Patents

Literature

177results about How to "Low coefficient of linear expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low coefficient of thermal expansion thermoplastic resin composition, preparation method and application thereof

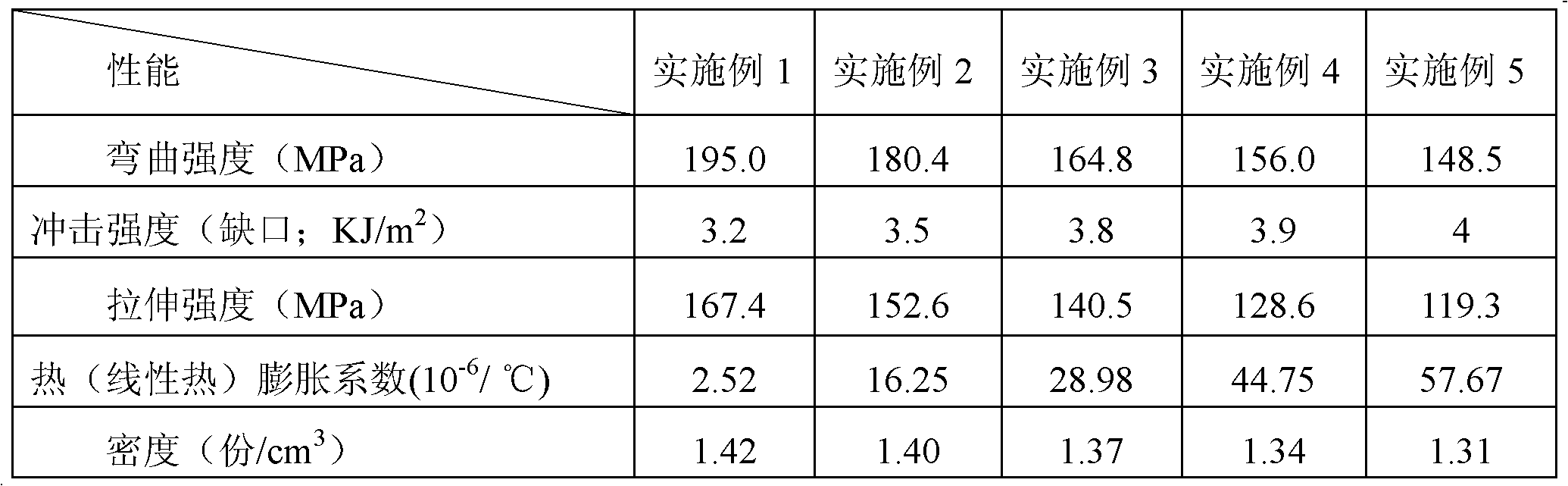

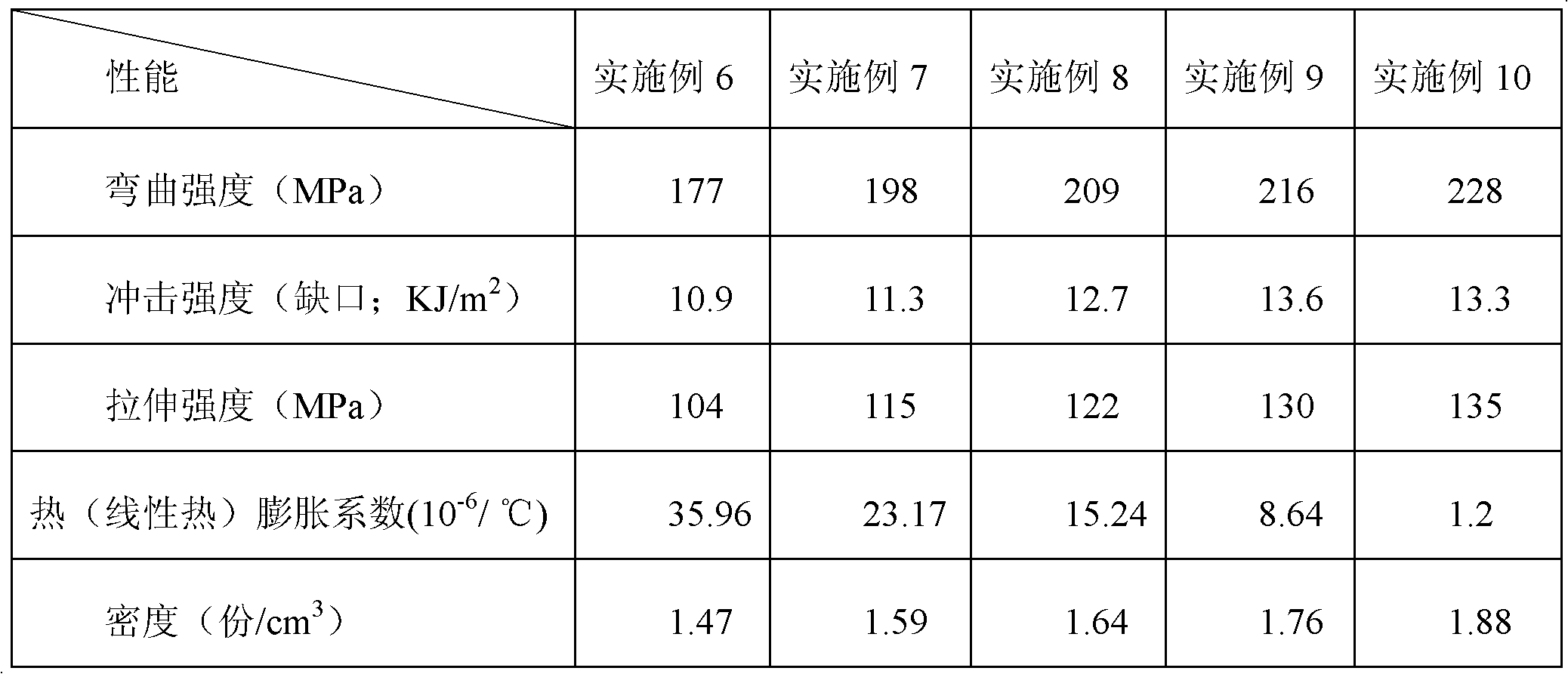

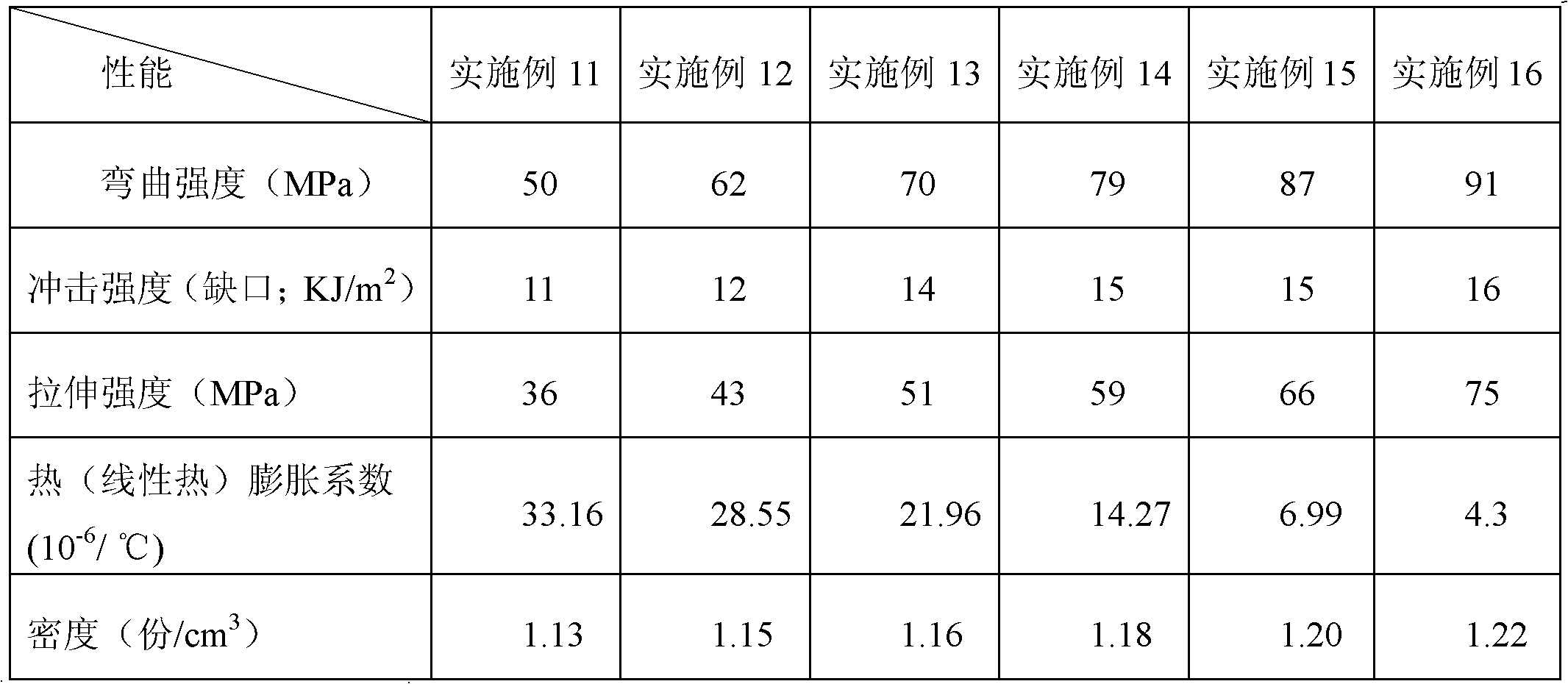

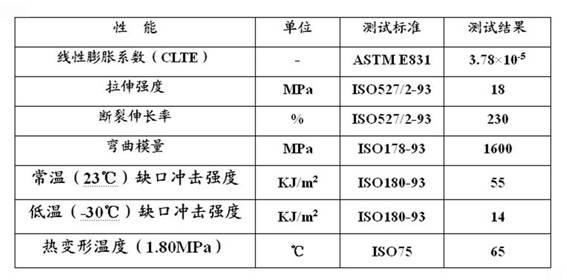

The invention belongs to the technical field of high polymer materials, and discloses low coefficient of thermal expansion thermoplastic resin composition, a preparation method and application of the low coefficient of thermal expansion thermoplastic resin composition. The resin composition is composed of, by weight, 340 to 900 parts of thermoplastic resin, 100 to 500 parts of carbon fibers, 0 to 5 parts of antioxygen, 0 to 5 parts of lubricating agent and 0 to 150 parts of flexibilizer. The preparation method comprises adding the 340 to 900 parts of the thermoplastic resin, the 0 to 5 parts of the antioxygen, 0 to 5 parts of the lubricating agent and the 0 to 150 parts of the flexibilizer to a high mixing machine to mix for 1 to 30 min, adding the mixture to a double-screw extruder, adding the 100 to 500 parts of the carbon fibers from the glass fiber feeding port or the side feeding port of the double-screw extruder to mix evenly, and carrying out extruding, dragging and prilling on mixed materials in the double-screw extruder to obtain the low coefficient of thermal expansion thermoplastic resin composition. The use of the low coefficient of thermal expansion thermoplastic resin composition applied to the fittings of a metal piece is provided. The thermoplastic resin is high in flexural modulus, tensile strength and impact strength, and low in linear expansion coefficient.

Owner:HEFEI GENIUS NEW MATERIALS

Glass fiber reinforced polypropylene composite material for car radiator grid and preparation process thereof

The invention discloses a glass fiber reinforced polypropylene composite material for a car radiator grid and a preparation process thereof. The composite material comprises the following components in percentage by weight: 32-78% of polypropylene, 0-2% of a thermal stabilizer, 0-2% of an additive, 0-2% of an illumination stabilizer, 0-2% of a nucleating agent, 5-20% of a flexibilizer, 2-10% of a compatilizer and 15-30% of chopped glass fiber. Due to the adoption of the chopped glass fiber for filling, the rigidity and the heat resistance of the material are greatly improved, the linear expansion coefficient (CLTE) of the material can be also reduced, and the problems of size change and deformation of a workpiece due to rapid change of external environment temperature are solved. The prepared composite material is excellent in heat resistance, high in rigidity, excellent in size stability and weather resistance and high in impact resistance, and satisfactorily meets the demand of the car radiator grid.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Low-linear-expansion-coefficient polypropylene composite and preparation method thereof

ActiveCN102504411ALow coefficient of linear expansionAvoid destructionBumpersPolypropylene compositesPolymer science

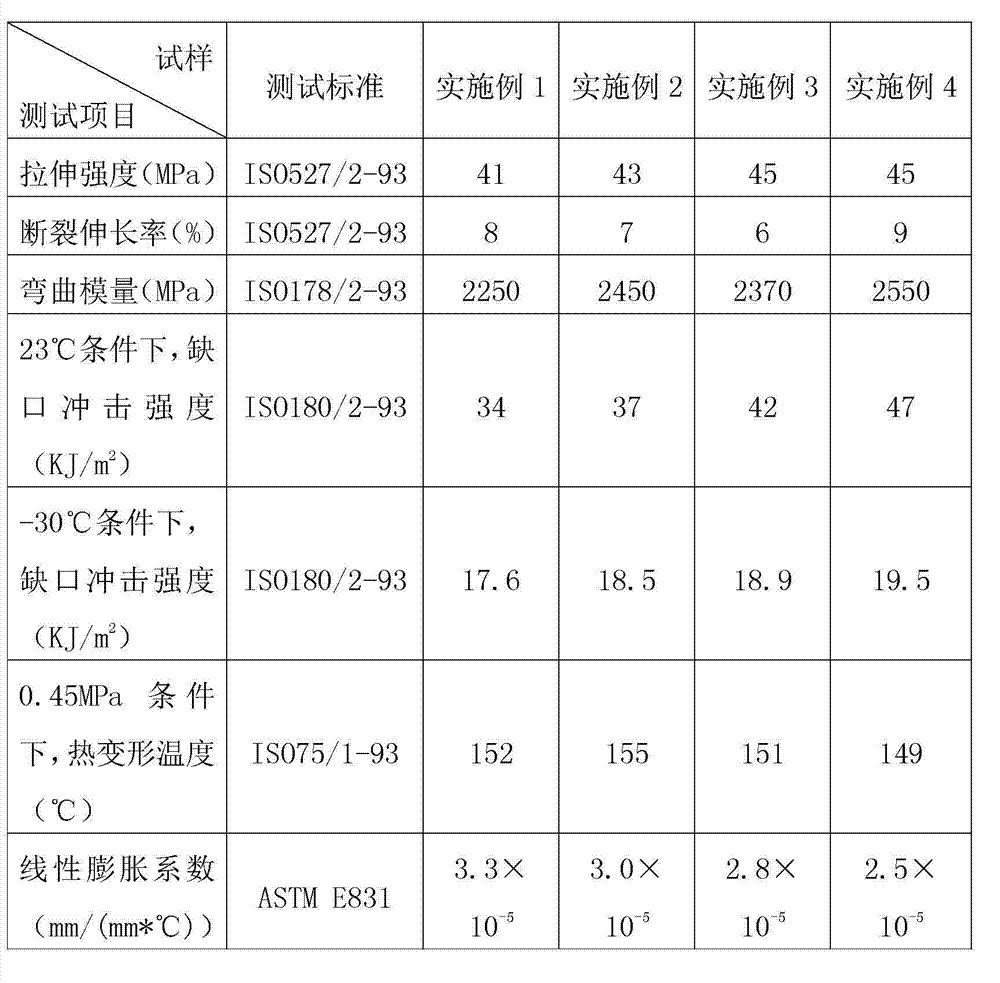

The invention relates to a low-linear-expansion-coefficient polypropylene composite, which comprises: 53 to 95 weight percent of polypropylene, 0 to 1 weight percent of heat stabilizer, 0 to 1 weight percent of lubricating agent, 0 to 20 weight percent of toughening agent, 0 to 5 weight percent of interface compatibilizer and 5 to 20 weight percent of wollastonite, wherein the wollastonite is prepared by mixing needle-like wollastonite with a length-diameter ratio of 10 to 30 and powder wollastonite with a length-diameter ratio of less than or equal to 5 according to a ratio of 1 / 4 to 4. The invention also discloses the preparation method of the polypropylene composite, which comprises: adding wollastonite into an extruder in a side feeding form from a side feed inlet and performing extrusion processing. The method can prevent the special structure of the wollastonite from being damaged due to long-time blending and make process control simple and material performance guaranteed easily. Compared with the conventional polypropylene material for automobile bumpers, the polypropylene composite prepared by the method has very low linear expansion coefficient (less than or equal to 4.0*10<-5>) and has very high heat resistance and high rigidity and toughness balancing performance.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

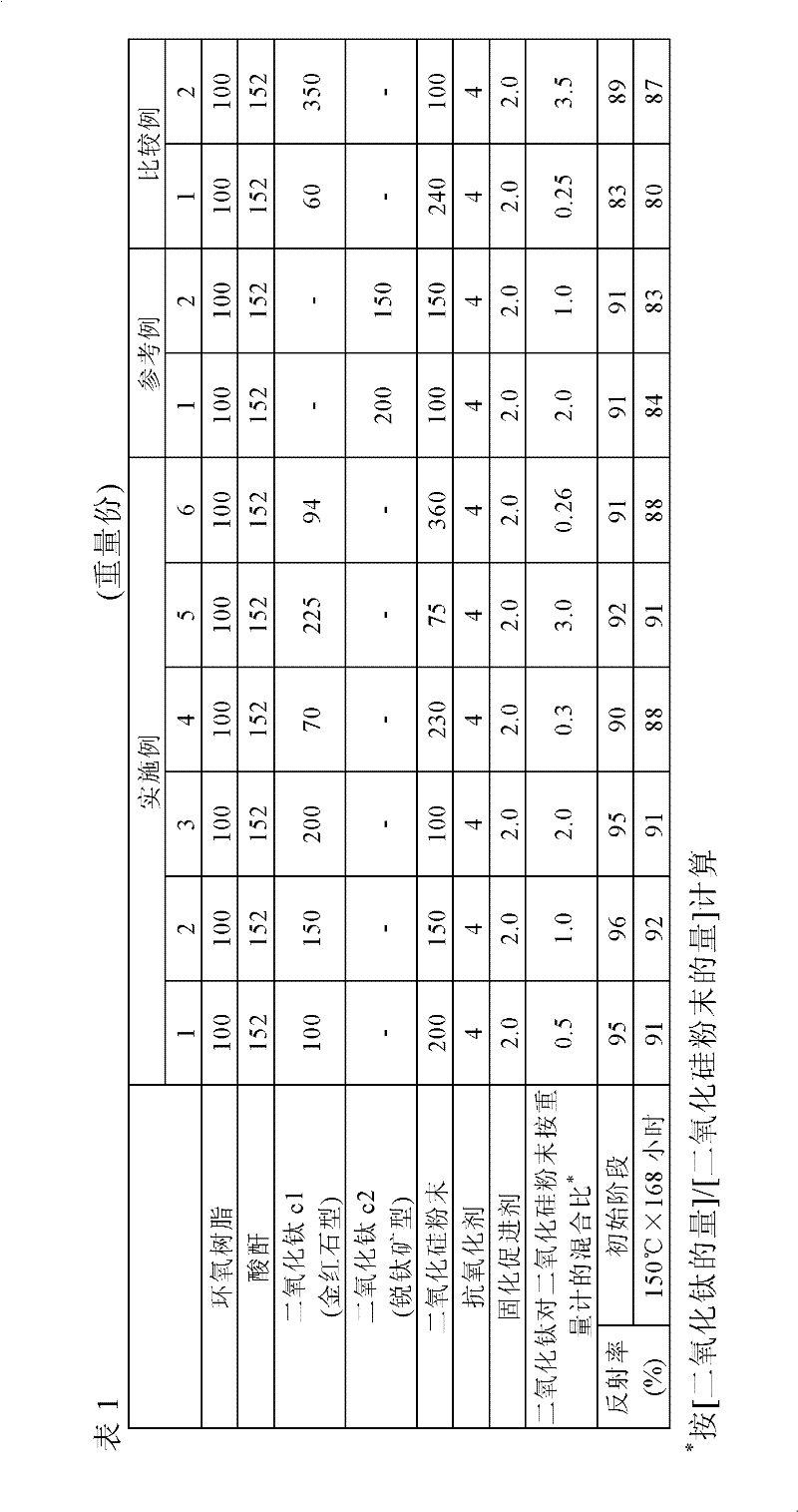

Epoxy resin encapsulating material composition

ActiveCN101173159ALow initial viscosityLow coefficient of linear expansionOther chemical processesSemiconductor/solid-state device detailsEpoxyChemical composition

An epoxy resin encapsulation material composition, the composition contains epoxy resin, a curing agent and inorganic filler particles containing a coupling agent, wherein the particle diameter of the inorganic filler particles containing a coupling agent is 0.1-200 microns , wherein the inorganic filler particles containing a coupling agent whose particle diameter is not more than 3 microns account for 5-20% by volume of the total amount of the inorganic filler particles containing a coupling agent. The epoxy resin encapsulating material composition provided by the present invention can greatly increase the filling ratio of the inorganic filler, thus making the epoxy resin encapsulating material composition provided by the present invention have low initial viscosity, excellent fluidity, and linear expansion coefficient Low, the production cost of obtaining epoxy resin encapsulation materials with the same initial viscosity is greatly reduced. In addition, the composition provided by the invention has excellent dielectric properties and is suitable for the packaging of various electronic components sensitive to stress, especially for automatic packaging of electronic components requiring high precision.

Owner:靖江德方科技服务有限公司

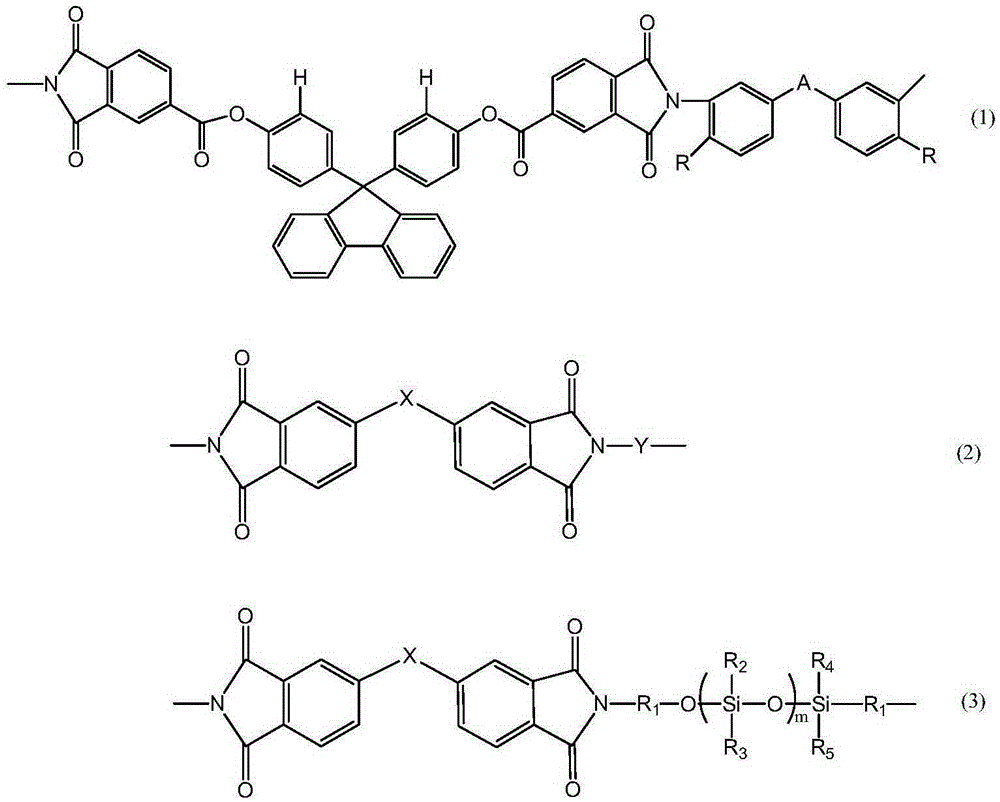

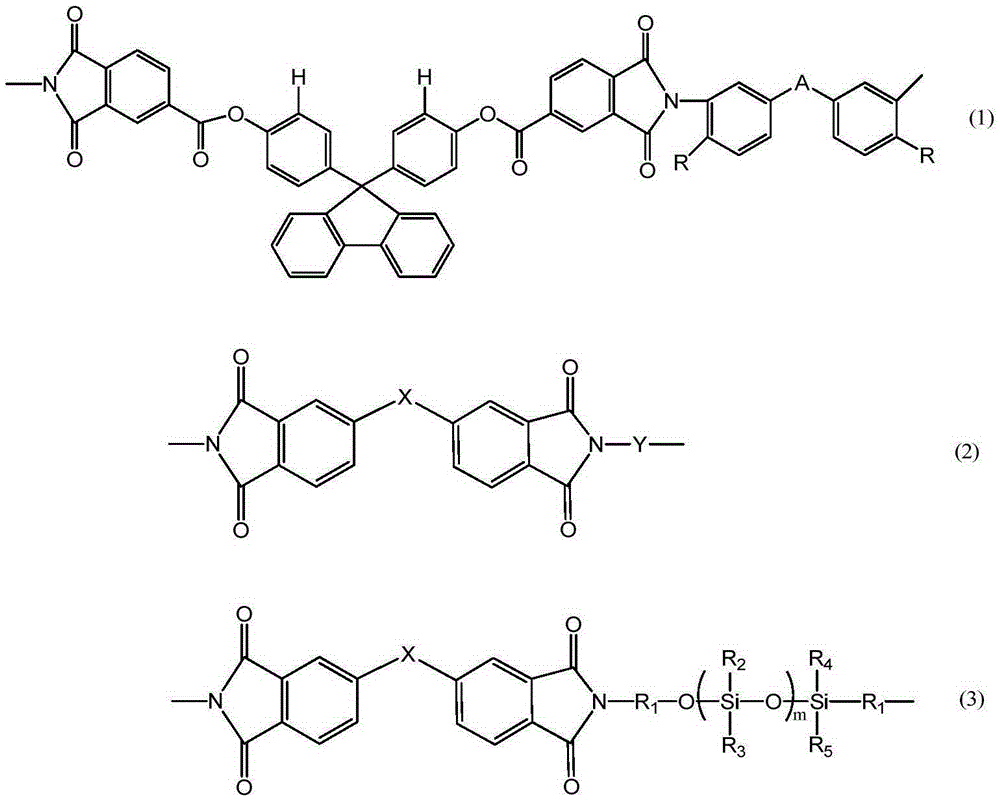

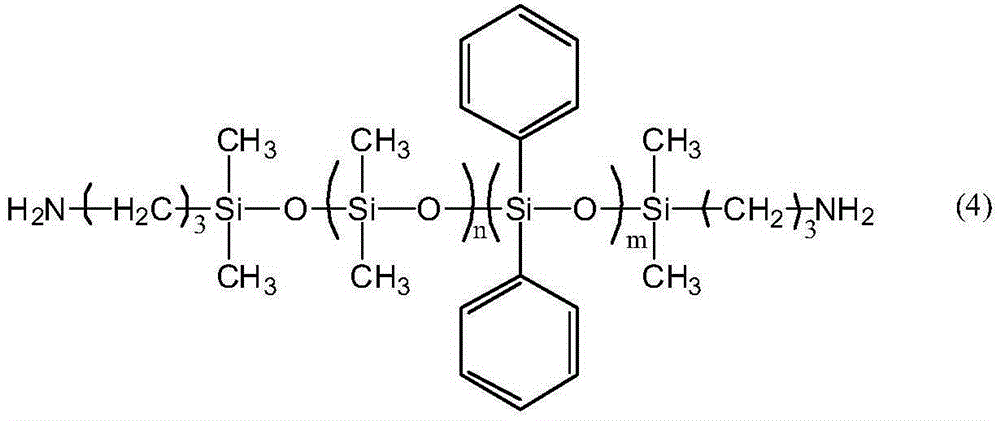

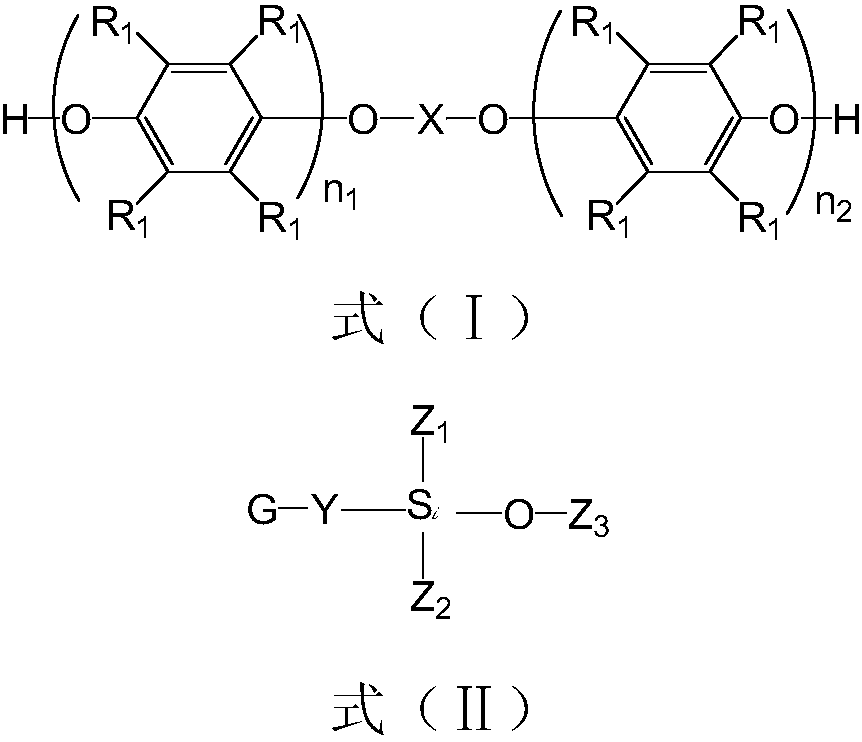

Positive photosensitive polyimide resin composition with ester bond connected fluorene unit and siloxane

ActiveCN105301902ASimple processEasy to operateCoatingsPhotosensitive materials for photomechanical apparatusPhotosensitizerHeat resistance

The invention discloses a positive photosensitive polyimide resin composition with an ester bond connected fluorene unit and siloxane. The composition contains (a) alkali soluble polyimide, (b) photosensitizer and (c) crosslinking agent. The (c) crosslinking agent is composed of one or two of a benzoxazine compound and a compound with one molecule provided with more than two epoxy groups according to any ratio. The weight ratio of (a), (b) and (c) is 100:(10-50):(5-20). The positive photosensitive polyimide resin composition has high coefficient of thermal expansion, high heat resistance and excellent photosensitive property.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

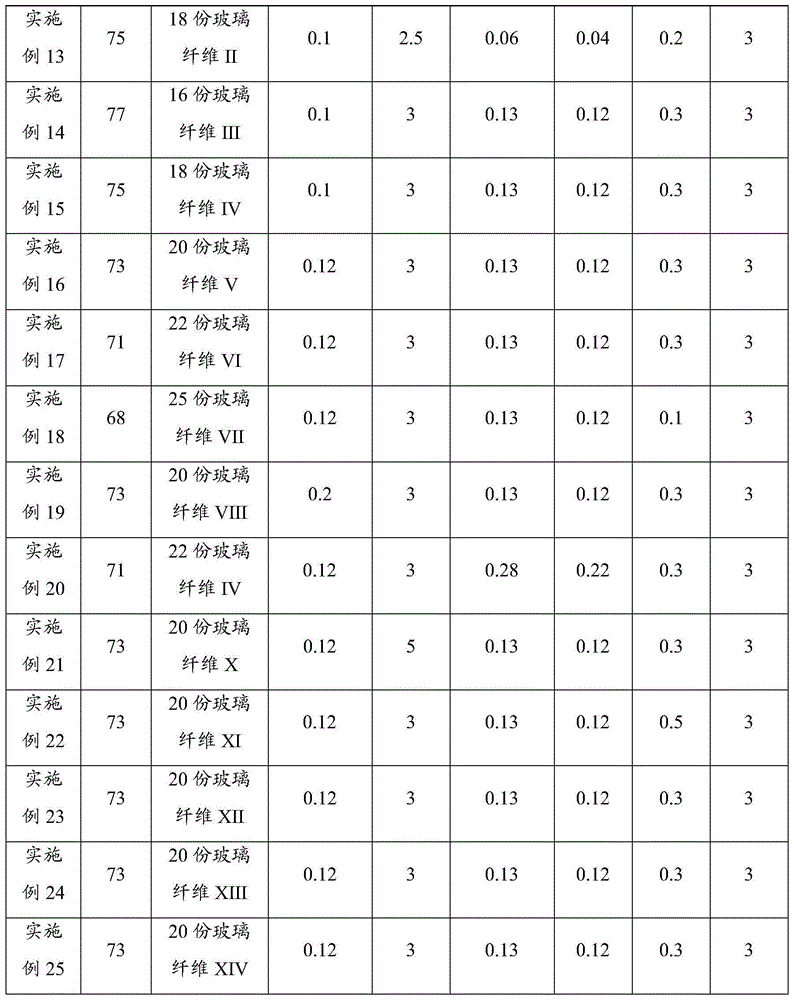

Glass fiber, surface treatment method of glass fiber, plastic and shell

InactiveCN104310803ALow coefficient of linear expansionImprove impact resistanceGlass fiberFlat glass

The invention relates to the technical field of materials, and particularly relates to a glass fiber, a surface treatment method of the glass fiber, a plastic and a shell, which are used for improving the capacity, of combining with ABS, of the glass fiber. The surface treatment method of the glass fiber comprises the following steps: putting the glass fiber to be treated in corrosive liquid to carry out corrosive treatment for 30-40 seconds, wherein the corrosive liquid comprises a corrosion inhibitor and an acidic water solution with mass fraction of 0.05-0.5% and 99.5-99.95%; putting the corroded glass fiber in a coupling agent to carry out infiltration; and drying the infiltrated glass fiber. Through the surface treatment, the capacity, of combining with ABS, of the glass fiber is relatively high; being added into ABS plastics, the glass fiber is capable of effectively enhancing the linear expansion coefficient of the ABS; and when the glass fiber is flat glass fiber, the shock resistance of the ABS plastics can be improved.

Owner:GUANGDONG HISENSE ELECTRONICS CO LTD

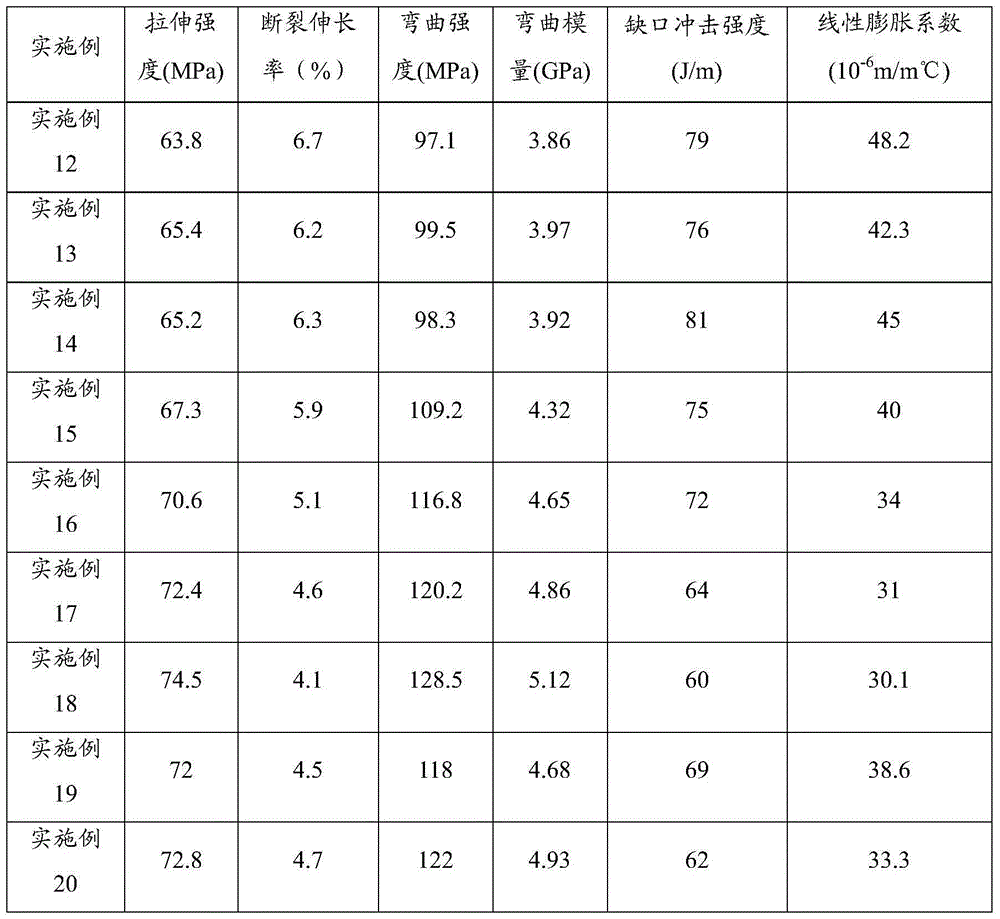

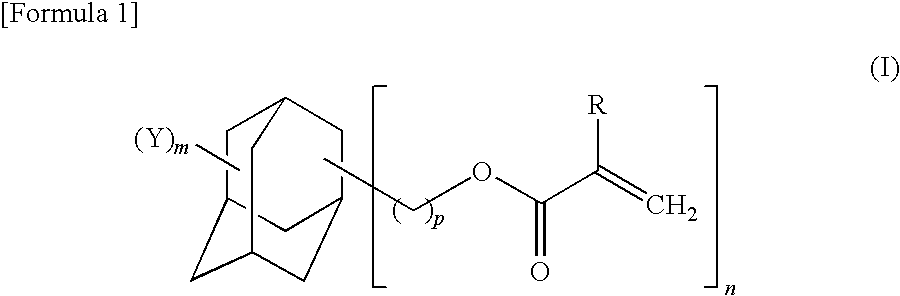

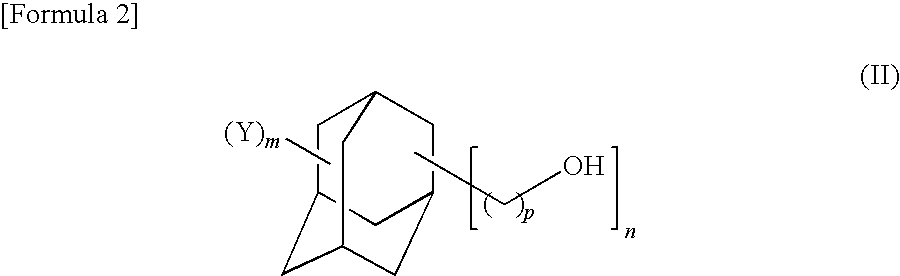

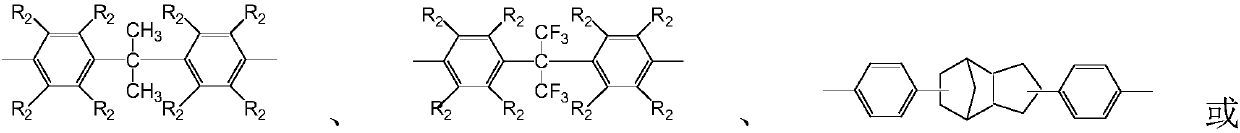

Adamantane derivative, process for production thereof, resin composition, and cured product of the resin composition

InactiveUS20100048757A1Improve heat resistanceImprove mechanical propertiesOrganic compound preparationCarboxylic acid esters preparationMethyl groupMechanical property

Disclosed herein is an adamantane derivative represented by the following general formula (I):(wherein R represents a hydrogen atom, a fluorine atom, a methyl group or a trifluoromethyl group; Y represents a hydrogen atom, a hydroxyl group, ═O formed by two Ys together, a carboxyl group, or a hydrocarbon group having 1 to 20 carbon atoms or a cyclic hydrocarbon group having 3 to 20 carbon atoms; m is 13 and n is 3, or m is 12 and n is 4; and p is an integer of one or more), a production method thereof, a resin composition containing the adamantane derivative, and a cured product thereof. The present invention provides a cured product advantageous as various coating agents, a microlens, a film condenser, a colored composition for a liquid crystal color filter, a pattern organizer formed in nanoimprinting, and the like, having transparency, heat resistance, good mechanical properties, low volume shrinkage, and low coefficient of linear expansion, as well as liquid adamantyl group-containing (meth)acrylates to produce the cured product, the production method thereof, and the resin composition.

Owner:IDEMITSU KOSAN CO LTD

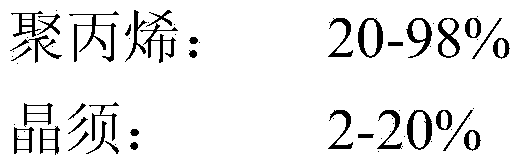

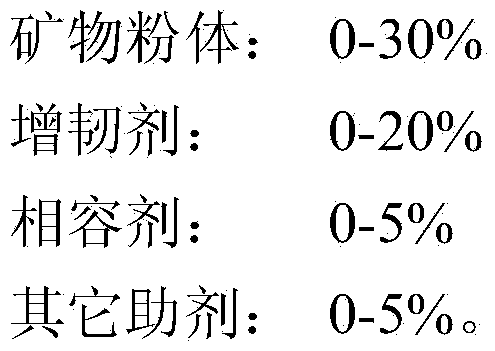

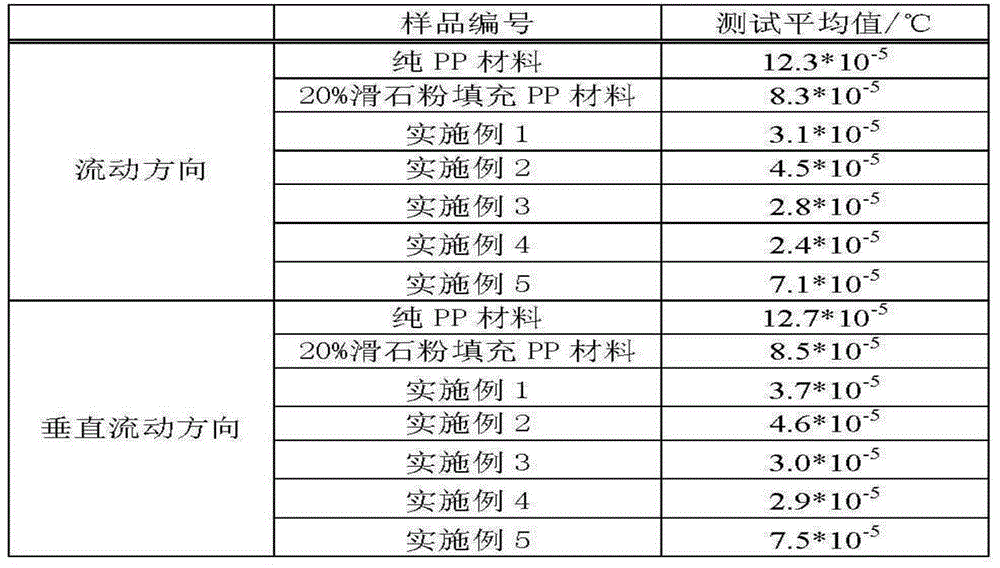

Isotropic polypropylene composition with low linear expansion coefficient and preparation method thereof

ActiveCN103665544ALow coefficient of linear expansionReach the use requirements of isotropic consistencyPolymer scienceDiameter ratio

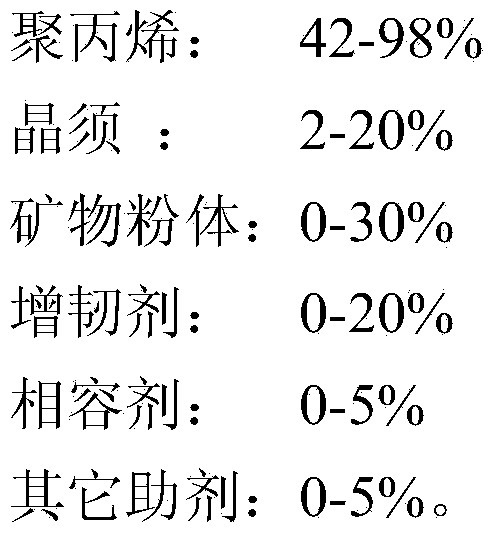

The invention discloses an isotropic polypropylene composition with low linear expansion coefficient and a preparation method thereof, and belongs to the field of modified plastics. The isotropic polypropylene composition with low linear expansion coefficient, provided by the invention, is prepared from the following components by mass percent: 20-98% of polypropylene, 2-20% of crystal whiskers, 0-30% of mineral powder, 0-20% of a flexibilizer, 0-5% of a compatilizer and 0-5% of other auxiliary agents, wherein the crystal whiskers adopt three-dimensional tetrapod-like structures and are isotropic, and the length-diameter ratio of each crystal whisker in single direction can reach 50 above. According to the polypropylene composition, the linear expansion coefficients of the polypropylene composition in the transverse and longitudinal directions can reach 4.0*10<-5> below by virtue of the added crystal whiskers, and the purpose of isotropy can be achieved. The polypropylene composition prepared through the method can be applied to inner and outer decorative parts of automobiles.

Owner:TIANJIN KINGFA NEW MATERIAL +1

Continuously-cast crystallizer copper liner

The invention discloses a continuously-cast crystallizer copper liner, which is prepared by a method comprising: preparing copper-aluminum alloy powder with an aluminum content of 0.03 to 0.6 weight percent, wherein the grain size of the copper-aluminum alloy powder is less than 150mum and the grain size of over 50 weight percent of powder is less than 74mum; filling the copper-aluminum alloy powder in an oxygen supply furnace, supply oxygen in a molar ratio of the oxygen to the aluminum in the copper and aluminum alloy of 3:2 to 6:2, and heating the copper-aluminum alloy powder to 100 to 300 DEG C to perform reaction for 3 to 30 hours; preparing dispersion copper powder ingot blanks; extruding the ingot blanks at 700 to 1,000 DEG C to a nearly formed pipe; drawing the extruded pipe blank by required specifications; and plating the surface of the drawn pipe blank. The copper alloy liner of the invention has the advantages that: casting efficiency can be improved greatly; the casting drawing speed can be improved by 1.5 to 2 times compared with the original drawing speed; the service life of the crystallizer copper pipe is improved greatly; and the productivity of the crystallizer is 1.5 to 3 times that of the traditional crystallizer.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Vinyl Polymer Powder, Curable Resin Composition and Cured Product

InactiveUS20140296437A1Good dispersionTurn fasterSemiconductor/solid-state device detailsSynthetic resin layered productsCrack resistanceGlass transition

A vinyl polymer powder, a curable resin composition containing the vinyl polymer powder and a curable resin, and a cured product obtained by curing the curable resin composition are provided. The vinyl polymer powder contains a vinyl polymer of which the glass transition temperature is 120° C. or higher and the mass average molecular weight is 100,000 or more, has excellent dispersibility in the curable resin composition, and rapidly turns the curable resin composition into a gel state by heating at a predetermined temperature in a short time. Further, the vinyl polymer powder decreases the linear expansion coefficient of the obtained cured product, and improves the crack resistance.

Owner:MITSUBISHI RAYON CO LTD

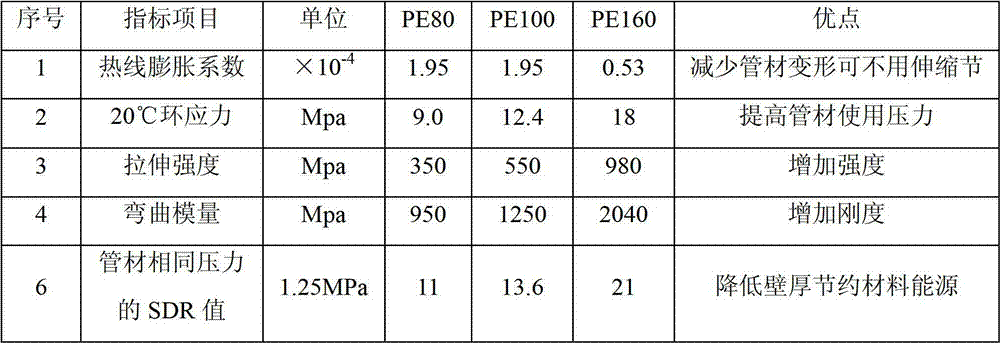

PE160 grade composite material for pipes and preparation method of composite material

InactiveCN102786729ALow coefficient of linear expansionImprove mechanical and thermal propertiesExpansion factorLinear expansion coefficient

The invention discloses a PE160 grade composite material for pipes. The PE160 grade composite material comprises the following ingredients in parts by weight: 100 parts of HDPE (high-density polyethylene) resin, 0.5 to 50 parts of inorganic rigid particles, 1 to 40 parts of ultrafine fibers and 0.05 to 10 parts of functional raw materials. The invention also discloses a preparation method of the material. The preparation method comprises the following steps that A, raw materials except the ultrafine fibers in the recipe are selected and are placed into a high mixing machine; B, the materials which are uniformly mixed in the step A are added into a material tube of a plastic extruding machine, the temperature is set, the screw rod rotating speed and the feeding speed are regulated, and the ultrafine fibers are fed in the second section of the plasticization; and C, normal wire drawing cooling, particle cutting, baking and package are carried out. The PE160 grade composite material has the beneficial effects that the goals of enhancing the intensity and the rigidity of polyethylene, reducing the linear expansion factor, improving the mechanical property and thermal performance can be realized, the work pressure is improved, the safety and the reliability are higher, the ring rigidity, the intensity and the toughness are more excellent, in addition, the weight is light, the impact resistance is high, and the damage cannot occur.

Owner:杨电云

Stress whitening resistant low-VOC (Volatile Organic Compounds) low-linear-expansion-coefficient polypropylene material

InactiveCN106832598AImprovement of bending stress whitening performanceGood dimensional stabilityAntioxidantSorbent

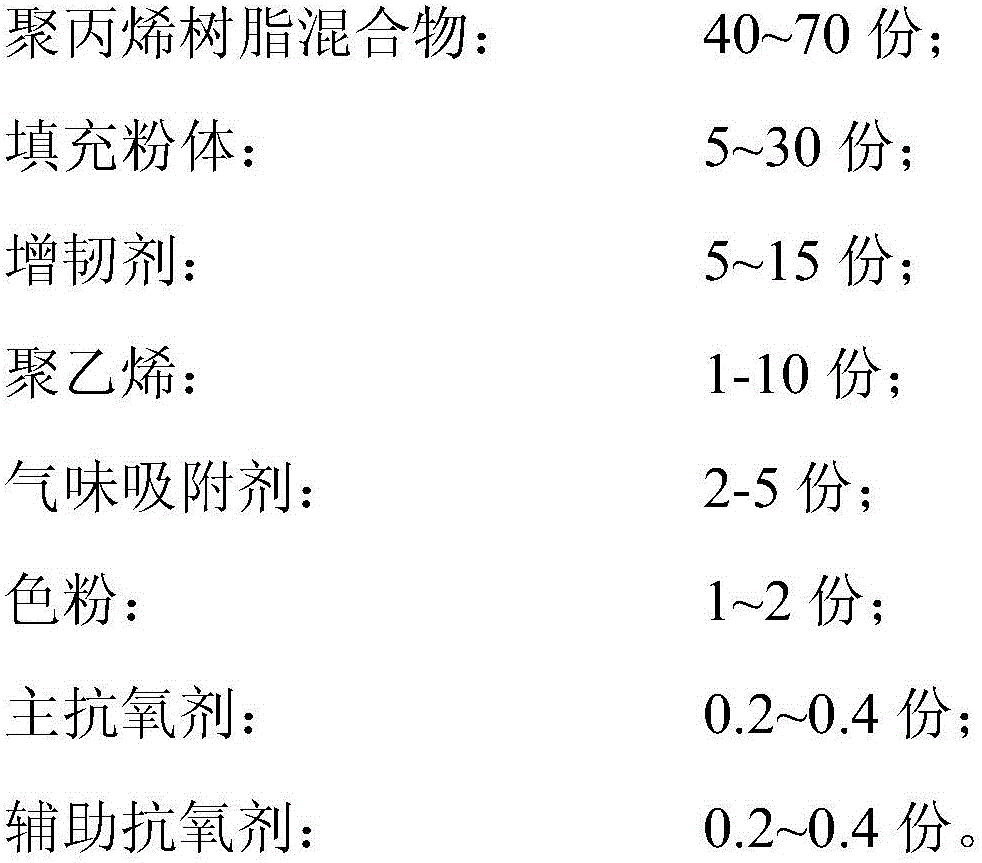

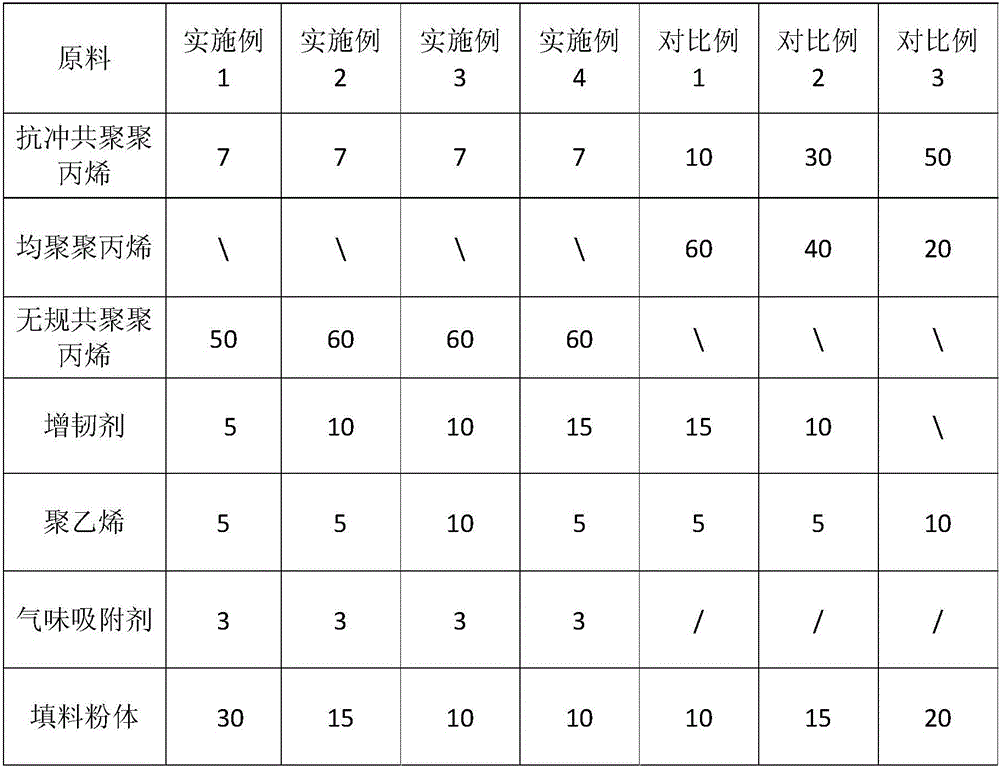

The invention provides a stress whitening resistant low-VOC (Volatile Organic Compounds) low-linear-expansion-coefficient polypropylene material. The stress whitening resistant low-VOC low-linear-expansion-coefficient polypropylene material is prepared from the following raw materials in parts by weight: 40 to 70 parts of polypropylene resin mixture, 5 to 30 parts of filling powder, 5 to 15 parts of toughening agent, 1 to 10 parts of polyethylene, 2 to 5 parts of smell adsorbent, 1 to 2 parts of toner, 0.2 to 0.4 part of primary antioxidant and 0.2 to 0.4 part of auxiliary antioxidant. In the stress whitening resistant low-VOC low-linear-expansion-coefficient polypropylene material, random copolymerization polypropylene is taken as a substrate, so that the anti-bending stress whitening performance of the material is enhanced remarkably; the toughening agent and the polyethylene are added, so that the stress whitening resistance is enhanced, the linear expansion coefficient and smell of the material are lowered on the basis of keeping other physical properties, and the size stability of the material is improved.

Owner:TIANJIN KINGFA NEW MATERIAL

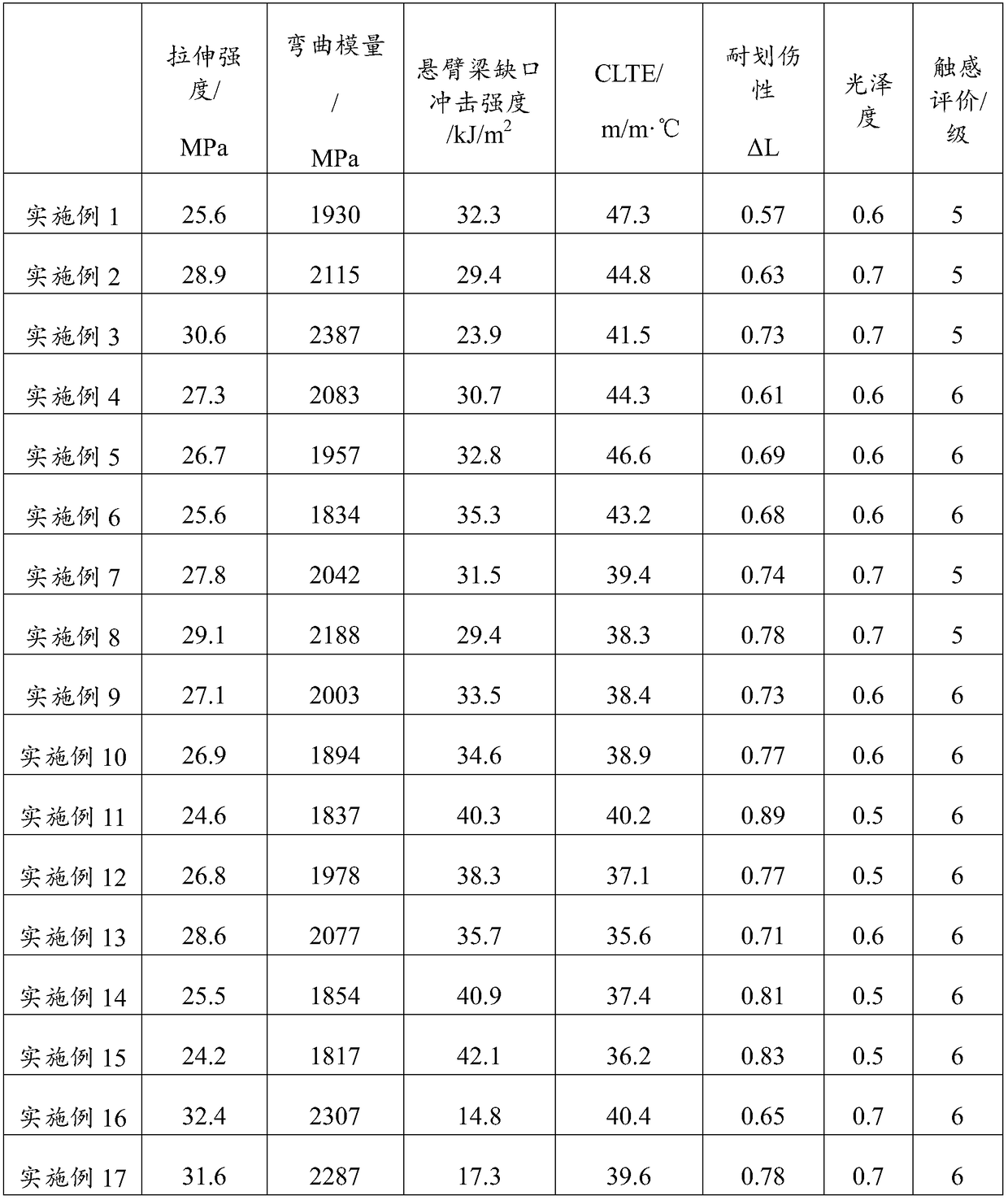

Low-linear expansion scratch-resistant highlight polypropylene composite material

The invention discloses a low-linear expansion scratch-resistant highlight polypropylene composite material and a preparation method thereof. The composite material is prepared from the following components in parts by weight: 50-80 parts of polypropylene, 10-50 parts of phenolic resin, 1-5 parts of curing agent, 10-40 parts of compatilizer, 0.1-0.4 part of antioxidant, 0.1-0.3 part of nucleating agent, 0.1-0.3 part of lubricating agent and 0-5 parts of other aids. The composite material has the characteristics of high glossiness, low linear expansion coefficient and scratch resistance and has high bending modulus and tensile strength of inorganic filler enhanced polypropylene composite material. Moreover, the preparation process is controllable, the production cost is low, and secondary pollution is avoided.

Owner:HEFEI GENIUS NEW MATERIALS

Polypropylene composite material capable of realizing light weight and with low linear expansion coefficient and preparation method thereof

InactiveCN105504528ALow coefficient of linear expansionGood toughness balanceAntioxidantLinear expansion coefficient

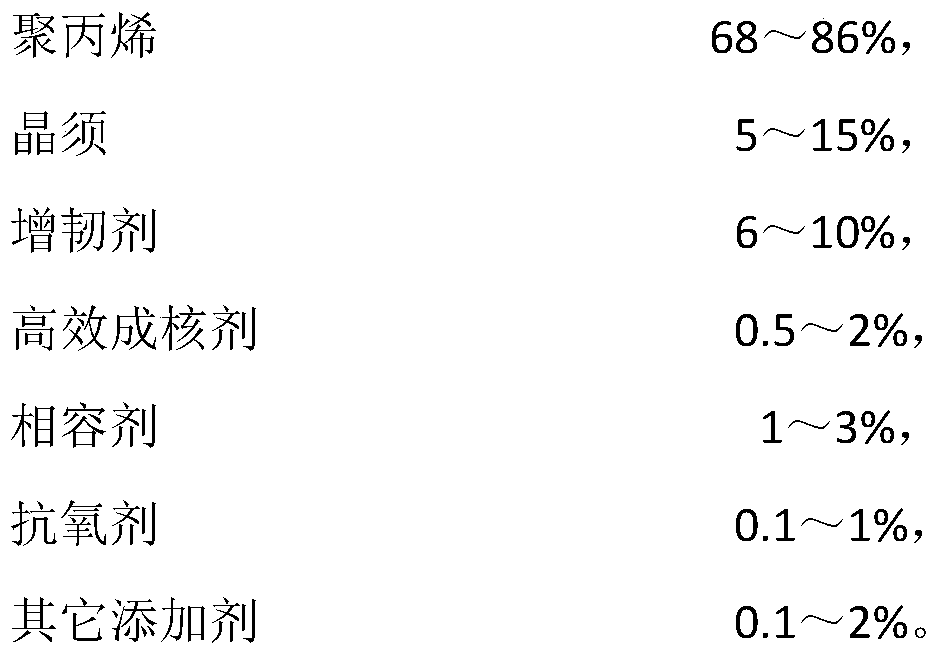

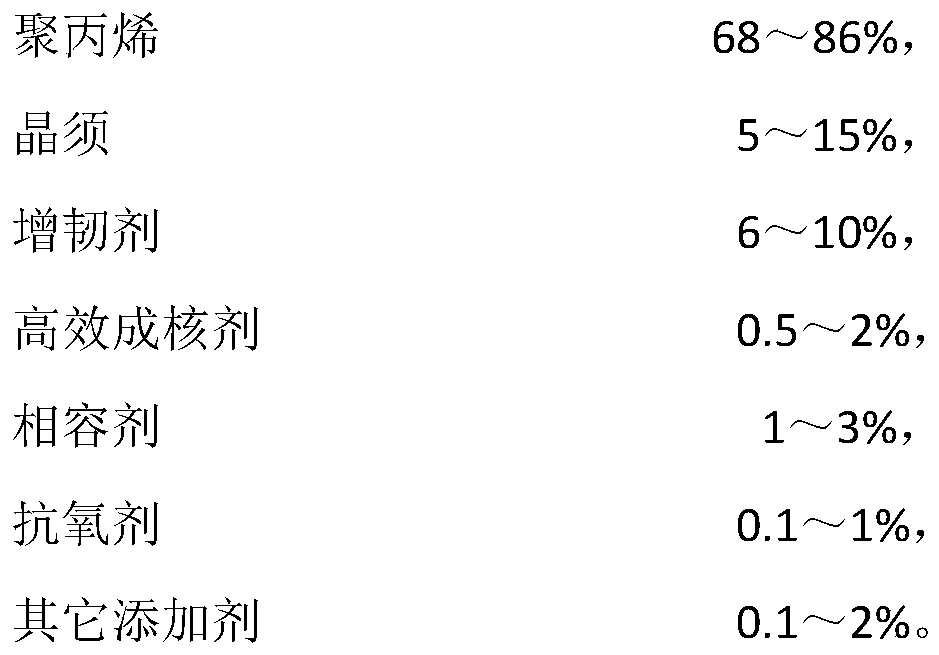

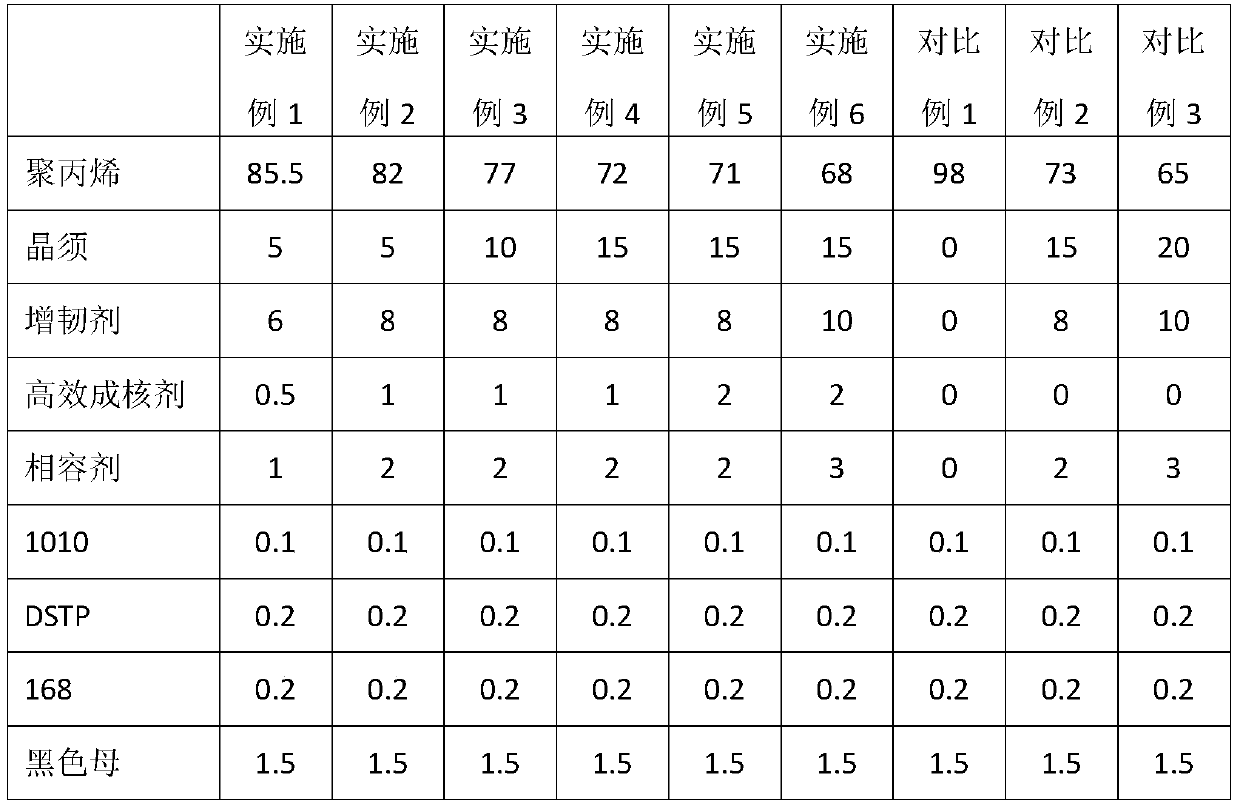

The invention discloses a polypropylene composite material capable of realizing light weight and with low linear expansion coefficient and a preparation method thereof. The polypropylene composite material consists of the following raw materials in percentage by weight: 68-86% of polypropylene, 5-15% of whiskers, 6-10% of flexibilizer, 0.5-2% of efficient nucleating agent, 1-3% of compatilizer, 0.1-1% of antioxidant and 0.1-2% of other additives. In the invention, by adding the efficient nucleating agent and a few whiskers, the linear expansion coefficient of the polypropylene material can be effectively reduced while the material is endowed with the isotropy character in the case of relatively low density of the composite material. The polypropylene composite material disclosed by the invention has excellent rigid-rough balance and can be widely applied to the fields such as automobile interior and exterior trim to realize light weight.

Owner:SHANGHAI PRET COMPOSITES

Low odor, scratch resistant and soft tactility polypropylene composition and preparation method thereof

The invention relates to a polypropylene composition, in particular to a low odor, scratch resistant and soft tactility polypropylene composition and a preparation method thereof. The polypropylene composition comprises the following raw materials in percent by weight: 30 to 60 percent of polypropylene, 20 to 35 percent of copolymer of ethylene and propylene, 10 to 30 percent of glass fiber, 5 to 10 percent of hyperbranched (ethylene and methyl acrylate) copolymer, 0.2 to 1 percent of an antioxydant, 0.2 to 1 percent of a light stabilizer, and 0.3 to 3 percent of an additive, wherein the total amount of the raw materials is 100 percent. The invention further provides the production method of the polypropylene composition. The polypropylene composition has the characteristics of high mechanical performance, strong impact resistance, scratch resistance, low odor, soft tactility, low linear expansion coefficient and the like.

Owner:SILVER AGE ENG PLASTICS DONGGUAN +2

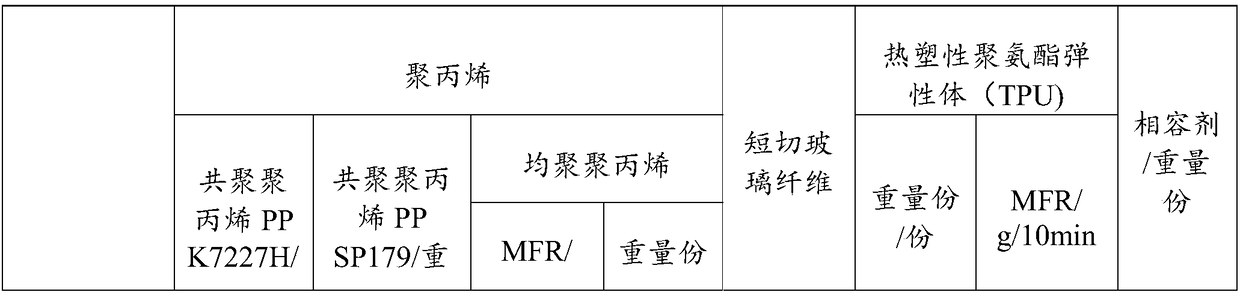

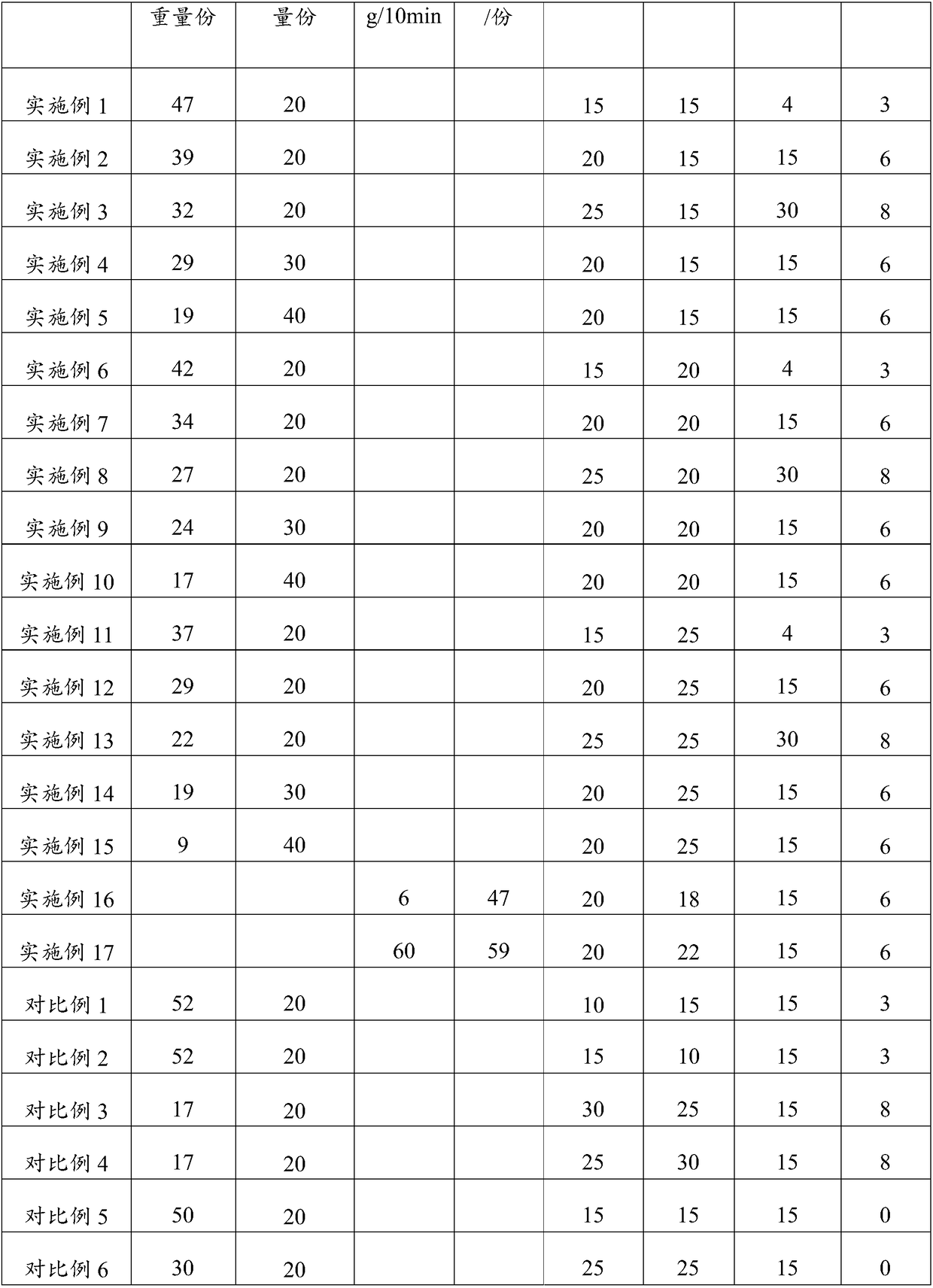

Polypropylene composite material and preparation method and application thereof

InactiveCN109206752ALow coefficient of linear expansionScratch resistantGlass fiberPolypropylene composites

The invention relates to a composite material and a preparation method and an application thereof, and in particular, relates to a polypropylene composite material and a preparation method and an application thereof. The polypropylene composite material comprises the following components in parts by weight: 42 to 67 parts of polypropylene, 15 to 25 parts of polyurethane, 15 to 25 parts of glass fibers and 3 to 8 parts of a compatibilizer. By introduction of polyurethane and the glass fibers at the same time, and by promotion of the compatibility, dispersion form and proportion of all the components, the obtained polypropylene composite material has five excellent properties: rigidity-toughness balance, low linear expansion coefficient, scratch resistance, low glossiness and good touch feeling. The polypropylene composite material can be widely applied in automobile interior trim parts such as main and auxiliary dashboards, door guard boards or stand columns.

Owner:WUHAN JINFA TECH CO LTD +1

Bumper material with low linear expansion coefficient and preparation method of bumper material

The invention provides a preparation method of a bumper material with a low linear expansion coefficient. By means of the method, the modified bumper material has the low linear expansion coefficient and simultaneously keeps an excellent mechanical property. The bumper material comprises components in parts by mass as follows: 40-90 parts of polypropylene resin, 5-30 parts of inorganic filler, 5-30 parts of styrene elastomer without double bonds and 0.2-0.4 parts of an antioxidant. The bumper material prepared through blending and extrusion of the components has the low linear expansion coefficient and the excellent mechanical property, the size stability of the bumper can be effectively improved, the assembly accuracy of the bumper is improved, and the regional limitation to production and assembly of the bumper is overcome.

Owner:NANJING JINSHAN AUTOMOBILE ENG PLASTIC

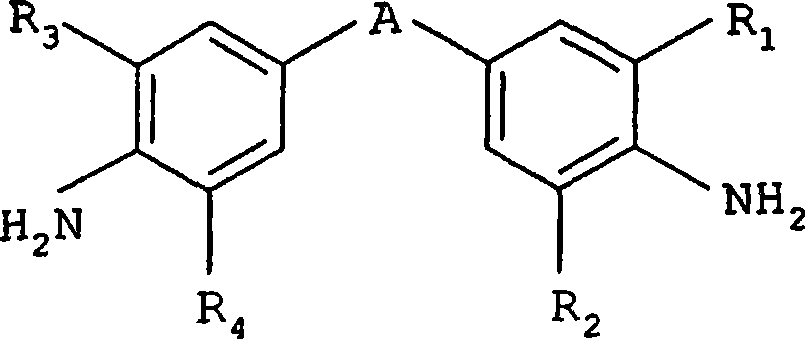

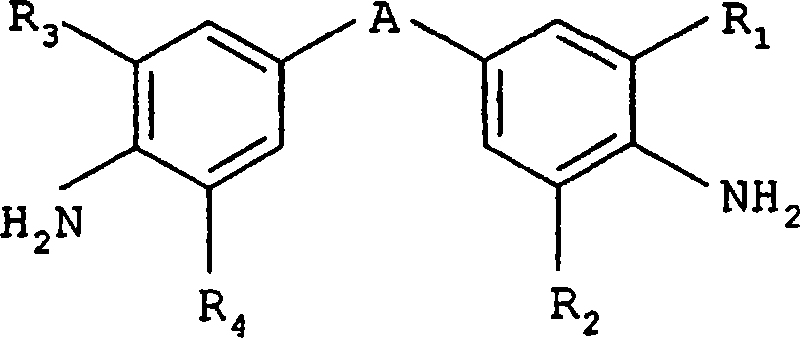

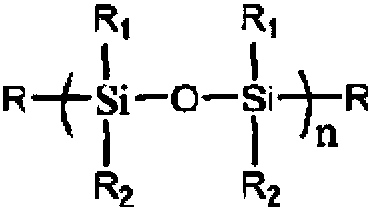

Polyimide, polyimide film and laminated body

InactiveCN101068851AHigh elastic modulusImprove adhesionPrinted circuitsThin material handlingMoisture permeationPolyimide membrane

A novel polyimide wherein a tetracarboxylic dianhydride comprising 3,3',4,4'-biphenyltetracarboxylic dianhydride as the essential component is the starting tetracarboxylic dianhydride component, and an amine comprising between 0.5 and 30 mole percent of a diamine represented by the following general formula is the starting diamine component. (wherein A is a direct bond or a crosslinking group, and R1-R4 each represent a substituent). It is possible to obtain a polyimide, a polyimide film and a laminated body with an improved adhesion property and an improved moisture permeation rate, even without surface treatment, comprising, as the essential tetracarboxylic dianhydride, 3,3',4,4'-biphenyltetracarboxylic dianhydride which has conventionally only yielded polyimides with low adhesive strength.

Owner:UBE IND LTD

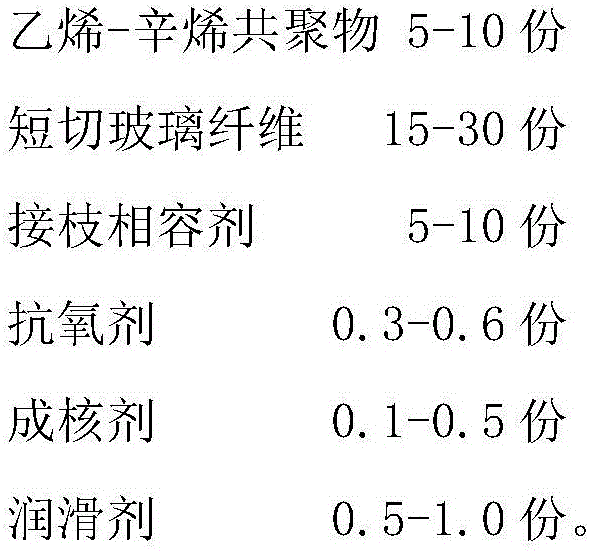

Special polypropylene composite material for reducing noise of air conditioner and preparation method of special polypropylene composite material

InactiveCN106243518ALow coefficient of linear expansionGood dimensional stabilityLow noisePolypropylene composites

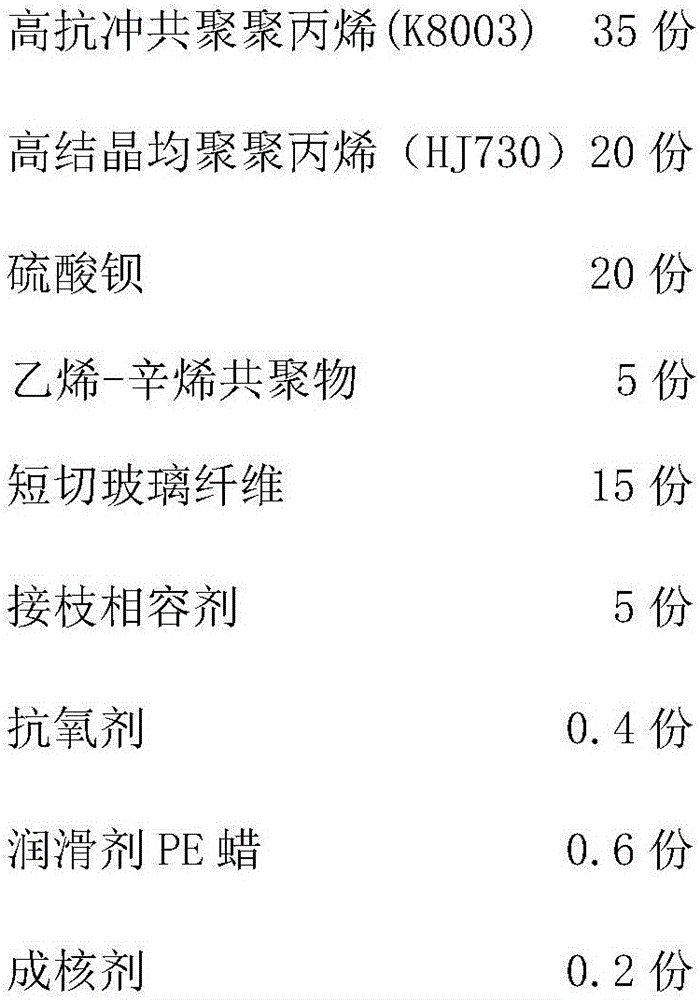

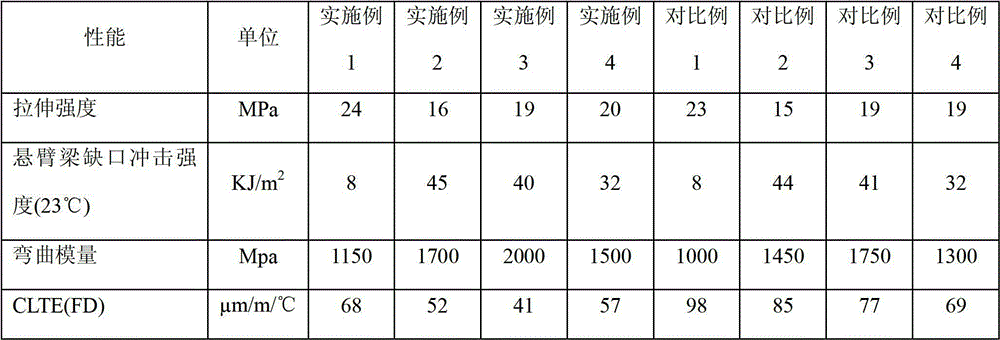

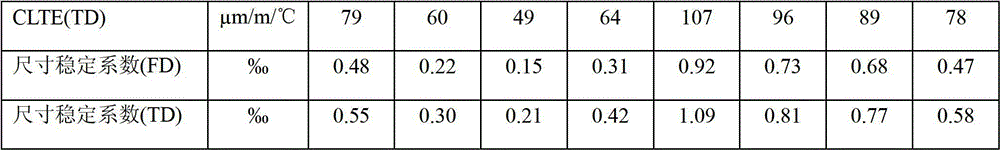

The invention discloses a special polypropylene composite material for reducing noise of an air conditioner and a preparation method of the special polypropylene composite material. The special polypropylene composite material is prepared from 50-60 parts of polypropylene, 15-30 parts of barium sulfate, 15-30 parts of chopped glass fibers, 5-10 parts of a grafting compatilizer, 5-10 parts of an ethylene-octene copolymer, 0.1-0.5 part of a nucleator, 0.5-1.0 part of an antioxidant, 0.5-1.0 part of a lubricant and 0-3 parts of other additives. The special polypropylene composite material has the characteristics of high intensity, high tenacity, low linear expansion coefficient and low noise. The material can be used for a chassis of a split wall hanging type air conditioner, so that the noise value of the air conditioner is notably reduced, and the use comfortableness of the air conditioner is improved.

Owner:ORINKO NEW MATERIAL CO LTD

Polypropylene composition with good dimensional stability and preparation method and application thereof

The invention discloses a polypropylene composition with a good dimensional stability and a preparation method and an application thereof. The polypropylene composition comprises 40% to 90% of polypropylene, 3% to 25% of elastomer, 0.2% to 2% of nucleating agents, 5% to 30% of mineral fillers and 1% to 5% of inorganic fillers, the nucleating agents are alpha-nucleating agents, the mineral fillers are superfine high silicon talcum powders, and the inorganic fillers are alkali-free boron-free silicate inorganic glass fibers. By means of the efficient nucleating agents and the superfine high silicon talcum powder fillers, after a workpiece is formed by injection moulding of the polypropylene composition, the polypropylene material is fully crystallized, so that the linear expansion coefficient of the polypropylene composition can be effectively reduced, and the dimensional stability is improved. By means of the inorganic fillers, the mechanical property of the material can not be reduced, simultaneously the subsequent crystallization of the polypropylene material can be controlled, and the dimensional stability of the polypropylene composition under the condition of long-time cold and heat cycling can be remarkably improved.

Owner:TIANJIN KINGFA NEW MATERIAL

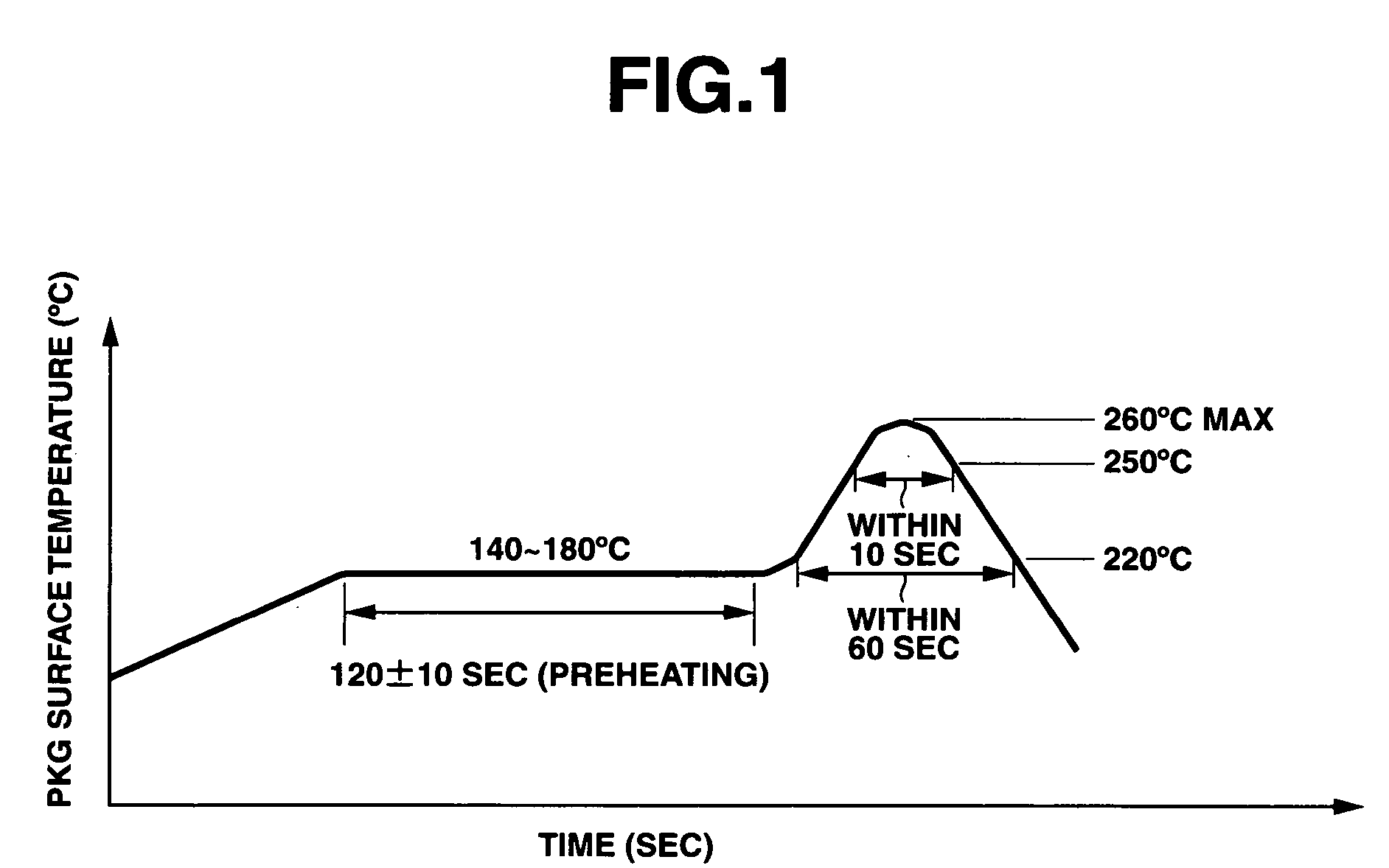

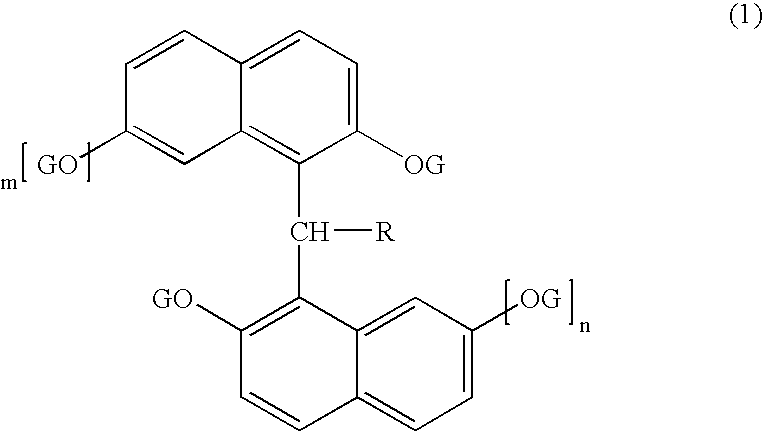

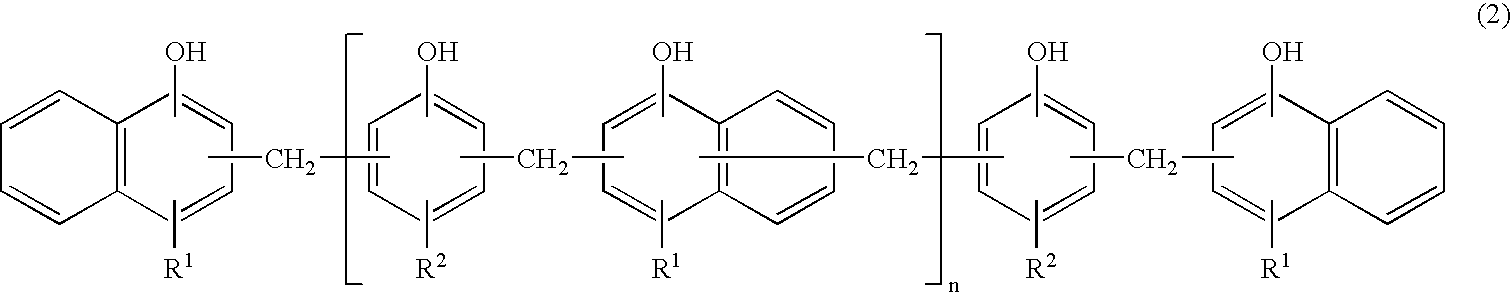

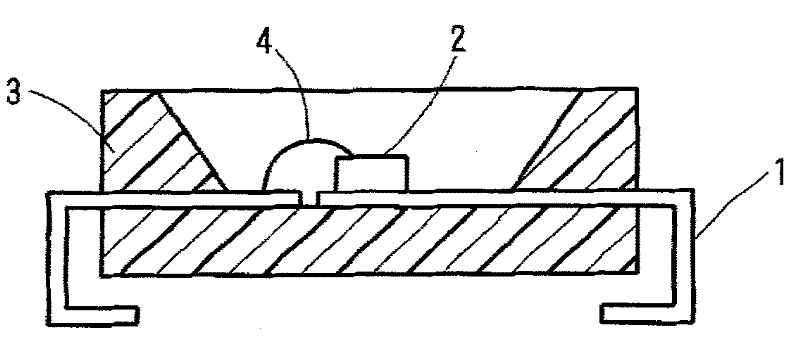

Semiconductor encapsulating epoxy resin composition and semiconductor device

ActiveUS20060216519A1Low coefficient of linear expansionHigh TgSemiconductor/solid-state device detailsSynthetic resin layered productsChemistrySoldering

An epoxy resin composition comprising (A) at least one epoxy resin comprising (a) a naphthalene ring-containing epoxy resin having at least one substituted or unsubstituted naphthalene ring in a molecule and having an epoxy equivalent of 175 to 210, (B) a phenolic resin having at least one substituted or unsubstituted naphthalene ring in a molecule, and (C) an inorganic filler, the substituted or unsubstituted naphthalene ring of the epoxy resin (a) being contained in an amount of 45 to 60% by weight in the total amount of the epoxy resin (A) is best suited for semiconductor encapsulation because it has good flow, a low coefficient of linear expansion, a high Tg, minimal moisture absorption, and crack resistance upon lead-free soldering.

Owner:SHIN ETSU CHEM CO LTD

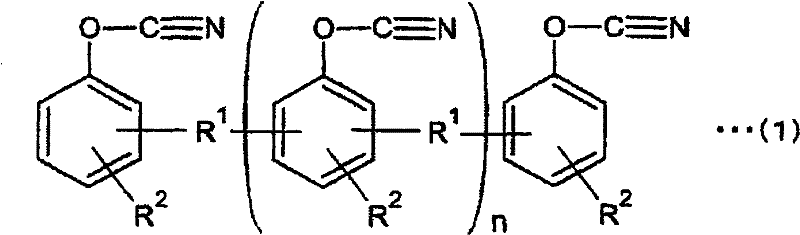

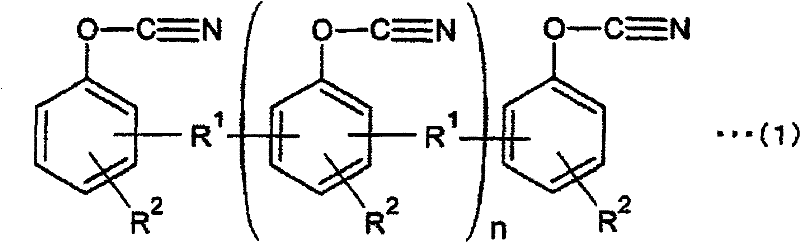

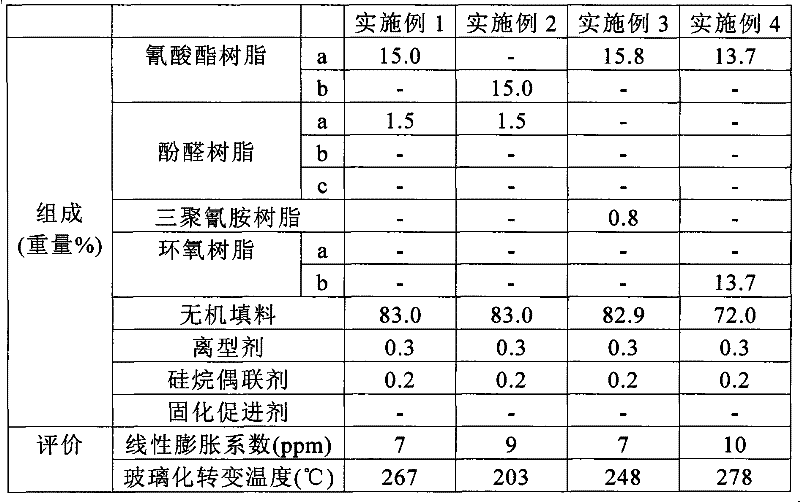

Resin composition for electronic component encapsulation and electronic component device

InactiveCN102190885ALow coefficient of linear expansionReduce warpageSemiconductor/solid-state device detailsSolid-state devicesElectronic componentMelamine

The present invention relates to a resin composition for electronic component encapsulation and an electronic component device, the resin composition including: A: a cyanate ester resin; B: at least one selected from the group consisting of a phenol resin, a melamine compound and an epoxy resin; and C: an inorganic filler.

Owner:NITTO DENKO CORP

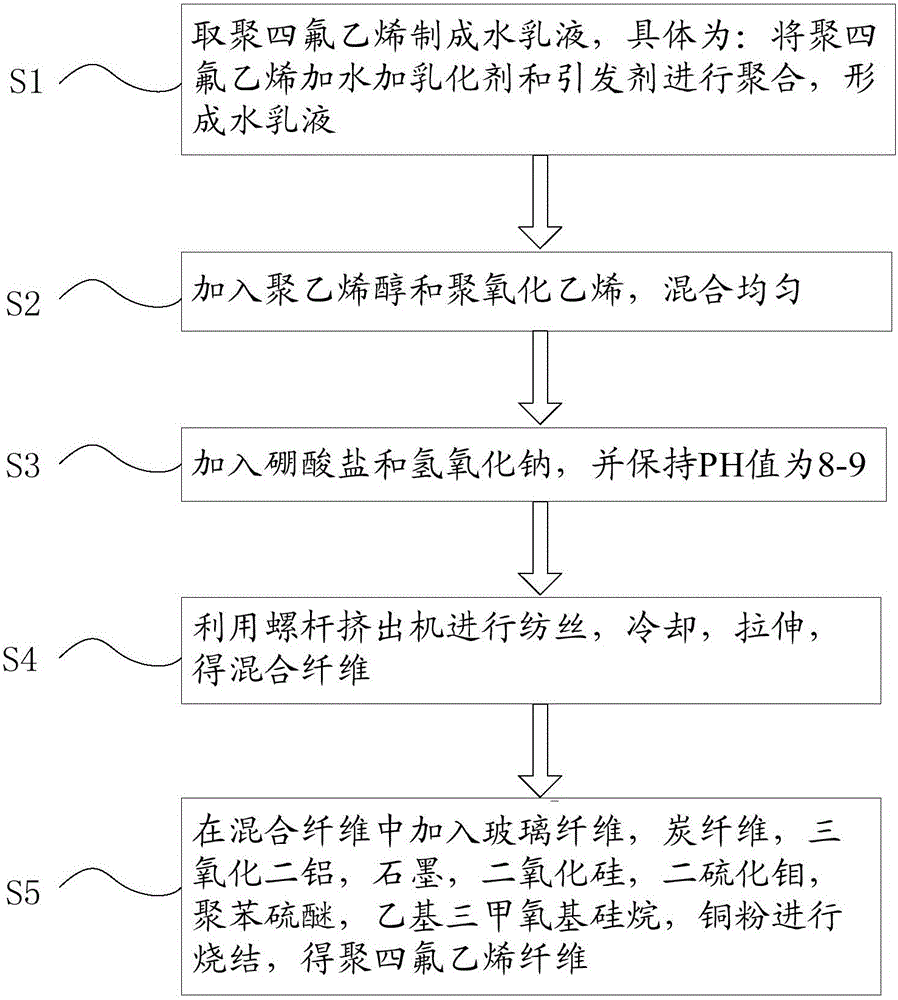

Polytetrafluoroethylene fiber

ActiveCN105970333AReduce the degree of volume changeGood dimensional stabilityMonocomponent halogenated hydrocarbon artificial filamentArtifical filament manufactureFiberHeat conducting

The invention discloses a polytetrafluoroethylene fiber, which comprises the following components in parts by weight: 80-90 parts of polytetrafluoroethylene, 15-23 parts of fiberglass, 20-24 parts of carbon fiber, 2-6 parts of aluminium oxide, 14-18 parts of graphite, 8-12 parts of silicon dioxide, 3-6 parts of molybdenum disulfide, 8-10 parts of polyphenylene sulfide, 6-9 parts of ethyl trimethoxy silane and 3-6 parts of copper powder. According to the polytetrafluoroethylene fiber provided by the invention, polytetrafluoroethylene is modified, special filler is used as an auxiliary material, the strength of the obtained polytetrafluoroethylene fiber is 20-30cN / dtex, the coefficient of linear expansion of the obtained polytetrafluoroethylene fiber is (2.13-3.38)*10<-5>k<-1>, hardness is obviously improved, and heat-conducting property is increased. In addition, since the coefficient of linear expansion is lowered, the volume change degree of the polytetrafluoroethylene fiber within the temperature of 250DEG C is also lowered, and the dimensional stability of the polytetrafluoroethylene fiber is also improved.

Owner:JIANGSU WENFENG CHEM FIBER GROUP

Ultralow-linear expansion coefficient polypropylene composite material and preparation method thereof

The invention relates to an ultralow-linear expansion coefficient polypropylene material and a preparation method thereof. The material is prepared from 90-98 parts of polypropylene, 2-10 parts of Sc2W3O12, 0.1-0.5 parts of a coupling agent, 0.1-1 part of a heat stabilizer, 0-1 part of a lubricant and 0-0.5 parts of white oil, wherein the weight part sum of the polypropylene and Sc2W3O12 is 100. One-dimensional Sc2W3O12 is added to the polypropylene material in order to reduce the linear expansion coefficient of the composite material, so the prepared polypropylene composite material has a low linear thermal expansion coefficient, and can be applied to the aerospace field, the optical field, the communication field and other fields with high material dimension change requirements.

Owner:HEFEI GENIUS NEW MATERIALS

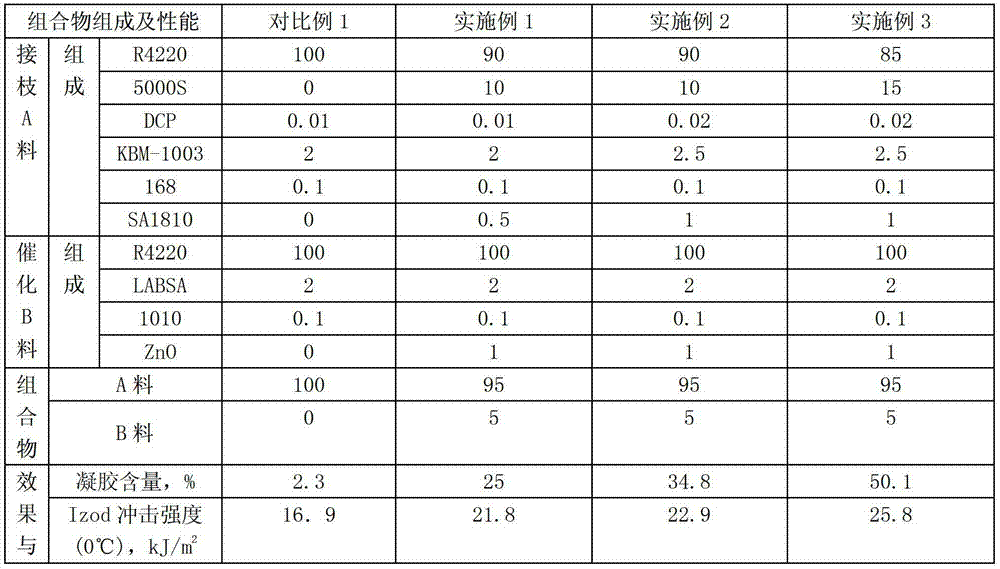

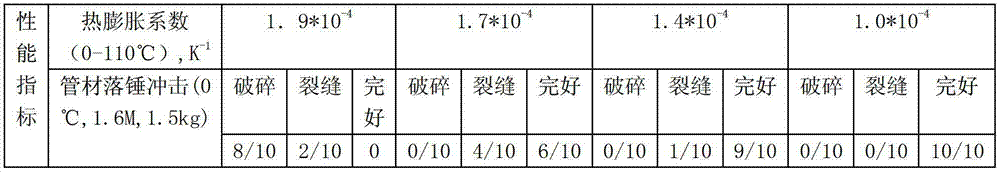

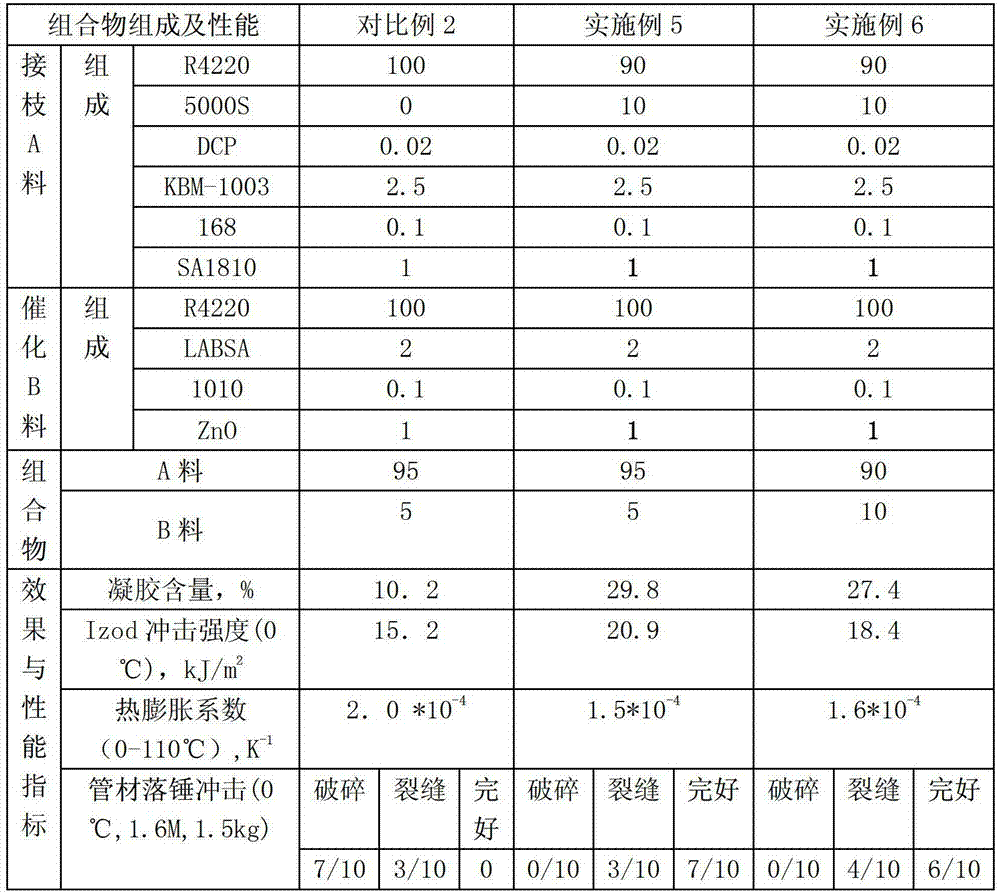

Special material for silicane grafted PPR (polypropylene random) pipe and preparation method thereof

The invention discloses a special material for a silicane grafted PPR (polypropylene random) pipe. The special material for the silicane grafted PPR pipe is formed by a material A and a material B in ratio in parts by weight of 90:10-95:5, wherein the material A comprises 80-95 parts of PPR, 5-20 parts of high-density polyethylene, 1-3 parts of unsaturated silicane, 0.01-0.03 part of initiator, 0.1-0.5 part of antioxidant and 0.1-2 parts of auxiliary crosslinking agent; and the material B comprises 100 parts of PPR, 1-3 parts of catalyst, 0.1-0.5 part of antioxidant and 1-5 parts of auxiliary catalyst. The preparation method comprises that the material A and the material B are respectively independently extruded and pelletized, then the material A and the material B are mixed to be uniform in proportion, and a pipe can be directly extruded. The special material disclosed by the invention is good in impact strength and creep resistance and can be widely applied to various pipeline products such as a hot and cold water pipe; and the preparation method is simple, and a long-time high temperature poaching process is not required, so that the preparation method disclosed by the invention is convenient for industrial production.

Owner:杭州恒标管业有限公司

High-rigidity, low-odor and low-linearity polypropylene whisker modified material

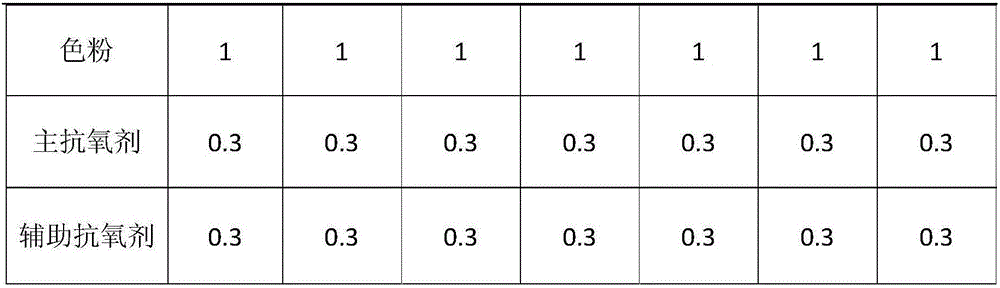

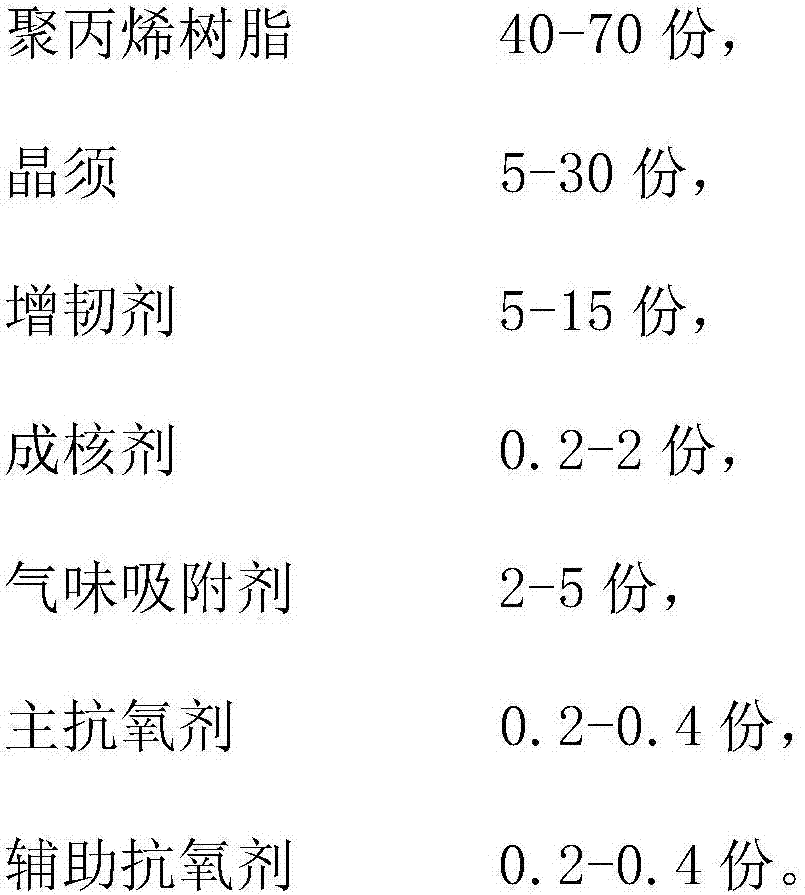

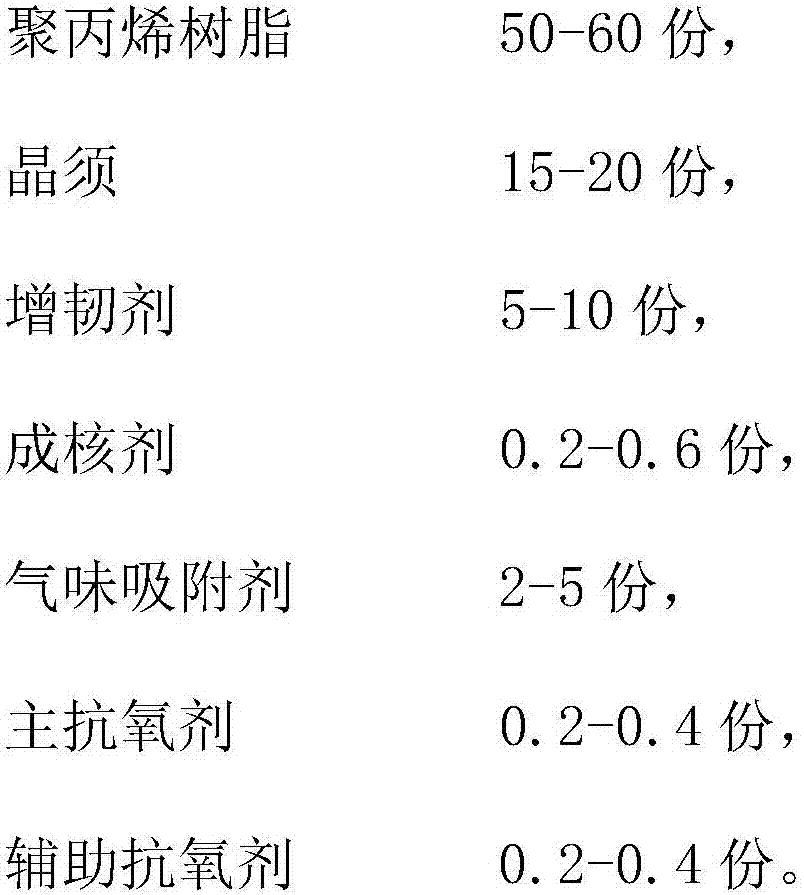

The invention provides a high-rigidity, low-odor and low-linearity polypropylene whisker modified material which is characterized in that the modified material is prepared from the following raw materials in parts by weight: 40-70 parts of polypropylene resin, 5-30 parts of whisker, 5-15 parts of flexibilizer, 0.2-2 parts of nucleating agent, 2-5 parts of odor adsorbent, 0.2-0.4 part of main antioxidant and 0.2-0.4 part of assistant antioxidant. According to the high-rigidity, low-odor and low-linearity polypropylene whisker modified material provided by the invention, by adopting proper polypropylene, elastomer and nucleating agent, the thermal deformation temperature and impact strength of the material are remarkably enhanced, the linear expansion coefficient of the material is reduced,and the dimensional stability of the material is improved; meanwhile, since few additional components are added, the color matching ability of the material is not influenced, and the material is easyto implement and has relatively wide applicability.

Owner:TIANJIN KINGFA NEW MATERIAL

Epoxy group-containing organosilicon modified poly(phenylene oxide) resin as well as a preparation method and application thereof

The invention relates to epoxy group-containing organosilicon modified poly(phenylene oxide) resin as well as a preparation method and application thereof. According to the preparation method, organosilane containing an alkoxy leaving group and an epoxy group is used for modifying double hydroxyl-terminated poly(phenylene oxide) resin, and an epoxy functional group and a silica structural unit areintroduced, and therefore, a defect that poly(phenylene oxide) resin has high curing temperature, poor compatibility with epoxy resin, poor binding force with inorganic materials or metals, poor wettability and solvent resistance, and the like is solved; the modified resin combines the advantages of poly(phenylene oxide) and organosilicon, so that the resin composition and a copper-clad plate prepared from the resin composition have excellent dielectric properties, heat resistance and dimensional stability, and also have good performance in the aspects of adhesion with inorganic materials ormetals, flame retardancy, toughness and the like.

Owner:GUANGDONG SHENGYI SCI TECH

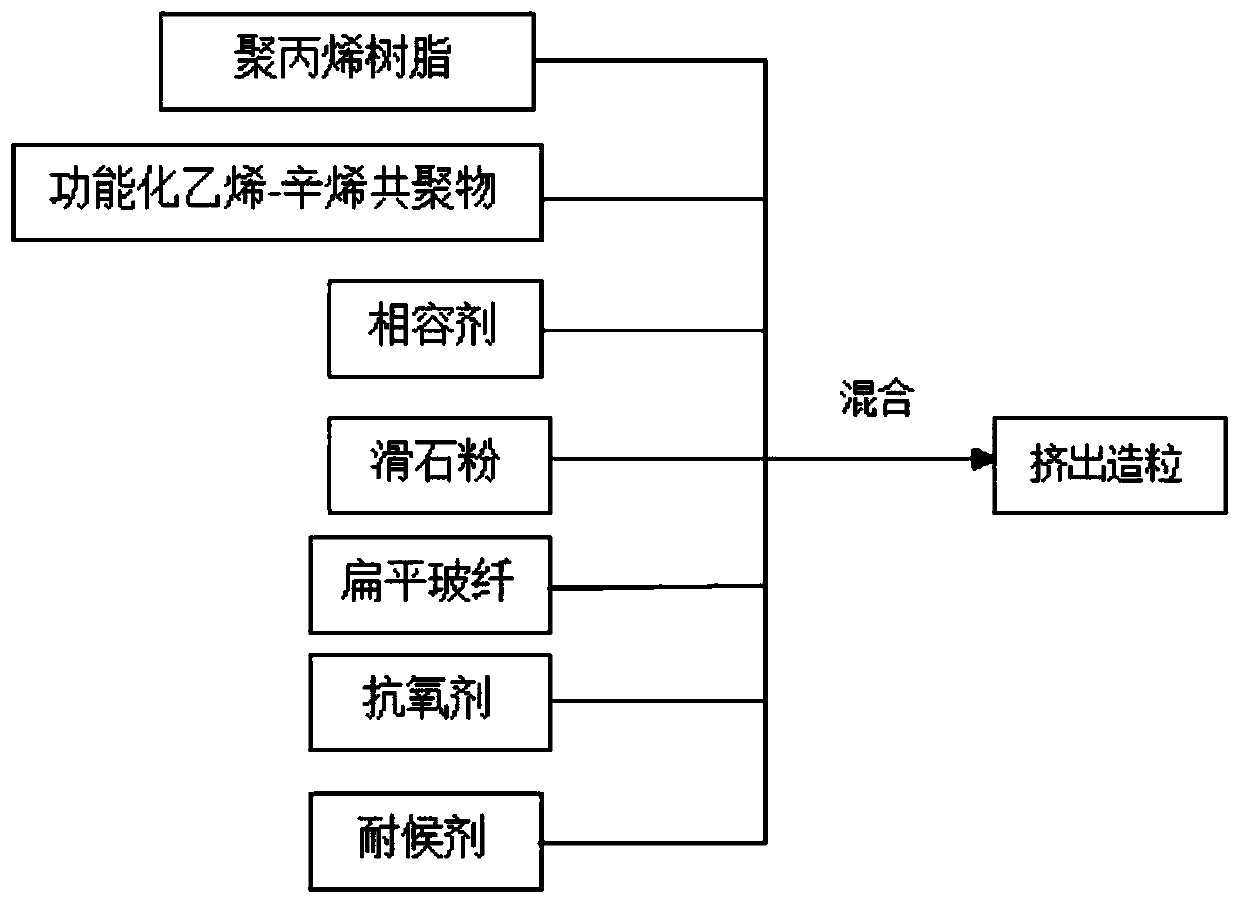

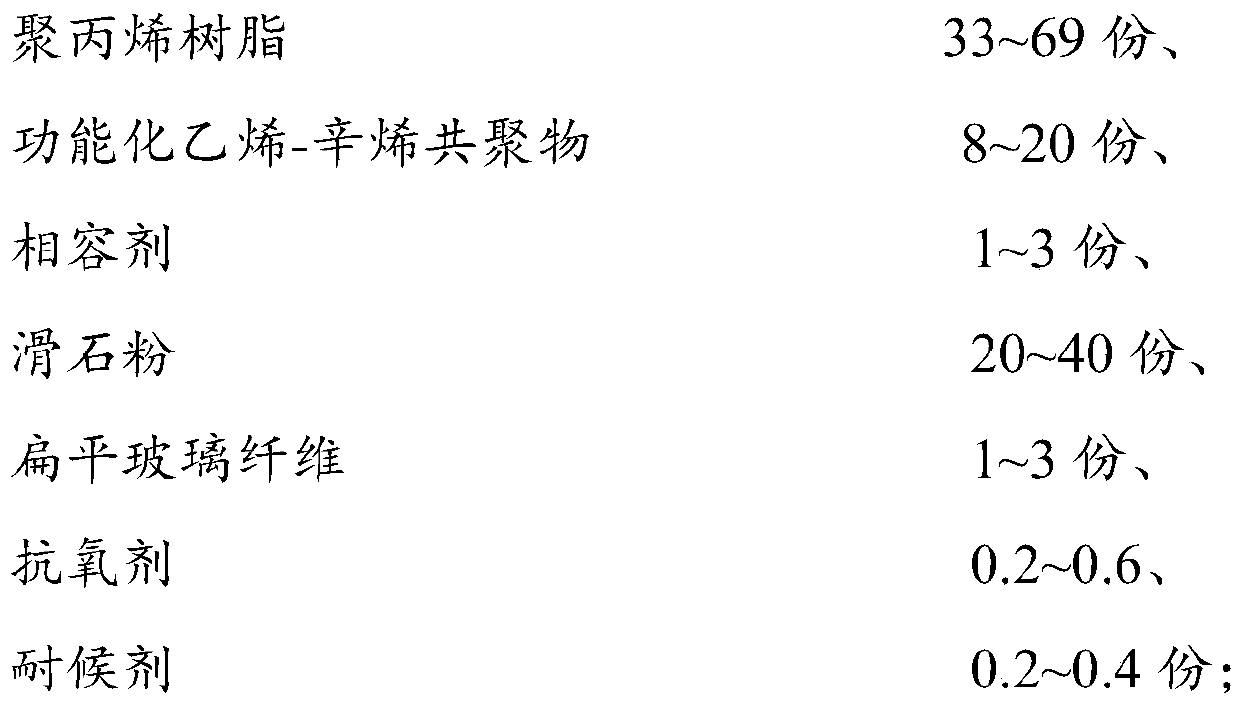

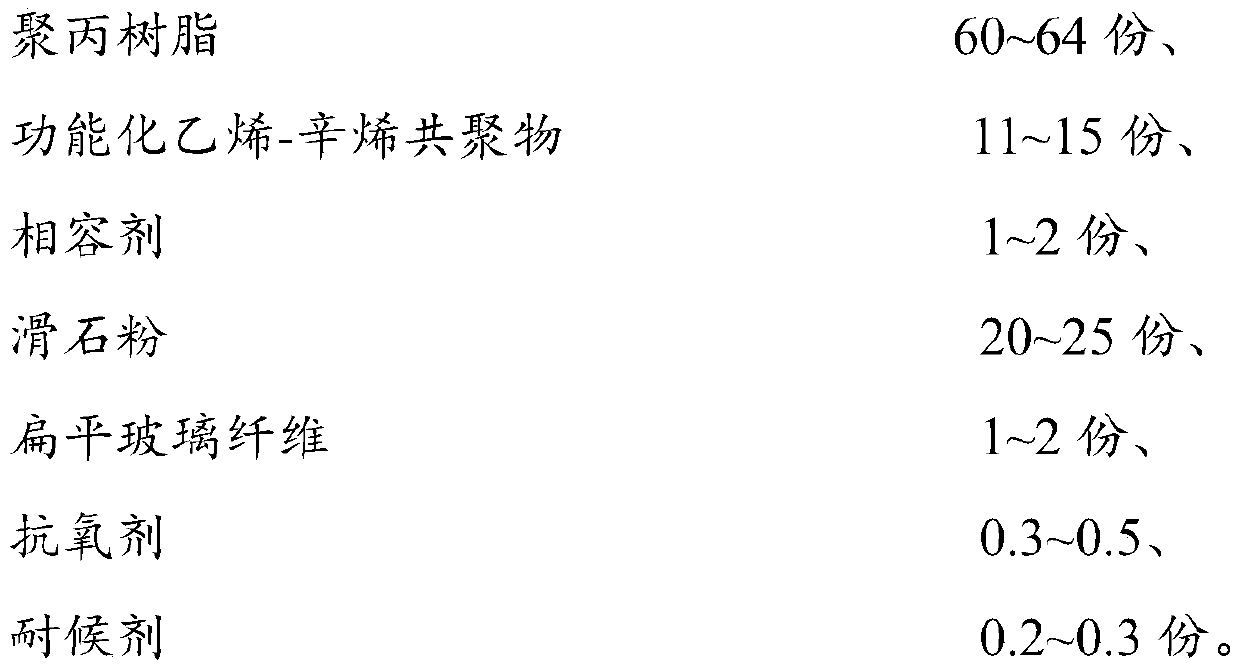

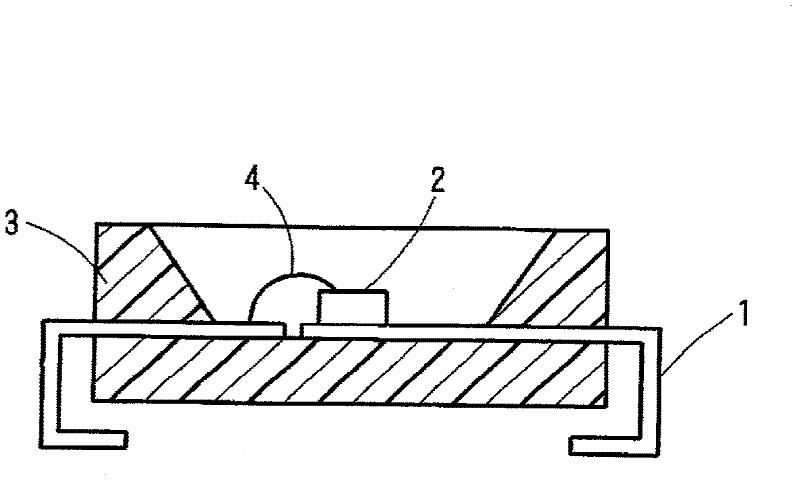

Polypropylene material with low linear expansion coefficient and preparation method of polypropylene material

The invention relates to a polypropylene material with a low linear expansion coefficient and a preparation method of the polypropylene material. The polypropylene material with the low linear expansion coefficient is prepared from the following raw materials: polypropylene resin, a functional ethylene-octylene copolymer, a compatilizer, talcum powder, flat glass fiber, an antioxidant and a weather resistant agent. By adjusting components and proportions of the raw materials, the polypropylene material has the low linear expansion coefficient and good mechanical properties, and can be appliedto automobile bumpers, apron boards and the like.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Resin composition for optical semiconductor element housing package, and optical semiconductor light-emitting device obtained using the same

InactiveCN102649868AHigh whitenessHigh light reflectivitySolid-state devicesSemiconductor devicesEngineeringLead frame

The present invention relates to a resin composition for forming an insulating resin layer for optical semiconductor element housing package having a concave portion in which a metal lead frame and an optical semiconductor element mounted thereon are housed, in which the resin composition includes the following ingredients (A) to (D), and the ingredients (C) and (D) are contained in a blend ratio (C) / (D) of 0.26 to 3.0 as a weight ratio thereof: (A) an epoxy resin; (B) an acid anhydride curing agent; (C) a white pigment; and (D) an inorganic filler.

Owner:NITTO DENKO CORP

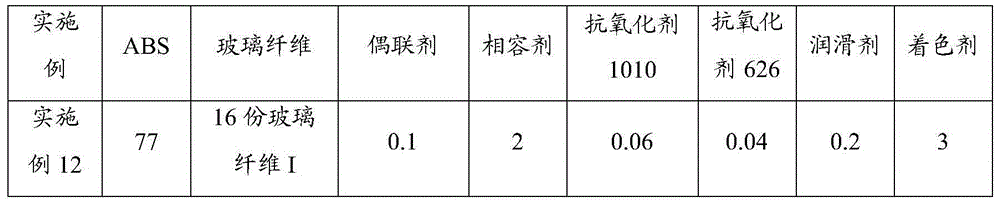

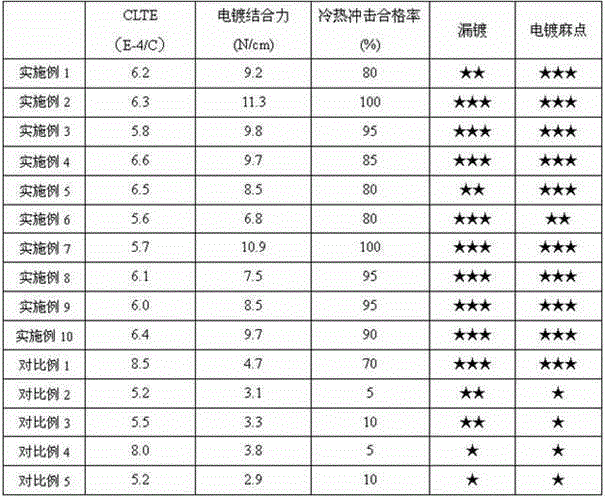

Low CLTE (coefficient of linear thermal expansion) electroplating PC/ABS (Polycarbonate/Acrylonitrile Butadiene Styrene) alloy material and preparation method thereof

ActiveCN103333480AReduce linear expansion coefficient differenceReduce crackingPolycarbonatePelletizing

The invention relates to a low CLTE electroplating PC / ABS (Polycarbonate / Acrylonitrile Butadiene Styrene) alloy material and a preparation method thereof. The low CLTE electroplating PC / ABS alloy material is prepared from the following raw materials in parts by weight: 30-80 parts of PC resin, 15-65 parts of ABS resin, 1-5 parts of talcum powder, 0.1-1 part of antioxygen and 0.1-1 part of lubricating agent. The preparation method comprises the following steps: adding all raw materials in a mixing agitator for mixing; then passing the obtained mixture through a double-screw extruder for blend granulation. According to the invention, the talcum powder is added into the materials, so that the CLTE of the PC / ABS alloy material is lowered; when the PC / ABS alloy material is machined after electroplating, the difference between the CLTE of the PC / ABS alloy material and the CLTE of an electroplating metal layer is reduced; therefore, the crack of the electroplating metal layer caused by deformation of the material due to cold and thermal impact is reduced, the high electroplating binding power is ensured, the surface of a product is smooth, the electroplating surface effect is good, and the preparation method is simple and practicable.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com