Patents

Literature

168results about How to "Play a toughening role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

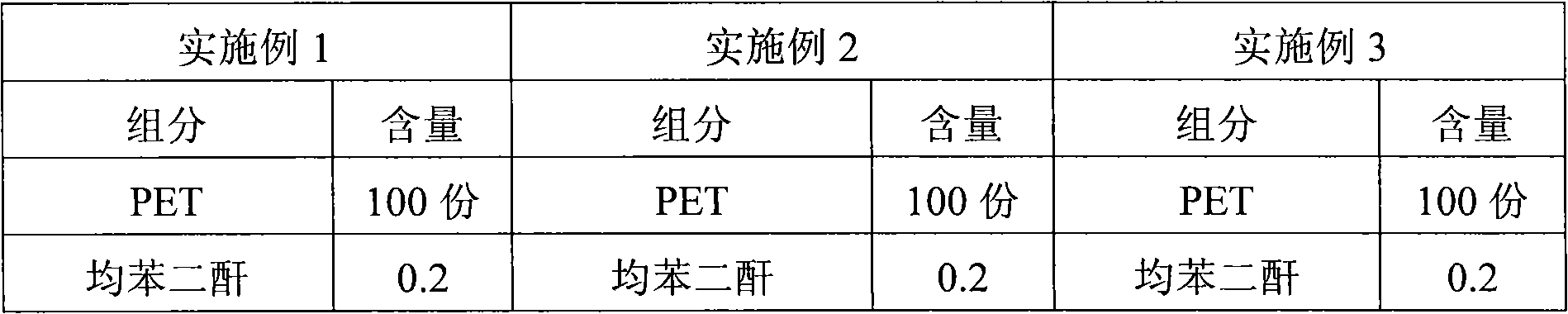

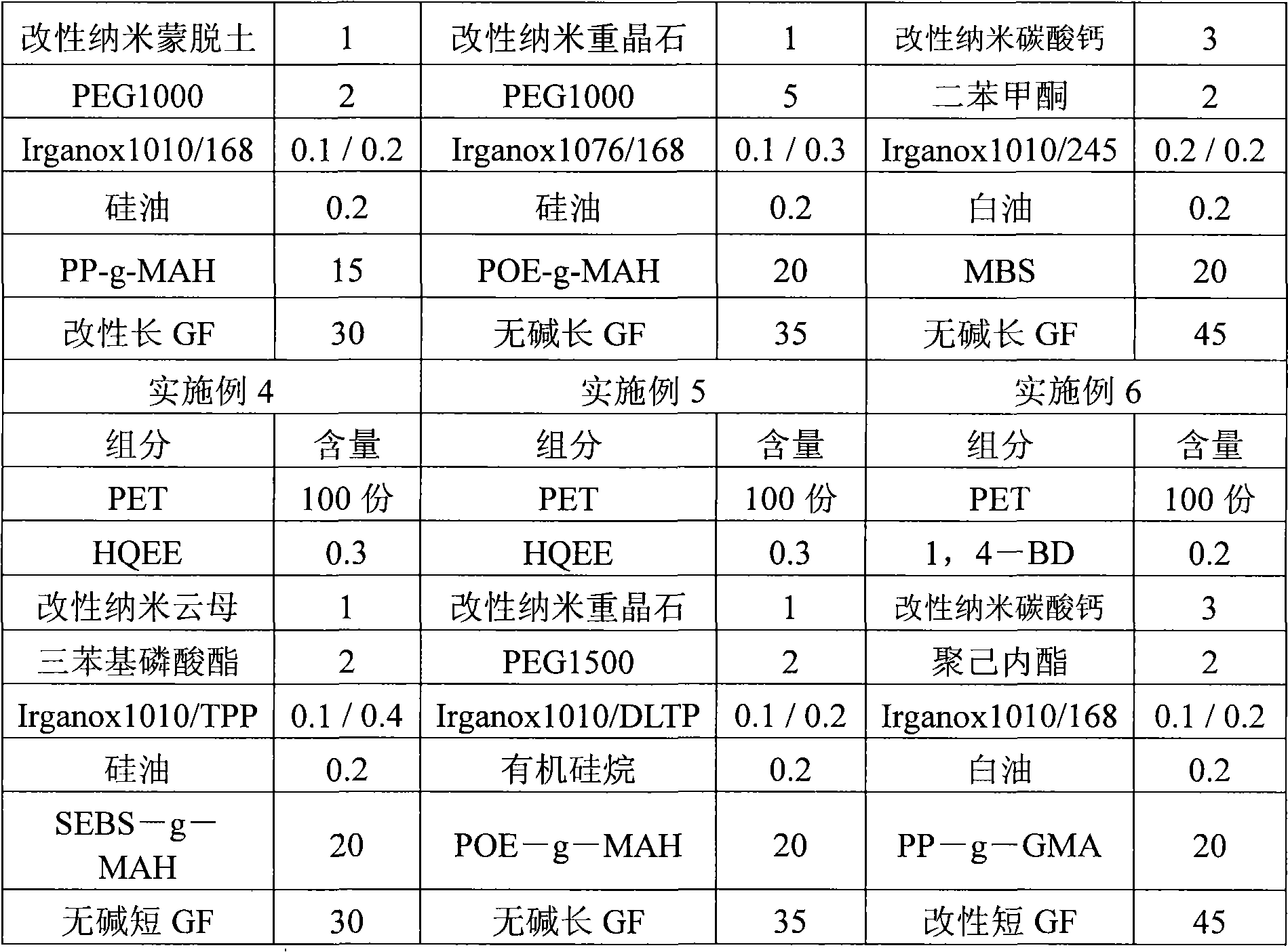

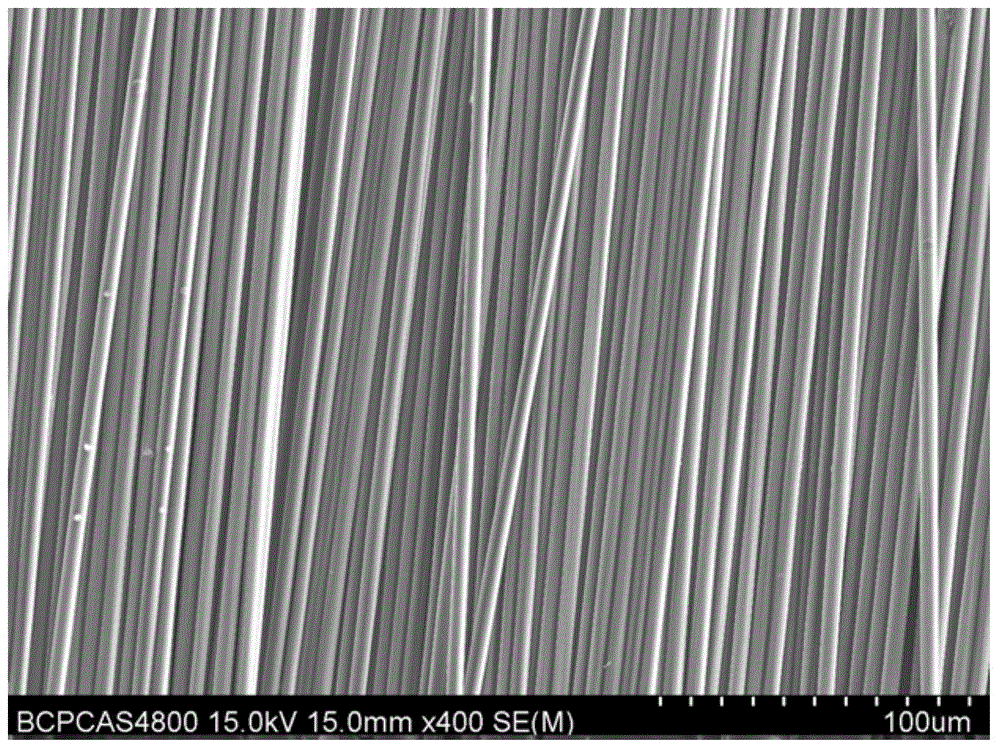

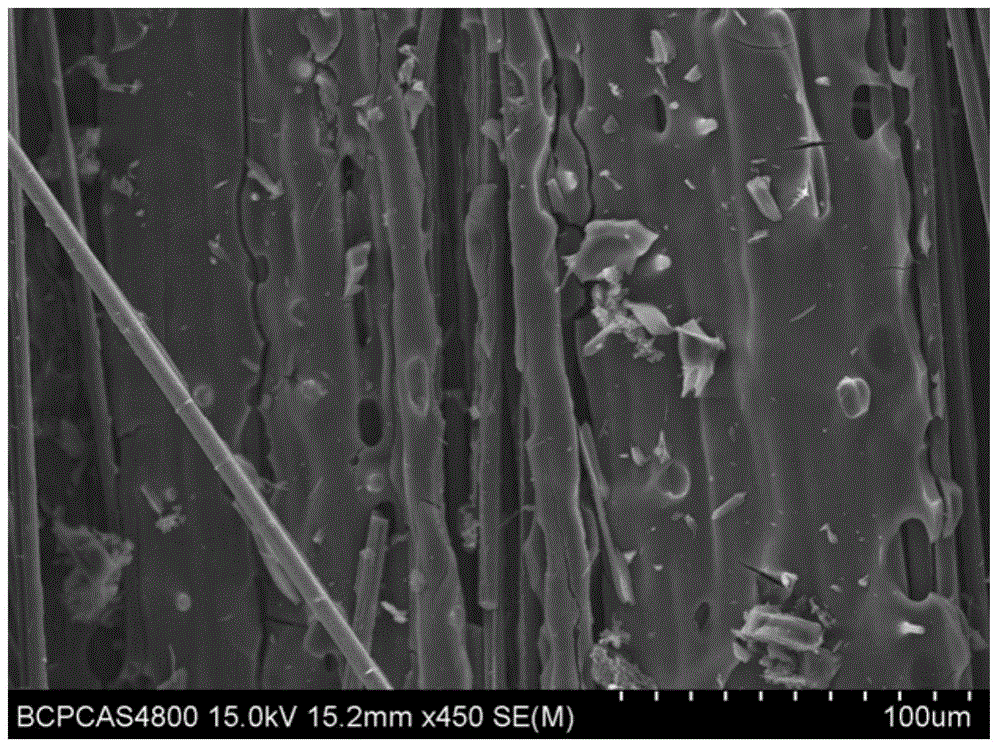

High-glaze strengthened toughened polyethylene glycol terephthalate nanometer composite material and preparation thereof

InactiveCN101280096AGood dispersion and compatibilityLow priceCrystallization ratePolyethylene glycol

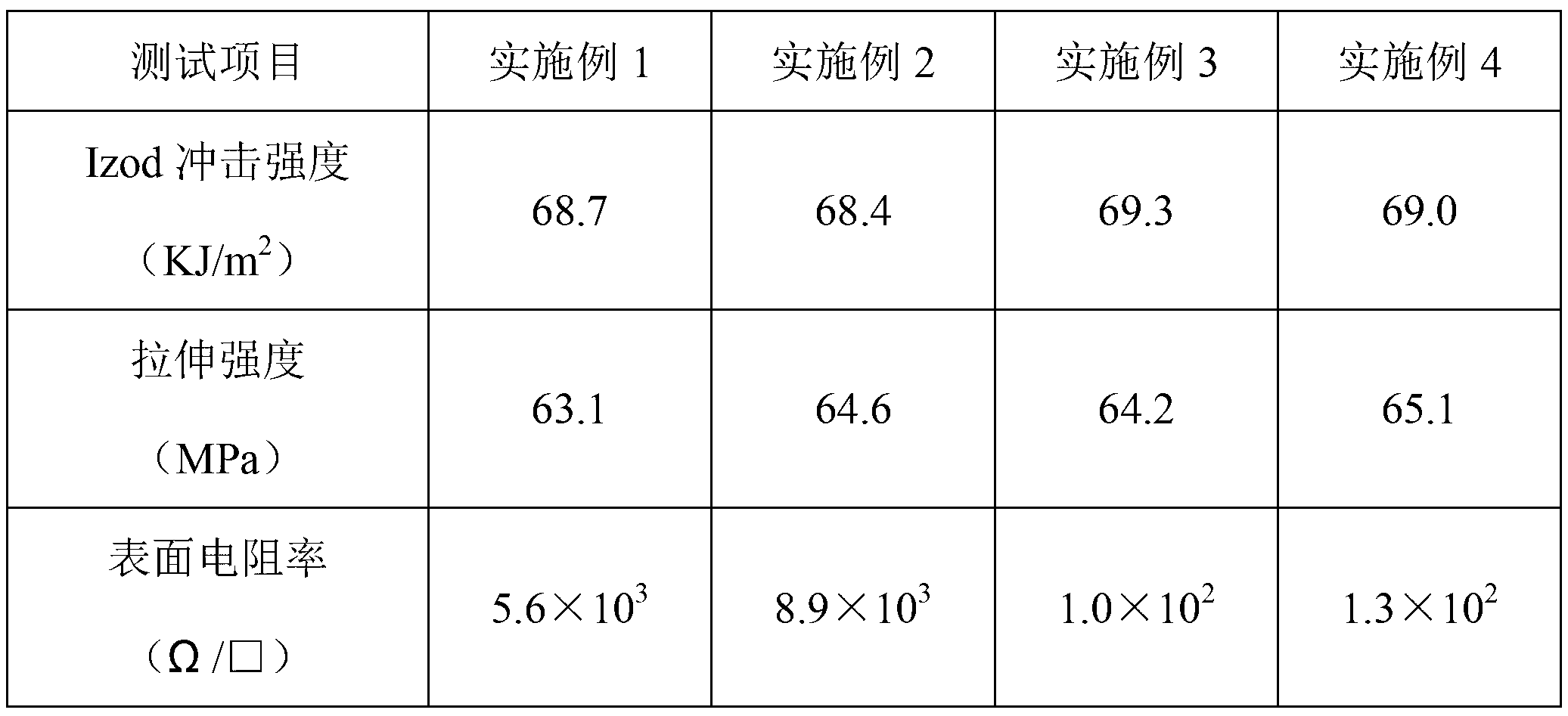

The invention relates to a high-gloss enhanced PET toughening composite material, which has the following components based on weight proportion: 100 portions of PET, 0.5-5.0 portions of modified nano-intensifier, 0.1-10 portions of nucleating acceleant, 5.0-25 portions of toughener, 10-45 portions of glass fibers, 0.1-1.0 portion of chain extender, 0.1-0.5 portion of antioxidant and 0.3-0.5 portion of lubricant. The preparation method is that the components are evenly mixed on a high-speed mixer and melted and blended by a twin-screw extruder to prepare the composite material. The composite material has the advantages of fast crystallization rate, high gloss and good mechanical properties.

Owner:SHANGHAI UNIV

Preparing method for nanometer toughening ultra-fine grain WC-Co cemented carbide

ActiveCN107475548AUniform particle sizeNarrow normal distribution of particle sizePorosityFlexural strength

The invention discloses a preparing method for nanometer toughening ultra-fine grain WC-Co cemented carbide. The preparing method for the nanometer toughening ultra-fine grain WC-Co cemented carbide comprises the following steps of that 0.1-0.5 micron ultra-fine powder of WC hard phase and Co binder phase is prepared by adopting an airflow crushing classification method and a high-pressure water atomization method correspondingly, and the ultra-fine grain cemented carbide is prepared through material matching and nano-metal mixed additives adding, airflow mixed powder sieving, ball milling waxing and drying sieving, mold pressing and cold isostatic pressing molding and pressure sintering and heat treating, wherein the nano-metal mixed additives are prepared by adopting vacuum electric arc smelting ingot casting plus rapid-in-situ packaging plasma arc process discharging method. The nano-metal mixed additives play the role of refining the cemented carbide granules, improving the material wettability, reducing the porosity and enhancing the local grain boundary strength, so that macro performances such as hardness, flexural strength and fracture toughness of the alloy are improved greatly. The preparing method for the nanometer toughening ultra-fine grain WC-Co cemented carbide has the advantages of being high in production efficiency, low in production cost, high in product quality and purity, and a great deal of man-hour and energy consumption are saved.

Owner:SHENYANG SHENGSHI WUHUAN TECH CO LTD

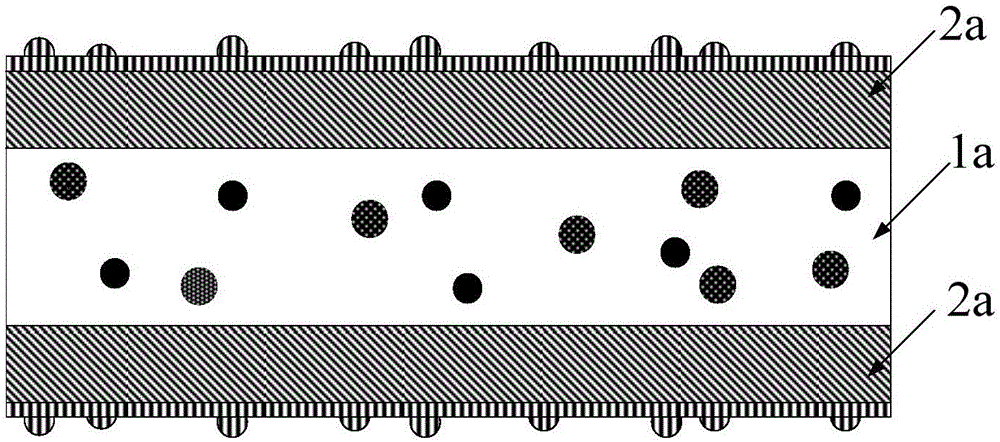

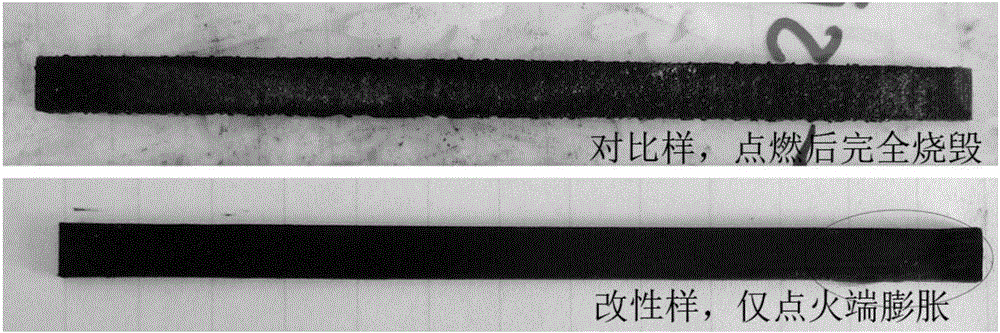

Flame-retardant modified carbon fiber prepreg and composite material product

ActiveCN104553177AInhibits air diffusionInhibit burningSynthetic resin layered productsFire retardantCombustion

The invention relates to flame-retardant modified carbon fiber prepreg and a composite material product with high flame retardance. A flame-retardant film with an interlayer combustion barrier action can be formed after being applied to a carbon fiber reinforced lamination resin based composite material, and the film has a certain thickness, consists of a thermoplastic toughening agent capable of being thermally dissolved into resin and a flame retardant and / or nano particles which are uniformly dispersed into the film, and is used for preparing the flame-retardant modified carbon fiber resin prepreg together with conventional carbon fiber resin prepreg. After the prepreg is prepared into the composite material, a continuous combustion barrier layer is formed among layers and is dispersed into a layer with a high carbon fiber content to take a collaborative barrier effect, thereby achieving a good flame retardance effect. UL94 perpendicular combustion method shows that the flame-retardant level can reach V0 above without overflowing smog in combustion, while an unmodified composite material has no flame-retardant level and generates a great amount of smog, and moreover, the iris layer has a dual-continuous complex-phase structure, and the toughness of the composite material can be improved.

Owner:AVIC COMPOSITES

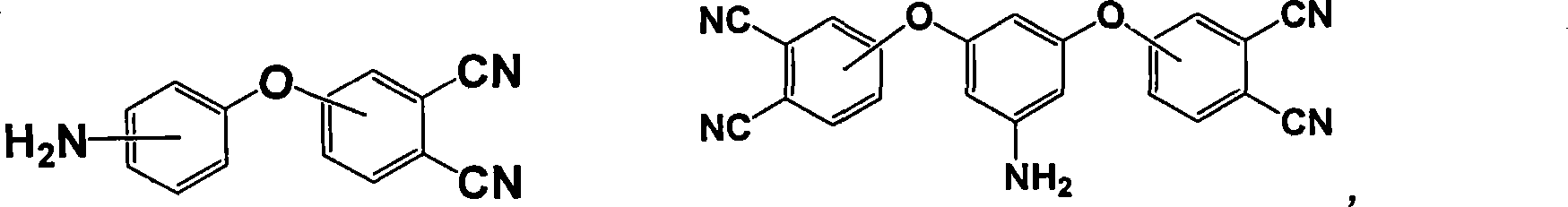

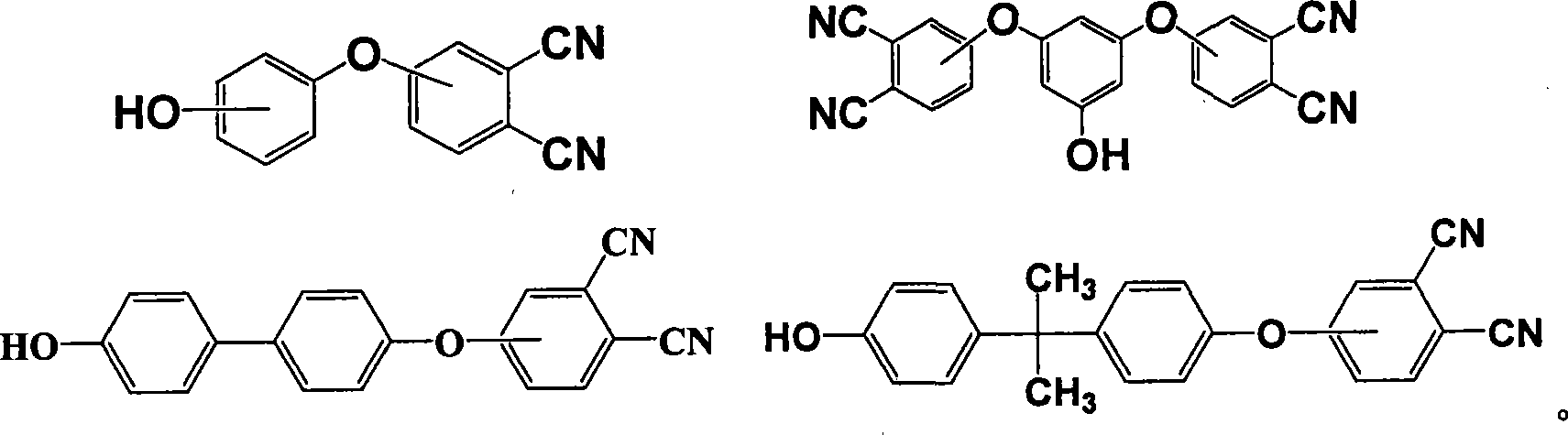

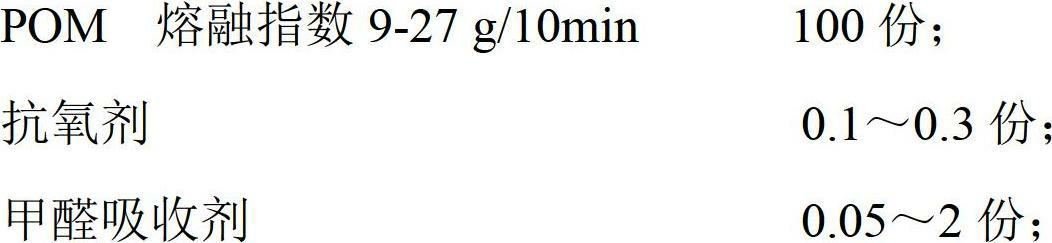

Poly-o-phthalonitrile resin and its preparing process

The precent invention discloses a poly-o-phthalonitrile resin and a preparetion method. After the solution blending, fusion blending or physical blending of 1 to 99 percent of o-phthalonitrile derivative with amino group or hydroxyl group and 1 to 99 percent of polyethernitrile with amino group or hydroxyl group, or 1 to 99percent of o-phthalonitrile derivative with amino group or hydroxyl group and 1 to 99 percent of o-phthalonitrile derivative, or 1 to 99 percent of polyethernitrile with amino group or hydroxyl group and 1 to 99 percent of o-phthalonitrile derivative, or 1 to 98 percent of o-phthalonitrile derivative with amino group or hydroxyl group, 1 to 98 percent of polyethernitrile with amino group or hydroxyl group and one to ninety eight percent of o-phthalonitrile derivative, the compound is solidified, so that the poly-o-phthalonitrile resin is prepared. Because the invention uses the o-phthalonitrile derivative with amino group or hydroxyl group or / and the polyethernitrile to prepare the poly-o-phthalonitrile resin, the performance of the resin can be regulated and controlled in a wide range, and the tenacity of the poly-o-phthalonitrile resin can also be increased, thus broadening the application field of the resin. The invention also has the advantages of simple steps and low cost.

Owner:SICHUAN UNIV

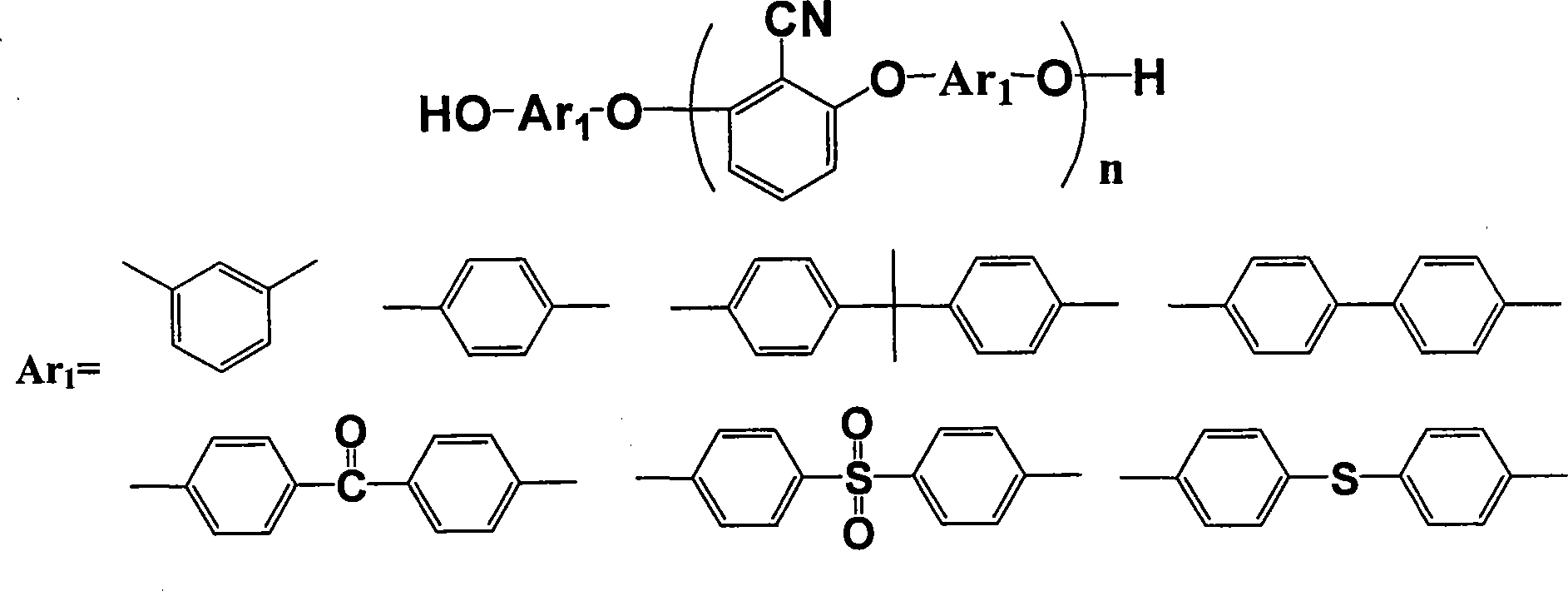

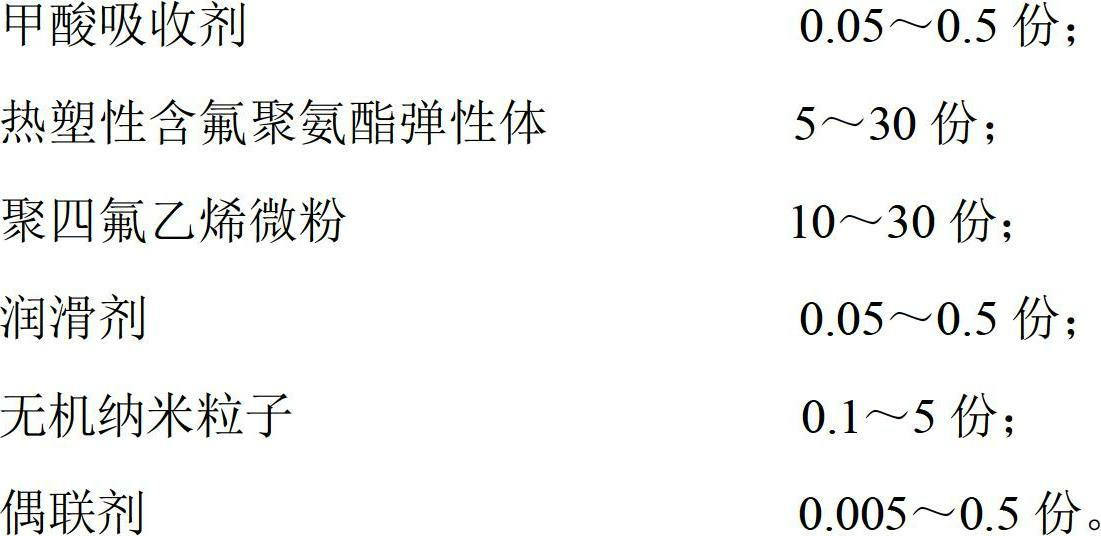

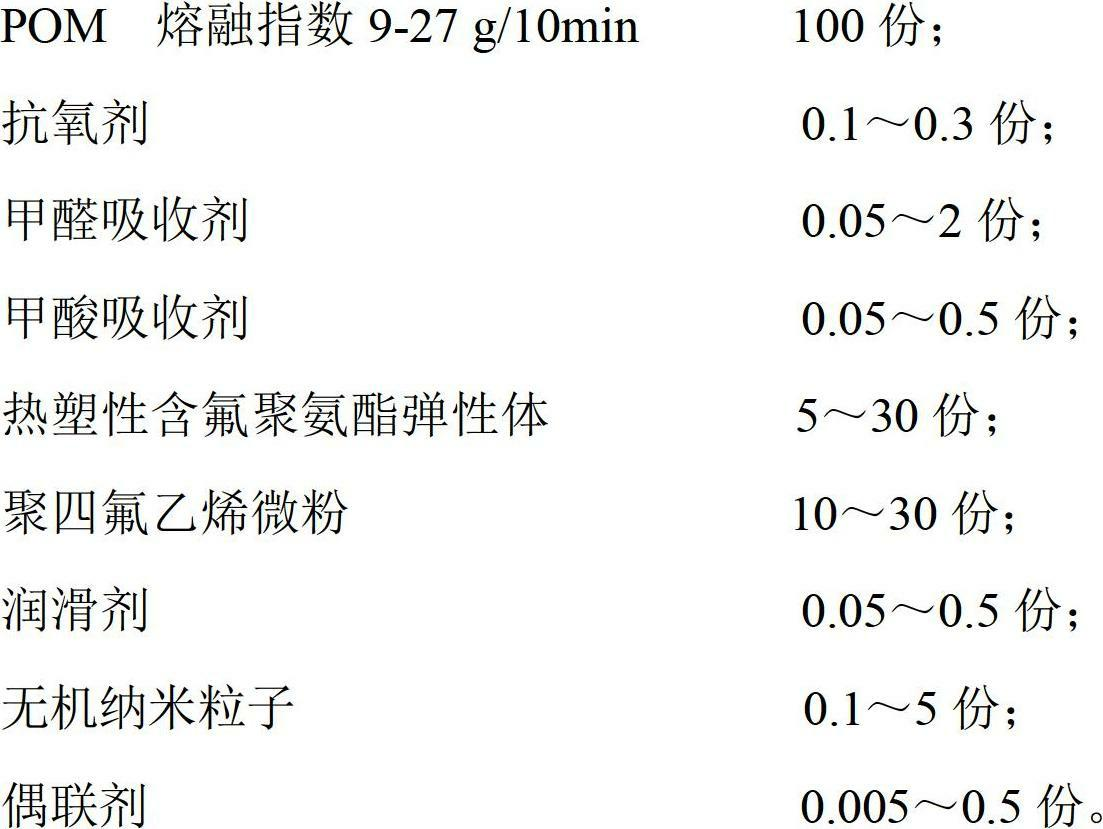

Wear resistant self-lubricating polyformaldehyde and preparation method thereof

The invention discloses wear resistant self-lubricating polyformaldehyde, which is prepared by the following components through a preparation method comprising the following steps: adding 100 parts of POM (polyoxymethylene) resin, 0.1-0.3 part of antioxidant, 0.05-2 parts of formaldehyde absorber, 0.05-0.5 part of formic acid absorber, 15-30 parts of thermoplastic fluorine-containing polyester elastomer, 10-30 parts of polytetrafluoroethylene micro-powder, 0.1-5 parts of inorganic nano-particles subjected to surface treatment and 0.05-0.5 part of lubricant into a high-speed mixer and mixing, melting and mixing by an exhaust type double-screw extruder, extruding and pelleting to obtain the polyformaldehyde, wherein a rotating speed of screws is 50-200 revolutions per minute, and the temperature of a charging barrel is 140-220 DEG C. According to the invention, the thermoplastic fluorine-containing polyester elastomer with excellent strength and toughness and better compatibility with POM and PTFE (polytetrafluoroethylene) and the inorganic nano-particles are composited with POM and PTFE, so that a tensile strength of the polyformaldehyde reaches 45 MPa, and a notch impact strength reaches about 20 KJ / m<2>.

Owner:YANKUANG GRP CO LTD

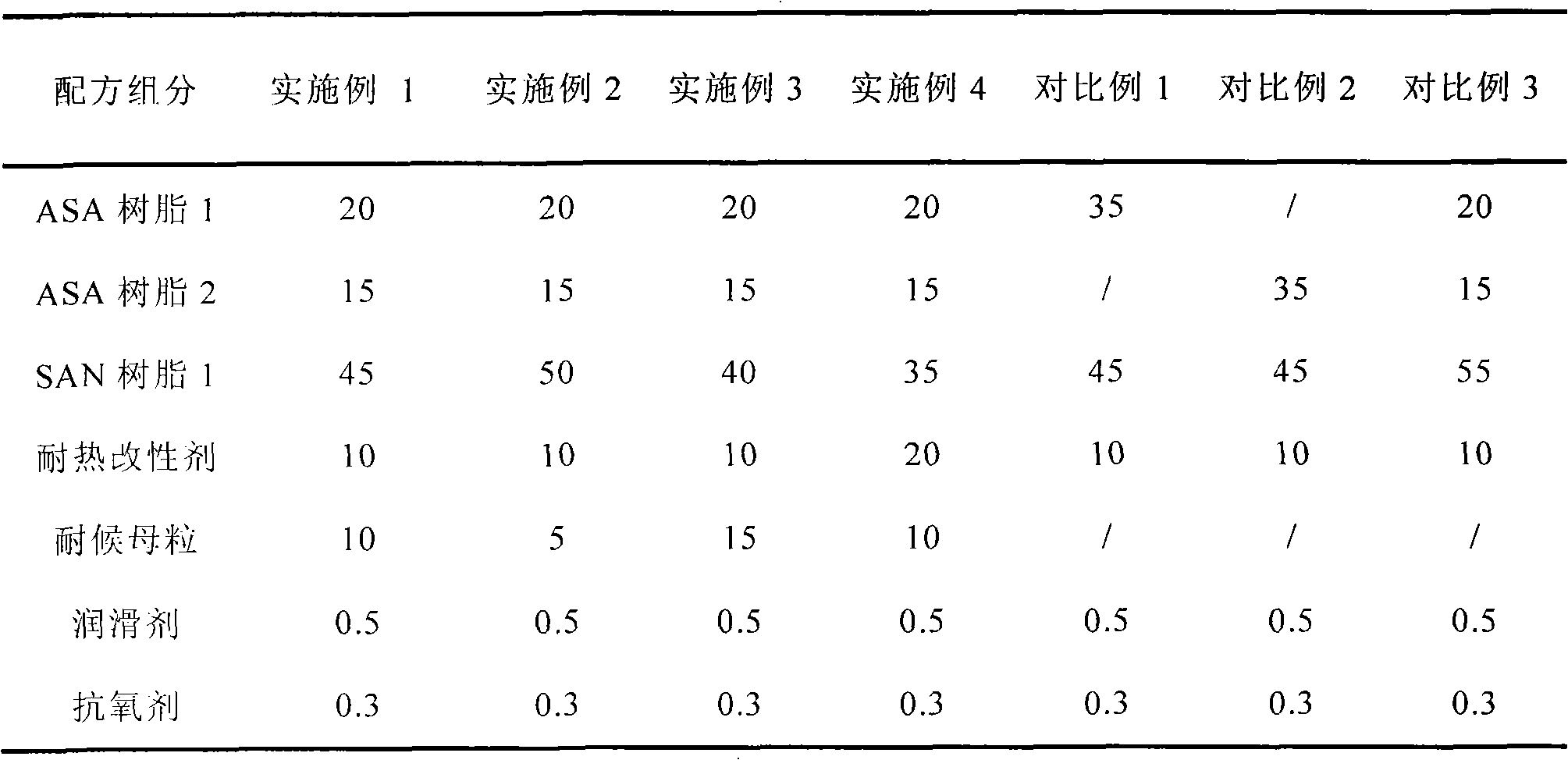

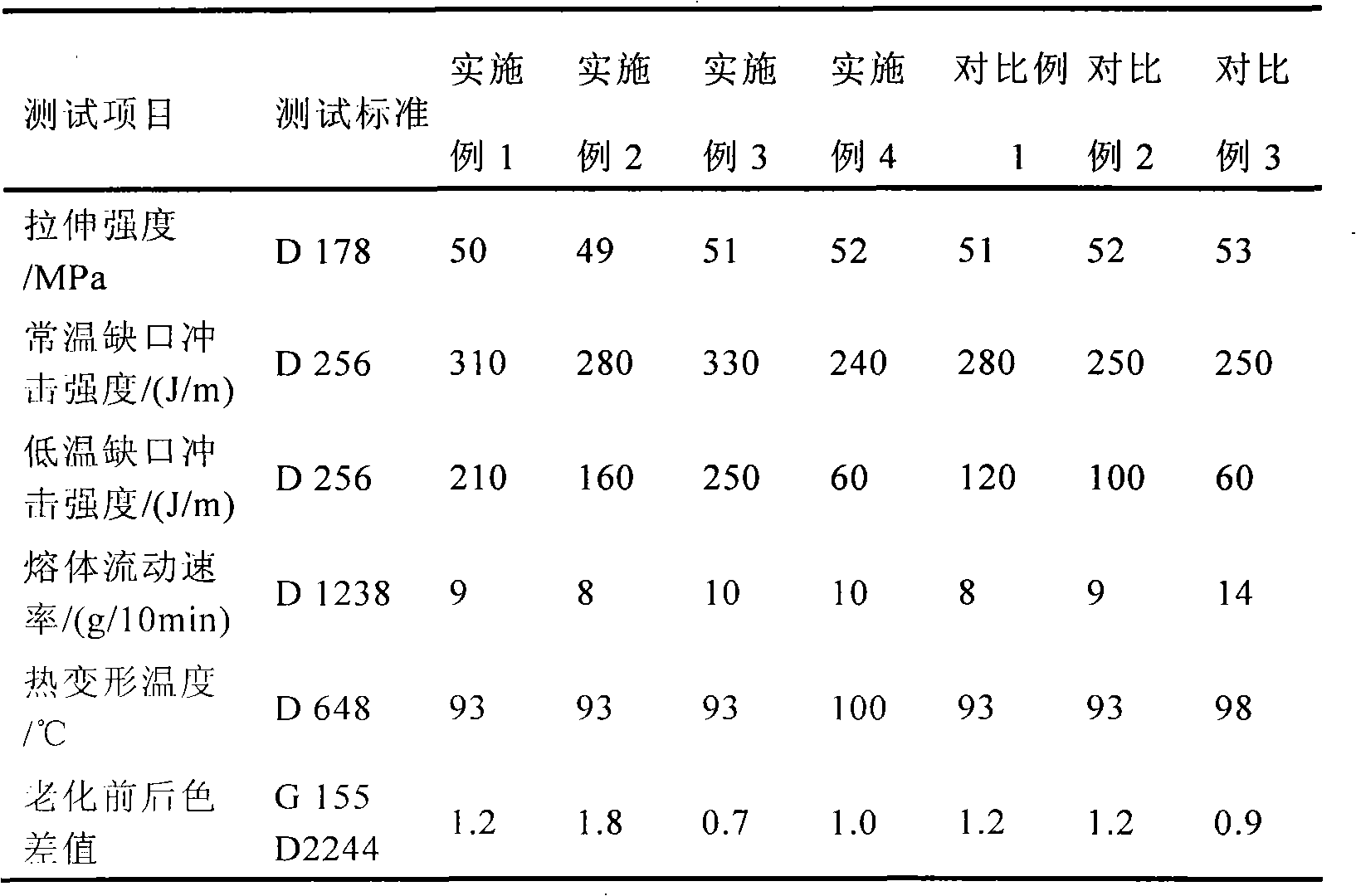

High-weather-resistance acrylate resin composition and preparation method thereof

The invention relates to a high-weather-resistance acrylate resin composition and a preparation method thereof. The raw materials of the high-weather-resistance acrylate resin composition comprise the following components in part by weight: 10 to 30 parts of acrylate rubber powder 1, 10 to 30 parts of acrylate rubber powder 2, 30 to 60 parts of SAN resin 1, 5 to 20 parts of heat-resistant modifier, 5 to 15 parts of weather-resistant master batch, 0.3 to 3 parts of lubricant and 0.05 to 0.5 part of antioxidant. The preparation method comprises the following steps of: stirring the raw materials except the weather-resistant master batch to obtain a mixture; adding the mixture from a main feed inlet of a double-screw extruder, and adding the weather-resistant master batch from a side feed inlet; and extruding and pelleting the raw materials by the double-screw extruder to obtain a sample. The high-weather-resistance acrylate resin composition prepared by the method has higher heat resistance, low-temperature impact resistance, weather resistance, excellent size stability and processing property, and is particularly suitable for automobile exterior trim parts, such as radiator grilles, rear-view mirrors, license plates, central pillar plates, outdoor triangular blocks and the like, with high requirements on weather resistance, heat resistance and low-temperature impact resistance.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Toughened lamination composite material and preparation method thereof

ActiveCN103171212APlay a toughening roleImprove permeabilityLamination ancillary operationsSynthetic resin layered productsFiberCarbon fibers

The invention provides a toughened lamination composite material and a preparation method of the toughened laminated composite material. The lamination composite material comprises a traditional carbon fiber lamination composite material and flexible foam body thin layers intercalated among layers of the traditional carbon fiber lamination composite material, specifically, the foam body thin layers with certain volume density and thickness as well as large openings and high aperture ratio are adopted as the toughened lamination composite material with inserted layers, the foam body thin layers with openings are intercalated among carbon fiber paving layers, under high forming pressure, the flexible foam body thin layers are compacted to achieve the density and thickness required for interlayer toughening, and finally the toughened composite material is obtained under resin forming and curing processes. According to the invention, the structure of the flexible foam body still has continuity and is distributed vertical to the interlayer direction, thus the lamination composite material with excellent toughness is obtained, and in addition, the permeability of the foam body can not influence the flow of resin in the forming process.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

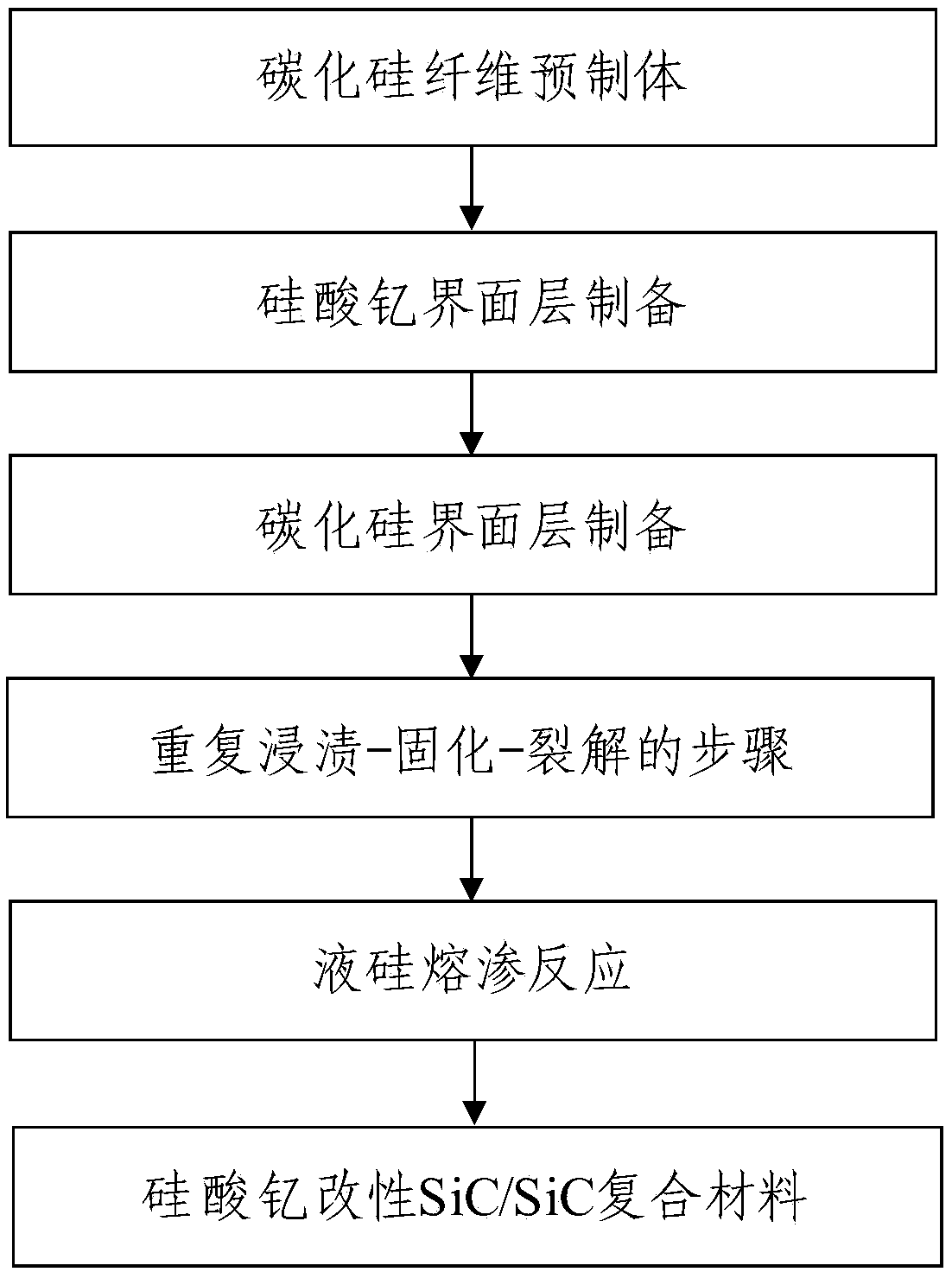

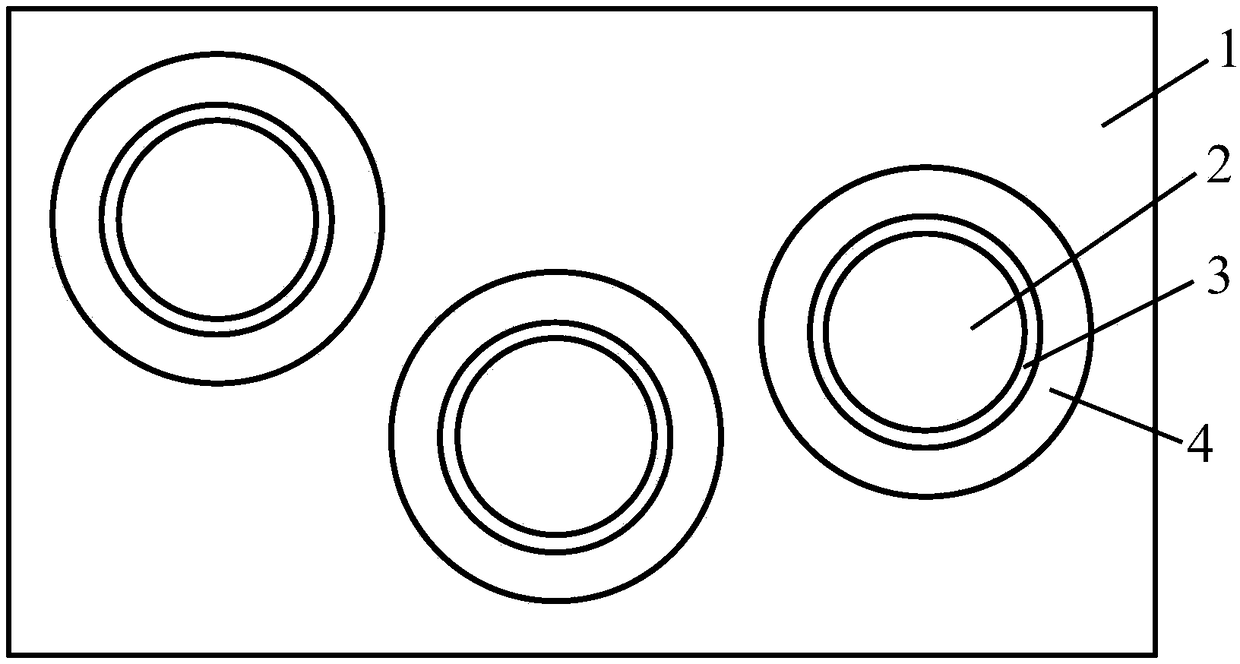

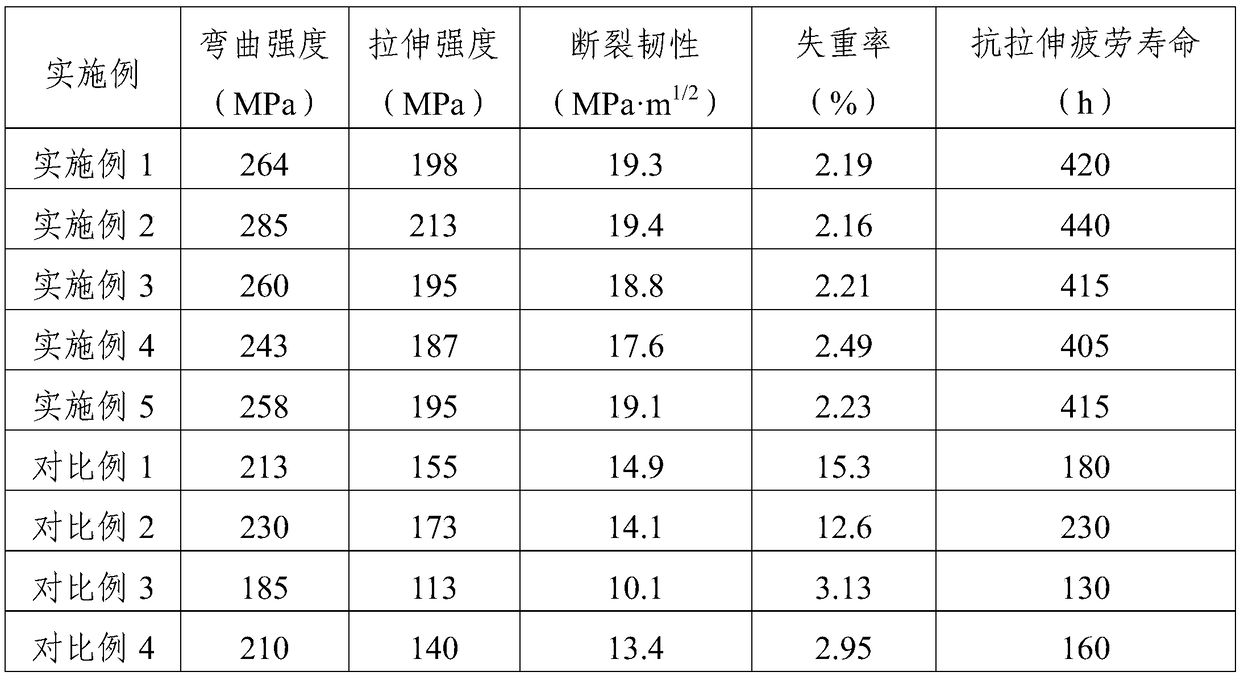

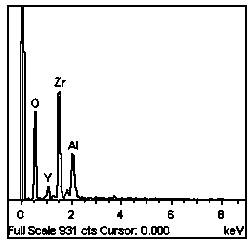

Yttrium silicate modified silicon carbide fiber reinforced silicon carbide composite material and preparation method thereof

ActiveCN109053207AGood chemical stabilityImprove high temperature resistanceWater vaporInterface layer

The invention relates to a yttrium silicate modified silicon carbide fiber reinforced silicon carbide composite material and a preparation method thereof. The preparation method comprises the following steps: (1) sequentially preparing a yttrium silicate interface layer and a silicon carbide interface layer on the surface of a silicon carbide fiber prefabricated body so as to obtain a yttrium silicate modified silicon carbide fiber prefabricated body; (2) soaking the yttrium silicate modified silicon carbide fiber prefabricated body prepared in the step (1) into a carbon precursor solution, and sequentially carrying out a curing step and a cracking step on the soaked yttrium silicate modified silicon carbide fiber prefabricated body; (3) at least repeating the step (2) once so as to obtaina porous silicon carbide fiber prefabricated body; (4) carrying out a liquid silicon infiltration reaction on the porous silicon carbide fiber prefabricated body prepared in the step (3), thereby obtaining a yttrium silicate modified SiC / SiC composite material. The yttrium silicate modified SiC / SiC composite material provided by the invention has excellent oxidation resistance, temperature resistance, vapor corrosion resistance, and the like, and is excellent in comprehensive property.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

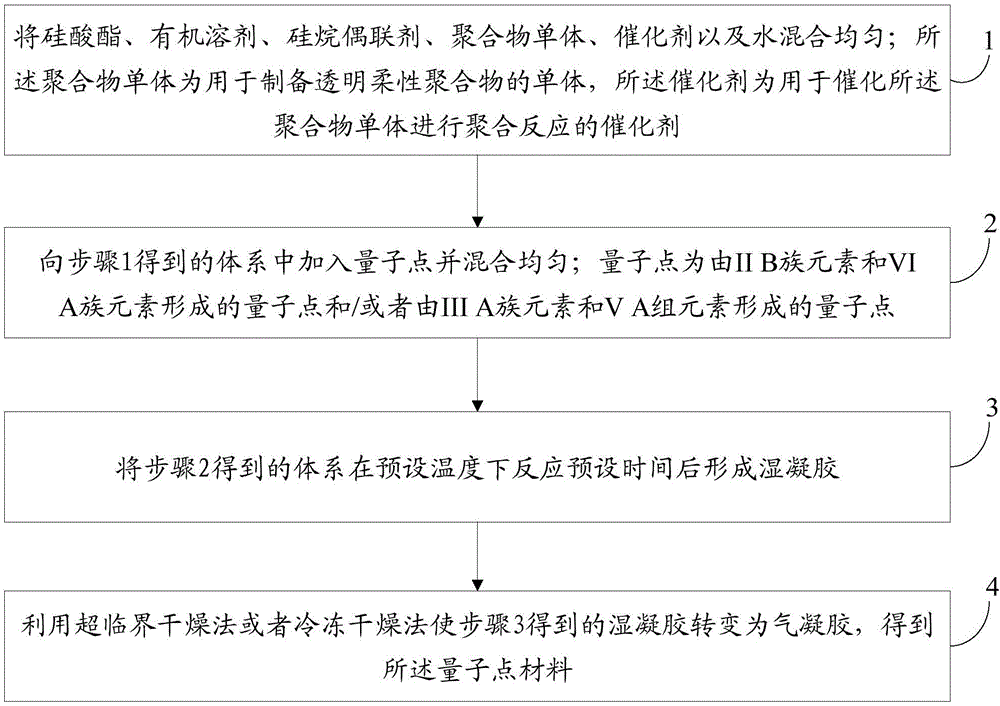

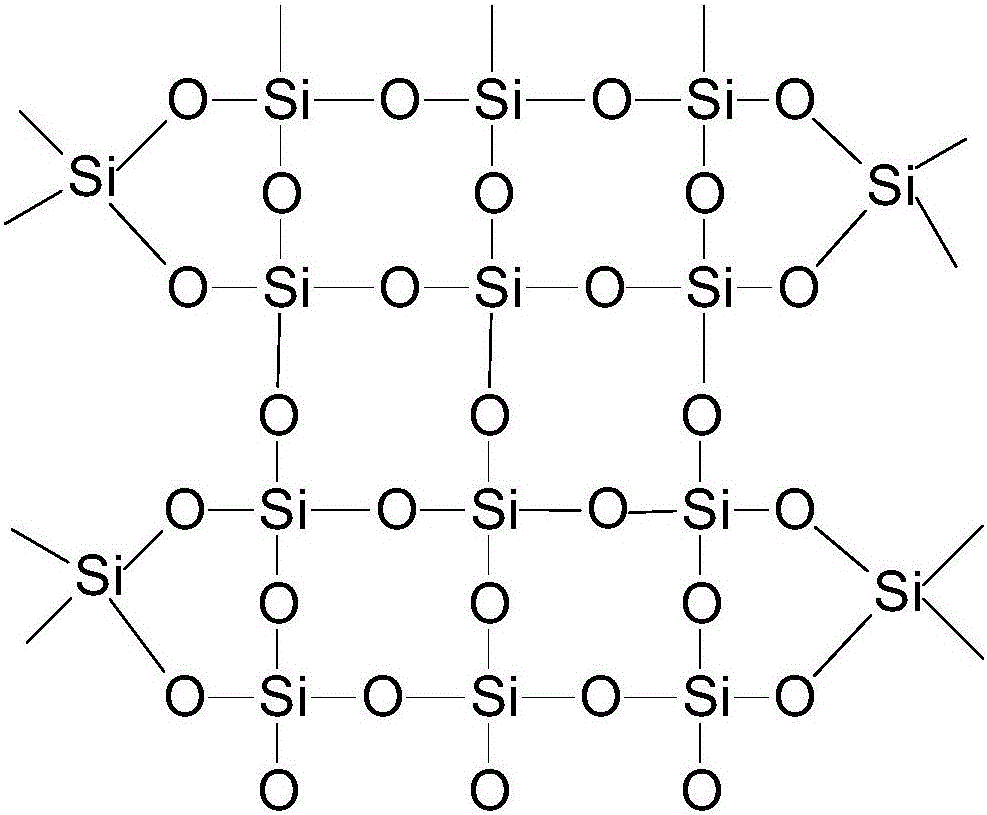

Quantum dot material, preparation method, quantum dot film, backlight module and display device

ActiveCN106432566AReduce dosageImprove luminous efficiencyLuminescent compositionsNon-linear opticsSupercritical dryingFreeze-drying

The invention discloses a quantum dot material, a preparation method, a quantum dot film, a backlight module and a display device, and belongs to the technical field of liquid crystal display. The preparation method of the quantum dot material includes the steps of a, evenly mixing silicate ester, organic solvent, silane coupling agent, polymer monomer, initiator and water, wherein the polymer monomer is a monomer for preparing a transparent flexible polymer, and the initiator is an initiator for initiating the polymerization reaction of the polymer monomer; b, adding quantum dots into a system obtained in the step a to be evenly mixed; c, making the system obtained in the step b react for a preset period of time at preset temperature to form wet gel; d, converting the wet gel obtained in the step c into aerogel through a supercritical drying method or a freeze-drying method to obtain the quantum dot material. The quantum dots are loaded on a three-dimensional network structure of silicon dioxide / organic polymer hybridized aerogel, the overlapping rate of the quantum dots is decreased, the light-emitting efficiency of the quantum dot film is improved, and meanwhile the water-oxygen insulation performance is improved.

Owner:HISENSE VISUAL TECH CO LTD

Preparation method of composite ceramic coating layer

A method for preparing an aluminum alloy element surface coating comprises the following steps of sequentially pre-treating the aluminum alloy element surface, preparing aluminum alloy element surface arcing-blocking coating, preparing aluminum alloy surface insulation composite ceramic coating and performing post-treatment; the preparation of aluminum alloy element surface arcing-blocking coating is to perform coating in a deionized water electrolyte system composed of NaOH, Na2SiO3, (NaPO3)6 and K2ZrF6; the system for the preparation of aluminum alloy element surface coating comprises a stainless steel solution tank (7), tooling (4), an aluminum alloy element (5), a stirrer (2), a thermometer (6), a water-circulating cooling device (1) and power supply equipment (8). The aluminum alloy member surface coating obtained from the method and the system of the invention has the advantages of high toughness and strong binding capacity with the surface of the aluminum alloy element, long service life and excellent heat insulation performance.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Modified polyformaldehyde composition

The invention relates to a polymer composition, and particularly relates to a modified polyformaldehyde composition. The modified polyformaldehyde composition comprises, by weight, 80-100 parts of polyoxymethylene, 10-15 parts of a conductive additive, 4-8 parts of a dispersing agent, 1-5 parts of a light-shielding agent and 0.2-0.5 part of an antioxidant, wherein the conductive additive is graphene. In the modified polyformaldehyde composition, the graphene is used as the conductive additive, so that the modified polyformaldehyde composition has good conductive performance; surface resistivity of polyformaldehyde is effectively reduced; and by adding other series of auxiliary agents, the obtained polyformaldehyde has strong anti-static capacity, good mechanical performance, ultraviolet resistance and strong thermal oxidation resistance.

Owner:SUZHOU SUNWAY POLYMER

Method for preparing aluminum alloy element surface coating and system thereof

ActiveCN102634832APlay a toughening roleImprove high temperature performanceAnodisationComposite ceramicPre treatment

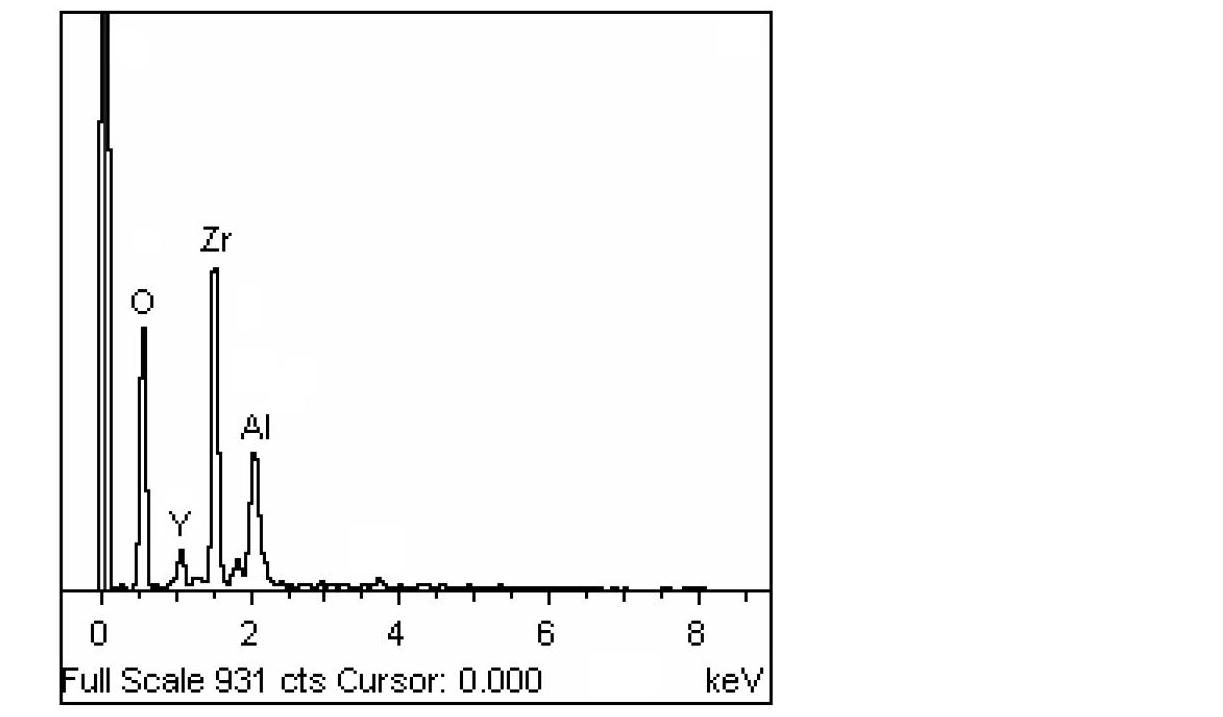

A method for preparing an aluminum alloy element surface coating comprises the following steps of sequentially pre-treating the aluminum alloy element surface, preparing aluminum alloy element surface arcing-blocking coating, preparing aluminum alloy surface insulation composite ceramic coating and performing post-treatment; the preparation of aluminum alloy element surface arcing-blocking coating is to perform coating in a deionized water electrolyte system composed of NaOH, Na2SiO3, (NaPO3)6 and K2ZrF6; the system for the preparation of aluminum alloy element surface coating comprises a stainless steel solution tank (7), tooling (4), an aluminum alloy element (5), a stirrer (2), a thermometer (6), a water-circulating cooling device (1) and power supply equipment (8). The aluminum alloy member surface coating obtained from the method and the system of the invention has the advantages of high toughness and strong binding capacity with the surface of the aluminum alloy element, long service life and excellent heat insulation performance.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Method for preparing aqueous epoxy resin curing agents

The invention relates to a method for preparing aqueous epoxy resin curing agents, which comprises the following steps: firstly, uniformly mixing vulcabond, dimethylolpropionic acid, terminal hydroxyl polymers, bisphenol A, organic solvents and catalysts, preparing terminal isocyanate polyurethane performed polymers through prepolymefization reaction, using imidazole and imidazole derivatives or pyrromonazole and imidazole derivatives as terminal sealing agents for reaction, and finally, neutralizing the imidazole and the imidazole derivatives or the pyrromonazole and the imidazole derivatives to obtain the aqueous epoxy resin curing agents. In the method provided by the invention, because both the sealing agents and the neutralizing agents can react with epoxy resin, no existence of free components after curing is ensured, active -NCO released after the sealing removal can react with carboxylic acid to reduce the hydrophilicity of a system and can also react with the epoxy resin to increase the cross linking density of curing objects, the toughening effect can be realized on the epoxy resin through the induction of the terminal hydroxyl polymers, and the bisphenol A can be used for enhancing the compatibility of the curing agents and the epoxy resin and improving the integrated performance of the curing objects.

Owner:SHAANXI UNIV OF SCI & TECH

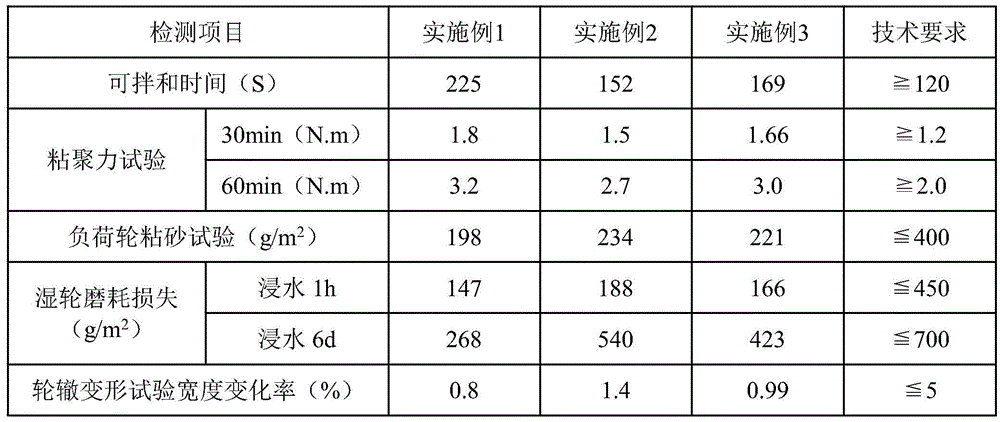

Ultra-viscous fiber resin asphalt wearing layer mixture and preparation method thereof

The invention discloses an ultra-viscous fiber resin asphalt wearing layer mixture and a preparation method thereof. The ultra-viscous fiber resin asphalt wearing layer mixture is prepared from the following raw materials in parts by weight: 2 to 10 parts of bisphenol-a epoxy resin, 6.5 to 8.5 parts of asphalt, 90 to 110 parts of minerals, 0.5 to 1.5 parts of a filler, 0.1 to 1 part of water and 0.01 to 0.2 part of fibers. The preparation method of the ultra-viscous fiber resin asphalt wearing layer mixture comprises the following steps: (1) firstly preparing resin asphalt: heating the asphalt to be 120 to 150 DEG C, adding the heated asphalt into a mixture A in the bisphenol-a epoxy resin, stirring for 10 to 20 min, then mixing and stirring the mixture A with a mixture B, so as to obtain the resin asphalt; (2) adding the minerals, the filler, the water and the fibers according to parts by weight, and blending the asphalt mixture under low temperature. Compared with a conventional preventive pavement maintenance micro-surface treatment technology, an ultra-viscous fiber resin asphalt wearing layer prepared from the mixture has obvious advantages.

Owner:JSTI GRP CO LTD

Slurry of high-performance aluminum nitride ceramic substrate and preparation method thereof

The invention provides slurry of a high-performance aluminum nitride ceramic substrate and a preparation method thereof. The slurry is prepared from the following components in parts by mass: 100 parts of aluminum nitride powder, 1-8 parts of a sintering aid, 0.1-4 part of sialon particles, 1-6 parts of a dispersing agent, 38-68 parts of a solvent, 3-12 parts of a binder and 3-10 parts of a plasticizer. The sintering aid is prepared from the following components in parts by mass: 0-8 parts of Y2O3, 0-5 parts of Sm2O3, 0-1 part of La2O3 and 0.05-3 part of metal aluminum powder; wherein the solvent is one or more of absolute ethyl alcohol, isopropanol and n-butyl alcohol. Sialon particles are dispersed in a slurry system to play a toughening role; the multi-element sintering aid is helpful for reducing the sintering temperature and promoting the sintering compactness; the metal aluminum powder can react with oxygen impurities, the heat conductivity is effectively improved, generation ofaluminum nitride is facilitated in the nitrogen atmosphere, and sintering densification is further promoted. The product is applied to alcohol and other non-toxic, low-toxicity and low-cost solvents for replacing benzene, ketone and other toxic solvents, and the problem that preparation of the aluminum nitride ceramic is not friendly to human beings and the environment is solved.

Owner:GUANGDONG UNIV OF TECH

Bumper material with low linear expansion coefficient and preparation method of bumper material

The invention provides a preparation method of a bumper material with a low linear expansion coefficient. By means of the method, the modified bumper material has the low linear expansion coefficient and simultaneously keeps an excellent mechanical property. The bumper material comprises components in parts by mass as follows: 40-90 parts of polypropylene resin, 5-30 parts of inorganic filler, 5-30 parts of styrene elastomer without double bonds and 0.2-0.4 parts of an antioxidant. The bumper material prepared through blending and extrusion of the components has the low linear expansion coefficient and the excellent mechanical property, the size stability of the bumper can be effectively improved, the assembly accuracy of the bumper is improved, and the regional limitation to production and assembly of the bumper is overcome.

Owner:NANJING JINSHAN AUTOMOBILE ENG PLASTIC

Method for shaping and toughening fiber reinforced composite material

The invention belongs to the technical field of composite material, and relates to a method for shaping and toughening a fiber reinforced composite material. In the invention, polyimide foam powder (such as poly tetracid diester diamide, polyimide foam precursor) are used for shaping and toughening a continuous fiber reinforced composite material; after the polyimide foam powder is uniformly dispersed on fiber fabric, the powder can be bonded onto the surface of the fabric when heated at a certain temperature; and when the powder is foamed at a higher temperature, the powder and the surface of the fabric can be mutually spliced, penetration bonding can be caused on fiber surface and a bridge structure is formed in situ, thus shaping and toughing effects are realized at the same time. The formed toughening bridge structure has the characteristics of high temperature tolerance and insolubility, and the problem of flowing difficulty in RTM (released to manufacturing) glue injection caused by overhigh viscosity is not caused.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Preparation method of toughening filler for organic glass

The invention discloses a preparation method of toughening filler for organic glass. The preparation method comprises the following steps: (1) surface pre-treatment; (2) primary modification treatment; and (3) secondary modification treatment. The filler particles prepared by the preparation method are of special structures which can toughen organic glass effectively, so that the comprehensive using quality of the organic glass is improved. The preparation method has a very good popularizing and applying value.

Owner:蚌埠承永玻璃制品有限公司

High abrasion-proof anti-heat vibration high-alumina brick and preparation thereof

The invention discloses a high abrasion-resistance and thermal shock-resistance high alumina brick, comprising the following compositions, by weight: 5 to 15 parts of 3 to 5mm special grade bauxite aggregate, 30 to 40 parts of 1 to 3mm special grade bauxite aggregate, 10 to 20 parts of 0 to 1mm special grade bauxite aggregate, 20 to 30 parts of special grade bauxite fine powder, 5 to 7 parts of zircon sand fine powder, 1 to 3 parts of Suzhou No.2 mud, 8 to 10 parts of complex binding agent and 4 to 6 parts of water. The invention also discloses a manufacturing method of the high abrasion-resistance and thermal shock-resistance high alumina brick. The high abrasion-resistance and thermal shock-resistance high alumina brick has properties of high intensity, refractoriness and high abrasion-resistance and thermal shock resistance. The high alumina brick and the manufacturing method are applied to circulating fluidized bed boiler cyclone separator flues, cyclone separator straight sections and cones, return feeders, metallurgical industrial furnaces and other heat equipment, and have advantages of simple manufacturing process and easy realization.

Owner:江苏耐基炉衬有限公司

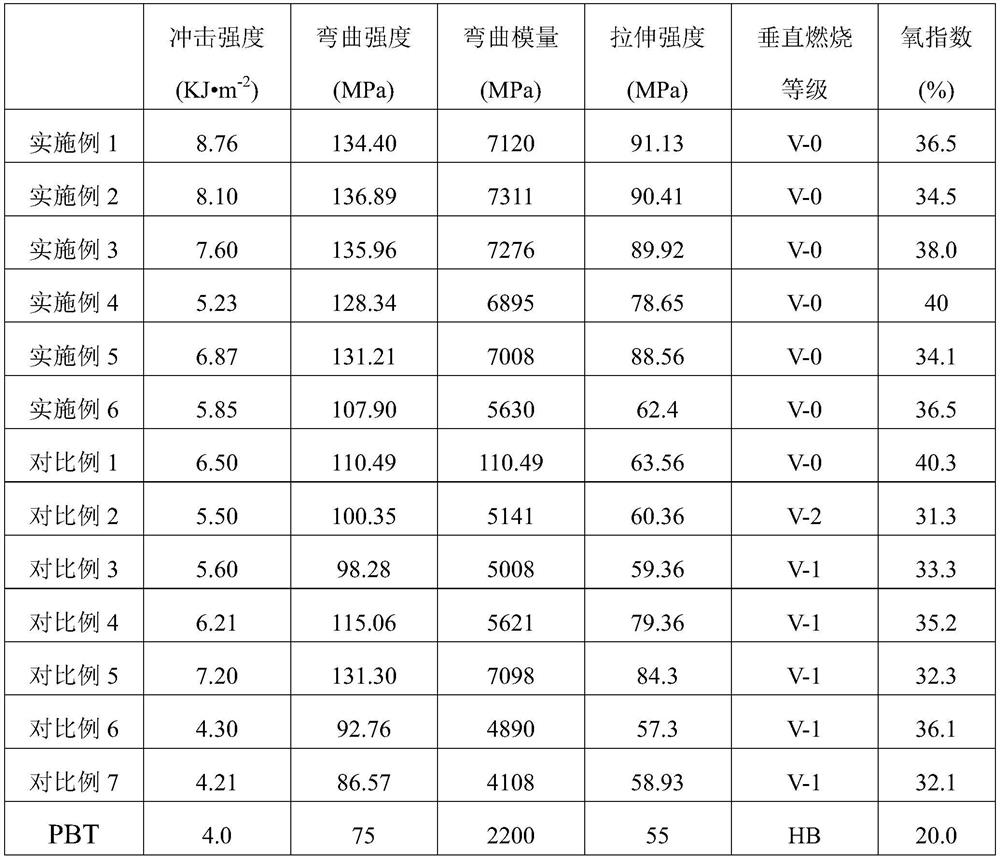

Flame-retardant composition and application thereof, PBT composite material and preparation method of PBT composite material

ActiveCN112812366AImprove mechanical propertiesImprove flame retardant performancePhosphorous acidPolymer science

The invention relates to a flame-retardant composition and application thereof, a PBT (polybutylene terephthalate) composite material and a preparation method of the PBT composite material. The flame-retardant composition is prepared from the following components in percentage by weight: 55 to 65 percent of aluminum diethylphosphinate, 15 to 26 percent of melamine polyphosphate, 10 to 15 percent of melamine cyanurate, 4 to 8 percent of organic modified montmorillonite and 0 to 5 percent of aluminum phosphite. When the flame-retardant composition and main materials such as PBT are melted and mixed to prepare the flame-retardant material, the prepared flame-retardant material can be decomposed to form a coke layer in the combustion process, the coke layer has the function of a heat-insulating oxygen-blocking protective layer, and meanwhile, the nitrogen-containing compound in the flame-retardant composition also has the functions of foaming and coke enhancement, and aluminum phosphite can achieve synergistic flame-retardant and whitening effects, so that the prepared flame-retardant material is good in flame retardance and can maintain good mechanical properties.

Owner:ZHEJIANG XINHUA CHEM

Special epoxy resin adhesive for stone material

InactiveCN106753124AImprove impact toughnessImproved impact toughness and increased peel strength of the adhesiveNon-macromolecular adhesive additivesRubber derivative adhesivesEpoxyResin adhesive

The invention discloses a special epoxy resin adhesive for a stone material. The special epoxy resin adhesive is prepared from the following raw materials in parts by weight: 100 parts of epoxy resin, 20 to 35 parts of amino-terminated liquid nitrile butadiene rubber, 20 to 50 parts of dicyandiamide, 2 to 5 parts of a curing accelerant, 3 to 10 parts of nano calcium carbonate, 2 to 10 parts of kaolin, 1 to 5 parts of fly ash and 5 to 12 parts of nano silicon dioxide. The special epoxy resin adhesive for the stone material, provided by the invention, has high binding force, good strength after curing, good impacting toughness and excellent weather-resisting performance.

Owner:安徽艾蒂贝生物股份有限公司

Bi-component adhesive for wood floor

InactiveCN103289623APlay a toughening roleImprove water resistanceNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesivePolyethylene glycol

The invention provides a bi-component adhesive for a wood floor. The bi-component adhesive comprises the following components in mass fraction: 50 to 100 parts of epoxy resin, 10 to 20 parts of epoxypropane butyl ether, 20 to 40 parts of castor oil glycidyl ether, 10 to 20 parts of polyethylene glycol, 5 to 10 parts of curing agent, 1 to 2 parts of preservative, 30 to 50 parts of silica powder, and 10 to 20 parts of waste tourmaline powder; the epoxy resin is the epoxy resin of glycidyl amine or glycidyl ester epoxy resin; the curing agent is a nitrogenous phenolic resin or modified anhydride curing agent; and the preservative is isothiazolinone. The adhesive can be stored for a long term and needs little time for curing completely at room temperature; and all raw materials adopted are safe and free of pollution and can release negative oxygen ions which are good for human body, so that the environmental protection is realized, the air can be purified, and the air quality is improved.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

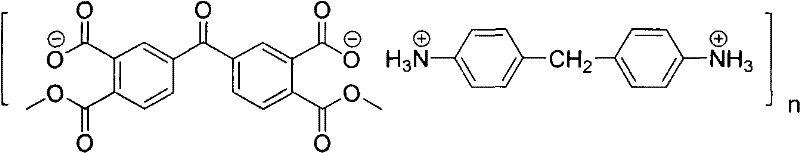

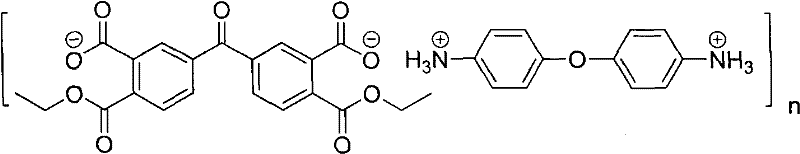

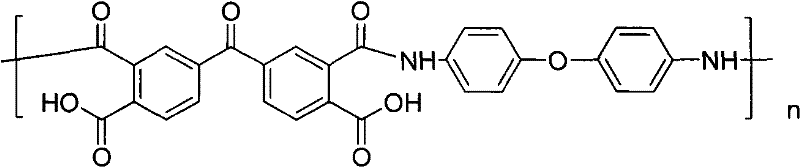

Method for synthesizing end-amino epoxy resin toughening type curing agent

The invention provides a method for synthesizing an end-amino epoxy resin toughening type curing agent, and aims at solving the technical problems of effectively improving the toughness and the impact strength of a resin casting body and composites thereof. The method particularly comprises the steps that 2 mol of aromatic diamine containing ether bonds is added into a three-neck flask, nitrogen is fed, and stirring at room temperature is conducted till the aromatic diamine containing the ether bonds is completely dissolved in organic solvent; 1 mol of aromatic dianhydride is added, the temperature is controlled to be 30 DEG C, and stirring is conducted for five hours to obtain yellowish transparent liquid; the yellowish transparent liquid is dropwise added to deionized water, stirring is conducted to obtain white turbid suspension, washing and suction filtration are conducted, and a white filter cake, namely, the end-amino epoxy resin toughening type curing agent, is obtained. According to the method for synthesizing the end-amino epoxy resin toughening type curing agent, the synthesis technology is simple, and operation is convenient; the aromatic diamine containing the ether bonds and the aromatic dianhydride are adopted to synthesize end-amino polyamide acid on the condition that the molar ratio is two to one; due to the fact that amido of the end-amino polyamide acid can conduct the prepolymerization reaction with epoxy groups of epoxy resin, the polyamide acid is introduced to the molecular structure of the epoxy resin, the toughening effect is achieved, and the impact strength of the composites is increased by 20 percent.

Owner:HUACHANG POLYMER EAST CHINA UNIV OFSCI & TECH

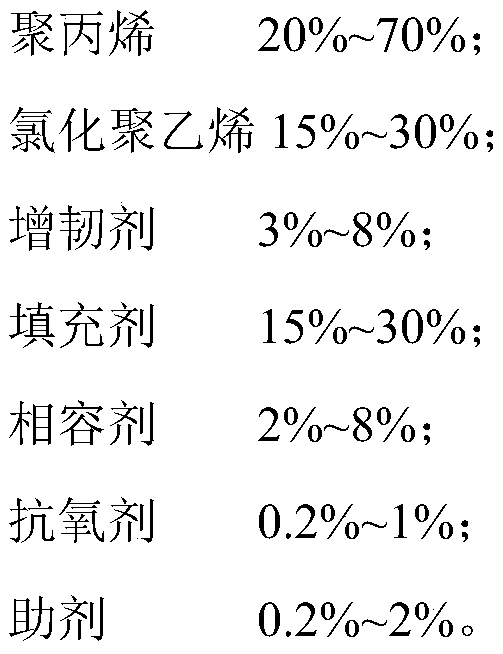

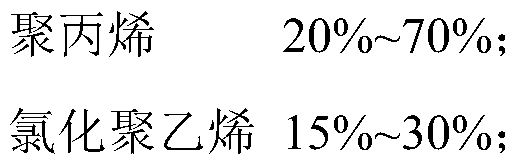

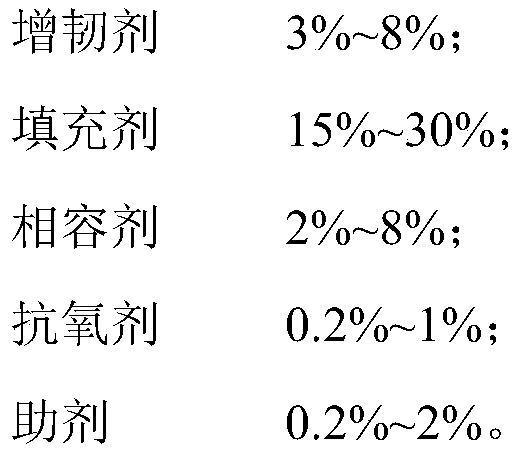

Easy-to-weld modified polypropylene composite with oil resistance and high oxygen index and preparation method of composite

The invention discloses an easy-to-weld modified polypropylene composite with oil resistance and high oxygen index and a preparation method of the composite. The easy-to-weld modified polypropylene composite with oil resistance and high oxygen index is prepared from raw materials as follows: polypropylene, chlorinated polyethylene, a flexibilizer, filler, a compatilizer, an antioxidant and an aid.Meanwhile, the invention also discloses the preparation method of the easy-to-weld modified polypropylene composite with oil resistance and high oxygen index. By modification of filling polypropylenewith chlorinated polyethylene and maleic anhydride grafted polypropylene, the polarity of the composite can be greatly increased, so that the molten material mutually diffuses and infiltrates under the action of high-frequency welding, and very good welding strength is realized. Modified polypropylene has oil resistance and high oxygen index, can meet the standard requirement of combustion characteristics, has very low combustion speed, plays a toughening role with other toughening agents and has good comprehensive mechanical performance.

Owner:GUANGDONG JUSHI CHEM CO LTD

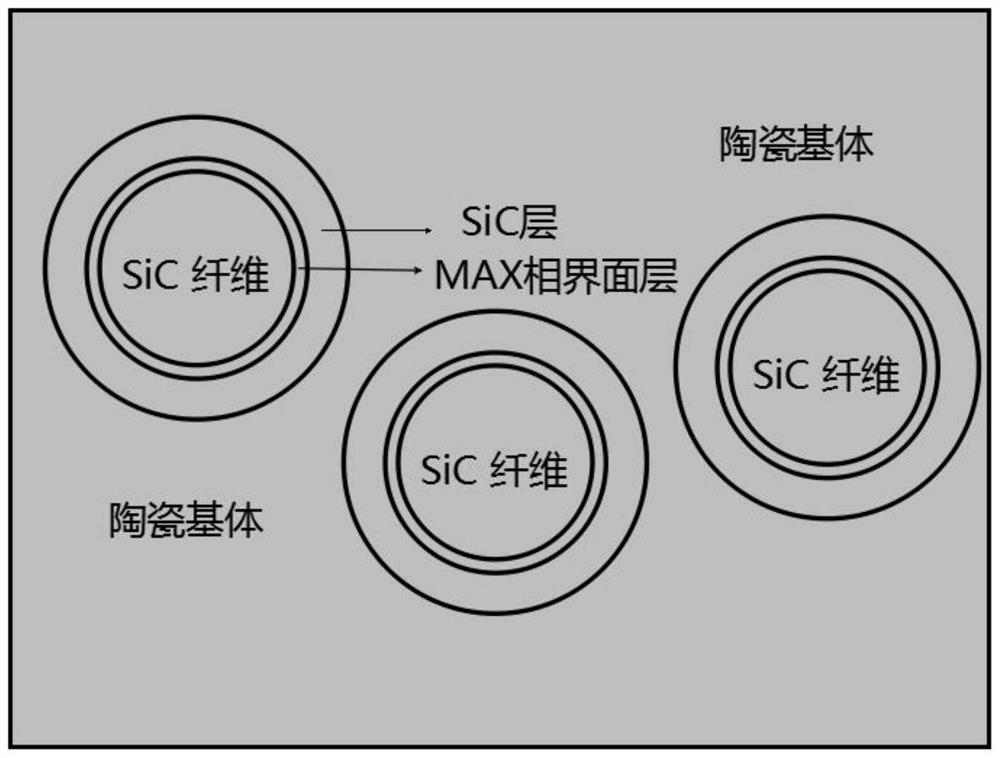

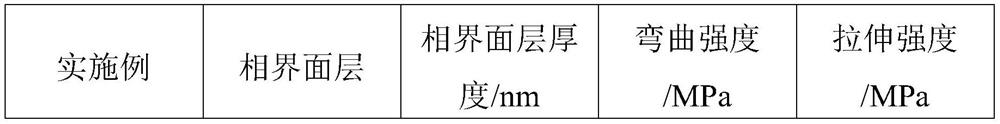

Ti3SiC2MAX phase interface layer modified SiC/SiC composite material and preparation method thereof

The invention relates to a preparation method of a Ti3SiC2 MAX phase interface layer modified SiC / SiC composite material, and belongs to the field of aerospace material preparation processes. A chemical vapor deposition method is adopted, a Ti3SiC2 MAX phase interface layer is deposited on the fiber surface in a SiC fiber prefabricated body, and the thickness is 200-1200 nm. And then, a SiC interface layer is deposited on the outer side of the Ti3SiC2 MAX phase interface layer through a chemical vapor deposition method, and the Ti3SiC2 MAX phase interface layer is completely coated with the SiC interface layer with the thickness ranging from 3 micrometers to 5 micrometers. Then a proper resin precursor for repeated dipping, curing and cracking treatment is selected to obtain a green body containing a porous carbon matrix; and finally, liquid silicon melting reaction is performed in a high-temperature infiltration furnace to obtain the SiC / SiC composite material. The Ti3SiC2 MAX phase has excellent chemical stability, heat-conducting property and friction property so that the performance of the SiC / SiC composite material under a high-temperature condition can be effectively improved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

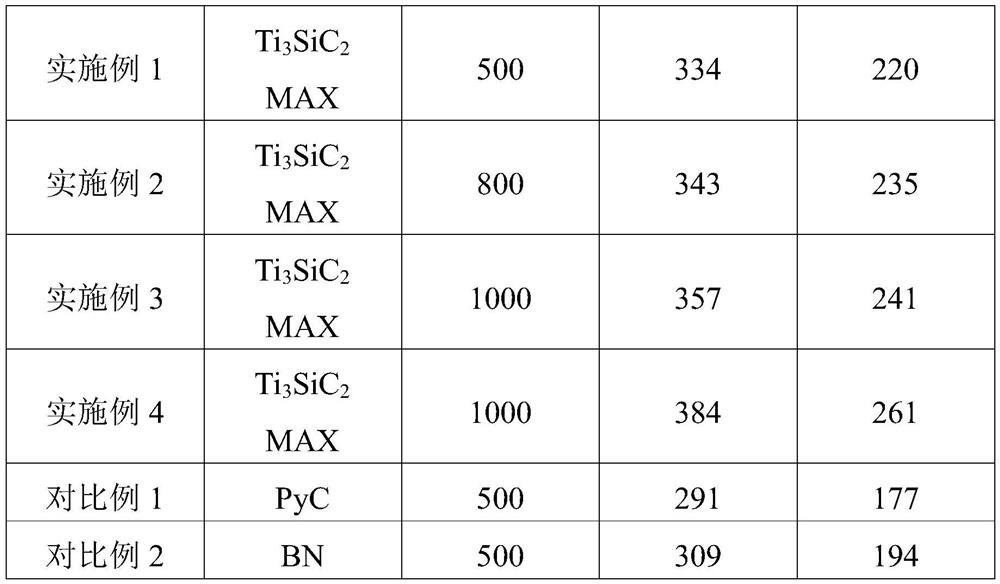

Environmentally-friendly dope for solidifying direct-vacuum aluminized paper by electron beam and preparation method thereof

The invention discloses an environmentally-friendly dope for solidifying direct-vacuum aluminized paper by an electron beam and a preparation method thereof. The preparation method comprises the following steps of: weighing 10-90 parts of epoxy resin, 5-30 parts of epoxy active diluents, 2-5 parts of initiators; agitating the epoxy active diluents and raising the temperature to 50-60 DEG C; adding the epoxy resin, agitating for 30 min; adding the initiators, filtering after uniform agitating and obtaining the required environmentally-friendly dope for solidifying the direct-vacuum aluminized paper by the electron beam. The dope has moderate viscosity and can be applied to prime coat and surface coating processes of the direct-vacuum aluminized paper; and compared with a dope layer of a traditional dope, a dope layer solidified by the electron beam is more greatly improved in temperature tolerance and flexibility, and the anti-burst performance during the bending of the direct-vacuum aluminized paper is improved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

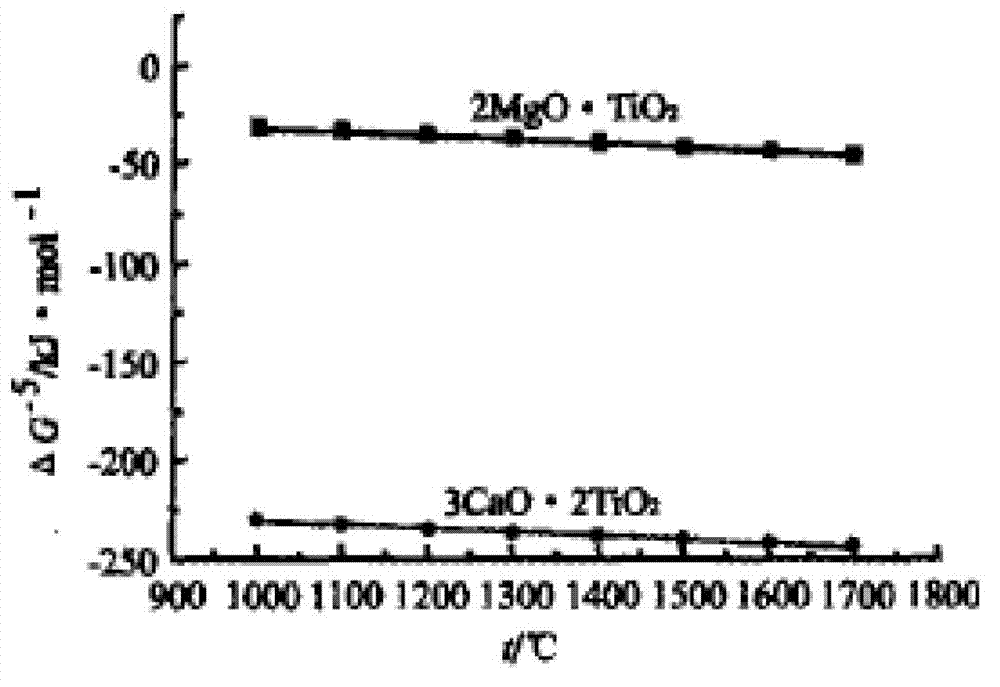

Mg-Ca-Zr-Ti brick for cement kiln and preparation method thereof

The invention relates to the field of Mg-Ca-containing refractory materials, in particular to a Mg-Ca-Zr-Ti brick for a cement kiln and a preparation method of the brick; the Mg-Ca-Zr-Ti brick for the cement kiln is characterized by comprising the following raw materials by weight percent: 95-99% of synthesized Mg-Ca sand, 1-5% of electric smelting stable zirconium oxide, 1-3% of titanium dioxide and bonding agent, wherein the weight of the bonding agent accounts for 2-5% of the total weight of the three raw materials, and paraffin is adopted as the bonding agent. The preparation method of the brick has the technological process steps of: preparing the raw materials, blending, mixing, drying, molding by pressing and sintering and is characterized in that the sintering temperature is between 1520 DEG C and 1570 DEG C. Compared with the prior art, on the premise that the advantages of a magnesite-dolomite brick are maintained, the Mg-Ca-Zr-Ti brick effectively overcomes the disadvantages of the conventional magnesite-dolomite brick, such as thermal shock resistance and high hydration rate; and the Mg-Ca-Zr-Ti brick has the characteristics of good thermal shock resistance and good hydration resistance, and can be used for replacing a magnesite-chrome brick used for a cement kiln burning zone, thus realizing non-chromium characteristic of the refractory brick for the cement kiln.

Owner:辽宁青花耐火材料股份有限公司

Composite material combustion barrier structure and composite material thereof

ActiveCN106626585APlay a toughening roleEasy Lay OvermoldingLayered productsCoatingsFiberCarbon fibers

The invention belongs to the technical field of preparation of structure-function integrated composite materials, and relates to a composite material combustion barrier structure and a composite material thereof. A carbon fiber prepreg of a prefabricated structured interlayer combustion barrier structure is developed, and the prefabricated structured interlayer combustion barrier structure is distributed on the surface of the prepreg, has a certain thickness and is in mesh distribution. The prepreg comprises resin, a thermoplastic toughening agent which is thermally dissolved into the resin, and fire retardants and / or nanoparticles which are evenly distributed into the thermoplastic toughening agent. After the prepreg is prepared into the composite material, a continuous combustion barrier layer is formed between layers and diffused into the layer with high carbon fiber content to play a cooperative barrier role, so that the composite material combustion barrier structure plays a good flame-retardant role. A UL94 vertical combustion method shows that the flame-retardant level can reach the V0 level, no smoke overflows in combustion, a composite material molding technology is facilitated due to the mesh distribution, and the influence on the outer surface performance of the composite material is avoided.

Owner:AVIC BASIC TECH RES INST

Epoxy resin daub for building joint filling and preparation method thereof

The invention discloses epoxy resin daub for building joint filling. The epoxy resin daub for building joint filling comprises a component A and a component B. The component A is prepared from the main raw materials in parts by weight: 45-55 parts of bisphenol A 128 epoxy resin, 15-20 parts of modified epoxy resin, 10-15 parts of terminal carboxyl nitrile rubber, 10-15 parts of polyimide resin, 8-11 parts of a modified carbon nanotube, 12-16 parts of filler and 1-2 parts of a coupler. The component B contains a low-temperature curing agent, a polyamide curing agent, a phenolic amine curing agent and dibutyl phthalate. The mass ratio of the component A to the component B is 10: (2-3). The invention also discloses a preparation method of the epoxy resin daub. By adding the modified epoxy resin, terminal carboxyl nitrile rubber and polyimide resin and matching with the modified carbon nanotube in use, the obtained daub is high in mechanical property, high in toughness, excellent in comprehensive performance, simple in preparation process and easy to produce.

Owner:上海固瑞泰复合材料科技有限公司

High-abrasion high-alumina brick with heat shock resistance and manufacturing method thereof

InactiveCN104030707AImprove erosion resistanceImprove thermal shock resistanceCycloneChromium carbide

The invention discloses a high-abrasion high-alumina brick with heat shock resistance. The high-abrasion high-alumina brick comprises the following components in parts by weight: 5-15 parts of 3-5mm super alum aggregate, 30-40 parts of 1-3mm super alum aggregate, 10-20 parts of 0-1mm super alum aggregate, 20-30 parts of super alum powder, 5-7 parts of zirconium carbide fine powder, 2 parts of chromium carbide powder, 1-3 parts of Suzhou mud NO.2, 8-10 parts of compound binder and 4-6 parts of water. The invention also discloses a manufacturing method of the high-abrasion high-alumina brick with heat shock resistance. The high-abrasion high-alumina brick with heat shock resistance disclosed by the invention has high strength, refractoriness, high abrasion and heat shock resistance, and is applicable to a circulating fluid bed boiler cyclone separator flue, cyclone separator straight section and cone body, a return feeder, a metallurgical furnace and other thermal equipment. The high-abrasion high-alumina brick is simple in manufacturing process and easy to realize.

Owner:张婷

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com