Patents

Literature

116results about How to "Improve structural compactness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength lightweight aggregate concrete and preparation method thereof

The invention relates to high-strength lightweight aggregate concrete and a preparation method thereof, and belongs to the technical field of building material concrete. The lightweight aggregate concrete is prepared from the following raw materials in parts by weight: 105-118 parts of cement, 180-185 parts of light coarse aggregate, 120-125 parts of fine aggregate, 65-70 parts of mineral admixtures, 9-24 parts of modified polypropylene fiber, 3.4-3.8 parts of concrete admixtures and 65-70 parts of water. The preparation method comprises the following steps that the raw materials are weighed according to the formula ratio, the light coarse aggregate is added into water accounting for one half of the total water amount for pre-wetting for 45-60 minutes, then the fine aggregate is added, stirring is carried out for 1-2 minutes, the cement, the mineral admixtures and the modified polypropylene fiber are continuously added, uniform stirring is carried out, then the concrete admixtures andthe rest water are added, and uniform stirring is carried out so as to obtain the high-strength lightweight aggregate concrete. The high-strength lightweight aggregate concrete and the preparation method thereof have the advantages that the strength is high, and the quality is stable.

Owner:武汉中阳明建材有限公司

Pouring material for manufacturing pellet ore rotary kiln and manufacturing method thereof

The invention relates to a casting material used for producing pellet rotary kiln and a preparation method thereof, the casting material is a combination, and contained components and weight percentage occupied in the combination contain: 70 to 92 percent of casting material basal body, 3 to 8 percent of micro powder of monox or micro powder of alumina, 0.001 to 5 percent of zirconium mullite or zirconite, 1 to 12 percent of carborundum, 0.005 to 5 percent calcium aluminate cement and 0.01 to 1 percent of dispersant; the casting material basal body is the combination of one or several of corundum, bauxite and porzite. The preparation method of the casting material has the following steps: first uniformly mixing the casting material basal body, then adding other components to be uniformly mixed, and finishing goods. The casting material contains the carborundum, the carborundum has the characteristic of difficult infiltration with furnace burden containing iron, and ring formation materials are difficult to be felted on a furnace brick lining; in addition, the carborundum can increase acidic furnace burden anti-corrosion performance of the casting material, and thus the life of the rotary kiln is enhanced. The preparation method of the casting material is simple and has low cost.

Owner:武钢集团有限公司

Flame-proof mending material for foundry ladle and manufacturing method thereof

The invention relates to a fire proof patching material used for foundry ladle and a preparation method thereof, the fire proof patching material is a combination, and the contained components and weight percentage occupied in the combination contain: 55 to 90 percent of patching material basal body, 1 to 35 percent of carborundum, 3 to 15 percent of monox micro powder or / and alumina micro powder, 0.5 to 15 percent of calcium aluminate cement, 0.01 to 3 percent of trimeric sodium phosphate or sodium hexametahposphate and 0.001 to 2 percent of sodium cellulose or sodium alginate; the patching material basal body is the combination of one or several corundum, bauxite and flint clay. The preparation method has the following steps: first uniformly mixing the patching material basal body, then adding other components to be uniformly mixed, and finishing goods. The fire proof patching material contains the carborundum, the carborundum has the characteristic of anti-corrosion to low-melting-point materials of fluorite, lime, soda, and the like, makes anti-corrosion performance of the patching material be enhanced, makes the patching material be not easy to be peeled off, and makes the life of the foundry ladle be enhanced. The preparation method of the fire proof patching material is simple and has low cost.

Owner:武钢集团有限公司

Heat resistant anticorrosive composite polyphenylene sulfide epoxy paint and its prepn

InactiveCN1887996AImprove physicsGood chemical propertiesInorganic pigment treatmentAnti-corrosive paintsEpoxyHigh intensity

The present invention discloses one kind of heat resistant anticorrosive composite polyphenylene sulfide epoxy paint and its preparation process. The anticorrosive paint consists of primer, finishing paint and intercoat paint. The primer consists of polyphenylene sulfide, epoxy resin, glass scale and cyanamide dimmer. The finishing paint consists of polyphenylene sulfide, epoxy resin, silicon carbide, 4, 4'-diamino diphenyl sulphone and cyanamide dimmer. The intercoat paint consists of polyphenylene sulfide, epoxy resin, silicon carbide, glass scale, dihydrazide sebacate and 4, 4'-diamino diphenyl sulphone. The anticorrosive paint produces no sag, and can form homogeneous and smooth coating with excellent physical and chemical performance, high heat resistance, high corrosion resistance, high impact strength, and high insulating performance.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Preparation method of high-nickel positive electrode material for lithium ion battery

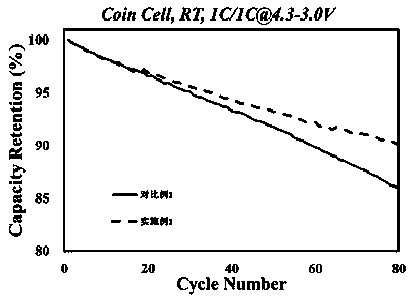

InactiveCN109461895AImprove structural compactnessGood crystallinityCell electrodesSecondary cellsTemperature cyclingStructural stability

The invention belongs to the technical field of lithium ion battery materials, and discloses a preparation method of a high-nickel positive electrode material for a lithium ion battery. The preparation method provided by the invention comprises the following steps: (1) preparing salt, alkali and complexing agent solutions; (2) adding the salt, alkali and complexing agent solutions to a reaction kettle in a cocurrent flow for reaction; (3) cleaning and drying to obtain a required precursor; (4) mixing the precursor with a lithium source and sintering at a time; (5) cleaning with a special washing liquid, filtering and rinsing; and (6) coating and returning to sinter to obtain the high-nickel positive electrode material for the lithium ion battery. According to the method provided by the invention, the high-nickel positive electrode material is first cleaned in the special washing liquid, a coating compound is mixed, and then an oxygen is used for sintering to disperse lithium inside thematerial uniformly; with such a method, while residual alkali on a surface of the material can be cleaned, the separation of internal lattice lithium is reduced, and the stability of an internal structure of the material is increased; and thus, the room-temperature and high-temperature cycling stability of the high-nickel material is improved.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

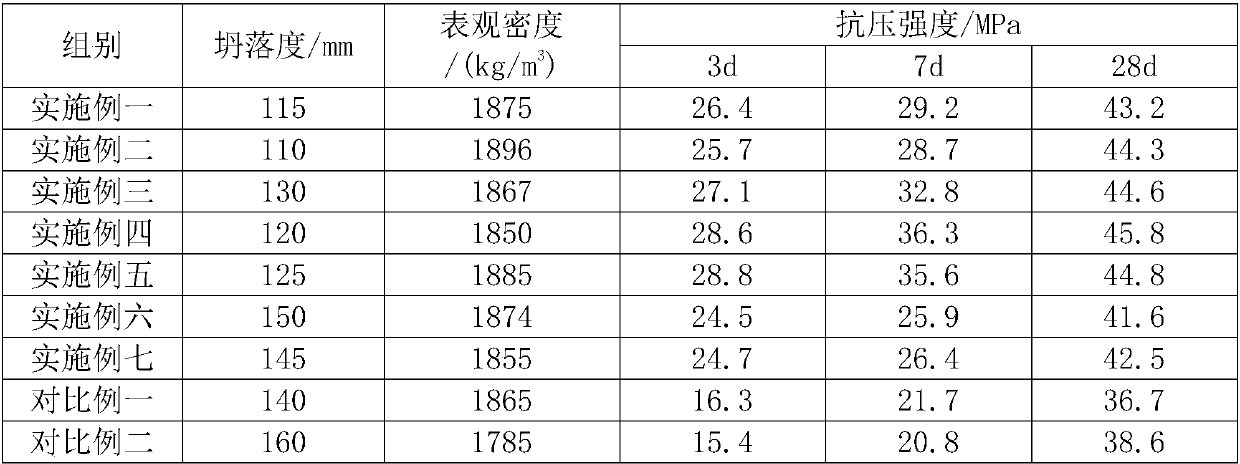

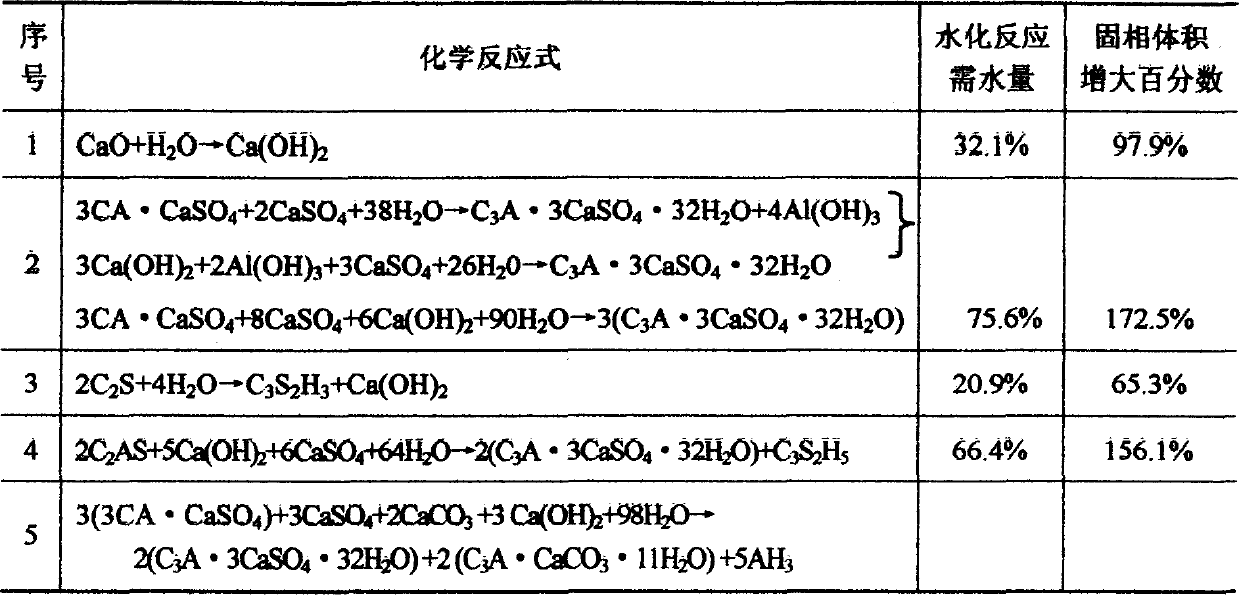

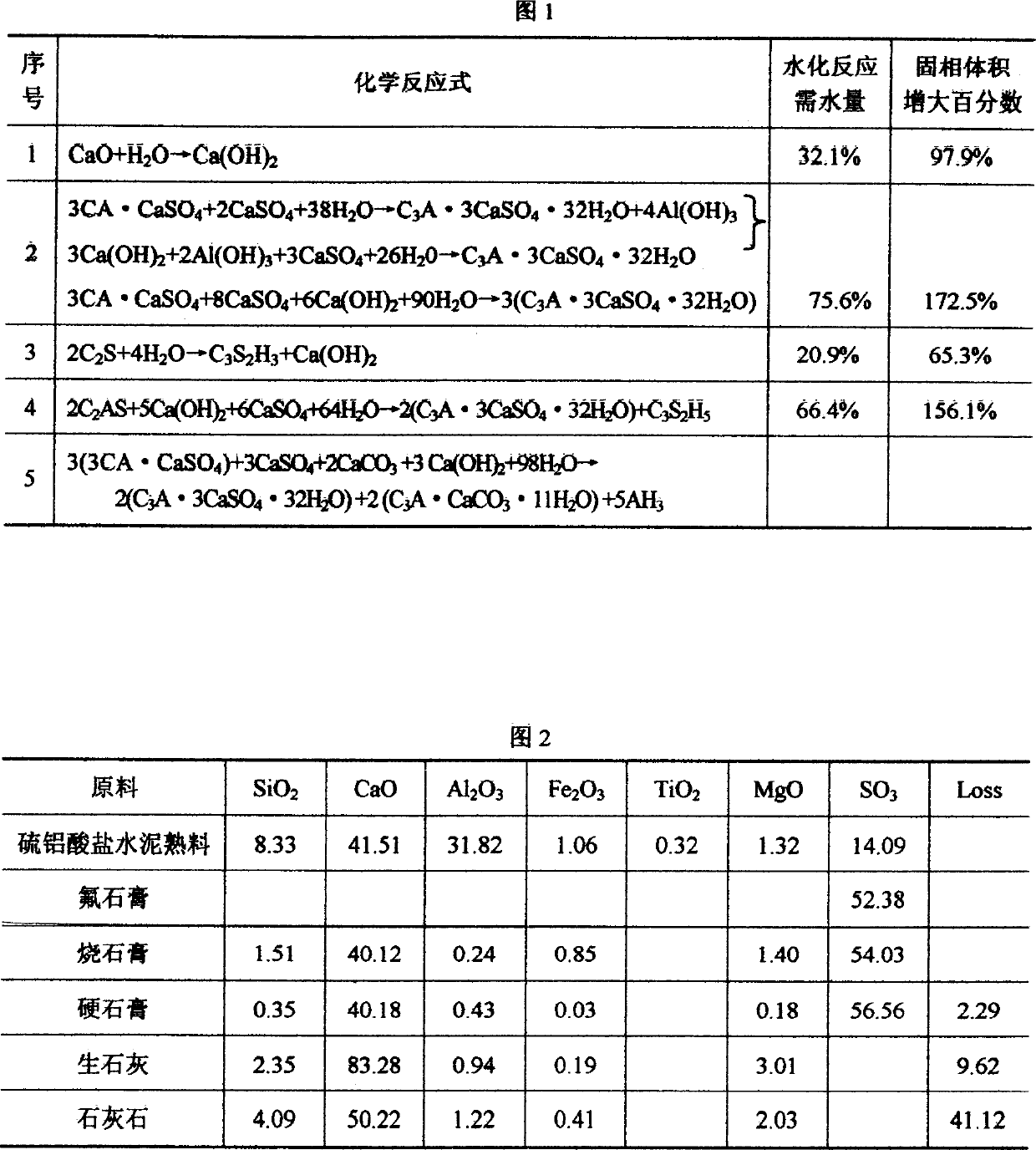

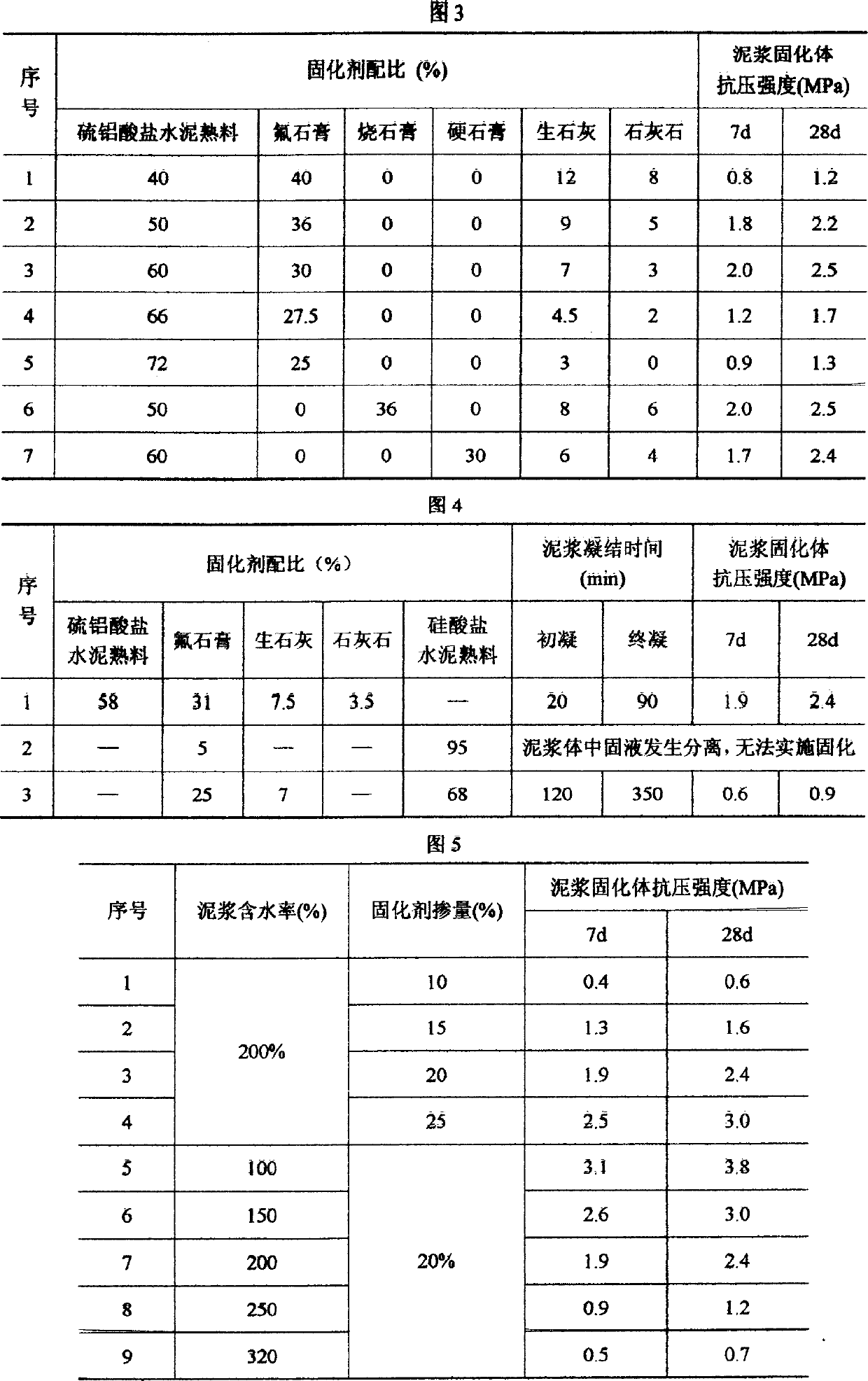

Silt curing agent and production method thereof

InactiveCN103708705AImprove structural compactnessImprove adhesionSludge treatment by de-watering/drying/thickeningBuilding productSludge

The invention discloses a silt curing agent and a production method thereof. The silt curing agent comprises the following components according to the following ratios: 18-20 parts of fluorite, 20-23 parts of sodium carbonate, 7-9 parts of quartz sand, 40-50 parts of gypsum, 10-12 parts of quick lime, and 6-8 parts of limestone. The silt curing agent disclosed by the invention can be used in the curing of silt or sludge with high water content from a sewage treatment plant, produced in industrial production or natural environment, and is also applicable to rapid setting and rapid hardening of cement slurry, high in curing strength, not easy to crack and good in strength durability, and the cured silt or cement is applicable to the machining of building products or directly used as a building material of civil engineering such as roads, dams and the like, thus being energy-saving and environment-friendly. Moreover, in the curing process of the sludge, certain volume expansion also can be generated, thus being conducive to the improvement of structure compactibility of the building products.

Owner:NANJING FORTUNE RECYCLING TECH

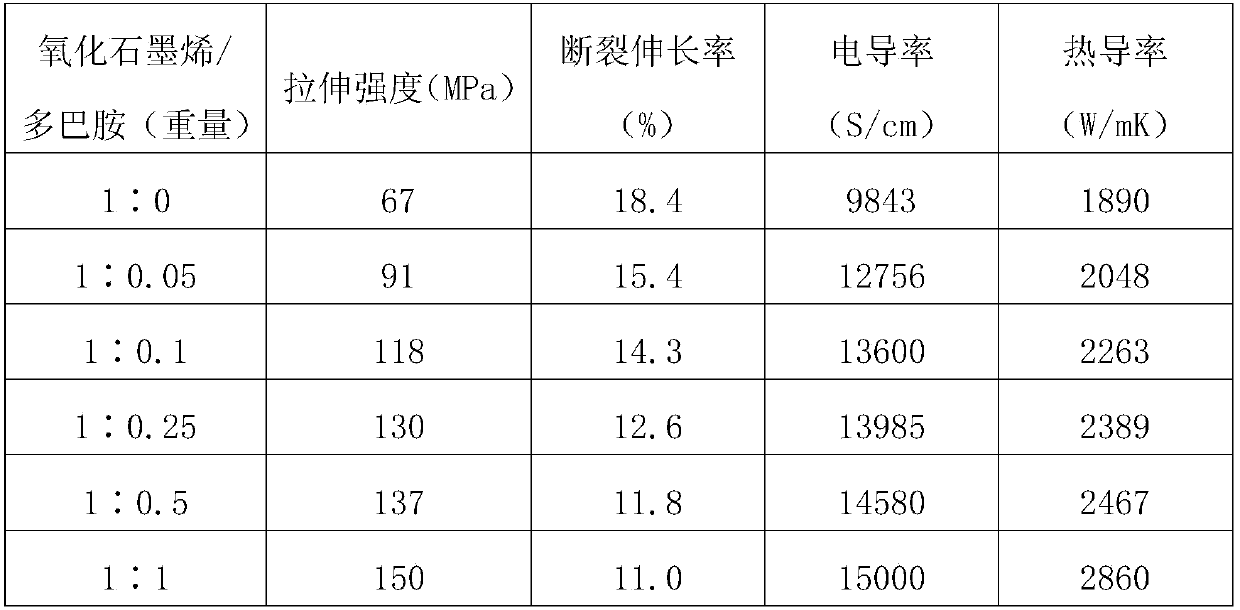

Thermal conductive graphene thin film and preparation method thereof

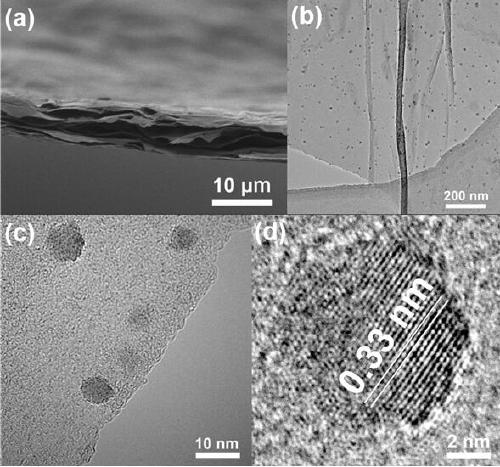

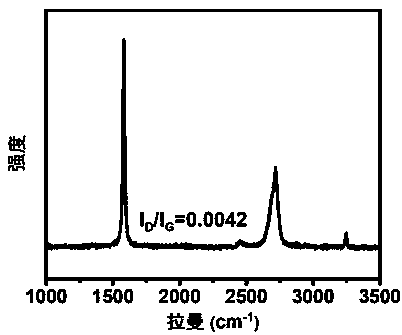

ActiveCN109627004AGood orientationReduce defectsConductive layers on insulating-supportsCarbon compoundsArgon atmosphereMechanical property

The invention discloses a thermal conductive graphene thin film and a preparation method thereof. The thermal conductive graphene thin film is made by blending a dopamine hydrochloride-Tris buffer solution and a graphene solution, the thin film is formed by stacking graphene sheets, carbon nanoparticles formed after polydopamine is carbonized are uniformly distributed in the graphene sheets and between the sheets, and the graphene sheets and the carbon nanoparticles are crosslinked together. The preparation method comprises the steps that a prepared graphene oxide water solution is mixed witha dopamine hydrochloride-Tris buffer solution, a graphene oxide-polydopamine water solution is taken for preparing the thin film through vacuum assistance, reduction is conducted by means of a reducing agent, the thin film obtained after reduction is heated to 800-1,000 DEG C for heat preservation under the argon atmosphere, then heating is conducted to 2,800-3,000 DEG C for heat preservation, cooling is conducted naturally to reach room temperature, and mechanical mold pressing is conducted on the graphitized graphene thin film. The thermal conductive graphene thin film has the high mechanical property and high thermal conductivity.

Owner:CHONGQING UNIV

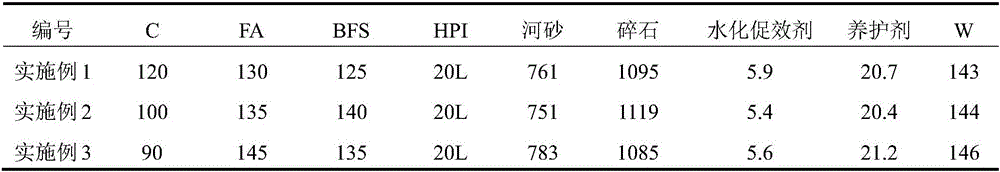

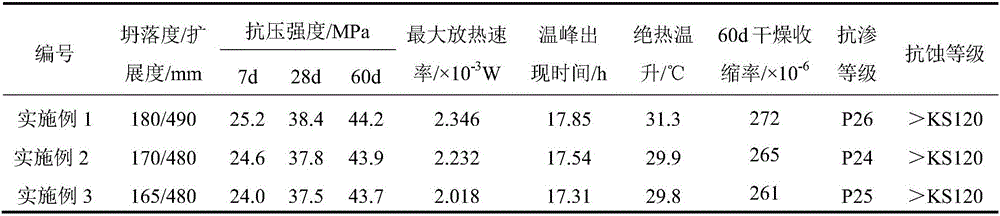

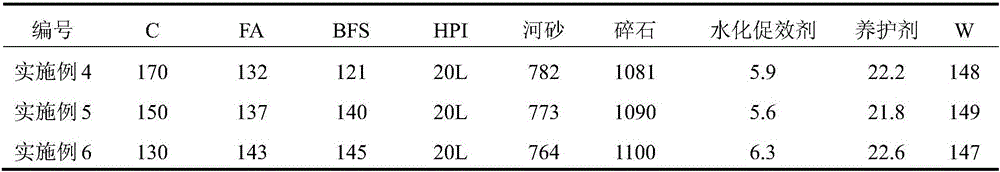

Low-temperature-rise anti-corrosion maritime mass concrete and preparation method thereof

ActiveCN106747088AEffective dispersionFully stimulate the activityHydration reactionAdditive ingredient

The invention discloses low-temperature-rise anti-corrosion maritime mass concrete. The low-temperature-rise anti-corrosion maritime mass concrete is prepared from cement, coal ash, mineral powder, broken stones, river sand, a hydrophobic pore-blocking ingredient (HPI), a hydration promotional reagent, an efficient slow-release water curing agent and water in a certain ratio. The low-temperature-rise anti-corrosion maritime mass concrete disclosed by the invention has the advantages that a disperse group of the hydration promotional reagent is utilized for fully dispersing gel material particles, the hydration rate and utilization rate of the gel material particles are effectively improved, the cement usage amount is reduced by about 10%, hydration adiabatic temperature rise of the mass concrete is lowered, production of temperature cracks is avoided, and the durability is improved; and the efficient slow-release water curing agent with water retention, water release and controllable and delayed expansion properties is adopted, so that the interior humidity of the concrete is guaranteed, and volume shrinkage deformation produced by cementitious paste hydration reaction in the concrete is compensated. The obtained maritime mass concrete has low temperature rise, low shrinkage, high anti-permeability and corrosion resisting properties and has important practical application values.

Owner:WUHAN UNIV OF TECH +1

Modified cement and application thereof

InactiveCN103130467APromotes hydrationImprove the resistance to electrochemical corrosionSlagWater reducer

The invention relates to modified cement and application thereof, belonging to the field of preparation of construction materials. The modified cement is characterized in that the modified cement comprises a cementing material and an additive, wherein the cementing material is composed of normal cement and slag micropowder, and the slag micropowder accounts for 40-60% of the total weight of the cementing material; and additive is composed of nano clay particles and a water reducing agent, the weight of the nano clay particles is 1% of the total weight of the cementing material, and the weight of the water reducing agent is 1.5-2% of the total weight of the cementing material. According to the invention, heavily-doped slag micropowder high-performance concrete is prepared by selecting materials as required according to the mixture ratio, the electrochemical etching resistance of the concrete can be obviously enhanced, the impermeability can be enhanced by 40-60%, the freezing resistance can be enhanced by more than 30%, the steel bar rust resistance can be enhanced 2-4 times, and the service life of a concrete structure can be prolonged 3-4 times.

Owner:DALIAN MARITIME UNIVERSITY

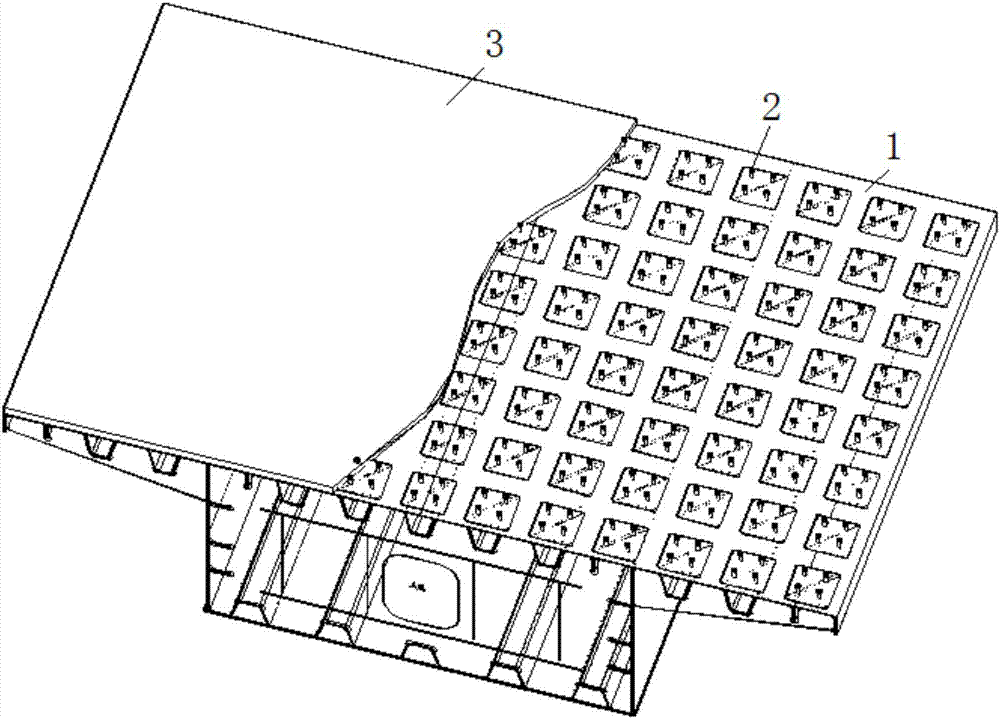

Composite steel fiber-concrete steel bridge deck based on cohesive cotter groups

ActiveCN107237259AHigh compressive strengthHas tensile strengthBridge structural detailsBridge deckHigh pressure

The invention provides a composite steel fiber-concrete steel bridge deck based on cohesive cotter groups. The preparation method comprises the following steps that 1, cleaning and shot blasting are conducted on the cover plate of the steel bridge deck by means of a high-pressure air gun; 2, cotter connecting components are arranged on the cover plate of the steel bridge deck in a bonding mode; 3, a fiber-concrete pavement layer is casted on the cover plate of the steel bridge deck with the cohesive cotter groups and the cotter connecting components in situ. By means of the composite steel fiber-concrete steel bridge deck based on the cohesive cotter groups, the structure stiffness can be improved, the stress amplitude of a fatigue detail place is reduced, and long service life design of an orthotropic steel bridge deck is achieved.

Owner:CHANGAN UNIV

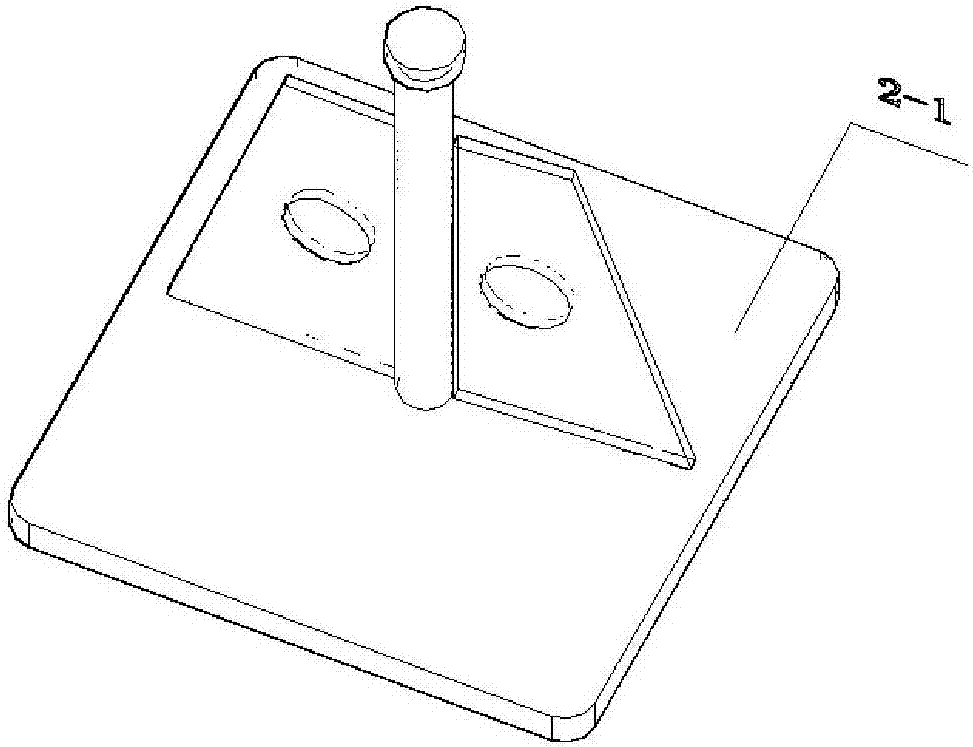

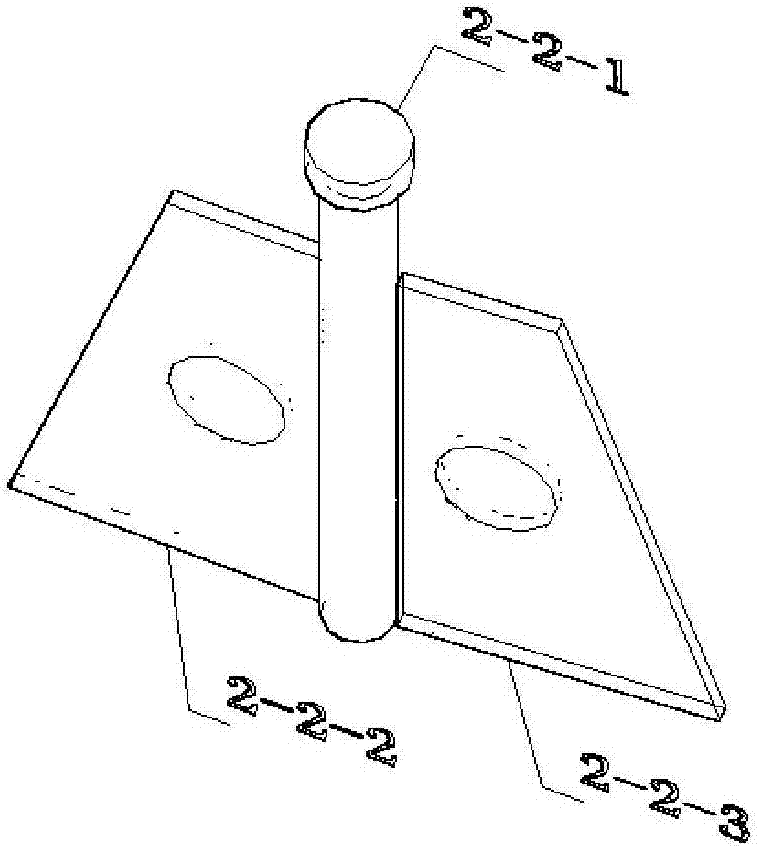

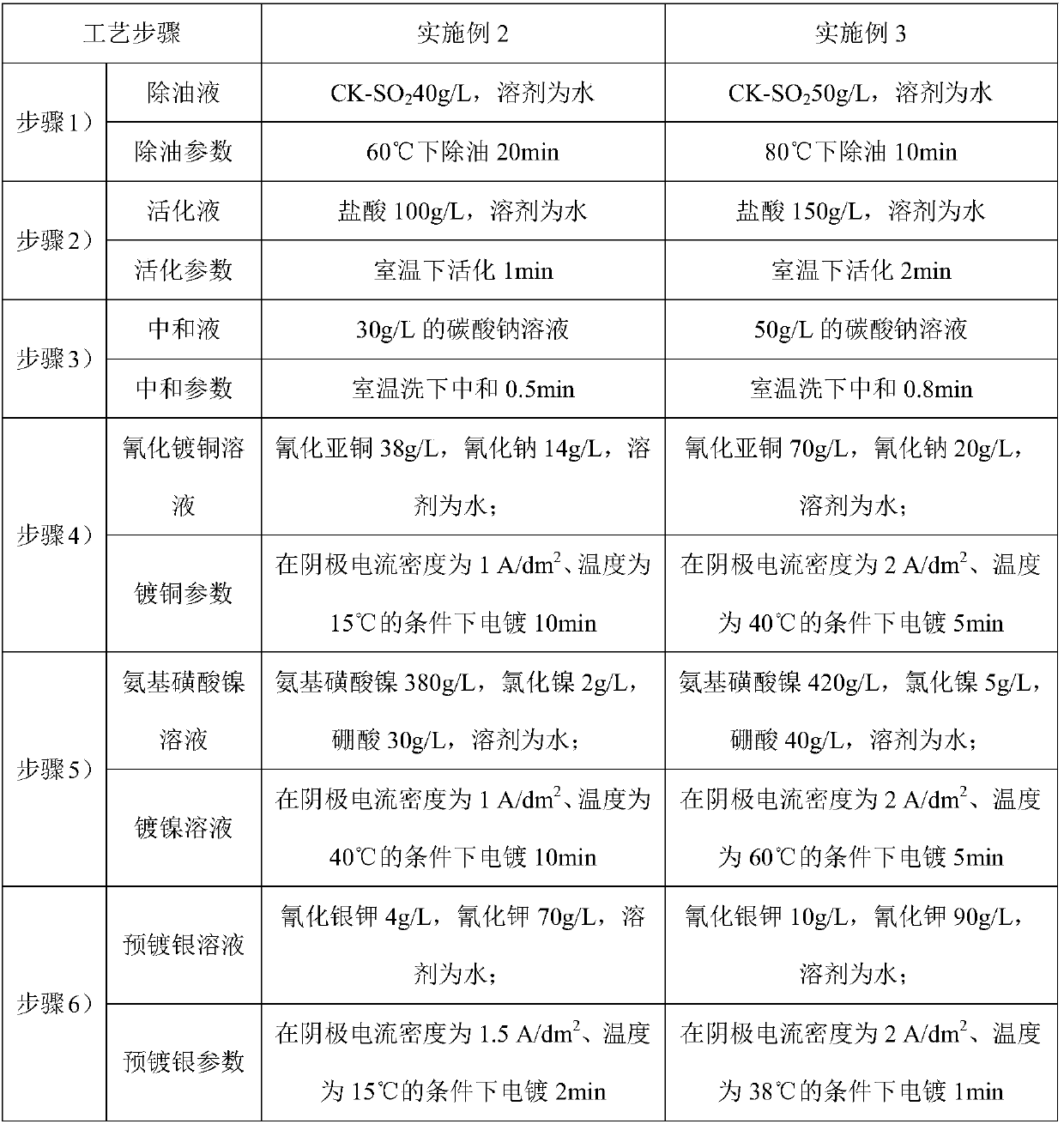

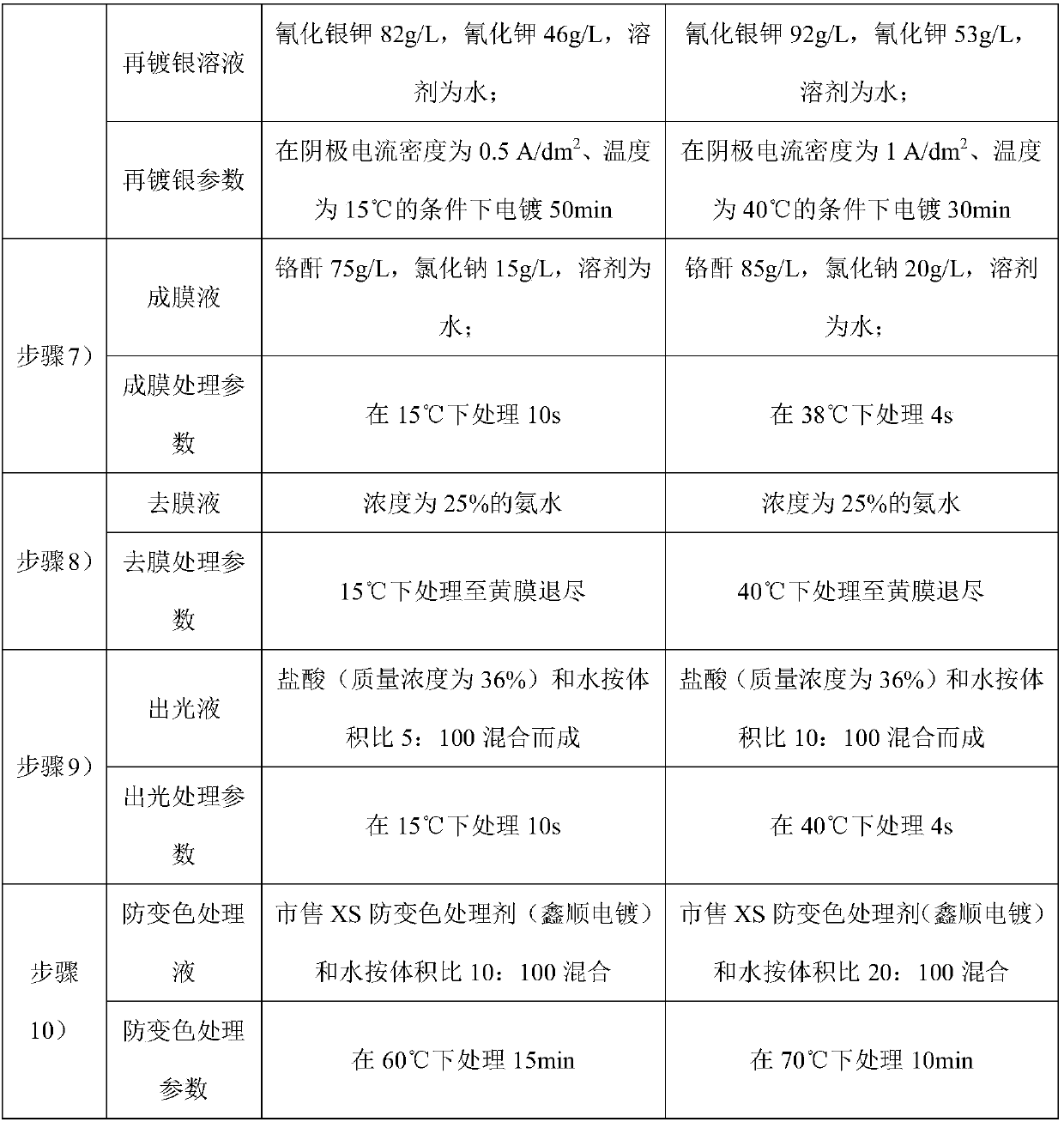

Alloy steel electrosilvering product and preparation method thereof

InactiveCN107620098AImprove bindingImprove high temperature binding forceCopper coatingSilver coating

The invention relates to an alloy steel electrosilvering product and a preparation method thereof. The alloy steel electrosilvering product comprises an alloy steel base body, a copper coating, a nickel coating and a silver coating, wherein the copper coating, the nickel coating and the silver coating are sequentially electroplated on the alloy steel base body from inside to outside. According tothe alloy steel electrosilvering product, the copper coating is used as a base layer, the structure compactness of the copper coating is good, the base layer can be effectively prevented from rusting,and the binding force of the base layer is improved; and the nickel coating is used as a middle layer, nickel cannot form weak eutectic with copper and silver on an interface, the compactness of theoverall coatings can be improved through interdiffusion of nickel and copper and interdiffusion of nickel and silver, the internal stress of the coatings is reduced, and thus the high-temperature binding force of the alloy steel electrosilvering product is improved. A thermal shock test below 550 DEG C shows that the alloy steel electrosilvering product has excellent high-temperature binding forceand can meet the use requirements under high-temperature environments.

Owner:河南航天精工制造有限公司

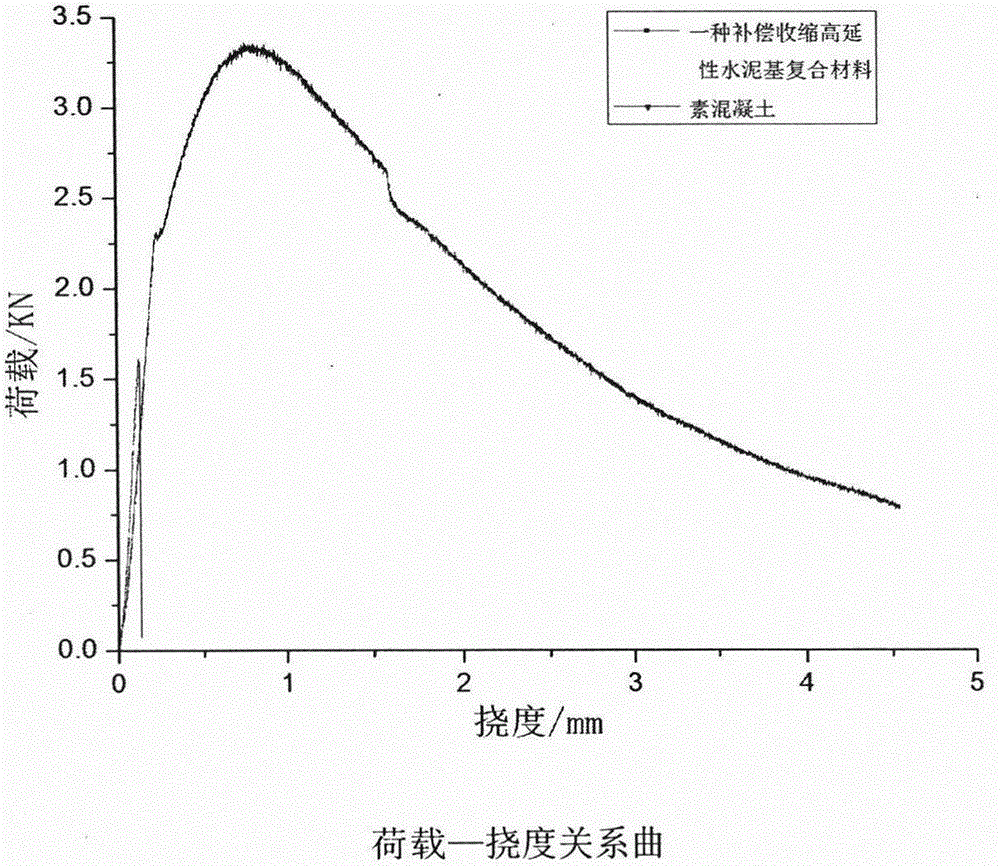

Shrinkage-compensating and high-ductility cement-based composite material

InactiveCN106477992AImproved durability and internal pore structureImproved shrinkage resistance and impermeabilityClimate change adaptationDuctilityExpansion joint

The invention discloses a shrinkage-compensating and high-ductility cement-based composite material. The shrinkage-compensating and high-ductility cement-based composite material is characterized by mainly being prepared from cement, composite mineral admixture, artificially grading sand with specific particle size, large-volume mixing fibers, additives and mixing water. When the shrinkage-compensating and high-ductility cement-based composite material is used, different fiber varieties are used according to actual projects, and the raw material proportion of the composite material is regulated through an adaptation experiment at the same time. By the method, the composite material is low in shrinkage and high in ductility and applicable to various complex load-bearing structures such as expansion joints, wet joints, bridge deck pavement and tunnel lining in traffic engineering.

Owner:黄志义

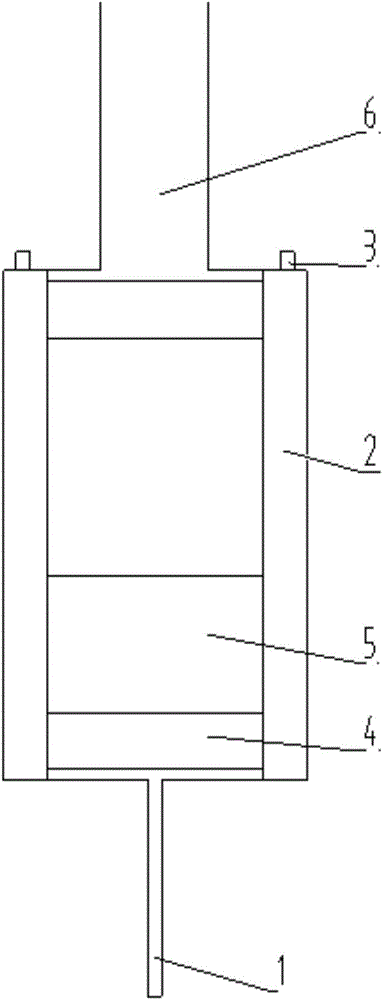

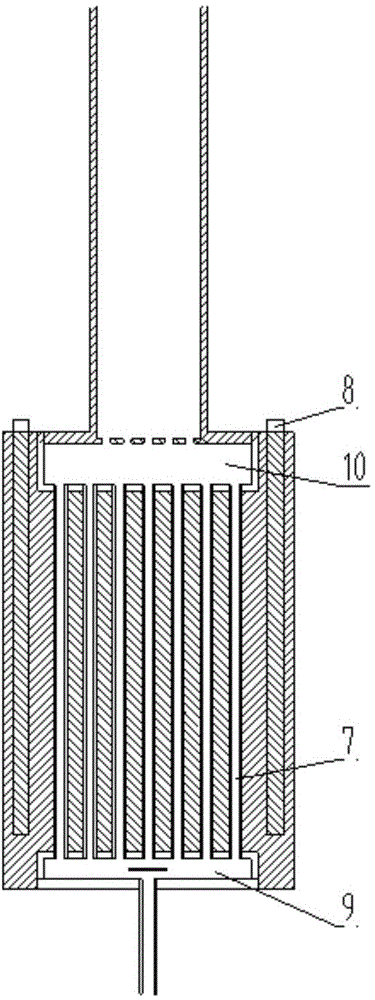

Liquid vaporizer adopting cast aluminium heating body

InactiveCN105222110AIncrease heat conduction areaFast heat conductionSteam generation heating methodsSteam boilersElectric heatingAluminium

The invention discloses a liquid vaporizer heating by adopting a cast aluminium heating body. The liquid vaporizer comprises a liquid storage cavity, a gas storage cavity and the cast aluminium heating body, wherein electric heating rods or electric heating wires are arranged in the cast aluminium heating body; the liquid storage cavity is formed in the lower part of the cast aluminium heating body, the gas storage cavity is formed in the upper part of the cast aluminium heating body, and the liquid storage cavity is connected with the gas storage cavity through more than one guide tube; and the liquid storage cavity, the gas storage cavity and the guide tube are all arranged in the cast aluminium heating body, and the cast aluminium heating body is formed by aluminium melting and casting. Because the electric heating rods of the vaporizer disclosed by the invention are integrally cast with a cast aluminium shell, the heat conduction area is large, the heat conduction of the electric heating rods can be accelerated, and the heat exchange efficiency is increased.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

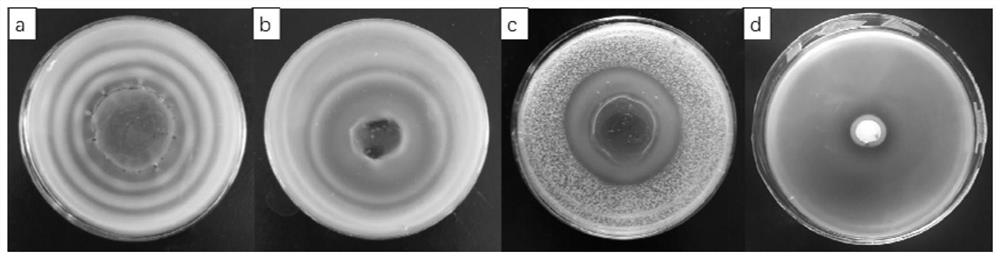

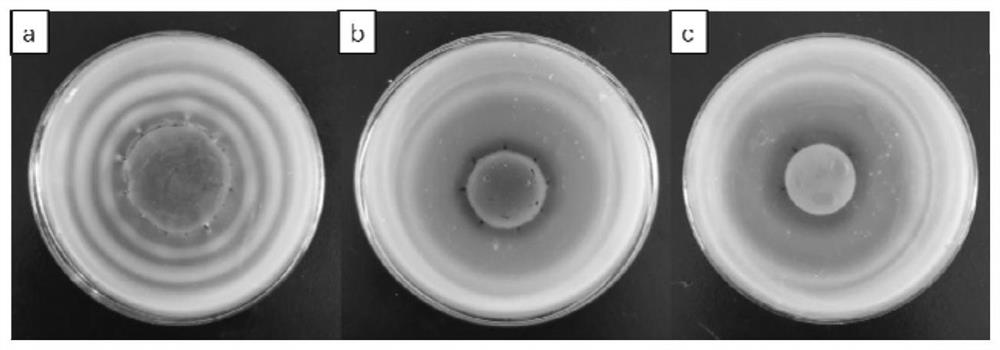

Preparation method of edible antibacterial film

The invention discloses a preparation method of an edible antibacterial film. The method comprises the following steps of: taking starch and chitosan as film-forming materials and nano ZnO as an additive, dissolving chitosan in an L-malic acid solution, adding a plasticizer to obtain a chitosan solution, dissolving starch in water, adding the plasticizer, performing gelatinizing in a water bath toobtain a starch solution, performing cooling, then performing mixing with the chitosan solution uniformly, adding nano ZnO, and carrying out high-speed shearing and mixing, conducting ultrasonic defoaming, coating a polytetrafluoroethylene mold with the mixed solution, and performing drying to form a film, thus obtaining the edible antibacterial film. The edible antibacterial film prepared by theinvention has excellent antibacterial performance and can be widely applied to the field of fresh keeping of fruits, vegetables, meat products, fresh milk and the like.

Owner:NANJING UNIV OF SCI & TECH

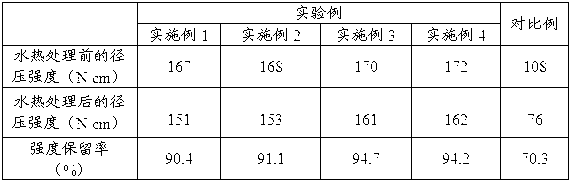

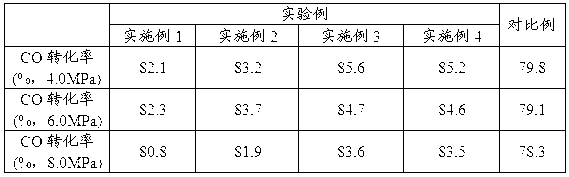

Carbon monoxide transformation catalyst carrier, preparation method of the carbon monoxide transformation catalyst carrier, and catalyst based on the carbon monoxide transformation catalyst carrier

ActiveCN103127959AIncrease conversion rateImproves hydration resistanceHydrogenCatalyst carriersPtru catalystCalcination

The invention provides a carbon monoxide transformation catalyst carrier for a high pressure technology. The carbon monoxide transformation catalyst carrier is prepared from 5 to 30 parts by weight of kaolin powder, 30 to 60 parts by weight of alumina powder and 10 to 40 parts by weight of magnesium oxide or magnesium hydroxide. Through utilization of kaolin powder, alumina powder and magnesium oxide or magnesium hydroxide having a certain ratio as raw materials, magnesium aluminate spinel structure compactness is effectively improved without increasing of a calcination temperature so that catalyst hydration resistance is improved; hydration under working conditions is avoided; high catalyst strength is kept in use; and crushing and wearing phenomenon is avoided.

Owner:FUZHOU UNIV +1

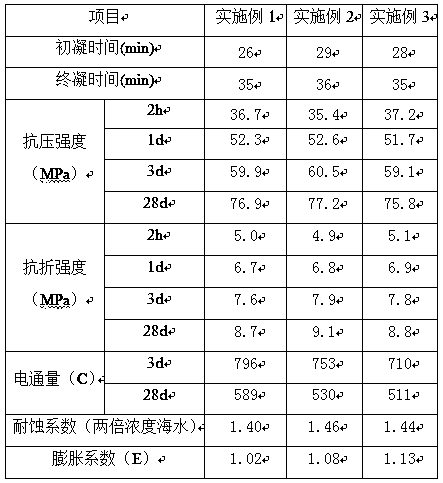

Marine sulphoaluminate cement for rapid construction and preparation method thereof

The invention discloses marine sulphoaluminate cement for rapid construction and a preparation method thereof. The marine sulphoaluminate cement is prepared from the following raw materials in parts by weight: 40-60 parts of sulphoaluminate cement clinker, 5-10 parts of modified nano calcium carbonate, 0.05-0.2 part of an efficient water reducing agent, 0-4 parts of a setting accelerator, 6-8 parts of an anti-cracking waterproof expanding agent, 3-5 parts of redispersible latex powder, 10-15 parts of clinker sea sand, 2-5 parts of silica fume, 6-10 parts of granulated blast furnace slag powderand 0.01-0.1 part of modified graphene. Concrete prepared from the marine sulphoaluminate cement can be quickly cured, has high early strength, can reach the demolding strength earlier, can be widelyapplied to ocean engineering buildings, and meets the requirement of quick construction in an ocean environment.

Owner:广西云燕特种水泥建材有限公司

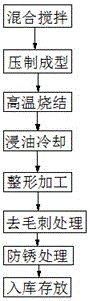

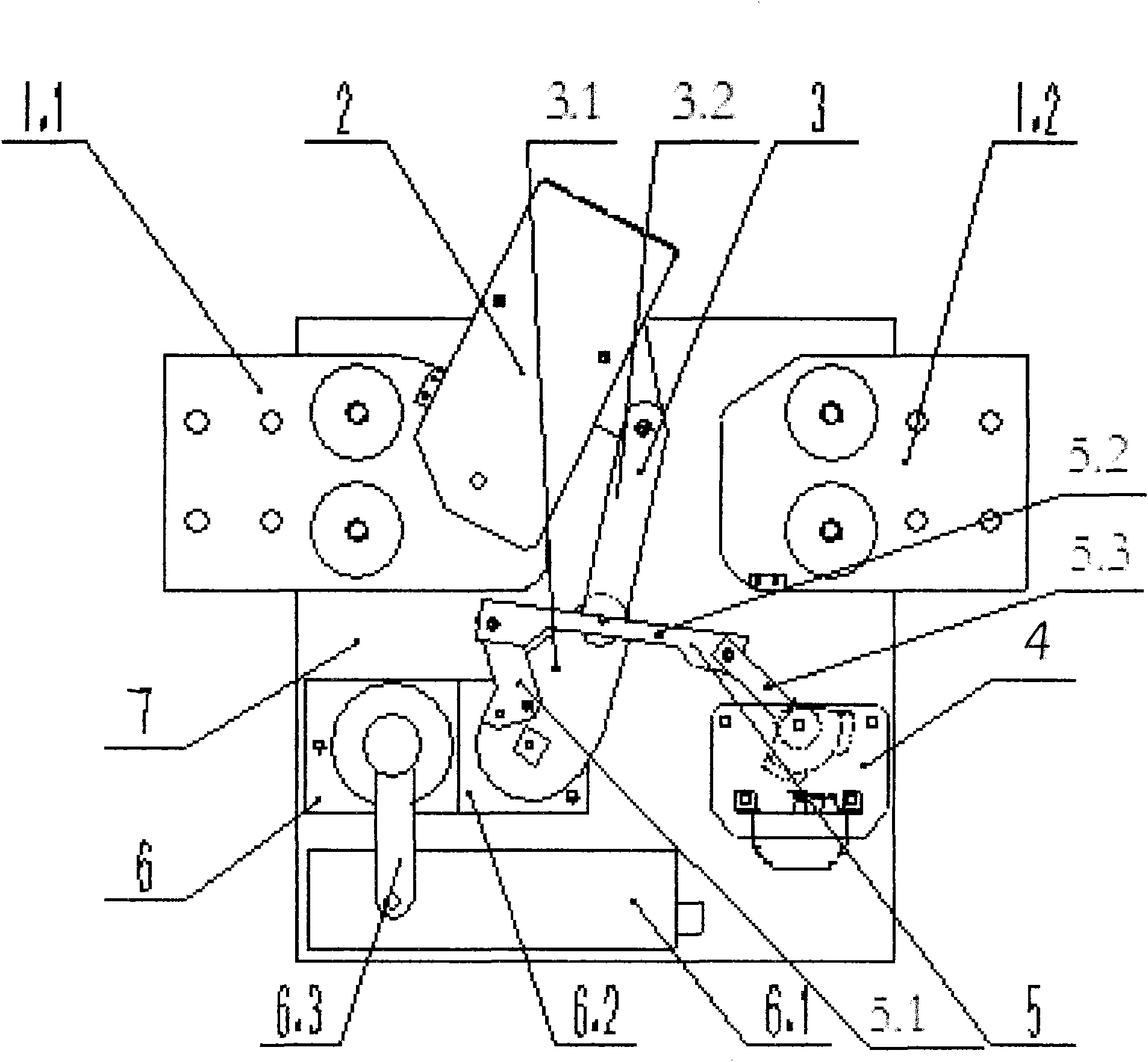

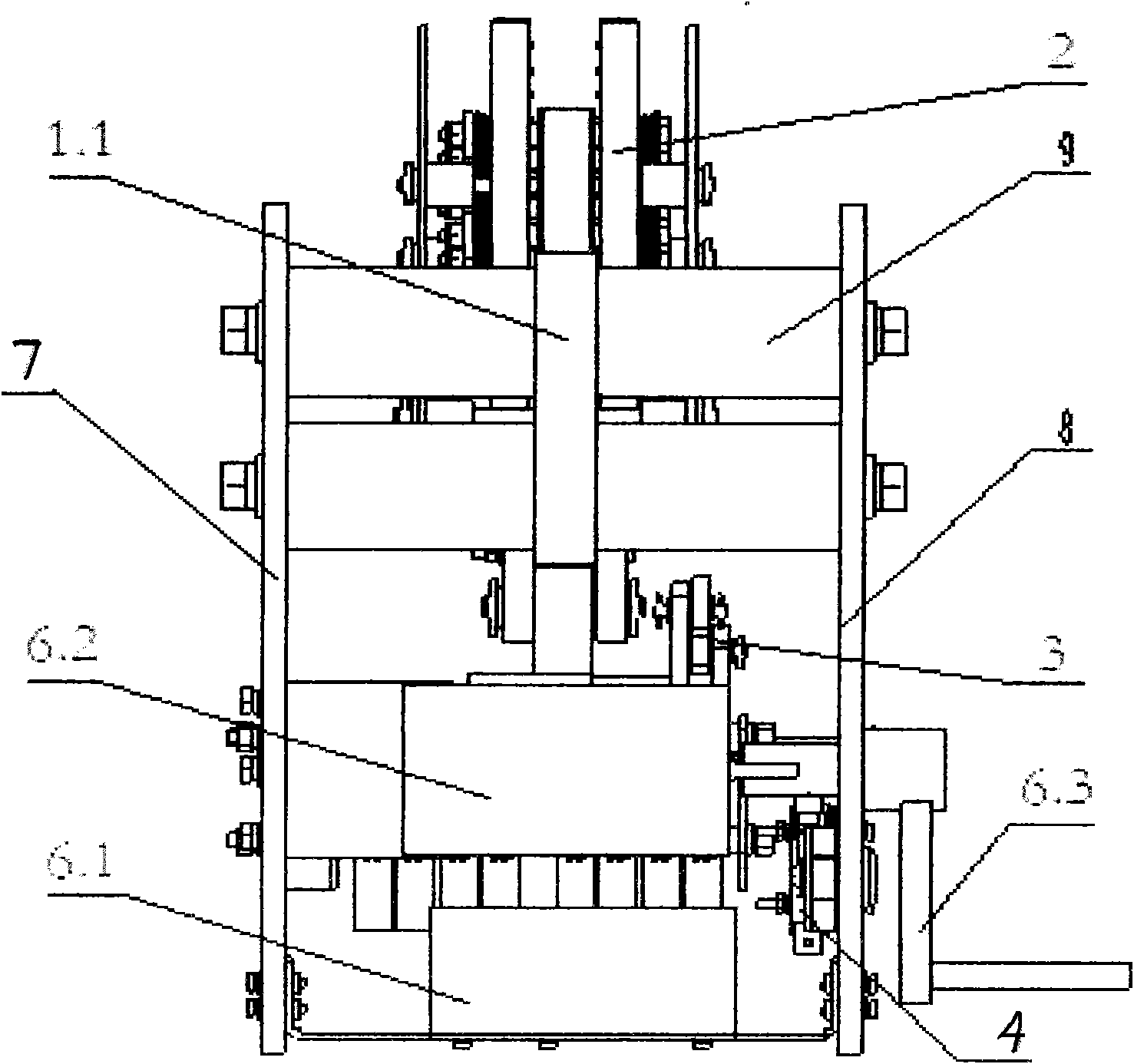

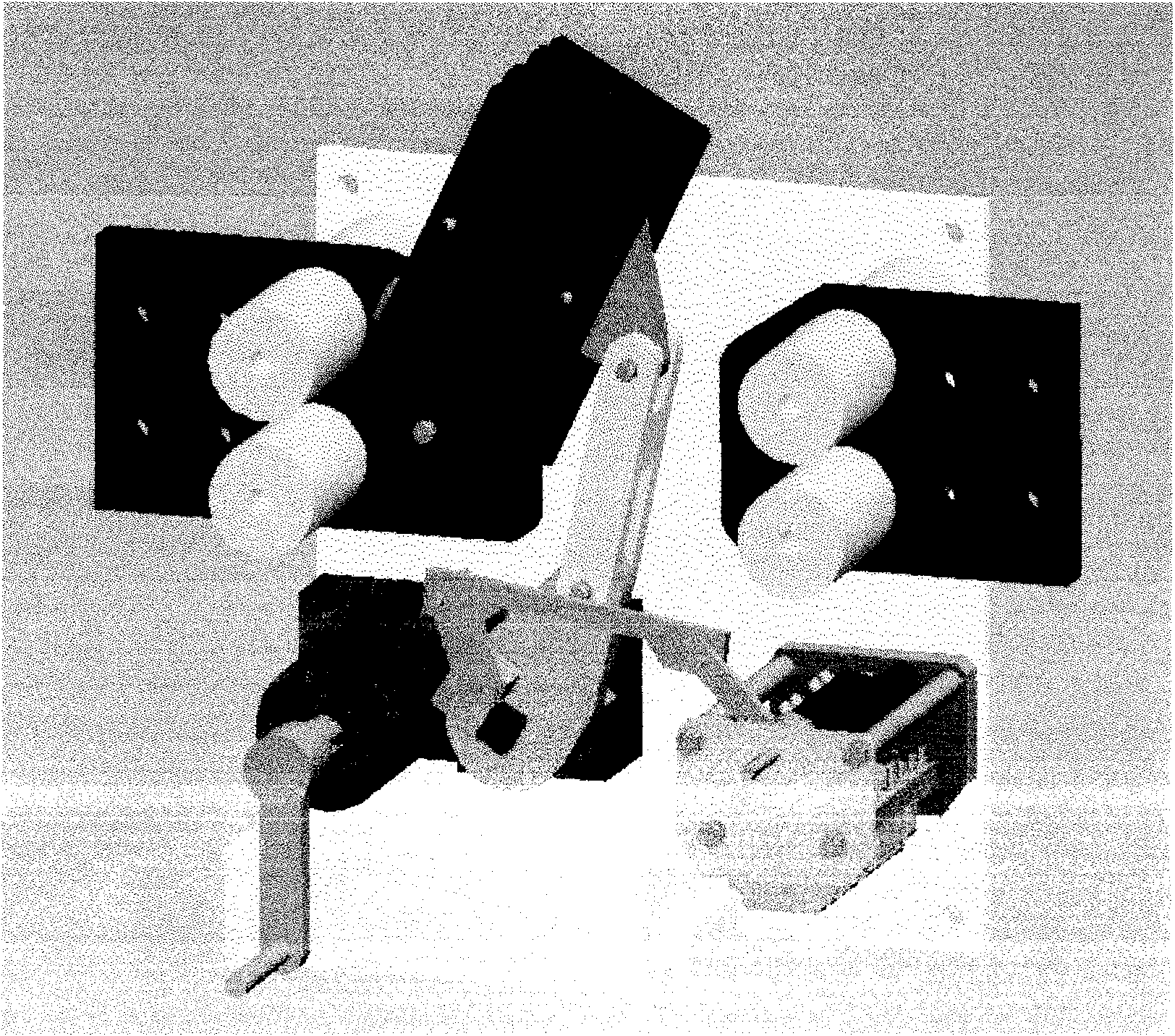

Powder metallurgy production technological method

The invention discloses a powder metallurgy production technological method which comprises the following steps: mixing and stirring, forming by compressing, sintering at high temperature, cooling through immersing in oil, carrying out shaping processing, deburring treatment and rust-proof treatment, putting in storage and storing. According to the powder metallurgy production technological method, metal powder with uniform particles is used as the raw material, and a manufactured product is excellent in structural compactness; the cooling technology through immersing in oil is excellent in cooling effect, so that a part is prevented from generating a crack, and the product quality is improved; and in addition, elimination of residual stress in the part is facilitated after the product is cooled through immersing in oil and placed after a period of time, so that the product quality is improved.

Owner:ANHUI AOTAI POWDER METALLURGY

Electric isolating switch

ActiveCN101645366AImprove transmission efficiencyImprove structural compactnessSwitch power arrangementsAir-break switch detailsControl systemEngineering

The invention relates to an electric isolating switch belonging to the control technical field in an electric system. The electric isolating switch comprises a connecting bus, a contact, a contact control system, a moving contact group, a link mechanism, an operating system and an auxiliary switch module, wherein the connecting bus is mounted between a front insulating board and a rear insulatingboard; the link mechanism is connected with the moving contact group; the operating system controls and provides power for opening and closing the moving contact group and comprises a reducing motor and a switching power supply; and the auxiliary switch module is connected with the reducing motor by an auxiliary switch module transmission mechanism and the link mechanism. The invention has the advantages of high mechanism efficiency, safety, reliability, simple structure, small size, easy assembly and adjustment, simple and convenient mounting and arrangement, and the like.

Owner:中国船舶重工集团公司第七一二研究所

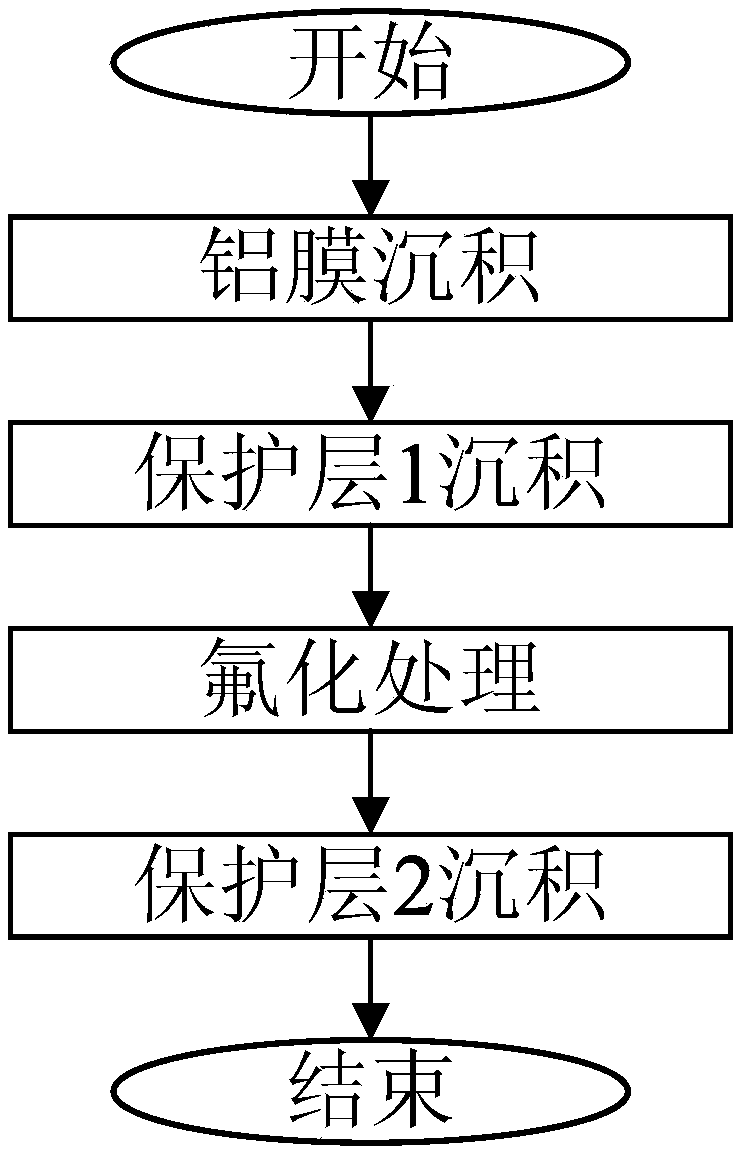

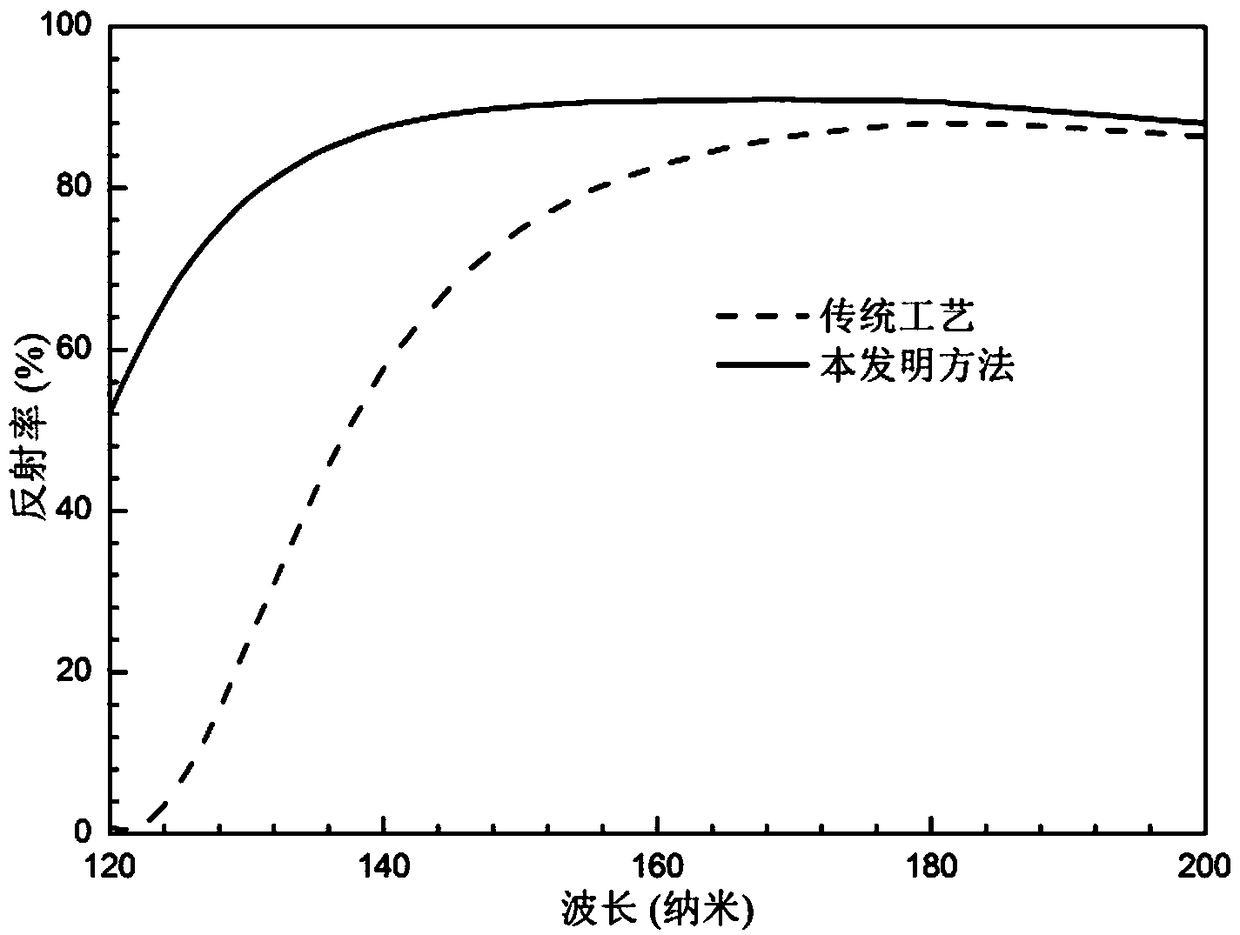

Preparation method of vacuum ultraviolet aluminum reflection mirror

ActiveCN109136840AEfficient removalReduce absorption lossVacuum evaporation coatingSputtering coatingOptical thin filmMedia layer

The invention discloses a preparation method of a vacuum ultraviolet aluminum reflection mirror and belongs to the technical field of optical thin film. The method mainly aims at key factors, influencing optical performance of the aluminum reflection mirror, in the vacuum ultraviolet aluminum reflection mirror, the key factors include aluminum film oxidation and structure defects and absorption loss of a medium protection layer, a physical vapor deposition technology is adopted for coating aluminum film, then a first protection layer is quickly deposited, the first and second layers of deposited thin film are fluoridated, and finally a second protection layer is deposited. Compared with a traditional preparation method of an aluminum reflection mirror, the method has the advantages that the influence of aluminum film oxidation and absorption loss of the medium layer to the optical performance of the vacuum ultraviolet aluminum reflection mirror can be well reduced, the structure compactness of the protection layer is improved, and the environment stability of the vacuum ultraviolet aluminum reflection mirror is improved. The method has the advantages of being high in targeting performance and quality, simple and easy to implement.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

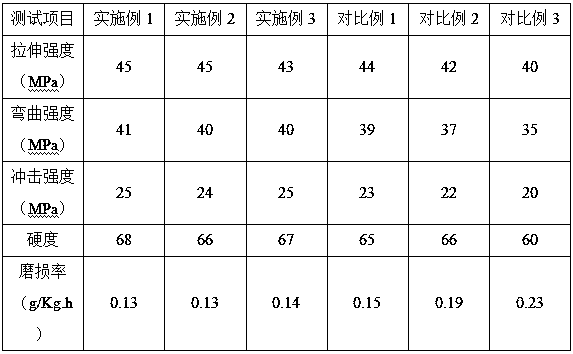

Wear-resistant and high-toughness material for 3D printing ceramic

InactiveCN110002848AImprove function and effectPromote redox reactionsAdditive manufacturing apparatusCeramic materials productionDispersityKerosene

The invention discloses a wear-resistant and high-toughness material for 3D printing ceramic, belongs to the field of ceramic materials, and solves the problem of poor wear resistance and toughness ofcommon ceramic materials at present. The ball milling efficiency can be improved by adding kerosene and absolute ethyl alcohol as ball milling media, and combustion of the kerosene can promote unoxidized metal components in a ball milling material to have a redox reaction. Aluminum oxide contained in fly ash and an Mg<2+> component in palygorskite can produce a magnesia-alumina spinel component with erosion resistance and abrasion resistance at high temperature. A boron oxide component contained in boric sludge added to aids is acid anhydride of boric acid, the acid anhydride can produce boric acid and metaboric acid with water and emit a lot of heat, a boehmite component is embedded in a hard roasted product to improve dispersity and binding force among structures, external friction canbe well scattered, quick wear can be avoided, adsorption can be formed in combination with acrylic resin, the structure compactness of a material system can be improved, and tensile strength and wearresistance can be improved.

Owner:何治伟

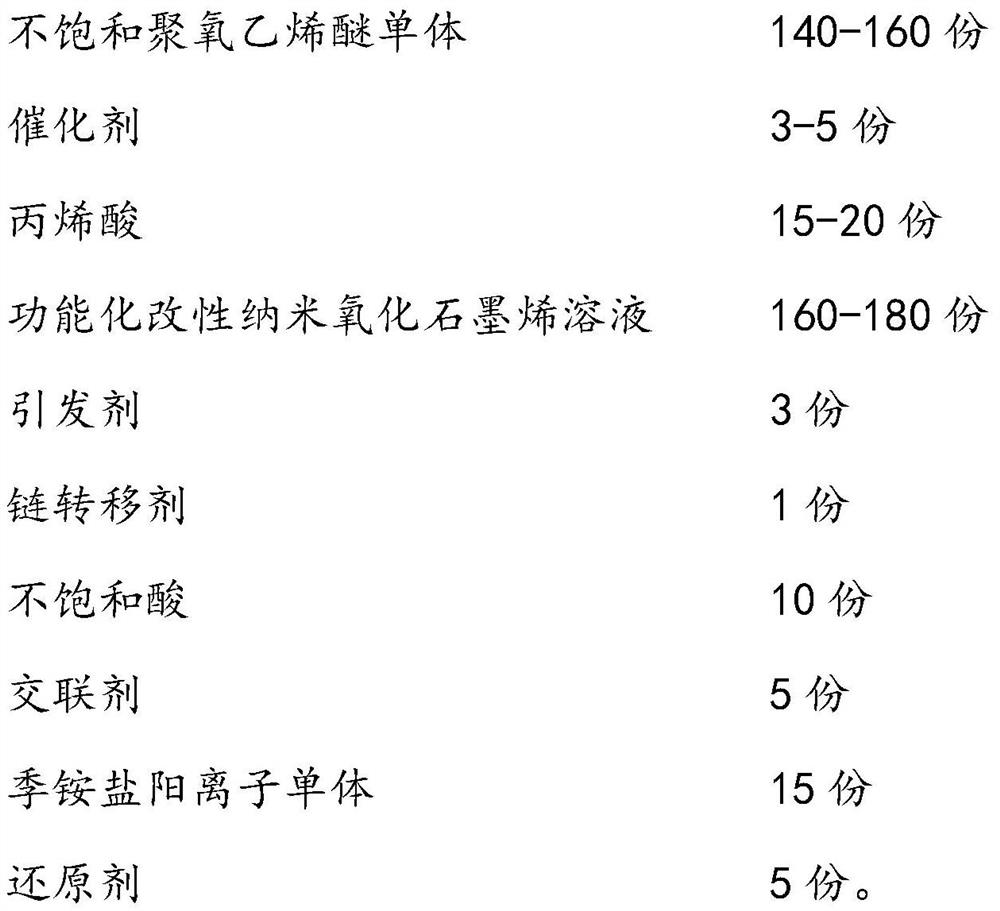

Anti-cracking shrinkage-reducing concrete admixture and preparation method thereof

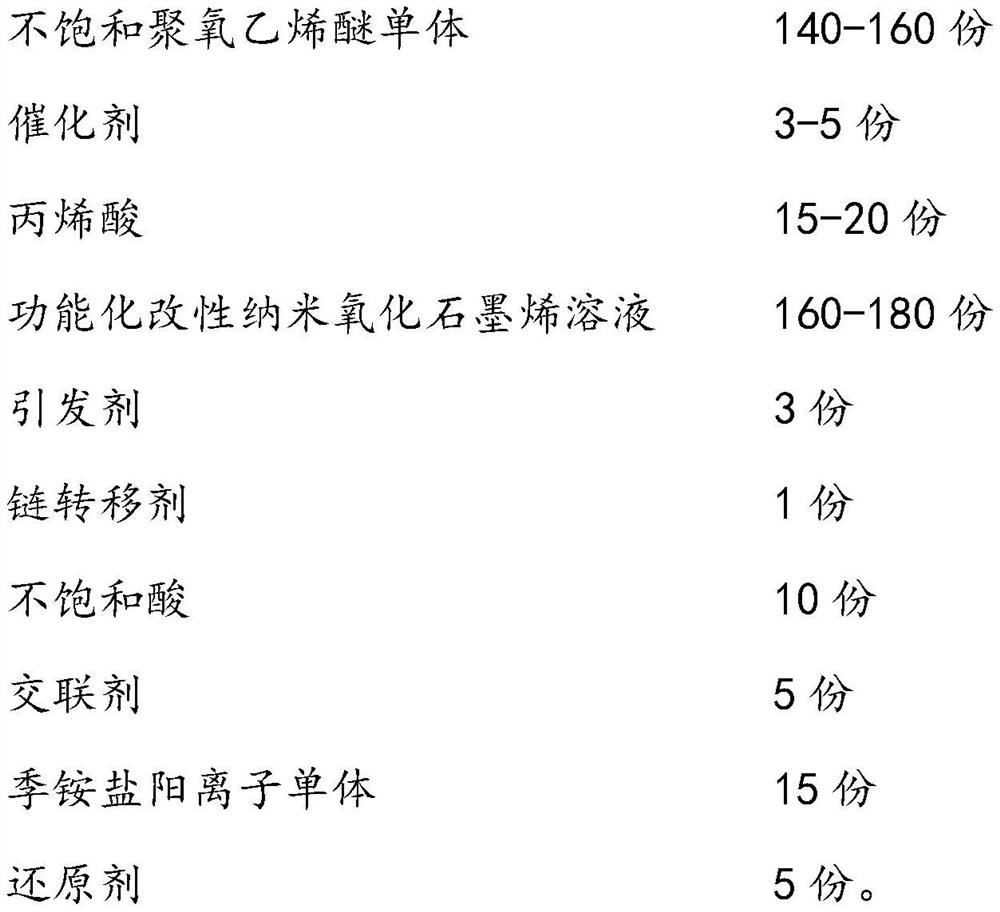

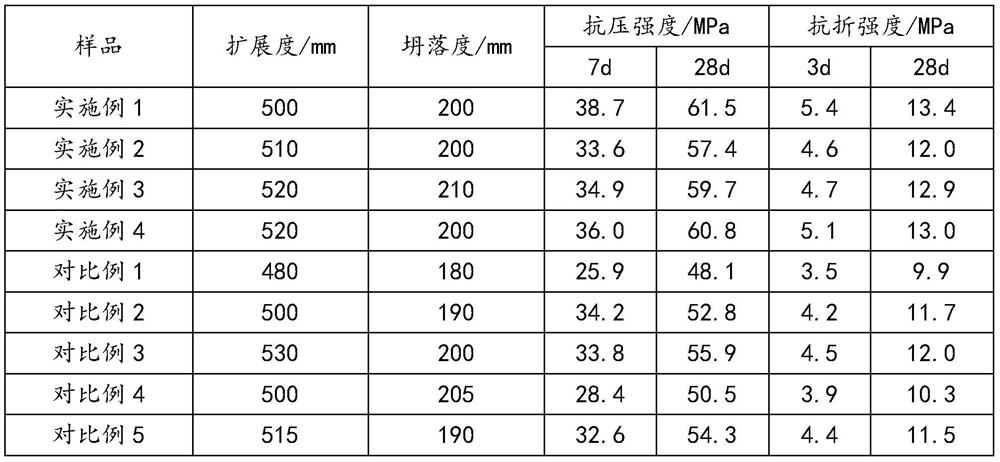

The invention relates to the technical field of building materials, in particular to an anti-crack shrinkage-reducing type concrete admixture and a preparation method thereof. The concrete admixture comprises the following preparation raw materials: an unsaturated polyoxyethylene ether monomer, a catalyst, acrylic acid, a functionalized modified nano graphene oxide solution, an initiator, a chain transfer agent, unsaturated acid, a cross-linking agent, a quaternary ammonium salt cationic monomer and a reducing agent. According to the anti-cracking shrinkage-reducing concrete admixture provided by the invention, a functionalized modified nano graphene oxide solution is introduced into a polycarboxylate-type water reducing agent polymerization system, and copolymerization modification is carried out on nano graphene oxide through the bonding effect between a large number of oxygen-containing functional groups, thus the composite modified concrete admixture with better dispersity and more stable properties is obtained, meanwhile, the effects of filling, connecting and healing micropore cracks are achieved, the interface and binding power are enhanced, and the structural properties of bubbles in concrete are improved, so that the crack resistance and shrinkage reduction properties of concrete are improved.

Owner:GUIZHOU KEZHIJIE NEW MATERIAL +1

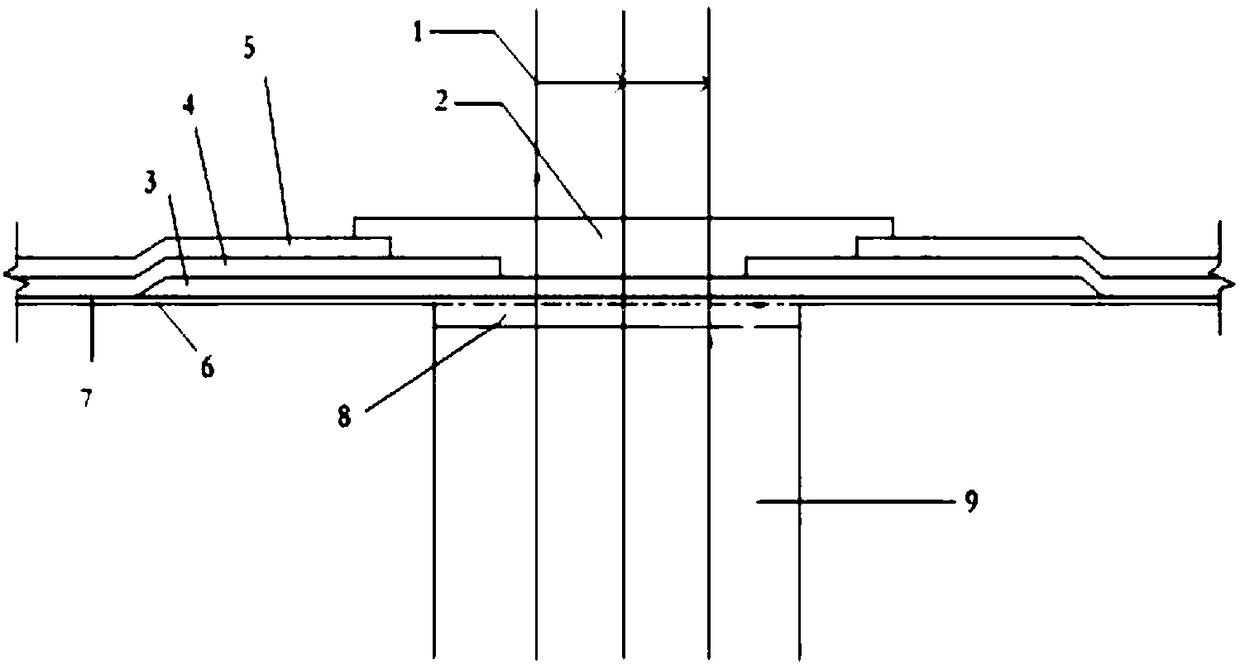

Waterproof construction method of anti-floating anchor

The invention discloses a waterproof construction method of an anti-floating anchor. The method comprises following steps that a cushion layer is poured on the bottom of a foundation pit, the cushionlayer is subject to interval drilling in sequence through an anchor drilling rig, after the drilling rig performs drilling to the design depth, primary pressure grouting is carried out, cement mortaris injected while a drill rod is lifted until the cement mortar flows out of a drilling hole; after the cement mortar of secondary pressure grouting is subject to initial setting and before final setting, a secondary grouting pipe descends along with the anti-floating anchor to enter a drill hole of the primary pressure grouting; secondary grouting is carried out; anti-pull bearing force test of the anti-floating anchor is carried out; if the anti-floating anchor is checked out, soil clipping layer on the root of the anti-floating anchor is chiseled and removed, cement waterproof mortar is smeared and is flushed with the cushion layer; waterproof joint treatment on the connecting position of the anti-floating anchor and the foundation is carried out. Through the method, water leaking risksare reduced, and the anti-pulling bearing force of the anti-floating anchor is high.

Owner:CHINA CONSTR SIXTH ENG BUREAU CIVILENG +1

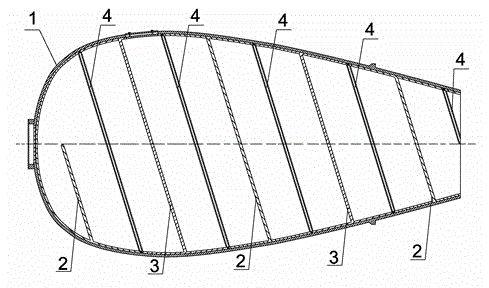

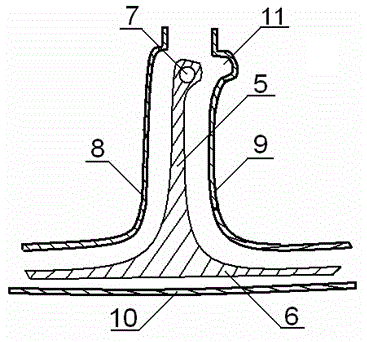

Vehicular composite concrete mixing drum and method for manufacturing same

ActiveCN102873754AReasonable structural designEasy maintenanceCement mixing apparatusYarnWinding machine

The invention discloses a vehicular composite concrete mixing drum and a method for manufacturing the same. The vehicular composite concrete mixing drum comprises an outer drum wall (1) and an inner drum wrapped in the outer drum wall (1). After being impregnated in curable resin, reinforced fiber yarns are wound on the outer surface of the inner drum via a winding process and then are cured on the outer surface of the inner drum to form the outer drum wall (1), and first spiral components (2) and second spiral components (3) are adhered with one anther by polyurethane adhesive (4) to form the inner drum. The vehicular composite concrete mixing drum is reasonable in structural design, high in abrasion resistance and corrosion resistance, long in service life and wide in application range, and is light. Besides, the method for manufacturing the mixing drum has the advantages that a special mold capable of realizing an integral injection molding function is designed according to structural characteristics of the inner drum of the concrete mixing drum, the outer drum wall is manufactured by a winding machine via the winding process, the manufacturing efficiency is high, and the mixing drum manufactured by the method is light and is high in abrasion resistance and corrosion resistance and low in manufacturing cost.

Owner:LIANYUNGANG ZHONGFU LIANZHONG COMPOSITES GRP

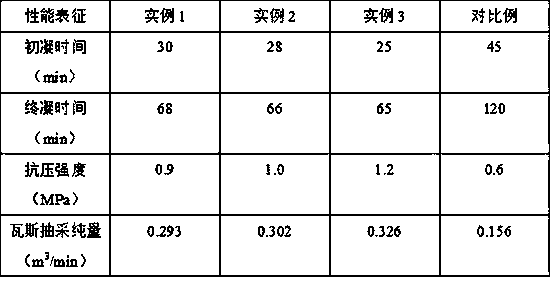

Anchoring blasting hole-sealing material and preparation method thereof

The invention relates to an anchoring blasting hole-sealing material and a preparation method thereof and belongs to the technical field of hole-sealing materials for mining. Bentonite is adopted as an anchoring point, a silane coupling agent having low viscosity and surface tension is utilized to enable bentonite to be quickly spread on a construction surface to soak rock surface cracks, and inorganic groups in the silane coupling agent can react with oxide on the surfaces of the cracks to generate stable silicon oxygen bonds; excellent water-absorbing expansion performance of bentonite is utilized to enable the hole-sealing material to fill the rock surface cracks and to seal, high strength and micro-expansibility after setting are realized, drill hole surrounding rock can be reinforced,and radius of a plastic zone is reduced; corrosion resistance of concrete is improved, curing performance is enhanced, and the material is enabled to have remarkable dynamic hardening effect; it shows that as hydration degree increases, heterogeneous degree of the material is lowered, and comprehensive performance meets actual needs of blasting hole-sealing materials.

Owner:姜香

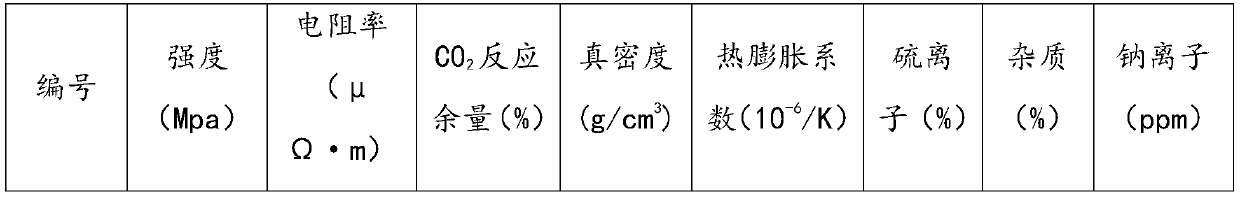

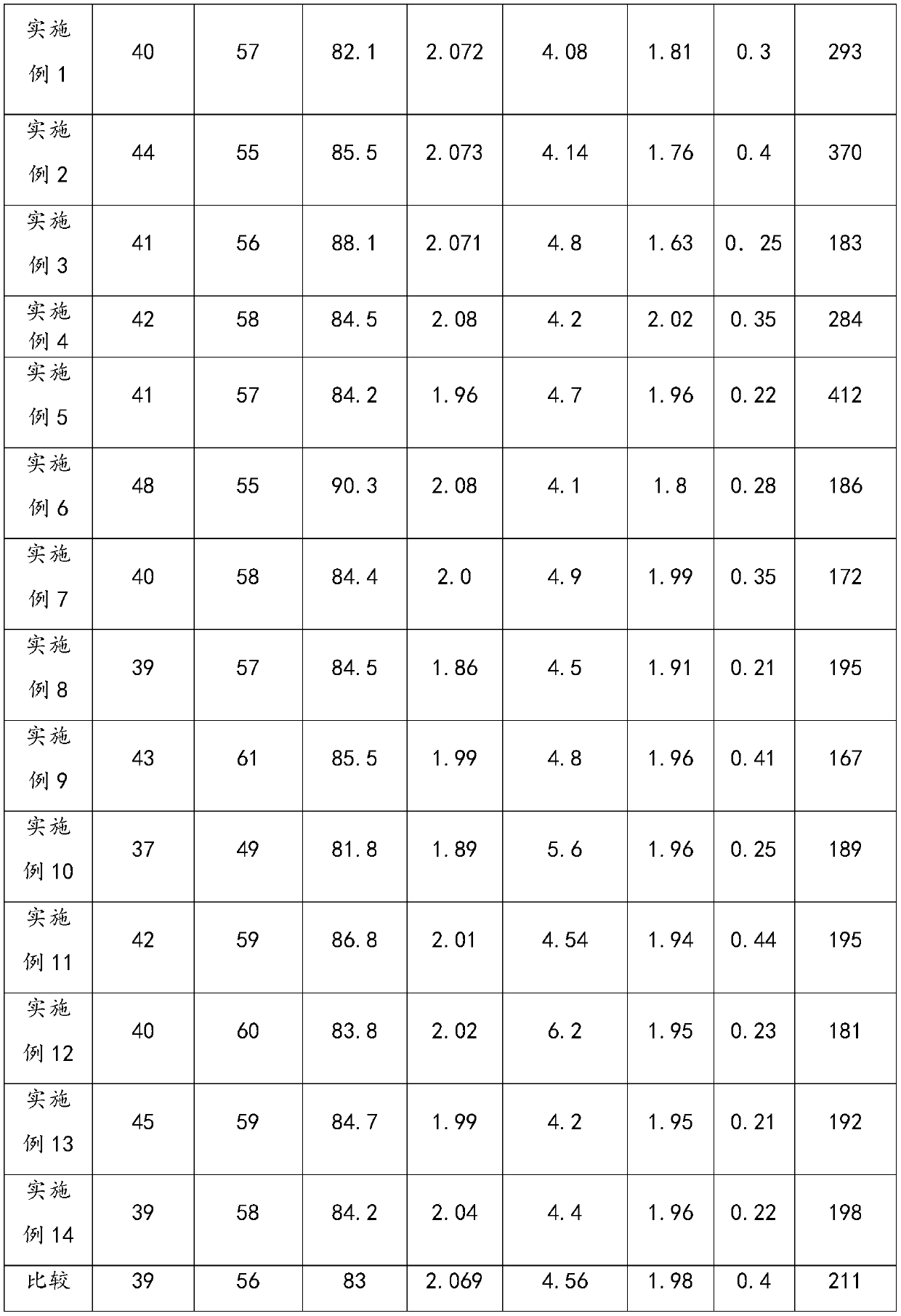

A kind of carbon anode and its preparation method and application

The invention provides a carbon anode and a preparation method and an application thereof, and belongs to the technical field of carbon industries. The carbon anode comprises the following raw materials: 85-95 parts of aggregate and 5-15 parts of a binder. The preparation method comprises the following steps: mixing the raw materials according to a mass proportion, forming, and performing heat treatment, to obtain the carbon anode. The binder is capable of using liquid phenolic resin as a main body. Compared with a binder of asphalt, mixing in a normal temperature can be realized, a forming technology adopts compression molding, the technology is simple, and operation conditions are moderate. After the phenolic resin is used for heating and solidifying, the carbon anode has the characteristics of excellent dimensional stability, and is capable of realizing rapid warming in a roasting stage, shortening roasting time, and improving production efficiency.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD +1

Preparation method for aluminum-silicon alloy micro-arc oxidation film layer

ActiveCN111893540AReduce the content of silicon phaseReduce mullite phase contentAnodisationAluminateMicro arc oxidation

The invention discloses a preparation method for an aluminum-silicon alloy micro-arc oxidation film layer. The preparation method for the aluminum-silicon alloy micro-arc oxidation film layer comprises the following steps of S1, pretreatment: removing silicon elements on the surface of an aluminum-silicon alloy substrate; and S2, micro-arc oxidation: placing the aluminum-silicon alloy treated in the step S1 in an alkaline electrolyte for micro-arc oxidation treatment, wherein a constant-voltage micro-arc oxidation mode or a segmented constant-current micro-arc oxidation mode is adopted in themicro-arc oxidation process, and the alkaline electrolyte mainly contains aluminate but contains no silicon elements. According to the scheme provided by the invention, the content of the loose porousmullite phase in the aluminum-silicon alloy micro-arc oxidation film layer is reduced, the structure compactness of the film layer is improved, the section of the film layer is changed in a gradientmode, the purpose of efficiently preparing the micro-arc oxidation ceramic film layer with excellent performance on the surface of the aluminum-silicon alloy is achieved, and the surface-strengthenedaluminum-silicon alloy is obtained.

Owner:DONGGUAN UNIV OF TECH

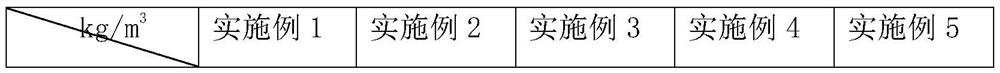

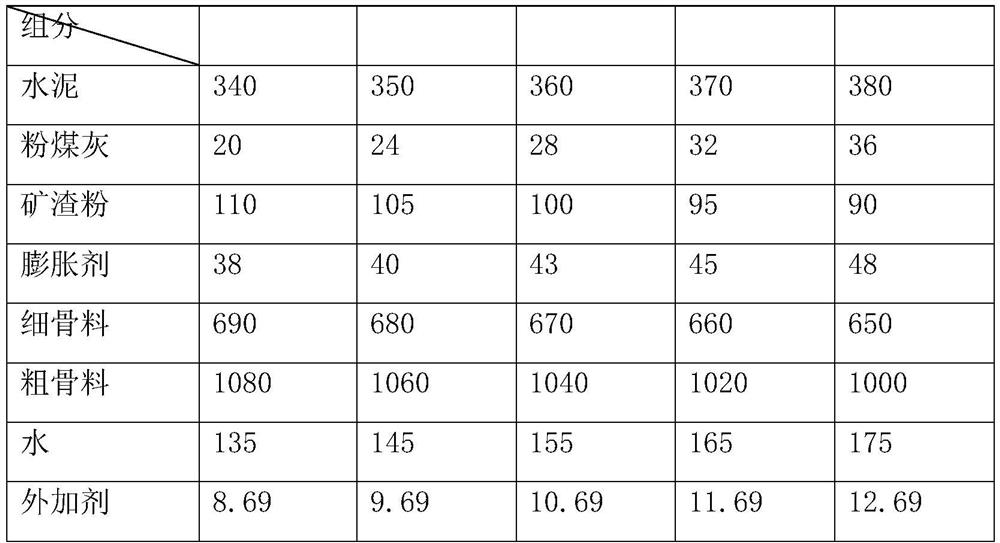

High-strength commercial concrete and preparation method thereof

The invention relates to the technical field of building materials, and particularly discloses high-strength commercial concrete and a preparation method thereof. The high-strength commercial concretecomprises the following components: cement, fly ash, slag powder, an expanding agent, fine aggregate, coarse aggregate, water and an additive, The pretreatment of the fly ash comprises the followingsteps: (1) mixing the fly ash with an acid solution, and performing washing and roasting to prepare porous fly ash; (2) atomizing an impermeable wear-resistant aid, depositing the atomized impermeablewear-resistant aid on the porous fly ash, and performing mixing and grinding to obtain fly ash particles, wherein the mass ratio of the porous fly ash to the impermeable wear-resistant aid is 1:(0.1-0.3); and (3) atomizing an excitant, depositing the atomized excitant on the fly ash particles, and placing the particles at 800-960 DEG C for 2-3h, wherein the mass ratio of the fly ash particles tothe excitant is 1:(0.3-0.5). The high-strength commercial concrete has the advantages of being high in impermeability, abrasion resistance and corrosion resistance and good in seepage scouring resistance and durability.

Owner:北京天地建设砼制品有限公司

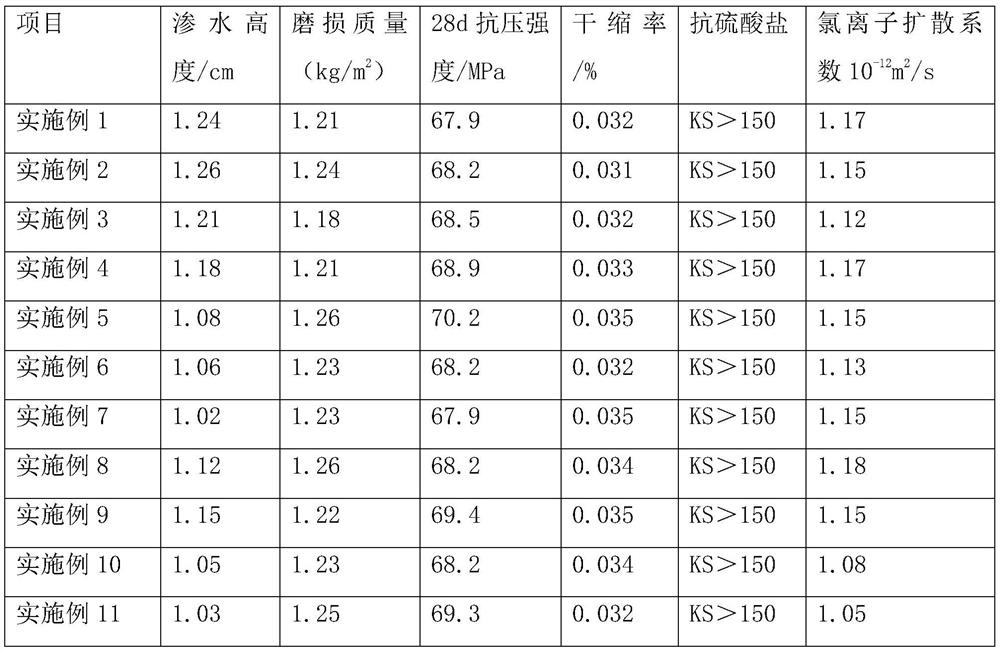

Deoxidizer carrier as well as sulfur-resisting deoxidizer based on carrier and preparation method of carrier

ActiveCN103143315AHigh strengthT% goodCatalyst carriersOther chemical processesSilicon oxideIron oxide

The invention claims a preparation method of a sulfur-resisting deoxidizer. A carrier is mainly acquired by preparing modified aluminum bauxite powder, alumina powder and titanium dioxide powder. Active components in the sulfur-resisting deoxidizer include Co, Mo and W. The preparation method of the sulfur-resisting deoxidizer disclosed by the invention has the advantages that the titanium dioxide included in the raw materials for preparing the carrier can significantly improve the deoxidization property of the deoxidizer; the modified aluminum bauxite powder included in the raw materials of the carrier is directly formed by modifying natural aluminum bauxite; the specific surface area is great, so that the usage amount of the aluminum oxide powder can be reduced, thereby achieving the purpose of reducing the cost; and meanwhile, the components comprising ferric oxide, silicon dioxide and the like in the aluminum bauxite can improve the property and the strength of the sulfur-resisting deoxidizer.

Owner:FUZHOU UNIV +1

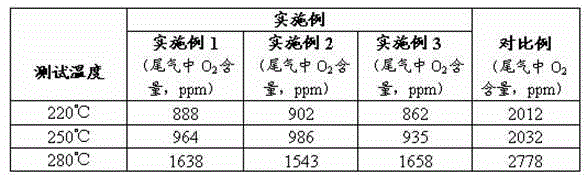

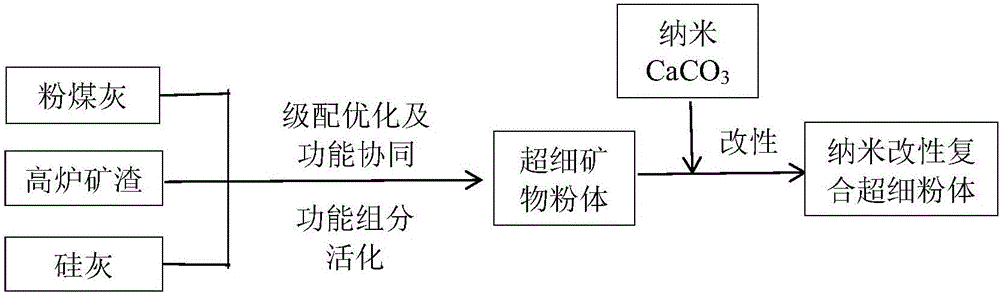

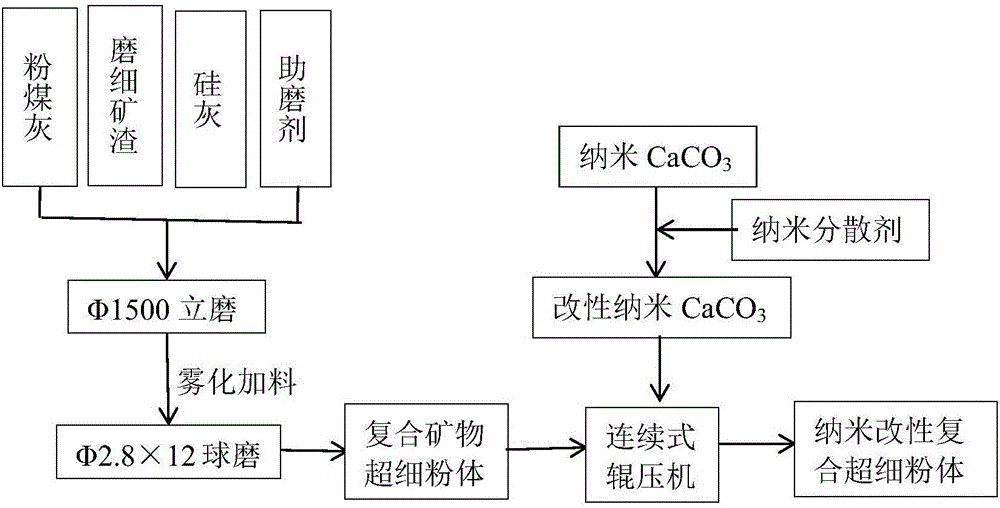

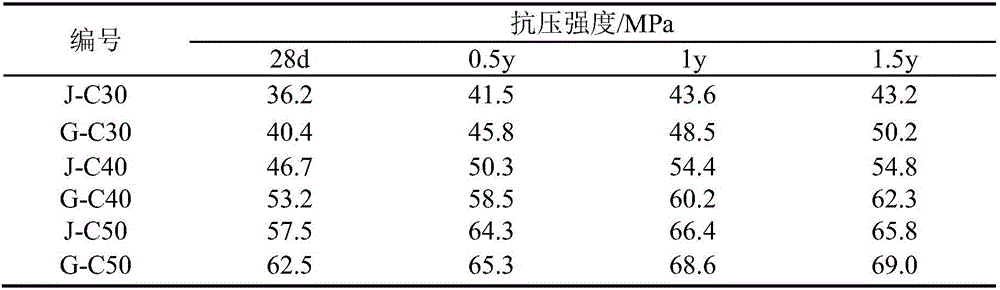

Nano modified composite powder for ocean-engineering concrete structure

ActiveCN106630720ATake full advantage of stackingGive full play to the synergistic effectSolid waste managementSlagNanoparticle

The invention relates to the technical fields of ocean-engineering materials and engineering, and aims at providing nano modified composite powder for an ocean-engineering concrete structure. The composite powder is formed by mixing the following raw material components in parts by weight: 20 to 30 parts of pulverized fuel ash, 25 to 40 parts of blast-furnace slag powder, 10 to 20 parts of silica fume, 5 to 10 parts of nano CaCO3 and 0.8 to 1 part of nano dispersant. By using the nano modified composite powder, the limitation that a single mineral component influences concrete performance is effectively removed; a compound multifunctional component can be used for effectively optimizing the grain composition of the concrete structure; the purpose of greatly improving the durability of the concrete structure is achieved. According to the nano modified composite powder, the high activity and the microcrystal nucleus effect of nano grains are sufficiently exerted; the effects of improving the impermeability and the durability of the ocean-engineering concrete structure are far superior to those of an ordinary mineral admixture. By using the nano modified composite powder, the reasonable composition and the uniform mixing of the high-activity grains are promoted; the optimization of formula design is achieved; a product has the properties of excellent corrosion resistance, shrinkage reduction, low hydration heat, shrinkage compensation and the like.

Owner:TAIZHOU BRANCH ZHEJIANG-CALIFORNIA INT NANOSYSTEMS INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com