Preparation technology of gravure plate roller

A preparation process, technology of gravure plate roller, applied in the direction of printing plate preparation, printing, etc., can solve the problems of high price, slow drying process characteristics, unfavorable environmental protection of ink, etc., achieve high steel utilization rate, reduce preparation cost, and service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

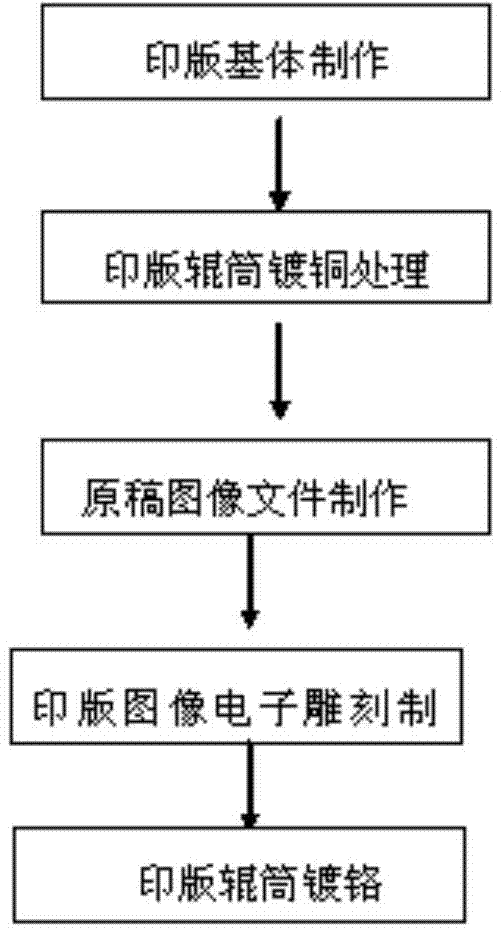

[0018] Such as figure 1 Shown, a kind of preparation technology of gravure plate roll is characterized in that comprising the steps:

[0019] (1) Production of printing plate substrate: According to the drawings of the printing plate rollers used in the printing machine, select seamless steel pipes for cutting, welding flanges, car chamfering, and grinding the surface of the printing plate rollers;

[0020] Selection of seamless steel pipes: the weight ranges from 10kg (narrow and small printing presses) to hundreds of kilograms (wide and large printing presses, monochrome gravure printing presses), and the wall thickness of steel pipes ranges from 10mm to 30mm;

[0021] (2) Copper plating treatment of the printing plate roller: use the sulfate copper plating method, and then go through the cutting process of the car-grinding machine or the polishing process of the grinding machine grinding and polishing machine;

[0022] (3) Manuscript image file production: scan the origina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com