Precise support rod type three-directional punching machine tool

A punching machine, rod-type technology, applied in punching machines, presses, manufacturing tools, etc., can solve the problems of high output torque requirements and electricity consumption of hydraulic stations, and achieve the effect of ensuring service life, saving electric energy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

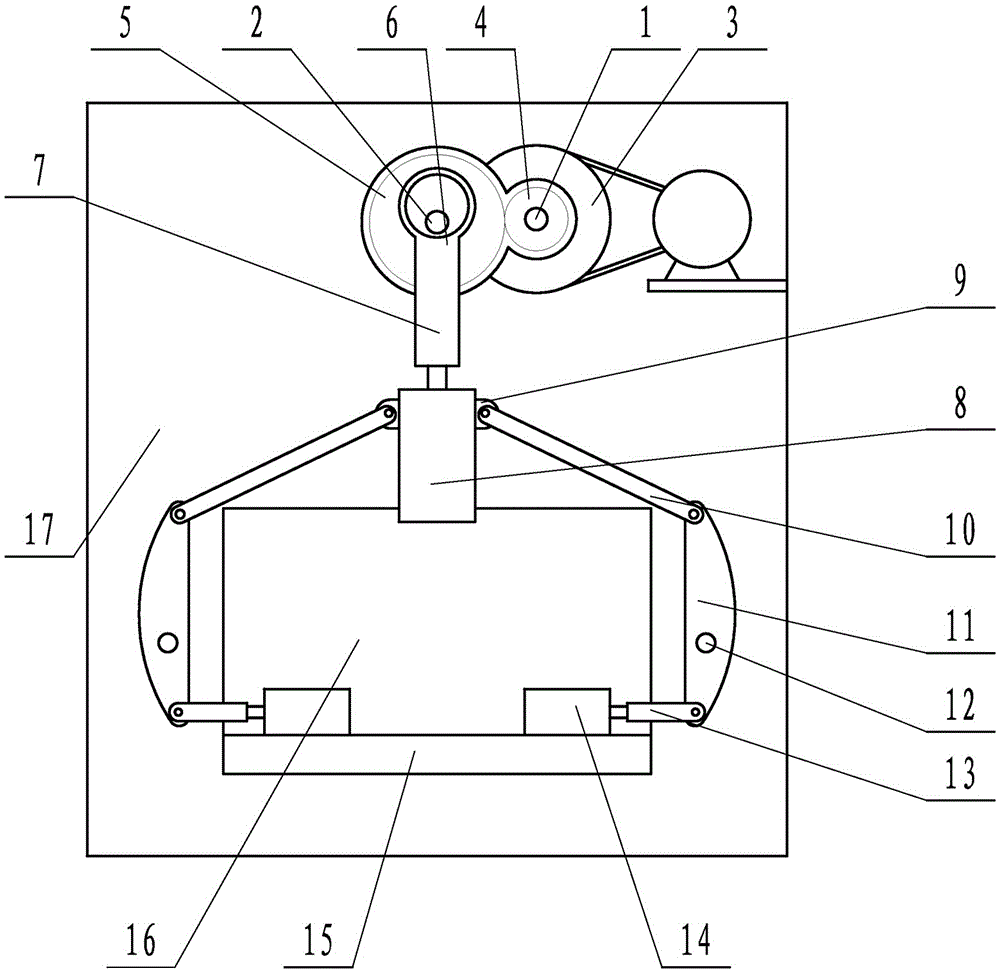

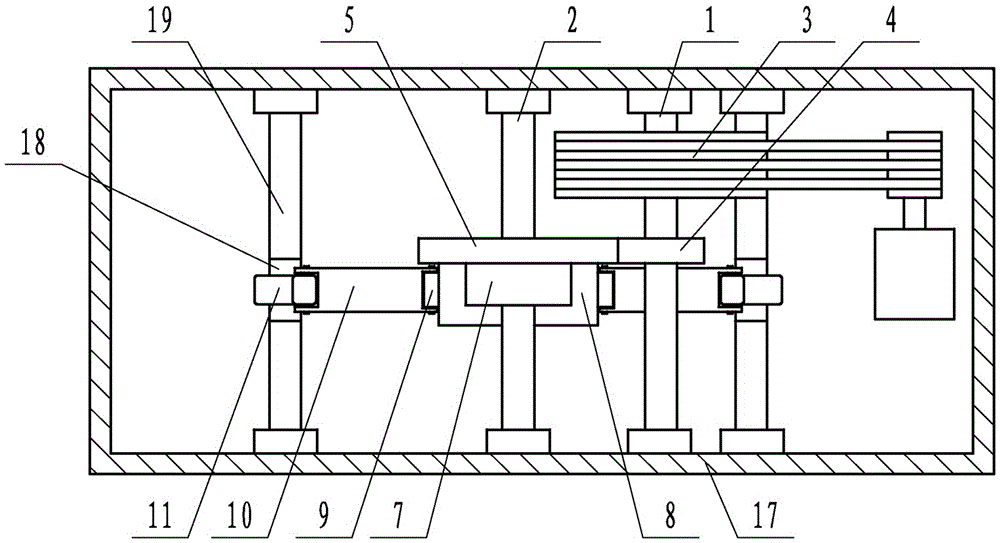

[0015] as attached figure 1 As shown, the present invention comprises transmission shaft 2, the eccentric wheel 6 that is arranged on the transmission shaft 2, the connecting rod 7 that one end is socketed with the eccentric wheel 6, the upper slider 8 that is arranged at the other end of the connecting rod 7, and the upper slider 8 connected horizontal punching device and drive device connected with transmission shaft 2. The horizontal stamping device comprises a stamping link 10, a rocker 11 hinged at one end to the stamping link 10, a slider link 13 hinged to the other end of the rocker 11, and a horizontal slider connected to the slider link 13 14. The rocker arm 11 is arranged on the frame 17 through the rocker arm shaft 12, and the other end of the stamping link 10 is hinged with the upper slider 8. The rocker shaft 12 is arranged on a side close to the slider connecting rod 13 . There are two horizontal punching devices, which are symmetrically arranged on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com