Flame-retardant composition and application thereof, PBT composite material and preparation method of PBT composite material

A technology of flame retardant composition and composite material, which is applied in the field of flame retardant materials, and can solve the problems of low flame retardant anti-dripping, low flame retardant efficiency, easy decomposition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

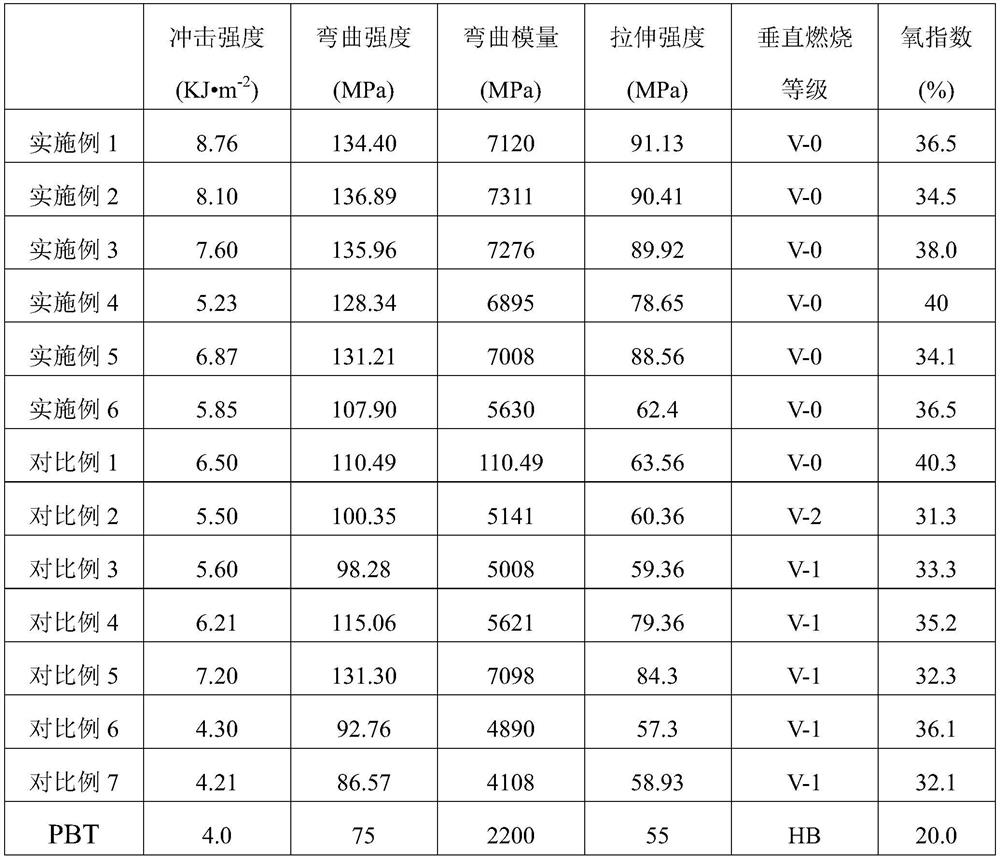

Examples

preparation example Construction

[0046] One embodiment of the present invention also provides a method for preparing a PBT composite material, including the following steps S10-S20.

[0047] Step S10, according to the raw material ratio of the above-mentioned PBT composite material, mix the flame retardant composition, polybutylene terephthalate and coupling agent to obtain a mixture.

[0048] In some embodiments, in step S10, the conditions for mixing the flame retardant composition, the polybutylene terephthalate and the coupling agent are: mixing at 80° C. to 120° C. for 10 minutes to 15 minutes.

[0049] It can be understood that the above mixing step can be carried out in any device capable of mixing substances in the art, specifically, the above mixing step is carried out in a high mixer, and the speed of the high mixer is 600rmp-900rmp.

[0050] In some of these embodiments, before the step of mixing the flame retardant composition, the polybutylene terephthalate and the coupling agent, a step of dryin...

Embodiment 1

[0059] 1) Couple 57.5kg of PBT, 11kg of aluminum diethylphosphinate, 3kg of melamine polyphosphate, 2kg of melamine cyanurate, 0.8kg of organic montmorillonite (DK2 type), 0.2kg of aluminum phosphite, and 0.5kg of silane The agent is placed in a high-speed mixer, and mixed for 12 minutes at a temperature of 90°C and a stirring speed of 700rmp. The materials are uniformly mixed under the action of the stirring paddle to obtain a mixture, which is discharged for use.

[0060] 2) Add the homogeneously mixed mixture in step 1) into the hopper of the twin-screw extruder that has been preheated to the set temperature, and the material is heated and melted while being mixed and conveyed forward by the screw rotation, and 25kg of long glass fibers are quantitatively Add it from the exhaust port in the middle of the extruder, mix it with the melt, extrude it through the die of the extruder, and form strips, cool it in a water tank, and then cut it into pellets with a pelletizer to obtai...

Embodiment 2

[0064] 1) Put 55.5kg of PBT, 12kg of aluminum diethylphosphinate, 4kg of melamine polyphosphate, 2kg of melamine cyanurate, 1kg of organic montmorillonite (DK2 type), and 0.5kg of silane coupling agent in a high-speed mixer , mixed at a temperature of 90° C. and a stirring speed of 700 rpm for 12 minutes, and the materials were uniformly mixed under the action of a stirring paddle to obtain a mixture, which was discharged for use.

[0065] 2) Add the homogeneously mixed mixture in step 1) into the hopper of the twin-screw extruder that has been preheated to the set temperature, and the material is heated and melted while being mixed and conveyed forward by the screw rotation, and 25kg of long glass fibers are quantitatively Add it from the exhaust port in the middle of the extruder, mix it with the melt, extrude it through the die of the extruder, and form strips, cool it in a water tank, and then cut it into pellets with a pelletizer to obtain a modified composite material.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com