Patents

Literature

185results about How to "Enhanced Interfacial Interaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene-containing insulated radiating composition and preparation and application thereof

ActiveCN103804942AHigh thermal conductivityImprove mechanical propertiesCoatingsPigment treatment with organosilicon compoundsHeat conductingGraphene

The invention discloses a graphene-containing insulated radiating composition and preparation and application thereof. The composition comprises the components of silica-coating graphene, insulated heat-conducting filler, a surface treating agent, and a function additive. The preparation method comprises the following steps of: hydrolyzing ethyl silicate on the graphene surface by the sol-gel method to obtain graphene coated with a silica film on the surface; adding the surface treating agent to a mixture of the insulated heat-conducting filler and modified graphene; uniformly agitating; then adding the function additive; and uniformly dispersing to obtain the insulated radiating composition. The composition has the advantages that the graphene is processed by insulating and coating, and the insulated heat-conducting filler and additive of other forms are coordinately added, thus the composition shows high radiating improvement effect in the plastic cement and coating fields; and the composition can be widely applied to a heating element and a radiating facility of various electronic products and electrical equipment, and can greatly improve the radiating effect as well as prolong the service life of devices.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

A water tree-resistant polyolefin cable material and a preparation method thereof

ActiveCN103289162AShorten the lengthExcellent water tree resistancePlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

The invention discloses a water tree-resistant polyolefin cable material and a preparation method thereof. The water tree-resistant polyolefin cable material comprises, by mass, 70 to 95 parts of low density polyethylene, 5 to 30 parts of water tree resistant masterbatch, 1 to 2 parts of a crosslinking agent, 0.3 to 0.5 parts of a crosslinking coagent, 1 to 2 parts of an antioxidant, and 0.1 to 0.5 parts of a rheology modifier. Porous particles in the prepared water tree-resistant polyolefin cable material have adsorption characteristics, so that a more uniform distribution of water is obtained, water will not gather to be droplets, the probability of water tree growth is reduced by 50% or more than that of a conventional cross-linked polyethylene cable material, and the water tree-resistant polyolefin cable material of the invention has excellent water tree resistance; an elastic modulus ratio increases by 30% than that of a conventional cross-linked polyethylene cable material, so the water tree-resistant polyolefin cable material of the invention has excellent mechanical strength and toughness; and the water tree-resistant polyolefin cable material of the invention meet electrical performance standards of chemically cross-linked polyethylene insulation materials used for medium / low-voltage cable, etc., and has good processability.

Owner:XI AN JIAOTONG UNIV

Electric insulation heat-conducting resin composite material and preparation method thereof

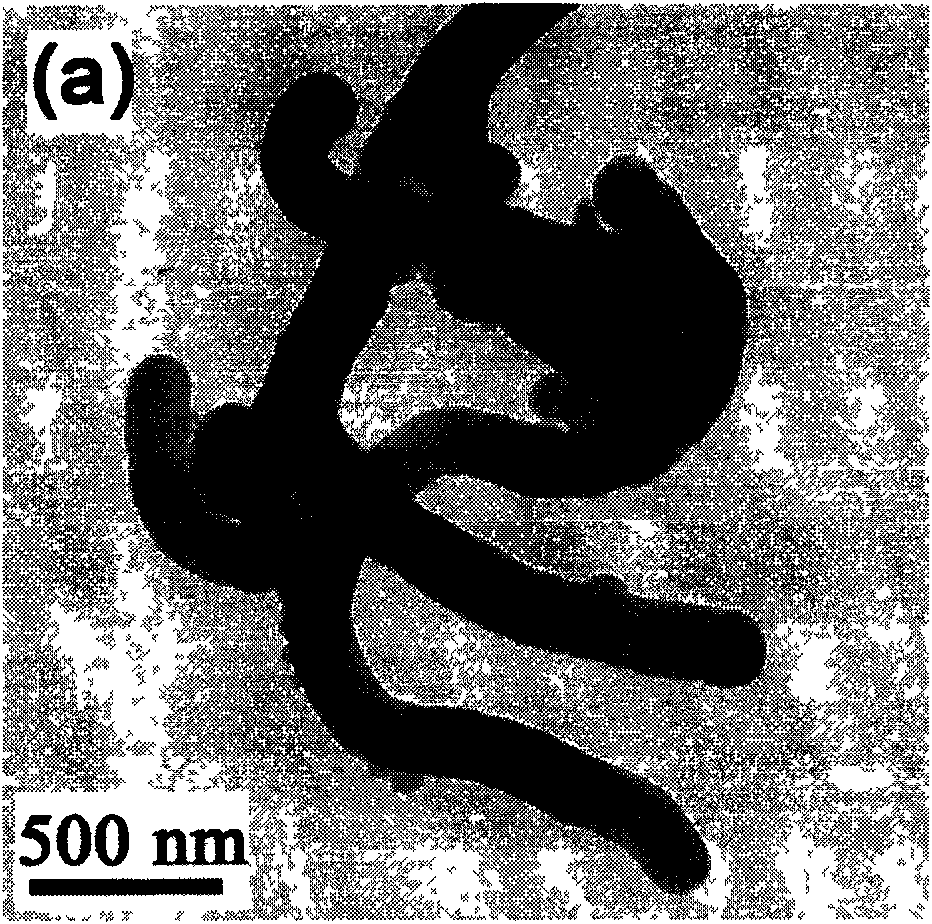

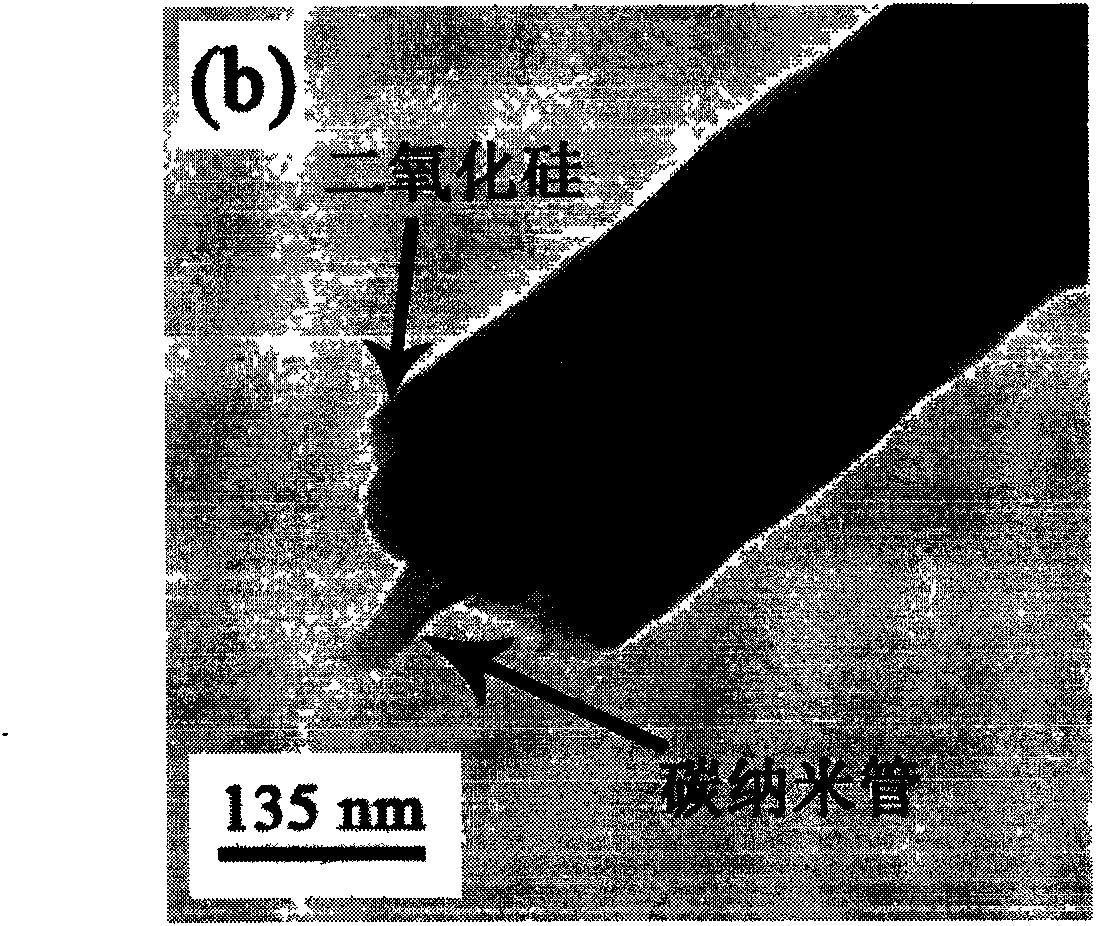

ActiveCN101597418AHigh thermal conductivityImprove insulation performanceInorganic pigment treatmentEpoxyHeat conducting

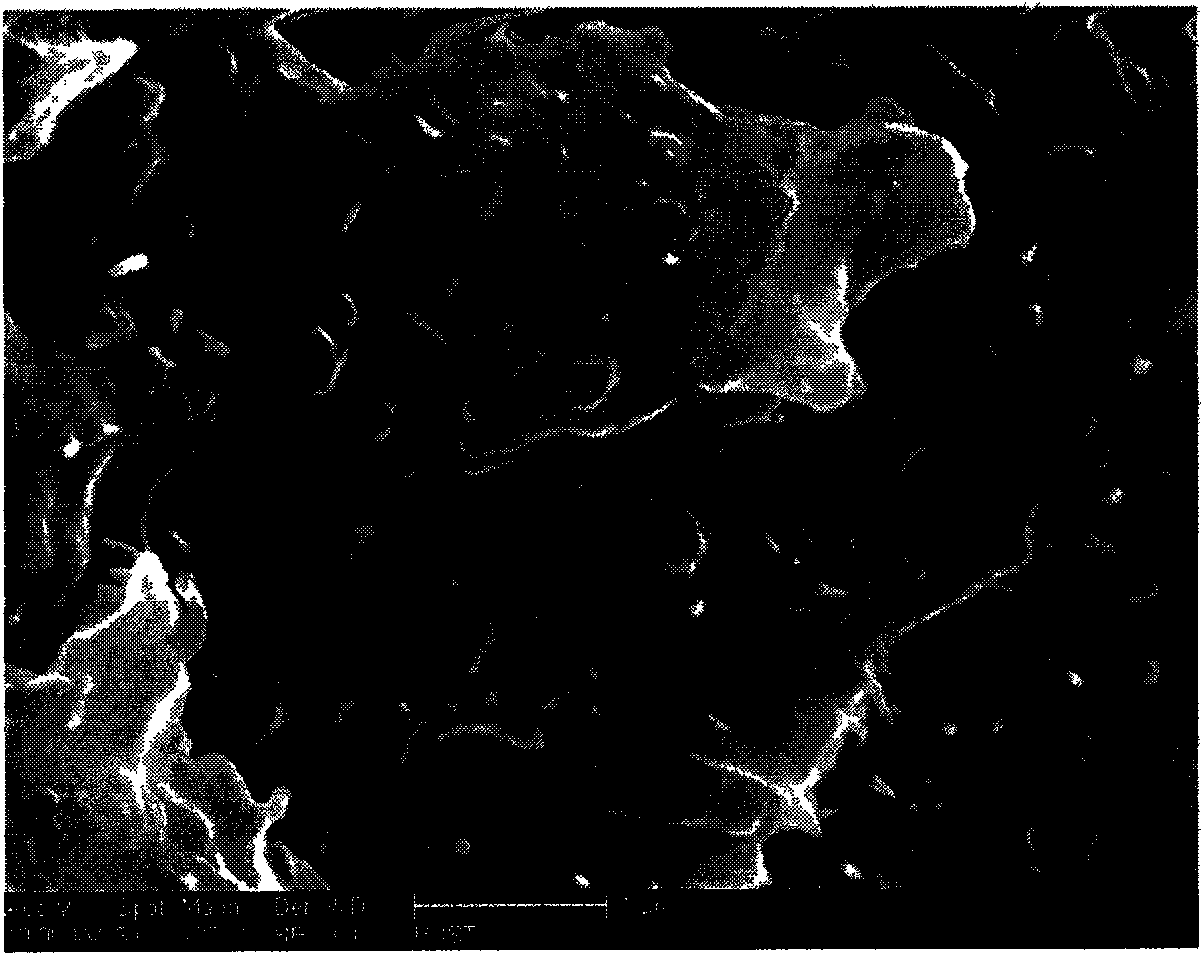

The invention provides a silicon dioxide-coated carbon nano tube-epoxide resin composite material with electric insulation property and high heat-conducting effect and a preparation method thereof, aiming at solving the defects of low coefficient of heat conductivity and the lack of electric insulation property of the existing carbon nano tube-filled composite materials. The steps are as follows: the sol-gel method is used for preparing SiO2-coated carbon nano tubes, and the tubes are dispersed in epoxide resin and then are solidified and molded. The material of the invention has the advantages that the use level of the silicon dioxide-coated carbon nano tube is low, the material can be favorably dispersed in the epoxide resin, the heat-conducting property of the carbon nano tube is played, and the surface of the carbon nano tube is enabled to be insulating, thereby improving the heat-conducting property of a polymer and meeting the requirement on electrical insulation property.

Owner:HUAZHONG UNIV OF SCI & TECH

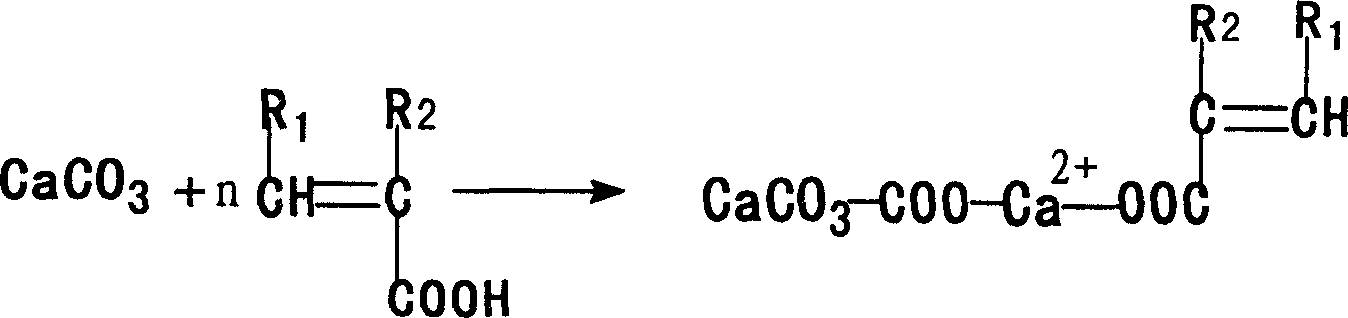

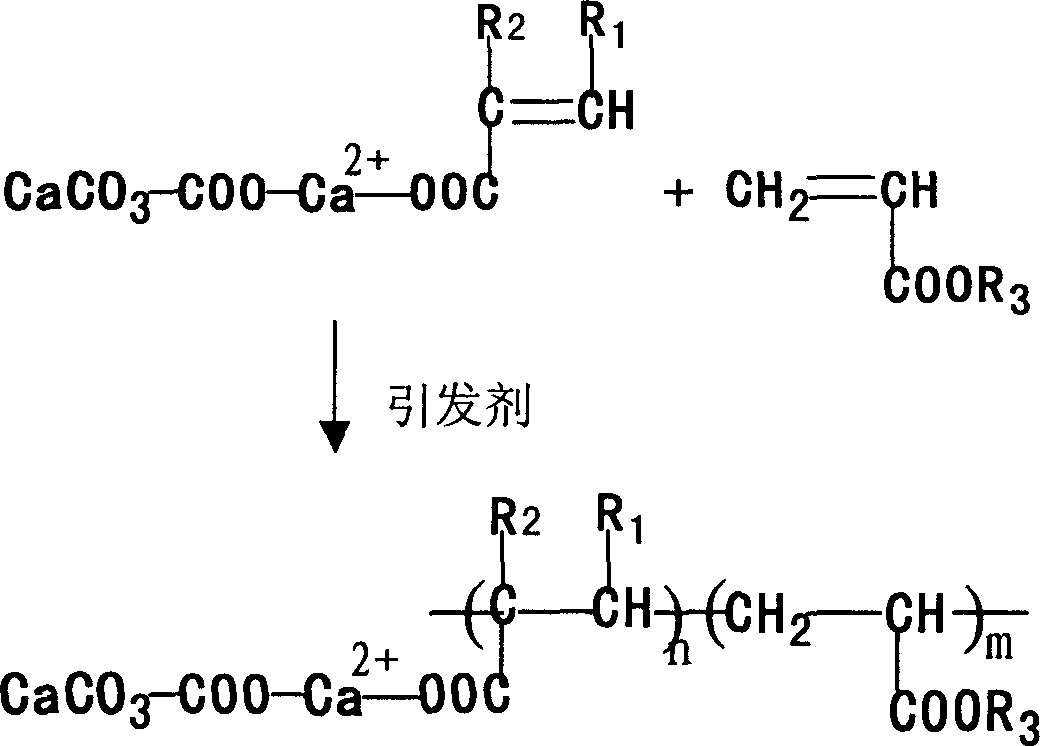

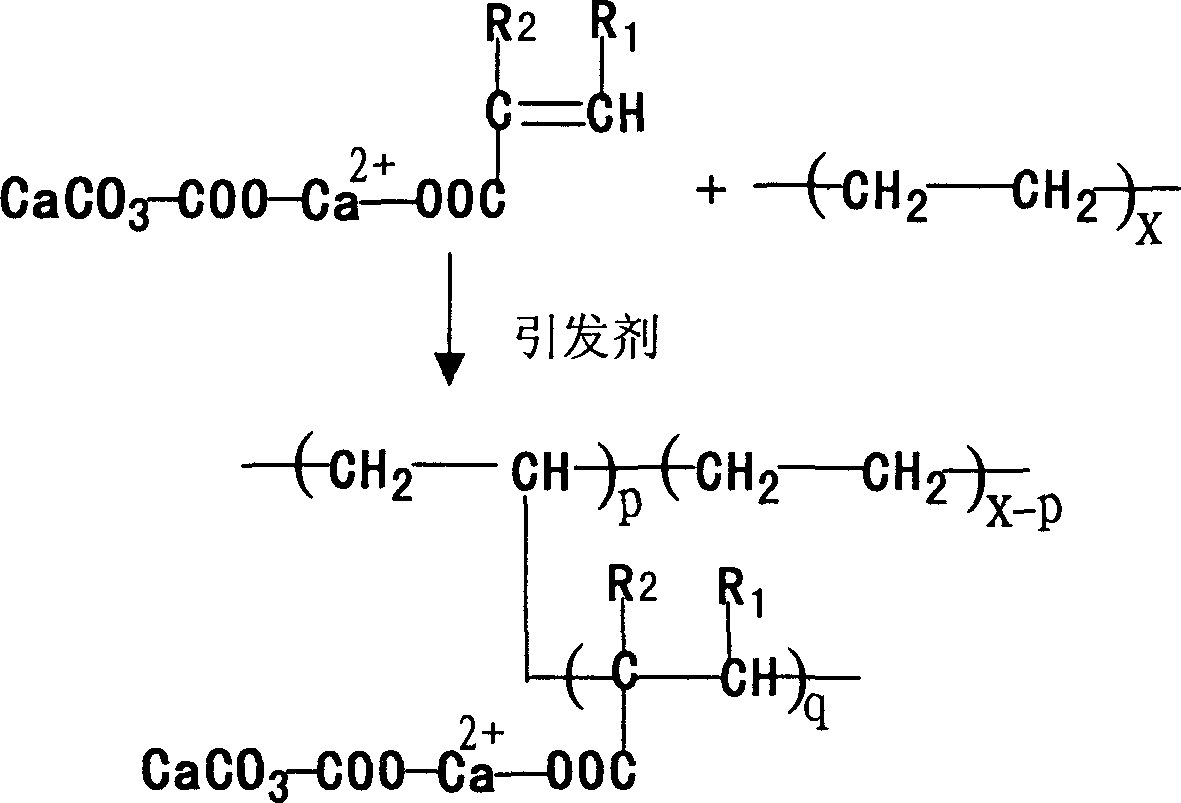

Process for preparing predispersed masterbatch of polyolefin and nano calcium carbonate

The invention relates to a method for preparation of predispersed master batch of polyolefin / nano-alcium carbonate, which includes: (1) adding nano-alcium carbonate into the kneading machine, afterwards, adding unsaturated acid monomer, long fatty chain monomer, initiating agent, polyethersulfonate, macromolecular coupling agent and polyolefin resin in turn, and kneading for 0.5-5 minutes; (2) discharging mixtures into the twin-screw extruder to perform squeezing, granulating and drying, then obtaining the predispersed master batch of polyolefin / nano-alcium carbonate, with a speed of host machine of twin-screw extruder of 50-600 revolutions per minute, a feeding speed of 20-400 revolutions per minute, a heating-up temperature of 80-220 DEG C; the invention is of few job steps, strong interaction between polyolefin and nano-alcium carbonate and is liable to disperse in the polymeric matrix. The said predispersed master batch of polyolefin / nano-alcium carbonate obtained by this invention can be widely used in enhancing, toughening and modifying various plastics, specially adapted for preparation of polyolefin permeability films and so on.

Owner:SOUTH CHINA UNIV OF TECH

3D printing molding method

A disclosed 3D printing molding method is characterized by comprising: mixing a polymer, an auxiliary agent and a solvent to obtain a paste, using the paste to perform 3D printing, and printing a layer again after the solvent of a previous layer is volatilized. The provided method is suitable for multiple polymer materials, and because of the effect of the solvent, 3D printing can be directly performed without any additional adhesives. A dissolving or swelling method is combined with the 3D printing technology, molding is realized without heating to a melting temperature or more, energy consumption is reduced and cost is saved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

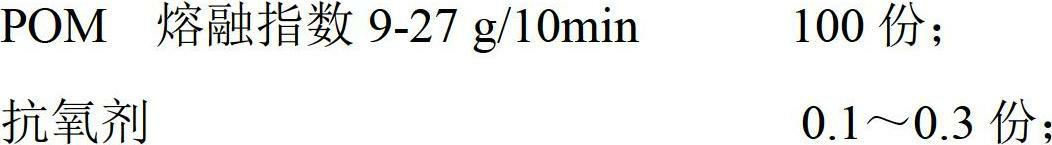

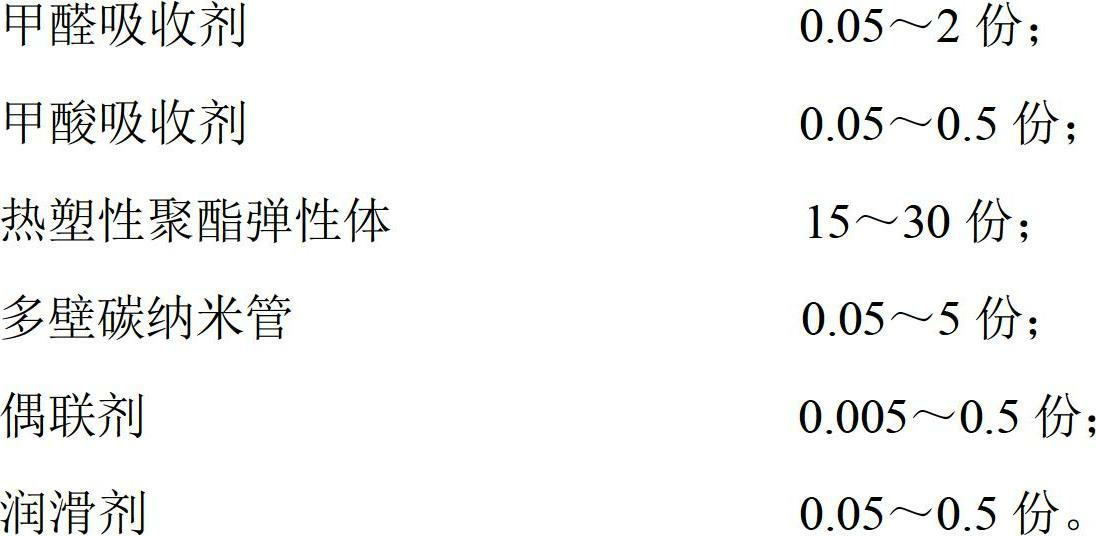

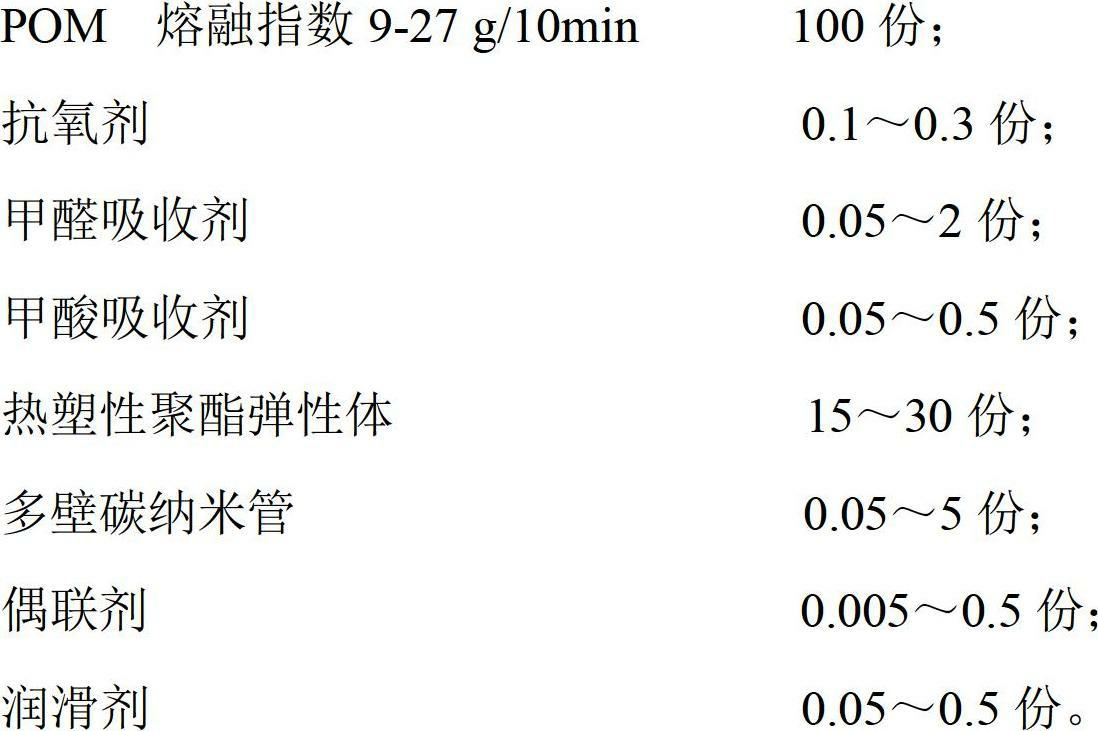

Reinforced and toughened polyformaldehyde and preparation method thereof

The invention discloses reinforced and toughened polyformaldehyde, which is prepared from the following components through a preparation method comprising the following steps: adding 10 parts of POM (polyoxymethylene) resin, 0.1-0.3 part of antioxidant, 0.05-2 parts of formaldehyde absorber, 0.05-0.5 part of formic acid absorber, 15-30 parts of thermoplastic polyester elastomer, 0.05-5 parts of functionalized multi-wall carbon nano tube subjected to surface treatment and 0.05-0.5 part of lubricant into a high-speed mixer and mixing, melting and mixing by an exhaust type double-screw extruder, extruding and pelleting to obtain the reinforced and toughened polyformaldehyde, wherein a rotating speed of screws is 50-200 revolutions per minute, and temperature of a charging barrel is 140-220 DEG C. The thermoplastic polyester elastomer with higher heat stability and excellent strength and toughness is adopted, and the functionalized multi-wall carbon nano tube with higher length-diameter ratio and better compatibility with a POM matrix, is composited with the POM so as to realizing reinforcing and toughening for the POM, so that a notch impact strength of the polyformaldehyde reaches about 25 KJ / m<2>, and a higher tensile strength is kept and reaches 41-45 MPa.

Owner:YANKUANG GRP CO LTD

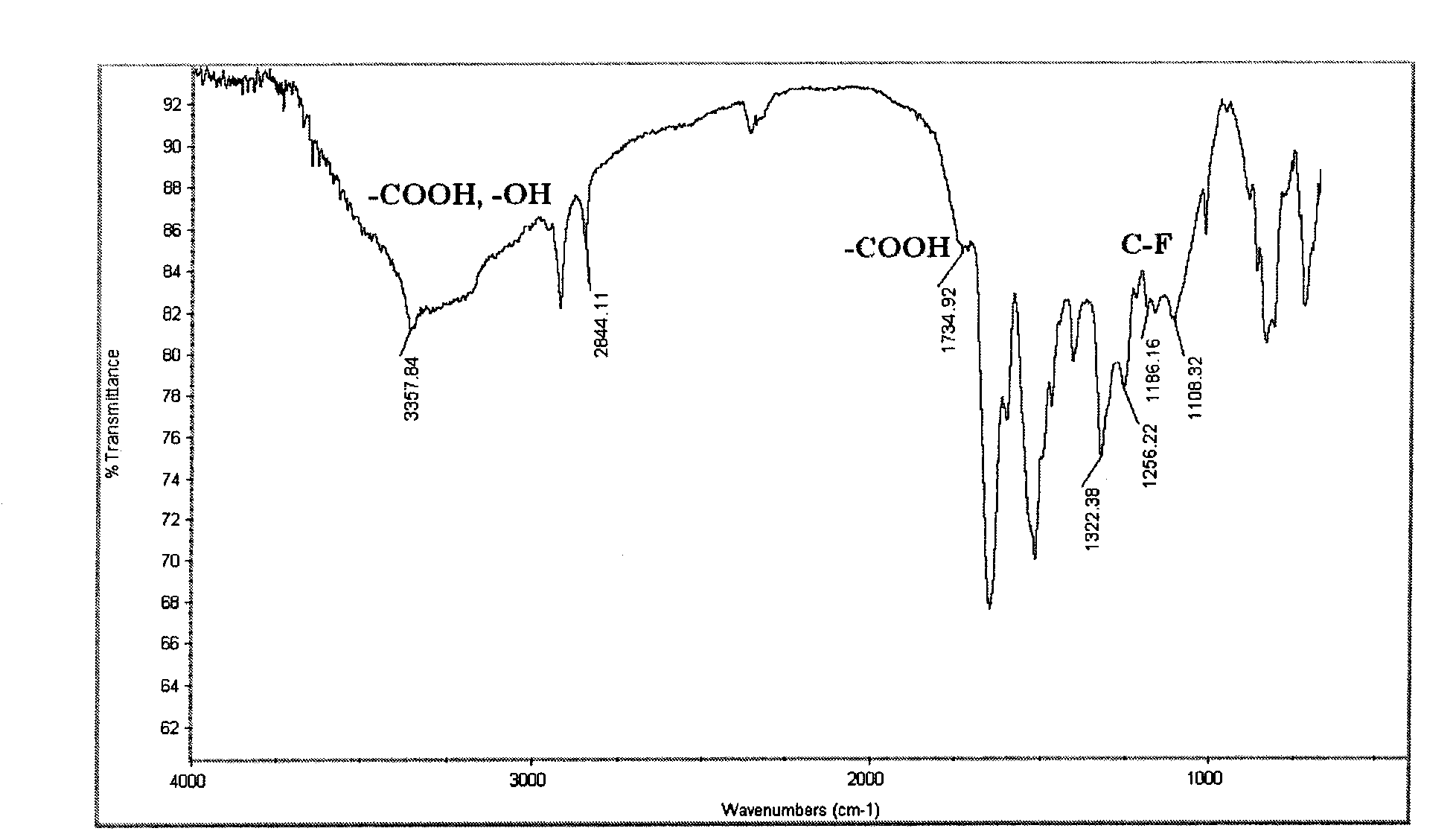

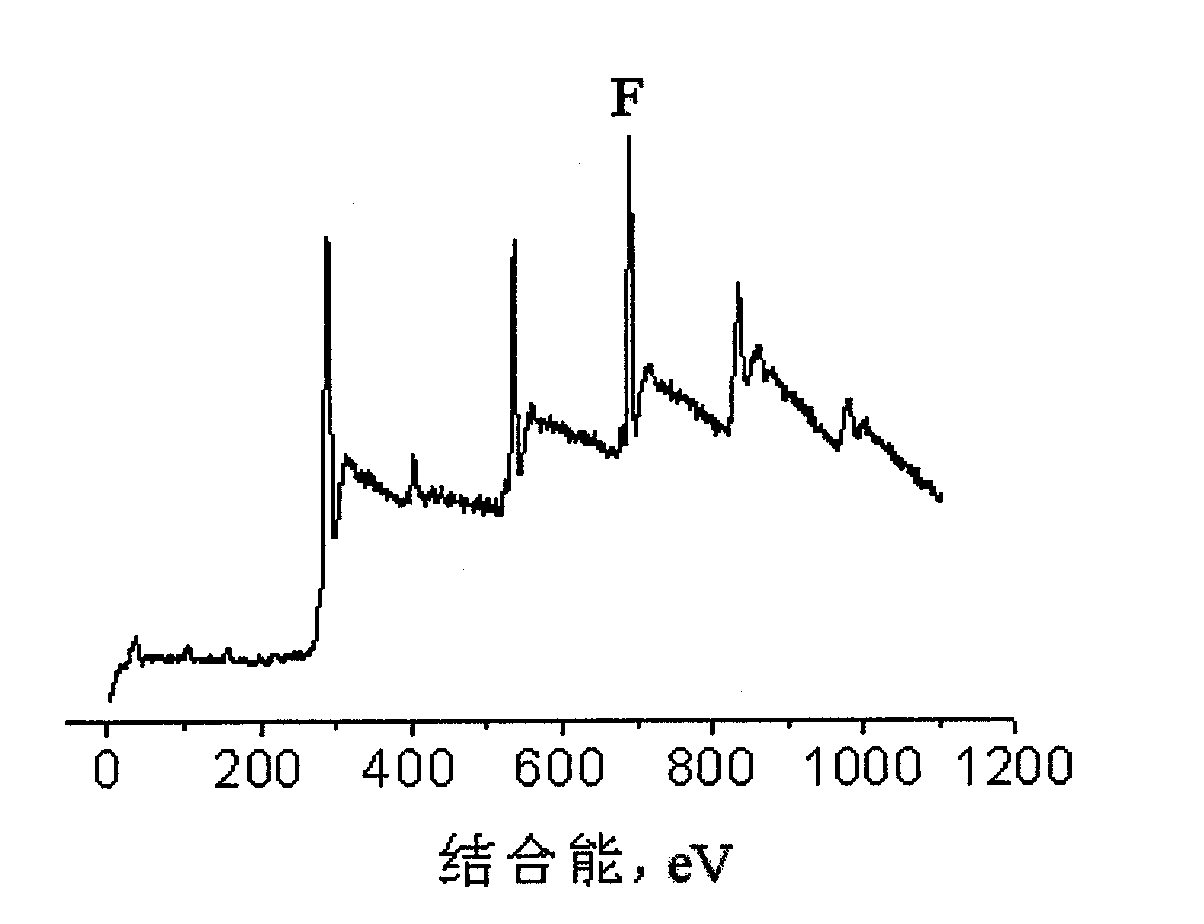

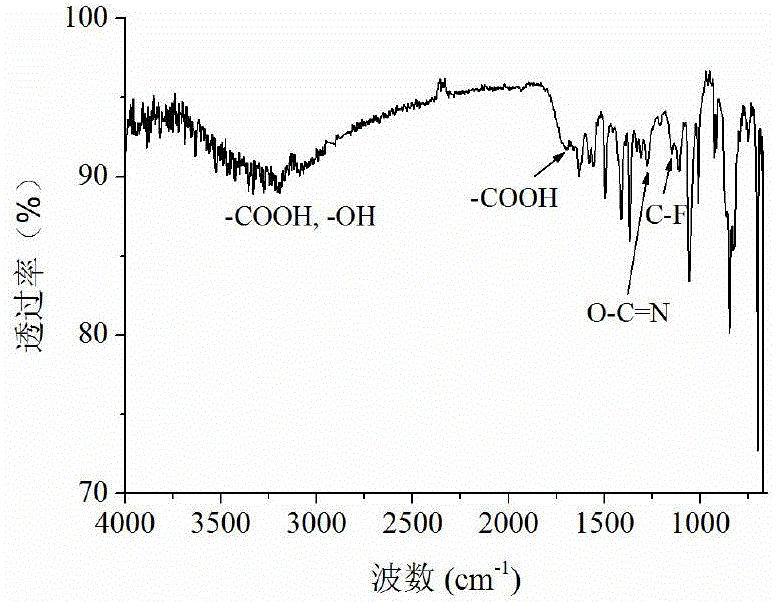

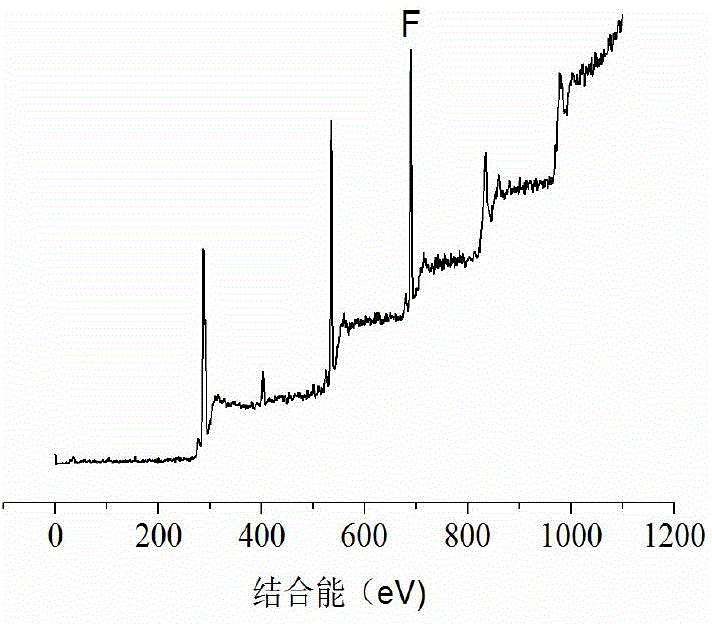

Aramid III fiber with fluorine-containing surface and preparation method thereof

InactiveCN101798748AHigh activityImprove mechanical propertiesFibre typesMonocomponent copolyamides artificial filamentAfter treatmentBiological activation

The invention discloses an aramid III fiber with a fluorine-containing surface, which is characterized in that: the surface of the fiber contains a carbon-fluorine covalent bond structure and a carboxyl-hydroxyl group; the contact angle between the surface of the fiber and water is 68 to 82 degrees; the shear strength between composite material layers prepared from the fiber is 47.3 to 55 MPa; and the tensile strength of gum dipped filaments is 4.6 to 5.4 GPa, and the tensile modulus is 145 to 168 GPa. The invention also discloses a method for preparing the aramid III fiber with the fluorine-containing surface. The fiber surface hydrophilicity of the aramid III fiber subjected to fluoridation is obviously improved; and the shear strength between the prepared composite material layers, and the tensile strength and the tensile modulus of the gum dipped filaments all can be improved by 20 to 30 percent. The method has the advantages of high fluoridation rate, short treatment time, can continuous surface treatment for the fiber on line, high stability of the surface activation effect after treatment, low cost and good application prospects.

Owner:SINOSELEN HI TECH

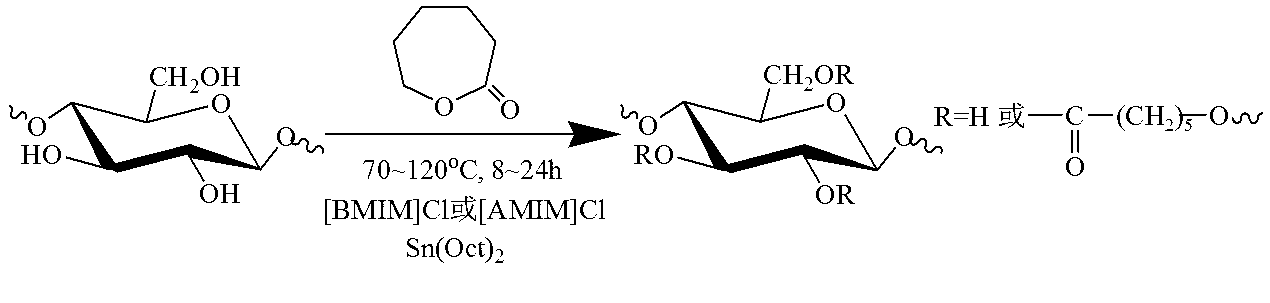

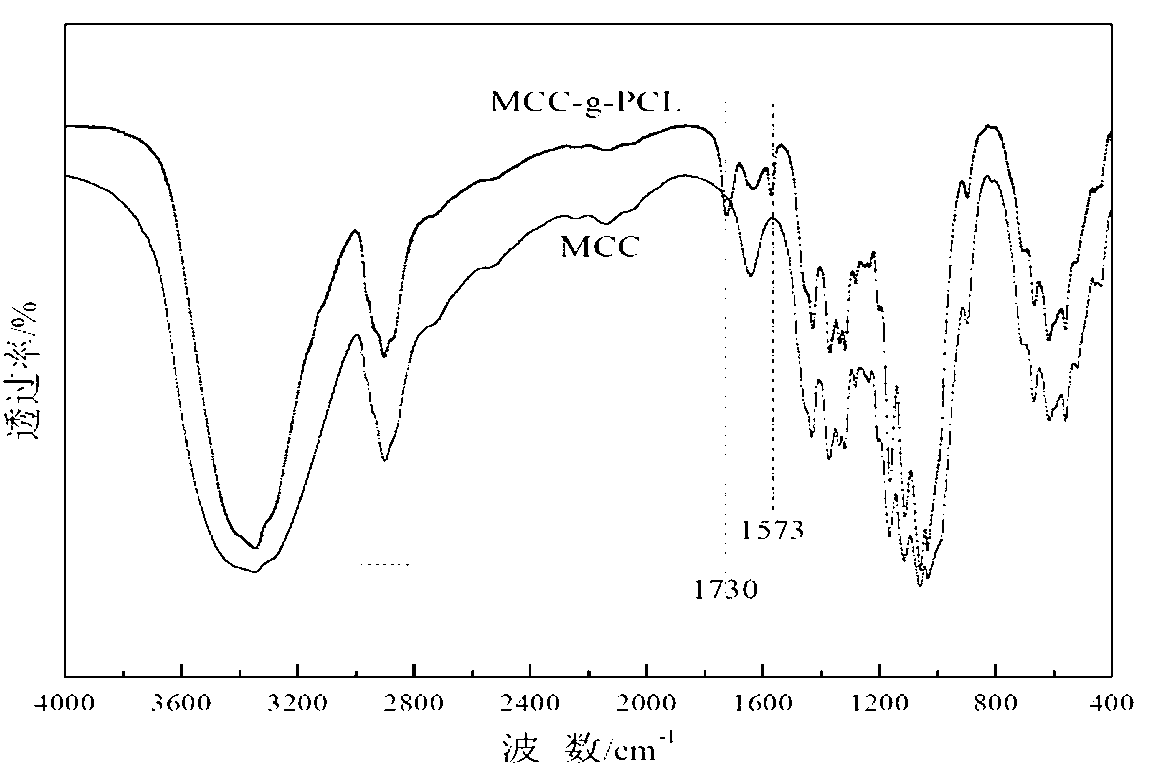

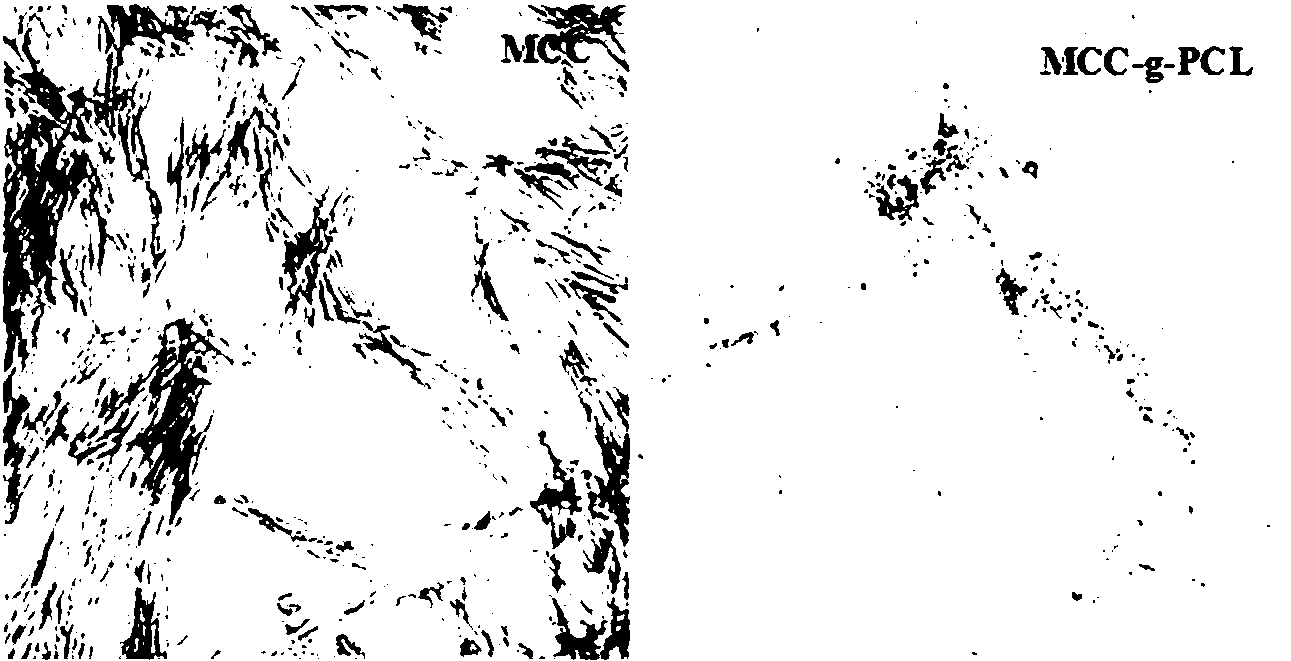

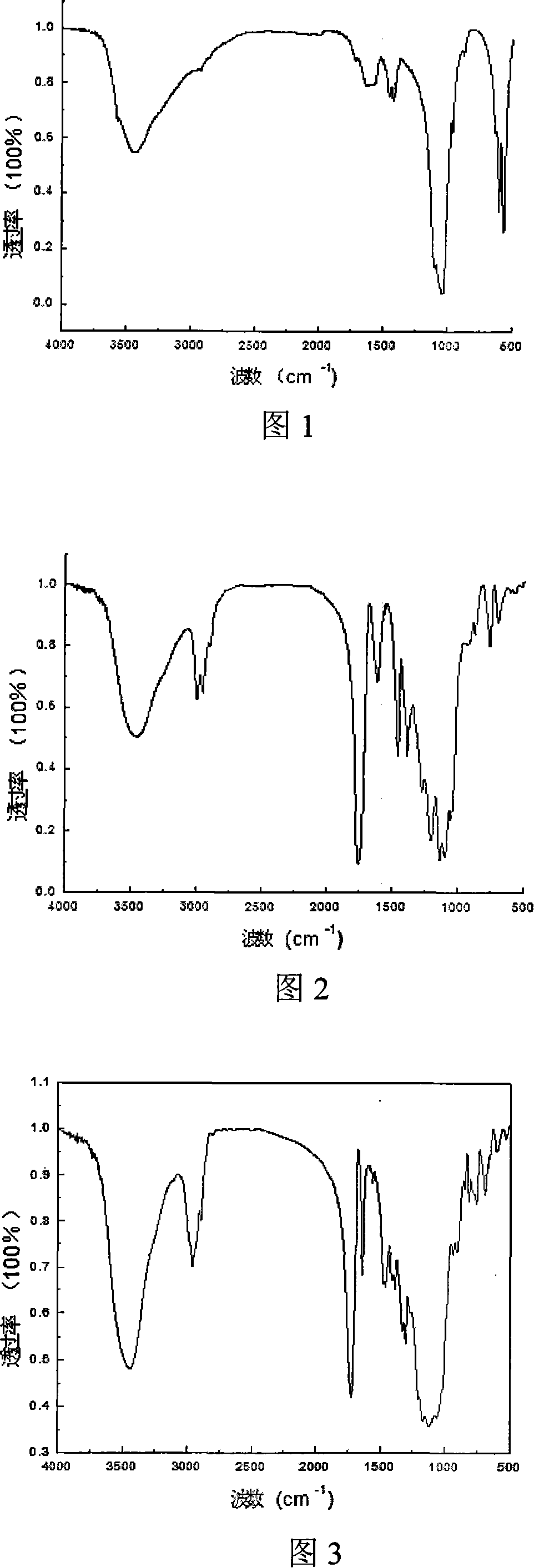

Natural polysaccharide-grafted polycaprolactone in ionic liquid as well as preparation method and application thereof

The invention relates to a preparation method of natural polysaccharide-grafted polycaprolactone in ionic liquid. The preparation method comprises the following steps of: (1) carrying out pretreatment on a raw material; (2) dissolving natural polysaccharide in ionic liquid; (3) grafting the natural polysaccharide in the ionic liquid with polycaprolactone: in a nitrogen atmosphere, slowly dropping a caprolactone monomer and rapidly adding a catalyst, magnetically stirring, controlling temperature at 70-115 DEG C and reacting for 12-24hours; and (4) precipitating by ethanol to obtain a crude product, adding methylene dichloride, magnetically stirring for 72hours, filtering, washing and drying to obtain the final product: natural polysaccharide-grafted polycaprolactone. The preparation method disclosed by the invention is green and environment-friendly, low in cost, and simple and efficient in process; and the obtained material can be completely biodegraded and directly processed and shaped or used as a cosolvent of other blending materials.

Owner:WUHAN UNIV OF TECH

Method of preparing compound osseous tissue renovating material interconsistency agent of polylactic acid/hydroxyapatite

The invention relates to a method for preparing an inclusive agent of a polylactic acid or hydroxyapatite composite bone tissue restoring material, which comprises the following steps: getting processed hydroxyapatite by refluxing hydroxyapatite in the alcohol solution with surface modifier as the coupler for 12-48 hours; dissolving polylactic acid macromole monomer with terminal ethenyl and the processed hydroxyapatite in the organic solvent with initiating agent; protecting with nitrogen; extracting after extracting and drying the reactor; separating and purifying no-grafted polylactic acid macromole monomer; extracting the remainder; drying; getting the inclusive agent. The inclusive agent has the wide application, the low cost, the simple method, the mild synthesis condition, the strong utility and the easy industry production, which provides the boundary interaction of the organic or inorganic phase in polylactic acid or hydroxyapatite composite bone tissue restoring material, and improves the ergology property of bone tissue restoring material.

Owner:JINAN UNIVERSITY

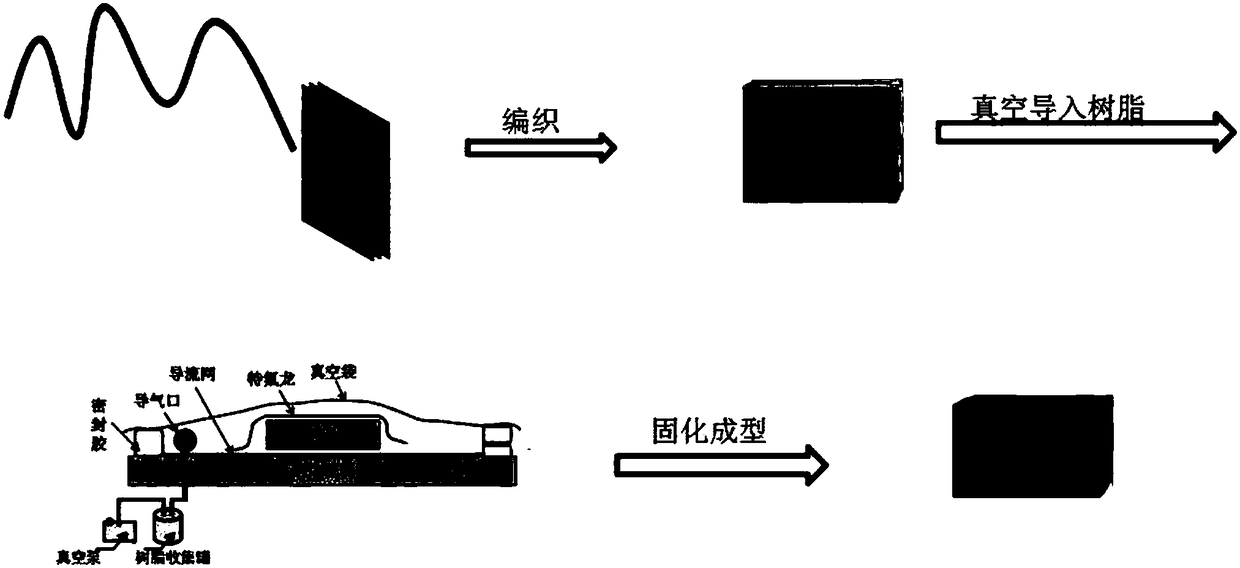

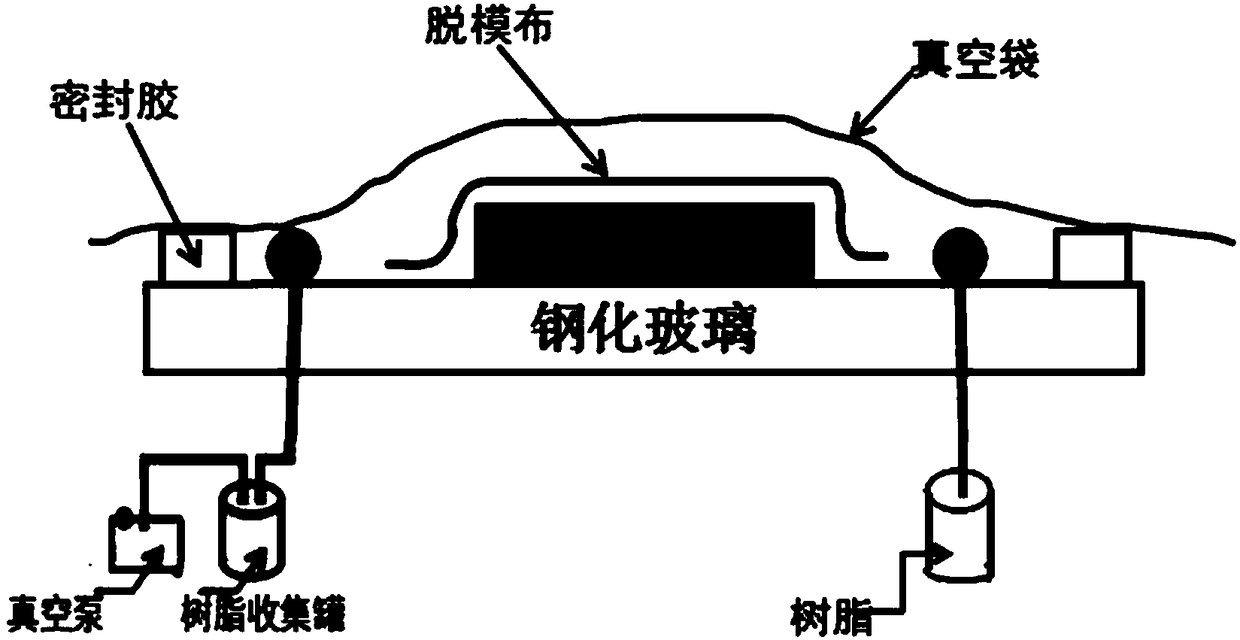

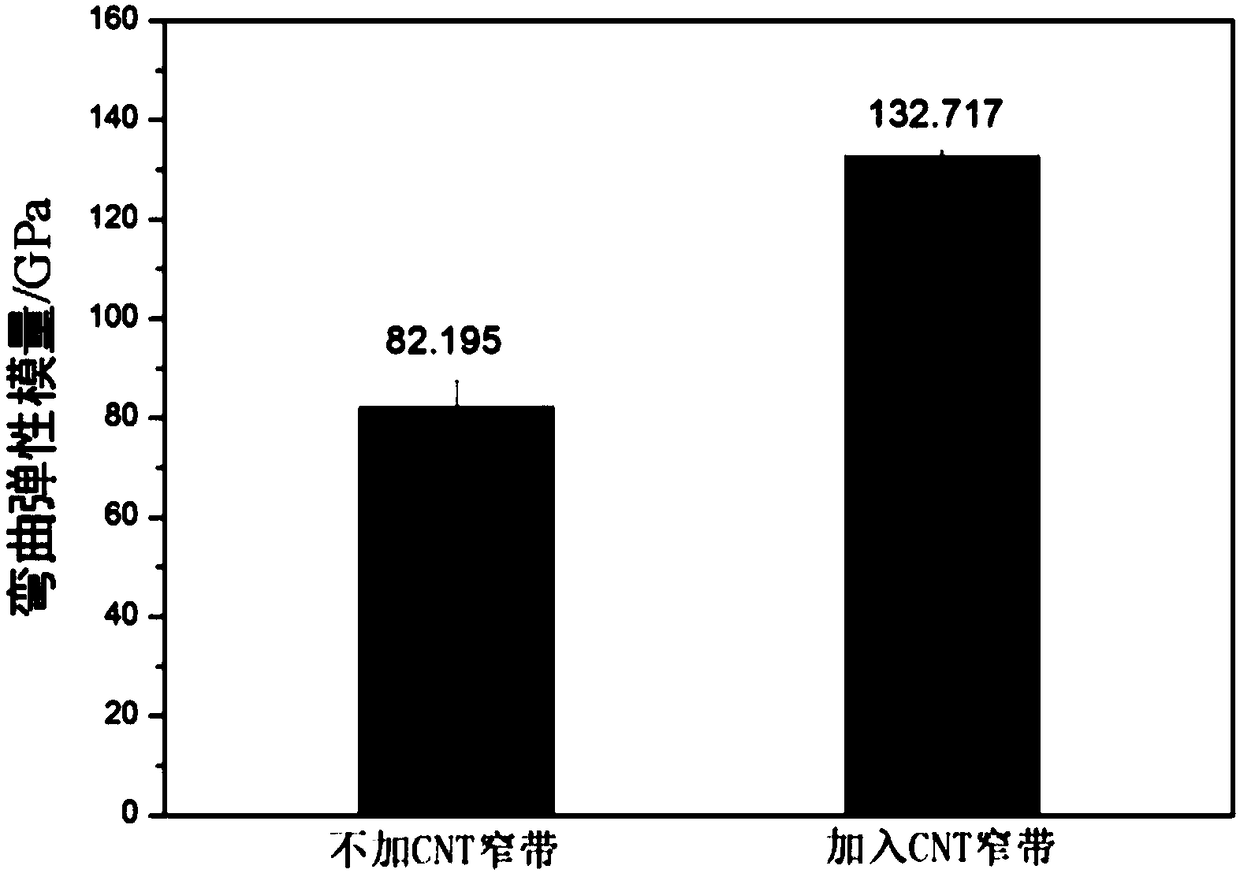

Interlayer toughened composite material and preparation method and application thereof

The invention discloses an interlayer toughened composite material and a preparation method and an application thereof. The preparation method comprises the following steps that a reinforcing body isprovided, the reinforcing body comprises a plurality of first fiber aggregates which are stacked in the thickness direction of the reinforcing body, wherein the first fiber aggregates comprise a plurality of first fibers which are arranged in a specified direction in an orientation manner; at least one braided body is woven with the plurality of first fiber aggregates in the thickness direction ofthe reinforcing body to form the braided structure, wherein each braided body continuously penetrates between every two adjacent first fibers in two or more first fiber aggregates; the weaving structure is soaked in a fluid containing a curable resin material, then curing treatment is carried out, and the interlayer toughened composite material is formed. According to the composite material and the method and the application, the nano-carbon material strips and the like are adopted as the weaving body to weave the reinforcing body in the thickness direction, gaps are avoided between the reinforcing bodies due to the fact that the strips are added, so that a large stress concentration point does not exist in the composite material, and the interlayer toughening performance of the compositematerial is improved.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Modified resin material for heat conduction and heat dissipation, preparation method and application of material

The invention relates to a modified resin material for heat conduction and heat dissipation, a preparation method and an application of the material, and mainly solves the problem of insufficient toughness of a heat dissipation material when the amount of a heat conduction filler is high in the prior art. The modified resin material used for heat conduction and heat dissipation comprises the following components in parts by weight: (A) 30-70 parts of matrix resins; (B) 20-60 parts of heat conduction fillers; (C) 0.1-20 parts of toughening agents; (D) 0-10 parts of other auxiliary agents. The modified resin material can better solve the problem, and can be used in industrial production of heat dissipation components such as electronics, household appliances, automobiles, lighting and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

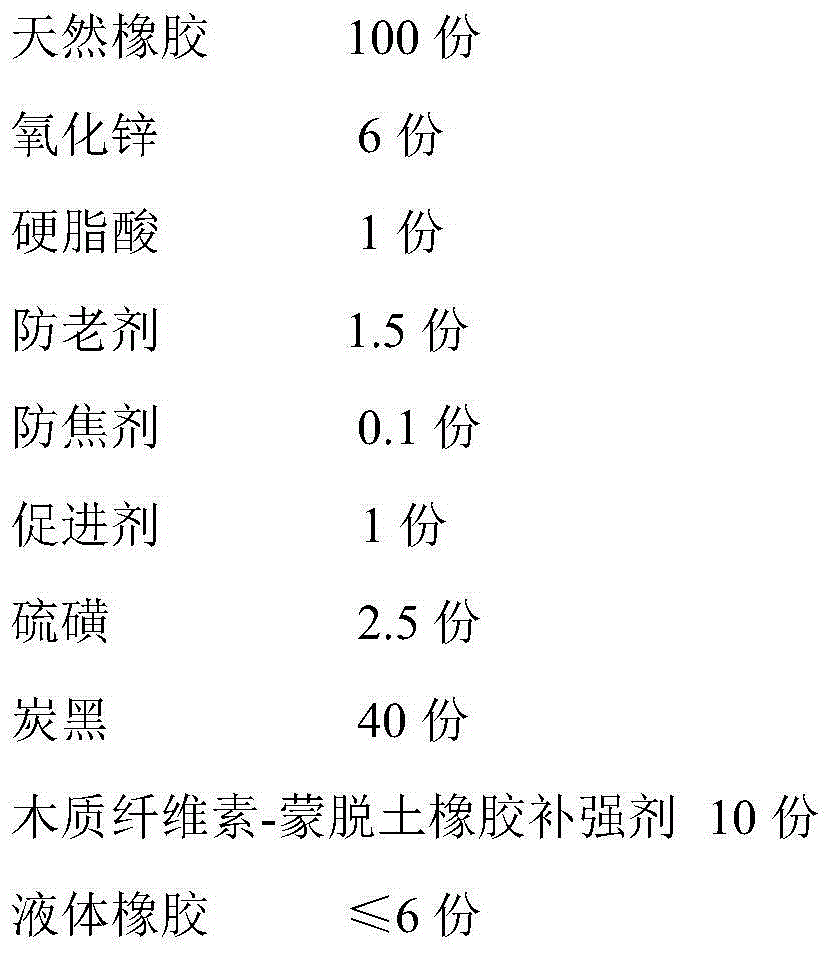

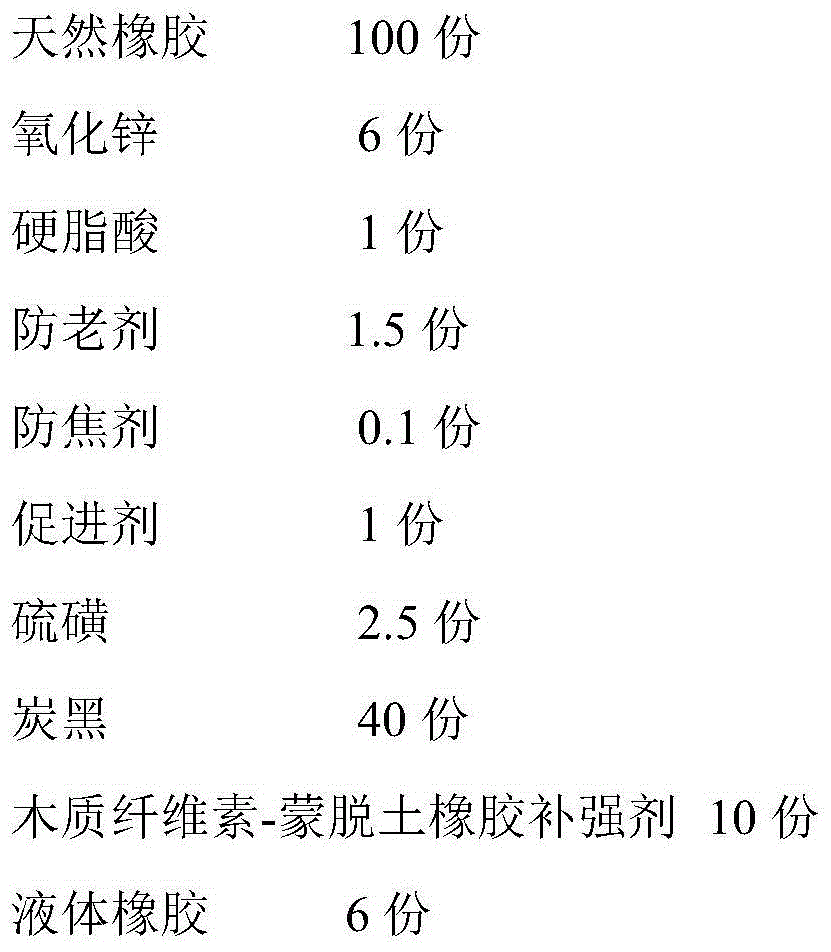

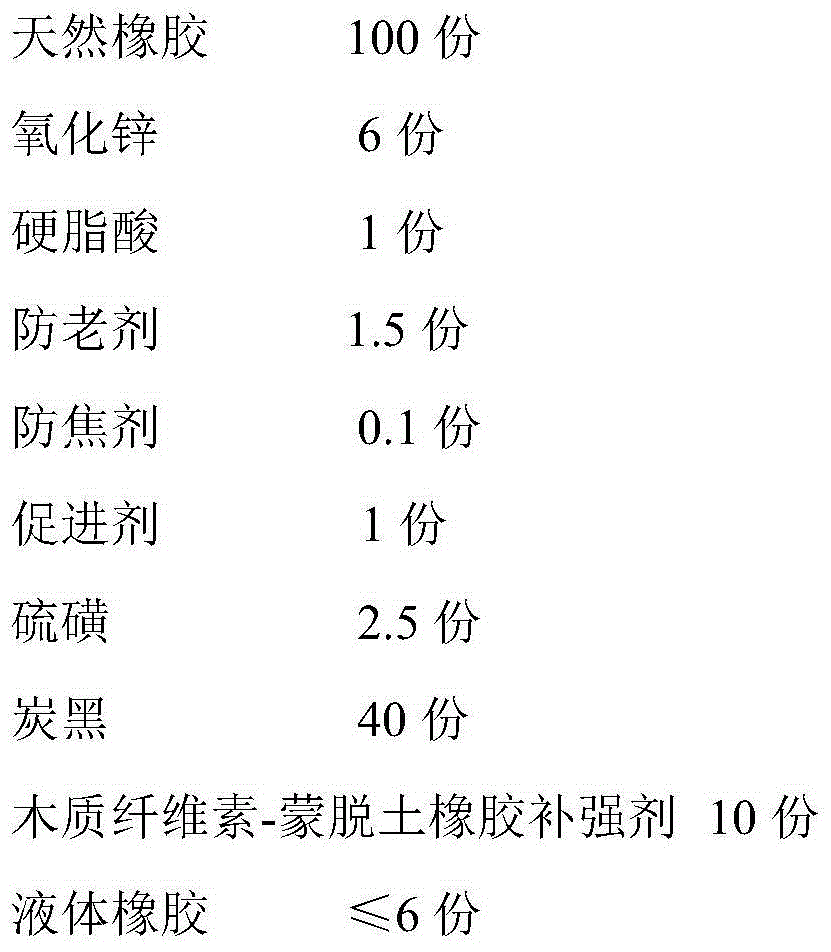

Rubber composite material and preparation method thereof

The invention provides a rubber composite material, which comprises the following components in parts by weight: 100 parts of natural rubber, 6 parts of zinc oxide, 1 part of stearic acid, 1.5 parts an antioxidant, 0.1 part of a scorch retarder, 0.7 part of an accelerator CZ, 0.3 part of an accelerator TMTD, 2.5 parts of sulfur, 40 parts of carbon black, 10 parts of a wood cellulose-montmorillonite rubber reinforcing agent, and less than or equal to 6 parts of liquid rubber. According to the composite material provided by the invention, the liquid rubber is added to a formula of rubber, so that the tensile strength and the elongation at break of rubber can be improved, the dispersion of the lignocellulose-montmorillonite reinforcing agent in a natural rubber matrix is improved, the interfacial interaction of the rubber and the wood cellulose-montmorillonite reinforcing agent is effectively enhanced, and the environment is protected. The invention also provides a preparation method of the rubber composite material. The preparation method has the advantages of simple process, low cost and easiness in industrial production.

Owner:合肥市和裕达塑业有限公司

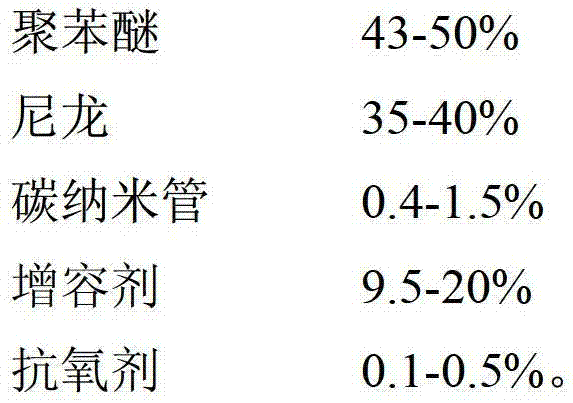

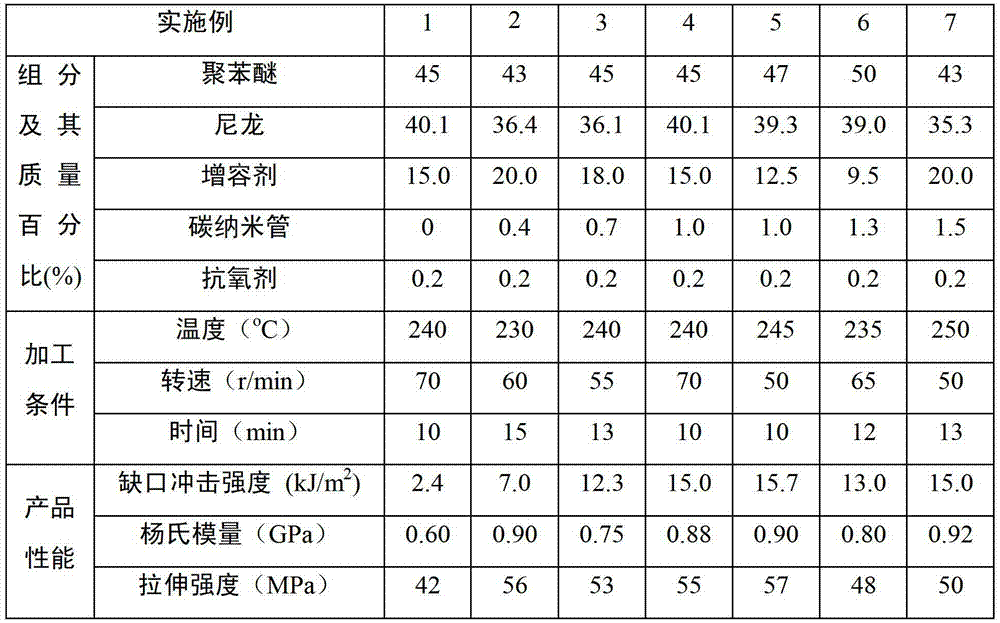

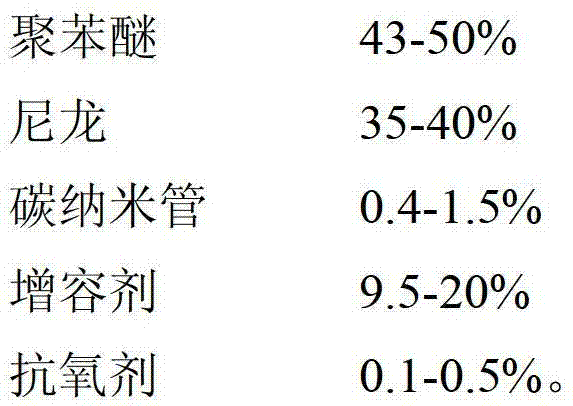

Composite material of polyphenyl ether/nylon/carbon nano tube and preparation method thereof

The invention relates to a composite material of polyphenyl ether / nylon / carbon nano tube and a preparation method thereof. The composite material is characterized by comprising the following components of 43-50% of polyphenyl ether, 35-40% of nylon, 0.4-1.5% of carbon nano tube, 9.5-20% of compatibilizer and 0.1-0.5% of antioxidant. The composite material of polyphenyl ether / nylon / carbon nano tube provided by the invention fully utilizes the characteristics that the carbon nano tube has high draw ratio, large specific surface area and good appetency on a polymer after polar treatment, and after the carbon nano tube is introduced to alloy, the mechanical property and the thermal property of the composite material are greatly improved; the prepared material is high in additional value; the application of the polyphenyl ether / nylon alloy in higher end field is expanded; and the requirements on high-performance materials in the fields such as electronics and electrical, aerospace, national defense and military are met.

Owner:宁波福天新材料科技有限公司

Polyoxymethylene (POM) encapsulation material and preparation method thereof

ActiveCN102702664AEnhanced Interfacial InteractionGood capacity increasePolyoxymethyleneThermoplastic elastomer

The invention belongs to the field of composite materials, and discloses a polyoxymethylene (POM) encapsulation material and a preparation method thereof. The POM encapsulation material comprises the following components in part by weight: 50 to 60 parts of thermoplastic elastomer (TPE), 30 to 40 parts of plasticizer, 10 to 15 parts of propene polymer (PP), 5 to 10 parts of compatibilizer, and 0.5 to 1 part of other aid. A twin-screw extruder is used for pelleting and extrusion, and the temperature range is 180 to 200 DEG C. Compared with that of the prior art, the cohesiveness between a product and POM is obviously improved, so that by a multi-component injection method, the encapsulation material is widely applied to POM / TPE combination, mechanical anchoring such as expensive undercutting is not needed, the process is simplified, the development period of the product is shortened, and cost is reduced.

Owner:昆山聚威工程塑料有限公司

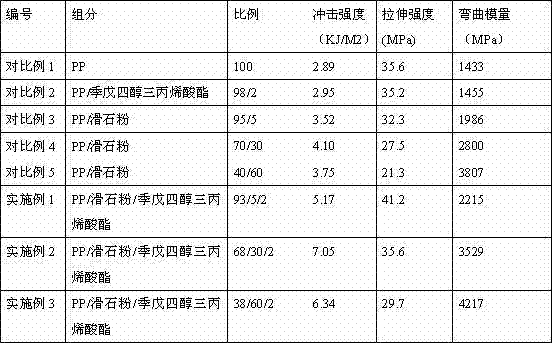

Strengthening and toughening polypropylene composite and preparation method thereof

ActiveCN102516655AEnhanced Interfacial InteractionAchieve high performancePolypropylene compositesPolymer science

The invention discloses a strengthening and toughening polypropylene composite, which comprises, by weight, 35 to 94 parts of polypropylene, 0.5 to 5 parts of polyfunctional monomer, 5 to 60 parts of inorganic filler and 0.2 to 4 parts of polypropylene universal antioxidant and processing agent. A preparation method of the strengthening and toughening polypropylene composite includes: mixing all components evenly, adding the components in a screw extruder to perform melt mixing reaction, extruding and prilling to obtain the strengthening and toughening polypropylene composite. In-situ graft reaction occurs in a melt mixing process through double bond of the polyfunctional monomer and polypropylene, simultaneously C=O bond of the polyfunctional monomer and hydroxy on the surface of the filler form hydrogen bond, interfacial interaction between the filler and a matrix is enhanced, thereby achieving high performance of the polypropylene composite. The obtained polypropylene composite not only has good toughness and rigidity, but also can restrain degradation of the polypropylene.

Owner:KINGFA SCI & TECH CO LTD +2

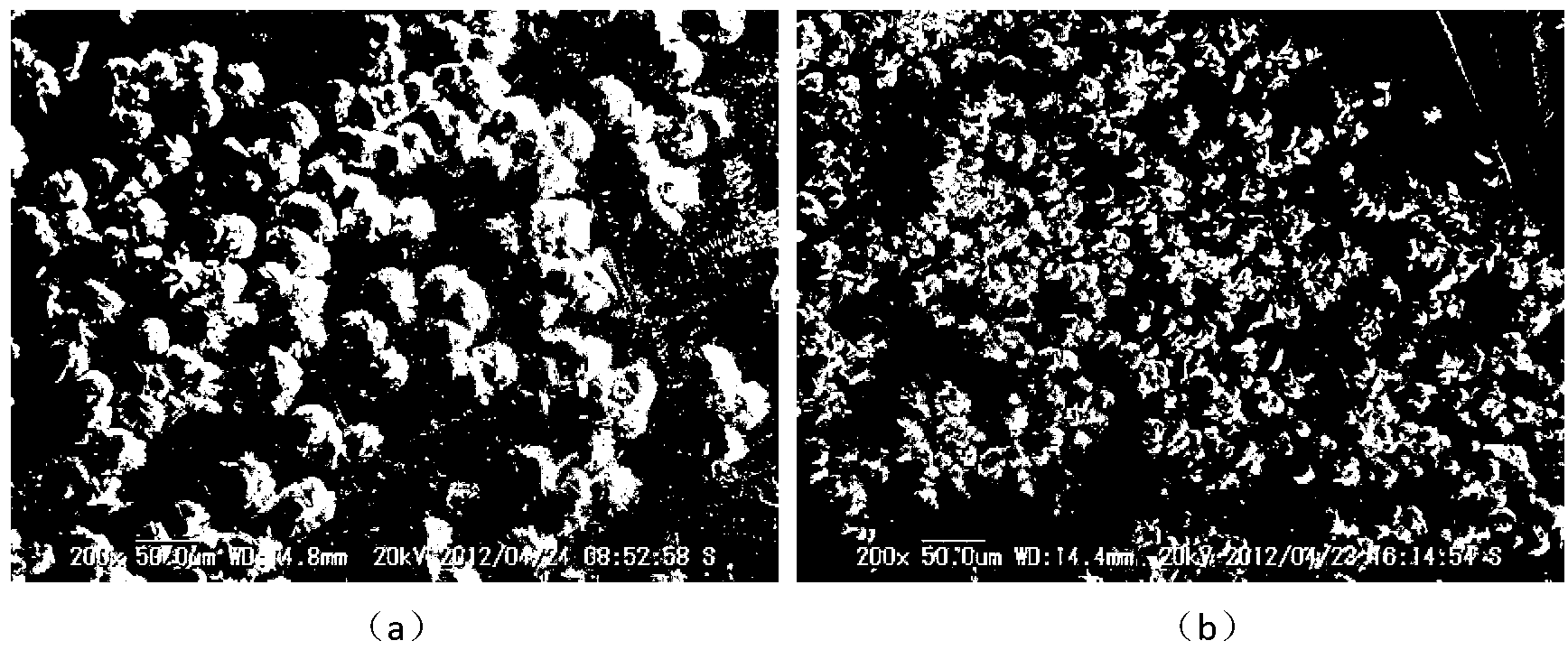

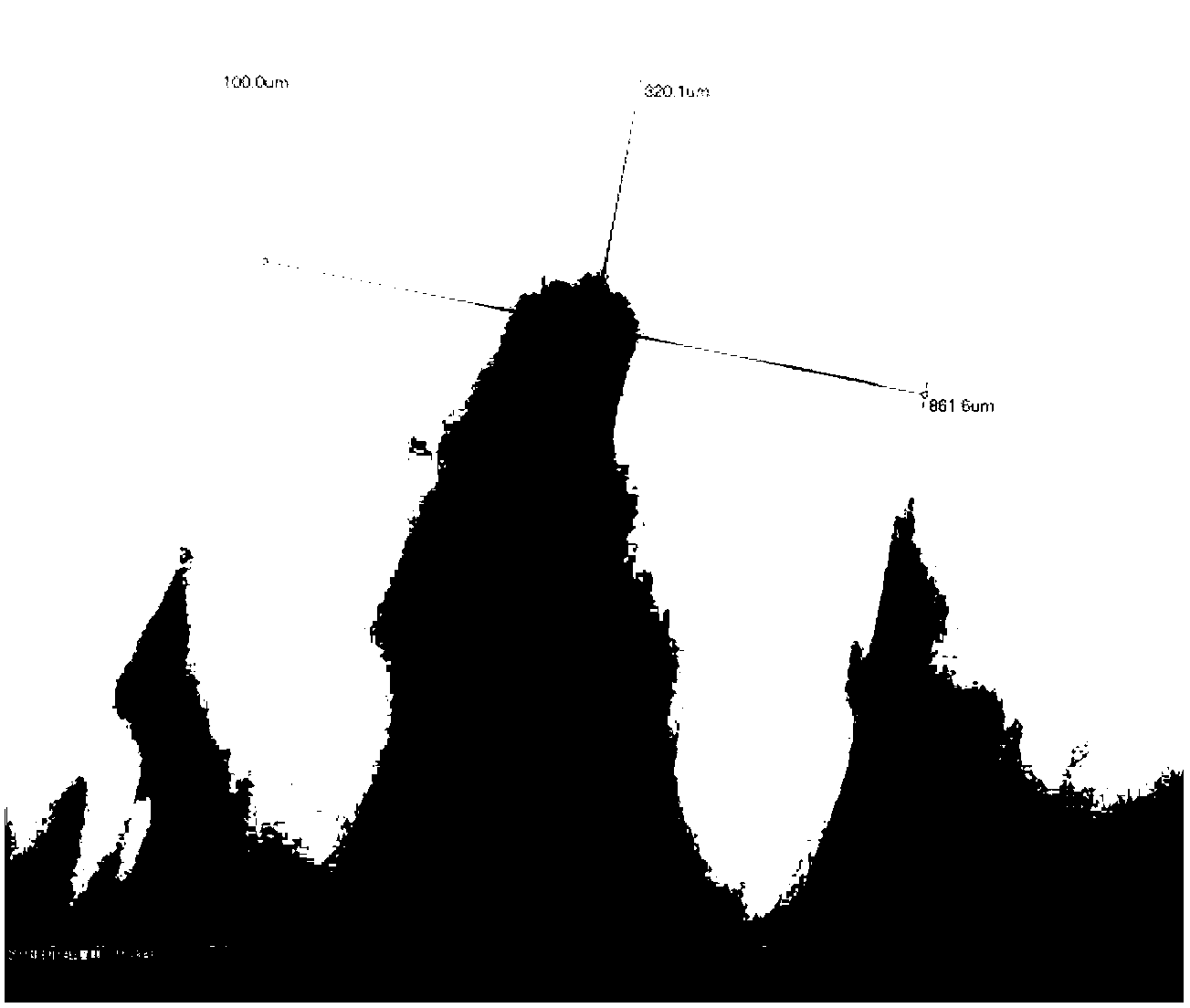

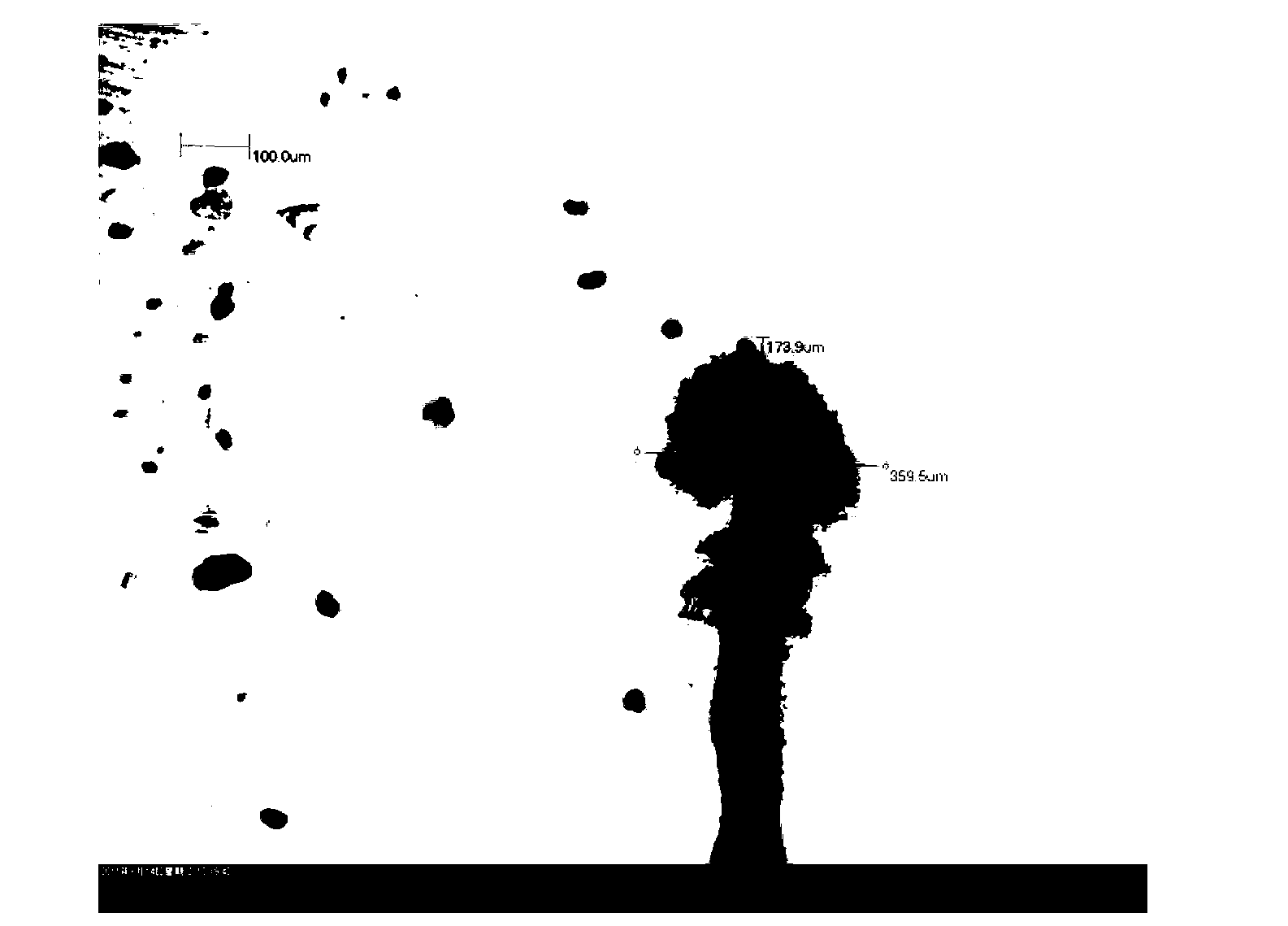

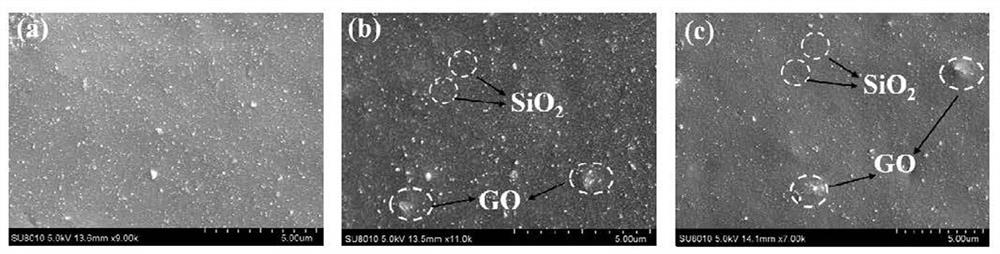

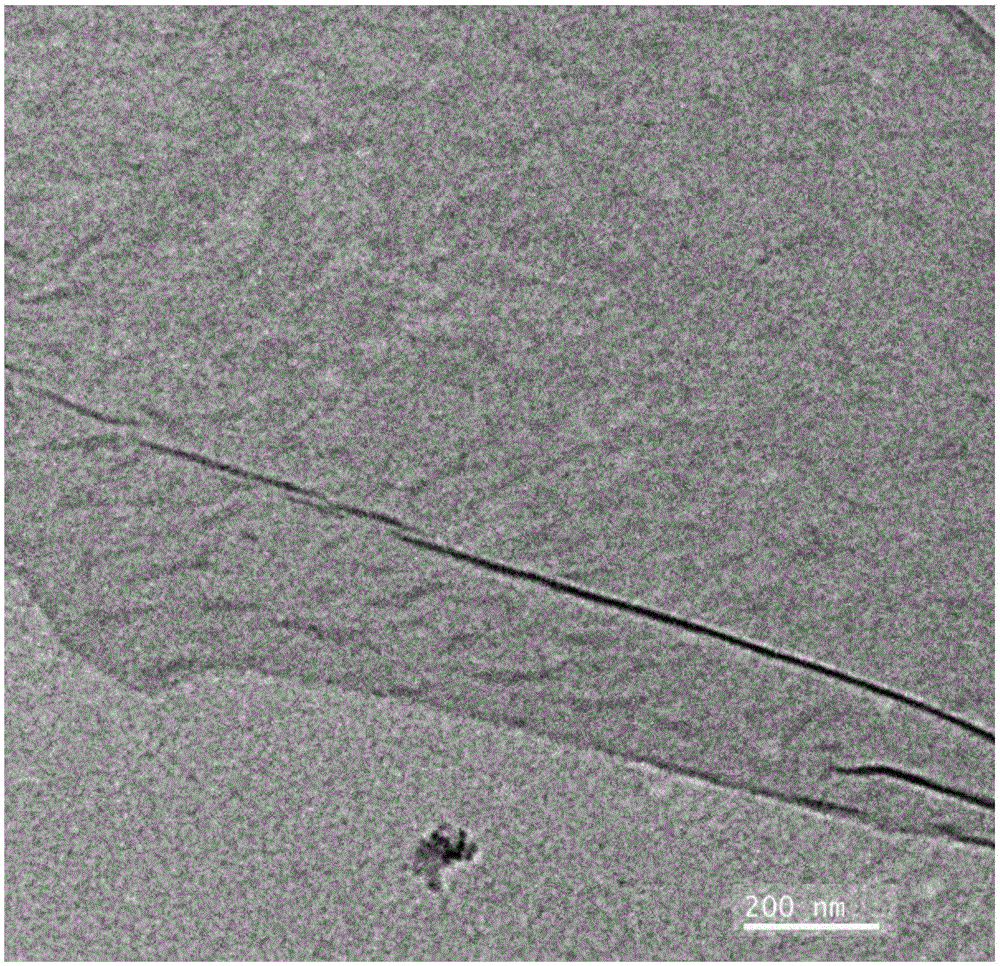

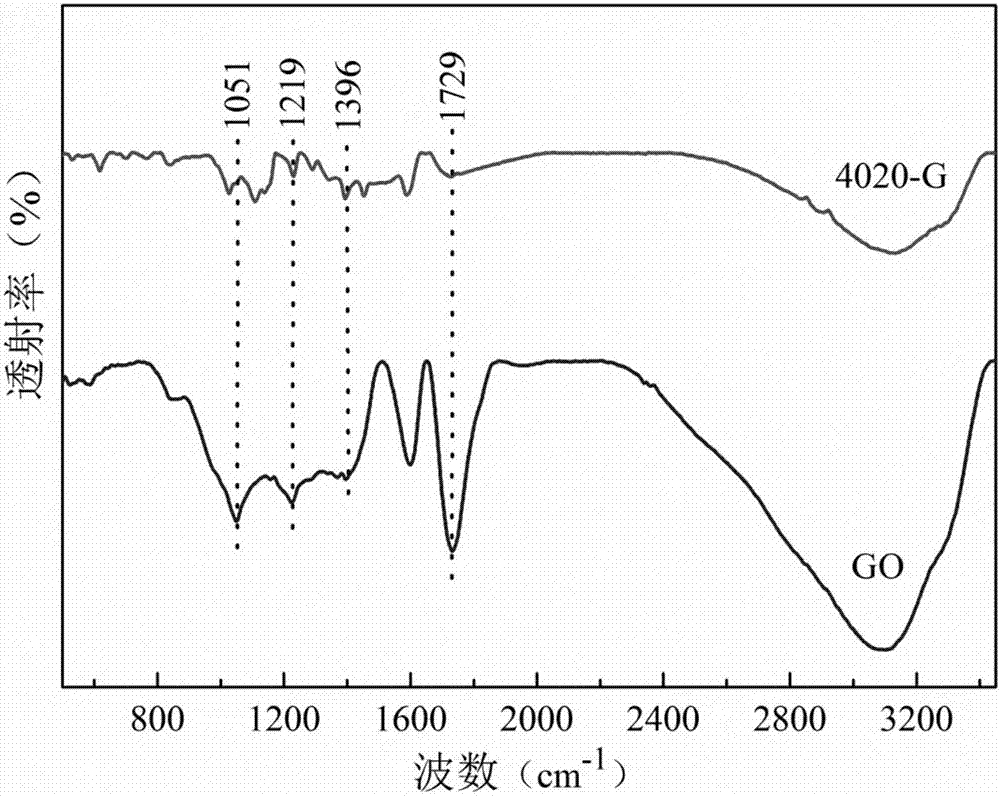

Preparation method of graphene-silicon dioxide modified natural rubber composite material with high thermal conductivity, low thermodynamic property and excellent mechanical property for tires

ActiveCN113462040AGood dispersionImprove thermal conductivitySpecial tyresRolling resistance optimizationSimple Organic CompoundsGraphene

The invention relates to the field of functional natural rubber composite materials, in particular to a preparation method of a graphene-silicon dioxide modified natural rubber composite material with high thermal conductivity, low thermodynamic property and excellent mechanical property for tires. GO aqueous dispersion liquid, SiO2 particles and natural rubber (NR) latex are used as raw materials, SiO2 is modified twice by adopting an organic compound and GO, and the GO-SiO2 modified NR composite material is prepared in a co-aqueous phase by utilizing a latex co-precipitation method. The preparation method has the advantages that the mixing section number, the mixing time, the mixing energy consumption and the dust pollution in the rubber preparation process can be reduced, the dispersity of GO-SiO2 in a rubber matrix can be improved, the interface interaction between GO-SiO2 and the rubber matrix is improved, and the mechanical property of the finally prepared rubber composite material is obviously improved; and meanwhile, friction heat generated between a filler and a matrix and interface thermal resistance between the filler and the matrix can be reduced, and temperature rise of the tire in the driving process is reduced, so that the thermal aging speed of the rubber tire in the dynamic use process is slowed down, and the service life of the rubber tire is prolonged.

Owner:ZHONGBEI UNIV +1

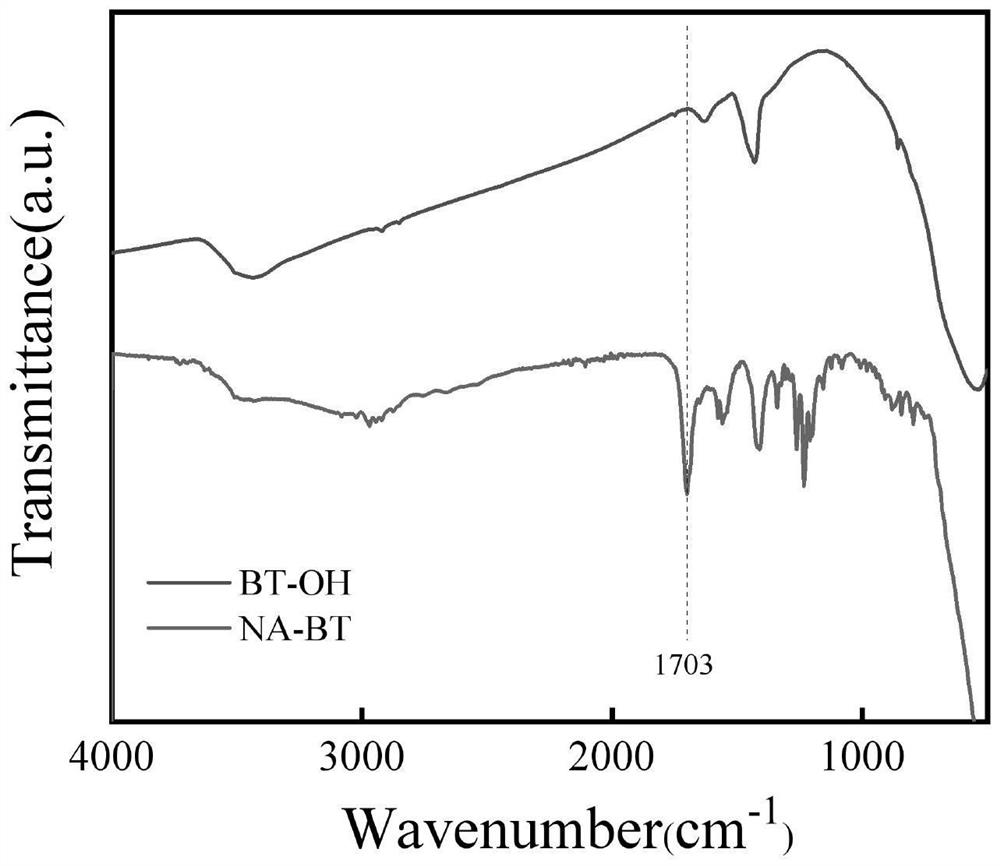

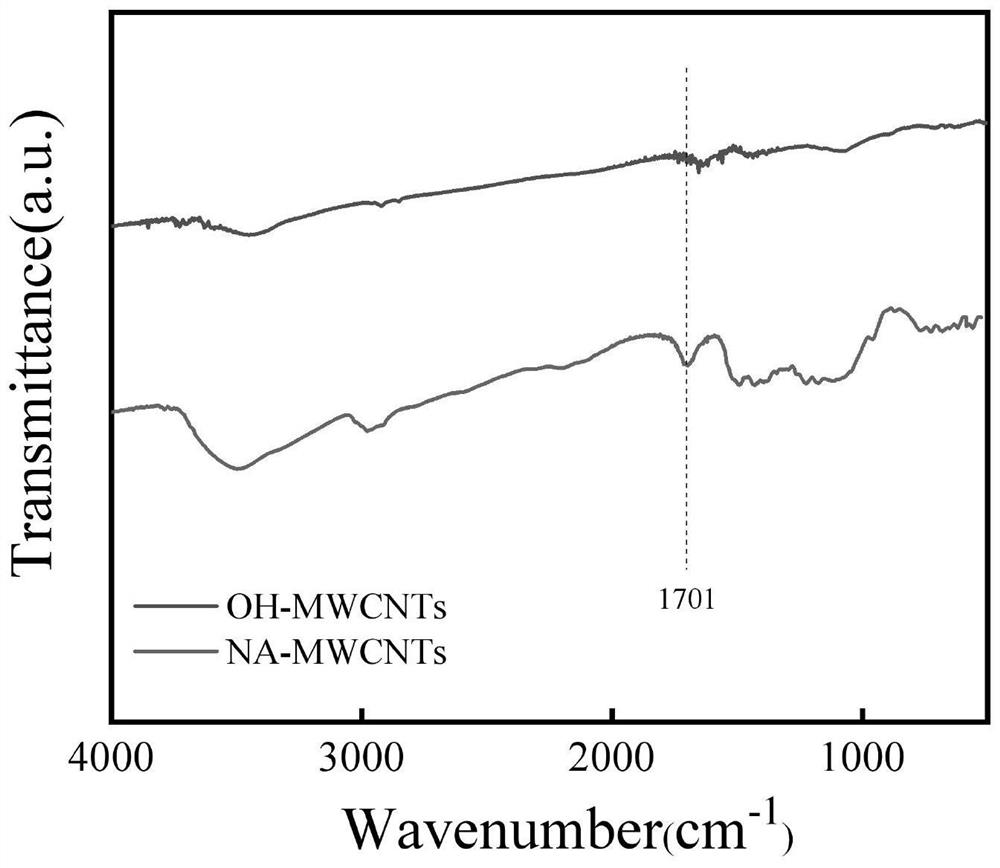

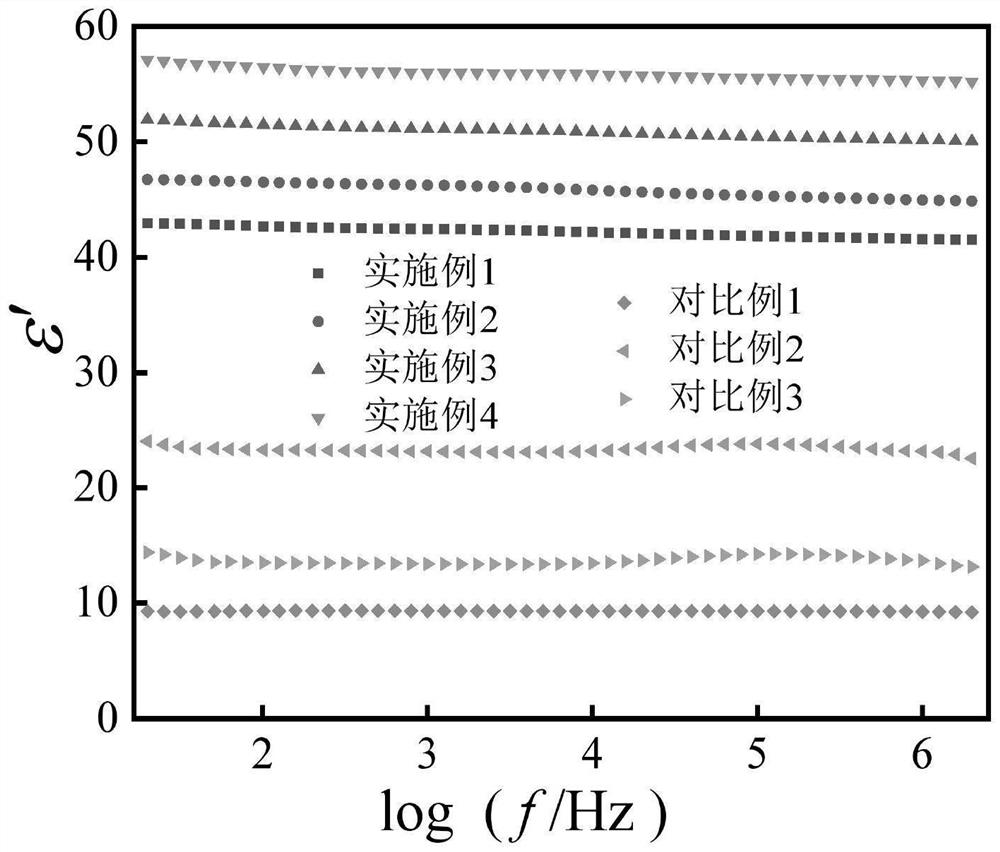

Multi-walled carbon nanotube/barium titanate/polydicyclopentadiene composite material based on front-end ring-opening metathesis polymerization and preparation method thereof

The invention discloses an MWCNTs / barium titanate / PDCPD composite material based on front-end ring-opening metathesis polymerization and a preparation method thereof. The PDCPD composite material is prepared from the following raw materials: dicyclopentadiene, 5-ethylidene-2-norbornene, a norbornene dianhydride grafted carbon nanotube, norbornene dianhydride grafted barium titanate, a catalyst and an inhibitor, wherein the mass fraction of the dicyclopentadiene and the 5-ethylidene-2-norbornene is 84.58%- 92.76%; the mass fraction of the catalyst is 0.06-0.07%; and the mass fraction of the inhibitor is 0.18-0.35%. Under the conditions of room temperature and 100Hz frequency, the dielectric constant of the prepared composite material exceeds 40, the dielectric loss is as low as 0.08, the glass transition temperature exceeds 160 DEG C, and the composite material has excellent thermal stability and mechanical properties. Meanwhile, processing equipment and a forming process for preparing the material are simple, the energy consumption in the processing process is low, the efficiency is high, the operation is easy, and the application of the PDCPD material in a severe environment is effectively expanded.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

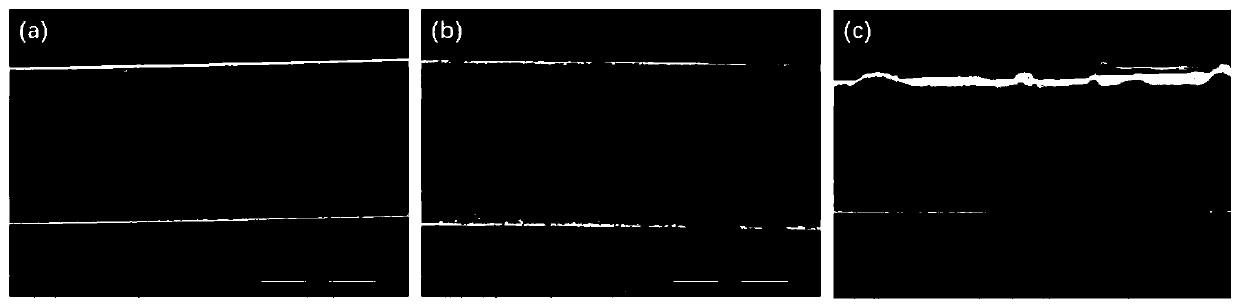

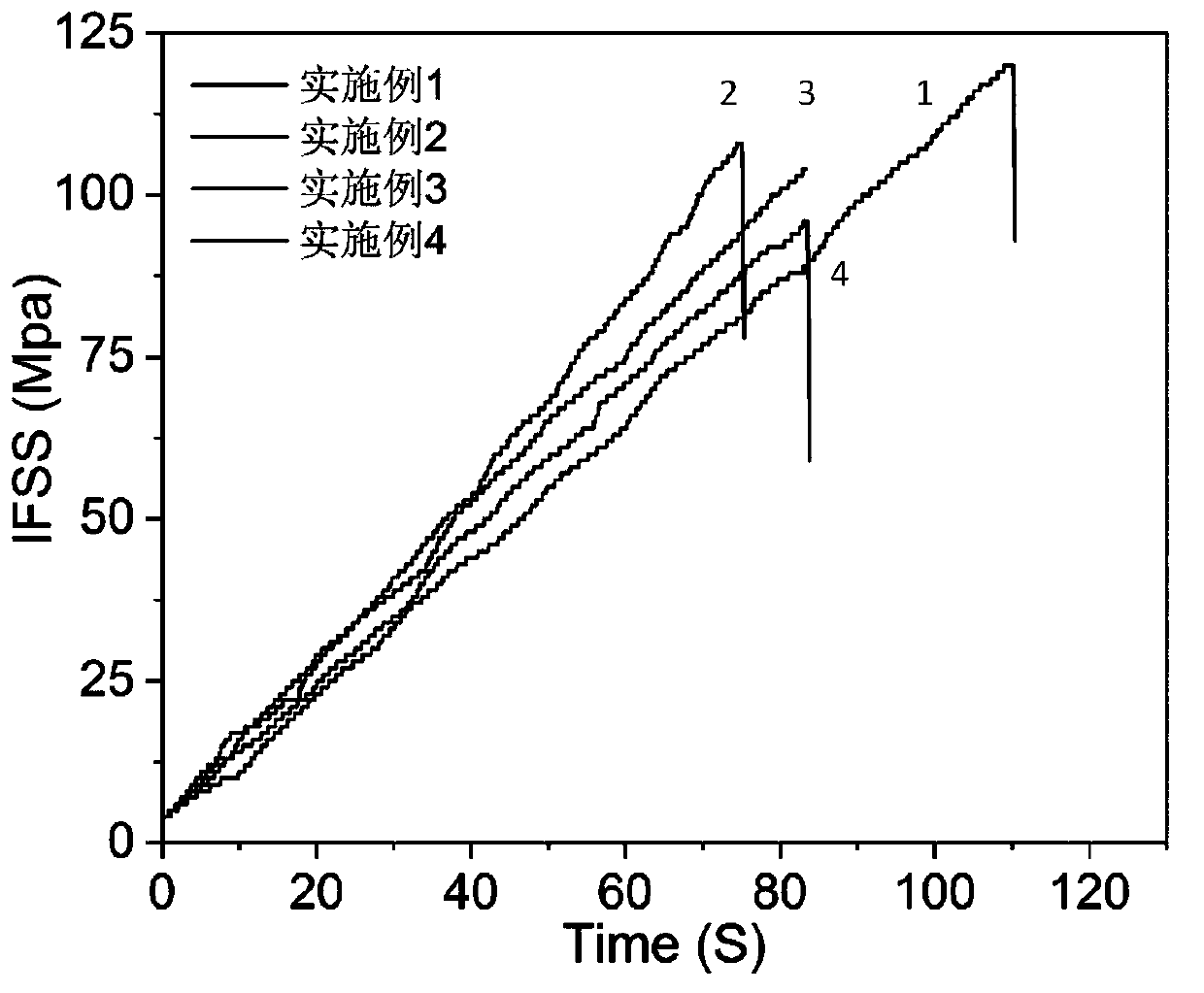

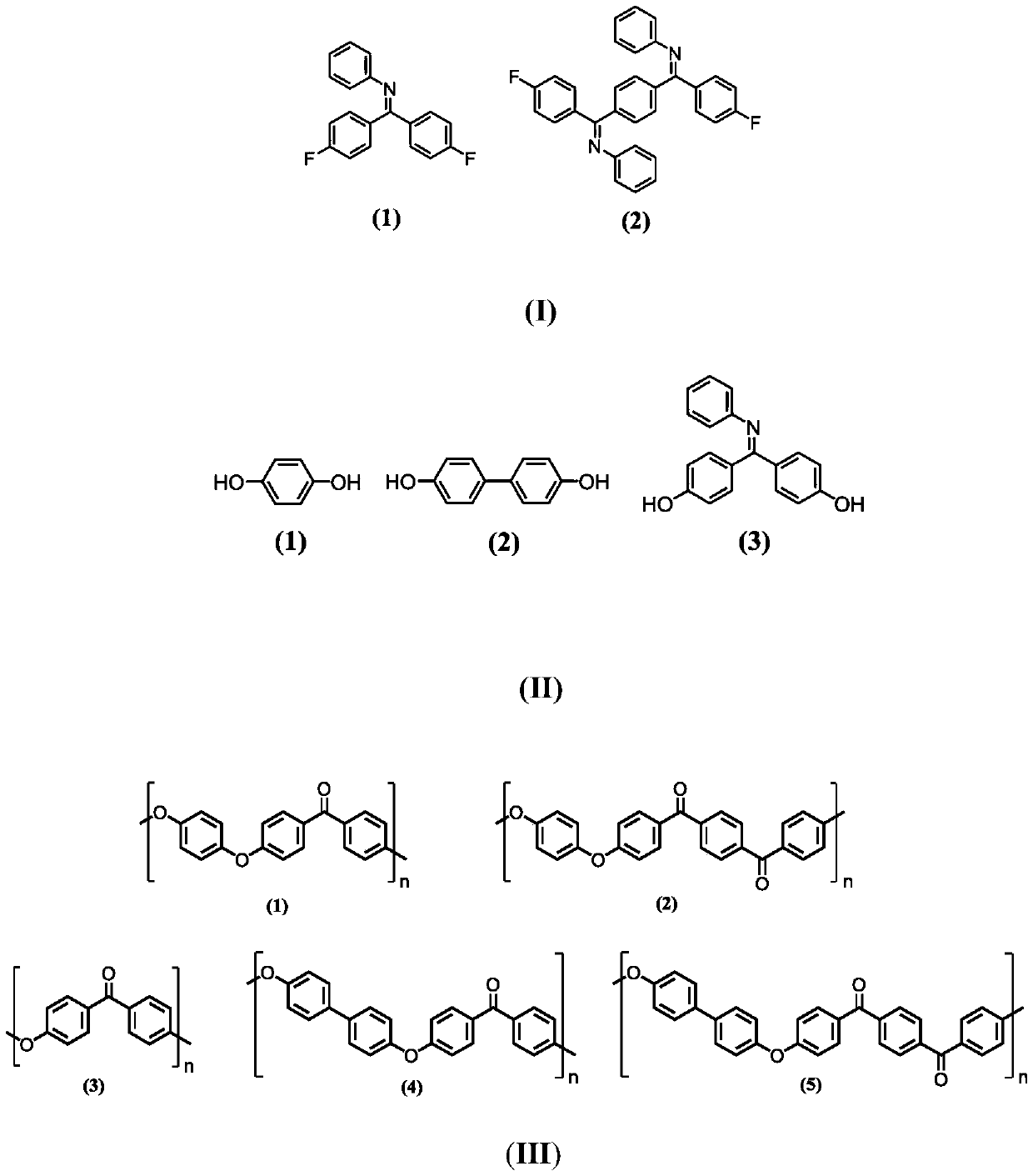

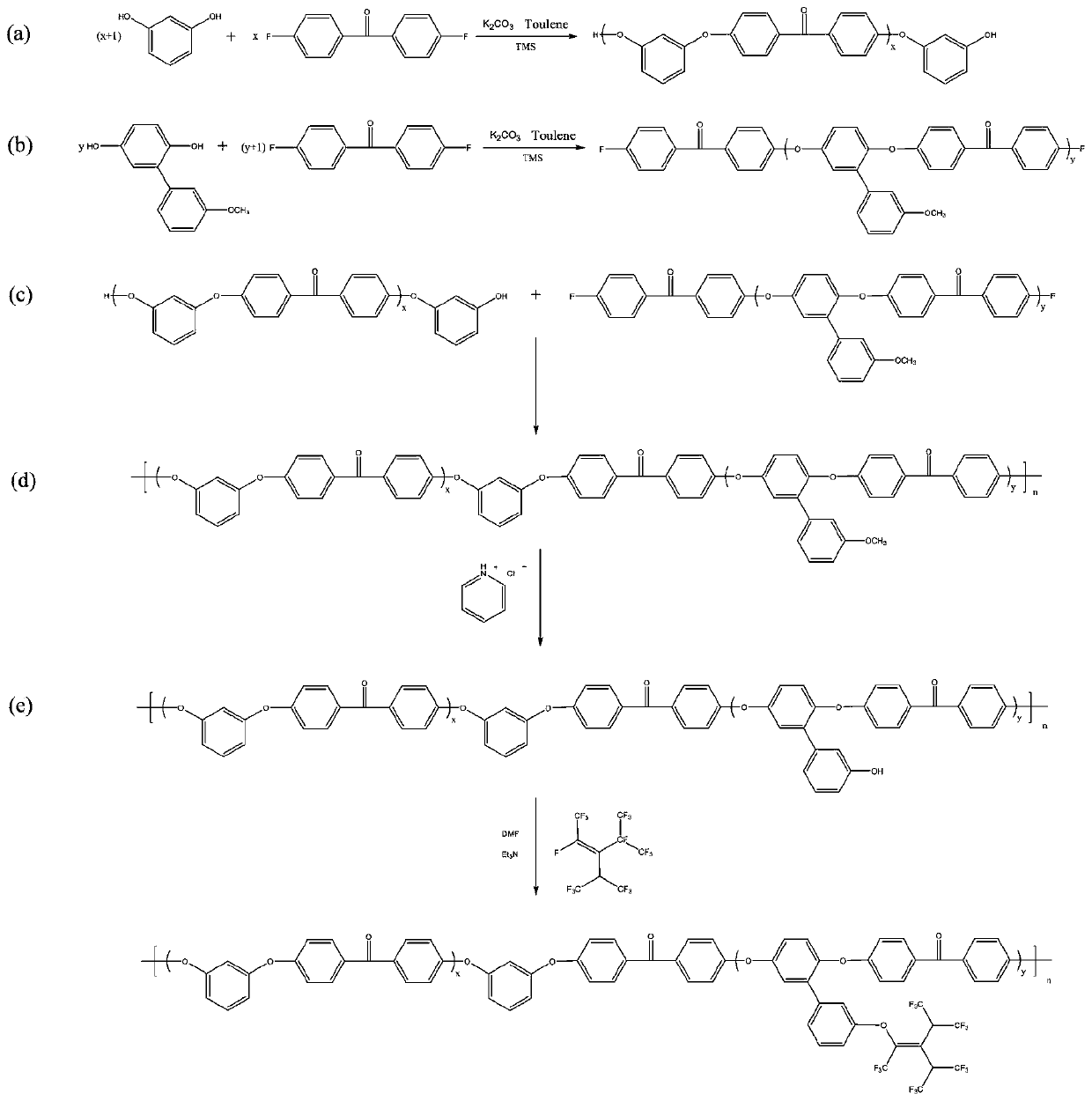

Carbon fiber modified with crystalized crosslinkable polyaryletherketone sizing agent and preparation method of carbon fiber

ActiveCN110820315ASimple structureImprove bondingPhysical treatmentCarbon fibresPolymer scienceCarbon fibers

The invention discloses a carbon fiber modified with a crystalized crosslinkable polyaryletherketone sizing agent and a preparation method of the carbon fiber and belongs to technical field of carbonfiber surface treatment. The preparation method includes subjecting double-fluorine monomer containing aniline side groups and bisphenol monomers to polymerization, or modifying crystalized polyaryletherketone, so as to obtain soluble amorphous polyaryletherketone polymer, and blocking thermotropic crosslinking groups to two terminals of the polymer; meanwhile, subjecting the carbon fiber to surface electrochemical reduction, and grafting the crosslinking groups which are the same as the mentioned to the surface of the carbon fiber; further, drafting the carbon fiber which is subjected to thesurface electrochemical reduction to pass through a sizing agent solution to size the carbon fiber, and performing acidification to recover the crystallinity of the polyaryletherketone sizing agent; finally, finishing the carbon fiber. The carbon fiber can be used for preparing a composite material, the composite material is subjected to high-heat treatment, so that the crosslinking reaction is initiated, the crystallinity of the polyaryletherketone polymer is improved, the sizing agent is allowed to have a crystalline texture and can form a chemical bonding with the surface of the carbon fiber, and further, the interference shear strength is improved, and the composite material has high temperature resistance and corrosion resistance performance.

Owner:JILIN UNIV

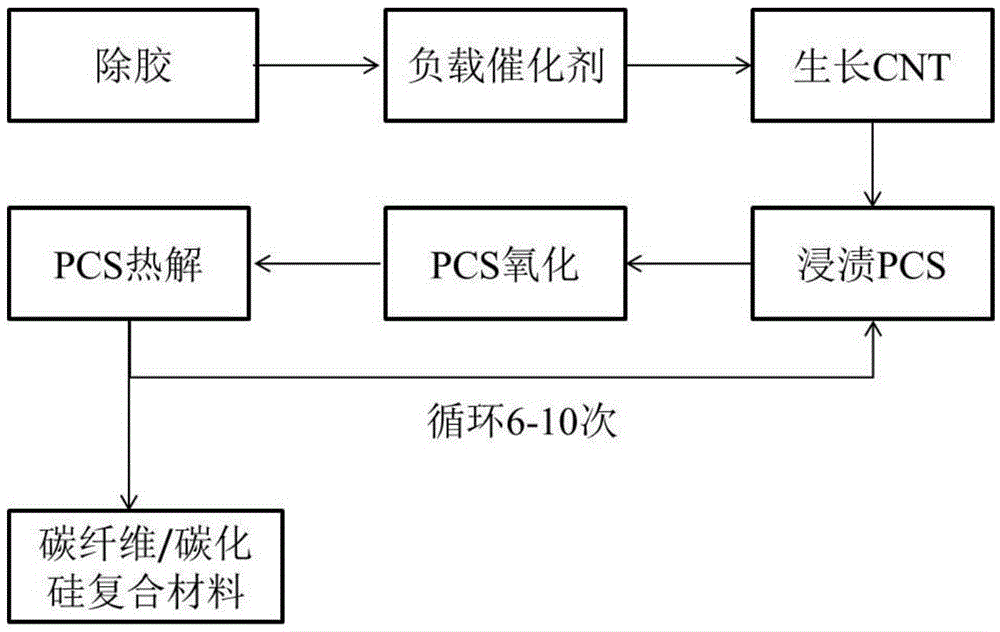

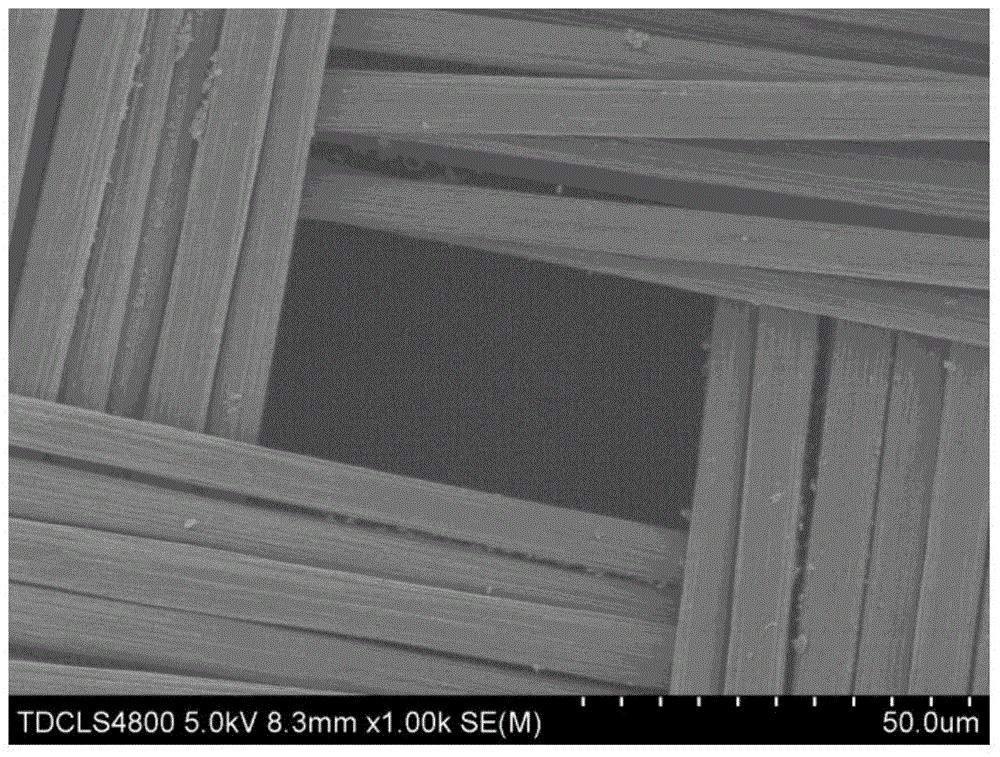

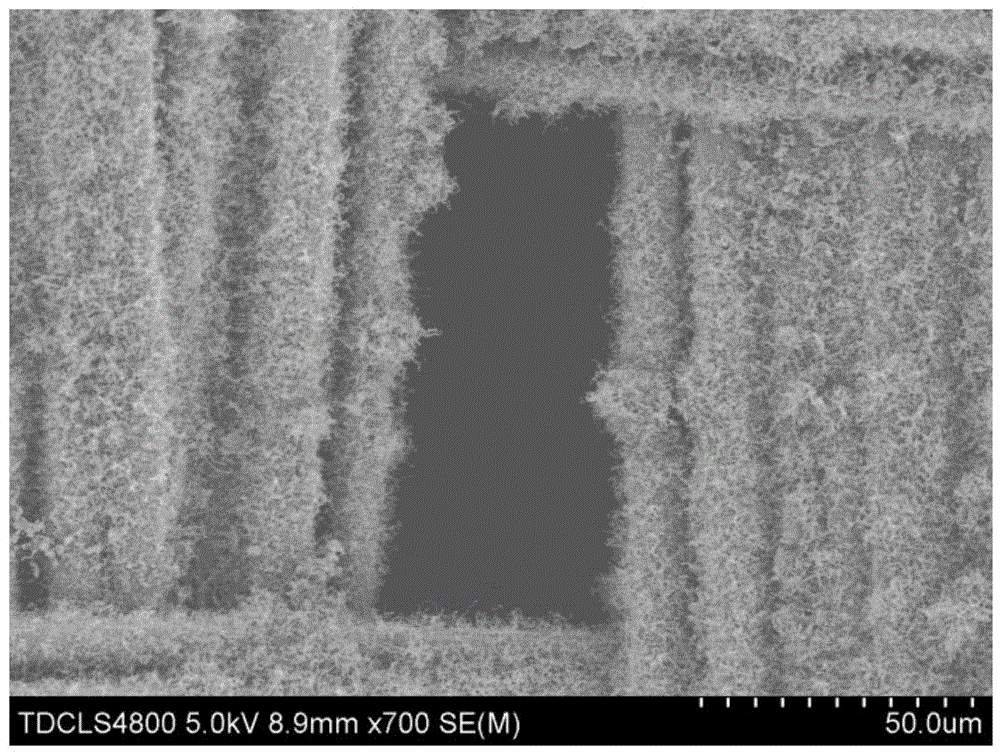

Preparation method of high-temperature-resistant oxidation-resistant heat-conducting carbon fiber/silicon carbide composite material

The invention relates to a preparation method of a high-temperature-resistant oxidation-resistant heat-conducting carbon fiber / silicon carbide composite material. The preparation method comprises the following steps: immersing carbon fiber fabrics in a Fe(NO3)3 solution, and drying; putting the catalyst-carried carbon fiber fabrics in a tube furnace; introducing Ar and H2; introducing a carbon source, and obtaining the carbon-nanotube-grown carbon fiber fabrics after the growth finishes; laminating 4-8 carbon fiber fabrics, and immersing in a polycarbosilane dimethylbenzene solution; taking out the laminated carbon fiber fabrics, and drying to form a block; carrying out oxidation in a muffle furnace for 1-2 hours; and putting the block into the tube furnace, introducing Ar, heating to 1200 DEG C, and cooling to obtain the high-temperature-resistant oxidation-resistant heat-conducting carbon fiber / silicon carbide composite material. The carbon fiber / silicon carbide composite material has favorable mechanical properties: the bending strength can reach 115 MPa or above, and the compression strength can reach 450 MPa or above. The method is simple, and has the advantages of low cost and low energy consumption.

Owner:TIANJIN UNIV

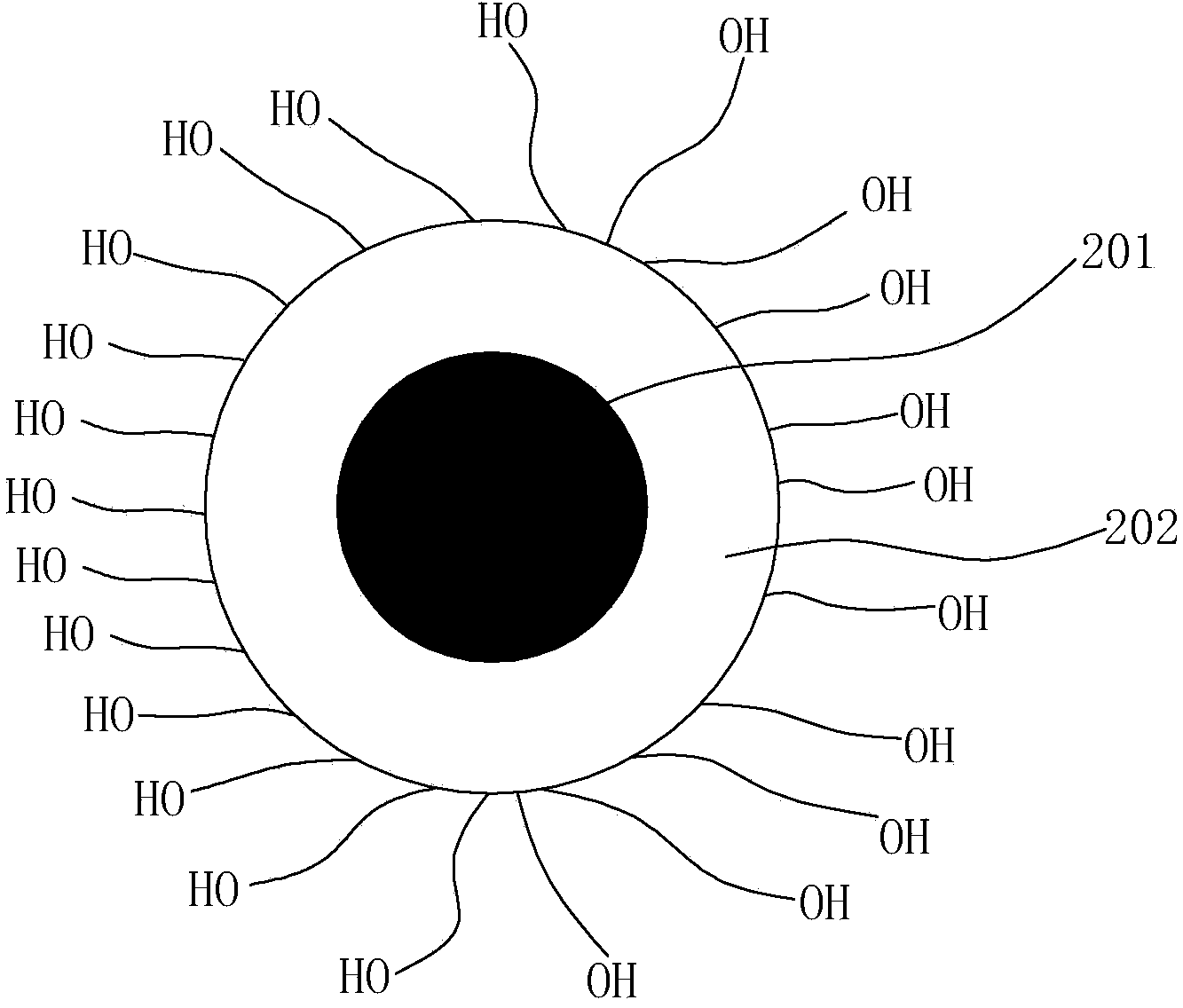

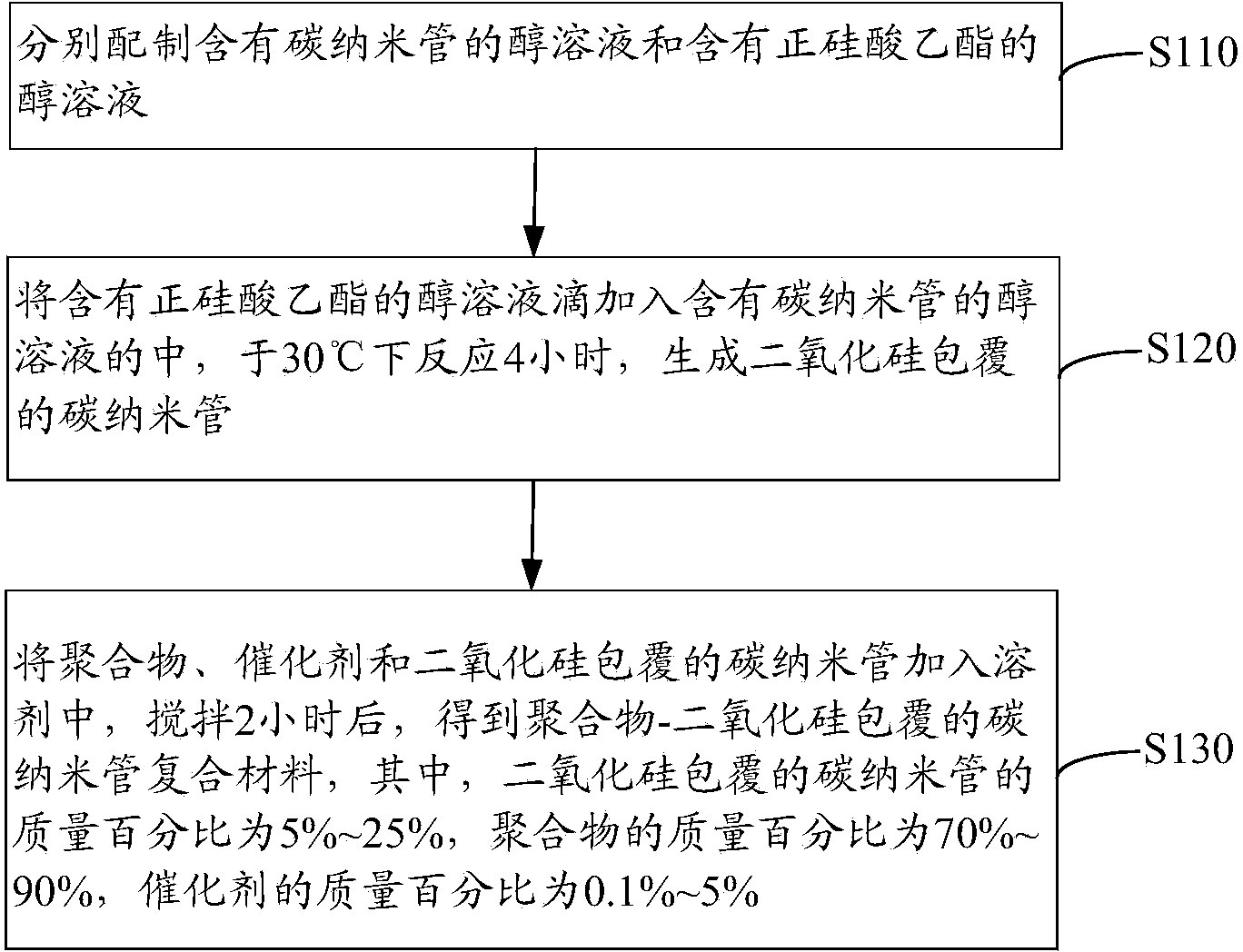

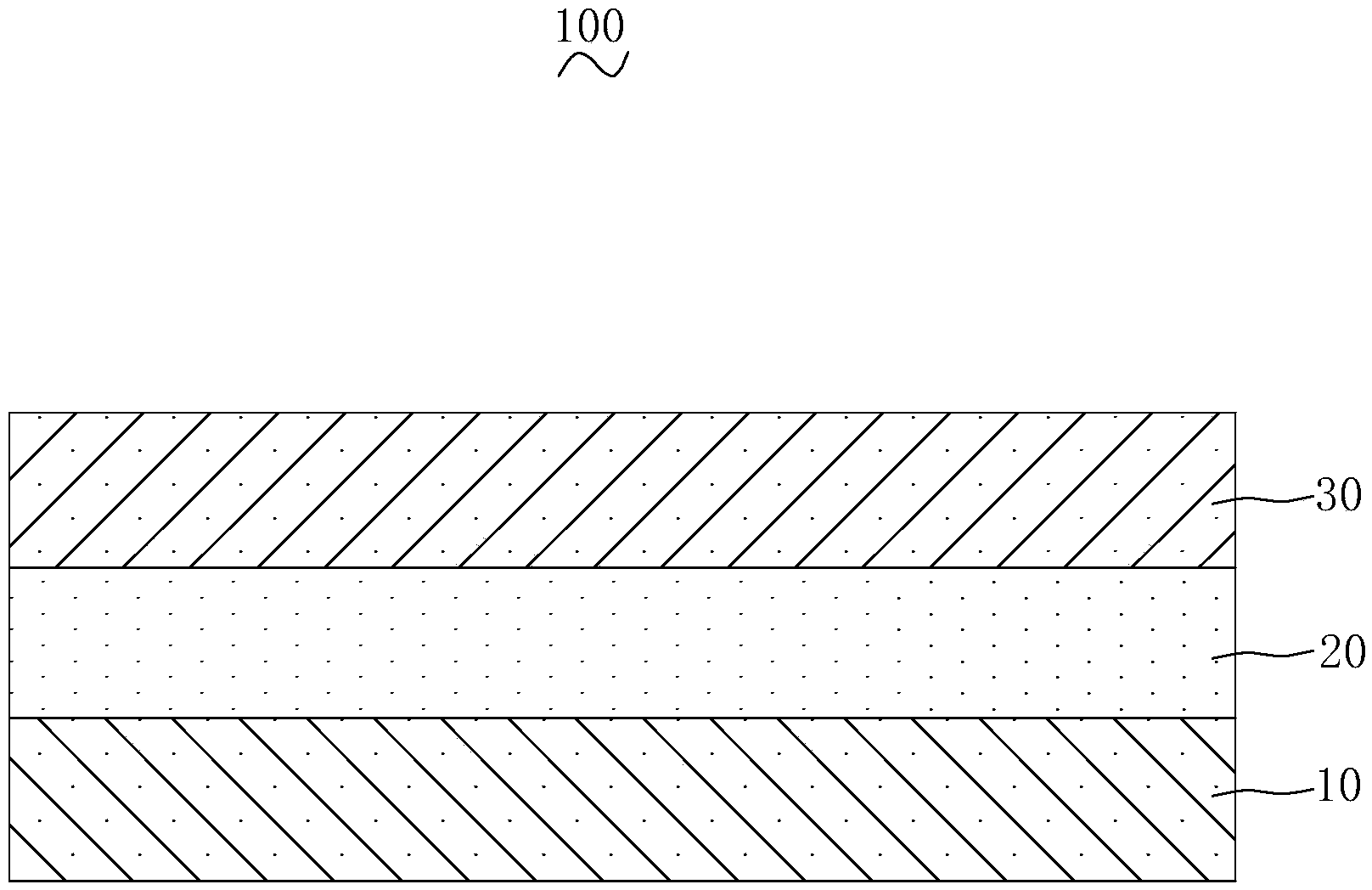

Polymer-silicon dioxide coated carbon nanotube composite material, preparation method thereof, prepreg and copper-clad substrate

ActiveCN103554909AImprove insulation performanceLow conductivitySynthetic resin layered productsElectrical equipmentCarbon nanotubeCopper

The invention relates to a polymer-silicon dioxide coated carbon nanotube composite material, a preparation method thereof, a prepreg and a copper-clad substrate. The polymer-silicon dioxide coated carbon nanotube composite material comprises 5%-25% of silicon dioxide coated carbon nanotubes, 70%-90% of polymer and 0.1%-5% of catalyst by weight. The silicon dioxide has high insulation performance so that the electrical conductivity of the silicon dioxide coated carbon nanotubes is low, and consequently, the electrical conductivity of the composite material is reduced; besides, the silicon dioxide also inhibits the aggregation of the carbon nanotubes, and simultaneously is capable of having an interface reaction with the polymer; as a result, the interfacial interaction is improved and the carbon nanotubes can be evenly dispersed in the polymer; and therefore, the polymer-silicon dioxide coated carbon nanotube composite material is beneficial to preparing a copper-clad substrate which is good in mechanical properties and low in dielectric properties.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

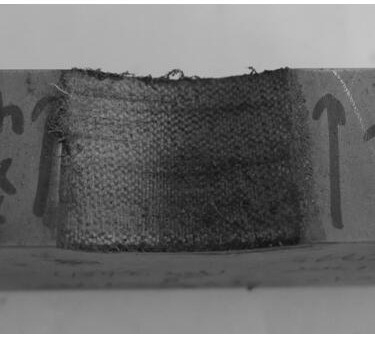

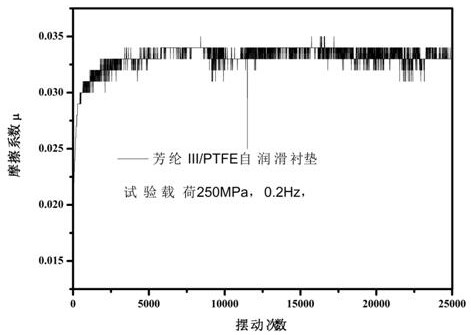

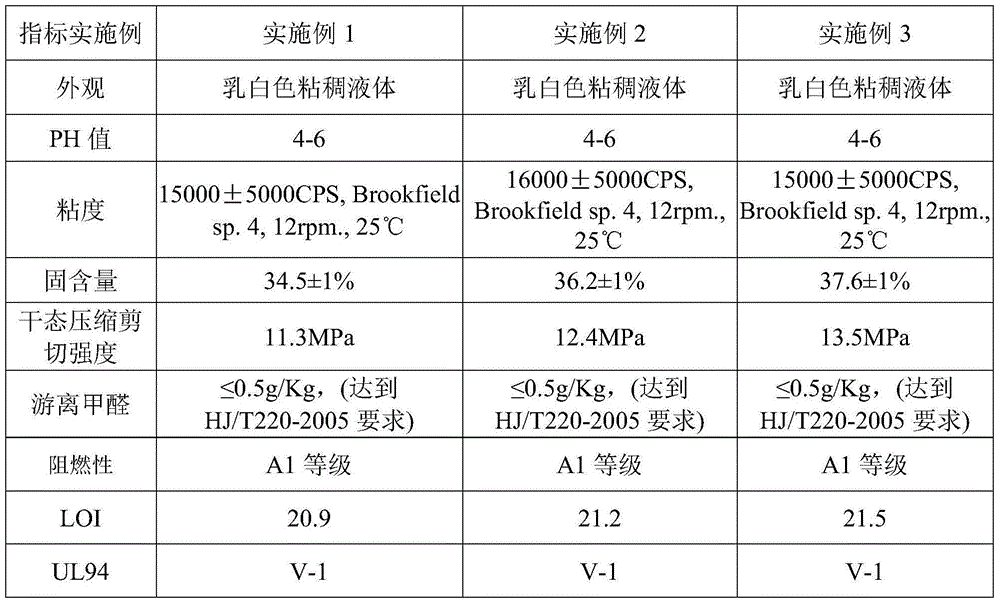

Aramid III fiber reinforced self-lubricating gasket composite material and preparation method thereof

ActiveCN113089327AImprove carrying capacityStable coefficient of frictionAbrasion resistant fibresTriethoxysilaneNanofiber

The invention discloses a preparation method of an aramid III fiber reinforced self-lubricating gasket composite material. The preparation method comprises the following steps: weaving is conducted on a weaving machine by taking sized aramid III fibers as weft yarns and taking twisted yarns of the aramid III fibers and PTFE fibers as warp yarns; and after being subjected to desizing treatment, the fabric is firstly soaked in a tannic acid-aminopropyltriethoxysilane aqueous solution for activation, then soaked in a MgAl-LDH precursor solution for enhanced modification through a hydrothermal interface reaction, then soaked in a dopamine-polyethyleneimine buffer solution for tackifying modification, and finally soaked in aramid nanofibers for toughening modification, and finally the strength-toughness integrated interface modified aramid fiber III / PTFE fabric grey cloth is obtained. The aramid III fiber reinforced self-lubricating gasket prepared by the preparation method has excellent mechanical properties and frictional wear properties, so that the composite material of the fabric self-lubricating gasket is greatly improved, and the comprehensive performance of fabric type self-lubricating parts is further improved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

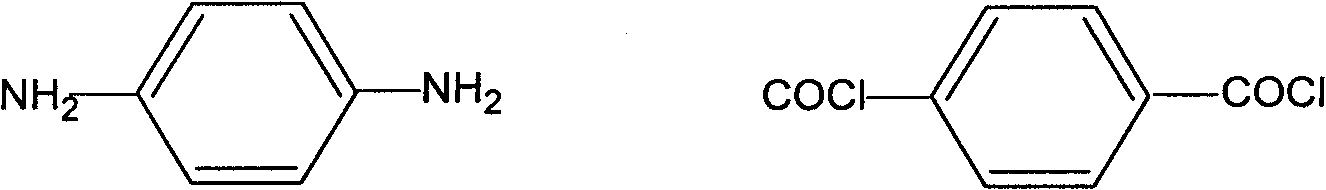

Polyparaphenylene benzo dioxazole fiber containing fluorine on surface and preparation method thereof

ActiveCN104911895AHigh activityImprove mechanical propertiesFibre typesHydrogen fluorideAir atmosphere

The invention discloses a polyparaphenylene benzo dioxazole fiber containing fluorine on surface, which is prepared through the following steps: the body of the polyparaphenylene benzo dioxazole fiber is treated by using a hydrogen fluoride gas, then is mixed by using fluorine / oxygen / inert gas, is subjected to fluoridation for 10 seconds to 2 hours at 5-150 DEG C, and finally is stored in air atmosphere for at least one hour. A contact angle between the surface of the obtained fiber and water is 60-90 degrees, the interlaminar shear strength of a composite material prepared from the fiber and epoxy resin is 30-45MPa, the tensile strength of an impregnated filament is 5.0-5.3GPa, and the tensile modulus is 264-280GPa. The polyparaphenylene benzo dioxazole fiber containing fluorine on surface is high in surface activity, interfacial interaction between the fiber and matrix resin is strong, the interlaminar shear strength of the composite material prepared by using the fiber can be improved by 50-125%, the tensile strength of the impregnated filament is improved by 4-10%, and the modulus is improved by 10-16%. According to the invention, the fluorination rate is high, the treatment time is short, the process is simple and controllable, the cost is relatively low, and the fiber has relatively strong application prospect.

Owner:SICHUAN UNIV

Organic montmorillonite and application thereof

ActiveCN105219306AIncrease spacingGood dispersionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses organic montmorillonite and application thereof. The organic montmorillonite is obtained by modifying montmorillonite so that adhesives can be prepared, wherein the organic montmorillonite has effects on gel protection and emulsification in the copolymerization process of vinyl acetate. Layered montmorillonite is dispersed in a polymer matrix and has the advantages of being high in storage stability, uniform in dispersion and high in interface bonding strength. Meanwhile, montmorillonite belongs to inorganic flame retardant and has the advantages of being excellent in mechanical performance, gas barrier property and fire retarding effect, low in cost, convenient to machine and the like, the mechanical performance of polymers is improved, and a new approach is created for polymer fire retardance.

Owner:顶立新材料科技股份有限公司

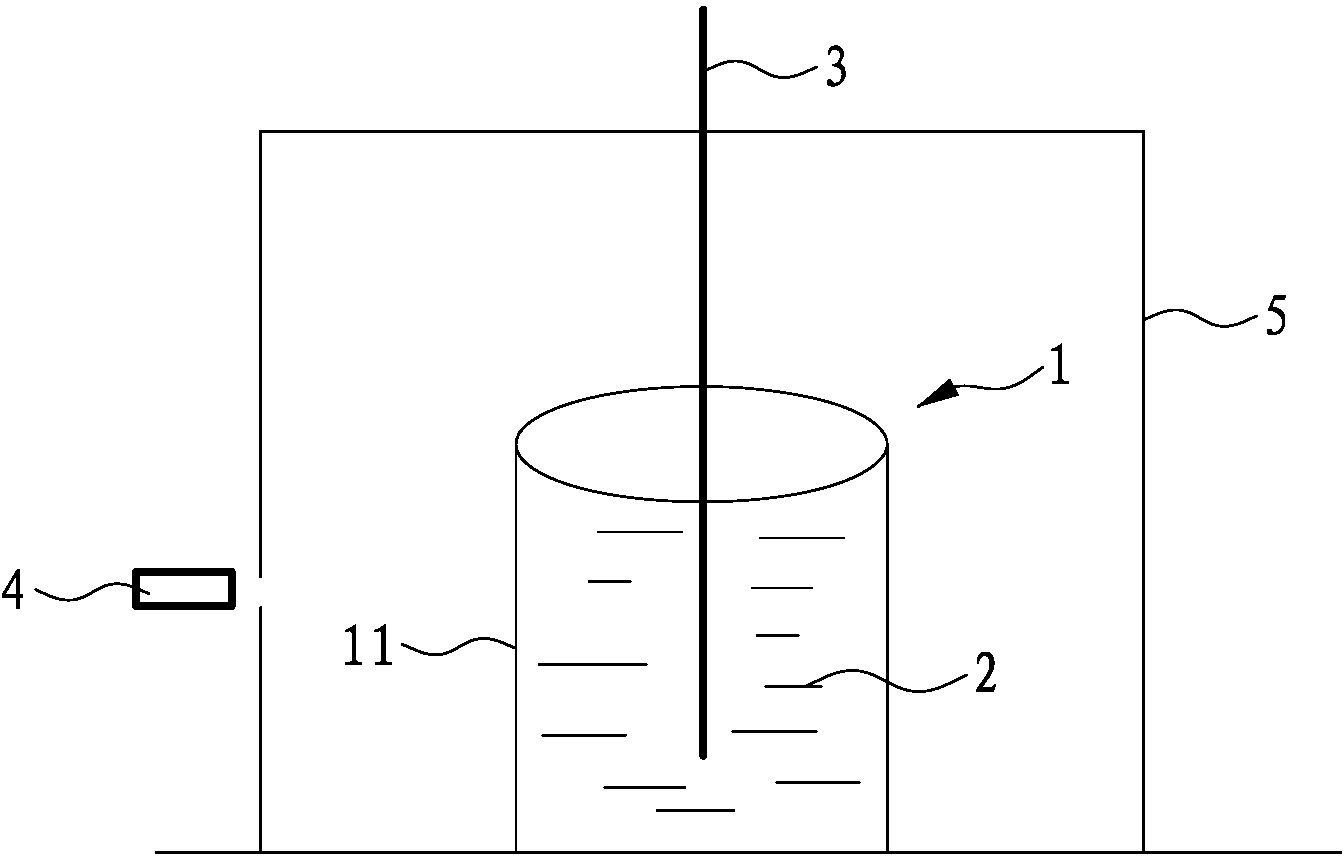

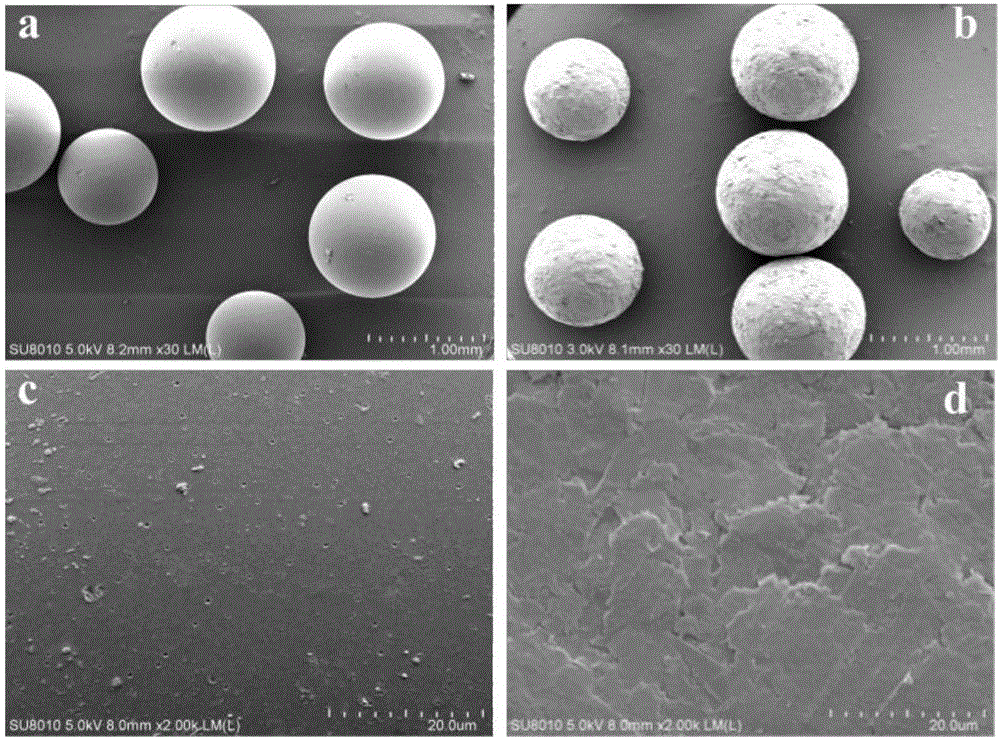

Graphene modified ultralow-density propping agent and preparation method thereof

InactiveCN106833601AHigh strengthLow thermal conductivityFluid removalDrilling compositionCross-linkMicrosphere

The invention belongs to the field of petroleum and gas fracturing extraction and in particular relates to a graphene modified ultralow-density propping agent and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing graphene, an olefin monomer, a cross-linking agent (divinyl benzene) and an initiator under ultrasonic or stirring conditions so as to obtain a monomer mixture in which a Pi-Pi assembly effect is achieved between graphene and aromatic ring components; adding the monomer mixture into an aqueous solution of dispersing agents, performing the processes of balling, cross-linking and curing under the heating condition so as to obtain a microsphere precipitate; and filtering, washing and drying, thereby obtaining the graphene modified ultralow-density propping agent. According to the method disclosed by the invention, the organic polymer microsphere has low density, while the graphene has the performances of ultrahigh strength, high thermal conductivity and high temperature resistance, and then the composite material has ultralow density as well as the characteristics of high strength and high temperature resistance, so that the deep-well hydraulic fracturing requirement is met.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

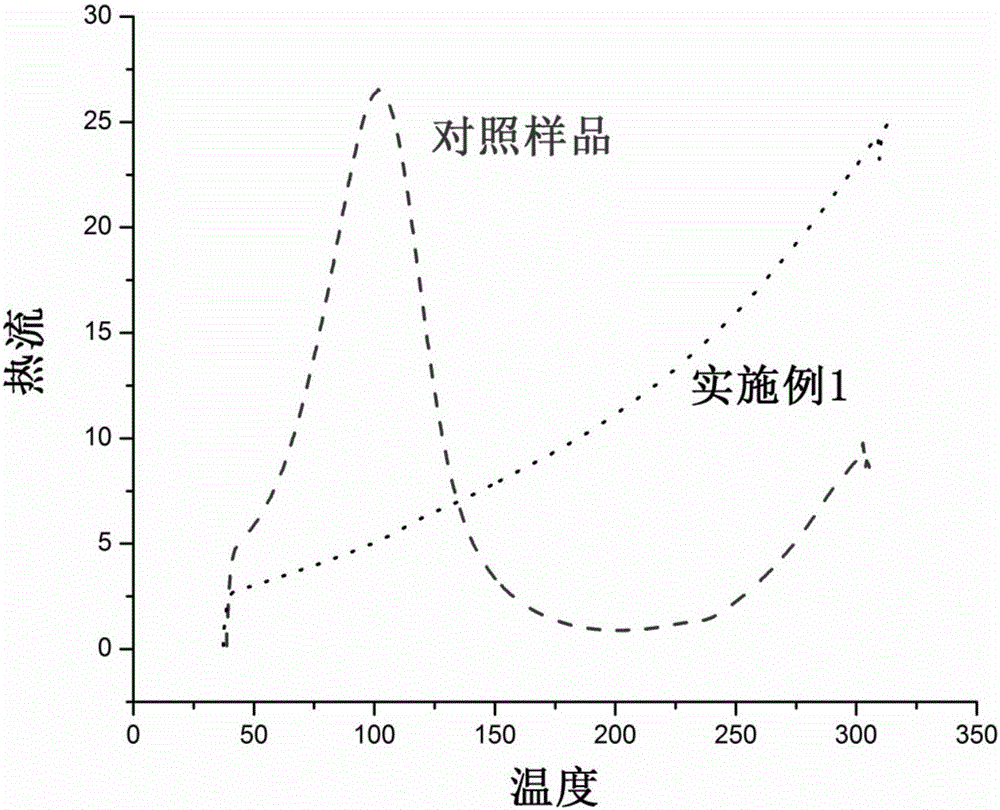

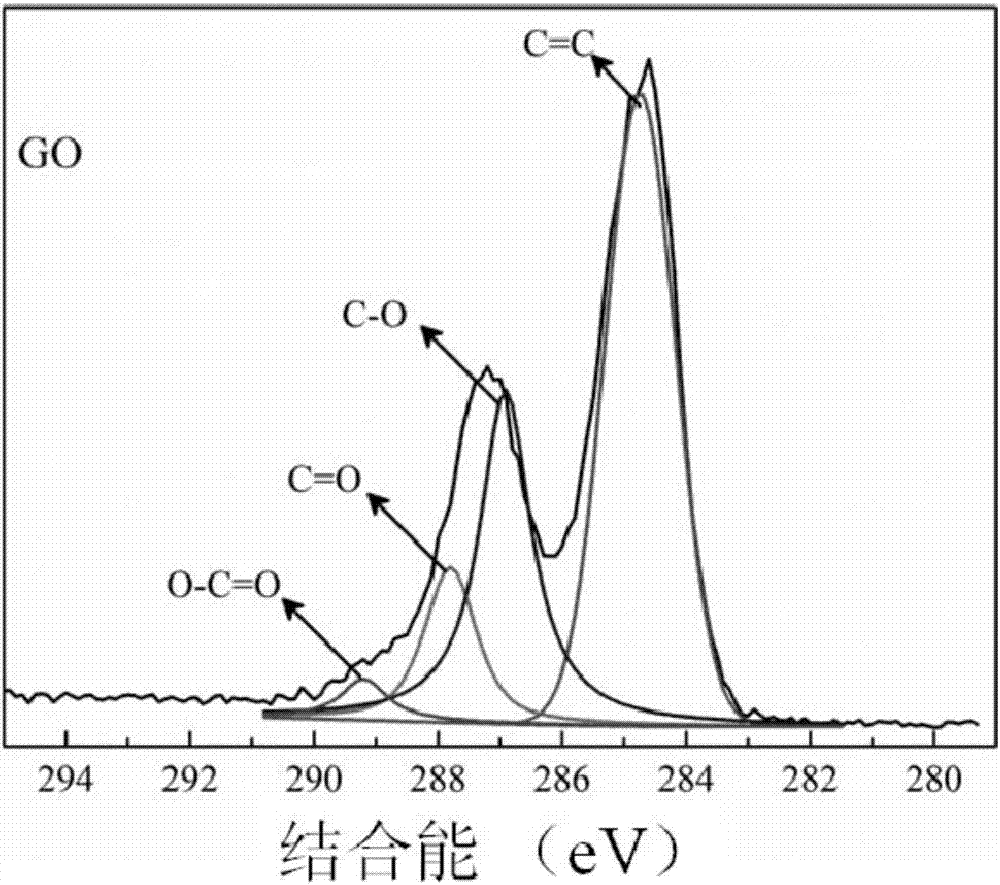

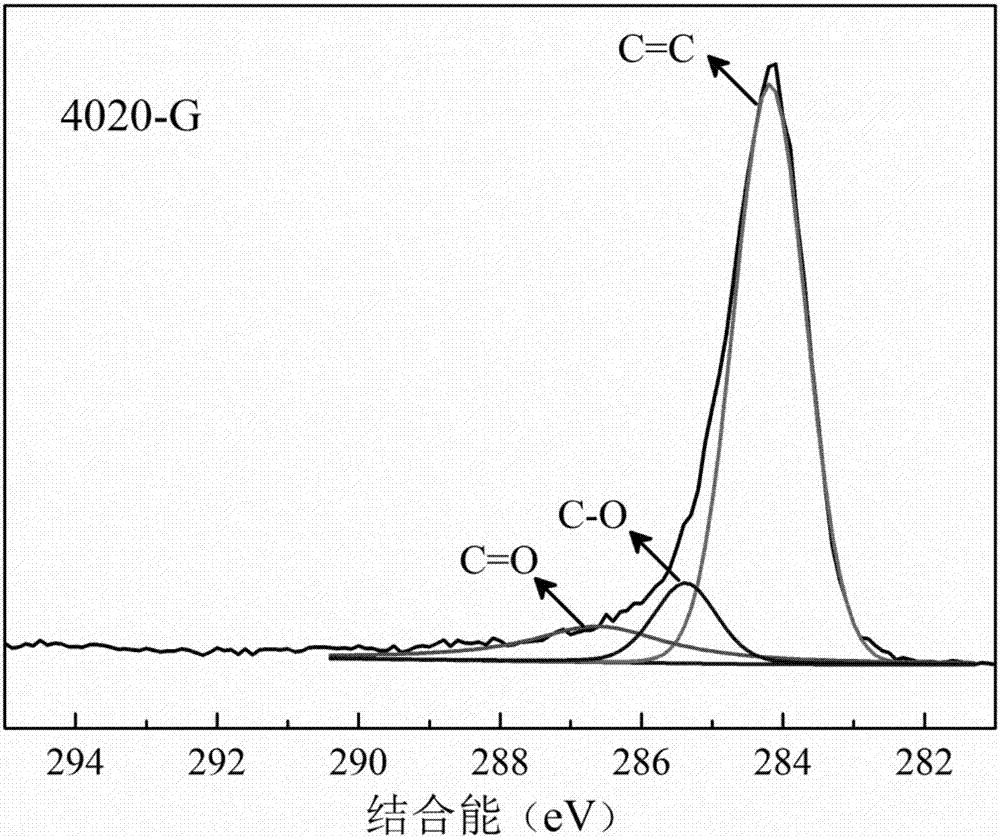

Rubber antioxidant-reduced and modified graphene oxide, as well as preparation method and application thereof

InactiveCN106854387ASignificant reinforcementAccelerated vulcanizationPigment treatment with non-polymer organic compoundsNano compositesGraphene nanocomposites

The invention discloses rubber antioxidant-reduced and modified graphene oxide, as well as a preparation method and application thereof. According to the method, graphene oxide can be reduced and modified only at the same time through one-step reaction, and the method specifically comprises the following steps: mixing the graphene oxide with water, and carrying out ultrasonic stripping, thereby obtaining graphene oxide aqueous dispersion; mixing a rubber adjuvant solution with the graphene oxide aqueous dispersion, and carrying out heating stirring, thereby obtaining the rubber antioxidant-modified graphene oxide. According to the preparation method, a reducing agent is nontoxic and environmentally-friendly; the method is simple and feasible; the reaction conditions are mild; the obtained graphene oxide is low in oxygen-containing functional group content and high in conjugation degree; part of an antioxidant is grafted to the surface of graphene, so that uniform dispersion of the graphene in rubber can be promoted, and the interface bonding effect on a rubber matrix can be enhanced; furthermore, migration and volatilization of the antioxidant can be avoided, and the interaction efficiency of the antioxidant is improved; therefore, the performance of a rubber / graphene composite material is improved. A new opportunity and a new way for green and macroscopic quantity preparation of the graphene and obtaining of a high-performance rubber / graphene nano composite material are supplied.

Owner:SOUTH CHINA UNIV OF TECH

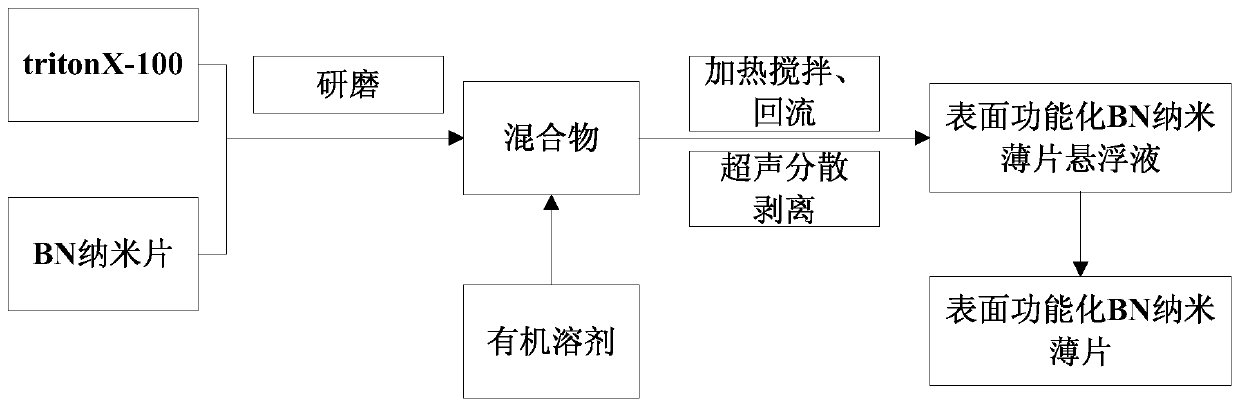

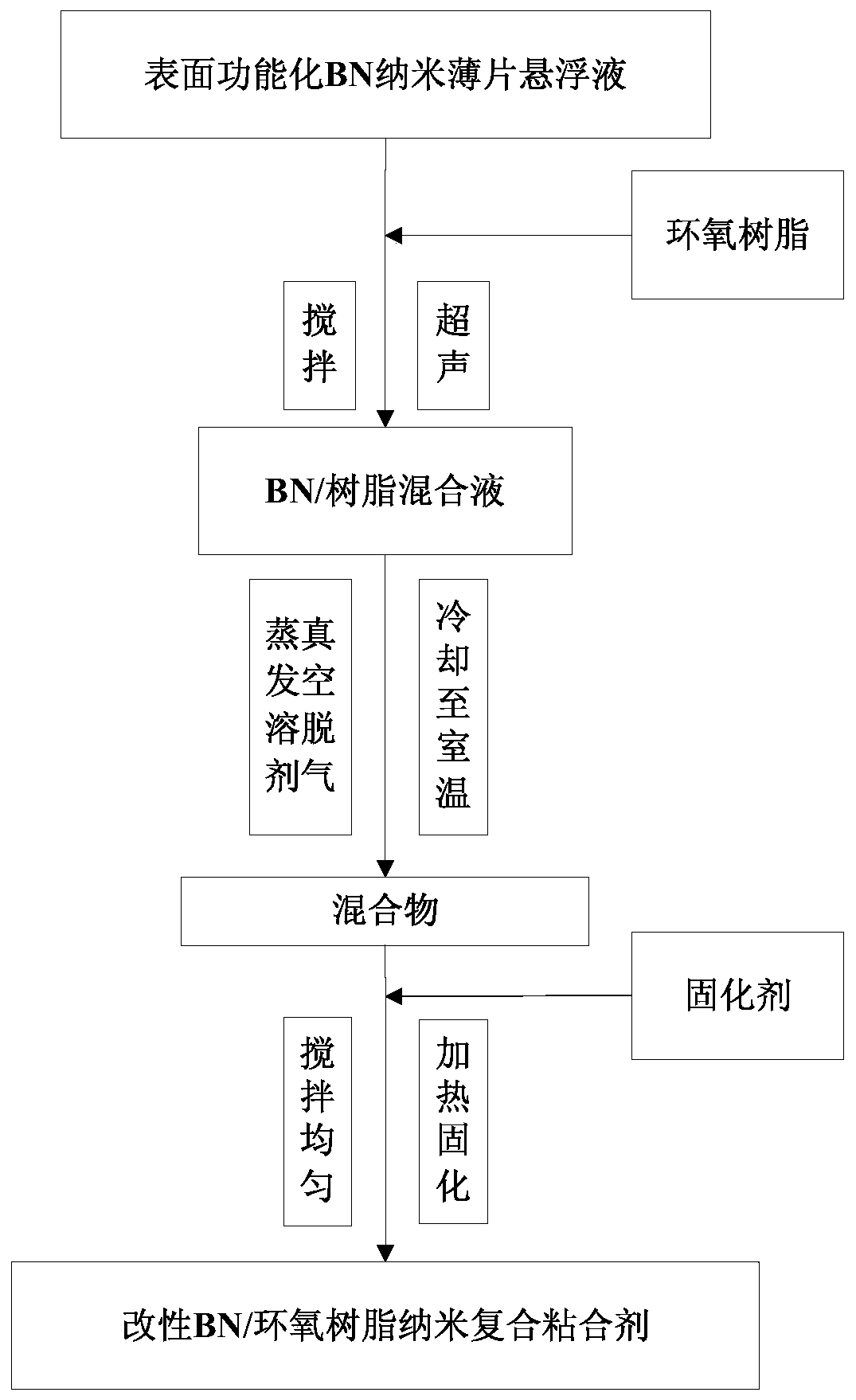

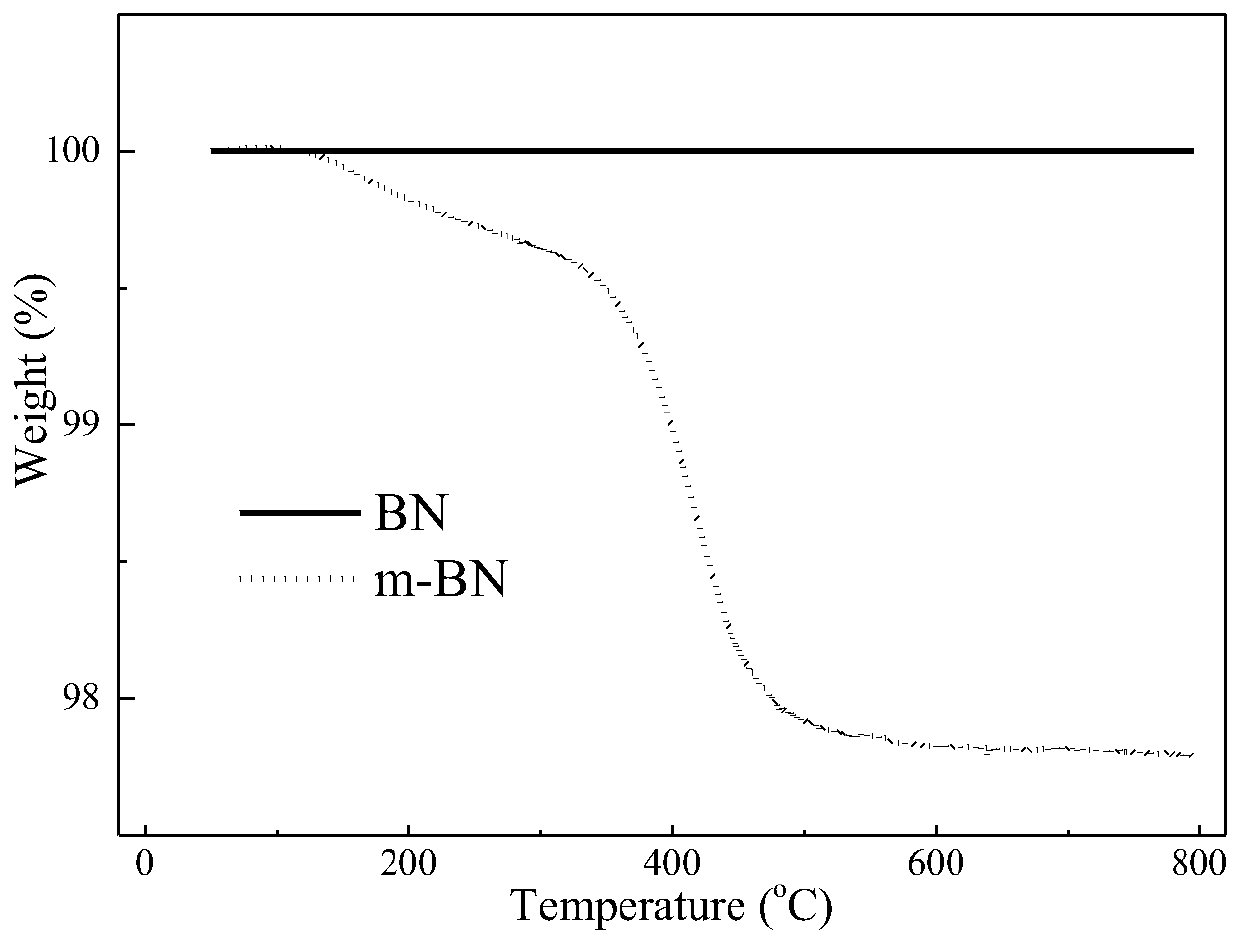

Surface-functionalized BN nanosheet, and preparation method and application thereof

InactiveCN111363381AFacilitate strippingGood dispersionNon-macromolecular adhesive additivesEpoxy resin adhesivesOrganic solventPolymer

The invention discloses a surface-functionalized BN nanosheet, and a preparation method and application thereof, belonging to the field of preparation and modification of BN nanosheets. The preparation method of the surface-functionalized BN nanosheet comprises the following steps of: uniformly mixing and grinding tritonX-100 and BN nanosheets, adding the mixed and ground mixture into an organic solvent, carrying out heating and stirring in a reflux condensation state, carrying out ultrasonic dispersing and stripping to obtain a surface-functionalized BN nanosheet suspension, and removing a solution to obtain the surface-functionalized BN nanosheet. TritonX-100 molecules on the surfaces of the BN nanosheets in the surface functionalized BN nanosheets are subjected to surface functionalization, so the BN nanosheets can be more uniformly dispersed in a polymer matrix; meanwhile, the surface functionalized BN nanosheets are physically entangled with polymer matrix molecules, so the intermediate interface interaction between the surface functionalized BN nanosheets and the polymer matrix is enhanced, and the interface modification remarkably improves the mechanical property and the thermal conductivity of a modified polymer system.

Owner:SHENYANG AEROSPACE UNIVERSITY

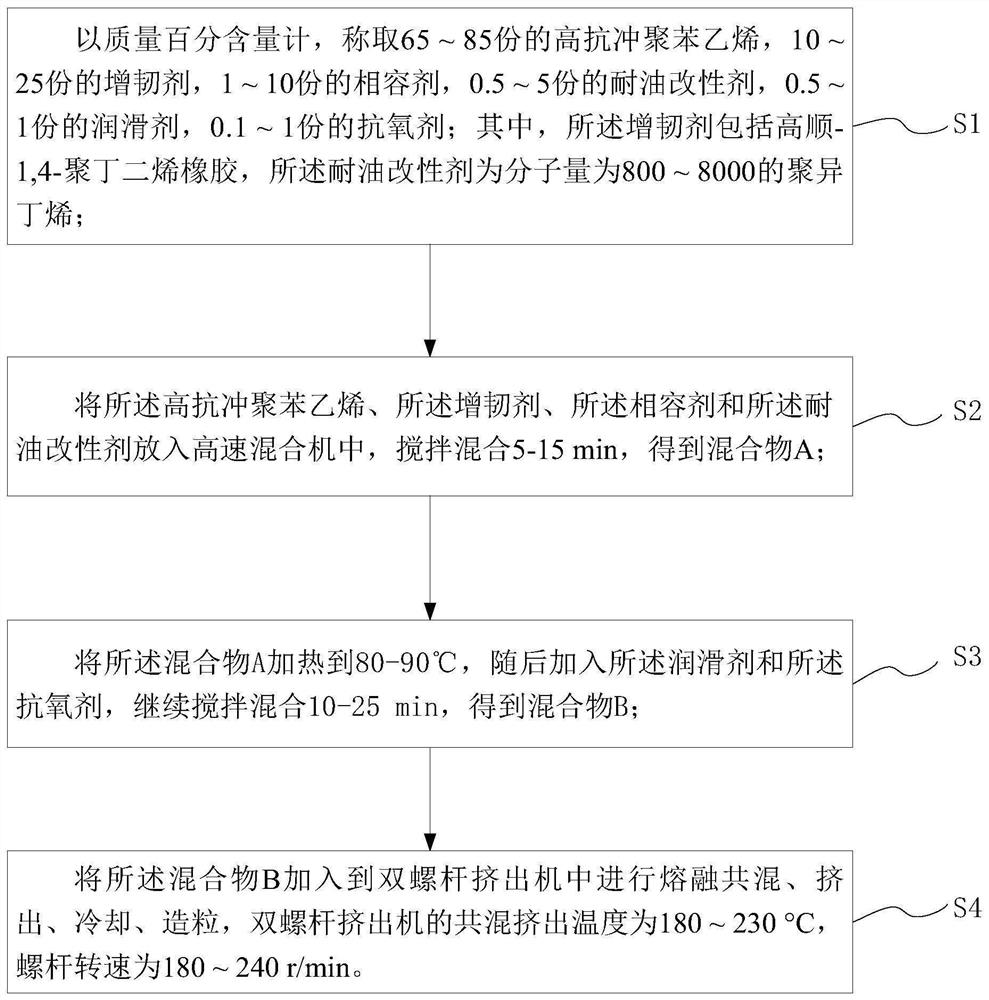

Refrigerator inner container, refrigerator inner container material and preparation method of refrigerator inner container material

The invention provides a refrigerator inner container, a refrigerator inner container material and a preparation method of the refrigerator inner container material. The refrigerator inner container material comprises the following components in parts by mass: 65-85 parts of high impact polystyrene, 10-25 parts of a toughening agent, 1-10 parts of a compatilizer, 0.5-5 parts of an oil-resistant modifier, 0.5-1 part of a lubricant and 0.1-1 part of an antioxidant, wherein the toughening agent is prepared from high cis-1, 4-polybutadiene rubber, and the oil-resistant modifier is polyisobutene with the molecular weight of 800-8000. According to the refrigerator inner container material, the components are matched for use, so that the refrigerator inner container material has low temperature resistance (resistant to -60 DEG C) and grease resistance, and has very high practical value.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

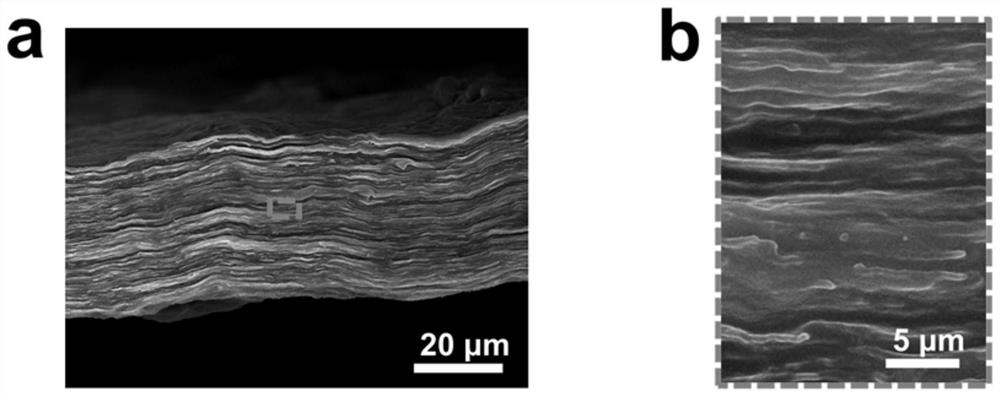

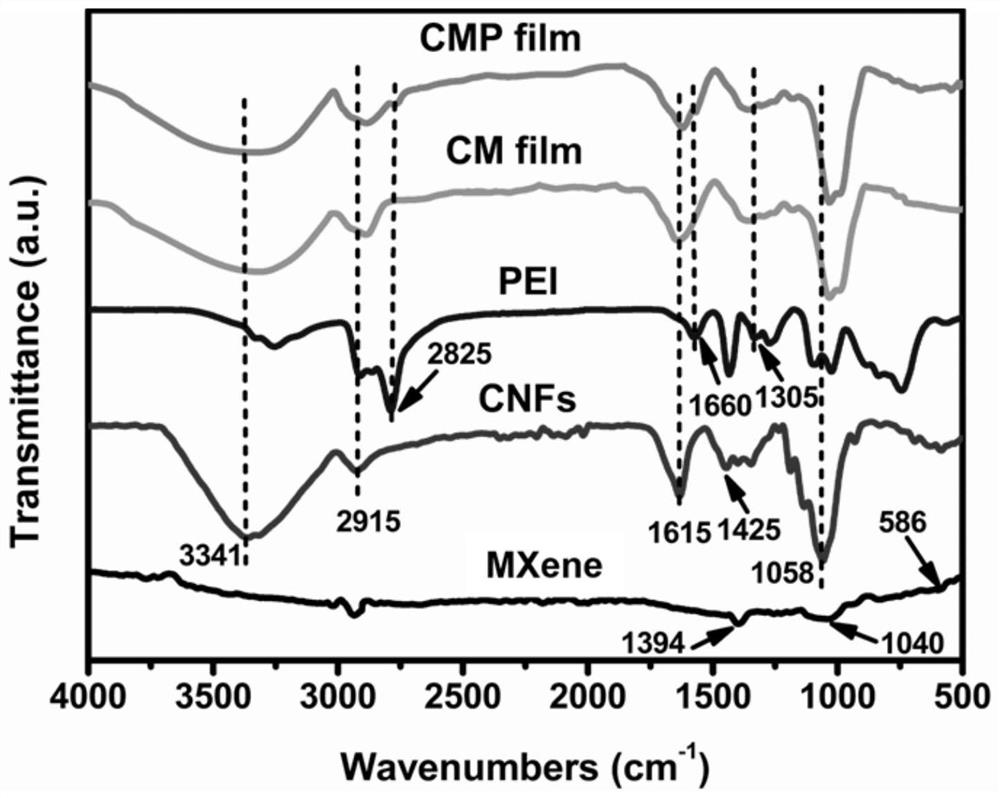

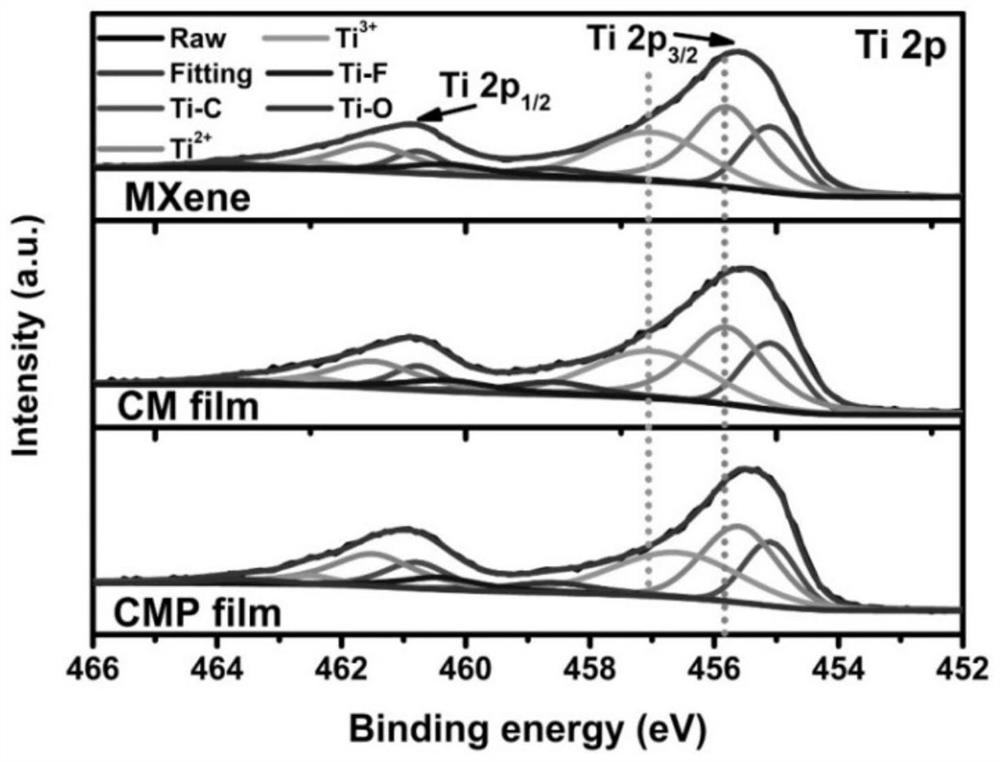

CNF-MXene-PEI high-strength and high-conductivity material as well as preparation method and application thereof

PendingCN113817230AEnhanced Interfacial InteractionImprove mechanical propertiesCellulosePolymer science

The invention provides a CNF-MXene-PEI high-strength and high-conductivity material as well as a preparation method and application thereof, and belongs to the technical field of functional materials. The CNF-MXene-PEI high-strength and high-conductivity material comprises cellulose nanofibers, MXene nanosheets and polyethyleneimine, the mass ratio of the cellulose nanofibers to the MXene nanosheets is 2: 3, and the addition amount of the polyethyleneimine is 1-5% of the mass of the cellulose nanofibers. The CNF-MXene-PEI high-strength and high-conductivity material prepared by the preparation method disclosed by the invention has excellent mechanical properties and conductivity, and can be applied to sensors, electric heating devices and energy storage devices.

Owner:NANJING FORESTRY UNIV

Polyether-ether-ketone/tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer/chopped quartz fiber material, preparation method and application

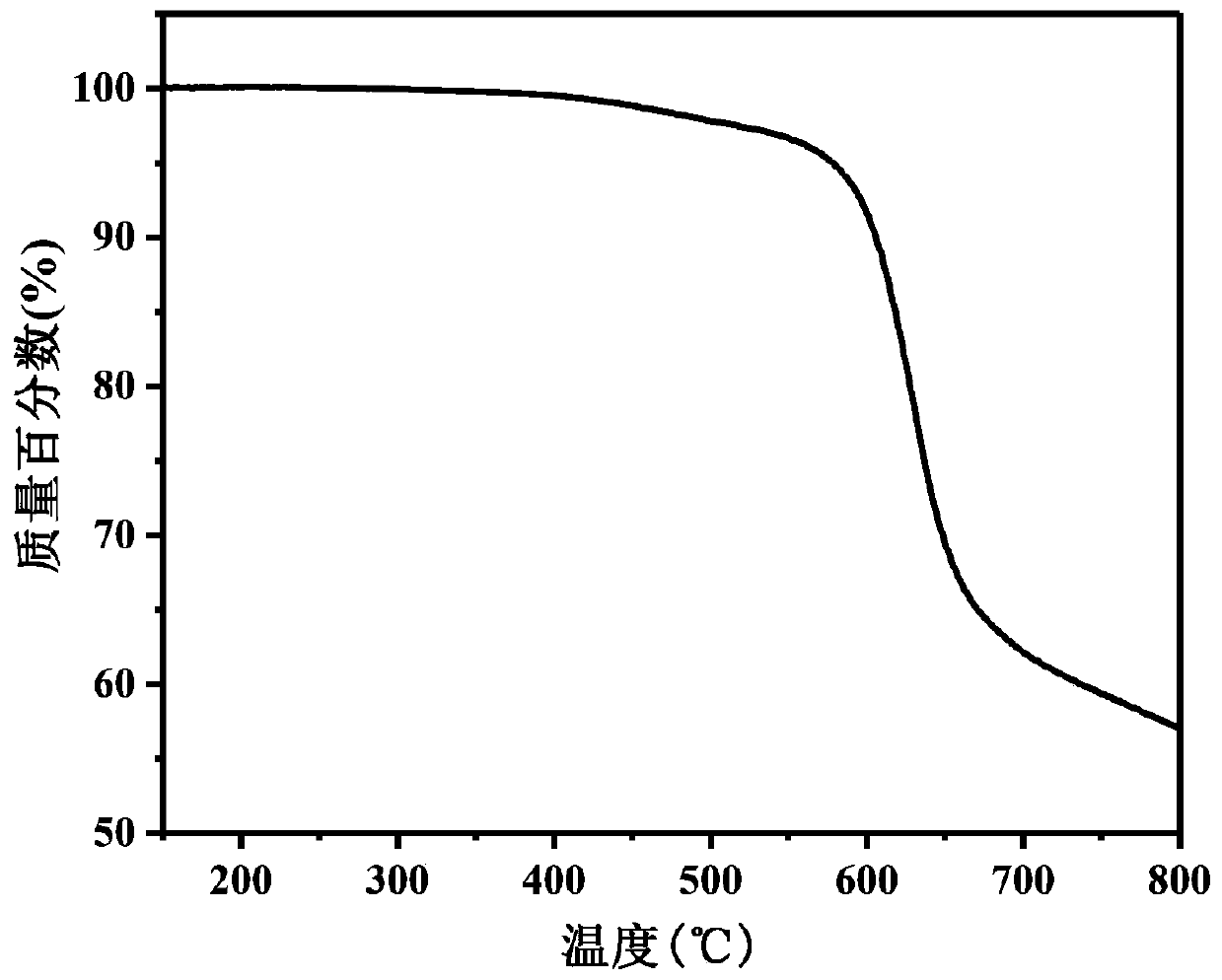

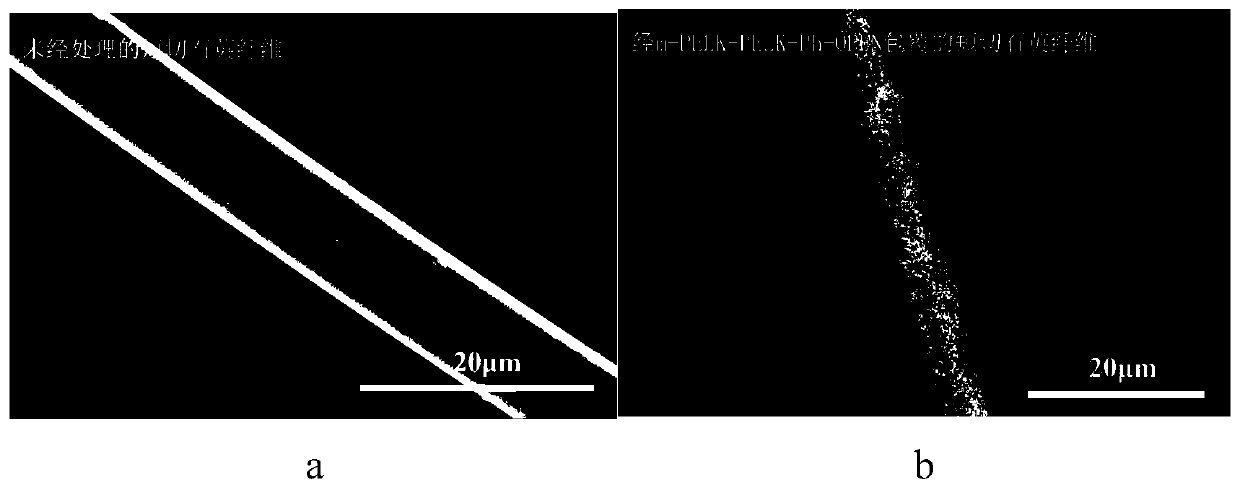

Belonging to the field of polymer composite materials, the invention provides a polyether-ether-ketone / tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer / chopped quartz fiber composite material, a preparation method and application thereof. According to the invention, a perfluorononenyloxy side group-containing polyether-ether-ketone block copolymer (m-PEEK-PEEK-Ph-OPFN) that has good compatibility with polyether-ether-ketone and a tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer, high temperature resistance and good match with a resin matrix is adopted for coating treatment onchopped quartz fiber; at the same time, a silane coupling agent is employed for surface modification treatment on hexagonal boron nitride to lower the agglomeration degree. Compared with filler without any treatment, the modified filler adopted by the invention has the characteristics of uniform dispersion in the composite material and strong interfacial interaction with the matrix.

Owner:JILIN UNIV

Transformer shell material and preparation method thereof

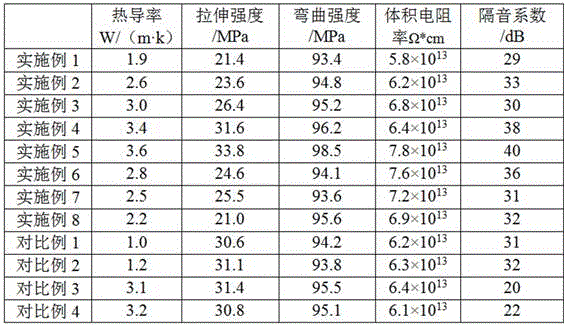

The invention discloses a transformer shell material which is characterized by comprising, by weight, 40-50 parts of polyurethane resin, 20-30 parts of nitrile-butadiene rubber, 10-20 parts of sound absorbing material, 8-16 parts of aluminum nitride, 4-8 parts of magnesium oxide, 10-15 parts of glass fiber, 1-3 parts of antioxidant and 2-5 parts of silane coupling agent. The heat conductivity of the prepared transformer shell material is 1.9-3.6W / (m*k), the transformer shell material is excellent in mechanical performance, good in insulation performance and excellent in sound absorbing effect, tensile strength is 21.0-33.8MPa, and bending strength is 93.4-98.5MPa.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com