Patents

Literature

67results about How to "Poor quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multimedia scenario editor calculating estimated size and cost

InactiveUS6072479ASlow responsePoor qualityElectronic editing digitised analogue information signalsMultimedia data retrievalImage objectApplication software

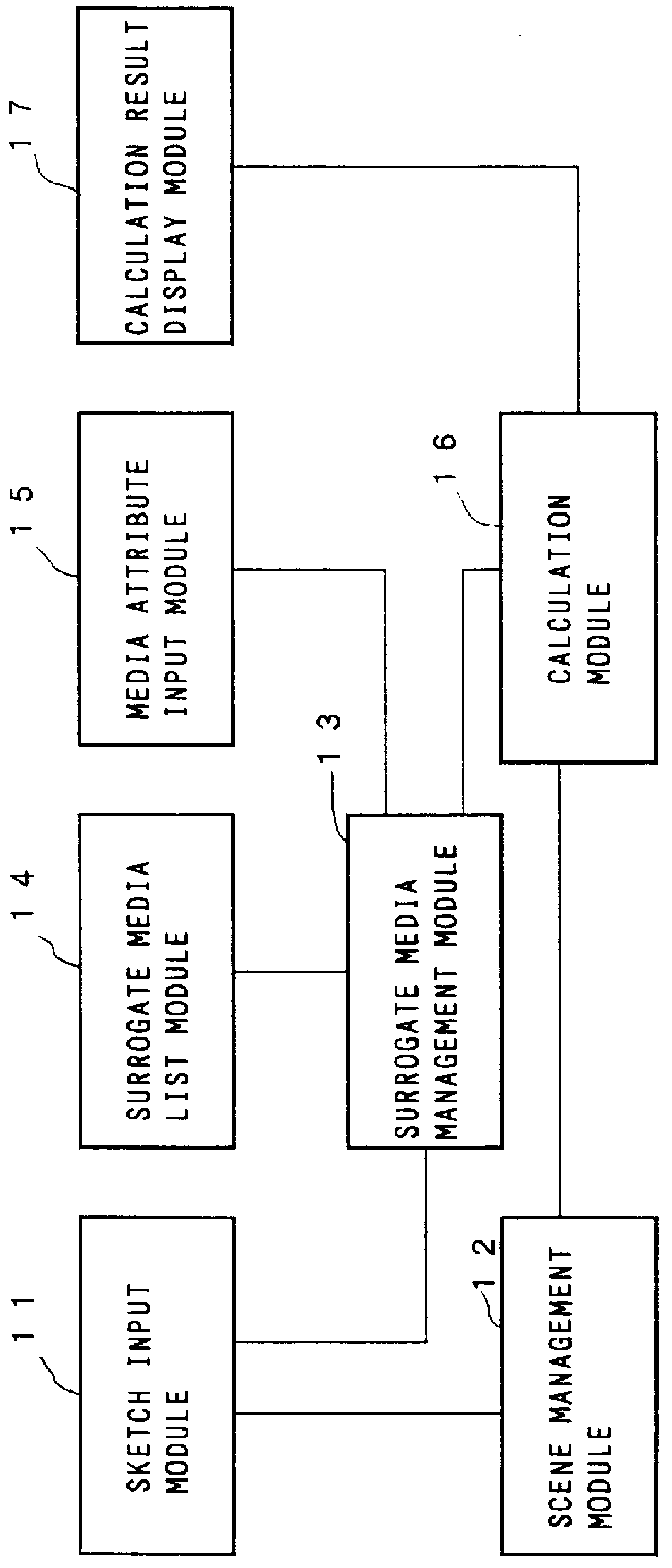

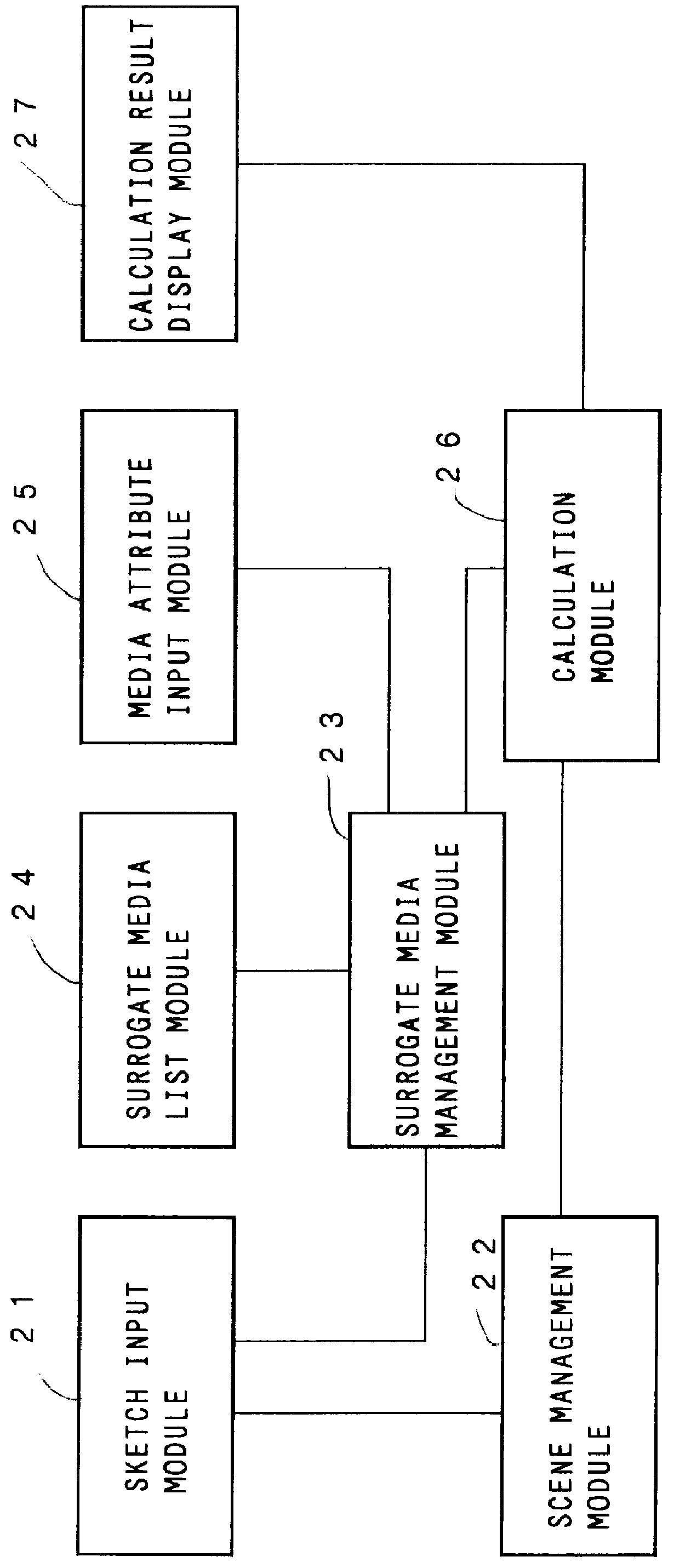

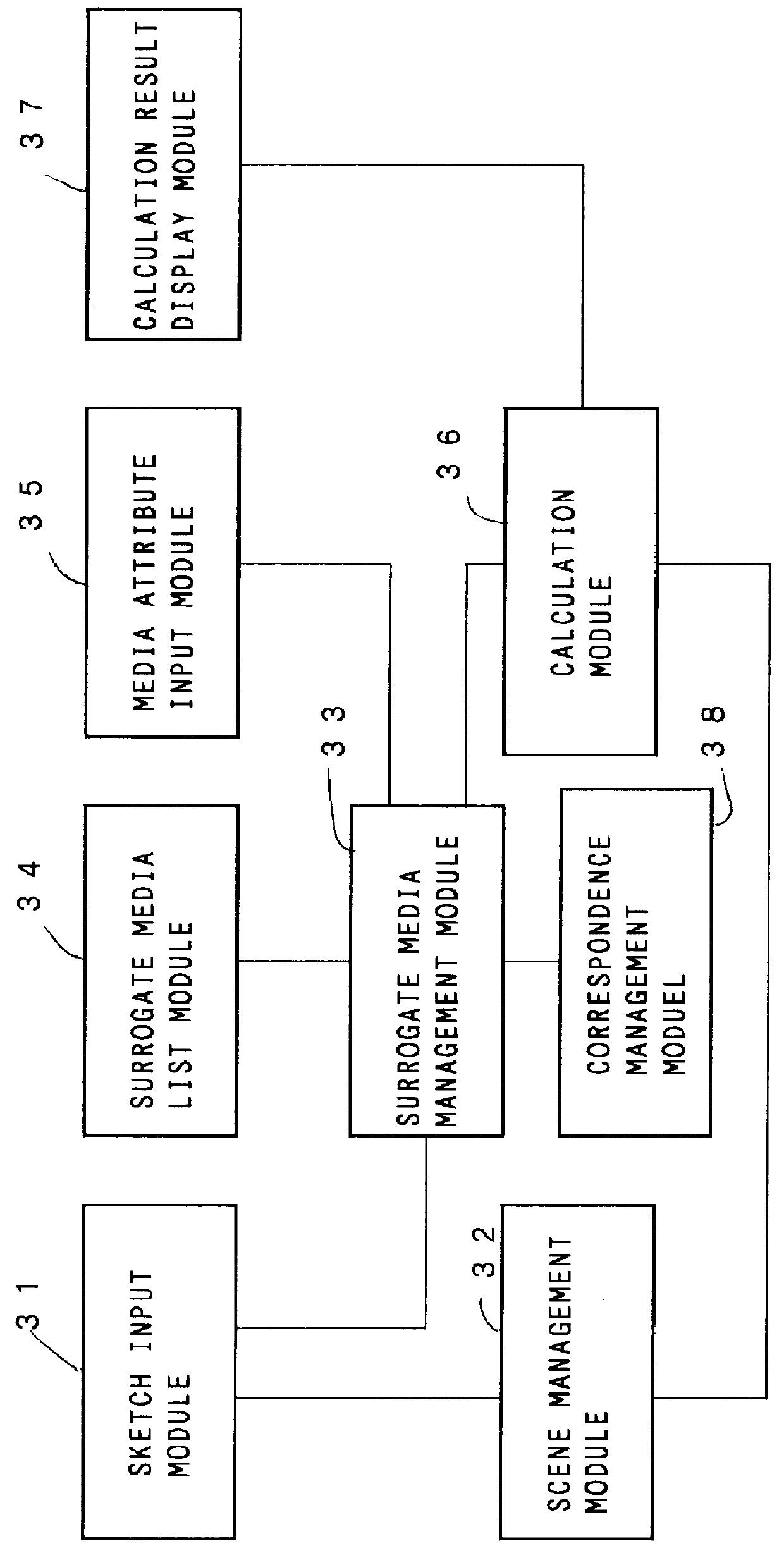

A scenario editing system comprises a drawing input module drawing graphic media objects or inputting existing media objects; a scene management module storing and managing said media objects; a surrogate media management module storing said media objects for use as surrogate media objects temporarily representing actual moving picture objects, voice objects, or image objects to be created later; a surrogate media list module displaying said surrogate media objects in a list of thumbnails; a media attribute input module allowing a user to enter a media-dependent attribute of an actual media object to be created, while said surrogate media list module displays the list; a calculation module calculating sizes of actual media data and adding up the media data sizes to estimate a total size of an overall application, based on said media-dependent attribute; and a calculation result display module displaying the result of said calculation. The media attribute input module allows a user to enter the name of a person in charge and scheduled development time as an attribute, wherein the calculation module adds up actual media creation costs for calculation of an estimate of the cost of each media type and an overall application, and wherein the calculation result display module displays cost information for each media type and for the overall application.

Owner:NEC CORP

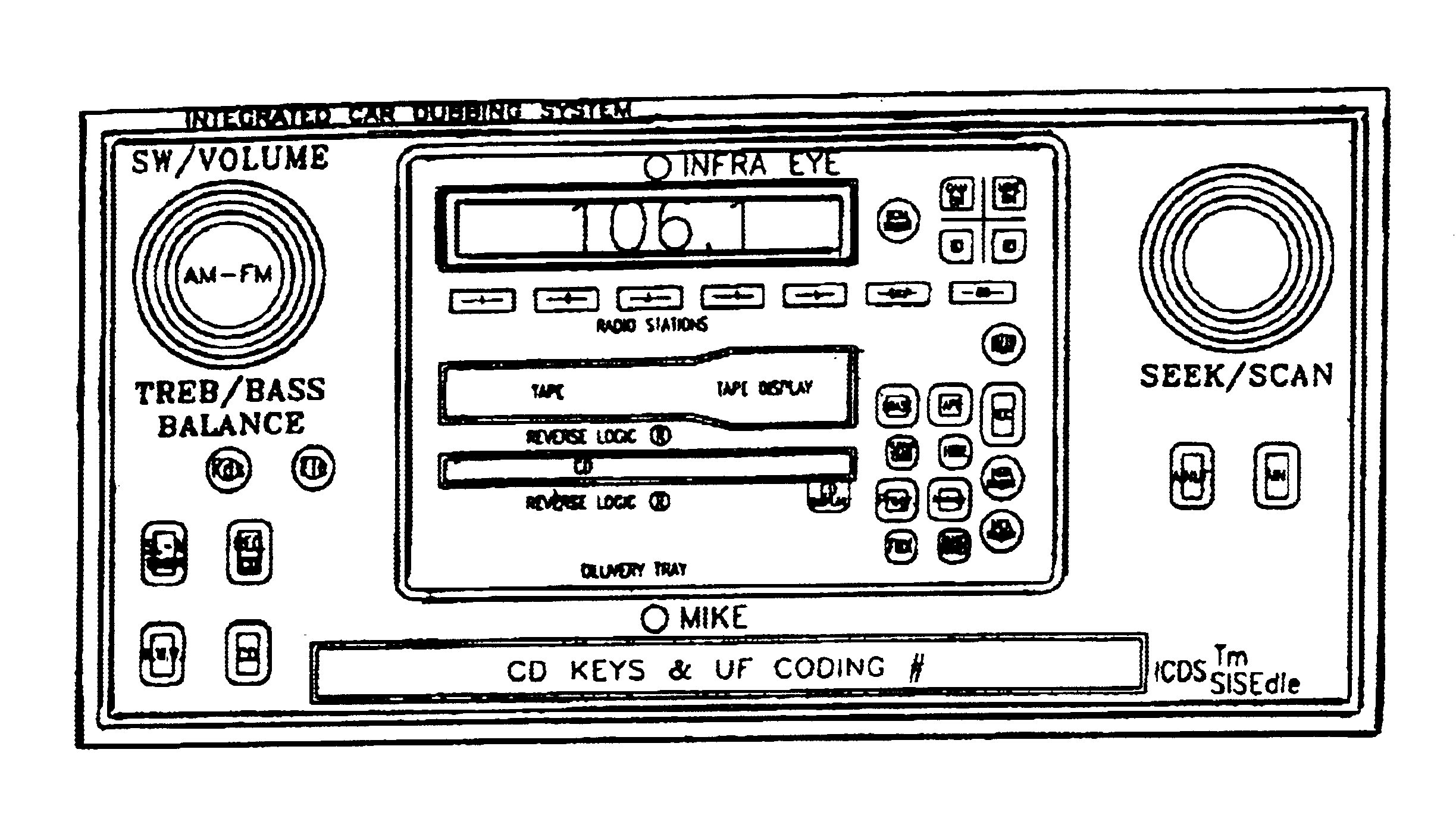

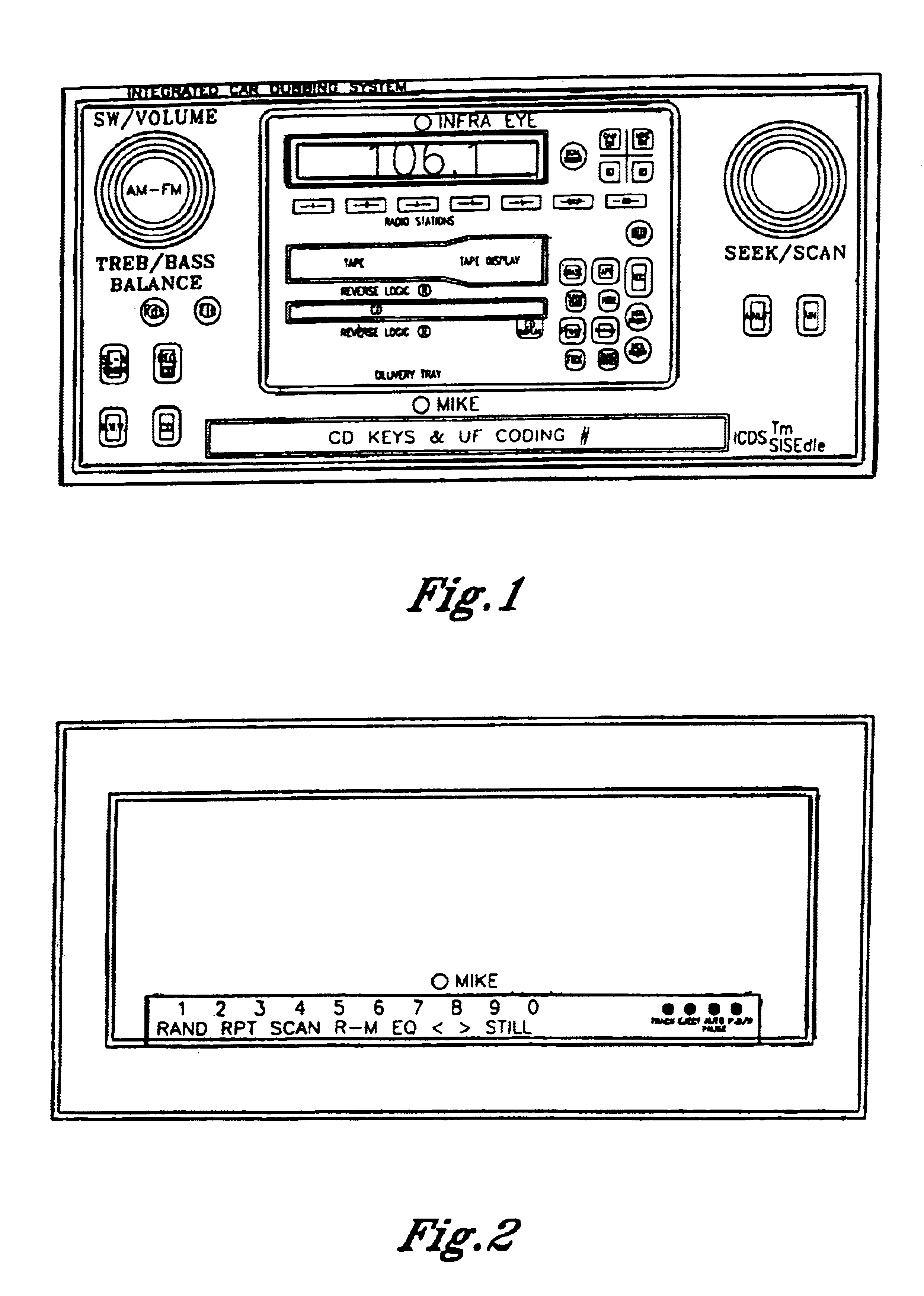

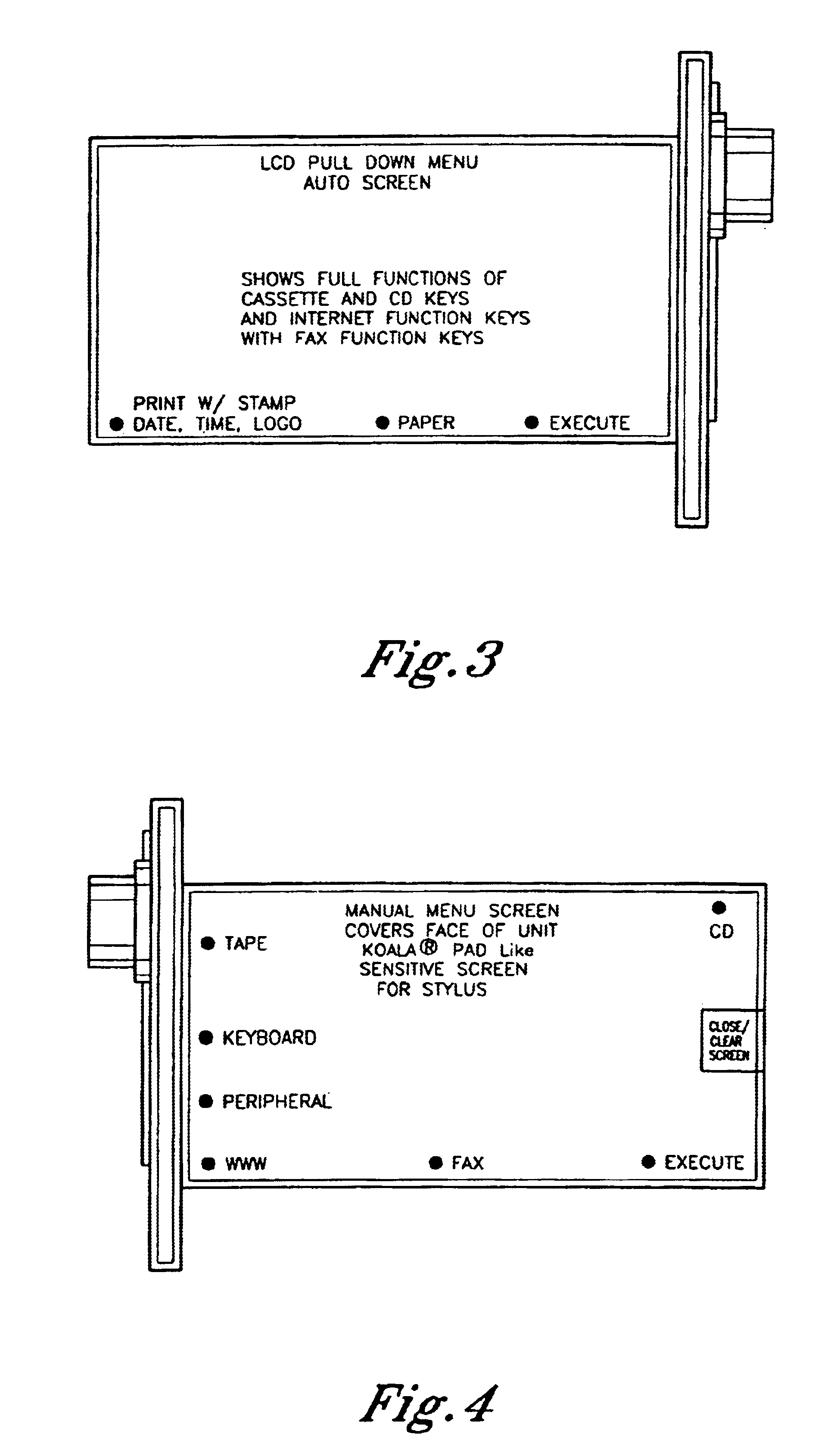

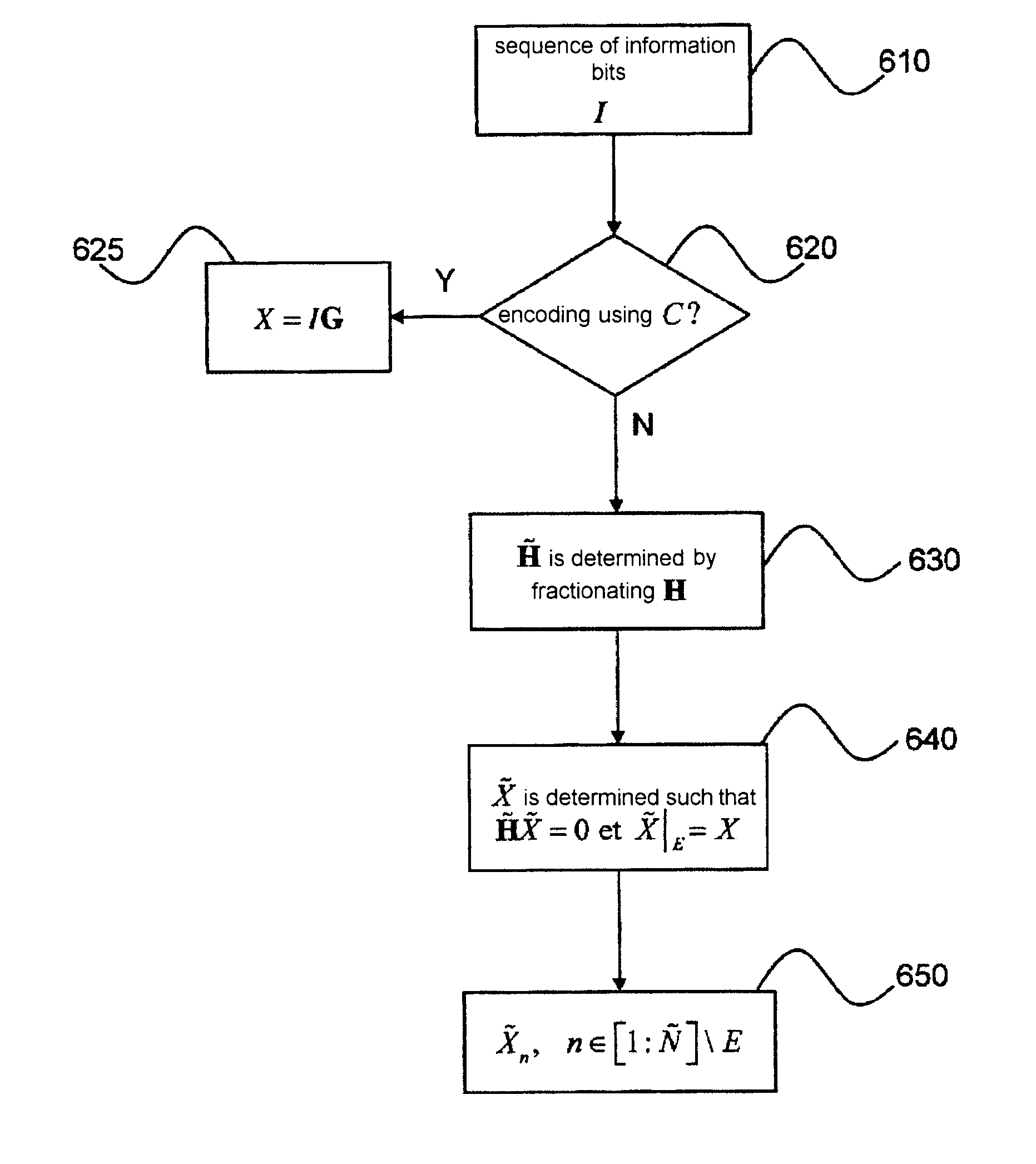

Integrated car dubbing system

InactiveUS6779196B1Poor qualityBad experienceGHz frequency transmissionRecord information storageDistortionSatellite

The present invention is a vehicular wireless audio / video record / playback unit, wherein the unit detects satellite, AM / FM radio and television broadcasts including new music release and live music and entertainment events and upon detection of a commercial break, station break, distortion or satellite interruptions, the unit pauses a recording function until the commercial or station break, distortion or satellite interruptions are eliminated. The unit supports internet access, on-line banking, stock market trading, commodity and precious stone / metal trading. When integrated into the vehicular audio system and led screen the microphone and infra red night vision camera provide for telephone / video conferencing, recording of impacts and unwarranted intruder with audible sound that alerts the motorist when the camera senses fatigue, and a retractable assembly mechanism that uses the vehicular ignition switch to retrieve, retract and / or bypass the unit in the vehicular electronic compartment, wherein the unit have a record / playback memory space, high speed dubbing / memory erase and sensor configuration with the remote control peripheral for accessing the unit at any convenient seat position and a dual purpose audio / video track disk having software downloaded as the unit for rebooting the cd player or re-configure the unit if there was a unit failure.

Owner:IGBINADOLOR PHILLIP

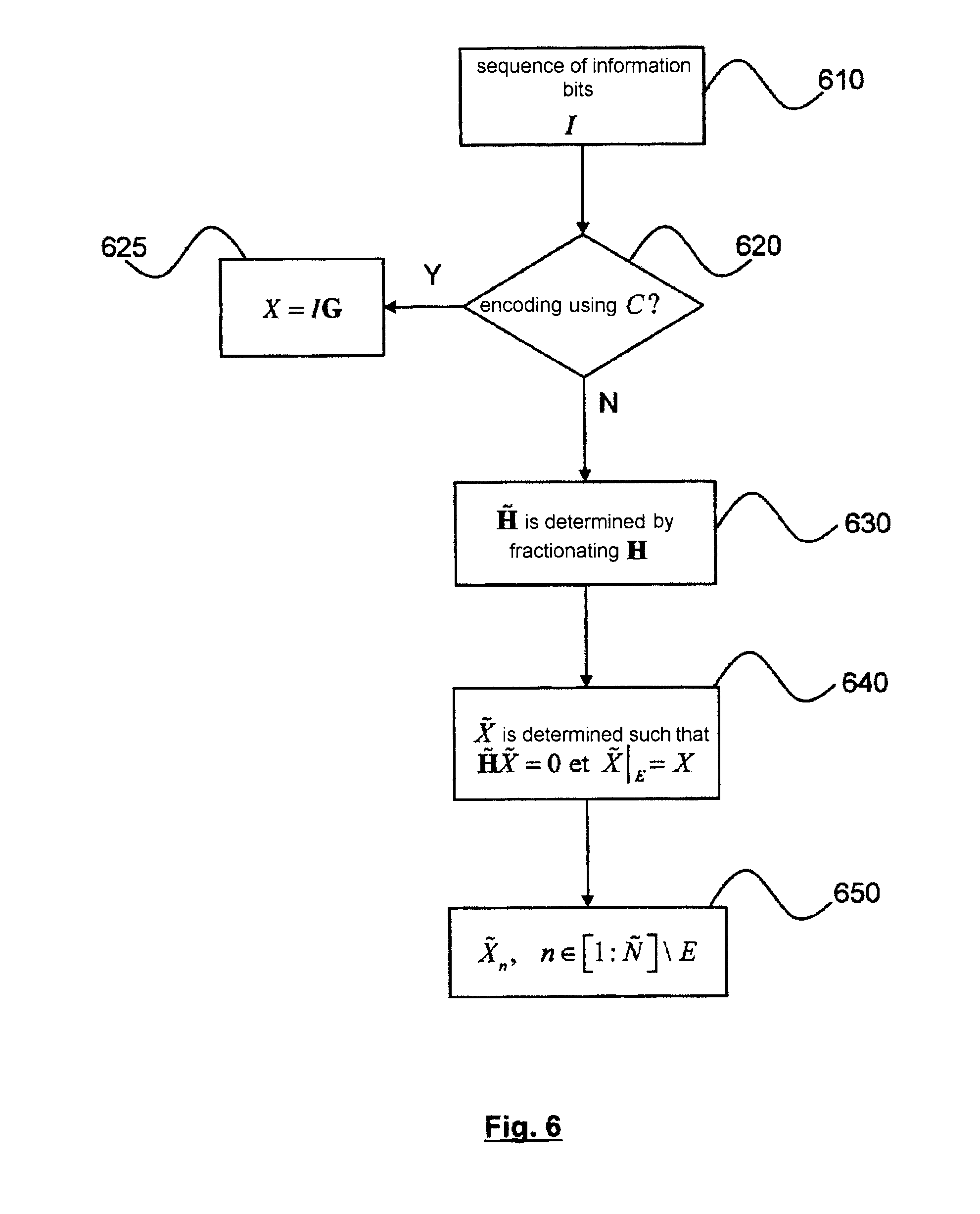

LDPC coding process with incremental redundancy

ActiveUS20110138260A1Poor qualityError correction/detection using convolutional codesCode conversionLink adaptationPacket transmission

The invention relates to a coding method with incremental redundancy in which it is determined (620) whether to carry out the coding of a sequence of information symbols using a first code (C), of the LDPC type, defined by a first check matrix, H, or rather using a second code ({tilde over (C)}), of lesser efficiency than that of the first code, the second code being defined by a second check matrix, {tilde over (H)}, obtained by fractionation (630) of the rows of the first check matrix. The invention finds application to, among others, a link adaptation method, a turbo-coding method, a distributed coding method within a cooperative network, a packet transmission method using an IR-HARQ protocol.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

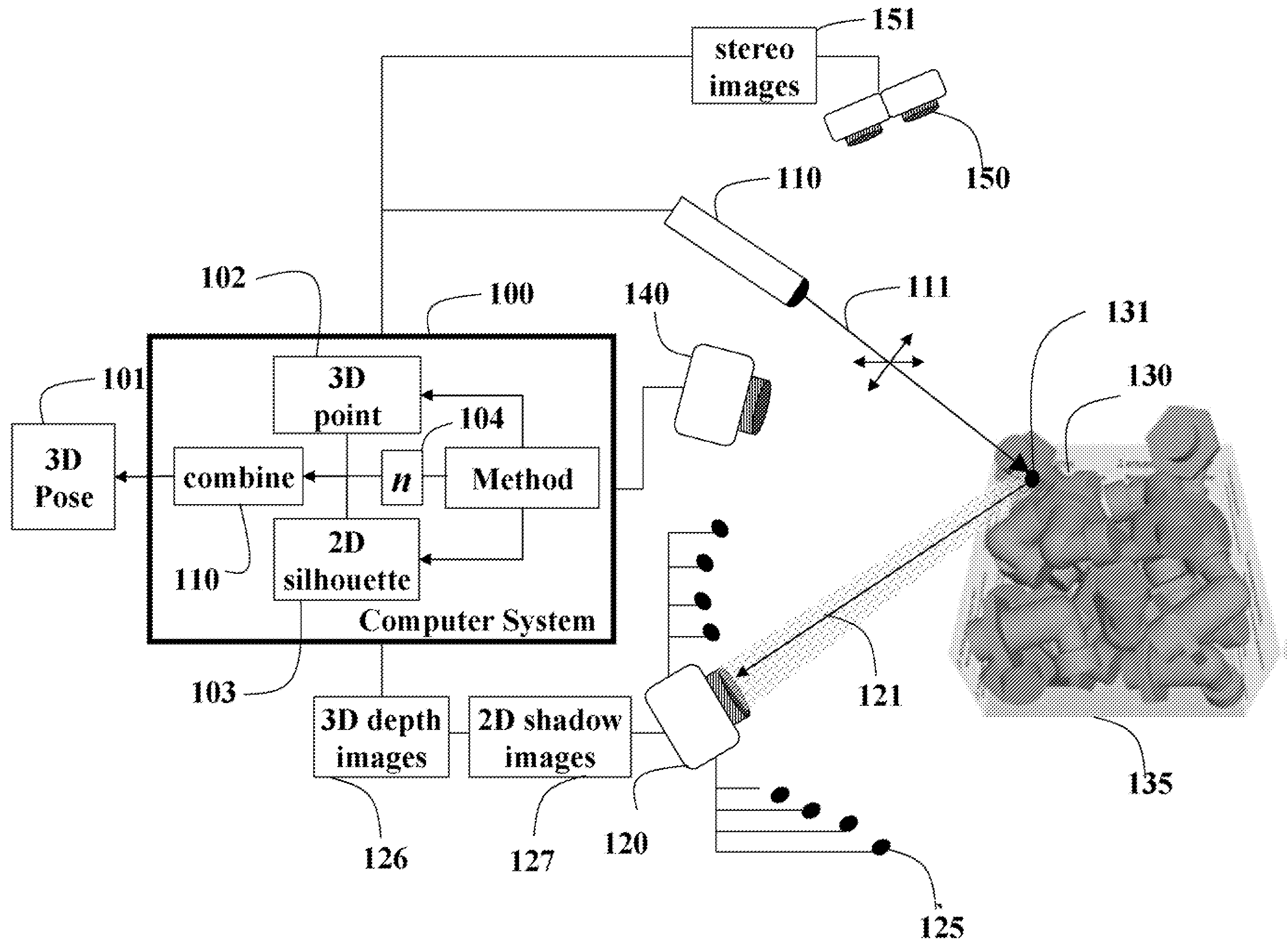

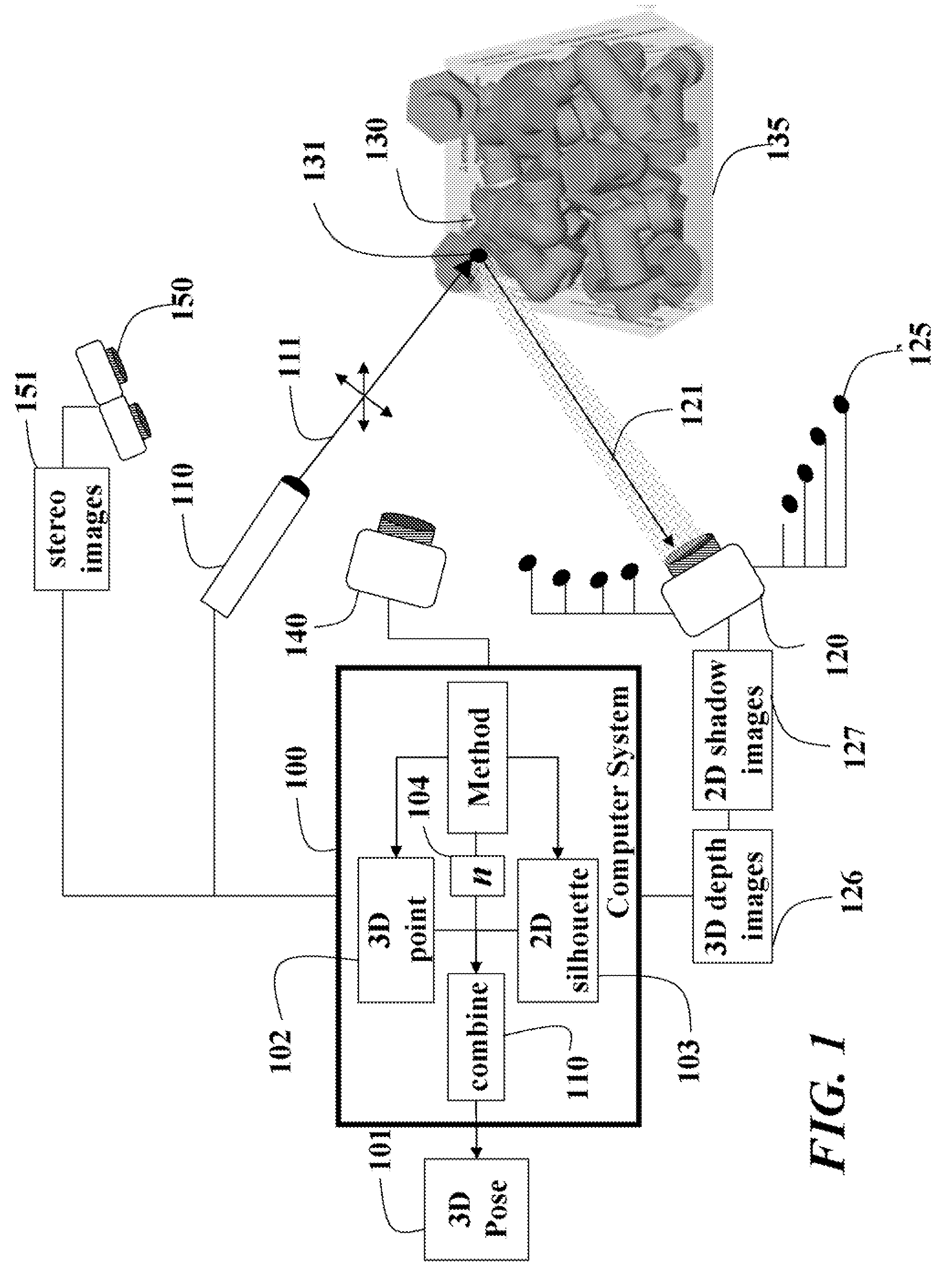

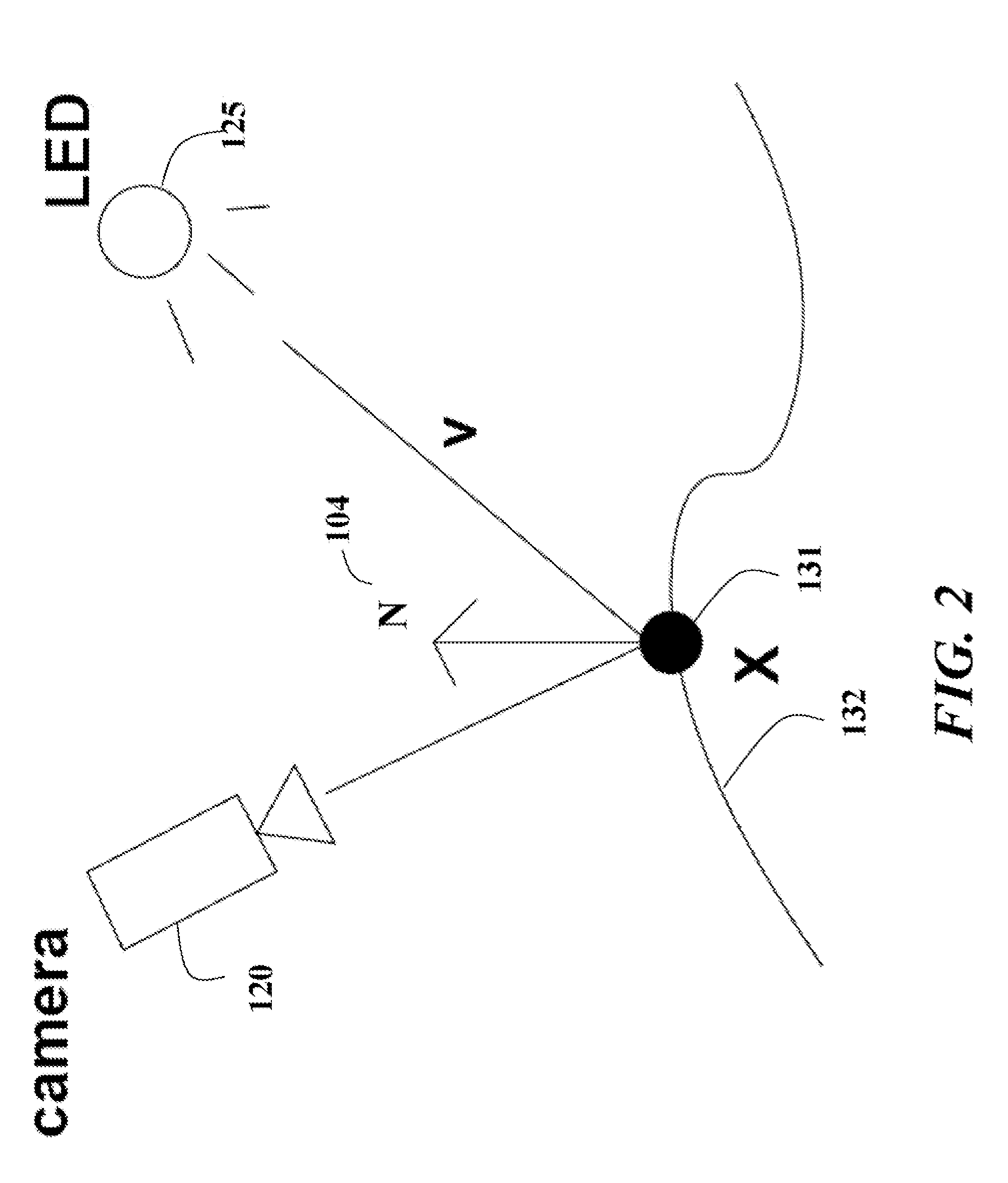

Method and system for determining poses of semi-specular objects

ActiveUS20090297020A1Lower-quality informationPoor qualityImage enhancementImage analysisLight sourceLaser beams

A camera acquires a set of coded images and a set of flash images of a semi-specular object. The coded images are acquired while scanning the object with a laser beam pattern, and the flash images are acquired while illuminating the object with a set of light sources at different locations near the camera, there being one flash image for each light source. 3D coordinates of points on the surface of the object are determined from the set of coded images, and 2D silhouettes of the object are determined from shadows cast in the set of flash images. Surface normals are obtained for the 3D points from photometric stereo on the set of flash images. The 3D coordinates, 2D silhouettes and surface normals are compared with a known 3D model of the object to determine the pose of the object.

Owner:MITSUBISHI ELECTRIC RES LAB INC

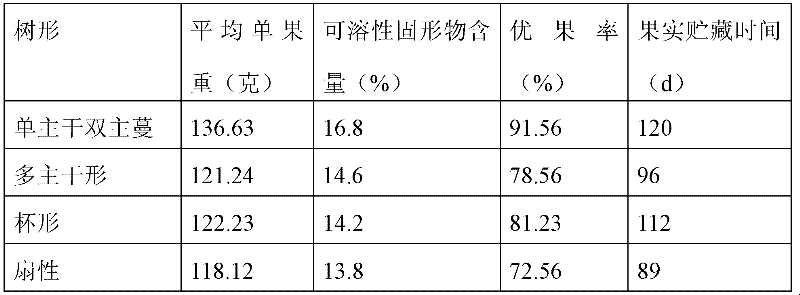

Kiwi fruit tree form with single trunk and double main tendrils and shaping trimming method of kiwi fruit tree form

The invention discloses a kiwi fruit tree form with a single trunk and double main tendrils and a shaping trimming method of the kiwi fruit tree from. The trunk of the tree form is perpendicular to the ground, the height of the trunk ranges from 1.8m to 2.1m, the two main tendrils reversely horizontally extend by 2m to 3m along a row direction after being annularly crossed at a rack surface, 20 to 30 side tendrils are distributed on two sides of each of the double main tendrils like feathers, the pitch between each two side tendrils on the same side ranges from 30 cm to 40 cm, the side tendrils are perpendicular to the main tendrils to horizontal extend, and after the tree form is formed, allowance of full buds of a kiwi fruit tree garden per mu range from 10000 to 12000 after the kiwi fruit tree garden is trimmed in winters. The shaping trimming method of the kiwi fruit tree form is simple, after a tree is cultivated and formed, strong new side tendrils are reserved in summers to be used as fruit mother tendrils to cultivate in the next year, residual sprout tillers and new tendrils are removed, the fruit mother tendrils in the current year are reduced or removed when trimming inthe winter, and are replaced by the new fruit mother tendrils, branches and tendrils are bound in time, operation is easy, the quality of fruit is high, shortcomings that an existing kiwi tree form is messy, trimming is troublesome and the quality of fruit is poor are overcome, and accordingly the method is suitable for simplified trimming for a kiwi fruit tree garden by low labor intensity.

Owner:NORTHWEST A & F UNIV

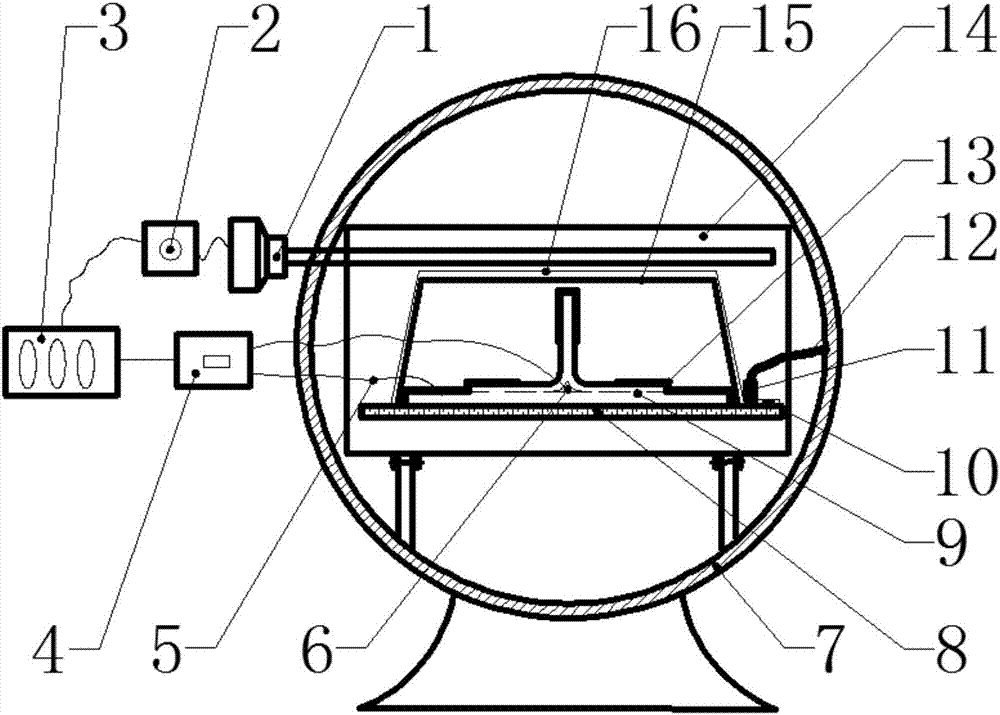

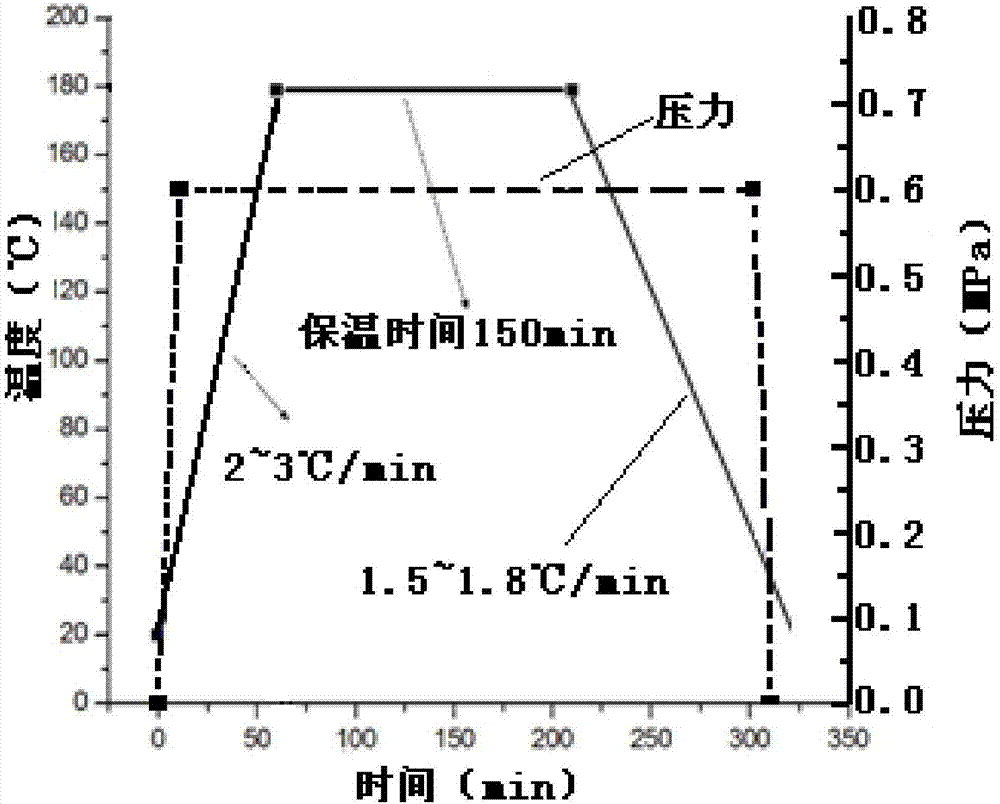

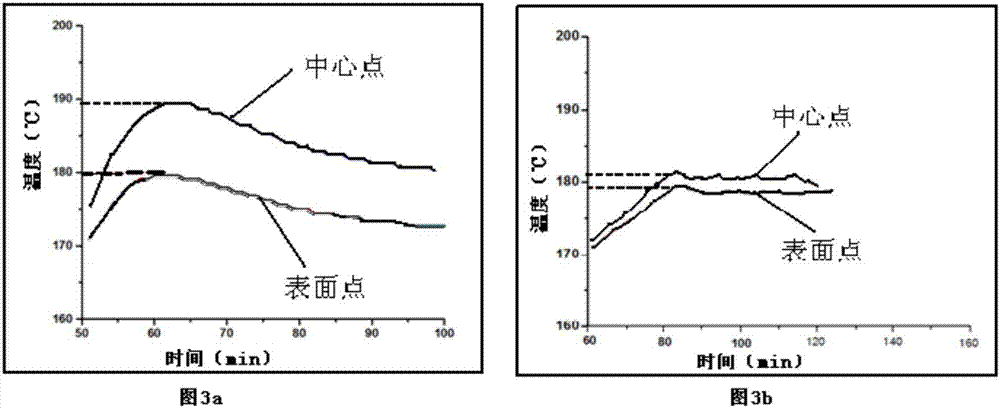

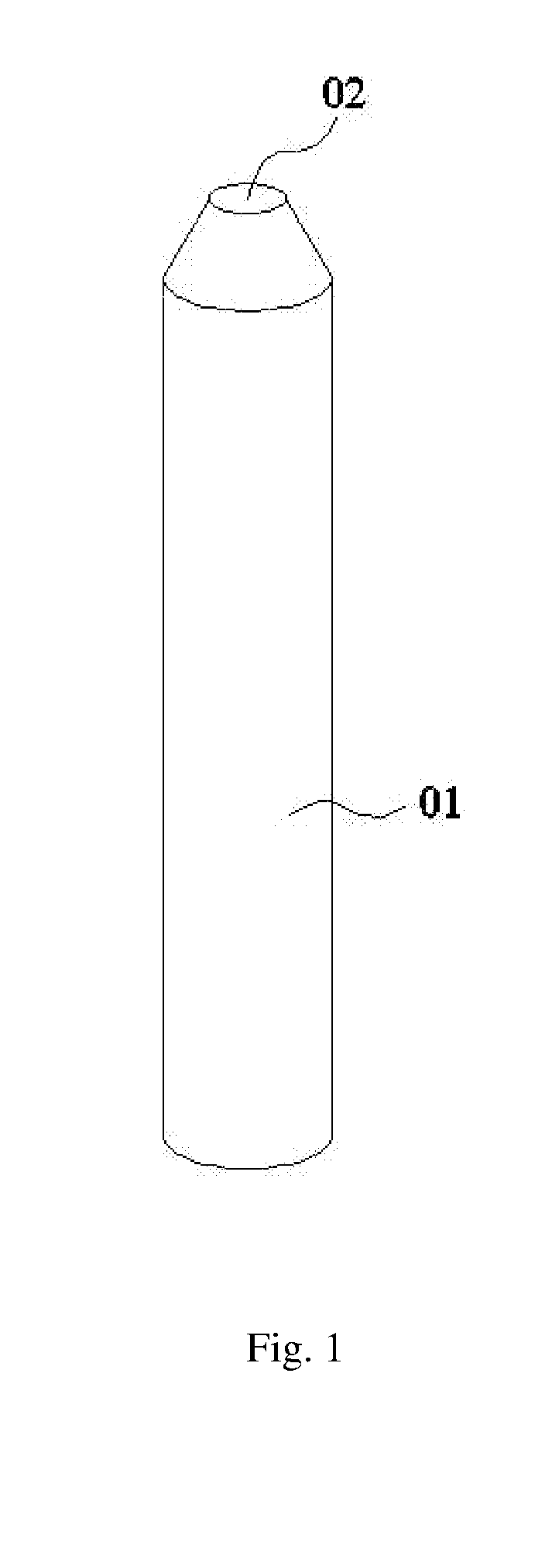

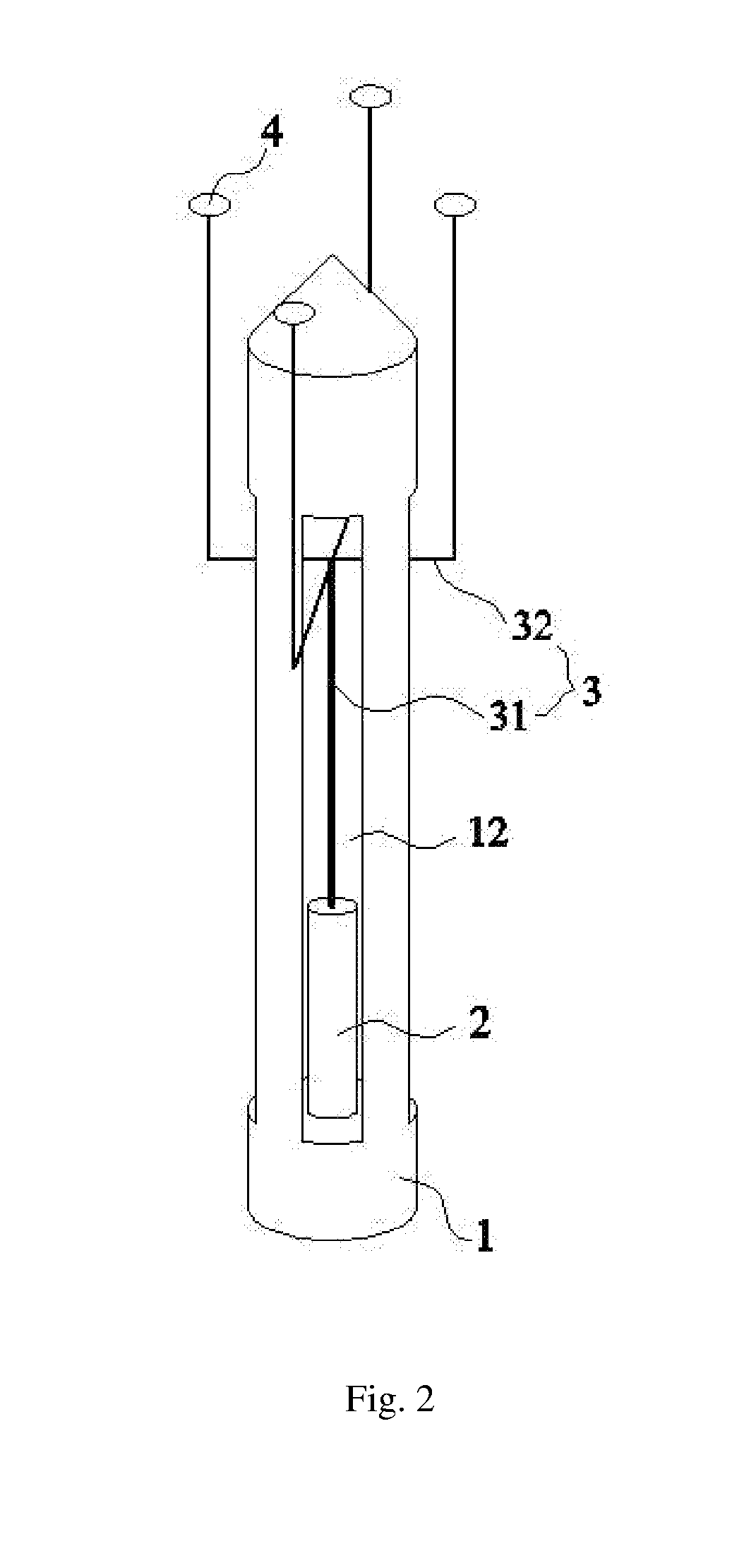

Method for performing composite heating on wave absorbing materials

The invention provides a method for performing composite heating on wave absorbing materials. The method is completed in a composite heating device consisting of a hot-press pot, a microwave cavity arranged in the hot-press pot, and a microwave generator emitting microwaves into the microwave cavity, wherein the microwave cavity comprises a porous wall plate, and the porous wall plate is used for controlling the microwaves generated by the microwave generator within the microwave cavity and besides not preventing exchange of internal gas and external gas of the microwave cavity; the wave absorbing materials are arranged in the microwave cavity; and before a wave absorbing material component is heated, an intense wave absorbing material layer is arranged on partial area of the outer surface of the wave absorbing material component. The heating method comprises the following steps of performing heating by the hot-press pot to raise the internal temperature of the wave absorbing material component to medium temperature; then, stopping heating the wave absorbing material component by the hot-press pot or setting the temperature control of the hot-press pot as a heat preserving state; and starting the microwave generator to raise the internal temperature of the wave absorbing material component to target temperature. Through the adoption of the method disclosed by the invention, the condition that a whole temperature field is uniform during the molding of a molded piece is guaranteed, so that molding precision is high, and properties are good.

Owner:CENT SOUTH UNIV

Blue-jewel-crystal multi-crucible melt growth technolgoy

ActiveCN101024898AThe structure of the temperature field is stableAdjustable temperature gradientPolycrystalline material growthFrom frozen solutionsFurnace temperatureHearth

The invention provides a multi-pot melt growth technique for growing sapphire crystals, comprising: (1) pretreating aluminum oxide raw material; (2) placing the pretreated aluminum oxide blocks and the oriented seed crystals into pots and moving into high temperature descending furnace, sealing the whole system and power-on to raise temperature, starting mechanical pump and diffusion pump in turn, vacuumizing to 10-3-10-4Pa, and when the furnace temperature up to 1500-1800deg.C, charging inert gas and continuing raising temperature to the set temperature (2100-2250deg.C); (3) when the furnace temperature up to the set temperature, preserving heat for 4-8 hours, regulating hearth temperature and pot positions to smelt raw material and seed crystal top to implement inoculation growth and setting solid-liquid interface temperature gradient at 10-50deg.C / cm and controlling pot descending rate at 0.1-3.0mm / h; and (4) after the crystal growth ends, making in-situ annealing treatment. And the process has features of raw material pretreatment, special temperature field design, multi-pot technique, in-situ annealing treatment, etc, and advantages of stable temperature field, adjustable temperature gradient, operating convenience, low average energy consumption, high yielding by one furnace, and beneficial to industrialized production.

Owner:苏州晶生新材料有限公司

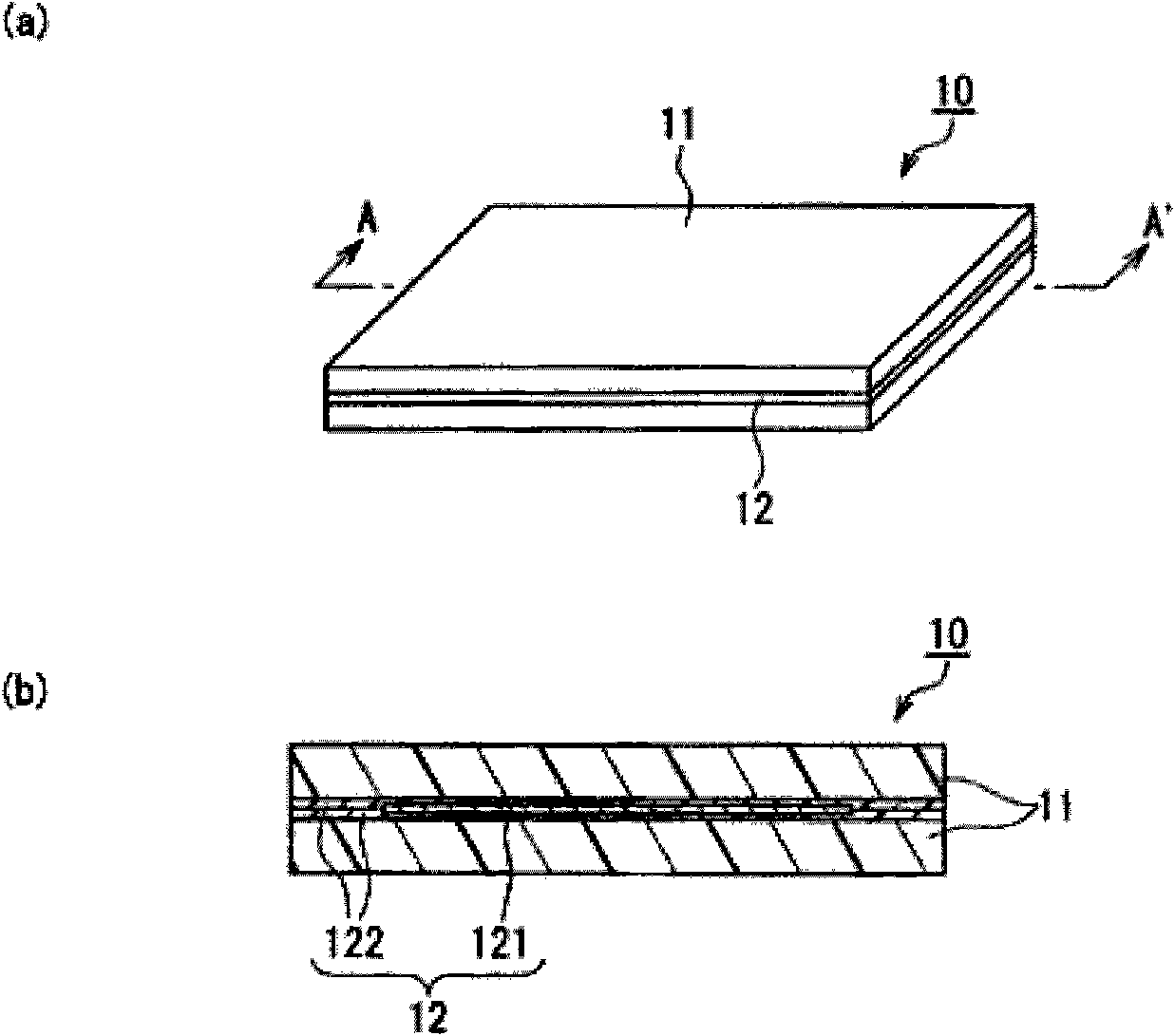

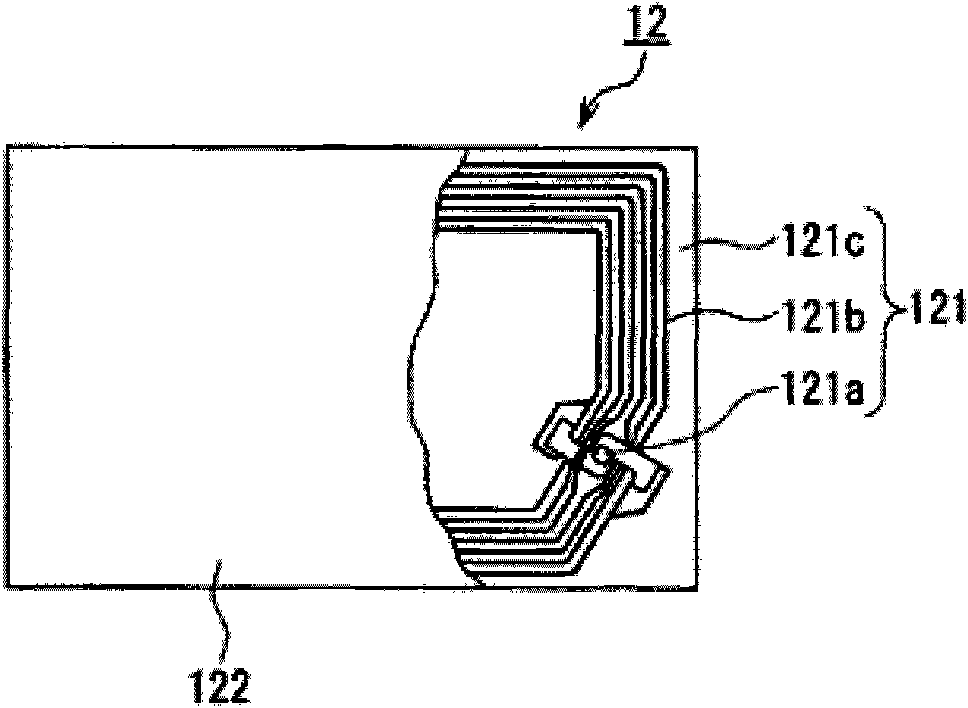

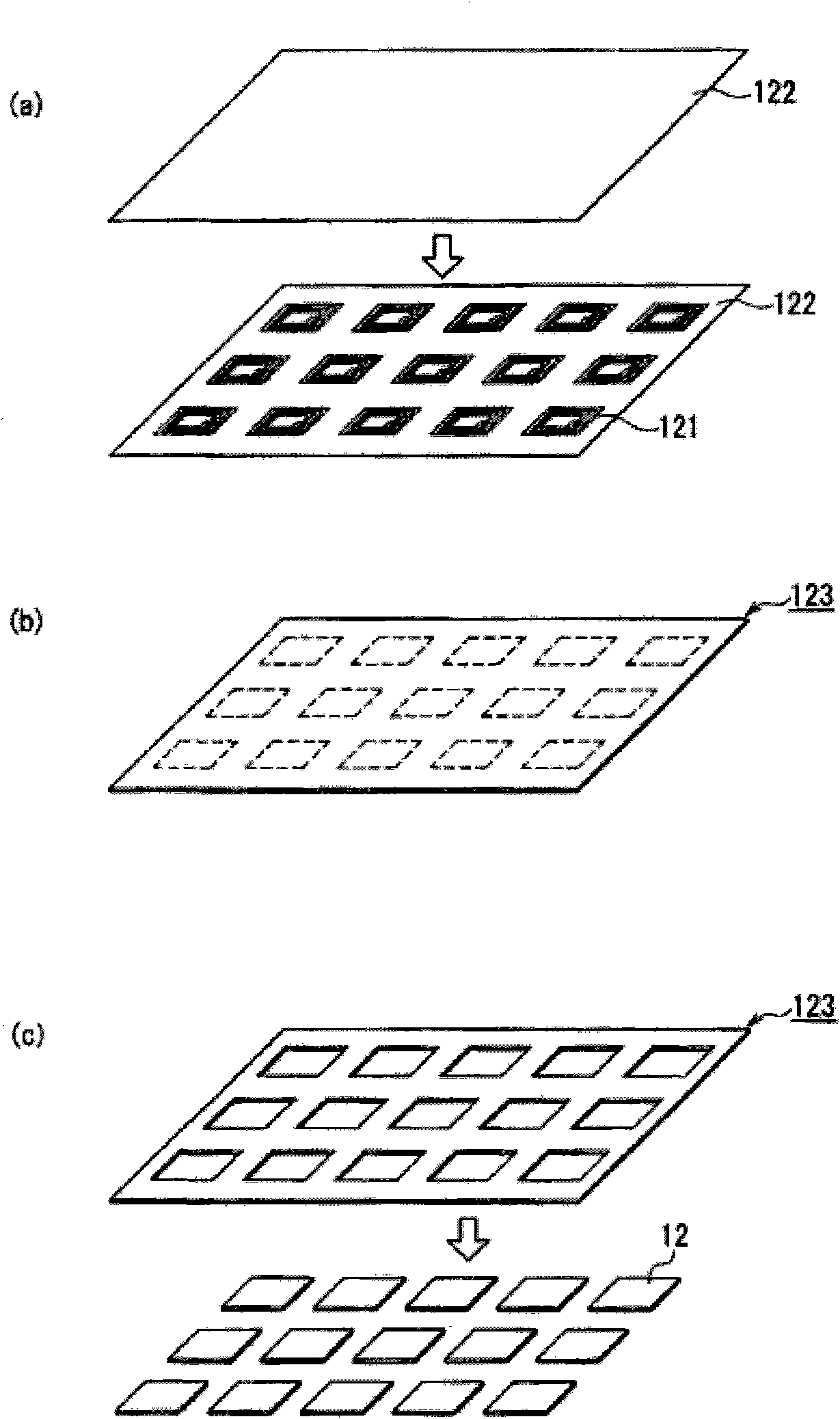

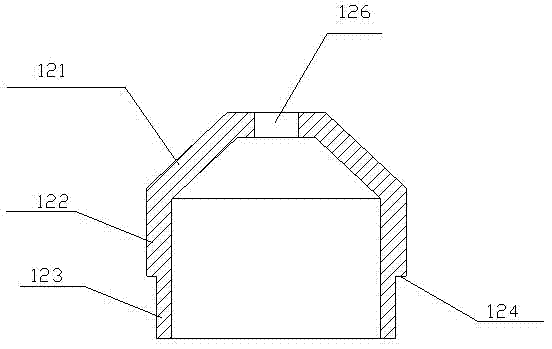

Token money for game incorporating RFID and method for producing the same

InactiveCN101662965APoor qualityApparatus for meter-controlled dispensingAdhesivesPolyethylene terephthalateEngineering

Structure of a token money for game incorporating an RFID in which the RFID is not removed easily and the FRID tag does not fail easily during production or use. The token money (10) for game has sucha structure as an RFID tag (121) covered with a flexible cover sheet (122) is held between laminate resin films or plates and hot pressed thus incorporating the RFID tag (121) in the body (11). Material of the cover sheet (122) is paper, polyvinyl, or polyethylene terephthalate, for example.

Owner:ANGEL PLAYING CARDS CO LTD

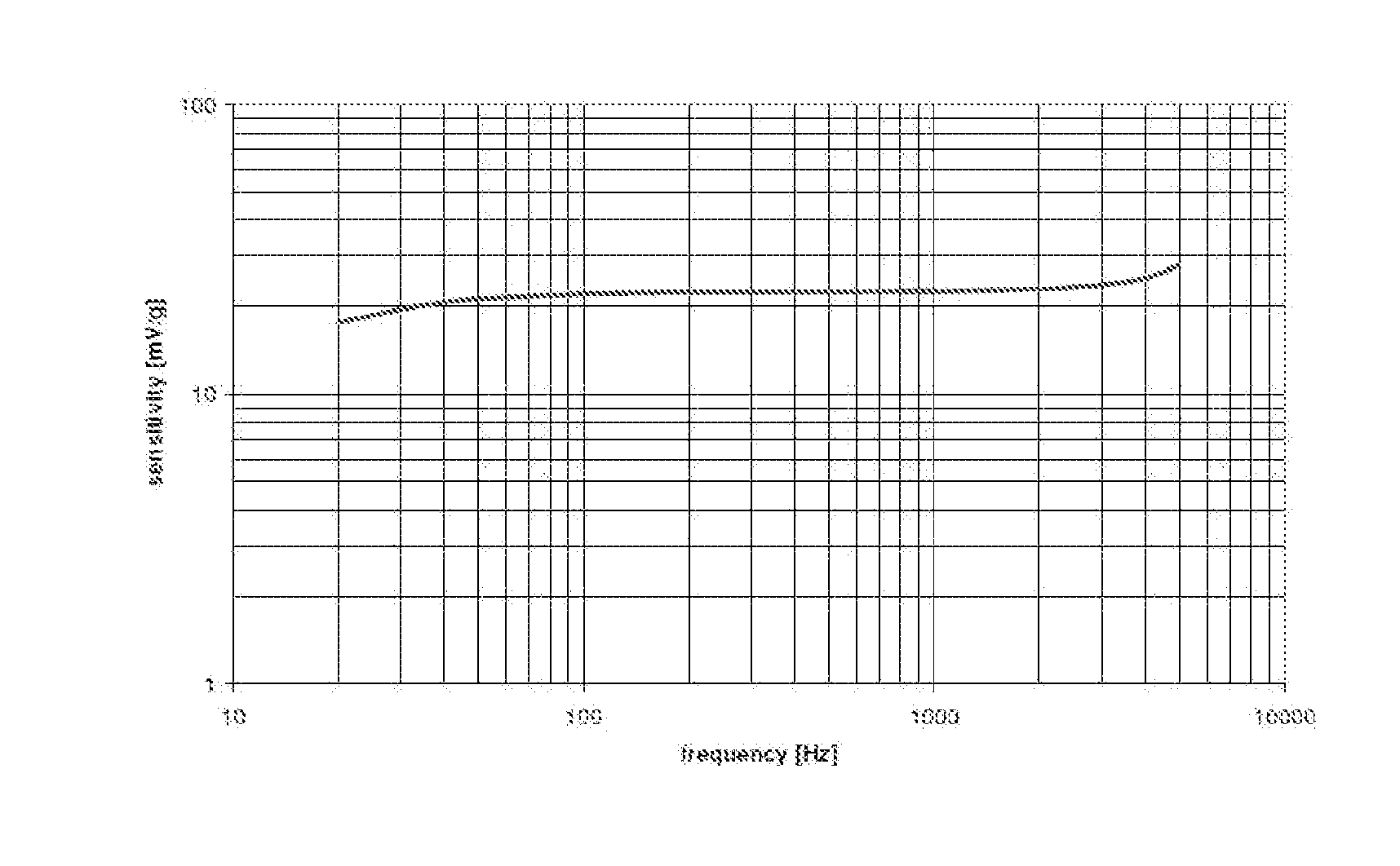

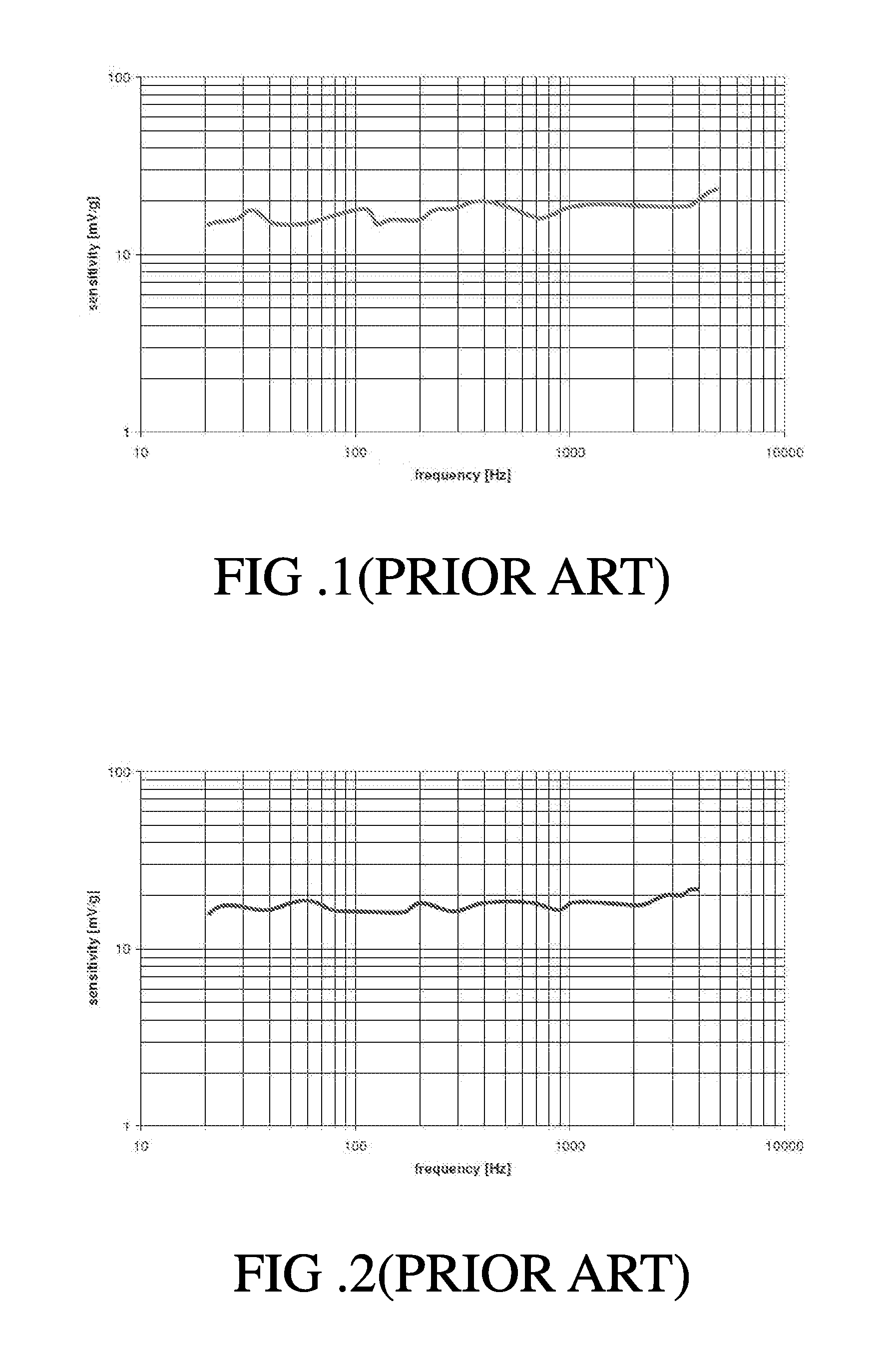

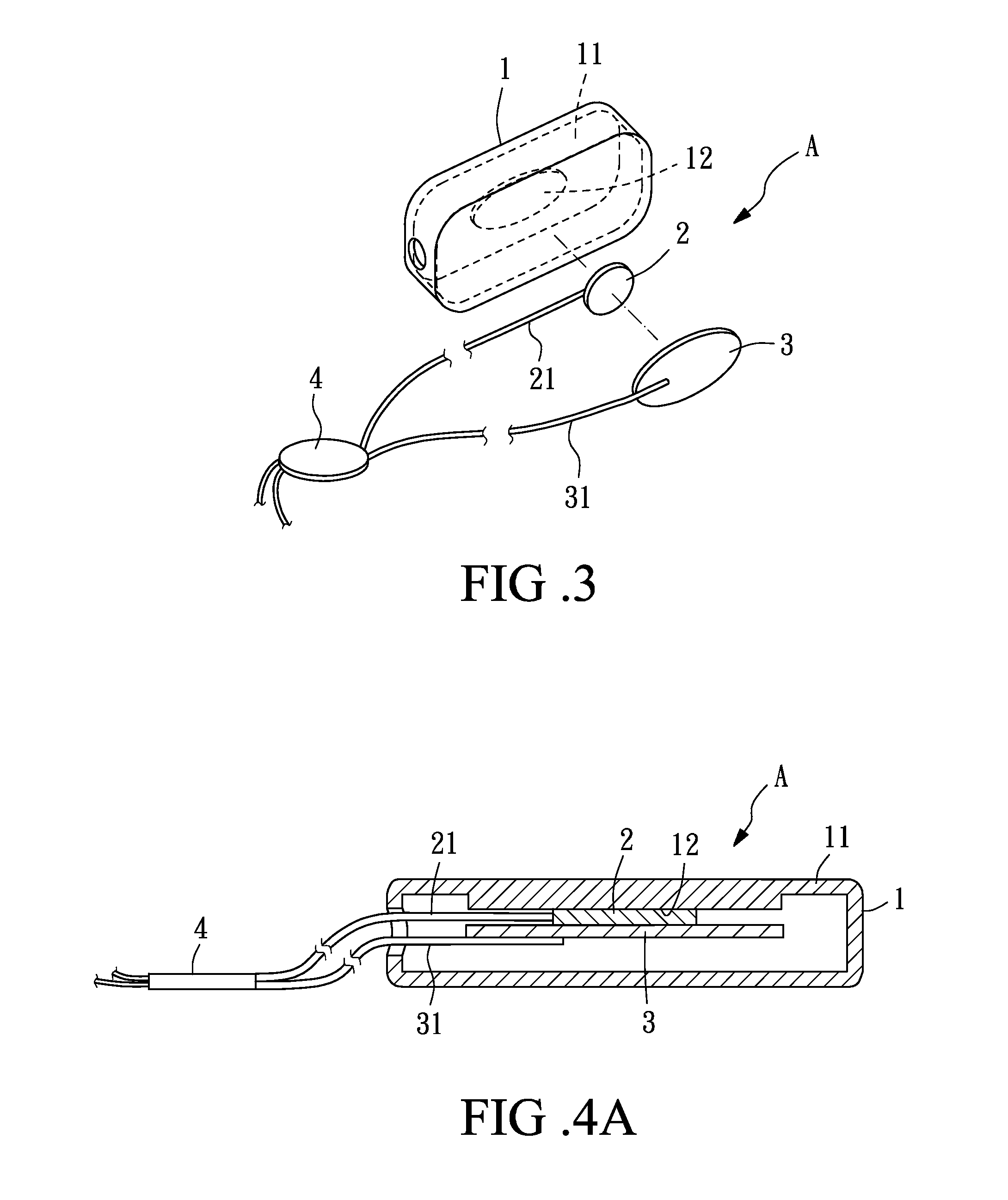

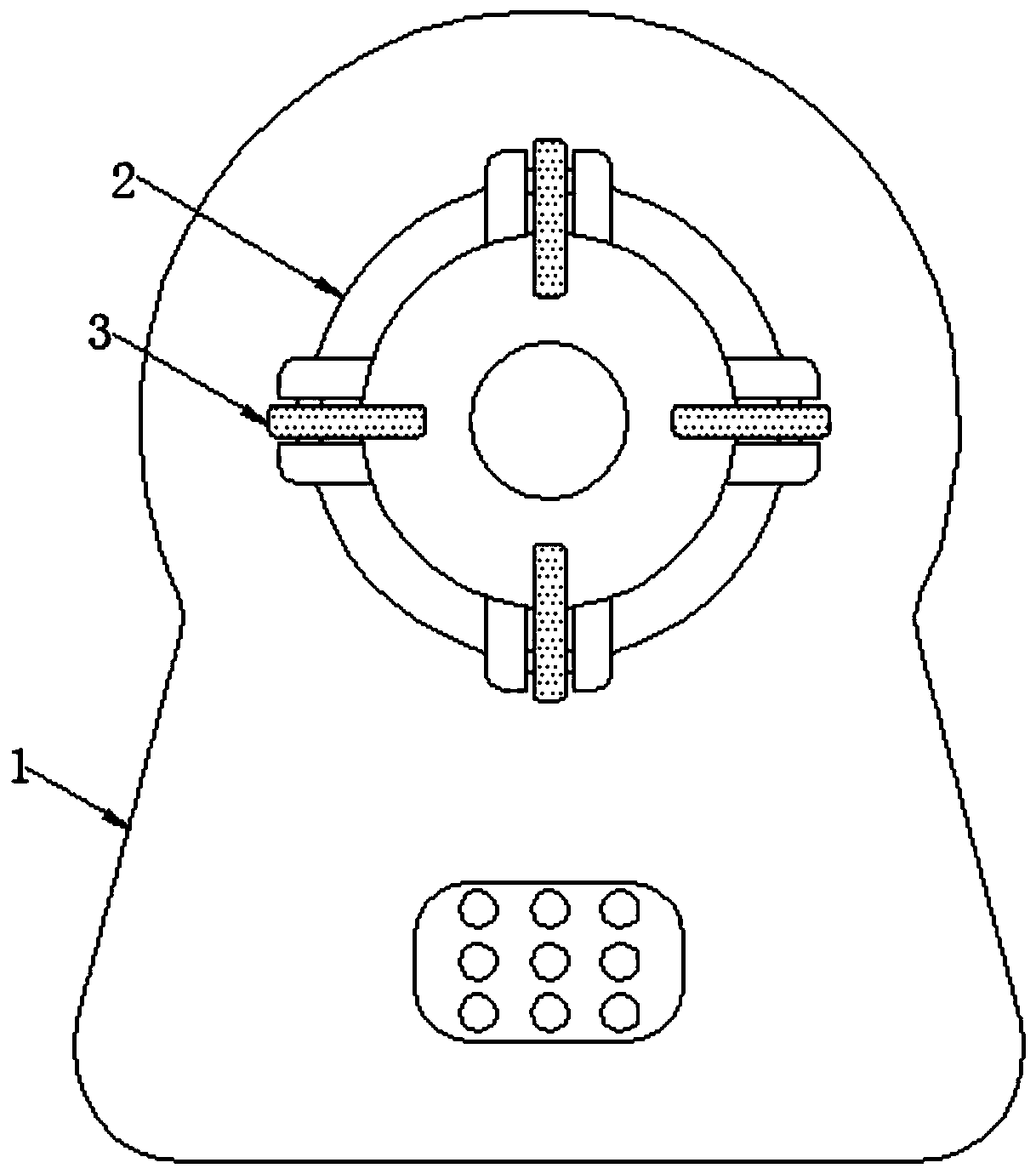

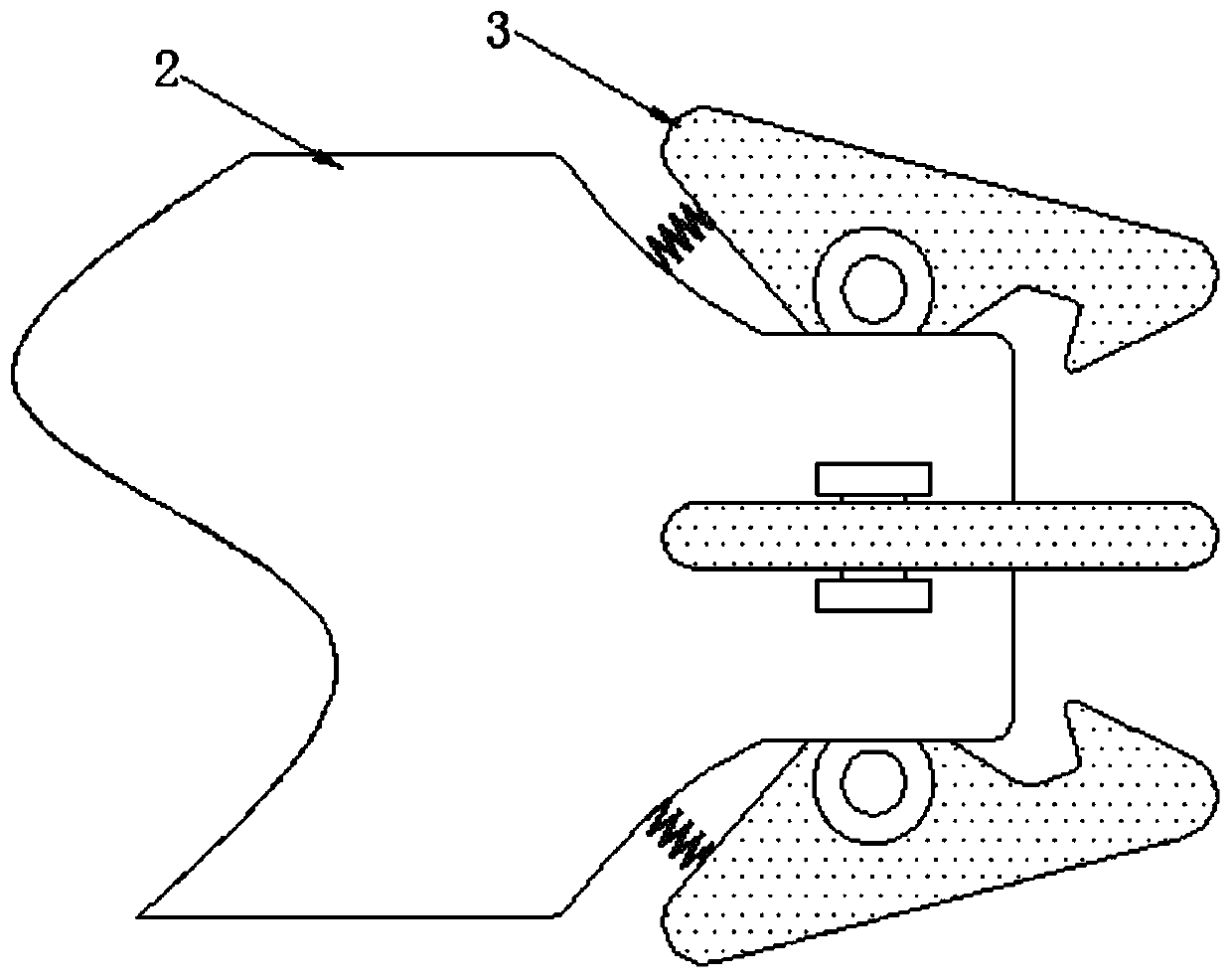

Throat-Vibration-Type Microphone and Communication Hands-Free Device Containing Same

InactiveUS20150104044A1Poor audio qualityPoor qualityMouthpiece/microphone attachmentsContact microphone transducersThroatMoving speed

A throat-vibration-type sensor includes a ceramic sheet and a copper sheet received in a box body, wherein the ceramic sheet and the copper sheet are electrically connected to an amplification circuit for voice communications. The volume and thickness of the throat-vibration-type sensor is reduced, the cost thereof is reduced, the assembly thereof is easy, and the reception effect is increased. The throat-vibration-type sensor is combined with a communication hand-free device which includes a control circuit board, a sound amplification device and a battery unit. The throat-vibration-type sensor is used for relieving the interference of external noise. The communication hand-free device combined with the throat-vibration-type sensor avoids the inability of identifying a voice signal because of a wind shear sound caused by a high moving speed of a wearer, to improve the overall utilization efficiency of the communication hand-free device.

Owner:NEOVICTORY TECH

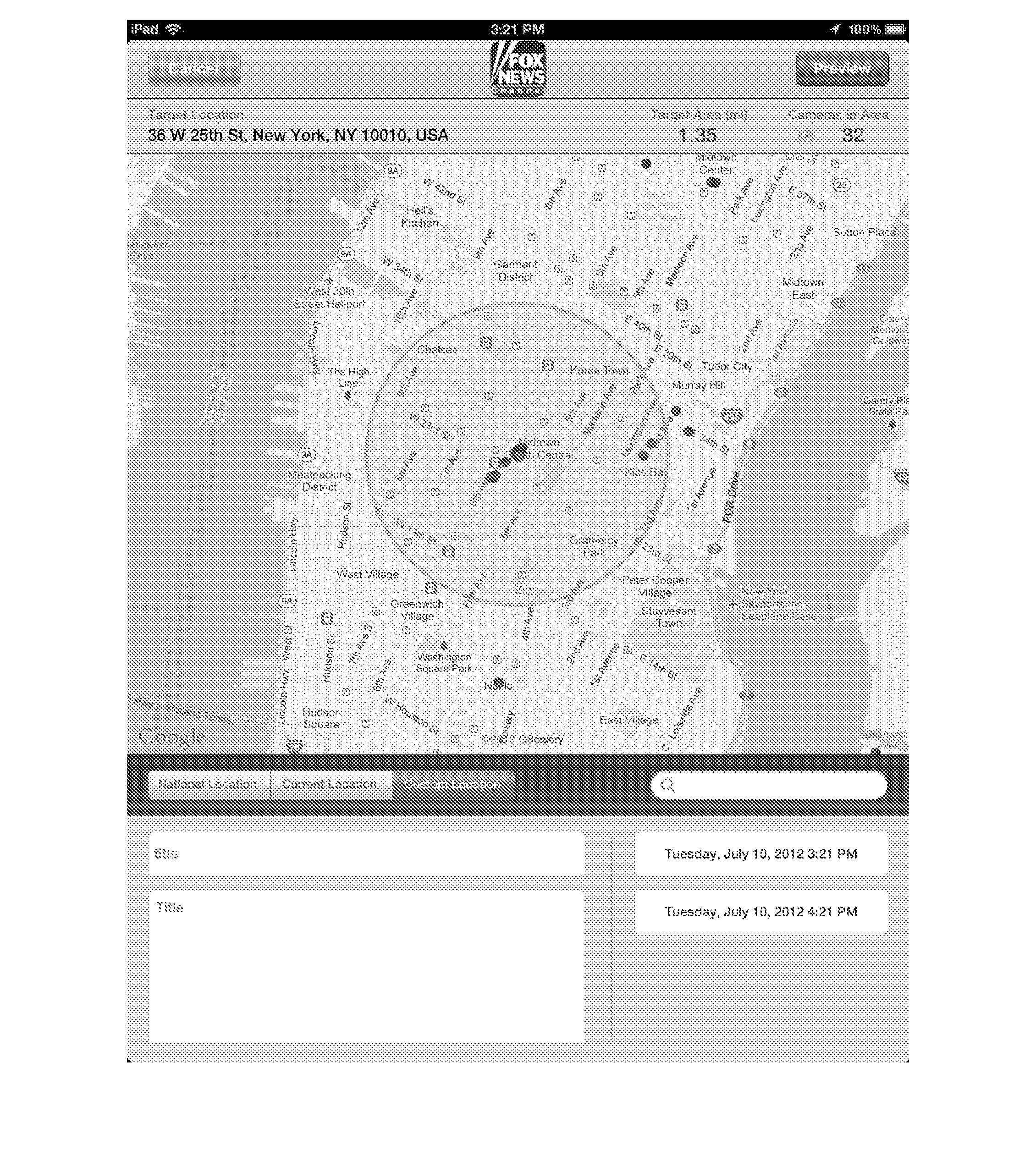

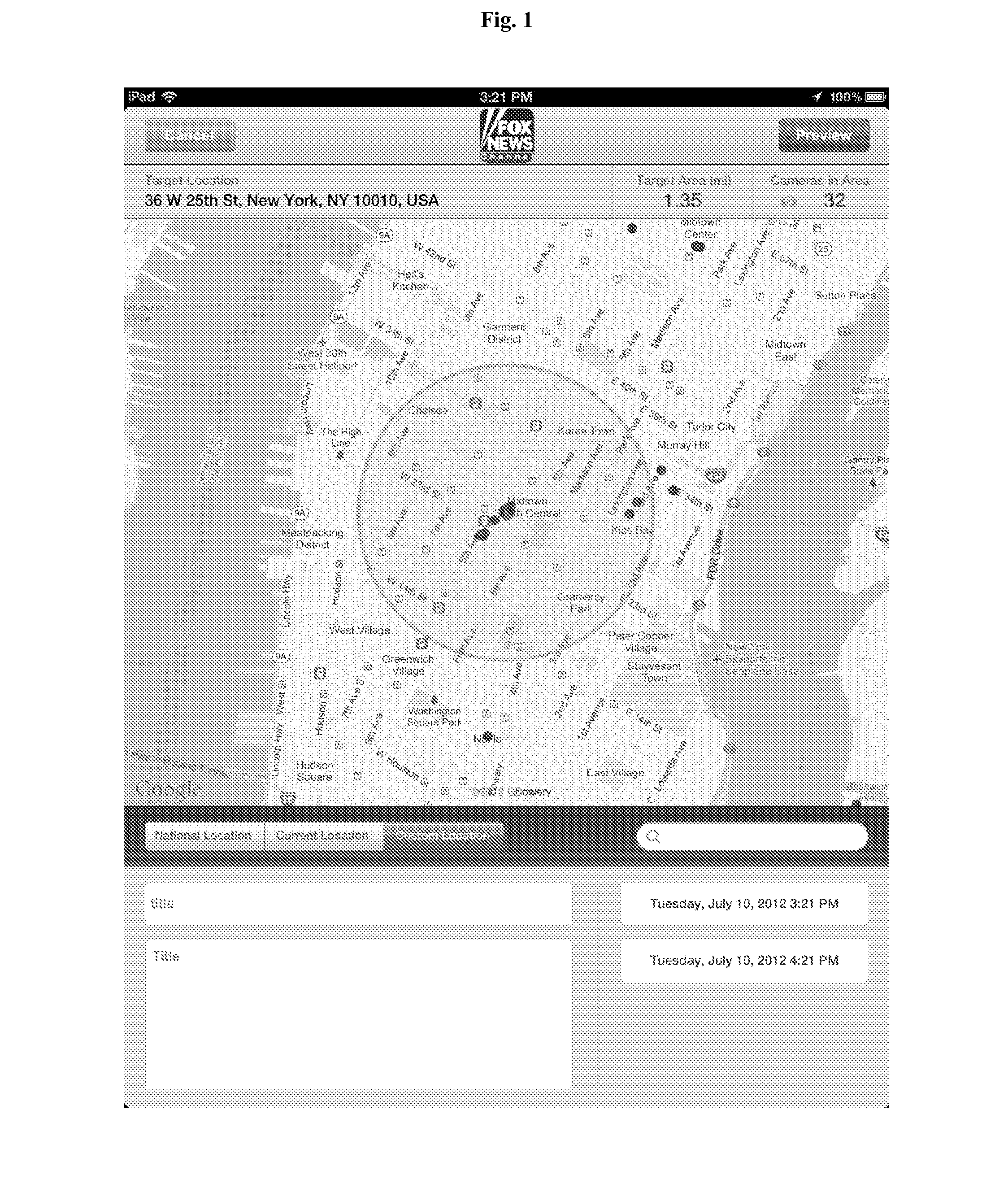

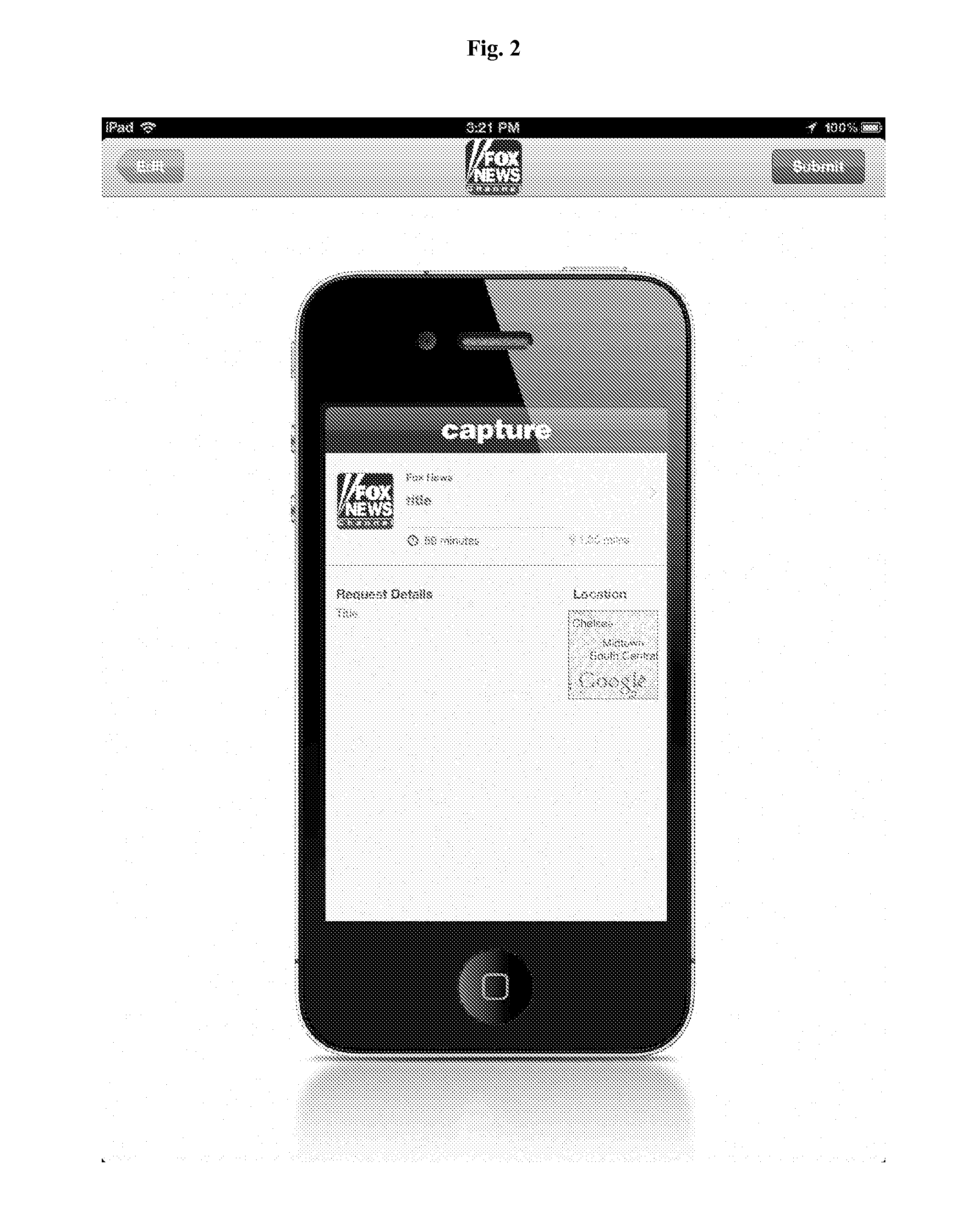

Targeted media capture platforms, networks, and software

InactiveUS20140108340A1Poor qualityDigital data information retrievalDigital data processing detailsReal-time computingSoftware

Platforms, networks, and software applications for targeted media capture, and methods of providing and using the same.

Owner:CAPTURE MEDIA

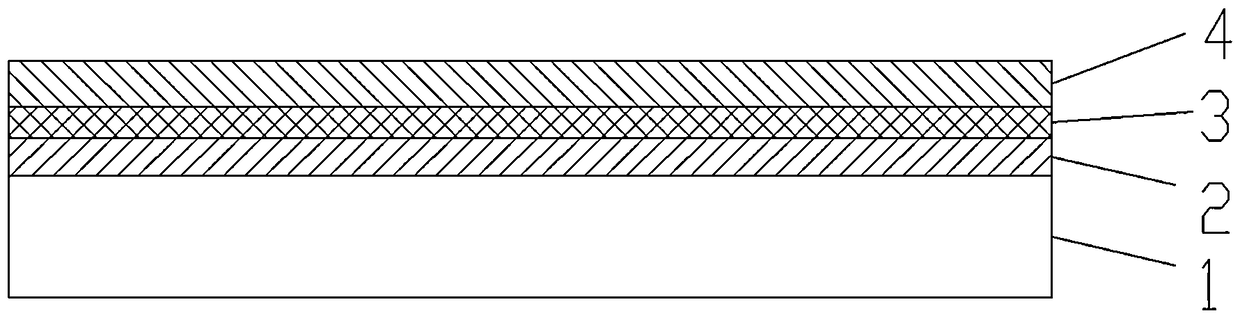

Electrode assembly of fuel cell and preparation method of electrode assembly

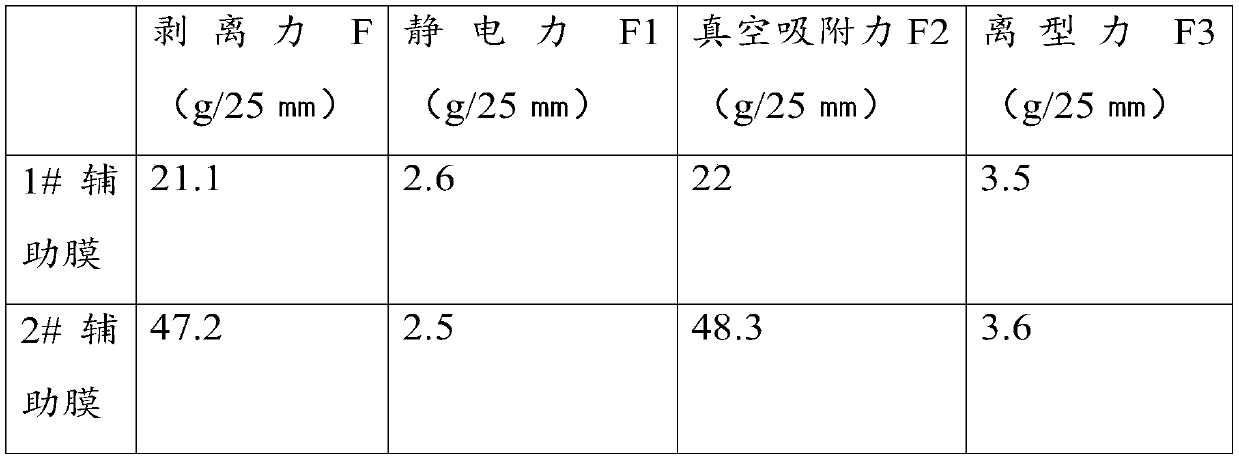

ActiveCN111082071AIncreased mechanical strength and dimensional stabilityGuarantee smoothnessCell electrodesFinal product manufactureElectrostatic adsorptionAtomic physics

The invention discloses an electrode assembly of a fuel cell and a preparation method of the electrode assembly and relates to the field of fuel cells. The electrode assembly of the fuel cell comprises a membrane layer, a detachable electrostatic auxiliary membrane attached to the membrane layer, and an electrostatic adsorption force and a vacuum adsorption force for connecting the membrane layerand the electrostatic auxiliary membrane, the membrane layer and the electrostatic auxiliary membrane are connected through an electrostatic adsorption force and a vacuum adsorption force so that themembrane layer can be separated from the electrostatic auxiliary membrane in a lossless mode; and the membrane layer comprises any one of a proton exchange membrane and a catalyst coating membrane. Through the arrangement, the mechanical strength and the size stability of the membrane layer are improved, so that effective grabbing, conveying and roll-to-roll conveying can be realized, meanwhile, when the static auxiliary membrane is separated, a catalyst on the surface of the membrane layer cannot be stuck away, the membrane layer cannot be damaged, and the good quality of the membrane layer is guaranteed.

Owner:武汉理工氢电科技有限公司

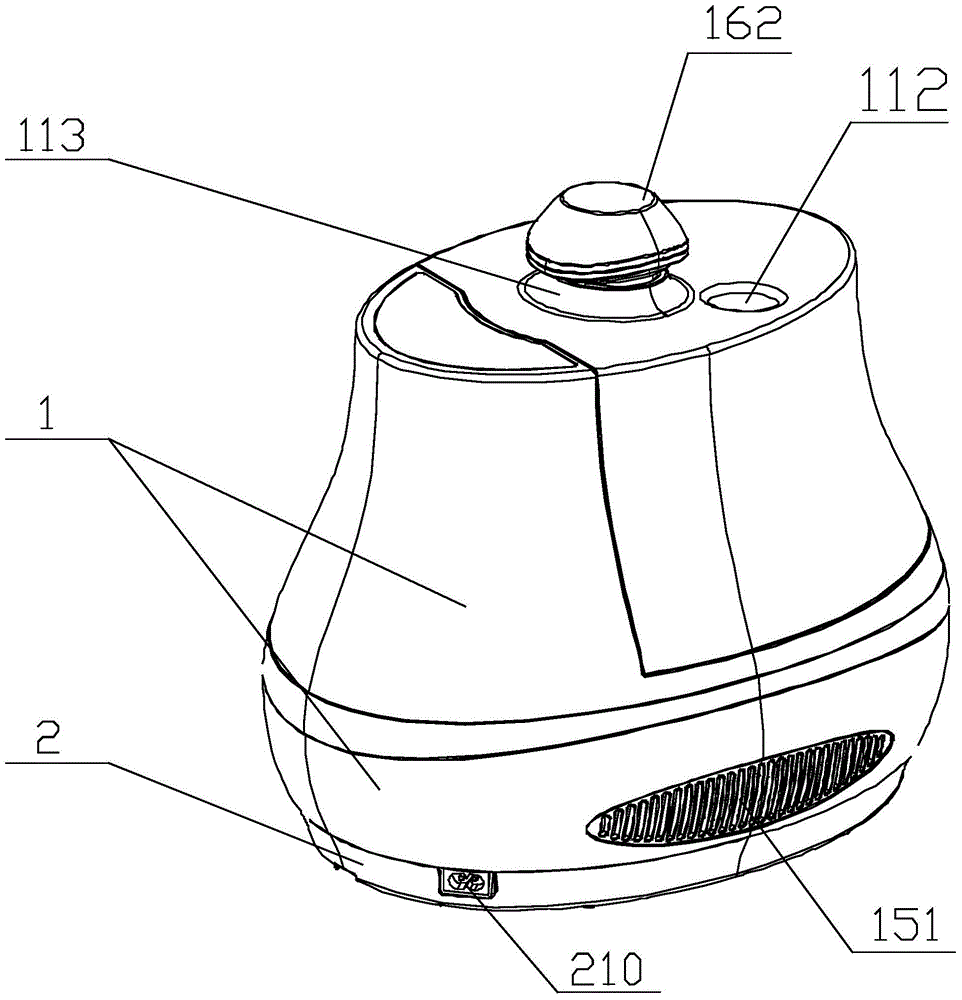

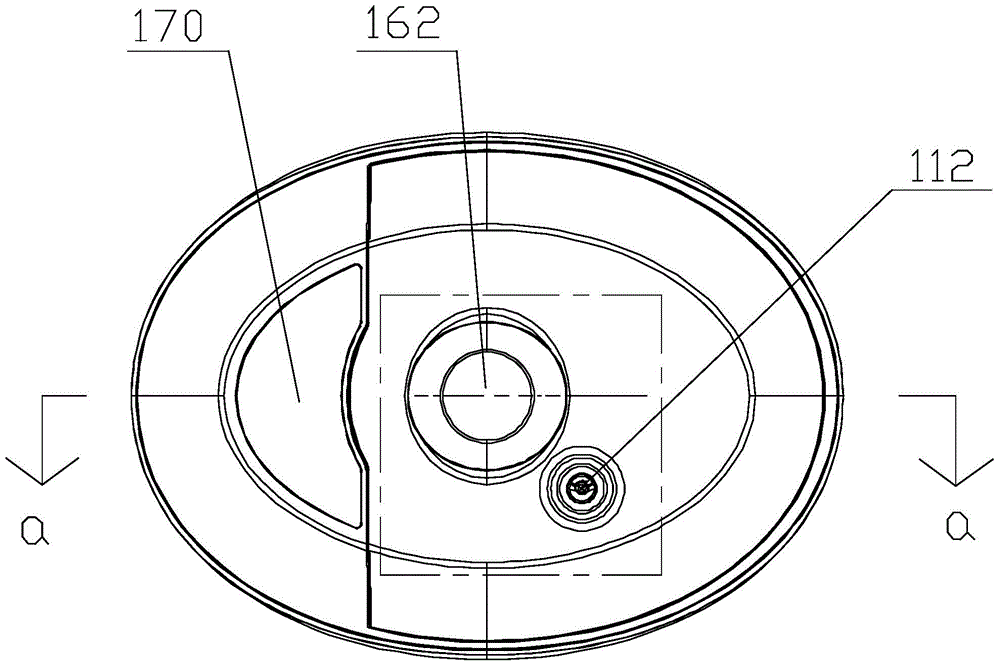

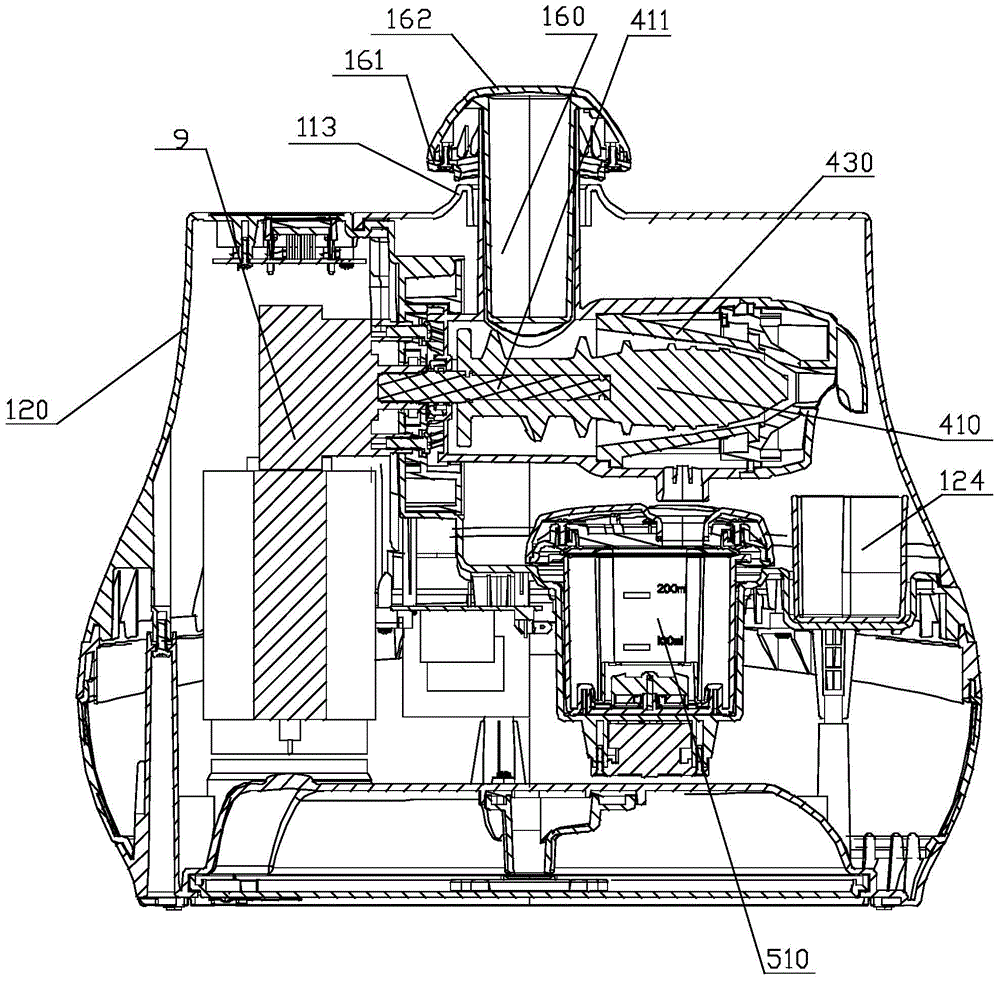

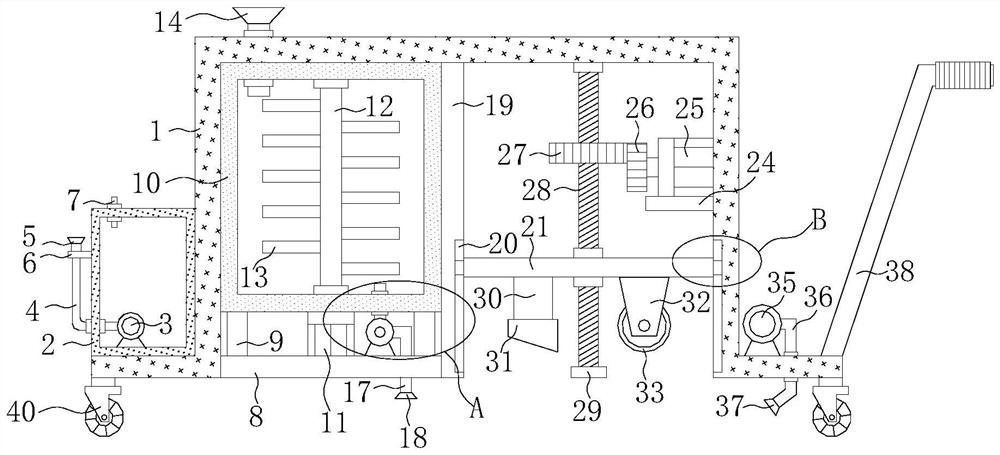

Full-automatic fruit and vegetable facial mask maker

ActiveCN104095762AIncrease nutritionHigh molding rateCosmetic preparationsToilet preparationsSlagEngineering

The invention relates to a full-automatic fruit and vegetable facial mask maker, in particular to a device for generating a facial mask by stirring and emulsifying fruit or vegetable juice and collagen. The full-automatic fruit and vegetable facial mask maker comprises a casing, a base, a facial mask forming disc, a juicing device, an emulsifying and stirring device and a driving device, wherein the driving device is arranged in the casing and used for supplying juicing driving force to the juicing device; the juicing device comprises a screw and a juicing chamber, one end of the screw is detachably connected with the driving device, the other end is nested in the juicing chamber, and the juicing chamber comprises a feeding port formed above the device, a juice outlet communicated with the emulsifying and stirring device as well as a slag hole; and the emulsifying and stirring device comprises magnetic levitation stirring and heating components, a controllable switch opening and a liquid level detector; and the facial mask forming disc can be drawn out of the facial mask maker, and a facial mask is taken out and obtained after a facial mask liquid is cooled and formed. The full-automatic fruit and vegetable facial mask maker adopts squeezing type juicing, the juice yield is high, and the juicing device and the emulsifying device adopt detachable structure, so that the devices can be cleaned.

Owner:GUANGDONG SHUNDE MINGYOU ELECTRIC CO LTD

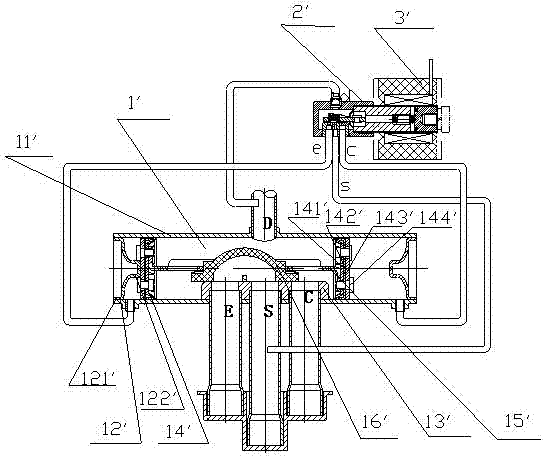

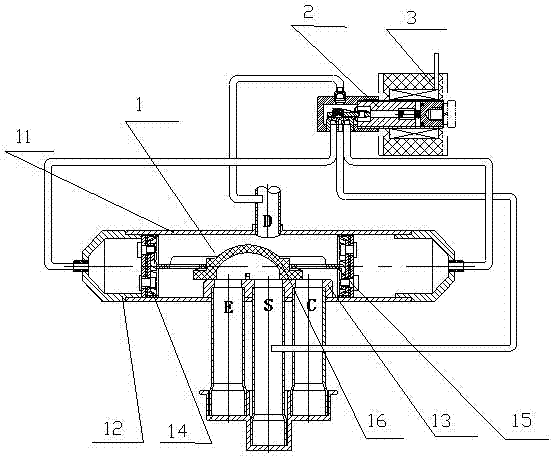

Switch valve

The invention discloses a switch valve comprising a main valve, a pilot valve and a coil. The main valve comprises a hollow cylindrical valve body, end caps plugging two ends of the valve body and a piston sliding in an inner cavity of the valve body. The switch valve is characterized in that each end cap which is cap-shaped comprises a cap top, a middle portion and a contact portion arranged sequentially axially, a step is arranged between the middle portion and the contact portion, and the step is welded and fixed after butting against the end face of the valve body. The steps formed by difference in outer diameter of the middle portions and the contact portions of the end caps butt against the ends of the valve body, so that the end caps and the valve body are positioned, and the end caps and the valve body are convenient to assemble; meanwhile, during reversing of the switch valve, the end, namely a ring surface, of each contact portion butts against the piston; since smoothness of the ends of the contact portions is easy to control, finally caused inferior quality of the switch valve resulting from screw falling off caused by uneven stress of the piston due to the fact that small-diameter portions of the end caps are unsmooth in the prior art is prevented.

Owner:ZHEJIANG DUNAN HETIAN METAL CO LTD

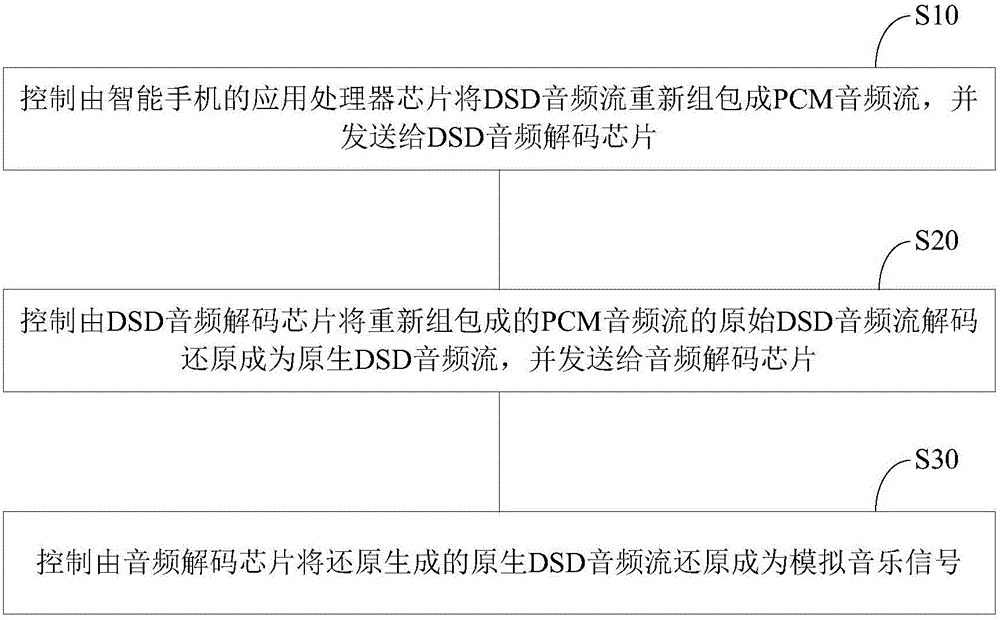

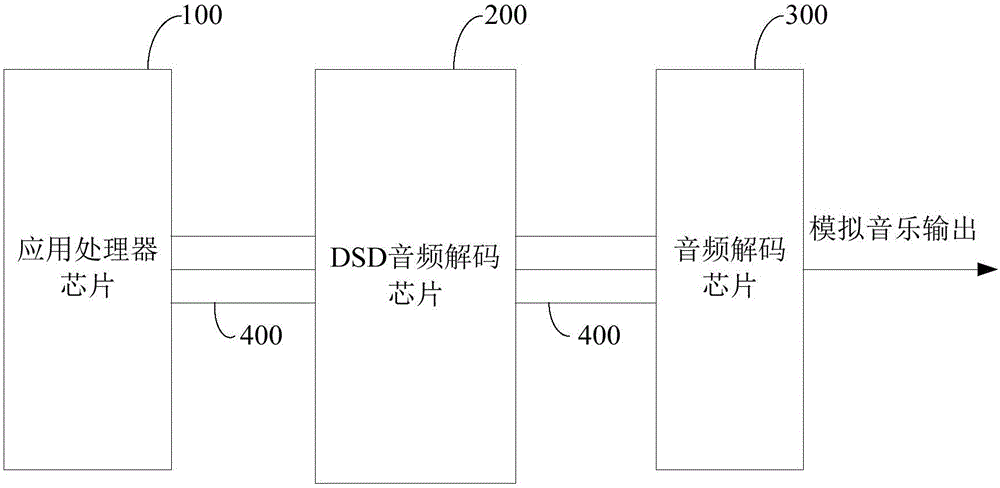

Smart phone native DSD audio decoding method and system and smart phone

ActiveCN105869647AGuaranteed sense of hearingPoor qualitySpeech analysisTelephone set constructionsData informationSpeech recognition

The invention relates to a smart phone native DSD audio decoding method and system and a smart phone. A DSD audio stream is repackaged into a PCM audio stream on an application processor chip, a native DSD audio stream is reverted by a DSD audio decoding chip through the PCM audio stream, the audio decoding chip reverts the native DSD audio stream into analog music signals for playing finally, conversion from DSD encoding to PCM encoding is not performed in the process, only the DSD audio stream is repackaged into the PCM audio stream, no data information is lost or changed, the quality of a music file cannot become worse, the listening feeling is guaranteed greatly, the smart phone can play the native DSD high quality audio stream, substantial push is provided for the HIFI music play function of the smart phone, and great contribution is made so that the public can enjoy excellent music experience through the smart phone.

Owner:XIAN RUIXIN MICROELECTRONICS CO LTD

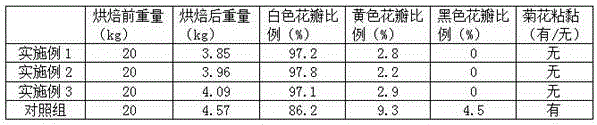

Chrysanthemum flower baking method

InactiveCN105660952AUniform killing effectGood colorTea substituesCooking & bakingChrysanthemum Flower

The invention discloses a chrysanthemum flower baking method in the technical field of Chinese herbal medicine processing in order to solve the problems of easy chrysanthemum flower scorching and ununiform heating in the process of chrysanthemum flower baking. The chrysanthemum flower baking method includes the following steps: fixation: steam is used for fixing chrysanthemum flowers to be processed, the spreading thickness of the chrysanthemum flowers is 4cm to 6cm, and time is 3 to 4 minutes; prebaking: the fixed chrysanthemum flowers are naturally aired to room temperature, and are put into a microwave dryer for prebaking; fine baking: the prebaked chrysanthemum flowers are naturally aired to room temperature, and are put into a baking room for fine baking; dampening: the finely baked chrysanthemum flowers are put into an airing room with an air humidity of 40 to 70 percent for cooling and dampening, and taken out after 10 to 20 days, a finished chrysanthemum flower product is obtained. When the method disclosed by the invention is adopted to bake chrysanthemum flowers, the operation of manually turning the chrysanthemum flowers is reduced, the efficiency of a microwave fixation machine is high, heating is uniform, not only is the color of the obtained chrysanthemum flowers vivid and uniform, but also the case of scorching is not discovered, and the quality of the chrysanthemum flowers is better.

Owner:ZHENGAN COUNTY WHITE CHRYSANTHEMUM MEDICINAL MATERIAL CO LTD

Spinning yarn conveying tensioning device capable of automatically adjusting spinning yarns to prevent slacking

ActiveCN111020848AAvoid affecting the yarn transmissionEasy to straightenWeft knittingWarp knittingYarnEngineering

The invention relates to the technical field of knitwear, and discloses a spinning yarn conveying tensioning device capable of automatically adjusting spinning yarns to prevent slacking. The device comprises a pay-off machine, and the outer side of the pay-off machine is movably connected with a pay-off drum; when a bobbin sleeves the outer side of the pay-off drum, a clamping block is squeezed torotate, and the bobbin is fixed, so that the bobbin is prevented from being separated from the pay-off drum in a spinning yarn conveying process of the bobbin; the spinning yarns are tightly attachedto the outer side of a second rotary disc, the second rotary disc is moved upwards to squeeze a spring, and when the spinning yarns are slacked, the second rotary disc is moved downwards under the action of the outer spring, so that subsequent straightening of the spinning yarns is facilitated and the property of linkage among structures is improved; and a first connecting rod moves downwards toenable a support rod to drive a first rotary disc to move upwards, the first rotary disc pulls the second rotary disc to move upwards through the spinning yarns, the spinning yarns are tightly attached to the outer side of the second rotary disc, and the spinning yarns are straightened again, so that the situation that the yarns are wound on the device due to slacking is avoided, and the situationthat the textile quality is poor due to slacking of the spinning yarns also can be avoided.

Owner:宁夏蓝欧纺织有限公司

Pavement patching device for highway machinery

InactiveCN111996888APoor qualityEasy to useRoads maintainenceAgricultural engineeringStructural engineering

The invention discloses a pavement patching device for highway machinery, and relates to the technical field of highway machinery. The pavement patching device for the highway machinery comprises a frame. A water tank is fixedly mounted at the top of the frame, a fixed base is fixedly mounted on the inner wall of one side of the frame, a stirring box is arranged above the fixed base, and supporting legs are fixedly mounted at the top of the fixed base. According to the pavement patching device for highway machinery, a water tank, a water pump, a hose, a nozzle, a fixing groove and an water inlet pipe are used cooperatively; the hose and the spray head are clamped and mounted on the fixing groove; a user can take the spray head to spray water to clean the ground and cracks needing to be repaired; and the handheld spray head is convenient for a user to use, and a situation that the repaired ground is not cleaned up so that the repairing of the pavement is influenced, the asphalt concreteis not in full contact with a repairing area, a repairing effect of the pavement is influenced, and the quality of the repaired pavement is poor is avoided.

Owner:湖州前锋机械配件厂

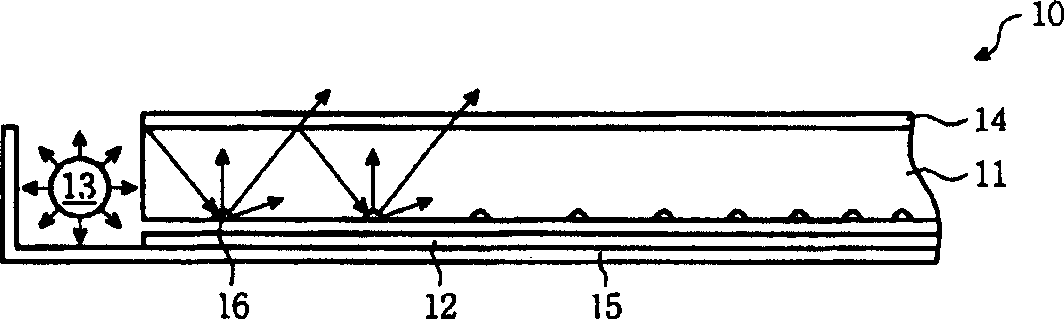

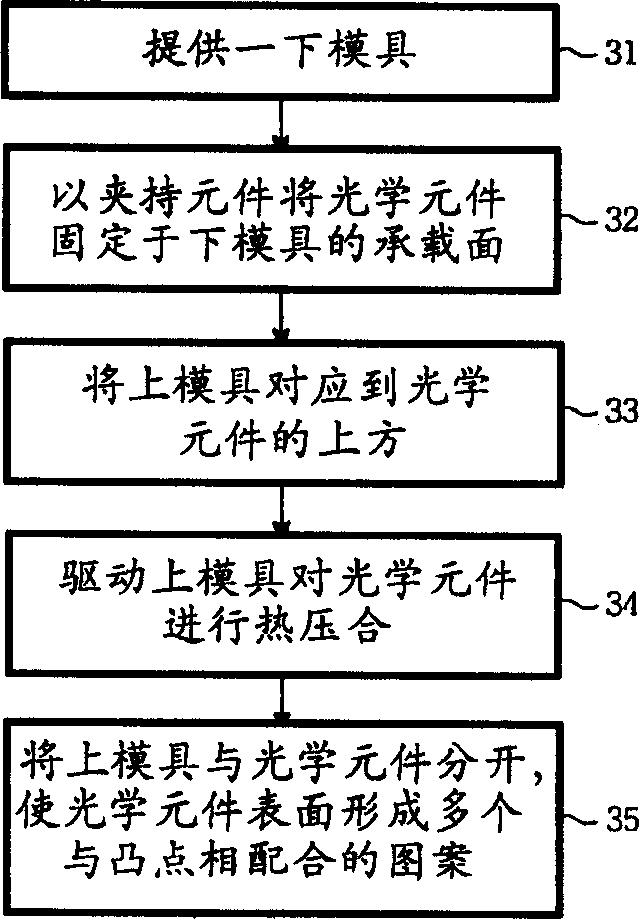

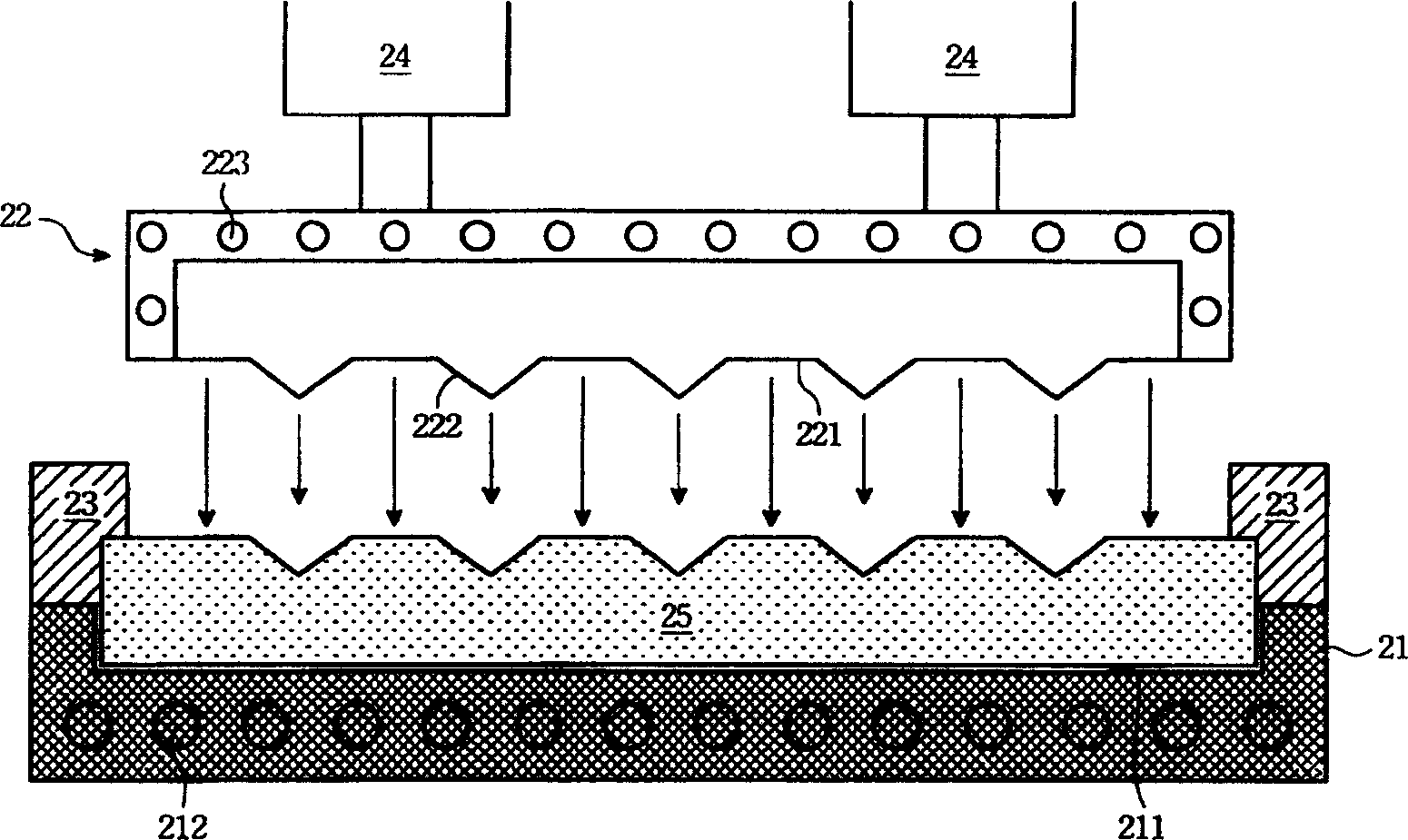

Processing method for forming pattern on the surface of optical element and apparatus thereof

A process for forming pattern on the optical assembly surface comprising the steps of, providing a lower die, securing an optical assembly onto the bearing surface of the lower die, aligning an upper die on the top of the optical assembly, wherein a plurality of projecting spots are arranged on the compression surface of the upper die, performing thermal compression to the optical assembly by driving the upper die using a driving device, thus forcing the projecting spot on the upper die embedded into the surface of the optical assembly, and finally splitting the upper die from the optical assembly, forming patterns corresponding to the multiple projecting spots on the surface of the optical assembly.

Owner:BENQ CORP

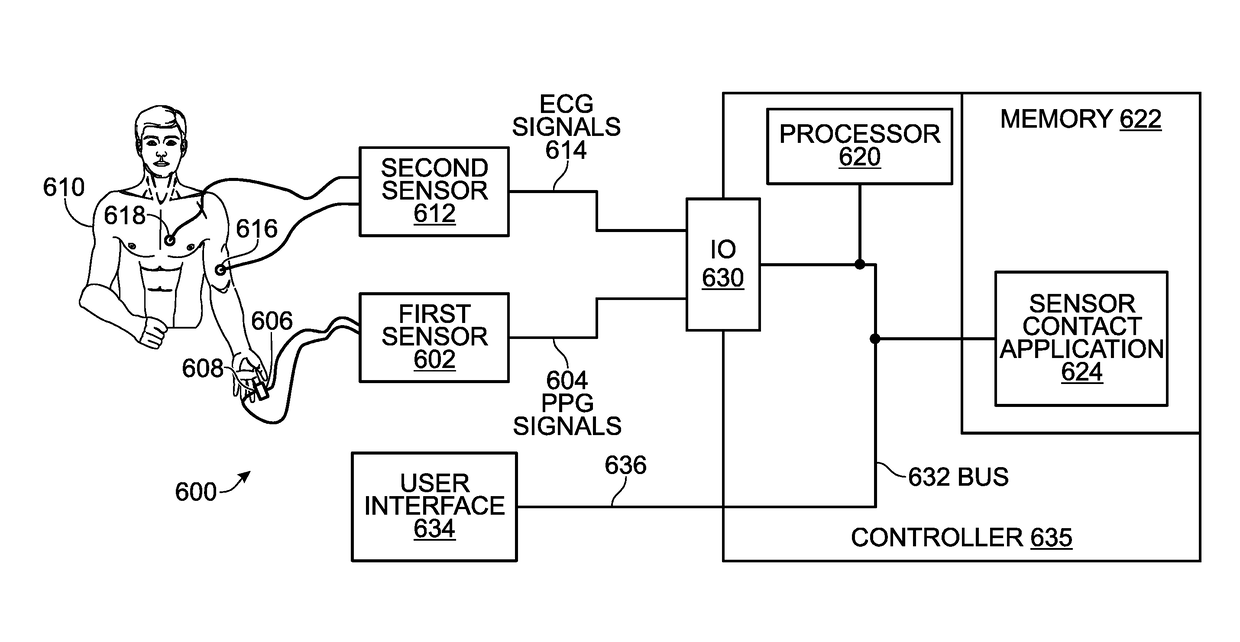

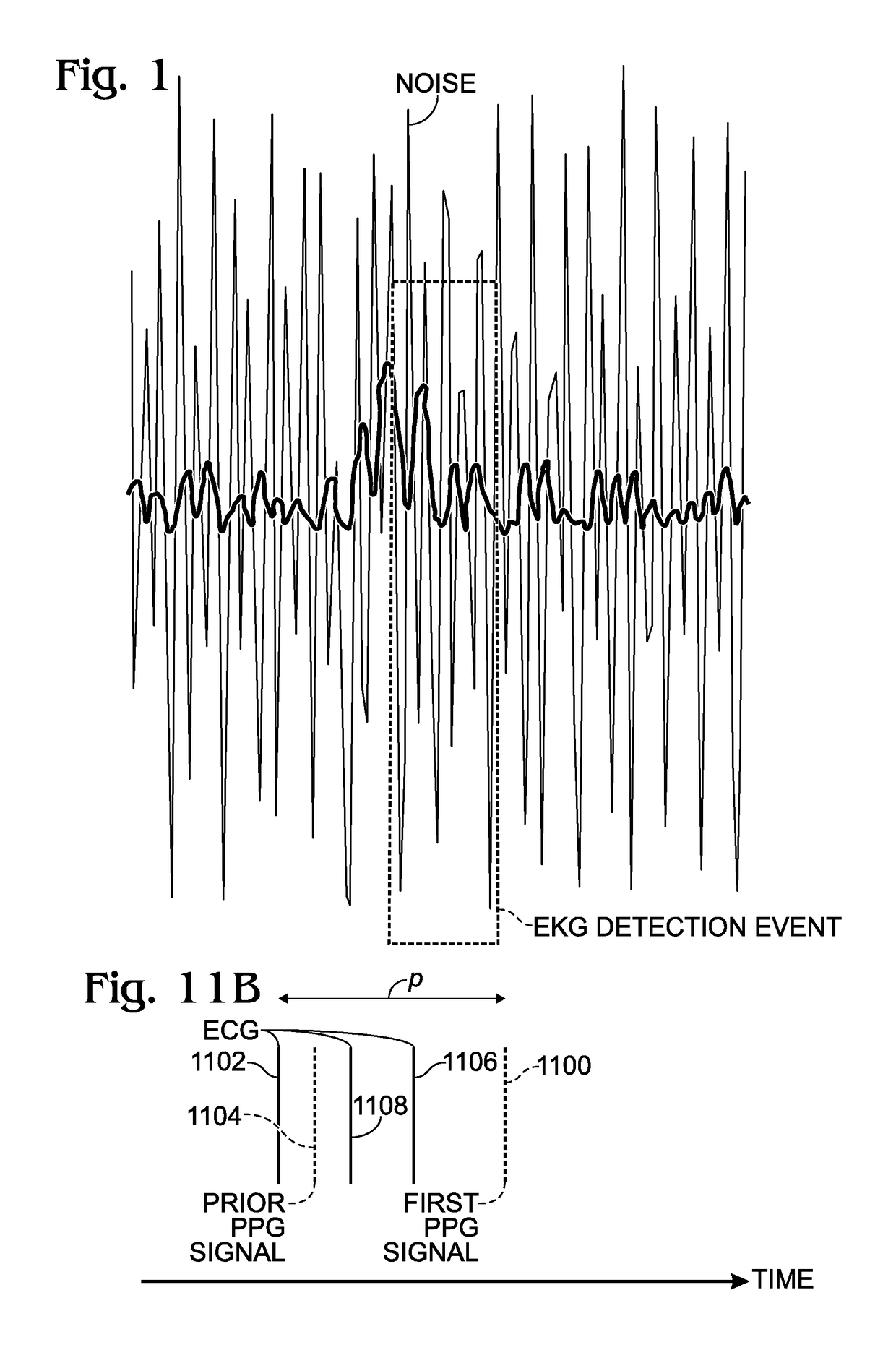

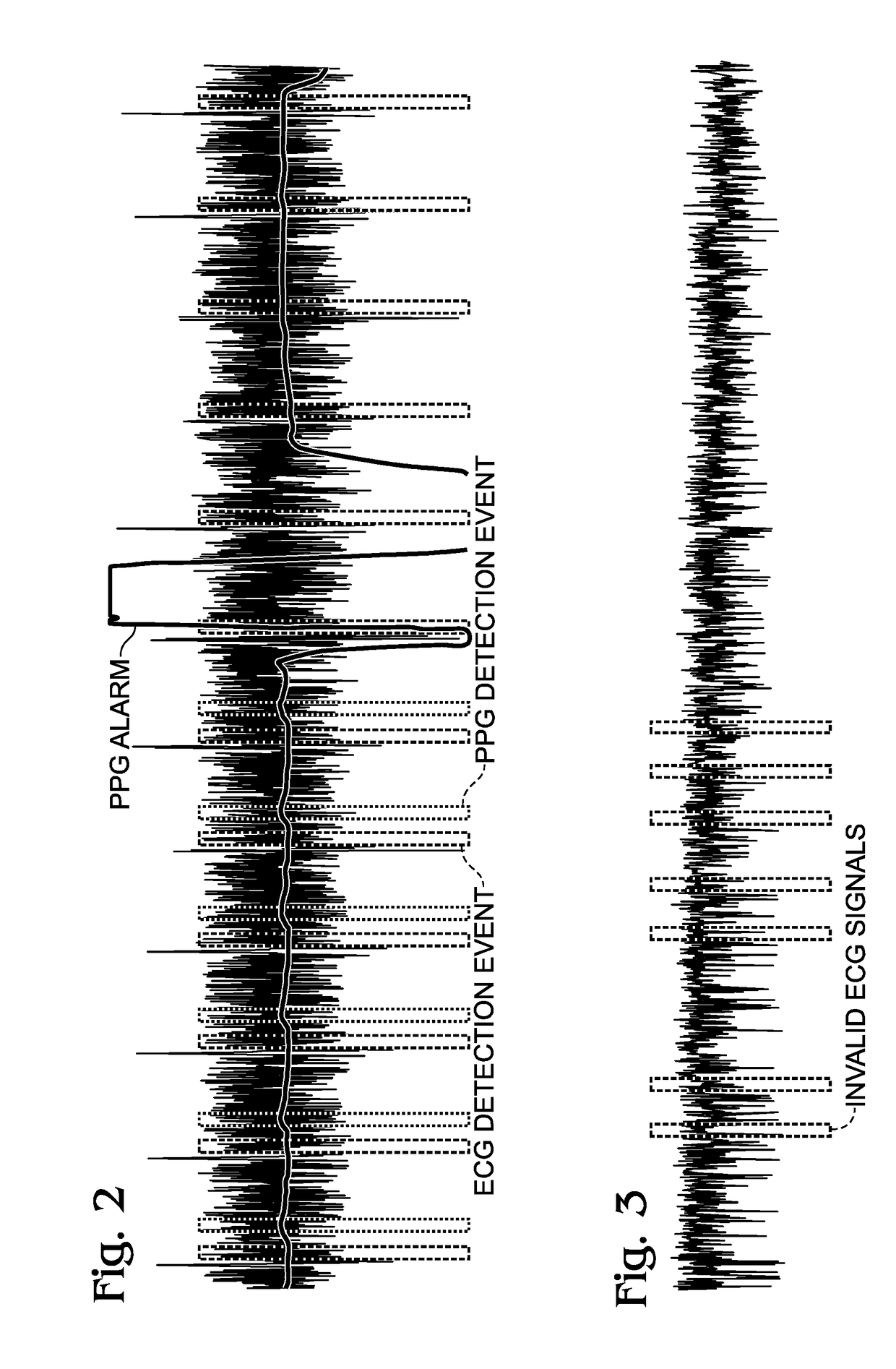

System and Method for Determining Poor Sensor Contact in a Multi-Sensor Device

InactiveUS20170143265A1Poor qualityReduce quality problemsElectrocardiographySensorsEcg signalHeart beat

A system and method are provided for determining sensor contact in a multi-sensor device. The method measures a series of photoplethysmography (PPG) heart beat signals, while simultaneously measuring a series of electrocardiogram (ECG) heart beat signals. The method detects a correlation in time between each of a plurality of PPG signals and corresponding ECG signals. In response to the timing between correlated PPG and ECG signals remaining within a first correlation deviation limit, a correlation state is determined. For example, a correlation state may be determined in response to a out of m number of correlated PPG and ECG signals remaining within the correlation deviation limit, where n and m are integers greater than zero.

Owner:LACAMAS LIFE SCI INC

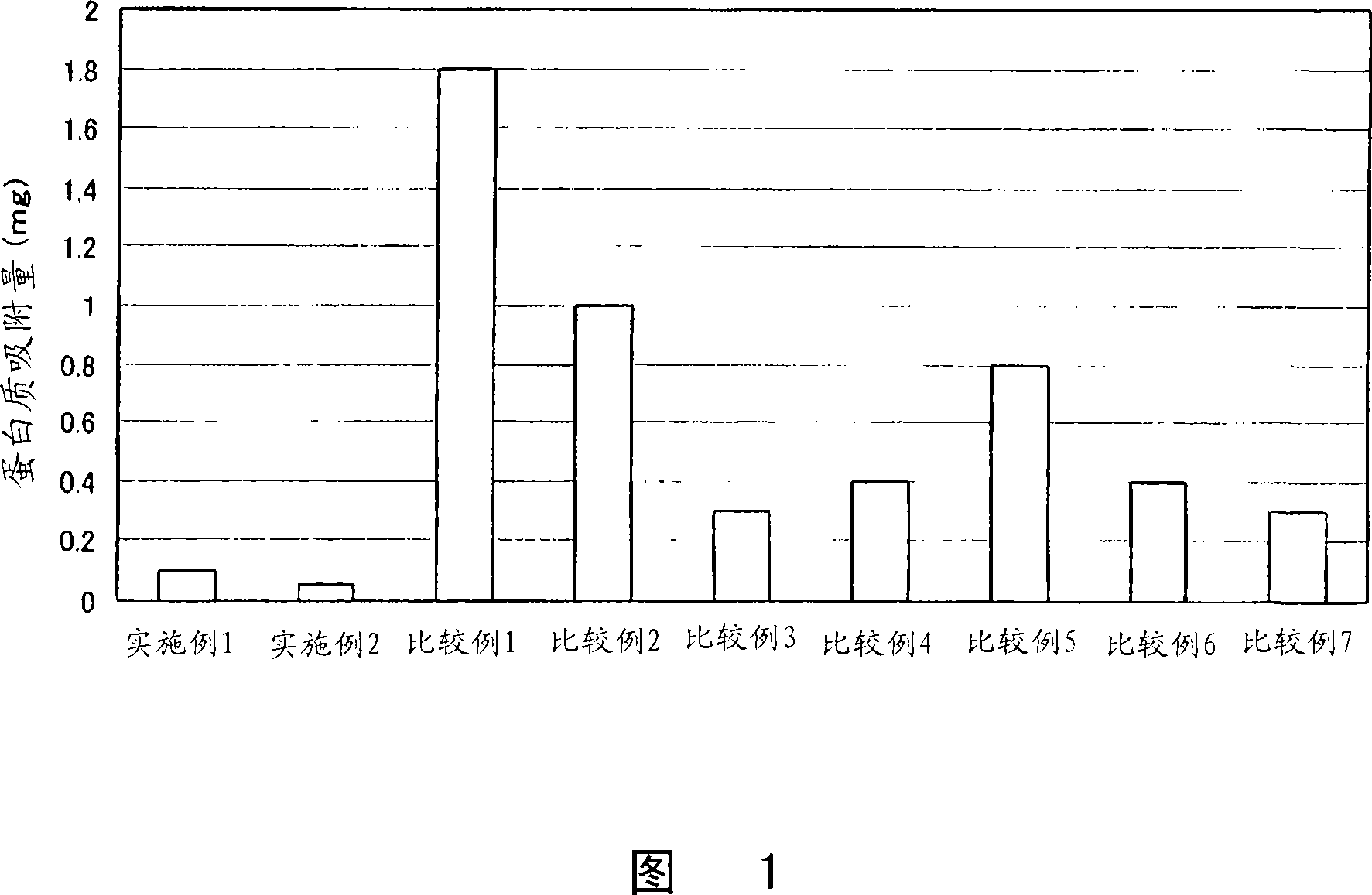

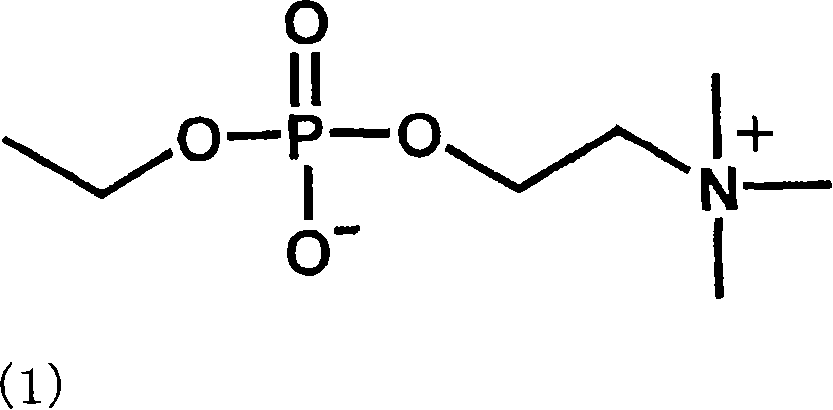

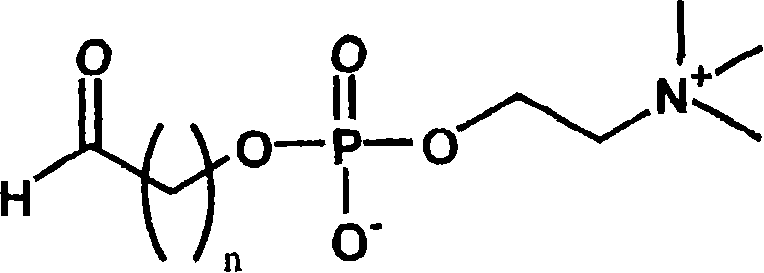

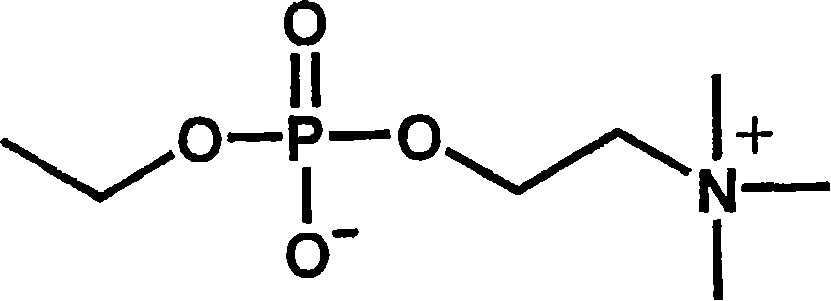

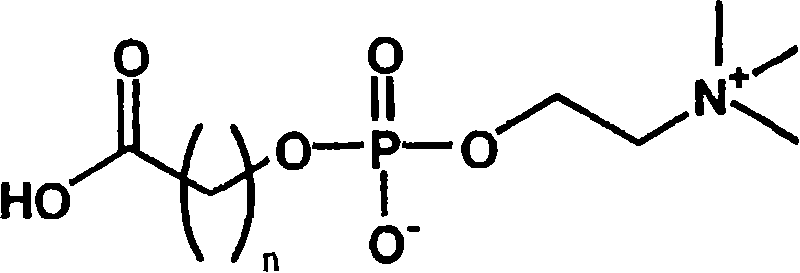

Protein adsorption-preventing ocular lens material and method for producing same

InactiveCN1957287AInhibition of protein adsorptionGood antifoulingIntraocular lensOptical partsOrganic solventPhosphorylcholine

Disclosed is a method for producing an ocular lens material which comprises a step for reacting and covalently bonding a compound having a phosphorylcholine group represented by the formula (1) below with the surface of an ocular lens material. This method for producing an ocular lens material is characterized in that a phosphorylcholine group-containing compound represented by the formula (2) below is reacted with an ocular lens material having an OH group in any one of water, an organic solvent and a water-organic solvent mixture, thereby being covalently bonded thereto by an acetal bond. The object of the present invention is to provide an eye lens material that prevents protein adsorption and a method of manufacturing thereof. In the formula (2), n is a natural number of 1-18.

Owner:SHISEIDO CO LTD +1

Ocular lens material and method for producing same

InactiveCN1961242AInhibition of adsorptionGood antifoulingIntraocular lensOptical partsOphthalmologyPhosphorylcholine

Disclosed is a method for producing an ocular lens material which comprises a step for reacting and covalently bonding a compound having a phosphorylcholine group represented by the formula (1) below with the surface of an ocular lens material. This method for producing an ocular lens material is characterized in that a phosphorylcholine group-containing compound represented by the formula (2) below is reacted with an ocular lens material, in an organic solvent, thereby being covalently bonded thereto by an acetal bond. With such a method, there can be provided an ocular lens material which prevents protein adsorption. In the formula (2), n is a natural number of 1-18.

Owner:SHISEIDO CO LTD +1

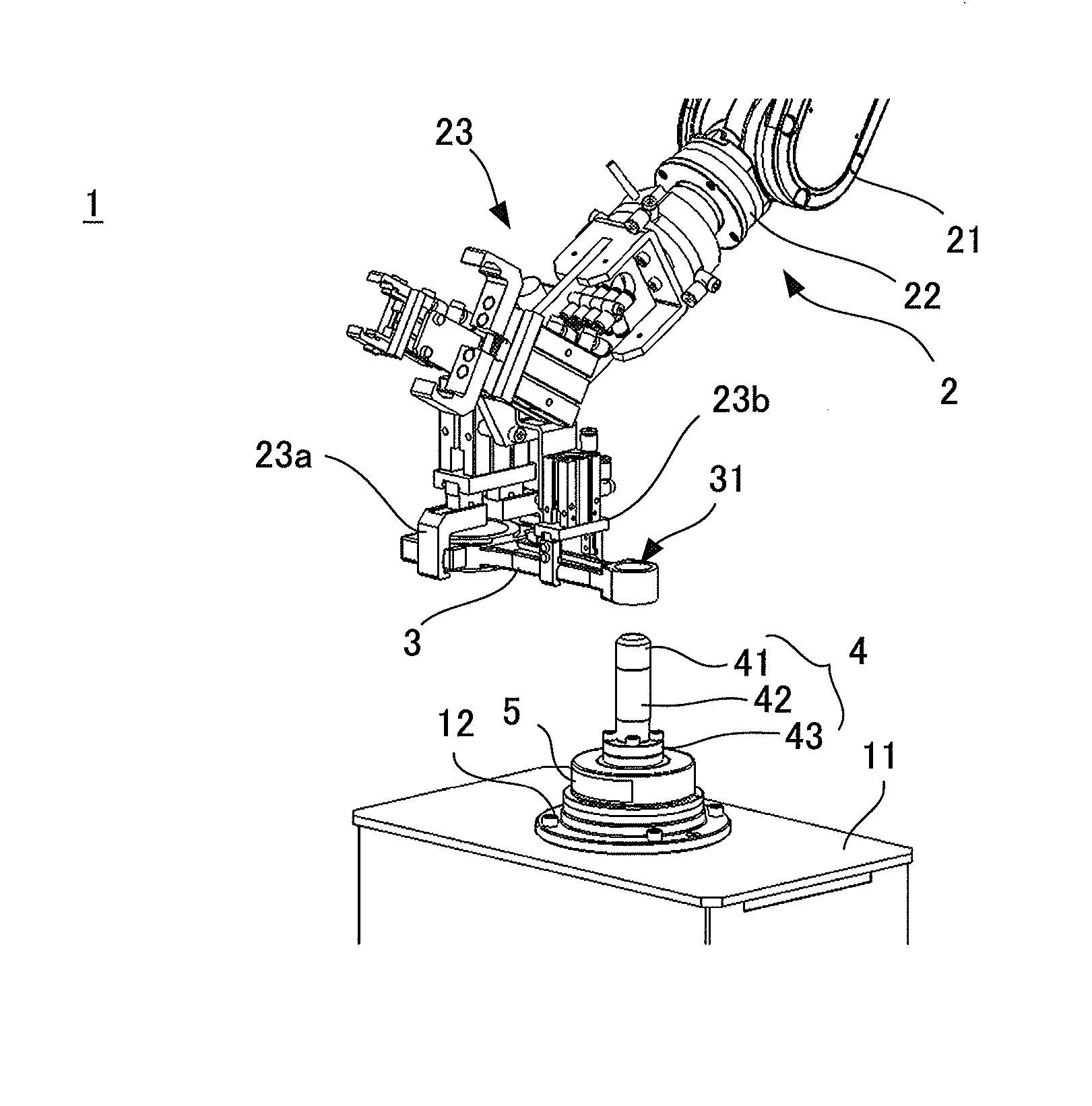

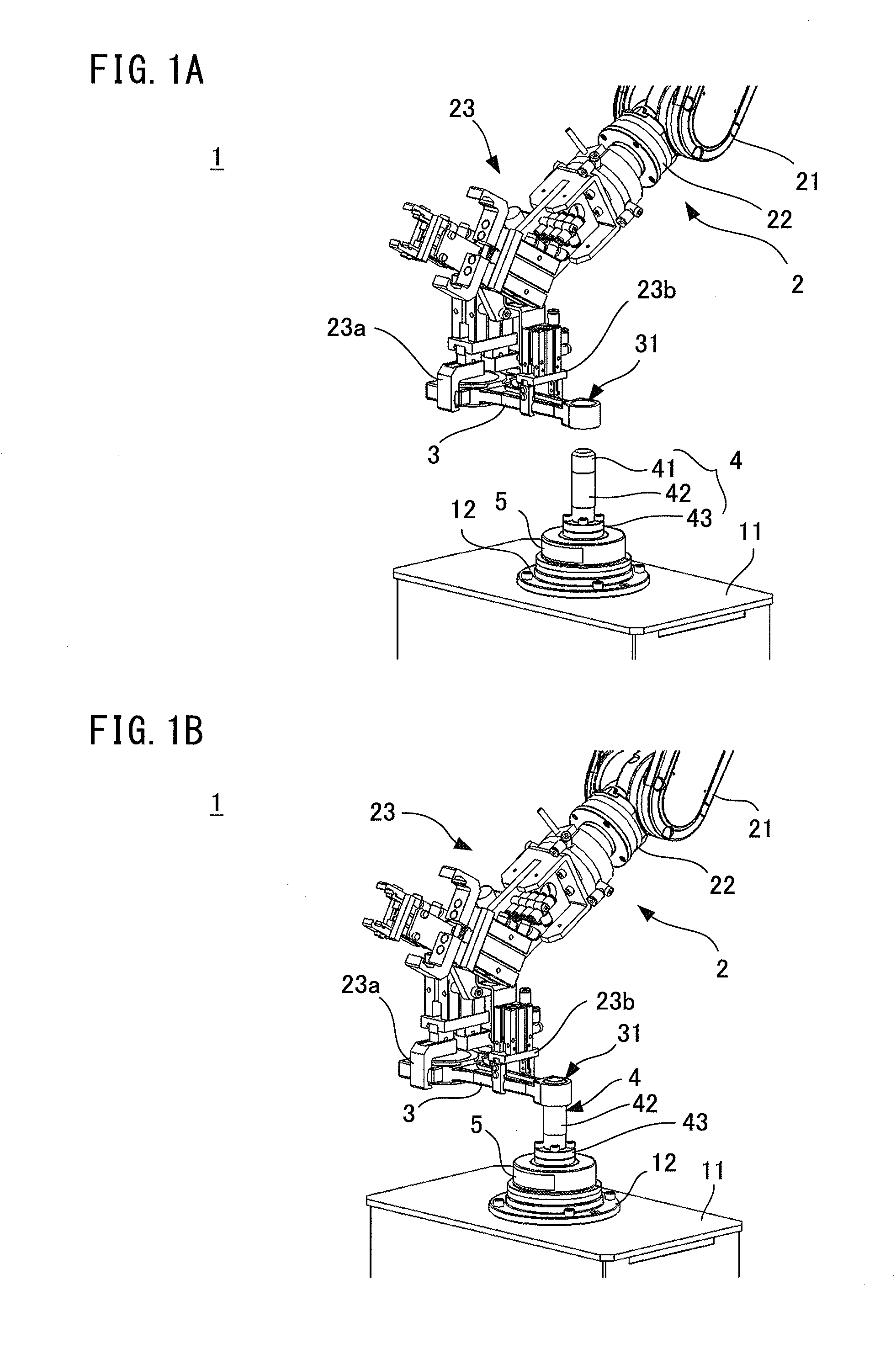

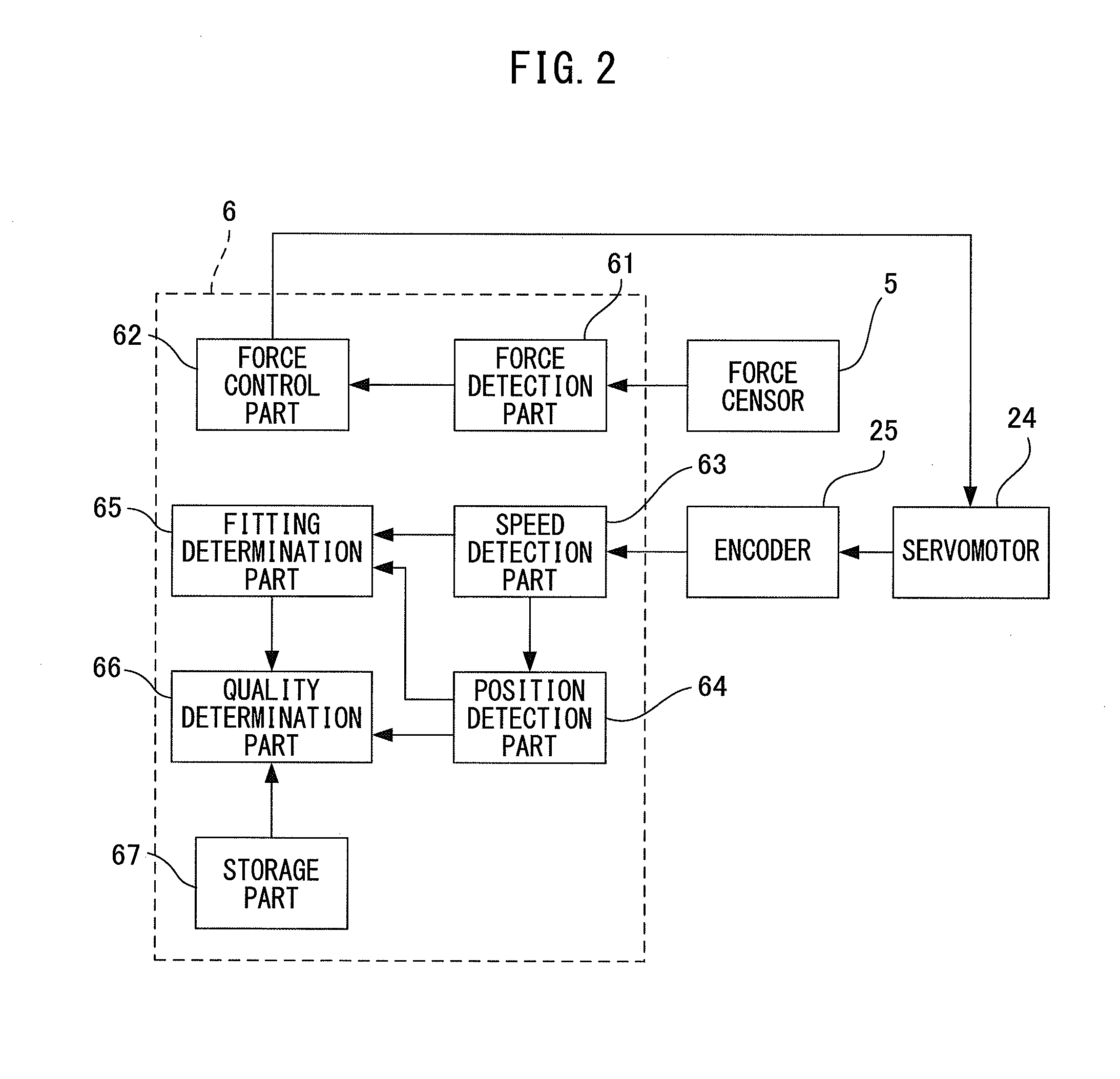

Inspection system for inspecting object using force sensor

InactiveUS20160008980A1Poor qualityProgramme controlProgramme-controlled manipulatorEngineeringForce sensor

An inspection system includes a force sensor for detecting force acting between an inspection gauge and an object formed with a machined portion. The inspection system determines the quality of the machined portion, based on a positional relationship between the object and the inspection gauge when the inspection gauge and the machined portion are fitted to each other. The fitting operation between the inspection gauge and the machined portion is carried out by a robot which is operated in accordance with force control using a detection value of the force sensor.

Owner:FANUC LTD

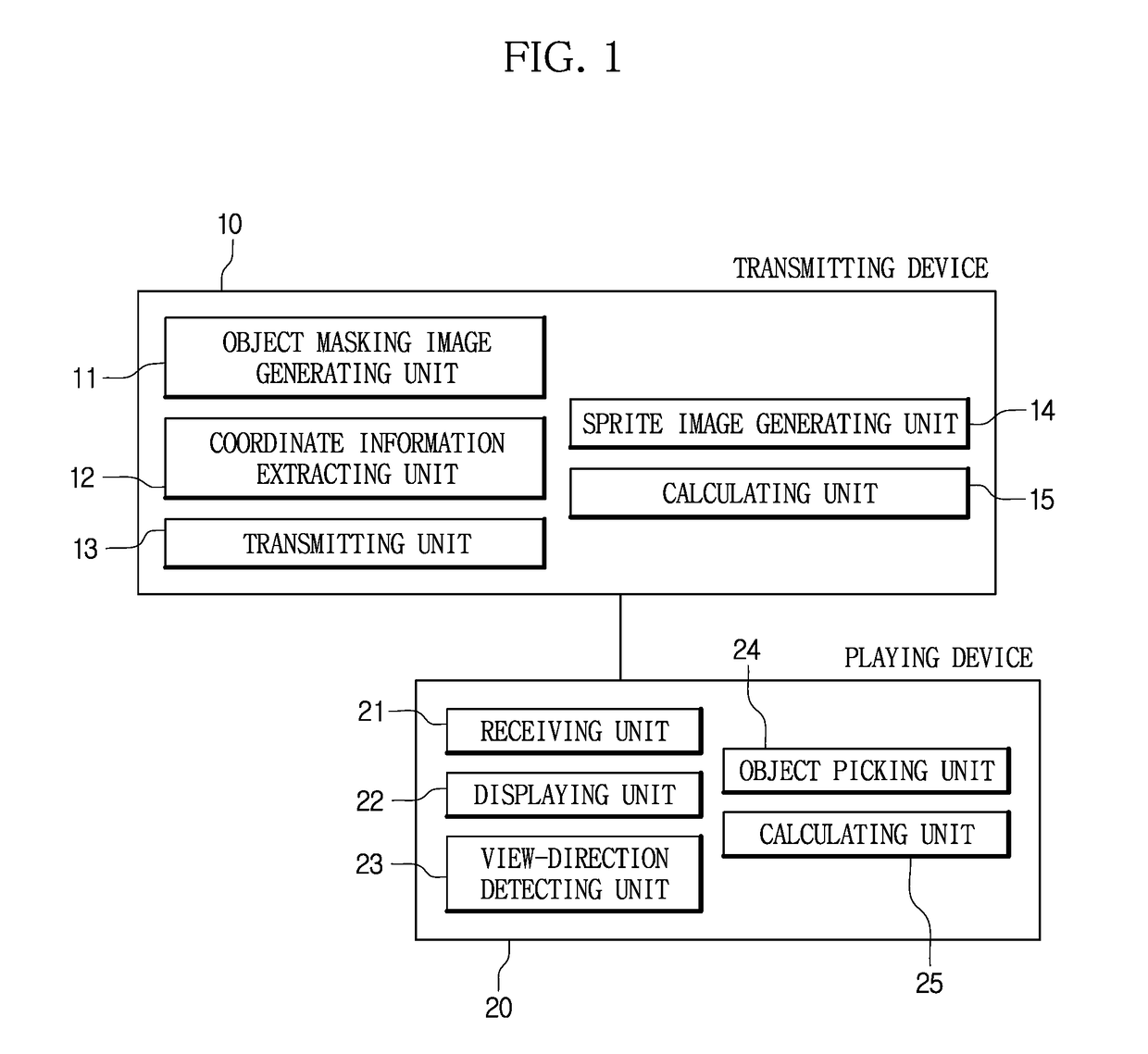

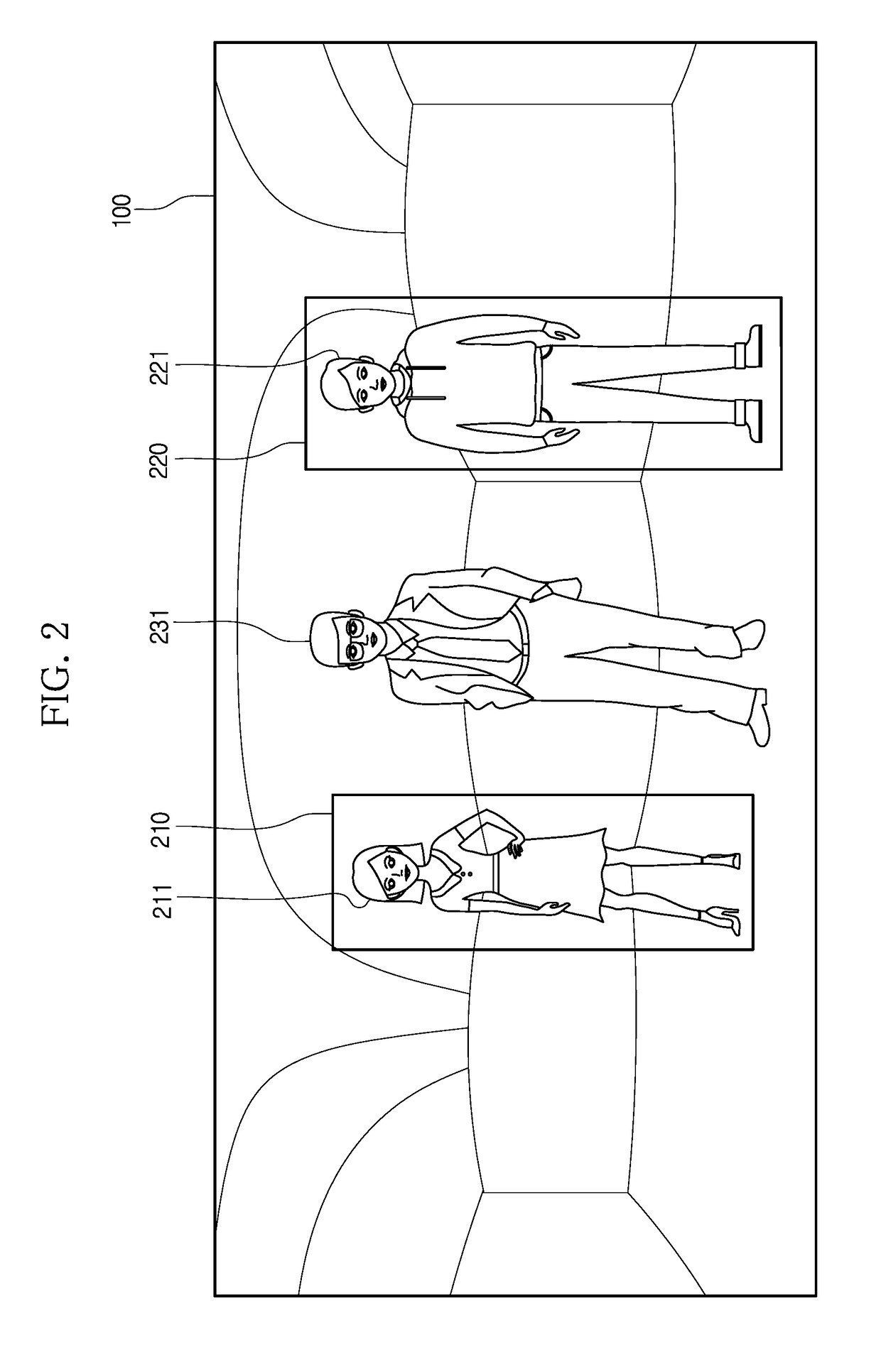

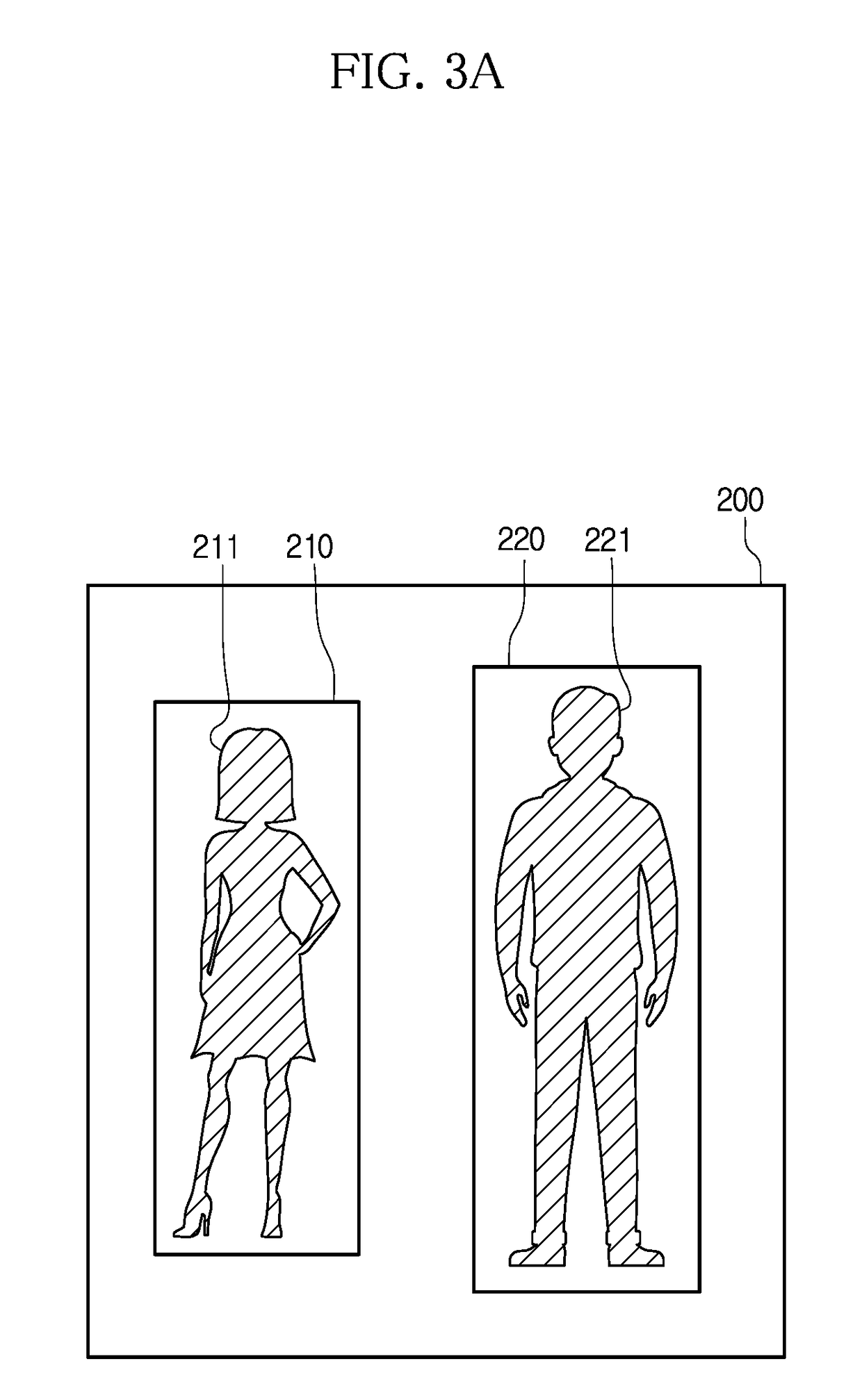

System for Picking an Object Base on View-Direction and Method Thereof

InactiveUS20180364800A1Smooth playbackPoor qualityInput/output for user-computer interactionProgramme-controlled manipulatorUltra high resolutionImage resolution

Exemplary embodiments relate to a system for picking an object based on view-direction including a transmitting device configured to extract an object region including an object from an original image, and transmit an object masking image of the extracted object region and the original image, and a playing device configured to receive the object masking image and the original image from the transmitting device, display the original image, and pick the object in the displayed original image based on view-direction of a user viewing the original image, and a method for picking an object based on view-direction through them. According to the present disclosure, it is possible to overcome the limit of decoding of conventional virtual reality devices and enable picking in an image with ultra high resolution.

Owner:FXGEAR

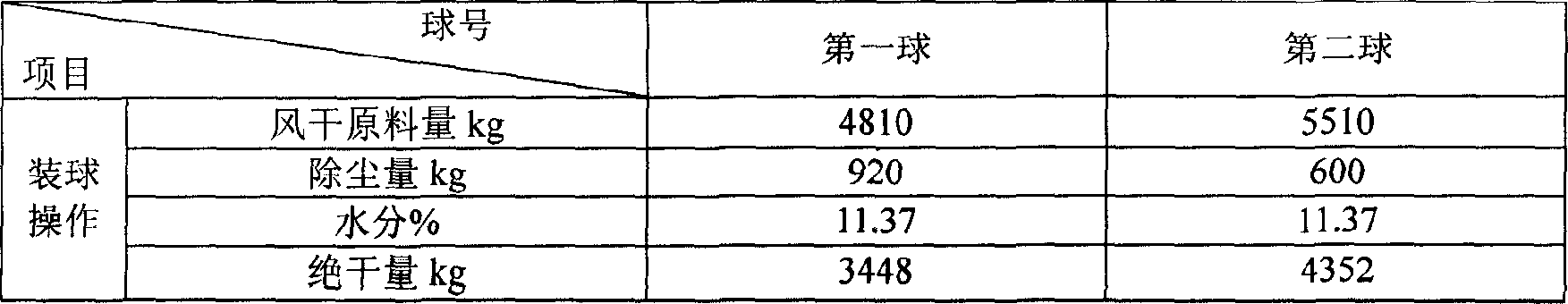

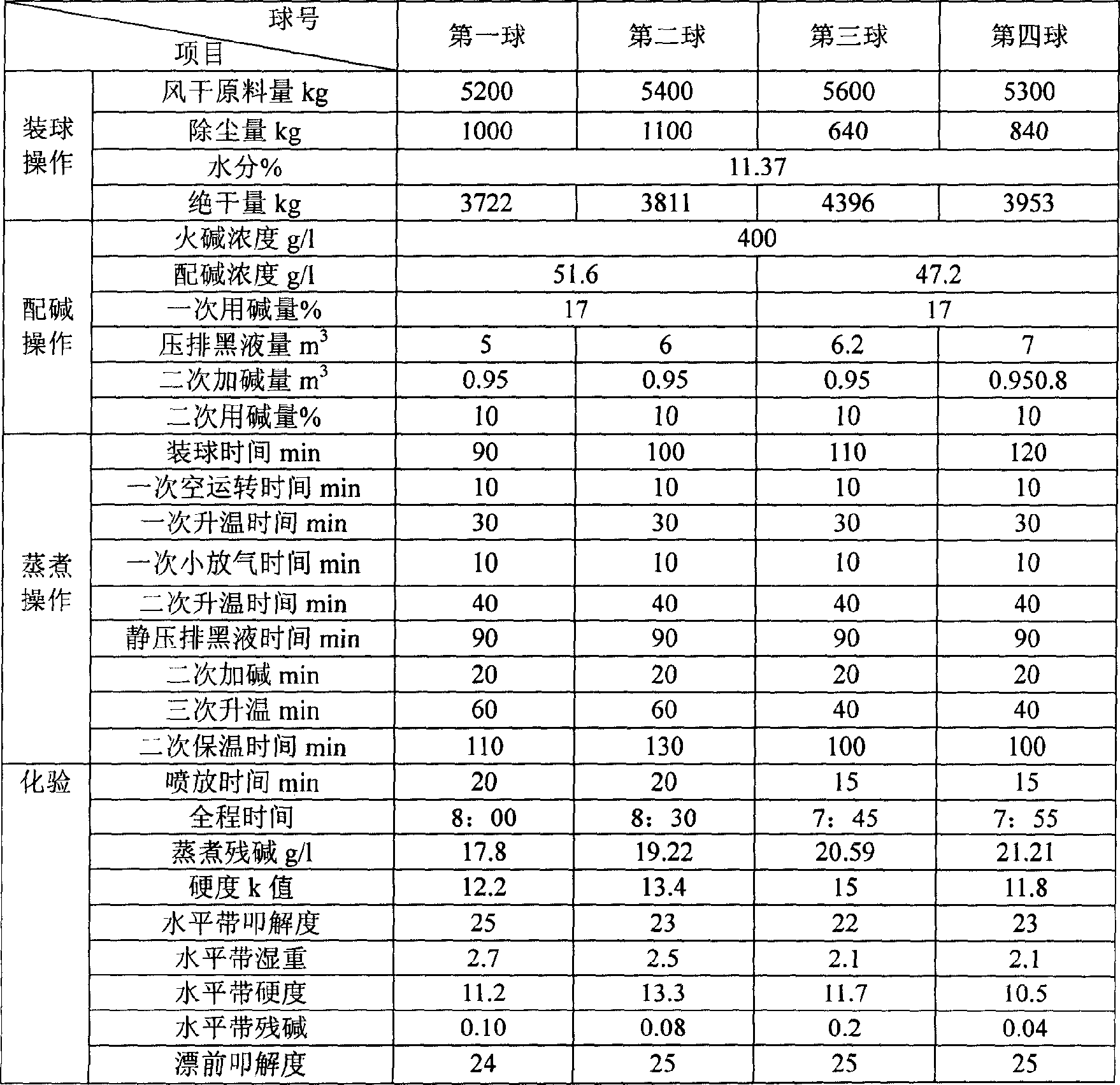

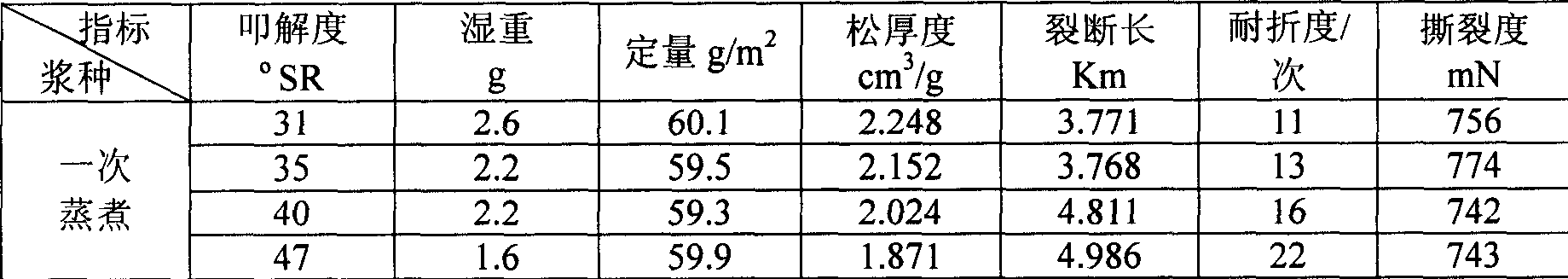

Method of preparing bleached chemical pulp using cotton stalk

ActiveCN1718919AIdeal qualityQuality improvementPulp bleachingPulping with inorganic basesPre treatmentChemical pulp

The present invention discloses a method for preparing bleached chemical pulp by using cotton stalk. The described method is an alkaline process, and includes the following steps: preparing material, impregnating treatment, first cooking or secondary cooking to obtain crude pulp, then washing pulp, bleaching so as to obtain the finished paper.

Owner:SHANDONG TRALIN PAPER

Substrate support structure, vacuum drying apparatus and method for vacuum drying a substrate

ActiveUS20160320124A1Poor qualityUneven brightnessDrying solid materials without heatNon-linear opticsPoor qualityEngineering

Disclosed is a substrate support structure, a vacuum drying apparatus and a method for vacuum drying a substrate. The substrate support structure comprises: a support pin having a top end for supporting a substrate; and an auxiliary support assembly including: a drive device; a support rod driven by the drive device; and a support disc disposed at a top end of the support rod and made of flexible material adapted to support the substrate, wherein the drive device is configured to drive the support rod to move in a direction parallel to an axial direction of the support pin so as to make the support disc positioned below or above the top end of the support pin as the support rod moves, so that the substrate is selectively supported by the support disc or the support pin. The substrate support structure, the vacuum drying apparatus and the method for vacuum drying a substrate can prevent the substrate from being easily scratched and avoid poor quality and uneven brightness of the substrate.

Owner:BOE TECH GRP CO LTD +1

A method for outdoor cultivation of ground fungus

ActiveCN105660181BWide adaptabilityGrow fastCalcareous fertilisersMagnesium fertilisersRural areaAgaric

Owner:HUBEI NORMAL UNIV

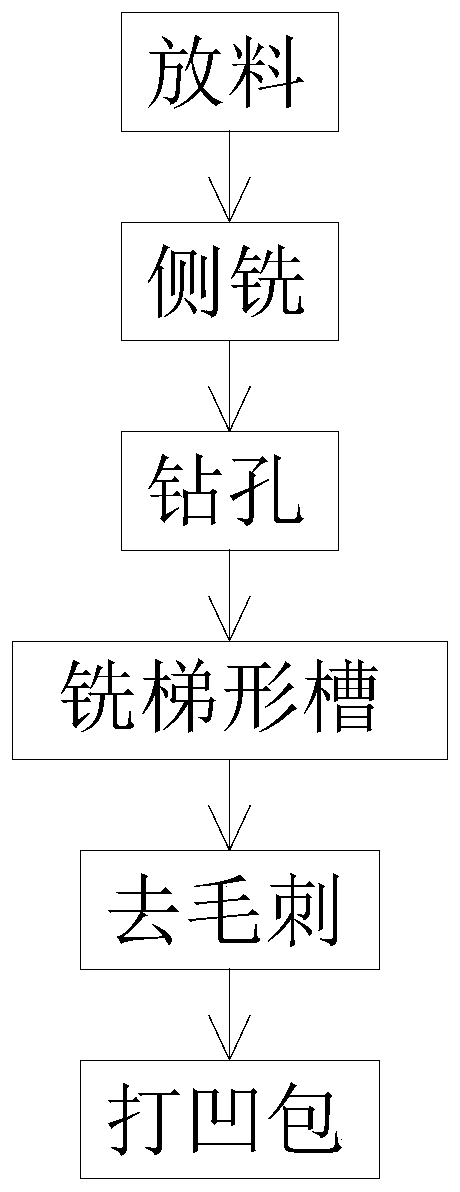

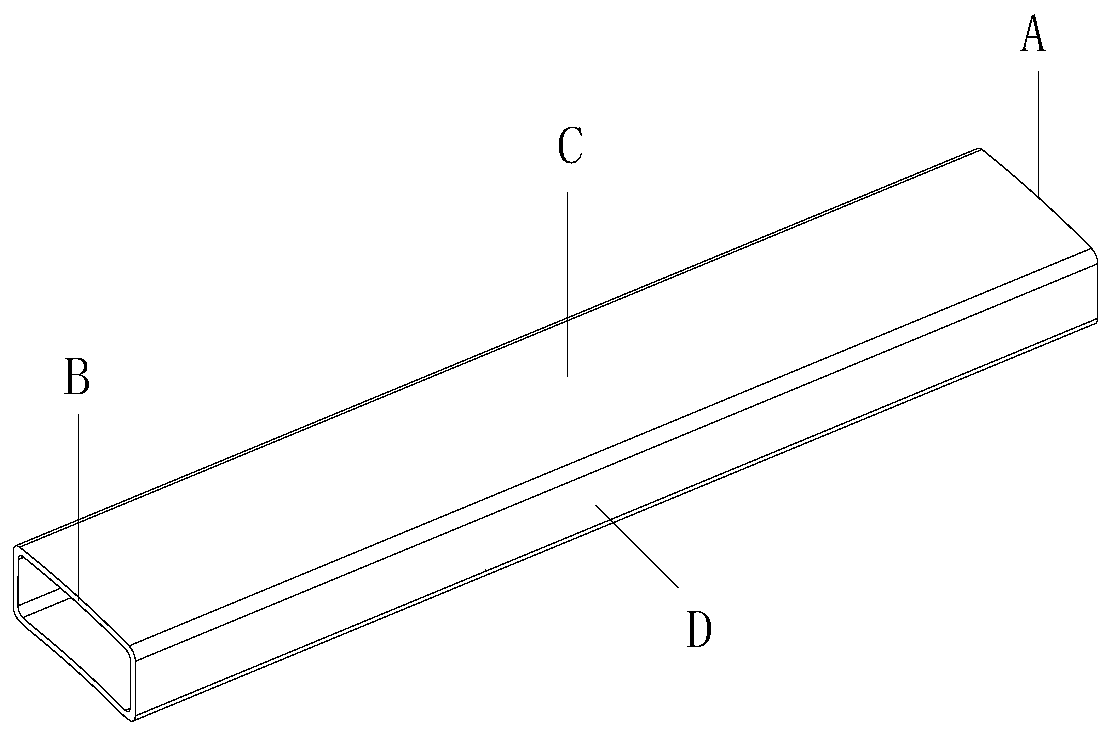

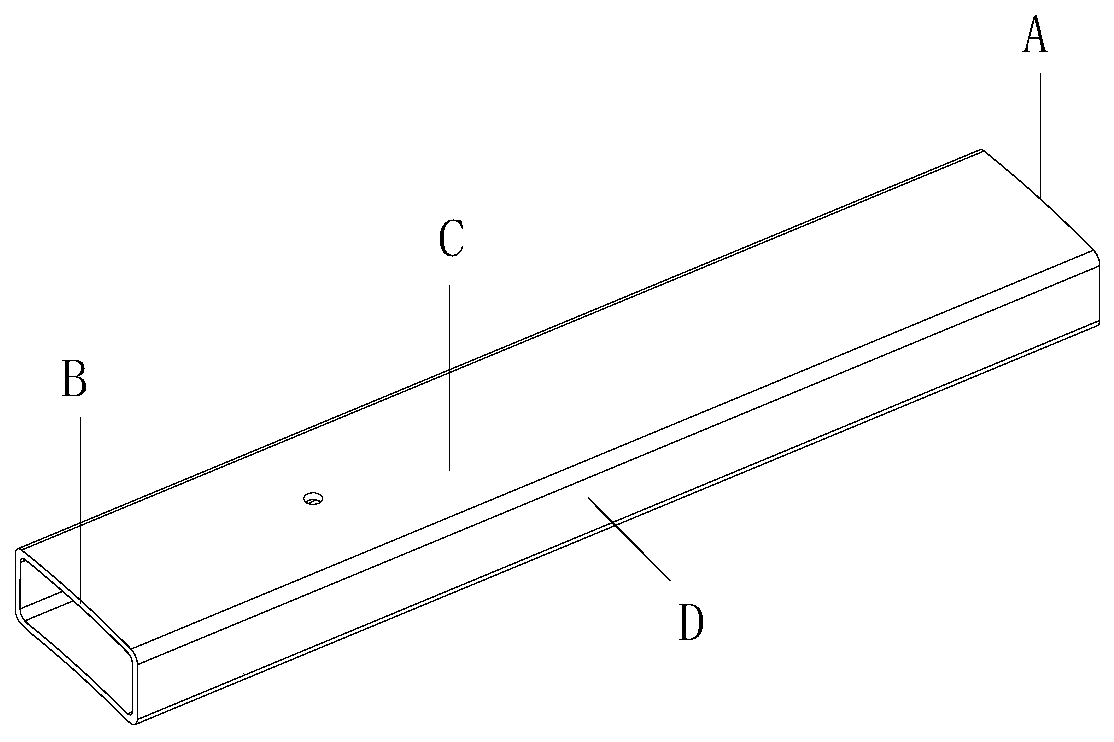

Aluminum tube milling process

The invention discloses an aluminum tube milling process. The aluminum tube milling process comprises the following steps that material placement is carried out, wherein a mechanical arm automaticallytakes and places an aluminum tube blank on a fixture, and the product fixture adopts the manner of indexing tray transportation; side milling is carried out, wherein a milling cutter is moved downwards to mill the two end faces A and B of the aluminum tube blank, and rough milling and finishing milling are carried out; drilling is carried out, wherein a drilling knife is moved downwards to drilla hole in the upper end surface C of an aluminum tube; dovetail groove milling is carried out, wherein a servo control electric spindle is used for driving the milling cutter to mill a trapezoidal groove in the end face B of the aluminum tube, and rough milling and finishing milling are carried out; deburring is carried out, wherein a diamond brush is used for deburring the end faces of the aluminum tube and the trapezoidal grooves; and concave bag punching is carried out, wherein the mechanical arm grips a product into a concave bag punching die, concave bag processing is carried out on the two side faces D of the aluminum tube. In the above steps, waste chippings are sucked away in dust extraction method, and the cutters are cooled by blowing the cold air. In the above manner, the present technology replaces conventional CNC machining operation, and multiple clamping, carrier replacing and debugging are avoided.

Owner:江苏富浩电子科技有限公司

Method for preparing ZnO thin films with buffer layers

InactiveCN108560051AAvoid contactImprove crystal qualityPolycrystalline material growthFrom chemically reactive gasesOptoelectronicsControllability

The invention discloses a method for preparing ZnO thin films with buffer layers. The method includes steps of S1, cleaning monocrystalline silicon substrates and removing oil stain and impurities onthe surfaces of the monocrystalline silicon substrates; S2, utilizing Al targets as target materials, placing the monocrystalline silicon substrates in vacuum chambers of magnetron sputtering equipment, filling the magnetron sputtering equipment with sputtering gas Ar and reaction gas N2, and sputtering coating AlN buffer layers on the surfaces of the monocrystalline silicon substrates; S3, utilizing Al targets and ZnO targets as target materials, and sputtering coating composite buffer layers comprising AlN and ZnO on the surfaces of the AlN buffer layers; S4, utilizing ZnO targets as targetmaterials, and sputtering coating ZnO film layers on the surfaces of the composite buffer layers to obtain the ZnO thin films with the buffer layers. The method has the advantages that the ZnO film layers can be prevented from being in direct contact with the monocrystalline silicon substrates, and accordingly the crystallization quality of the plated ZnO film layers can be improved; integral procedures are simple magnetron sputtering film coating, are simple and are high in controllability and repeatability.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

Preparation method of low-fat high-protein yogurt, and yogurt prepared by preparation method

The invention discloses a preparation method of a low-fat high-protein yogurt, and the yogurt prepared by the preparation method. The preparation method of the low-fat high-protein yogurt comprises the following steps: S1, sequentially weighing skim milk powder, white granulated sugar, a strain, a stabilizing agent and water, adding water to dissolve skim milk powder, then adding white granulatedsugar and the stabilizing agent, and sequentially performing homogenizing, sterilizing, cooling, inoculating and fermenting to obtain a mixture A; S2, weighing nuts, and performing baking and cooling;S3, soaking the baked nuts in the step S2 in a soybean protein membrane solution, fishing out the nuts, and performing oven-drying to obtain a mixture B; and S4, adding the mixture B into the mixtureA, and performing stirring to obtain a finished product. The prepared yogurt has the advantages of being relatively good in edible taste, high in protein and low in fat.

Owner:北京和润乳制品厂

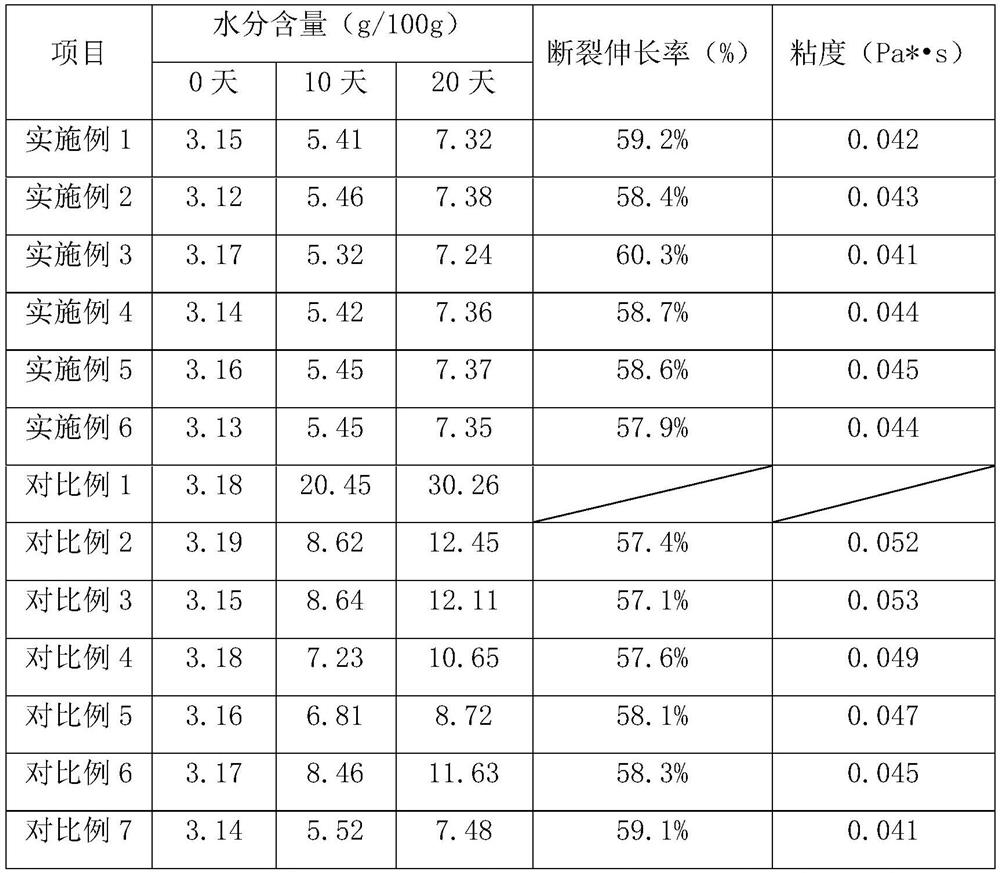

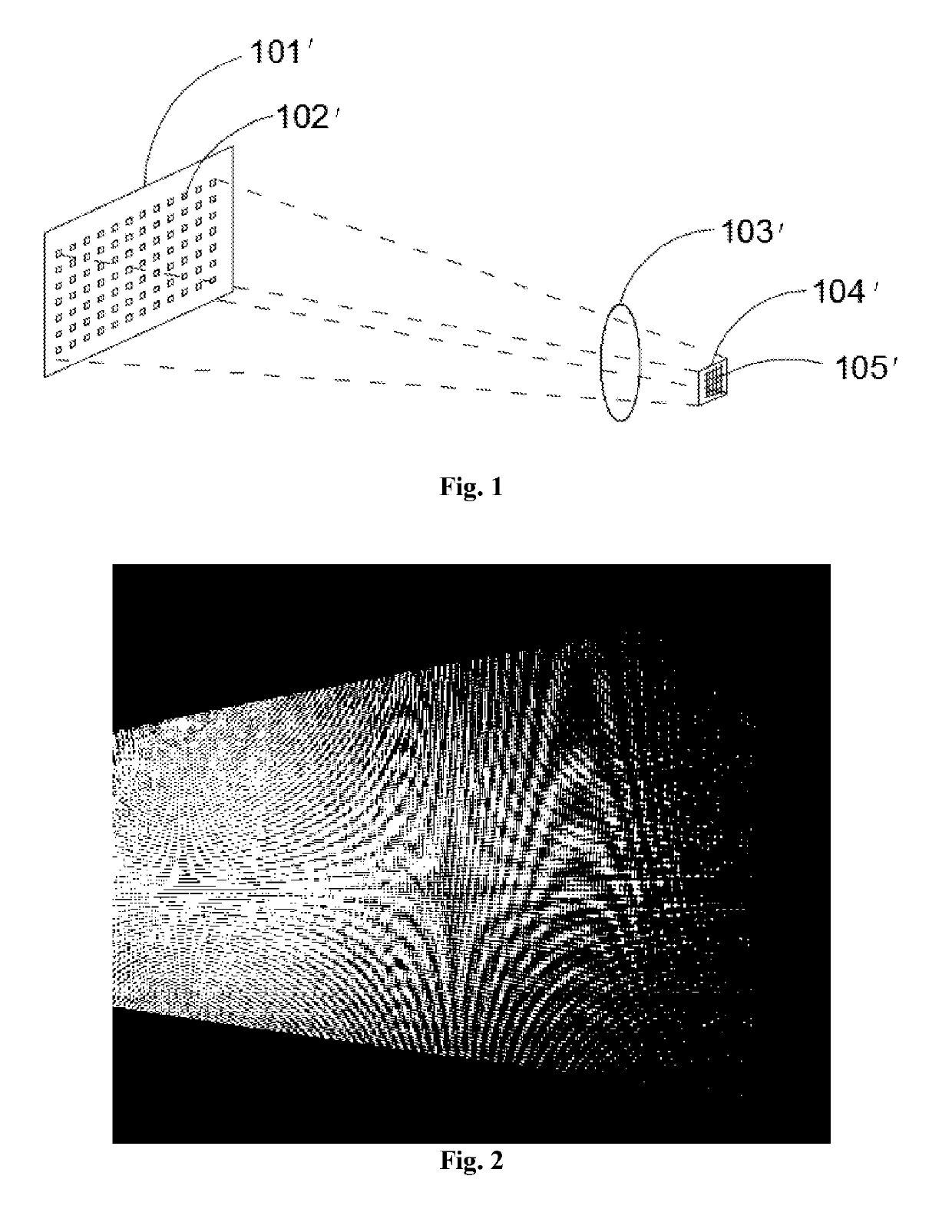

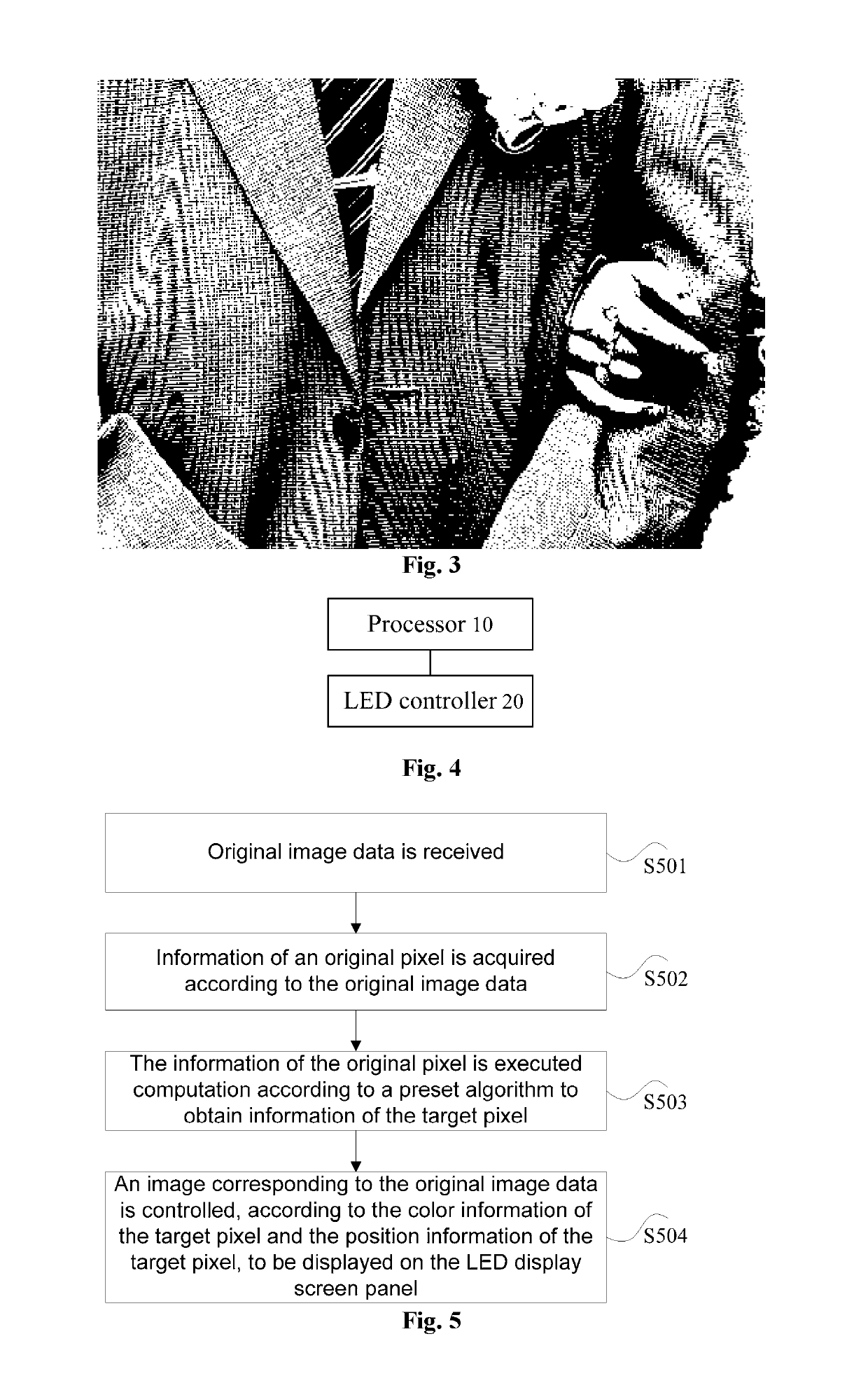

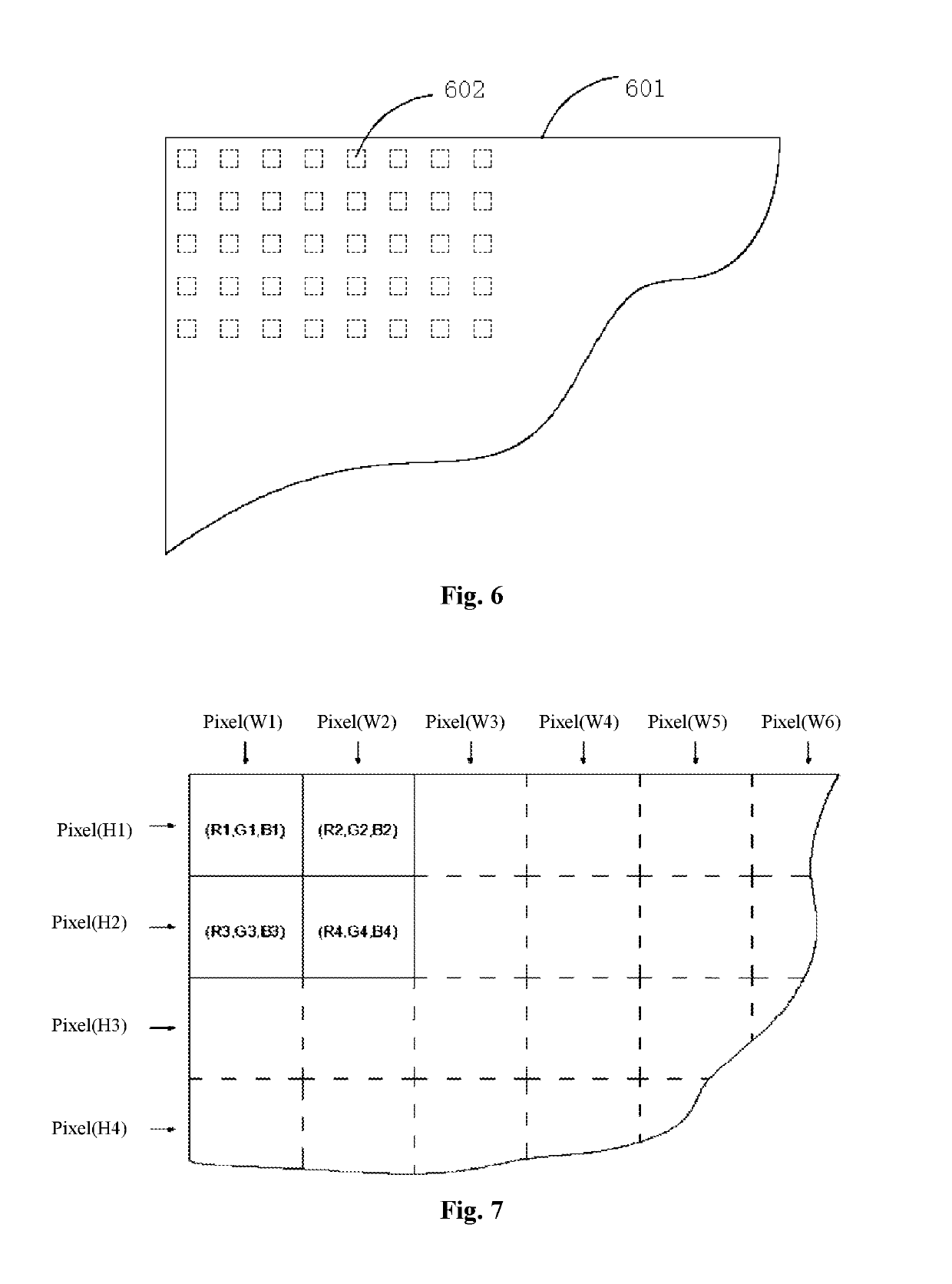

Image processing method and device for LED display screen

ActiveUS10417955B2Poor qualityImprove display image qualityCathode-ray tube indicatorsDigital output to display deviceLED displayImaging data

Provided herein is an image processing method and device for a Light Emitting Diode (LED) display screen. The image processing method for an LED display screen includes: receiving original image data; acquiring information of an original pixel according to the original image data; executing the information of the original pixel computation according to a preset algorithm to obtain information of target pixels; and controlling an image corresponding to the original image data according to the color information of the target pixel and the position information of the target pixel to be displayed on the LED display screen panel. The disclosure improves the quality of a displayed image of an LED display screen.

Owner:LEYARD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com