Patents

Literature

148results about How to "Improves hydration resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light alkane dehydrogenation catalyst with good hydrothermal stability and preparation method thereof

InactiveCN104128175AImproves hydration resistanceAvoid chalkingHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneDehydrogenation

The invention relates to a light alkane dehydrogenation catalyst with good hydrothermal stability and a preparation method thereof. The catalyst comprises the following components, by weight, 5-40% of Cr2O3, 30-85% of Al2O3, 0.1-30% of MO and 0.5-5% of Me2O, wherein M is Mg, Zn or a mixture of Mg and Zn; and Me is one of alkalis or a mixture of more than two of alkalis. The light alkane dehydrogenation catalyst has advantages of good hydrothermal stability, high activity and high selectivity, and is used in a dehydrogenation reaction of C3-C5 alkane.

Owner:YANTAI UNIV

Thermal-state mending material taking forsterite as raw material for converters and preparation method thereof

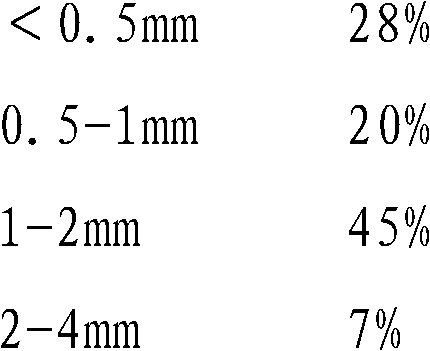

The invention relates to a thermal-state mending material taking forsterite as a raw material for converters and a preparation method thereof. The technical scheme is as follows: adopting 45-70wt% of sintered magnesia particles, 5-15wt% of graphite and 15-40wt% of forsterite fine powder as raw materials; adding simple substance silicon powder accounting for 1-10wt% of the weight of the raw materials and liquid pitch modified phenolic resin accounting for 15-25wt% of the weight of the raw materials; and stirring for 5 to 30 minutes to obtain the slurry thermal-state mending material taking forsterite as the raw material for converters. While being used, the thermal-state mending material is poured into the converter, the converter is rotated to enable the mending material to flow to the charging position, the tapping position, the bedding face and the furnace bottom of the steelmaking converter which are in need of thermal-state mending and the mending material is sintered by the heat in the converter. The material has the characteristics of abundant raw materials, low production cost, excellent hydration-proof performance, easiness in sintering at a high temperature and convenience in combination with the converter lining and is beneficial for prolonging the service life of materials of the converter lining.

Owner:北京炜润达冶金材料有限公司 +1

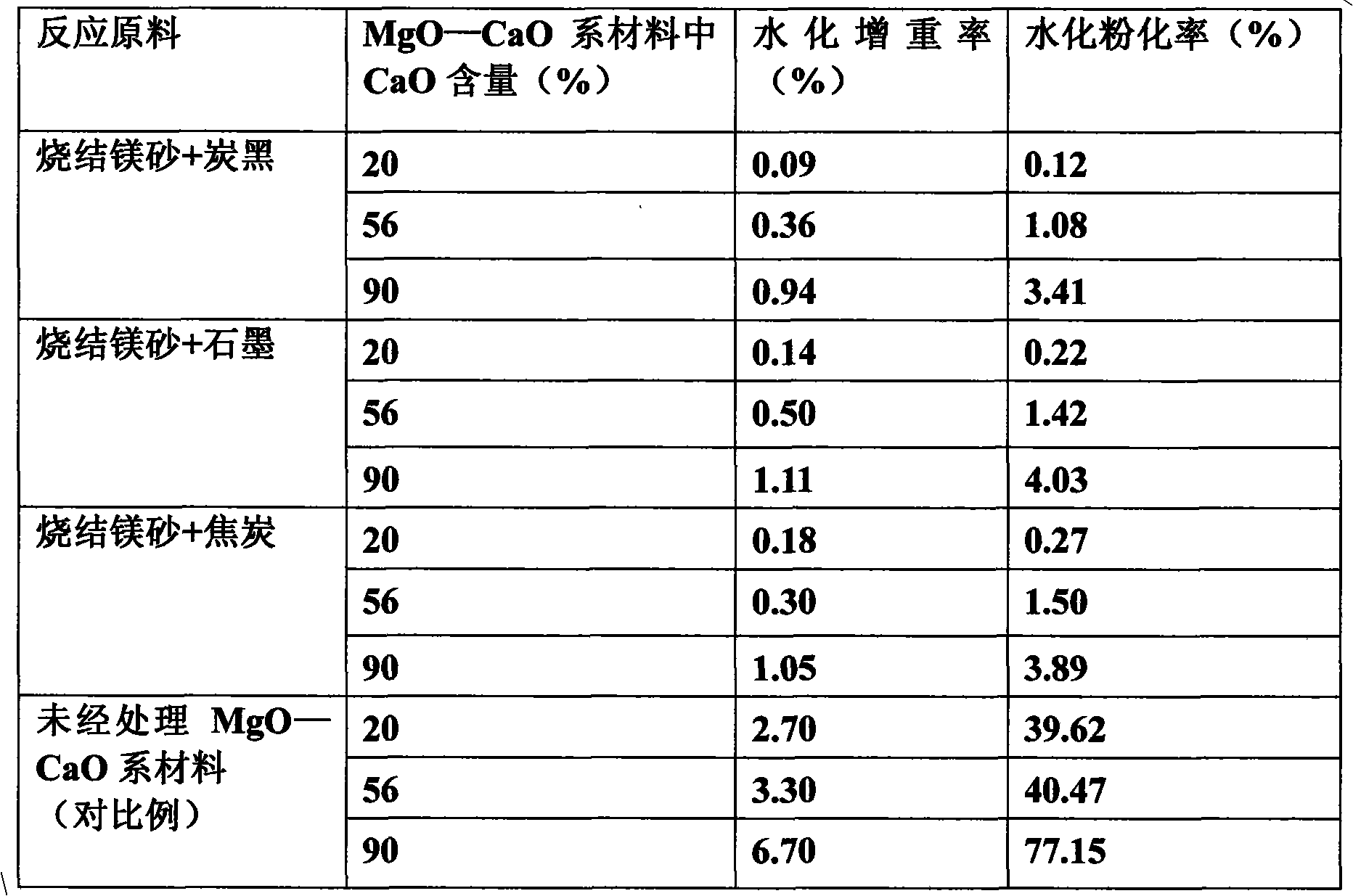

Hydration-resistant MgO-CaO series fireproofing material and preparation method thereof

The invention discloses a hydration-resistant MgO-CaO series fireproofing material and a preparation method thereof. The surface of the prepared MgO-CaO series fireproofing material is covered with a compact MgO hydration-resistant film layer. The preparation method of the invention is as follows: magnesium sand and carbon serve as reaction raw materials; MgO-CaO series material is arranged above the mixture of the magnesium sand and the carbon, and a reaction vessel is arranged in a controlled atmosphere furnace; the controlled atmosphere furnace is vacuumized, and Ar is led in the furnace for protection; the furnace body is heated, O2 is led in, and the magnesium sand and the carbon have carbothermal reduction reaction to generate Mg steam; the Mg steam diffuses to the vicinity of MgO-CaO series material so as to react with the lead-in O2; an MgO compact film is generated on the surface of the MgO-CaO series material; after the MgO compact film generated by vapor phase deposition totally covers the CaO on the surface of the MgO-CaO series material, the hydration-resistant MgO-CaO series fireproofing material can be obtained. Because the MgO compact film prevents CaO from contacting with water, the hydration-resistant performance of the MgO-CaO series fireproofing material is obviously improved. The preparation method is simple and convenient to operate, the raw materials fully react, and the production cost is low.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

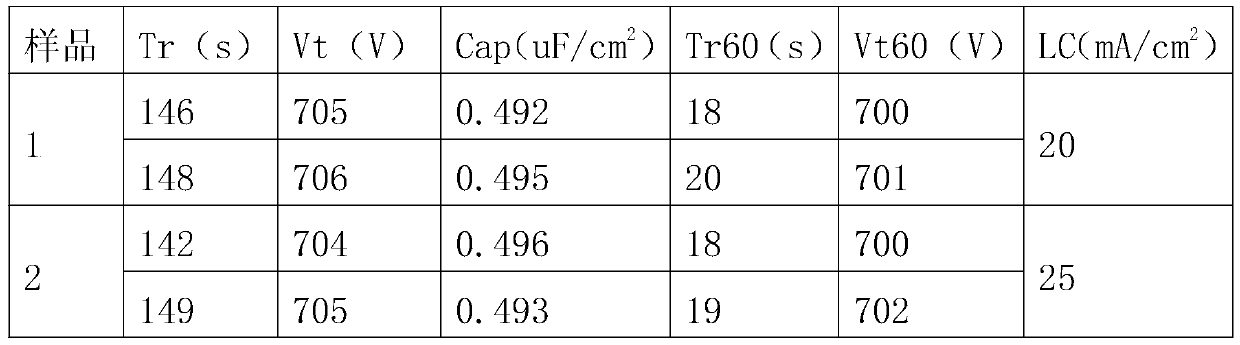

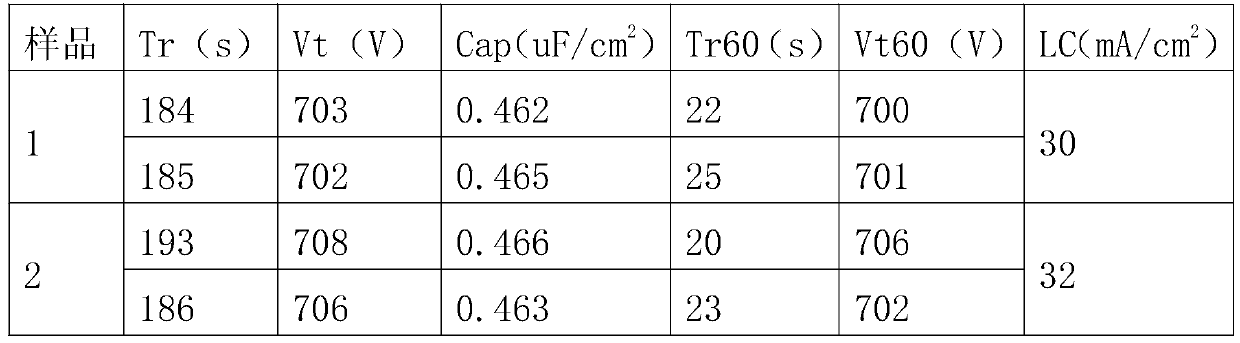

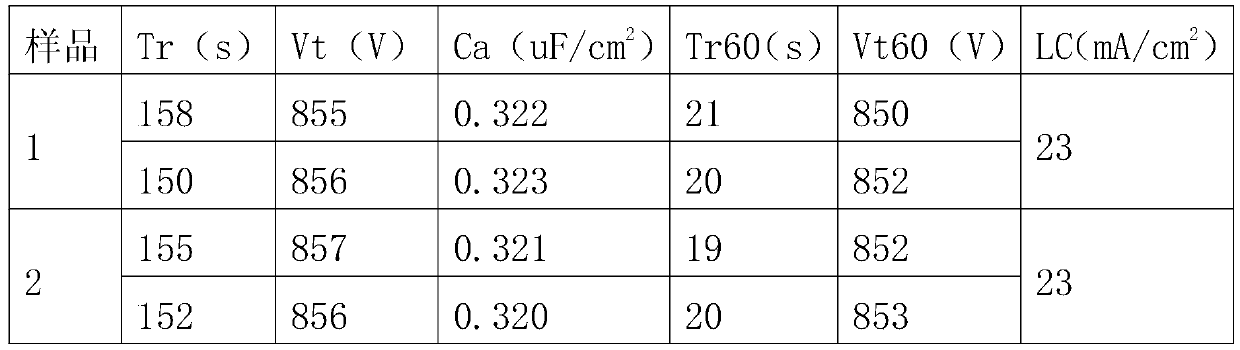

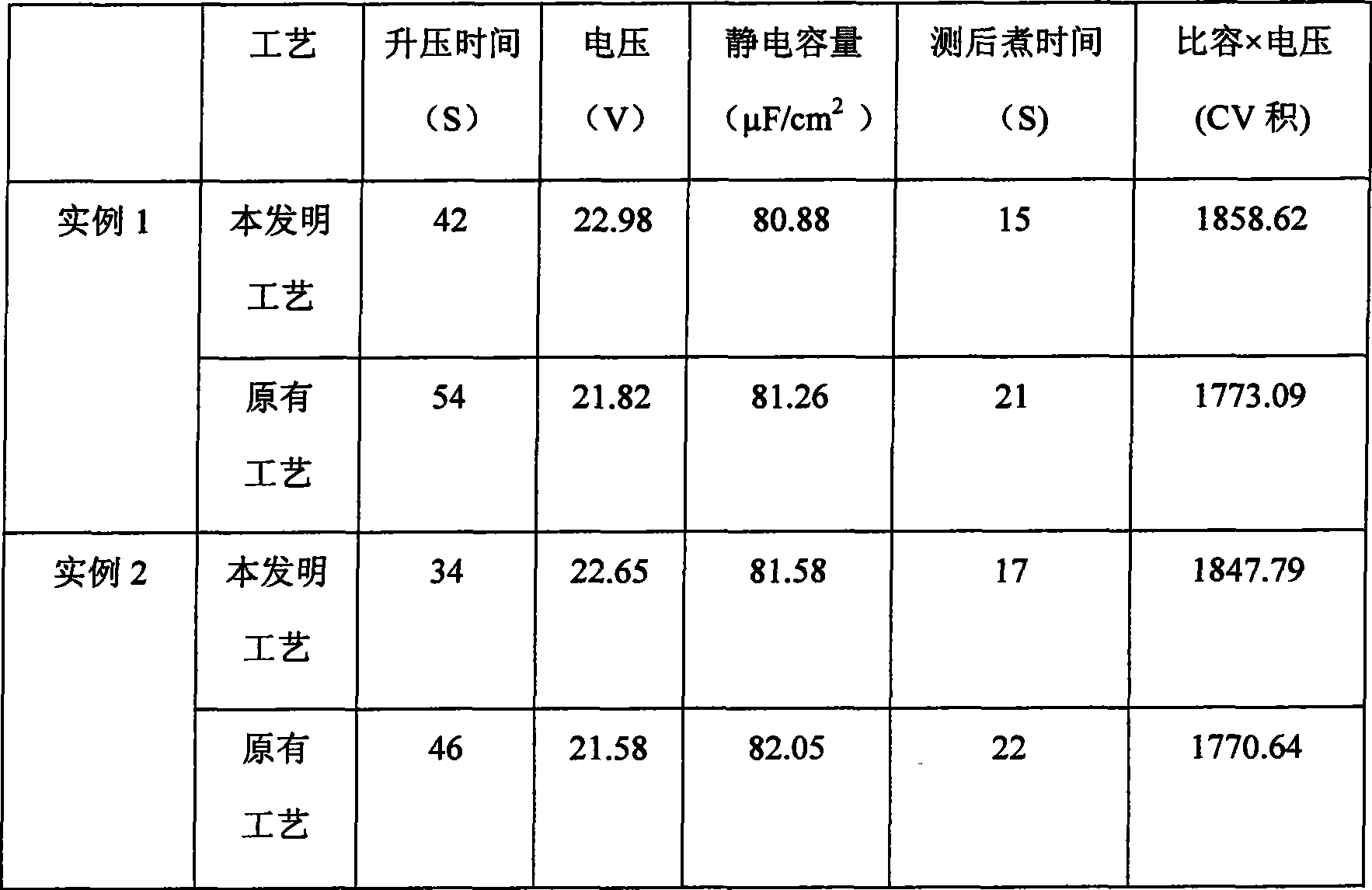

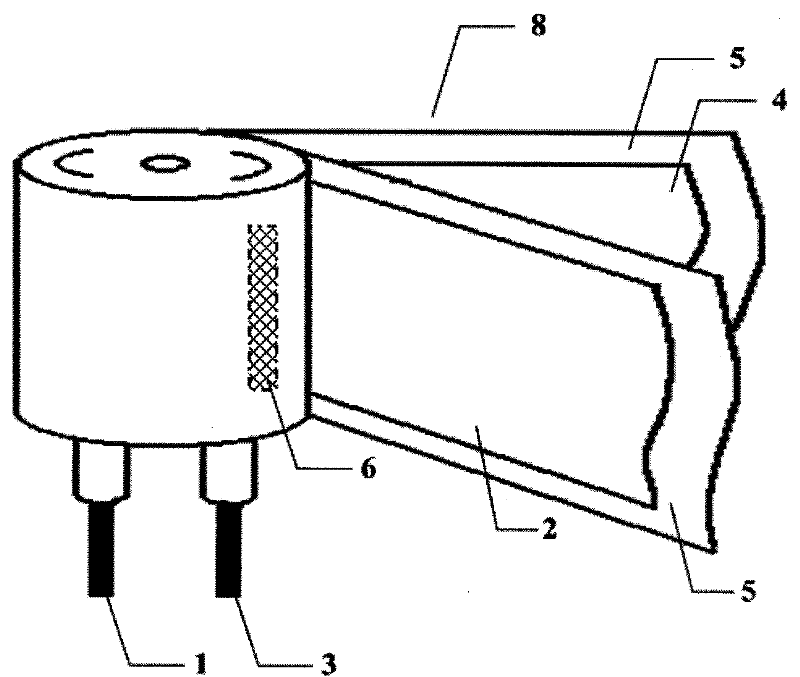

Formation method for anode foil of extra-high voltage aluminum electrolytic capacitor

ActiveCN110219032AImprove leakage currentIncrease lossAnodisationElectrolytic capacitor manufacturePhosphoric acidPre treatment

The invention relates to a formation method for an anode foil of an extra-high voltage aluminum electrolytic capacitor. The formation method for the anode foil of the extra-high voltage aluminum electrolytic capacitor comprises the following steps: (1) pre-treatment; (2) first level formation; (3) second level formation; (4) third level formation; (5) four level formation; (6) five level primary formation; (7) primary high temperature treatment; (8) phosphoric acid treatment; (9) fifth level secondary formation; (10) secondary high temperature treatment; (11) fifth level third formation; and (12) post-treatment. According to the formation method, the voltage in each level formation is greater than that applied in the previous level formation. The formation method also comprises a liquid feeding treatment which is carried out after second level formation or third level treatment. The formation method for the anode foil of the extra-high voltage aluminum electrolytic capacitor is simpleto control, and the bath solution components are relatively simple and better to control, so that the formation method is suitable for industrial batch production.

Owner:XINJIANG JOINWORLD CO LTD

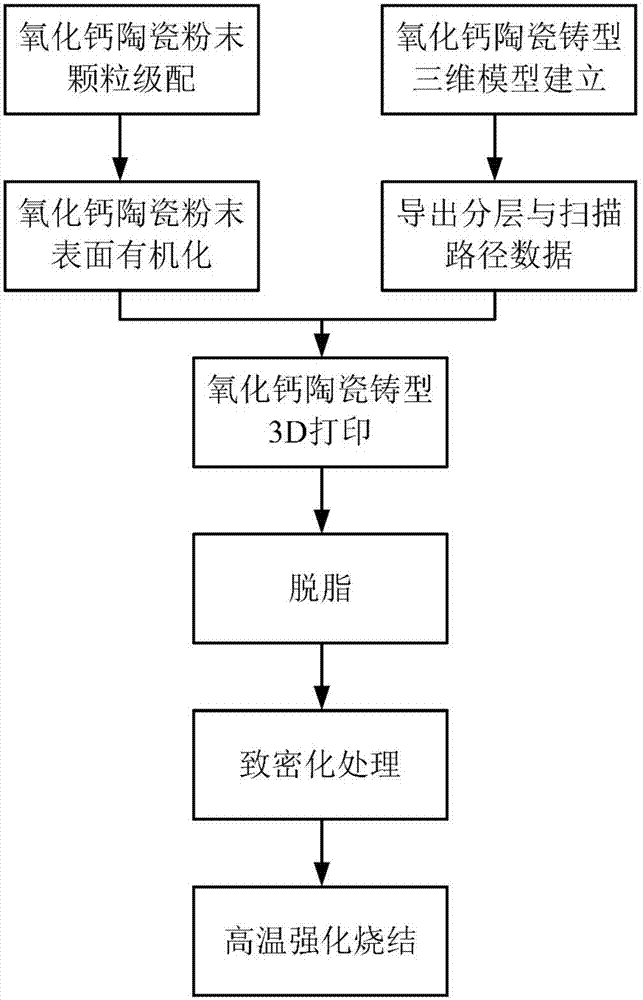

Calcium oxide-based ceramic mold manufacturing method based on 3D (Three Dimensional) printing technology

ActiveCN107021771AGuaranteed dimensional accuracyInhibition of hydrationAdditive manufacturing apparatusFiberHigh intensity

The invention a calcium oxide-based ceramic mold manufacturing method based on a 3D (Three Dimensional) printing technology. The method comprises the following steps: after carrying out organic treatment on calcium oxide ceramic powder subjected to grain size gradation, adding a proper amount of an sintering auxiliary agent and enhanced short fibers and uniformly mixing to prepare calcium oxide-based ceramic powder for 3D printing; carrying out the 3D printing by utilizing a photo-cured adhesive and the calcium oxide-based ceramic powder subjected to the organic treatment, so as to form a calcium oxide-based ceramic mold green body; carrying out degreasing, reactive melt infiltration and high-temperature intensified sintering on the calcium oxide-based ceramic mold to finally obtain a high-strength calcium oxide-based ceramic mold; carrying out surface hydration-proof treatment on the prepared ceramic mold. By adopting the method, the hydration resistance of the calcium oxide-based ceramic mold is improved; the calcium oxide-based ceramic mold prepared by the method has a good high-temperature comprehensive performance and can meet casting requirements of an alloy with higher temperature and (B2) metal with active high-temprature chemical properties, and a mold core is easy to remove.

Owner:XI AN JIAOTONG UNIV

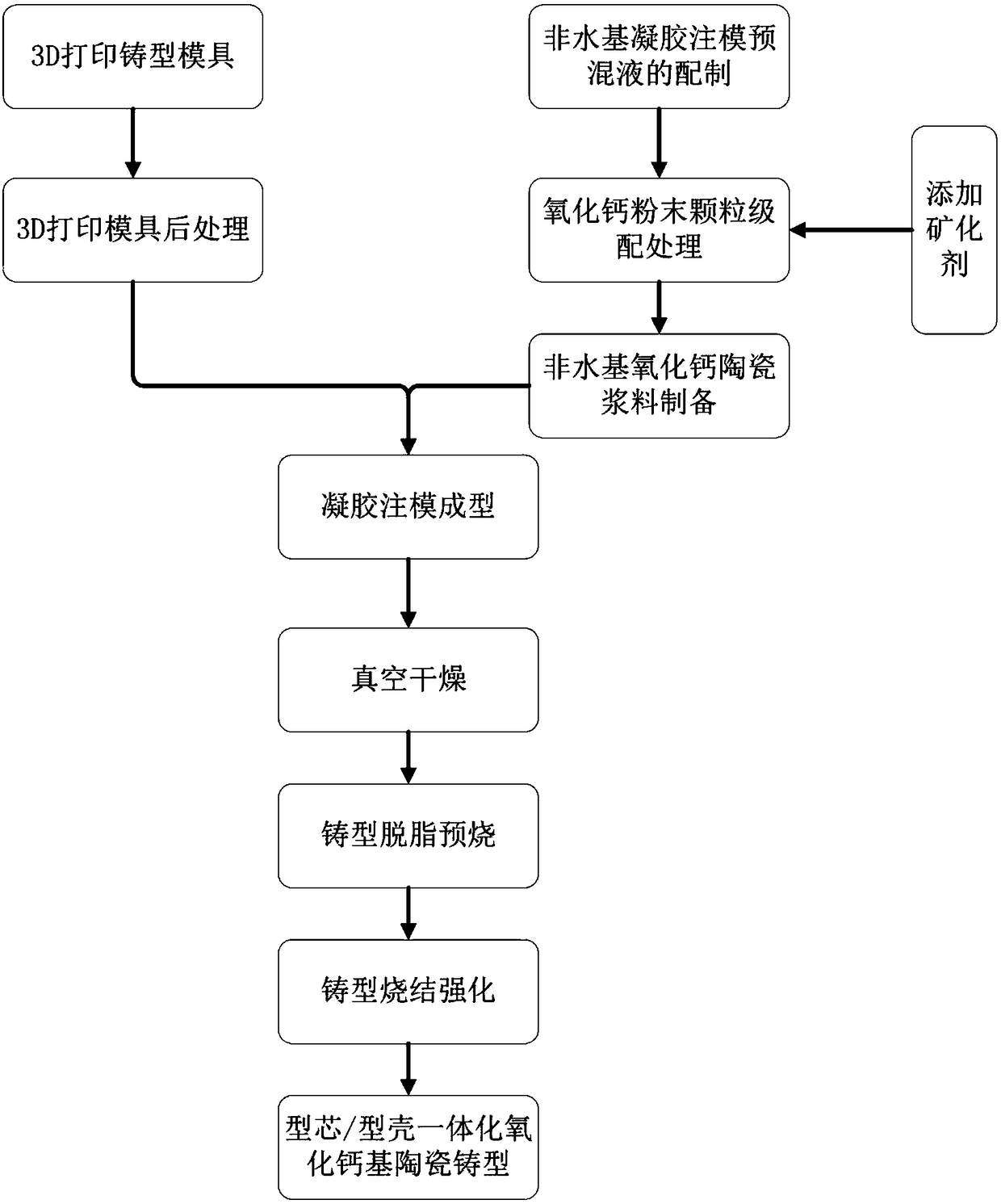

Non-water-based gel injection molding rapid-manufactured calcium oxide-based ceramic casting mold and preparation method thereof

InactiveCN108059445AInhibition of hydrationImprove sintering performanceAdditive manufacturing apparatusWater basedNiobium

The invention discloses a non-water based gel injection molding rapid-manufactured calcium oxide-based ceramic casting mold and a preparation method thereof, and belongs to the technical field of rapid precision casting. The method is characterized in that a mold required for 3D printing technology rapid manufacture is used, and simultaneously a non-water-based gel injection molding technology isapplied, so that the problem of hydration of calcium oxide powder during a casting mold preparation process is effectively solved, and the method can be successfully applied to the preparation of a mold core / mold shell integrated calcium oxide-based ceramic casting mold with complex internal structural parts and components. The manufactured calcium oxide-based ceramic casting mold has good overallperformance, and can meet the casting requirements of ultrahigh-temperature alloys such as a new generation of niobium-silicon-based high-temperature alloy and active light alloys such as titanium-aluminium alloy and magnesium-aluminium alloy, and the core removal performance is extremely excellent, so that the technical problems of difficult removal and high rejection rate of silicon oxide-basedand aluminium oxide-based mold cores are solved, therefore, the non-water based gel injection molding rapid-manufactured calcium oxide-based ceramic casting mold is a huge improvement on an existinginvestment mold precision casting and molding technology, and has broad market prospect and market value.

Owner:XI AN JIAOTONG UNIV

Method for producing hydration-resistant high-purity calcium oxide crucible

InactiveCN103172390AImproves anti-hydrationImprove thermal shock resistanceGranularityVacuum induction furnace

The invention relates to a method for producing a hydration-resistant high-purity calcium oxide crucible, which is designed for solving the technical problems that low purity of calcium oxide generally existing in the existing calcium oxide crucible easily results in the introduction of impurities into melting metal and alloy; high purity of calcium oxide results in the easy hydration of the crucible and easy cracking of the crucible during use, the service life of the crucible is short and so on. According to the method, high-purity calcium carbonate is electrically molten to obtain calcium oxide clinker which is then crushed to appropriate sizes and subsequently subject to combined gradation; the graded calcium oxide clinker is mixed with zirconia powder, then an anhydrous binder is added in the mixed powders; and a calcium oxide crucible blank is obtained by cold isostatic pressing, and then is sintered to obtain the hydration-resistant high-purity calcium oxide crucible. The method has the advantages that the performanceof metal or alloy smelted in a vacuum induction furnace with the hydration-resistant high-purity calcium oxide crucible as the liner surpasses that of the graphite crucible, the hydration resistance and the thermal shock resistance are improved, and the sintering temperature of calcium oxide is lowered; cold isostatic pressing forming is adopted so that the crucible forming is more convenient and simpler; the crucible is widely applied to the vacuum smelting industry due to the characteristics of high purity and good mechanical performance.

Owner:SHENYANG XINJIN POWDER ENG

A kind of synthetic magnesium calcium sand and preparation method thereof

InactiveCN102285806AHigh purityNo damage to high temperature performanceCalcium hydroxideMechanical press

The invention relates to synthetic calcium magnesite and a preparation method thereof. The preparation method comprises the steps of firstly carrying out ball milling on 25-30wt% of calcium hydroxide and 70-75wt% of magnesium hydroxide to reach the grain size within 30 mu m, heating the ball-milled mixture in a muffle furnace to 700-900 DEG C, and insulating heat for 0.25-0.5 hour; adding water the amount of which is 20-25wt% of the mixture to the calcined mixture, and digesting for 1-2 hours; and then adding an additive the amount of which is 1-3wt% of the digested mixture to the digested mixture, stirring, carrying out mechanical press shaping by a semi-dry method, naturally drying for 12-15 hours, baking at the temperature of 100-120 DEG C for 12-15 hours, finally firing in a high-temperature furnace at the temperature of 1600-1750 DEG C, insulating heat for 3-5 hours and crushing to obtain the synthetic calcium magnesite. The preparation method provided by the invention has the advantages of simple process and no need for special synthesis equipment and treatment technology. The synthesized calcium magnesite has the characteristics of high purity, wide application range, good sintering performance, good hydration resistance, and no influence on high-temperature use performance.

Owner:WUHAN UNIV OF SCI & TECH

Composite bonding agent for sliding plate refractory material and preparation method thereof

InactiveCN101942286ALow priceImprove antioxidant capacityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesBreaking strengthAlcohol

The invention relates to a composite bonding agent for a sliding plate refractory material and a preparation method thereof. The technical scheme of the preparation method comprises the following steps of: adding absolute ethyl alcohol into phenolic resin to prepare 30 to 60 weight percent of solution of phenolic resin and absolute ethyl alcohol; adding modified white carbon black into the solution of phenolic resin and absolute ethyl alcohol, wherein the adding amount of the modified white carbon black is 1 to 15 weight percent of the phenolic resin; stirring for 3 to 6 hours at the temperature of 30 to 50 DEG C to obtain mixed liquid of white carbon black and modified phenolic resin; and decompressing and distilling the mixed liquid to remove ethanol so as to obtain the composite bonding agent for the sliding plate refractory material. The preparation method has the advantages of simple process, low production cost and contribution to industrial production. The modified white carbonblack is spherical, so that the white carbon black can be uniformly and well dispersed in a phenolic resin substrate with good dispersion effect. The prepared composite bonding agent has the advantages of high residual carbon rate and high oxidization resistance in a middle temperature area. The sliding plate refractory material prepared from the composite bonding agent has the advantages of relatively high breaking strength and compression strength, relatively low volume density and relatively high hydrability resistance.

Owner:WUHAN UNIV OF SCI & TECH

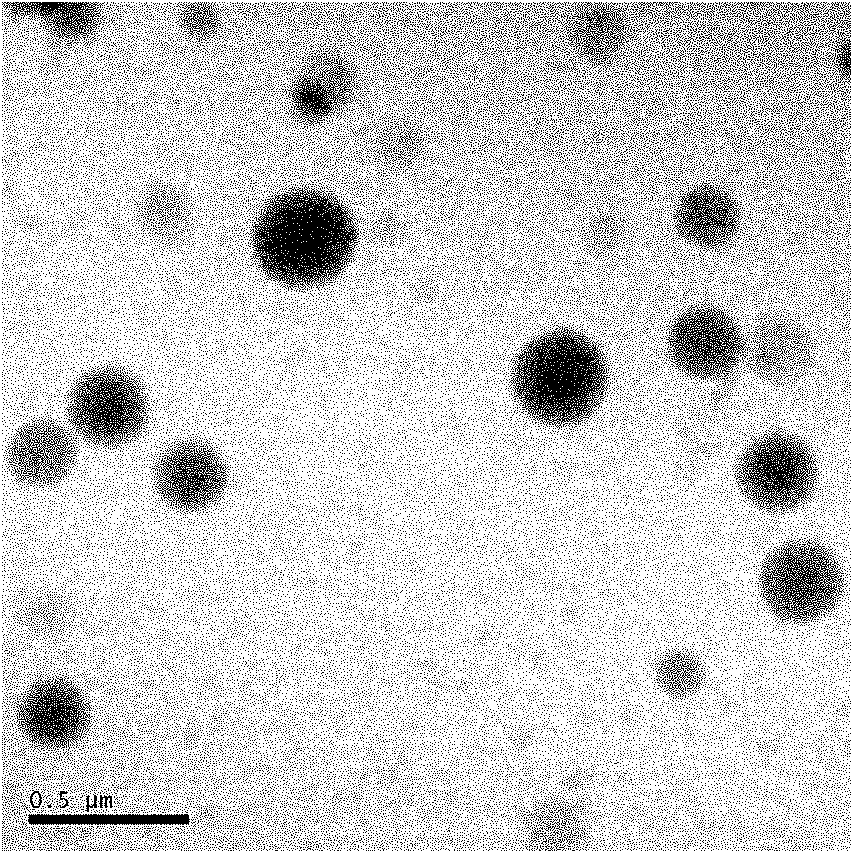

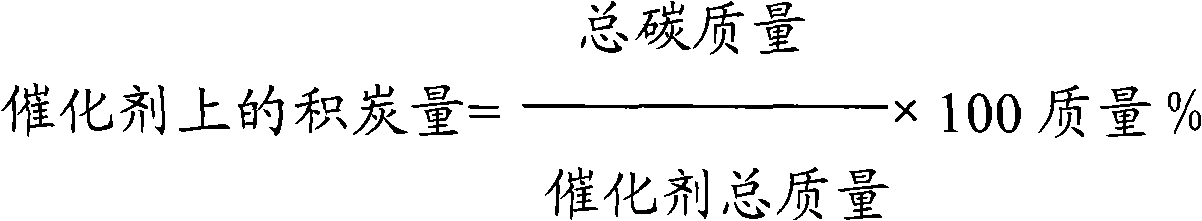

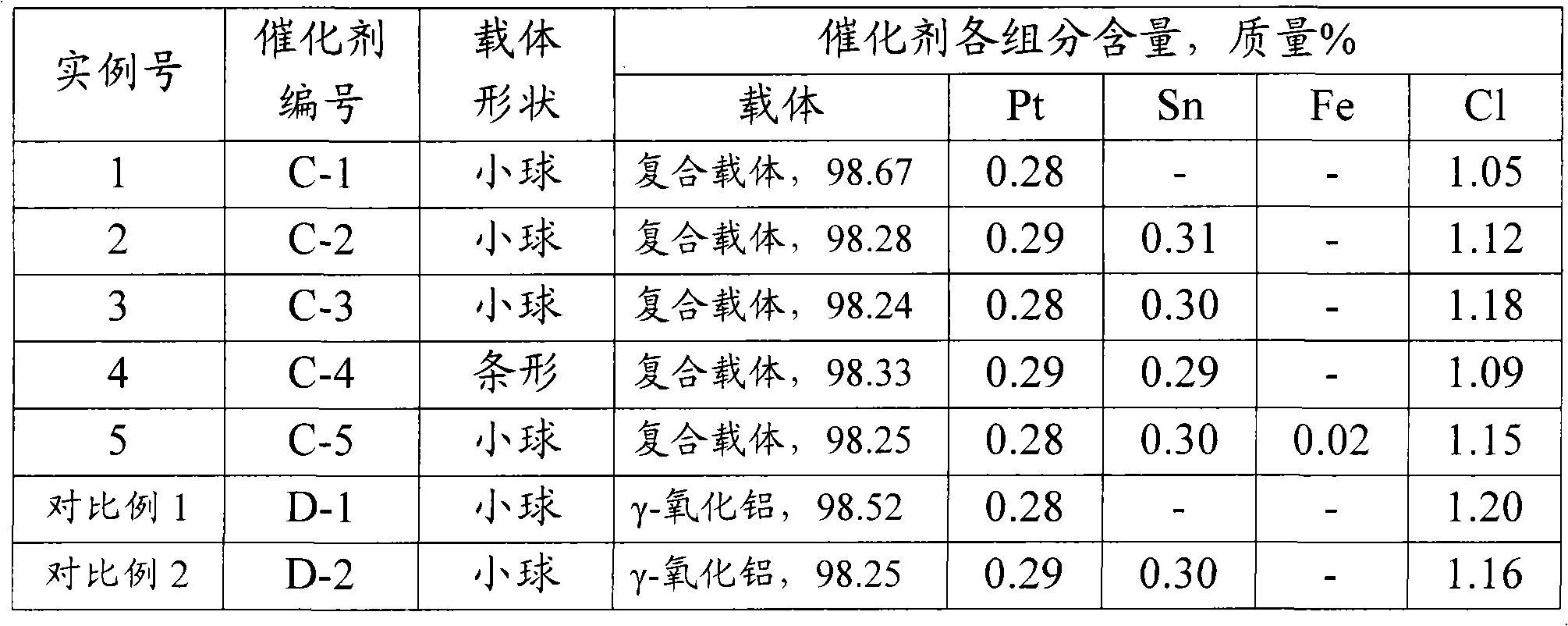

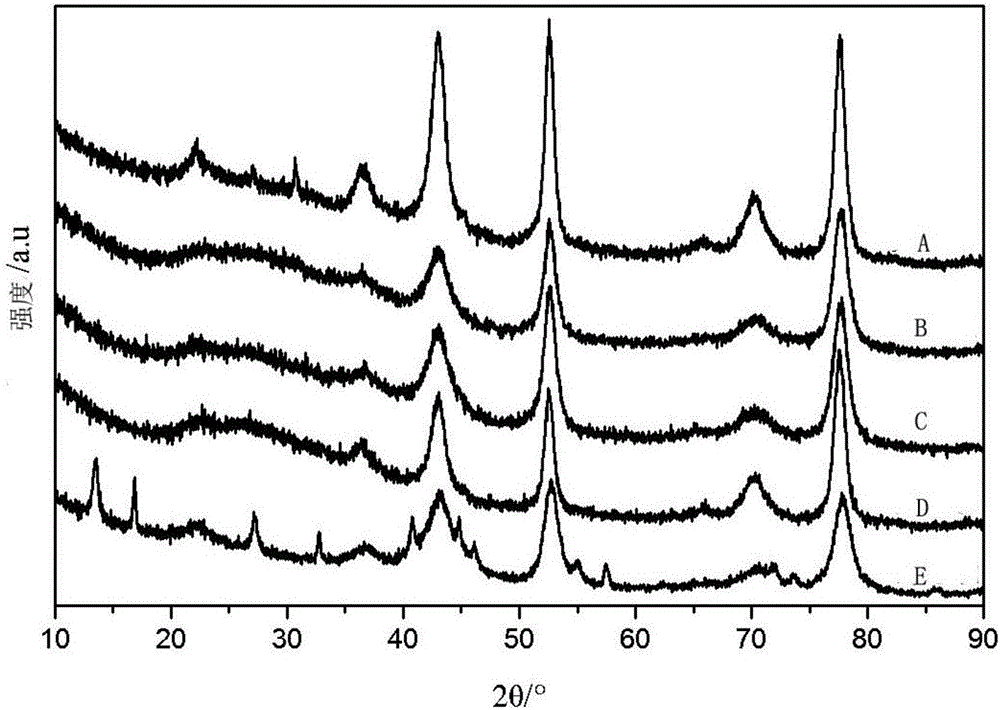

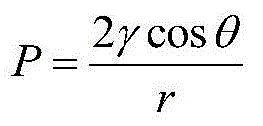

Petroleum naphtha reforming catalyst and preparation method thereof

ActiveCN101294102AReduce carbon depositionImproves hydration resistanceNaphtha reformingPetroleum naphthaAromatic hydrocarbon

A naphtha reforming catalyst comprises composite carriers 93 to 99wt%, noble metals 0.01 to 5.0wt% and halogen 0.1 to 5.0wt%, wherein the composite carriers comprise aluminum oxide and Mg(Al)O composite oxide, wherein the mass ratio of MgO to Al2O3 is 1:(100 to 250). The catalyst is used for naphtha reformation reaction and has the advantages of higher yield of aromatic hydrocarbon and higher anti-coking capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mold release agent for casting accumulator grids and preparation method of mold release agent

InactiveCN107442740AReasonable ratio of ingredientsImprove spraying effectFoundry mouldsFoundry coresAdhesivePhosphate

The invention discloses a release agent for battery grid casting and a preparation method thereof. The release agent comprises the following raw materials in parts by weight: 0.2-0.6 parts of polytetrafluoroethylene, 0.1-0.3 parts of aluminum dihydrogen phosphate, cork 1-5 parts of powder, 0.2-0.6 parts of sodium silicate, 0.6-1.5 parts of glass fiber powder, 0.1-0.6 parts of attapulgite, 0.6-2.5 parts of nano-silicon dioxide, 3-8 parts of modified aluminum tripolyphosphate, Adhesive 0.1-0.5 parts, stabilizer 0.2-0.8 parts, deionized water 90-120 parts. The preparation method adopts conventional mixing, heating and stirring. The mold release agent of the present invention has good sprayability, adhesion, temperature resistance, small surface tension, high compressive strength, smooth exhaust, can significantly reduce the phenomenon of air holes and cracks in the grid, and can also reduce the number of spray molds , improve production efficiency and save costs.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

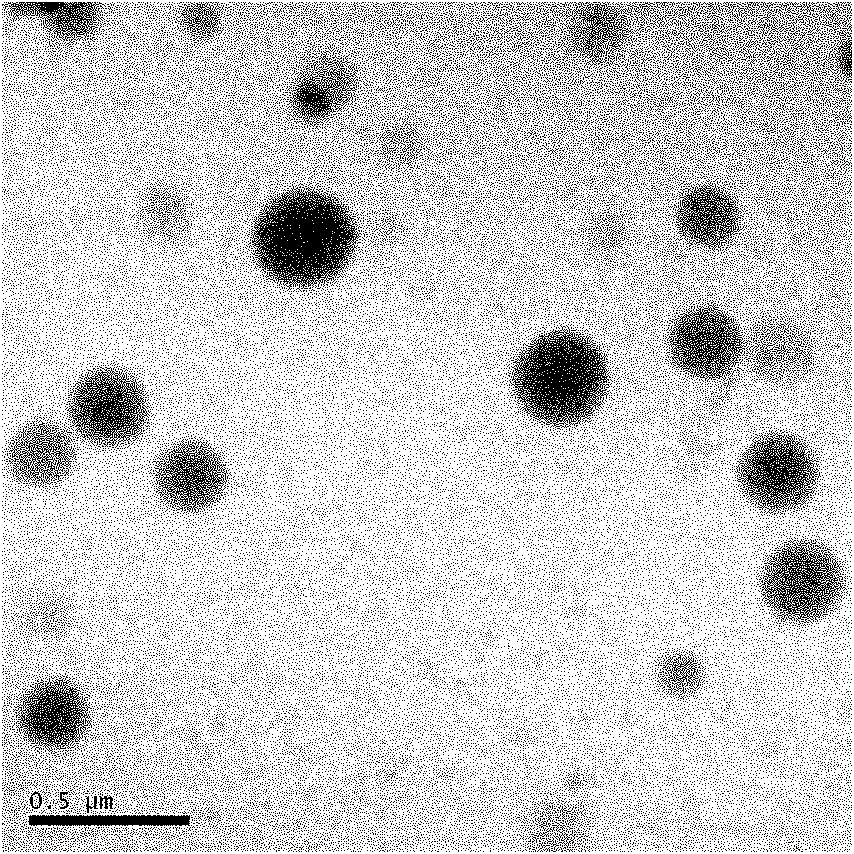

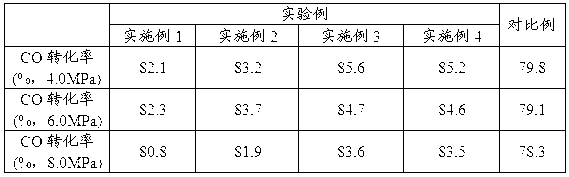

Carbon monoxide conversion catalyst carrier, catalyst based on carrier, and preparation method thereof

ActiveCN105032497AImproves hydration resistanceHigh mechanical strengthHydrogenCatalyst carriersAluminum IonHigh absorption

The invention provides a catalyst carrier with conversion and adsorption purification performances. Modified bauxite added into the raw materials of the catalyst carrier has fluxing and pore-forming functions. Through modification, most of iron oxide in bauxite is removed, such that the modified bauxite contains a large amount of high-activity aluminosilicate compound. As a fluxing agent, during catalyst preparation, the aluminosilicate compound assists in significantly improving the migration rates of magnesium and aluminum ions during a roasting process, such that MgAl2O4 generation under low temperature is promoted. Therefore, the catalyst carrier provided by the invention has relatively high hydration resistance and mechanical strength. Also, with the modification treatment, modified bauxite is adopted as a macroporous hard template for preparing the catalyst. With a roasting treatment, macro-pores are formed in the catalyst carrier structure, such that the catalyst carrier has relatively high absorption purification capacity upon macromolecular particles such as oil and dust.

Owner:FUJIAN PROVINCE SINOGASHOLDER EQUIP INSTALLATION CO LTD

Preparation method and application of moisture-proof modified electrical-grade magnesium oxide

ActiveCN109135339AImprove moisture resistanceImproves hydration resistanceMagnesiaPigment treatment with organosilicon compoundsMoisture resistanceSilicon oxide

The invention provides a preparation method of moisture-proof modified electrical-grade magnesium oxide. The preparation method comprises the steps that electrical-grade magnesium oxide powder and a silicon oxide assistant are mixed to prepare an electrical-grade magnesium oxide base material; an organic silicon moisture-proof agent and a diluent are mixed to prepare an organic silicon moisture-proof agent alkyl mixture; the organic silicon moisture-proof agent alkyl mixture is electrostatically sprayed to the electrical-grade magnesium oxide base material, mixing and stirring are performed toobtain modified electrical-grade magnesium oxide powder, and the moisture-proof modified electrical-grade magnesium oxide is prepared after drying. The invention also provides the moisture-proof modified electrical-grade magnesium oxide obtained through the above steps and application thereof. The moisture-proof modified electrical-grade magnesium oxide adopts the electrostatically sprayed organic silicon moisture-proof agent alkyl mixture, the organic silicon moisture-proof agent is uniformly sprayed to the surface of the electrical-grade magnesium oxide powder to form a hydrophobic dampproof coating, the moisture resistance, water resistance and insulation properties can be remarkably improved, the use amount of the organic silicon moisture-proof agent is saved, and the moisture-proof modified electrical-grade magnesium oxide is economic and friendly to the environment.

Owner:LIAONING JIASHUN CHEM SCI & TECH CO LTD

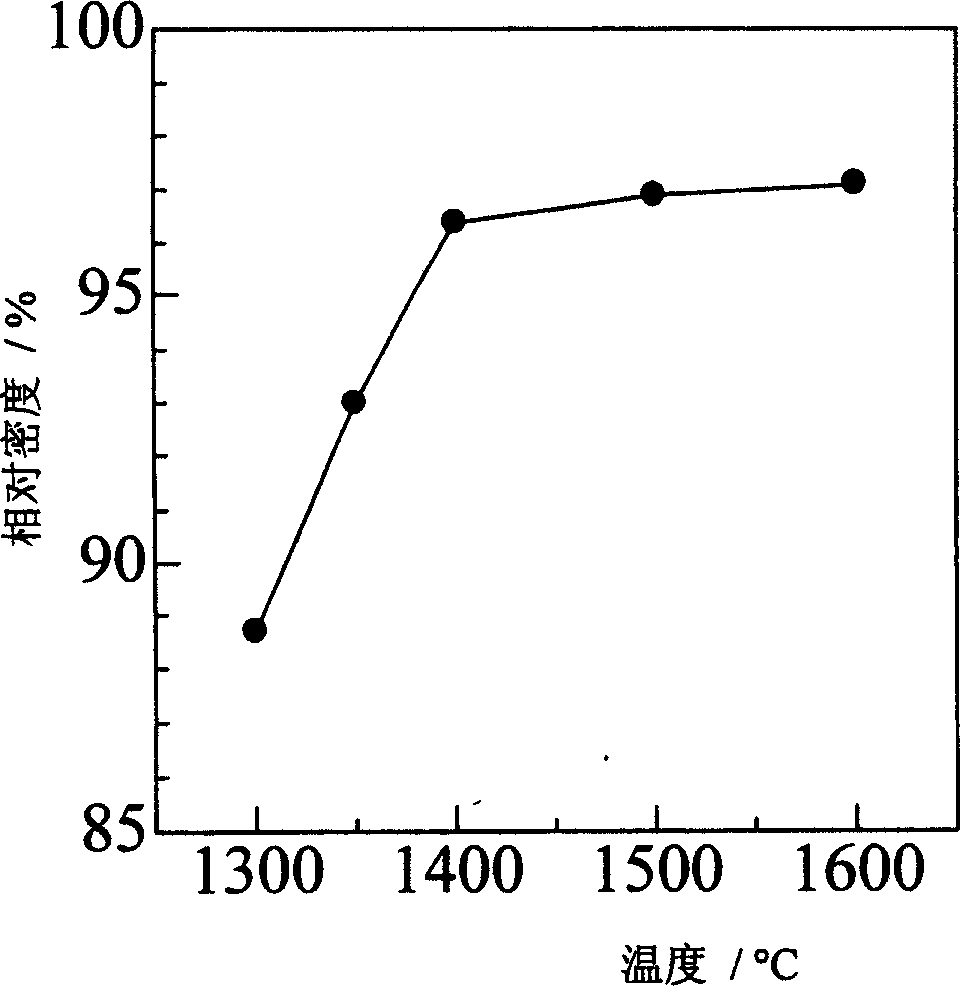

Method for preparing compact calcium oxide sand

InactiveCN1803703ALower firing temperatureImproves hydration resistanceCalcium carbonateProduct property

The three-step preparation method for CaO sand comprises: first, calcining the limestone for CaO and then the light CaCO3; adding 0.1-5% micro-powder of MgO or ZrO2 with size <=3 mu m into the light CaCO3 to mix evenly and briquette; then, re-calcining for 2-5h at 1200-1600 DEG C, natural cooling to normal temperature, and obtaining the sand. This invention decreases fire temperature obviously, and improves the product property without low-melting point phase.

Owner:NORTHEASTERN UNIV

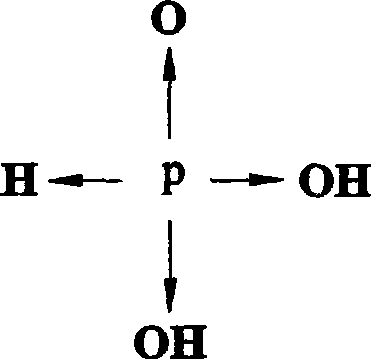

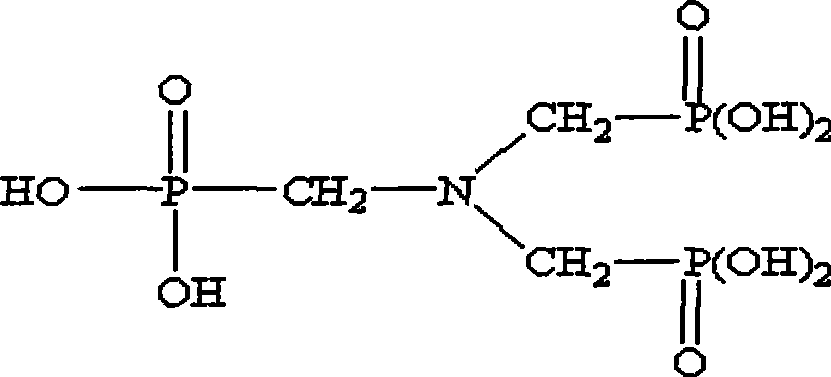

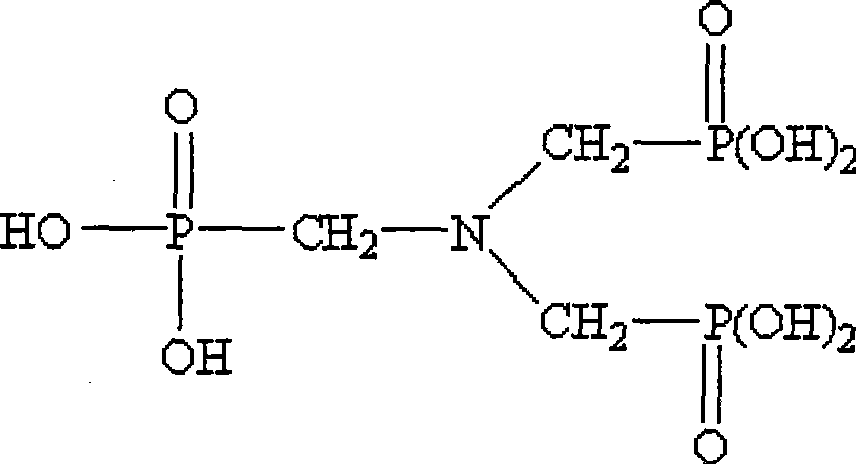

Low voltage aluminum electrolysis capacitor formed foil production method

ActiveCN101425384AReduce solubilityHigh capacitanceElectrolytic capacitorsMetallic material coating processesChemical treatmentSolubility

The invention relates to a preparation method of a formed foil used for low-voltage aluminum electrolytic capacitors. The aluminum foil is respectively added with two new treating agents during formation, i.e. phosphite and amino trimethylene phosphonic acid ( ATMP); the aluminum foil which generates a filam is put in a phosphate dilute solution to be chemically treated, and a layer of aluminum phosphide film is generated on the surface of the aluminum foil to improve the hydration resistance of the foil; the aluminum foil is formed in an ATMP solution, which ensures that not only a hydration resistant phosphating film can be generated, but also the formed aluminum foil has high efficiency and more complete covering; the solubility of oxide film is much lower, thereby a very good water resistant film is obtained and the aluminum foil obtains higher electrostatic capacity simultaneously.

Owner:YIDU DONGYANGGUANG FORMED FOIL

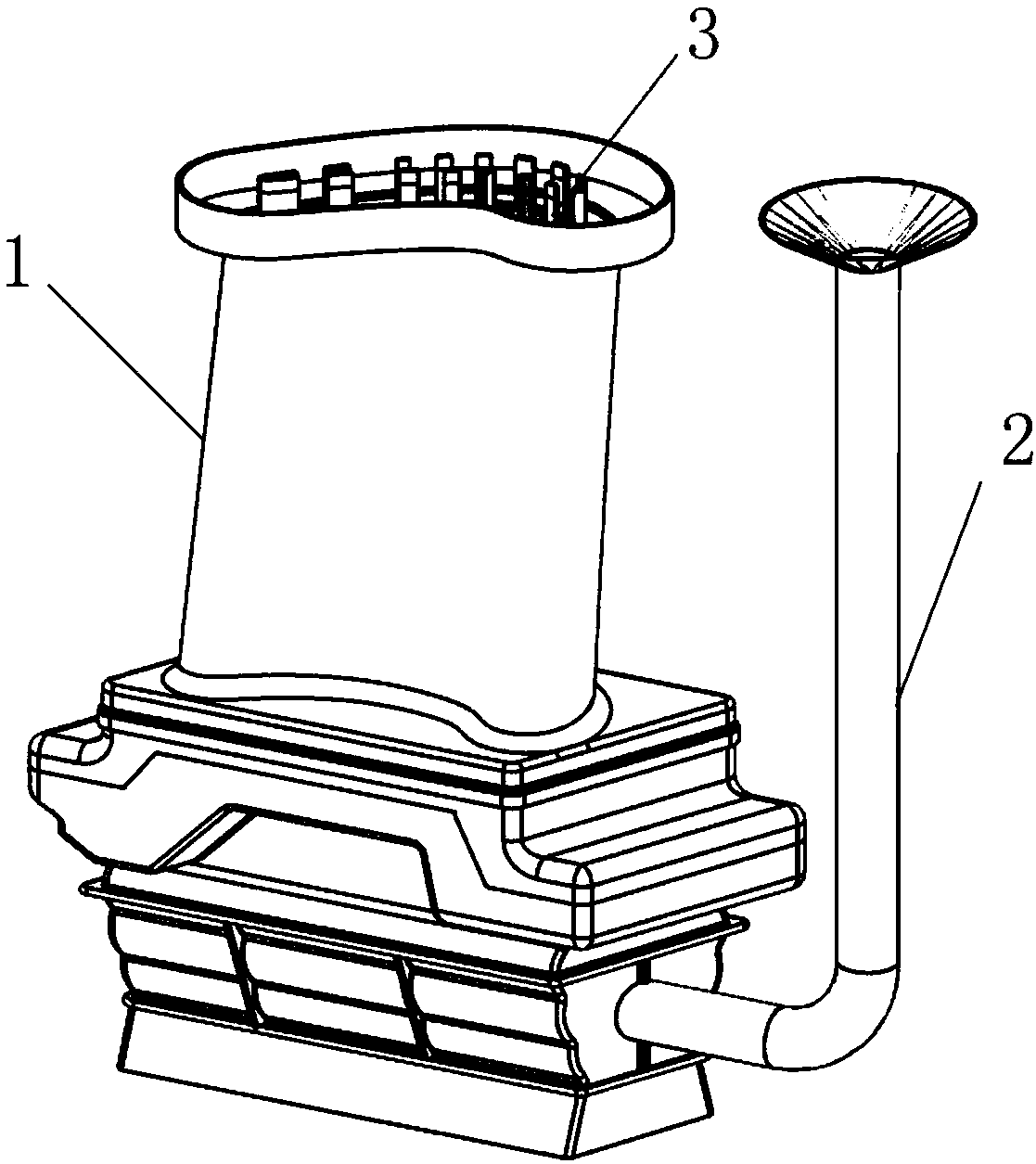

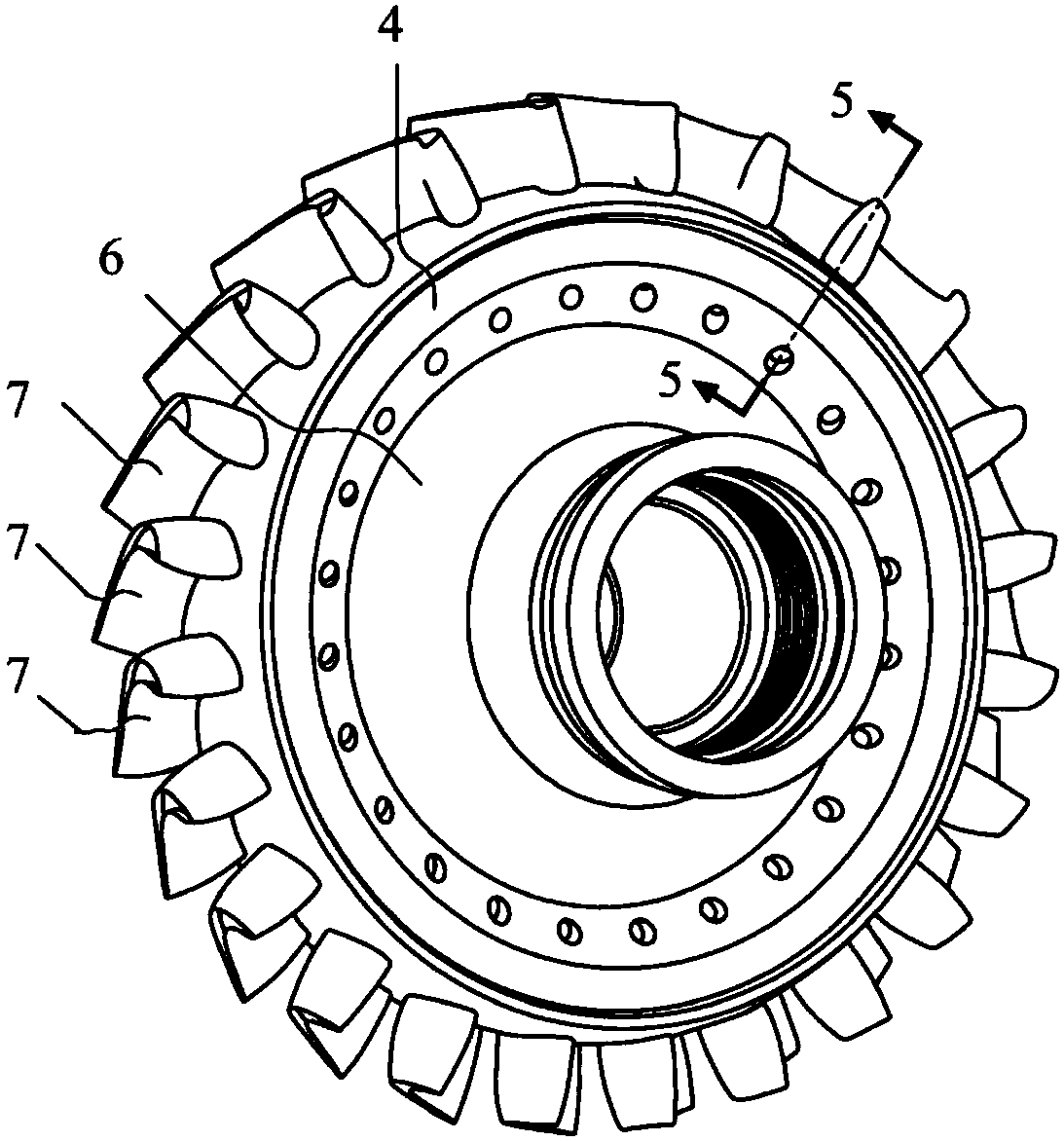

Protection material for plasma spray header as well as preparation method and application method thereof

InactiveCN103539433AImproves hydration resistanceExcellent resistance to plasma corrosionYttriumCorrosion resistant

The invention discloses a protection material for a plasma spray header and relates to a plasma equipment anticorrosion technology used in a semiconductor etching technique. The protection material for the plasma spray header mainly comprises magnesium oxide taken as a main material, calcium oxide with the doping content of 0.5-3wt% in the main material and yttrium oxide with the doping content of 0.5-5wt% in the main material. The invention also provides a preparation method and an application method of the protection material. By adopting the protection material, anticorrosion property of the plasma spray header in a high plasma environment for a long time can be obviously improved, and service life of the plasma spray header can be prolonged, so that production cost of a semiconductor material is reduced.

Owner:CHENGDU ULTRA PURE APPLIED MATERIAL

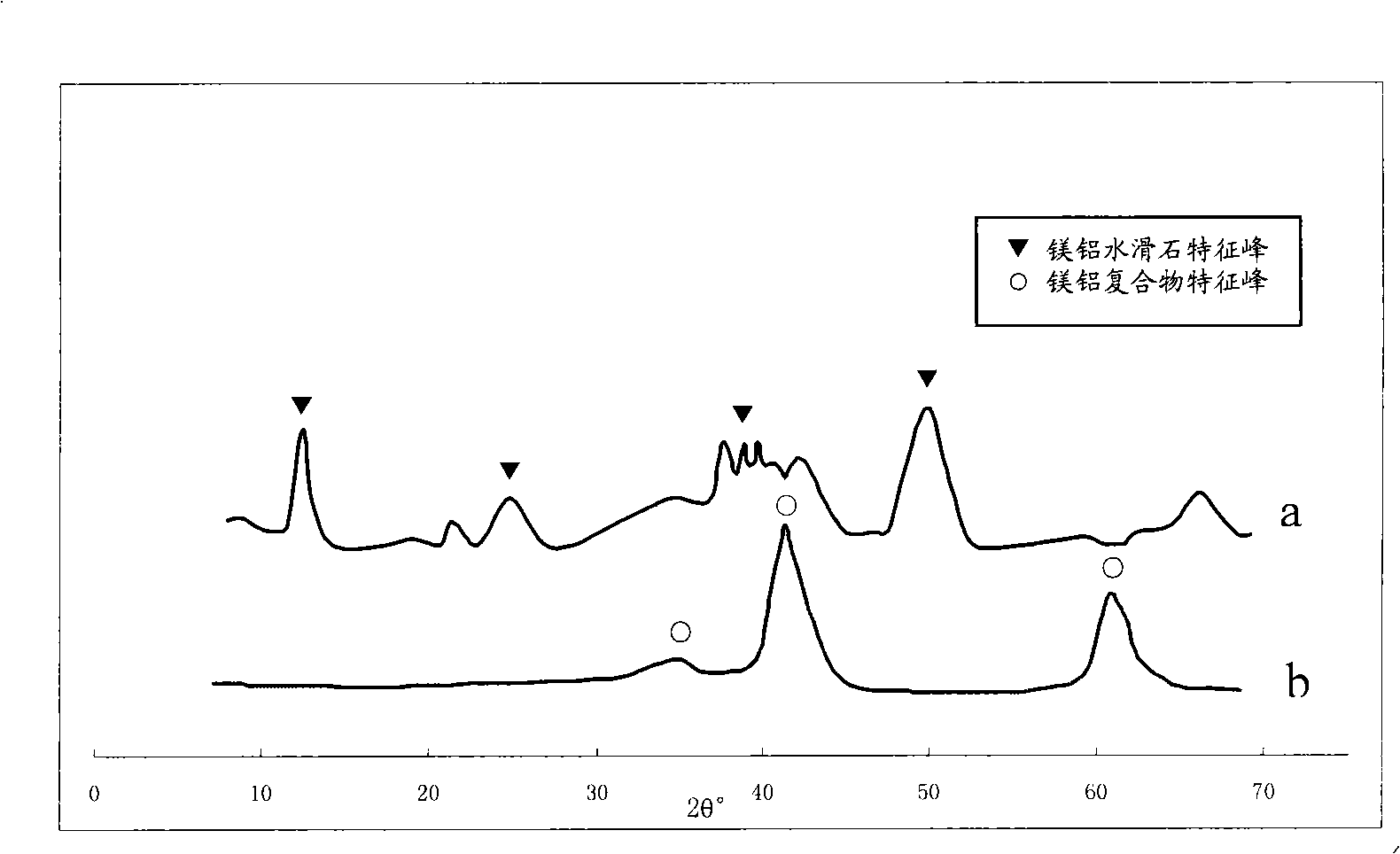

Carbon monoxide transformation catalyst carrier, preparation method of the carbon monoxide transformation catalyst carrier, and catalyst based on the carbon monoxide transformation catalyst carrier

ActiveCN103127959AIncrease conversion rateImproves hydration resistanceHydrogenCatalyst carriersPtru catalystCalcination

The invention provides a carbon monoxide transformation catalyst carrier for a high pressure technology. The carbon monoxide transformation catalyst carrier is prepared from 5 to 30 parts by weight of kaolin powder, 30 to 60 parts by weight of alumina powder and 10 to 40 parts by weight of magnesium oxide or magnesium hydroxide. Through utilization of kaolin powder, alumina powder and magnesium oxide or magnesium hydroxide having a certain ratio as raw materials, magnesium aluminate spinel structure compactness is effectively improved without increasing of a calcination temperature so that catalyst hydration resistance is improved; hydration under working conditions is avoided; high catalyst strength is kept in use; and crushing and wearing phenomenon is avoided.

Owner:FUZHOU UNIV +1

High-calcium-oxide-content calcium oxide material and preparation method thereof

The invention relates to a high-calcium-oxide-content calcium oxide material and a preparation method thereof. The technical scheme of the preparation method is that 30wt% to 70wt% of calcium oxide particle and 30wt% to 70wt% of calcium oxide fine powder are used as raw materials, anhydrous phenolic resin which is 2wt% to 6wt% of the raw materials is additionally added, and an obtained mixture is agitated for 2 to 20 minutes, is subjected to compression molding, then is subjected to heat treatment for 8 to 24 hours in a condition of 180 to 300 DEG C, and is naturally cooled, so that the high-calcium-oxide-content calcium oxide material is obtained. The preparation method is simple in process; the prepared high-calcium-oxide-content calcium oxide material is high in usage temperature, stable in high-temperature performance and good in anti-hydration performance, can be used for purifying a high-temperature fused mass, and is suitably used as a high-temperature material for smelting a high-purity fused mass.

Owner:WUHAN UNIV OF SCI & TECH

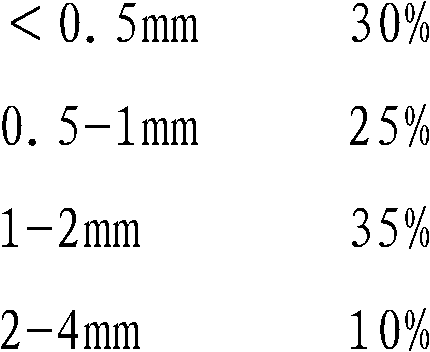

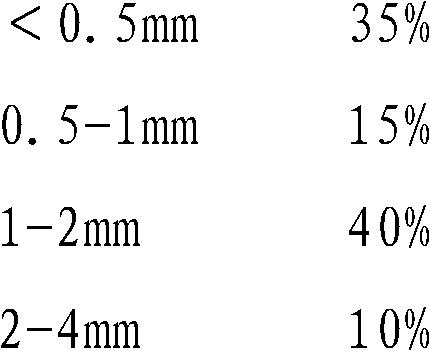

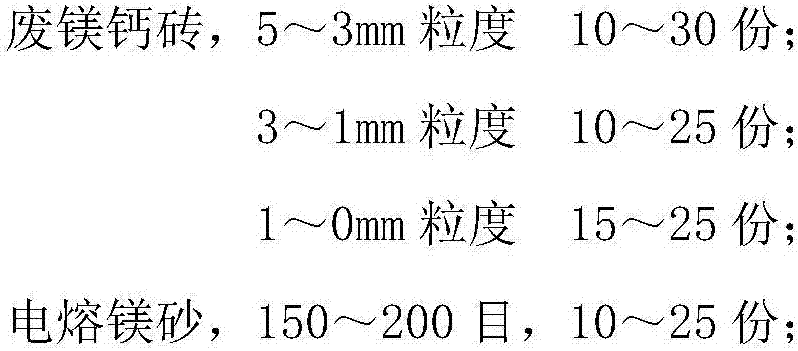

Method for producing magnesium calcium ramming material for AOD furnace from waste magnesia-calcium bricks

The invention relates to a method for producing a magnesium calcium ramming material for an AOD furnace from waste magnesia-calcium bricks. The magnesium calcium ramming material comprises 10-30 parts by weight of waste magnesia-calcium bricks having particle sizes of 5 to 3 mm, 10-25 parts by weight of waste magnesia-calcium bricks having particle sizes of 3 to 1 mm, 15-25 parts by weight of waste magnesia-calcium bricks having particle sizes of 1 to 0 mm and 10-25 parts by weight of fused magnesite of 150-200 meshes. The magnesium calcium ramming material also comprises 1.5-12% of a binder on the basis of the above raw material total weight. The waste magnesia-calcium bricks are subjected to water repellent treatment. The method realizes recycling of the waste magnesia-calcium bricks and observably improves water repellent performances of the magnesium calcium ramming material. The magnesium calcium ramming material satisfies refractory material use requirements on an AOD refining furnace, has a long storage life and effectively reduces an enterprise production cost.

Owner:辽宁利尔镁质合成材料股份有限公司 +1

Method for manufacturing foil by composite oxidation film at low pressure

InactiveCN101423964AHigh passivation treatment efficiencyReduce solubilityAnodisationElectrolytic capacitorsLow voltageAluminum silicate

The invention relates to the technical field of formed foils, in particular to a method for manufacturing a composite oxide film low-voltage formed foil. The method is as follows: firstly, a formed foil is treated by sodium silicate, and an aluminum silicate film is generated on the surface of the formed foil, is a good hydration resistant film and can improve the hydration resistance of the formed foil; and secondly, the formed foil is formed in a mixture of ATMP and ammonium adipate, and a hydrous aluminum phosphate film with good water resistance is generated. The aluminum silicate film and the hydrous aluminum phosphate film can effectively prevent reaction of an alumina film and water, improve the hydration resistance of the composite oxide film low-voltage formed foil, and prolong the service life of a capacitor.

Owner:DONGGUAN HEC CONDENSER CO LTD

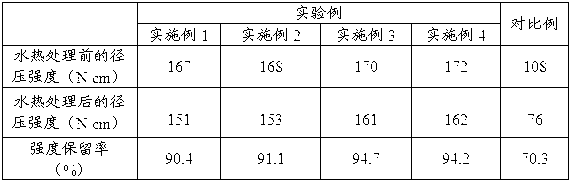

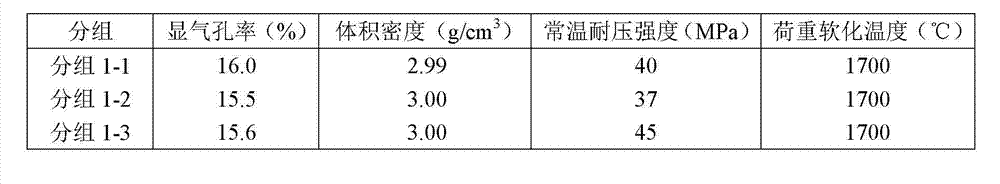

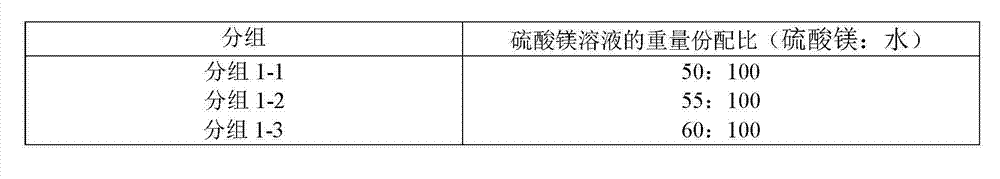

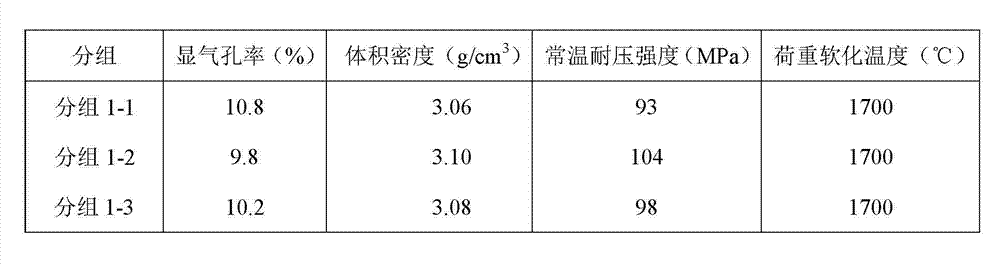

Waterproof treatment method for magnesium refractory bricks

The invention relates to the field of waterproofing of magnesium refractory bricks and in particular relates to a waterproof treatment method for magnesium refractory bricks. The waterproof treatment method is characterized in that as magnesium sulphate has the characteristics of crystal water, postproduction impregnation is carried out on the magnesium refractory bricks under vacuum condition to achieve the waterproof aim; and the waterproof treatment method comprises the following concrete operational steps of: 1) preparing a magnesium sulphate solution; 2) piling up the magnesium refractory bricks and vacuumizing; 3) injecting the magnesium sulphate solution to submerge and soak the magnesium refractory bricks; and 4) taking out the magnesium refractory bricks and carrying out heat treatment. Compared with the prior art, the waterproof treatment method for the magnesium refractory bricks has the beneficial effects that the treated magnesium refractory bricks are low in gas hole ratio, the compression strength is improved, and the treated magnesium refractory bricks have high anti-hydration capability, the problem that magnesia-alumina spinel bricks in a maerz active lime shaft kiln, magnesite-chrome bricks in a working layer of an RH (relative humidity) refining furnace and fired magnesite bricks in a permanent layer of a metallurgy electric furnace and a converter are hydrated can be effectively solved, and the reduction of influence of poor conditions such as humid climate and rainy days in the south of China to properties of the magnesium refractory bricks can be facilitated, so that the service life of the magnesium refractory bricks is prolonged.

Owner:辽宁青花耐火材料股份有限公司

Preparation method for preparing anti-hydration magnesia-calcia refractory through phosphate tailing

The invention discloses a preparation method for preparing an anti-hydration magnesia-calcia refractory through phosphate tailing. The anti-hydration magnesia-calcia refractory is prepared according to the following steps that A, the phosphate tailing is dried, smashed, ground, sieved, precalcined, naturally cooled to the room temperature to be taken out, ground and sieved, and thus precalcined phosphate tailing is obtained; and B, the precalcined phosphate tailing, nano-titania, nano zirconium dioxide and a binding agent are mixed evenly, and through forming, drying and calcining, a finishedproduct is obtained. The anti-hydration magnesia-calcia refractory with the high volume density and good normal-temperature compressive strength is obtained, the preparation process is simple and easyto operate, the phosphate tailing is mainly taken as a main raw material, and the problems that the phosphate tailing is low in utilization rate, and the magnesia-calcia refractory is prone to beinghydrated are solved.

Owner:GUIZHOU UNIV

Anti-hydration magnesia castable

The invention discloses an anti-hydration magnesia castable, which includes following components: 25-35 parts of magnesite, 15-25 parts of spinel, 15-25 parts of corundum, 5-10 parts of calcium aluminate cement, 2-8 parts of silicon dioxide micro-powder, 1-5 parts of graphite, 3-10 parts of sodium hexametaphosphate, 4-9 parts of boric acid, 2-6 parts of oxalic acid, 3-9 parts of calcium oxide, 5-10 parts of boron oxide, 2-8 parts of nickel oxide, 15-25 parts of organic fibers and 0.1-3 parts of metallic aluminum powder. The magnesia castable has an excellent anti-hydration property.

Owner:赵彬

Method for preparing high-purity hydration-resisting calcium oxide crucible

InactiveCN105906356APromotes sintering densificationImproves hydration resistanceCompression moldingCalcium hydroxide

The invention discloses a method for preparing a high-purity hydration-resisting calcium oxide crucible, wherein the method includes the steps: (1) adding yttrium oxide in a high-purity calcium hydroxide powder, carrying out ball milling, and then drying; (2) pressing the dried material into blocks, and then calcining to obtain a sintered material; (3) crushing and screening the sintered material; (4) mixing the screened material, then adding an anhydrous binder, mixing evenly, and then placing the mixture into a crucible mold; (5) vibrating to compact the material in the crucible mold, then carrying out cold isostatic pressing, and carrying out compression molding of the material, to obtain a calcium oxide crucible blank; and (6) sintering the calcium oxide crucible blank, to obtain the calcium oxide crucible. The prepared calcium oxide crucible has good thermal shock resistance and relatively high service life, better solves the problems that a conventional calcium oxide crucible is easy to hydrate when the purity is high and has impurities easily introduced to pollute melted metals and alloys when the purity is low, and is widely applied in pure steel and ultra-pure metal smelting.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

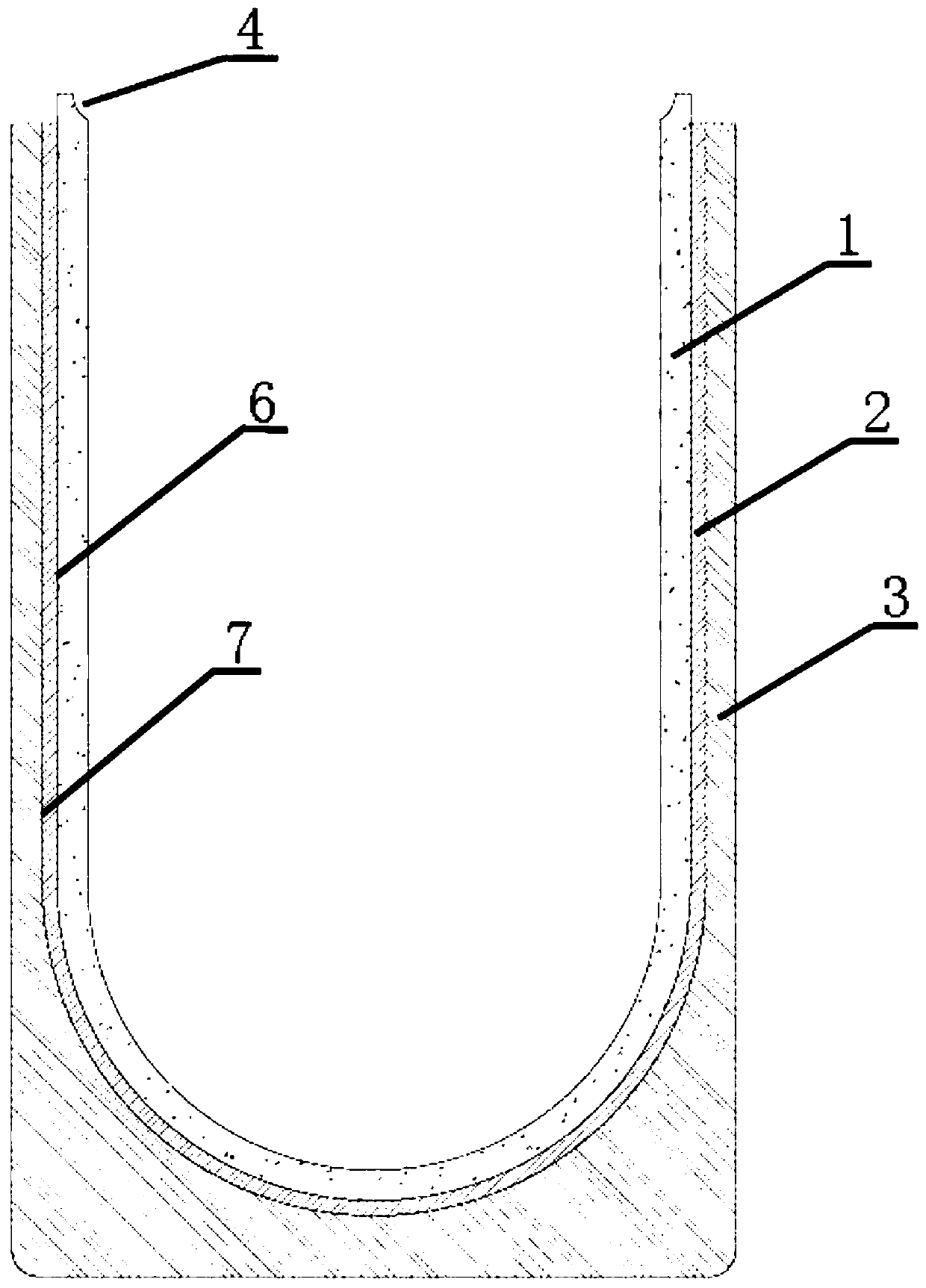

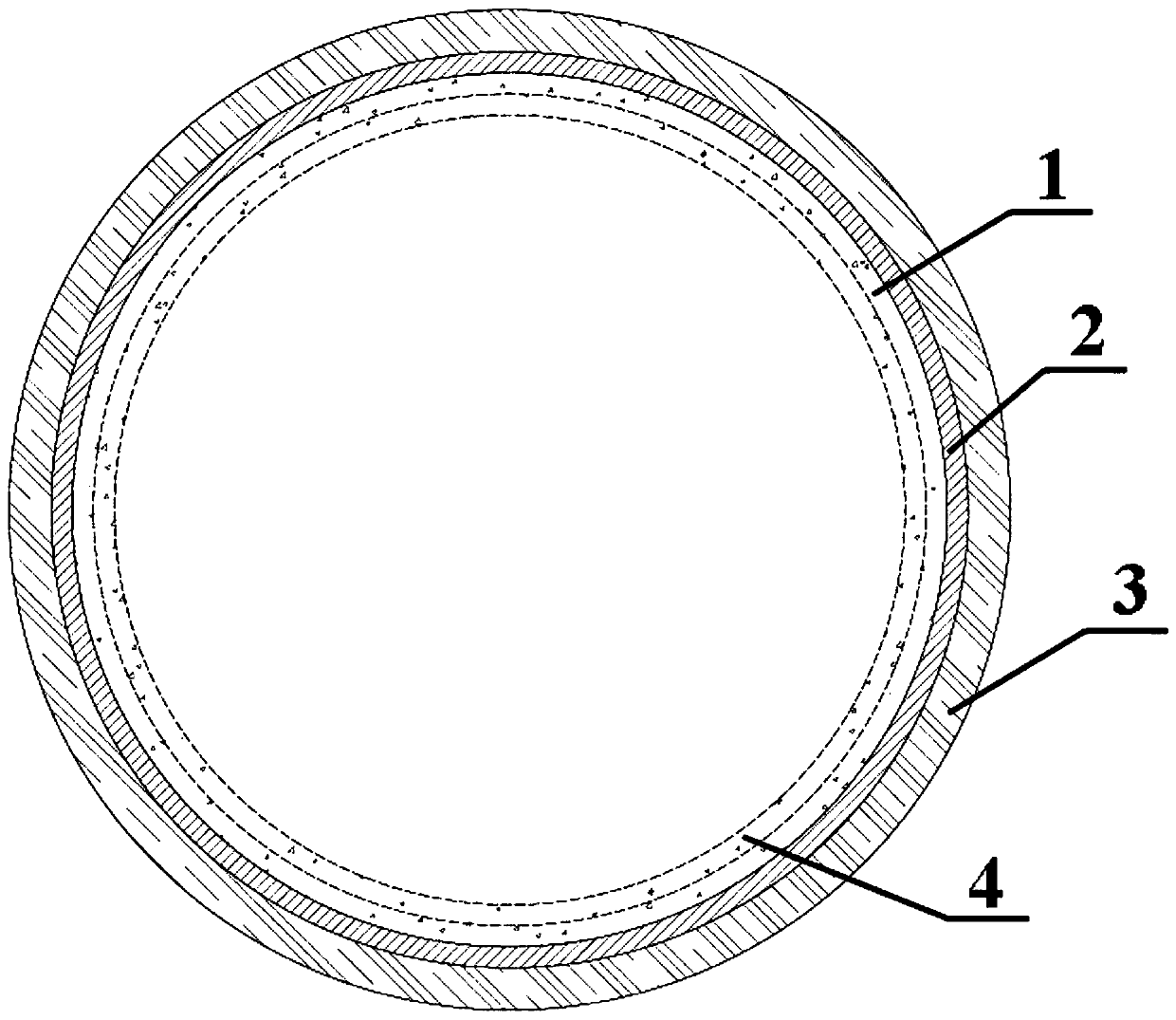

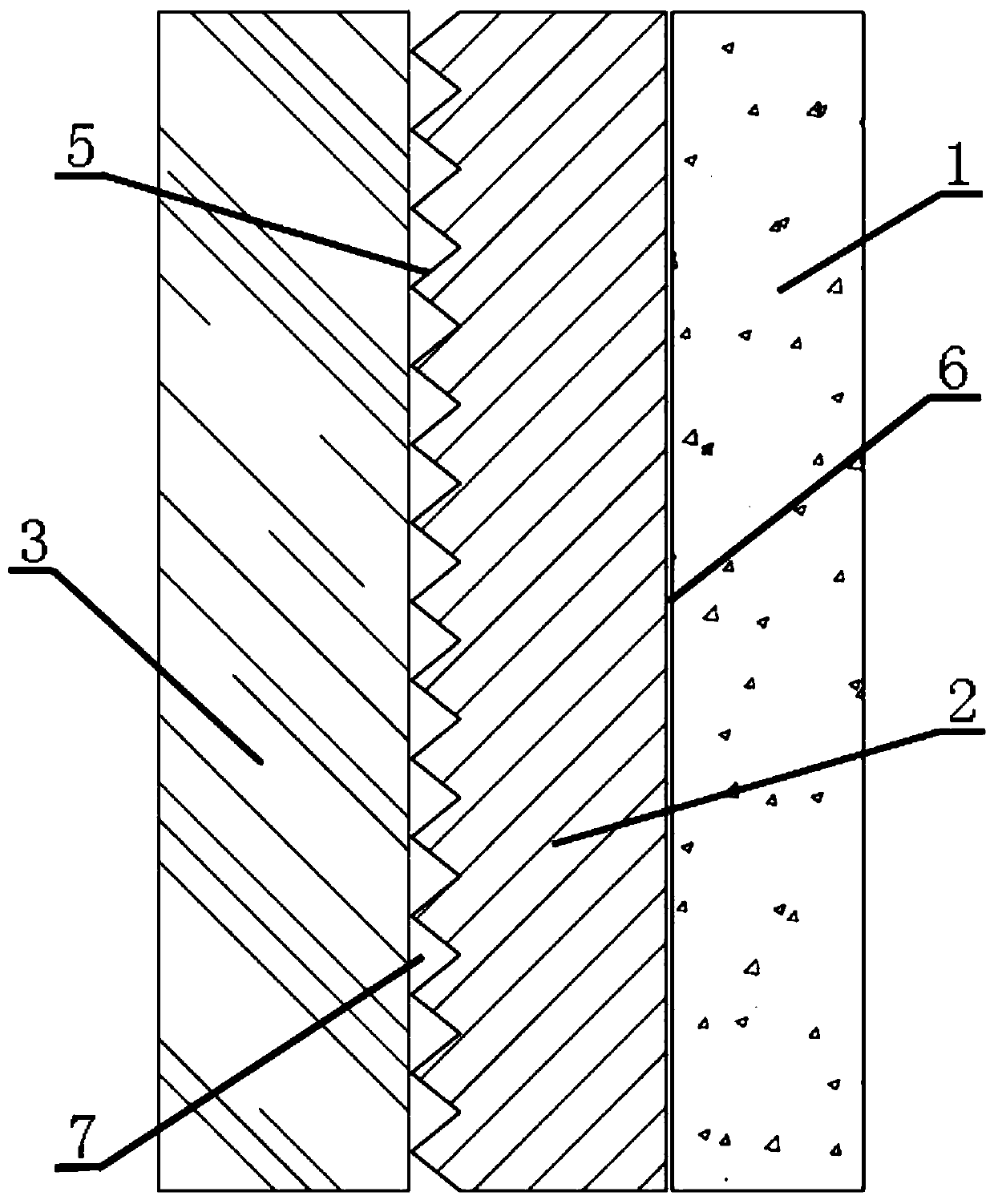

Composite multi-layer crucible for induction melting of bismuth aluminum alloy and preparation method thereof

ActiveCN109824370AImprove structural strengthChemically stableLayered productsCrucibleSmelting process

The invention discloses a composite multi-layer crucible for induction melting of a bismuth aluminum alloy and a preparation method thereof.The problem in the prior art thata crucible suitable for theinduction melting of the bismuth aluminum alloy does not exist is solved. The composite multi-layer crucible comprises an inner layer crucible, a middle layer crucible and an outer layer crucible which are fixedly connected from the inside to the outside; the inner layer crucible is prepared from 92.5-97.5 parts of cerium oxide, 1.0-2 parts of calcium oxide, 0.5-2.0 parts of bismuth oxide and 1.0-3.5 parts of silicon carbide; the middle layer crucible is made of graphite; the outer layer crucible is prepared from 90-95 parts of calcium oxide, 1-3 parts of magnesium oxide, 2-4 parts of ceriumoxide, 1-1.5 parts of zirconiaand 0.5-1.5 parts of clay. The composite multi-layer crucible has a high strength structure, can shield a considerable portion of an induced magnetic field, has stable chemical properties, and has no splashing phenomenon in the smelting process, the degree of oxygenation is low, some single-layer structures can be replaced and can be reused, and the service life is long.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Aluminum electrolytic capacitor applying high hydrous electrolyte and method for making aluminum electrolytic capacitor

InactiveCN102237201AOvercoming High Temperature Hydration ProblemsSolve the problem of glitch-prone short circuitLiquid electrolytic capacitorsCapacitor electrodesMoistureThin sheet

The invention relates to an aluminum electrolytic capacitor applying high hydrous electrolyte and a method for making the aluminum electrolytic capacitor. A capacitor body consists of a positive foil connected with a positive guide needle, a negative foil connected with a negative guide needle and electrolytic paper positioned between the positive foil and the negative foil; a thin sheet is coated on the upper side surface at a tongue position in the negative guide needle and is a pressurized negative foil thin sheet which is made of the negative foil and subjected to voltage processing; and an oxide film is arranged on the surface of the thin sheet. The method for making the aluminum electrolytic capacitor comprises nine steps, namely cutting, connecting by nails, winding, roasting, impregnating, assembling, sleeving pipes, charging and testing. The pressurized negative foil thin sheet which is made of the negative foil and subjected to voltage processing is coated on the upper side surface at the tongue position in the negative guide needle before winding, and the capacitor body after the completion of winding is impregnated in the electrolyte with the moisture content of 5 to 25 percent. The aluminum electrolytic capacitor improves high-temperature stability and frequency characteristic of a product, and is suitable to be used at high temperature of above 100 DEG C.

Owner:王兴久

Preparation method and application method of polyether amine catalyst

The invention relates to the field of polyether amine preparation, in particular to a preparation method and an application method of a catalyst for synthesizing polyether amine. The preparation method of the polyether amine catalyst comprises the following steps: (1) potassium-based montmorillonite is prepared; (2) primary impregnation is carried out, namely, a supported catalyst comprises an active component and an auxiliary agent, a gamma-Al2O3 carrier is loaded with a metal salt solution containing an active component and an auxiliary agent by adopting an isopyknic impregnation method, anddrying and roasting are carried out to obtain a carrier loaded with the metal oxide; (3) secondary impregnation is carried out, namely, an equal amount of an organic amine solution of the potassium-based montmorillonite obtained in the step (1) is added into a metal salt solution for impregnation which is half of the metal salt solution in the step (2), the carrier loaded with the metal oxide obtained in the step (2) is impregnated, and drying and roasting are carried out to obtain a catalyst; and (4) reduction is carried out, namely, the modified carrier loaded with the metal oxide obtainedin the step (3) is put into a rotary furnace, and H2 is introduced for reduction to obtain the polyether amine catalyst.

Owner:ZHEJIANG HUANGMA TECH +3

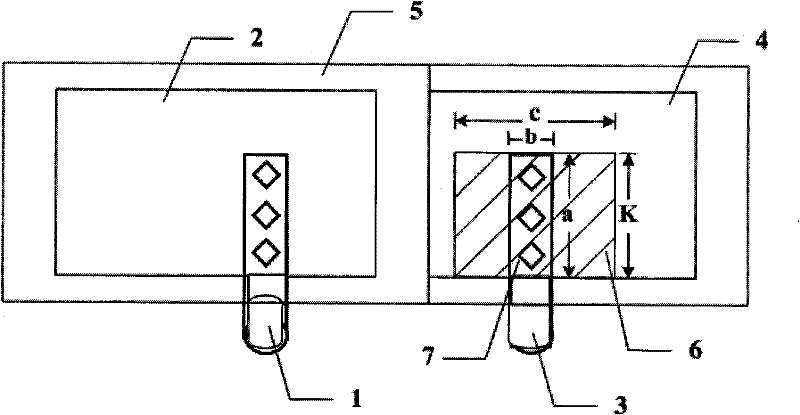

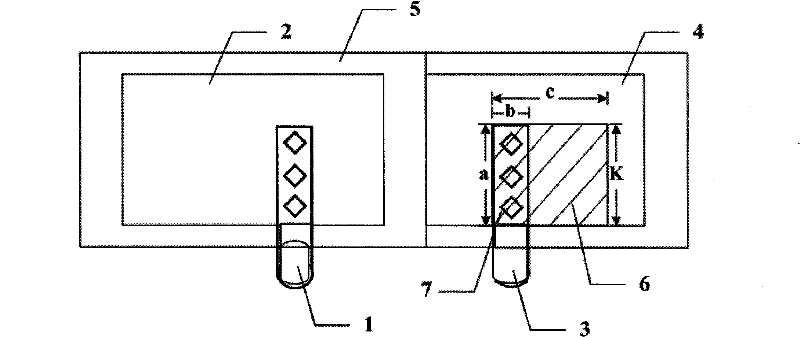

Preparation method of MgO-CaO-ZrO2 sand

The invention relates to a preparation method of MgO-CaO-ZrO2 sand. The preparation method comprises the following steps: carrying out heat treatment on dolomite ore and magnesite ore, hydrating, sieving with a 0.2 mm sieve, drying a filter body obtained by sieving, and grinding to 200 meshes or below to obtain MgO-CaO2 powder; placing MgO-CaO powder and Zr(OH)4 sol in a mixer to be evenly mixed,conducting ball pressing after mixing, and drying till the moisture is smaller than 1%; and finally, placing the mixture in a kiln to be calcined, and obtaining the MgO-CaO-ZrO2 sand. The MgO-CaO-ZrO2sand prepared by the preparation method disclosed by the invention is good in hydration resistance, high in refractoriness, high in thermal stability and strong in alkaline slag corrosion resistance,has a purification effect on molten steel, and is an ideal raw material for preparing high-grade materials such as magnesium-calcium refractory materials and ceramics.

Owner:海城市军刚中档镁砂有限公司

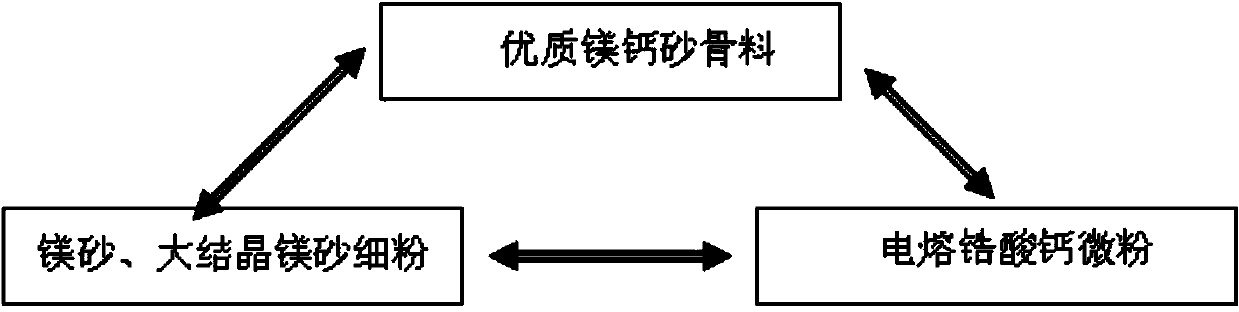

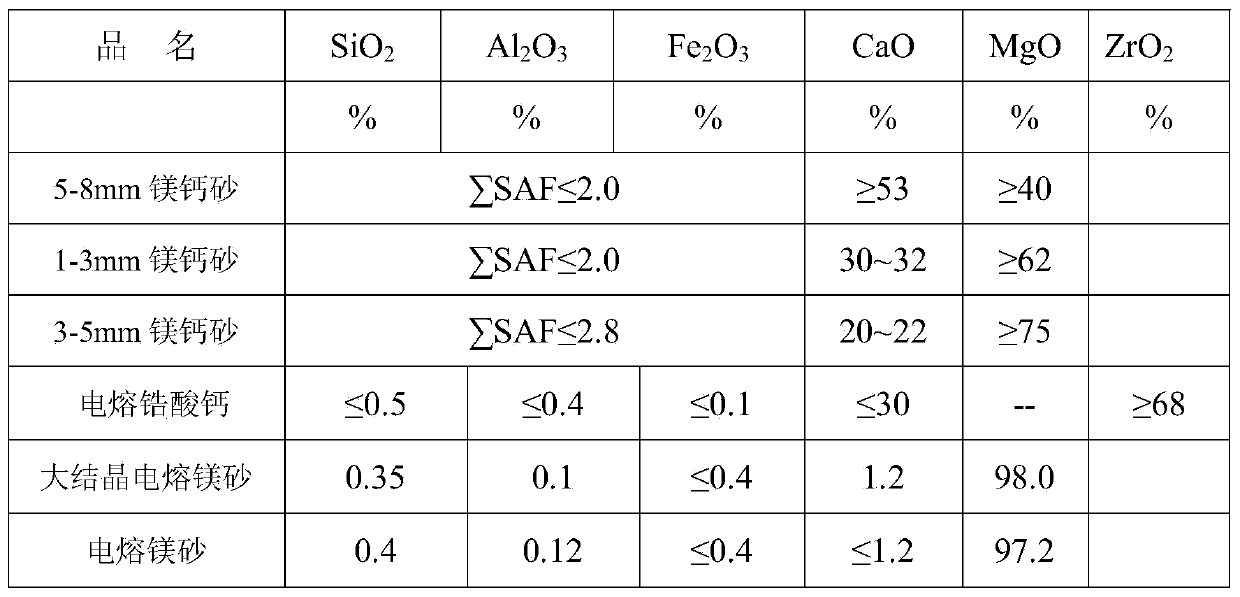

Dolomite-periclase-calcium zirconate composite fireproof material and preparation method thereof

The invention relates to a high-quality dolomite-periclase-calcium zirconate composite fireproof material suitable for smelting stainless steel, special steel AOD furnace and refining ladles. The adopted raw materials mainly comprise, by weight, 8-10% of magnesium calcium sand with a particle size of 5-8 mm, 9-18% of magnesium calcium sand with a particle size of 3-5 mm, 10-22% of magnesium calcium sand with a particle size of 1-3 mm, 5-10% of calcium zirconate with a particle size of 0.5-1 mm, 5-10% of magnesia with a particle size of 0.5-1 mm, 3-10% of 600 mesh electric melting calcium zirconate, 15-24% of magnesia with a particle size of less than or equal to 0.5 mm, 3-10% of 400 mesh 98 large crystal magnesia, 1-3% of a binding agent, and 1-2% of a sintering agent, wherein the raw materials are subjected to mixing, molding, sintering, finished product inspection, package and other steps to prepare the material.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

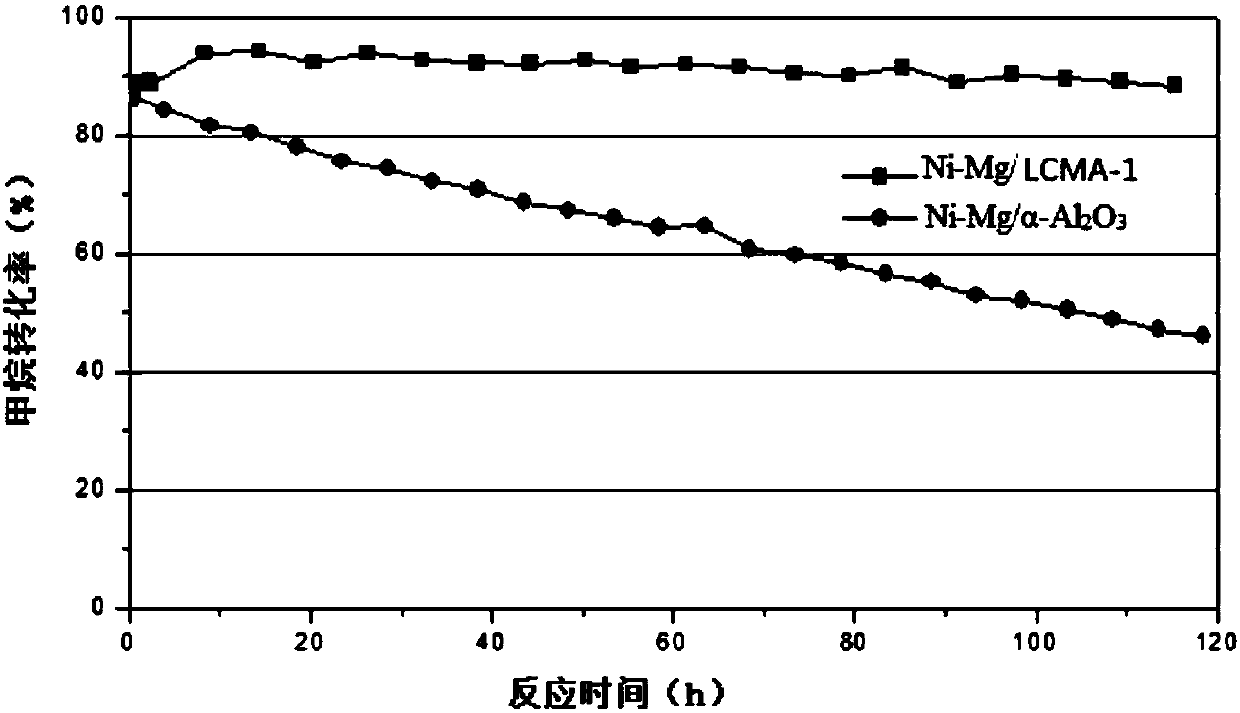

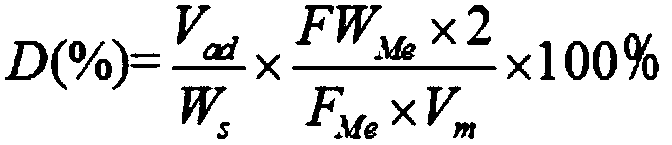

Catalyst carrier, supported catalyst, preparation methods and applications of catalyst carrier and supported catalyst, and method for preparing hydrogen by methane steam reforming

ActiveCN109718865AInhibition formationFacilitated DiffusionCatalyst carriersHydrogenSteam reformingHydrogen

The invention relates to the field of catalyst preparation, and discloses a catalyst carrier, a supported catalyst, preparation methods and applications of the catalyst carrier and the supported catalyst, and a method for preparing hydrogen by methane steam reforming. The carrier comprises La modified aluminum oxide, CaO and MgO, the carrier has pores with pore sizes of larger than 100 nm, and a volume of pores with pore sizes of larger than 100 nm is 75-95% of a total pore volume of the carrier. The carrier provided by the invention has high strength and high hydrothermal stability, and whenthe carrier provided by the invention is adopted to prepare a methane steam reforming catalyst, a dispersion degree of active metals, activity of the catalyst, carbon deposition resistance and structural stability can be significantly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com