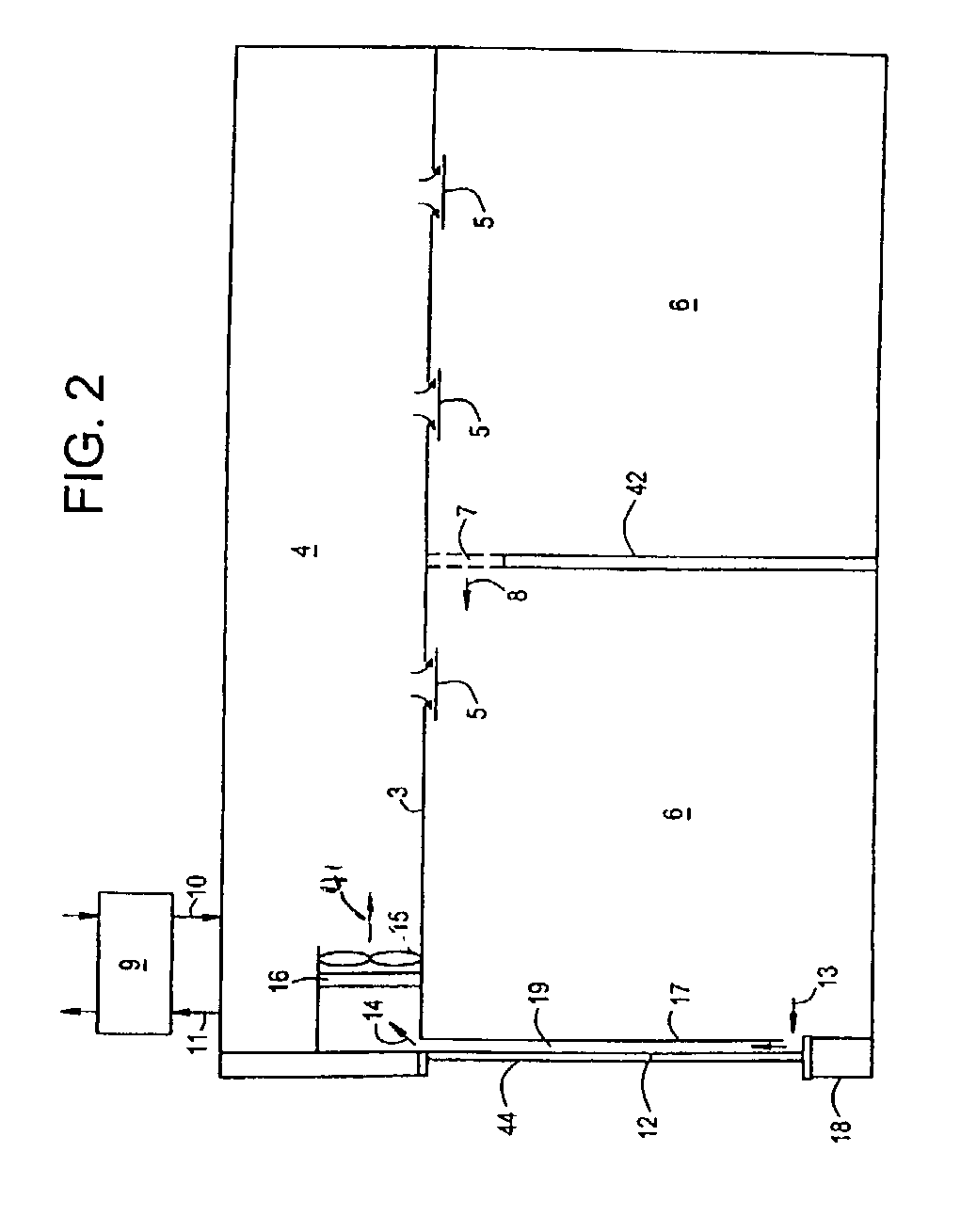

High-efficiency air handler

InactiveUS20030000230A1Lighting and heating apparatusCooling fluid circulationCeiling fanPressure rise

A high-efficiency air handler that is suitable for moving large volumes of air. The air handler comprises a coil and a fan. The total air volume moving through the unit is preferably over about 2000 CFM, with a total fan static pressure rise of less than about 0.5 inches and preferably less than 0.2 inches of water. The fan is preferably a modified ceiling fan with a rotational speed of less than about 450 rpm. The air handler is preferably part of a system where dehumidification and sensible cooling functions are separate. The separate dehumidification allows for much higher supply air temperatures, preferably within about 10° F. of the space temperature. Low-velocity air distribution through a ceiling plenum or a vent into the space allows for very low fan static pressures, which greatly reduces fan energy use compared to conventional ducted systems. The low static pressures and high supply-air temperatures allow the use of existing drop ceiling construction with little modification. The system can also include low-cost thermal storage. Latent thermal storage is in the form of a concentrated liquid desiccant solution. Chilled water storage is another option. The result is a major improvement in energy efficiency and comfort while reducing installed cost and peak electrical demand of the system.

Owner:KOPKO WILLIAM L

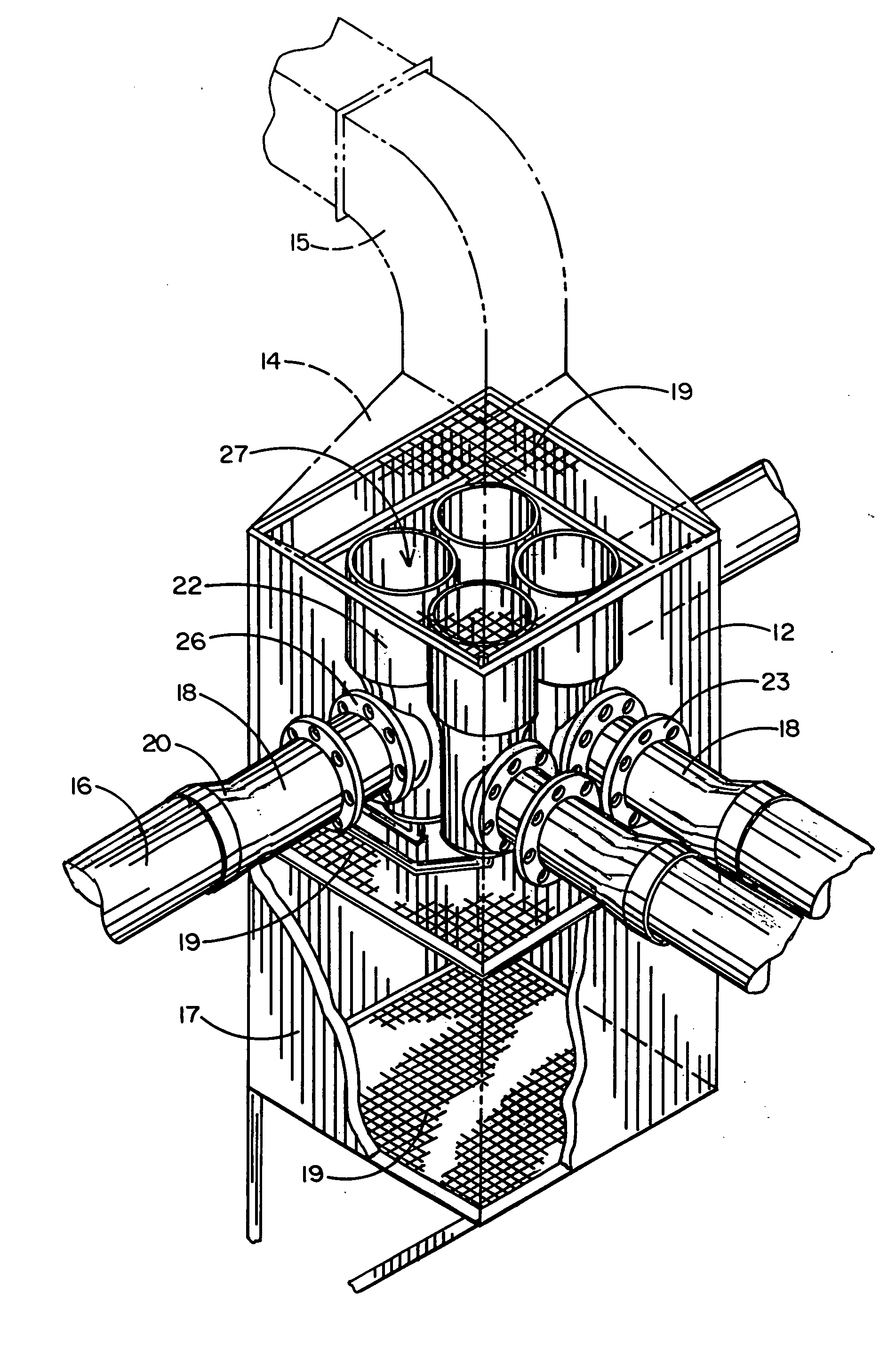

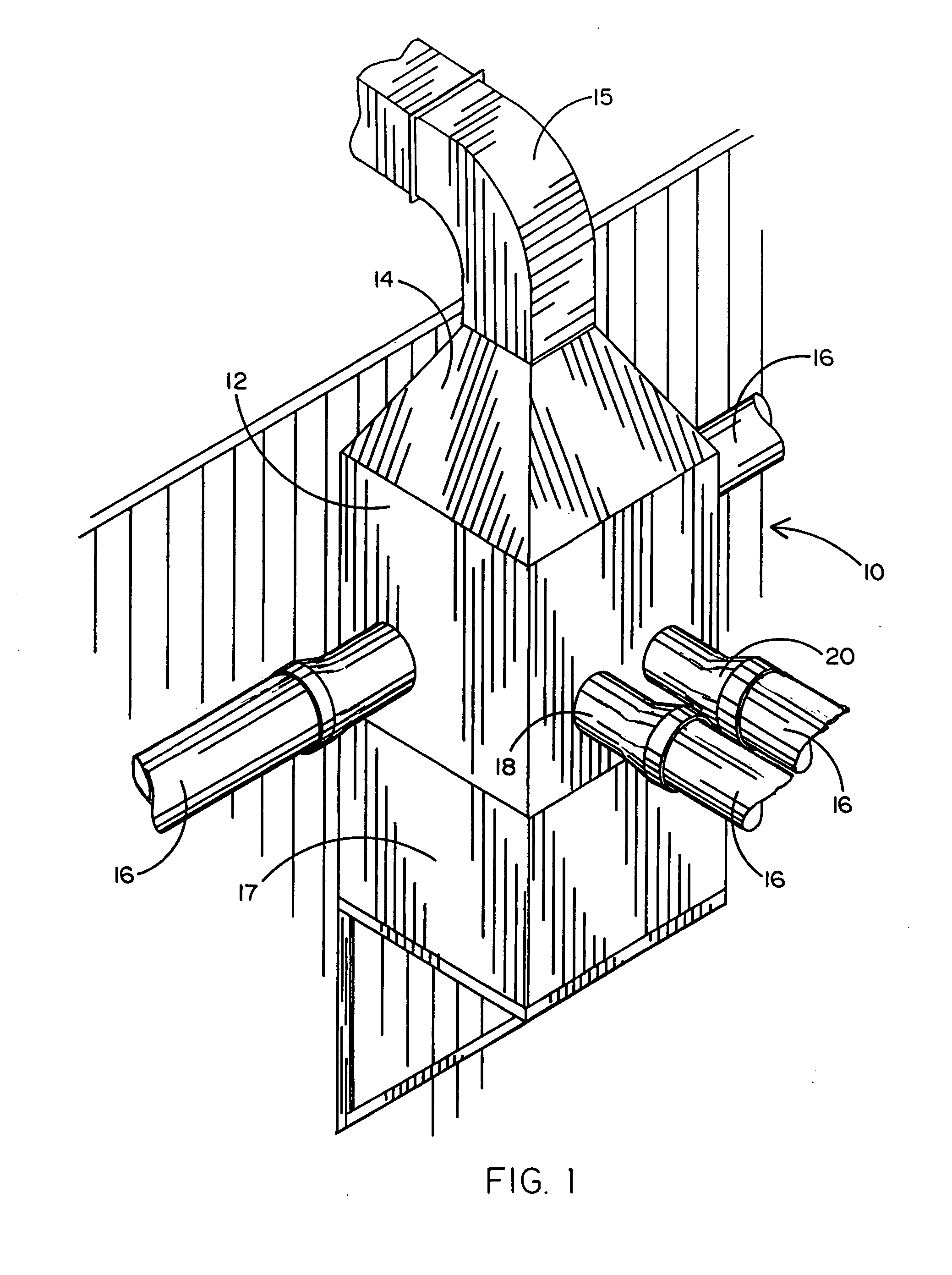

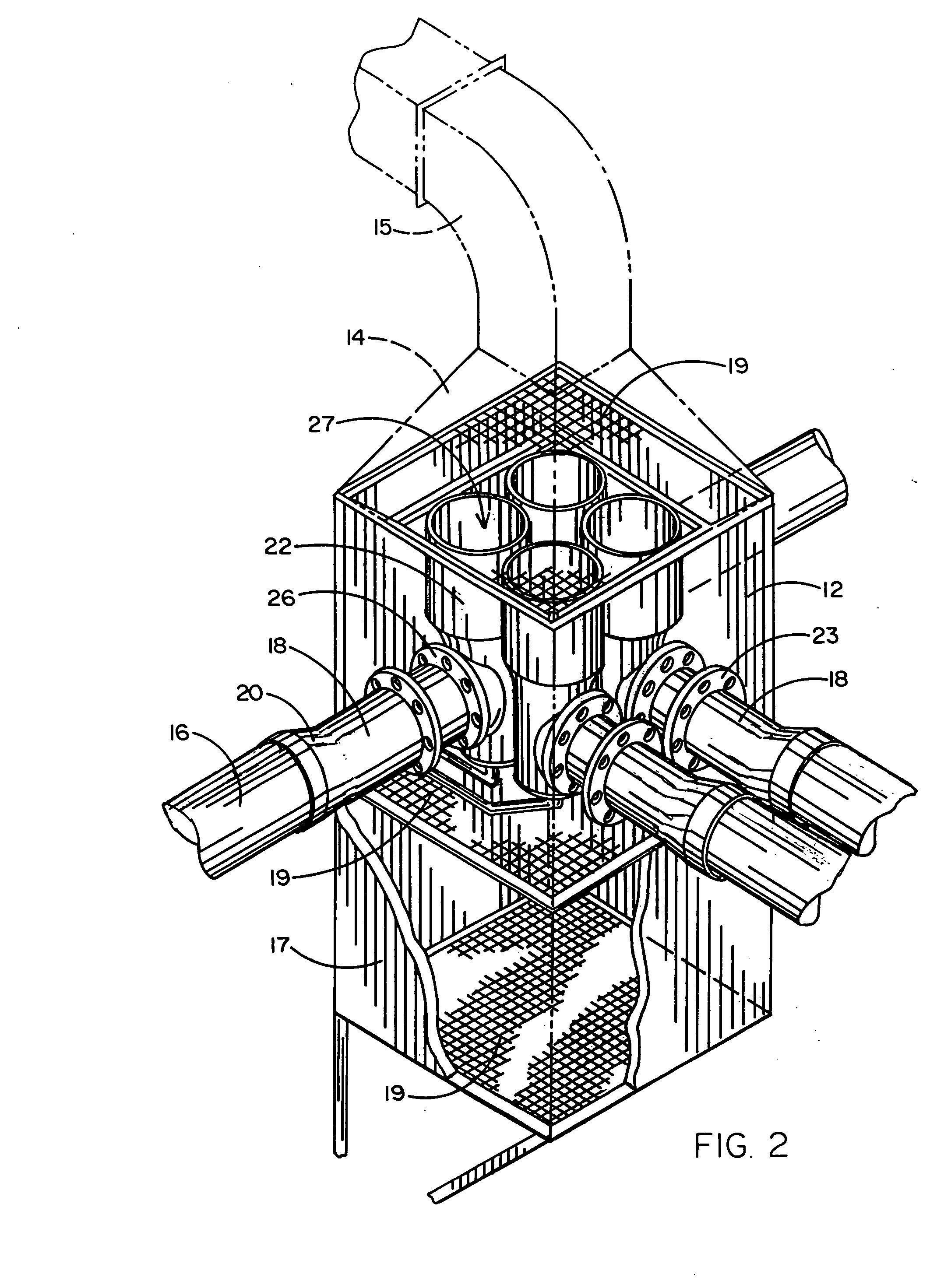

Barometric thermal trap and collection apparatus and method thereof for combining multiple exhaust streams into one

InactiveUS20090042070A1Controllable and more efficientIncrease contentFuel cell heat exchangeGas turbine plantsScrubberCogeneration

A device that, in any situation where multiple streams of hot or very hot gases or exhaust are generated, can collect gases into one stream and divert the stream efficiently to any manner of reformers, treatment devices, scrubbers, exchangers, etc. The exhaust flow from multiple fuel cell stacks are mixed in a single stream within the invention. This must be done carefully so that the exhaust stack pressure is approximately atmospheric at a variety of operating conditions. The mixing occurs in a device (the invention) called a Barometric Thermal Trap (BaTT). The fuel cell exhaust has a fairly high steam and CO2 content. The steam represents a potentially significant source of latent heat. Typical fuel cell heat recovery units avoid capturing the latent heat due to its relatively low condensing temperature (140 degrees Fahrenheit) and the resultant acidic level of the condensate due to the presence of CO2, which forms carbonic acid. By combining the exhausts into one stream, the BaTT system makes these problems manageable and more cost effective. Design calculations indicate that a Combined Heat and Power (CHP) efficiency of 82% is possible, which is much higher than provided by standard heat recovery designs.

Owner:UNIV INC AT CALIFORNIA STATE UNIV NORTHRIDGE THE

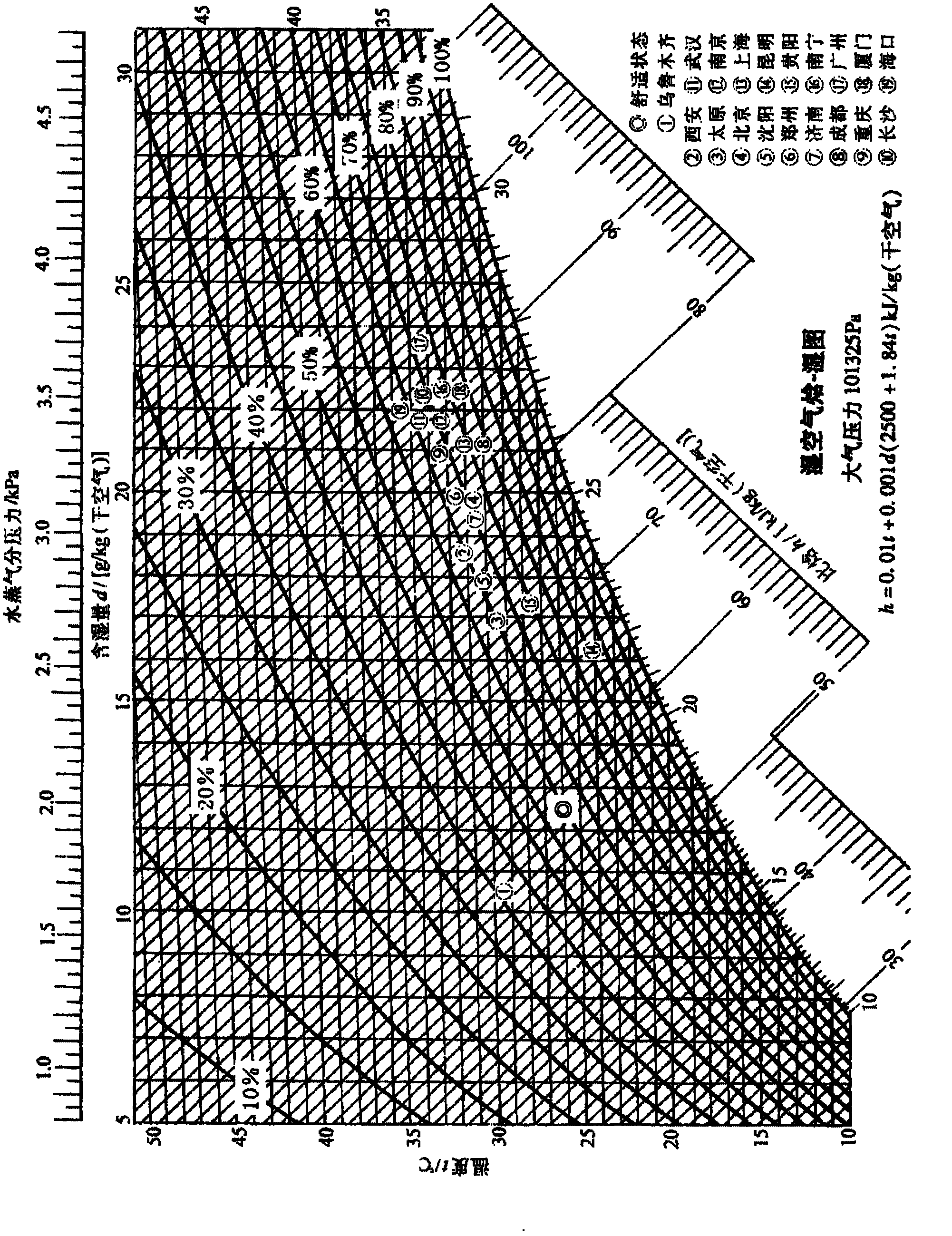

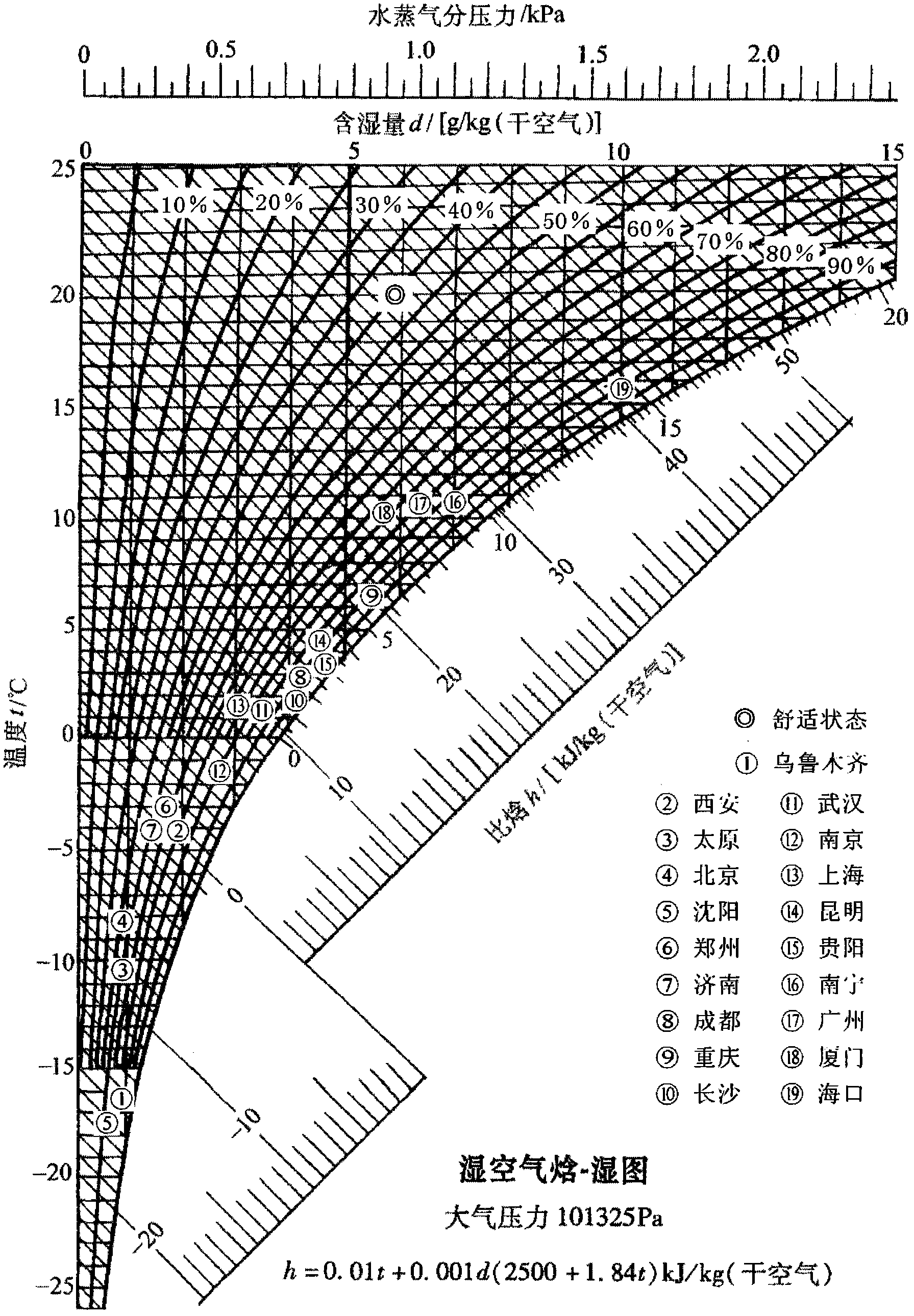

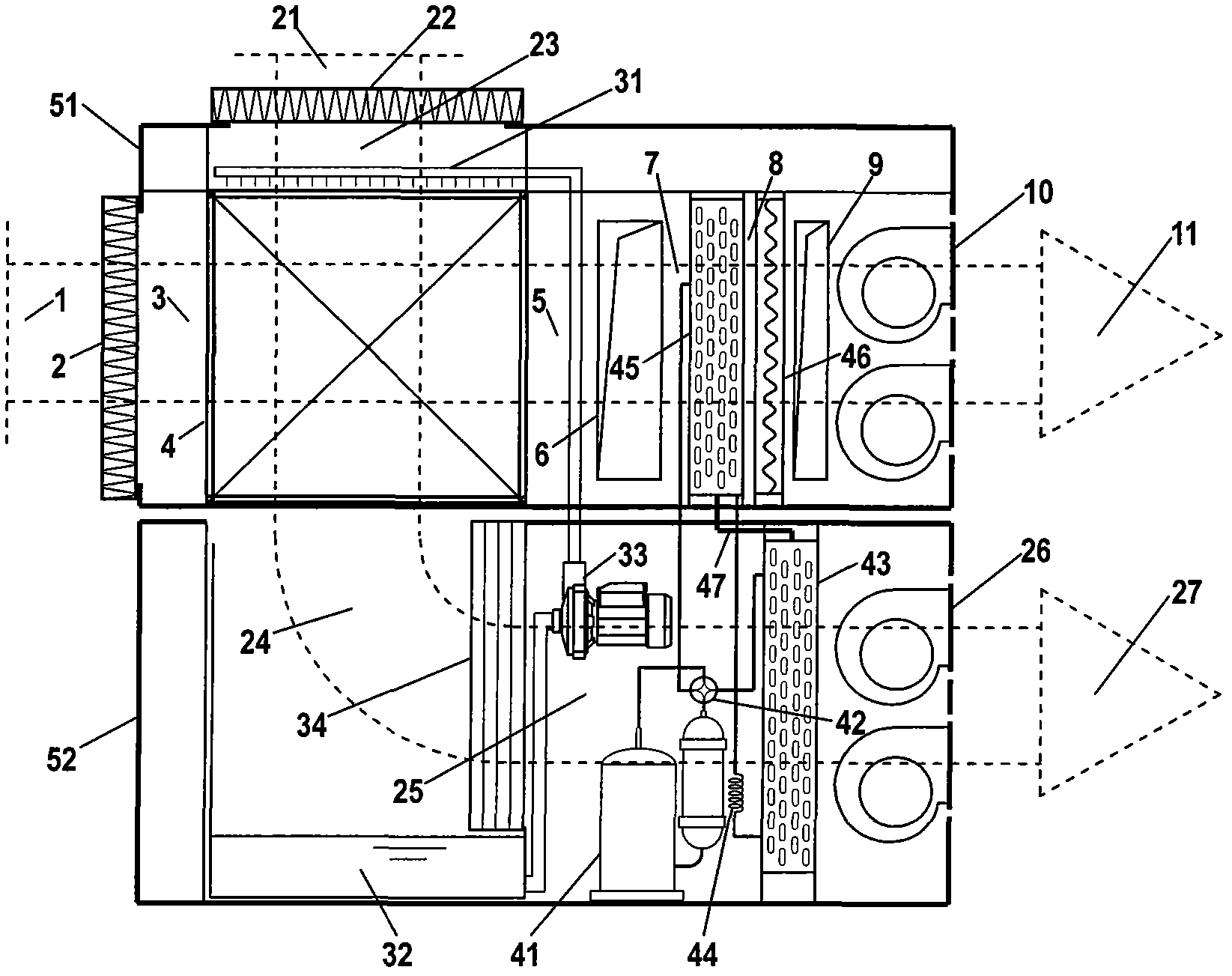

Fresh air conditioner

InactiveCN102425822AHuge latent heat ratioAvoid waterway hazardsEnergy recovery in ventilation and heatingLighting and heating apparatusIndoor air qualityFresh air

The invention relates to the field of heating ventilation air conditioners, in particular to an improved air treatment method and a fresh air conditioner device. The invention improves the problems of traditional fresh air treatment and air conditioners and particularly emphasizes that a plate-type air-air heat exchanger and indirect water evaporative cooling are used for recycling energy of sensible heat and latent heat in air exhaust in the fresh air treatment process of damp and hot regions in summer and condensed water is directly evaporated on an evaporator to improve the working condition of a compressor. Under the condition of quantificationally supplying outdoor fresh air, the energy efficiency ratio of the fresh air conditioner is increased, the thermal pollution, damp pollution and noise pollution of the fresh air conditioner to environments are reduced, the indoor air quality is improved, and meanwhile, the fresh air conditioner provides the manufacture, installation and using convenience for a local region all-air central air conditioner. The fresh air conditioner provided by the invention and a design and manufacture method of the fresh air conditioner are applicable throughout the year in various regions, particularly in the damp and hot regions; and the fresh air system provides controlled, comfortable and healthy air environments for indoor activity space of people and air conditioner environments for technology for processing, storage and the like.

Owner:张洪

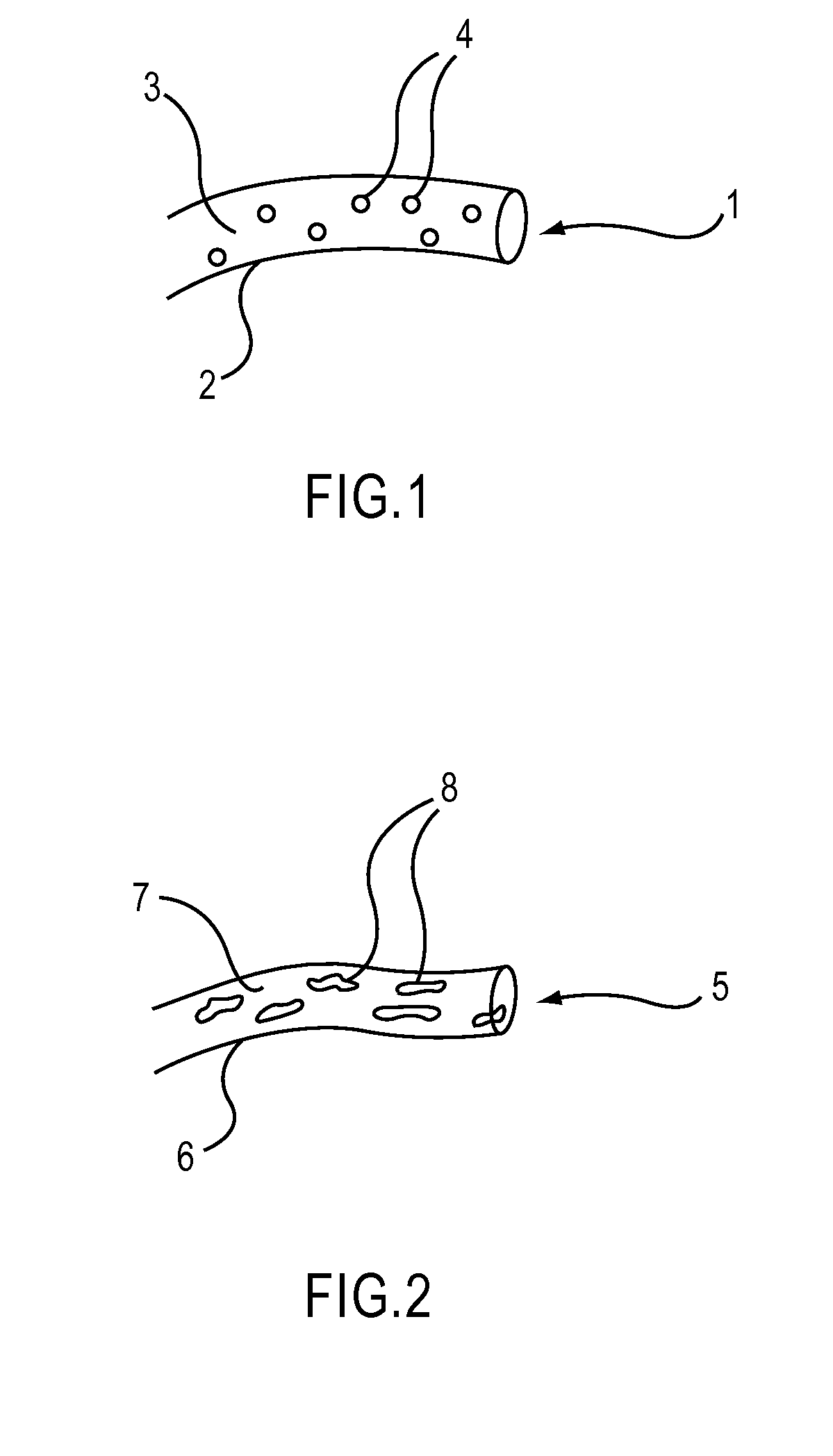

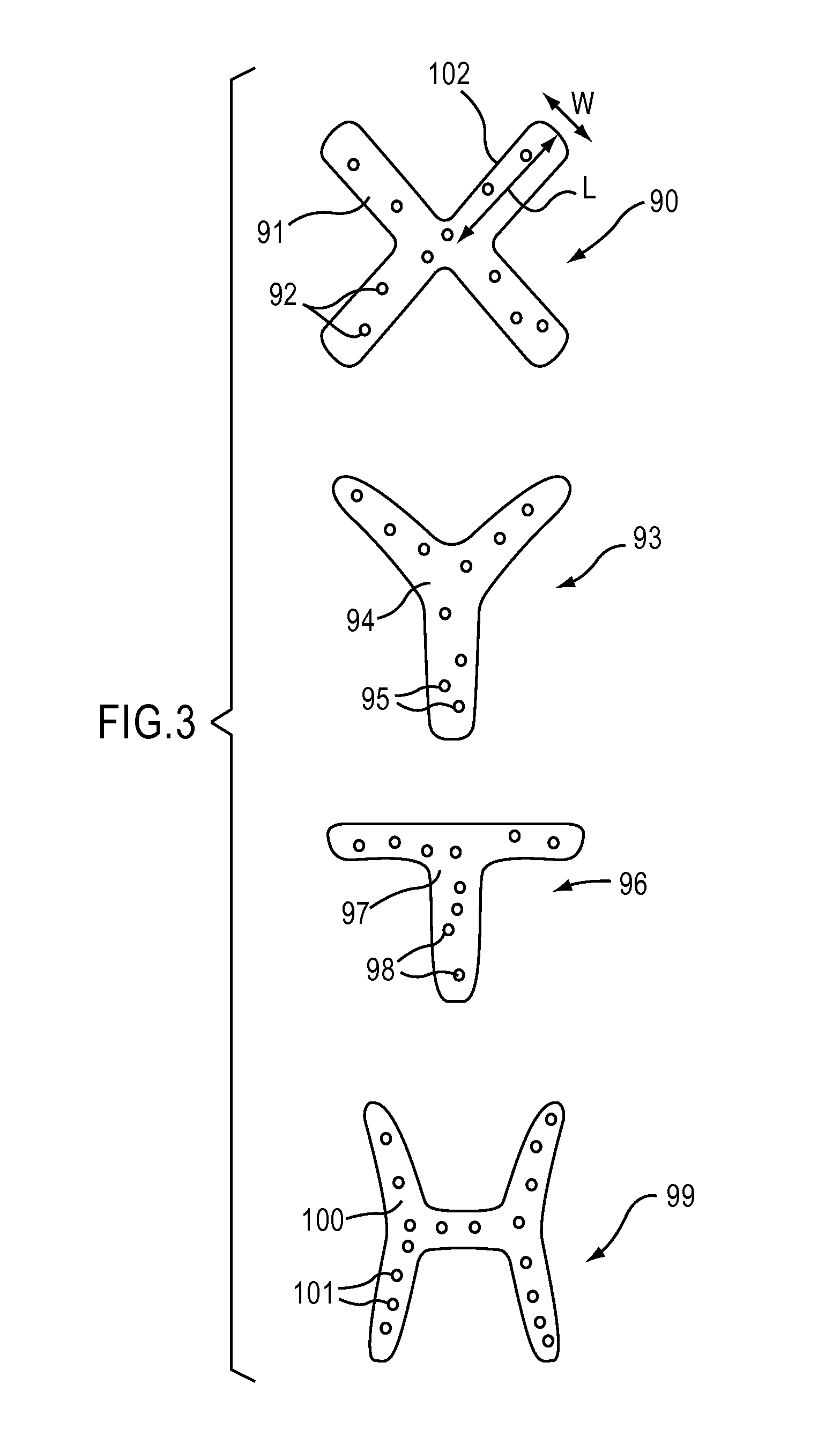

Post formation profile processing

This invention relates to the post-formation processing of extruded or injection molded profiles in an economic manner without the need to purchase a blow molding machine, yet still effect post-formation radial expansion or contraction by the application of sufficient degree of heat or the performing of the operation sufficiently quickly to permit the utilization of the retained latent heat from the extrusion or injection molding process.

Owner:MERCURY PLASTICS LLC

Portable moist heat system

ActiveUS20090287280A1Increase speedImproved controllable uniform applicationExothermal chemical reaction heat productionNervous disorderBlood flowWater vapor

A portable moist heat delivery system comprising a water vapor generating portion comprising a water vapor source and a heat source; a water vapor-air regulating portion, said water vapor-air regulating portion comprising a water vapor-air mixing layer, and a water vapor-air distribution layer; said water vapor generating portion and said water vapor-air regulating portion being in fluid communication; and said water vapor-air regulating portion having a latent heat delivery surface disposed adjacent said water vapor-air regulating portion which delivers moist heat at a preselected temperature range wherein about 15% to about 95% of the moist heat is latent heat of condensation. Methods include delivering improved pain relief, blood flow, relaxation, and reduced cardiac workload.

Owner:BRIDGES CONSUMER HEALTHCARE LLC

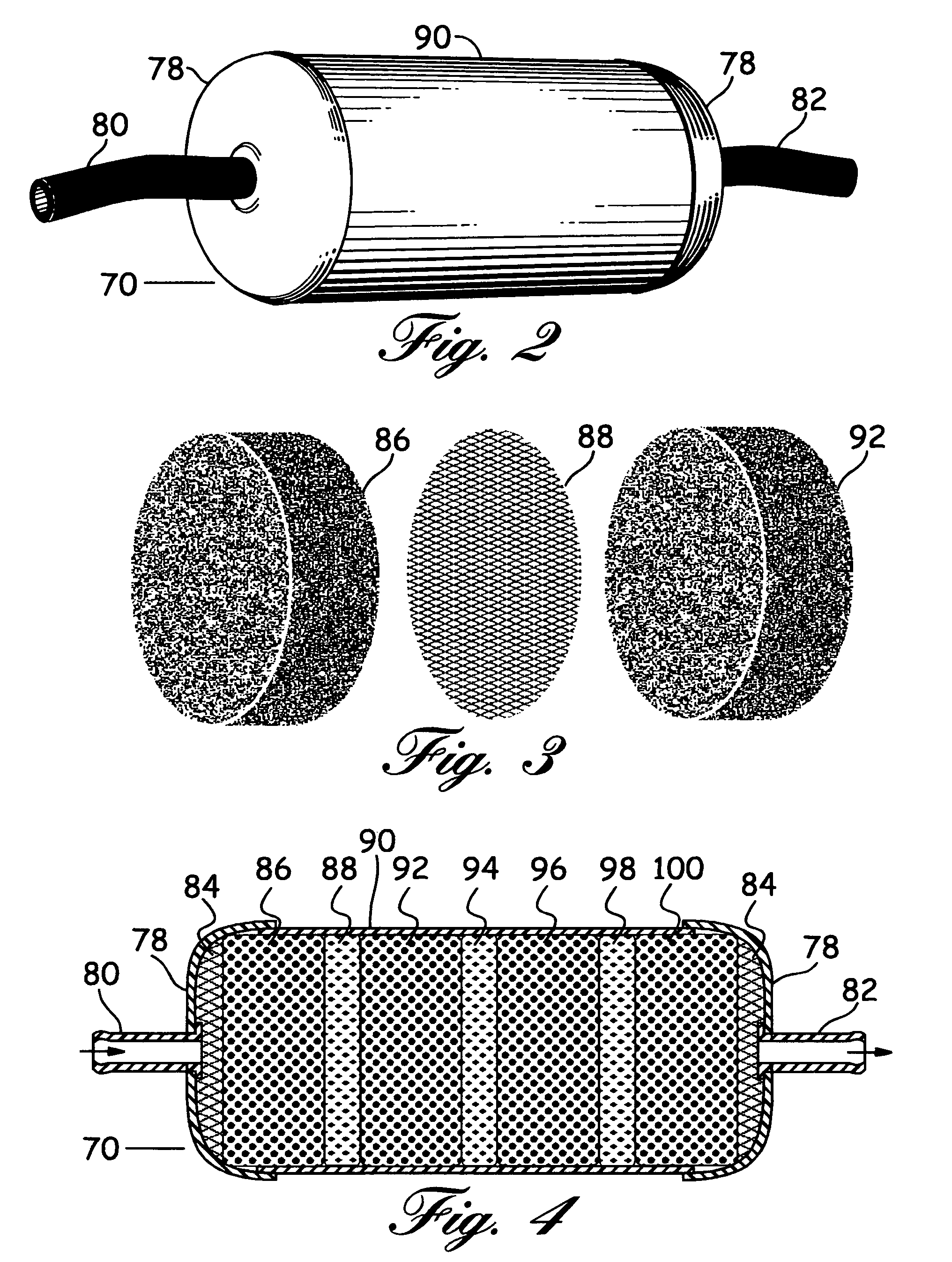

Adsorbent of latent-heat storage type for canister and process for producing the same

ActiveUS20050247202A1High melting pointEvenly distributedCombination devicesNon-fuel substance addition to fuelLatent heat storageDesorption

The present invention provides a latent-heat storage type adsorbent composition for canisters that can effectively prevent changing in temperature due to the heat of absorption / desorption and has a high butane working capacity; a process for producing the adsorbent; and a canister employing the latent-heat storage type adsorbent composition for canisters. The present invention relates to a latent-heat storage type adsorbent composition for canisters which compromises an adsorbent adsorbing a fuel vapor and a heat-storage material comprising microencapsulated phase-changing material which absorbs or releases latent heat in response to temperature change, and a method for producing such an adsorbent.

Owner:OSAKA GAS CO LTD

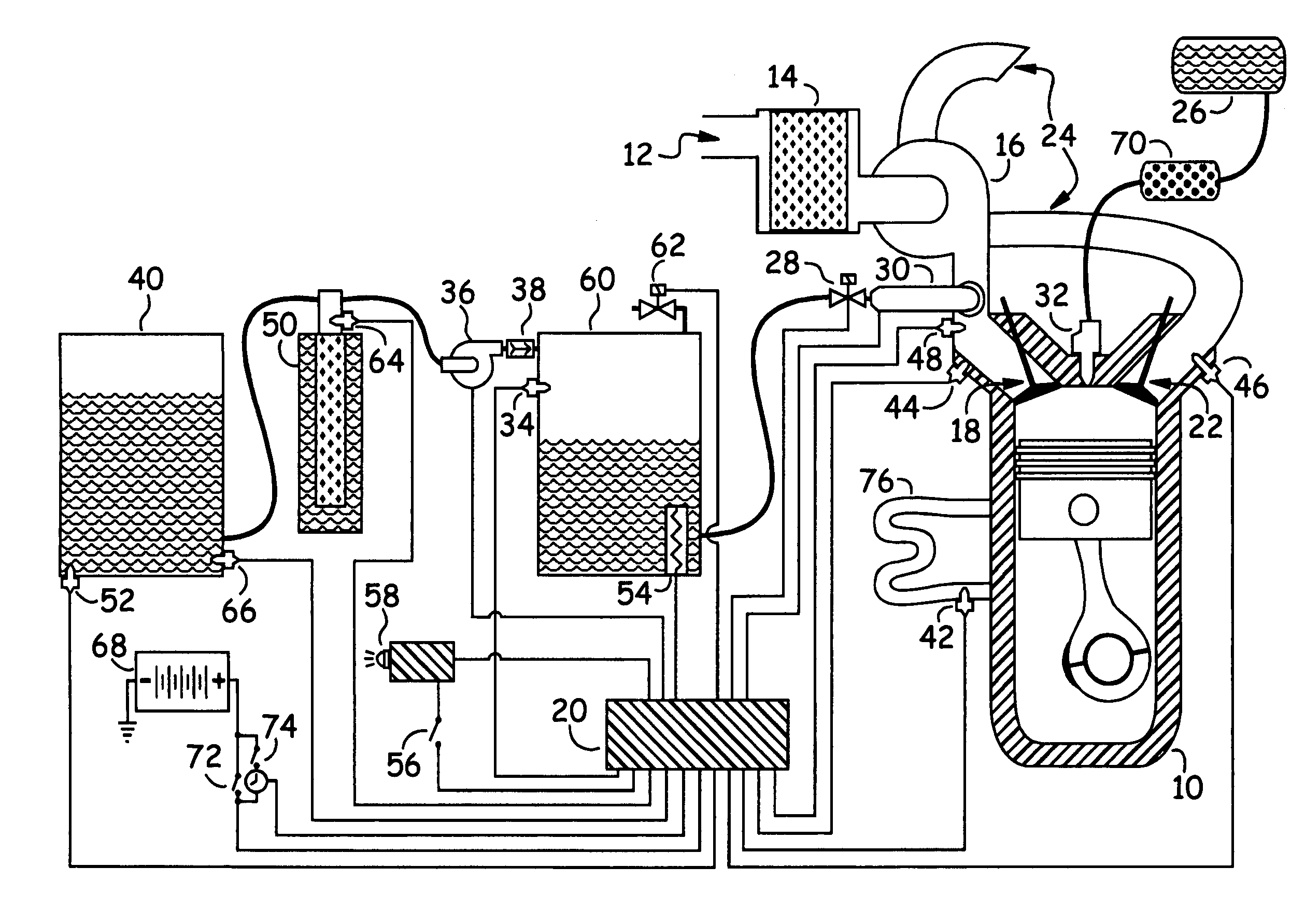

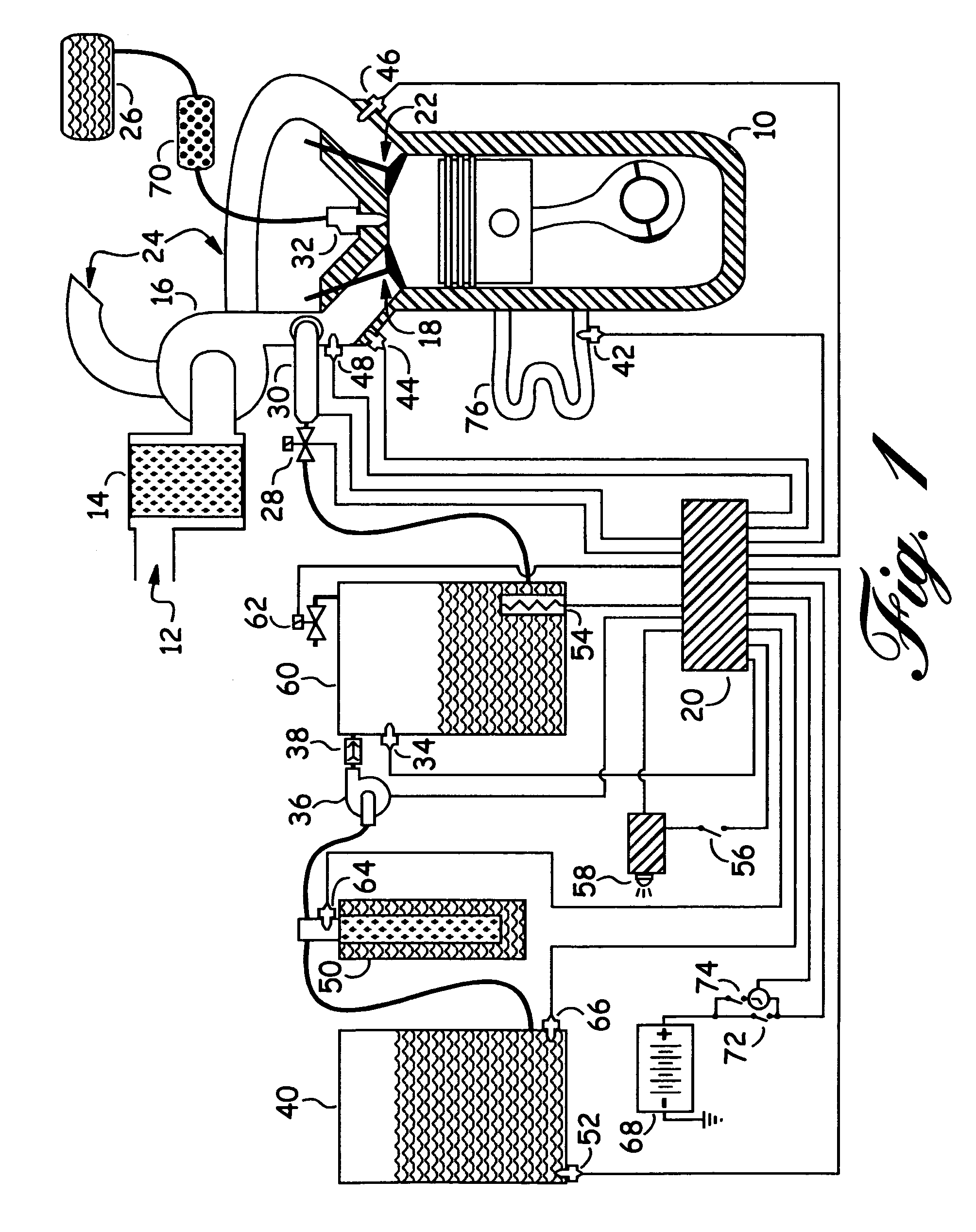

Emissions reduction system for an internal combustion engine

InactiveUS7013845B1Reduce harmful emissionsImprove performanceInternal combustion piston enginesNon-fuel substance addition to fuelPrime moverNitrogen oxides

A dual system for overall engine emissions control, including prevention of excessive formation of nitrogen oxides and carbon compounds 1) by cooling and humidifying intake air and 2) by restructuring and modifying hydrocarbon fuels, resulting in a more complete combustion, a significant reduction of the latent heat of combustion and increased combustion potency. The invention utilizes one or more ultrasonic devices to create an aqueous vapor from an ultra-pure water supply, said vapor varying in quantity according to engine size and load, having electronic sensors and controls for precision switching, metering and delivery. Simultaneously, while humidifying the intake air, the hydrocarbon fuel is passed from a fuel supply through a catalytic reactor to restructure the hydrocarbon molecules into a more homogeneous, more combustible and cleaner-burning fuel. Thus equipped, said internal combustion engine can be run as a fuel conserving, low emissions prime mover.

Owner:CONTEGO MEDICAL INC

Adsorption type cooling apparatus, method of controlling cold output of same, and fin type adsorbent heat exchanger for use in same

InactiveUS6041617AQuick assemblyPrevent movementBoiler absorbersEnergy efficient heating/coolingEvaporationEngineering

According to the invention, the temperature and flow rate of cooling water for removing the heat of absorption are controlled artificially according to the cold output of load water by utilizing heated cooling water after the removal of the heat of absorption or heat source water, etc. According to the invention, a coolant tank and a load heat exchanger unit are provided as separate units. A load carrier is provided for cooling the load while partly evaporating the coolant through heat exchange between liquid coolant supplied from the coolant supplied from the coolant tank through a pump and the load. Mixture fluid of liquid coolant and vapor coolant after the heat exchange in the load cooler are returned to the coolant tank for separation of gas and liquid. Because the coolant tank and the load cooler are provided separately, the heat exchange with the load is performed by utilizing the latent heat of evaporation of coolant independently of possible temperature variations in the coolant tank. It is thus possible to obtain load heat at a constant temperature.

Owner:MAYEKAWA MFG CO LTD

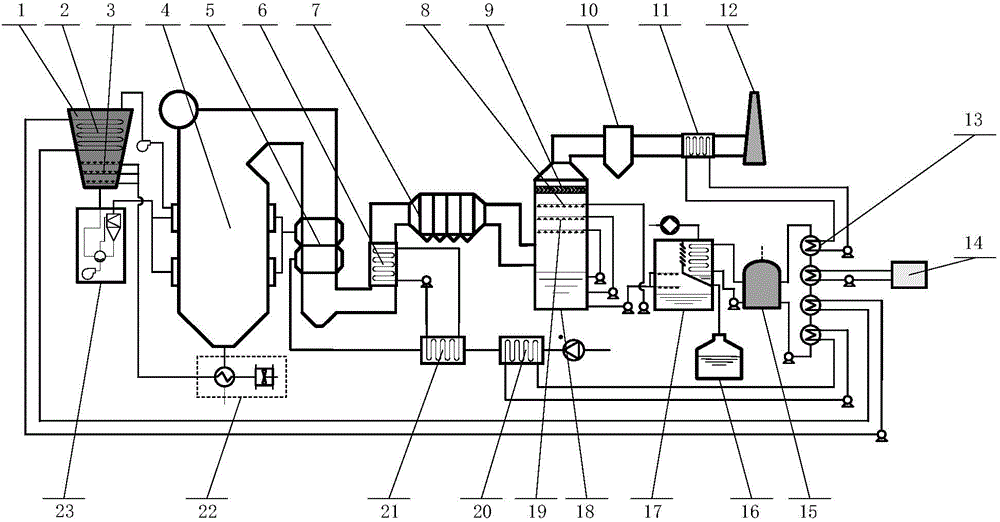

Coal-fired power plant flue gas heat regenerative system and energy-saving water-saving ultra-clean discharging method

ActiveCN104930539AImprove solubilityImprove desulfurization efficiencyIndirect carbon-dioxide mitigationLump/pulverulent fuel preparationSlurryWater vapor condensation

The invention discloses a coal-fired power plant flue gas heat regenerative system and an energy-saving water-saving ultra-clean discharging method. The temperature of the flue gas is reduced to about 90-110 DEG.C through a low-temperature coal economizer, and the recycled flue gas heat heats primary and secondary wind entering a boiler through a steam air heaters, so that the first stage of heat regenerative cycles is achieved. The temperature of the flue gas at the outlet of a desulfurization tower is reduced to 30-40 DEG.C through a vacuum flash evaporation and solidification device and a low-temperature heat pump heat exchange device, and a part of water vapor of the flue gas is condensed and collected, so that water is saved. The low-temperature heat pump heat exchange device absorbs the latent heat released in flue gas sensible heat and condensation processes, and dry as-fired coal and air are heated, so that the second stage of heat regenerative cycles is achieved. A boiler slag discharge system recycles the waste heat of heat slag, and the as-fired coal is heated, so that the third stage of heat regenerative cycles is achieved. When the waste heat is not used up, the remained waste heat can be utilized, so that energy is saved. Low-temperature desulphurization slurry led out from the vacuum flash evaporation and solidification device is injected into the desulfurization tower, so that the desulphurization efficiency is improved, and an ultra-clean discharging objective is achieved.

Owner:SHANDONG UNIV +2

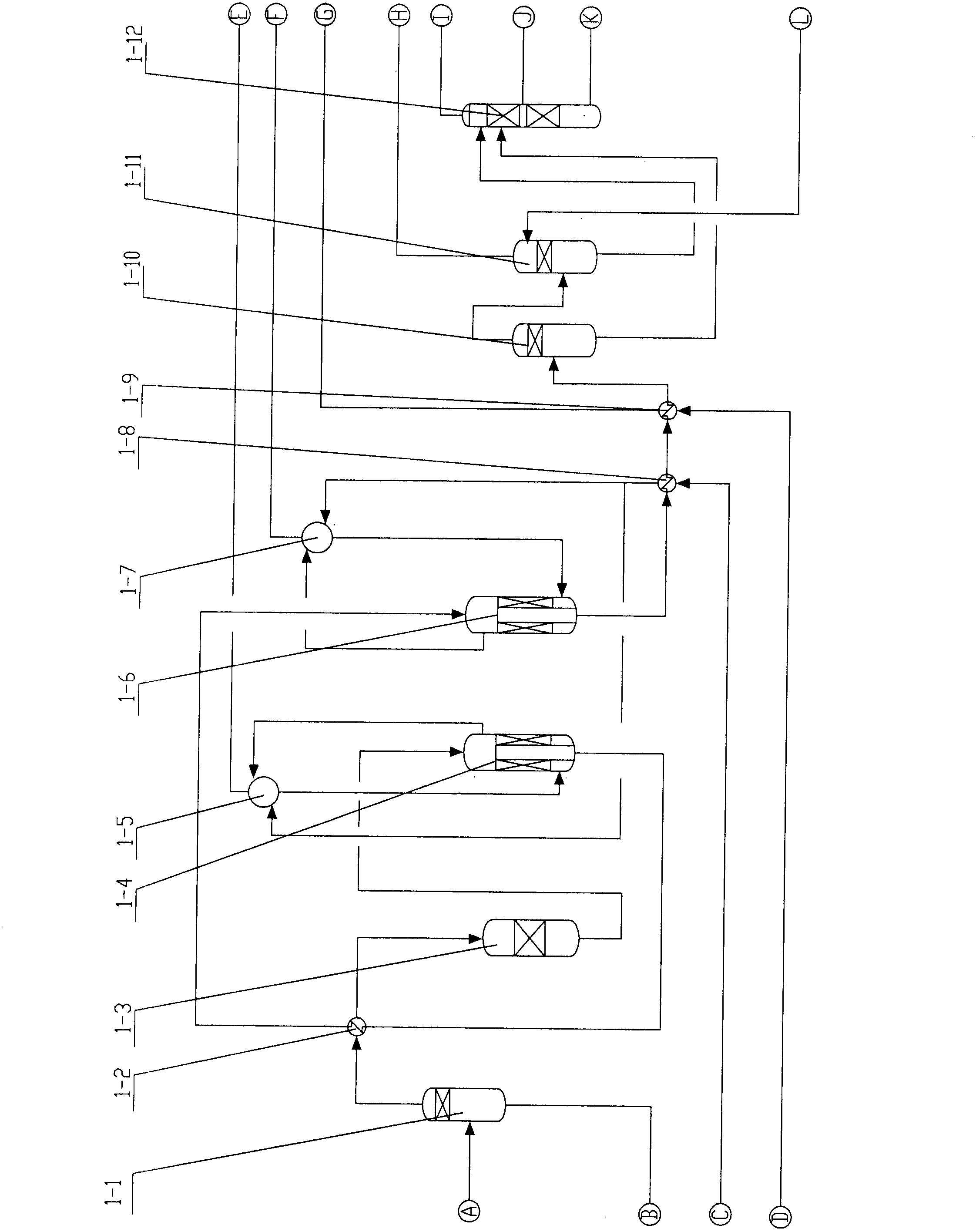

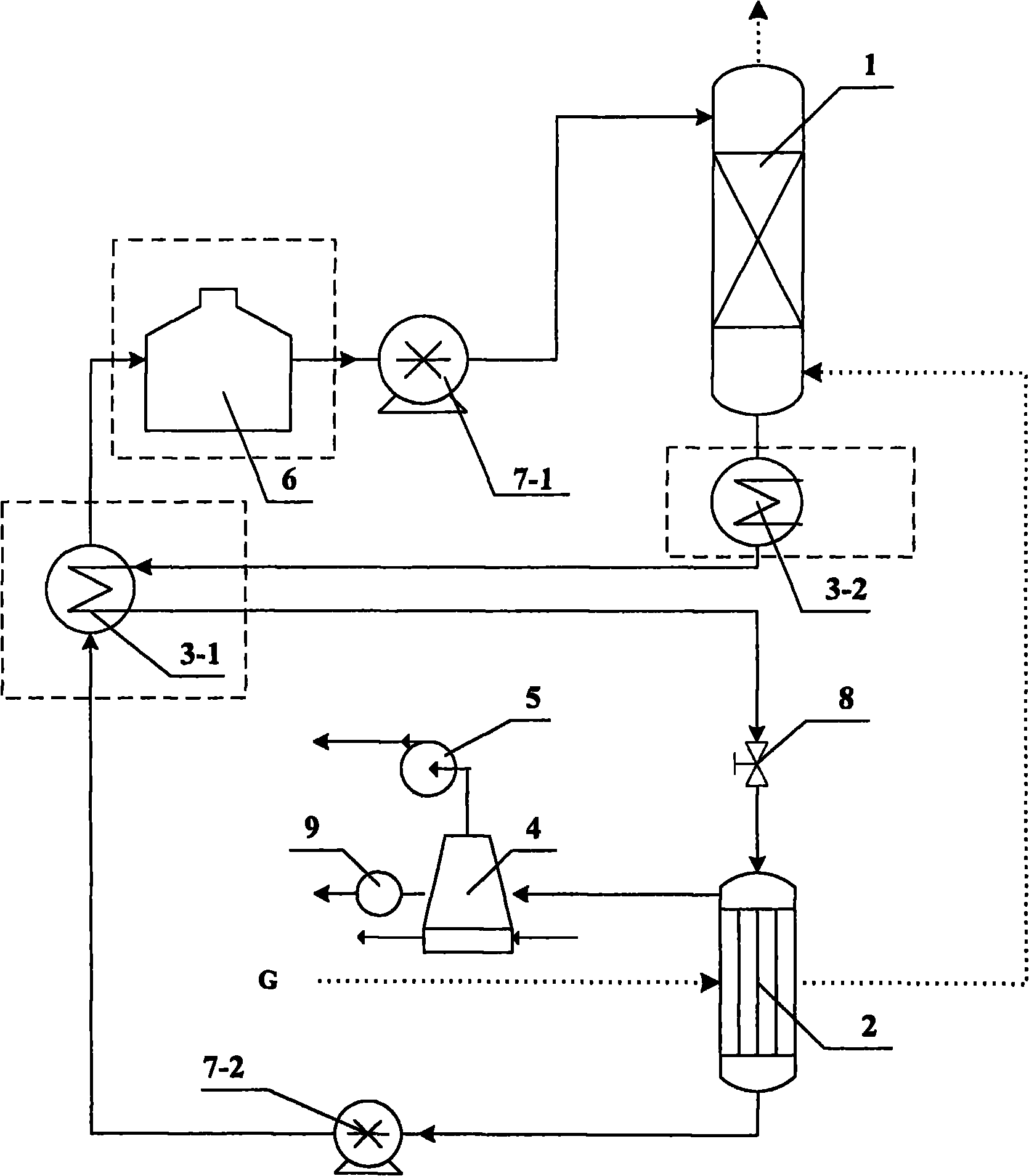

Water heat-transfer shift process for by-product high-grade steam energy-saving deep conversion

ActiveCN102701149AGuaranteed service lifeEliminate "dew point corrosion"HydrogenChemical recyclingComing outThermal energy

The invention relates to a water heat-transfer shift process for by-product high-grade steam energy-saving deep conversion. According to the process, a primary water heat-transfer shift converter and a secondary shift converter are adopted, CO in feed gas reacts with H2O to generate H2 and CO2 under the catalysis of a Co-Mo (copper-zinc) catalyst, and CO in shift gas coming out of a shift system is less than or equal to 0.1% (dry basis). In the process, CO is subject to deep conversion, the feed gas (containing water gas, semi-water gas, natural gas conversion gas or coke-oven gas conversion gas) utilization rate is high, the shift catalyst is not overheated, and the catalyst has a long service life; meanwhile, by-product saturated steam with the pressure of 0.5 to 9.0 MPa is generated, sensible heat and latent heat in the shift gas are further recovered by deoxygenated water and desalted water, low-grade heat energy is converted into high-grade heat energy, cooling water consumption is reduced, the temperature of` the shift gas coming out of a process system is lower than or equal to 40 DEG C, equipment is few, the flow is short, the investment is small, and the resistance is low (less than or equal to 0.05MPa).

Owner:NANJING DUNXIAN CHEM TECH

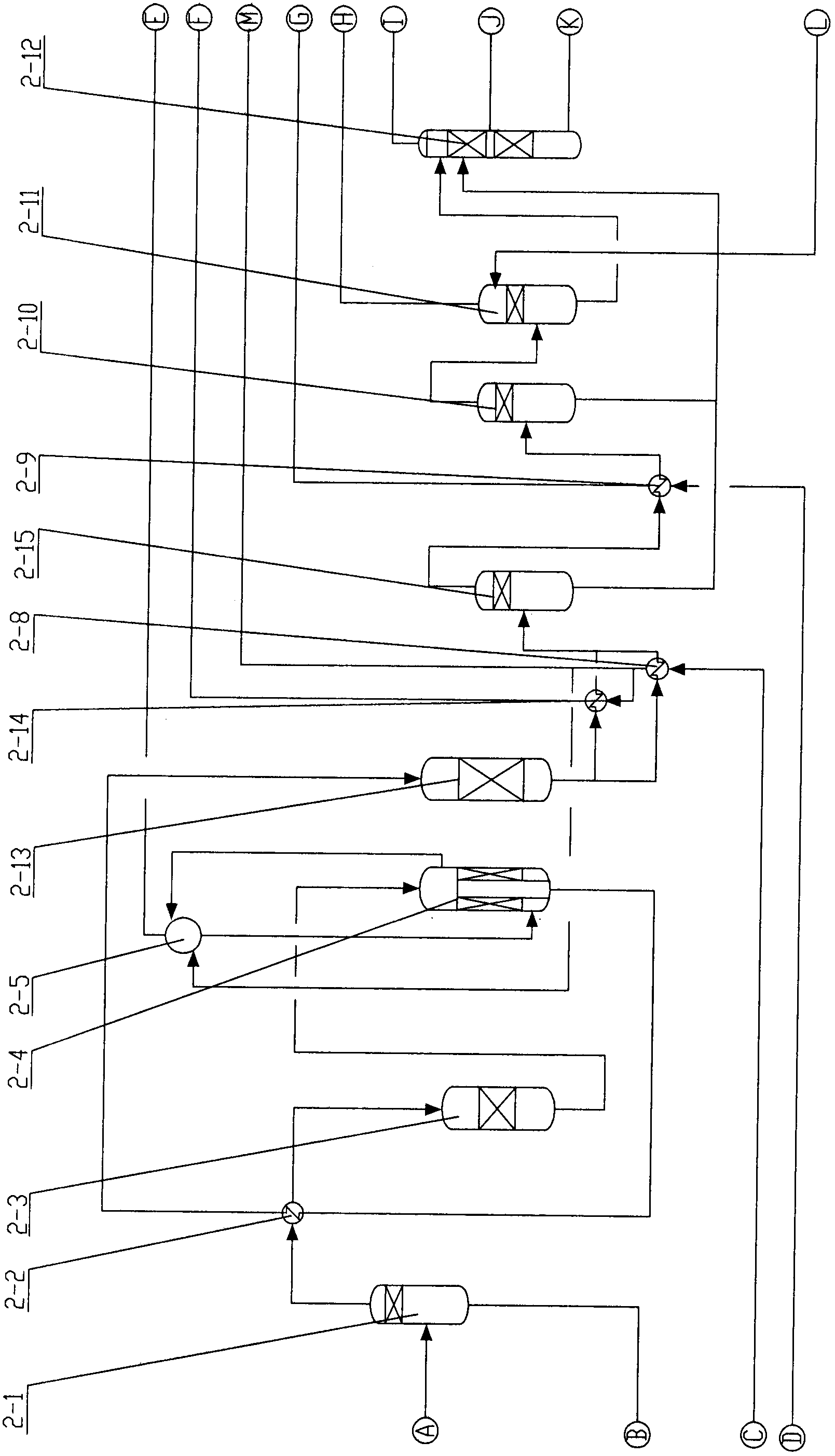

Mud drying system and use method thereof

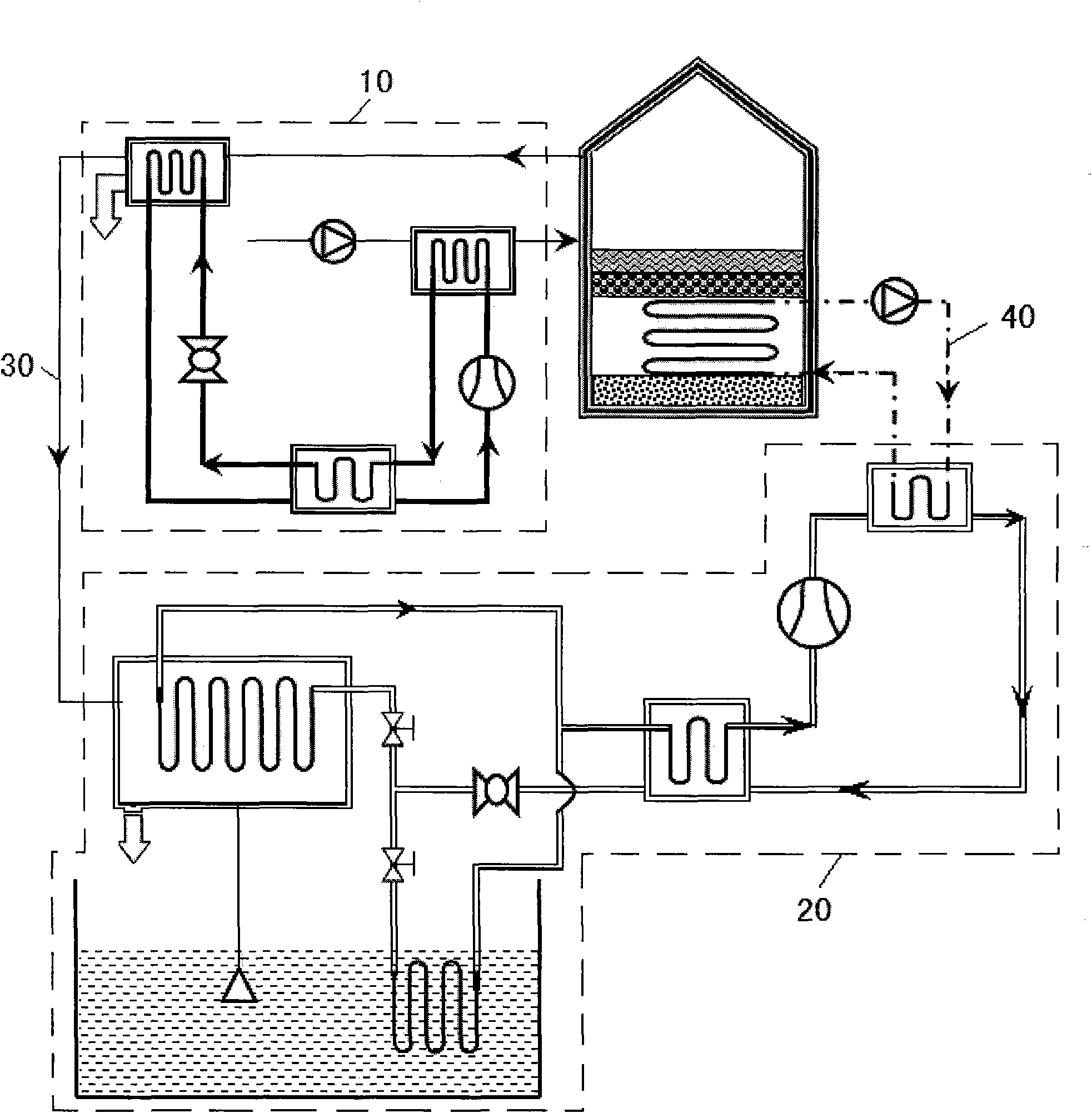

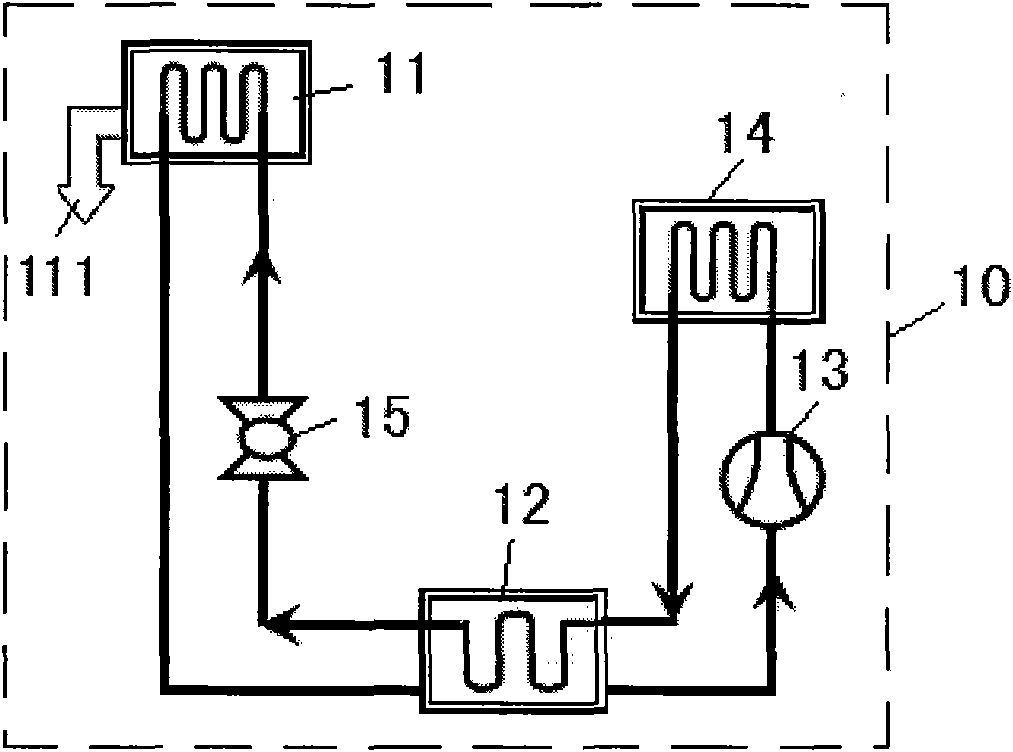

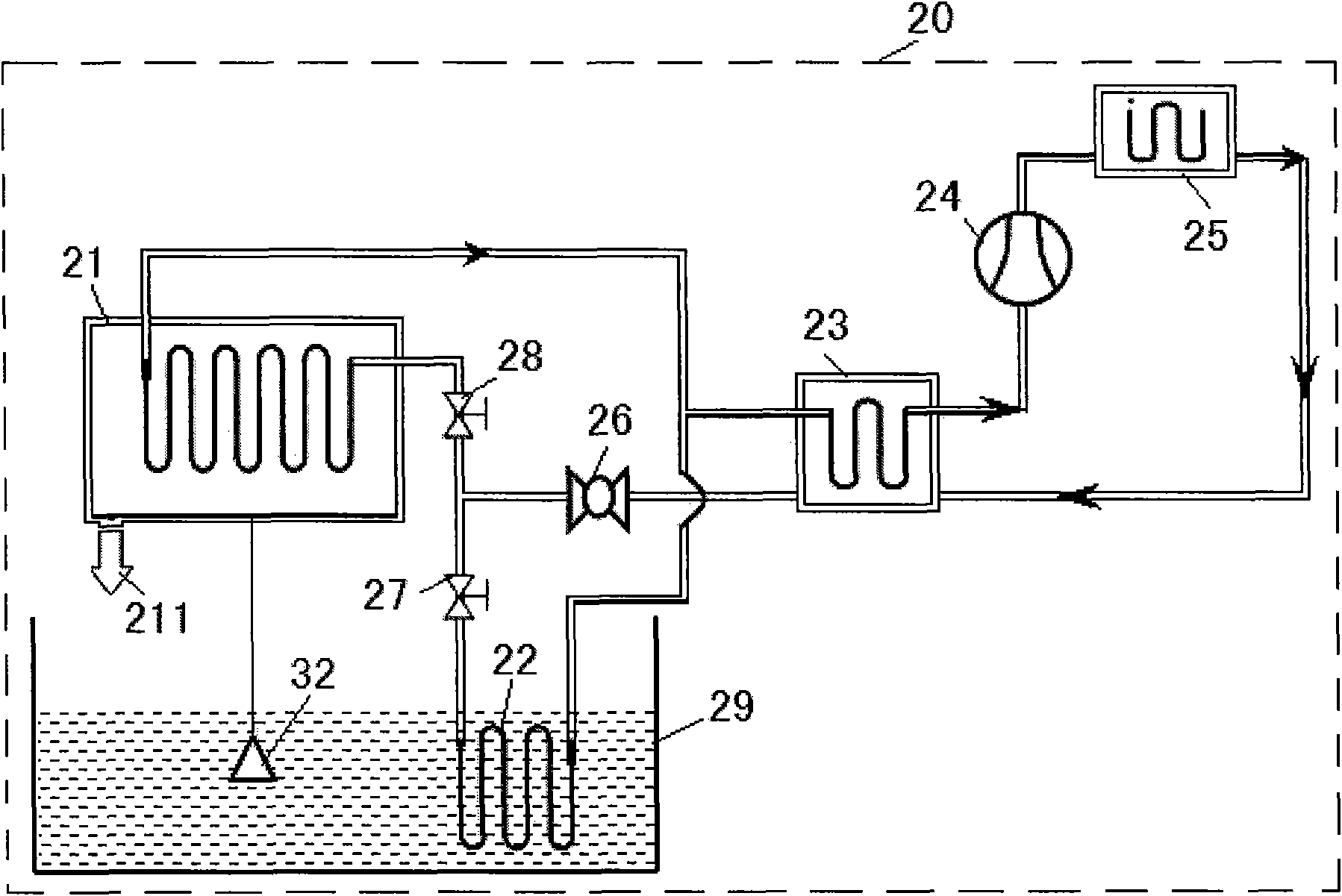

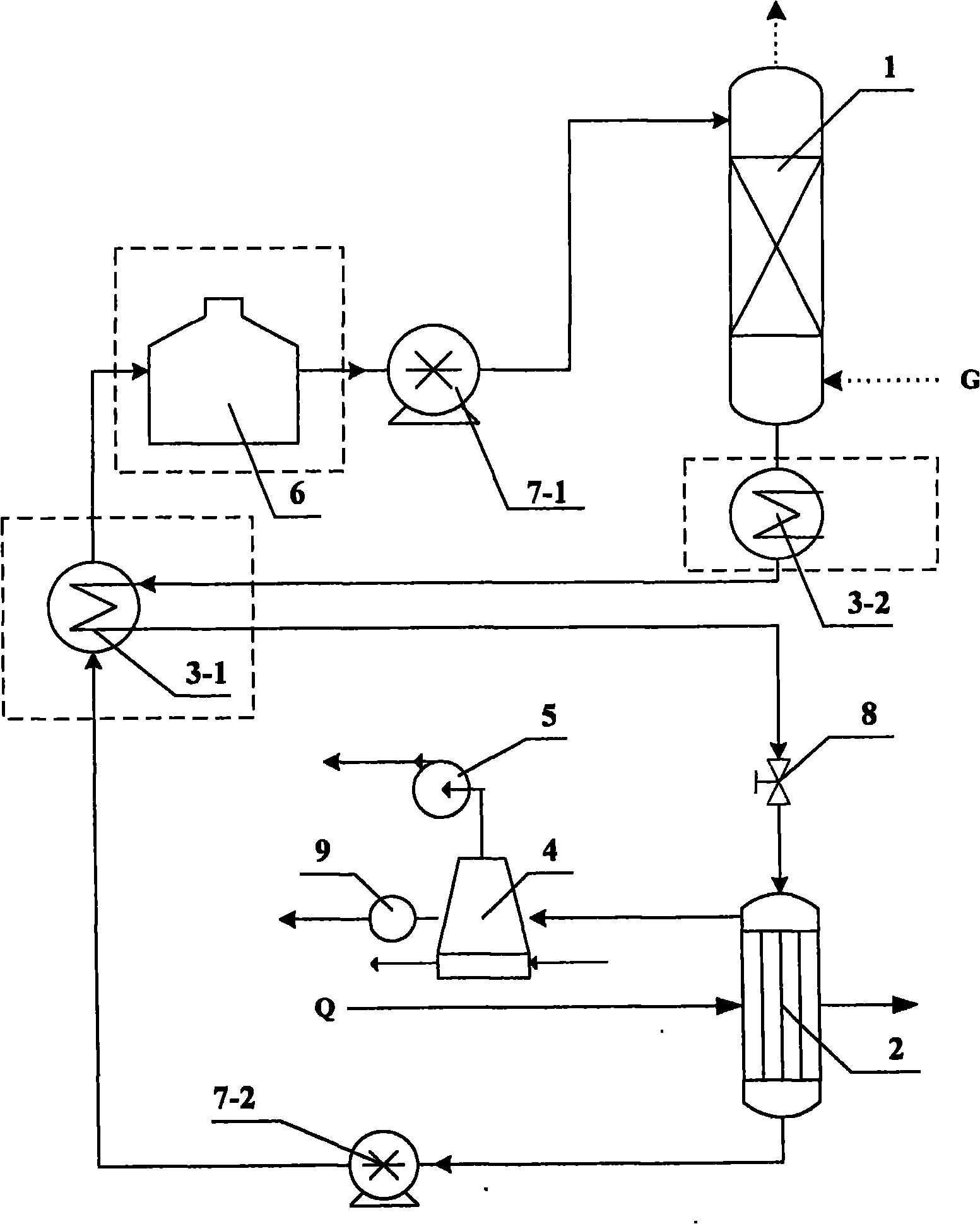

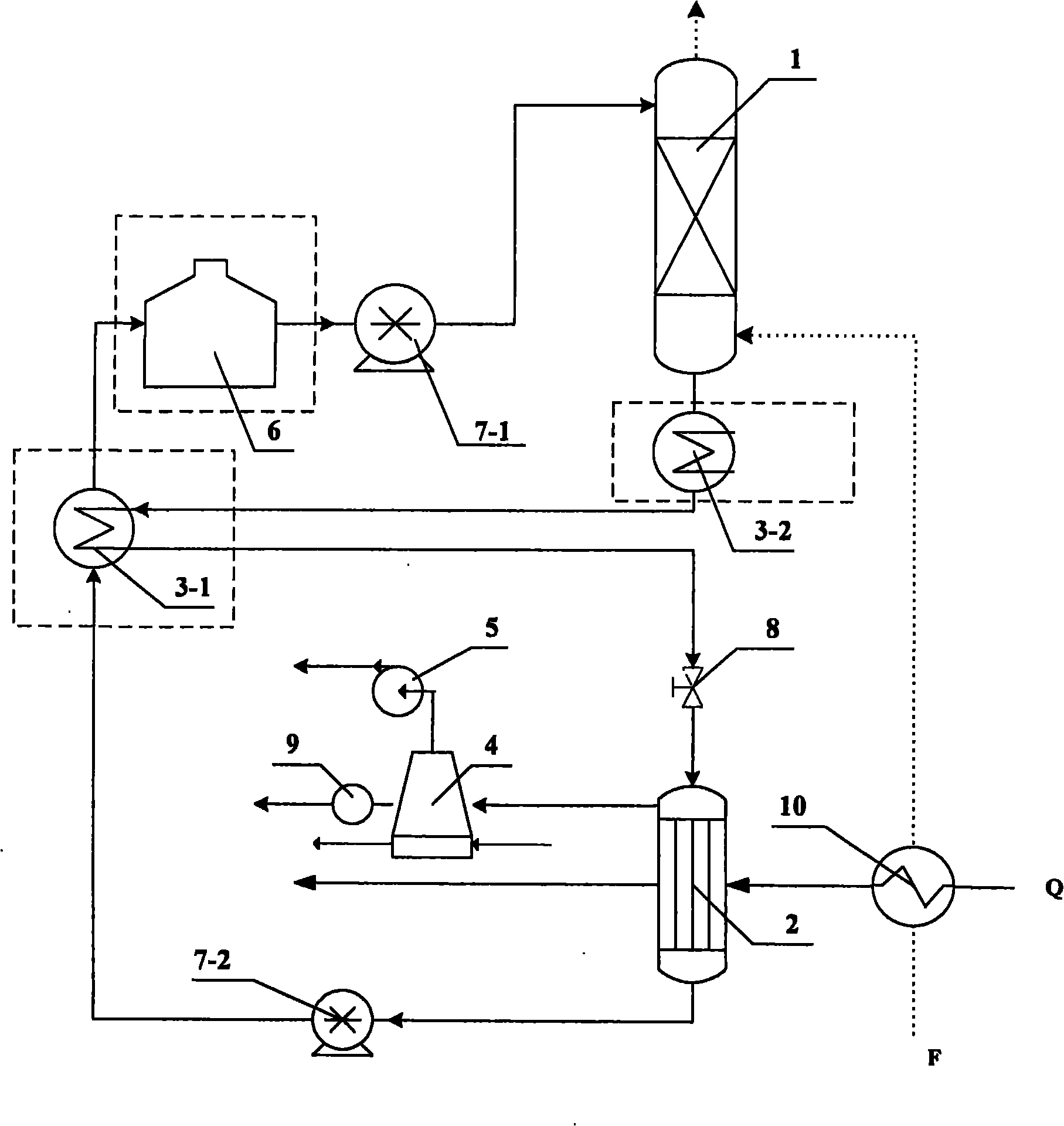

ActiveCN101618930AHigh drying yieldReduce drying energy consumptionSludge treatment by de-watering/drying/thickeningHeat pumpsSludgeWater circulation

The invention relates to a mud drying system and a use method thereof. The mud drying system comprises a transcritical heat pump auxiliary heat supplying loop, a heat pump auxiliary heat supplying loop, an air heating and waste heat recovering loop and a hot water circulation loop; the transcritical heat pump auxiliary heat supplying loop comprises an evaporator, an internal heat exchanger, a compressor, a gas cooler and a throttle valve; the heat pump auxiliary heat supplying loop comprises an evaporator, a wastewater and waste heat recovering evaporator, an internal heat exchanger, a compressor, a condenser, a throttle valve, two stop valves and a wastewater tank; the air heating and waste heat recovering loop comprises a hothouse, an air compressor, a gas discharging and carrying port, a first evaporator, the other evaporator and a condenser; and the hot water circulation loop comprises a pump, a hothouse and the condenser in the heat pump auxiliary heat supplying loop. The invention adopts the hothouses to obtain solar energy to heat mud and utilizes the transcritical heat pump auxiliary heat supplying loop and the heat pump auxiliary heat supplying loop to recover the sensible heat and the latent heat in humid air to heat mud, thereby lowering the energy consumption for drying the mud. The invention can be widely applied to various mud processing fields.

Owner:TSINGHUA UNIV +3

Method for simultaneously recovering water and latent heat in high-humidity flue gas and heat pump device

InactiveCN101922821AOptimizing Process ParametersLow costClimate change adaptationEnergy efficient heating/coolingHigh humidityFlue gas

The invention discloses a method for simultaneously recovering water and latent heat in high-humidity flue gas and a heat pump device, relating to the technique of energy-saving equipment. A heat exchanger is arranged in an absorber of the heat pump device, the top of the absorber is provided with a flue gas discharging pipe, the bottom of the absorber is provided with a dilute solution outlet, the side surface of the bottom is provided with a gas inlet pipe, the side surface of the top is provided with a concentrated solution inlet, and a concentrated solution pipeline is communicated with a spray head at the inner upper part of a cavity; the top of a regenerator is provided with a dilute solution inlet, the bottom of the regenerator is provided with a concentrated solution pipeline outlet, a gas-liquid heat exchanger is arranged in the regenerator, and an inlet and an outlet of the gas-liquid heat exchanger are communicated with a flue gas pipe; the flue gas pipe is communicated with the gas inlet pipe at the bottom of the absorber after passing through the regenerator; the bottom of the absorber is communicated with the regenerator through a dilute solution pipeline, in which a regulating valve is arranged; and the regenerator runs under negative pressure, and the bottom of the regenerator is communicated with the absorber through the concentrated solution pipeline, in which a solution pump is arranged. The method and the device directly recover the water and the latent heat in the flue gas and have the advantages of equipment simplification, better energy saving, environmental protection and economic benefit.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

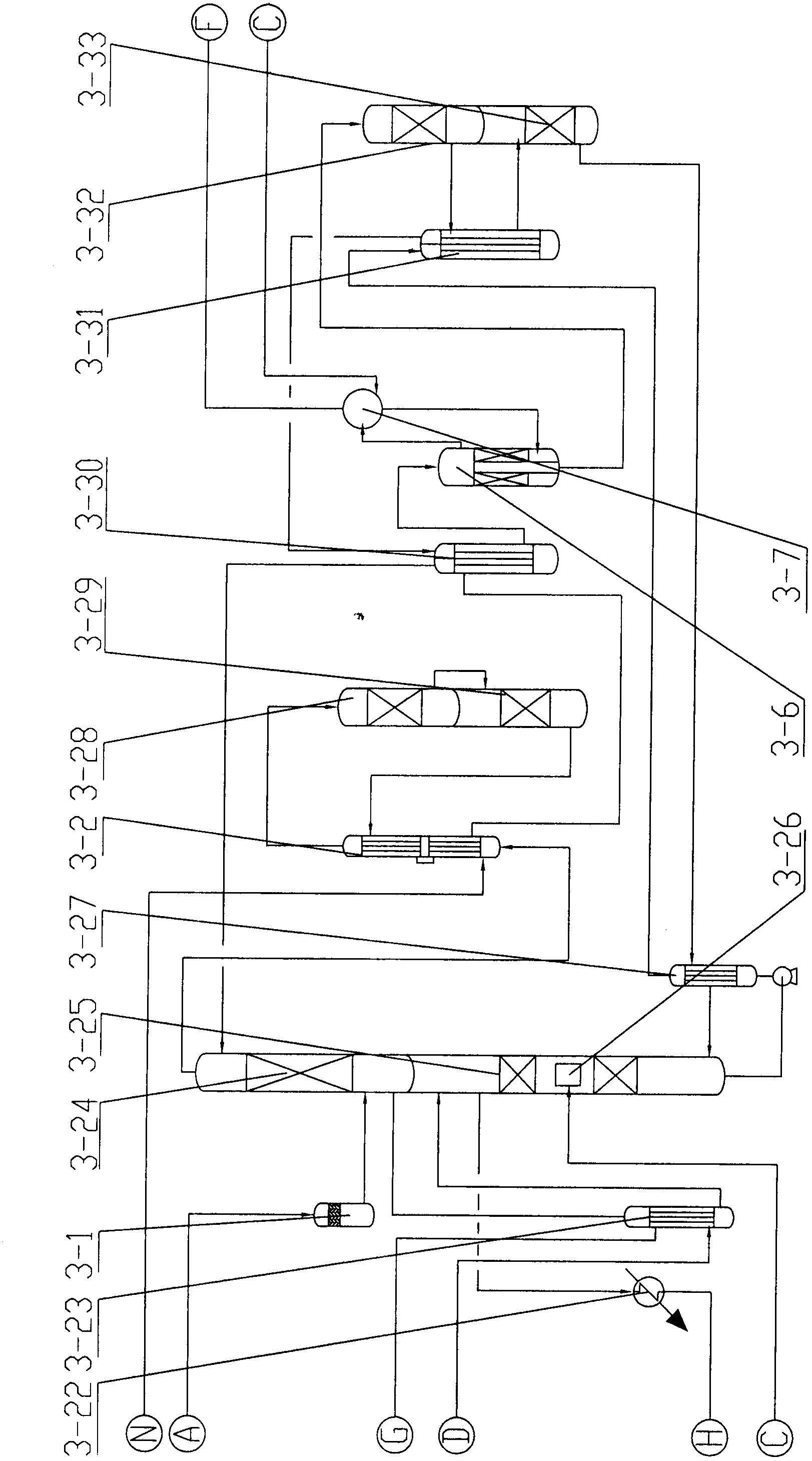

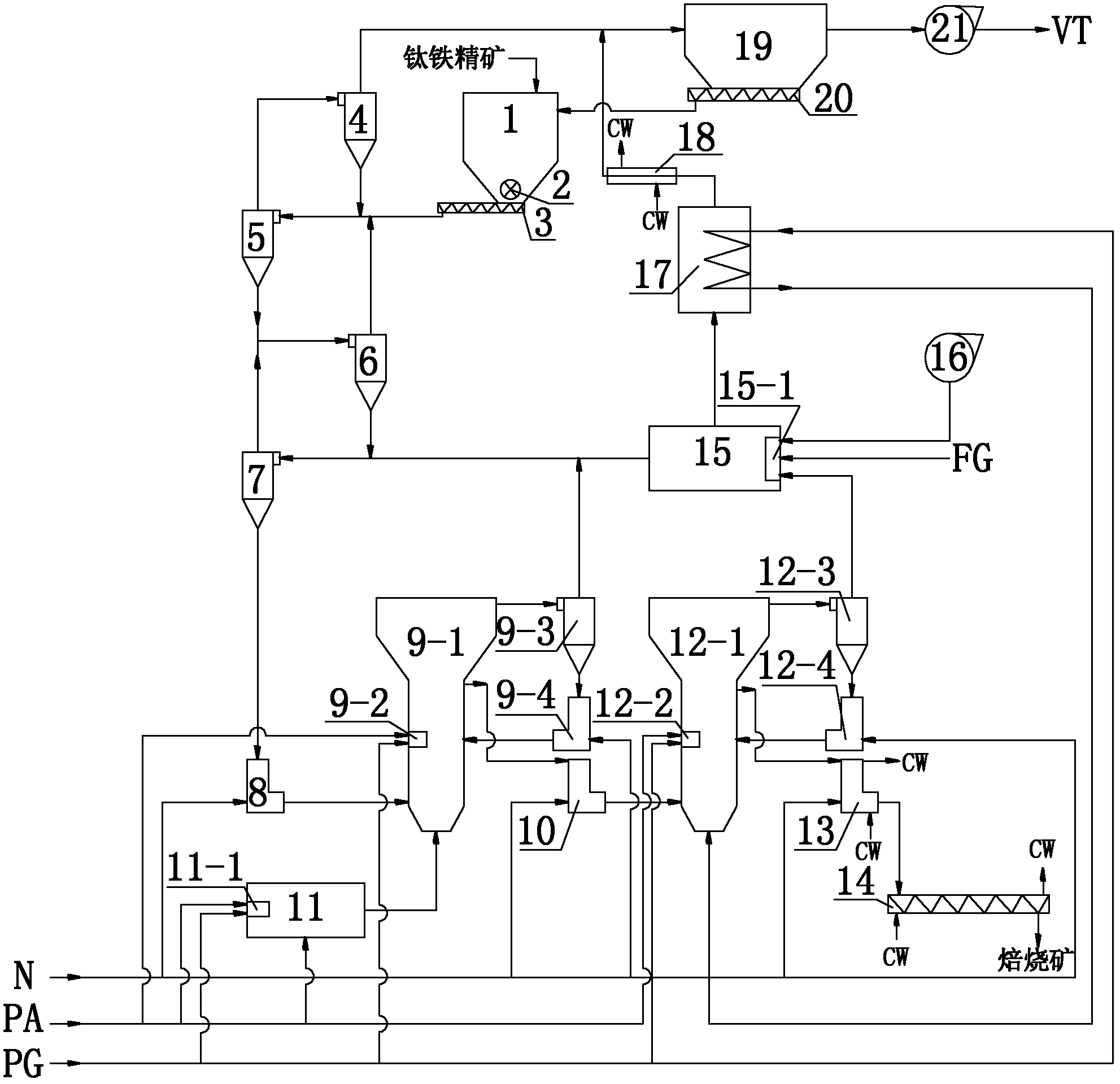

System for fluidized oxidizing/reducing roasting modification of titaniferous iron concentrate and roasting process

The invention discloses a system for fluidized oxidizing / reducing roasting modification of titaniferous iron concentrate and a roasting process. A fluidized bed oxidation reactor is adopted for the oxidizing roasting of titaniferous iron concentrate powder, and fluidized air is preheated by a hot blast heater and mineral powder is preheated by a multistage cyclone preheater so as to provide heat for oxidizing roasting; the oxidized mineral powder enters the fluidized bed reduction reactor for reducing roasting, and heat is provided for the reducing roasting through heating coal gas by a coal gas preheater; and latent heat of unreacted reducing gas in roasting tail gas of the reduction reactor is firstly released through combustion in a combustion chamber, one path of hot flue gas after the combustion is mixed with the tail gas of the oxidation reactor and then enters the multistage cyclone preheater to exchange heat with the cold titaniferous iron concentrate powder, heat is recycled while the titaniferous iron concentrate is preheated, and the other path of hot flue gas is used for preheating cold coal gas to warm the fluidized coal gas entering a reducing furnace so as to strengthen a reducing condition. The system has the advantages of high oxidizing / reducing efficiency, high heat utilization efficiency in a roasting process and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Phase-change constant-temperature material and pad body

The invention relates to a phase-change material, in particular relating to a phase-change constant-temperature material. The invention also relates to a pad body, in particular relating to a pad body containing the phase-change constant-temperature material. The phase-change material can ensure constant temperature within a certain period of time, is large in latent heat and stable in property, and can be repeatedly used. The phase-change material is fine and smooth like sand as compared with the original phase-change material. The phase-change material is prepared through the following steps: evenly mixing 16wt%-20wt% of water, 1wt% of thickener, 3wt%-4wt% of nucleating agent and 1wt% of dispersing agent, so that the mixture is of a uniform thickness shape; adding 75wt%-78wt% of mirabilite; and evenly mixing so that the components are evenly dispersed. The phase-change material can be added in the pad body to serve as a cold-hot bag, and insulation is durable. The pad body containing the phase-change material consists of small grids which are of strip shapes, the grids are tightly distributed, and a pouring material port is reserved on each grid and used for pouring the phase-change material.

Owner:JIANGSU YISHUN MEDICAL DEVICES CO LTD

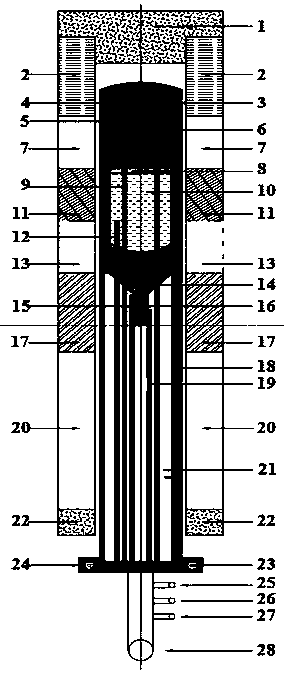

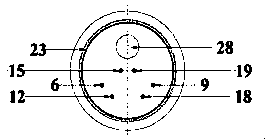

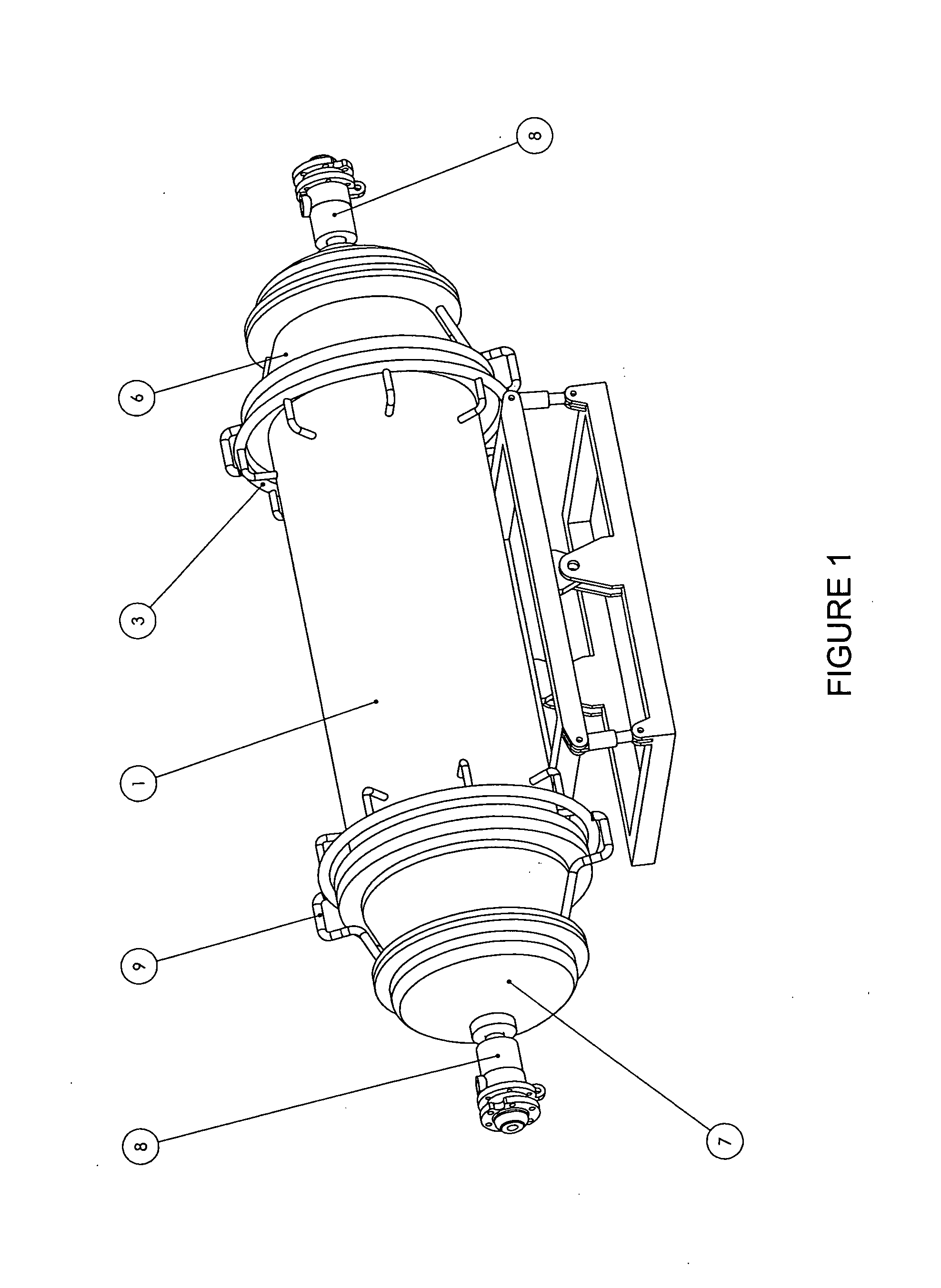

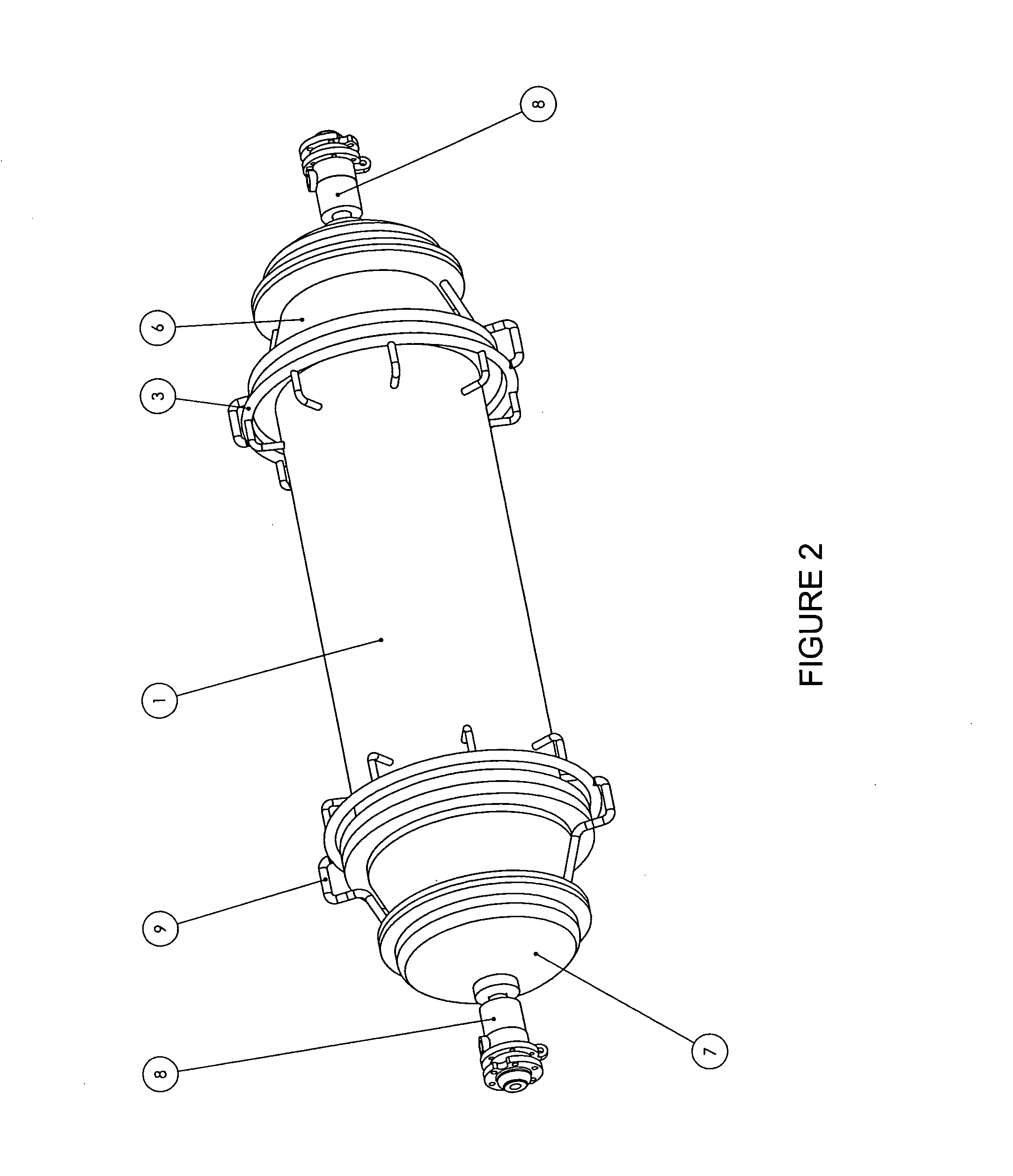

VGF/VB gallium arsenide single-crystal furnace structure and growing method

InactiveCN109252220AIncreased crystallization latent heat releaseIncrease crystallization ratePolycrystalline material growthFrom frozen solutionsSingle crystalMaximum size

The invention discloses a VGF / VB gallium arsenide single-crystal furnace structure and a growing method. According to the VGF / VB gallium arsenide single-crystal furnace structure, a resistance heatingfurnace which is relatively lowest in production cost and is provided with multiple temperature zones is adopted; a support structure adopts graphite; the support strength is improved; the loading amount is favorably increased; release of latent heat of growth crystallization is facilitated; the crystal yield of crystal growth is favorably improved; a sealing structure with a reusable quartz tubeand a stainless steel flange is adopted; a 1-atm air charging and discharging automatic valve is additionally arranged on an air channel pipeline, so that the balance of inner air pressure and outerair pressure of the quartz tube can be effectively guaranteed, and the influence of deformation of the quartz tube on reuse is avoided. A VGF method and a VB method are used for growing crystals; whenthe crystals are grown by the VB method, the sunken degree of a concave solid-liquid interface of the VGF growth method can be improved, so that the crystal yield is favorably improved. The single-crystal furnace and the growth method are used for growing the gallium arsenide single crystals with maximum size of 8 inches; meanwhile, the quartz tube can be reused, so that the production cost can be reduced; a CO atmosphere doping manner also can be used for controlling the resistivity and the axial resistivity uniformity of semi-insulating gallium arsenide.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

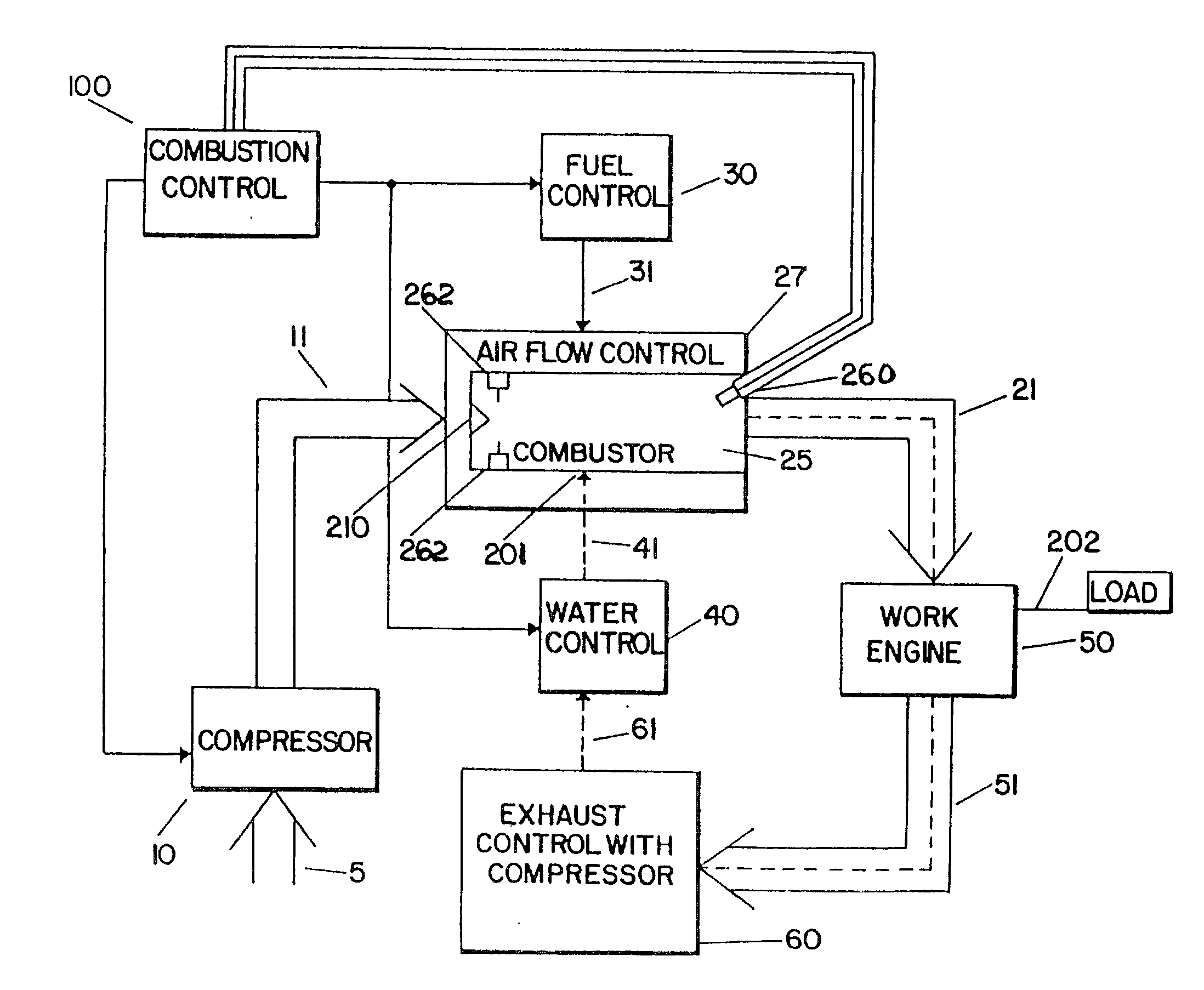

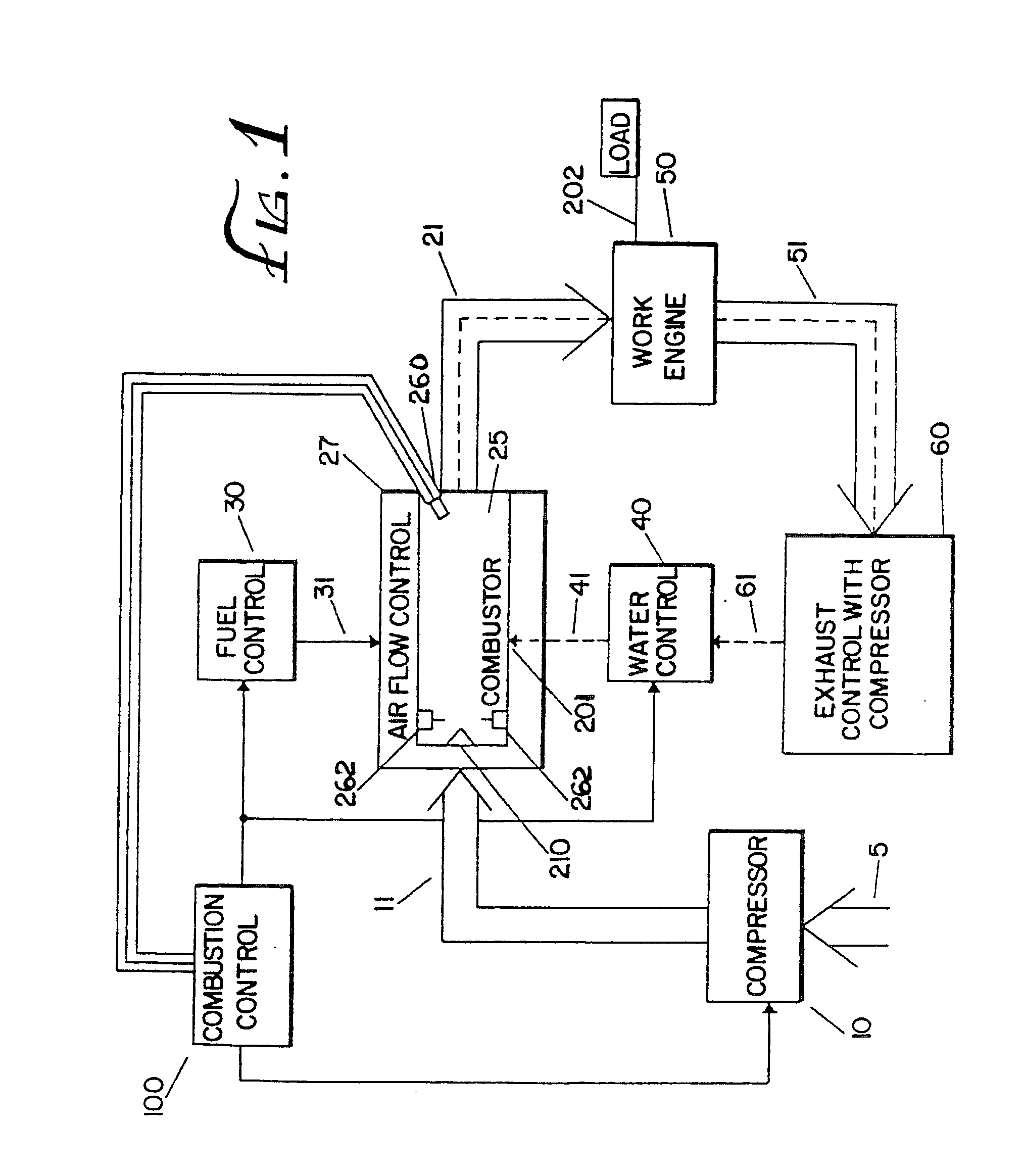

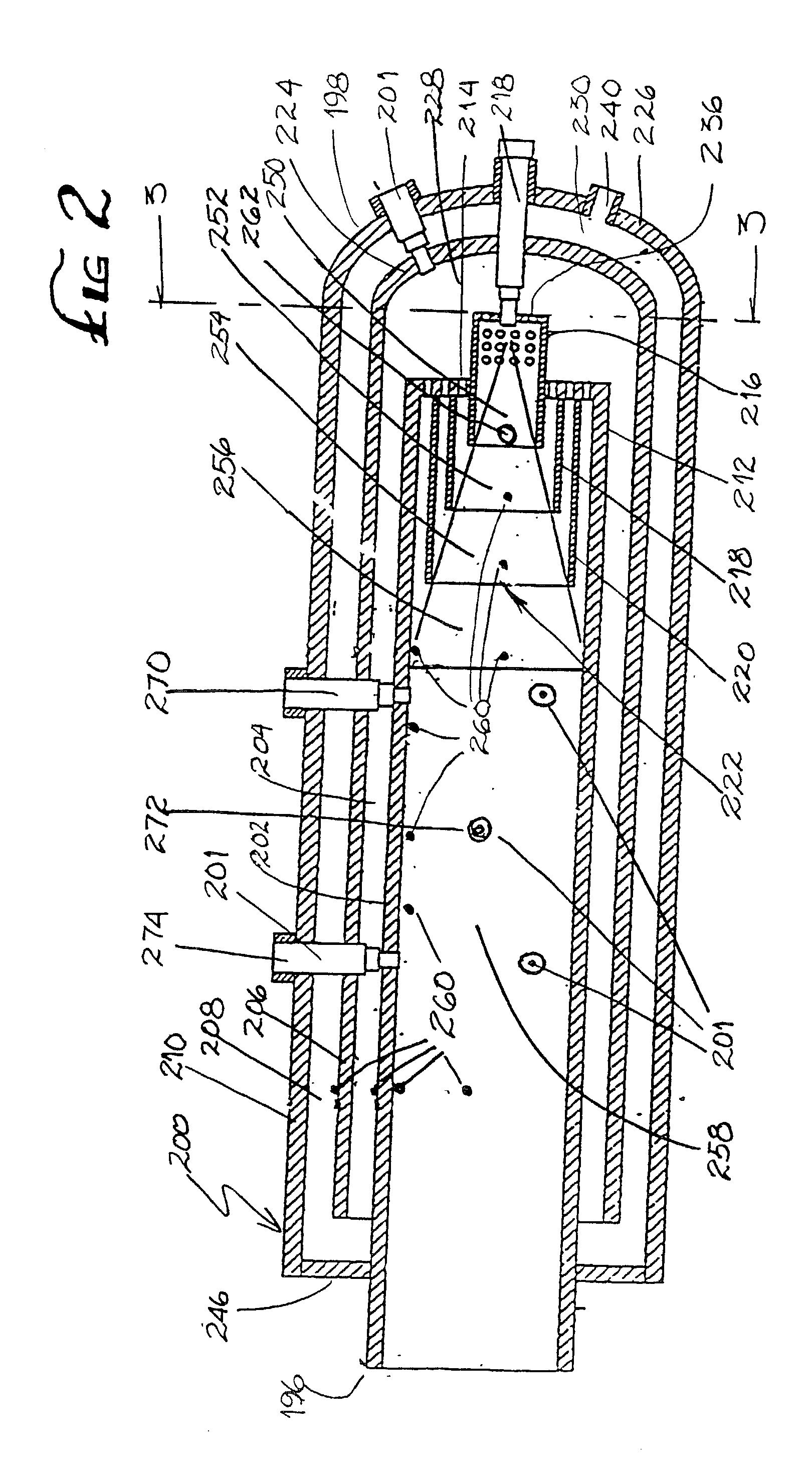

High efficiency low pollution hybrid brayton cycle combustor

InactiveUS20030014959A1Efficient and clean and pollution free powerIncrease horsepowerGas turbine plantsEfficient propulsion technologiesHybrid typeCombustion chamber

A power generating system and method operating at high pressure and utilizing a working fluid consisting of a mixture of compressed non-flammable air components, fuel combustion products and steam. The working fluid is substantially free of CO and NO.sub.x. Fuel and compressed air at an elevated temperature and at a constant pressure are delivered to a combustion chamber, the amount of air being chosen so that at least about 90% of the oxygen in the air is consumed during combustion. The quantity of air and fuel supplied to the combustion chamber may be varied provided a constant fuel to air ratio is maintained. Superheated water is delivered under pressure to the combustion chamber, and is converted substantially instantaneously to steam. The quantity of water delivered is controlled such that the latent heat of vaporization of the water maintains the temperature of the working fluid at a desired level. Heat may be transferred from the working fluid exiting the work engine to the water to heat the water to the desired temperature for delivery to the combustion chamber. The quantity, temperature and pressure of the air, fuel and water introduced in to the combustion chamber are independently controllable. A zoned burner may be employed in which a portion of the compressed air may be mixed with the fuel in a first zone prior to ignition, with the remaining compressed air being added at one or more locations downstream of the point of ignition.

Owner:GINTER J LYELL

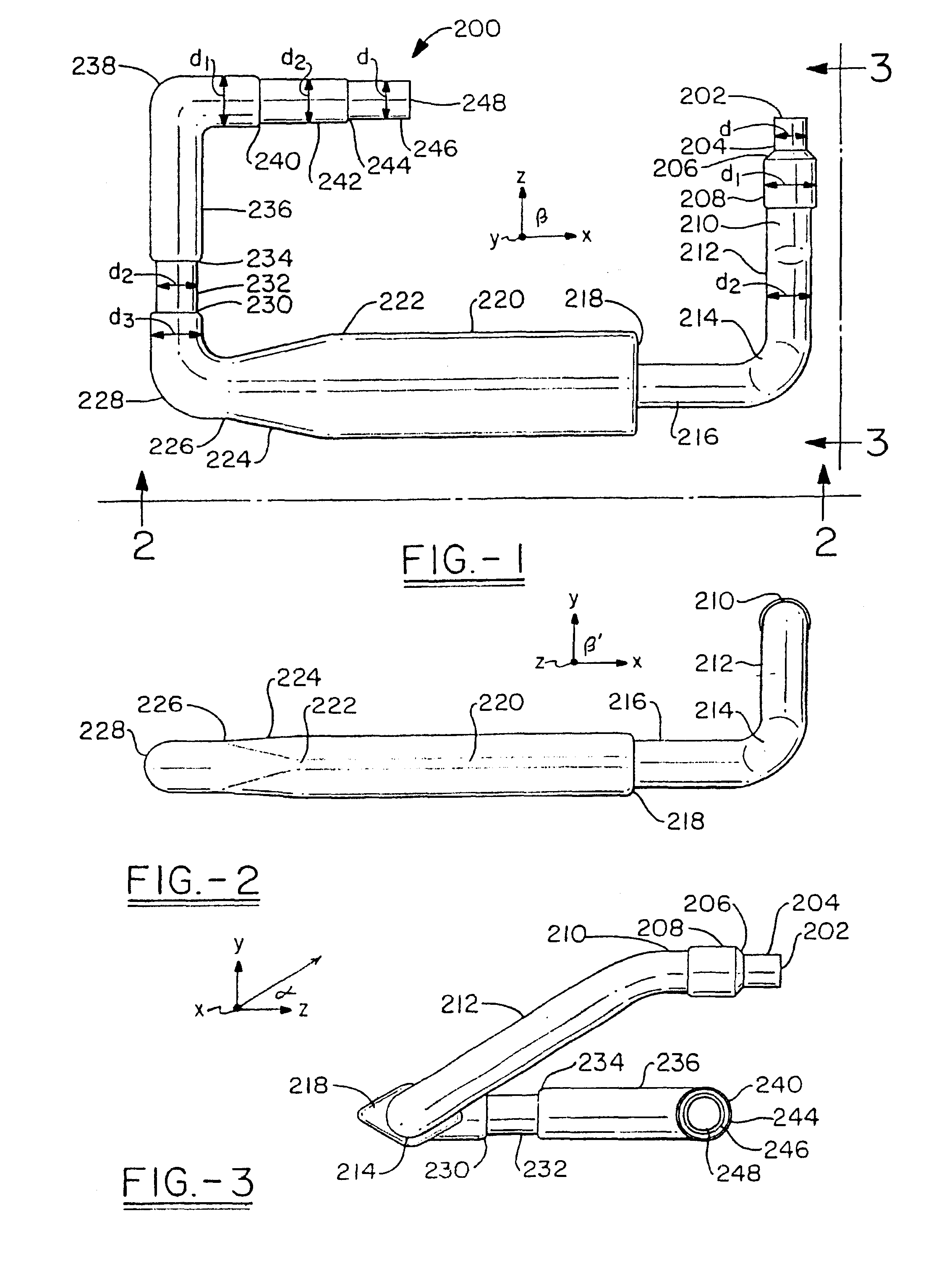

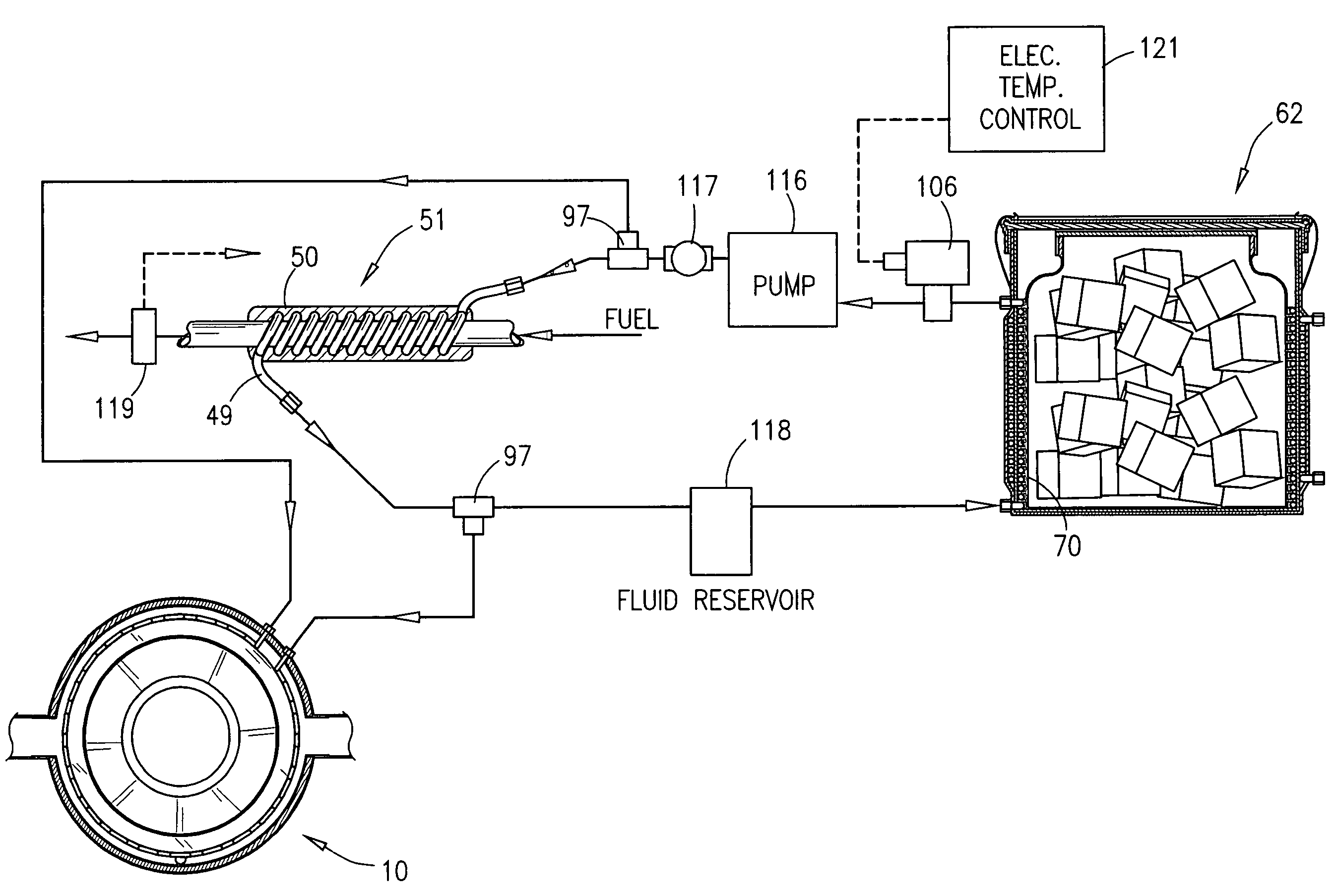

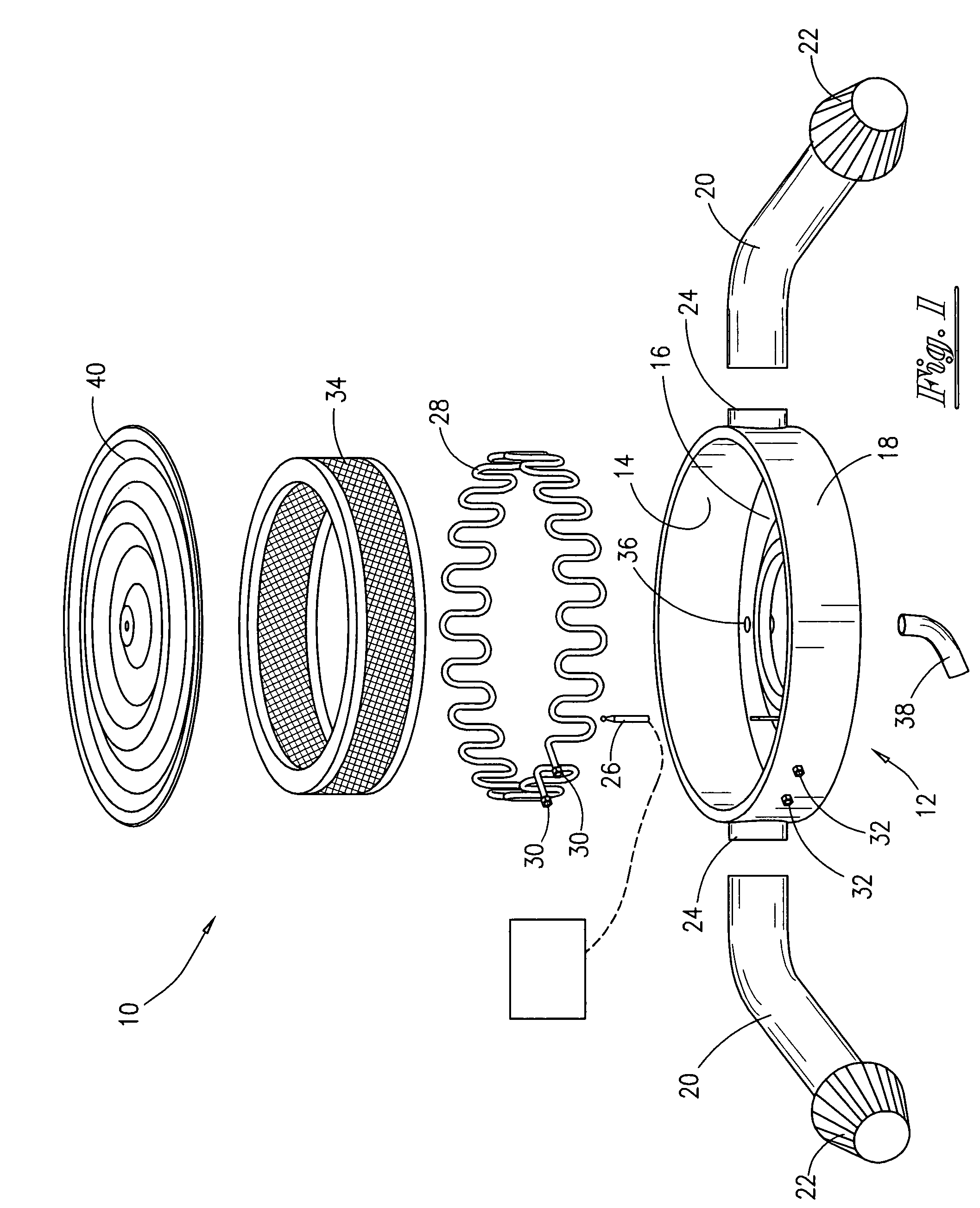

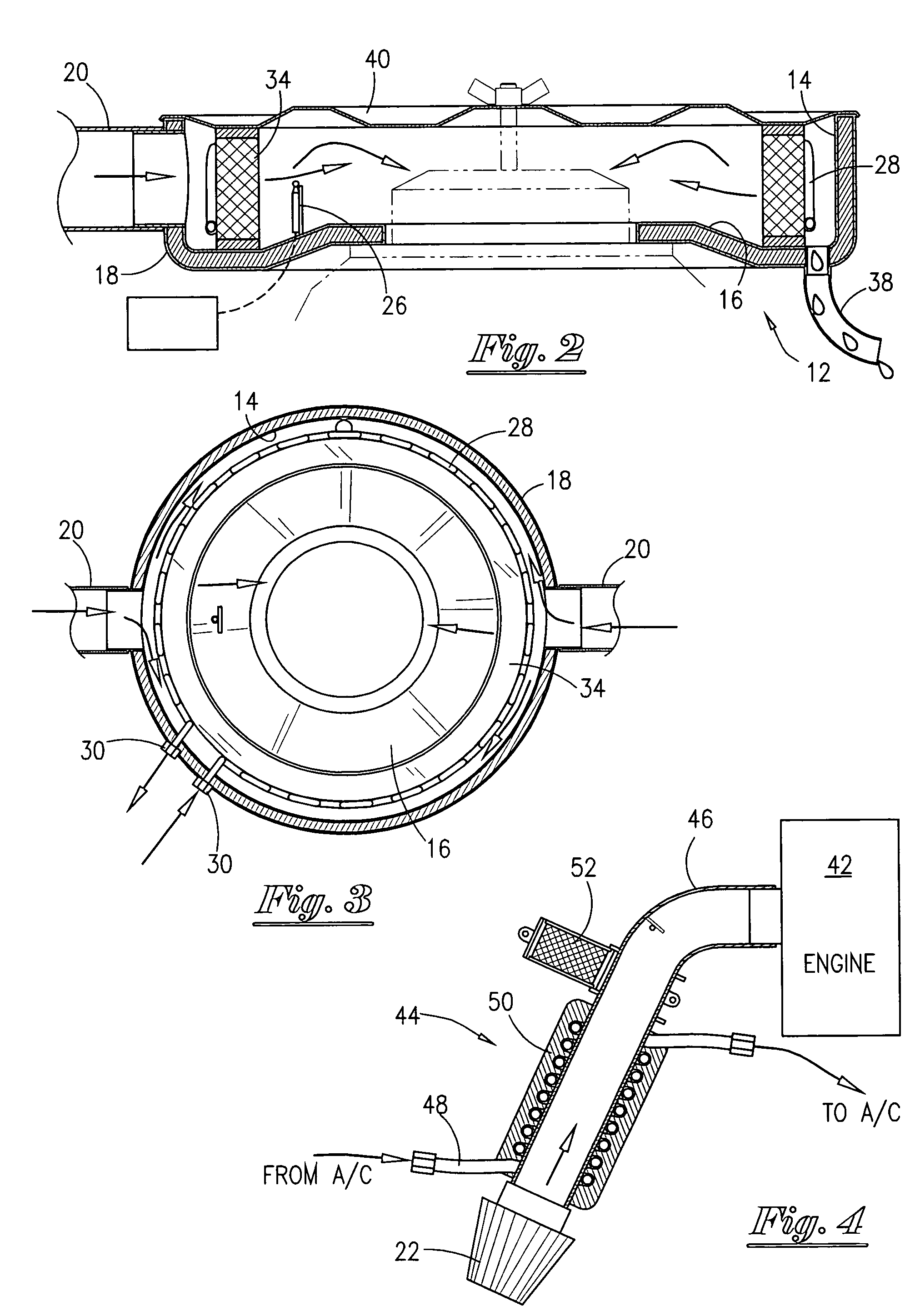

Engine air intake and fuel chilling system and method

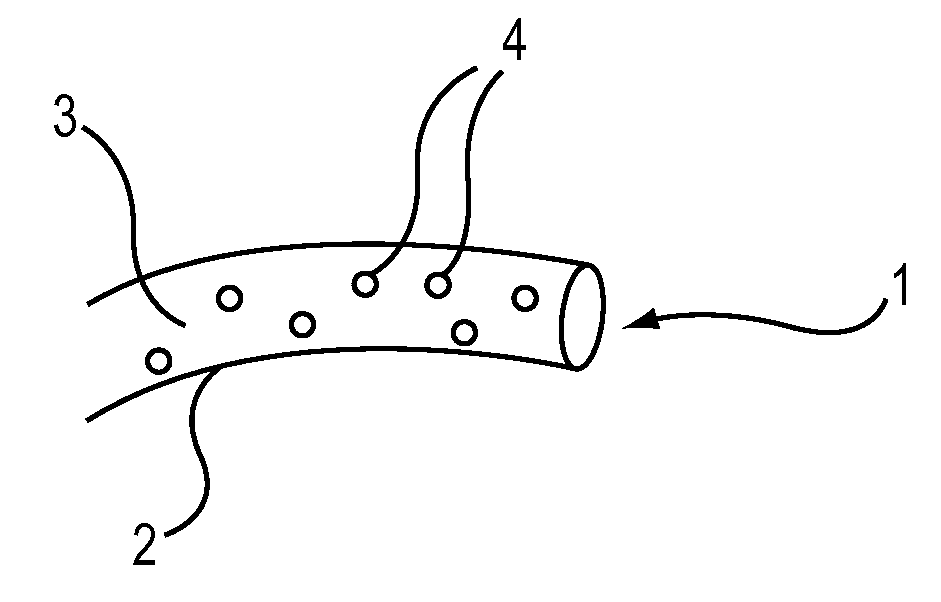

InactiveUS7658183B1Eliminate latent heatReduce the temperatureInternal combustion piston enginesThermal treatment of fuelRefrigerated temperatureControl system

A combustion engine intake air cooler system is disclosed that utilizes the vehicle air conditioning system to chill the engine intake air supply by conducting latent heat from the intake air passing through the intake air ducts using an external tubular induction coil in contact with and surrounding the air intake duct and connected to the vehicle air conditioning refrigeration system. Other embodiments include a refrigeration conduction coil located within a sealed and insulated, carburetor air breather and a refrigeration conduction coil in contact with the engine fuel line. An on board refrigerator using dry ice is also disclosed as a refrigeration system for the conduction coils when no vehicle air conditioning system is available. An intake air temperature sensing and control system is also provided.

Owner:SUPERCOOLER

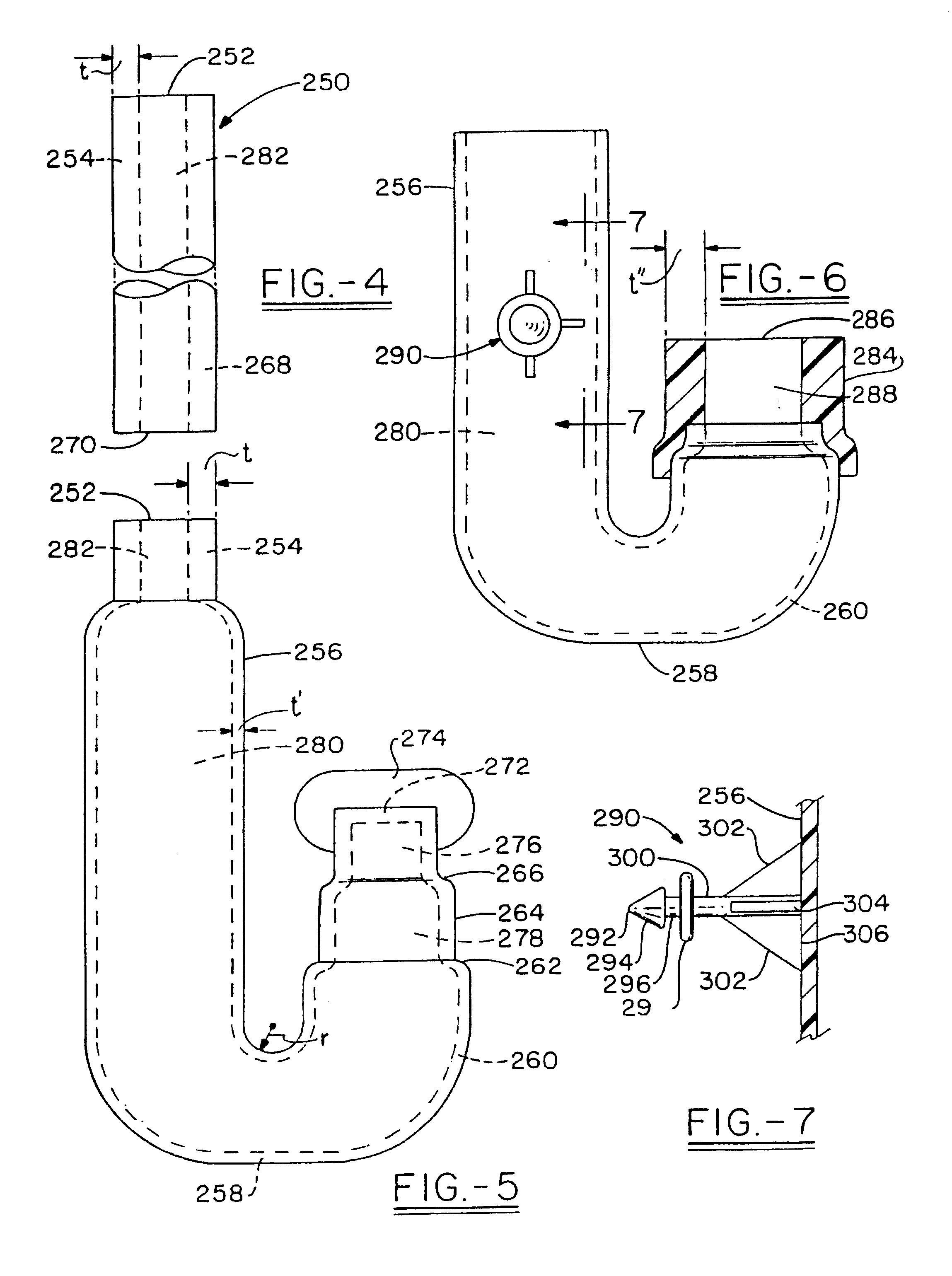

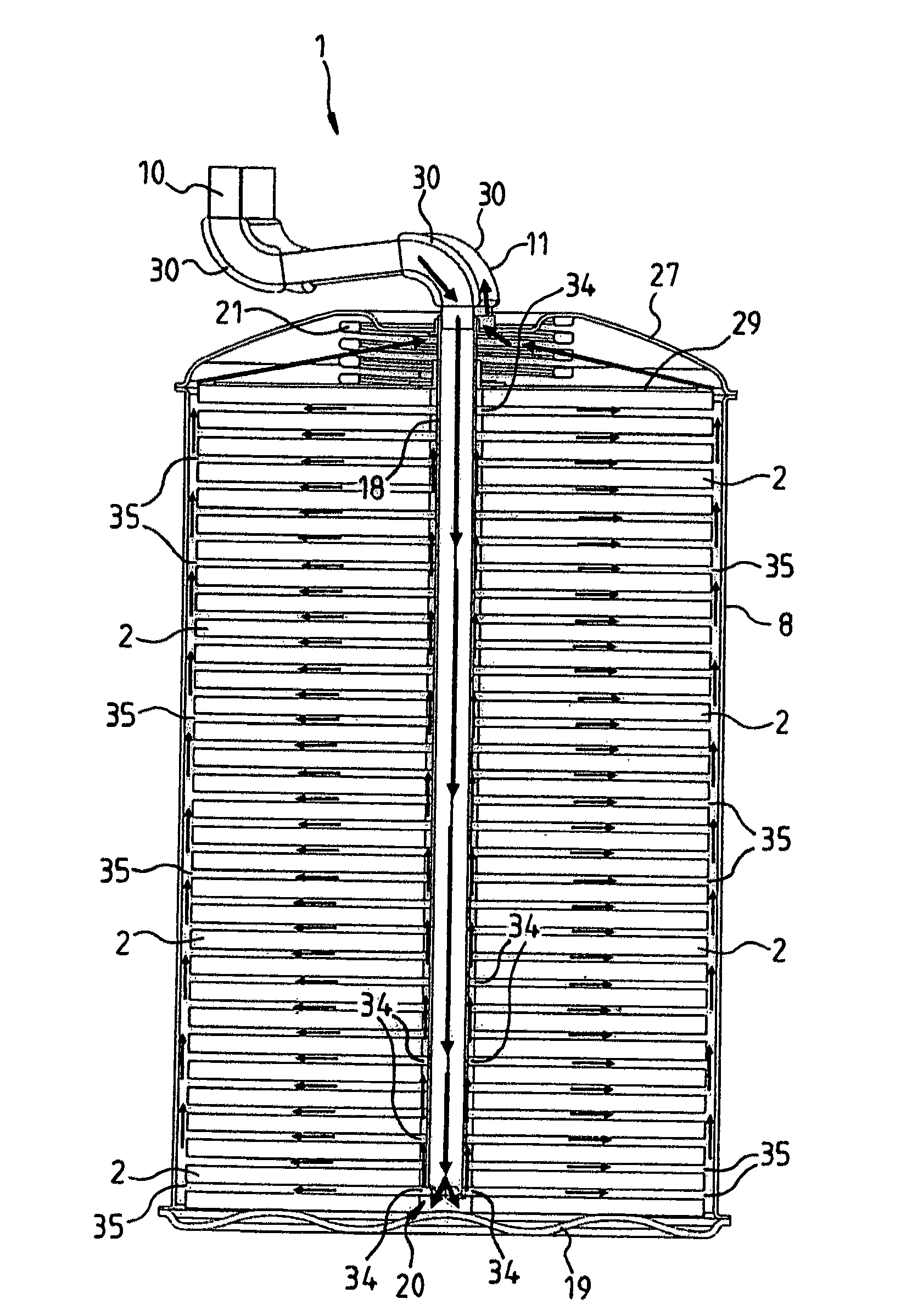

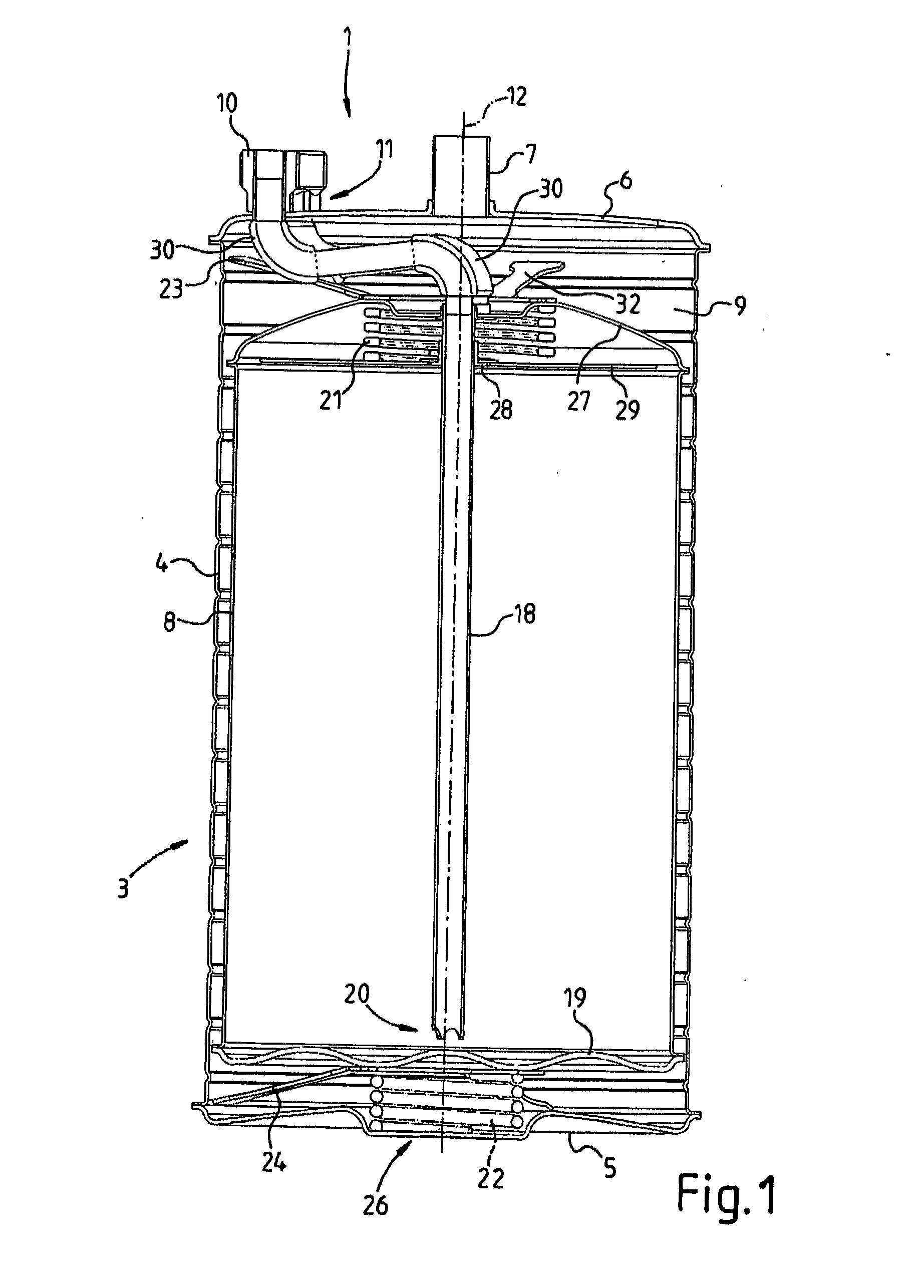

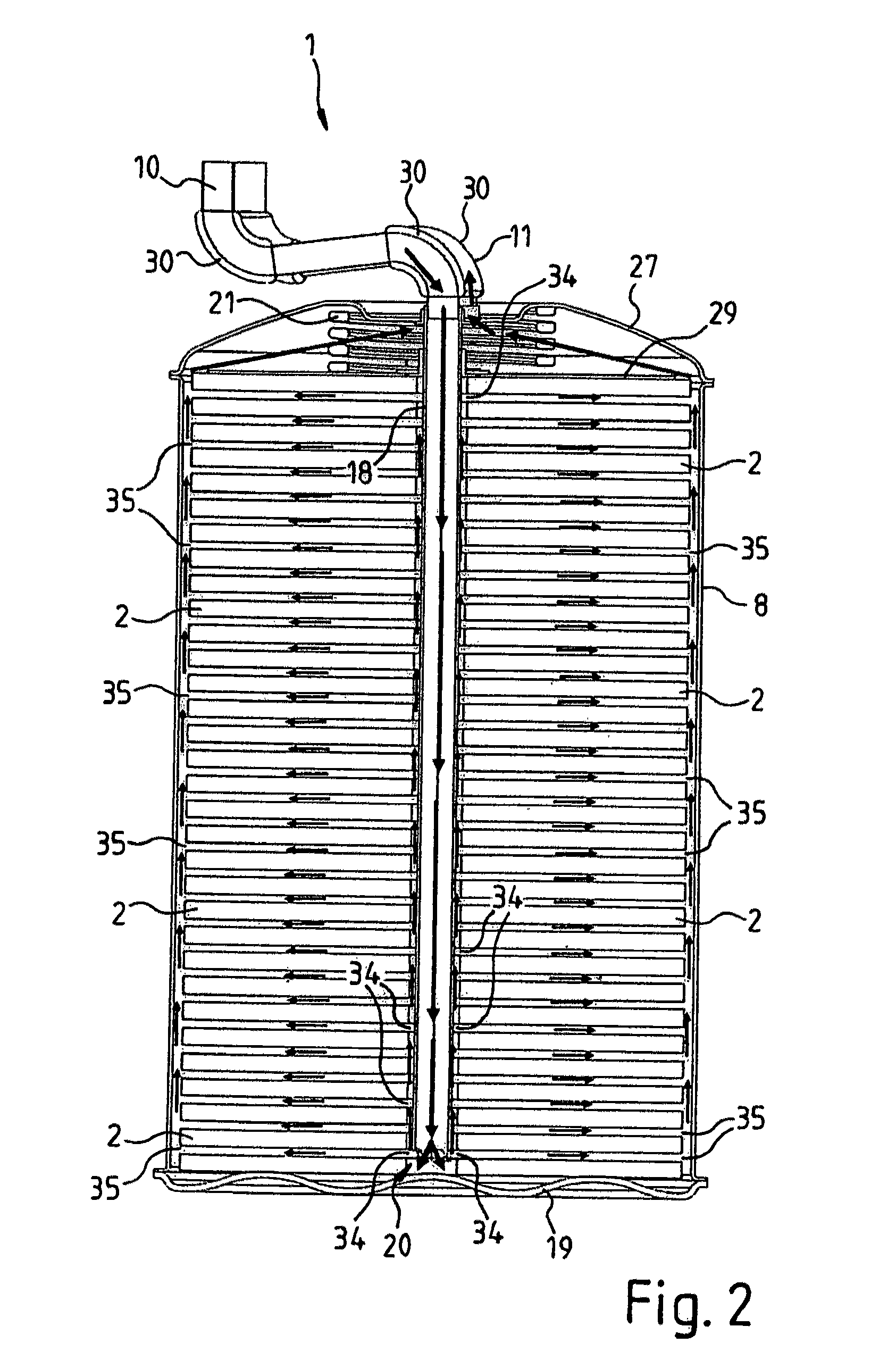

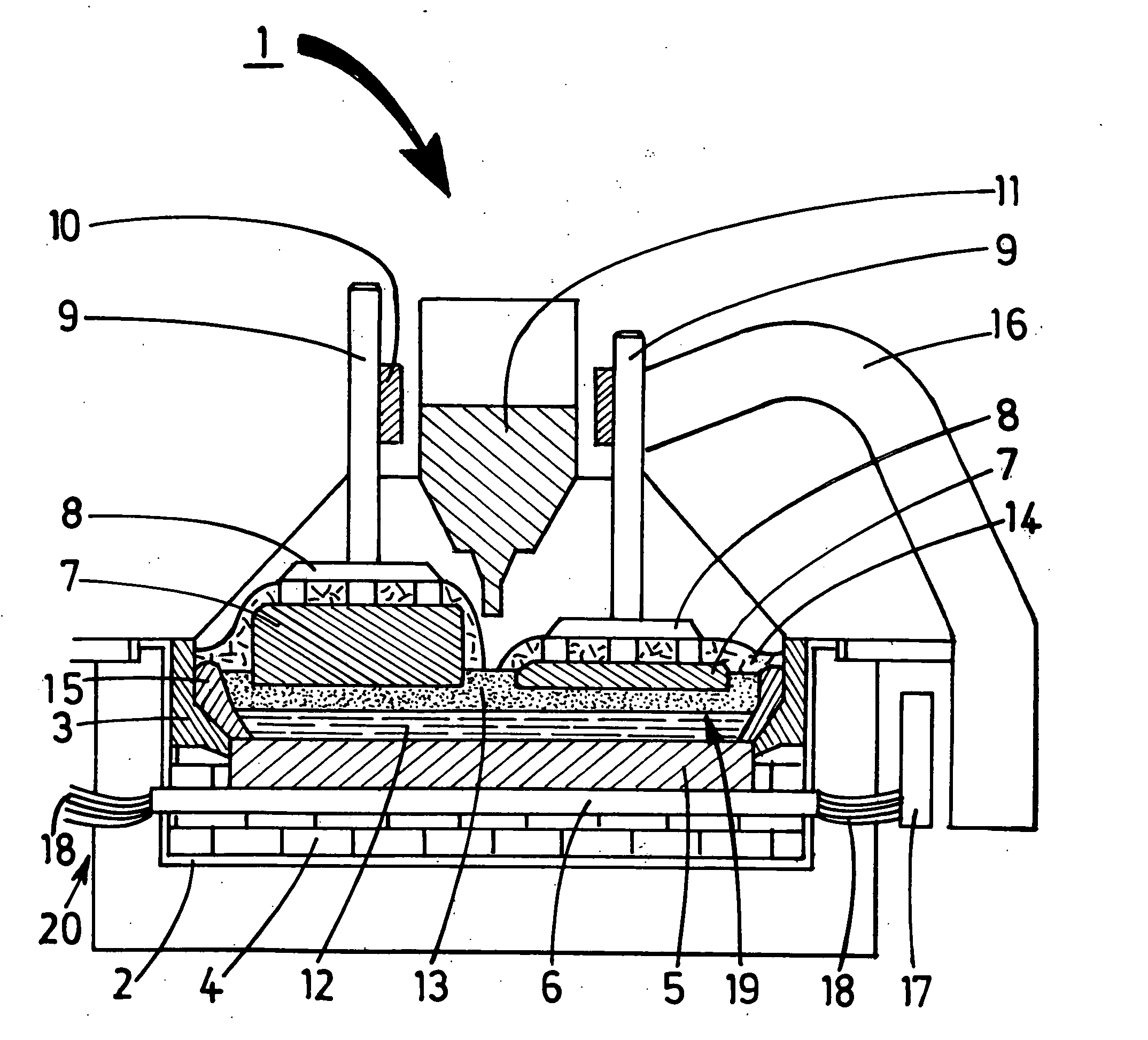

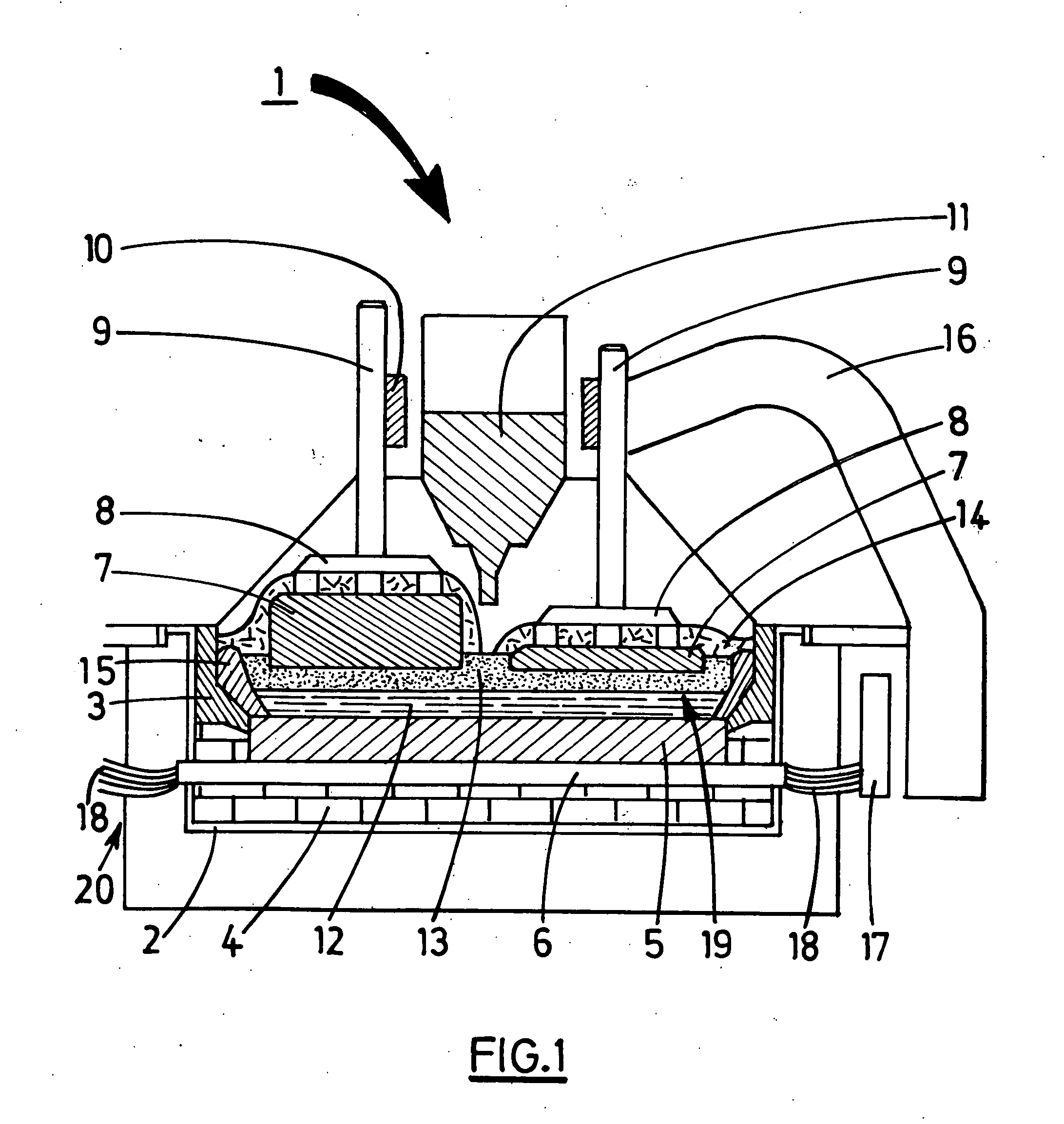

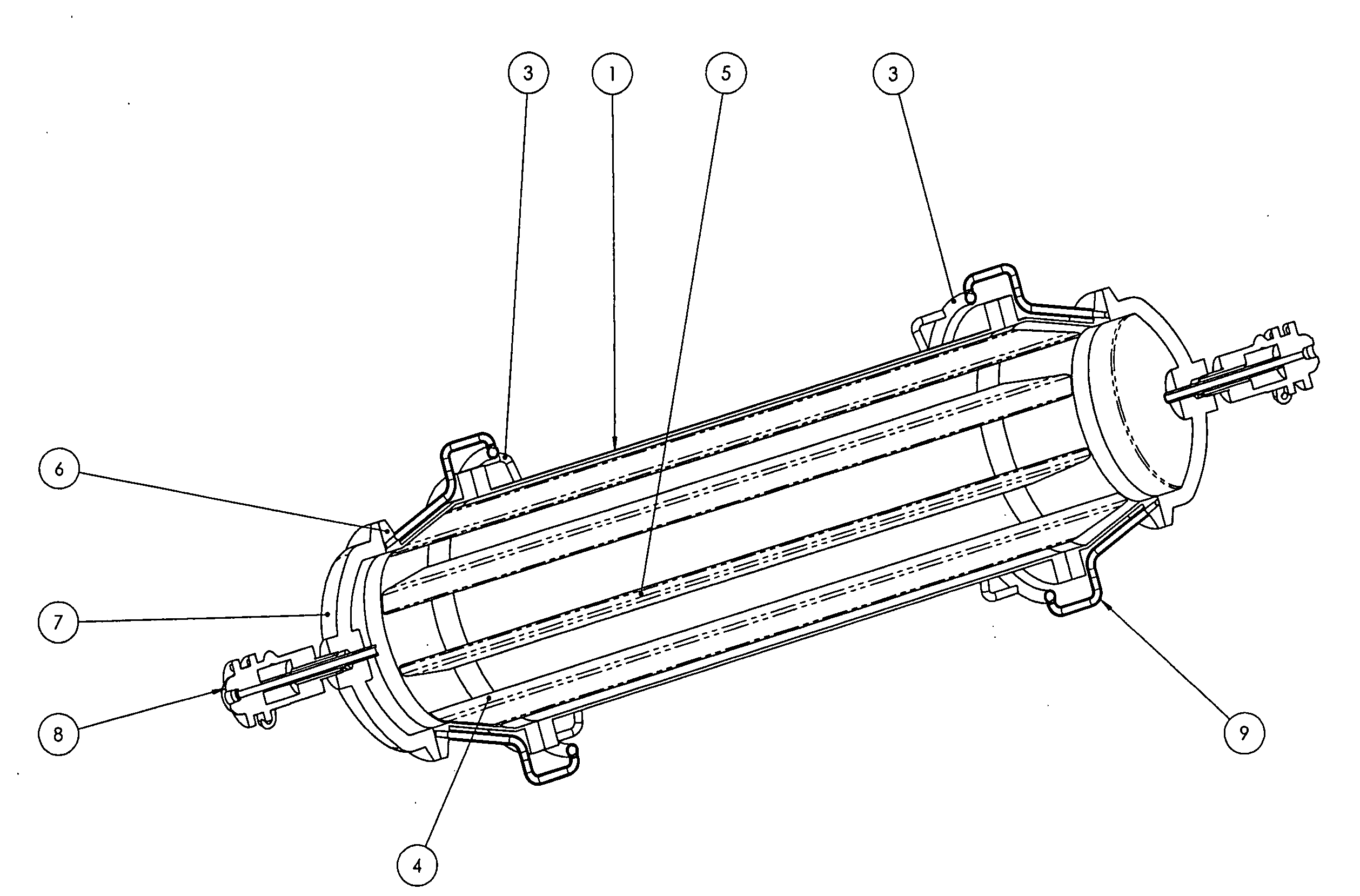

Latent heat store

InactiveUS20120241120A1Low stressEasy to useThermal insulationHeat storage plantsCommon drainEngineering

Owner:HANDTMANN SYSTTECHN

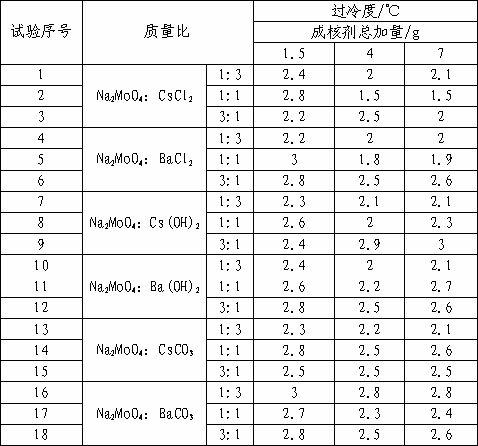

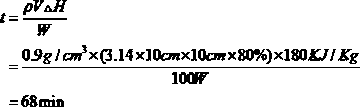

Calcium chloride hexahydrate phase change energy storage material composition

InactiveCN102134473AHigh latent heat of phase changeGood temperature regulationHeat-exchange elementsCalcium Chloride HexahydrateEnergy storage

The invention discloses a calcium chloride hexahydrate phase change energy storage material composition, which comprises calcium chloride hexahydrate, a nucleating agent, a thickener, other functional additives and the like. The phase change temperature of the composition is 23 to 25 DEG C, the degree of supercooling is less than 3 DEG C, and the latent heat of phase change is more than 180kJ / kg. The composition has high phase change stability, passed 3,000 times of tests of cold and hot circulation and can keep the uniform distribution of the nucleating agent in a short time period.

Owner:益田润石(北京)化工有限公司

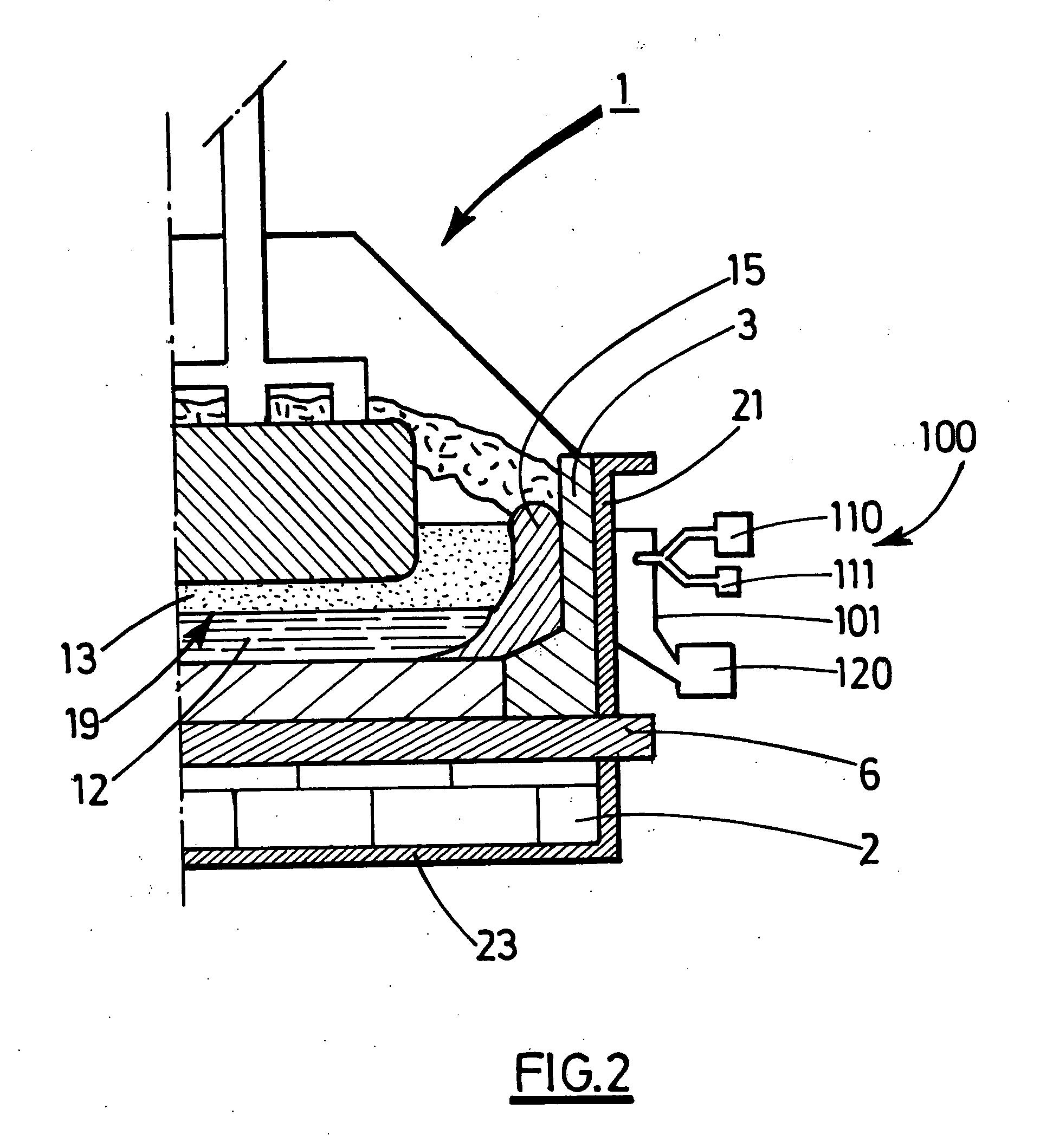

Method and system for cooling an electrolytic cell for aluminum production

InactiveUS20060118410A1Increase heating powerIncrease heating capacityCellsLighting and heating apparatusElectrical batteryHeat transfer fluid

The invention relates to a cooling method of a igneous electrolytic cell for aluminium production wherein heat transfer fluid droplets (or “divided heat transfer fluid”) are produced, preferentially in a confined volume in contact with a specified surface of at least one wall of the shell of the pot of the electrolytic cell, so as to induce the evaporation of all or part of said droplets by contact with said surface and remove the heat from said surface. The invention also relates to a cooling system capable of implementing the cooling method. The invention makes it possible to obtain a high cooling efficiency due to the latent heat of vaporisation of the heat transfer fluid.

Owner:ALUMINUM PECHLNEY

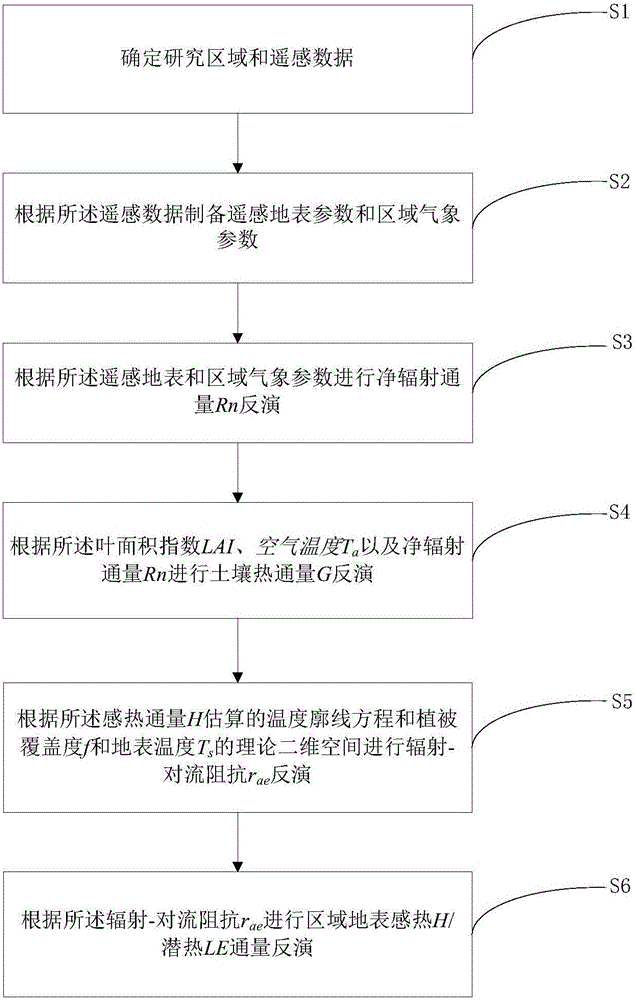

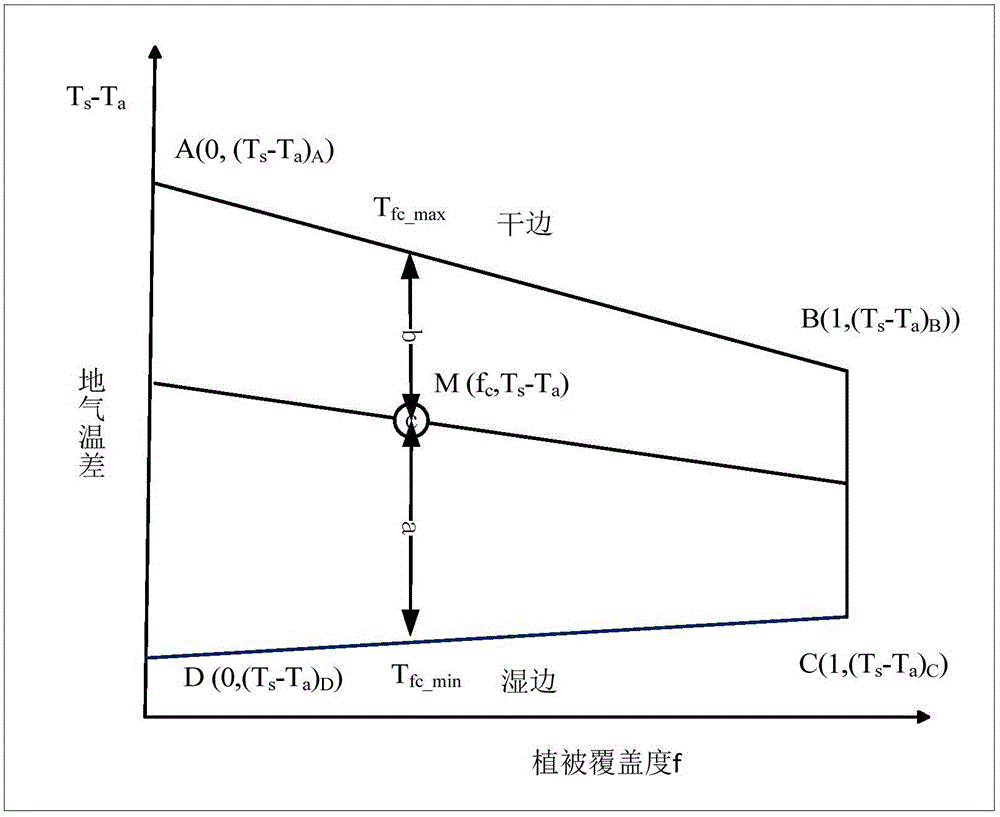

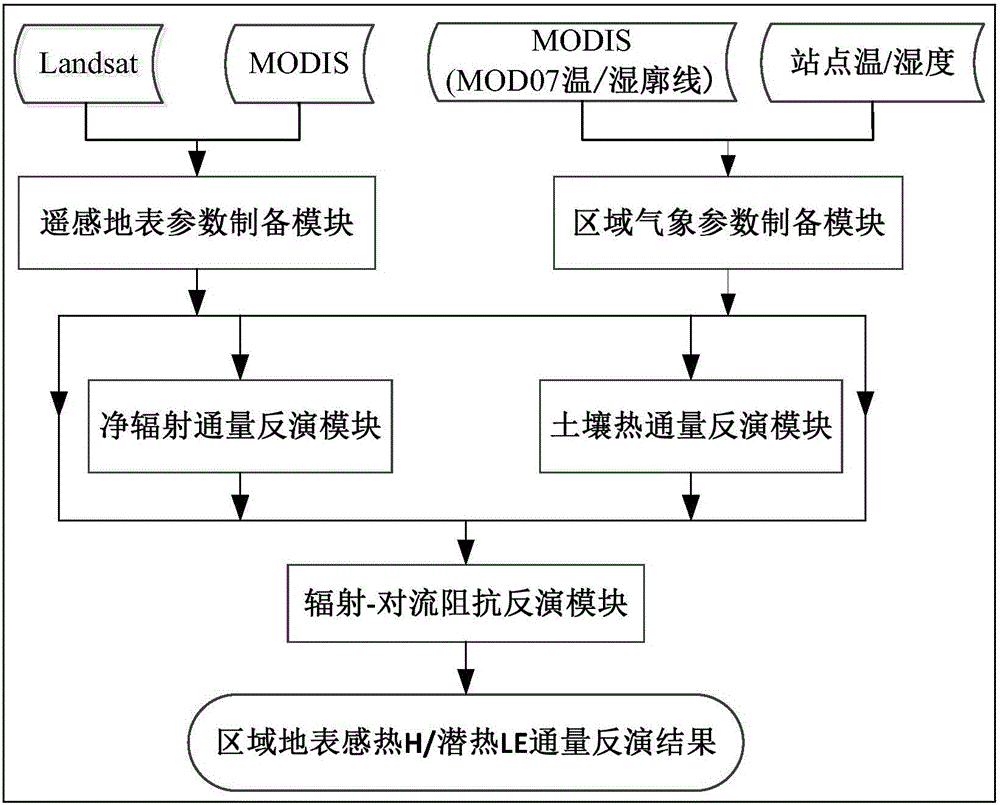

Regional earth surface sensible heat/latent heat flux inversion method and system based on remote sensing data

InactiveCN106169014AInformaticsSpecial data processing applicationsEarth surfaceNormalized Difference Vegetation Index

The invention discloses a regional earth surface sensible heat / latent heat flux inversion method based on remote sensing data. The method comprises the following steps that a research area and the remote sensing data are determined; remote sensing earth surface and regional meteorological parameters are prepared according to the remote sensing data, wherein the remote sensing earth surface parameters comprise a normalized difference vegetation index NDVI, vegetation coverage f, albedo, earth surface emissivity Emiss, earth surface temperature Ts and a leaf area index LAI, and the regional meteorological parameters comprise air temperature Ta and relative humidity RH; net radiation flux Rn inversion is conducted according to the remote sensing earth surface and regional meteorological parameters; soil heat flux G inversion is conducted according to the leaf area index LAI, the air temperature Ta and net radiation flux Rn; radiation-convection impedance rae inversion is conducted according to theoretical two-dimensional space of the net radiation flux Rn, soil heat flux G, the vegetation coverage f and the earth surface temperature Ts and a temperature profile equation estimated through sensible heat flux; regional earth surface sensible heat H / latent heat LE flux inversion is achieved according to radiation-convection impedance rae.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

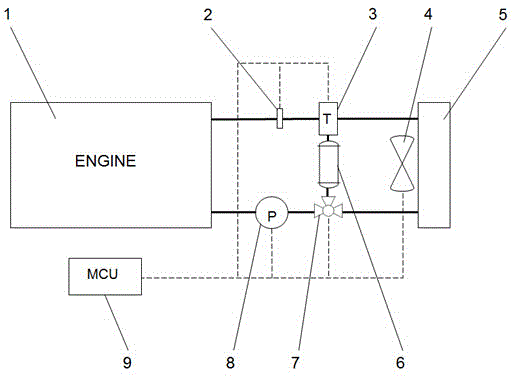

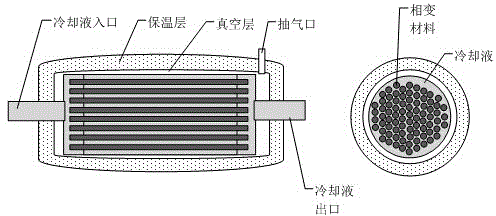

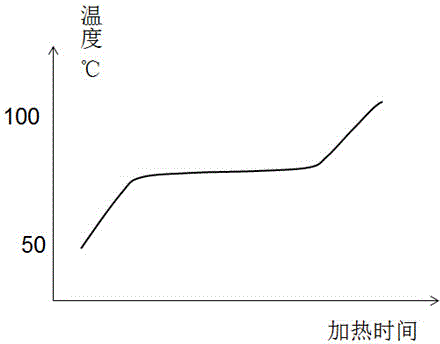

Engine coolant waste heat utilization engine warming system adopting solid-liquid phase change heat reservoir and method of engine coolant waste heat utilization engine warming system

ActiveCN104989548AImprove waste heat utilizationSolve the problem of waste heat utilizationCoolant flow controlInternal combustion piston enginesEnergy preservationCoolant flow

The invention discloses an engine coolant waste heat utilization engine warming system adopting a solid-liquid phase change heat reservoir and a method of the engine coolant waste heat utilization engine warming system. The system comprises a temperature sensor, an electronic thermostat, an electronic fan, a radiator, the solid-liquid phase change heat reservoir, an electronic three-way valve and an MCU. Coolant flows through the phase change heat reservoir to heat phase change materials. The phase change happens to the phase change materials, the phase change materials absorb a large amount of latent heat, and residual heat of an engine is transferred into the phase change heat reservoir to be stored and used for starting engine warming. The electronic thermostat and the electronic three-way valve are controlled by the MCU and kept running synchronously all the time. The premise that normal work of an engine cooling system is not influenced is ensured. After the engine stops, large circulation is closed through the electronic thermostat and the electronic three-way valve. The phase change heat reservoir is sealed and enters the energy preservation state. Thus, under the condition that the existing engine power consumption is hardly increased, waste heat recycle is achieved. The engine warming starting process is achieved under the condition that the engine power consumption is not increased.

Owner:ZHEJIANG UNIV +1

Waste treatment autoclave to provide for steam - assisted drying

InactiveUS20100135851A1Efficient regenerationWaste processingTransportation and packagingSteam pressureSteam condensation

An autoclave system provides a means of sterilizing municipal solid waste, hydrolyzing many of its components, and preparing the material for post-autoclave automated separations. The present apparatus provides a means of drying the solid waste in the vessel, while conserving the energy used to dry the vessel. Non-contact steam is recovered through separations of steam and water, with condensate steam pressure regenerated by mechanical vapor recompression and condensate water returned to the boiler / steam generator. Heat transfer to combustion air, by heat transfer via heat pump to generate additional steam, and / or by mechanical vapor recompression recovers the latent heat of loose contact steam condensate. The process design provides for in-vessel drying while reducing the energy cost of operating a waste autoclave, as compared to the current art.

Owner:ESTECH

Solar water heater phase change heat storage material and its preparing method

InactiveCN1821340AHigh thermal efficiencyReduce volumeSolar heat devicesHeat-exchange elementsSolar waterZinc Acetate Dihydrate

The present invention discloses a kind of phase change heat storing material for solar water heater and its preparation process. The phase change heat storing material consists of sodium acetate trihydrate 80-90 wt%, barium hydroxide octahydrate 1-10 wt%, sodium borate decahydrate 1-5 wt%, zinc acetate 1-5 wt%, sodium dodecyl benzene sulfonate 1-5 wt% and gelatin 1-5 wt%. During the preparation, the mixture of the above said materials are heated to smelt completely to form the eutectic mixture, which is mounted inside solar water heater. The phase change heat storing material for solar water heater has phase change temperature fitting the operation temperature of solar water heater, high phase change latent heat, no overcooling and phase separation, no toxicity, no corrosion, stable performance and high repeatability, and is especially suitable for use in solar water heater.

Owner:NANJING UNIV

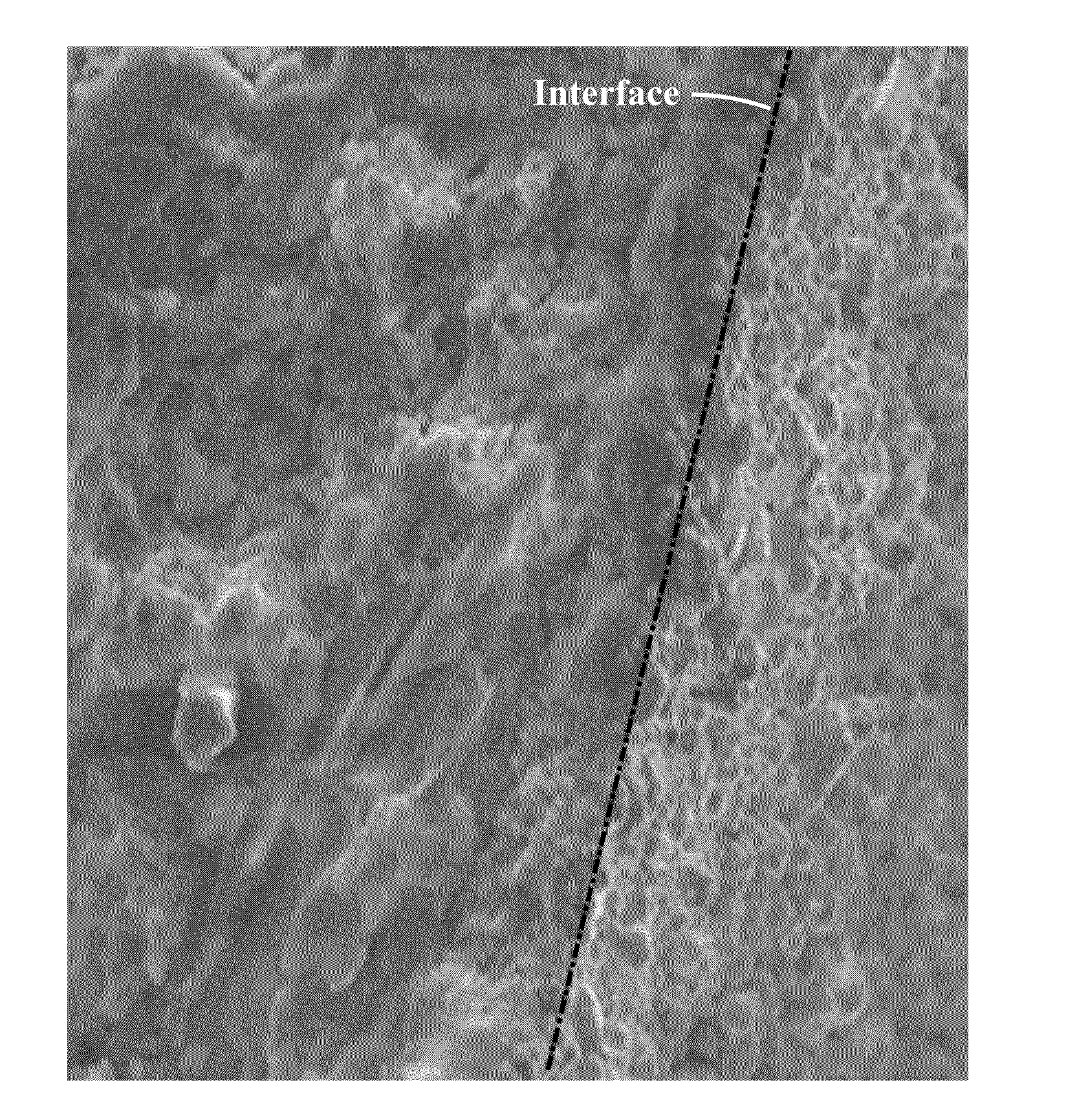

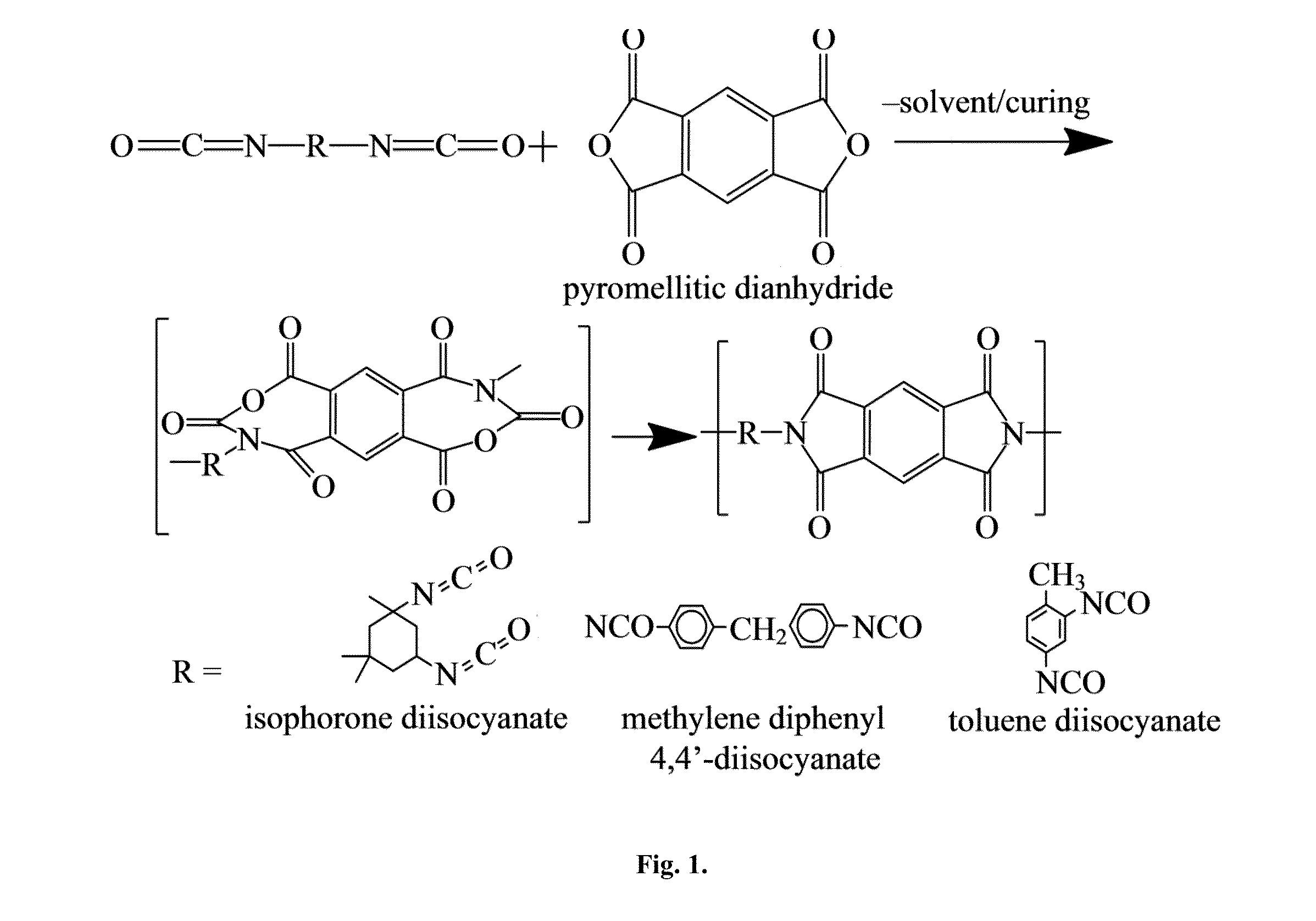

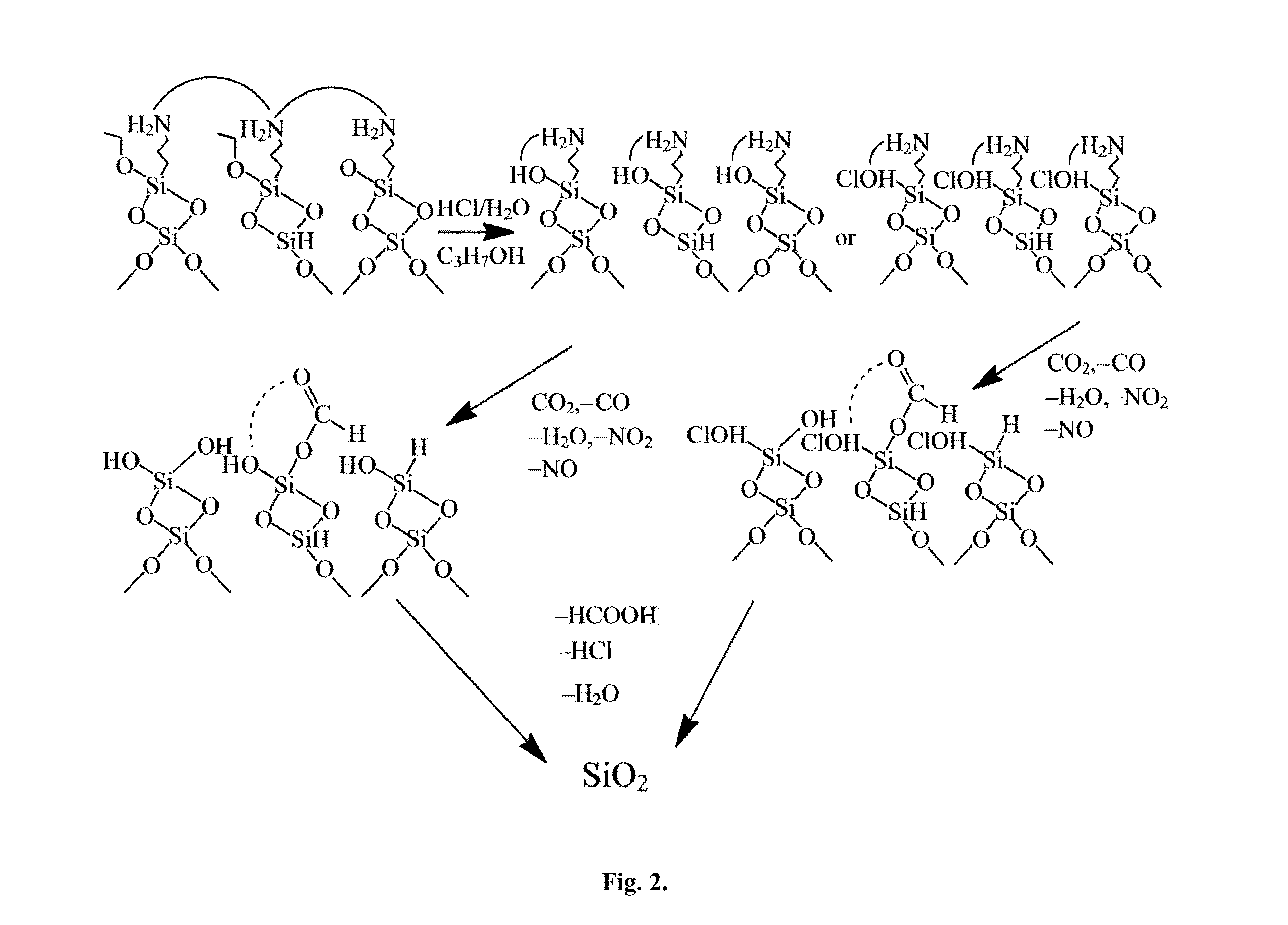

Method of encapsulating a phase change material with a metal oxide

ActiveUS20140197355A1Increase energy densityLow costPretreated surfacesHeat-exchange elementsThermal energy storageHeat energy

Storage systems based on latent heat storage have high-energy storage density, which reduces the footprint of the system and the cost. However, phase change materials (PCMs), such as NaNO3, NaCl, KNO3, have very low thermal conductivities. To enhave the storage of PCMs, macroencapsulation of PCMs was performed using a metal oxide, such as SiO2 or a graphene-SiO2, over polyimide-coated or nickel-embedded, polyimide-coated pellets The macro encapsulation provides a self-supporting structure, enhances the heat transfer rate, and provides a cost effective and reliable solution for thermal energy storage for use in solar thermal power plants. NaNO3 was selected for thermal storage in a temperature range of 300° C. to 500° C. The PCM was encapsulated in a metal oxide cell using self-assembly reactions, hydrolysis, and simultaneous chemical oxidation at various temperatures.

Owner:UNIV OF SOUTH FLORIDA

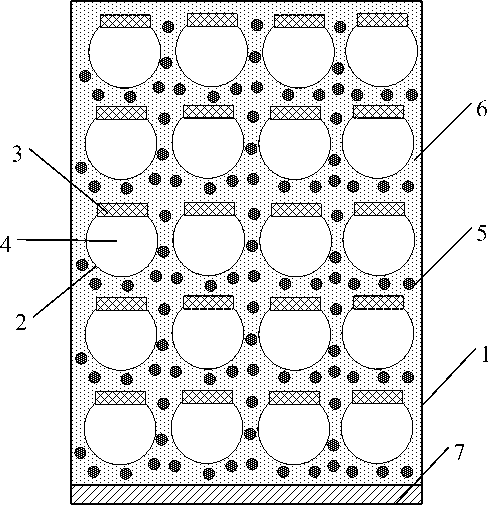

Phase change energy storage device

ActiveCN103344147ALarge latent heat of phase changeHigh latent heat of phase changeHeat storage plantsEnergy storageParaffin waxWarm water

The invention relates to a phase change energy storage device which is characterized by being composed of an outer shell, a paraffin cavity, a plastic cap, paraffin, metal particles and low-melting-point metal. The outer shell is used as a peripheral frame of the phase change energy storage device to be tightly attached to a heat source. A paraffin phase change unit is composed of the paraffin cavity, the plastic cap and the paraffin and evenly filled into the outer shell. The paraffin phase change unit is a heat absorption portion of the phase change energy storage device. The metal particles are filled into the gap between the paraffin phase change unit and the outer shell. The low-melting-point metal is filled into the gap among the outer shell, the metal particles and the paraffin phase change unit so as to enable heat energy to be rapidly transmitted to the paraffin. The paraffin cavity is made of metal so as to be beneficial to heat transfer. The plastic cap is made of flexible plastics so as to compensate a volume expansion effect generated by the paraffin phase exchange. According to the phase change energy storage device, the high latent heat properties of the paraffin are utilized, and the energy storage performance is excellent. Meanwhile, the high heat conductivity properties of the metal particles and the low-melting-point metal are utilized, and the heat conductive performance is excellent. Finally, due to the design of a plurality of paraffin energy storage units, the normal operation of the system can be still ensured when a single energy storage unit in the system loses efficacy. The phase change energy storage device is simple in structure, easy to machine, small in low-melting-point metal charging amount, low in cost and capable of being widely used for heat energy utilization fields such as solar thermal power generation, hot water waste heat recovery, warm water bottles and warmers.

Owner:北京依米康散热技术有限公司

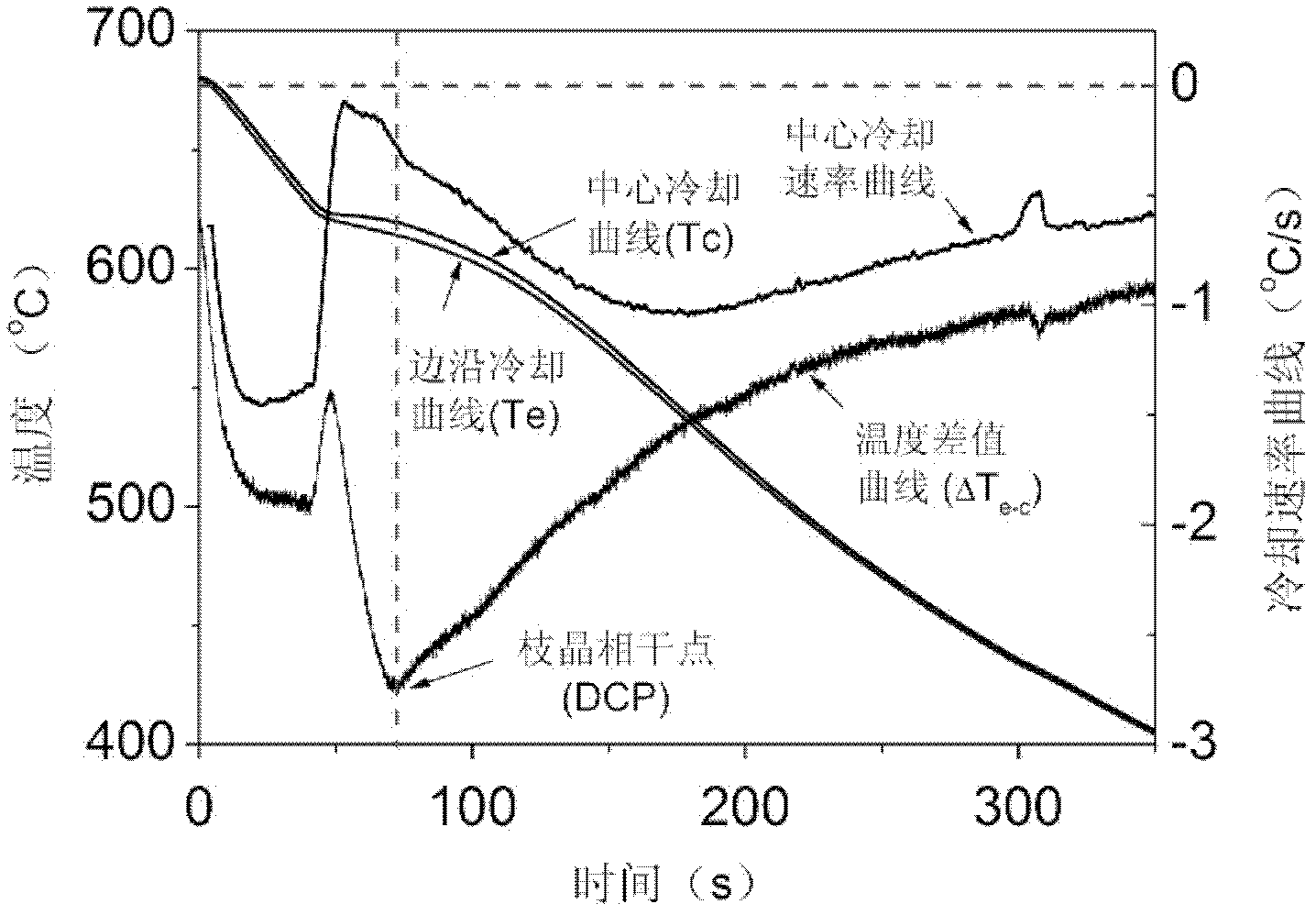

Thermal analysis and detection method and device for solidification grain size of magnesium alloy melt

ActiveCN102998324ALow costMetamorphic effect in timeParticle size analysisMaterial thermal analysisSolid phasesAlloy element

The invention provides a thermal analysis and detection method and device for solidification grain size of a magnesium alloy melt and belongs to the fields of magnesium alloy melt treatment and casting solidification. The thermal analysis and detection method provided by the invention comprises that certain amounts of magnesium and magnesium alloy melt are poured into a sampling cup to be cooled, two thermocouples are adopted for respectively determining temperatures at the center and the edge of the melt in a solidification process in a magnesium alloy melt cooling process, a temperature acquisition device is used for acquiring temperature data, a computer program is used for recording variation of the temperatures at the center and the edge of the melt in the solidification process along with time, then dendritic crystal coherence point solid phase fractional number is determined by virtue of a thermal analysis and detection method, and the dendritic crystal coherence point solid phase fractional number is compared with a standard value to judge a refining or roughening effect on the grain size of a magnesium alloy by modification, grain refining or alloying element addition. According to the thermal analysis and detection method and device provided by the invention, recalescence is not required in a thermal analysis cooling curve of the solidification process, the thermal analysis and detection method and device provided by the invention are especially applicable to the magnesium alloy with lower solidification latent heat release, a modification effect can be represented within a wider solidification speed range, and solidification grain size can be predicted.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com