Carbon monoxide transformation catalyst carrier, preparation method of the carbon monoxide transformation catalyst carrier, and catalyst based on the carbon monoxide transformation catalyst carrier

A technology for changing catalysts and carbon monoxide, which is applied in the field of coal gasification and can solve problems such as wear, fragmentation, and poor hydration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

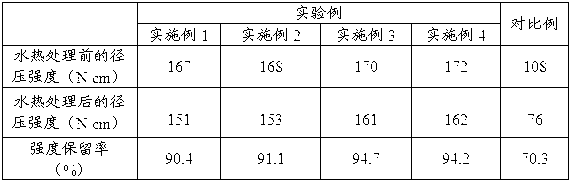

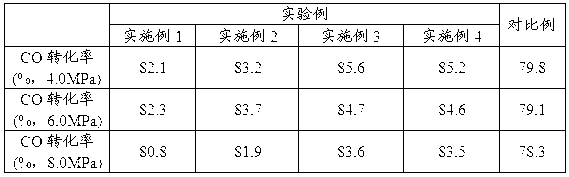

Examples

Embodiment 1

[0039] The carbon monoxide conversion catalyst carrier in this example is prepared from the following raw materials:

[0040] Kaolin powder, 5 parts by weight;

[0041] Aluminum oxide powder, 30 parts by weight;

[0042] Magnesium oxide, 10 parts by weight;

[0043] Wherein said kaolin powder has a particle size of 40 mesh and a specific surface area of 100m 2 / g; the particle size of the alumina powder is 30 mesh.

[0044] The preparation method of the above-mentioned carbon monoxide shift catalyst carrier in this embodiment includes:

[0045] (1) Fully knead the kaolin powder, alumina powder and magnesia in the above parts by weight;

[0046] (2) Extrude the mixture obtained after fully kneading;

[0047] (3) Dry the extruded product obtained in step (2), the drying temperature is 110°C, and the drying time is 120 minutes;

[0048] (4) Roasting the product obtained in step (3), the calcination temperature is 550° C., and the calci...

Embodiment 2

[0051] The carbon monoxide conversion catalyst carrier in this example is prepared from the following raw materials:

[0052] Kaolin powder, 30 parts by weight;

[0053] Aluminum oxide powder, 60 parts by weight;

[0054] Magnesium hydroxide, 40 parts by weight;

[0055] Wherein said kaolin powder has a particle size of 80 mesh and a specific surface area of 140m 2 / g; the particle size of the alumina powder is 40 mesh.

[0056] The preparation method of the above-mentioned carbon monoxide shift catalyst carrier in this embodiment includes:

[0057] (1) Fully knead the kaolin powder, alumina powder and magnesium hydroxide in the above parts by weight;

[0058] (2) Extrude the mixture obtained after fully kneading;

[0059] (3) Dry the extruded product obtained in step (2), the drying temperature is 150°C, and the drying time is 240min;

[0060] (4) Roasting the product obtained in step (3), the calcination temperature is 700° C....

Embodiment 3

[0063] The carbon monoxide conversion catalyst carrier in this example is prepared from the following raw materials:

[0064] Kaolin powder, 5 parts by weight;

[0065] Aluminum oxide powder, 30 parts by weight;

[0066] Magnesium oxide, 10 parts by weight.

[0067] Peptizer, 3 parts by weight;

[0068] Pore-forming agent, 1 part by weight;

[0069] Extrusion aid, 2 parts by weight;

[0070] Adhesive, 1 part by weight.

[0071] Wherein said kaolin powder has a particle size of 50 mesh and a specific surface area of 120m 2 / g; the particle size of the alumina powder is 120 mesh. The peptizing agent is nitric acid; the pore-forming agent is oxalic acid; the extrusion aid is squash powder; and the binder is cement.

[0072] The preparation method of the above-mentioned carbon monoxide shift catalyst carrier in this embodiment includes:

[0073] (1) Fully knead the kaolin powder, alumina powder and ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com