Environmentally-friendly dope for solidifying direct-vacuum aluminized paper by electron beam and preparation method thereof

A technology of electron beam curing and vacuum aluminized paper, applied in paper coating, papermaking, coating, etc., can solve the problems of poor coating leveling, easy cracking of coating, insufficient toughness, etc., and achieve good temperature resistance and bending Good anti-burst performance and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Put 20g of octyl glycidyl ether into the equipped three-necked bottle, start stirring and raise the temperature to 50℃~60℃, add 5g novolac epoxy resin F-51 and 75g epoxy resin E-51 in sequence, stir for 30min, then add 3g of initiator diphenyliodonium hexafluorophosphate, stirred evenly, filtered, and discharged to obtain an environmentally friendly electron beam curing coating for direct vacuum aluminized paper.

Embodiment 2~5

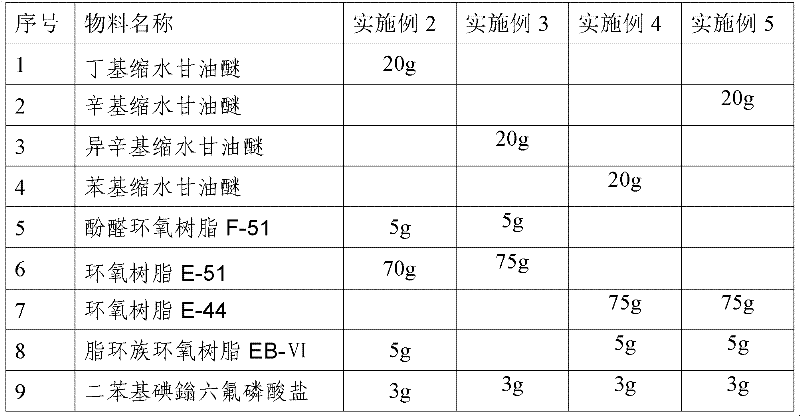

[0024] The preparation process is the same as in Example 1, and the specific formula is shown in Table 1.

[0025] Table 1

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com