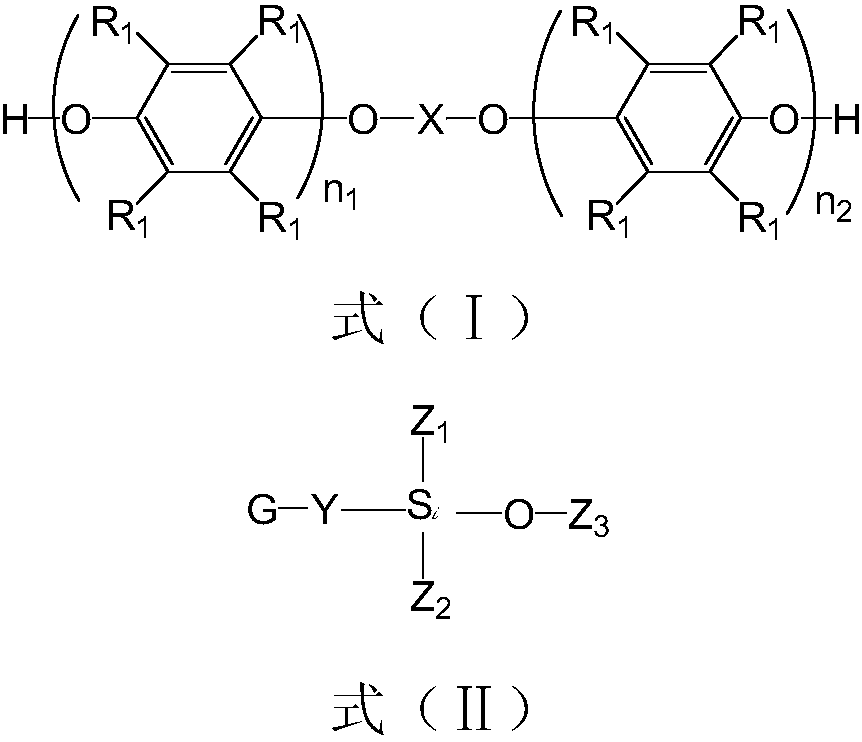

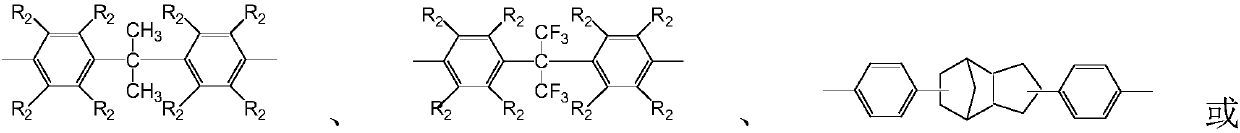

Epoxy group-containing organosilicon modified poly(phenylene oxide) resin as well as a preparation method and application thereof

A technology of polyphenylene ether resin and epoxy resin, which is applied in circuit substrate materials, electrical components, printed circuits, etc., can solve the problems of deterioration of dielectric properties, complicated preparation methods, influence on the dielectric properties of polyphenylene ether and glass transition temperature and other problems, to achieve the effect of improving processability, good adhesion and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

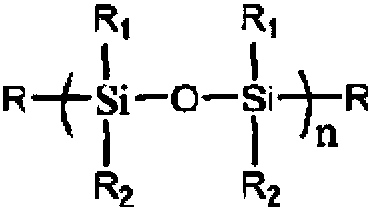

Method used

Image

Examples

Embodiment

[0081] (1) Synthesis of modified polyphenylene ether resin

[0082] Weigh 425g of RPE-HL, add toluene and heat to 80°C and stir to dissolve. After the dissolution is complete, add 98.6g of KBM-303, stir evenly, then add 0.5g of dibutyltin dilaurate, set the heating temperature to 110-115°C, start Slowly add deionized water dropwise for reflux reaction, control the speed of dropping distilled water according to the reaction temperature, so as to control the reaction temperature between 90-100°C, after reacting for 8 hours, remove water and methanol under reduced pressure at 80-100°C, Then add toluene to prepare a resin solution with a solid content of about 50%, and test its epoxy equivalent to be 418g / eq.

[0083] By repeating the above operations and changing the proportions of various reactants, different silicone-modified polyphenylene ether resins containing epoxy groups can be obtained, as shown in Table 1 for details.

[0084] Table 1

[0085]

[0086]

[0087] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com