Patents

Literature

680 results about "Copper coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper plating is a coating of copper metal on another material, often other metals. Plating is designed to increase durability, strength, or visual appeal, and copper plating specifically is often used to improve heat and electrical conductivity. Copper plating is seen most often in wiring and cookware.

Process for the electrolytic deposition of metal layers

InactiveUS6099711AOptimize allocationImpairing propertyCellsElectrolysisHigh current densityMetal coating

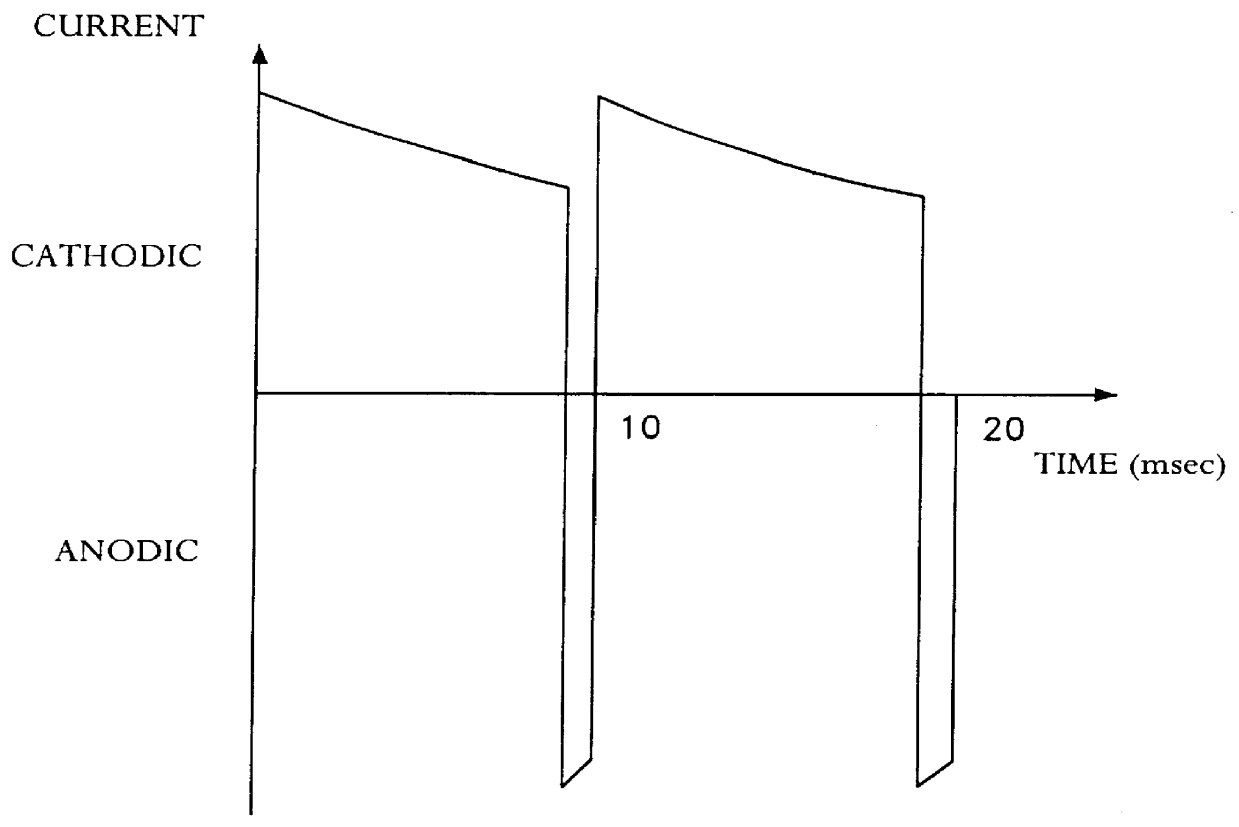

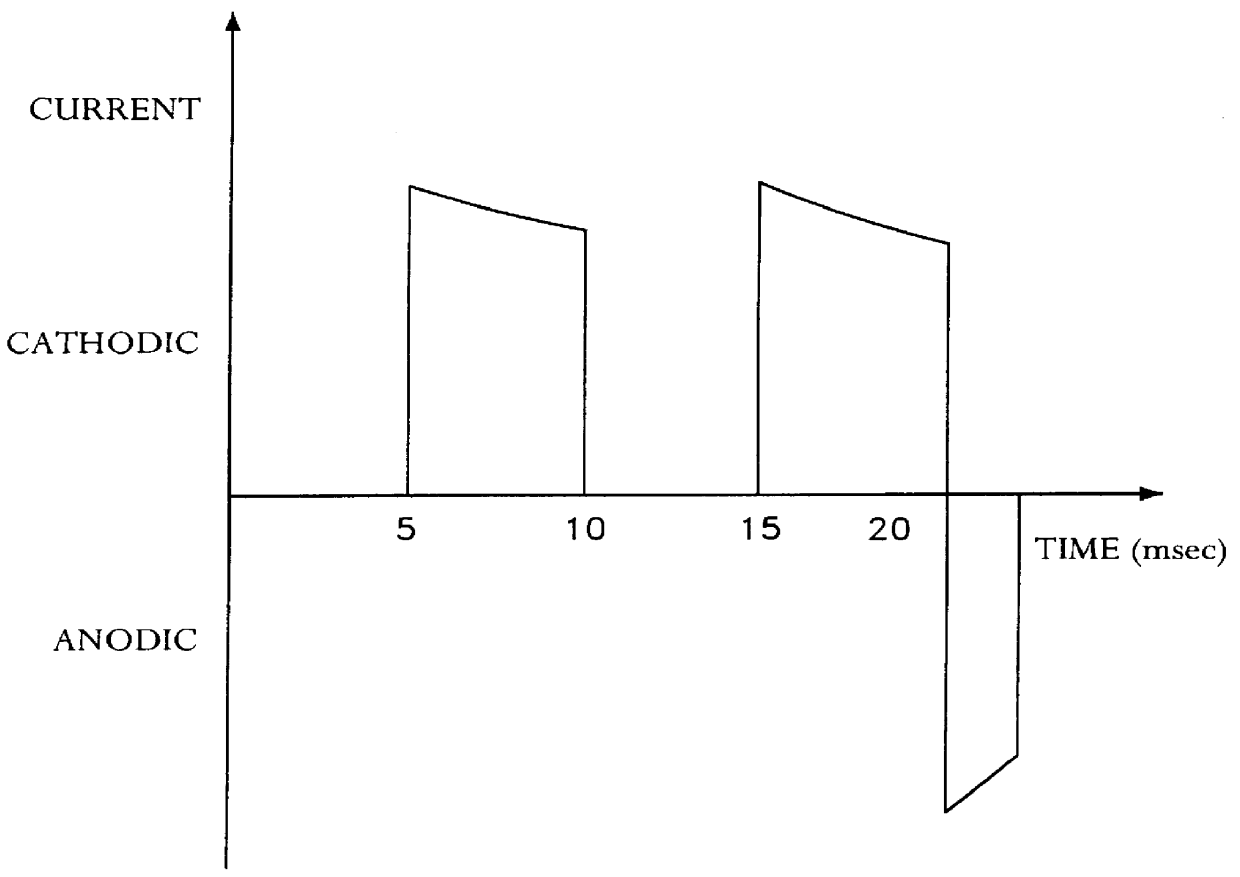

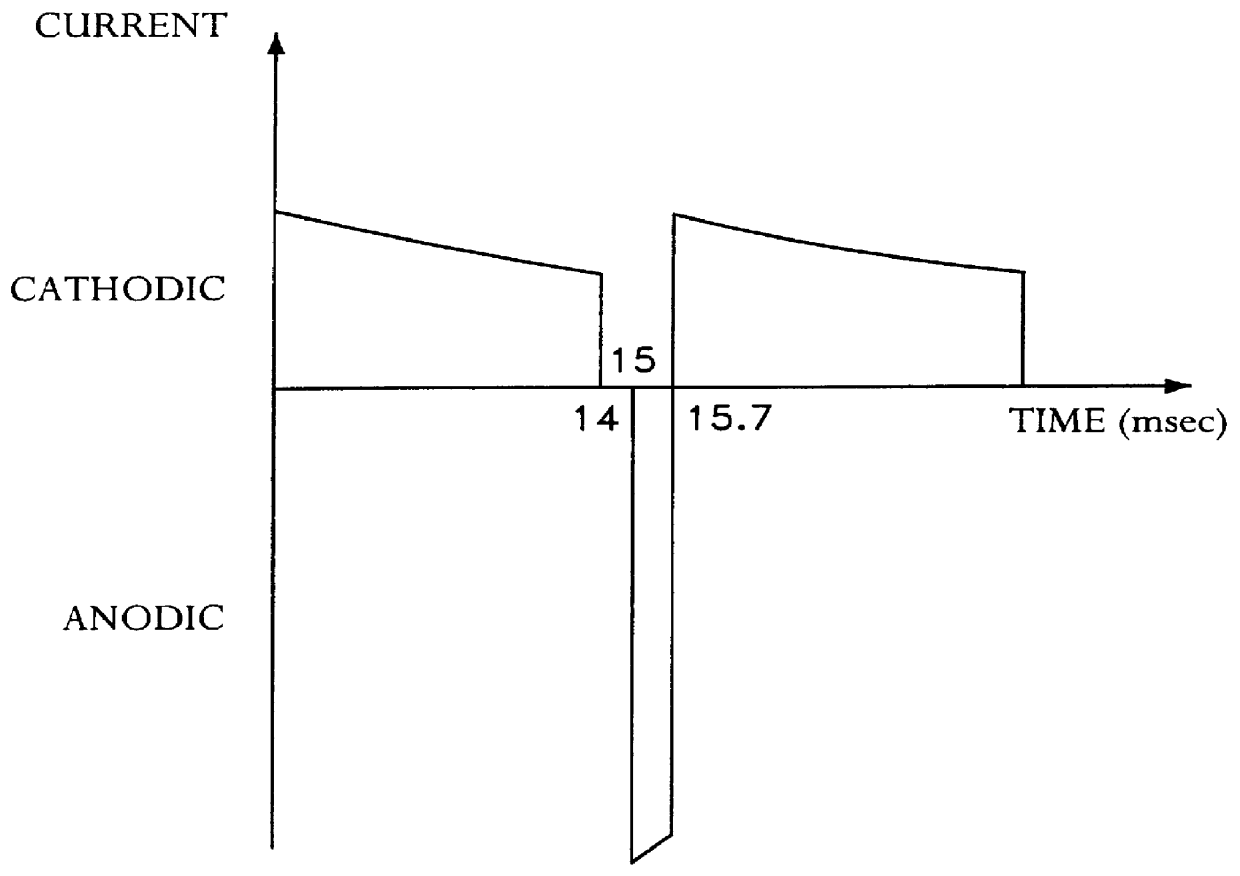

PCT No. PCT / EP96 / 05140 Sec. 371 Date Apr. 23, 1998 Sec. 102(e) Date Apr. 23, 1998 PCT Filed Nov. 21, 1996 PCT Pub. No. WO97 / 19206 PCT Pub. Date May 29, 1997The invention relates to a method for the electrolytic deposition of metal coatings, in particular of copper coatings with certain physical-mechanical and optical properties and uniform coating thickness. According to known methods using soluble anodes and applying direct current, only uneven metal distribution can be attained on complex shaped workpieces. By using a pulse current or pulse voltage method, the problem of the coatings being of varying thickness at various places on the workpiece surfaces can indeed be reduced. However, the further problem of the geometric ratios being changed continuously during the depositing process by dissolving of the anodes is not resolved thus. This can be avoided by using insoluble anodes. In order to guarantee sufficient stability of the anodes and a bright coating even at those points on the workpiece surfaces, onto which the metal is deposited with high current density, it is essential to add compounds of an electrochemically reversible redox system to the depositing solution.

Owner:ATOTECH DEUT GMBH

Method of Chrome Plating Magnesium and Magnesium Alloys

ActiveUS20090317556A1Liquid surface applicatorsLiquid/solution decomposition chemical coatingCopper coatingChrome plating

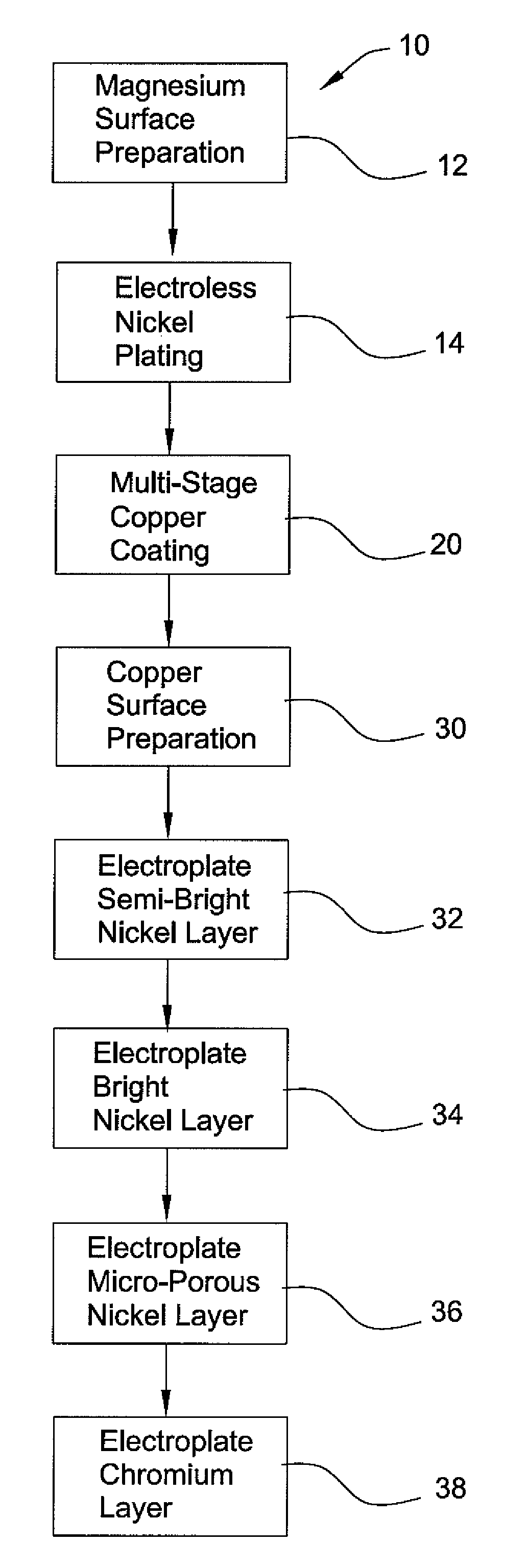

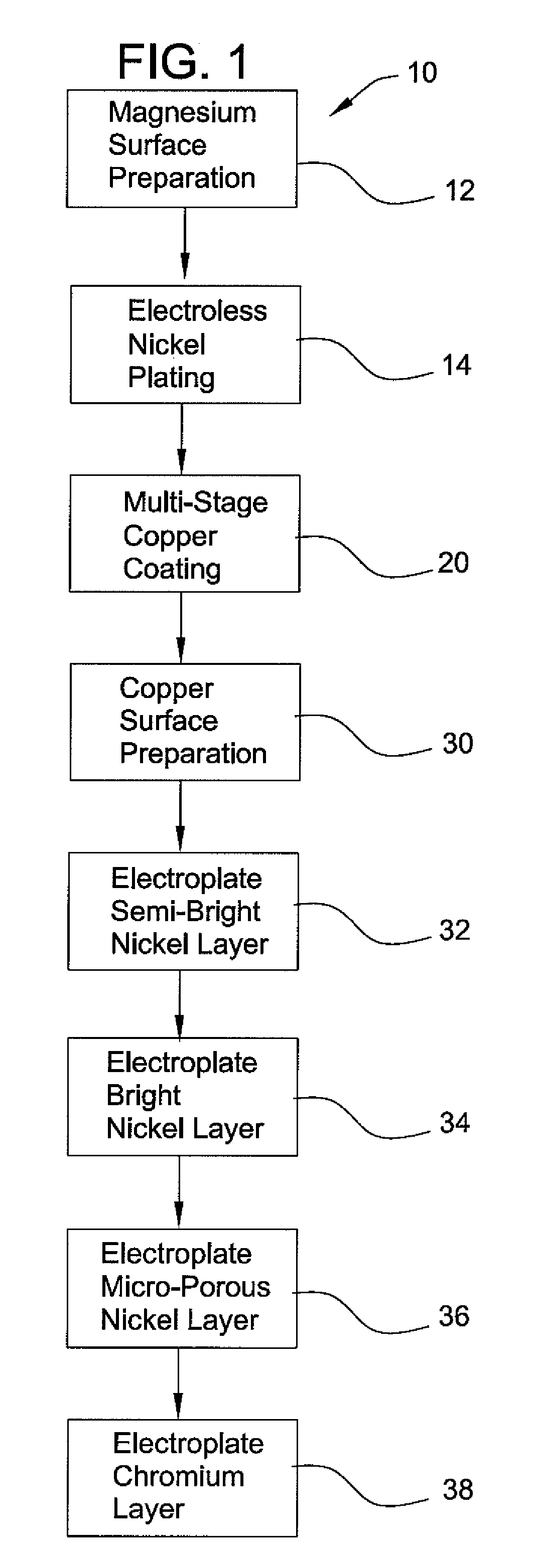

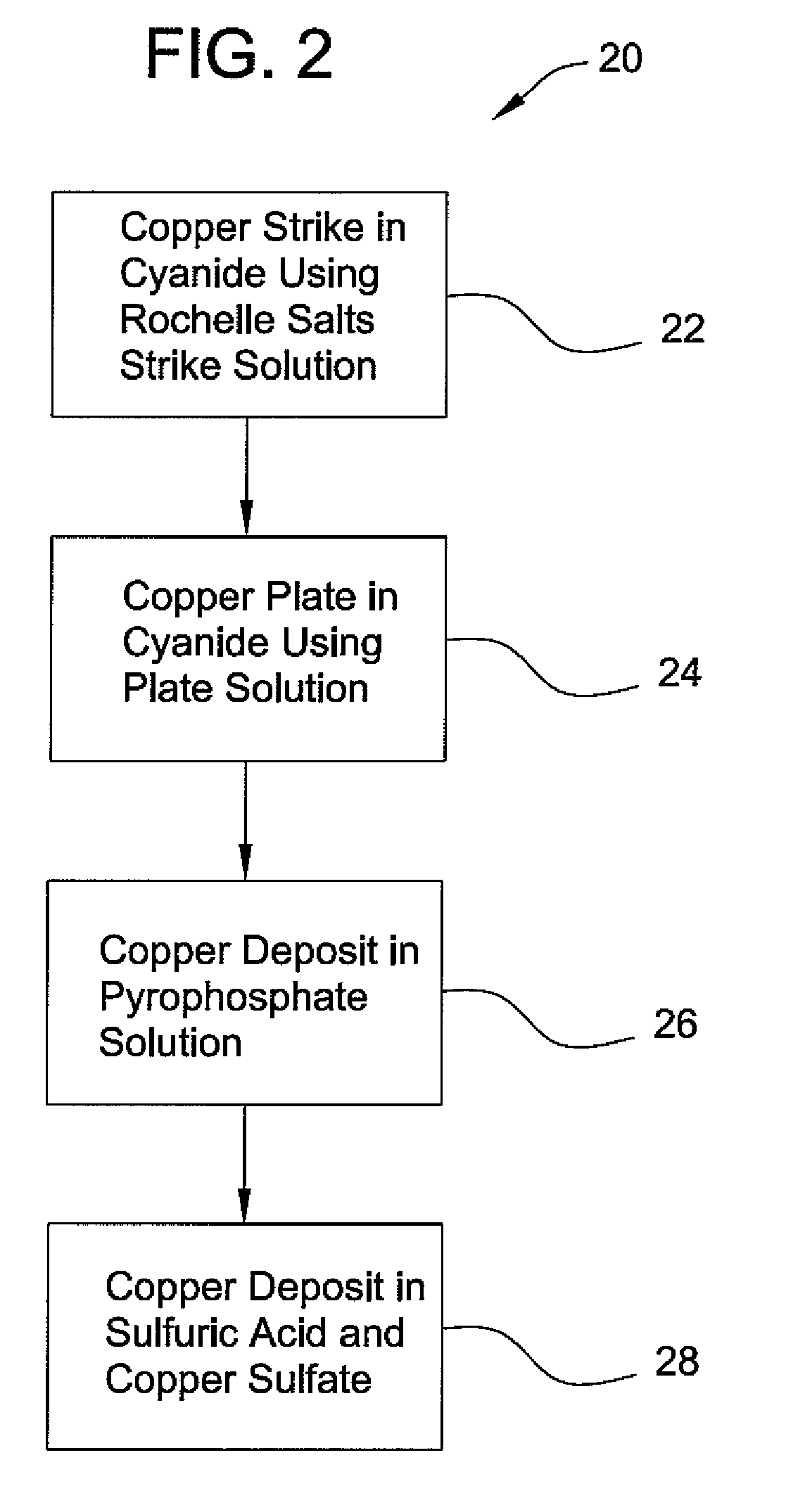

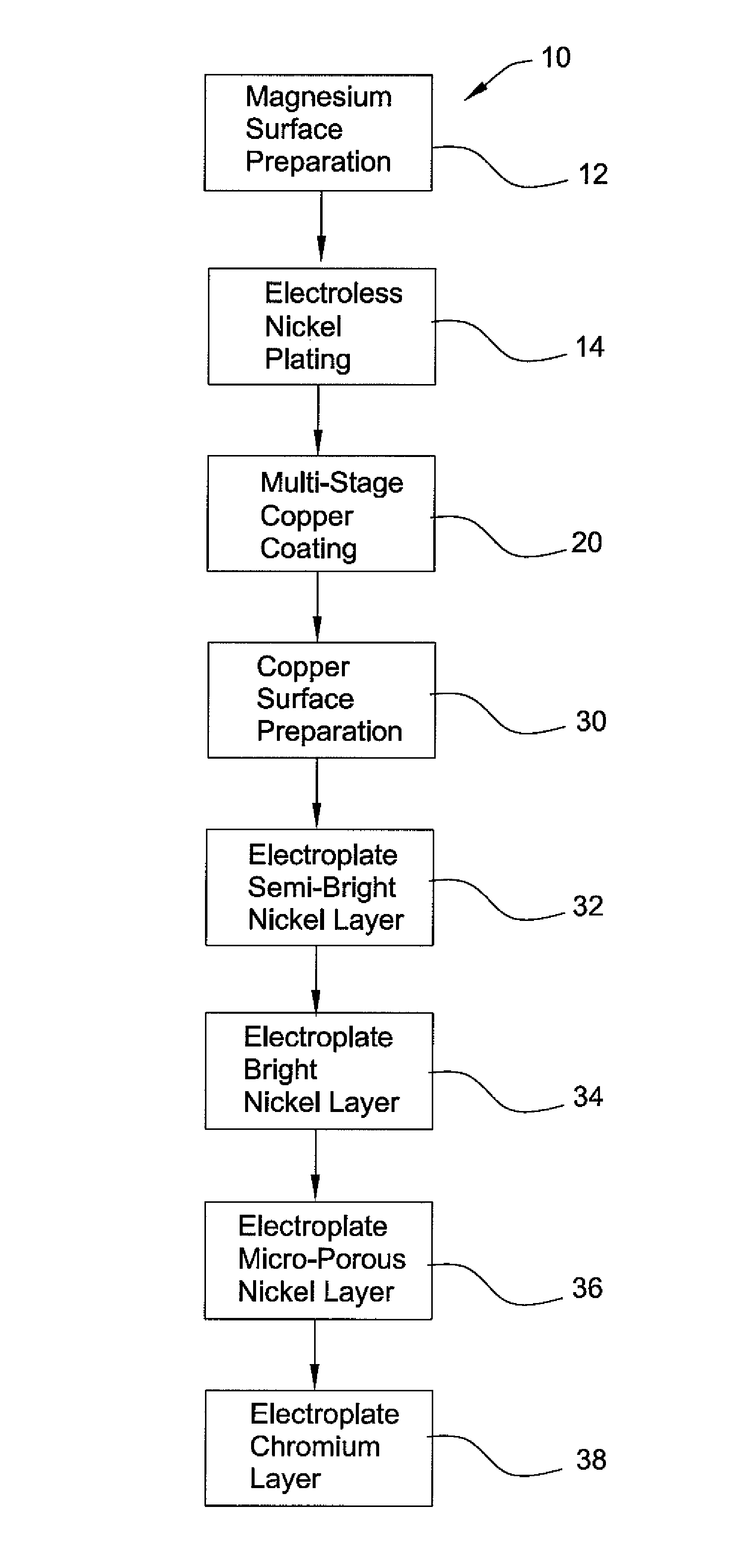

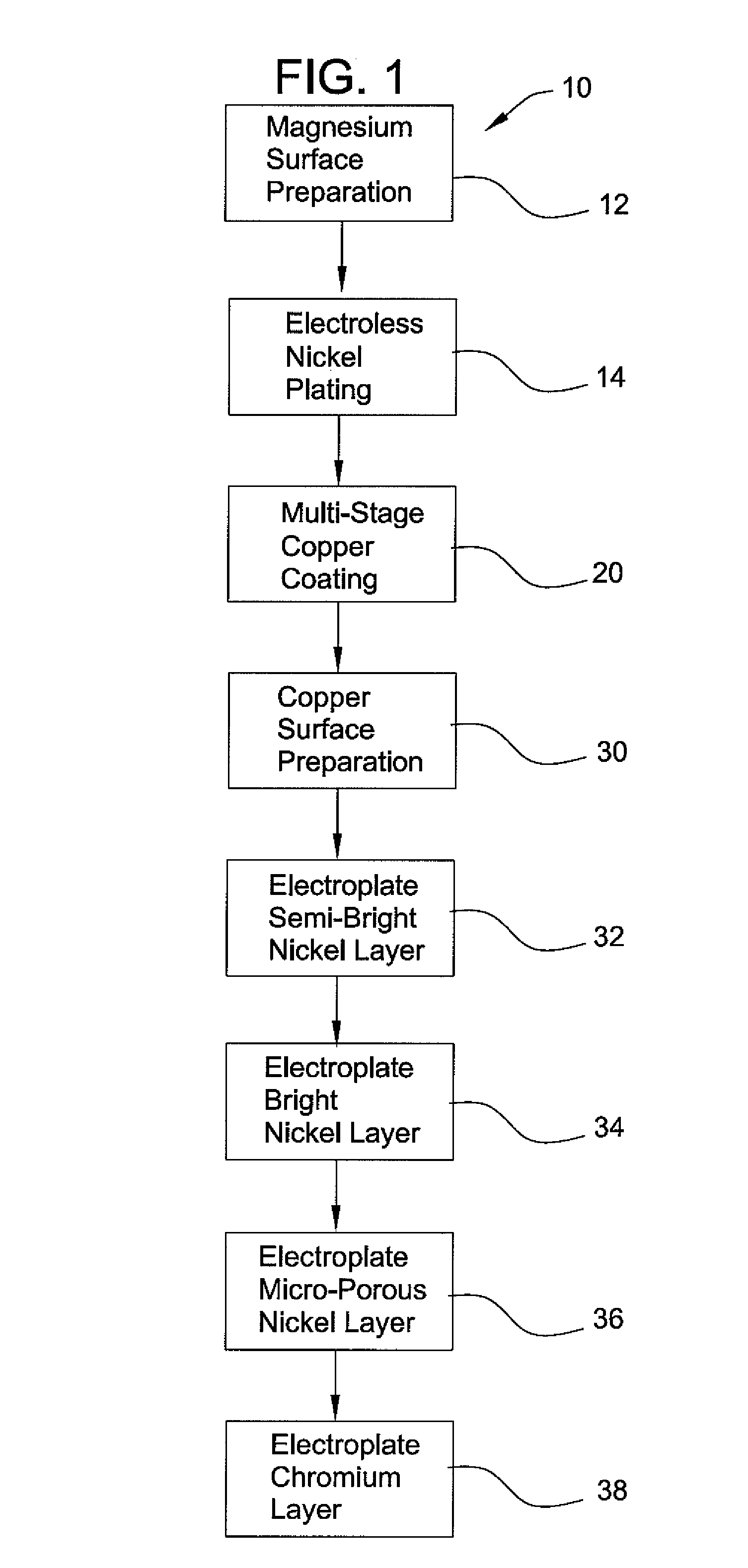

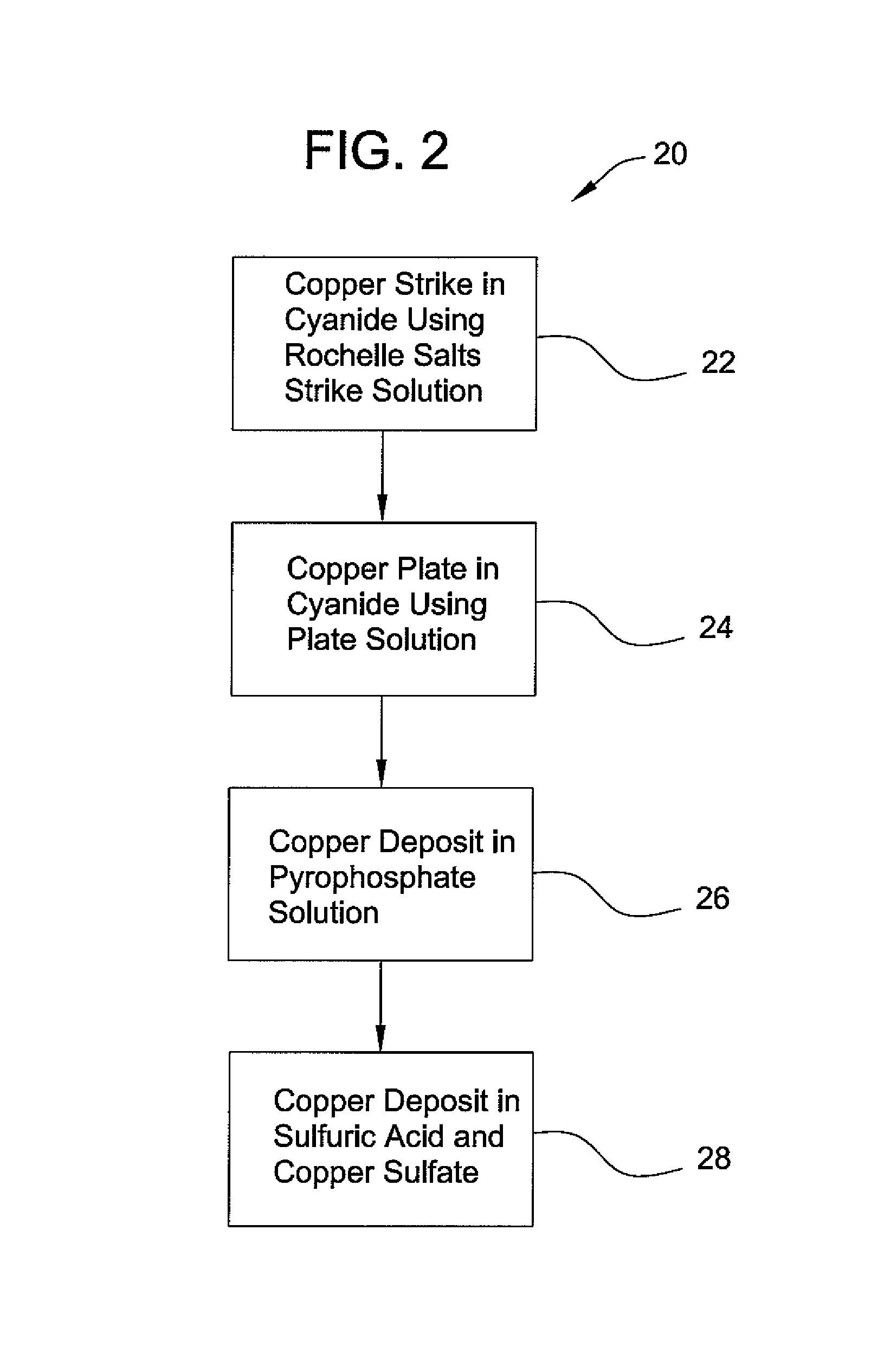

A process for chrome plating magnesium and its alloys. The process uses a combination of electroless nickel plating, a multi-stage copper coating transition system and multiple layers of electrodeposited nickel to form a corrosion resistant system of substantial impermeability and interlayer adherence suitable for direct chromium electroplating.

Owner:ARLINGTON PLATING

Electroplating method for magnesium and magnesium alloy

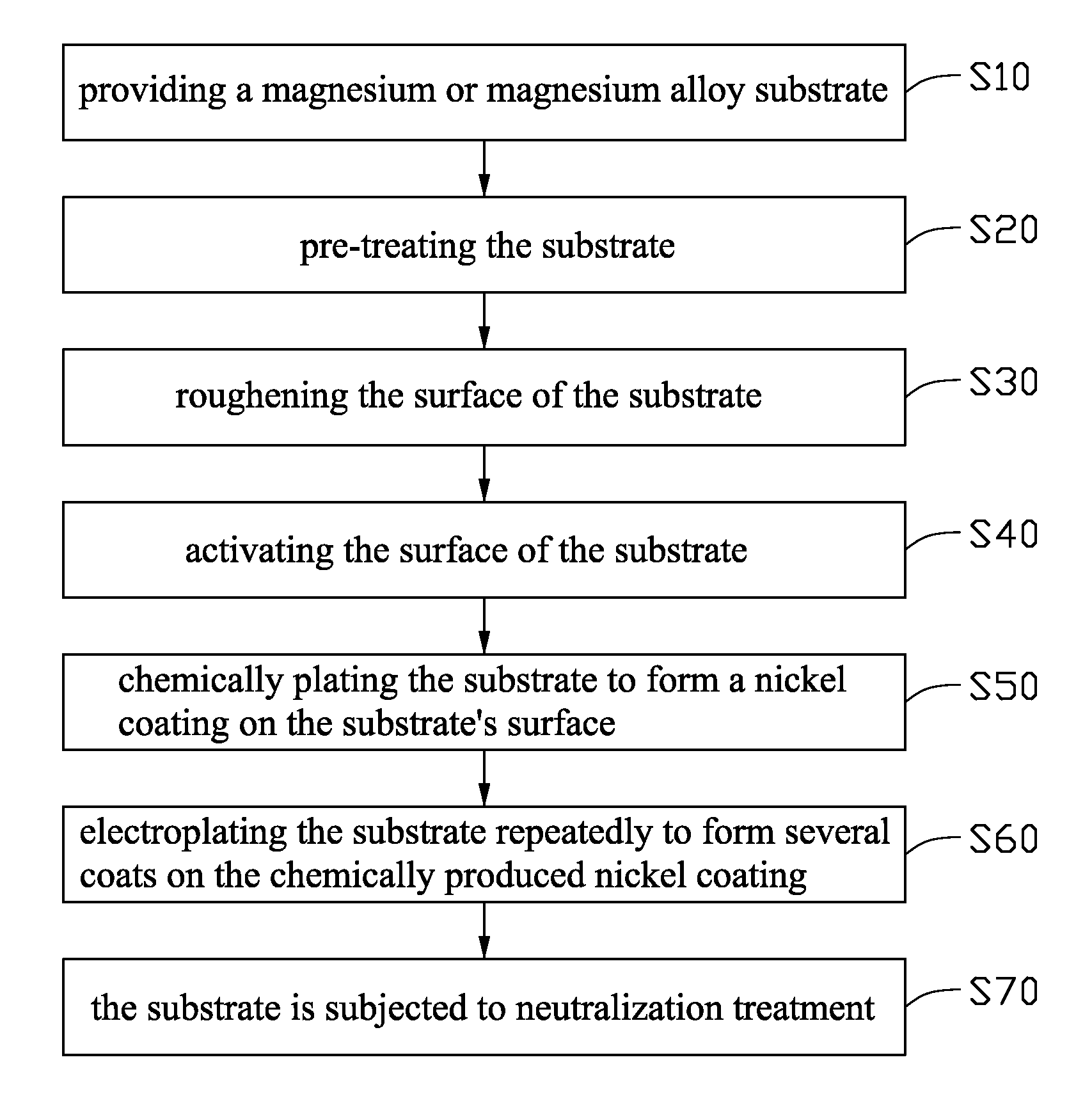

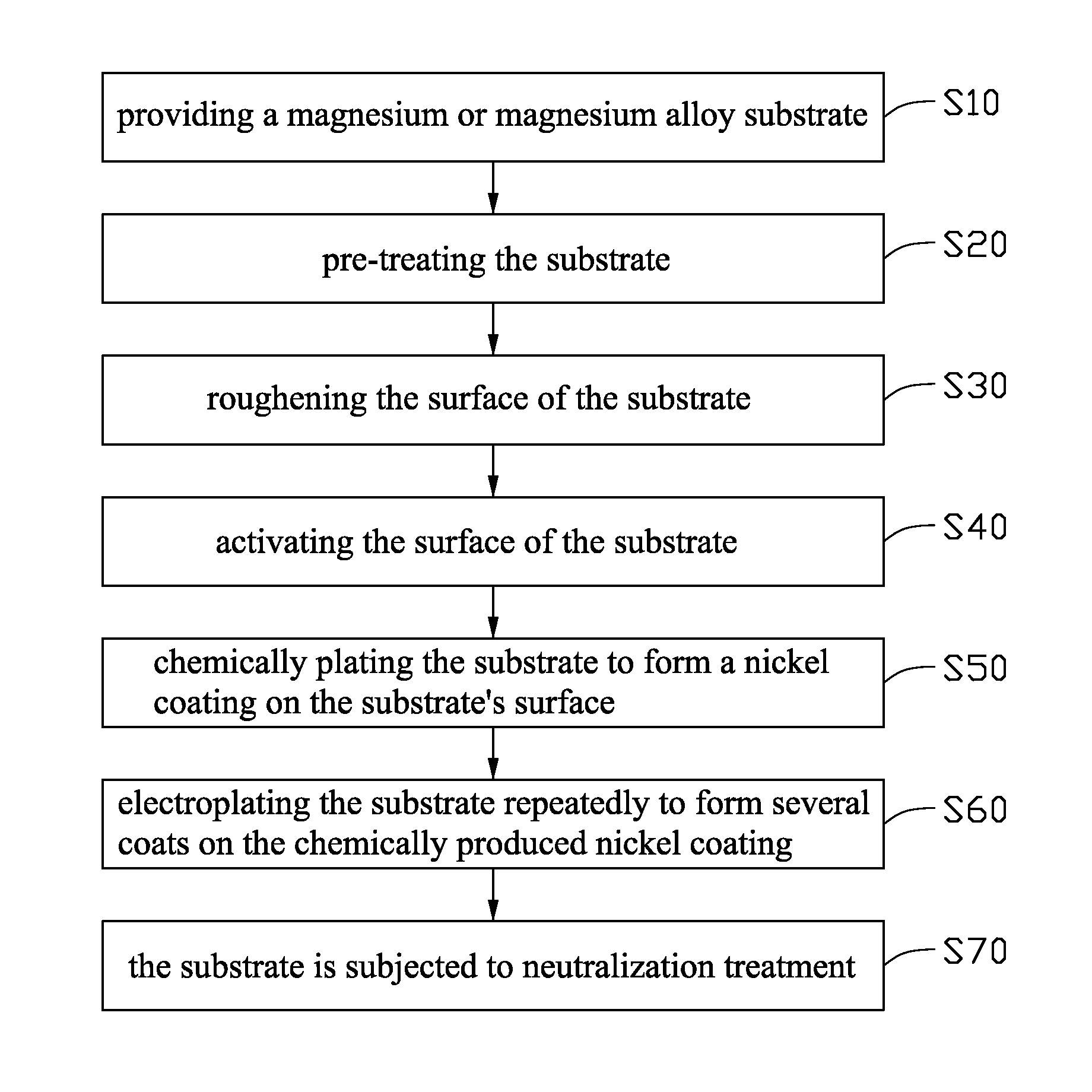

An electroplating method for magnesium and magnesium alloys, comprising: providing a magnesium or magnesium alloy substrate and pre-treating it to be cleaned; roughening the surface of the substrate; activating the surface of the substrate; chemically plating the substrate to form a nickel coating on its surface; and electroplating the substrate to form, in order, a first nickel coating, a copper coating, a second nickel coating, and a chromium coating on the chemically produced nickel coating.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

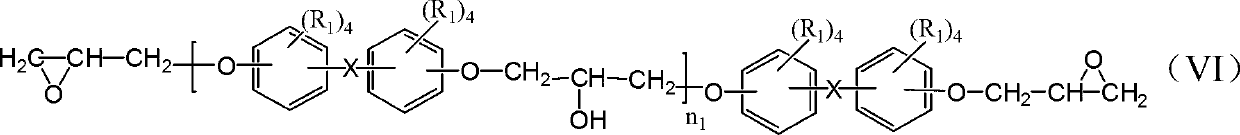

A preparation method of gum-free flexible copper-coating plate

PendingCN101157077AImprove heat resistanceGood flexibilityPretreated surfacesCoatingsDielectricCopper foil

The invention discloses a preparation method for a non-glue type flexible copper clad laminate. The invention has the method that monomer aromatic diamine is dissolved in non-protonic polar solvent, and aromatic tetracid dianhydride with the equal molar is added into the solution, thereby generating polyamic acid solution with 10 to 30 percent of the solid content in a polyamic way; dehydrating agent and catalyst are dropwise added into the solution, and the chemical imidization is performed at 10 to 80 DEG C, thereby obtaining polyimide precursor solution; the polyimide precursor solution is coated on the copper foil surface with the 60 to 70 micron thickness, and heated to remove the solvent, and the thermal imidization is further performed at 250 to 300 DEG C, thereby obtaining the non-glue type flexible copper clad laminate. The non-glue type flexible copper clad laminate of the invention has the excellent heat resistant performance, is suitable for the non-lead welding meeting the environmental protective requirement, has small crimpability, good dimensional stability, better mechanical strength, high peel strength, and high flexibility resistance, and simultaneously has lower thermal expansion coefficient, dielectric constant, and water absorption.

Owner:湖北省化学研究院

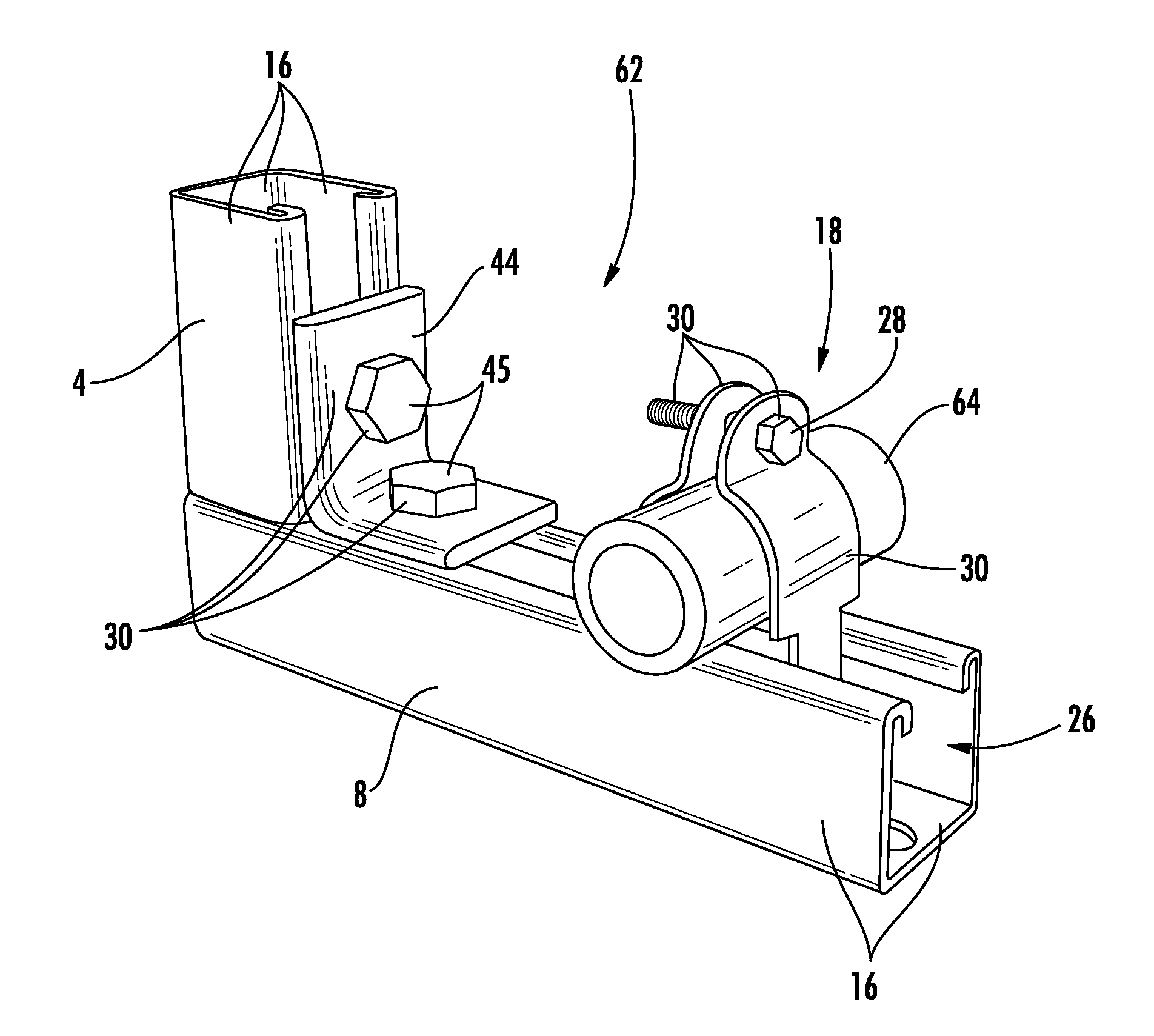

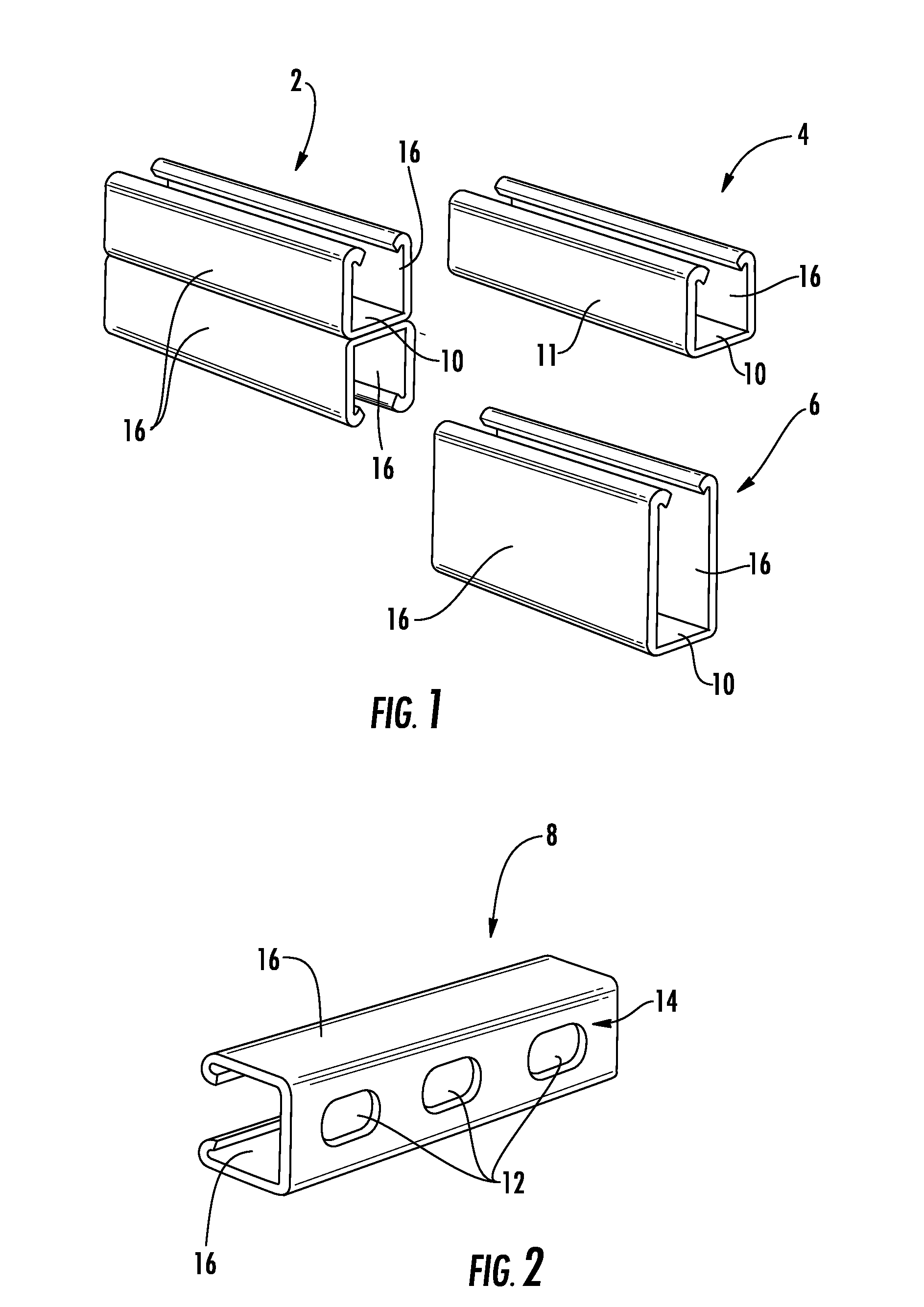

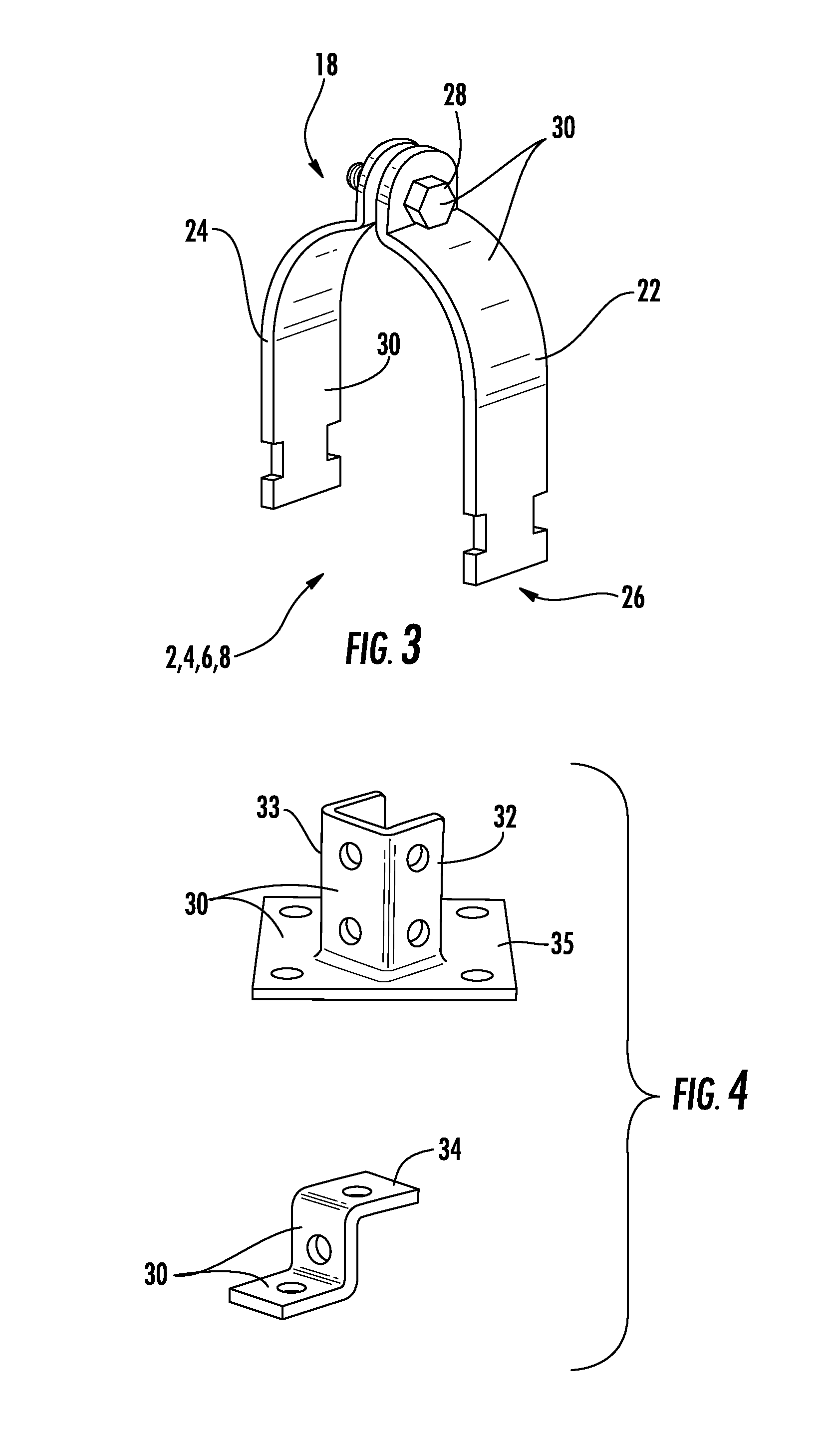

Enhanced corrosion resistant channels, fittings and fasteners

A corrosion resistant support system includes a first channel member having a first corrosion resistant coating. The first corrosion resistant coating is a zinc-aluminum-magnesium coating. A fitting is engageable with said channel member and a first mechanical fastener to couple the fitting to the channel member, the fitting and the first mechanical fastener having a second corrosion resistant coating. The second corrosion resistant coating is a thermal diffusion galvanized coating or a zinc-aluminum-magnesium coating. The first channel member and the first mechanical fastener may also have a third corrosion resistant coating disposed over the first and second corrosion resistant coatings, respectively. The third corrosion resistant coating can be a Perma-Green™ coating, a powder coating, an electrocoating (E-coat or Electrophoretic deposition coating), a paint coating, an epoxy coating, a polyvinyl chloride (PVC) coating, a trivalent chromium coating, a hexavalent chromium coating, a zinc coating, and / or a copper coating.

Owner:UNISTRUT INT CORP

Cathode current collector, and preparation method and application of cathode current collector

ActiveCN107369810AIncrease energy densityHigh tensile strengthNitrogen-metal/silicon/boron binary compoundsElectrode carriers/collectorsCopper platingEvaporation

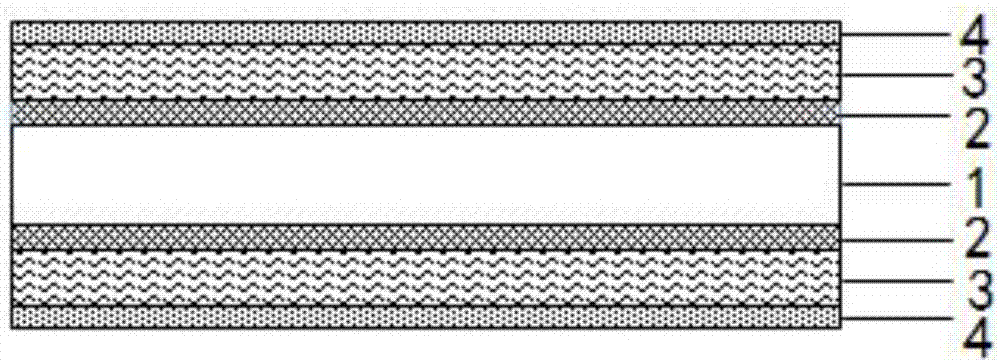

The invention discloses a cathode current collector, and a preparation method and an application of the cathode current collector. The cathode current collector is in a multilayer structure, and comprises a plastic film, wherein the upper and lower surfaces of the plastic film are sequentially coated with bonding force reinforcement layers, copper coating layers and antioxidation layers. The preparation method comprises the steps of coating the bonding force reinforcement layers on the plastic film by utilizing a magnetron sputtering coating technology, coating the copper coating layers by utilizing an evaporation coating technology, and coating the antioxidation layers by utilizing an electron beam evaporation coating technology or the magnetron sputtering coating technology. The application of the cathode current collector is mainly in a lithium ion battery. The cathode current collector can realize lightweighting of the battery, improves the energy density, lowers the cost, and can reduce the possibility of falling and oxidation of the copper coating layers.

Owner:CONTEMPORARY AMPEREX TECH CO

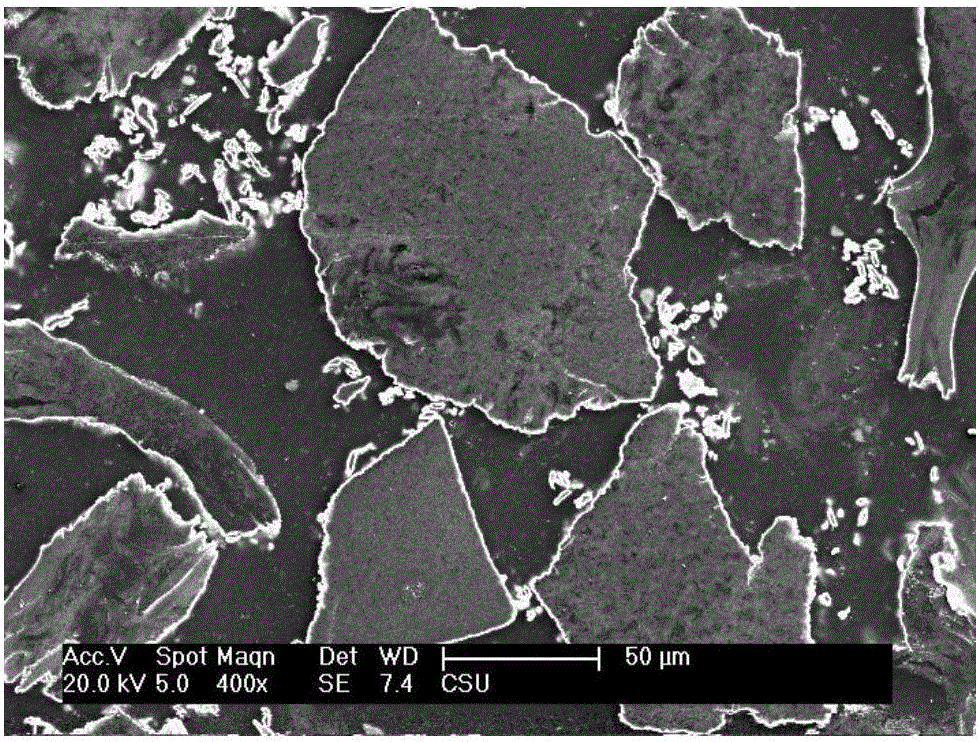

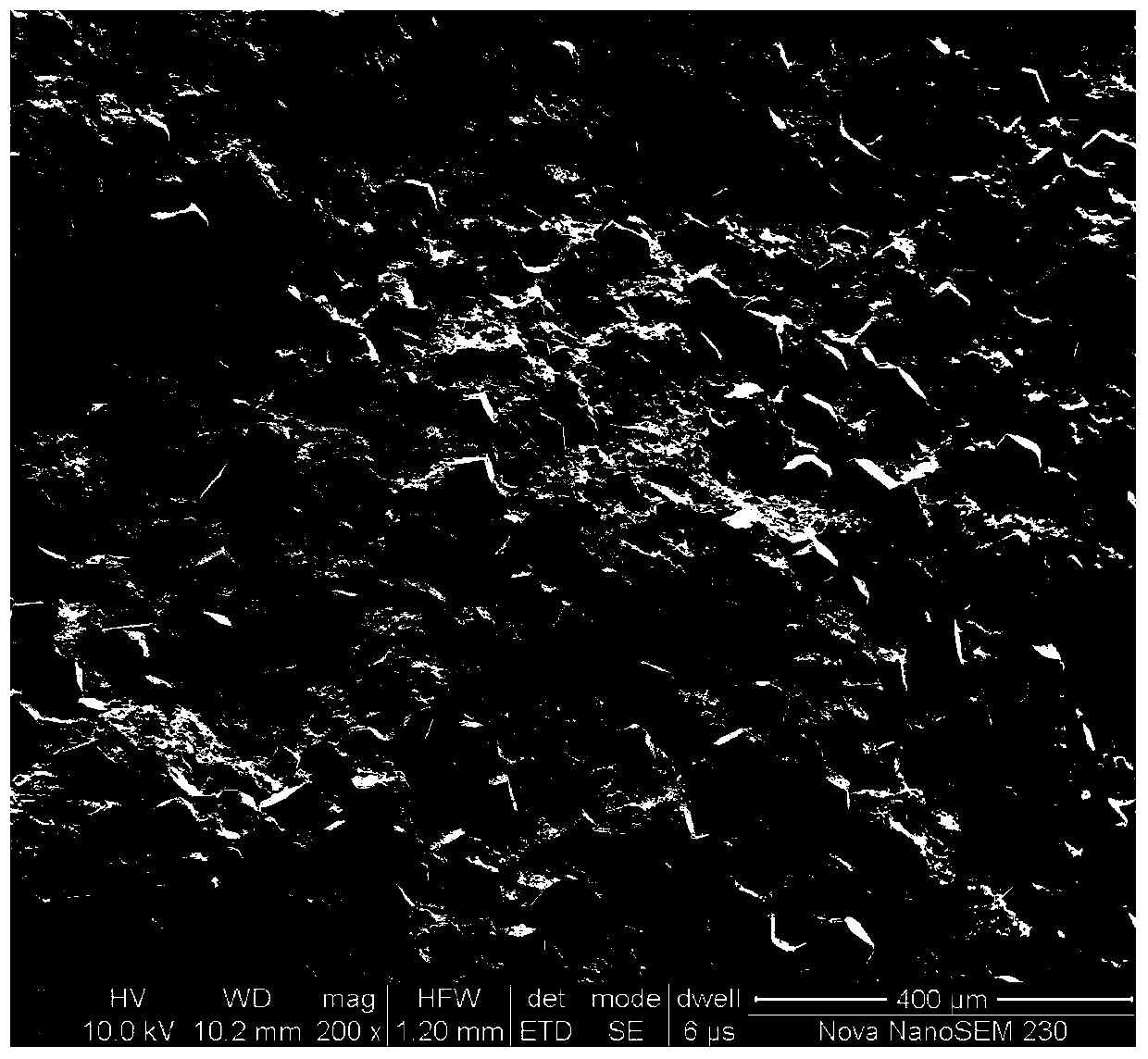

Copper-carbon composite material and preparing method thereof

ActiveCN106424713APromotes even distributionImprove performanceTransportation and packagingMetal-working apparatusFiberCarbon composites

The invention discloses a copper-carbon composite material and a preparing method thereof. Natural flake graphite, colloidal graphite, nano graphite, carbon fiber and the like can be selected as a carbon material in the copper-carbon composite material. The preparing method of the copper-carbon composite material includes the steps that firstly, a chemical nickel plating method is used for preparing a nickel plating carbon material; then a chemical copper plating method is used for plating copper on the nickel plating carbon material; and finally, vacuum semi-solid-state low-pressure sintering is conducted on the copper plating carbon material under the copper melting point temperature, and the copper-carbon composite material is prepared. The copper-carbon composite material and the preparing method thereof have the beneficial effects that a layer of even thin nickel plating layer is formed on the surface of carbon through the nickel plating method so as to reduce the wetting angle of the carbon material, the copper plating layer is formed on the surface of the nickel plating carbon material through the copper plating method so that a three-dimensional copper network can be formed by the material in the sintering process, and the bonding strength of a base body is improved through vacuum semi-solid-state low-pressure sintering. The two phases of the base body and the carbon of the copper-carbon composite material prepared through the method are distributed evenly and are well combined, and the good electricity and mechanical properties and the good frictional wear performance are achieved.

Owner:CENT SOUTH UNIV

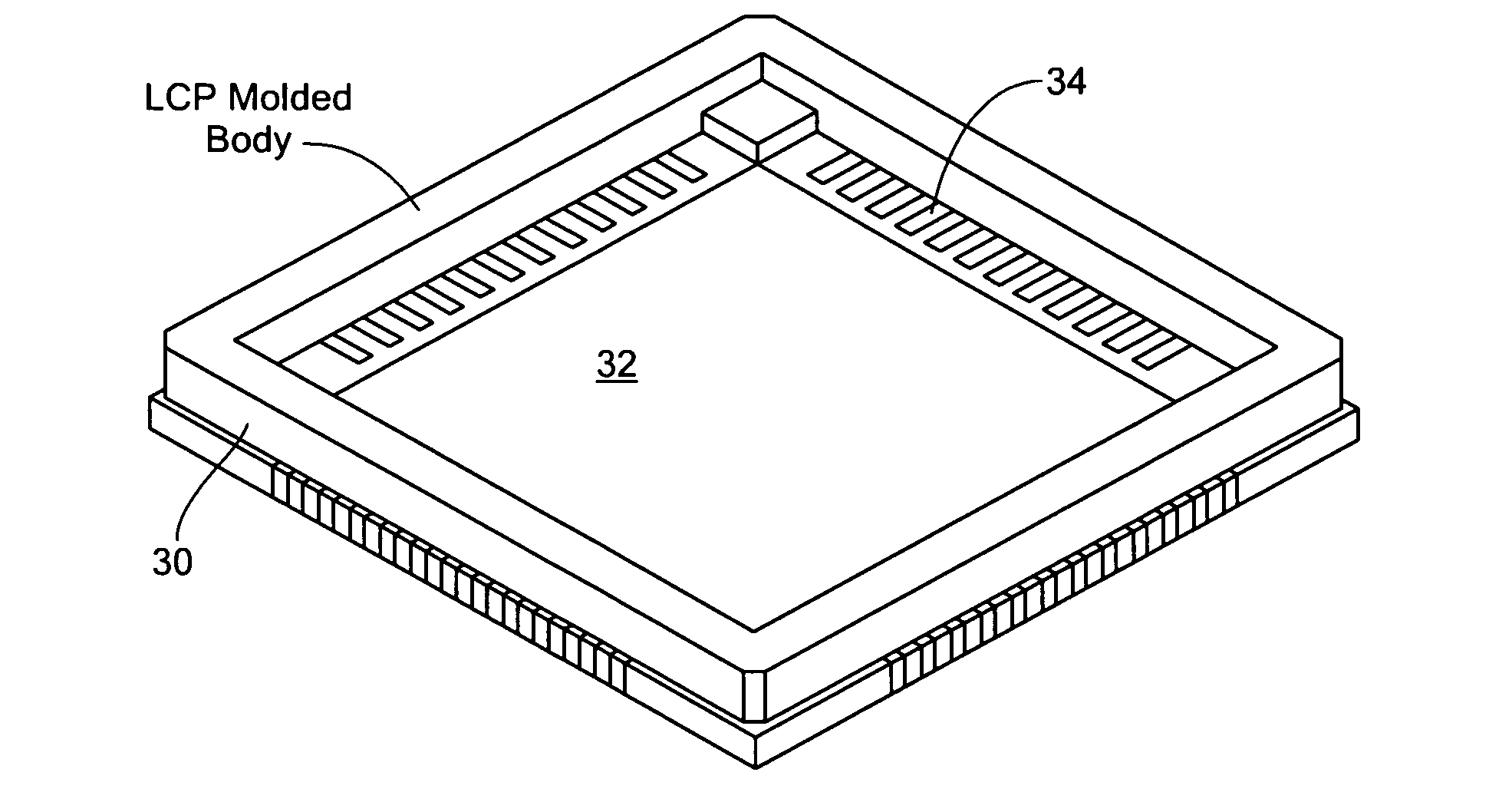

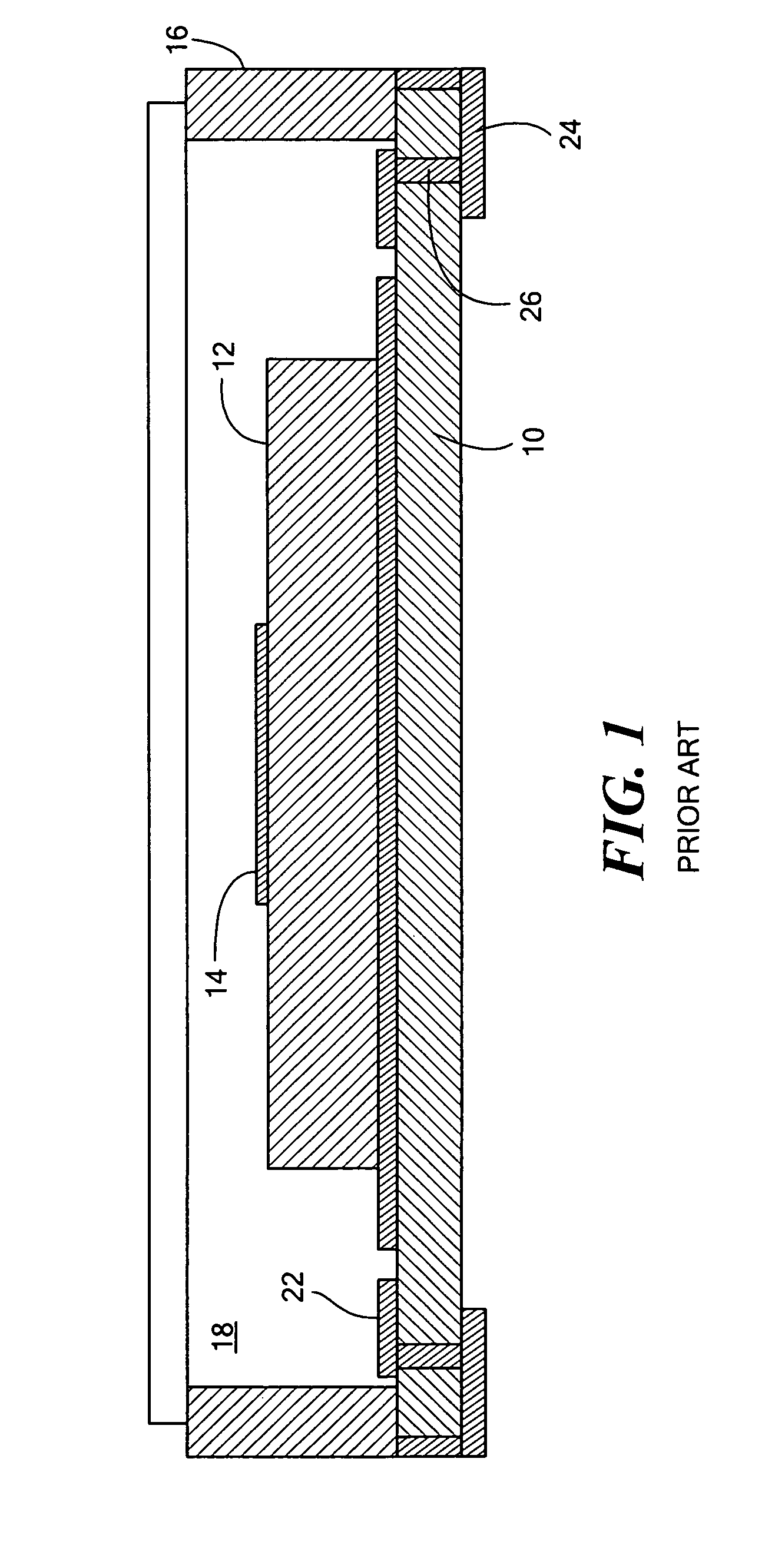

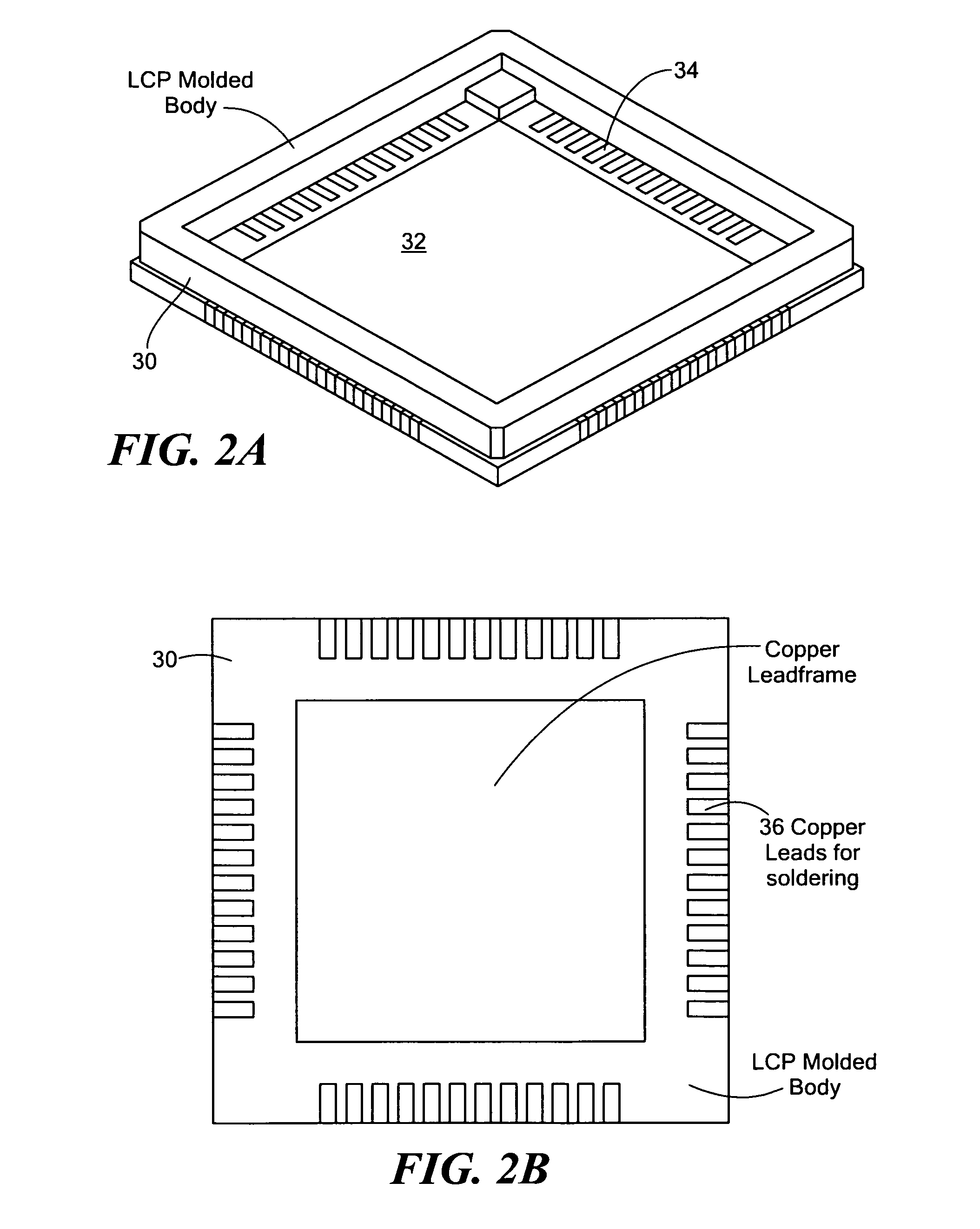

Plastic electronic component package

InactiveUS20080150064A1Eliminate needImprove adhesionEngine sealsSemiconductor/solid-state device detailsCopper coatingPlastic materials

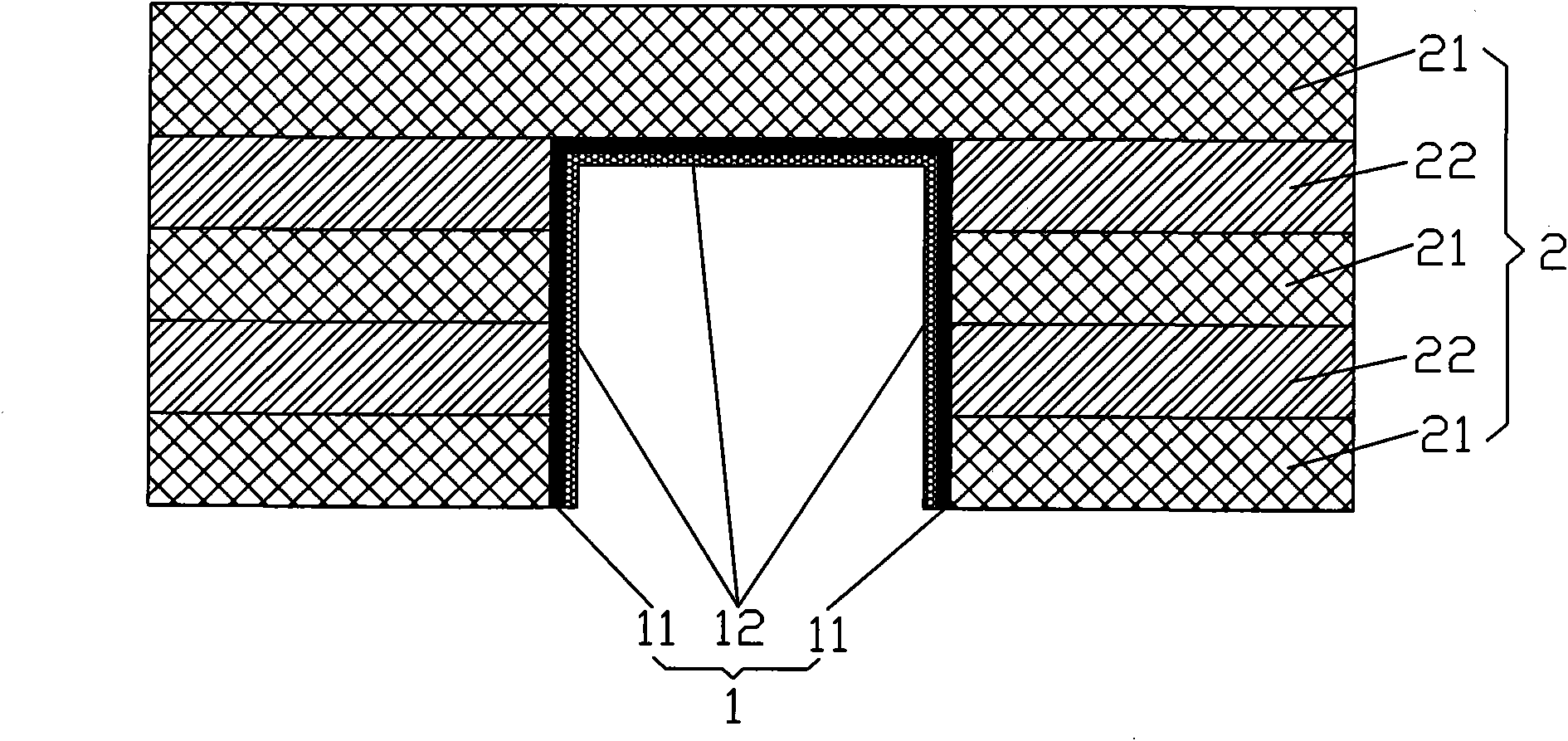

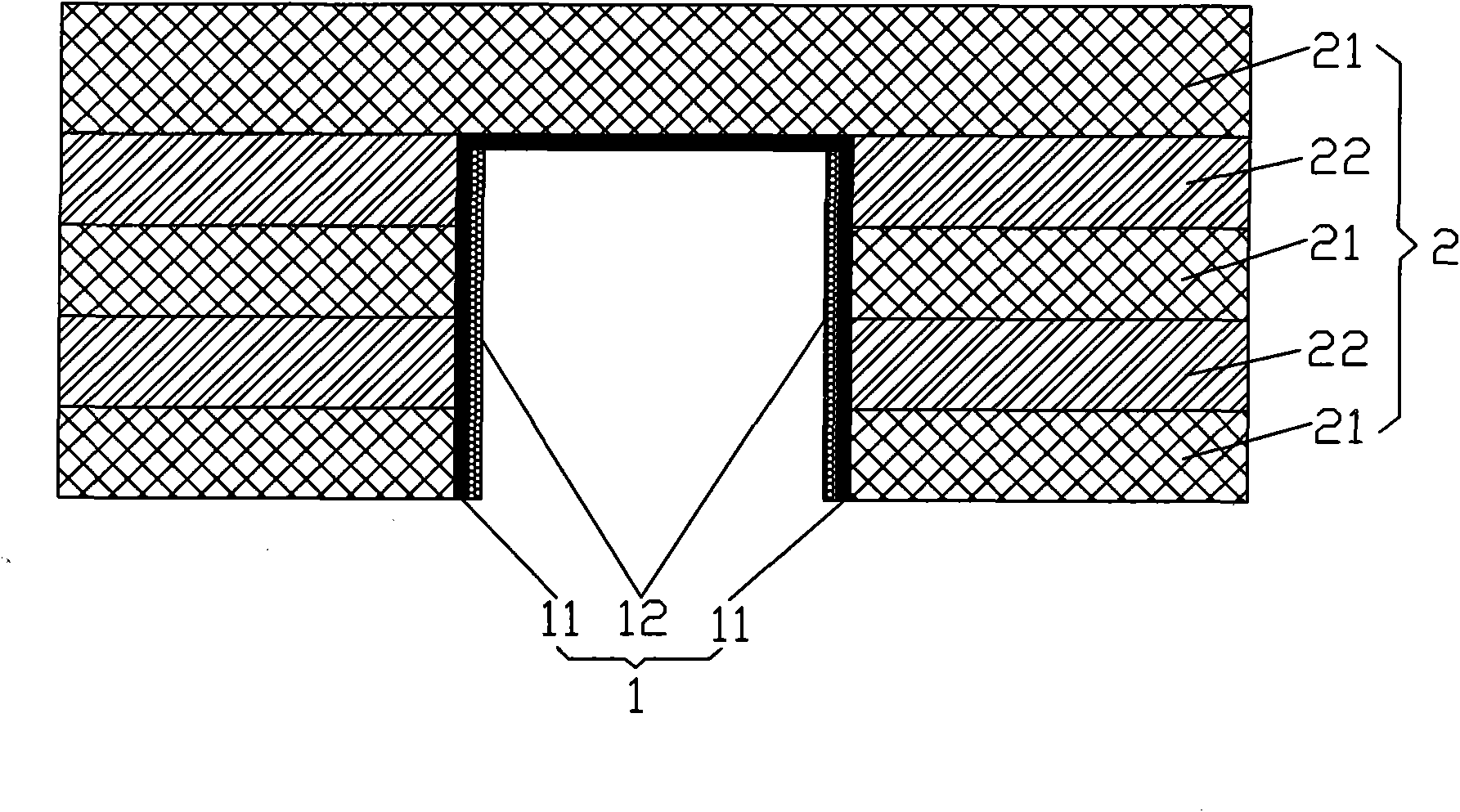

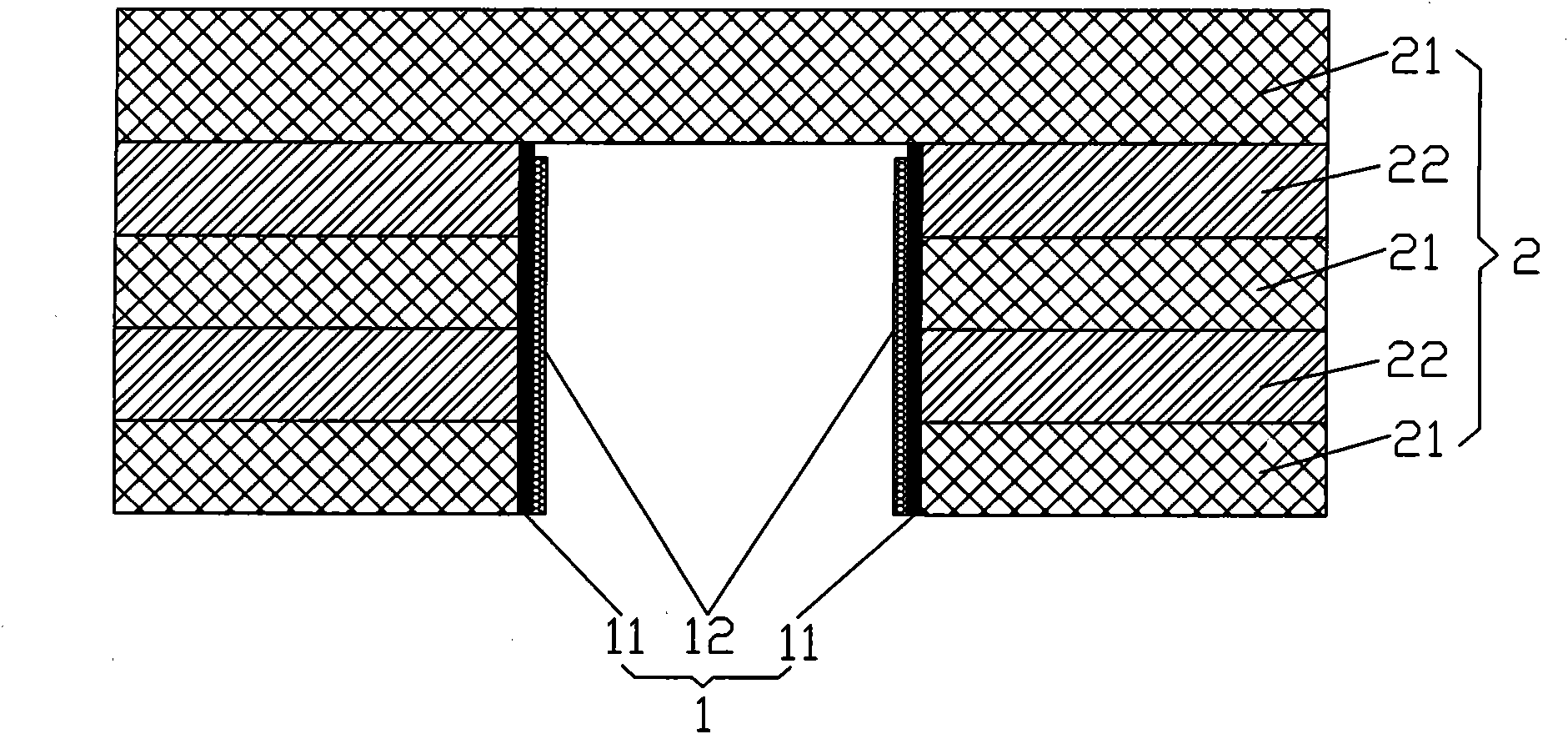

A plastic package for an image sensor or other electronic component which comprises a plastic body, preferably of LCP material, molded around a leadframe and defining a cavity in which the image sensor is to be disposed. A lid assembly is provided having a transparent glass lid retained in a plastic lid frame which is weldable or otherwise bondable to the plastic body of the package to enclose the image sensor mounted in the cavity. The leadframe is usually composed of copper or a copper alloy, or a ferrous alloy having a copper coating. An interfacial layer is formed on the surfaces of the leadframe at least in those portions which are in contact with the plastic body which serves to provide substantially improved adhesion between the leadframe and the plastic material to achieve a hermetic bond between the metal and plastic materials. The interfacial layer is composed of a cuprous oxide base layer formed on a surface of the leadframe, and a cupric oxide layer formed on the cuprous oxide layer. The cupric oxide outer layer has an acicular structure which provides an interlocking mechanism for adhesion to the plastic material molded thereto in forming the package.

Owner:IQLP

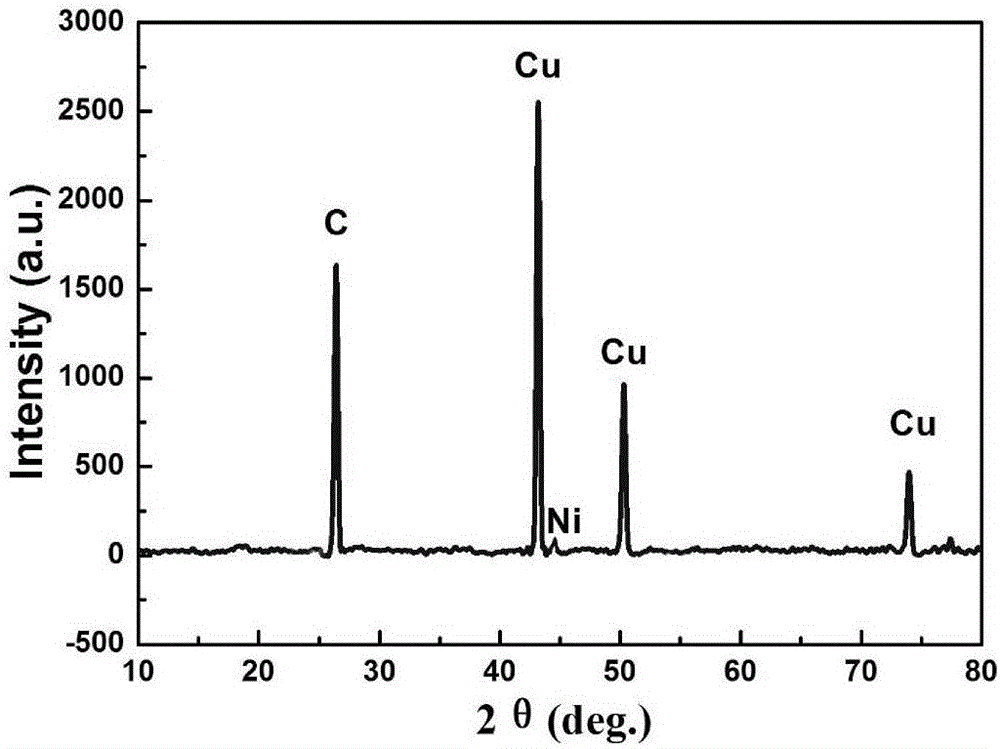

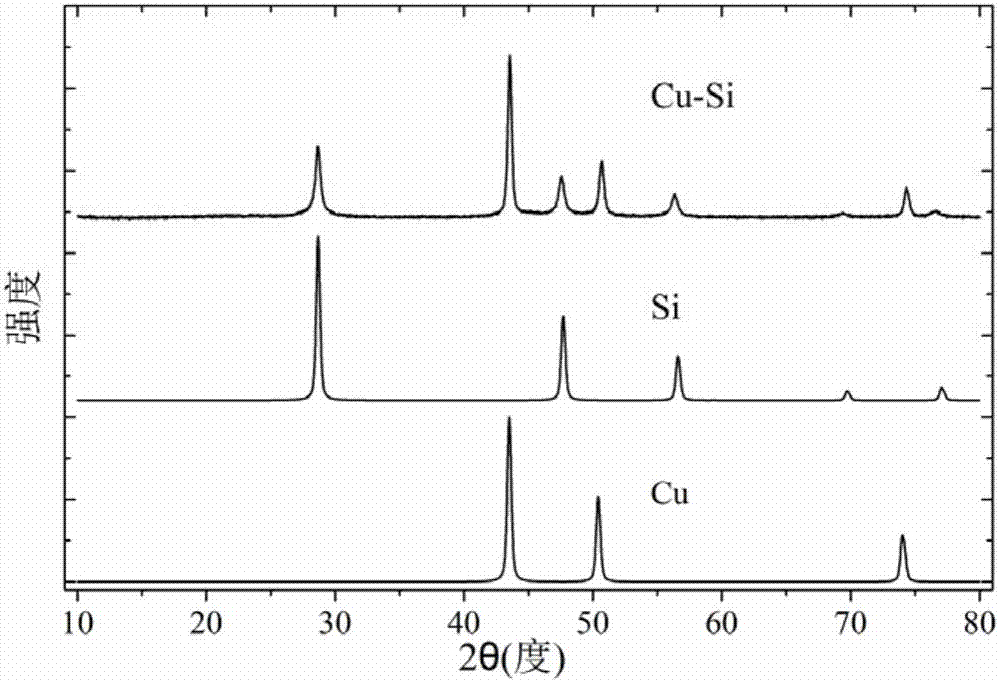

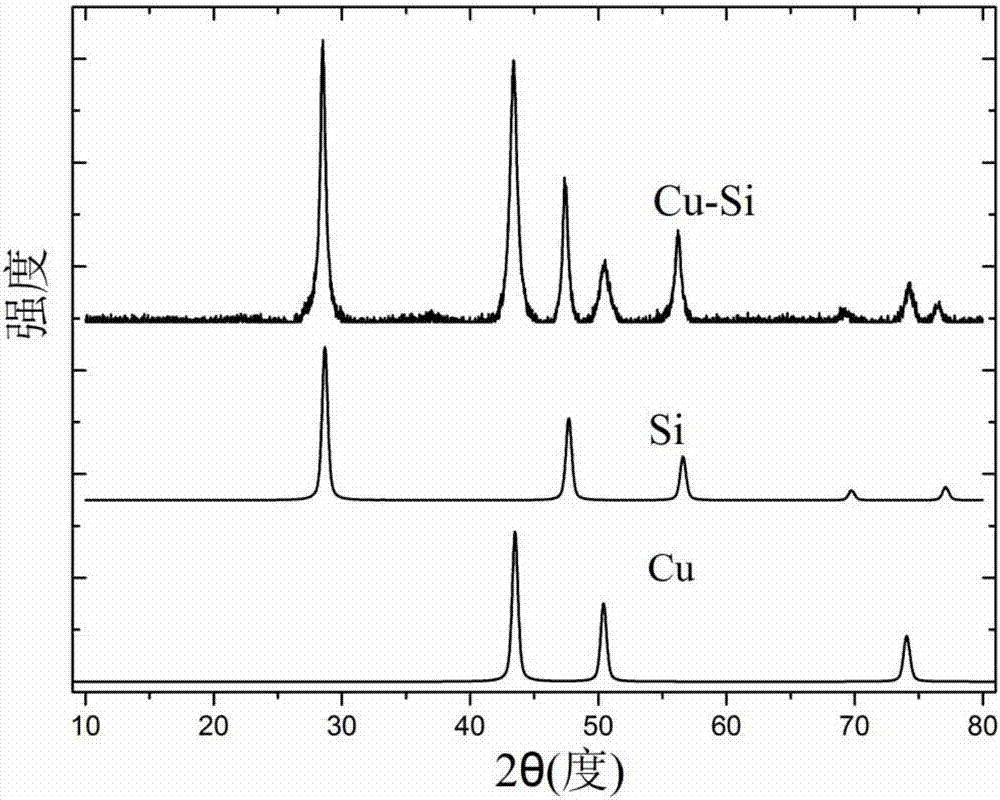

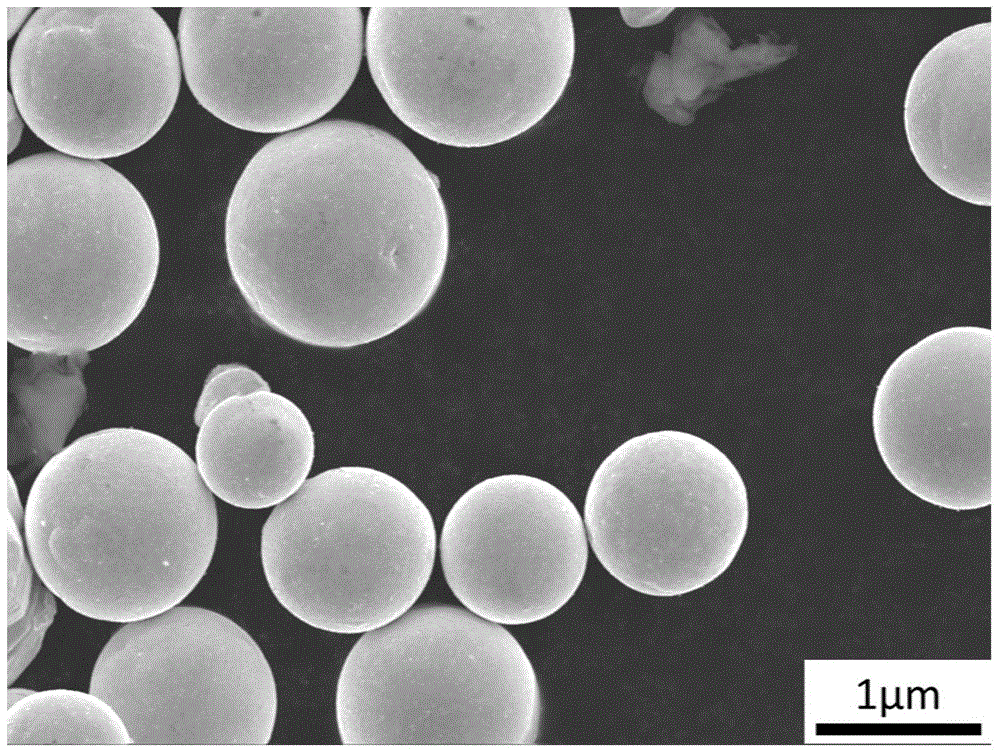

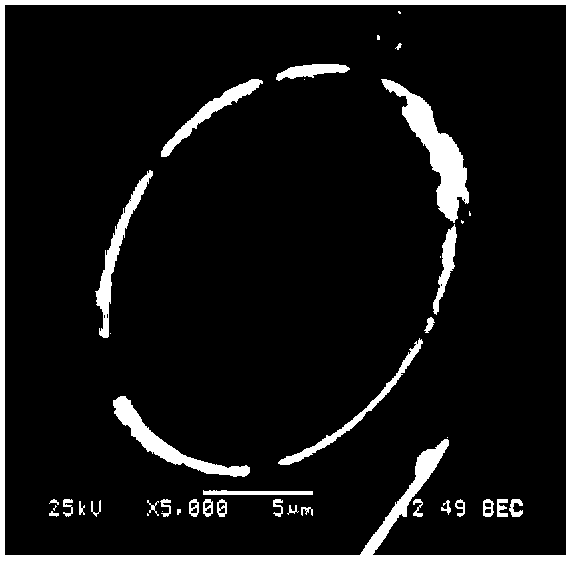

Dual-layer-coated nanometer silicon negative electrode material and preparation method and application thereof

InactiveCN107492651AThe synthesis process is simpleLow costMaterial nanotechnologyNegative electrodesExtensibilityLithium

The invention provides a dual-layer-coated nanometer silicon negative electrode material and a preparation method and an application thereof. The negative electrode material comprises silicon-based nanoparticles, a copper layer for coating the surfaces of the silicon-based nanoparticles, and a conductive protection layer for coating the surface of the copper layer. The nanometer copper has super-plastic extensibility and conductivity; in addition, the existing calculation already proves that lithium ions can penetrate through the nanometer copper, so that the copper coating layer can suppress volume expansion of the silicon-based nanoparticles and keep the silicon-based nanoparticles not cracked; therefore, direct contact between the silicon-based nanoparticles and an electrolyte can be avoided effectively, thereby forming a stable SEI and improving conductivity of an electrode; however, the nanometer copper is easily oxidized to form copper oxide and cuprous oxide to form an adverse SEI on the surface; and therefore, the surface of the nanometer copper is coated with the conductive protection layer so as to effectively suppress oxidization of the nanometer copper, thereby improving electrochemical performance.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

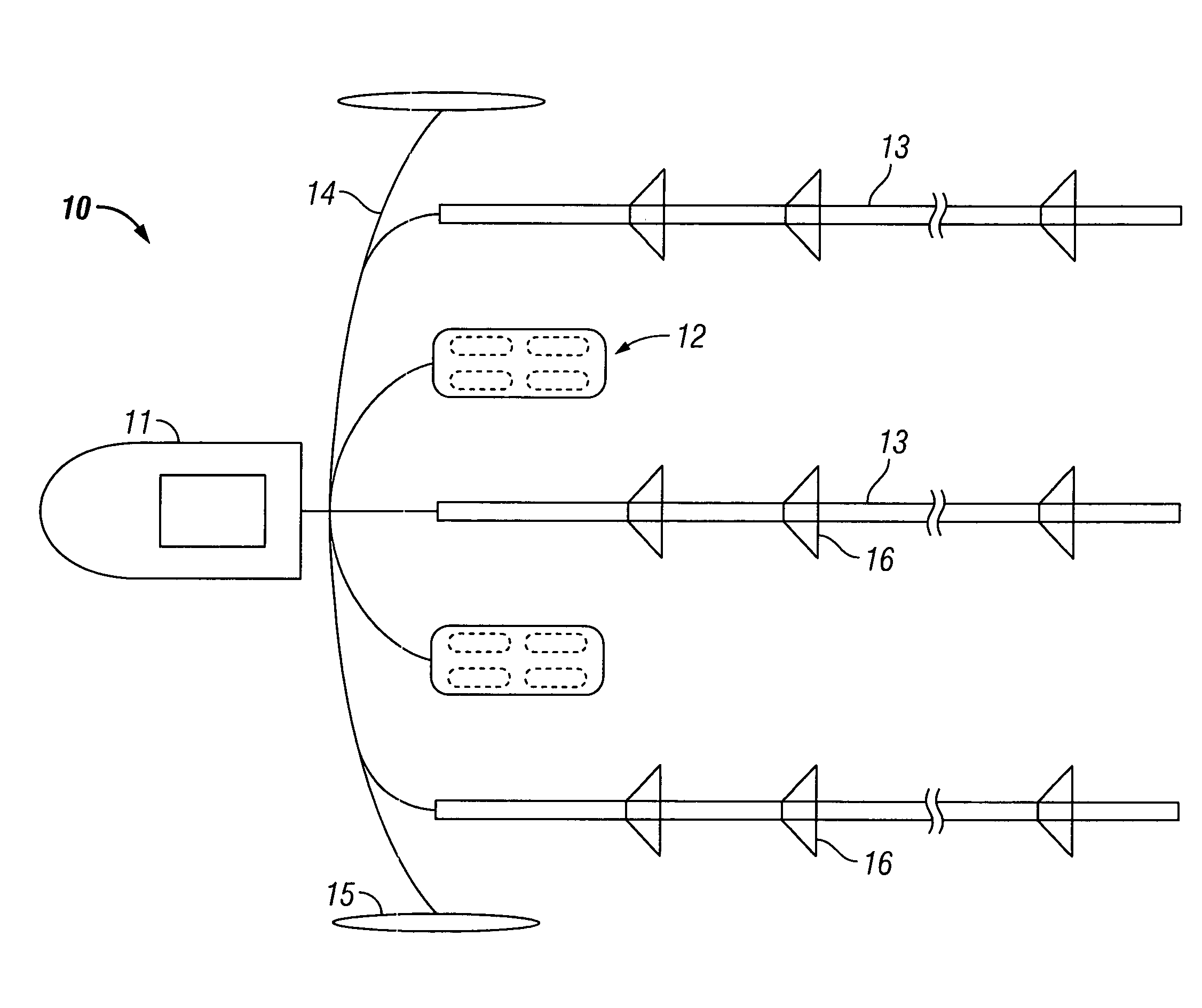

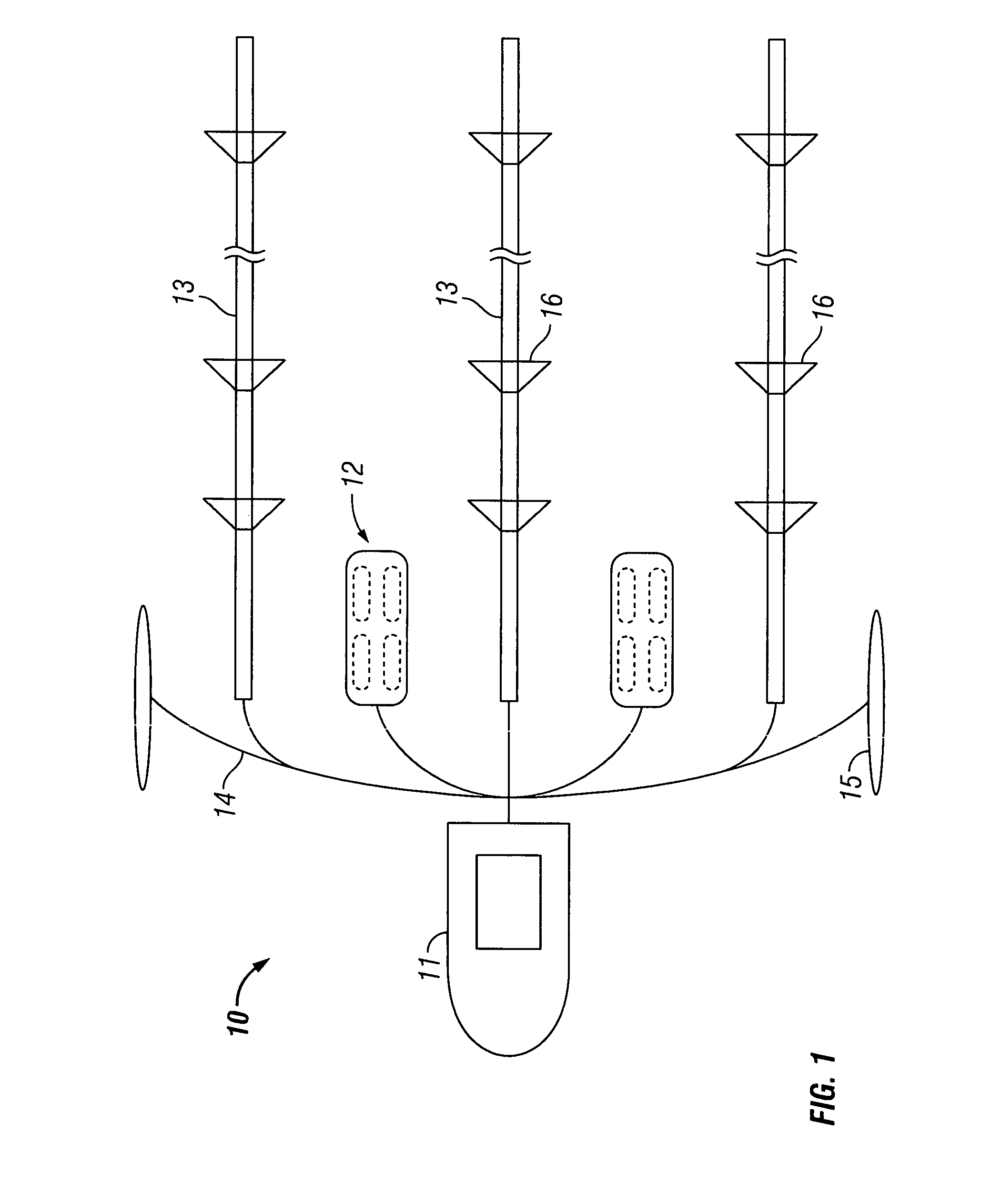

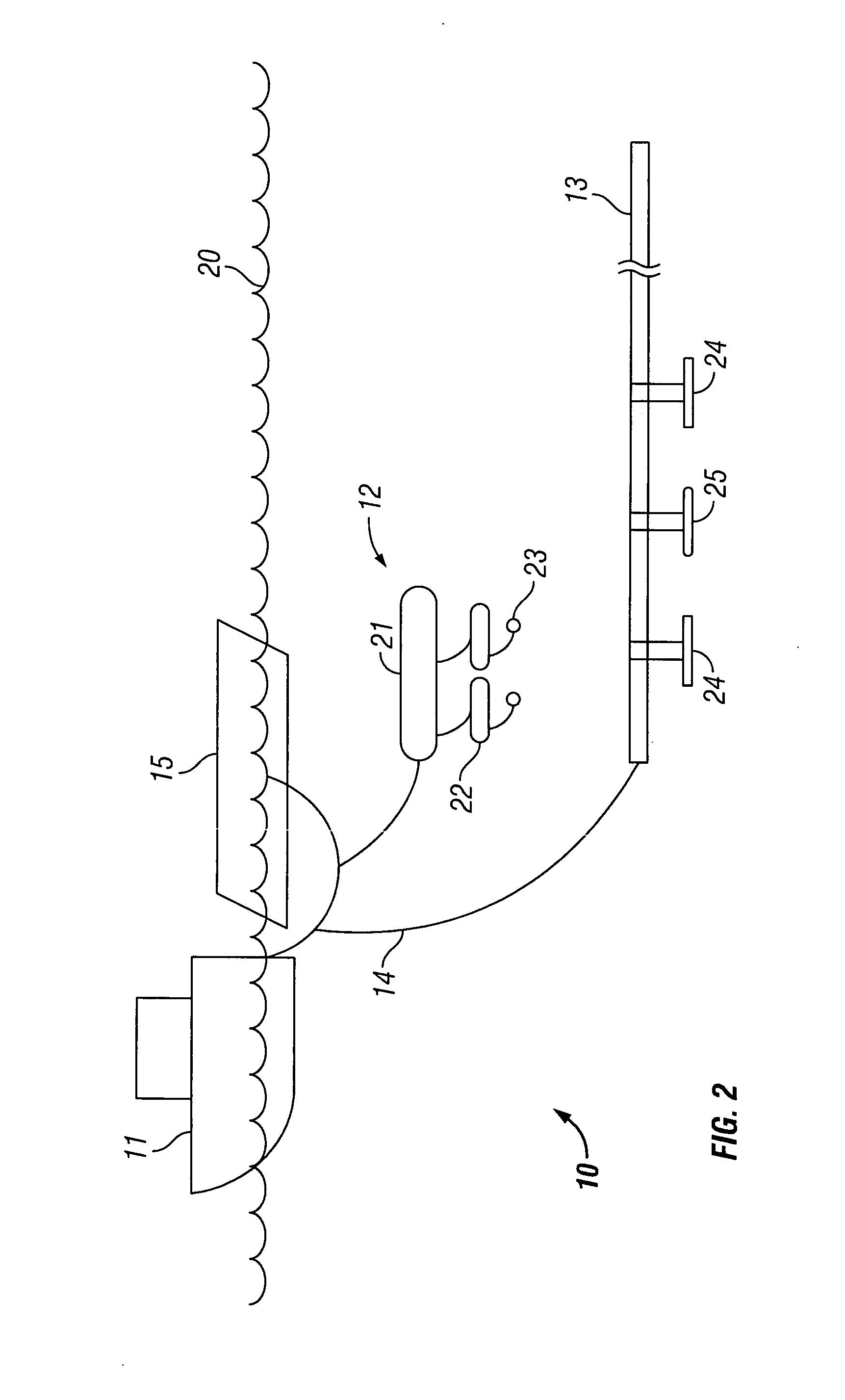

System and method for using copper coating to prevent marine growth on towed geophysical equipment

A system comprises towed marine seismic equipment marine seismic equipment, adapted for towing through a body of water; and a coating of copper particles covering the marine seismic equipment to protect from marine growth. A method comprises towing marine seismic equipment having a coating of copper particles thereon to protect from marine growth.

Owner:PGS GEOPHYSICAL AS

High-conductivity composite carbon fiber and preparation method thereof

InactiveCN103144356ALow resistivityImprove conductivityVacuum evaporation coatingSputtering coatingMetal coatingYarn

The invention discloses a high-conductivity composite carbon fiber and a preparation method thereof, and belongs to composite carbon fibers and a preparation method thereof. The high-conductivity composite carbon fiber provided by the invention consists of carbon fibers as well as metal coatings and graphene coatings, which are sequentially adhered on the surfaces of the carbon fibers from bottom to top; the carbon fibers are carbon fiber yarns, carbon fiber bundles, carbon fiber cloth, carbon fiber paper or carbon fiber fabrics; the metal coatings are a metal copper coating, a metal nickel coating or a metal iridium coating; and the thicknesses of the metal coatings are 50-500nm. The composite carbon fiber prepared by the invention has excellent conductivity and heat conductivity, can conduct or dissipate lightning stroke energy rapidly, and improves the thunder stroke resistant capability of the carbon fiber material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Metal-ceramic bond diamond grinding wheel and production method thereof

ActiveCN103692371AGood self-sharpeningImprove gripAbrasion apparatusGrinding devicesPowder mixtureCopper plating

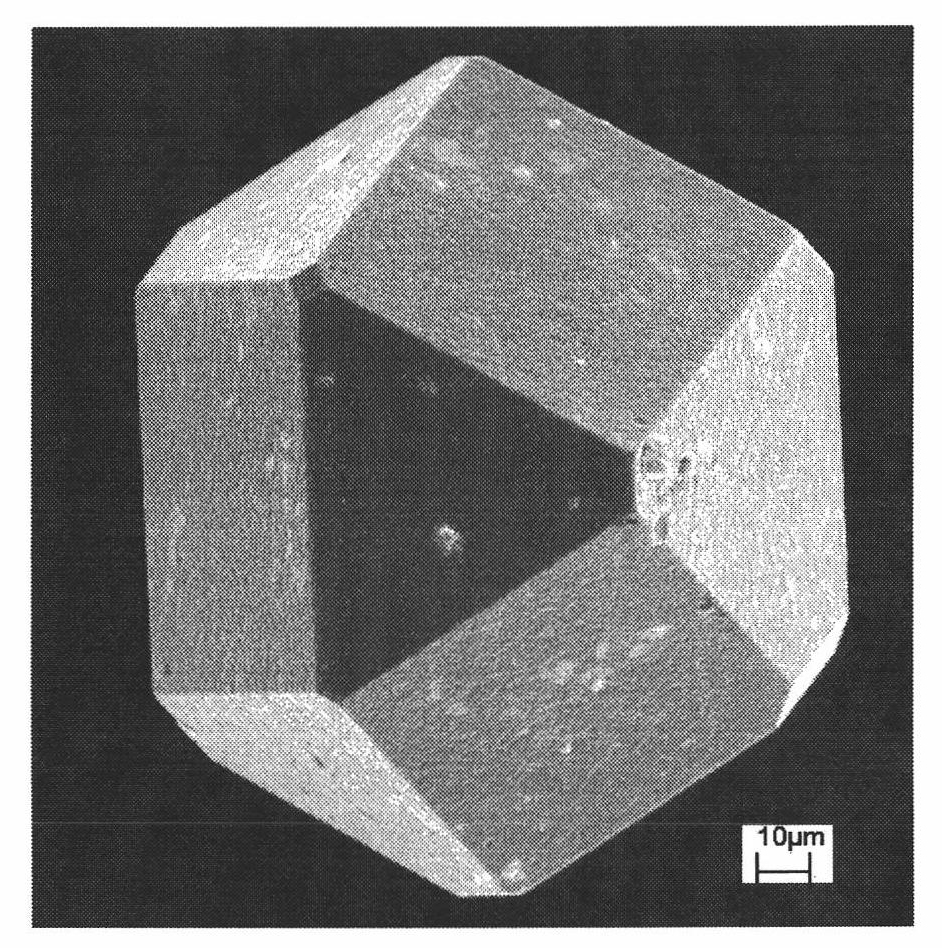

The invention discloses a novel metal-ceramic bond diamond grinding wheel having the high strength and form-holding property in metal bond grinding wheels and the high self-sharpening property in ceramic bond grinding wheels, and a production method thereof. The metal-ceramic bond diamond grinding wheel is produced by: 1, preparing powder mixture out of 60-70% of copper-plated diamond powder, 15-20% of (W, Ti)C powder, 5-10% of tin powder, and 5-15% of iron group powders; mixing according to the above components and ratio to obtain the powder mixture; 2, forming, namely pressing the powder mixture into blanks by pressure forming; 3, sintering, namely subjecting the blanks to inert atmosphere low-pressure sintering, heating the blanks to 850-1050DEG C during sintering, and holding the temperature for 10-30 minutes. The copper-plated diamond powder is composed of particles with average particle size of 5-80 micrometers, and the particles are composed of diamond cores and copper coatings covering the diamond cores. Inert atmosphere during sintering is 5-10Mpa.

Owner:长沙市萨普新材料有限公司

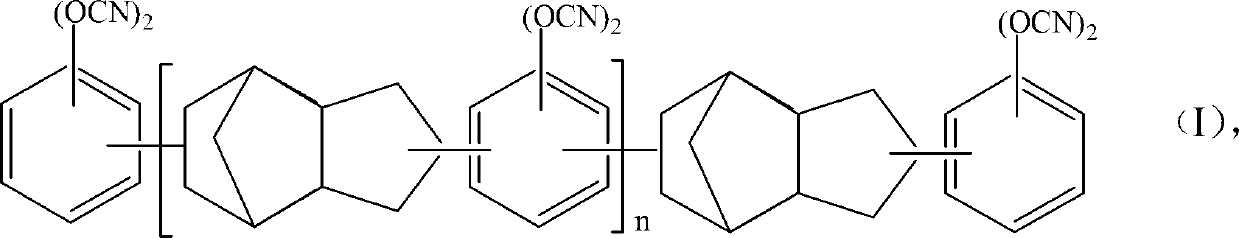

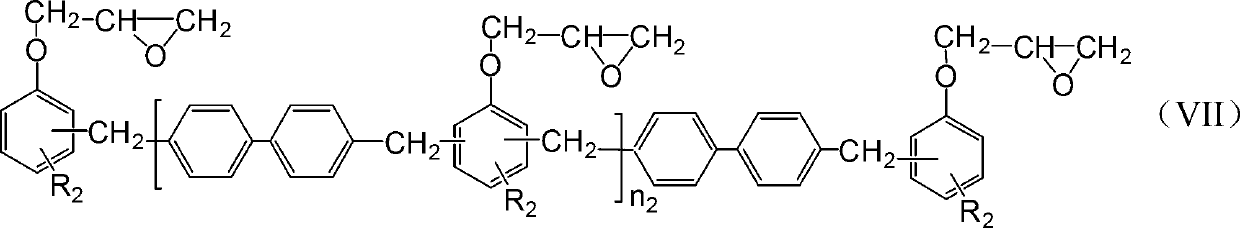

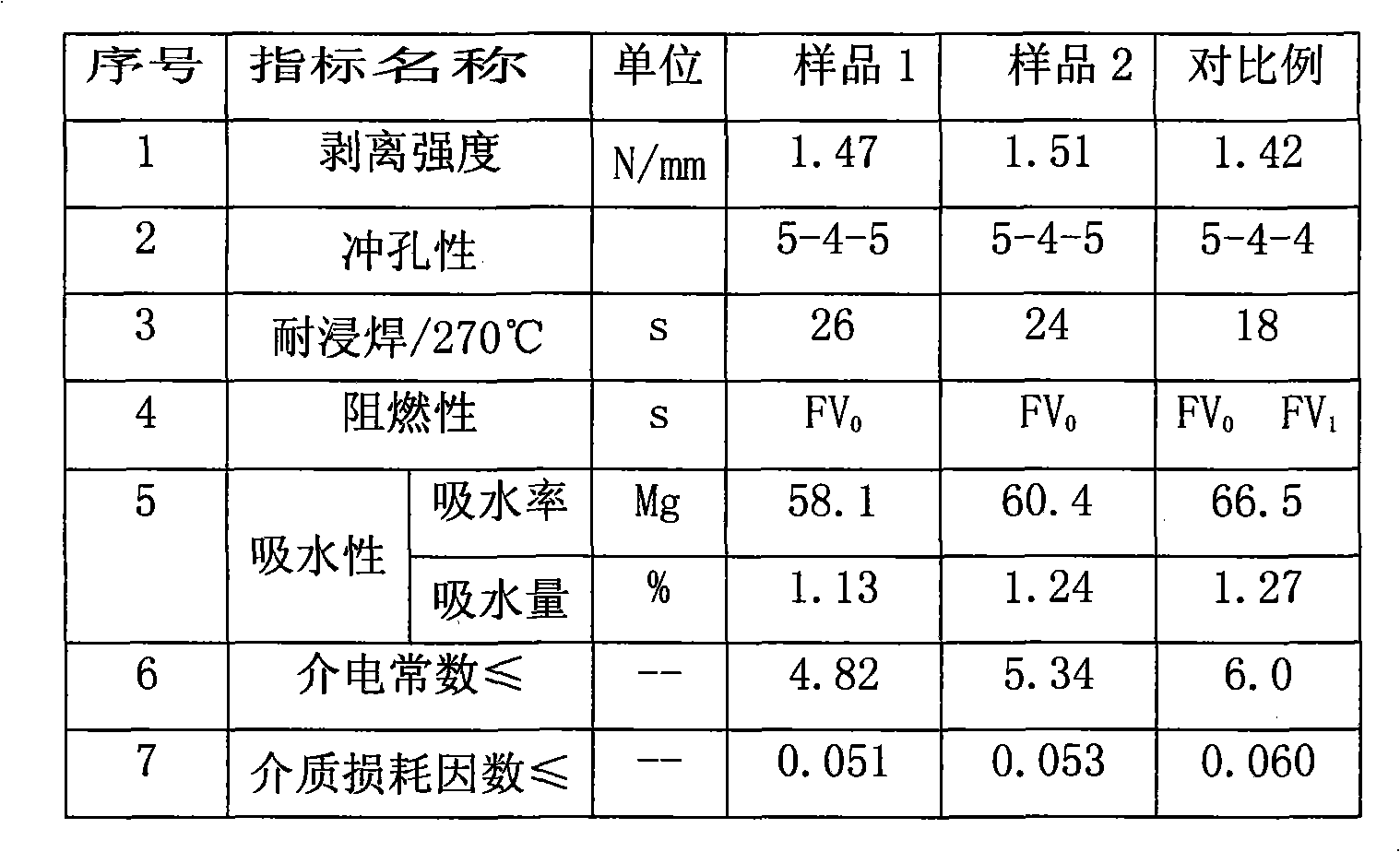

Thermosetting cyanate resin composition and application of thermosetting cyanate resin composition

ActiveCN102942684AOvercome the disadvantage of high water absorptionImprove heat resistanceSynthetic resin layered productsEpoxyCopper coating

The invention relates to a thermosetting cyanate resin composition, which comprises the following components: polyfunctional cyanate, epoxy resin, flame retardant agent and inorganic filler. The thermosetting cyanate resin composition is used for preparing resin substrates, resin compound metal copper foils, prepregs, laminating plates, copper-coating plate laminating plates, printed circuit boards and the like. The thermosetting cyanate resin composition has good heat resistant property, humidity resistant property and flame retardant property and low heat expansion coefficient.

Owner:GUANGDONG SHENGYI SCI TECH

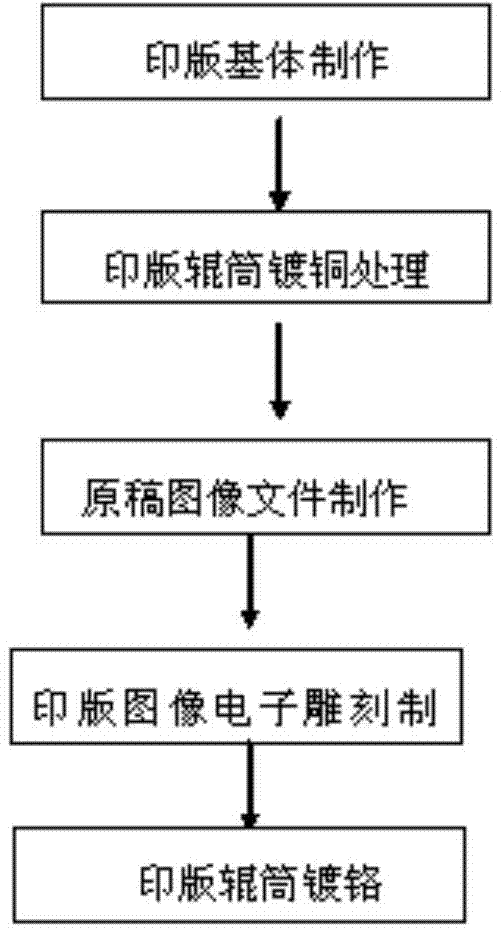

Preparation technology of gravure plate roller

InactiveCN103568470AReduce manufacturing costMeet the requirementsForme preparationCopper coatingCopper plating

The invention discloses a preparation technology of a gravure plate roller. The preparation technology comprises the following steps: preparing a printing plate base body; carrying out copper coating processing on a printing plate roller; preparing an original image file; electronically engraving and preparing a printing plate image; chroming the printing plate roller. When the printing plate roller is prepared, the utilization rate of steel products is high, the working allowance of steel is low, the preparation cost of the roller is reduced, the prepared plate roller accords with the operating requirement, and the service life is long.

Owner:ANHUI PRINTING MECHANICAL & ELECTRICAL

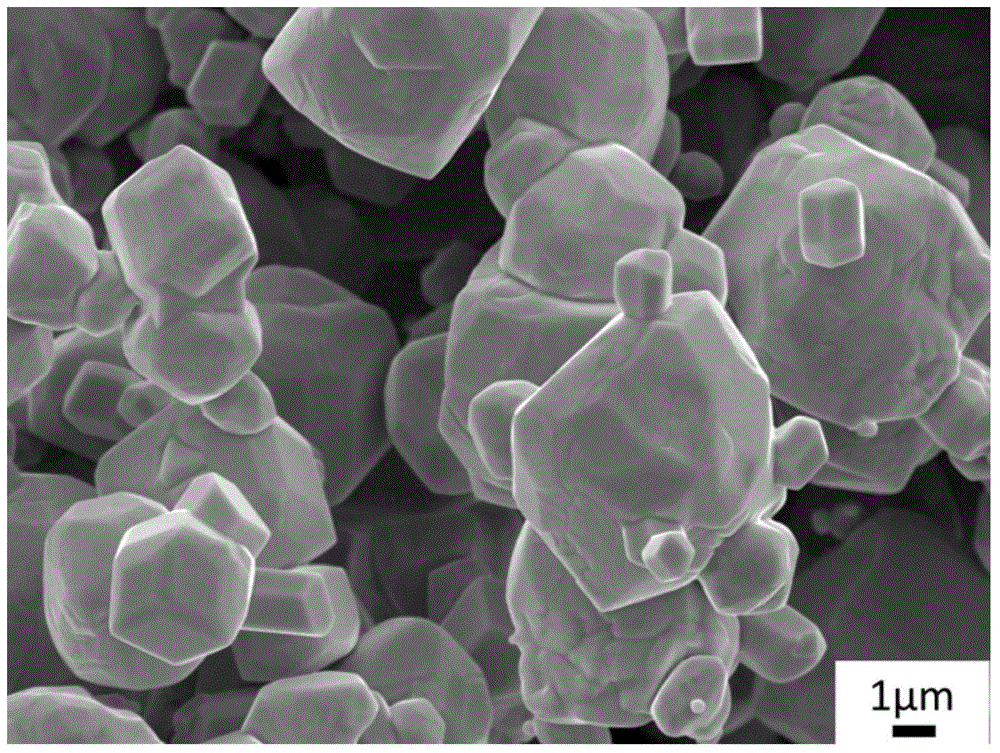

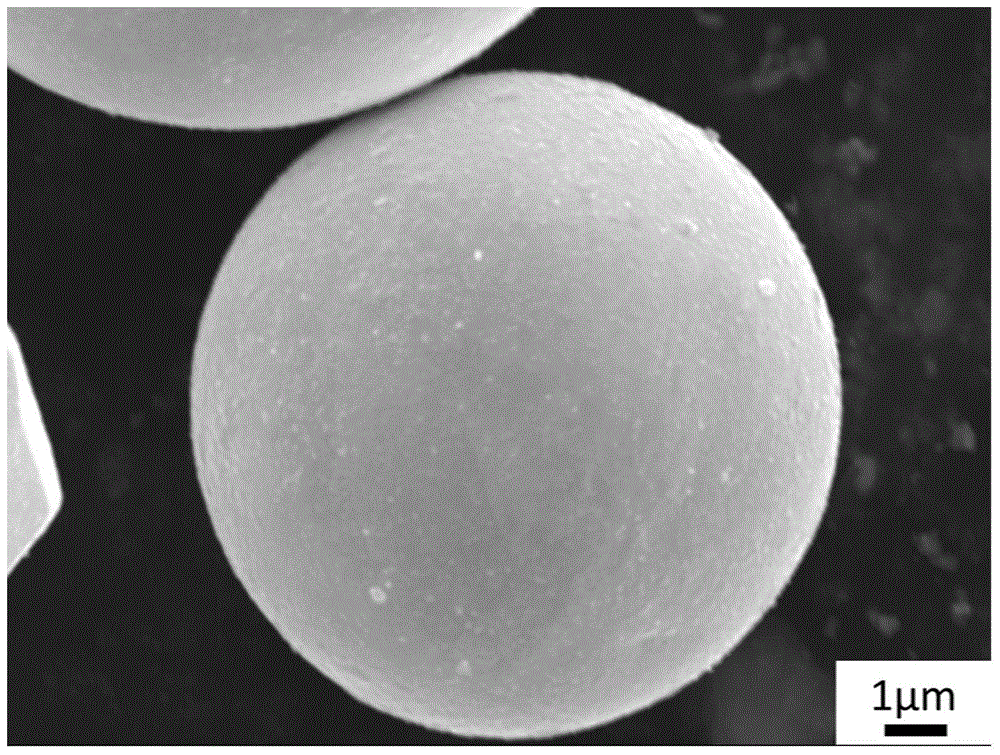

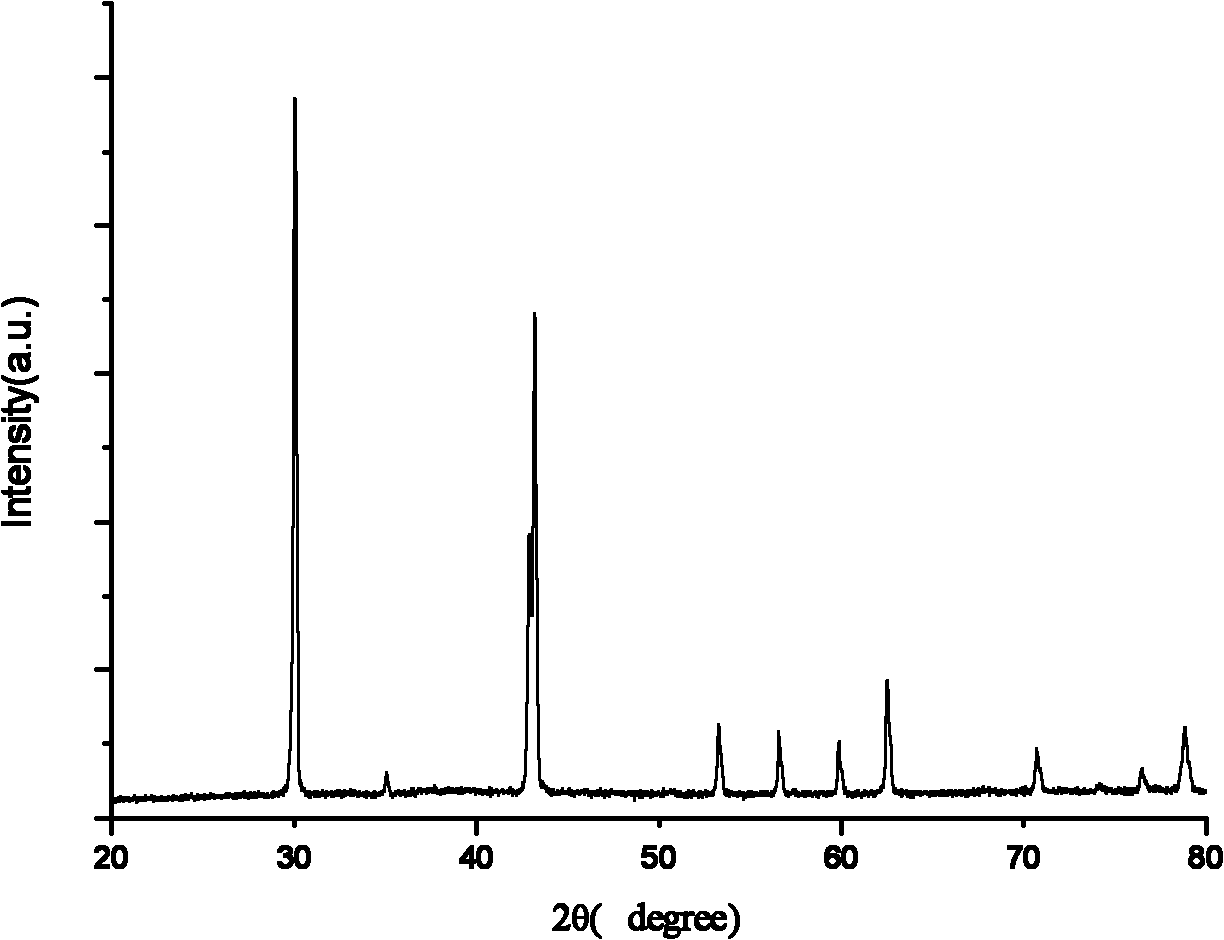

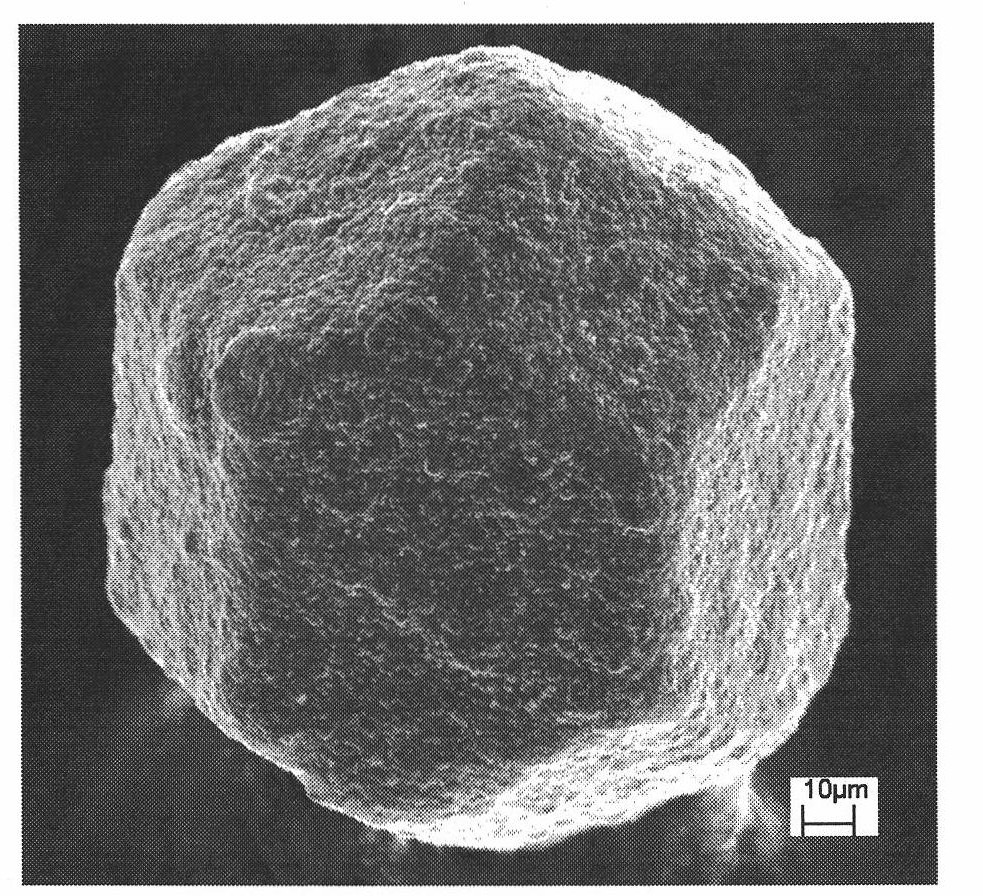

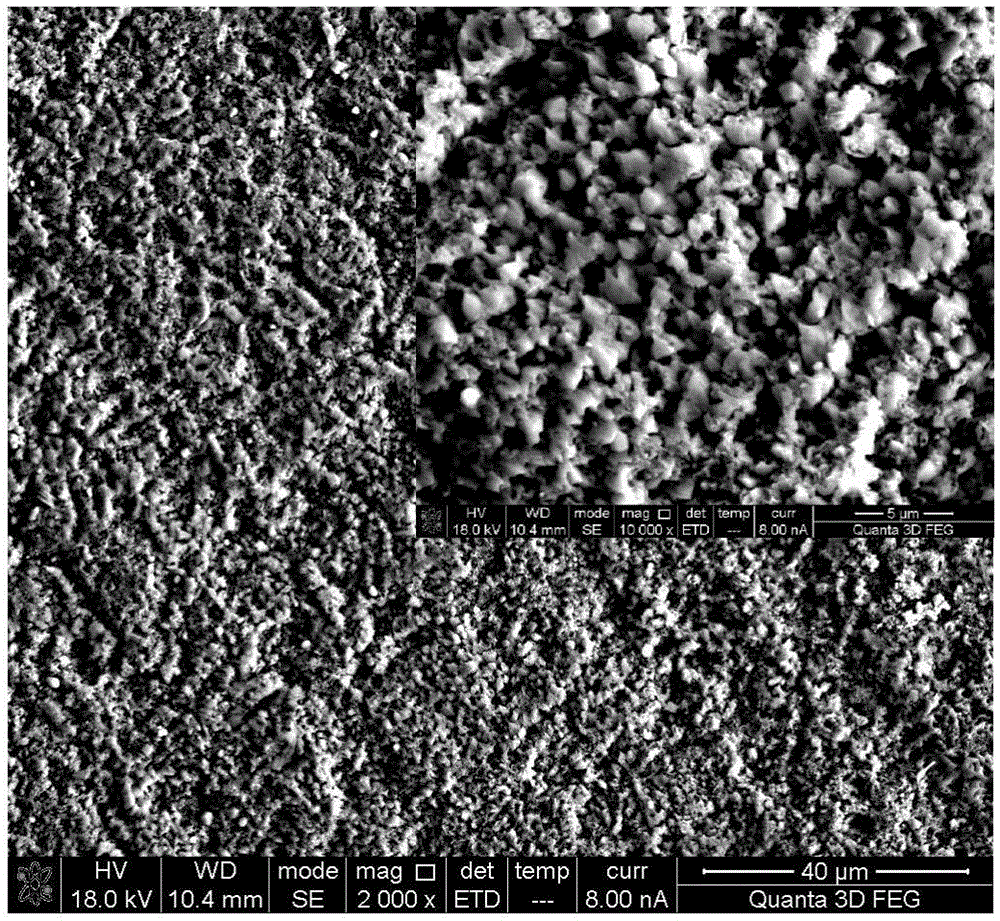

Spherical copper coating tungsten composite powder, preparation method and application thereof

The invention relates to a spherical copper coating tungsten composite powder, a preparation method and an application thereof. The copper coating tungsten composite powder is in a core-shell structure, the shell is a copper plating layer, the core is tungsten powder, and the weight ratio of the tungsten elements and copper elements of the copper coating tungsten composite powder ranges from 5 to 95 : 95 to 5; the spherical copper coating tungsten composite powder has the advantages of fine dispersion performance, high liquidity, even ingredients and high purity. The preparation method includes processing ordinary tungsten powder by a plasma spheroidizing technology, allowing the copper to deposit on the surface of the tungsten powder evenly by the intermittent copper electroplating process, and cleaning and drying the composite powder coated with copper. The spherical copper coating tungsten composite powder is prepared by combining the plasma spheroidizing and intermittent copper electroplating, the method is simple, reliable and easy to operate, the electroplating speed, the electroplated layer thickness and copper content range can be adjusted effectively, the copper-tungsten composite material comprehensive performances can be improved effectively, the expanded application prospect is provided, and the method can be applied to industrialized mass production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Cardanol modifying phenolic resin composition and method for producing environmental protection type flame-proof paper-base copper-coating board

ActiveCN101265352ALow costImprove heat resistanceCircuit susbtrate materialsFiberTetrabromobisphenol A

The invention relates to a cardanol modified phenol-formaldehyde resin and a method for producing an environmentally protective flame-retardant paper-based copper-covering plate by using the resin compound, and belongs to the technology field of the production method of the copper-covering plate. The cardanol modified phenol-formaldehyde resin is used for producing the copper-covering plate with cheap cardanol substituting for industrial phenyl hydroxide and tung oil partly. The cardanol is refined and abstracted from the raw oil extracted from fruits grown on a cashew which is a tropical plant. The modified resin compound contains flame retardants, such as nitride, phosphide, tetrabromobisphenol A and so on, and the flame retardants are free of such hazardous materials as polybrominated biphenyl, polybrominated diphenyl oxide and so on. Wood chip paper is dipped with the modified resin to form prepregs. Subsequently, a plurality of pieces of prepregs are stacked up, and are compressed into the copper-covering plate at a certain temperature and certain pressure. The copper-covering plate can reduce the product cost and ensure the performance, and is friendly to the environment.

Owner:SHANDONG JINBAO ELECTRONICS

Preparation method for copper/zinc coating on surface of glass fiber

ActiveCN102701603ALarge specific surface areaAppropriate lossLiquid/solution decomposition chemical coatingSuperimposed coating processGlass fiberCopper plating

The invention relates to a preparation method for a copper / zinc coating on the surface of glass fiber. The preparation method comprises the following steps: pretreating the surface of the glass fiber; chemically plating copper on the surface of the glass fiber; and electroplating zinc on the surface of the glass fiber. The glass fiber can conduct electricity by an electroless plating copper process; and the zinc coating is prepared on the surface of the glass fiber by an electroplating zinc process. By the process, the copper coating is successfully deposited on the glass fiber, the copper content reaches 10 to 80 percent, and the glass fiber is changed from insulation into conduction. The zinc is electroplated on the basis and the zinc content of the coating reaches 10 to 60 percent. The process is low in cost and easy to implement. The prepared zinc coating has excellent performance. The zinc coating with excellent performance is easy to prepare by improving the formula of plating solution. The preparation method for the copper / zinc coating on the surface of the glass fiber is suitable for large-scale production and can replace the conventional preparation process of the composite glass fiber material.

Owner:CENT SOUTH UNIV

Manufacturing process of waveguide slot

ActiveCN102110866AGuaranteed qualityHigh positioning accuracyWaveguide type devicesCopper coatingPrinting ink

The invention provides a manufacturing process of a waveguide slot, which is suitable for the manufacturing field of a PCB board. In the manufacturing process provided by the invention, a tin coating which is disposed outside the bottom of a groove is burn off by laser while a copper coating inside the bottom of the groove is not removed due to the difference between the absorption rates of tine and copper to laser and the difference between the energy requirements for burning tin and copper with laser, so that the laser can be prevented from reaching to a core plate under the copper coating;then the copper coating inside the bottom of the groove is removed by etching, a tin coating disposed outside the side wall of the groove is removed by means of a common process method, a protection player is subsequently coated on a copper coating which is disposed inside the side wall of the groove, so that a waveguide slot of which the side walls are provided with metal layers (a copper coating and a protection layer) and the bottom does not have a metal layer. According to the invention, the manufacturing is simple, a liquid photoimageable (PLI) type printing ink step of the existing technology is replaced by a laser drilling step, the cost is relatively low, the position accuracy of the laser drilling machine is high, the quality of the waveguide slot can be ensured completely, so the volume production of the product can be carried out.

Owner:SHENNAN CIRCUITS

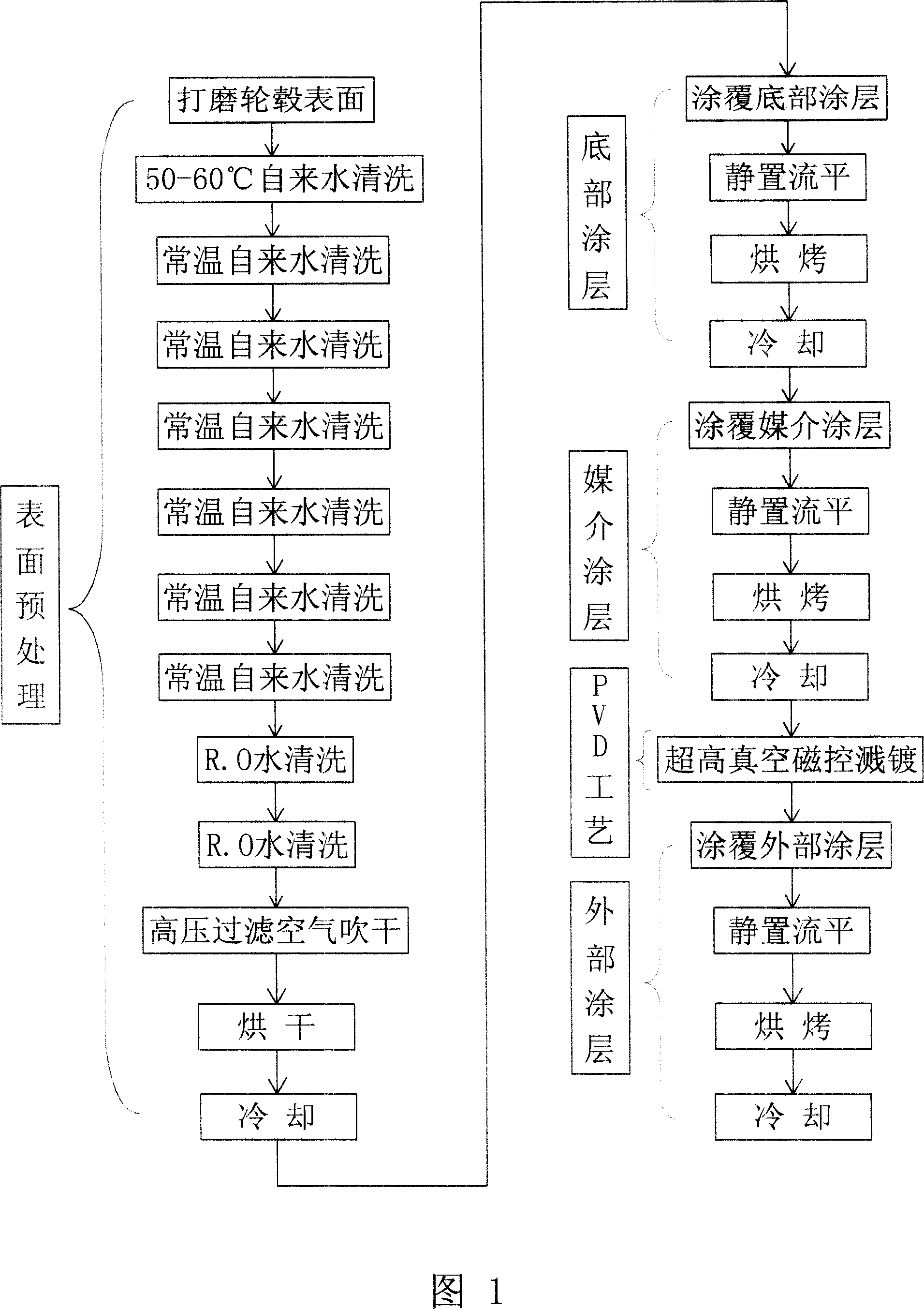

Technological process for lauminizing or coppering on aluminium or aluminium-magnesium alloy substrate

InactiveCN101067204ANo pollutionOvercoming the common magnetic effect problemVacuum evaporation coatingPretreated surfacesCoated surfaceSputtering

The technological process of forming aluminum or copper coating on aluminum or Al-Mg alloy base material includes the following steps: 1. polishing the surface and washing; 2. applying color paint containing acrylate resin to form the base coating; 3. applying paint containing polybutadiene resin to form the intermediate coating; 4. ultrahigh vacuum magnetically controlled sputtering to form aluminum or copper coating onto the intermediate coating, with the coating color being altered by means of the technological parameters; and 5. painting transparent outer protecting coating. The present invention provides a unique surface treating process, and the coating has environment friendship, excellent adhesion, high heat resistance and good decorating effect.

Owner:YULIN AUTOMOBILE FITTINGS KUNSHAN

Copper-coating foil microwave dielectric plate with high dielectric constant and preparation method thereof

The invention relates to a copper-coating foil microwave dielectric plate with high dielectric constant and a preparation method thereof. The preparation method comprises the following steps of modifying the surface, and preparing modified ceramic powder or modified glass fiber; fully mixing 50 to 80wt% of modified ceramic powder, 2 to 10wt% of modified glass fiber, and 15 to 45wt% of PTFE (polytetrafluoroethylene) resin; adding 2 to 10wt% of surfactant into a mixture, and continuing to mix; adding 5 to 20wt% of flocculant, until precipitate is formed, and filtering; drying, and crushing into a bread crumb-shaped matter; adding 2 to 20wt% of plasticizer, and mixing to form a dough-shaped matter; putting onto a calendering machine, calendering, and forming, so as to obtain a raw base sheet; drying, sequentially overlapping the dried base sheets, hot pressing and sintering, and naturally cooling. The preparation method has the advantages that the dough-shaped matter after the mixing of the raw material has excellent fluidity and forming property; by adopting a calendaring roll to repeatedly calender, the uniformity of thickness and dielectric property is guaranteed; by adopting a calendering technology, the problem of molding technology size and uniformity are solved.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

Acid bright copper-plating electroplating process

The invention relates to an acid bright copper-plating electroplating process. The process comprises the steps of preparation of a copper plating solution, workpiece pretreatment, acid bright copper plating and the like. The process can continuously plate multiple copper coatings which are some millimeters thick on the surface of a metal substrate without electroplating for several times; the process guarantees good binding force between electroplated cast copper and the substrate, and can bear external force from turning, milling, drawing, externally throwing and other machining; and a plating solution is good in stability and uniform in surface.

Owner:河南江河机械有限责任公司

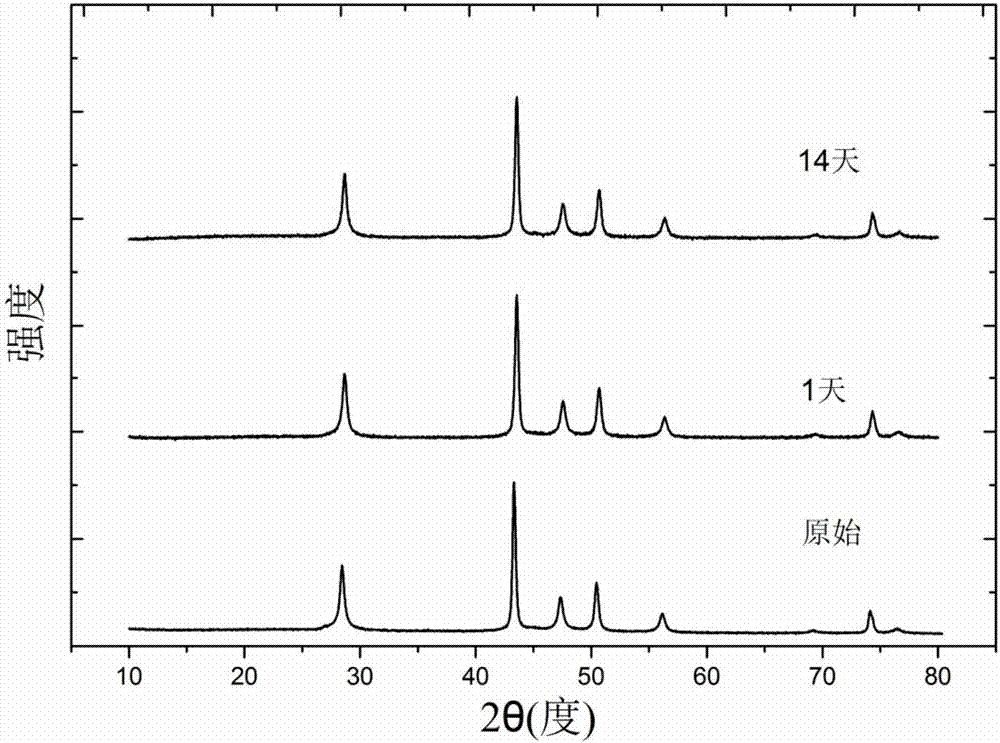

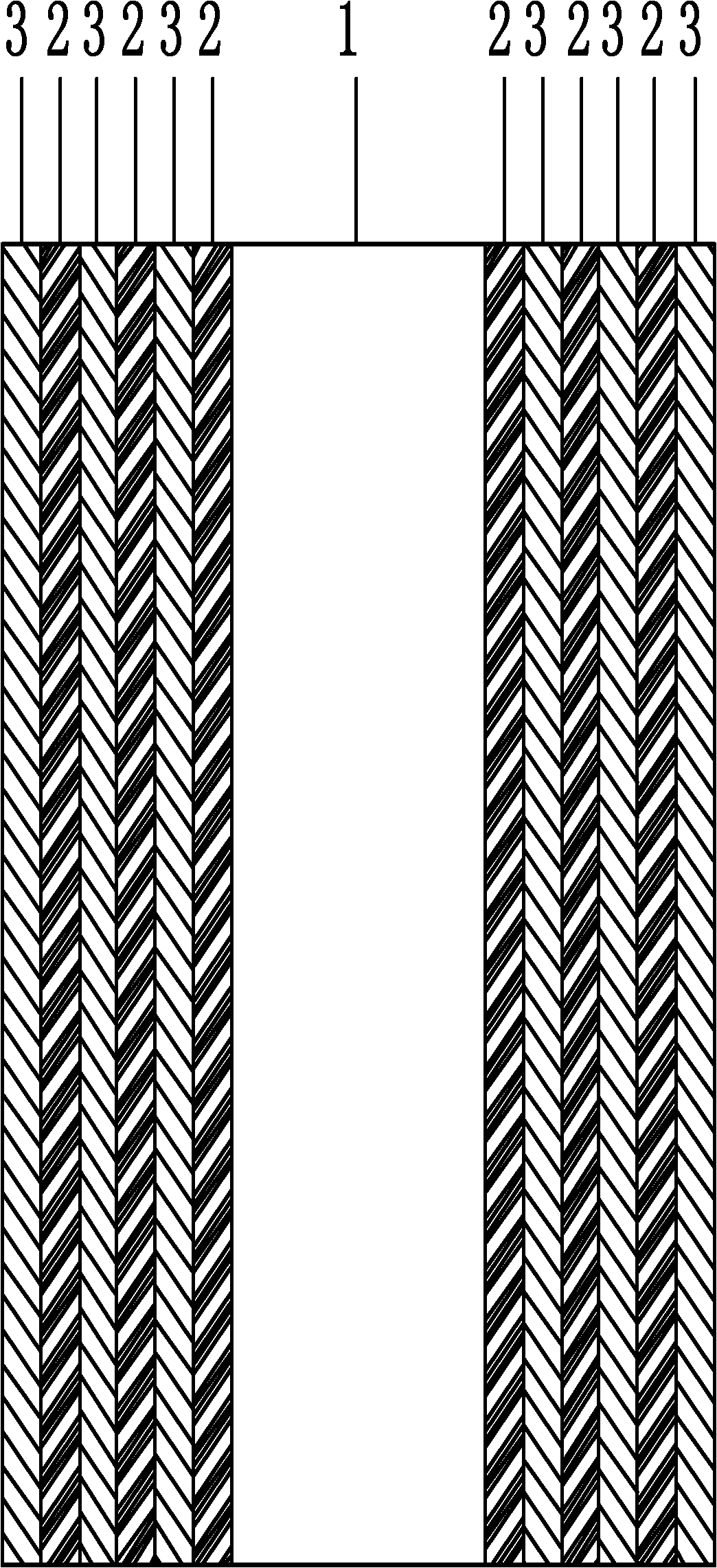

Tin/copper foam alloy cathode material for lithium ion cells and preparation method thereof

ActiveCN102013488AImprove conductivityImprove cycle performanceCell electrodesCopper coatingMicrometer

The invention discloses a tin / copper foam alloy cathode material for lithium ion cells and a preparation method thereof. In the invention, foam copper serving as a substrate is coated and plated with tin / copper alternate multilayer lamination structure; and then the tin / copper alloy cathode material is obtained by heat treatment. A tin coating is formed directly on the foam copper strip substrate, and a copper coating is formed on the outmost layer; in the multilayer lamination structure, each coating is 0.1 to 1.0 micrometer thick, and the thicknesses of all coatings are the same; the thickness ratio of each tin coating to each copper coating is 1:1.7-1:2.1; and the heat treatment temperature is 150 to 400 DEG C and the heat treatment time is 0.5 to 6 hours. The tin / copper foam alloy cathode material prepared by the method has a high charge-discharge specific capacity and high cycle performance; and the maximum primary discharge specific capacity is up to 610mAh / g, and after 50 circles, the specific capacity reduces only by 1 to 3 percent. In the invention, the preparation process is simple, and large-scale industrial production can be performed.

Owner:HUNAN YONGSHENG NEW MATERIALS

Composite coating capable of preventing marine biofouling and spraying method thereof

InactiveCN102191500AImprove bindingEnsure antifouling effectMolten spray coatingSuperimposed coating processElectricityCopper coating

The invention relates to a composite coating capable of preventing marine biofouling and a spraying method thereof. The high velocity oxygen fuel spraying and cold spraying technologies are adopted to prepare a transition layer, an insulated coating and an antifouling coating on a metal substrate and achieve the aims of anticorrosion and anifouling. The spraying method comprises the following main steps: (1) pretreating the surface of the metal substrate; (2) performing high velocity oxygen fuel spraying; and (3) performing cold spraying. The method is adopted to prepare an insulated ceramic coating and a pure copper coating on the surface of the metal substrate so that the anticorrosion and anifouling of the two coatings are combined organically and the high-performance composite coating can be formed. The method adopts high velocity oxygen fuel spraying, higher binding force exists between the prepared transition layer and insulated layer and the substrate; when cold spraying is adopted, red copper can not be oxidized and the anifouling effect of red copper can be ensured; and the transition layer, insulated layer and antifouling functional layer of the composite coating are designed, thus electrical insulation is realized between the antifouling functional layer and the metal substrate and the antifouling effect can be fully realized.

Owner:周建奇

Method of chrome plating magnesium and magnesium alloys

ActiveUS8152985B2Liquid surface applicatorsLiquid/solution decomposition chemical coatingCopper coatingChrome plating

A process for chrome plating magnesium and its alloys. The process uses a combination of electroless nickel plating, a multi-stage copper coating transition system and multiple layers of electrodeposited nickel to form a corrosion resistant system of substantial impermeability and interlayer adherence suitable for direct chromium electroplating.

Owner:ARLINGTON PLATING

Method for preparing diamond enhanced copper based composite with high volume fraction

InactiveCN102071332AEvenly distributedImprove thermal conductivityInterfacial thermal resistanceVacuum evaporation

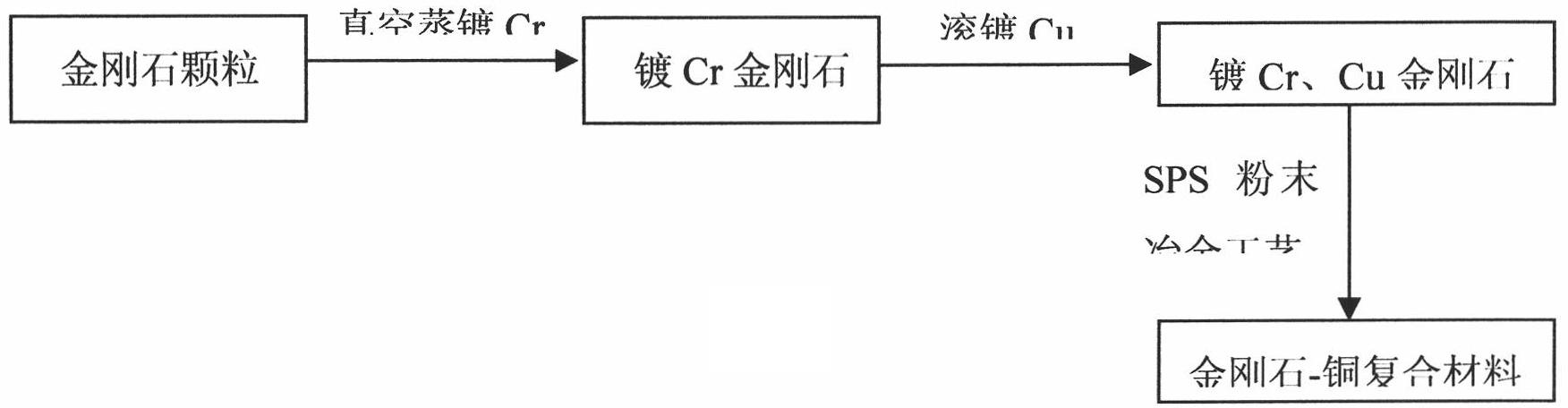

The invention relates to a diamond enhanced copper based composite and a preparation method thereof, belonging to the metal based composite field. In the composite of the invention, the volume ratio of diamond to copper is 40-70:60-30 and the particle size of diamond is 38-212mu m. The preparation method comprises the following steps: plating a 0.1-2mu m of Cr layer on the surface of diamond through vacuum evaporation after the surface pretreatment of diamond; placing the diamond plated with Cr in a barrel to perform copper element barrel plating and thickening, wherein the copper coating on the surface of diamond is 7-20mu m in thickness and the weight of the obtained diamond is increased by 100%-170%; and directly placing the obtained diamond in a spark plasma sintering (SPS) furnace to prepare the diamond-copper composite. The method of the invention directly uses the thicker copper coating on the surface of diamond as base material, thus avoiding the problem that diamond is not mixed uniformly with copper powder so as to cause the additional interfacial thermal resistance; and all kinds of composites with different diamond contents can be obtained by changing the increased weight of diamond, thus the maneuverability is high and the technology is simple. The composite has higher thermal conductivity and can be used in the fields such as electronic packaging.

Owner:UNIV OF SCI & TECH BEIJING

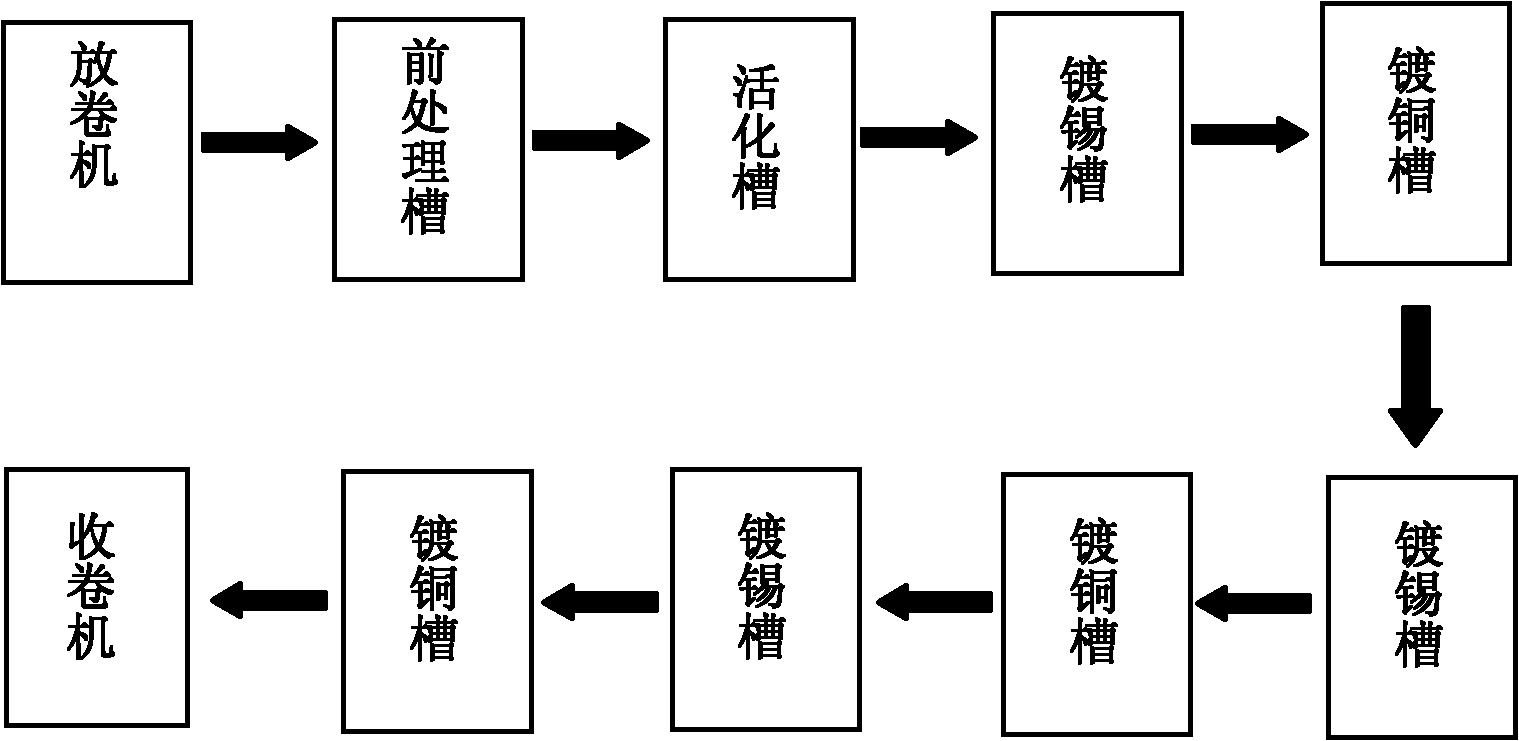

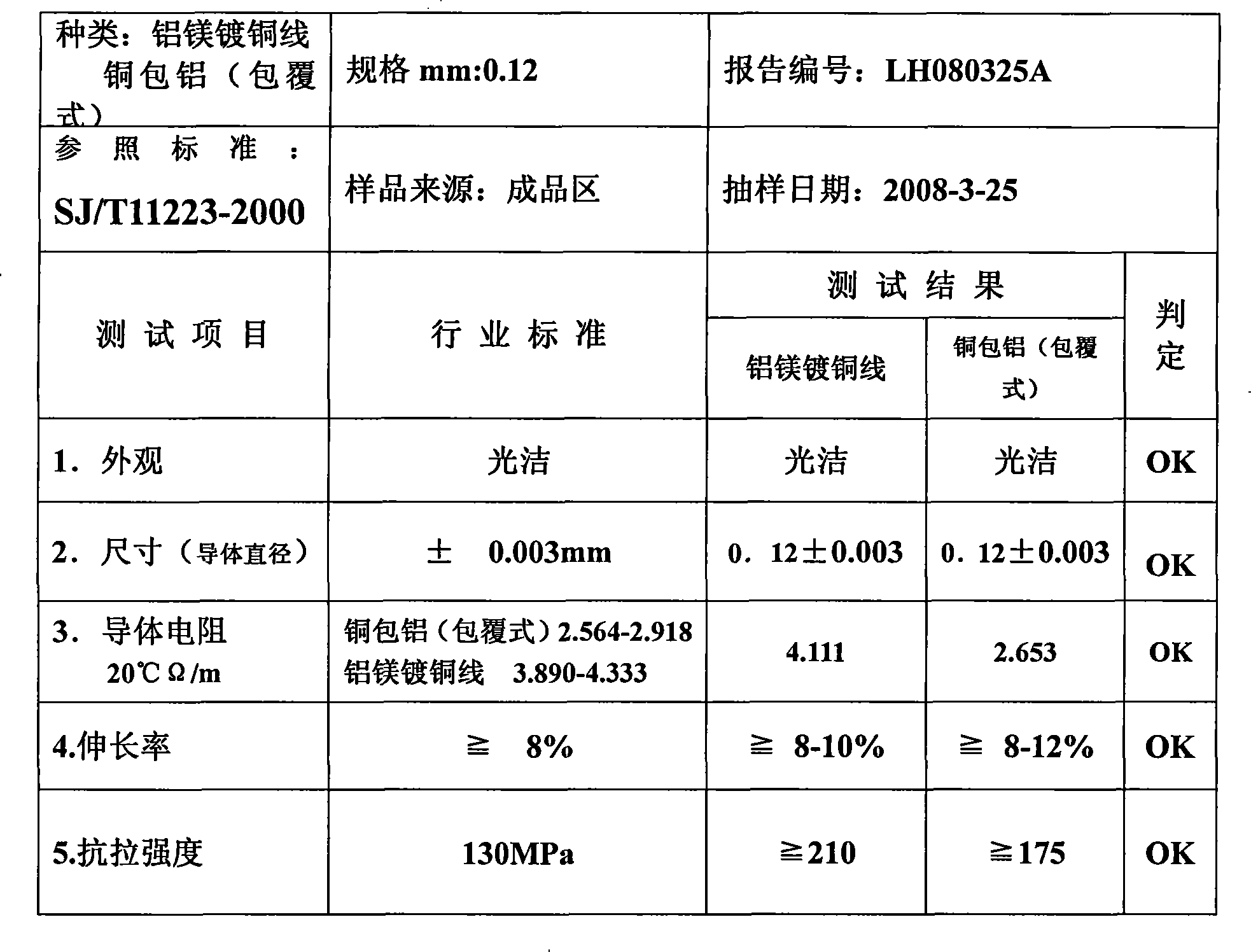

Technique for producing aluminum magnesium plating copper wire copper-coating

A manufacturing process of plating copper by using aluminum-magnesium copper-plating wire comprises the following steps: arranging wire, cleaning by alkali, cleaning by water, cleaning by sulfuric acid, cleaning by water, cleaning by alkali, cleaning by water, a first time soaking zinc, cleaning by water, removing the zinc by nitric acid, cleaning by water, a second time soaking zinc, cleaning by water, cleaning by hot water, pre-plating nickel, cleaning by water, activating, acidicly plating copper, cleaning by water, carrying out the anti-oxidation treatment, cleaning by hot water, drying and taking out the wire. The manufacturing process is characterized in that the process of the first time zinc soaking is that completing the first time zinc soaking in solution with temperature of 12-27DEG C for 30-60 sec after mixing with 60 parts water, 7 parts zinc oxide, 31 parts superalkali, 2 parts potassium sodium tartrate and 0.06 parts iron trichloride. By adopting the manufacturing process of the invention, the aluminum-magnesium copper-plating wire has the double advantages that aluminium conductor has light weight and low cost, copper conductor has high conductivity and good chemical stability, wherein the specific weight of copper is about 18-19%, mean density is 2.8g / cm3, the length of aluminum-magnesium copper plating wire whose size and weight are the same with that of pure copper wire is 3.1 times than that of the pure copper wire, tensile strength is more than or equal to 210, which enables the aluminum-magnesium copper plating wire uneasily to break and improves the quality of the products.

Owner:丹阳利华电子有限公司

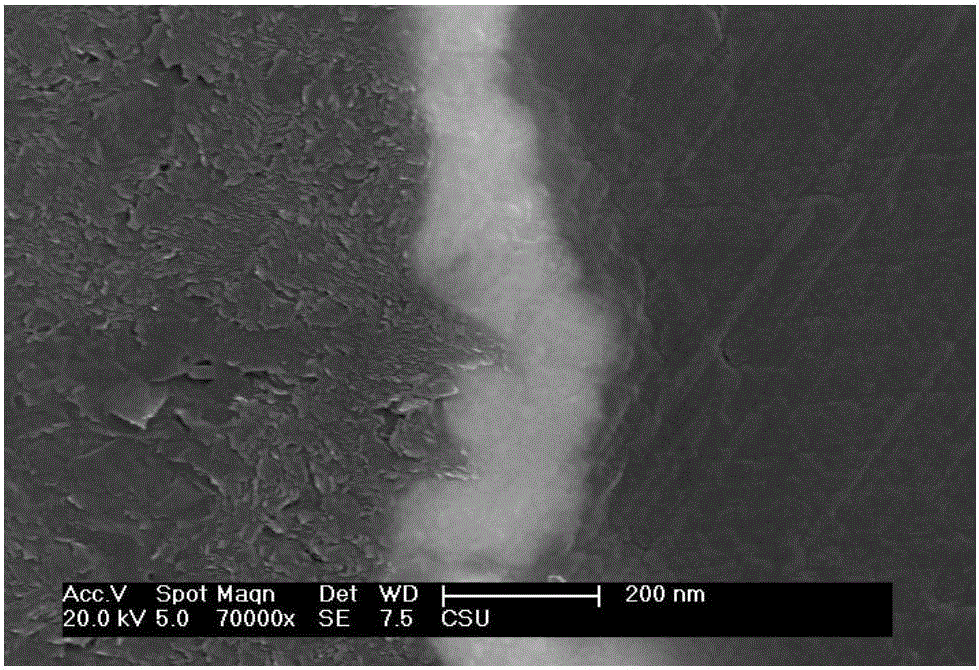

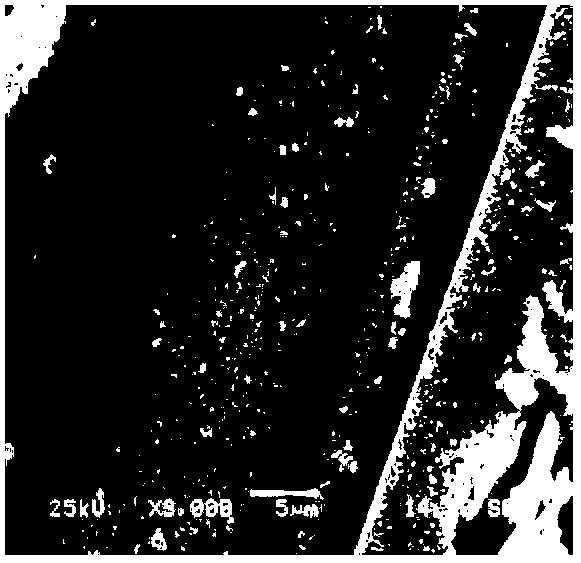

Method for manufacturing single walled carbon nanotube surface nickel copper coating

InactiveCN103586464AImprove surface activityUniform and complete coatingLiquid/solution decomposition chemical coatingChemical platingCopper coating

The invention discloses a method for manufacturing a single walled carbon nanotube surface nickel copper coating and belongs to the technical field of carbon nanotube surface processing techniques. The method includes the following steps that a method for combining ultrasonic processing and a chemical dispersing agent is adopted for sequentially carrying out scattering, purifying, sensitization and excitation on a single walled carbon nanotube in advance. Afterwards, by means of a method of chemical plating, a nickel layer and a copper layer are sequentially deposited on the surface of the single walled carbon nanotube. The method for manufacturing the single walled carbon nanotube surface nickel copper layer is practical, effective and controllable. The copper layer obtained on the surface of the carbon nanotube is high in purity, free of oxide and even and complete in coating and capable of being tightly combined with the surface of the carbon nanotube. The good heat conducting performance and the good electricity conducting performance of pure copper are reserved on the coating. Wettability and interface combining strength between the carbon nanotube and a composite copper base body are improved. The application range of the carbon nanotube in fields is widened, wherein the fields include carbon nanotube reinforced metal base composite materials, nanometer electronic appliances, biosensors and the like.

Owner:HUBEI UNIV OF TECH

Method for preparing micro-nano porous structure on titanium or titanium alloy surface

ActiveCN105925949ASignificant surface effectSignificant sizeVacuum evaporation coatingSputtering coatingAcid etchingCopper atom

The invention discloses a method for preparing a micro-nano porous structure on a titanium or titanium alloy surface. The method is characterized in that the titanium or titanium alloy surface is subjected to surface copper plating, then heat treatment and dealloying, and particularly comprises the following steps: cleaning the titanium or titanium alloy surface; arranging a copper coating on the titanium or titanium alloy surface via surface electroplating or magnetron sputtering; performing heat treatment to diffuse copper atoms into the titanium or titanium alloy surface; dealloying by adoption of solid-phase method magnesium powder or liquid-phase method molten magnesium; and finally, cleaning and drying with acid and water to obtain titanium or titanium alloy with micro-nano pores in the surface. Compared with the prior art, the method is simple and easy, can overcome the shortcomings of the conventional powder sintering method, acid etching method, anodic oxidation method, spray method and the like, is suitable for small and large titanium or titanium alloy materials, can be used for easily preparing the micro-nano porous structure on the titanium or titanium alloy surface and is wide in applicability.

Owner:SOUTHEAST UNIV

Process of zine pressure casting non cyanogen alkaline immersion plating copper

InactiveCN100999819AImprove bindingEliminate pollutionSuperimposed coating processCopper platingGluconic acid

The cyanide-free alkaline copper dip plating process for die cast zinc part includes the following steps: dewaxing die cast zinc part, deoiling, soaking in alkaline immersion liquid at 15-60 deg.c and pH 7.5-13.0 for 5 sec to 15 min to form replacing copper layer. The alkaline immersion liquid contains two-valent copper ion, and one or several kinds of inorganic or organic complexing agent selected from pyrophosphoric acid, tartaric acid, citric acid, gluconic acid, EDTA and HEDP acid radical ion a in the concentration of 1-150 g / L. The process of the present invention may be used to replace cyanide copper plating to form copper coating with high adhesion force without cyanide pollution.

Owner:GUANGZHOU UNIVERSITY

Chemical copper plating solution and technique thereof

InactiveCN101078111AAvoid pollutionLow costLiquid/solution decomposition chemical coatingChemical solutionCopper plating

A kind of chemical solution used to copperize, the following are the weight percent of the major components of it: blue vitriod0.8-3, Fe vitriol 0-0.5, complex agent 3-6, sodium hypophosphorous acid 4-6, ammonia sulfate 0.5-1, sulfourea 0-0.01. The following is the procedure of the copper coating method with the above copper coating solution: to widen and activate the plastic board->to clean->to make it electric->to clean->to coat nickel-copper alloy on it by chemical method. The following are the content of the chemical method: the plastic pretreated according the above description will be immersed in the above chemical solution used to copperize, the pH of which has been adjusted to 10-13 by vitriol and stranger ammonia water, the working temperature of it is 20-70deg.C, the time to copperize is 5-20 minutes. The chemical solution used to copperize in this patent does not contain formaldehyde, it improve the working circumstance, and is easy to control, the cost of it is lower, and it own high economical benefit and society benefit.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com