Patents

Literature

132results about How to "Good hydration resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of medium and high pressure formed foil

InactiveCN101246779ANo overly erosive side effectsGood hydration resistanceCapacitor electrodesOrganic acidChemistry

The invention relates to a preparing method of a middle-high voltage formed foil, comprising the steps that: a middle-high voltage etched foil is put in pure water with a temperature no less than 96 DEG C to hydrate; the hydrated foil is electrified three to four levels to form; the formed foil is heated; the heated foil is put into the processing liquid including phosphorus-containing inorganic acid and / or phosphorus-containing organic acid to middle processing; the middle processed foil is put into the forming liquid to first reforming, with the same forming liquid as that of the second step; the first reformed foil is reheated; the reheated foil is second reformed; and the high-middle voltage formed foil is got. The invention has the advantages that: the passivation is highly effective, the passivant can be freely selected, the control scope of the parameter of the passivation is large, the processing process is more energy-saving and time-saving, as well as more suitable for current workshop scale production.

Owner:RUYUAN YAO AUTONOMOUS COUNTY DONGYANGGUANG FORMED FOIL CO LTD

Production of electrolytic capacitor anode aluminum foil

InactiveCN101030487AIncrease temperatureIncrease concentrationAnodisationElectrolytic capacitorsElectrolysisPhosphoric acid

The invention is concerned with the manufacture method for the anodic foil of the electrolytic capacitor, which is the manufacture method by using motor, it is: cleans the corrosive foil with pure water - oxalic acid forming - cleans with hot water - conducts forming in four stages - heat treatment - re-forming - treats with the phosphoric acid - re-forming - heat treatment - re-forming - drying. The advantages of the invention are low wastage, better flexibility, shorter voltage boosting, and better hydration proof.

Owner:DONGGUAN HEC CONDENSER CO LTD

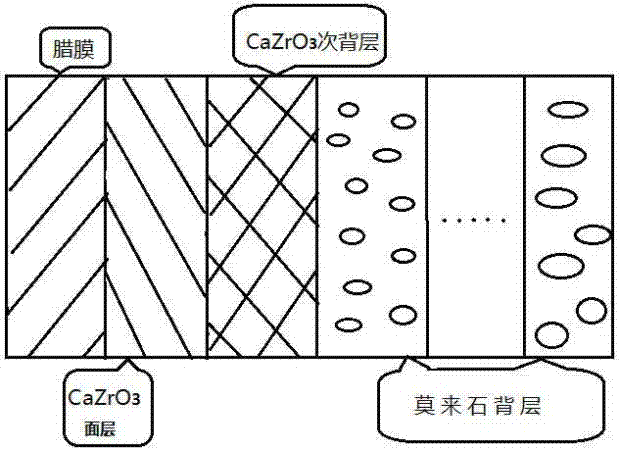

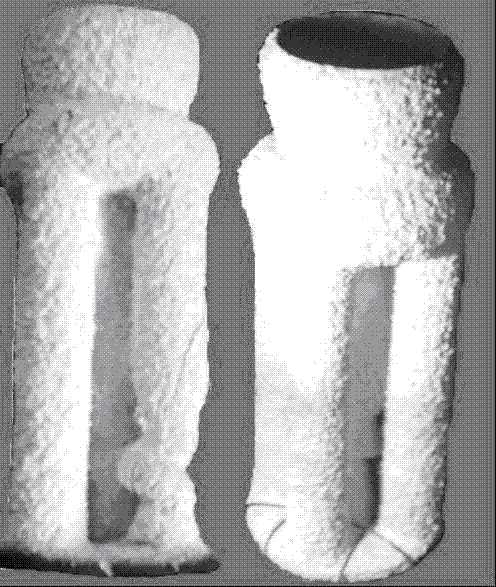

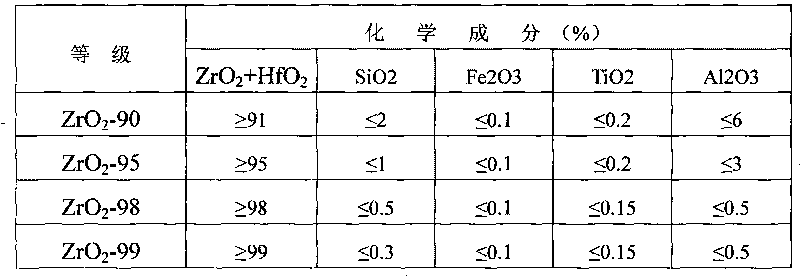

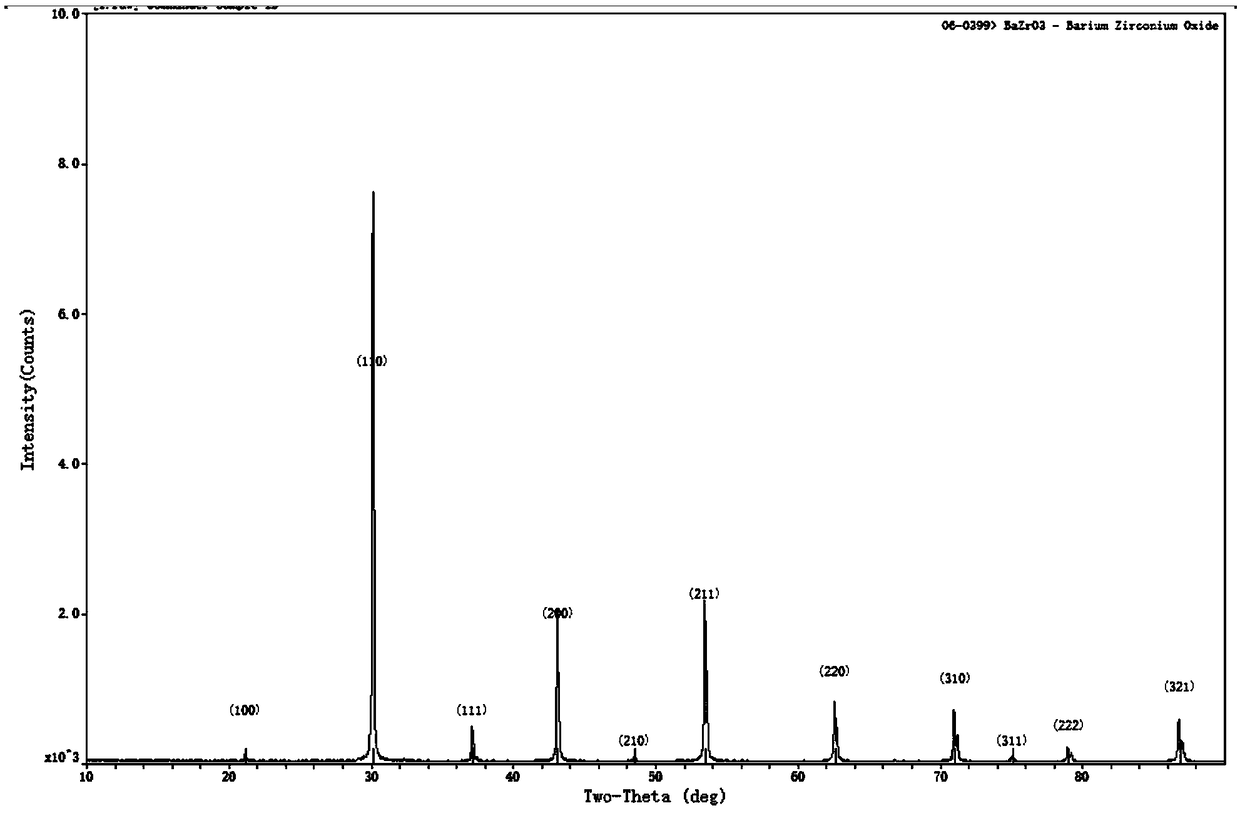

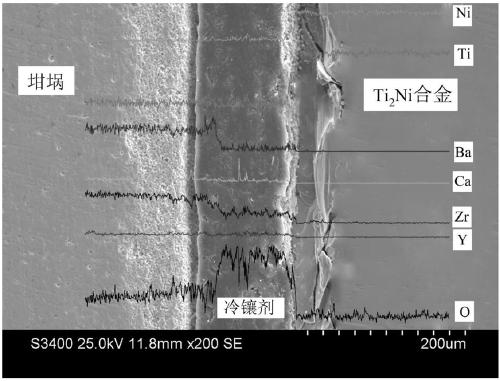

CaZrO3 mold shell used for titanium and titanium alloy precision casting and preparation method

ActiveCN103071764AHighlight substantiveSignificant progressFoundry mouldsFoundry coresZirconateTitanium

The invention discloses a CaZrO3 mold shell used for titanium and titanium alloy precision casting and a preparation method, which is characterized in that calcium zirconate is taken as a filling material, binders which are not reacted with a titanium alloy such as zirconium acetate or yttrium sol are pretreated, molded, hardened, roasted and the like to prepare the mold shell. The mold shell has small reaction degree with titanium and the titanium alloy, the thickness of contamination formed on the casting surface is small; the calcium zirconate ceramic mold shell has high strength, the casting surface has high fineness; a paint containing calcium zirconate is stable and is not easy to be gelled, the suspensibility is good, and the preservation time is long.

Owner:SHANGHAI UNIV +1

Pure inorganic acid formation process for positive electrode foil for high-voltage bolt type aluminium electrolytic capacitor

ActiveCN105405658AExtended service lifeImprove electricity qualityAnodisationElectrolytic capacitor manufactureAluminium foilAluminium

The invention discloses a pure inorganic acid formation process for a positive electrode foil for a high-voltage bolt type aluminium electrolytic capacitor. The pure inorganic acid formation process is characterized by comprising the steps of dipping an etched foil into water for performing a dipping treatment to generate a hydrate film on the surface of the etched aluminium foil, then putting the etched aluminum foil, after the aluminum foil is subjected to the dipping treatment, into a dicarboxylic acid solution for further performing the dipping treatment, next putting the aluminum foil into a phosphate solution for performing a first time of formation to generate a dielectric oxide film on the surface of the aluminium foil; and then performing a second time of boric acid formation, and performing a roasting treatment and a phosphoric acid treatment to obtain the final positive electrode aluminium foil. According to the pure inorganic acid formation process for the positive electrode foil for the high-voltage bolt type aluminium electrolytic capacitor, the produced positive electrode foil is better in of electric property, low in current leakage, and high in hydration resistance, so that the formation process can particularly satisfy the high-quality demand of the high-voltage bolt type aluminium electrolytic capacitor; the service life of the high-voltage bolt type aluminium electrolytic capacitor can be prolonged, and the market competitiveness of the product is further enhanced; and in addition, experiments prove that the current leakage can be reduced by more than 28% by the formation process, and the service life of the aluminium electrolytic capacitor is improved by more than 1700 hours proved by an accelerated life test.

Owner:XINJIANG XIBU HONGYUAN ELECTRONICS CO LTD

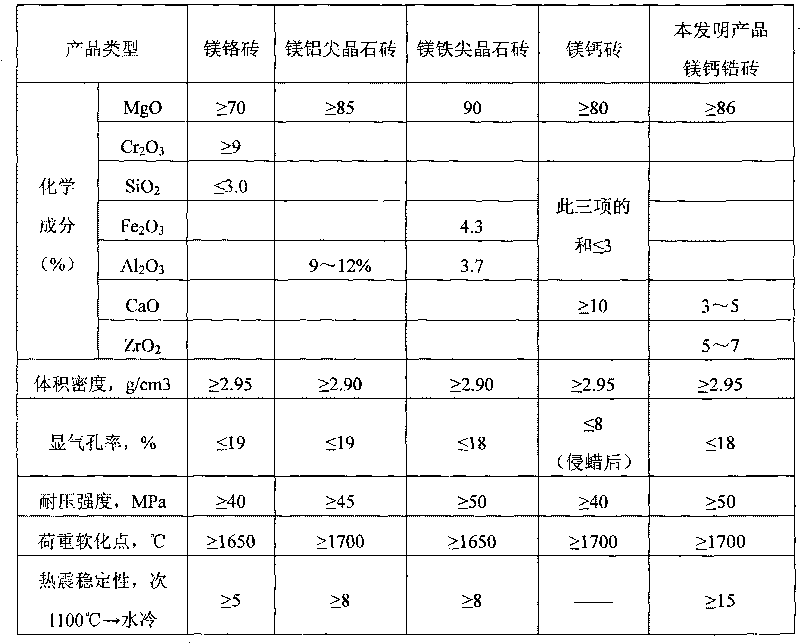

Calcium zirconate and magnesia calcium zirconate brick prepared by calcium zirconate for cement kiln

InactiveCN101759229AGood hydration resistanceImprove performanceZirconium compoundsCement kilnCalcium hydroxide

The invention discloses calcium zirconate and a magnesia calcium zirconate brick prepared by the calcium zirconate for a cement kiln; in the calcium zirconate, desilicated zirconia and calcium hydroxide are adopted as raw materials and a sintering synthesis method is used to prepare; the calcium zirconate in the invention has remarkable de-hydration property, good chemical stability and good thermal-shock stability, and is very suitable for usage of refractory material for the cement kiln; 3.5-0mm of the calcium zirconate, 4-1mm of high-purity magnesia, 1-0mm of high-purity magnesia, 0.088-0mm of high-purity magnesia and spent pulping liquid are used as raw materials to prepare the magnesia calcium zirconate brick for the cement kiln; the magnesia calcium zirconate brick in the invention is a non-chrome environment-friendly product suitable for the cement kiln, has the advantages of good alkali resistance and good spalling resistance of a magnesia calcium brick, and is suitable for the using characteristics of the kiln which is used for processing garbage waste, compared with the pleonaste brick, the magnesia calcium zirconate brick has good advantages; in addition, the hydration problem of the magnesia calcium brick is overcome; thereby being an ideal refractory material for cement kiln clinkering zones.

Owner:GONGYI TONGDA ZHONGYUAN REFRACTORY TECH

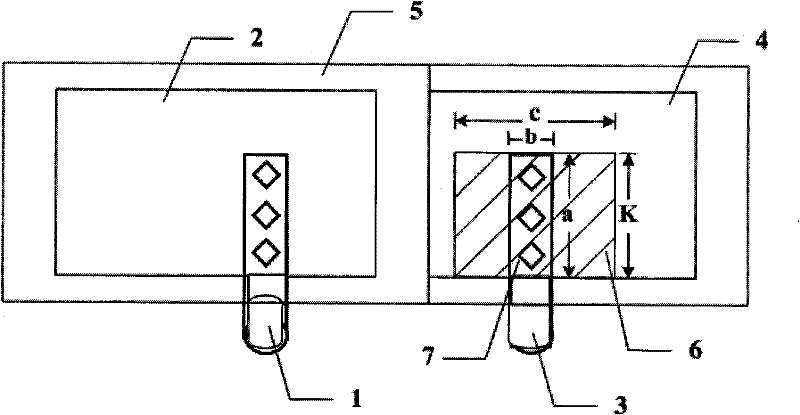

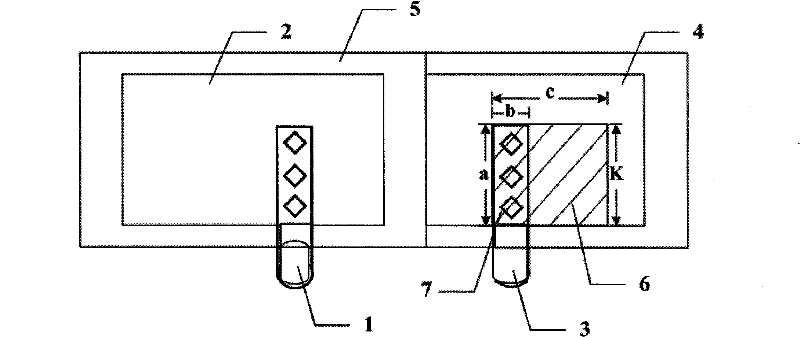

Method for manufacturing low-pressure chemical synthesis foil for aluminum electrolysis capacitor and middle treatment groove

InactiveCN101235529ANo loss of capacitanceHigh passivation treatment efficiencyElectrolytic capacitorsPhosphatisationChemical synthesisElectricity

The invention relates to a method for forming foil by low voltage of an aluminum electrolytic capacitor and a treatment groove for forming foil, wherein the method comprises the following steps: placing the formed foil which is treated by forming treatment under the highest forming voltage into a medium treatment groove and a groove solution, and proceeding the medium treatment, then proceeding subsequent forming treatment, an electrode plate which is corresponded with the formed foil is arranged in the treatment groove, the groove solution comprises phosphorus acid and / or ammonium phosphate component, the medium treatment comprises the following steps: placing the anode of direct current power supply on the formed foil, placing the cathode of the direct current power supply on an electrode plate, imposing electricity to the forming foil, the voltage value of the imposing electrical treatment is lower than that of the highest formed. The forming method of the invention and the treatment groove has the advantages that the efficiency of deactivation treatment is high, the coverage of the deactivation treatment is more comprehensive and thoroughly, which can simultaneously obtain higher electrostatic capacity, good water resistance and hydratability.

Owner:乳源县立东电子科技有限公司

Formation method for anode foil of intermediate-voltage aluminum electrolytic capacitor

InactiveCN102709059AIncrease specific volumeGood hydration resistanceElectrolytic capacitorsPhosphateThree stage

The invention discloses a formation method for an anode foil of an intermediate-voltage aluminum electrolytic capacitor, and belongs to the technical field of manufacture of anode foils of aluminum electrolytic capacitors. According to the formation method for the anode foil of the intermediate-voltage aluminum electrolytic capacitor, ammonium adipate is adopted as four-stage formation electrolyte. The technical scheme is that: the method comprises the following steps of: performing three-stage formation by adopting a solution of ammonium adipate as electrolyte, performing the formation of a fourth stage by using a boric acid and ammonium dihydrogen phosphate, performing high-temperature treatment, performing treatment by using a phosphate solution, and performing drying to obtain the anode foil of the intermediate-voltage aluminum electrolytic capacitor. The ammonium adipate is adopted as the formation electrolyte, so that the obtained anode foil of the capacitor is high in specific capacity and high in hydration resistance, boosting time is shortened, and a Tr60 value is decreased.

Owner:YONGJI SUHAI ALUMINUM

Thermal-state mending material taking forsterite as raw material for converters and preparation method thereof

The invention relates to a thermal-state mending material taking forsterite as a raw material for converters and a preparation method thereof. The technical scheme is as follows: adopting 45-70wt% of sintered magnesia particles, 5-15wt% of graphite and 15-40wt% of forsterite fine powder as raw materials; adding simple substance silicon powder accounting for 1-10wt% of the weight of the raw materials and liquid pitch modified phenolic resin accounting for 15-25wt% of the weight of the raw materials; and stirring for 5 to 30 minutes to obtain the slurry thermal-state mending material taking forsterite as the raw material for converters. While being used, the thermal-state mending material is poured into the converter, the converter is rotated to enable the mending material to flow to the charging position, the tapping position, the bedding face and the furnace bottom of the steelmaking converter which are in need of thermal-state mending and the mending material is sintered by the heat in the converter. The material has the characteristics of abundant raw materials, low production cost, excellent hydration-proof performance, easiness in sintering at a high temperature and convenience in combination with the converter lining and is beneficial for prolonging the service life of materials of the converter lining.

Owner:北京炜润达冶金材料有限公司 +1

Hot-state repair material made from waste magnesia-carbon brick and used for converter and preparation method thereof

InactiveCN102531653AWide variety of sourcesExtend your lifeSolid waste disposalConvertersSteelmaking

The invention relates to a hot-state repair material made from waste magnesia-carbon bricks and used for converters and a preparation method thereof. The invention adopts the technical scheme as follows: the hot-state repair material made from waste magnesia-carbon bricks and used for converters is produced by preparing the following raw materials: 45 wt% to 70 wt% of waste magnesia-carbon brick particles, 5 wt% to 15 wt% of graphite and 15 wt% to 40 wt% of forsterite fine powders, adding elemental silicon powders of 1 wt% to 10 wt% the total weight of the raw materials and liquid asphalt-modified phenol-formaldehyde resin of 15 wt% to 25 wt% the total weight of the raw materials, and stirring for 5 to 30 min. The hot-state repair material is muddy. When the hot-state repair material is used, the hot-state repair material is poured into a converter, the converter is shaken to make the hot-state repair material flow to the positions required for hot-state repair of the feed port, the steel discharge port, the face and the bottom of the steel-making converter feed, and the hot-state repair material is sintered by the heat inside the converter. The hot-state repair material has the characteristics of abundant raw materials, low production costs, hydration resistance and facilitation of improvement on the service life of a converter lining material.

Owner:北京炜润达冶金材料有限公司 +1

Magnesia-calcium clinker adopting core-shell coated structure and preparation method of magnesia-calcium clinker

The invention relates to magnesia-calcium clinker adopting the core-shell coated structure and a preparation method of the magnesia-calcium clinker. According to the technical scheme, dolomite ore is crushed to 5-8 mm, subjected to heat treatment at the temperature of 900-1,000 DEG C for 0.5-1 h and ball-milled to have the particle size smaller than 80 mu m, and light-burned fine dolomite powder is obtained; then the light-burned fine dolomite powder and water are blended in the mass ratio being 100:(35-40) and mixed in a disk granulating machine for 0.2-0.3 h for granulating formation; formed particles are immersed in Cu(OH)2 gel for 1-2 min, and dolomite particles adopting the coated structure are obtained; then the dolomite particles adopting the coated structure are dried at the temperature of 30-35 DEG C for 12-15 h, dried at the temperature of 110-120 DEG C for 6-12 h, heated to the temperature of 1,200-1,400 DEG C in a resistance furnace, kept at the temperature for 2-3 h and cooled with the furnace, and the magnesia-calcium clinker adopting the core-shell coated structure is obtained. The magnesia-calcium clinker adopting the core-shell coated structure and the preparation method of the magnesia-calcium clinker have the characteristics that the production cost is low, the preparation technology is simple and the energy consumption is low, the prepared magnesia-calcium clinker adopting the core-shell coated structure has the complete core-shell coated structure and the excellent hydration resistance.

Owner:WUHAN UNIV OF SCI & TECH

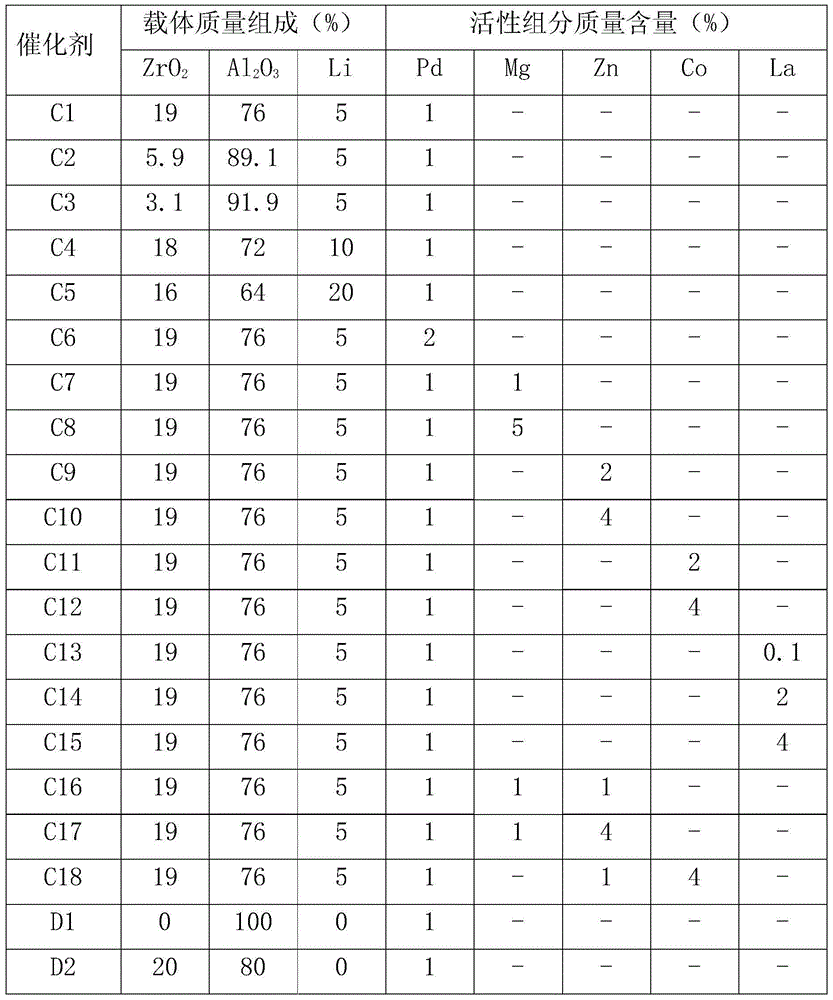

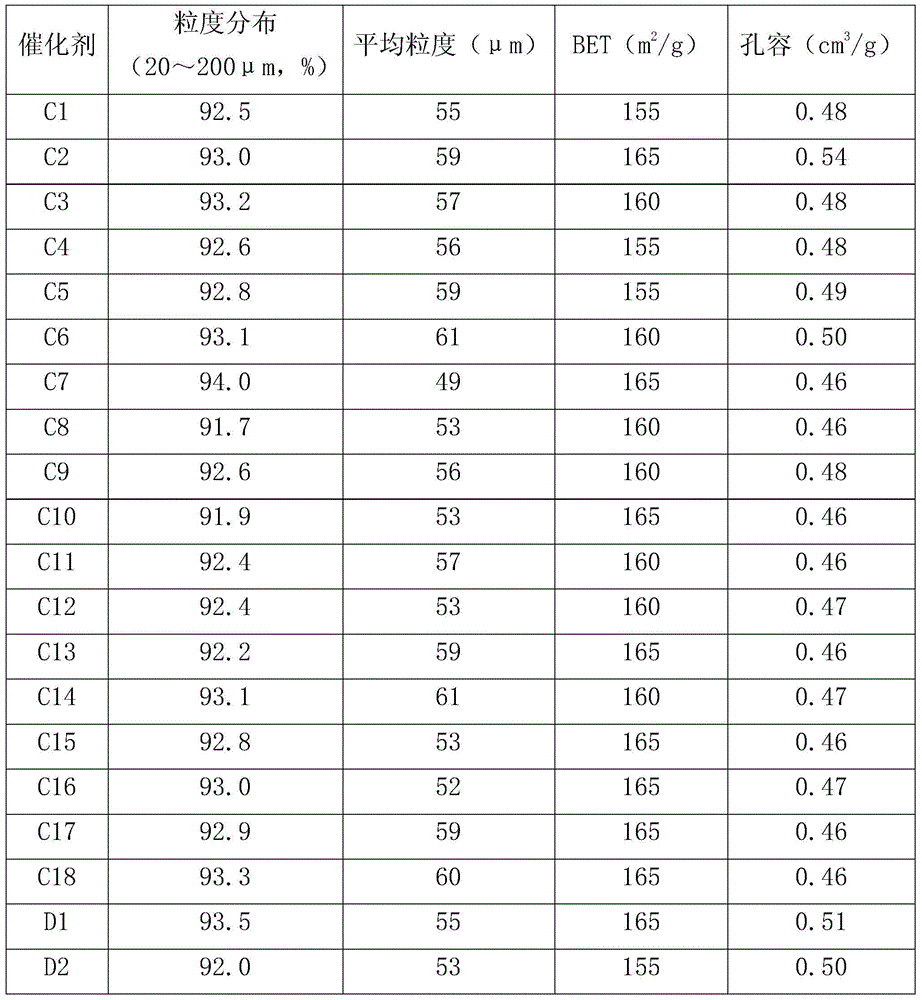

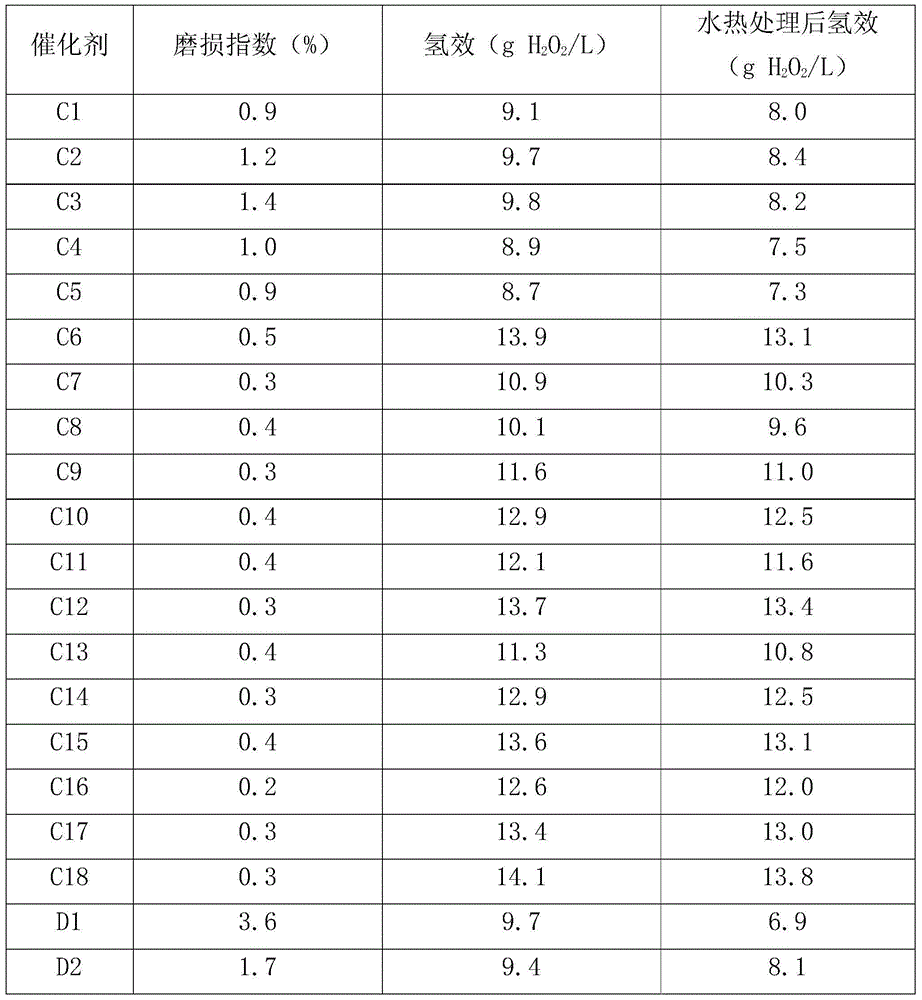

Palladium-based hydrogenation catalyst and application of palladium-based hydrogenation catalyst to anthraquinone hydrogenation

ActiveCN104549246AHigh activityImprove wear resistancePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsMass ratioCerium

The invention discloses a palladium-based catalyst. The palladium-based catalyst is characterized in that composite oxide prepared by zirconium dioxide and activated aluminum oxide and modified by lithium is used as a supporter, palladium is used as a main active component, one or more of magnesium, calcium, lanthanum, cerium, ferrum, cobalt, nickel and zinc is selected as an assistant active component, the mass ratio of zirconium dioxide ZrO2 and activated aluminum oxide AlO2O3 is 1: (1-40), the mass content of lithium in the supporter is 0.1-20%, the mass content of palladium in the catalyst is 0.02-10%, and the mass content of the assistant active component in the catalyst is 0-8%. Compared with the prior art, the catalyst is obviously improved in the aspects of activity, wearing resistance and anti-hydration performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

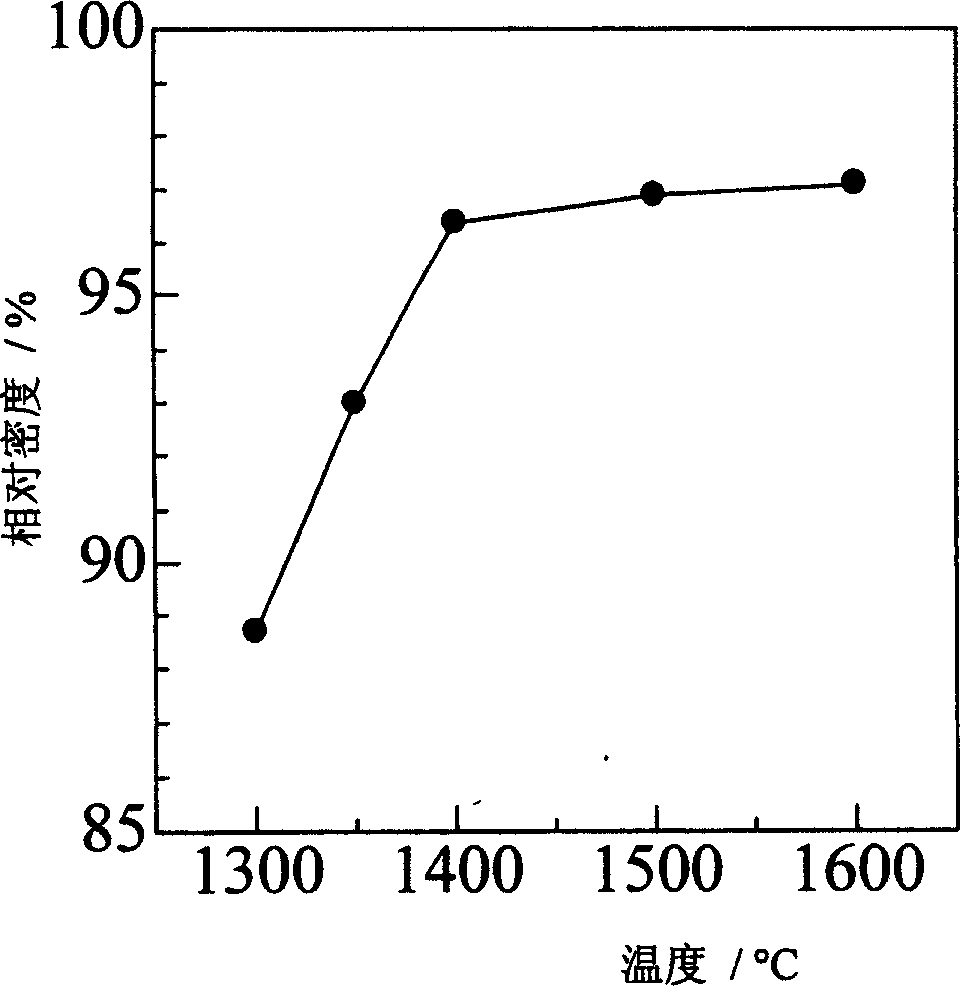

A kind of synthetic magnesium calcium sand and preparation method thereof

InactiveCN102285806AHigh purityNo damage to high temperature performanceCalcium hydroxideMechanical press

The invention relates to synthetic calcium magnesite and a preparation method thereof. The preparation method comprises the steps of firstly carrying out ball milling on 25-30wt% of calcium hydroxide and 70-75wt% of magnesium hydroxide to reach the grain size within 30 mu m, heating the ball-milled mixture in a muffle furnace to 700-900 DEG C, and insulating heat for 0.25-0.5 hour; adding water the amount of which is 20-25wt% of the mixture to the calcined mixture, and digesting for 1-2 hours; and then adding an additive the amount of which is 1-3wt% of the digested mixture to the digested mixture, stirring, carrying out mechanical press shaping by a semi-dry method, naturally drying for 12-15 hours, baking at the temperature of 100-120 DEG C for 12-15 hours, finally firing in a high-temperature furnace at the temperature of 1600-1750 DEG C, insulating heat for 3-5 hours and crushing to obtain the synthetic calcium magnesite. The preparation method provided by the invention has the advantages of simple process and no need for special synthesis equipment and treatment technology. The synthesized calcium magnesite has the characteristics of high purity, wide application range, good sintering performance, good hydration resistance, and no influence on high-temperature use performance.

Owner:WUHAN UNIV OF SCI & TECH

Hydration-resistant hot-state mending material for steelmaking converter and preparation method thereof

InactiveCN102584281AAbundant raw materialsGood hydration resistanceSteelmakingUltimate tensile strength

The invention particularly relates to a hydration-resistant hot-state mending material for a steelmaking converter and a preparation method thereof. The technical scheme of the preparation method is that 40 to 70wt% of sintered magnesia particles or fused magnesia particles, 5 to 20wt% of flake graphite and 15 to 40wt% of forsterite fine powder are taken as raw materials, elementary silicon powder occupying 1 to 10wt% of the raw materials and liquid phenolic resin occupying15 to 30wt% of the raw materials are added to the raw materials and stirred with the raw materials for 5 to 30 minutes, and then the hot-state mending material for the hydration-resistant steelmaking converter is manufactured; and the hot-state mending material is mud-shaped. When in use, the mending material is poured into the converter, and the converter is shaken to enable the mending material to flow to positions of a material loading part, a part discharging part, a large surface part and a converter bottom, which need to be mended in a hot state, and be sintered by relying on heat in the converter. The hot-state mending material has the characteristics of rich raw material, environmental friendliness, short sintering time, good hydration-resistant performance, high high-temperature strength, erosion resistance and long service life.

Owner:北京炜润达冶金材料有限公司 +1

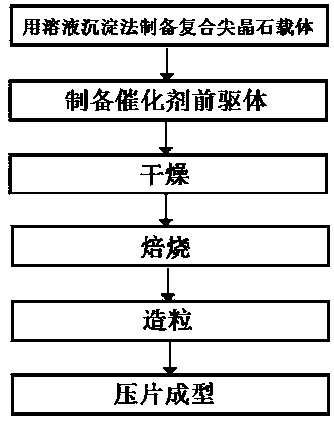

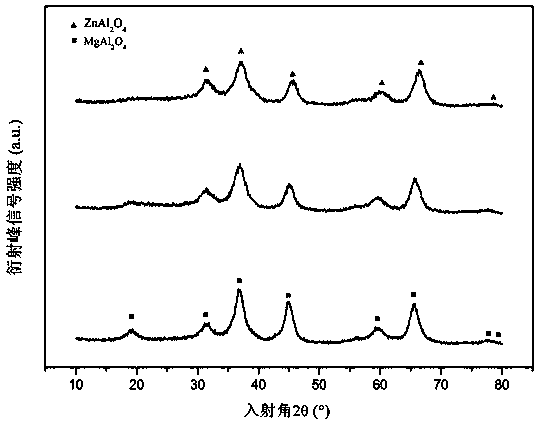

Catalyst for synthesis of natural through methanation of coal and preparation method thereof

InactiveCN108043413AHigh selectivityImprove stabilityGaseous fuelsCatalyst activation/preparationAluminateMethanation

The invention provides a catalyst for synthesis of natural through methanation of coal. According to the invention, magnesium aluminate spinel and zinc aluminate spinel are used as a compound oxide carrier; nickel nitrate is used as an active component; oxides of titanium, manganese, lanthanum and cerium are used as auxiliary agents; and the mass of the above components sums to 100%, wherein the active component accounts for 15 to 40%, and the auxiliary agents account for 0.5 to 5%, with the balance being the compound oxide carrier. A preparation method for the catalyst comprises the followingsteps: (1) preparation of the compound spinel carrier by using a solution precipitation process; (2) preparation of a catalyst precursor; (3) drying; (4) roasting; (5) granulation; and (6) compression molding. The preparation method of the invention improves the selectivity and stability of the catalyst and reduces production cost by adjusting the proparts of raw materials, the type of a pore-enlarging agent and roasting conditions; and the prepared catalyst has a high specific surface area, high reactivity, high temperature resistance, good hydration resistance and high mechanical strength,and can be used in the industrialization of coal-based methanation synthesis of natural gas.

Owner:EAST CHINA UNIV OF SCI & TECH

Process for preparing hydration-resistance high-calcium magnesia-calcium sand

The invention belongs to a process for preparing magnesia-calcium sand for use in clean steel smelting. The process for preparing the hydration-resistance high-calcium magnesia-calcium sand comprises the following steps of: grinding highly purified dolomite until the size of the obtained fine powder is less than 10mum; putting the fine powder in a high-speed mixer, adding aqueous solution of polyvinyl alcohol in an amount which is 5 to 10 percent of the weight of the highly purified dolomite powder in the mixer, fully mixing the mixture and obtaining uniform wet powder, and pressing the wet powder to obtain finished blanks; burning the dry blanks obtained by drying the finished blanks at a temperature of between 1,650 and 1,700 DEG C to obtain the high-calcium magnesia-calcium sand. The method is characterized by improving sintering activity of the dolomite by mechanical activation, avoiding any additional sintering auxiliary agent, preparing the high-calcium magnesia-calcium sand in high density by the one-step calcining at a lower temperature, effectively lowering production cost, simplifying production process and ensuring purity of the magnesia-calcium sand.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

High-stability polynary composite oxide refractory material for high-activity high-temperature alloy smelting, and application and preparation method thereof

The invention discloses a high-stability polynary composite oxide refractory material for high-activity high-temperature alloy smelting, and an application and a preparation method thereof. The refractory material mainly comprises, by mole, 46.2-53.5% of a transition metal element compound, 0.5-2.5% of a rare earth element compound, and the balance of an alkaline earth metal element compound. Therefractory material has the advantages of good stability, good hydration resistance, good resistance to erosion of high-activity high-temperature alloy, realization of high alloy purity after smeltingof the high-activity alloy, and significant reduction of the pollution to the high-activity alloy, and a crucible produced from the high-stability polynary composite oxide refractory material can beused for smelting the high-temperature alloy, and has the advantages of good hydration resistance, easiness in storage, good thermal shock resistance, low production cost, and suitableness for industrial production.

Owner:SHANGHAI UNIV

Production method of low pressure formed foil

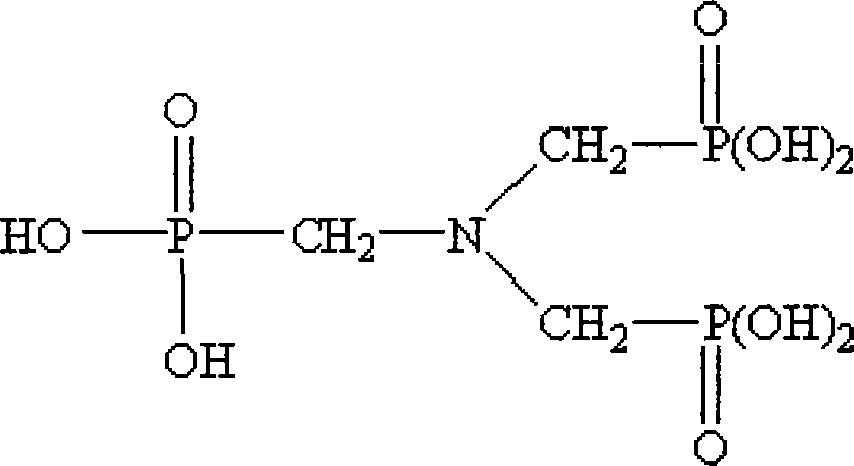

The invention relates to a preparing method of a low-voltage formed foil, comprising the steps that: A) a low-voltage etched foil is formed; B) the formed foil is depolarized; C) the depolarized foil is first reformed; D) the first reformed foil is first heated; E) the first heated foil is second reformed, with a bath solution including ammoniun adipate solution added with phosphoric acid and / or monoammonium phosphate; F) the second reformed foil is put into organic multi-component phosphinic acid solution, electrified and post-processed ; and G) the post-processed foil is second heated to get the low-voltage formed foil. The preparing method can get better passivation effect and high passivation efficiency at the same time, saves resources, facilitates environment protection, and is more fit for workshop practical production conditions.

Owner:RUYUAN YAO AUTONOMOUS COUNTY DONGYANGGUANG FORMED FOIL CO LTD

Calcium oxide foam ceramic and preparation method thereof

The invention relates to calcium oxide foam ceramic and a preparation method thereof. The preparation method thereof is technically characterized by comprising the following steps of mixing 90 to 99.5wt% of calcium hydroxide powder and 0.5 to 10wt% of other hydroxides, so as to obtain mixed powder; adding 0.1 to 3wt% of additive and 30 to 100wt% of water into the mixed powder, and mixing in a wet way, so as to obtain slurry; soaking a polyurethane sponge into the slurry for 2 to 20min, fetching out the polyurethane sponge containing the slurry, and extruding; drying the extruded polyurethane sponge at the temperature of 110 DEG C for 12 to 24h, so as to obtain a prefabricated block of the calcium oxide foam ceramic; finally, putting the prefabricated block of the calcium oxide foam ceramic into a heating furnace, heating to 1400 to 1700 DEG C, insulating heat for 1 to 5h, and naturally cooling, so as to obtain the calcium oxide foam ceramic. The calcium oxide foam ceramic has the advantages that the technology is simple, the cost is low, and the energy consumption is low; the prepared calcium oxide foam ceramic has high use temperature, stable high temperature property and good anti-hydration property, and is suitable for using as a high-temperature material for smelting high-purity melts.

Owner:WUHAN UNIV OF SCI & TECH

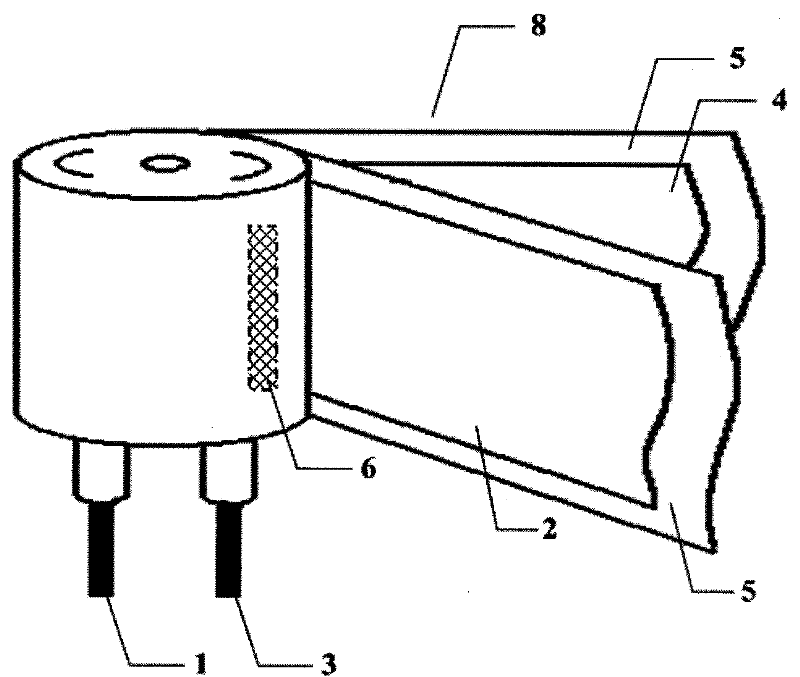

Carbon monoxide conversion catalyst carrier, catalyst based on carrier, and preparation method thereof

ActiveCN105032497AImproves hydration resistanceHigh mechanical strengthHydrogenCatalyst carriersAluminum IonHigh absorption

The invention provides a catalyst carrier with conversion and adsorption purification performances. Modified bauxite added into the raw materials of the catalyst carrier has fluxing and pore-forming functions. Through modification, most of iron oxide in bauxite is removed, such that the modified bauxite contains a large amount of high-activity aluminosilicate compound. As a fluxing agent, during catalyst preparation, the aluminosilicate compound assists in significantly improving the migration rates of magnesium and aluminum ions during a roasting process, such that MgAl2O4 generation under low temperature is promoted. Therefore, the catalyst carrier provided by the invention has relatively high hydration resistance and mechanical strength. Also, with the modification treatment, modified bauxite is adopted as a macroporous hard template for preparing the catalyst. With a roasting treatment, macro-pores are formed in the catalyst carrier structure, such that the catalyst carrier has relatively high absorption purification capacity upon macromolecular particles such as oil and dust.

Owner:FUJIAN PROVINCE SINOGASHOLDER EQUIP INSTALLATION CO LTD

Method for preparing compact calcium oxide sand

InactiveCN1803703ALower firing temperatureImproves hydration resistanceCalcium carbonateProduct property

The three-step preparation method for CaO sand comprises: first, calcining the limestone for CaO and then the light CaCO3; adding 0.1-5% micro-powder of MgO or ZrO2 with size <=3 mu m into the light CaCO3 to mix evenly and briquette; then, re-calcining for 2-5h at 1200-1600 DEG C, natural cooling to normal temperature, and obtaining the sand. This invention decreases fire temperature obviously, and improves the product property without low-melting point phase.

Owner:NORTHEASTERN UNIV

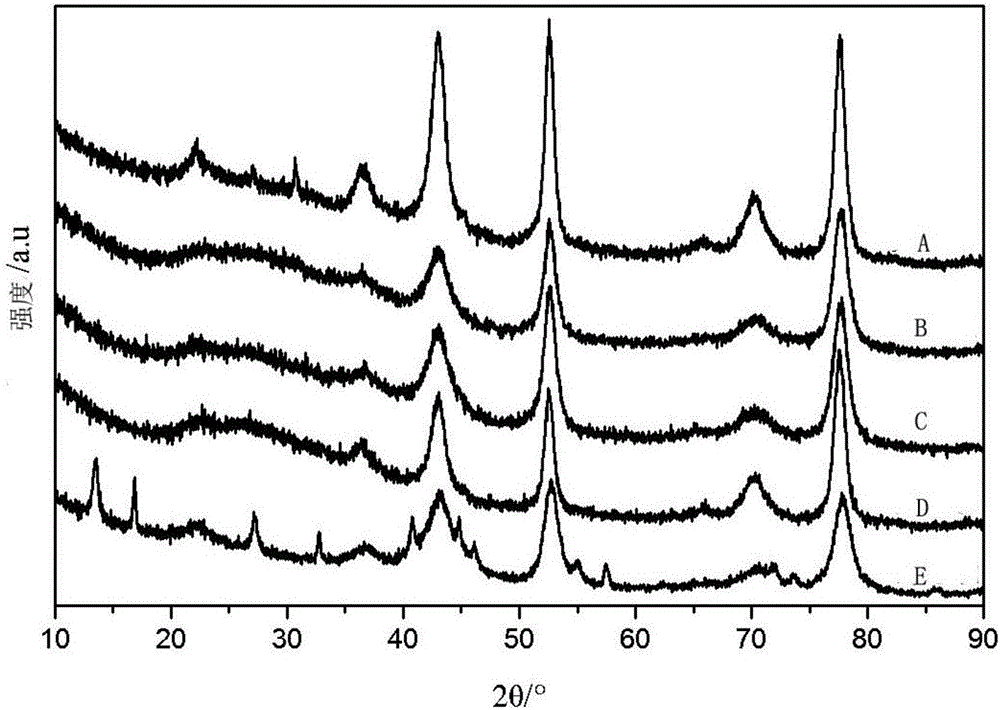

Method for preparing hydration resistant calcia material

InactiveCN101462758AHigh densityGood hydration resistanceCalcium/strontium/barium oxides/hydroxidesHigh densityYttrium

The invention relates to material preparation technology, in particular to a method for preparing a hydration-resistance calcium oxide material. The method obtains a calcium oxide material which has the advantages such as excellent hydration-resistance performance and high density by adding 0 to 30mol percent additives containing nickel, yttrium or ytterbium or other elements and adopting a proper sintering mode. The microstructure of the material has the characteristics of coating a layer of second phrase with excellent hydration-resistance performance on the surfaces of calcium oxide grains, along with high density and good heat and shock resistant performance. The technology has the characteristic that the calcium oxide material of which the granular surfaces have hydration-resistance coatings is obtained by adding the additives and adopting a proper sintering system, and that the material has high density, excellent heat and shock resistant performance and so on. In addition, the method is low in sintering temperature, energy-saving and environmentally-friendly, simple in process and favorable for large-scale production and improves production efficiency.

Owner:NORTHEASTERN UNIV

Self-binding calcium oxide material and preparation method thereof

The present invention relates to a self-binding calcium oxide material and a preparation method thereof. The technical scheme comprises: adopting 40-70 wt% of calcium oxide particles, 10-40 wt% of calcium oxide fine powder and 3-20 wt% of nanometer calcium oxide as raw materials, additionally adding 2-10 wt% of dimethicone, stirring for 2-30 min, carrying out press molding, placed the molded billet into a drying container filled with silica gel, naturally drying for 24 h in a closed environment, carrying out a heat treatment for 8-24 h at a temperature of 300-1500 DEG C, naturally cooling, placing into a container filled with dimethicone, carrying out vacuum impregnation for 30 min, and draining to obtain the self-binding calcium oxide material. According to the present invention, the preparation process is simple, and the prepared self-binding calcium oxide material has characteristics of high purity, good chemical stability, good hydration resistance, excellent melt erosion resistance and excellent permeation property, can absorb the inclusion in the melt, and can be used as the lining material of ultra-pure steel or alloy smelting.

Owner:WUHAN UNIV OF SCI & TECH

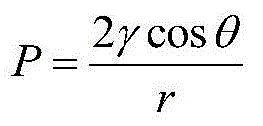

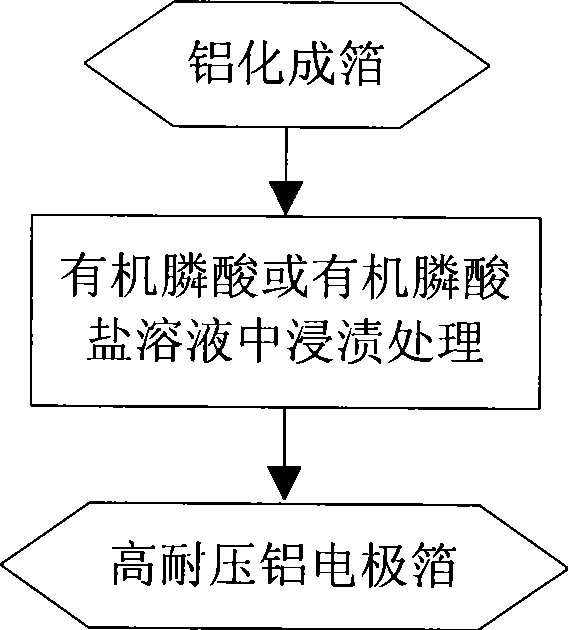

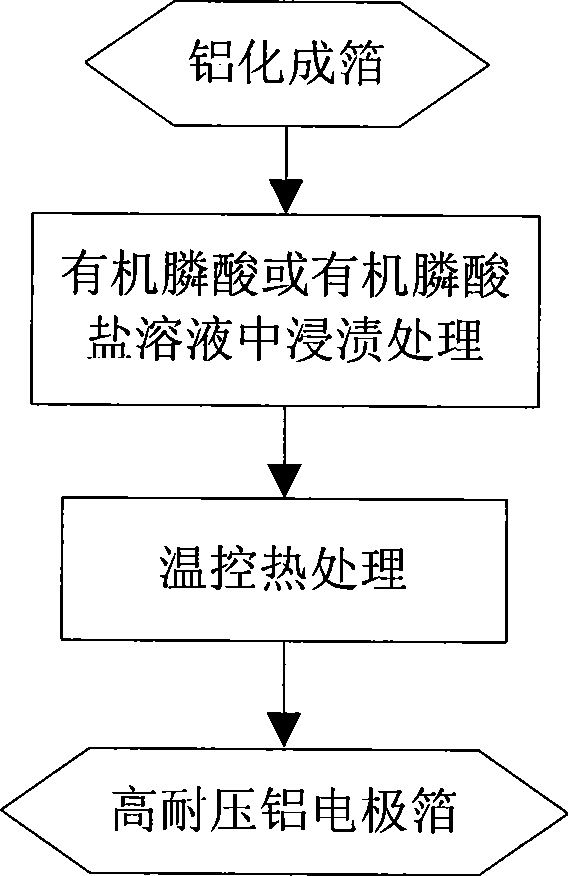

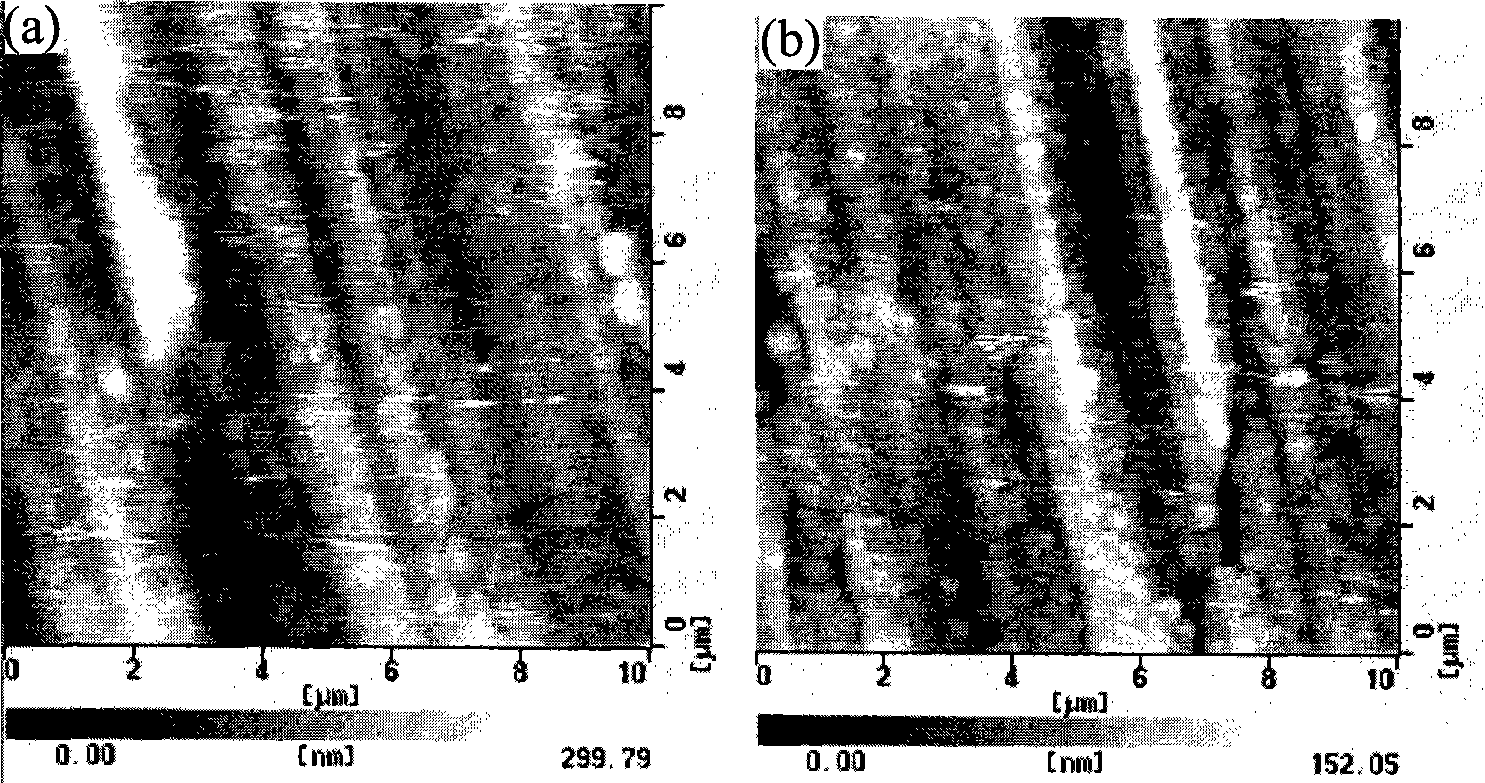

Method for preparing water proof aluminum electric pole foil

InactiveCN101457382AClear surface microstructureGood hydration resistanceElectrolytic capacitorsSurface reaction electrolytic coatingSurface oxidationPhosphoric acid

A preparation method of a hydration resistant aluminum electrode foil belongs to the technical field of electronic materials, and relates to the preparation method of an aluminum electrode foil in an aluminum electrolytic capacitor. The preparation method is realized according to a technical thought of inhibiting a 'wet electronic state' effect of an oxide film on the surface of the aluminum electrode foil to improve the hydration resistance of the aluminum electrode foil. The preparation method specifically comprises the following steps: soaking anodized aluminum electrode foil in organic phosphoric acid or an organic phosphonate solution containing a plurality of phospho structures, and then heating by temperature control to obtain the aluminum electrode foil with the high hydration resistance. A used hydration resistant treating agent can be intensively bonded on the surface of aluminum oxide and occupy active points of the surface, thus well inhibiting generation of the 'wet electronic state' effect and finally improving the hydration resistance of the aluminum electrode foil. The preparation method is realized completely in an aqueous solution system, has simple application equipment and short processing time, is compatible with the chemosynthesis line in the existing industry and can be directly merged into the chemosynthesis line in the existing industry.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Magnesium aluminate binder

A magnesium aluminate bonding agent is characterized in that the magnesium aluminate raw material is formed by the mixture ratio of the following weight percent. The inorganic composition components consist of aluminum sulphate, citric acid, boric acid and magnesia. The product is characterized by carbon free, inorganic combination, no need of high temperature sintering, which can be used after drying at 100 to 200 DEG C, thus greatly reducing the production cost, reducing molten steel pollution and improving the service life. The product can be used in the tank lining, tundish lining, quadrel, air permeable upper quadrel, filling pipe end, drain end, slag dam and steel-tapping hole. The product has the performance of slag adhesion resistance, pretty high high-temperature, medium-temperature and low-temperature strength and has the advantages of reducing molten steel inclusion by more than 90 percent, relieving the labor strength of the workers, shortening masonry labor hour, accelerating the turnover of the molten steel tank for 5-10 times comparing with the existing product. Furthermore, the product has excellent hydration resistance, which can be immersed in the water for 30 days without any change, thus facilitating deposition.

Owner:梁德军

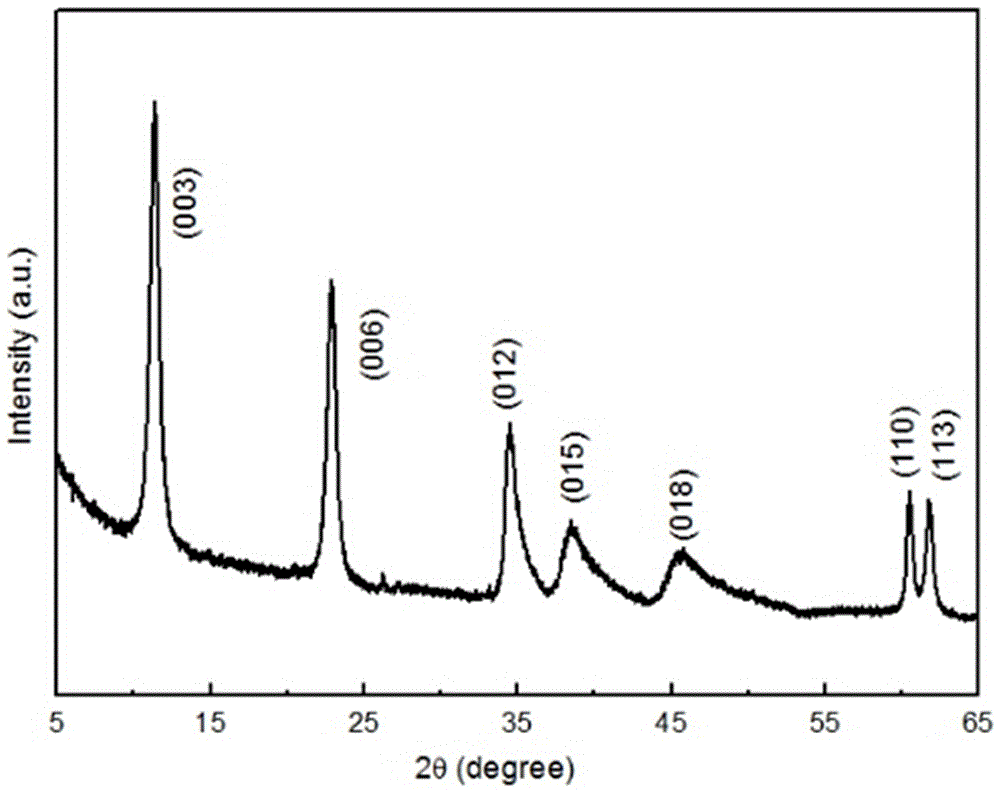

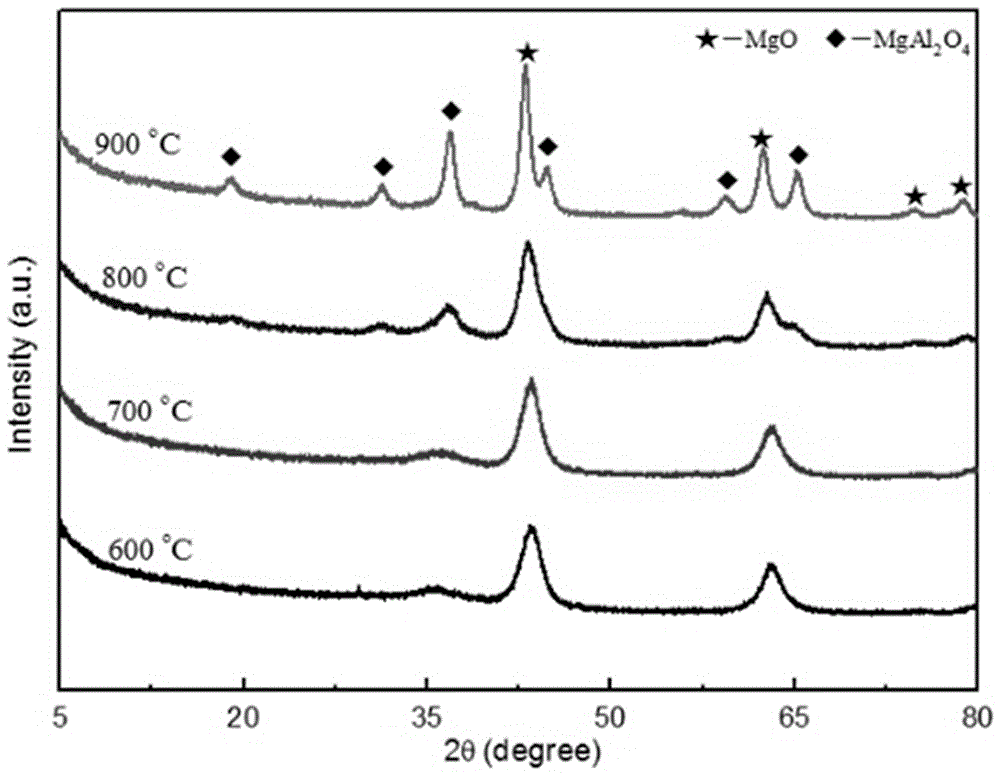

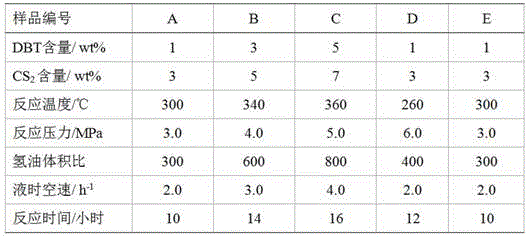

Preparation method of high-activity diesel hydrodesulfurization catalyst

ActiveCN106512984AEasy to makeEasy to operateMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatment productsHydrodesulfurizationEconomic benefits

The invention discloses a preparation method of a high-activity diesel hydrodesulfurization catalyst, and particularly relates to the preparation method of the high-activity diesel hydrodesulfurization catalyst adopting binary magnesium aluminum hydrotalcite as a carrier. The catalyst adopts binary magnesium aluminum hydrotalcite which is prepared through the coprecipitation method and is subjected to pretreatment as the carrier, and the carrier carries one or more transition metals in the VIB and / or VIII family. The catalyst prepared through the method has the characteristics of high mechanical strength, good anti hydration, and the like, the catalyst represents relatively high hydrodesulfurization activity after being applied to the diesel hydrodesulfurization reaction, and the conversion rate of the prepared catalyst for dibenzothiophene (DBT) is 95% or above; and besides, the method is simple in preparation technology, easy and convenient to operate and low in cost, and has good economic benefits and environmental benefits.

Owner:邵武绿闽环保科技有限公司

Aluminum electrolytic capacitor applying high hydrous electrolyte and method for making aluminum electrolytic capacitor

InactiveCN102237201AOvercoming High Temperature Hydration ProblemsSolve the problem of glitch-prone short circuitLiquid electrolytic capacitorsCapacitor electrodesMoistureThin sheet

The invention relates to an aluminum electrolytic capacitor applying high hydrous electrolyte and a method for making the aluminum electrolytic capacitor. A capacitor body consists of a positive foil connected with a positive guide needle, a negative foil connected with a negative guide needle and electrolytic paper positioned between the positive foil and the negative foil; a thin sheet is coated on the upper side surface at a tongue position in the negative guide needle and is a pressurized negative foil thin sheet which is made of the negative foil and subjected to voltage processing; and an oxide film is arranged on the surface of the thin sheet. The method for making the aluminum electrolytic capacitor comprises nine steps, namely cutting, connecting by nails, winding, roasting, impregnating, assembling, sleeving pipes, charging and testing. The pressurized negative foil thin sheet which is made of the negative foil and subjected to voltage processing is coated on the upper side surface at the tongue position in the negative guide needle before winding, and the capacitor body after the completion of winding is impregnated in the electrolyte with the moisture content of 5 to 25 percent. The aluminum electrolytic capacitor improves high-temperature stability and frequency characteristic of a product, and is suitable to be used at high temperature of above 100 DEG C.

Owner:王兴久

Preparation method of MgO-CaO-ZrO2 sand

The invention relates to a preparation method of MgO-CaO-ZrO2 sand. The preparation method comprises the following steps: carrying out heat treatment on dolomite ore and magnesite ore, hydrating, sieving with a 0.2 mm sieve, drying a filter body obtained by sieving, and grinding to 200 meshes or below to obtain MgO-CaO2 powder; placing MgO-CaO powder and Zr(OH)4 sol in a mixer to be evenly mixed,conducting ball pressing after mixing, and drying till the moisture is smaller than 1%; and finally, placing the mixture in a kiln to be calcined, and obtaining the MgO-CaO-ZrO2 sand. The MgO-CaO-ZrO2sand prepared by the preparation method disclosed by the invention is good in hydration resistance, high in refractoriness, high in thermal stability and strong in alkaline slag corrosion resistance,has a purification effect on molten steel, and is an ideal raw material for preparing high-grade materials such as magnesium-calcium refractory materials and ceramics.

Owner:海城市军刚中档镁砂有限公司

Porous material based on in-situ foamed AlON-AlN and preparation method thereof

The invention relates to a porous material based on in-situ foamed AlON-AlN and a preparation method thereof. The preparation method is characterized by mixing uniformly 100 parts of Al4O4C powder bymass and 20 to 30 parts of deionized water by mass to obtain an Al4O4C slurry; mixing and stirring 2 to 5 parts of a foaming agent by mass and deionized water which is 10 to 12 times of the foaming agent to obtain a foam; adding the foam into the Al4O4C slurry, stirring well while adding the foam, pouring into a mold, standing under natural conditions, drying at 60 to 80 DEG C, and demolding to achieve an Al4O4C blank; placing the Al4O4C blank in an atmosphere furnace, performing heat preservation on the blank at 1500 to 2000 DEG C for 1 to 5 hours in a nitrogen atmosphere, and naturally cooling to obtain a porous material based on in-situ foamed AlON-AlN. The preparation method disclosed by the invention has the advantages of low preparation temperature, simple process and low cost, and the prepared porous material based on in-situ foamed AlON-AlN has a strong bonding force, a good thermal stability and a light weight.

Owner:WUHAN UNIV OF SCI & TECH

Unfired ferro silicon nitride-alumina composite carbon-free sliding plate and preparation method thereof

InactiveCN103304245AMeet production requirementsReduce manufacturing costOxide compositeAlumina composite

The invention relates to an unfired ferro silicon nitride-alumina composite carbon-free sliding plate and a preparation method thereof, belonging to the field of refractory materials. The sliding plate is composed of the following raw materials in percentage by weight: 55-90% of corundum, 0-20% of activated alumina, 0-30% of ferro silicon nitride and phenolic resin accounting for 2-6% of total dosage of the raw materials to serve as a binding agent. The preparation method comprises the steps of: weighing the raw materials according to the proportions, uniformly mixing the raw materials, smelting the raw materials to obtain pug, pressing forming the pug, and the drying the pug at 120-600 DEG C for 5-25hours. The product is of an oxide-non oxide composite structure and has the following excellent physical performance indexes: the apparent porosity is 3-11%, the bulk density is 3.0-3.35g / cm<3>, the normal temperature compressive strength is 100-260MPa and the high temperature flexural strength is10-50Mpa. The product provided by the invention needs no high temperature firing and oil immersion procedures, so that the production cost is greatly reduced.

Owner:UNIV OF SCI & TECH BEIJING

Passivating metal magnesium particles and passivating method thereof

ActiveCN103695884AEvenly wrappedPrecise active magnesium contentLiquid surface applicatorsMetallic material coating processesGraphiteOrganosilicon

The invention discloses passivating metal magnesium particles and a passivating method thereof. The passivating metal magnesium particles comprise the following components in percentage by weight: less than or equal to 99% and greater than or equal to 92% of Mg, less than or equal to 0.002% of S, less than or equal to 0.01% of Cu, less than or equal to 0.001% of P and less than or equal to 1.2% and greater than or equal to 0.1% of H2O. The passivating method comprises the following steps: (I), preparing a metal magnesium particle passivator, placing metal magnesium particles in the passivator, and then naturally cooling to room temperature; (II), coating a coating on the surface of the magnesium particles: firstly, coating an organic silicon compound on the surface of the metal magnesium particles, coating magnesium oxide on the surface of the metal magnesium particles, then, coating compound rare earth on the on the surface of the metal magnesium particles, and finally coating graphite powder on the surface of the metal magnesium particles; and (III), sieving the metal magnesium particles cooled to room temperature. The metal magnesium particle passivating layer is uniform in coating, and the storage and use safety is ensured.

Owner:JIANGSU ZHENGDA FURNACE CHARGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com