Method for simultaneously recovering water and latent heat in high-humidity flue gas and heat pump device

A heat pump device, high humidity technology, applied in heat pump device, recovery of water and latent heat, simultaneous recovery of water and latent heat in high humidity flue gas, can solve problems such as unfavorable utilization of low temperature waste heat, increase of heat transfer links, increase of equipment investment, etc. Achieve good energy saving, reduce heat transfer links, and reduce the cost of absorbent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

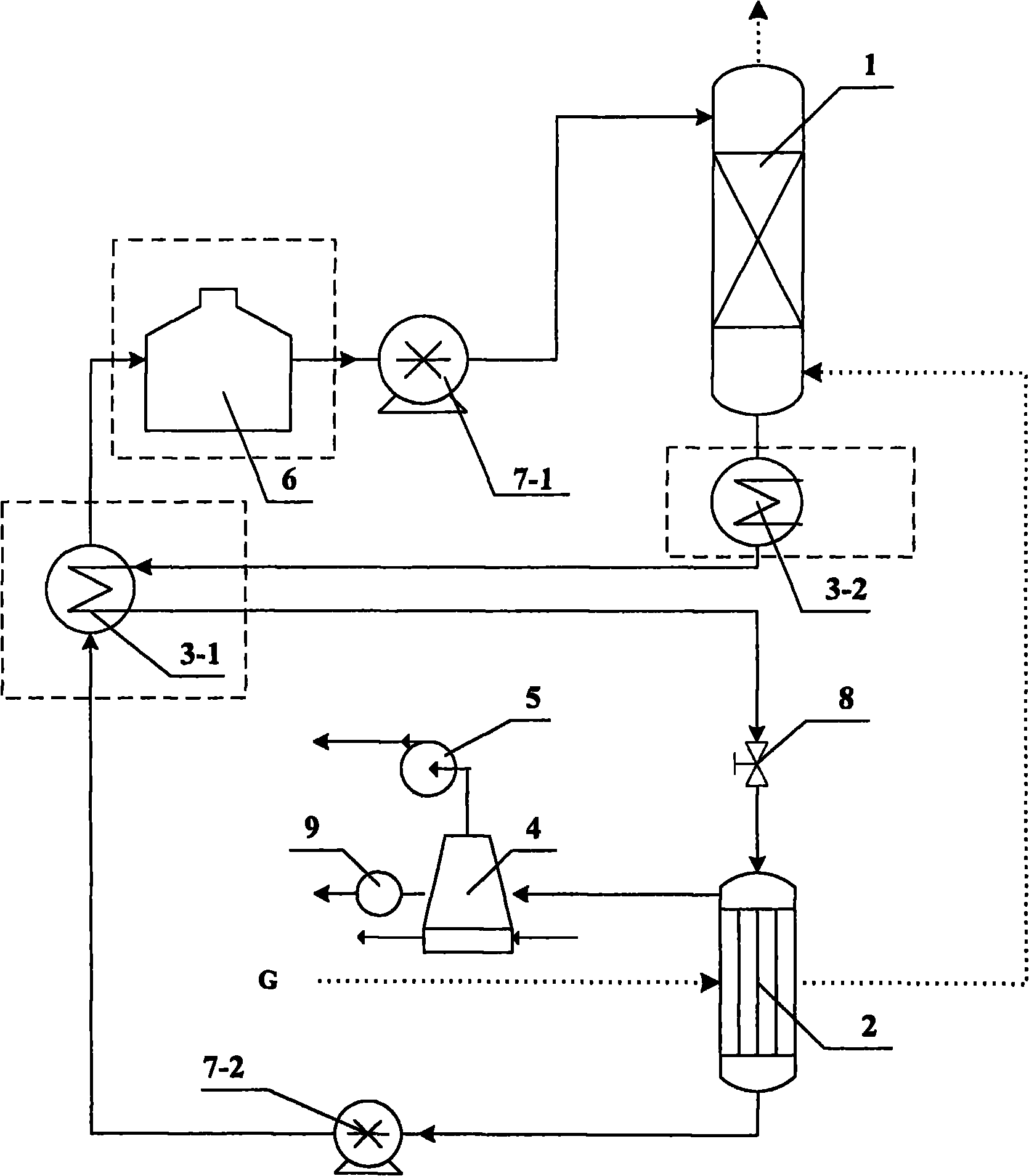

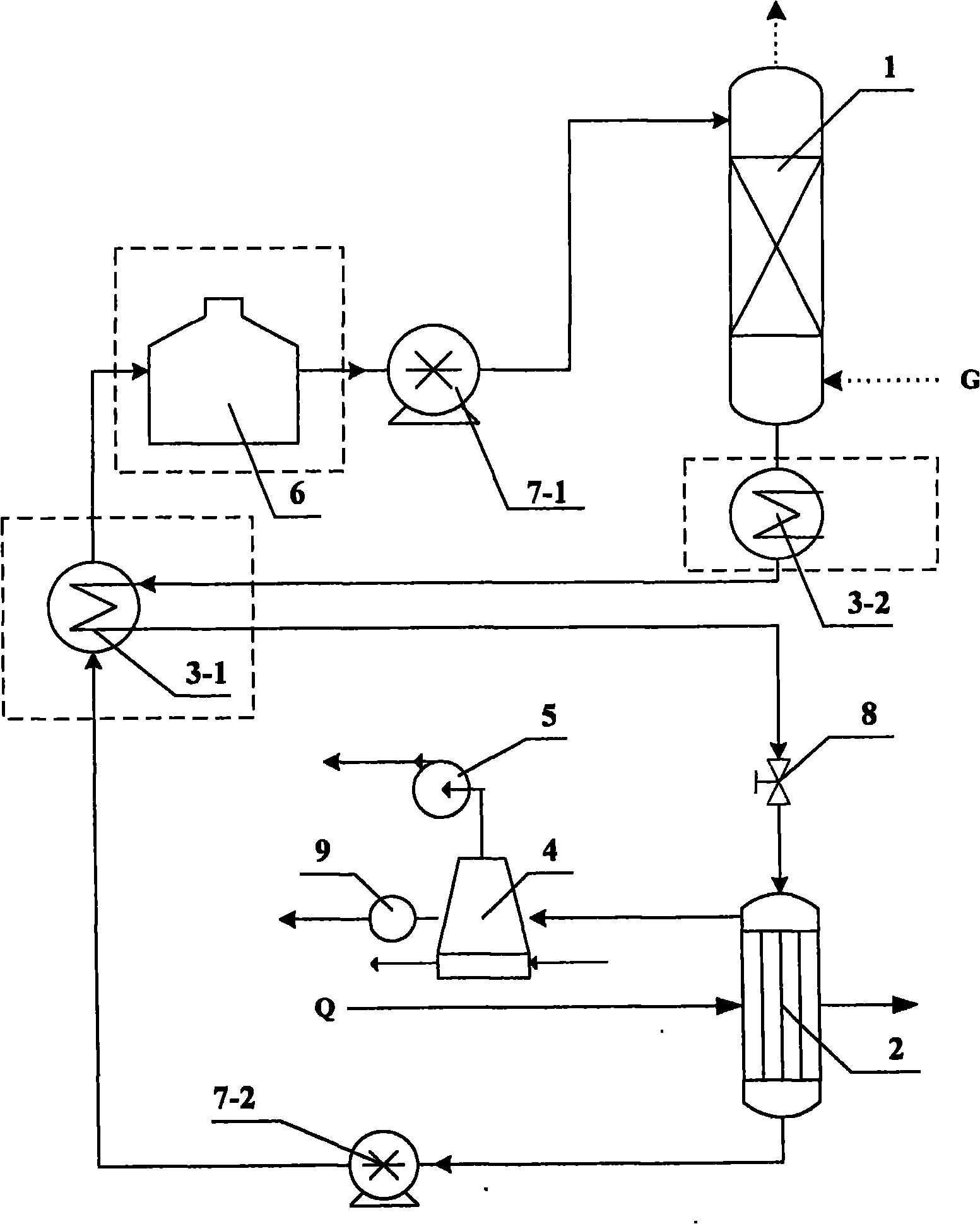

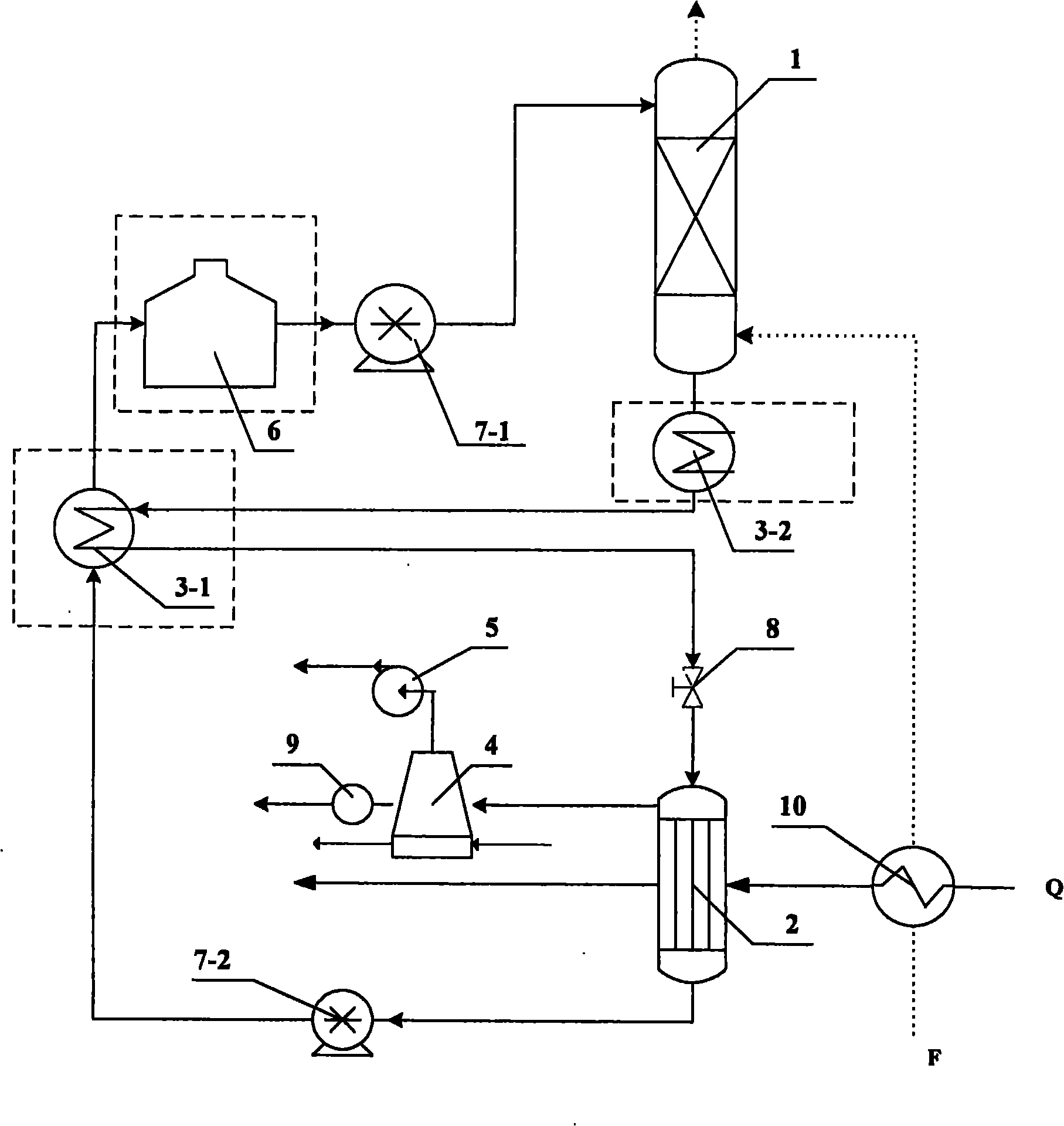

[0043] A method for simultaneously recovering water and latent heat in high-humidity flue gas of the present invention is an open cycle second-type absorption heat pump, including an absorption unit, a regeneration unit, a heat recovery unit, and a water recovery unit. Absorbent adopts calcium chloride aqueous solution. Such as Figure 5 , the flue gas enters the absorption unit, and the concentrated solution absorbs the water in the flue gas in the absorption unit to become a high-temperature dilute solution (latent heat is released when the water is absorbed); the high-temperature dilute solution passes through the heat recovery unit to release heat recovery and becomes a lower temperature dilute solution Then enter the regeneration unit; the recovered heat is sent to the heating pipe network in the heating unit; the dilute solution in the regeneration unit is heated and evaporated by the heat source to become a concentrated solution, and the concentrated solution enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com