Water heat-transfer shift process for by-product high-grade steam energy-saving deep conversion

A high-grade, steam technology, applied in the field of , can solve the problems of over-temperature catalyst, hidden danger of system operation, short service life of catalyst, etc., and achieve the effect of facilitating self-unloading of catalyst, preventing dew point corrosion, and easy temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

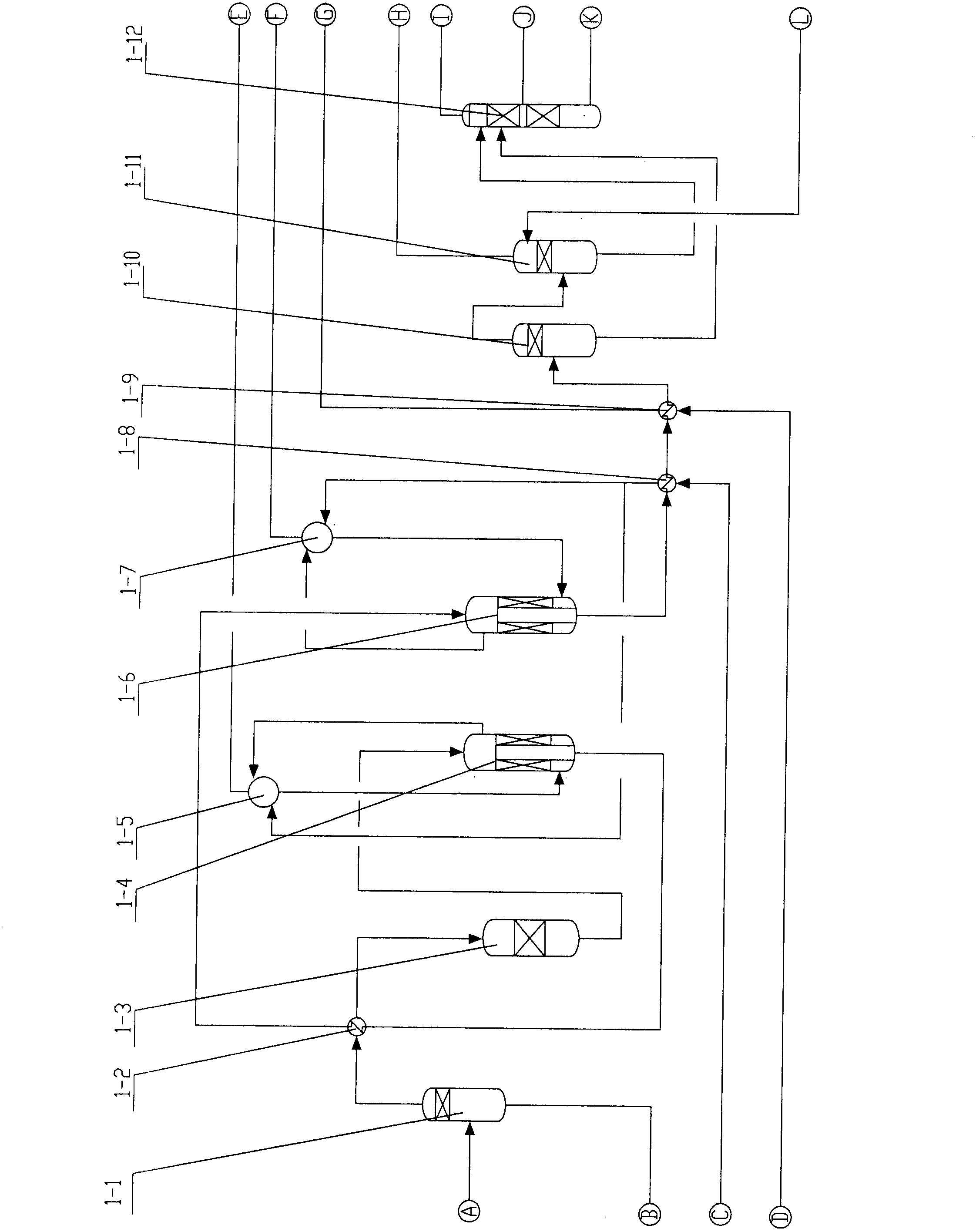

[0054] as attached figure 1 As shown, the raw material gas from the gasification device enters the interior of 1# gas-liquid separator 1-1 for downward swirling (the gas swirls downward to facilitate separation), and after the dust and water are separated, they reverse 180° and enter the center pipe, and then It is further filtered through a stainless steel wire mesh to ensure that the gas is clean.

[0055] The raw gas coming out of 1# liquid separator 1-1 enters the raw gas heater 1-2 for heat exchange, and when the temperature reaches 240°C (feed temperature ≥ dew point temperature 30°C), it enters the detoxification tank 1-3, and the gas passes through the upper detoxification tank. After the poison is detoxified, it directly enters a small amount of catalyst bed in the lower part for reaction, and the temperature rises to 300°C (the reaction temperature is controlled by the amount of catalyst loading ≤ 300°C), and this part of the catalyst is used to further absorb and re...

Embodiment 2

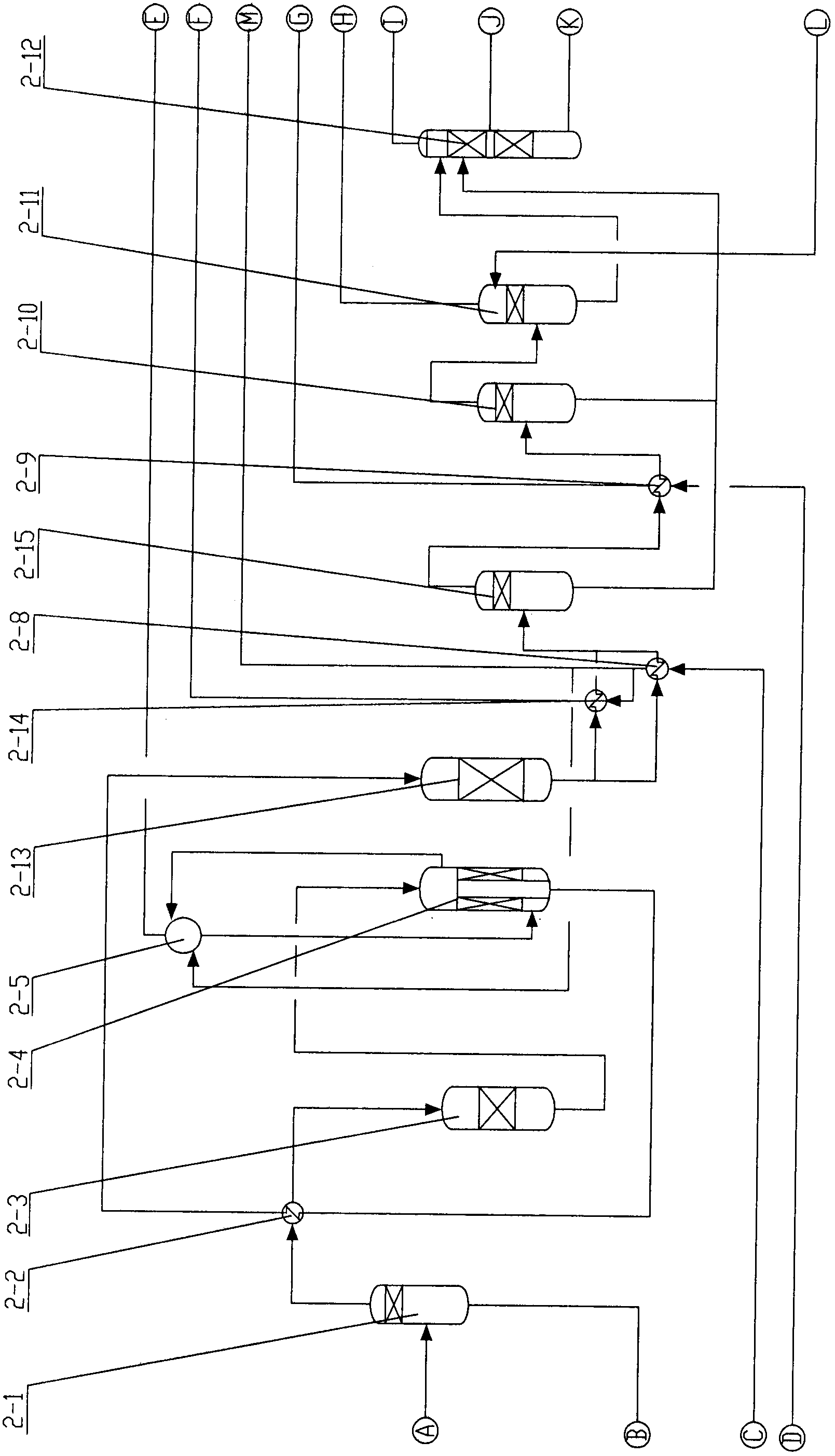

[0062] as attached figure 2 As shown, the raw material gas from the gasification device enters the interior of 1# gas-liquid separator 2-1 for downward swirl flow (the gas swirls downward to facilitate separation), and the dust and water are separated and reversed 180° into the center pipe, and then It is further filtered through a stainless steel wire mesh to ensure that the gas is clean.

[0063] The raw material gas from the 1# liquid separator 2-1 enters the raw gas heater 2-2 for heat exchange, and when the temperature reaches 300°C (feed temperature ≥ dew point temperature 30°C), it enters the detoxification tank 2-3, and the gas passes through the upper detoxification tank. After the poison is detoxified, it directly enters a small amount of catalyst bed in the lower part for reaction, and the temperature rises to ~300°C. This part of the catalyst is used to further absorb and remove harmful substances in the water gas under high temperature conditions. The gas exitin...

Embodiment 3

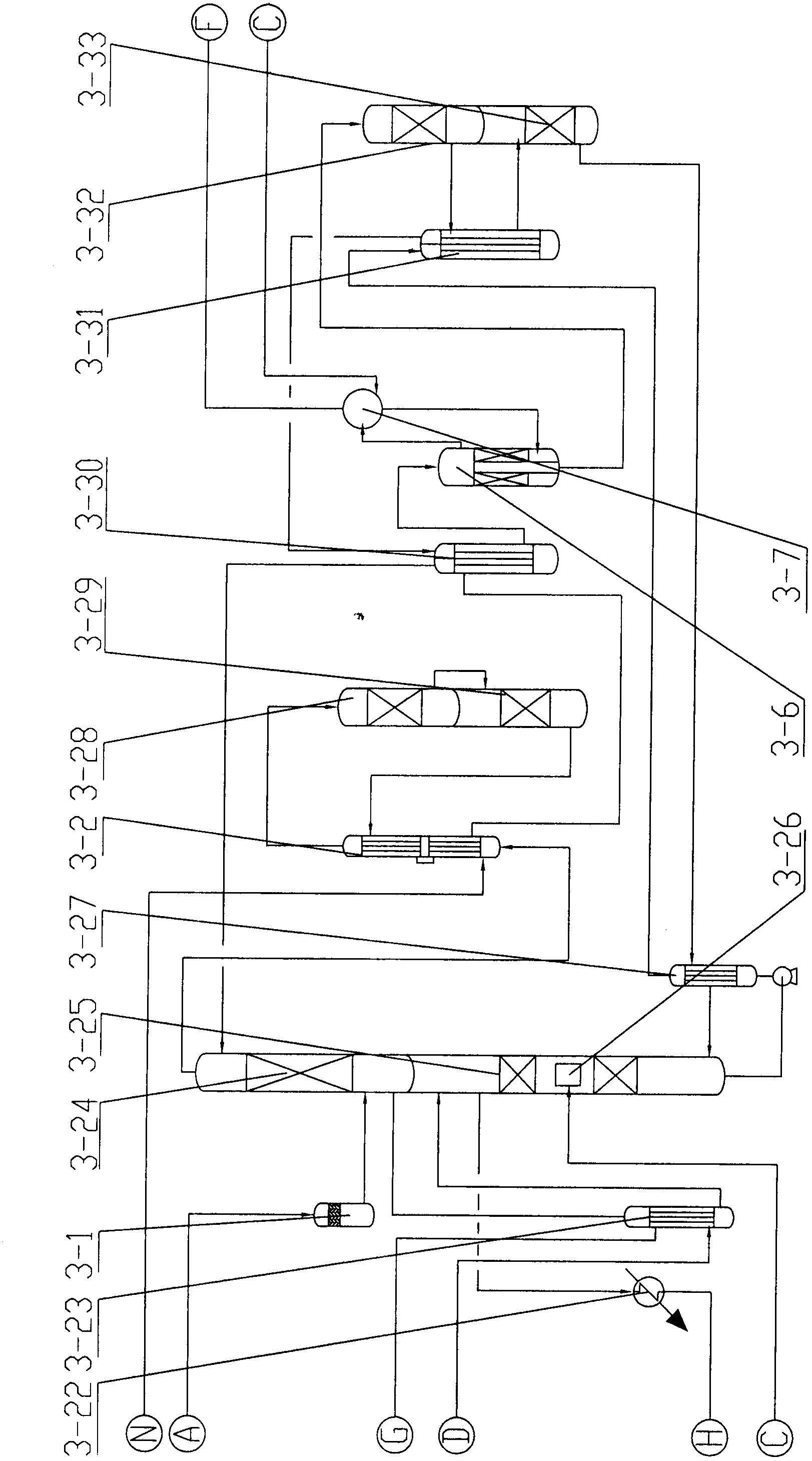

[0077] as attached image 3 As shown: the raw gas from the gasification device enters the interior of 1# gas-liquid separator 3-1 for downward swirling (the gas swirls downward to facilitate separation), and after the dust and water are separated, they reverse 180° and enter the center pipe, and then It is further filtered through a stainless steel wire mesh to ensure that the gas is clean.

[0078]The raw material gas after separation of oil and water enters the saturation tower 3-24 to exchange heat with the hot water entering the tower for humidification, and the gas exiting the saturation tower 3-24 is heated to 300-350°C by the raw gas heater 3-2 and enters the first stage of the intermediate transformation furnace Layer 3-28 reacts, and then enters the second stage of medium transformation bed layer 3-29 for reaction. After the reaction, the transformed gas enters the raw material gas heater 3-2 at 420-440°C, and enters the first-stage cooler 3 after the temperature drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com