Rubber composite material and preparation method thereof

A composite material and rubber technology, which is applied in the field of preparation of rubber-like polymer composite materials, can solve the problems that the improvement effect of natural rubber polymer tensile strength and elongation at break is not obvious, and is suitable for large-scale application and low cost , Improve the effect of tensile strength and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

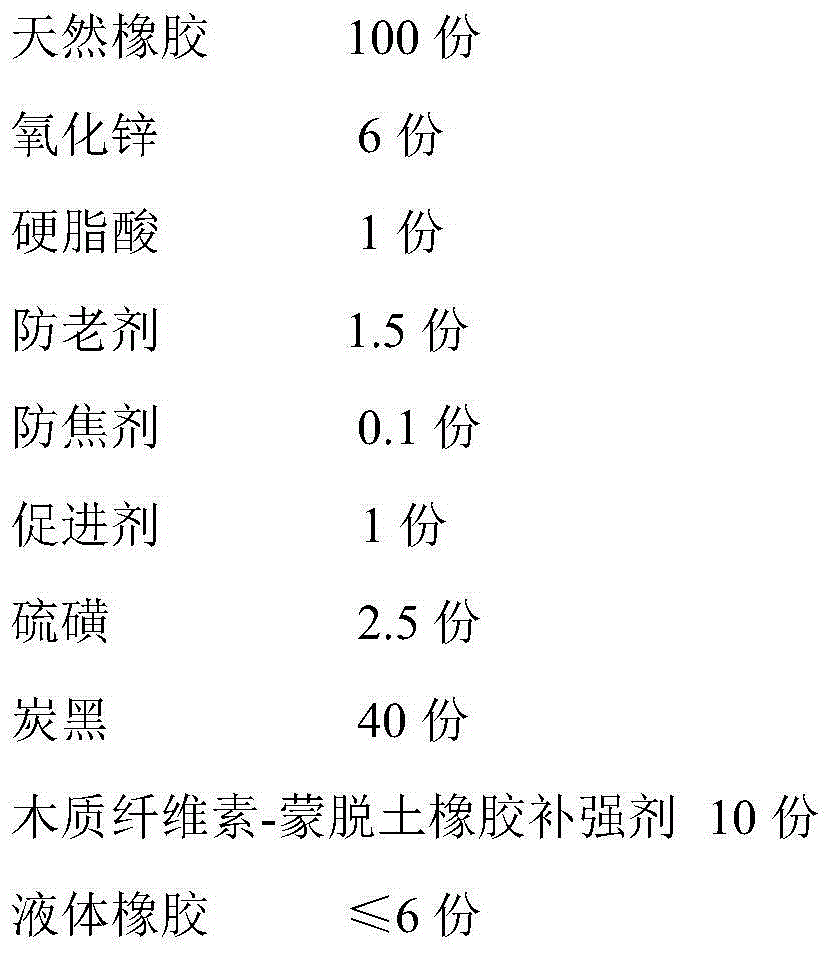

Embodiment 1

[0031] A rubber composite material, consisting of the following components by weight: 100 parts of natural rubber, 6 parts of zinc oxide, 1 part of stearic acid, 1.5 parts of antioxidant 4010NA, 0.7 part of accelerator CZ, 0.1 part of anti-scorch agent CTP, 40 parts of carbon black N330, 10 parts of lignocellulose-montmorillonite rubber reinforcing agent, 2.5 parts of sulfur and 0.3 parts of accelerator TMTD.

[0032] The preparation method of the rubber composite material of the present embodiment comprises the following steps:

[0033] (1) Preparation of lignocellulose-montmorillonite rubber reinforcing agent: join lignocellulose 15g and deionized water 750ml in a 1000ml beaker, stir and mix evenly to obtain lignocellulose suspension; Add 60 g of organic montmorillonite treated with octadecyl dimethyl benzyl ammonium chloride to the plain suspension, stir and react for 6 h at 80°C, wash the reaction product until neutral after the reaction, dry and dry Ball milling until th...

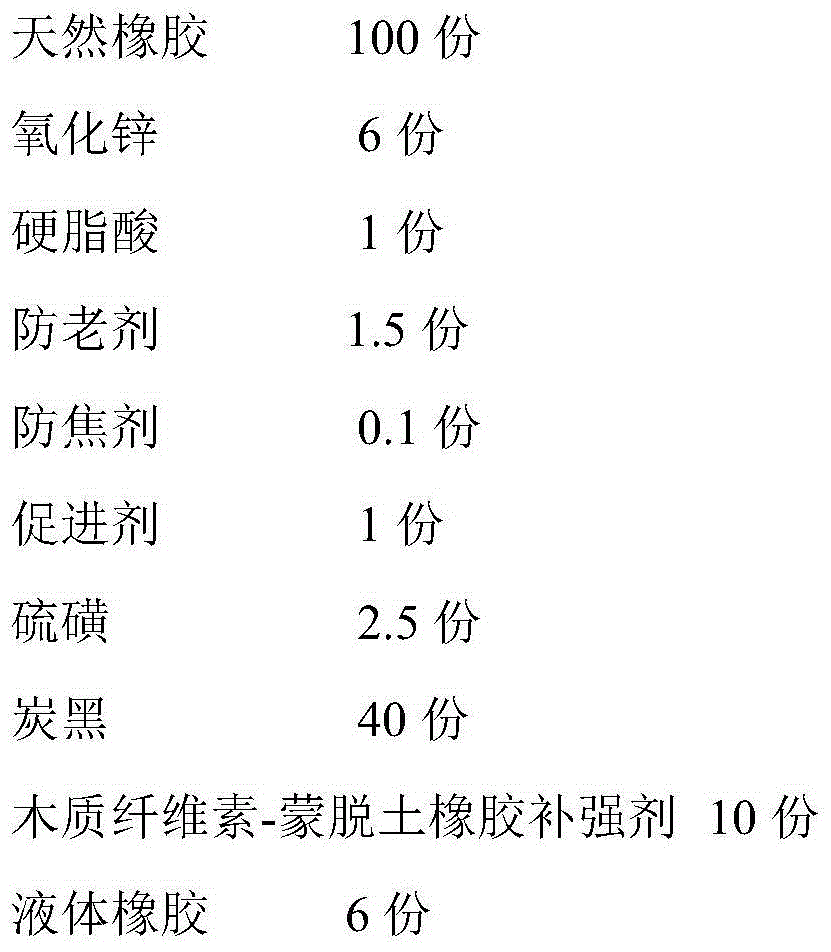

Embodiment 2

[0038] A rubber composite material, consisting of the following components by weight: 100 parts of natural rubber, 6 parts of zinc oxide, 1 part of stearic acid, 1.5 parts of antioxidant 4010NA, 0.7 part of accelerator CZ, 0.1 part of anti-scorch agent CTP, Carbon black N33040 parts, lignocellulose-montmorillonite rubber reinforcing agent 10 parts, liquid rubber LBR3072 parts, sulfur 2.5 parts and accelerator TMTD 0.3 parts.

[0039] The preparation method of the rubber composite material of this embodiment is the same as that of Embodiment 1.

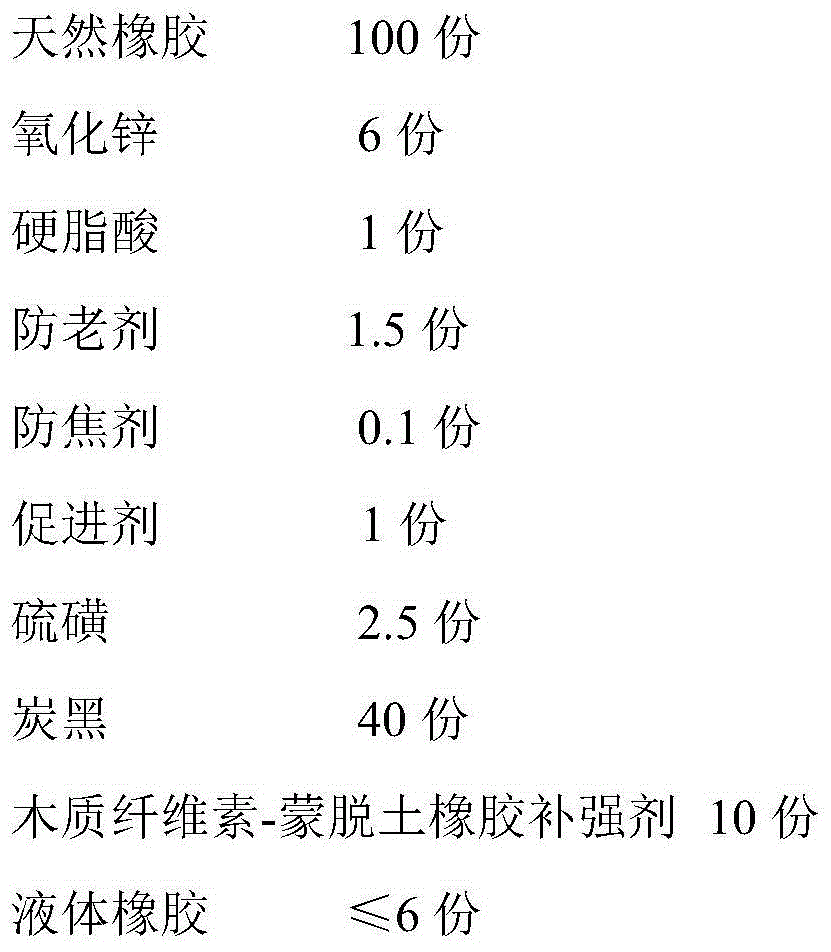

Embodiment 3

[0041] A rubber composite material, consisting of the following components by weight: 100 parts of natural rubber, 6 parts of zinc oxide, 1 part of stearic acid, 1.5 parts of antioxidant 4010NA, 0.7 part of accelerator CZ, 0.1 part of anti-scorch agent CTP, Carbon black N33040 parts, lignocellulose-montmorillonite rubber reinforcing agent 10 parts, liquid rubber LBR3074 parts, sulfur 2.5 parts and accelerator TMTD 0.3 parts.

[0042] The preparation method of the rubber composite material of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com