Aluminum electrolytic capacitor applying high hydrous electrolyte and method for making aluminum electrolytic capacitor

An aluminum electrolytic capacitor and water-containing electrolyte technology, applied in liquid electrolytic capacitors, electrolytic capacitors, capacitors and other directions, can solve problems such as inability to overcome high temperature hydration problems, improve hydration resistance and acid and alkali resistance, improve stability, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

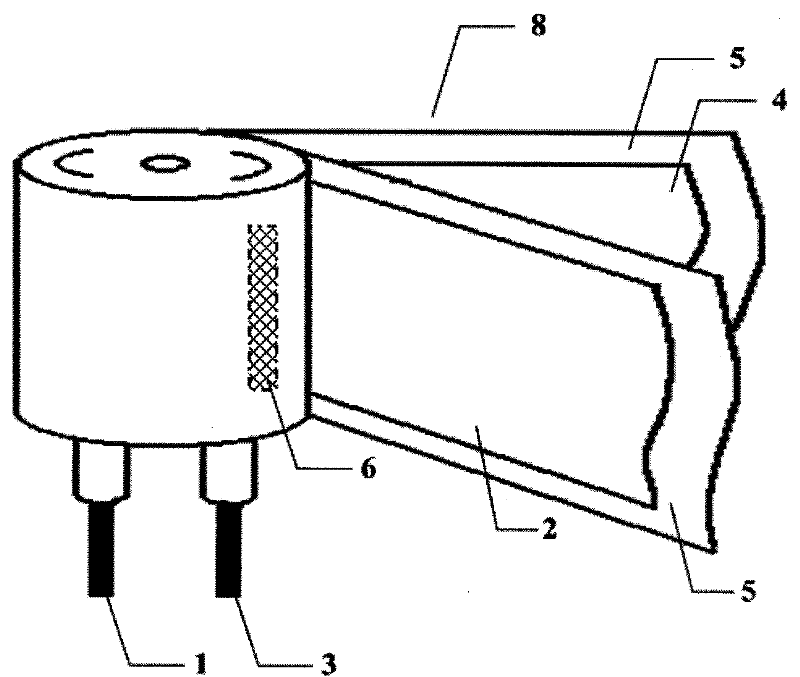

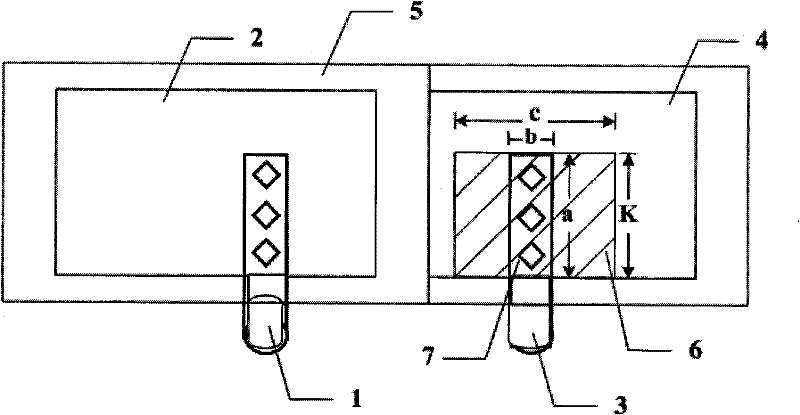

[0029] Such as figure 1 and Figure 7 As shown, the present invention provides an aluminum electrolytic capacitor using a high-water electrolyte. The capacitor body 8 is composed of a positive electrode foil 2 nailed to the positive guide pin 1, a negative electrode foil 4 nailed to the negative guide pin 3, and a positive electrode foil 4 that is arranged on the positive electrode. The electrolytic paper 5 is formed between the negative electrode foil 2 and the negative electrode foil 4. After the negative electrode foil 4 is subjected to voltage treatment, an oxide film is formed on its surface. The electrolytic paper 5 is used to isolate the positive electrode foil 2 and the negative electrode foil 4. The rear side surfaces of the positive electrode foil 2 and the negative electrode foil 4 . The upper surface of the tongue position 7 in the negative guide pin 3 is covered with a thin sheet, which is a pressurized negative electrode foil sheet 6 made of the same material as...

Embodiment 2

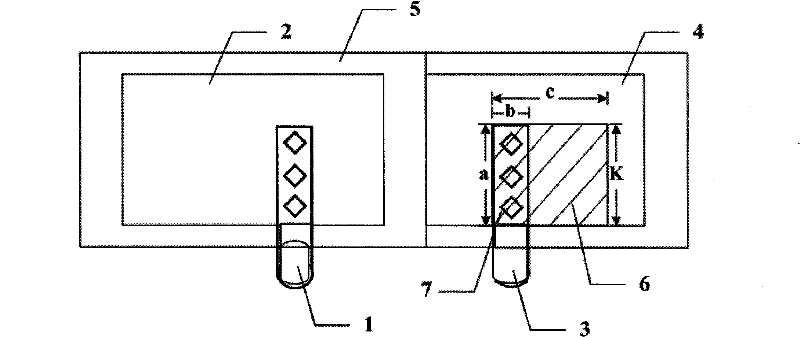

[0035] Such as Figure 8As shown, the present invention provides an aluminum electrolytic capacitor using a high-water electrolyte. The capacitor body 8 is composed of a positive electrode foil 2 nailed to the positive guide pin 1, a negative electrode foil 4 nailed to the negative guide pin 3, and a positive electrode foil 4 that is arranged on the positive electrode. The electrolytic paper 5 between the foil 2 and the negative electrode foil 3 is constituted. After the negative electrode foil is subjected to voltage treatment, an oxide film is formed on its surface. The electrolytic paper is used to isolate the positive electrode foil and the negative electrode foil. The electrolytic paper can be respectively arranged on the rear surfaces of the positive electrode foil and the negative electrode foil. The upper surface of the tongue in the negative guide pin is covered with a thin sheet, which is a pressurized negative electrode foil sheet made of the same material as the ne...

Embodiment 3

[0041] The invention provides an aluminum electrolytic capacitor using a high-water electrolyte. The capacitor body is composed of a positive electrode foil nailed to a positive guide pin, a negative electrode foil nailed to a negative guide pin, and an electrolytic capacitor disposed between the positive electrode foil and the negative electrode foil. The negative electrode foil is composed of paper. After the negative electrode foil is subjected to voltage treatment, an oxide film is formed on its surface. The electrolytic paper is used to separate the positive electrode foil and the negative electrode foil. The electrolytic paper can be respectively arranged on the rear surface of the positive electrode foil and the negative electrode foil. Wherein, the width K of the electrolytic paper may be greater than or equal to the width a of the tongue position, and the length c of the electrolytic paper may be greater than or equal to the length b of the tongue position.

[0042] Si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com