Polyether-ether-ketone/tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer/chopped quartz fiber material, preparation method and application

A technology of perfluoroalkoxy vinyl ether and tetrafluoroethylene, which is applied in the field of polymer composite materials, can solve the problems of low dielectric properties, low surface energy characteristics, poor material strength, etc., and achieves low dielectric constant, low Linear expansion coefficient, the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

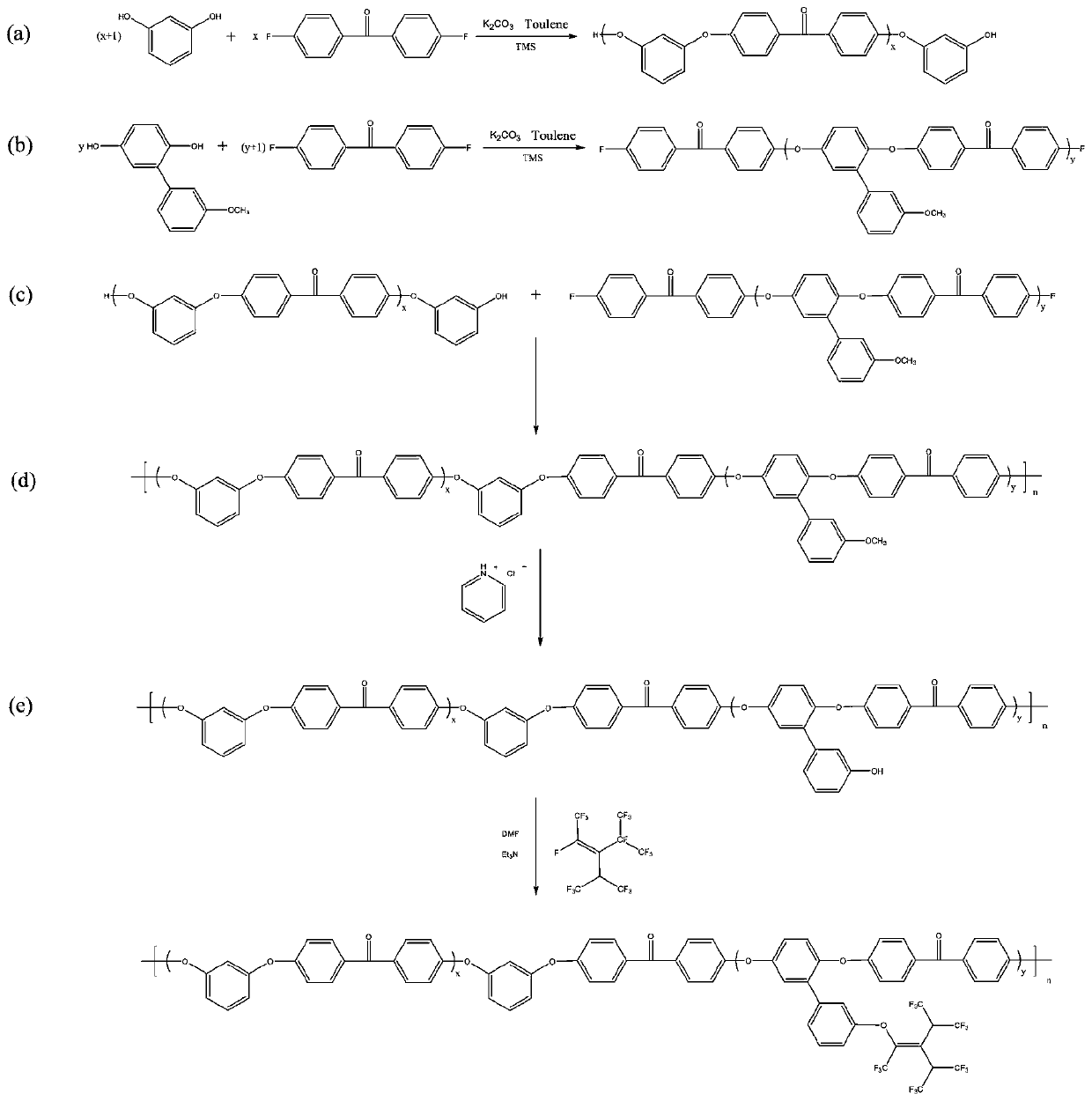

Method used

Image

Examples

preparation example Construction

[0067] The present invention also provides a preparation method of the polyether ether ketone / tetrafluoroethylene-perfluoroalkoxy vinyl ether copolymer / chopped quartz fiber composite material described in the above technical solution, comprising the following steps:

[0068] After mixing the polyetheretherketone block copolymer containing perfluorononenyloxy side groups with chloroform, adding chopped quartz fibers, mixing the obtained mixed solution with absolute ethanol, followed by suction filtration and drying to obtain Chopped quartz fibers coated with polyether ether ketone block copolymers with perfluorononenyloxy side groups;

[0069] After mixing the silane coupling agent, absolute ethanol, water and hexagonal boron nitride, heating in a water bath, suction filtration, washing with absolute ethanol and drying in sequence to obtain hexagonal boron nitride modified by the silane coupling agent;

[0070] Hexagonal nitrogen modified by polyetheretherketone resin, fusible ...

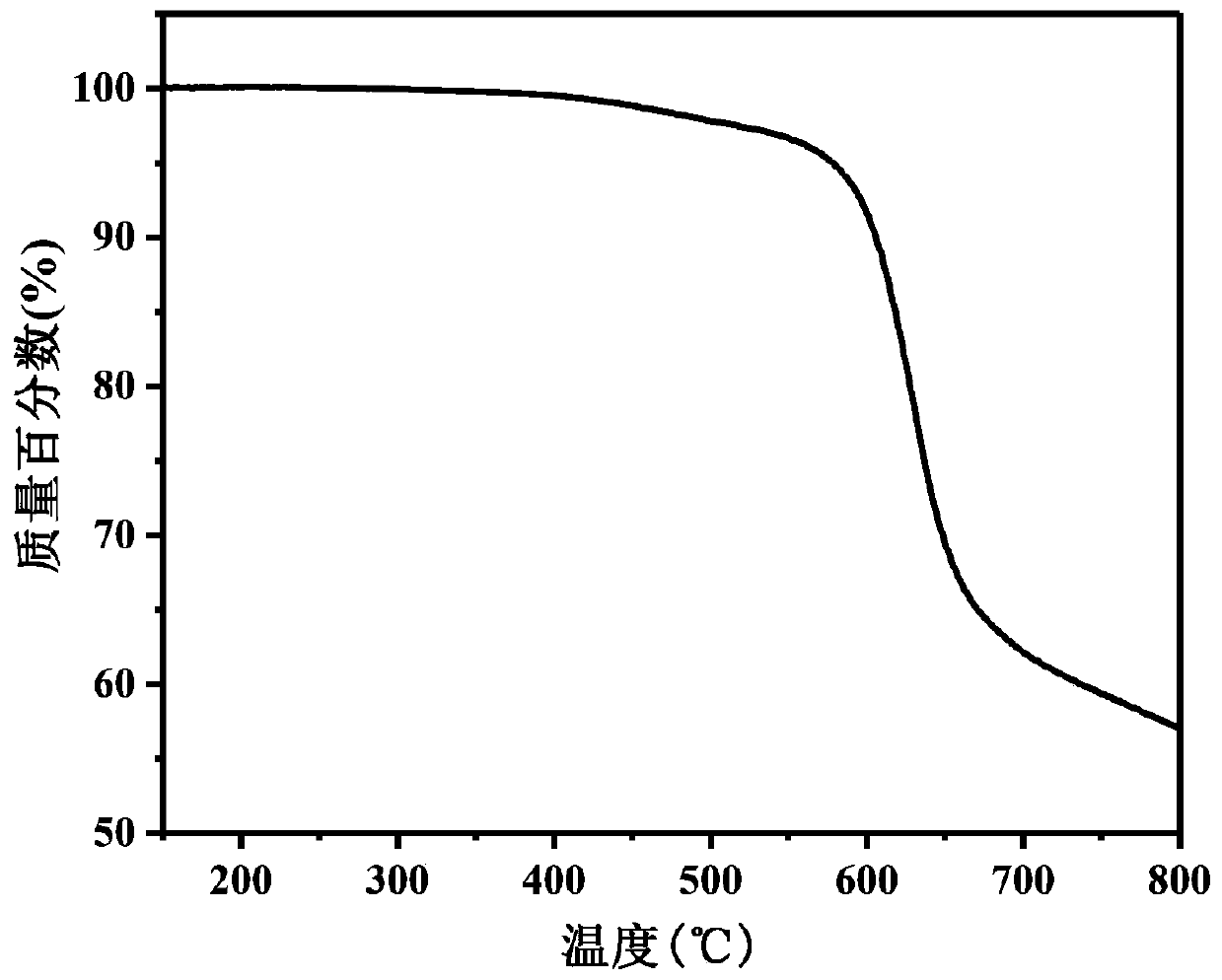

Embodiment 1

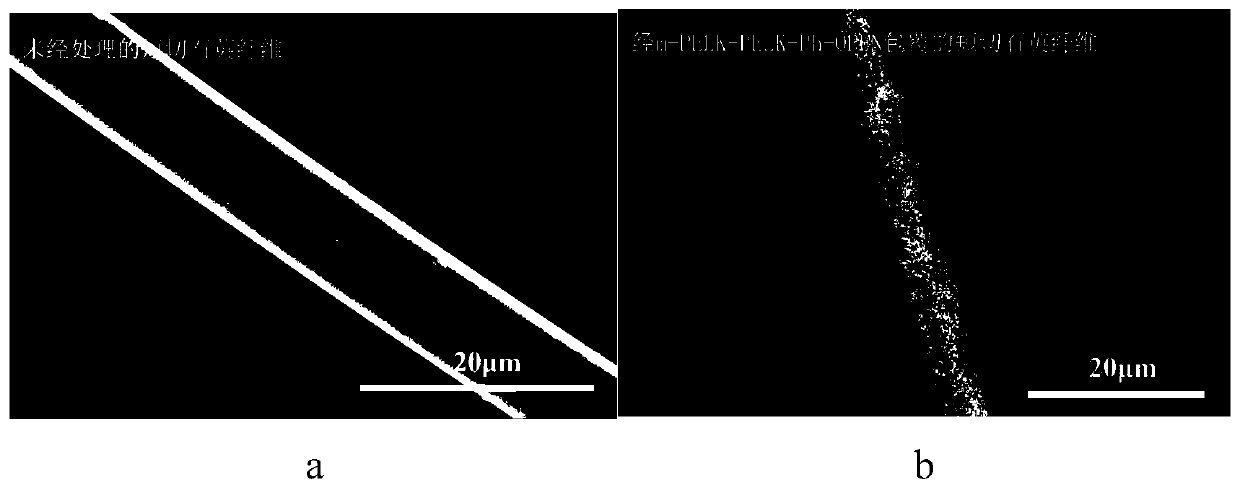

[0089] Preparation of chopped quartz fiber coated with 5wt% m-PEEK-b-PEEK-Ph-OPFN / 5wt% KH550 modified hexagonal boron nitride / 15wt% PFA / PEEK composite

[0090] Add 0.5g m-PEEK-b-PEEK-Ph-OPFN into 50mL of chloroform, mechanically stir at 25°C until completely dissolved, add 5g of chopped quartz fiber, continue stirring at 25°C for 6h, and then dissolve the mixture Slowly pour it into absolute ethanol while stirring, wash with absolute ethanol three times after suction filtration, and dry at 70°C to obtain chopped quartz fibers coated with m-PEEK-b-PEEK-Ph-OPFN, The mass ratio of chopped quartz fiber to m-PEEK-b-PEEK-Ph-OPFN is 10:1.

[0091] Add 0.2g KH550 to 50mL of absolute ethanol, then add 5mL of distilled water, stir mechanically for 10min, then add 5g of hexagonal boron nitride, ultrasonically disperse for 1h, heat in a water bath at 70°C for 6h, suction filter, and use absolute ethanol After washing 3 times and drying at 70°C, KH550 modified hexagonal boron nitride was ...

Embodiment 2

[0096] Preparation of chopped quartz fiber coated with 10wt% m-PEEK-b-PEEK-Ph-OPFN / 5wt% KH550 modified hexagonal boron nitride / 15wt% PFA / PEEK composite

[0097] Add 0.8g m-PEEK-b-PEEK-Ph-OPFN into 90mL chloroform, mechanically stir at 25°C until completely dissolved, add 10g of chopped quartz fiber, continue stirring at 25°C for 7h, and then dissolve the mixture Slowly pour it into absolute ethanol while stirring, wash with absolute ethanol three times after suction filtration, and dry at 70°C to obtain chopped quartz fibers coated with m-PEEK-b-PEEK-Ph-OPFN, The mass ratio of chopped quartz fiber to m-PEEK-b-PEEK-Ph-OPFN is 12.5:1.

[0098] Add 0.2g KH550 to 50mL of absolute ethanol, then add 5mL of distilled water, stir mechanically for 12min, then add 5g of hexagonal boron nitride, ultrasonically disperse for 1h, heat in a water bath at 70°C for 8h, suction filter, and use absolute ethanol After washing 3 times and drying at 70°C, KH550 modified hexagonal boron nitride was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com