Alloy steel electrosilvering product and preparation method thereof

A technology for alloy steel and electroplating silver, applied in the field of alloy steel electroplating silver products and their preparation, can solve problems such as poor high temperature bonding force, and achieve the effects of good structure compactness, corrosion prevention, and high temperature bonding force improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The silver-plated alloy steel product of this embodiment comprises an alloy steel substrate and a copper coating, a nickel coating and a silver coating sequentially electroplated on the alloy steel substrate from inside to outside, wherein the thickness of the copper coating is 2 μm, and the thickness of the nickel coating is 2 μm , The thickness of the silver plating layer is 6 μm.

[0027] The preparation method of the alloy steel electroplated silver product of the present embodiment comprises the following steps:

[0028] 1) Put the alloy steel substrate in the degreasing liquid, degrease at 70°C for 15 minutes, then perform hot water washing (hot water temperature is 75°C) and flowing cold water washing (cold water temperature is 25°C) in sequence to obtain degreasing parts ; The composition of degreasing liquid is: degreasing agent CK-SO 2 45g / L, the solvent is water;

[0029] 2) Place the degreasing part obtained in step 1) in the activation solution, activate ...

Embodiment 2

[0040] The silver-plated alloy steel product of Example 2 has the same structure as that of Example 1, and the thicknesses of the copper coating, the nickel coating and the silver coating are 1.5 μm, 2 μm, and 6 μm, respectively.

Embodiment 3

[0041] The silver-plated alloy steel product of Example 3 has the same structure as that of Example 1, and the thicknesses of the copper plating, nickel plating, and silver plating are 1.8 μm, 2 μm, and 7 μm, respectively.

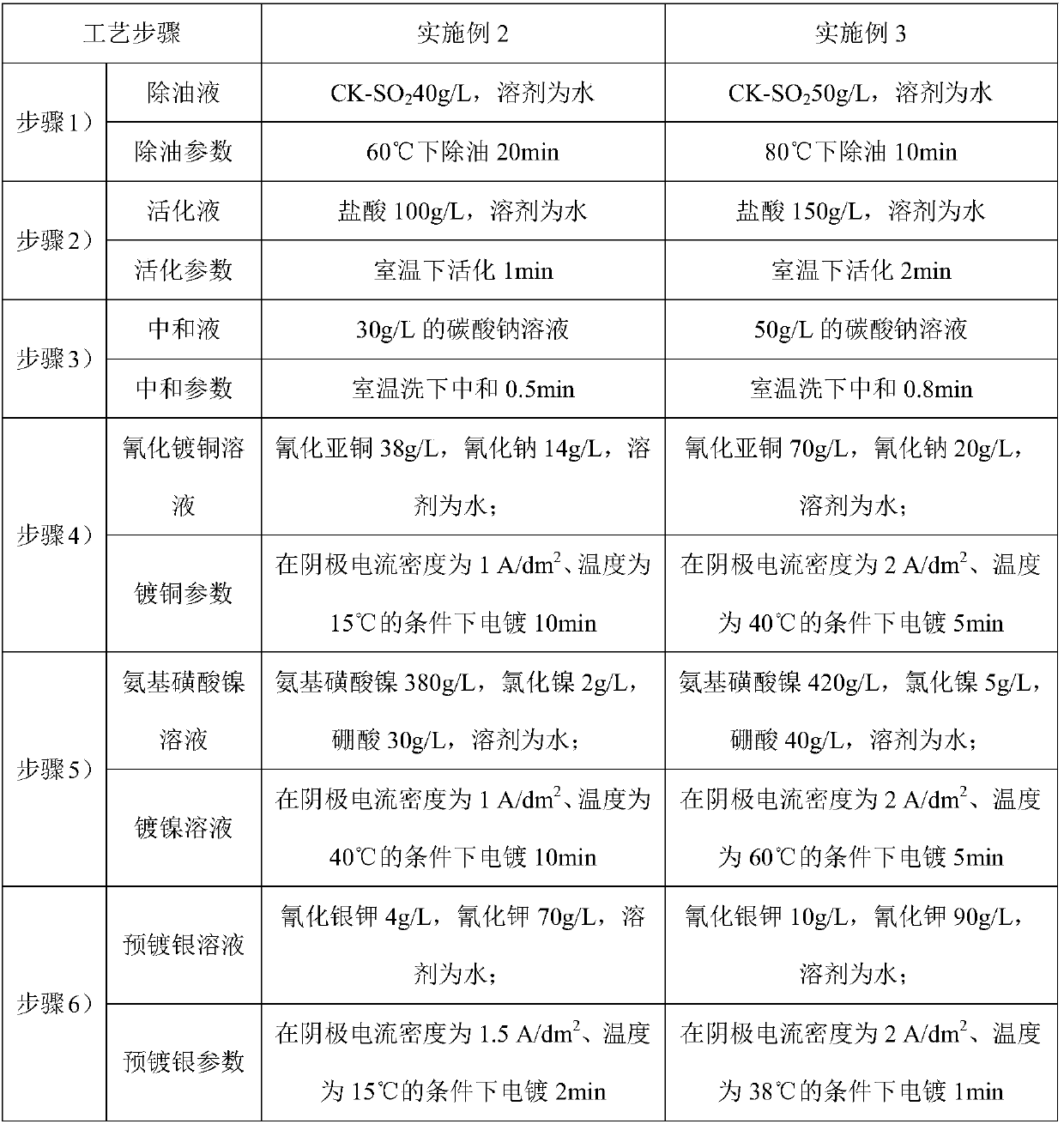

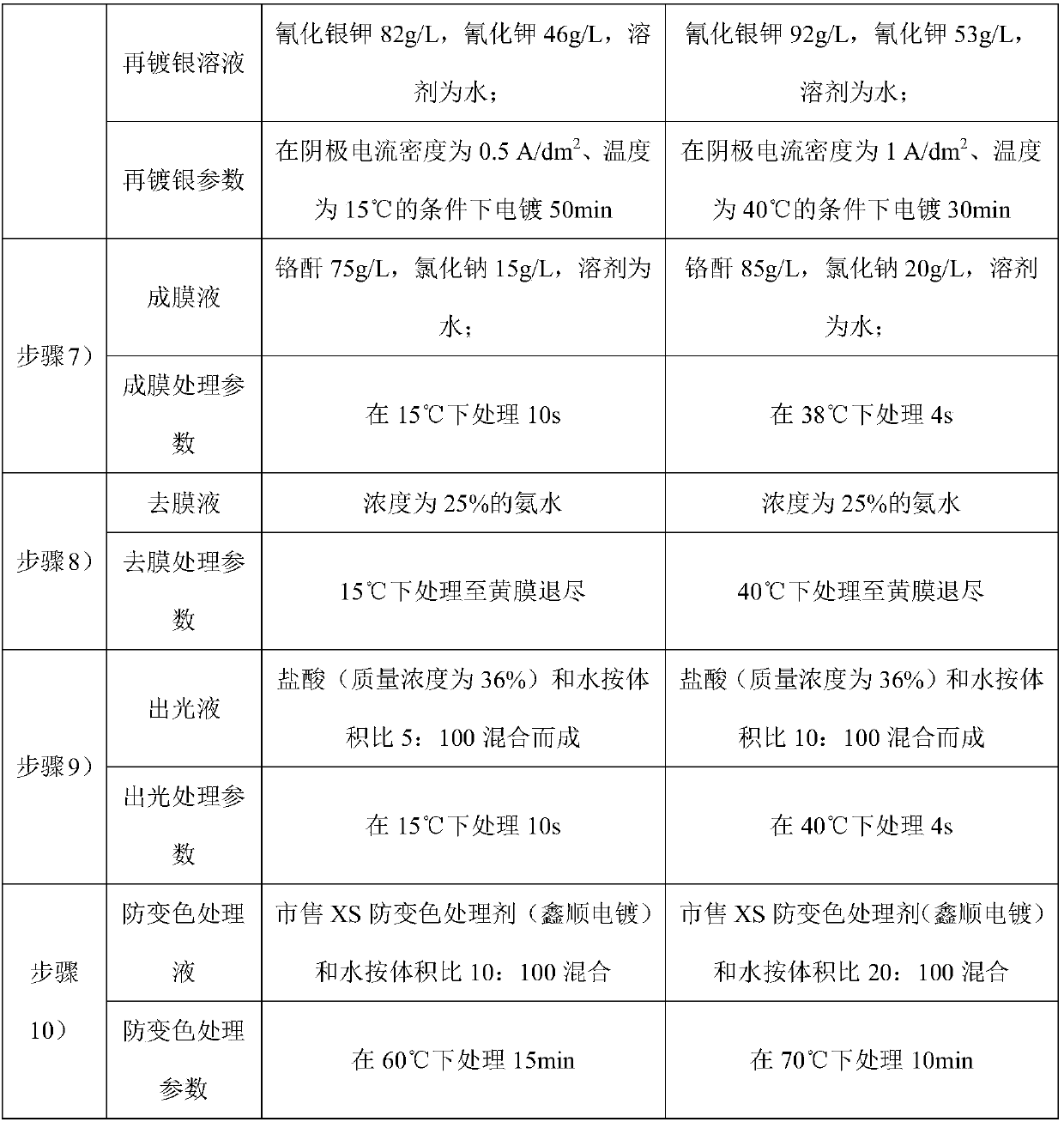

[0042] The preparation methods of the silver-plated alloy steel products of Examples 2 and 3 are basically the same as those of Examples, and the process parameters of each step are listed in Table 1.

[0043] The preparation process parameter of the alloy steel electroplating silver product of table 1 embodiment 2 and embodiment 3

[0044]

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com