Ocular lens material and method for producing same

A manufacturing method and glasses technology, applied in glasses/goggles, intraocular lenses, eye implants, etc., can solve problems such as failure to obtain contact lenses, achieve excellent antifouling effect, inhibit protein adsorption, and improve water retention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

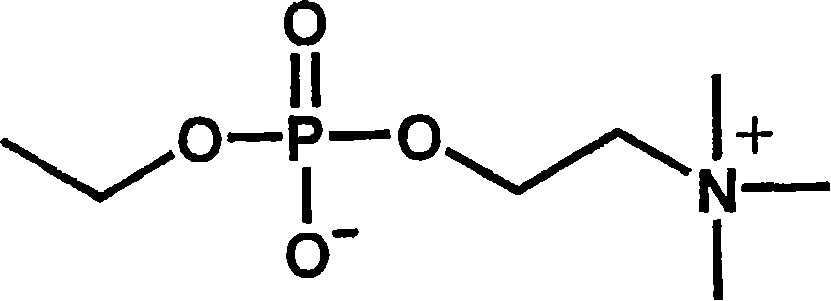

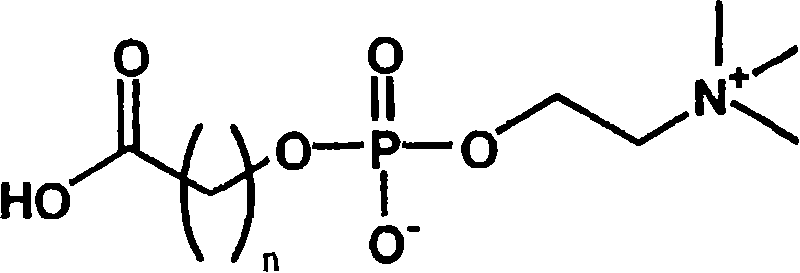

[0041] (the preparation method of the phosphorylcholine-containing compound of formula (2))

[0042] Phosphocholine groups can be prepared completely synthetically. However, the synthesis conditions are complicated, must be strictly anhydrous conditions, and the preparation cost is high.

[0043] On the other hand, phosphorylcholine can be extracted in the form of lecithin, which is a constituent of the cell membrane. In this case, 1-α-glycerophosphocholine can be obtained easily and at a lower cost by removing the fatty acid moiety by hydrolysis. The inventors of the present invention have found that a phosphorylcholine group-containing compound having a carboxyl group can be easily obtained by oxidatively cleaving the diol portion of this 1-α-glycerophosphorylcholine.

[0044] The most representative synthesis method is: oxidizing 1-α-glycerophosphorylcholine in water, acetonitrile and other solvents through sodium periodate and ruthenium trichloride to obtain the target ca...

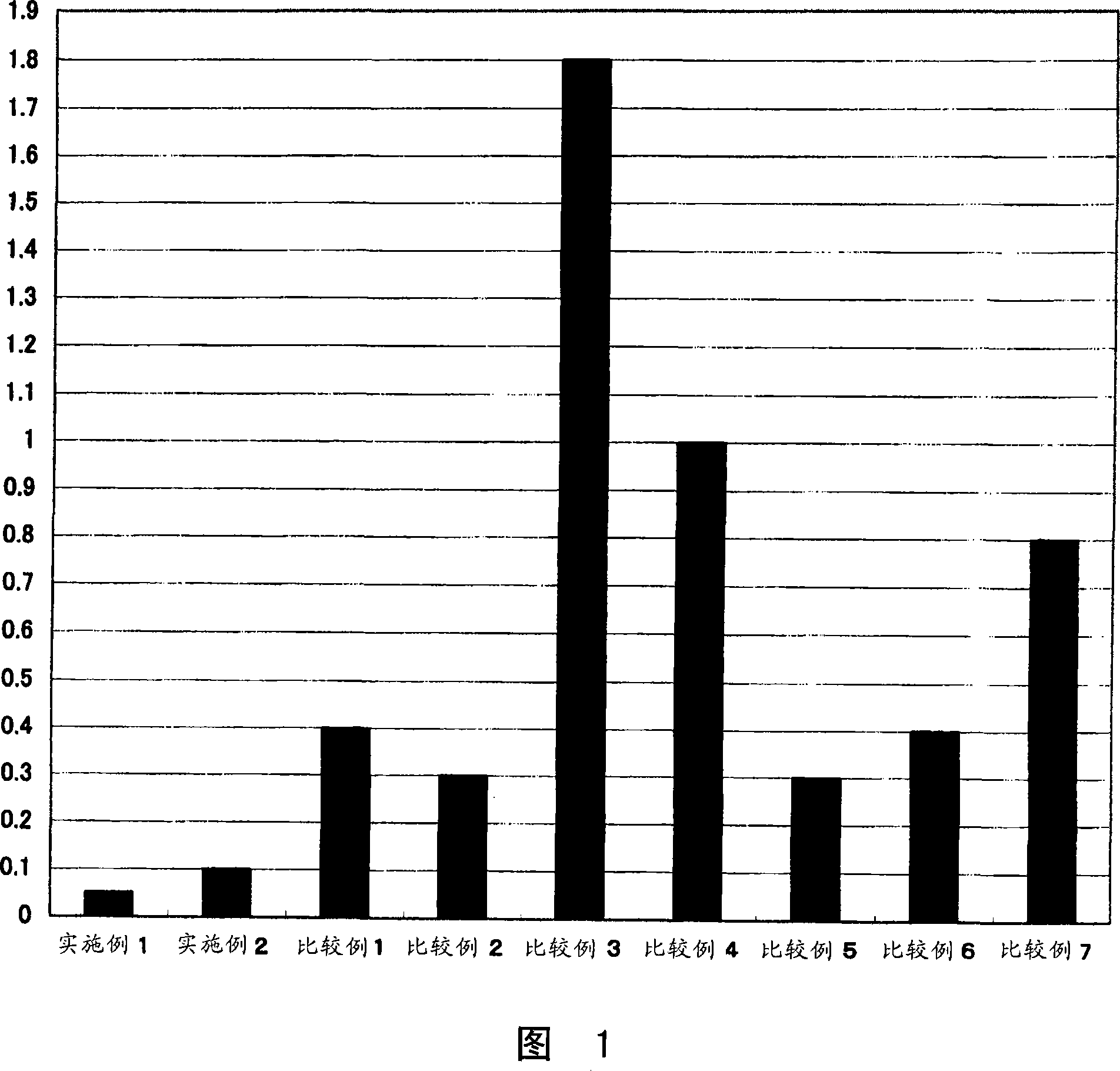

Embodiment 1

[0076] (Example 1: A contact lens in which a compound of formula (2) forms an ester bond with Polymacon (a soft contact lens Medalist manufactured by BaushLomb Co., Ltd.) via a carboxylic acid halide)

[0077] 10 mg of the compound of formula (2) was added to 2 ml of dimethylformamide, 5 mg of thionyl chloride was added, followed by stirring for 30 minutes. Soak 1 piece of Polymacon fully replaced with dimethylformamide to remove water, add 0.2ml of triethylamine, and then react for 4 hours. The reaction solution was sufficiently washed with pure water to obtain a contact lens.

Embodiment 2

[0078] "Example 2: A contact lens in which an ester bond is formed between a compound of formula (2) and Nelfilcon A (Fokas de Iris made by Cibabizion)"

[0079] Fully replace Nelfilcon A with dimethylformamide to remove water, then soak in 2ml of dimethylsulfoxide, add 10mg of the compound of formula (2), 1-ethyl-3-(3-dimethylaminopropyl) Carbodiimide hydrochloride 7 mg, then reacted for 6 hours. The reaction solution was sufficiently washed with pure water to obtain a contact lens.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com