Method for preparing aluminum alloy element surface coating and system thereof

A technology of aluminum alloy surface and surface coating, applied in the field of composite ceramic coating, which can solve the problems of fast heat transfer, limited application range of aluminum alloy, low melting point of aluminum alloy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

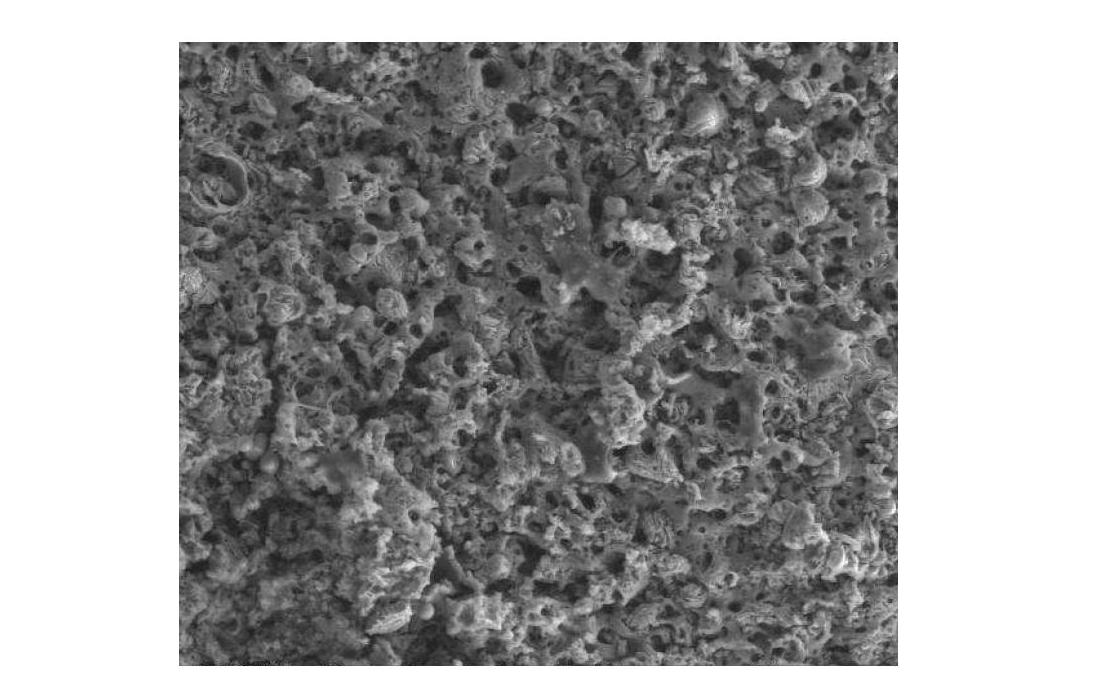

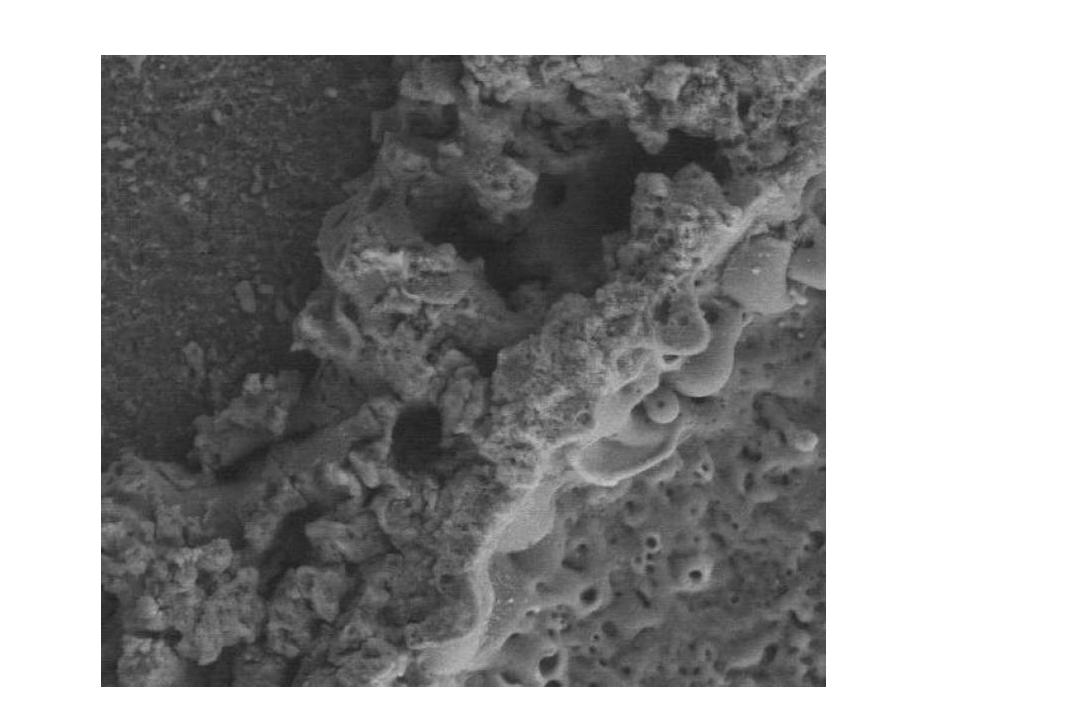

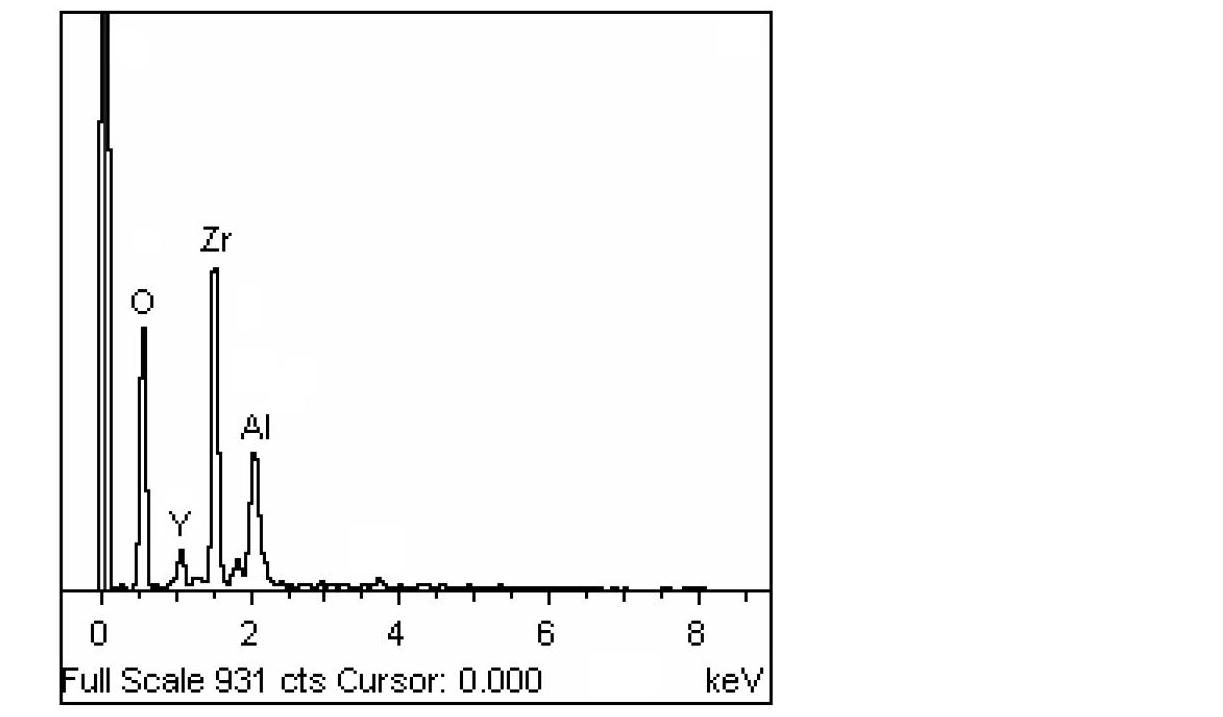

Image

Examples

Embodiment 1

[0040] A preparation system for surface coating of aluminum alloy components, such as Figure 4As shown, it is composed of stainless steel solution tank 7, tooling 4, aluminum alloy components 5, agitator 2, thermometer 6, cooling water circulation heat dissipation device 1 and power supply equipment 8, wherein the stainless steel solution tank 7 contains the above electrolyte 3, stainless steel solution A thermometer 6, an agitator 2, a tooling 4 and an aluminum alloy element 5 are arranged in the tank 7, and are all immersed in the electrolyte 3, wherein the aluminum alloy element 5 is arranged in the tooling 4, and the positive and negative poles of the power supply device 8 are connected to the The aluminum alloy element 5 and the tooling 4 are connected respectively; the cooling water circulation cooling device 1 is arranged on the bottom of the stainless steel solution tank 7 and communicates with the stainless steel solution tank 7 through a pipeline; wherein the power s...

Embodiment 2-7

[0053] Embodiment 2-7: carry out according to the following raw materials and process parameters, and the rest are the same as embodiment 1.

[0054]

[0055]

[0056]

[0057] The surface coating of the aluminum alloy element prepared above has high toughness and strong bonding force with the surface of the aluminum alloy element, and it can be reliably used for 15s-28s in a high temperature environment of 2000-3000 ° C, which meets its use requirements in a high temperature environment .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com