Patents

Literature

650results about How to "Slow response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method, system and personalized web content manager responsive to browser viewers' psychological preferences, behavioral responses and physiological stress indicators

InactiveUS20050288954A1Efficient in operationMinimal delayDiagnostic recording/measuringSensorsSubject specificContent management

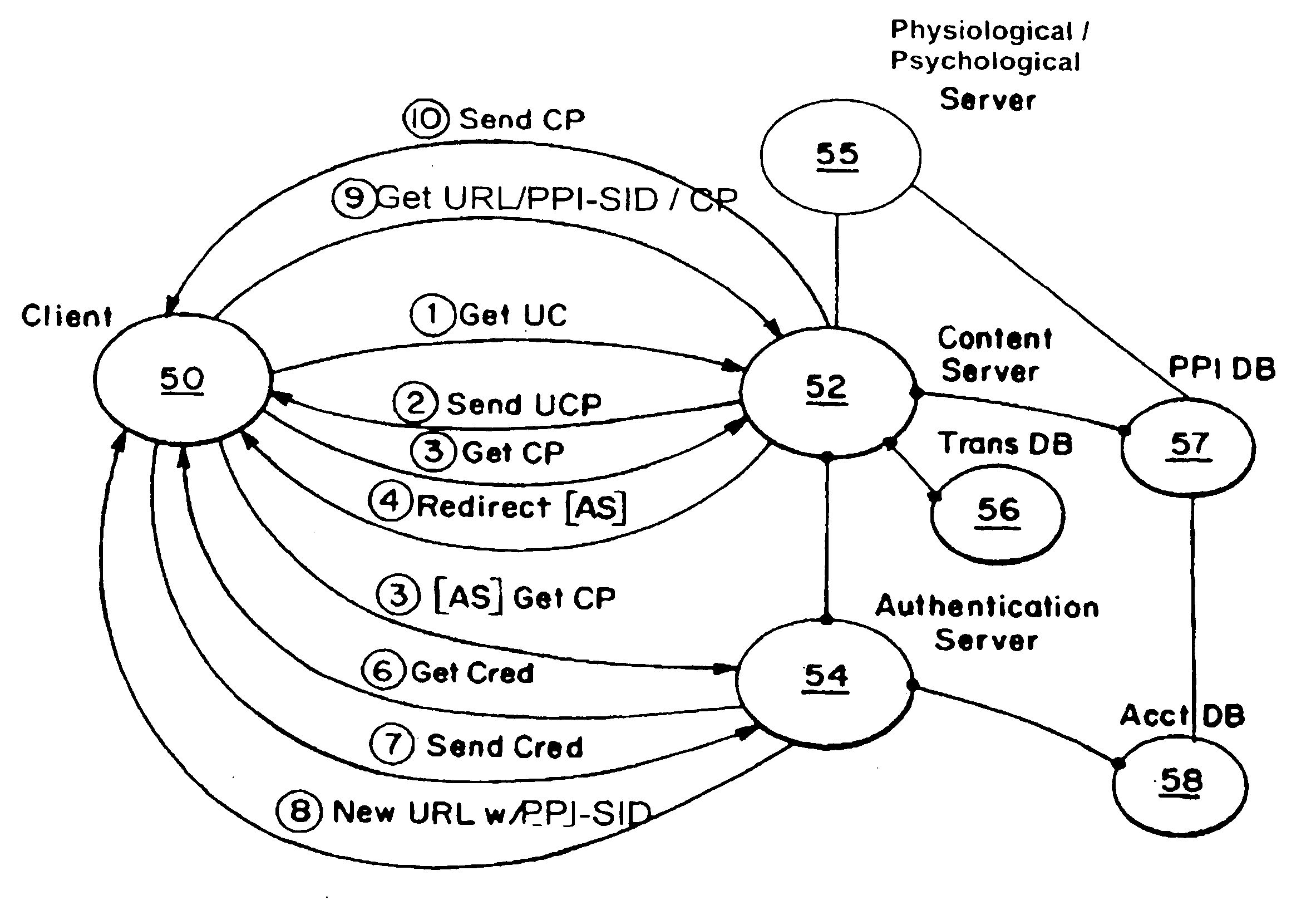

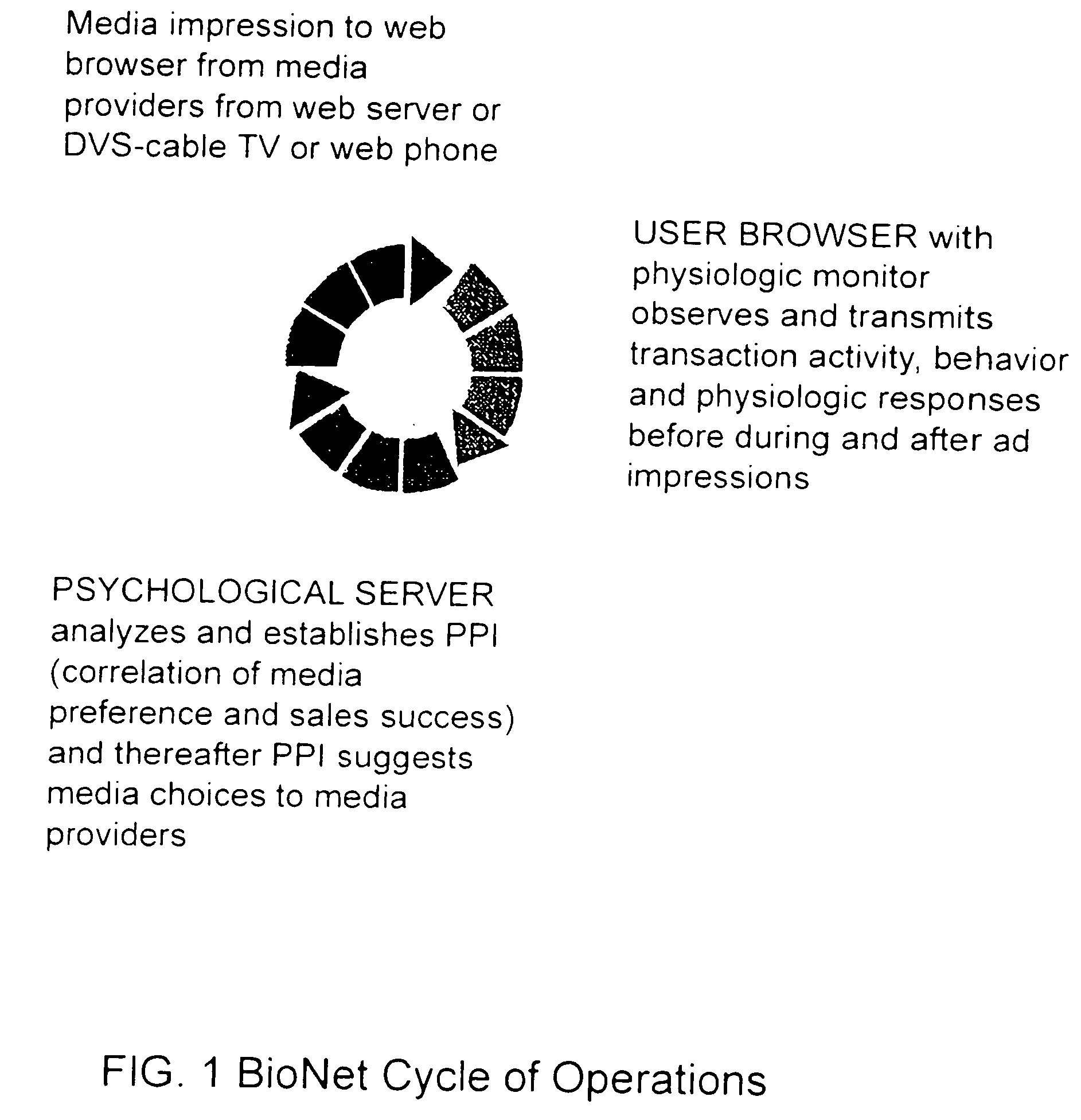

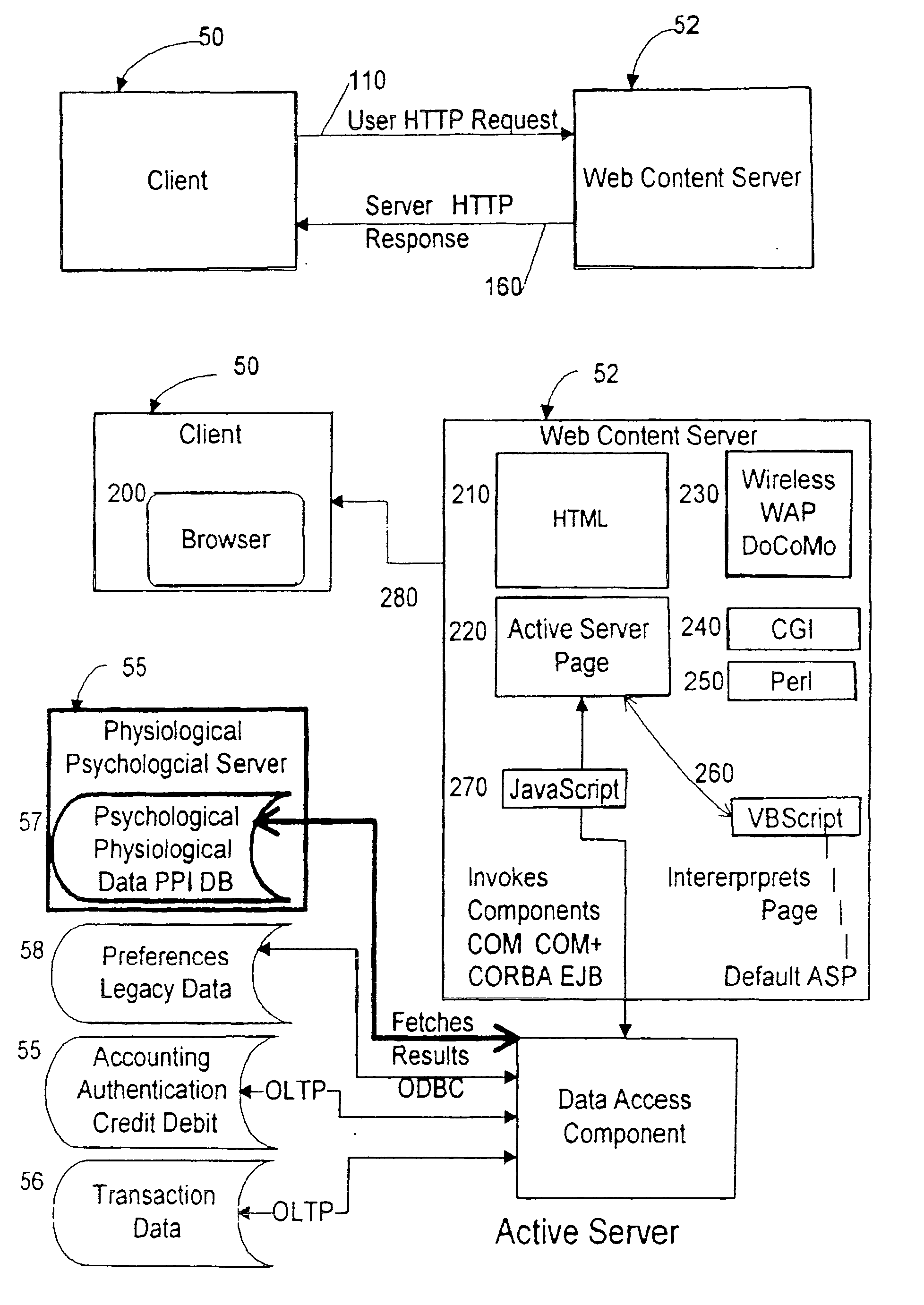

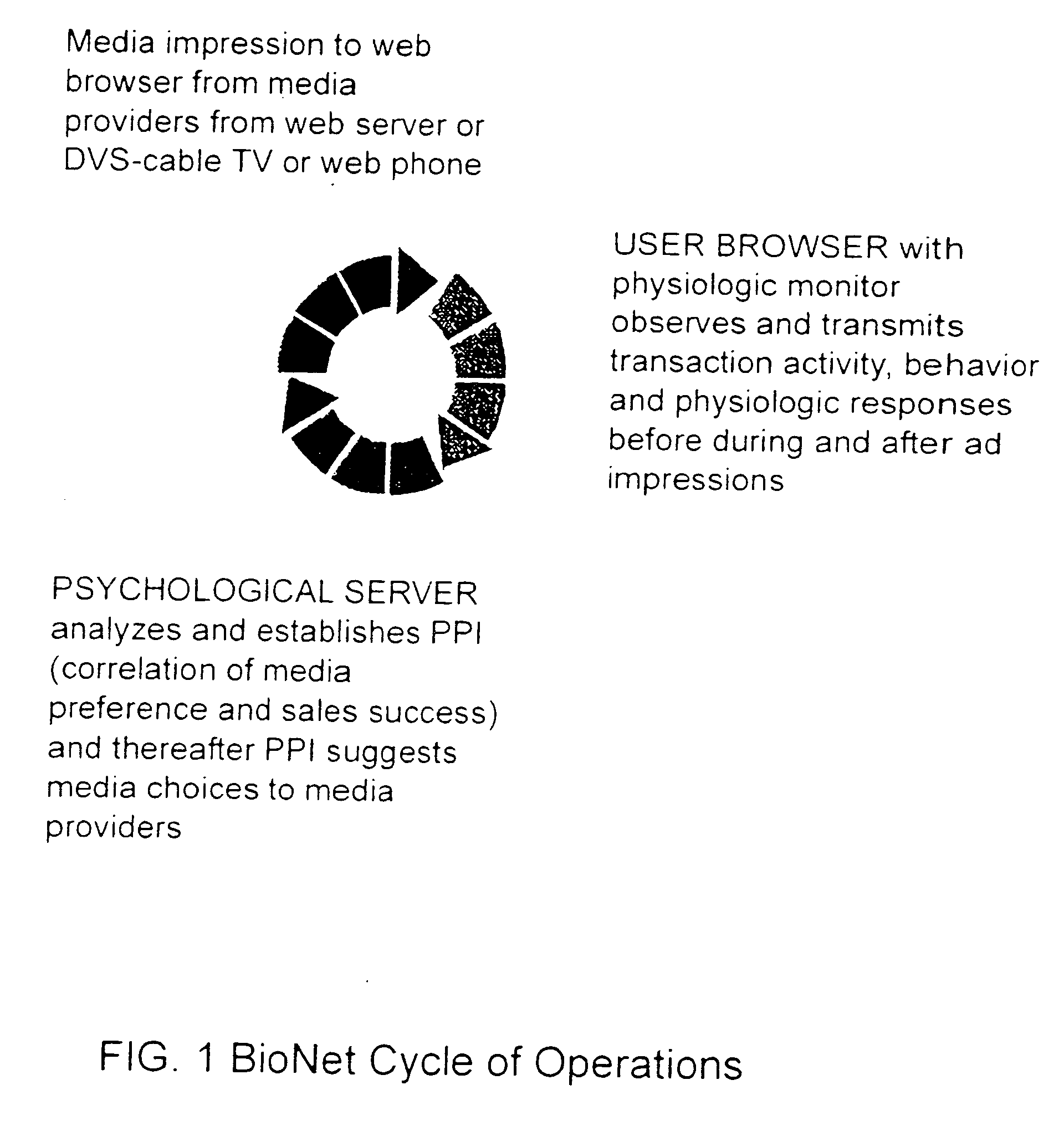

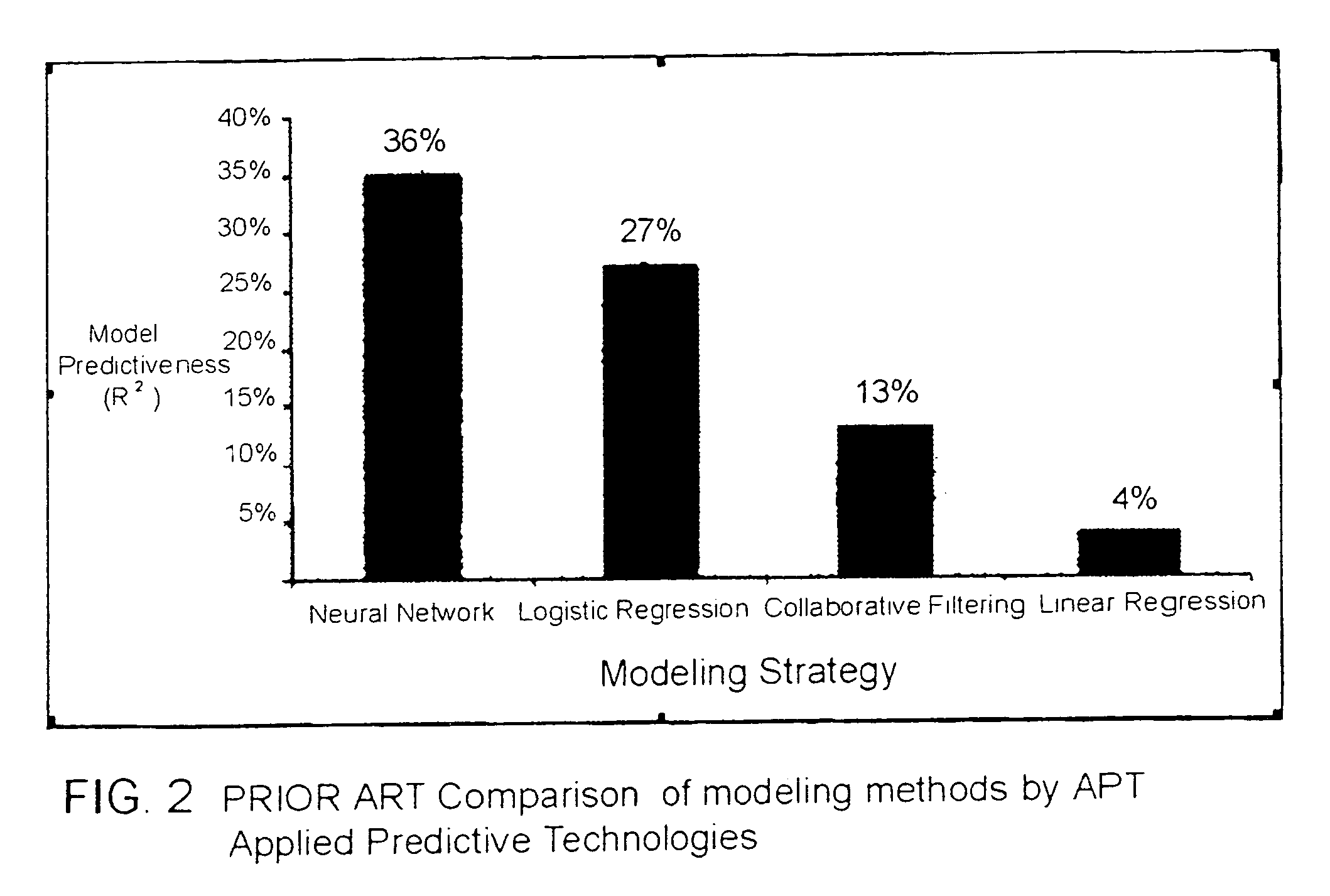

A BioNet method, system and personalized web content manager responsive to browser viewers' psychological preferences, behavioral responses and physiological stress indicators for an advertising measurement and recommendation system that correlates the physiologic parameter responses to impressions of (World Wide Web and multimedia Web television) advertisements with post-impression transactional activity, clickthroughs and sales, to measure the effectiveness of the advertisements and recommend preferred media choices and media themes to media providers.

Owner:MCCARTHY JOHN +1

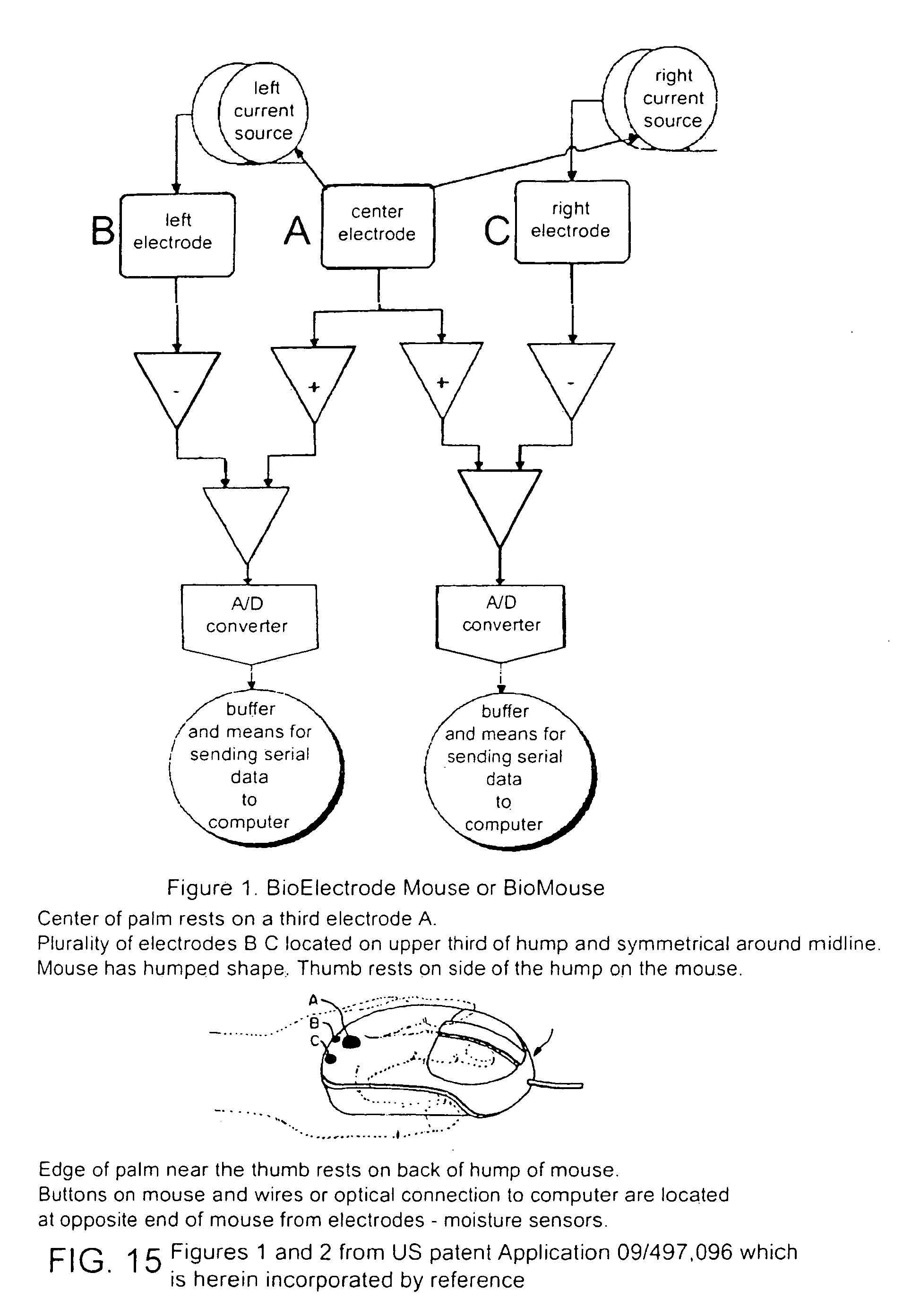

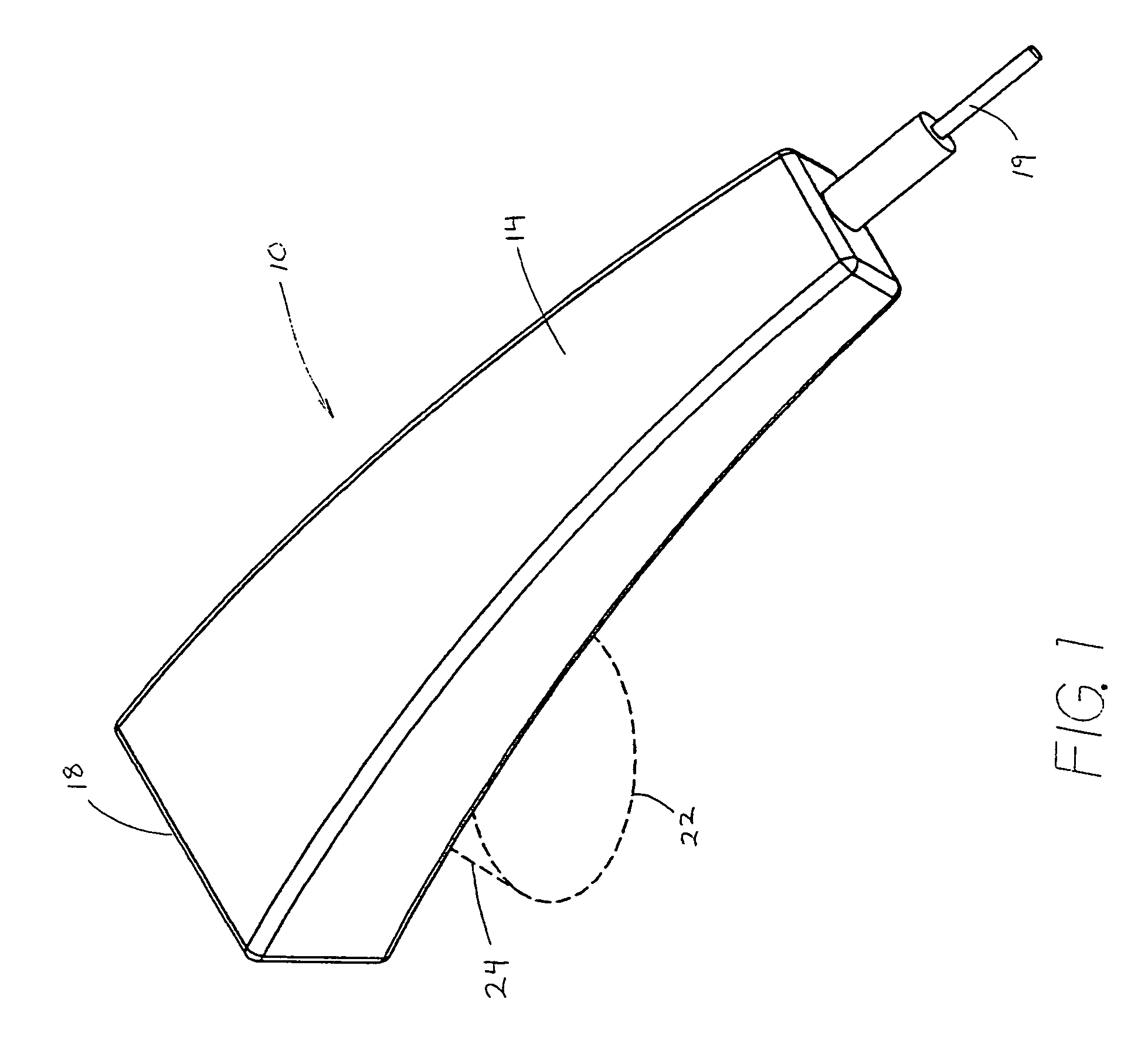

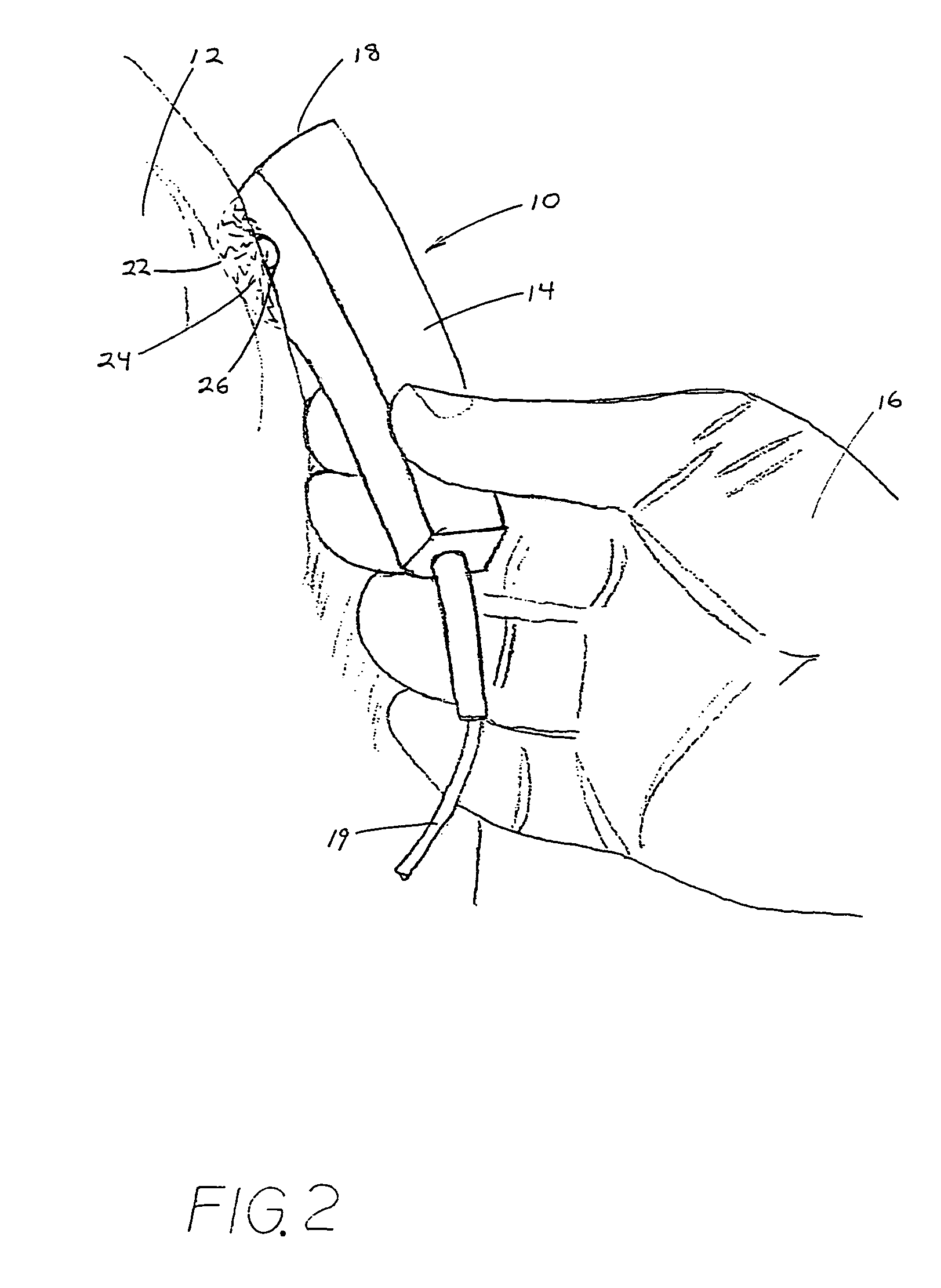

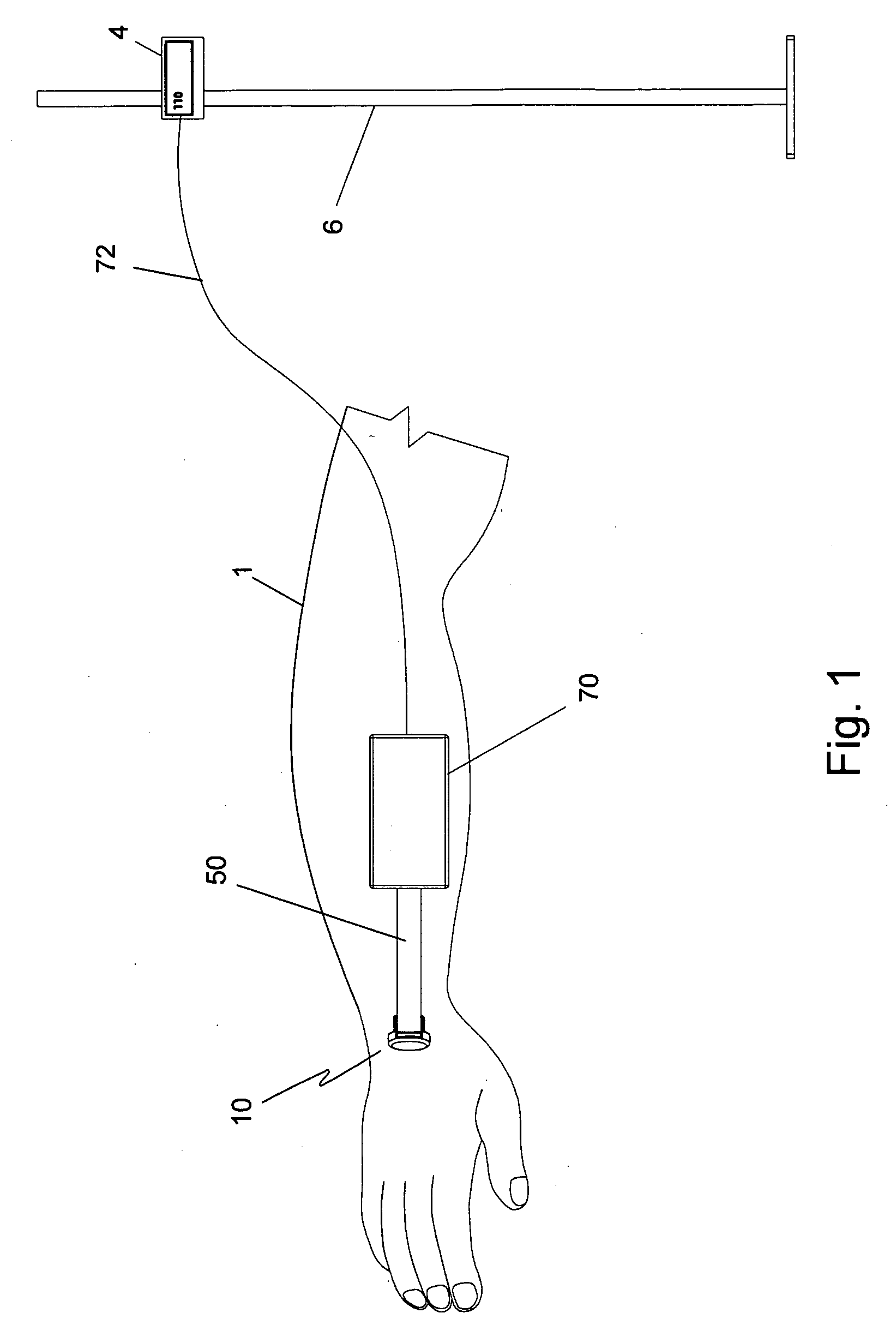

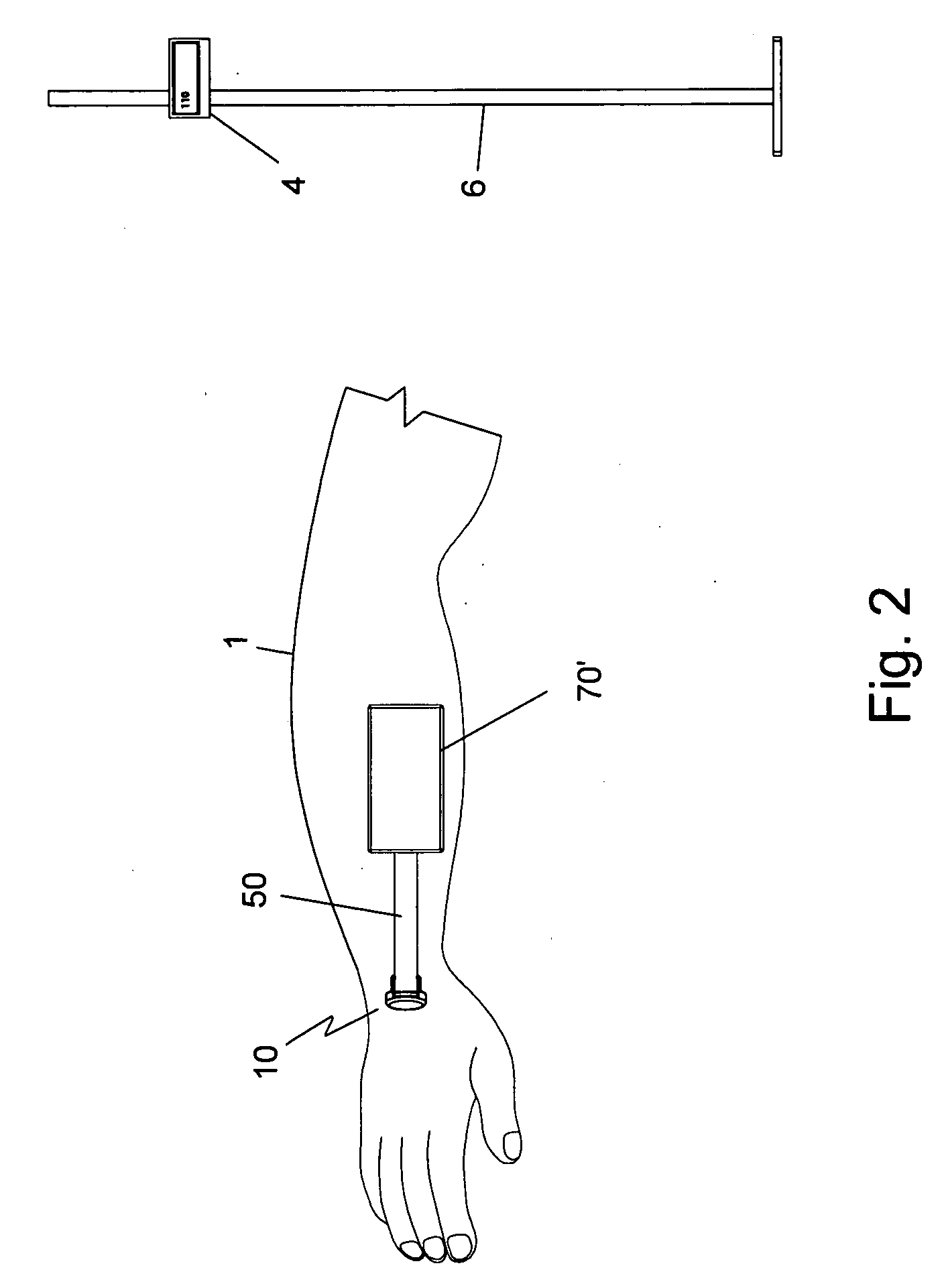

Input device for web content manager responsive to browser viewers' psychological preferences, behavioral responses and physiological stress indicators

InactiveUS20060293921A1Easy and efficient to manufactureLow costDiagnostic recording/measuringSensorsPulse oximetersBehavioral response

Owner:MCCARTHY JOHN +1

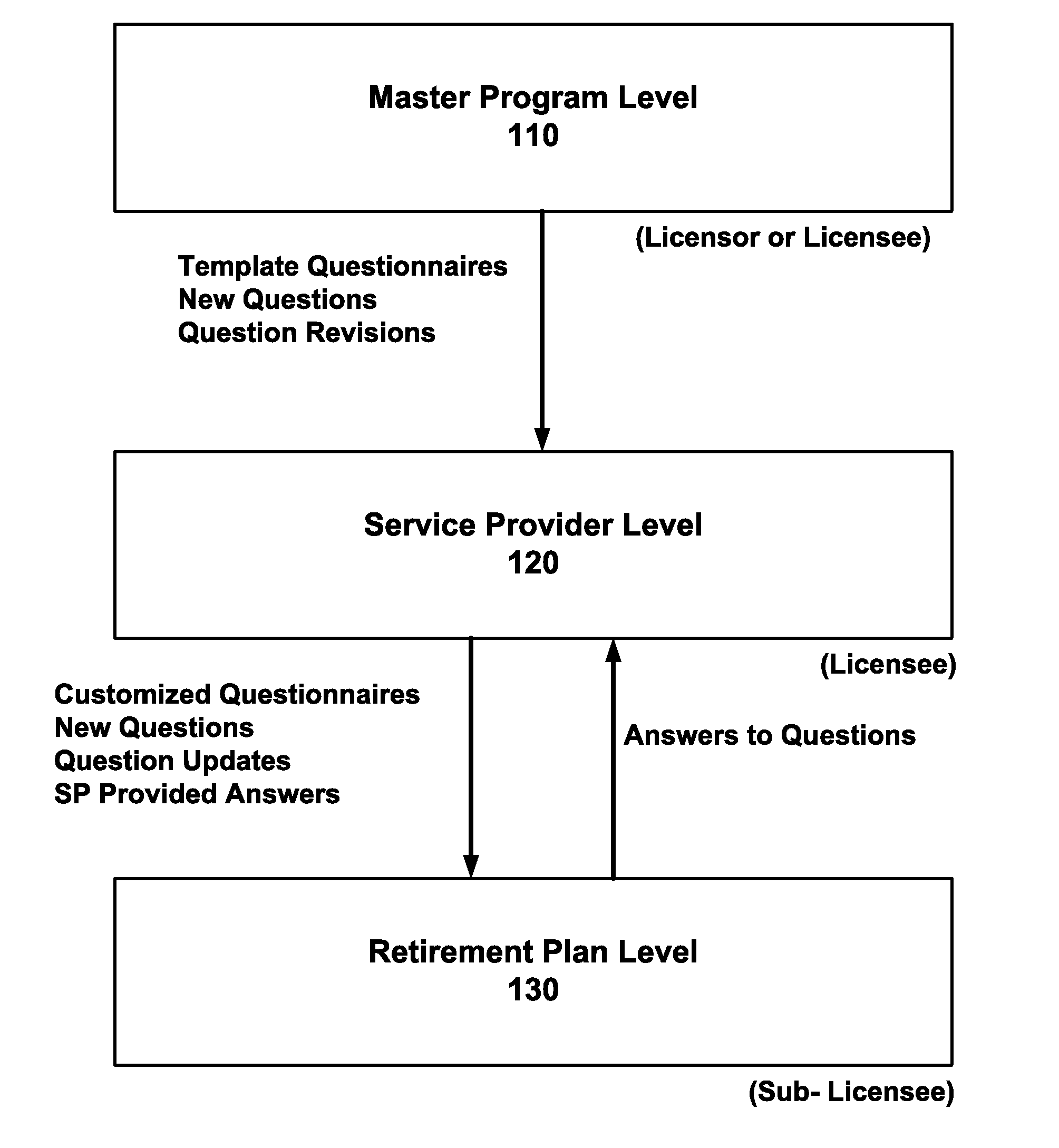

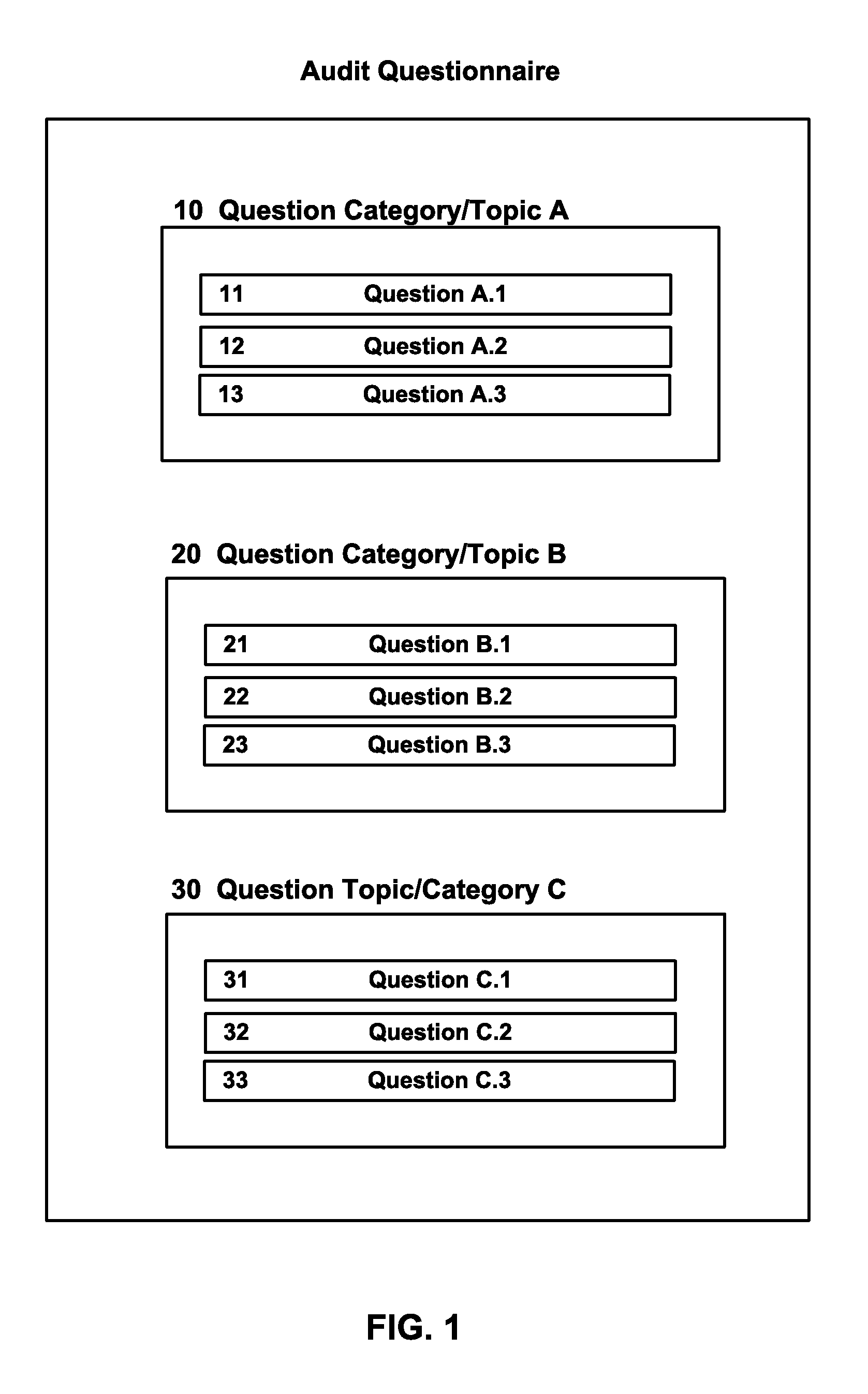

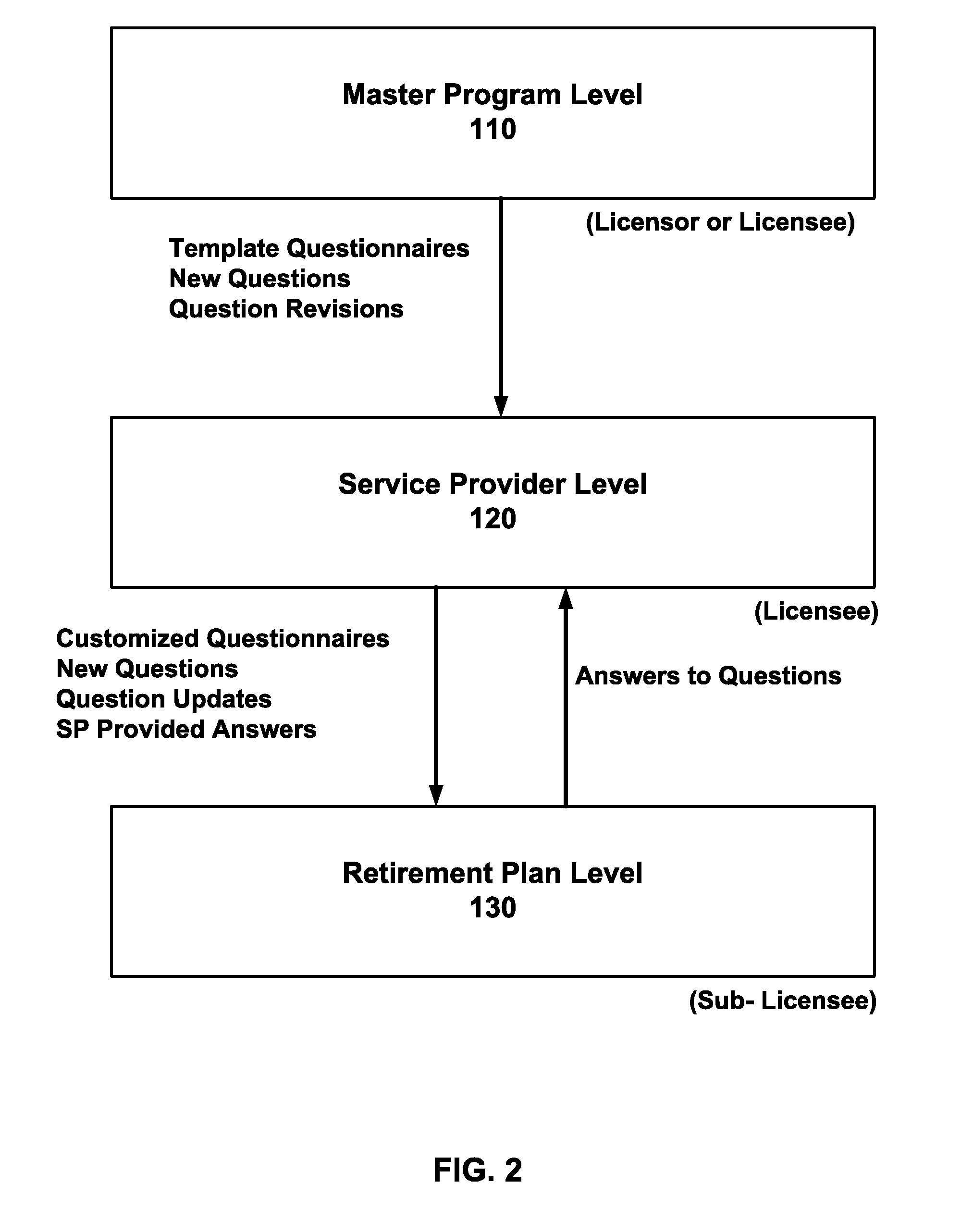

System and method for monitoring fiduciary compliance with employee retirement plan governance requirements

InactiveUS20100235297A1Efficient audit experienceSimplify complianceFinanceThree levelService provider

An employee retirement plan Fiduciary Audit® questionnaire development, implementation, and reporting system which includes the following interrelated and interdependent web based processes: (1) question and related support development and distribution, (2) organization of questions into questionnaires, (3) assignment of people resources involved, and 4) production and distribution of reports to present findings. The processes occur interactively at three levels: (1) a Master Program level, (2) a Service Provider level, and a (3) Retirement Plan level.

Owner:FIDUCIARY AUDIT SERVICES TRUST

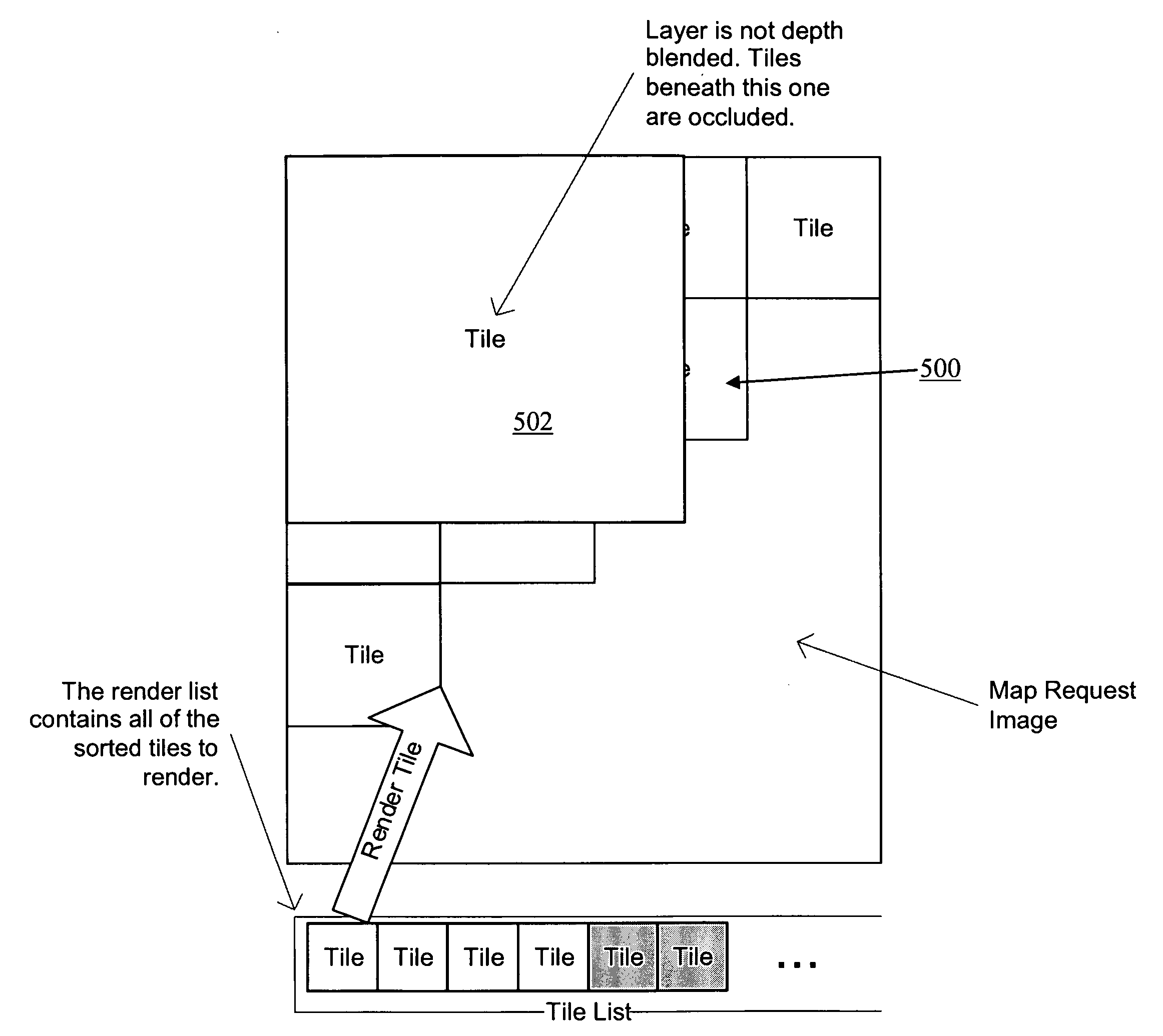

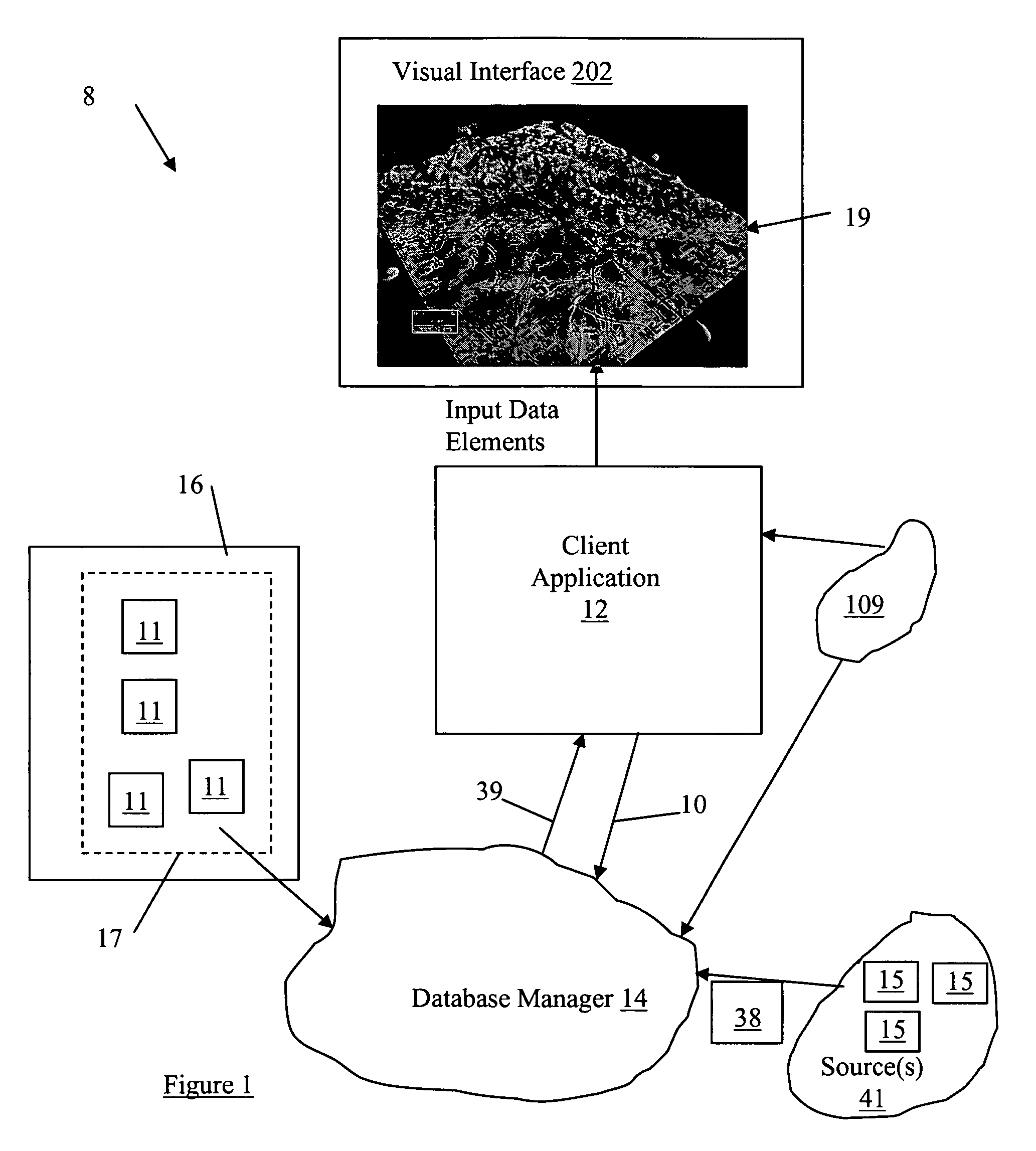

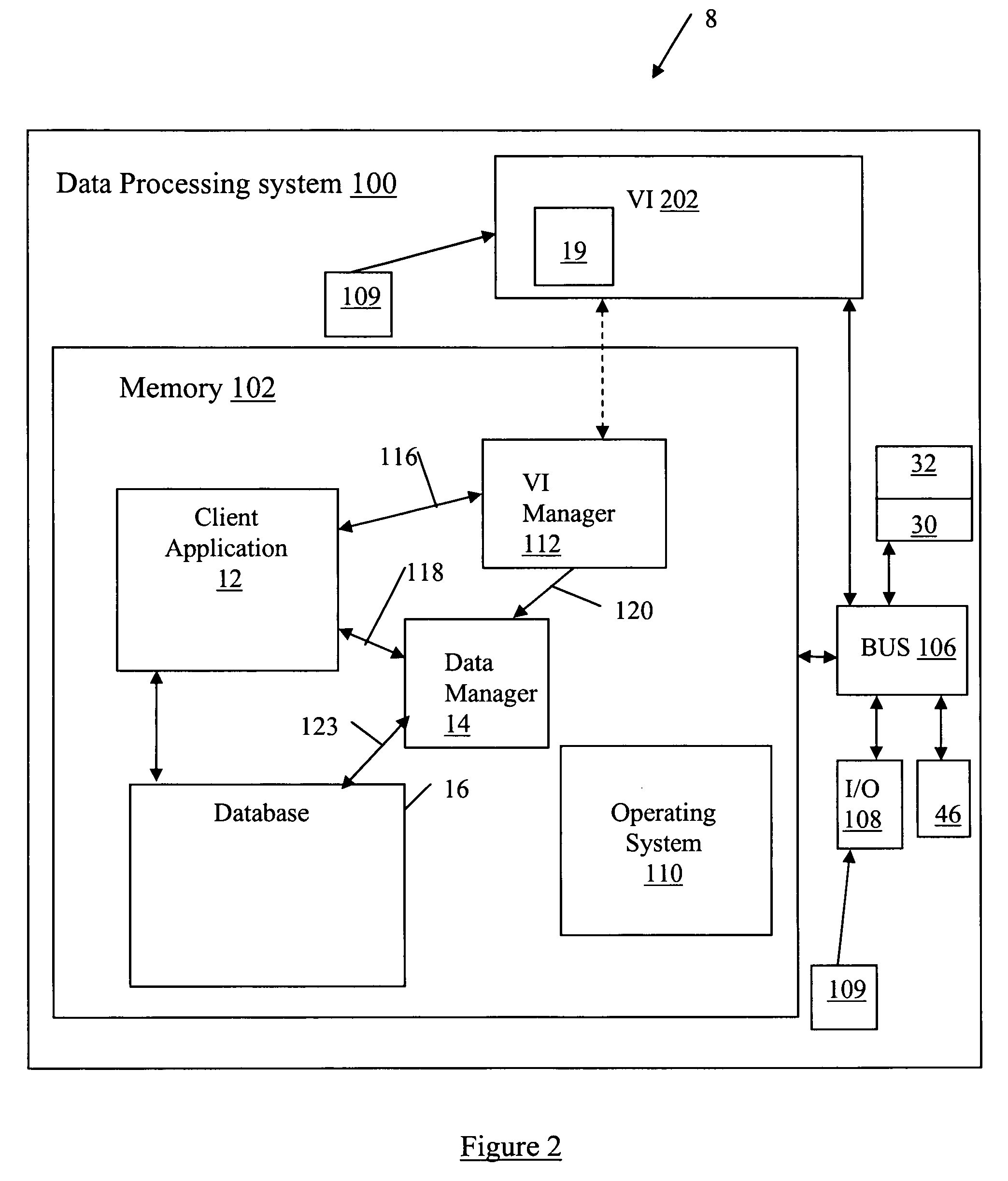

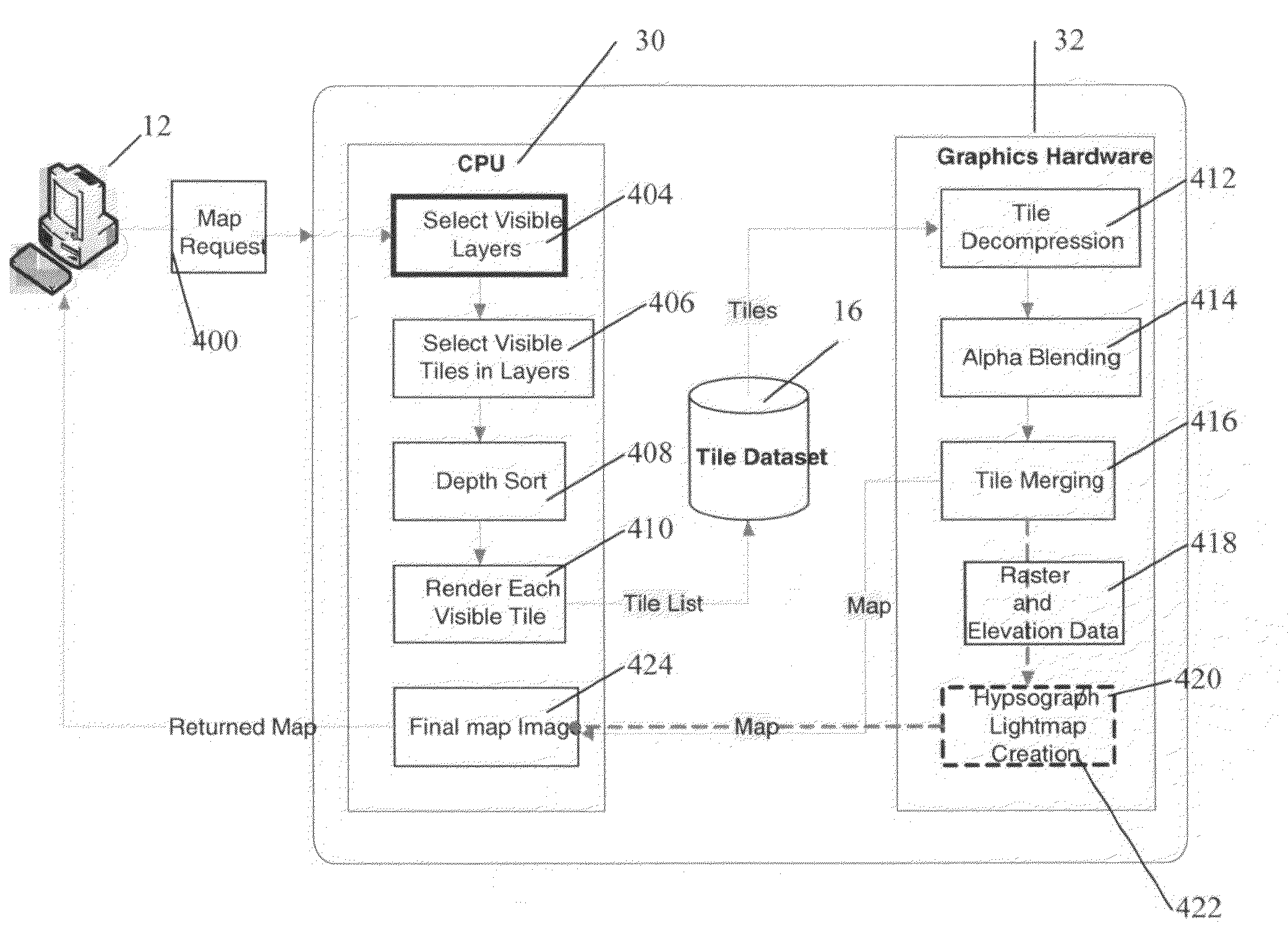

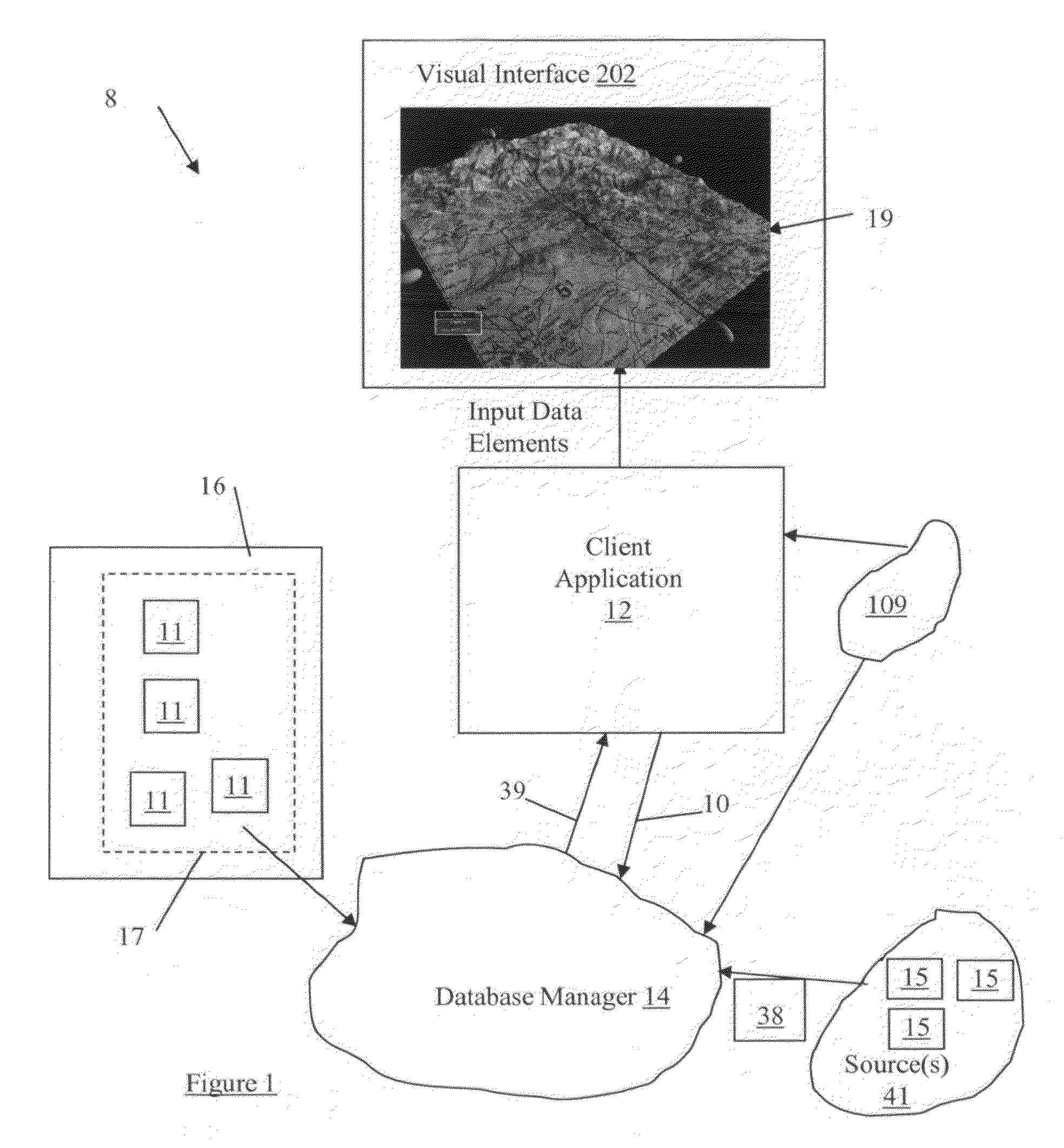

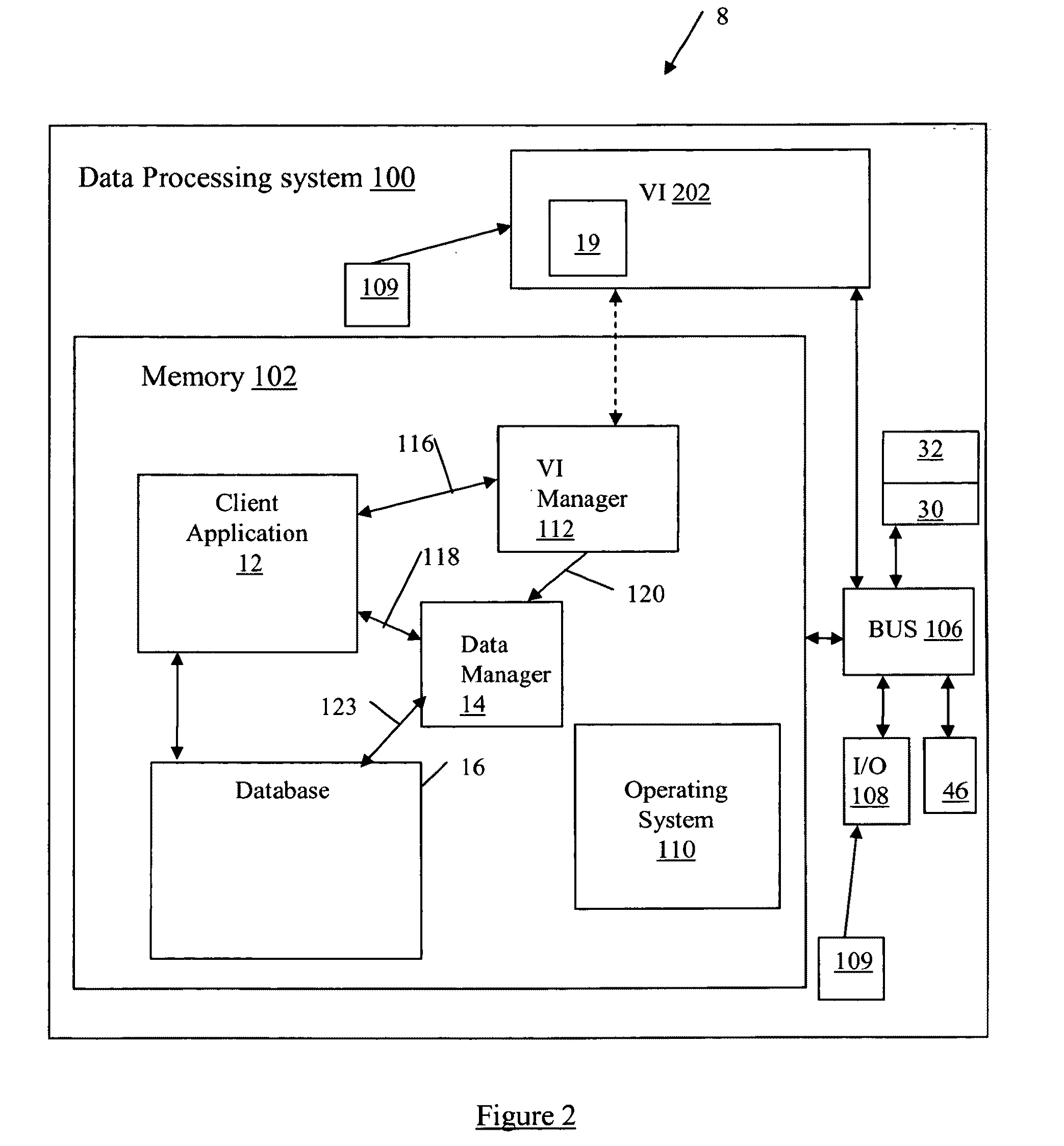

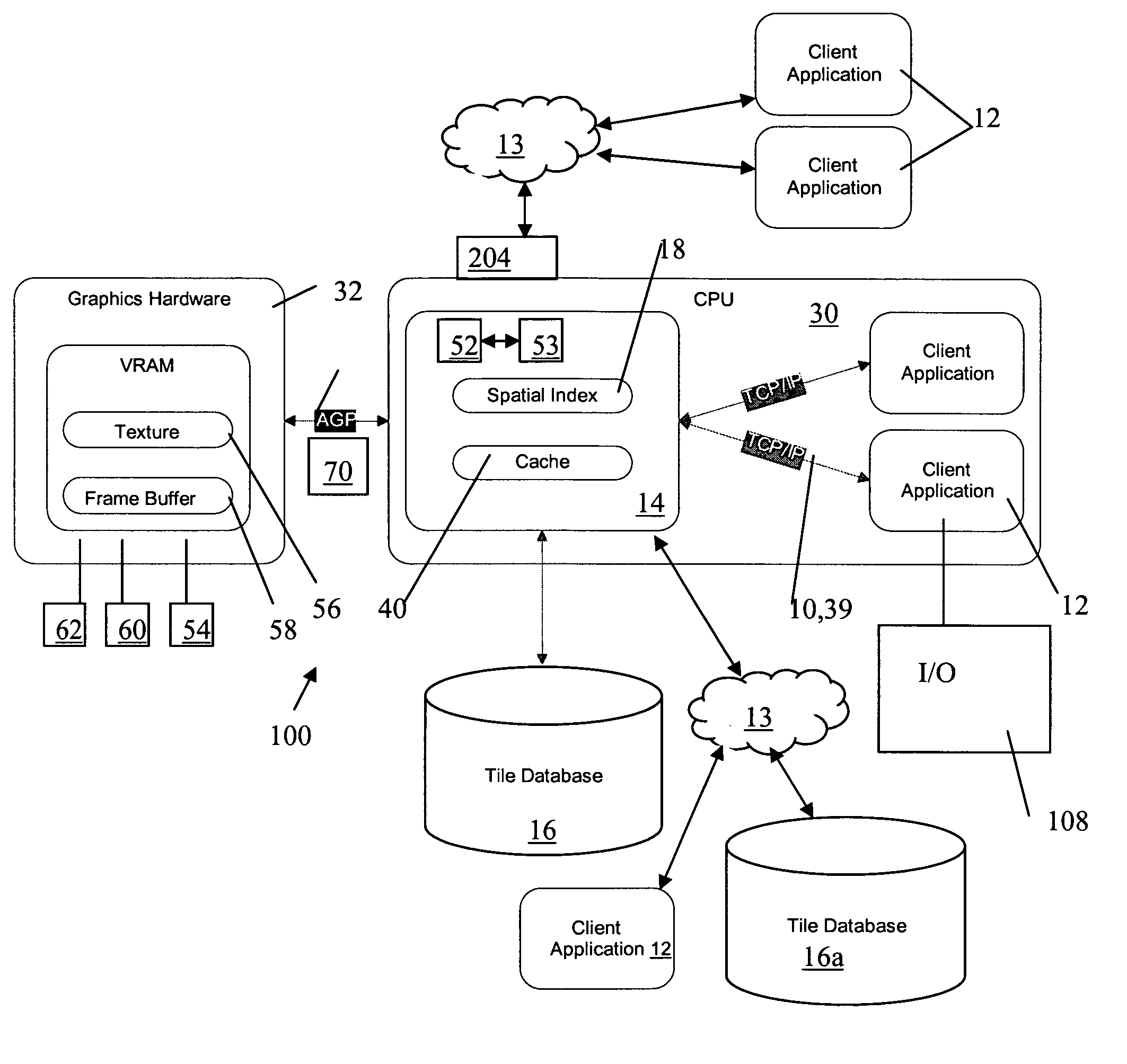

System and method for processig map data

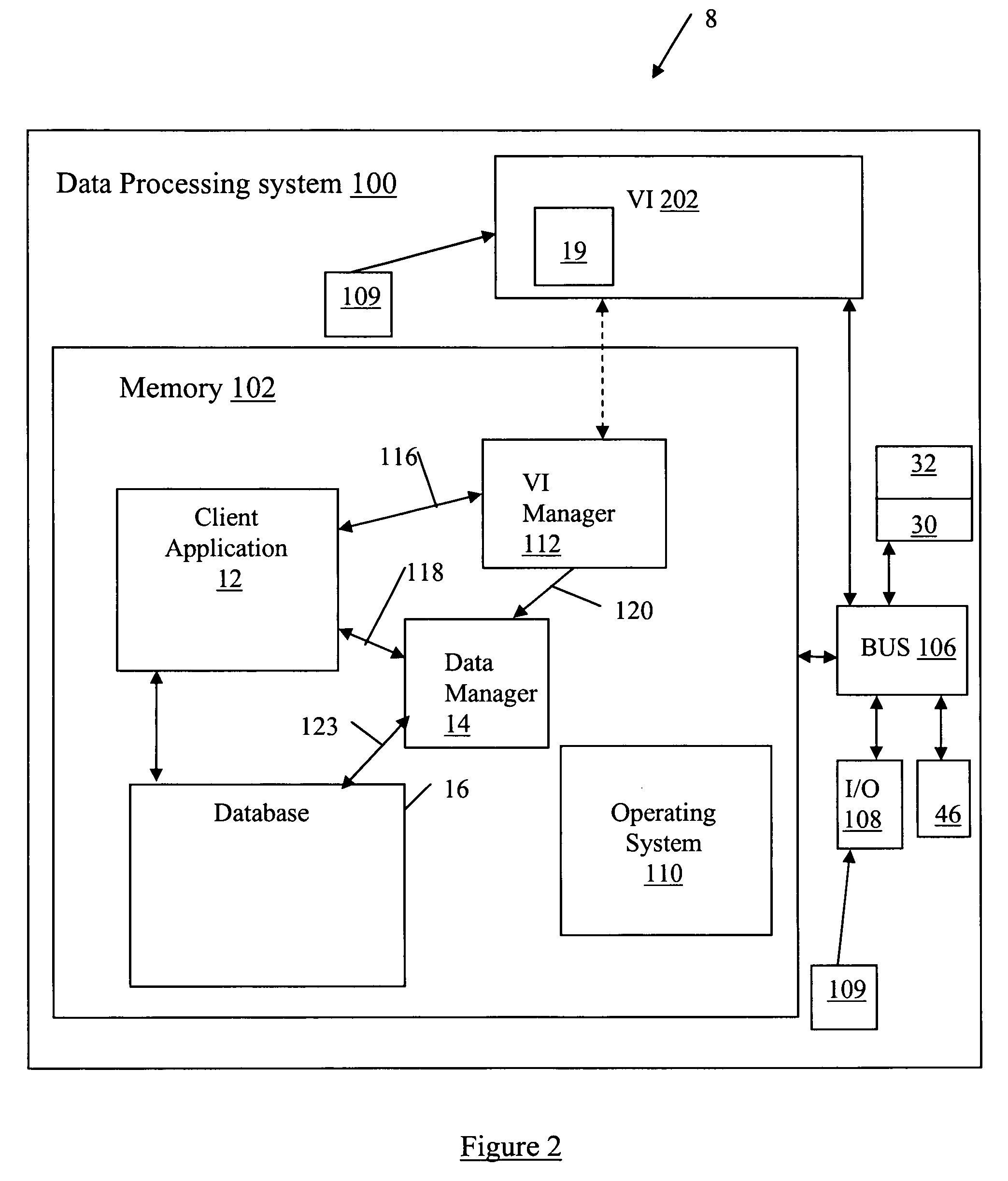

ActiveUS20060170693A1Easy to useEasy accessGeometric image transformationMemory adressing/allocation/relocationGraphic systemData store

A system and method is provided for assembling graphics information as a graphics display for presentation on a visual interface, the graphics information including a plurality of image tiles stored in a data store. The system and method comprise a management module for receiving a graphics request message and for coordinating processing of a selected number of the image tiles to generate at least one representative image tile as the graphics display in response to the graphics request message. The system and method also comprise a graphics system coupled to the management module for receiving processing information from the management module to facilitate access to the selected number of the image tiles. The selected number of image tiles are processed as a combination to generate the least one representative image tile, such that the graphics system includes graphics hardware such as a GPU / VPU configured for processing the graphics information.

Owner:UNCHARTED SOFTWARE INC

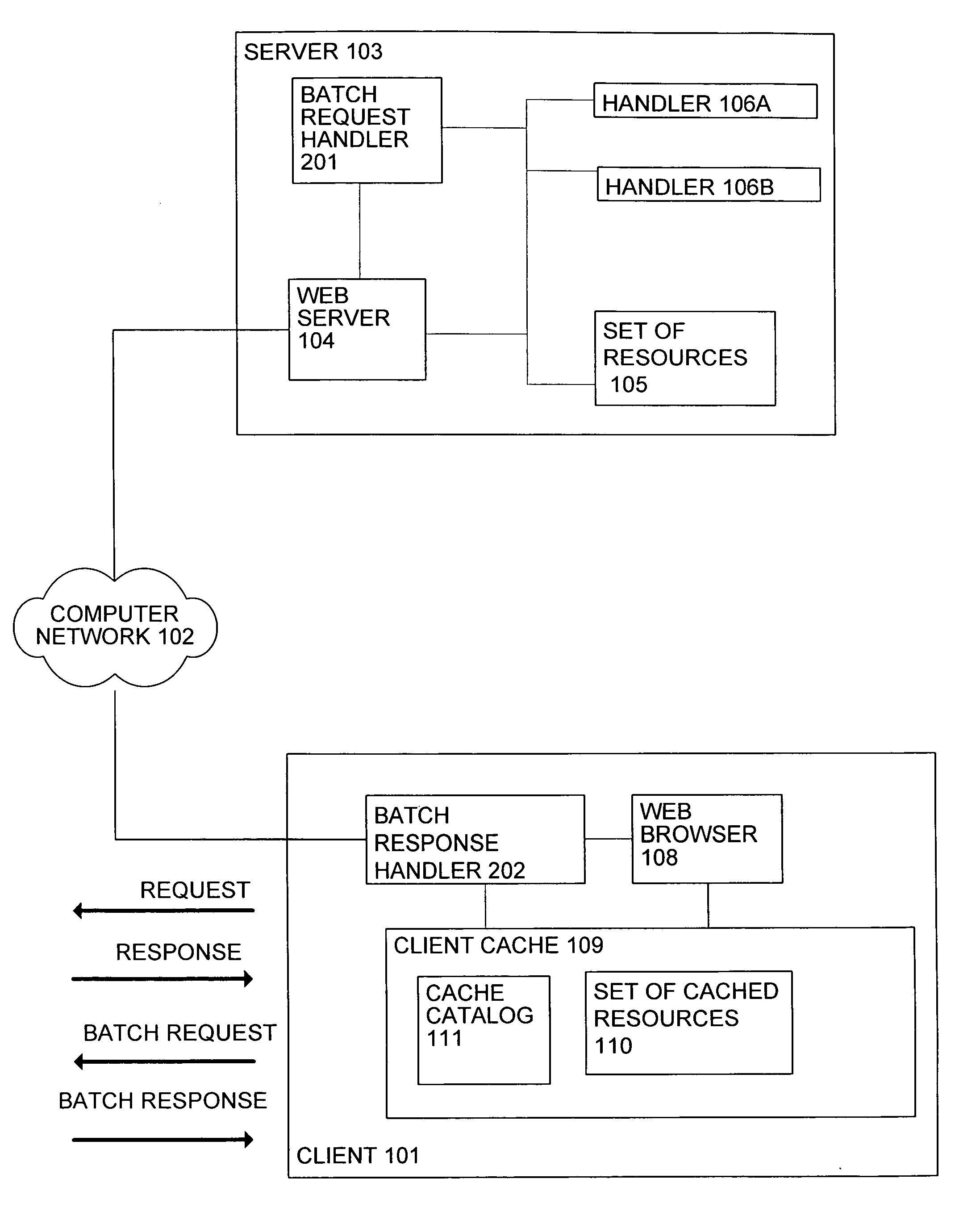

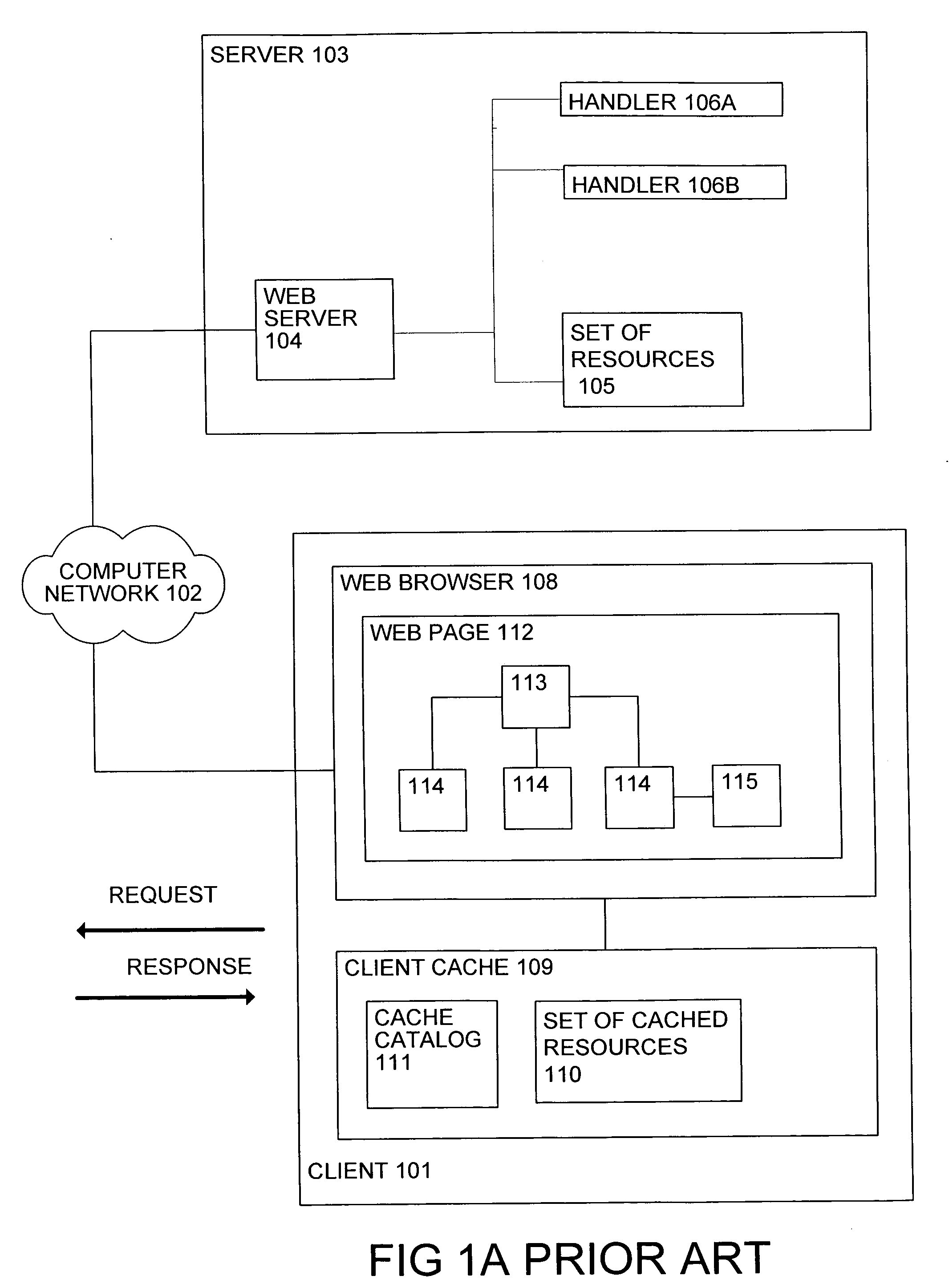

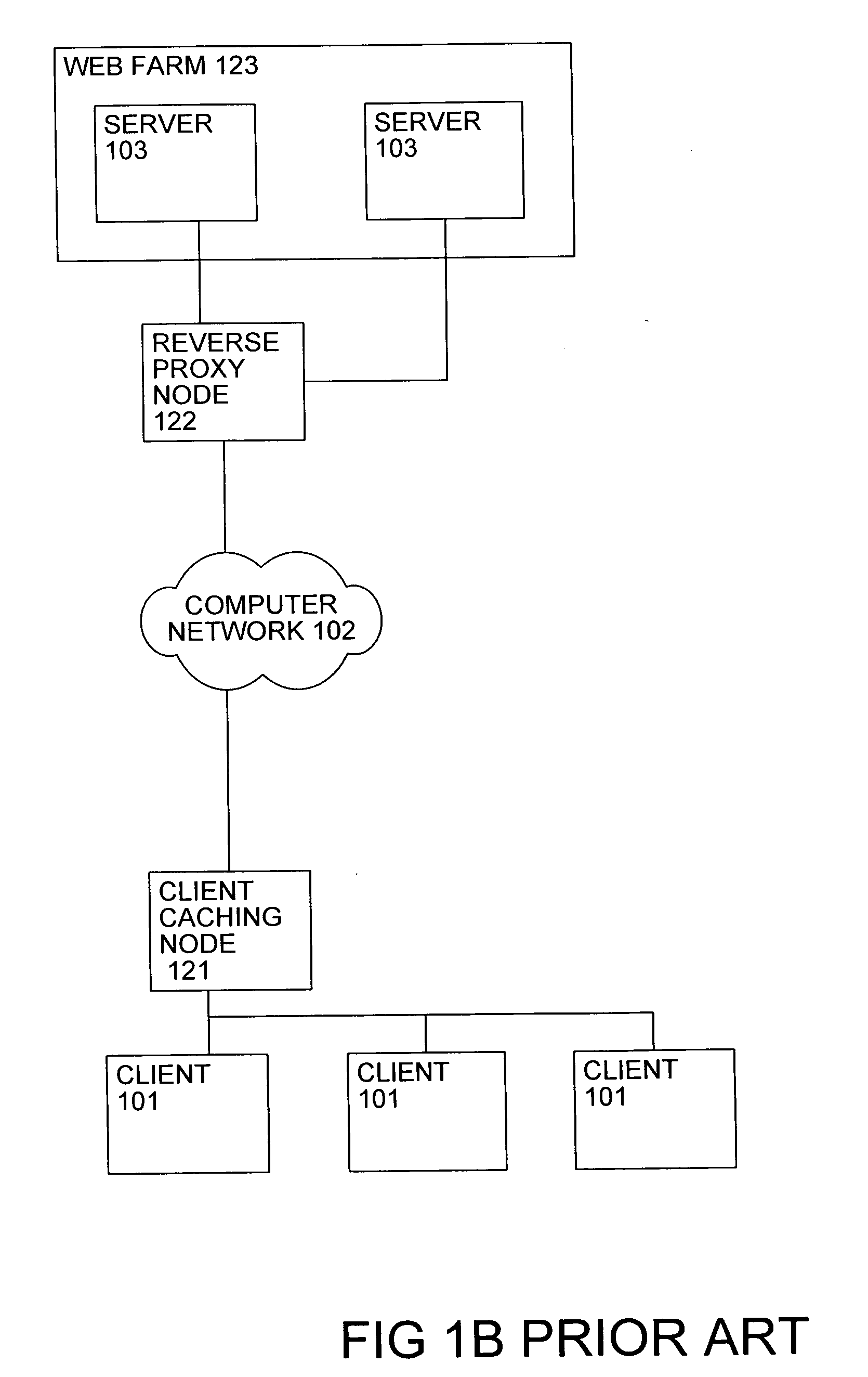

Method and system for reducing web page download time

InactiveUS20110066676A1Improve user experienceReduce in quantityDigital data information retrievalMultiple digital computer combinationsWeb applicationWeb browser

In one embodiment web page response time is improved by requesting multiple resources in a batch request, receiving said resources in a batch response, and disjoining the resources and corresponding HTTP headers before caching on the client. The resources are retrieved by web browser from the cache separately without loss of cache granularity. Client parses base page to determine the embedded resources and includes in the batch requests only web addresses those resources that are uncached or may be expired. To reduce required bandwidth, server validates caching information of every resource before sending the batch response. In another embodiment web application performance for mobile users is improved by combining individually requested resources into the batch response on a network node positioned on a link between cellular network and the Internet.

Owner:KLEYZIT VADIM

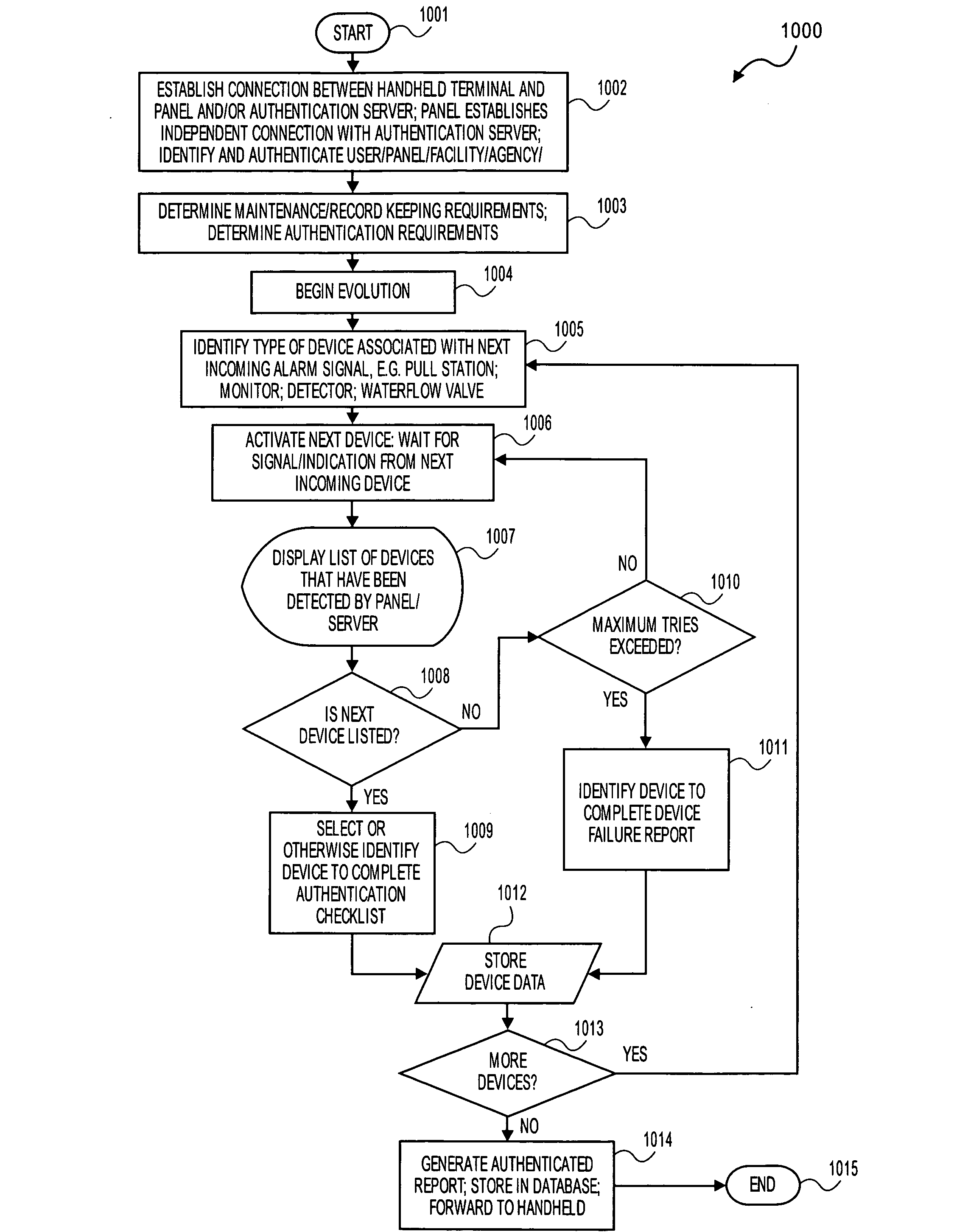

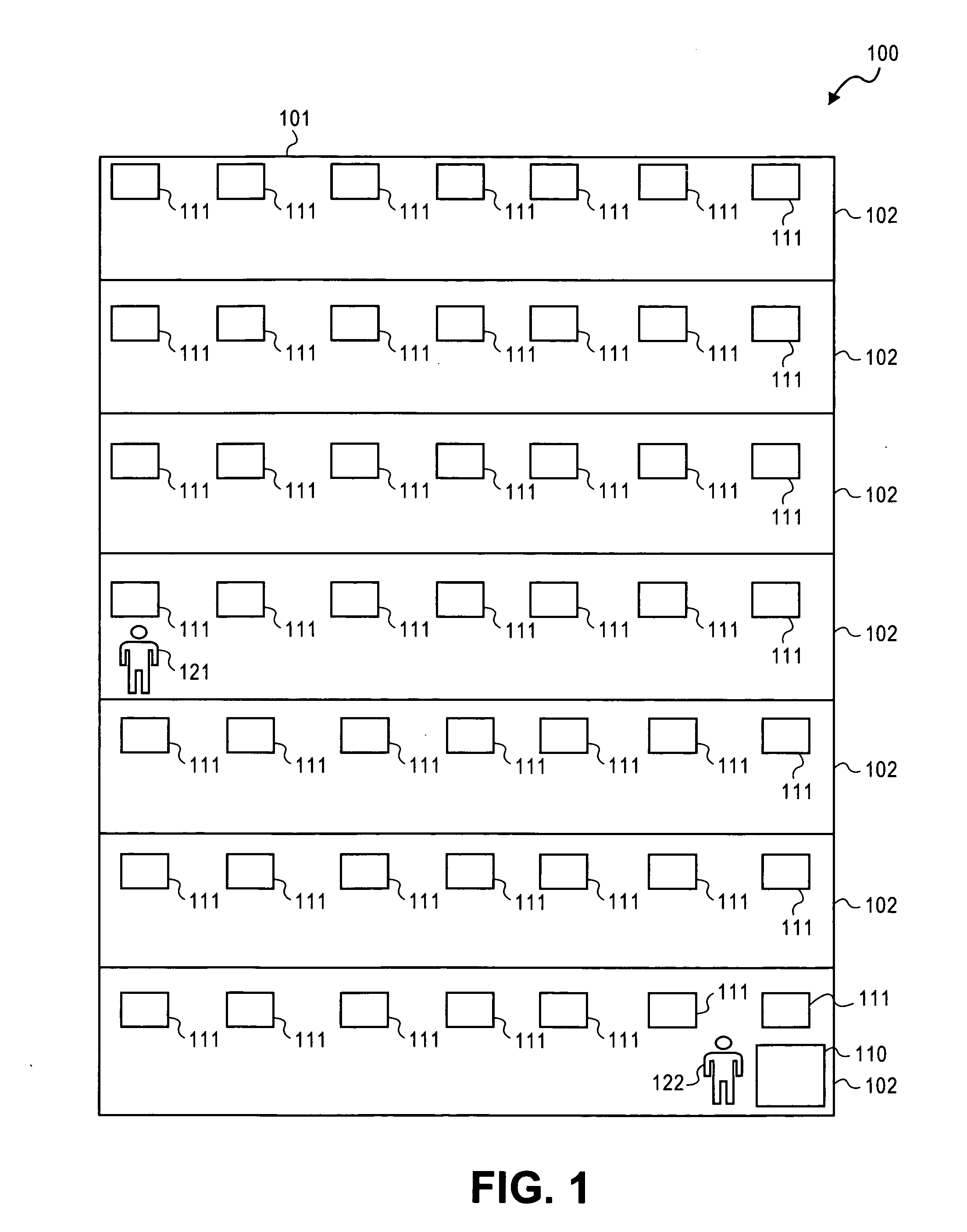

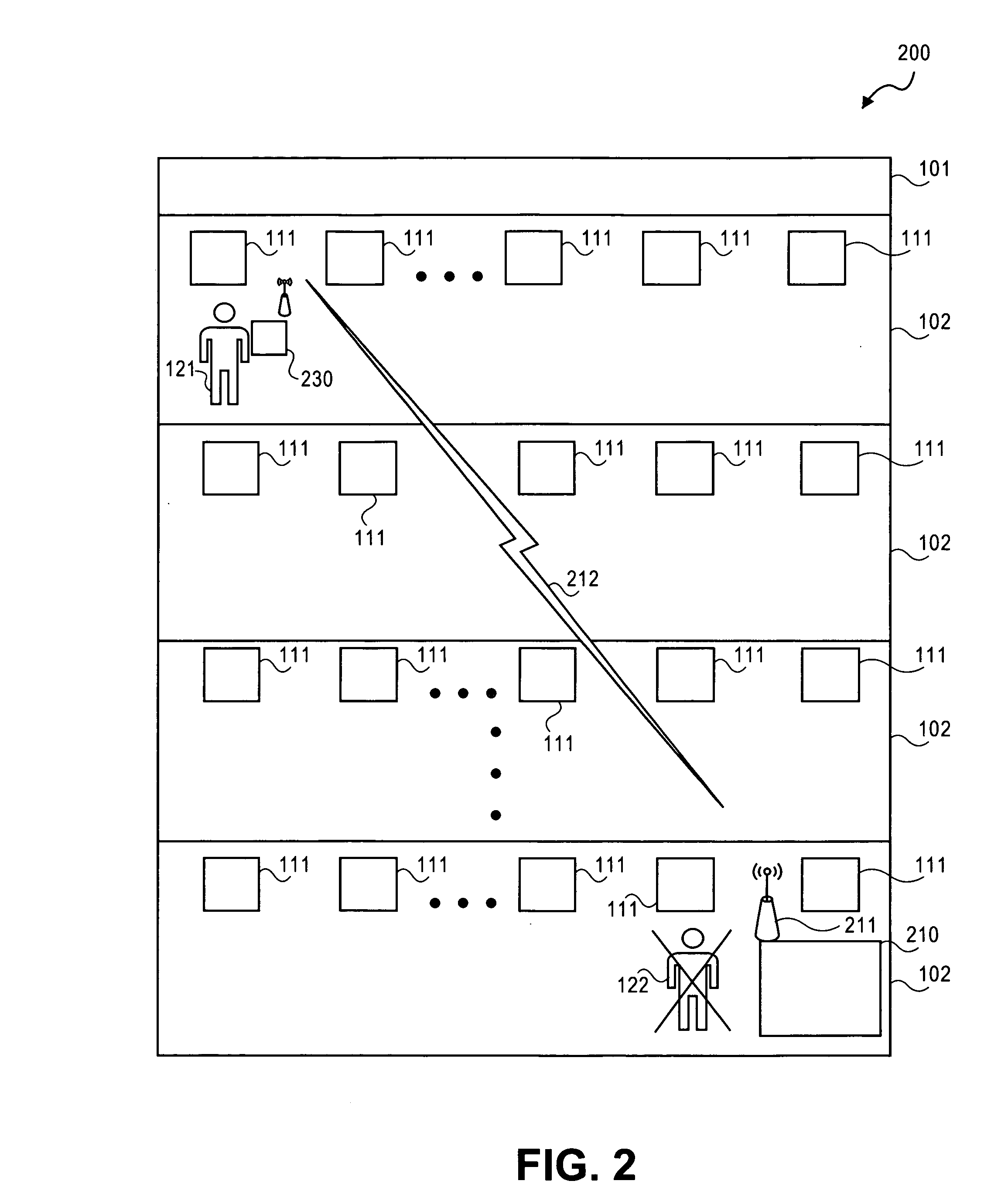

Method and apparatus for authenicated on-site testing, inspection, servicing and control of life-safety equipment and reporting of same using a remote accessory

A method, apparatus, remote accessory and authentication server are provided for facilitating operations such as an authenticated test of life safety equipment having components including a control panel and sensors. The life safety equipment requires testing according to a fire code. An access procedure is conducted to identify equipment and testing requirements and to establish a communication session between the equipment and an authentication server during an authenticated test. Another access procedure is conducted to provide access for a remote device for facilitating the authenticated test and to establish a communication session between the remote device and an alarm system or authentication server, or the like. Information associated with an impending activation of one of the sensors is received from the remote device and information associated with the sensor, when activated, is reported if detected by the alarm system, to the authentication server and the reported activation information is forwarded to the remote device. Authentication information associated with the activated sensor whether or not detected is received from the remote device and an authenticated report is forwarded to the remote device when all of the alarm condition sensors are tested according to test procedures.

Owner:CAMPION JR CHRISTOPHER M +1

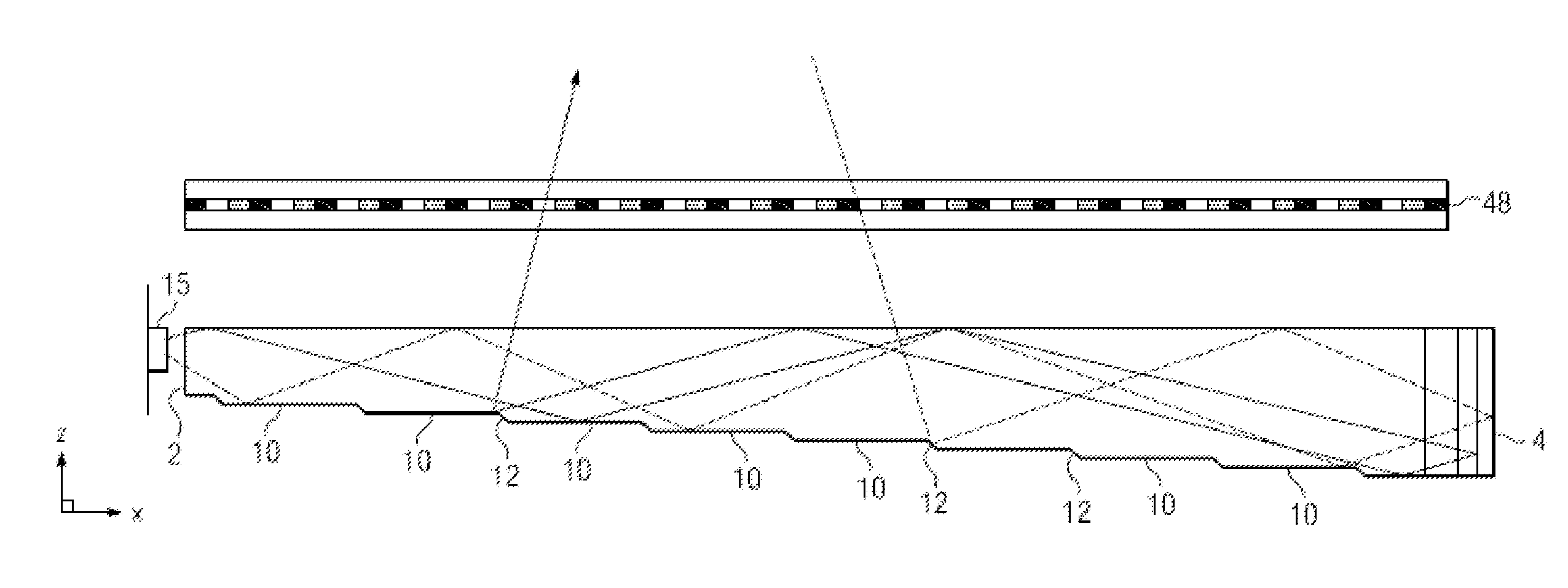

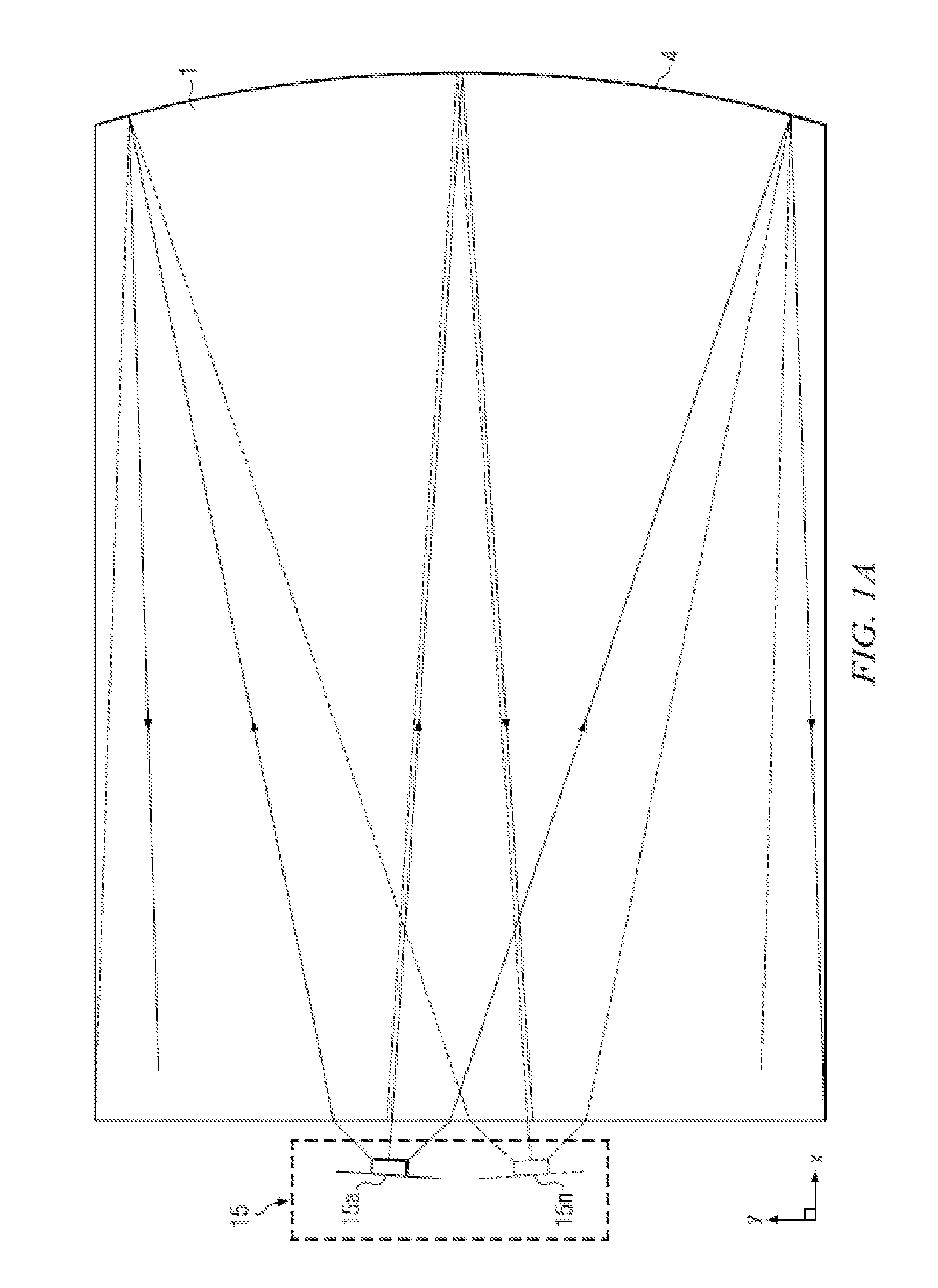

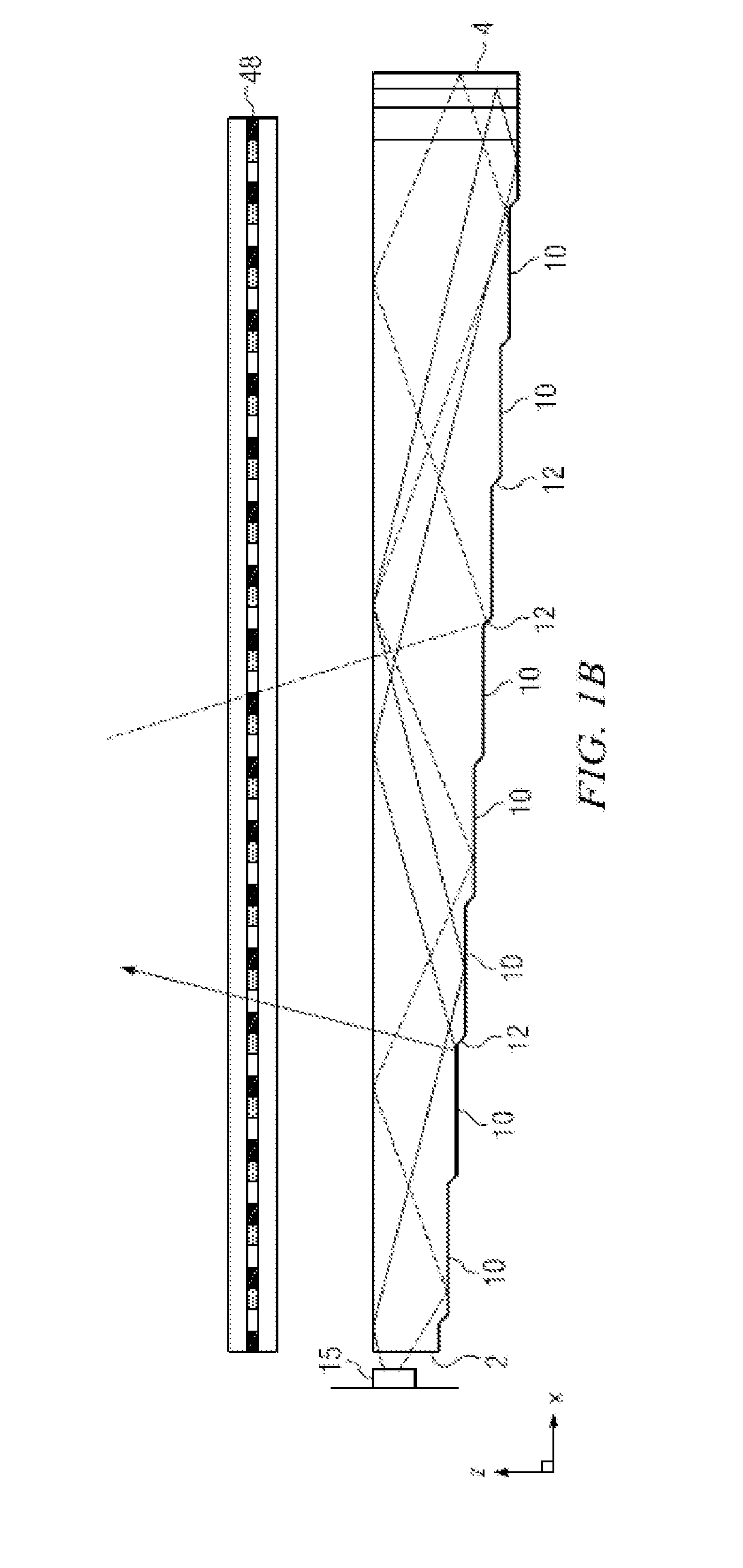

Spatially multiplexed imaging directional backlight displays

InactiveUS20130328866A1Slow responseReduce complexityMechanical apparatusPlanar/plate-like light guidesSpatial light modulatorDisplay device

Disclosed is an imaging directional backlight that cooperates with a spatial light modulator to direct light into a first viewing window for one set of image pixels and into a second viewing window for a second set of image pixels. The waveguide may comprise a stepped structure, where the steps further comprise extraction features hidden to guided light, propagating in a first forward direction. Returning light propagating in a second backward direction may be refracted, diffracted, or reflected by the features to provide discrete illumination beams exiting from the top surface of the waveguide. Viewing windows are formed through imaging individual light sources and hence defines the relative positions of system elements and ray paths. Such an apparatus may be used to achieve an autostereoscopic display with a flat structure, not requiring fast response speed spatial light modulators.

Owner:REALD SPARK LLC

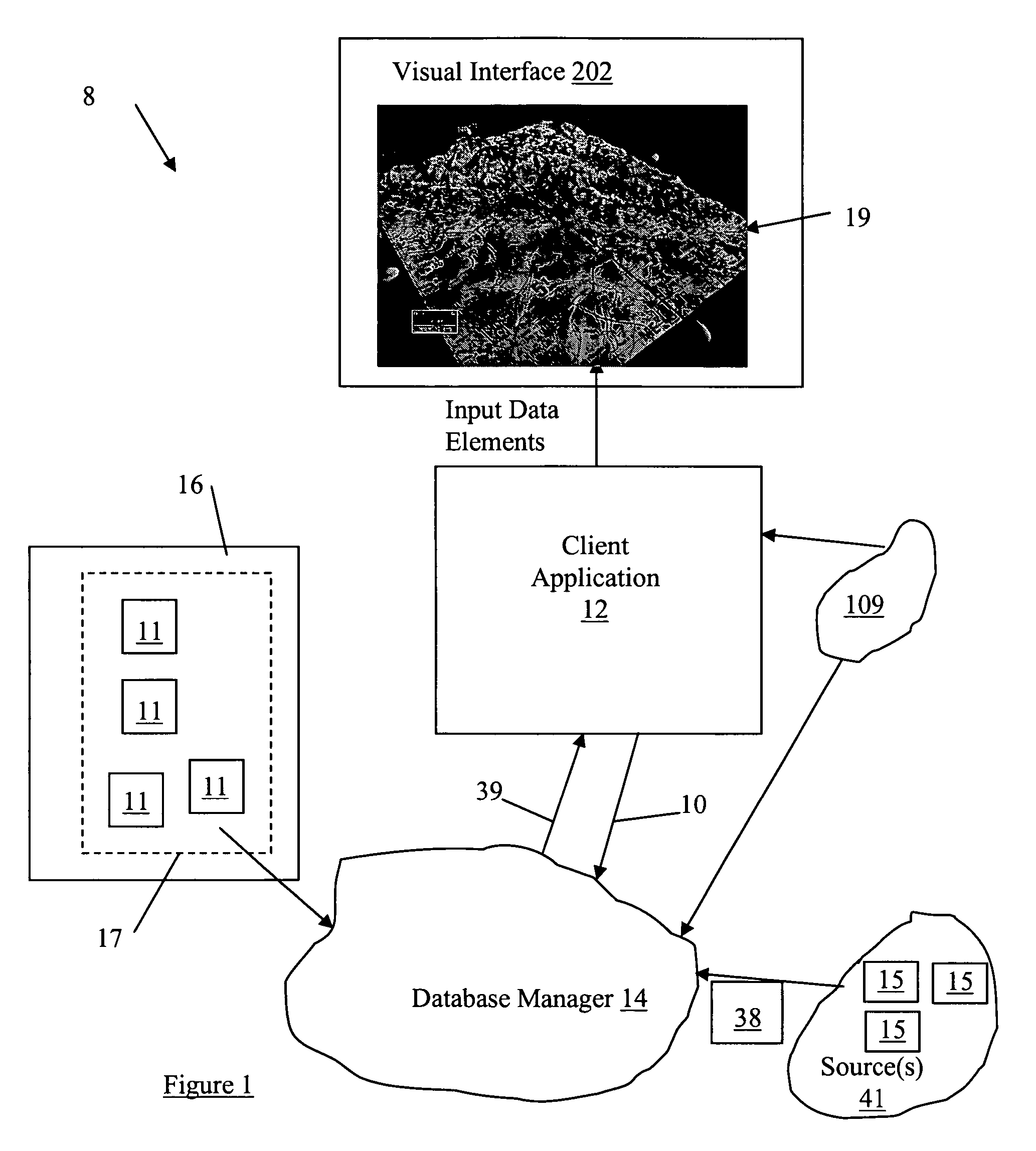

System and method for processing map data

ActiveUS20100007669A1Easy to useEasy accessGeometric image transformationDigital computer detailsGraphic systemProcess map

A system and method is provided for assembling graphics information as a graphics display for presentation on a visual interface, the graphics information including a plurality of image tiles stored in a data store. The system and method comprise a management module for receiving a graphics request message and for coordinating processing of a selected number of the image tiles to generate at least one representative image tile as the graphics display in response to the graphics request message. The system and method also comprise a graphics system coupled to the management module for receiving processing information from the management module to facilitate access to the selected number of the image tiles. The selected number of image tiles are processed as a combination to generate the least one representative image tile, such that the graphics system includes graphics hardware such as a GPU / VPU configured for processing the graphics information.

Owner:UNCHARTED SOFTWARE INC

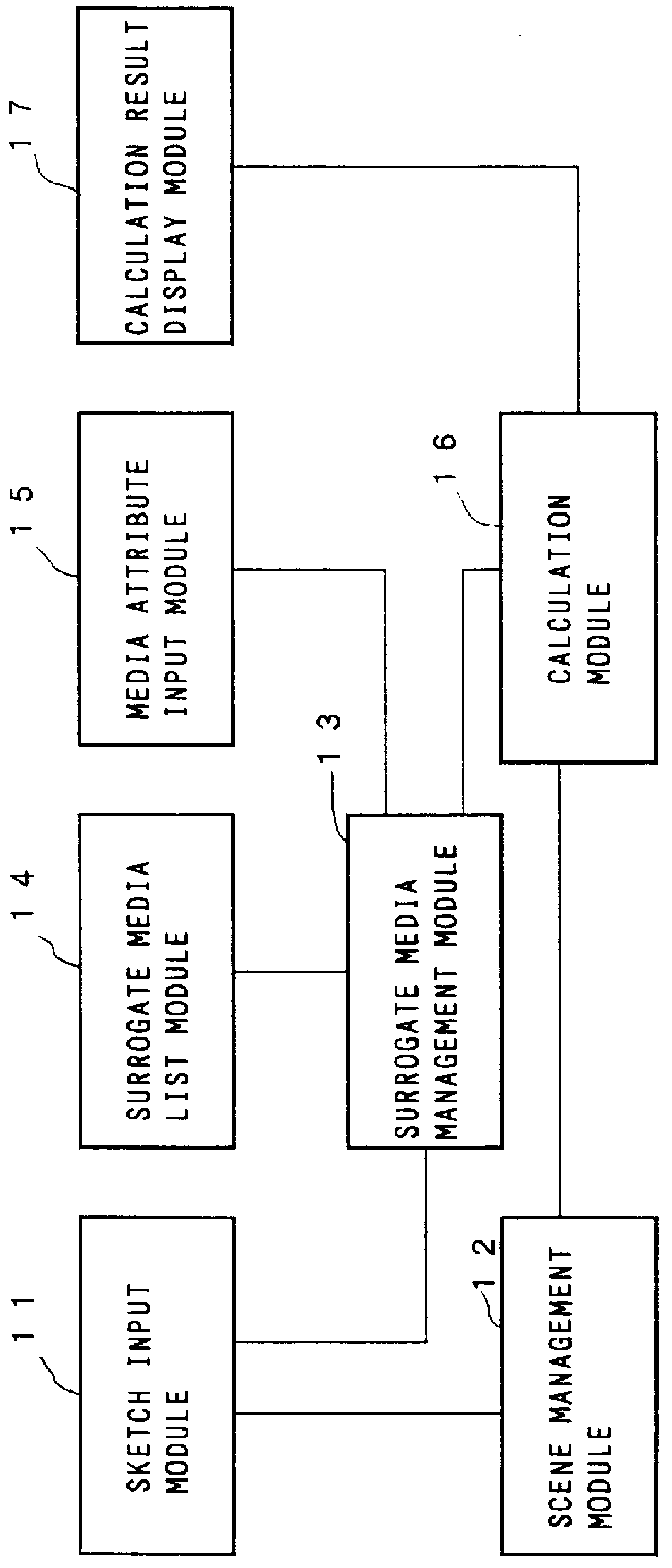

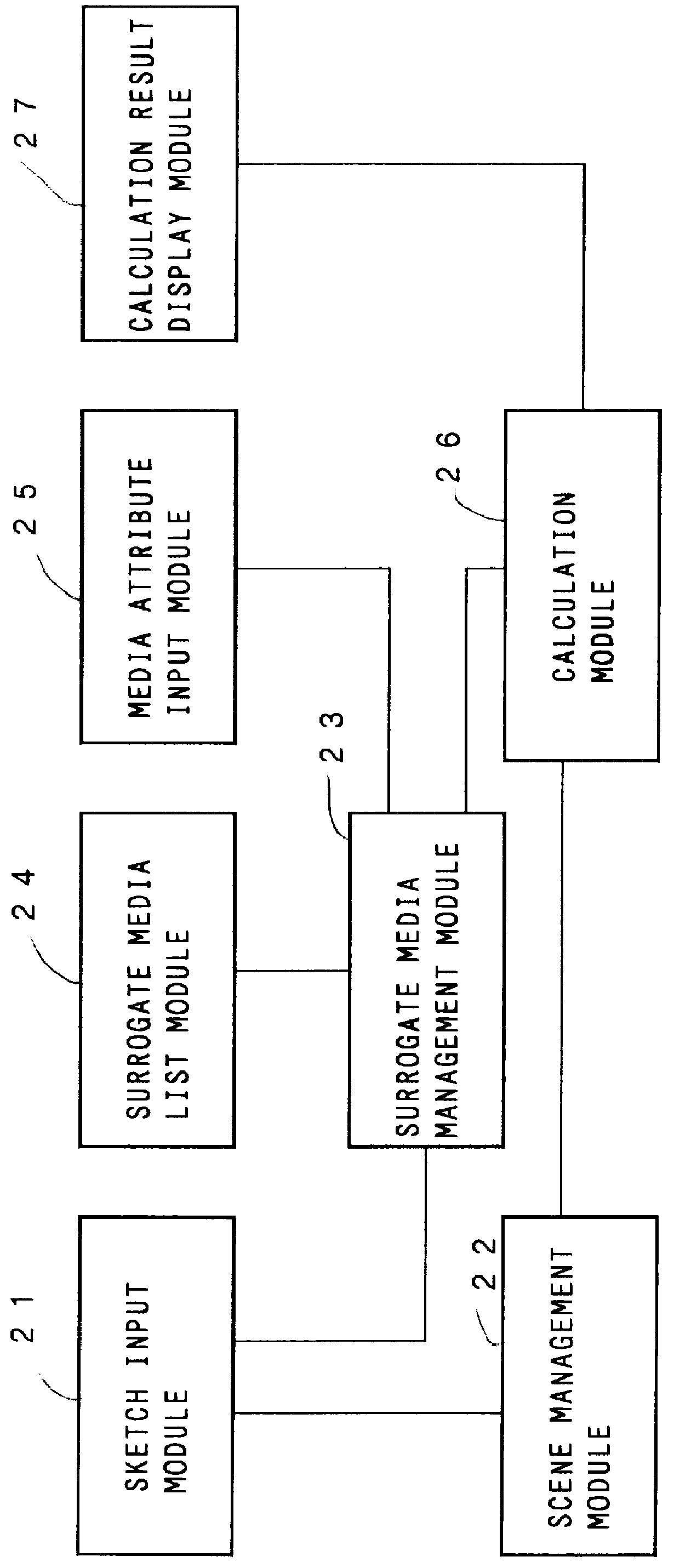

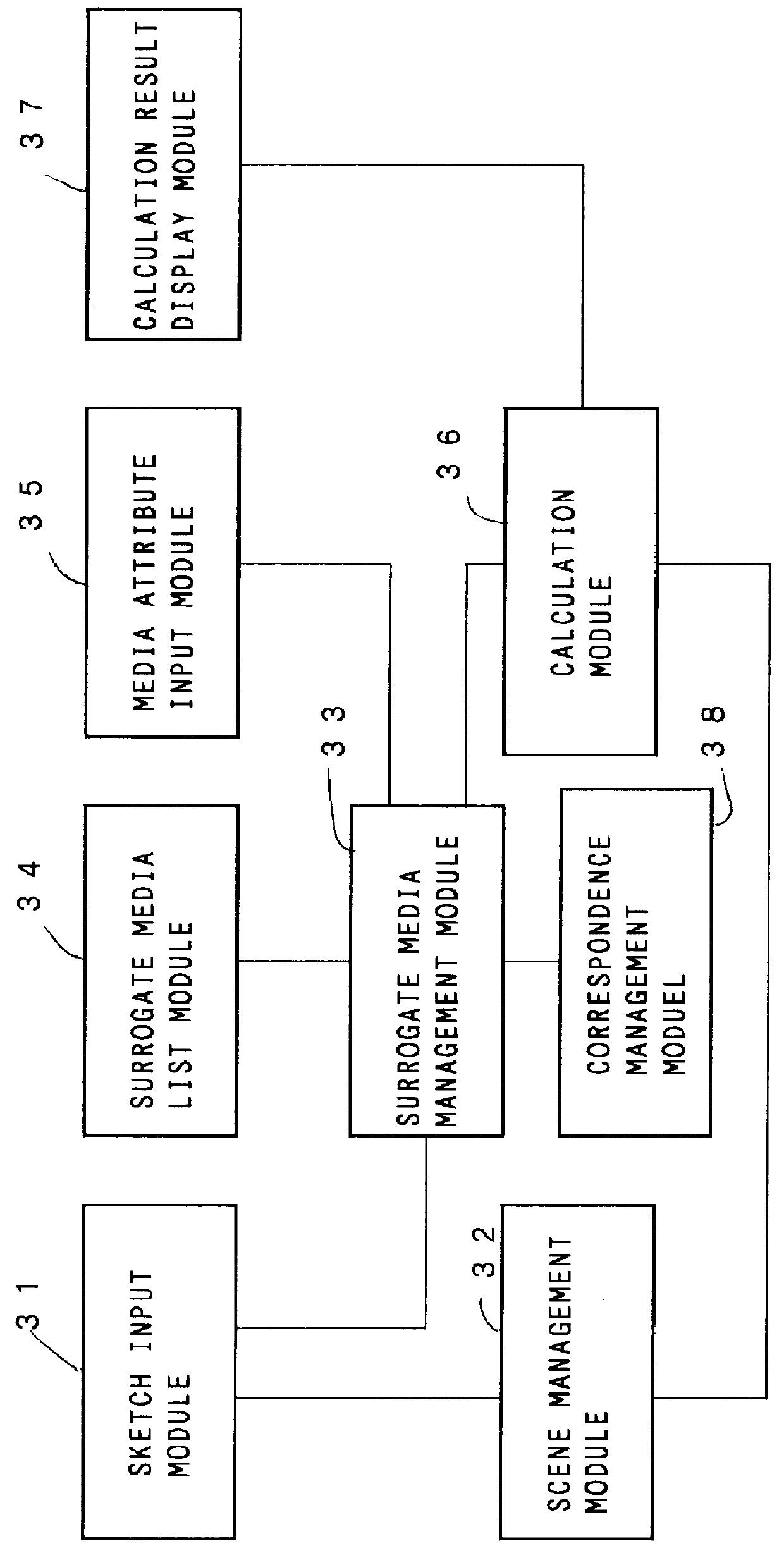

Multimedia scenario editor calculating estimated size and cost

InactiveUS6072479ASlow responsePoor qualityElectronic editing digitised analogue information signalsMultimedia data retrievalImage objectApplication software

A scenario editing system comprises a drawing input module drawing graphic media objects or inputting existing media objects; a scene management module storing and managing said media objects; a surrogate media management module storing said media objects for use as surrogate media objects temporarily representing actual moving picture objects, voice objects, or image objects to be created later; a surrogate media list module displaying said surrogate media objects in a list of thumbnails; a media attribute input module allowing a user to enter a media-dependent attribute of an actual media object to be created, while said surrogate media list module displays the list; a calculation module calculating sizes of actual media data and adding up the media data sizes to estimate a total size of an overall application, based on said media-dependent attribute; and a calculation result display module displaying the result of said calculation. The media attribute input module allows a user to enter the name of a person in charge and scheduled development time as an attribute, wherein the calculation module adds up actual media creation costs for calculation of an estimate of the cost of each media type and an overall application, and wherein the calculation result display module displays cost information for each media type and for the overall application.

Owner:NEC CORP

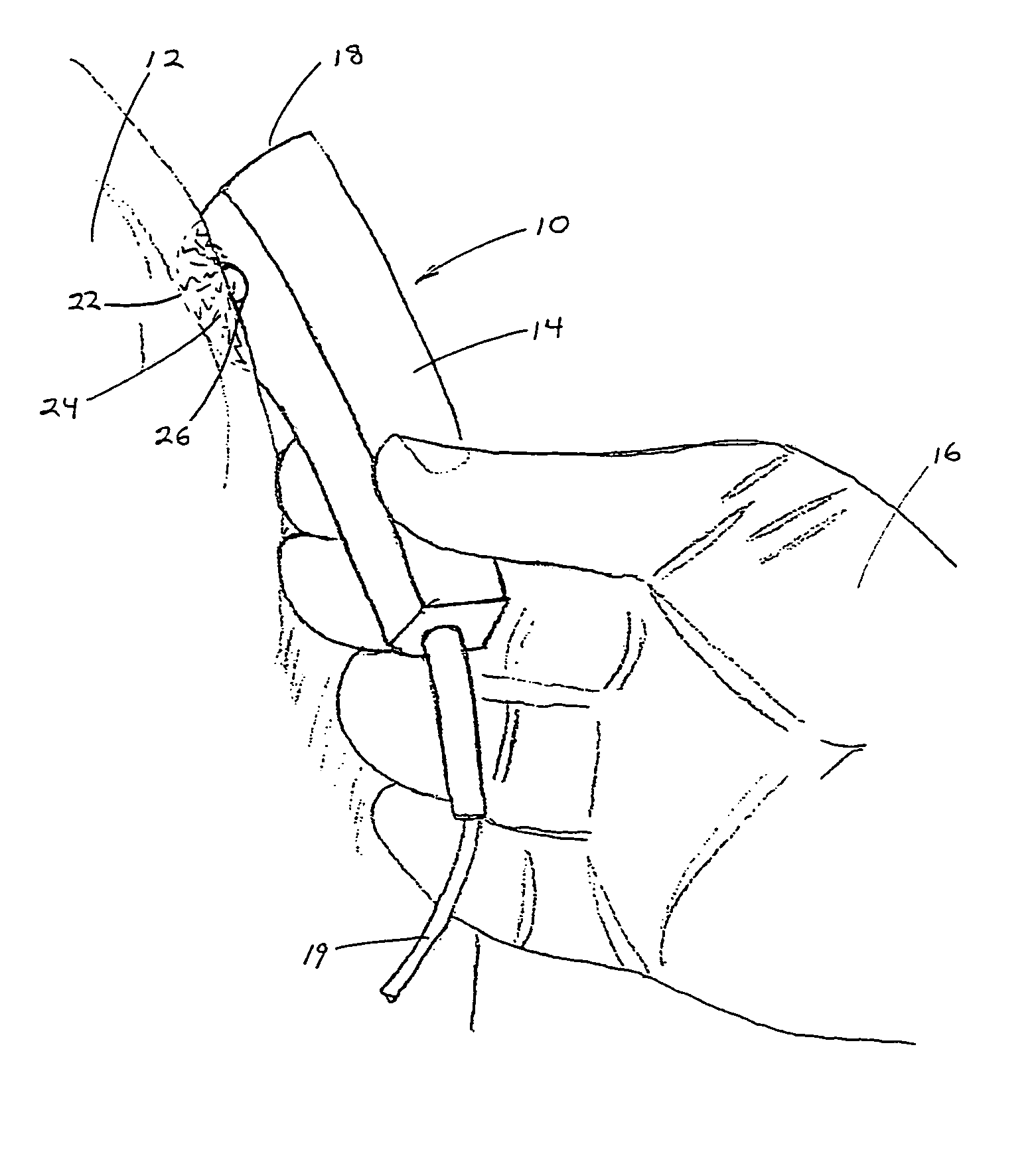

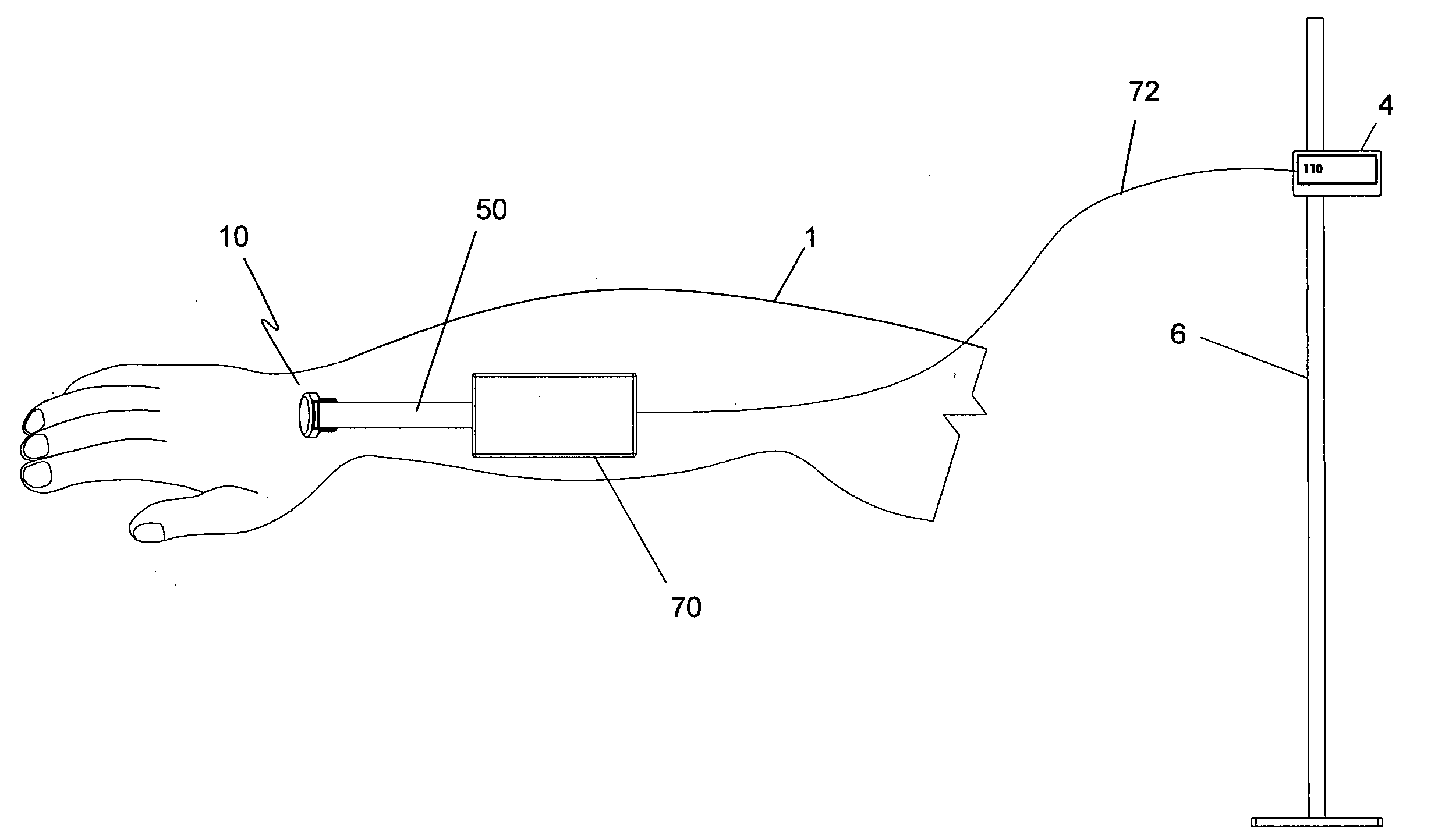

Method and apparatus for pulsed electromagnetic therapy

An apparatus and method for applying pulsed electromagnetic therapy to humans and animals. A straight wire element is employed to generate the magnetic field. A power and timer circuit supplies current pulses that approximate square pulses in form, so that the straight wire element generates magnetic pulses having rapid rise and fall times. Peak field strength is approximately 2 gauss at a 1 cm distance from the straight wire element, and the duration of peak field strength is approximately 200 nanoseconds. The pulses are repeated at a frequency of about 70 Hz. The straight wire element and circuit may be housed in a hand-held probe, with an LED illuminating the skin area to provide a visual indication of effective range, or a plurality of the straight wire elements and associated circuits may be embedded in a conformable pad that is placed over the affected area of the body.

Owner:GORDON GLEN A

System and method for processing map data

ActiveUS7551182B2Easy to useEasy accessGeometric image transformationMemory adressing/allocation/relocationGraphic systemDisplay device

Owner:UNCHARTED SOFTWARE INC

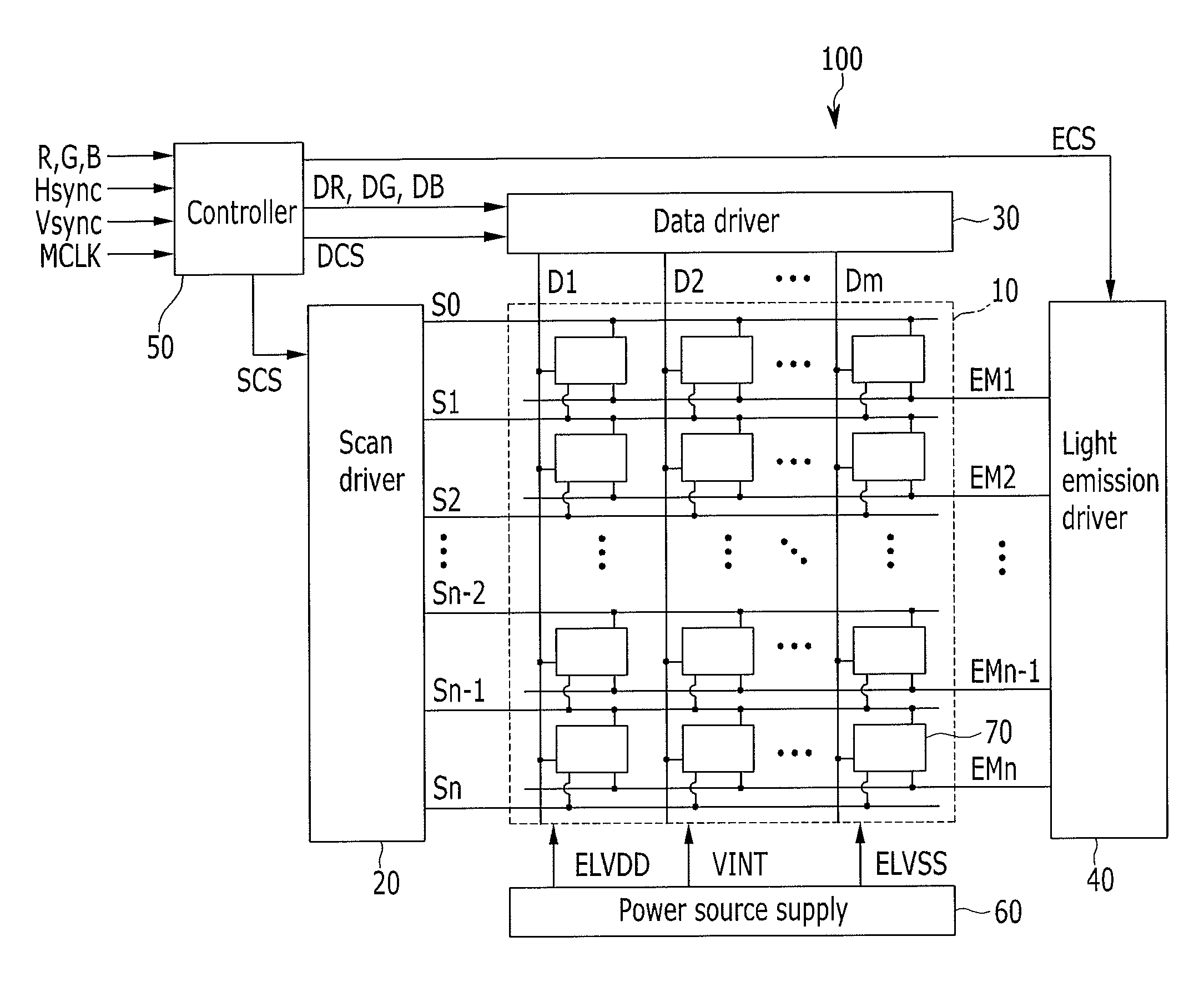

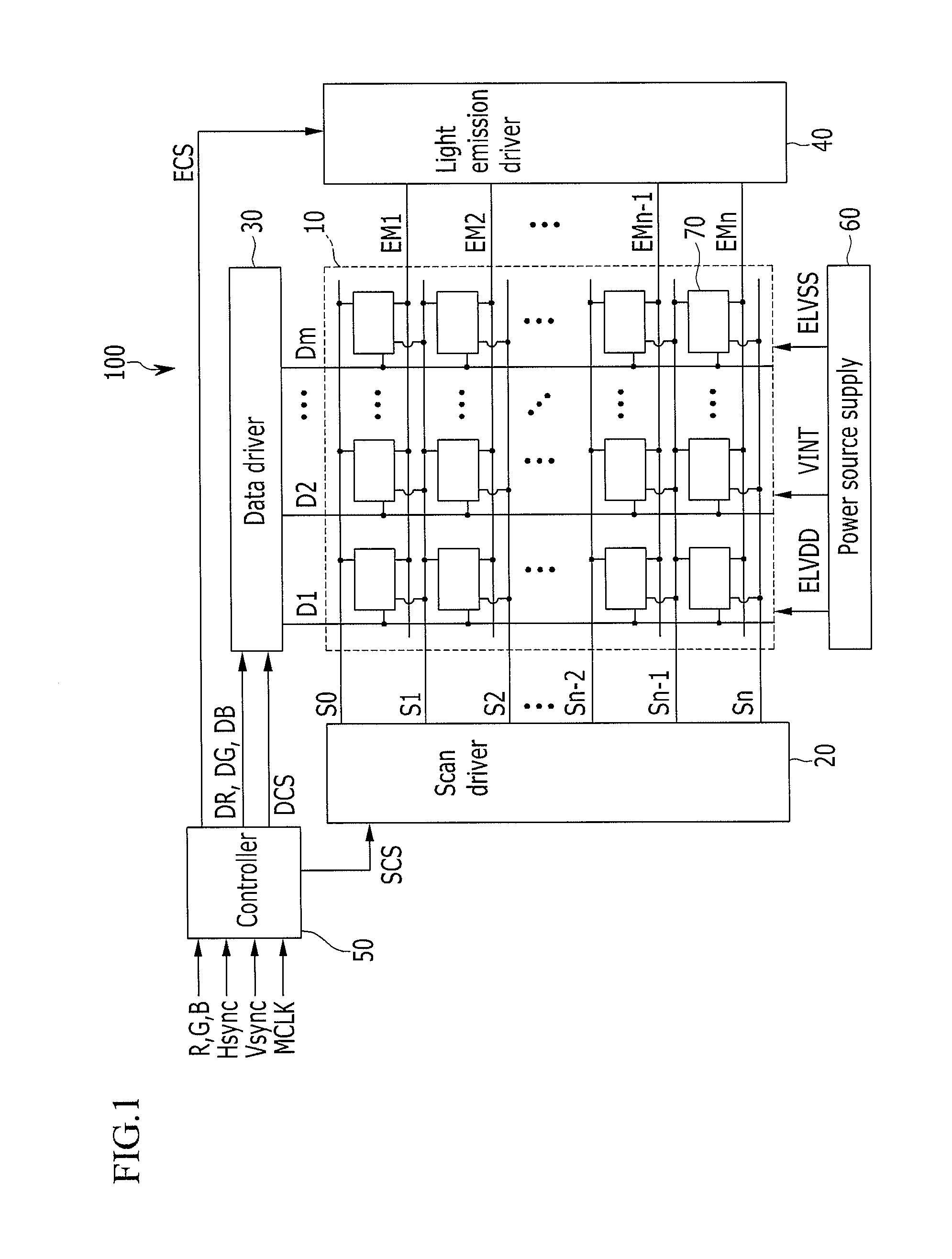

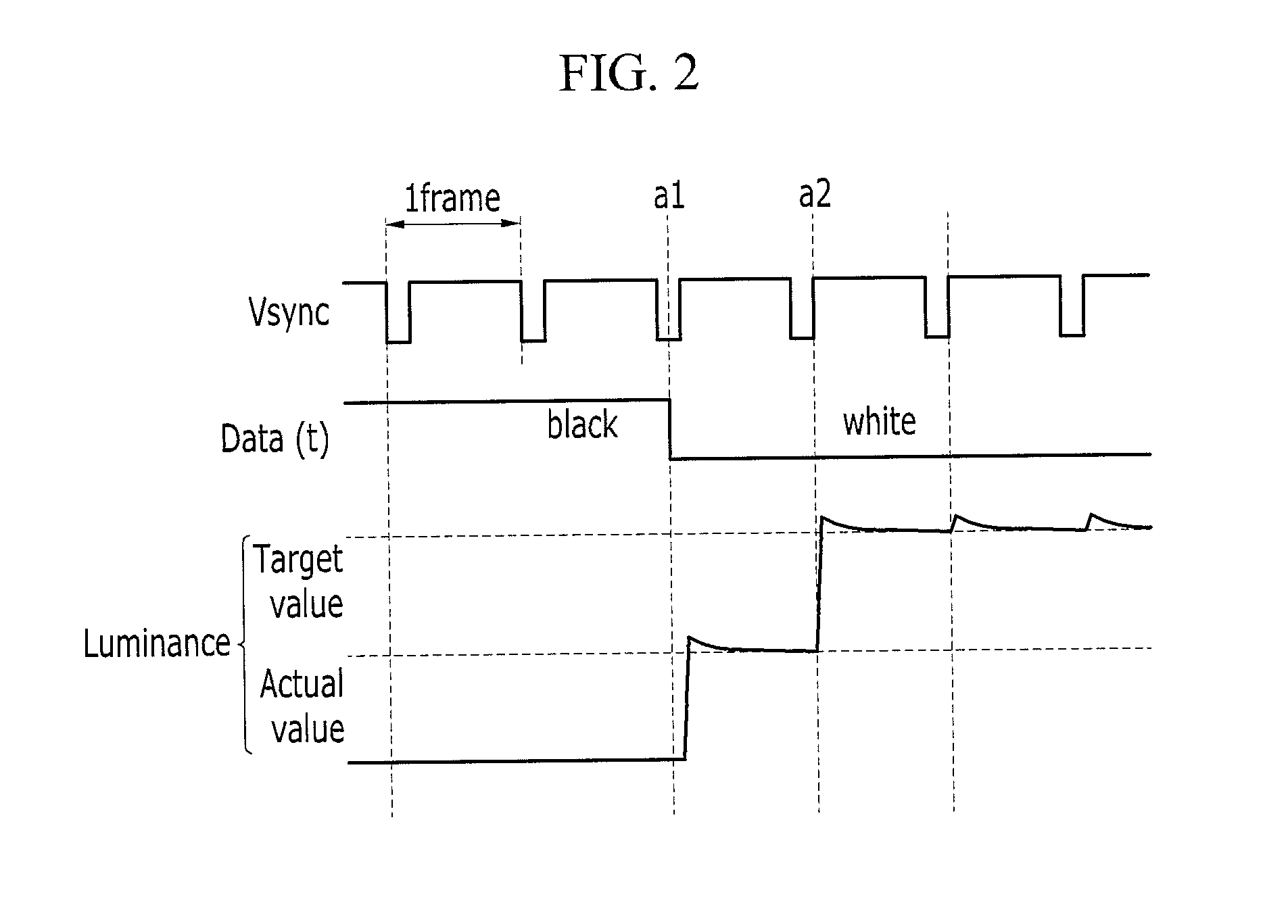

Pixel, display device including the same, and driving method thereof

ActiveUS20120147060A1Reduce delay in responseReduce stickCathode-ray tube indicatorsInput/output processes for data processingPower flowControl line

A display device includes: a display unit including pixels coupled to scan lines for transmitting scan signals, data lines for transmitting data signals, and light emission control lines for transmitting light emission control signals; a scan driver; a data driver; and a light emission driver. Each pixel includes: an OLED; a driving transistor to transmit a driving current corresponding to a data signal to the OLED; a first transistor to transmit the data signal to the driving transistor according to a first scan signal; a second transistor to apply a first power source voltage to a first electrode of the driving transistor according to a second scan signal, during an initialization period for initializing a gate electrode voltage of the driving transistor; and a capacitor including a first electrode coupled to a gate electrode of the driving transistor and a second electrode coupled to a first power source supply.

Owner:SAMSUNG DISPLAY CO LTD

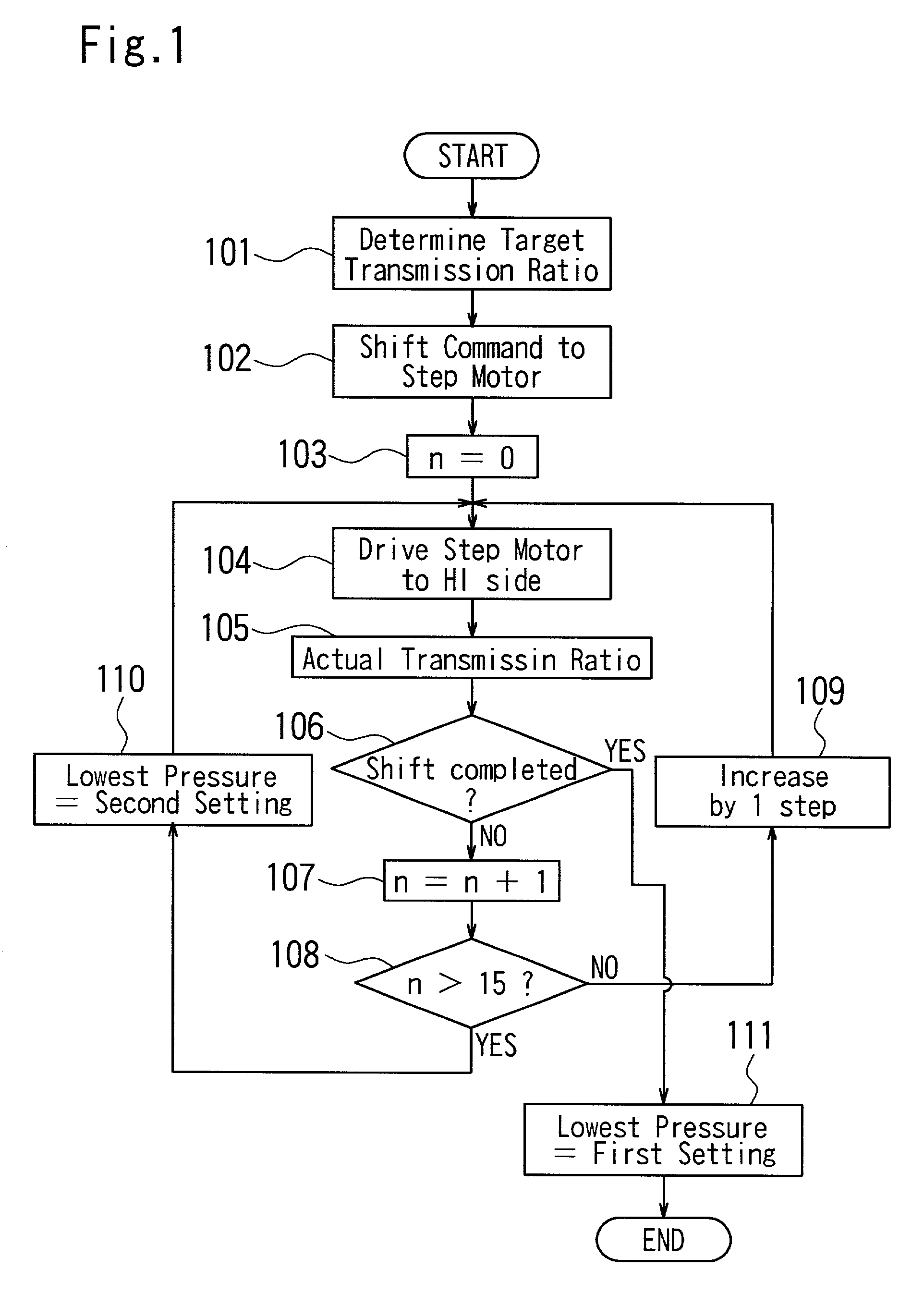

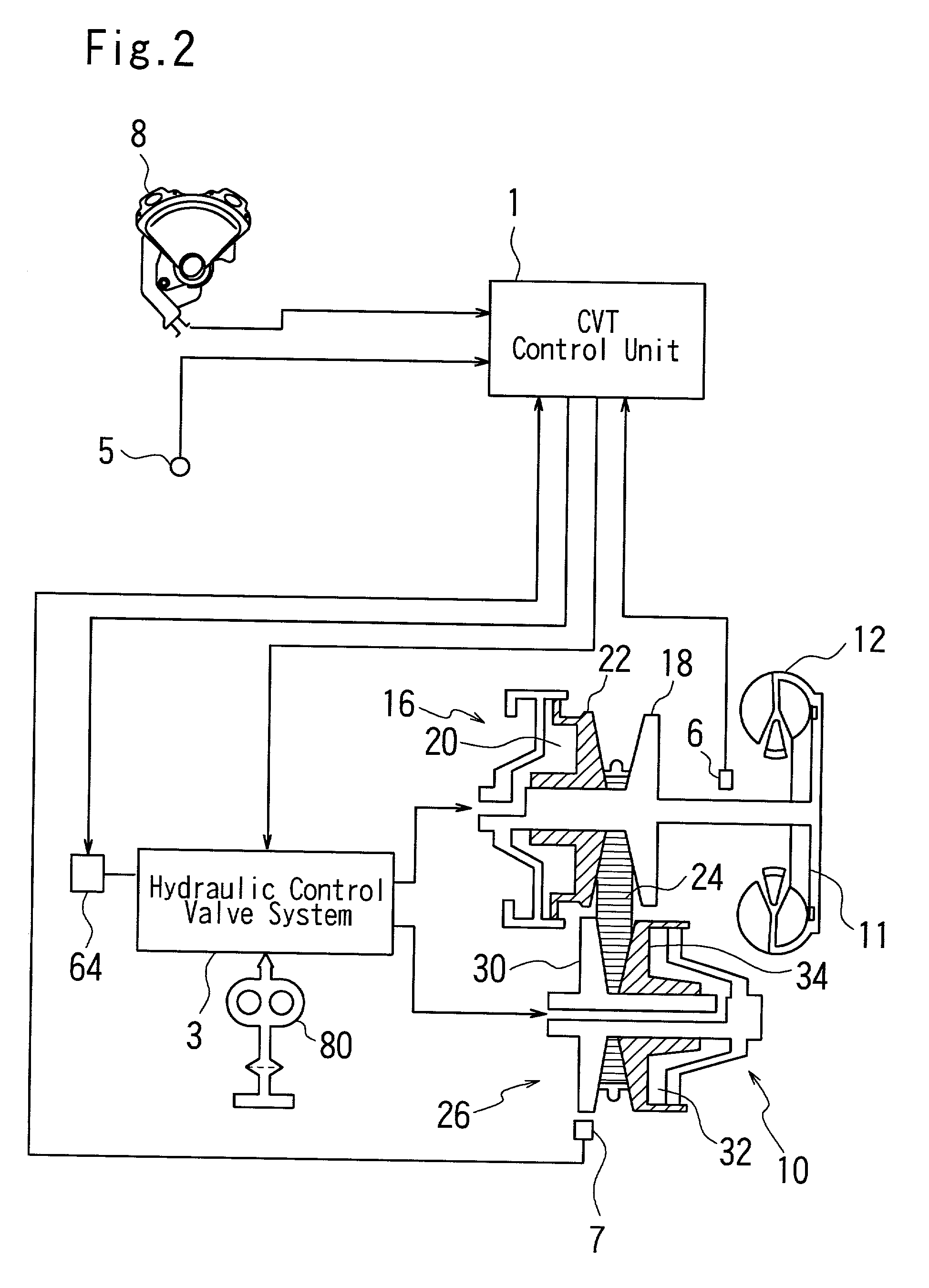

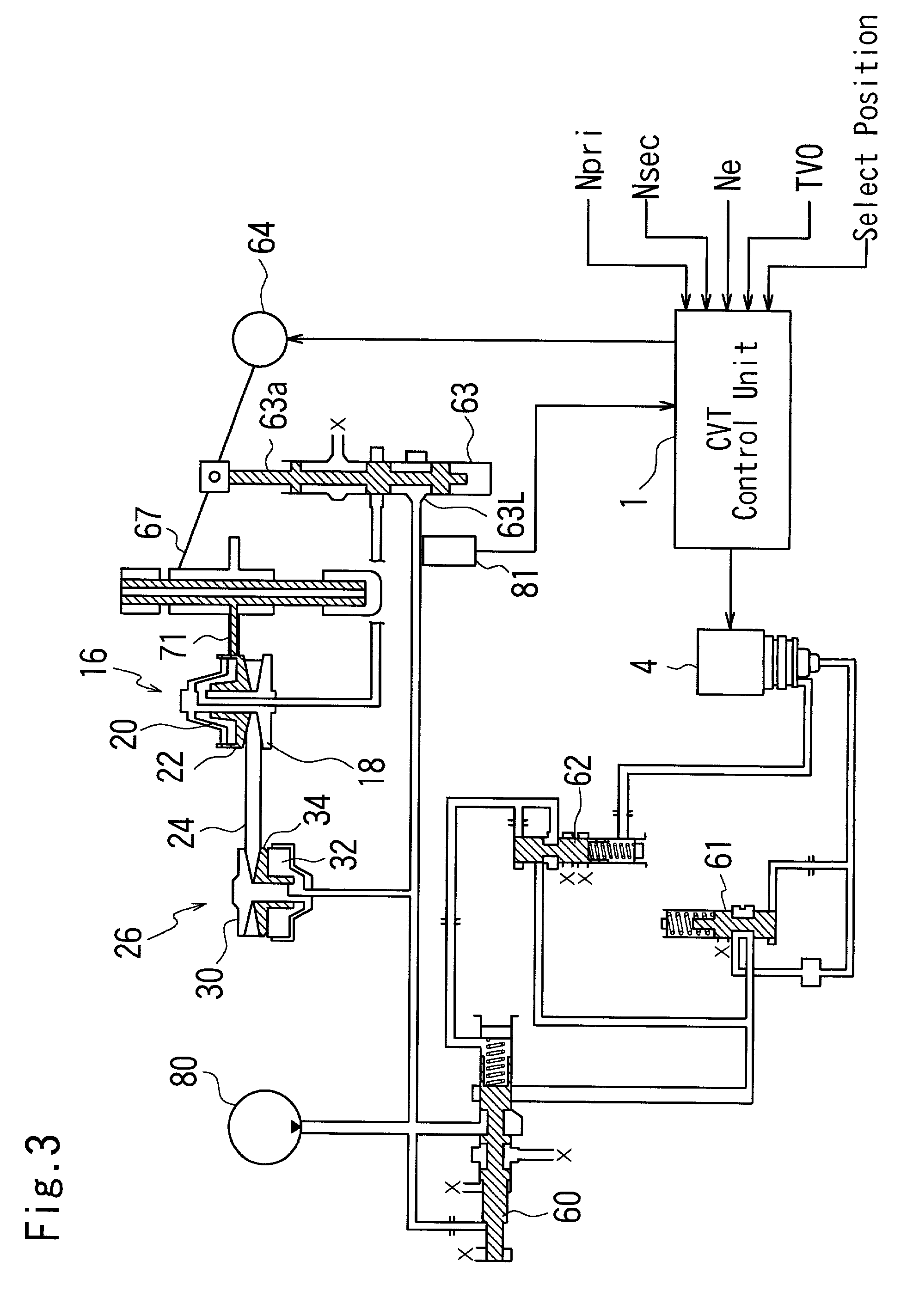

Hydraulic control system for a continuously variable transmission

InactiveUS20010023217A1Less frictional lossIncrease line pressureGearingRoad transportControl systemRotation velocity

A transmission mechanism of the continuously variable transmission comprises a set of primary and secondary pulleys between which a belt is provided. The CVT control unit is operable to supply line pressure directly to a secondary pulley and also to a primary pulley via a shift control valve associated with a step motor in such a manner as to control a transmission ratio. The CVT control unit calculates a standard step position of the step motor corresponding to the target transmission ratio and provides a command signal representative of a difference between the standard step position and the current position of the step motor. The shift control valve actuated by the step motor controls the pressure to be supplied to the primary pulley. The actual transmission ratio obtained on the basis of the rotation speeds of the pulleys is compared with the target transmission ratio. If the shift is not accomplished, the CVT control unit commands additional step number. Unless the shift to the HI side is accomplished at the time when the additional step number reaches the threshold value, the line pressure is increased so as to achieve the shift. Thus, the transmission normally operates with a low line pressure sufficiently to reduce a frictional loss at the contact areas of the belt and the pulleys, thereby resulting in an enhanced fuel economy.

Owner:JATCO LTD

Temperature-compensated in-vivo sensor

InactiveUS20090275815A1Accurate analyte measurementBody temperature can fluctuateCatheterDiagnostic recording/measuringAnalyteCoupling

An in-vivo sensor assembly includes an assembly body having a body proximal end and a body distal end, a plurality of sensor elements including at least an analyte sensor element containing an enzyme that is a substrate of the analyte to be measured, a reference sensor element and a temperature sensor element disposed at or near the body distal end wherein the at least an analyte sensor element and the reference sensor element are exposed to the sample fluid and the temperature sensor is capable of measuring the temperature of and adjacent to the analyte sensor element, and an electrical coupling means disposed at the body proximal end and configured to couple to the at least an analytical sensor element, the reference sensor element and the temperature sensor element.

Owner:SANVITA MEDICAL CORPORATION

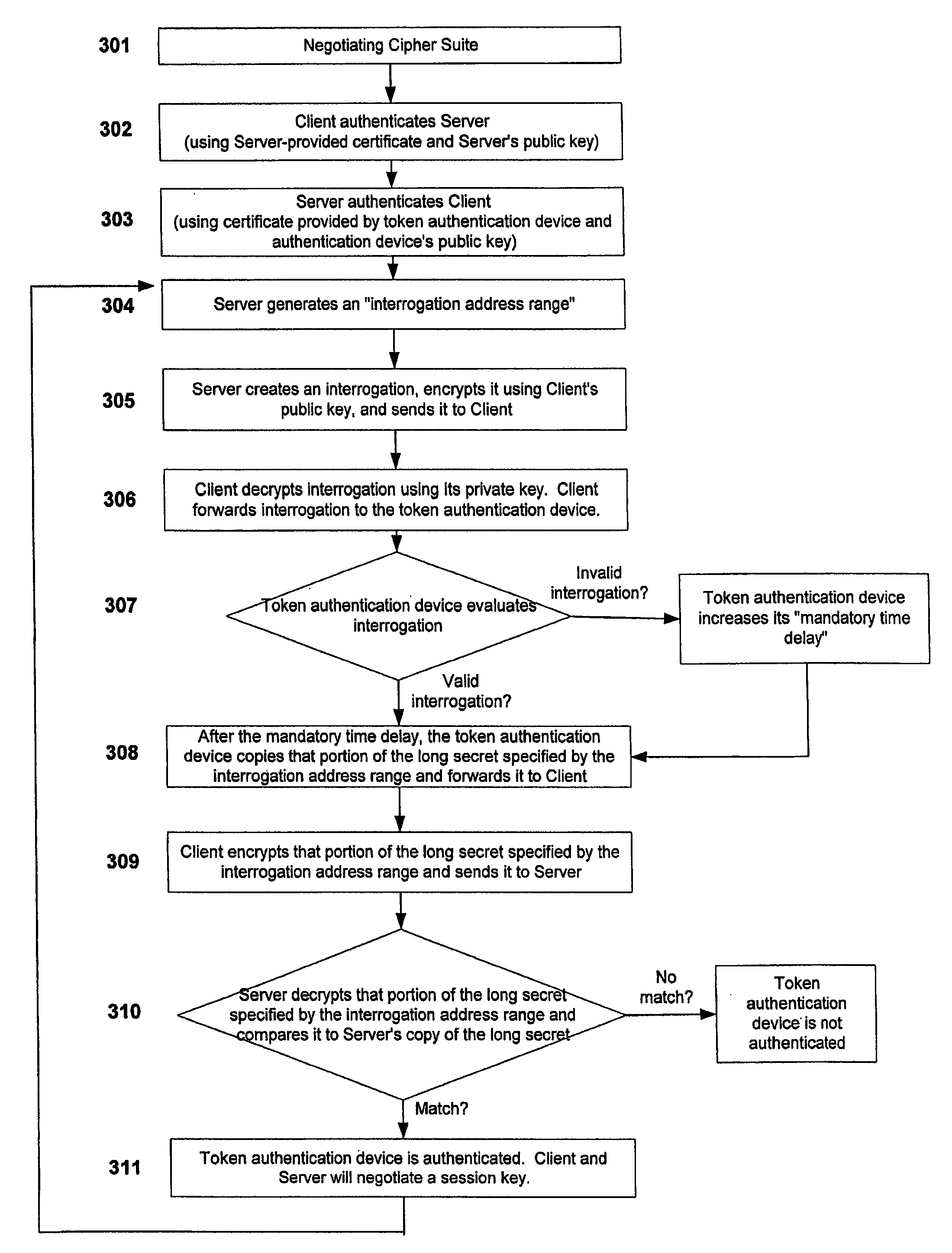

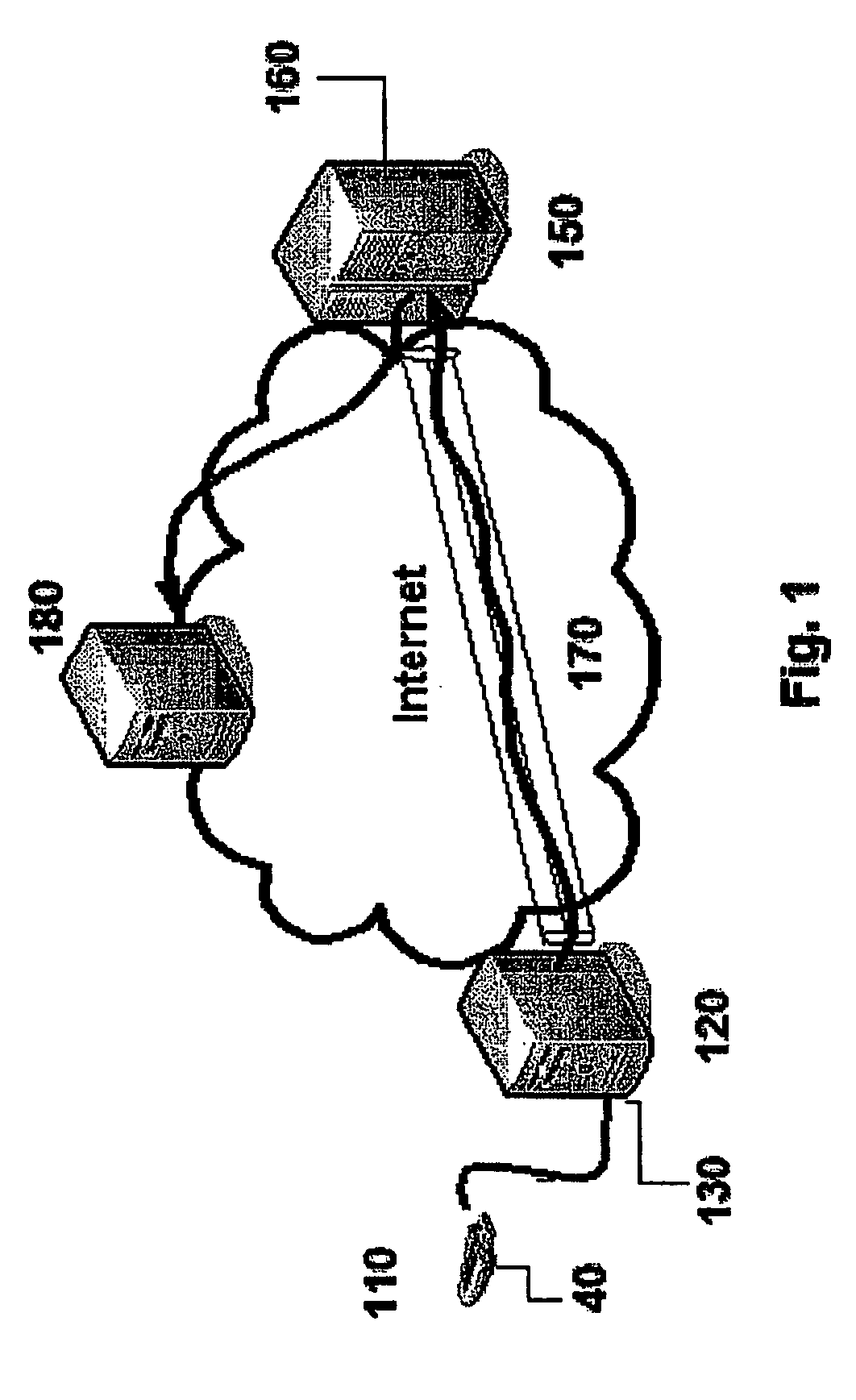

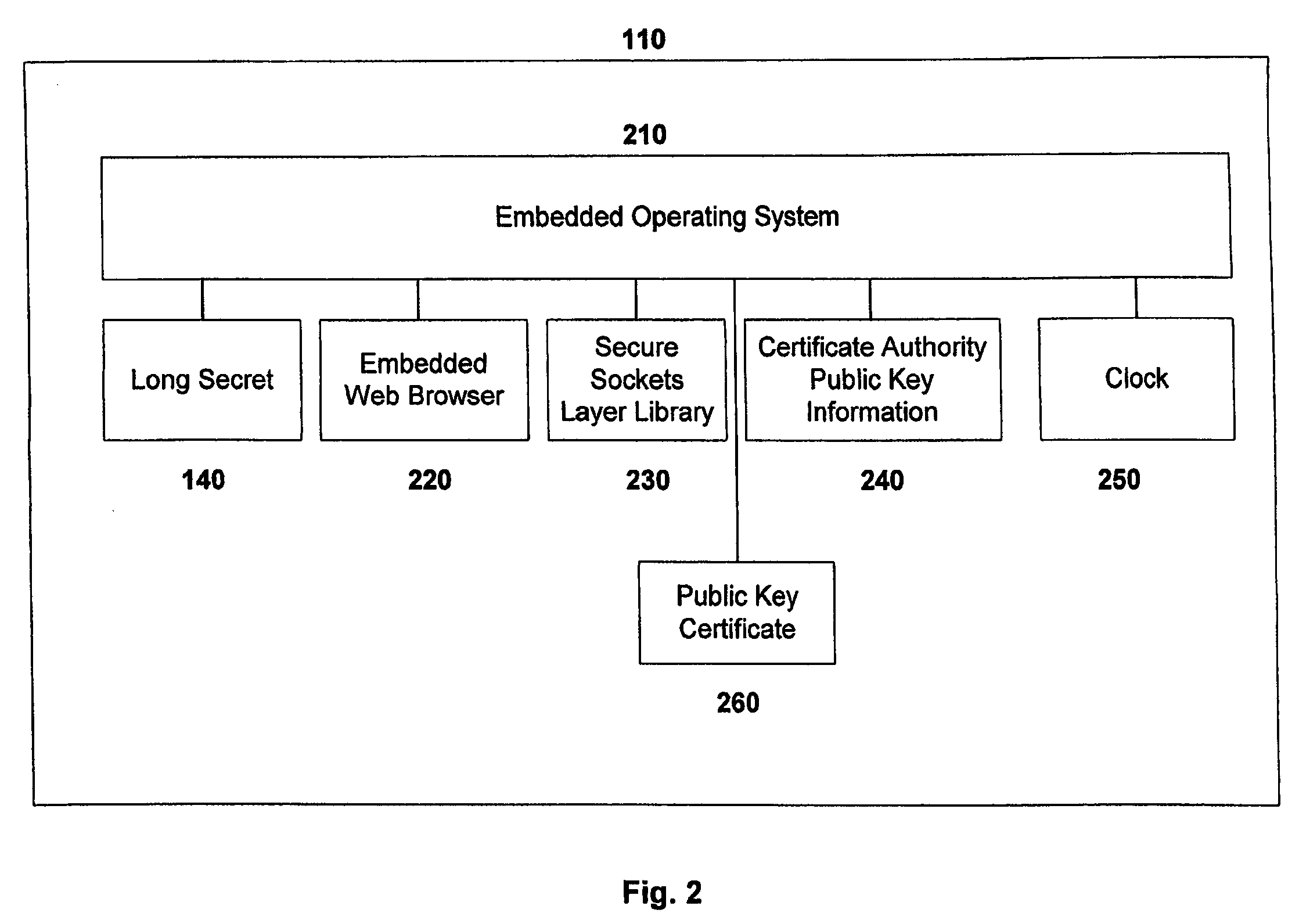

Apparatus, system, and method for authenticating users of digital communication devices

InactiveUS20080086771A1Short timeMinimizing chanceDigital data processing detailsUser identity/authority verificationDigital signatureComputer science

A computer authentication device comprising a memory containing a long secret or digital signature, portions of which are requested by a server computer or other device. The authentication device evaluates the nature and timing of authentication requests and selectively varies the time delay for responding to such authentication requests. Such selective variation in response times impedes the unauthorized or malicious copying of the authentication device's authentication credentials.

Owner:LI KANG +1

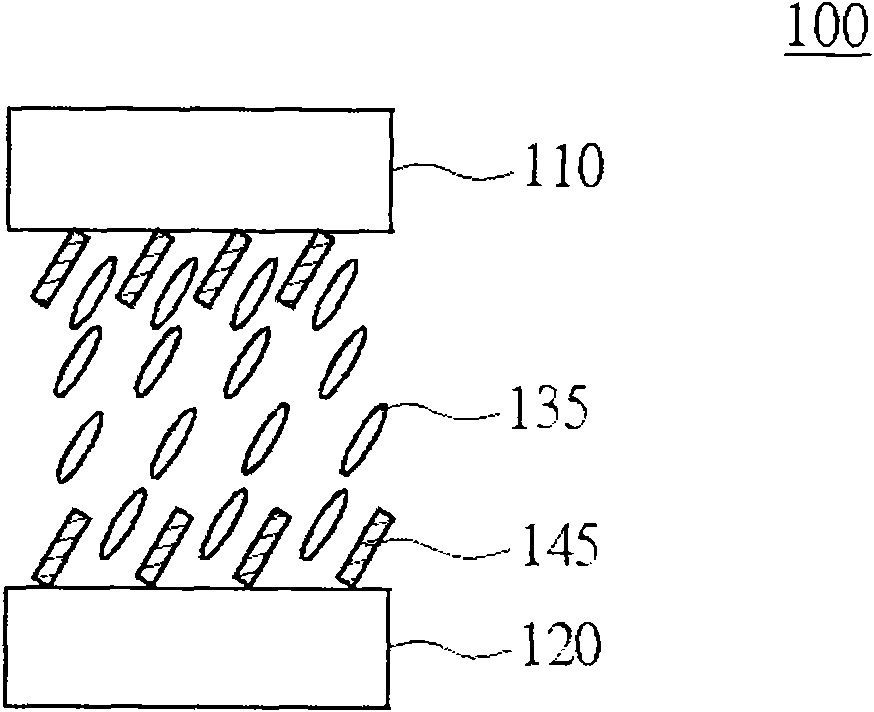

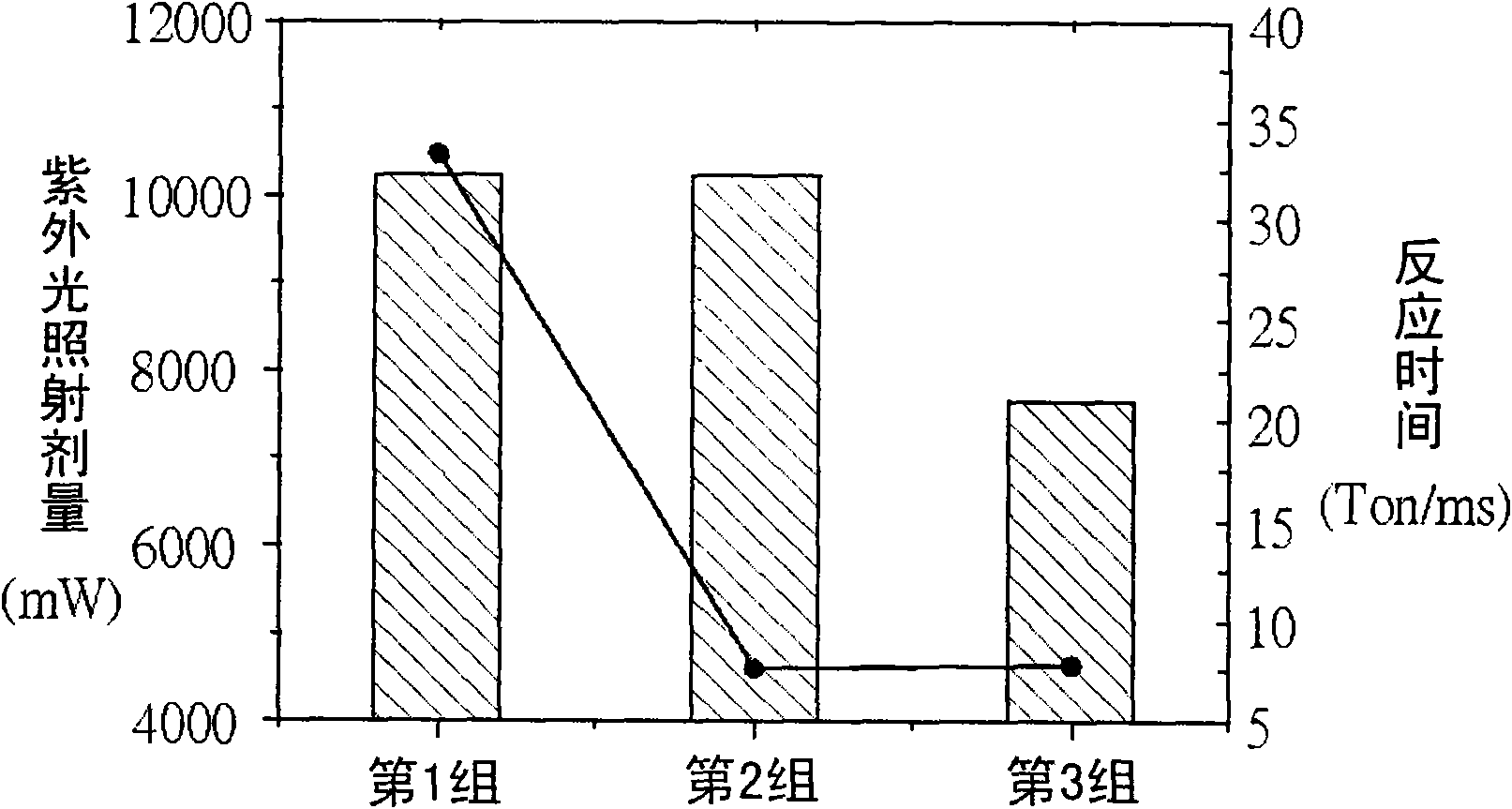

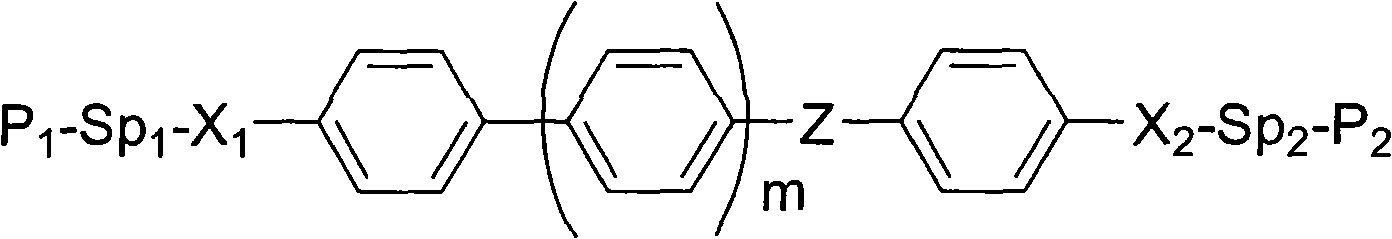

Polymerisable monomer applied to display panel and liquid crystal material

InactiveCN101671252ASlow responseLess UV exposureLiquid crystal compositionsOrganic chemistryCrystallographySulfur

The invention relates to a polymerisable monomer applied to a display panel. The polymerisable monomer is expressed by a chemical formula above, wherein, m is not less than 0, 'Z' is selected from oxygen atom, sulfur atom, carbonyl, carboxyl, methoxyl, methylthio, sulfenyl, ethylene carbonyl, carboxyethenyl, difluoromethoxyl, difluoromethylthio, ethyleneyl, difluoroethyl, tetrafluoroethyl, ethenyl, difluoroethenyl and ethinyl or single bonds; 'X1' and 'X2' are independently selected from oxygen atom, sulfur atom, methoxyl, carbonyl, carboxyl, amine formacyl, methylthio, ethylene carbonyl and carboxyethenyl or single bond; 'Sp1' and 'Sp2' are independently spacer groups or single bonds; and 'P1' and 'P2' are independently polymerisable groups. The invention further relates to a liquid crystal material which contains liquid crystal molecules and the polymerisable monomer.

Owner:AU OPTRONICS CORP

Continuously variable transmission and method of operation thereof

A continuously variable transmission is disclosed comprising a transmission input, a transmission output, and a continuously variable ratio unit (“variator”) arranged to be coupled between the transmission input (205) and output (240) by means of at least one clutch (230,250) thereby to enable transfer of drive between the input and the output at a continuously variable transmission ratio. The variator is connected to a hydraulic control circuit (50) and so subject to a hydraulic control pressure which is adjustable by the control circuit and is also influenced by changes in variator ratio. The variator is constructed and arranged such as to adjust its ratio to provide a variator reaction torque which corresponds to the control pressure. The transmission further comprising means (311,310) for adjusting the torque capacity of the clutch while it is engaged so that by controlling torque loading applied to the variator, the clutch influences the control pressure and the reaction torque.

Owner:ALLISON TRANSMISSION INC

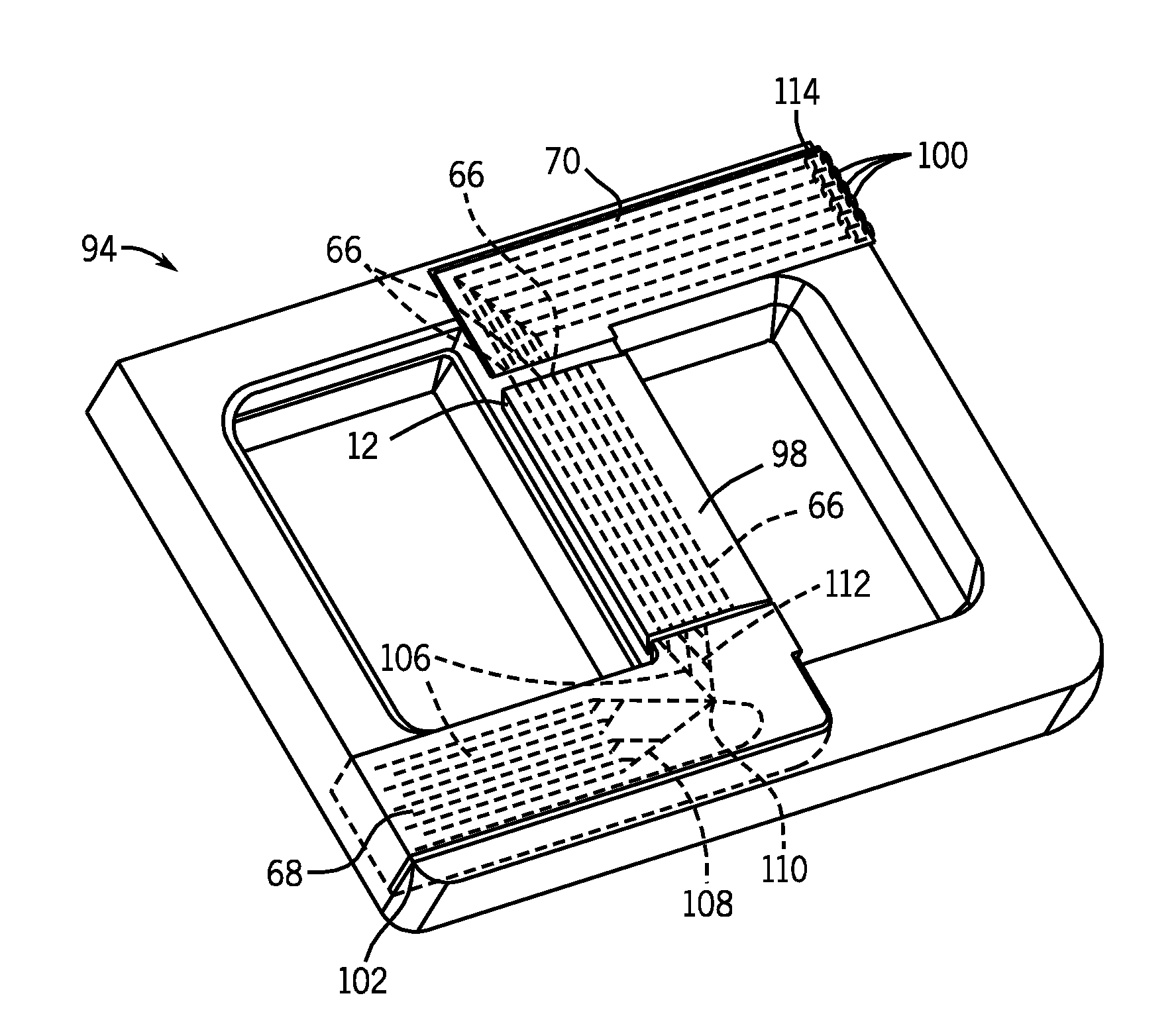

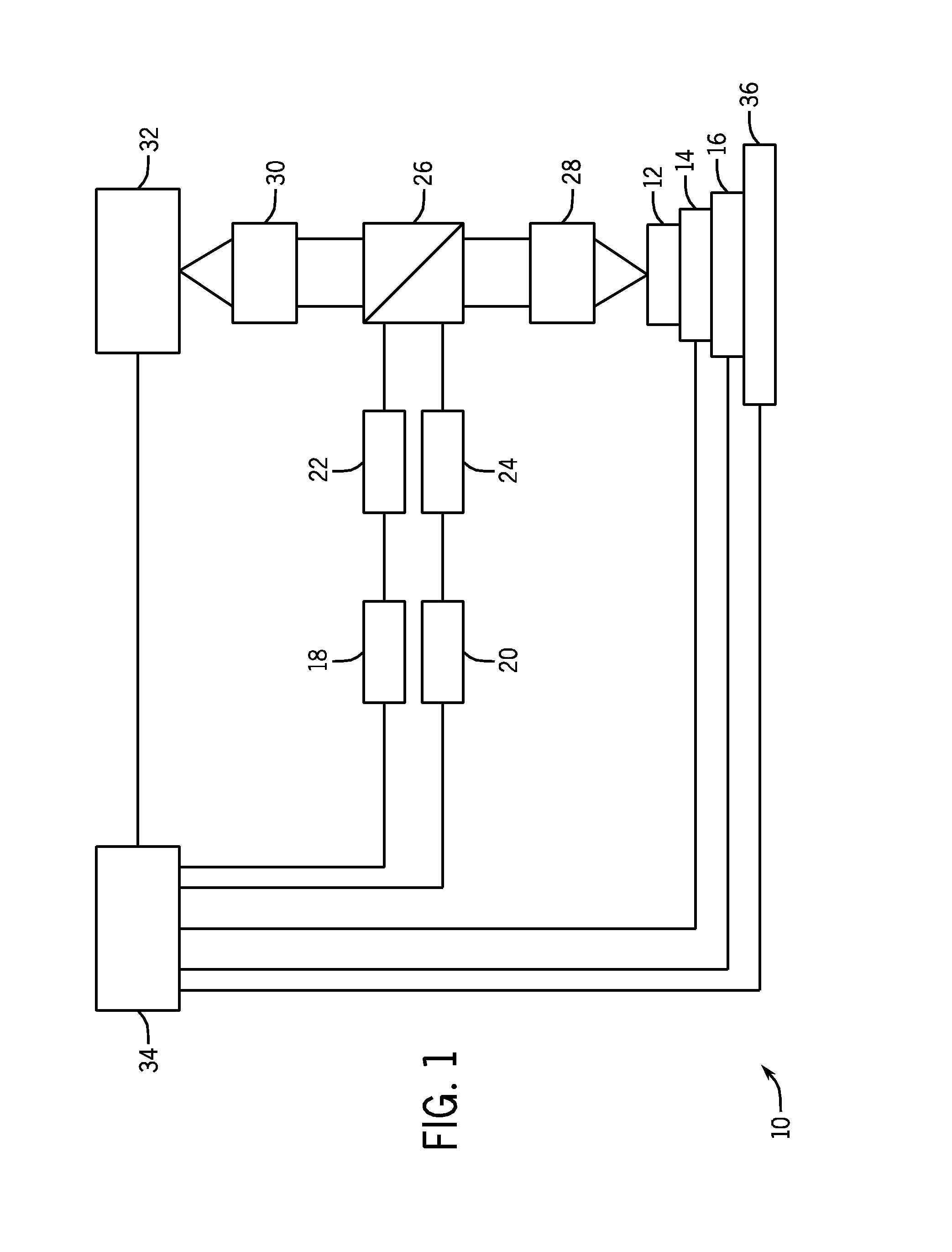

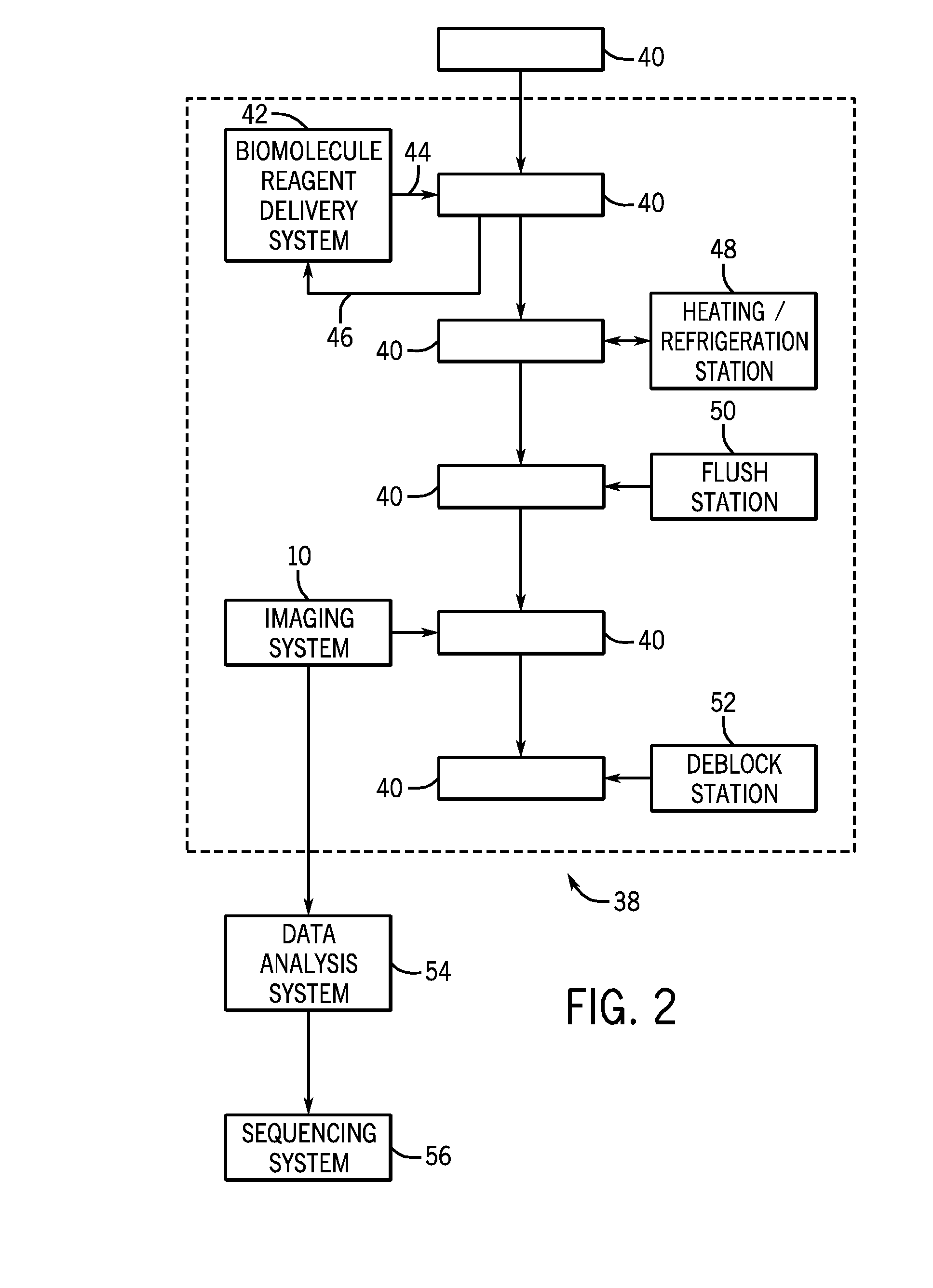

Biological sample temperature control system and method

InactiveUS20100087325A1Remove heatSlow responseHeating or cooling apparatusLibrary screeningTemperature controlTotal internal reflection

The present invention provides a novel approach for controlling the temperature of biological samples on a support structure. The support structure may, for instance, be a flow cell through which a reagent fluid is allowed to flow and interact with biological samples. A thermoelectric heat exchange device, such as a Peltier device, may be used to heat or cool the biological samples on the support structure. In addition, a fluid circulating heat exchange device, such as a water heating or cooling system, may be used to heat or cool the thermoelectric heat exchange device. In general, the support structure may be located on top of the thermoelectric heat exchange device which, in turn, may be located on top of the fluid circulating heat exchange device. The thermoelectric heat exchange device and fluid circulating heat exchange device may be integrated into a holder bench which may be part of a station within an imaging processing system. The holder bench may be configured to hold multiple support structures at a time. In addition, the support structures may be configured to be evaluated and imaged using both epifluorescent and total internal reflection (TIRF) excitation techniques.

Owner:ILLUMINA INC

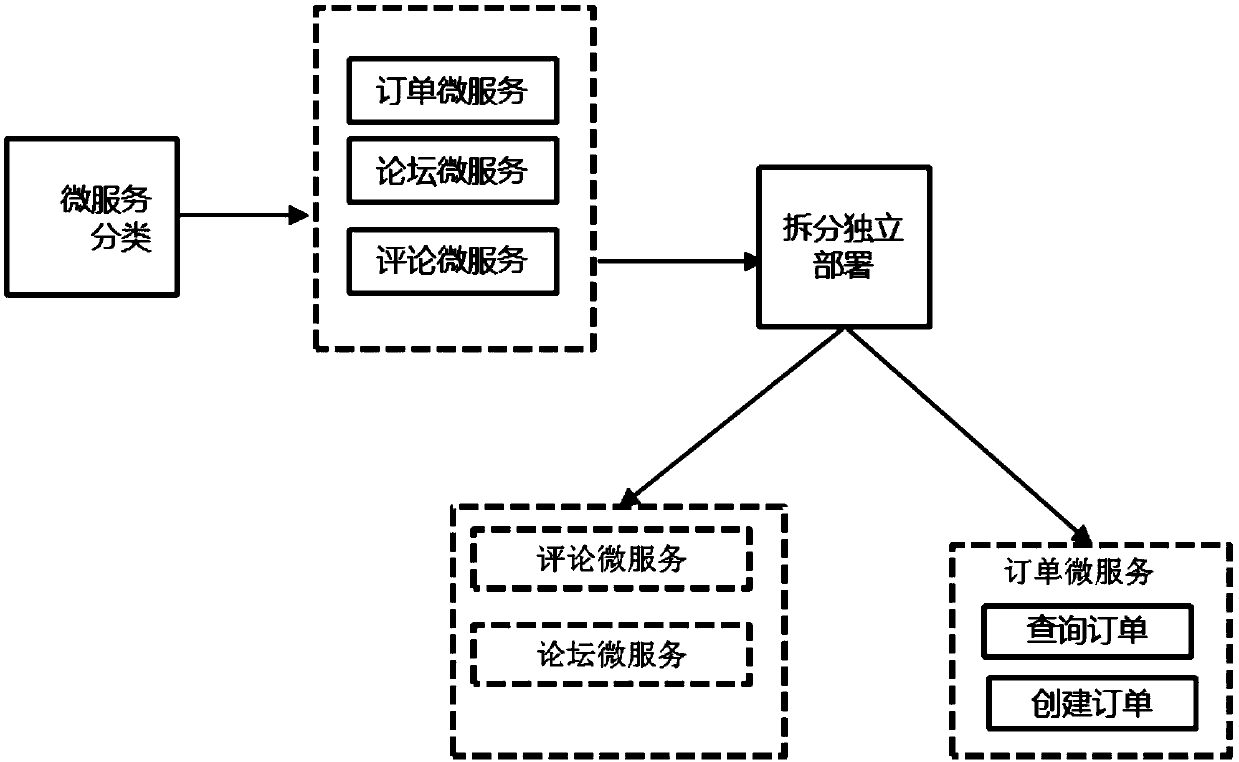

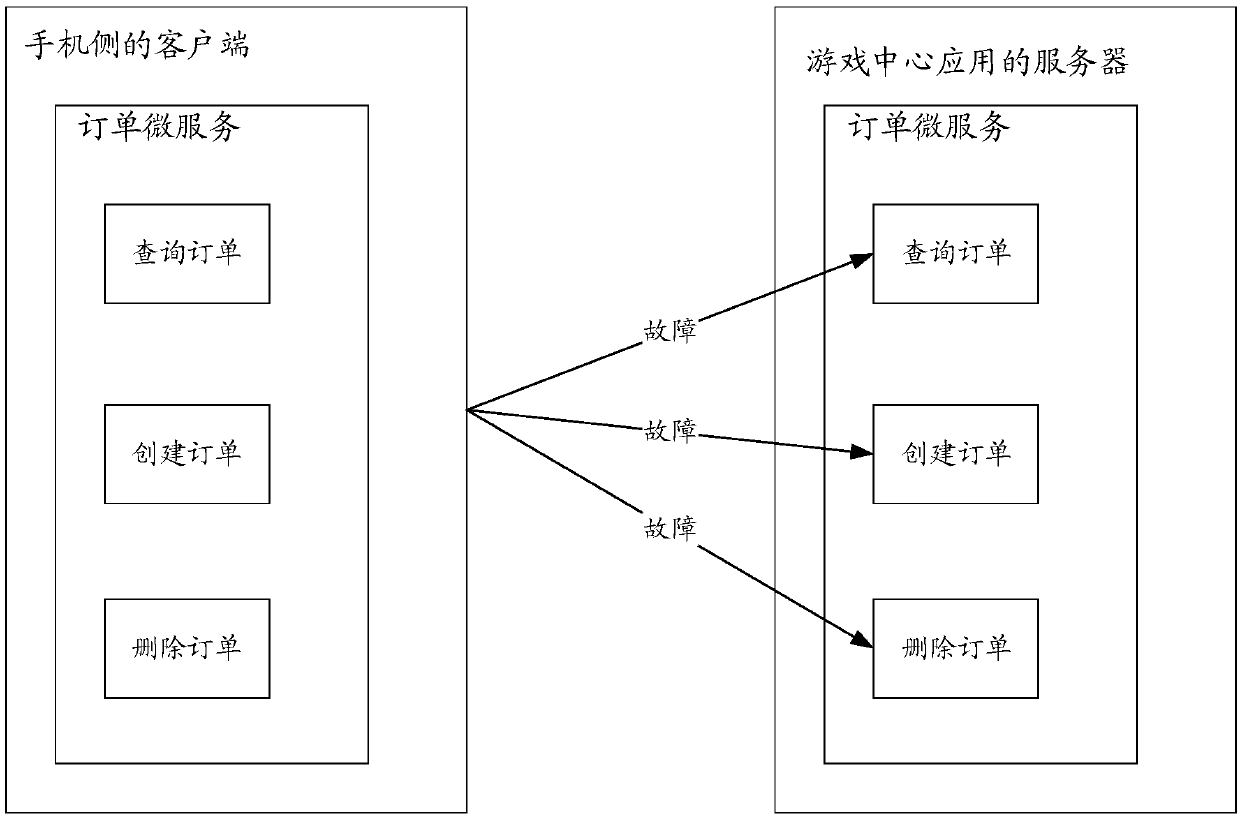

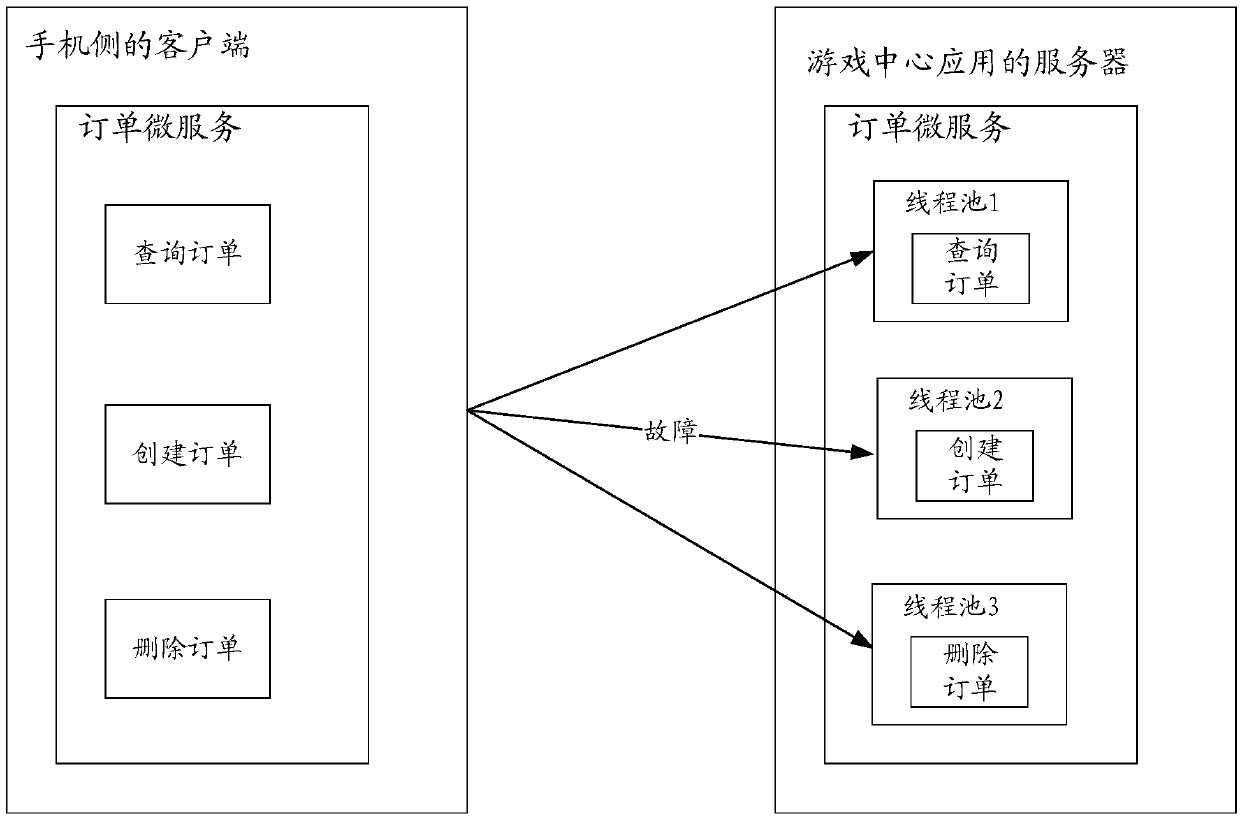

Micro-service processing method and micro-service processing equipment

ActiveCN109582472APrevent proliferationReduce hardware costsInterprogram communicationVideo gamesComputer terminalComputer science

The invention provides a micro-service processing method and micro-service processing equipment, which are applied to a server for providing a micro-service, and the method comprises the following steps that: the server receives a message for calling the micro-service from a terminal for consuming the micro-service, and the message comprises a service identifier and an interface identifier of a target micro-service; And then the server determines a corresponding target thread pool according to the service identifier and the interface identifier of the target micro-service, and finally calls the working thread in the target thread pool to execute the message, and the method can limit the fault influence range in the thread pool, prevents the fault influence range from diffusing into the whole micro-service process, and is low in hardware and operation and maintenance cost.

Owner:HUAWEI TECH CO LTD

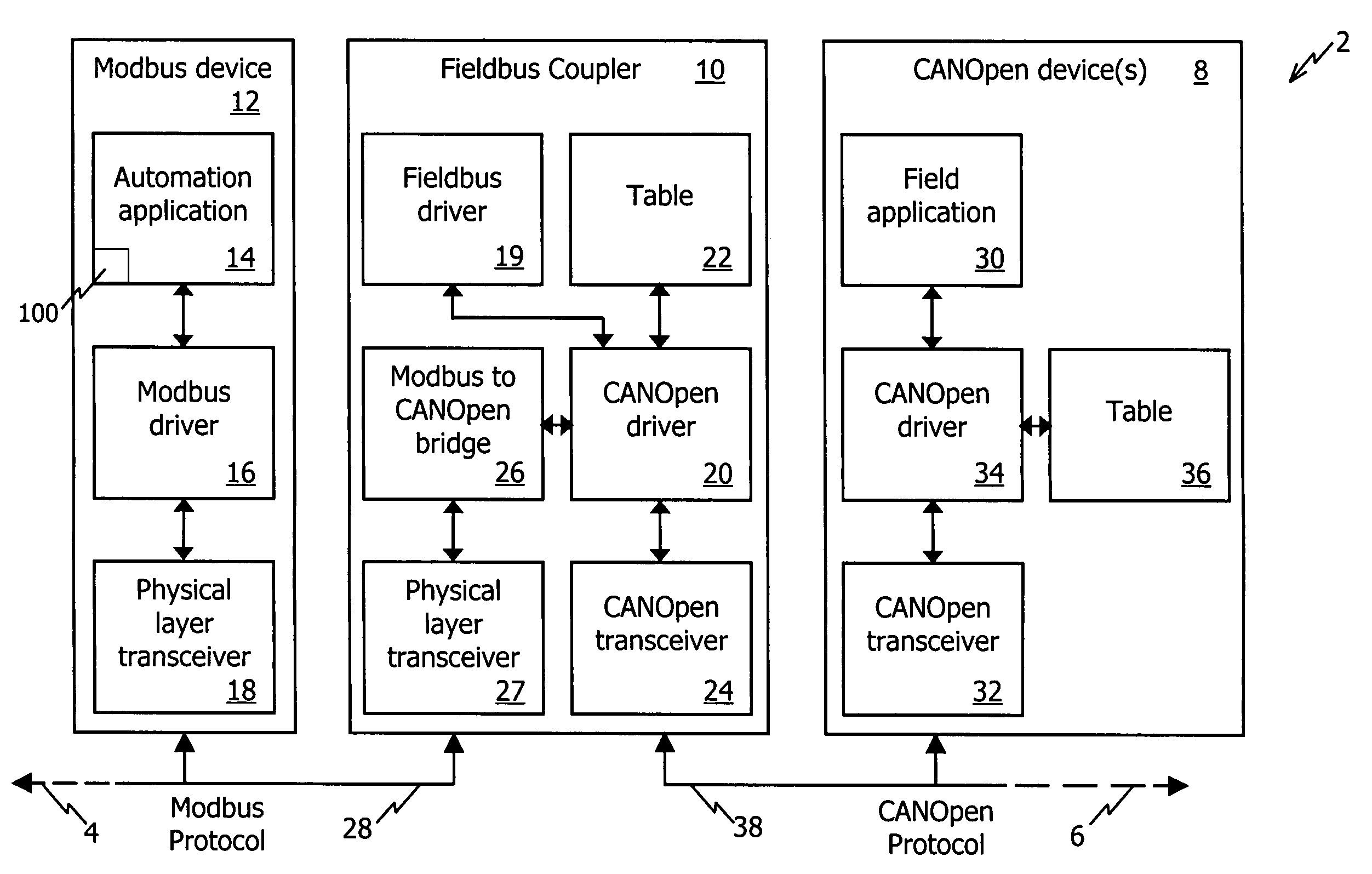

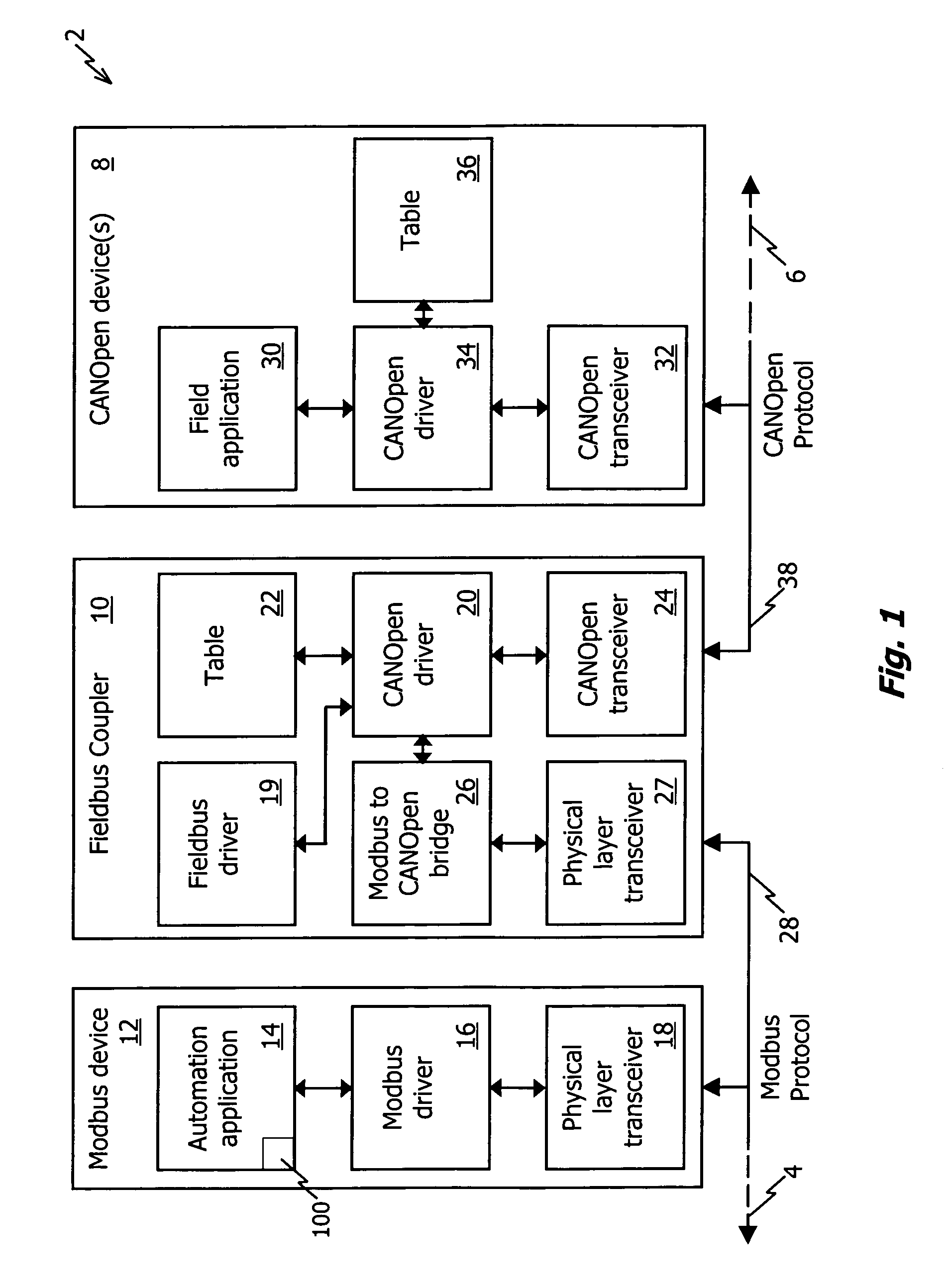

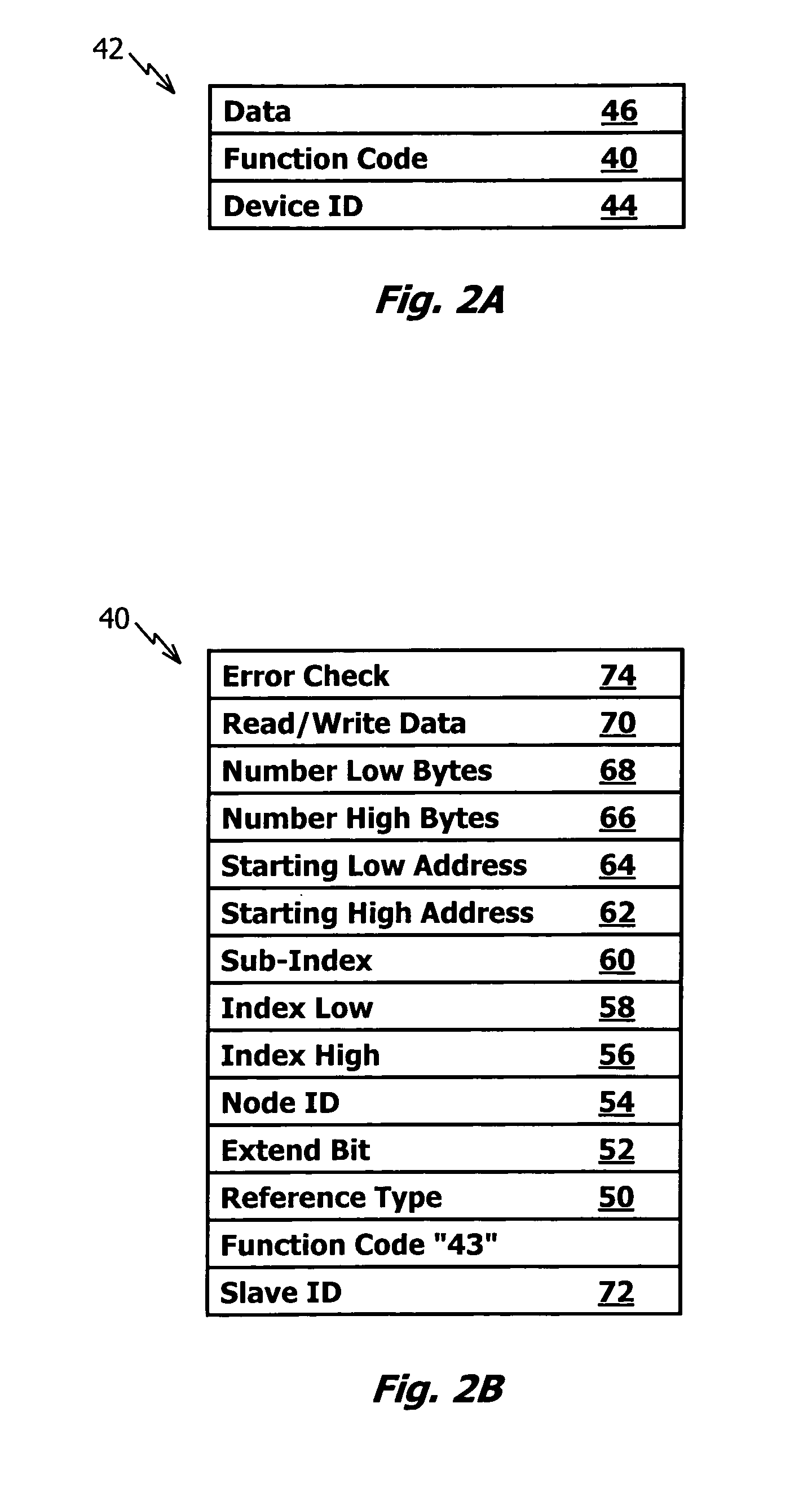

Method, system and program for the transmission of modbus messages between networks

InactiveUS7051143B2Short response timeSlow responseComputer controlMultiple digital computer combinationsModbusNetworking protocol

The present invention is directed to facilitating communication within an automation system having a plurality of networks and network protocols. Specifically, a Modbus network is operably connected to a network. A fieldbus coupler operably connected to both networks having a program facilitates communication within the automation system wherein devices connected to the network can be accessed for monitoring and / or controlling via Modbus commands. The fieldbus coupler (FBC) program accepts a Modbus function code containing one or more embedded message of varying types. The FBC program using additional information contained in the Modbus function code and the message type reads or writes only the required information to and from the field devices. This specific read or write request of the information and the embedding of more than one message type reduces overhead and bandwidth usage, thus improving bus response time and efficiency.

Owner:SCHNEIDER AUTOMATION INC

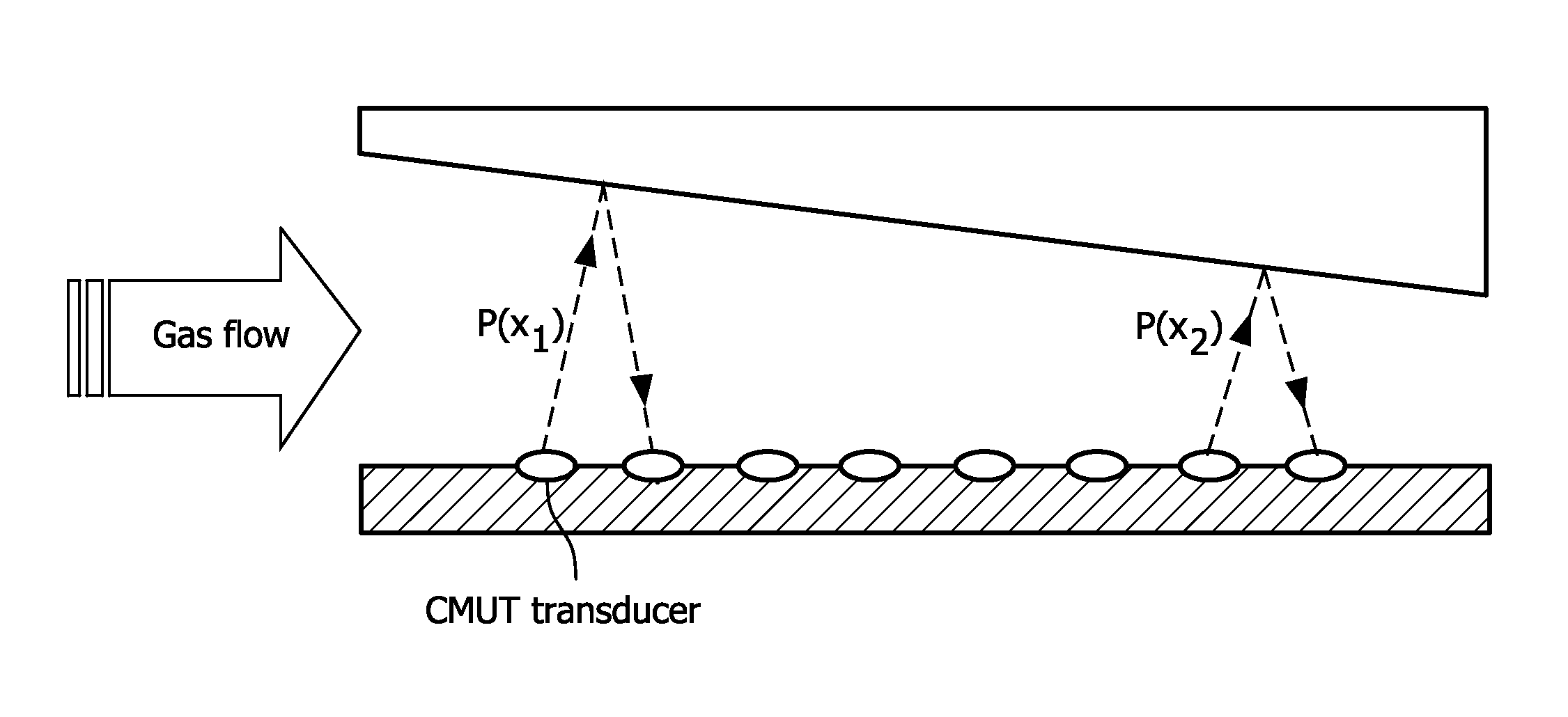

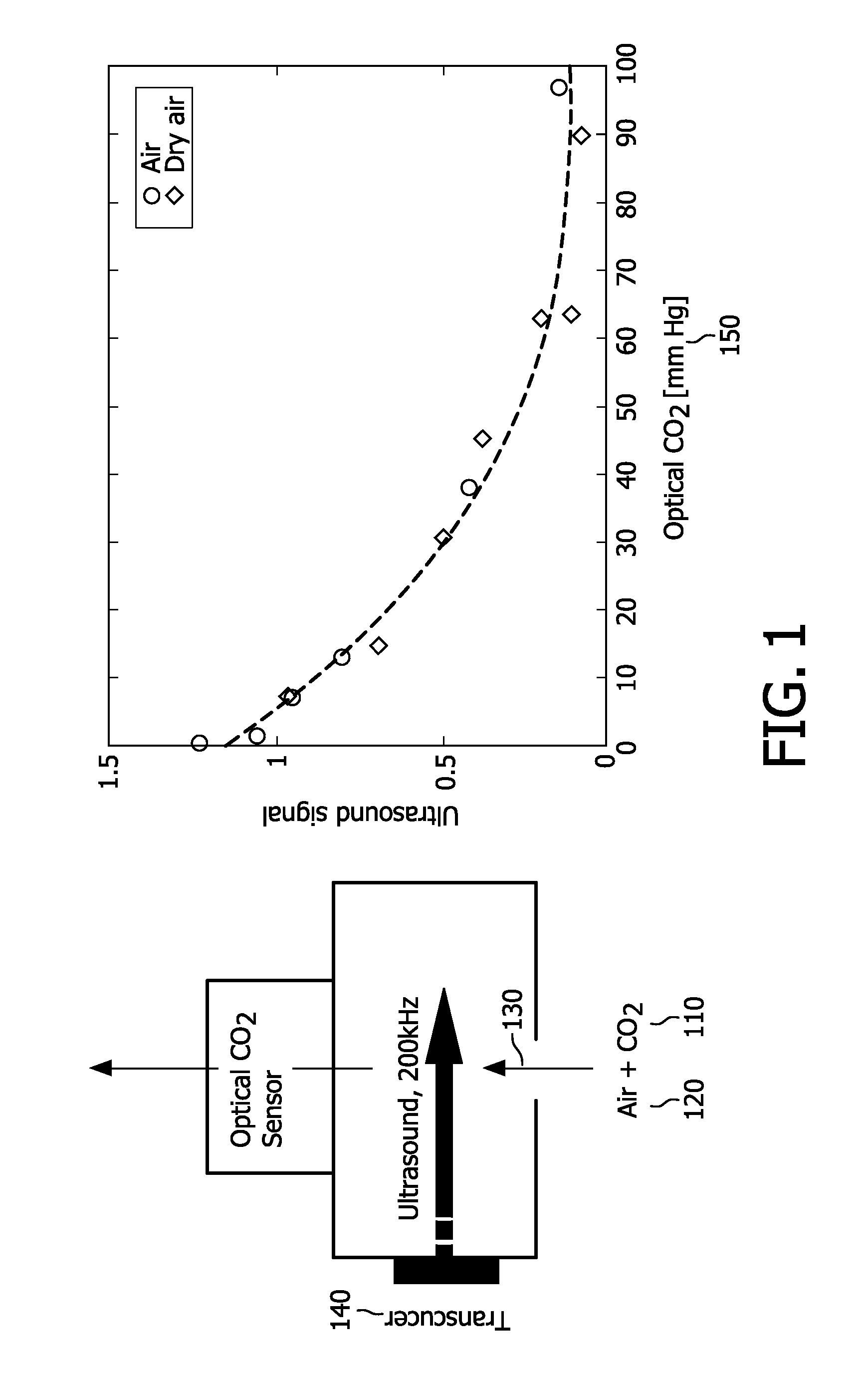

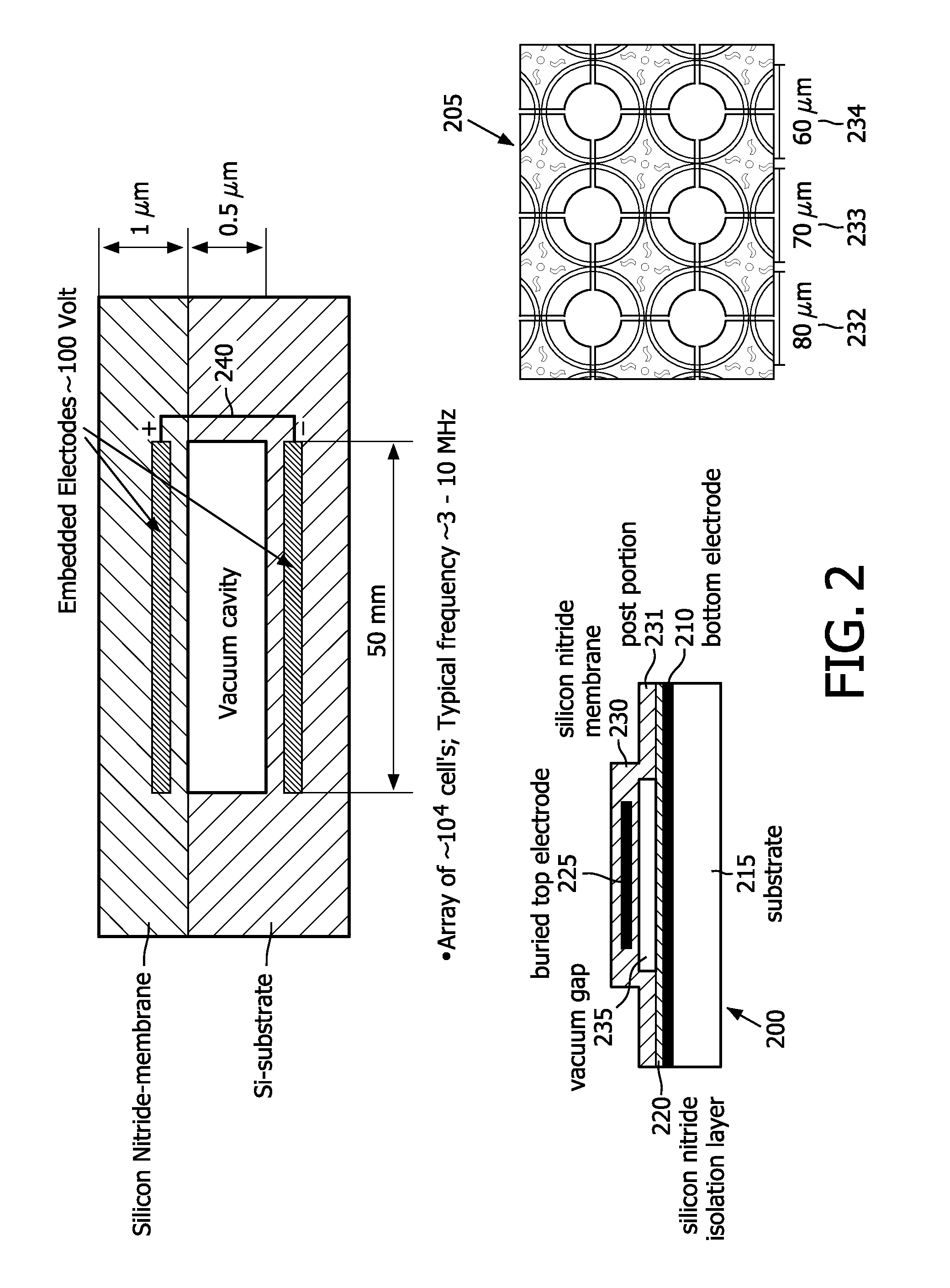

Gas sensing using ultrasound

ActiveUS8689606B2Avoid short lengthExtensive averagingAnalysing fluids using sonic/ultrasonic/infrasonic wavesWithdrawing sample devicesSonificationGas composition

Owner:KONINKLJIJKE PHILIPS NV

Acidifying agent composition

InactiveCN101089118ASlow responseSlow dissolving abilityDrilling compositionPhosphoric acidSalt content

The acidifying agent composition consists of the component A of at least one selected from HCl, phosphoric acid, HNO3 and organic carboxylic acid; the component B is HF or compound capable of producing HF; the component C of organic amine phosphonic acid; the component D of organic nitrogen-containing compound capable of producing ammonium salt through reaction with acid or its ammonium salt; and water. The acidifying agent composition of the present invention is used in eliminating deep blockage of sandstone reservoir and eliminating blockage in oil well, water well and deep stratum, and has obvious blockage eliminating effect and antiscaling performance on reservoir with high salt content and high scaling tendency. It has long effective acidifying period.

Owner:YANGTZE UNIVERSITY

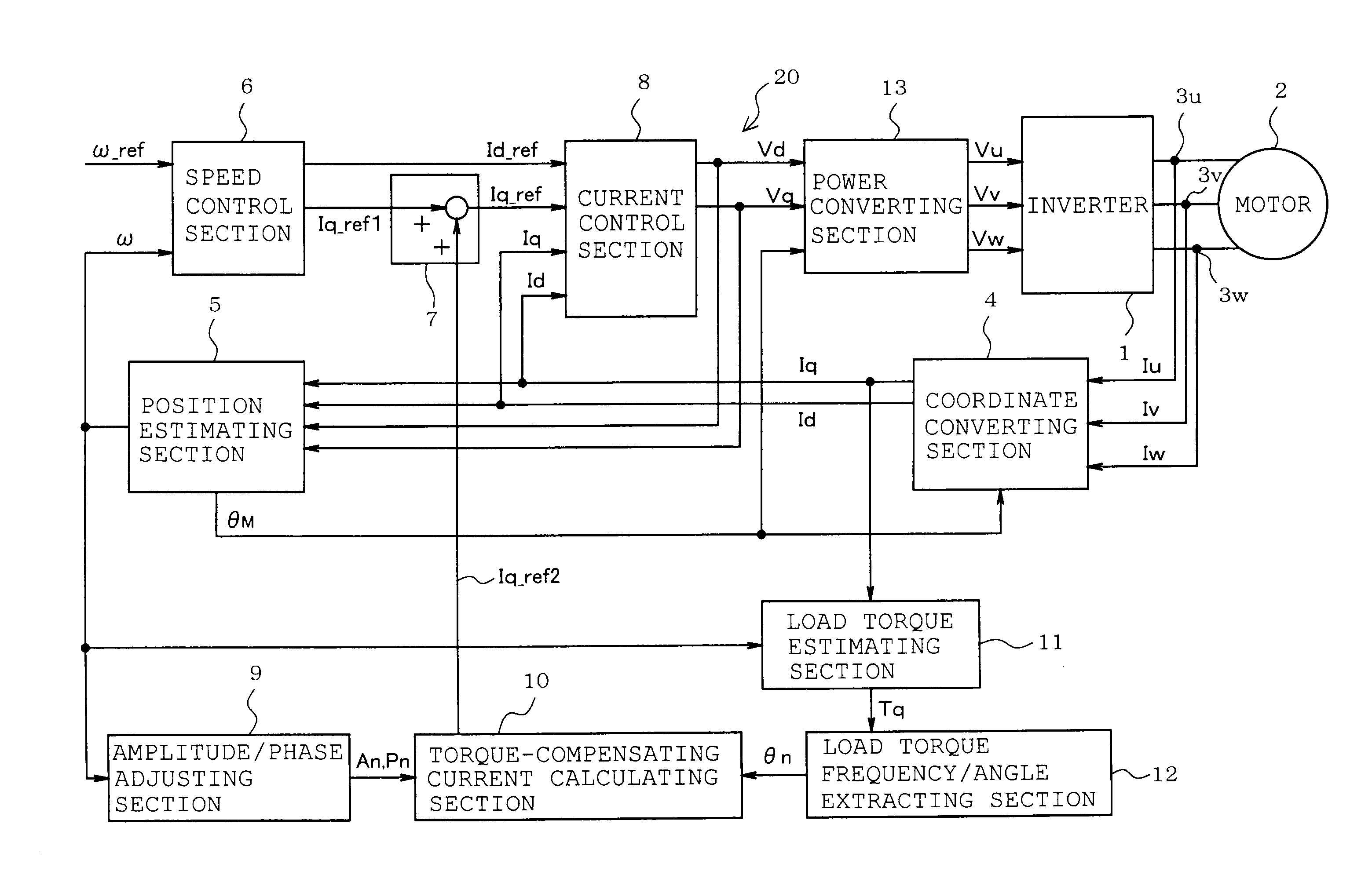

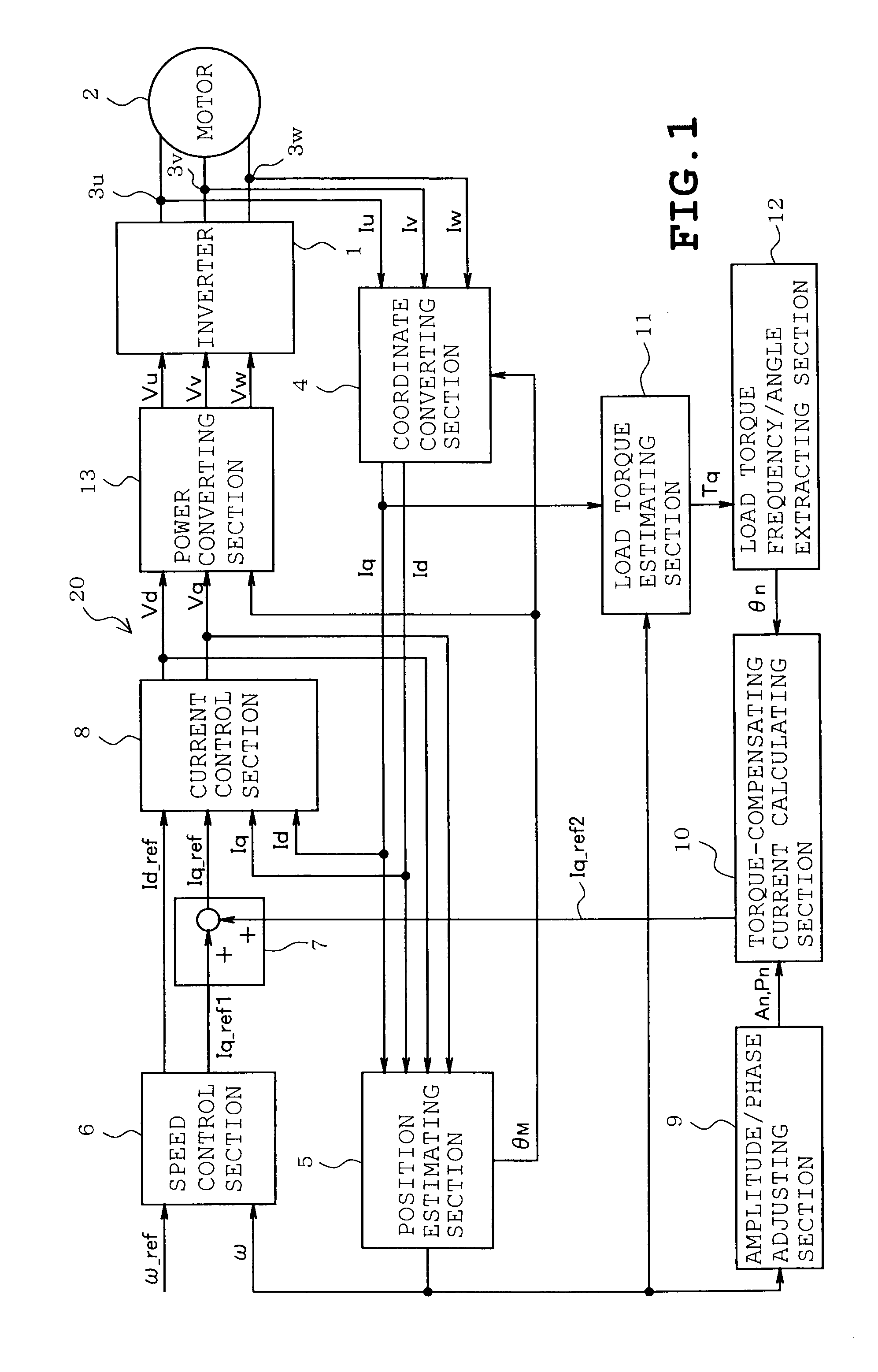

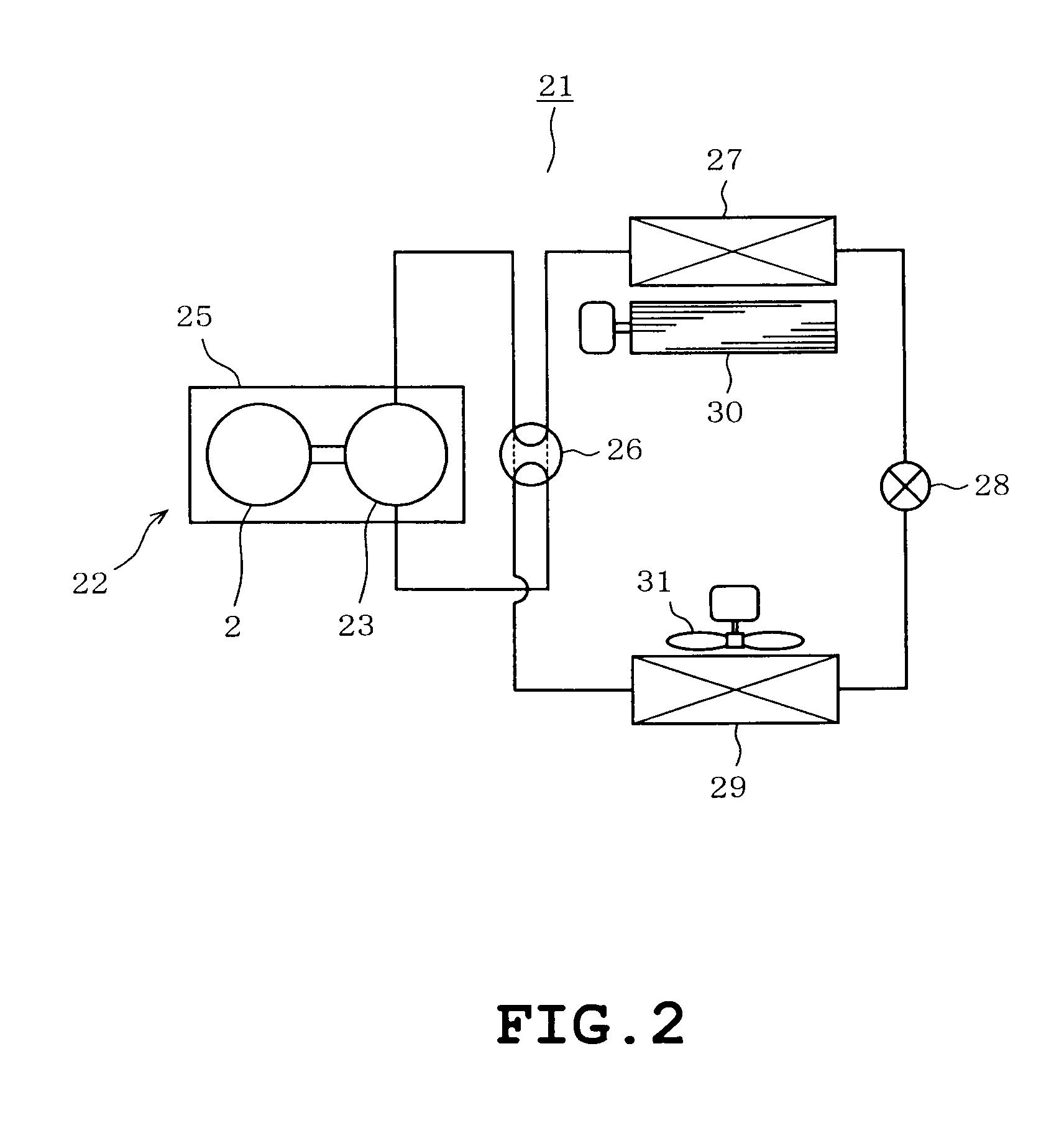

Motor control device and electrical equipment with motor controlled thereby

ActiveUS20110234144A1Precise torque controlSuppress fluctuationsTorque ripple controlCommutation monitoringPhysicsEngineering

A motor control device includes a current detecting unit detecting current flowing into a motor winding, a speed / electrical angle estimating unit estimating a rotational speed and an electrical angle of the motor, based on the current, a load torque estimating unit estimating load torque to be developed by a load, from a torque current obtained based on the current and the electrical angle, a motor constant and inertia moment of the motor inclusive of the load, a load torque phase calculating unit calculating a phase of periodic fluctuation indicated by the load torque, a torque-compensating current determining unit determining a sinusoidal torque-compensating current, based on the load torque phase, and an amplitude / phase adjusting unit detecting speed fluctuation of the motor to adjust amplitude and phase of the torque compensating current by increasing or decreasing the amplitude and the phase so that the speed fluctuation is reduced.

Owner:KK TOSHIBA

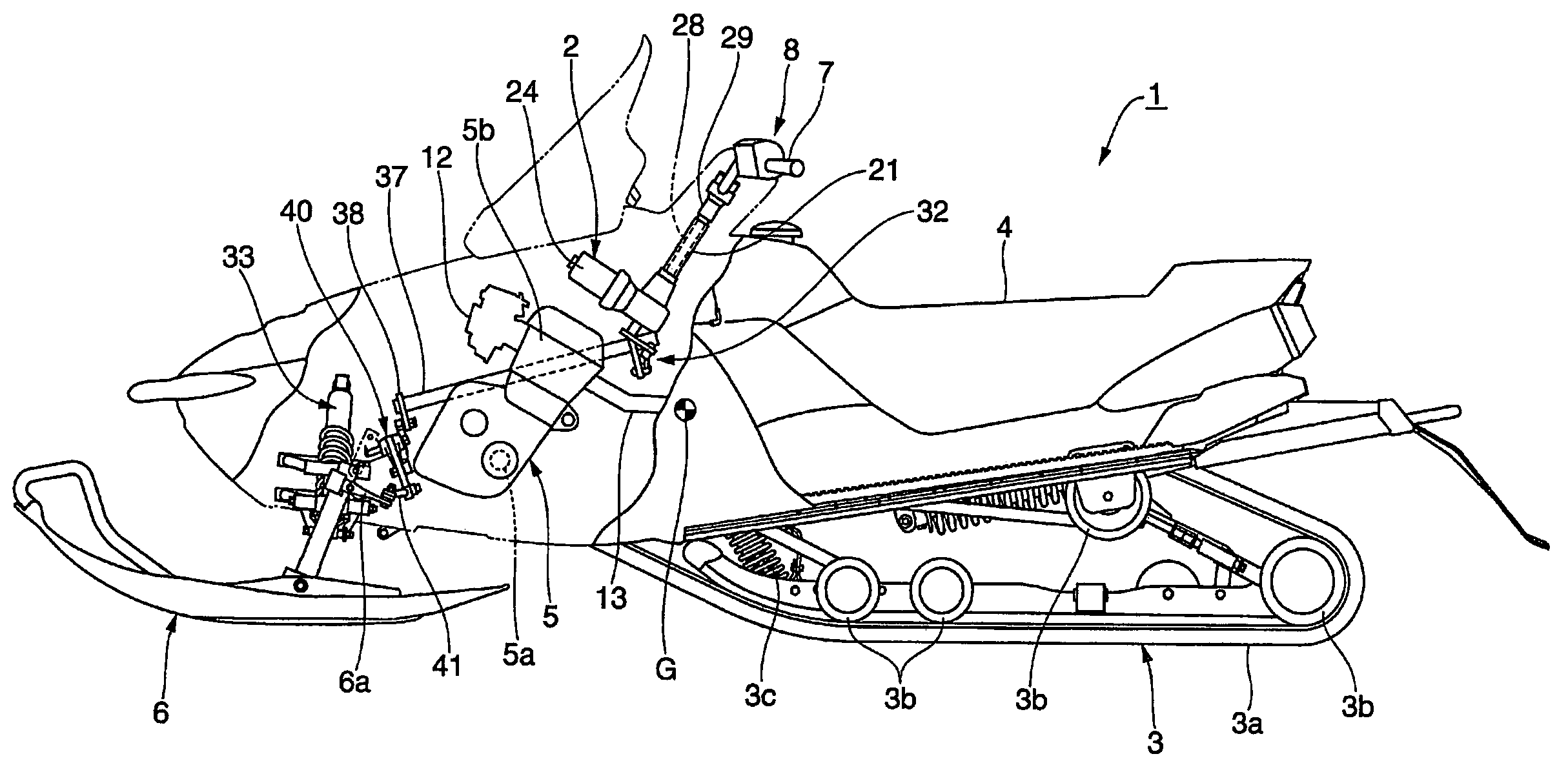

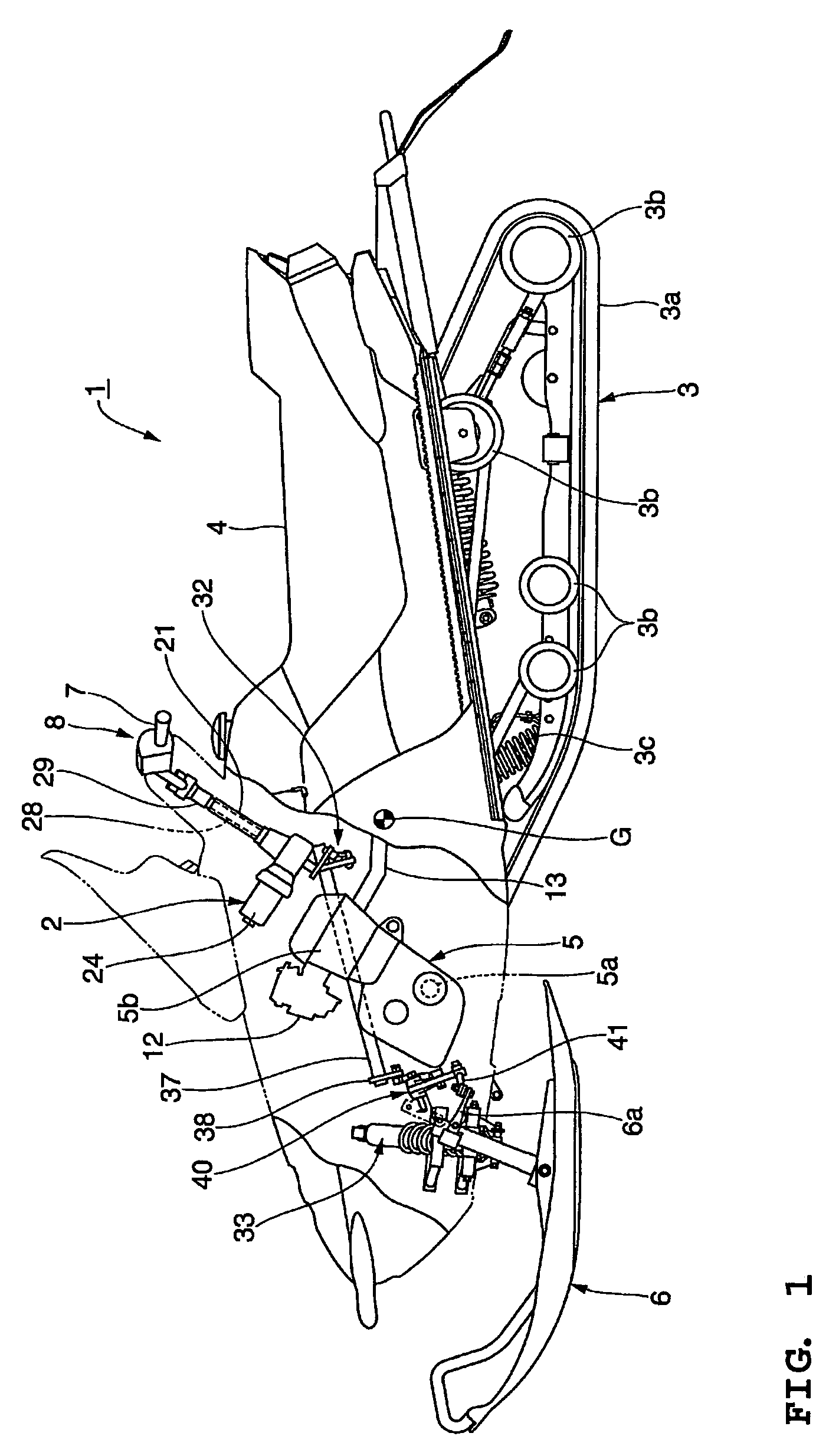

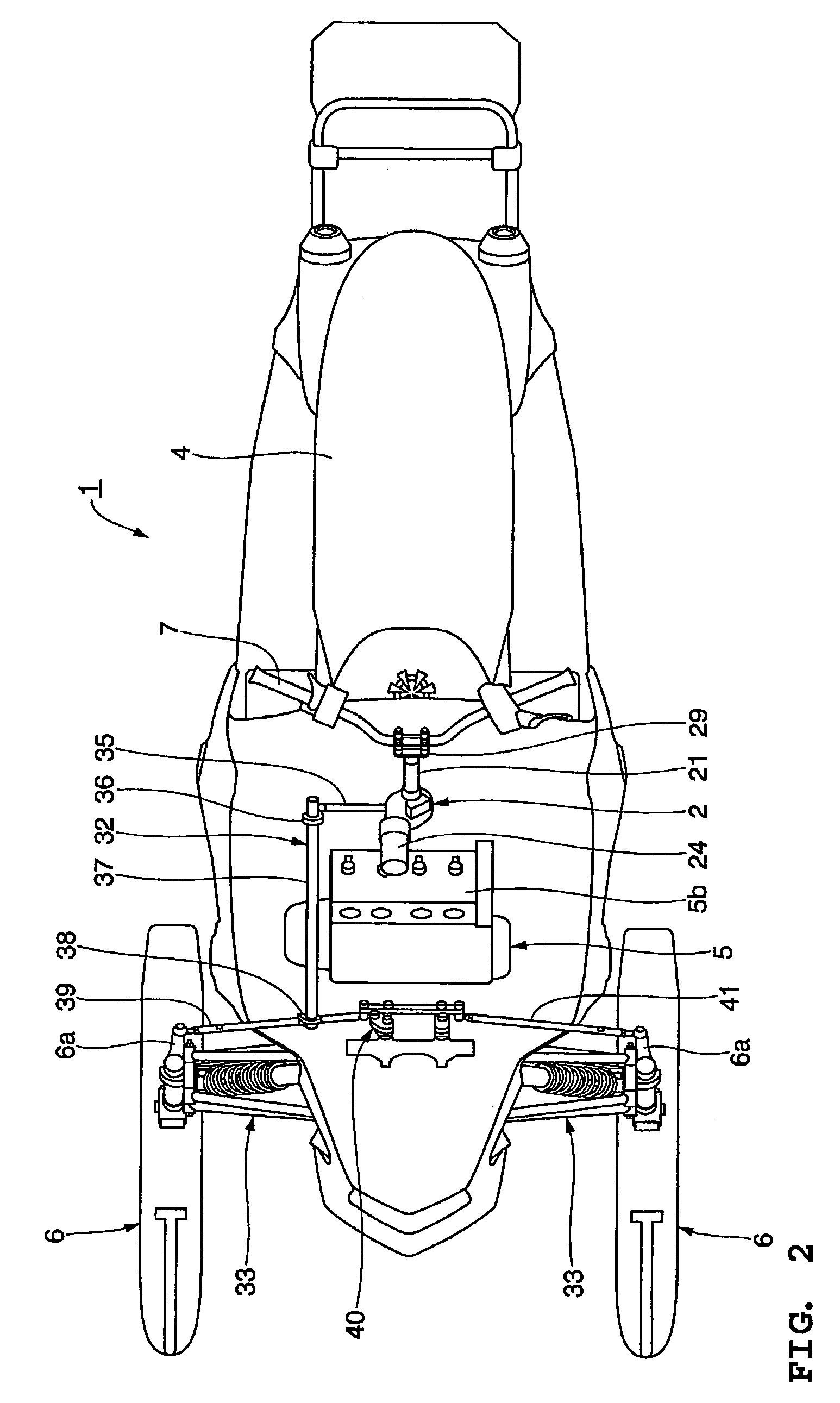

Snowmobile power steering system

ActiveUS7096988B2Limit positional freedomProblem balanceSledgesSteering deviceInternal combustion enginePower steering

A snowmobile comprises a frame assembly. An internal combustion engine is mounted to the frame assembly. A steering assembly is mounted to the frame assembly. The steering assembly comprises a steering shaft having a first portion and a second portion. The first portion of the steering shaft is coupled to a steering input mechanism. The second portion of the steering shaft is coupled to a power steering device. The power steering device is coupled to a steering linkage. The steering linkage is coupled to a steering ski.

Owner:YAMAHA MOTOR CO LTD

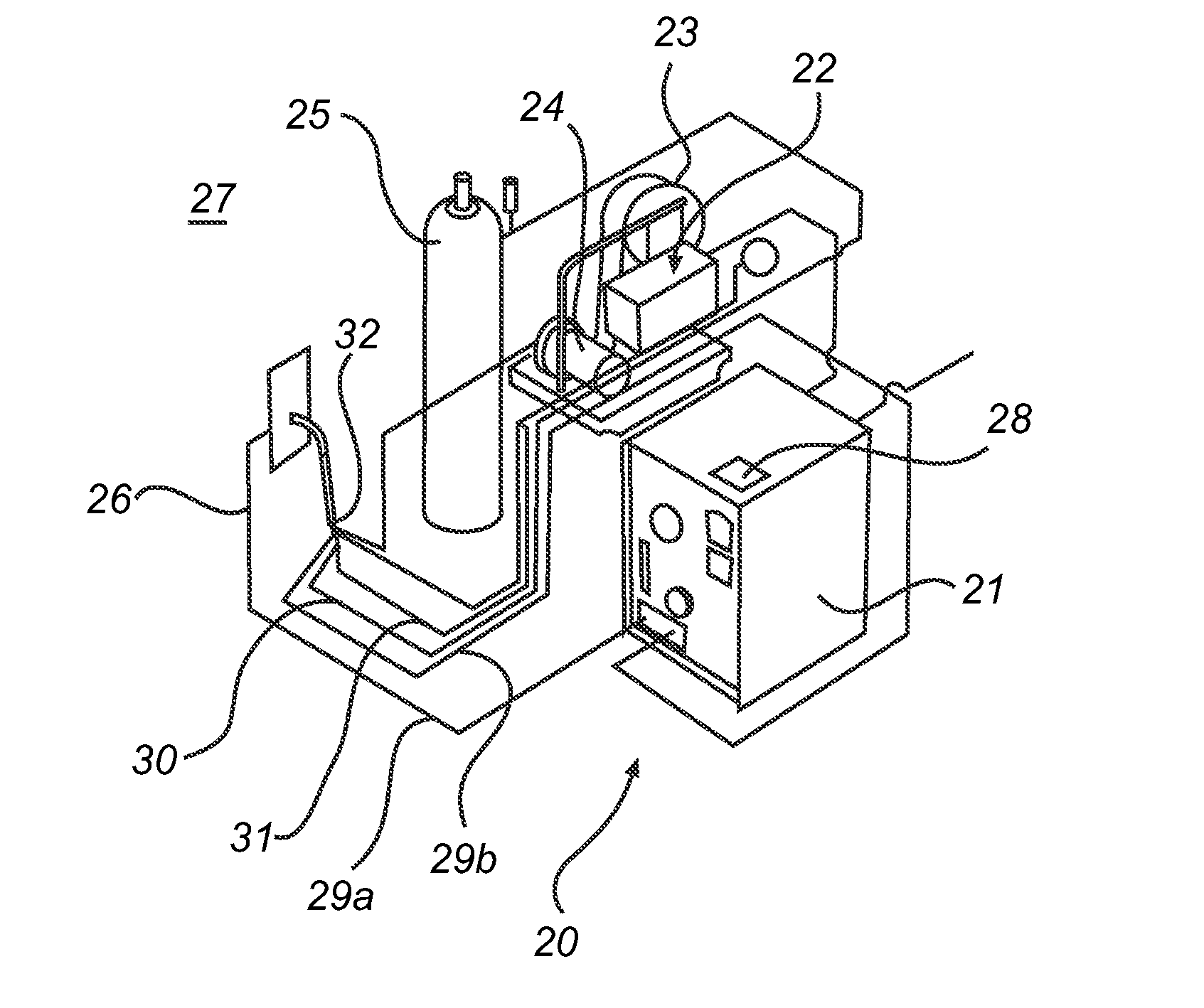

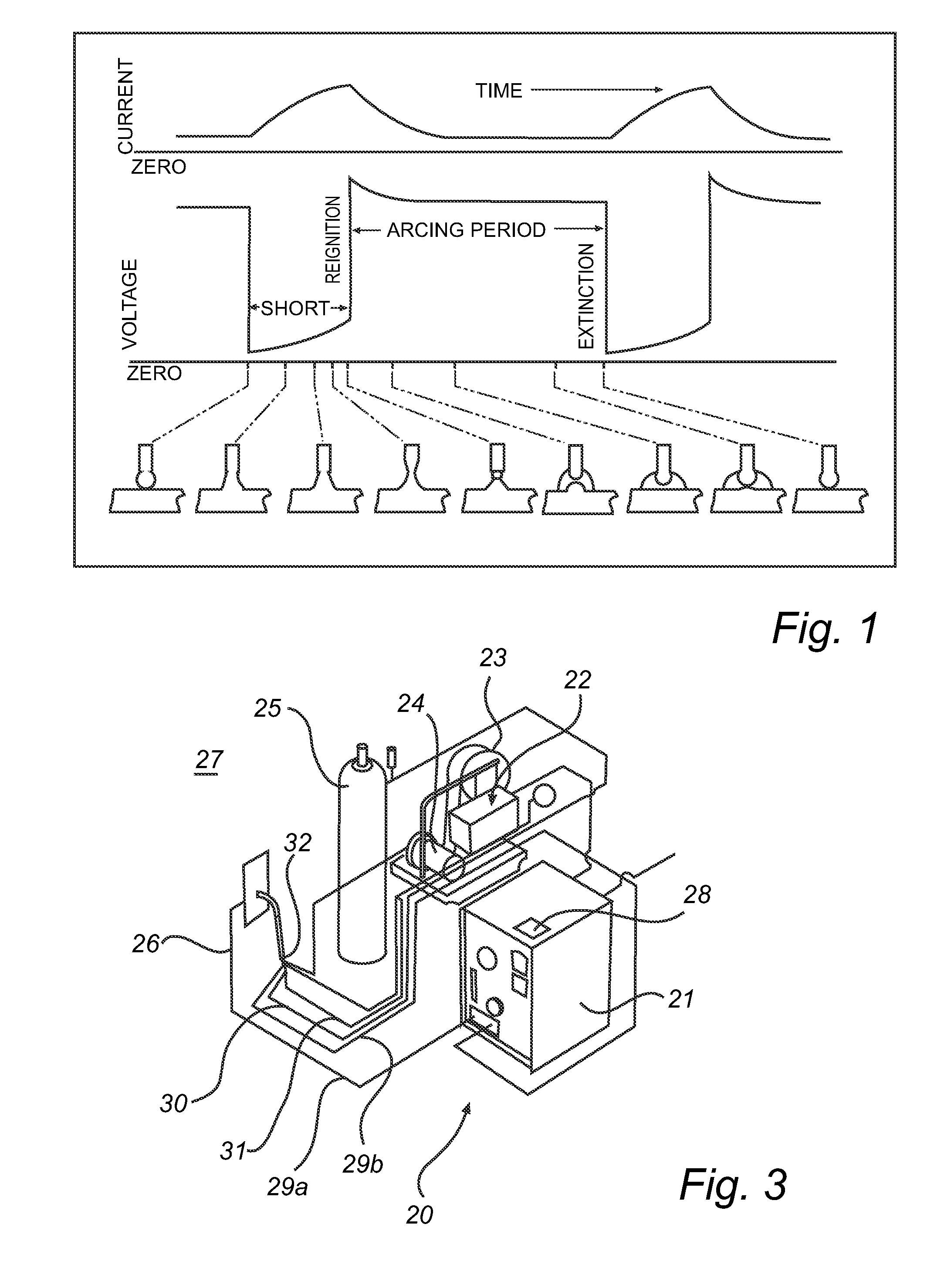

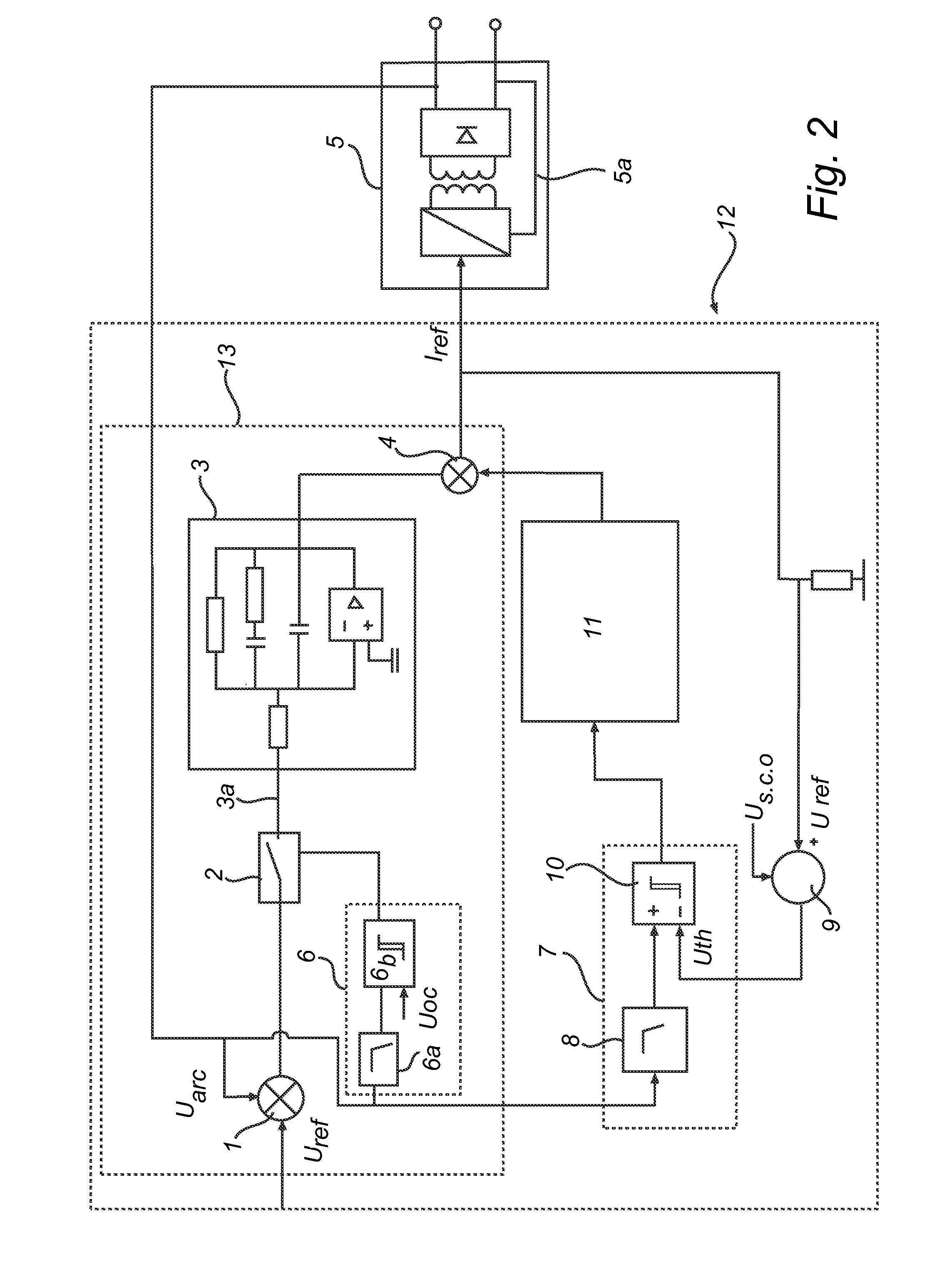

Short arc welding system

A system for controlling a weld-current in an arc welding apparatus for short arc welding comprising a current regulator included in a voltage feedback loop from a power supply to a welding electrode and a ramp generator arranged to provide current ramps during a short circuit phase at said welding electrode.

Owner:ESAB AB

High slender spindle-shaped apple tree form and trimming method thereof

InactiveCN101755655ACrown small and tallStrong result abilityCultivating equipmentsDecapitationUltimate tensile strength

The invention discloses a high slender spindle-shaped apple tree form and a trimming method thereof. As a whole, the tree form is of high slender spindle shape. After an apple tree is formed, the crown diameter of the apple tree is small, slender and high. The apple tree is 3.5-4.0m high and the trunk of the apple tree is 0.8-0.9m high. Thirty to fifty spirally arranged small boughs are grown on the central leading trunk of the apple tree. The average length of the small boughs is 1m. The average angle between the central trunk and the small bough is 115 degrees. The top-to-bottom spacing among the small boughs on the same side is 0.25m. The trimming method of the high slender spindle-shaped tree form is simple. Other boughs require no decapitation but branch drawing except that the central trunk requires short-cutting in winters in 1-2 years. Thereby, the trimming method can be popularized in tree forms of simplified trimming and low labor strength.

Owner:NORTHWEST A & F UNIV

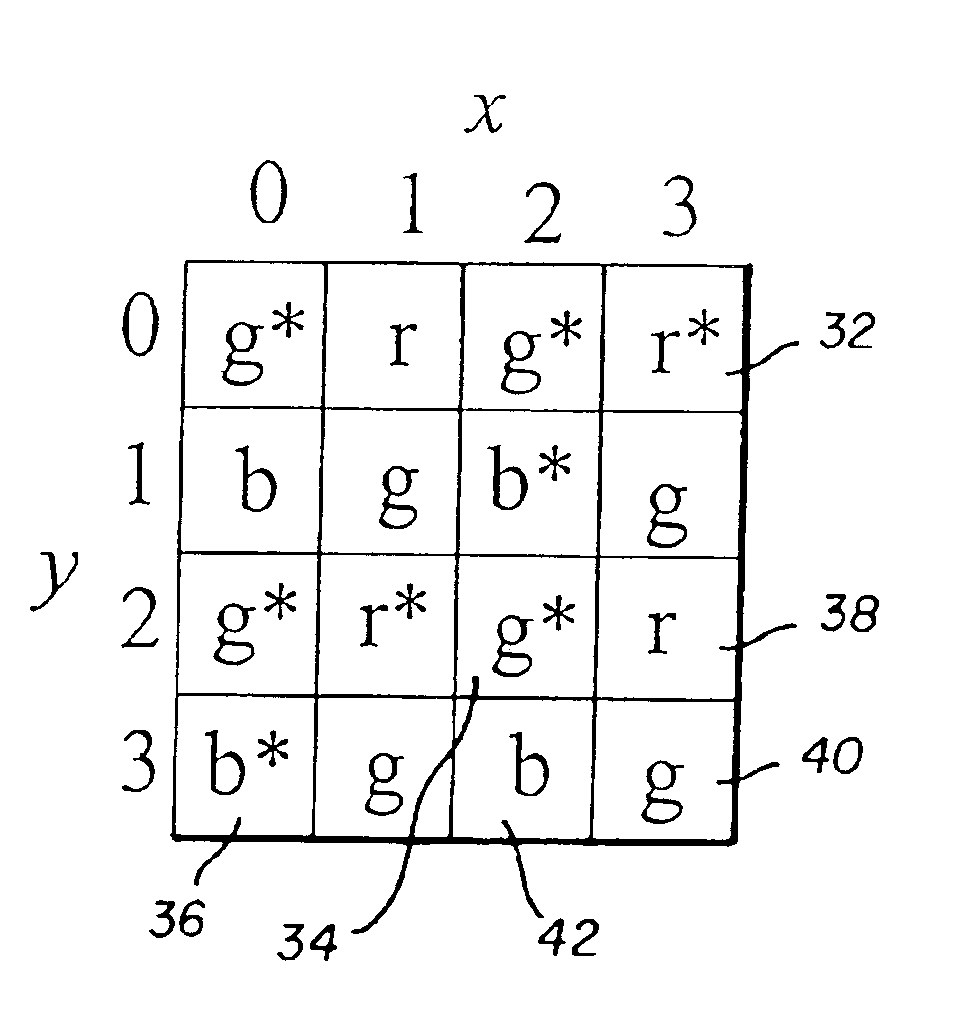

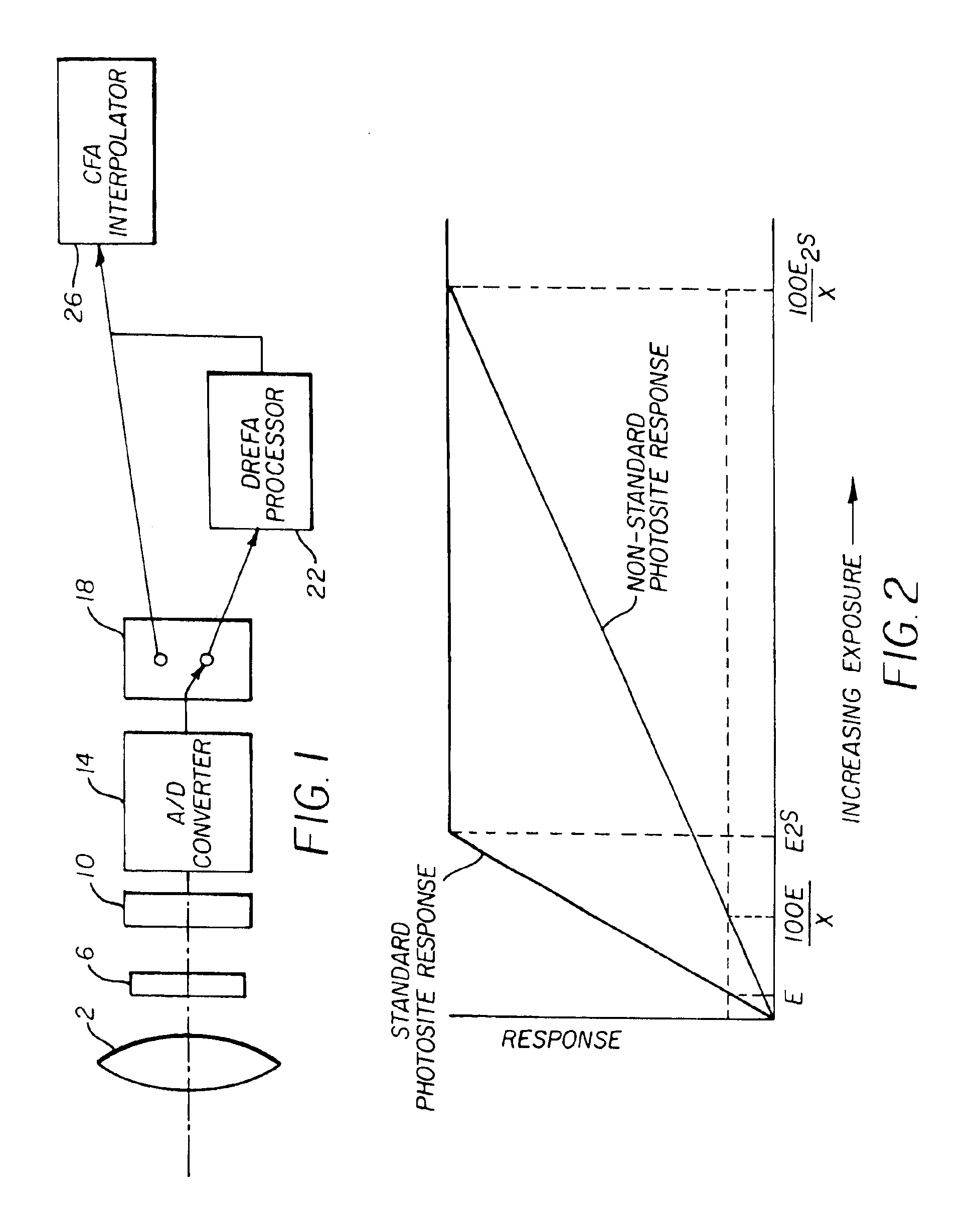

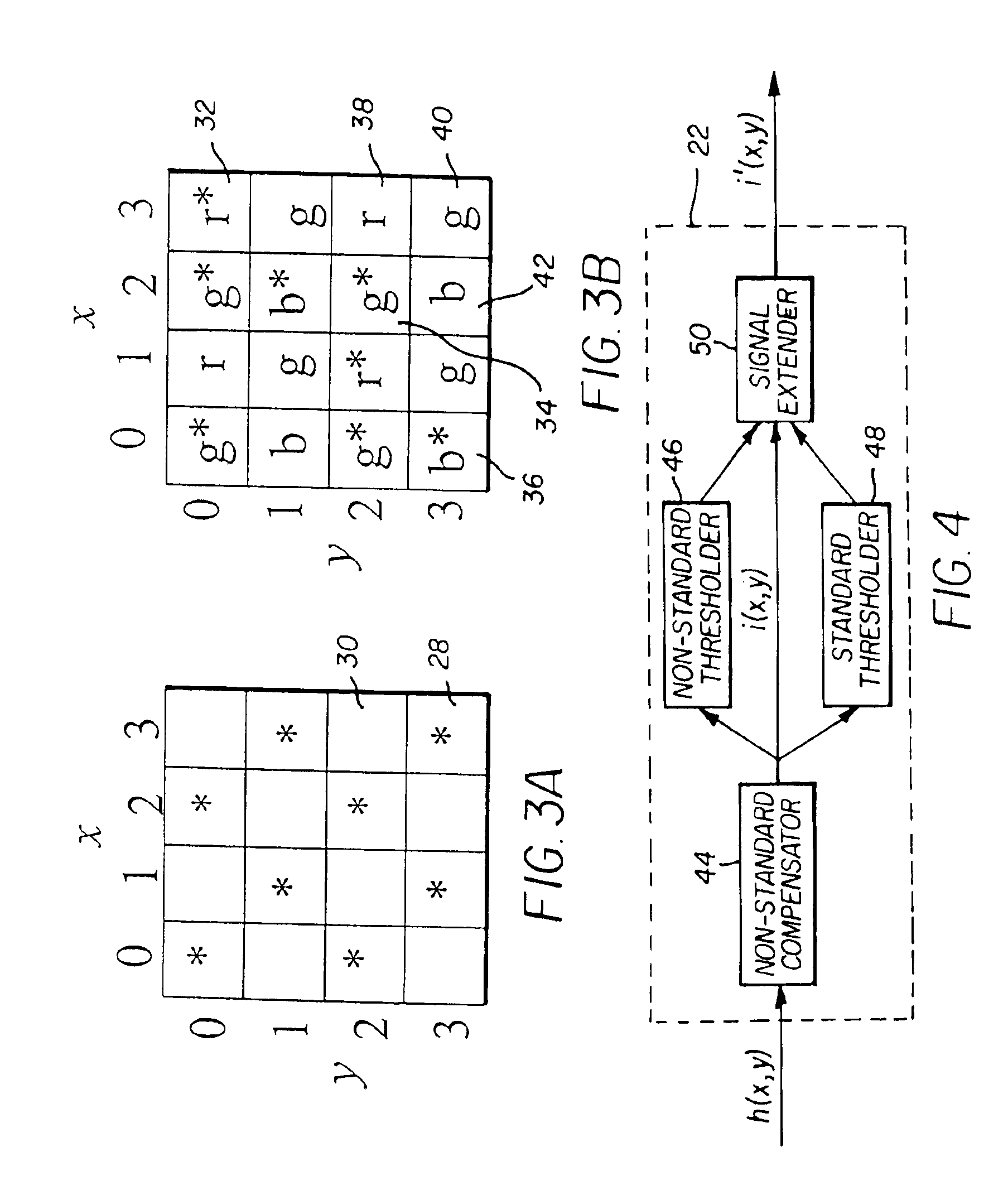

Method and apparatus to extend the effective dynamic range of an image sensing device

InactiveUS6909461B1Slow responseImprove dynamic rangeTelevision system detailsTelevision system scanning detailsLight spotEngineering

An image capture system generates an extended effective dynamic range from a signal provided by an image sensor by utilizing an image sensing device having standard photosites with a predetermined response to a light exposure and non-standard photosites with a slower response to the same light exposure. An optical section exposes the image sensing device to image light, thereby causing the image sensing device to generate an image signal and a processing section expands the response of the standard photosites to increased light exposures by utilizing the image signals from neighboring non-standard photosites. Furthermore, the processing section may expand the response of the non-standard photosites to decreased light exposures by utilizing the image signals from neighboring standard photosites. The differential response of the image sensor is provided by a structural element, such as an array of lenslets, a mask or a neutral density filter, overlying the photosites and providing the standard photosites with a predetermined standard response to a light exposure and the non-standard photosites with a slower response to the same light exposure.

Owner:OMNIVISION TECH INC

Hot Melt Wetness Indicator Adhesive Composition Containing UV Fluorescent Agent

ActiveUS20100264369A1Excellent heat and environmental stabilityHigh fastnessMachines/enginesAbsorbent padsWater insolubleFluorescence

A wetness indicating adhesive composition comprising an adhesive base composition incorporating a fluorescing agent in the adhesive base composition that only fluoresces when wet, and not when dry. In one embodiment, the adhesive base composition may be composed of water soluble, or at least partially water soluble, components, and in another embodiment the adhesive base composition may be composed of water sensitive components as for example one or more water insoluble polymers and a surfactant. The fluorescing agent can either be dissolved or dispersed in the adhesive base composition, and is preferably a water soluble fluorescing agent that becomes visible under ultraviolet light only when an article such as a disposable diaper becomes wet.

Owner:BOSTIK INC

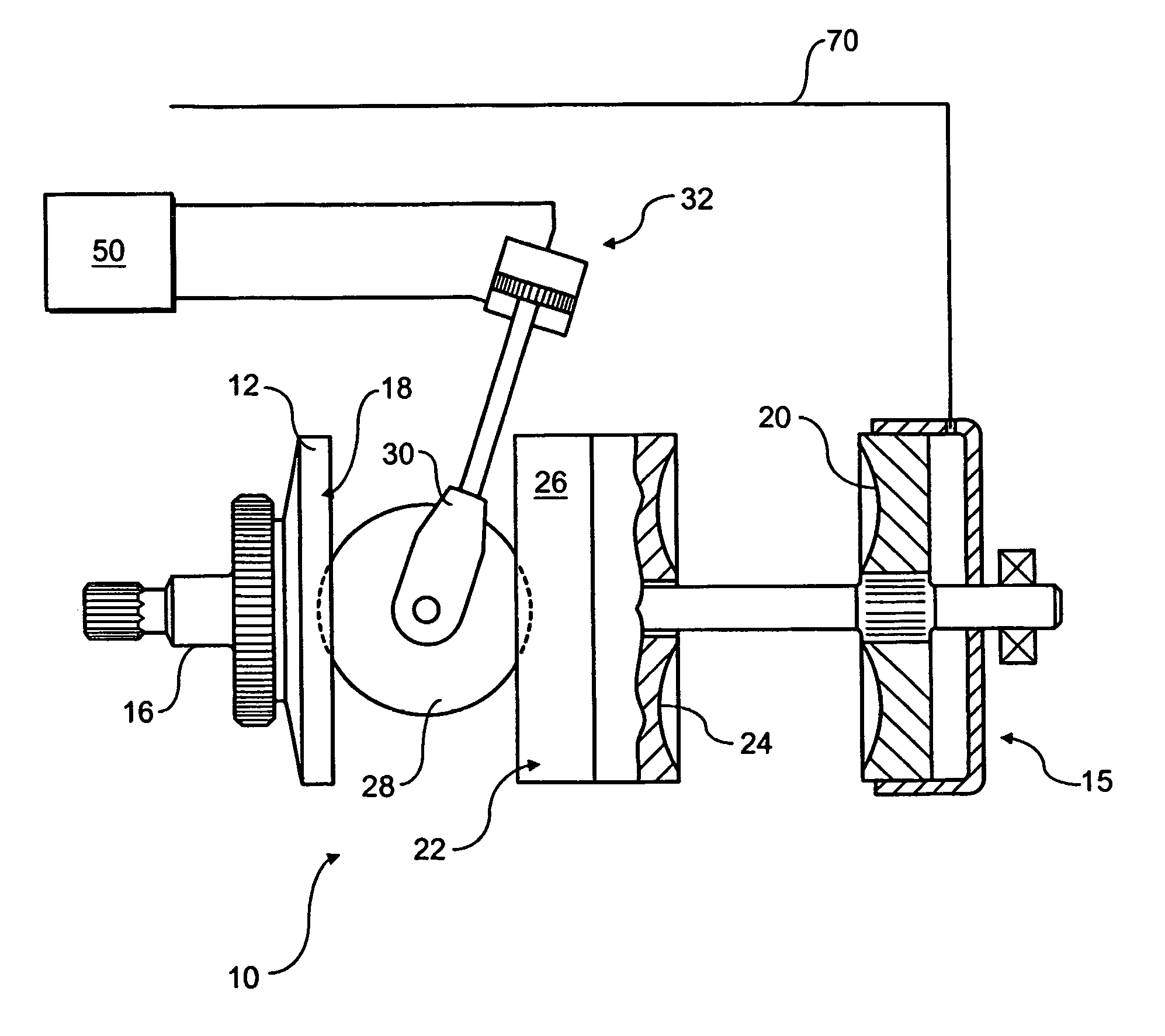

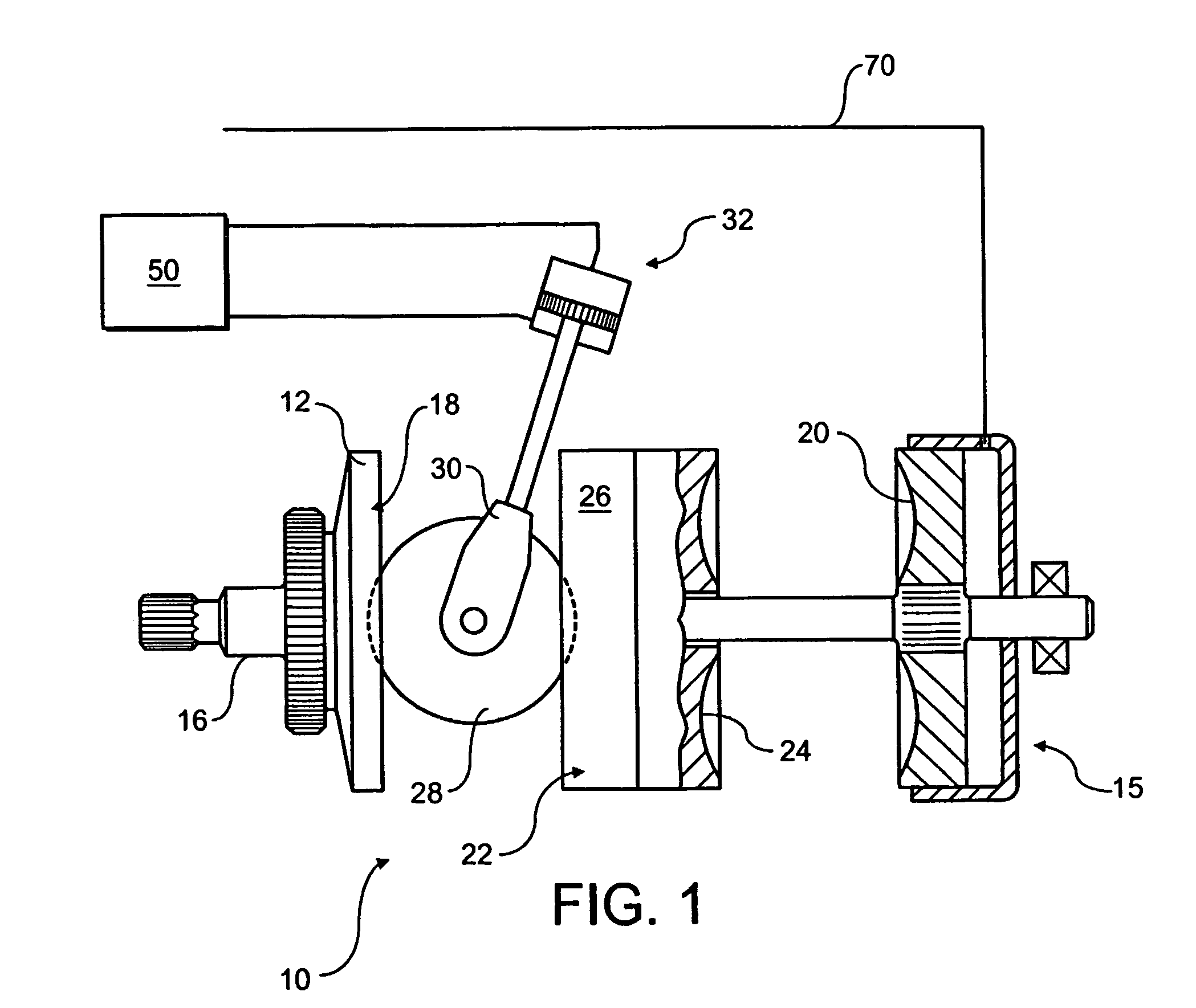

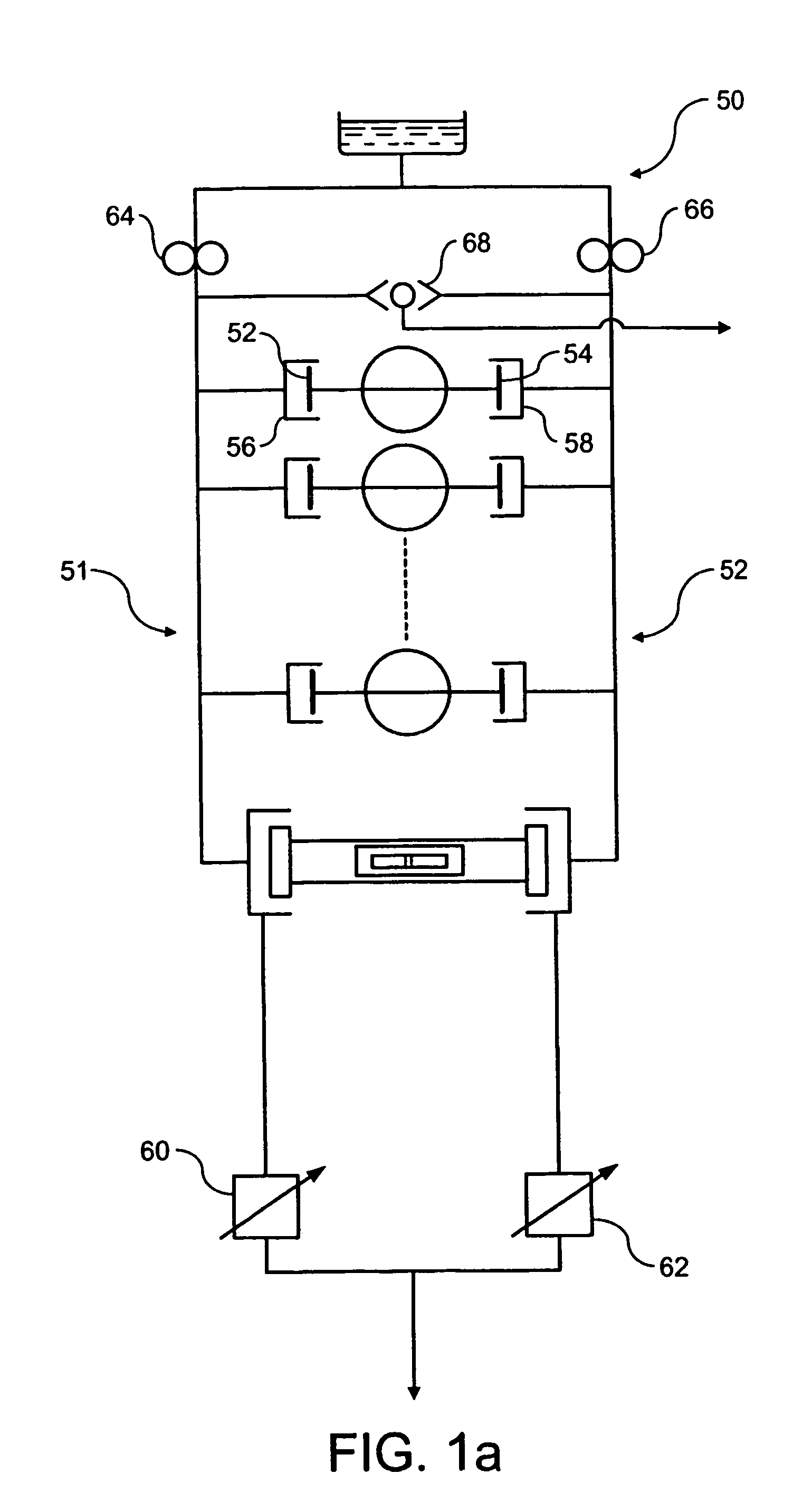

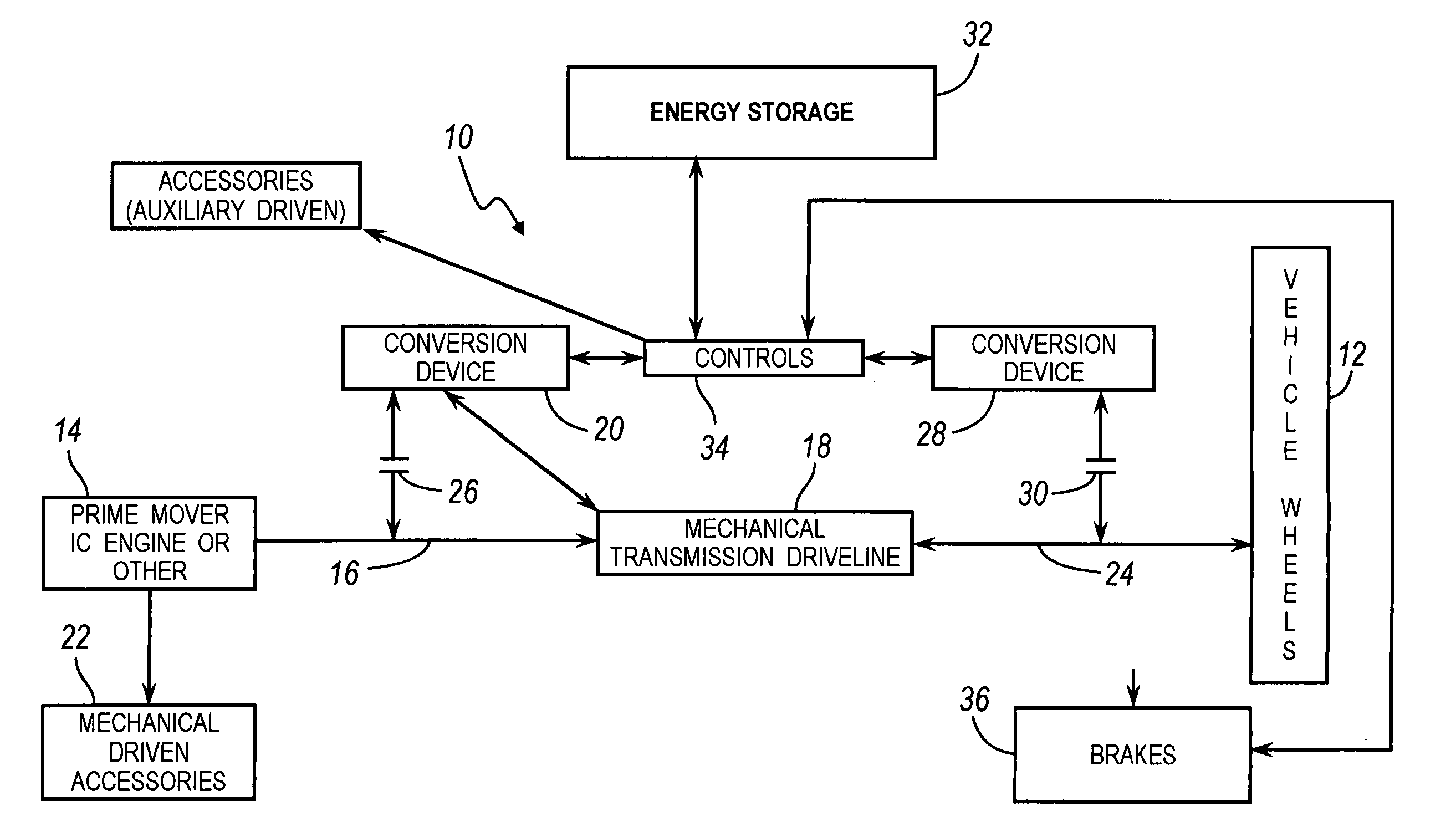

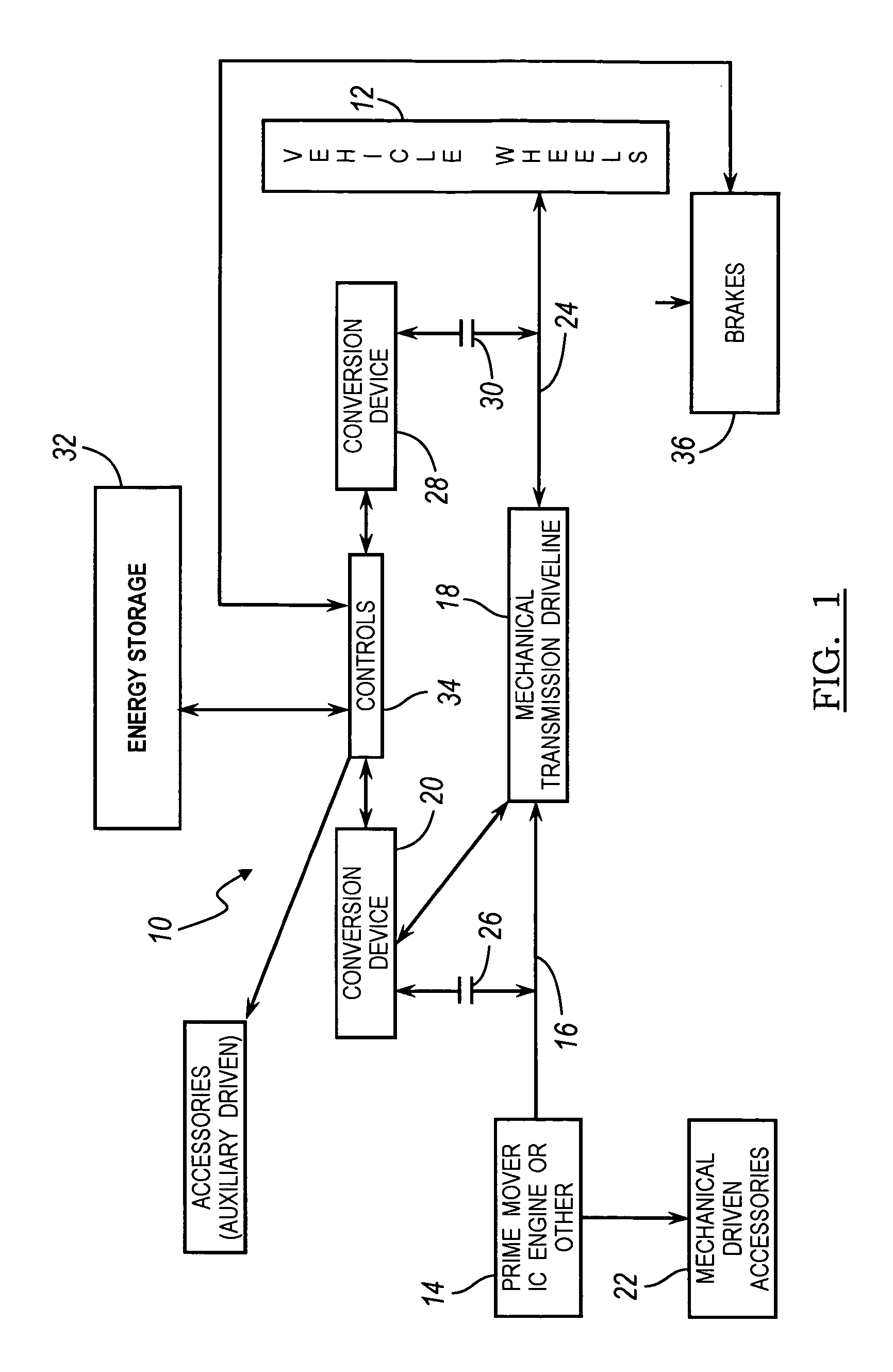

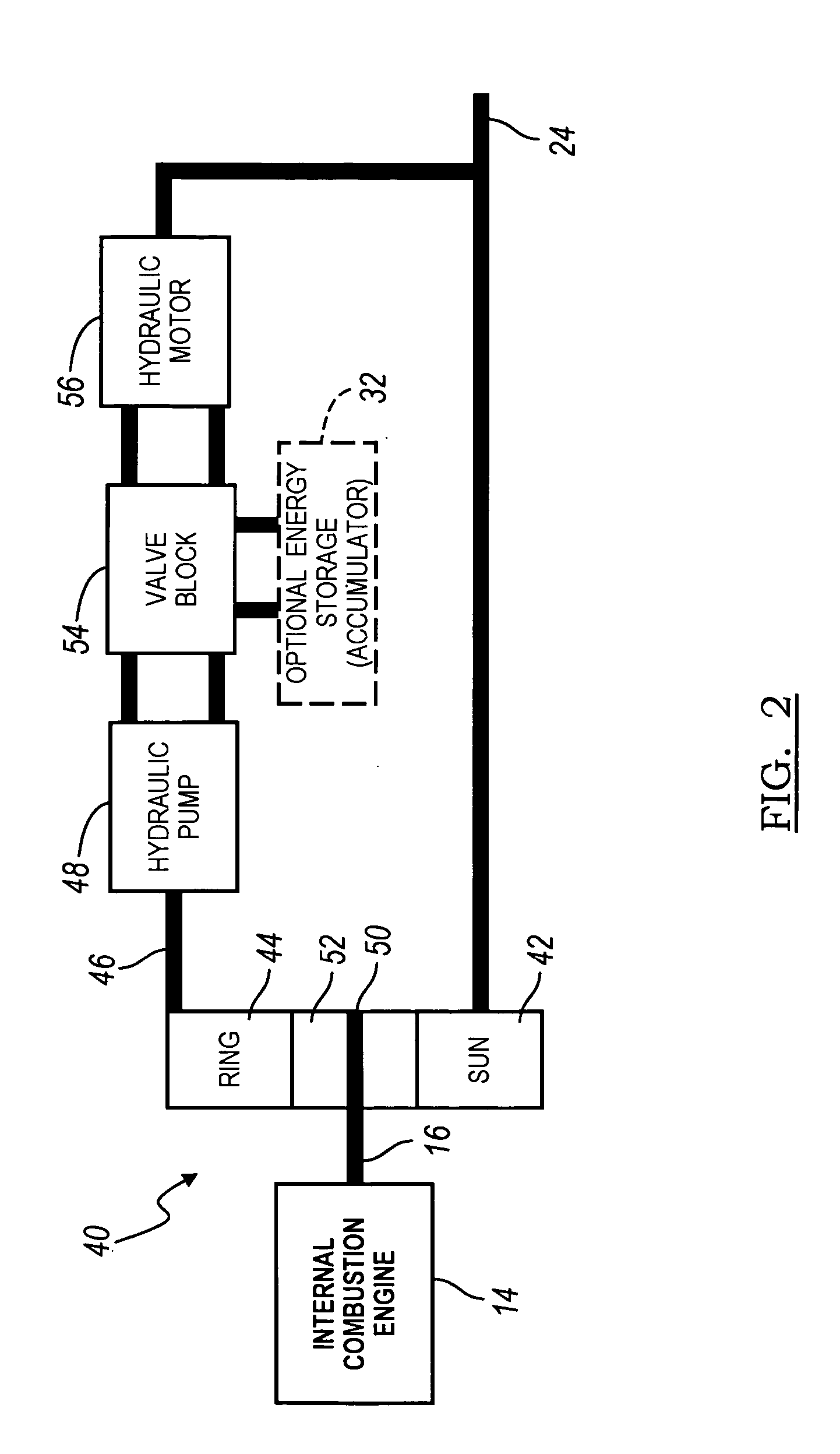

Vehicle powertrain that compensates for a prime mover having slow transient response

InactiveUS20060145482A1Reduce particulate emissionLower costEngine controllersMachines/enginesForms of energySupply energy

A powertrain for transmitting power in a vehicle includes a prime mover having a relatively slow transient response, and a storage device for storing energy in a predetermined form. A transmission includes an input driveably connected to the prime mover and an output driveably connected to vehicle drive wheels, producing a range of ratios of a speed of the output to a speed of the input that varies from negative to positive and includes zero. An energy conversion device, driveably connected to the prime mover and drive wheels, converts rotational power transmitted to the energy conversion device from the wheels and the prime mover to a form of energy that can be stored in the storage device, and drives the wheels using energy supplied to the energy conversion device from the storage device. A control device alternately transmits energy from the storage device to the energy conversion device, and transmits energy from the energy conversion device to the storage device.

Owner:FORD GLOBAL TECH LLC

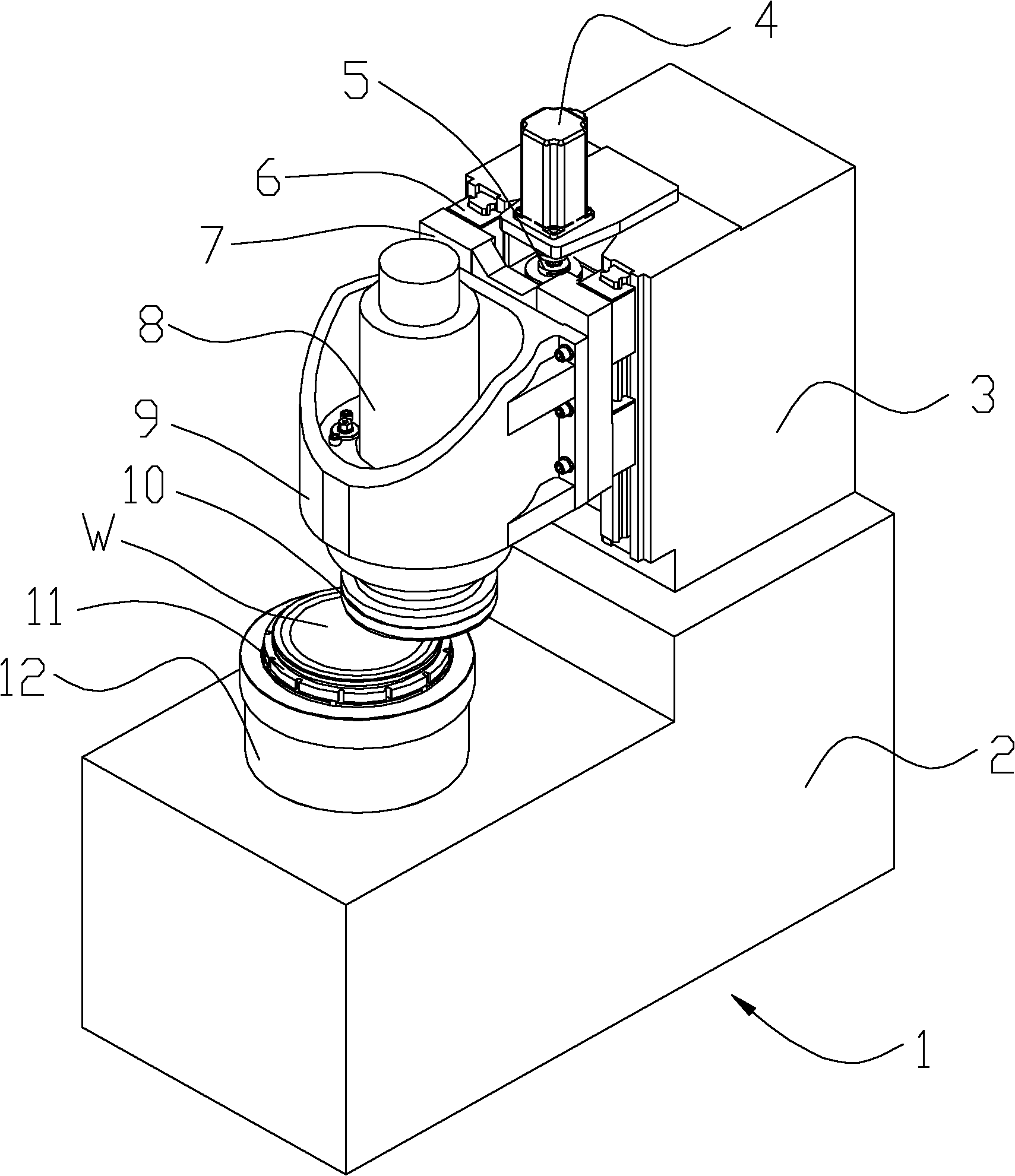

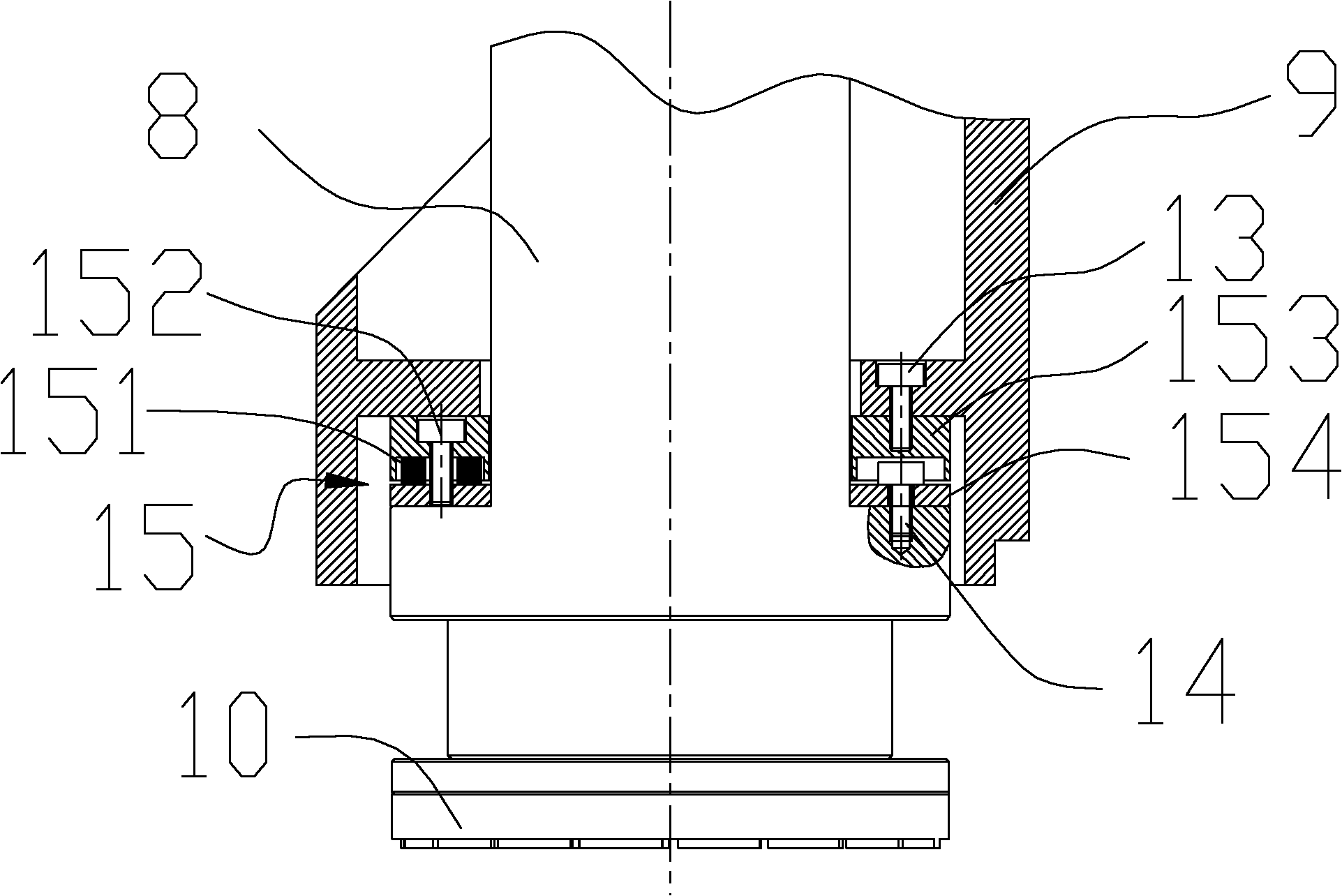

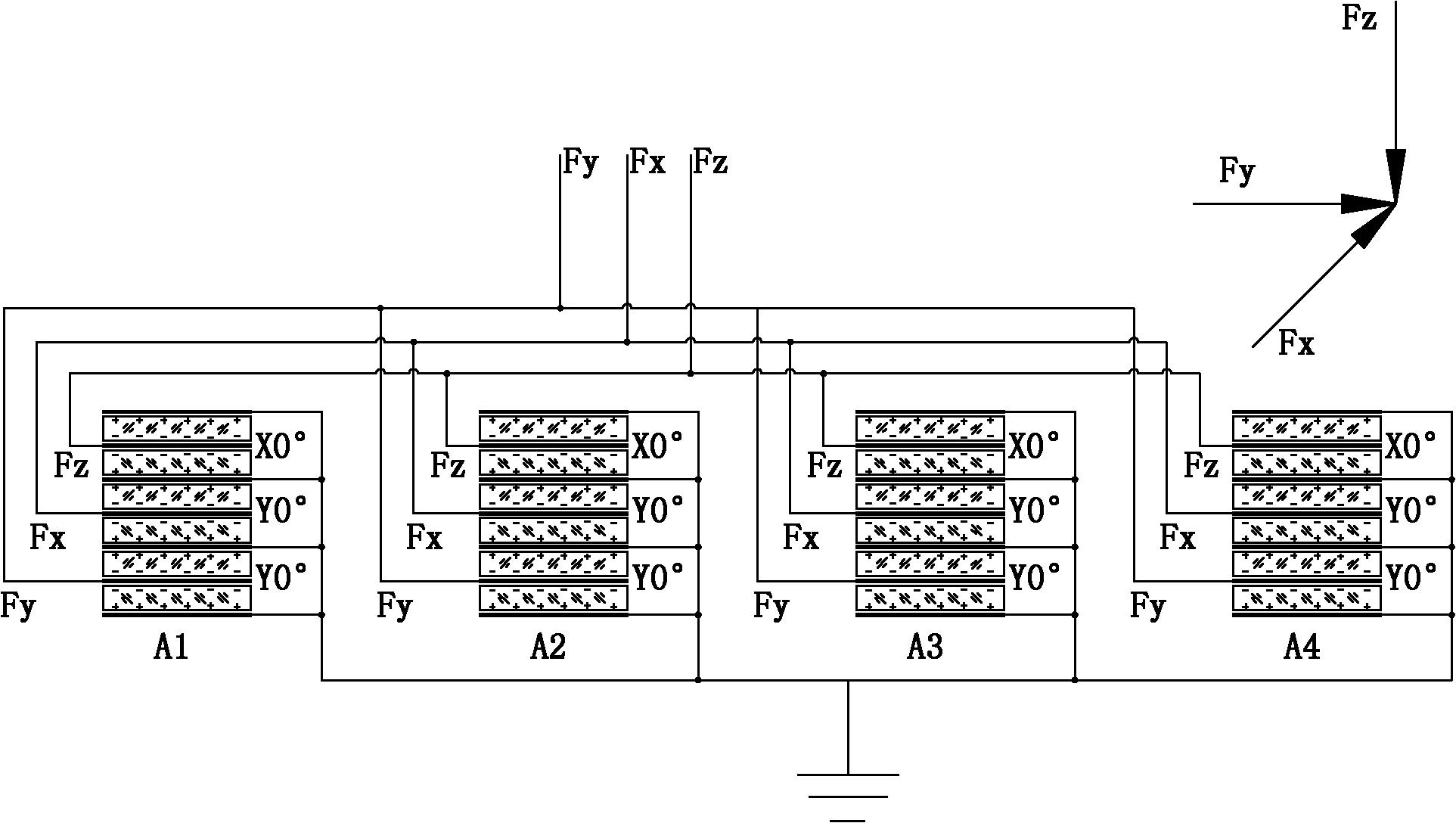

Semiconductor wafer grinding force on-line measurement device and force-controlling grinding method

ActiveCN102009387AImprove machining accuracyImprove processing qualityGrinding feed controlMeasurement deviceTangential force

The invention belongs to the ultraprecision machining field of the hard and brittle semiconductor crystalline materials and relates to a grinding force on-line measurement device used in the grinding process of the semiconductor wafer and a force-controlling grinding method. The invention discloses a semiconductor wafer grinding force on-line measurement device which is used as the feedback element of a grinding force adaptive control system. The grinding force measurement device adopts the piezoelectric measuring principle and contains a sensor part and a data processing unit, wherein the sensor part is used for the on-line measurement of the radial force Fr, the tangential force Ft and the axial force Fz; and the data processing unit is used to collect and analyze the grinding force data and perform feedback control to the feed speed and feed amount of the grinding wheel, thus the aim of on-line measurement can be achieved. The invention has the following advantages: the grinding force on-line measurement device has simple structure, and the modifications to the original equipment are less; the grinding force on-line measurement links are fewer, the response speed is fast, and the precision is high; and the grinding efficiency of the semiconductor wafer can be increased and the thickness of the damaged layer is reduced.

Owner:宁波知行半导体有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com