Mg-Ca-Zr-Ti brick for cement kiln and preparation method thereof

A technology of magnesia-calcium-zirconium-titanium bricks and cement kilns, which is applied in the field of magnesia-calcium-zirconium-titanium bricks for cement kilns and its production. It can solve the problems of easy hydration and poor thermal shock resistance, and achieve good hydration resistance and refractoriness. High, solve the effect of poor thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

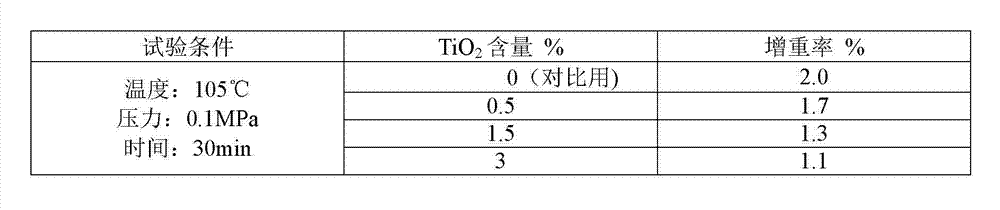

[0036] Take 98% of magnesia-calcium sand, 1.5% of fused stabilized zirconia, and 0.5% of titanium dioxide to prepare brick materials according to the weight percentage. After firing at ℃, the refractory material is obtained.

[0037] After testing, the performance of the refractory material is: the bulk density is 2.99 g cm -3 , The apparent porosity is 14.8%, the normal temperature compressive strength is 58MPa, the high temperature flexural strength is 3.6 MPa, the number of forced air cooling at 950°C is 100 times, and the weight gain rate after the hydration test is 1.7%.

Embodiment 2

[0039] Take 97% of magnesia-calcium sand, 1.5% of fused stabilized zirconia, and 1.5% of titanium dioxide to prepare brick materials according to the weight percentage. After firing at ℃, the refractory material is obtained.

[0040] After testing, the performance of the refractory material is: the bulk density is 3.08 g cm -3 , the apparent porosity is 12.5%, the normal temperature compressive strength is 72MPa, the high temperature flexural strength is 4.5MPa, the number of forced air cooling at 950°C is 100 times, and the weight gain rate after the hydration test is 1.3%.

Embodiment 3

[0042] Take 98.5% of magnesia-calcium sand, 1% of fused stabilized zirconia, and 0.5% of titanium dioxide to prepare brick materials according to the weight percentage. After firing at ℃, the refractory material is obtained.

[0043] After testing, the performance of the refractory material is: the bulk density is 3.03 g cm -3 , the apparent porosity is 13.5%, the normal temperature compressive strength is 65MPa, the high temperature flexural strength is 3.7 MPa, the number of forced air cooling at 950°C is 80 times, and the weight gain rate after the hydration test is 1.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Normal temperature compressive strength | aaaaa | aaaaa |

| High temperature flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com