Modified polyformaldehyde composition

A polyoxymethylene composition and polyoxymethylene technology, applied in the field of polymer compositions, can solve problems such as performance defects, and achieve the effects of compensating for the loss of mechanical properties, maintaining properties, inhibiting degradation and recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

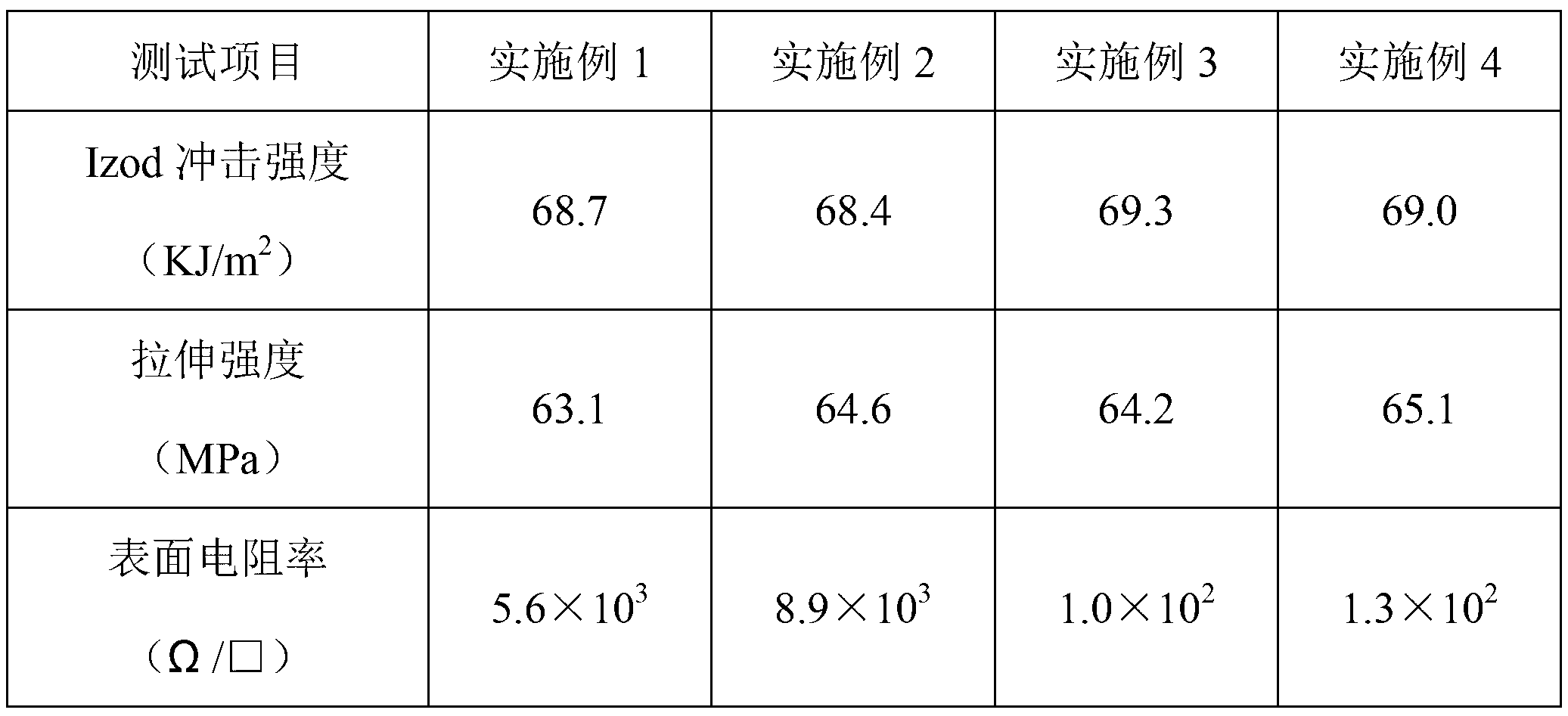

Embodiment 1

[0017] First, 10 parts of graphene and 4 parts of dispersant polyvinylpyrrolidone are pre-mixed and dispersed, and then the graphene-dispersant mixture is mixed with 80 parts of polyoxymethylene, 1 part of light shielding agent zinc oxide and 0.2 part of antioxidant tetrakis (β-( 3,5-di-tert-butyl-4-hydroxyphenyl) propionate) pentaerythritol ester is mixed in a high-speed mixer, then extruded through a parallel twin-screw mixing extruder, cooled and granulated.

Embodiment 2

[0019] First, 12 parts of graphene and 5 parts of dispersant polyvinylpyrrolidone are pre-mixed and dispersed, and then the graphene-dispersant mixture is mixed with 90 parts of polyoxymethylene, 2 parts of light shielding agent titanium dioxide and 0.3 parts of antioxidant β-(4-hydroxyl Phenyl-3,5-di-tert-butyl) n-octadecyl propionate is mixed in a high-speed mixer, then extruded through a parallel twin-screw mixing extruder, cooled and granulated.

Embodiment 3

[0021] First, 14 parts of graphene and 7 parts of dispersant polyvinylpyrrolidone were pre-mixed and dispersed, and then the graphene-dispersant mixture was mixed with 90 parts of polyoxymethylene, 4 parts of light shielding agent zinc oxide and 0.4 parts of antioxidant 2,6-di The tert-butyl-p-cresol is mixed in a high-speed mixer, then extruded through a parallel twin-screw mixing extruder, cooled and granulated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com